Page 1

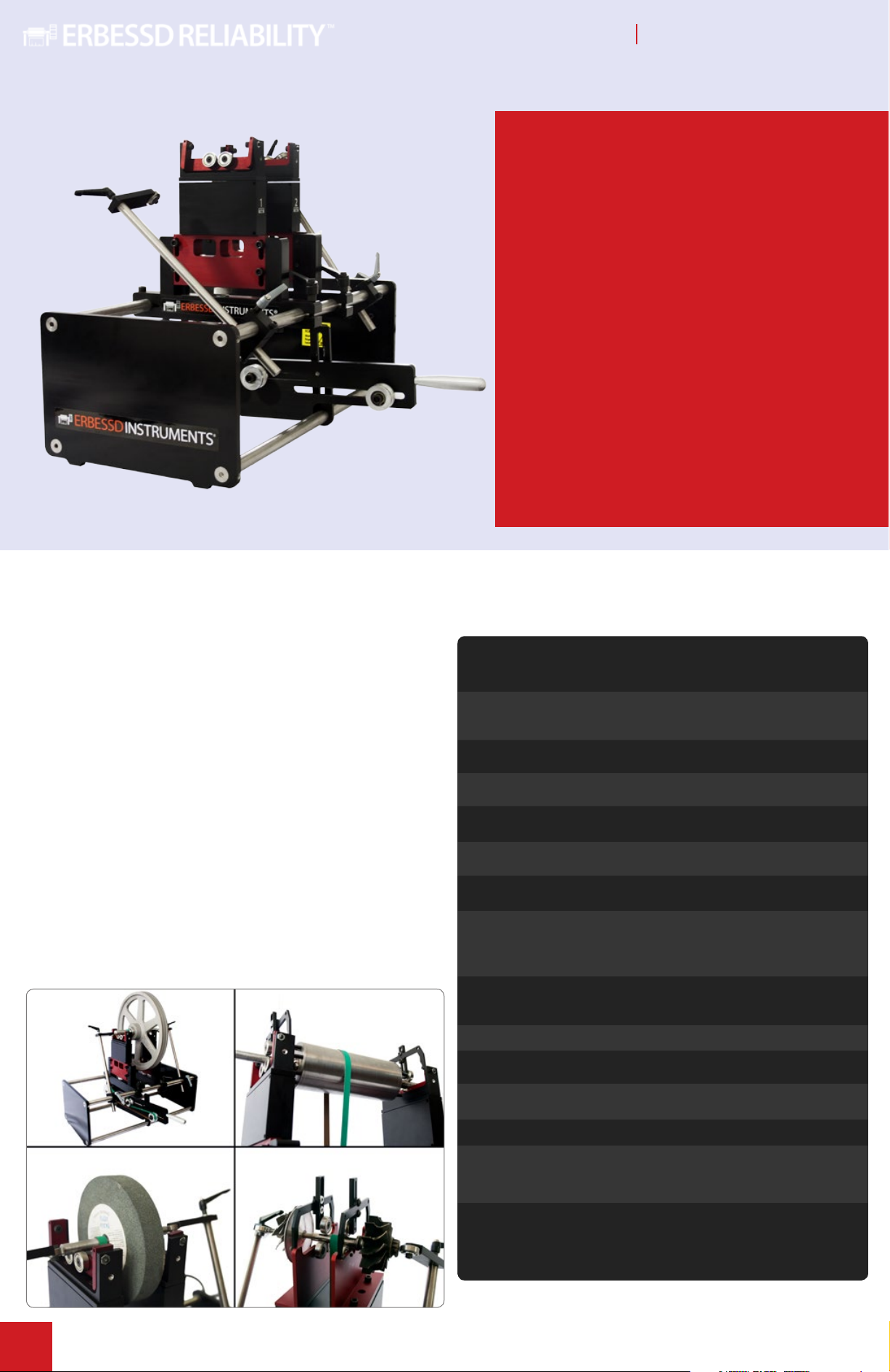

Balancing Machine

Page 2

EI SERIES

BALANCING MACHINES

EI-30

EI-30 is a horizontal

balancing machine

delivering the highest

precision ideal for low weight

and high speed rotors. The

low inertia reduces the

resistance to the vibration

and increases the sensitivity

and precision of the

Characteristics

Characteristics Technical Specs

• Balancing in 1 and 2 planes without trial weights

• Variable speed with inverter

• Easy to use and easy to adjust

• Adjustable pulleys

• Adjustable height for each support

• Manual ajustment for the transmission system

• Bearing supports minimize mechanical

looseness

• Balancing speed 60 to 15,000 RPM

• Slices cantilever

• Optical RPM sensor

• Isolates Mechanic parts to avoid corrosion

balancing process.

Technical Specs

Max symmetric load

Dimensions (L x An x Al)

Weight 30 kg (66 lb)

Maximum rotor diameter 533 mm (21 in)

Maximum weight per base 15 kg (33 lb)

Maximum radial displacement 6.35 mm (0.250 in)

Maximum sha diameter 50 mm (2 in)

Shorter distance between

supports

*Using the support for short rotors

609 x 304 x 431 mm

30 kg (66 lb) /

0.1 kg (0.22 lb)

(24 x12 x 17in)

31 mm (1.25 in) /

12 mm (0.5 in)

2

Longest distance between supports

Aceleccrometer sensitivity 100 mV/g

Power transmision Flat band

Lubrication Type-I (manual)

Precision ±0.01 mm/s

Speed Driver

Motor characteristics

500 mm (19.75 in)

Input: 127/230 VAC~

50/60Hz

Output: 0 - 90/180 VDC

124 W (1/6 hp)

90 VDC / 1.8 A

1,800 RPM

Page 3

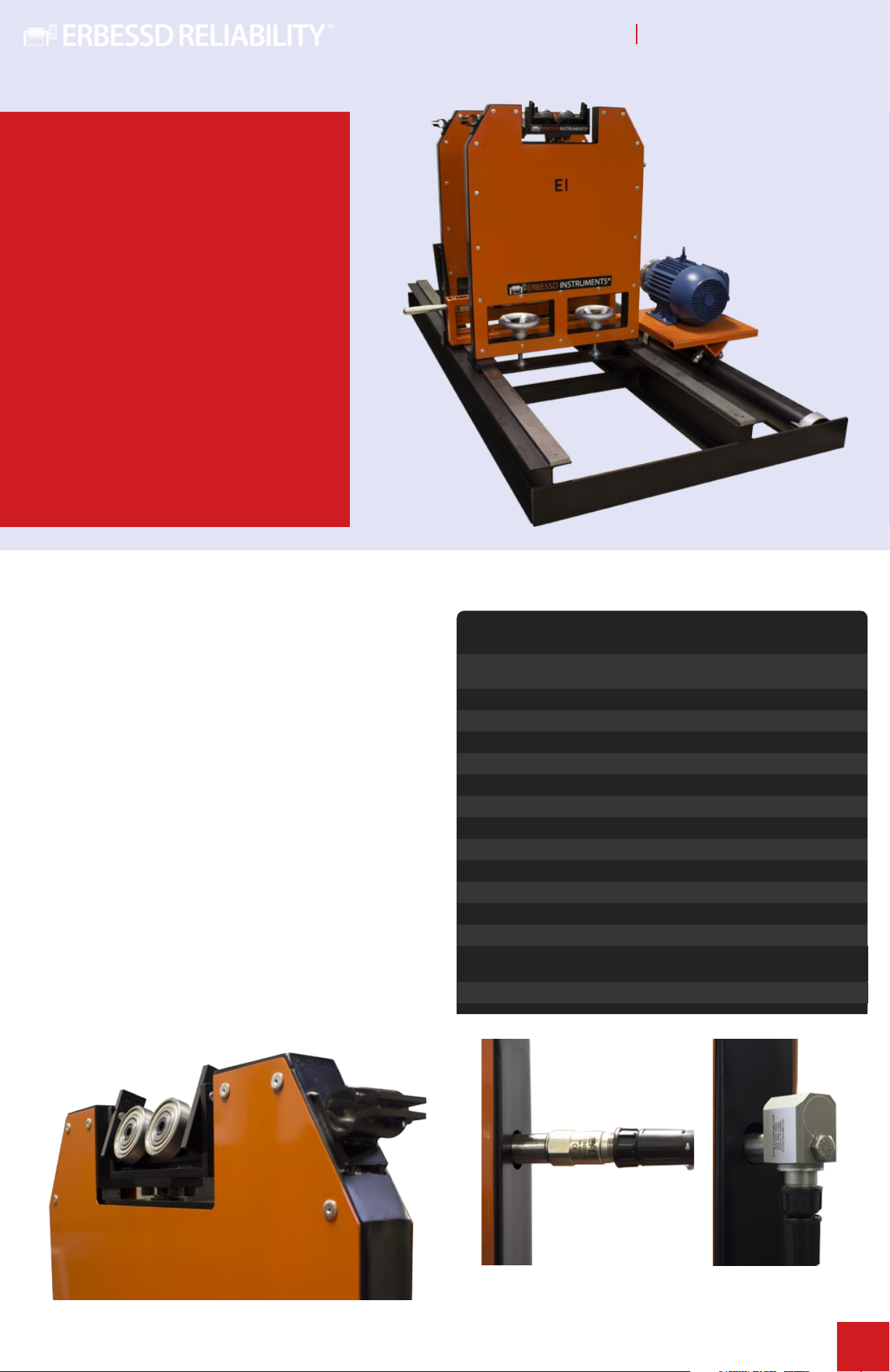

The EI-300 balancing

machine is ideal for

all types of rotating

parts up to 300 kg, like

rollers,electric motor

rotors, crankshas, fans,

mills and more. The so

bearing suspensions are

manufactured using the

EI SERIES

BALANCING MACHINES

EI-300

highest quality lowest

friction components.

Characteristics

• Balancing in 1 and 2 planes without trial

weights

• Variable speed with inverter

• Ajustable pulleys

• 3 liberty axis per pedestal

• Easy ajustment of the transmission system

and support distance

• So bearing suspension to minimize

mechanical looseness.

• Axials supports

• Sealed Sensors to avoid corrosion

• Slices cantilever

• Easy calibration

Technical Specs

Max symmetric load

Dimensions (L x An x Al)

weight 200 kg (440 lb)

Maximum rotor diameter 1600 mm (63 in)

Maximum weight per base 150 kg (330 lb)

Maximum radial displacement 12 mm (0.5 in)

Maximum sha diameter 101 mm (4 in)

Distance between supports min/max 100 mm (4 in) / 1778 mm (70 in)

Transmision V Band Type A

Lubrication Type-I (manual)

Precision ±0.01 mm/s

Acelerometer sensitivity 100 mV/g

ISO 2953 Reducción de desbalanceo por sec.

Residual Unbalance 1 gmm / 100 kg rotor

Motor characteristics

Speed shier Included, 2.28 kW AC (3 hp)

220/440 V, 3 phases, 4 poles

300 kg (660 lb) /

1 kg (2.20 lb)

2000 x 950 x 900 mm

(79 x 37.5 x 35.5 in)

97%

2.28 kW (3 hp)

Slices Cantilever

Extern Sensor

90º Sensor (Opc)

3

Page 4

EI SERIES

BALANCING MACHINES

EI-1000

The EI- 1000 balancing

machine is perfect for all

kind of rotating assets up

to 1000 kg , like rollers,

motor rotors, crankshafts,

mills and many more.The

soft bearing suspensions

are manufactured utilizing

the highest quality

antifriction components.

Characteristics Technical Specs

• Balancing in 1 and 2 planes without trial

weights

• Variable speed with inverter

• Adjustable pulleys

• 3 liberty axis per pedestal

• Easy ajust of the transmission system and

support distance

• So bearing suspension to minimize

friction

• Axials supports

• Sealed sensors to avoid corrosion

• Auto-aligned slices

• Easy calibration

Max symmetric load

Dimensions (L x An x Al)

Weight 200 kg (440 lb)

Maximum rotor diameter 1800 mm (71 in)

Maximum weight per base 500 kg (1100 lb)

Maximum radial displacement 12 mm (0.5 in)

Maximum sha diameter 101 mm (4 in)

Min / Max distance between

supports

Transmission Flat B

Lubrication Type-I (manual)

Precision ±0.01 mm/s

Accelerometer sensitivity 100 mV/g

ISO 2953 unbalance reduction per sec.

Residual Unbalance 2 gmm / 100 kg rotor

Motor Characteristics

Speed shier Incluided, 3.73 kW AC (5 hp)

100 mm (4 in) / 1778 mm (70 in)

1000 kg (2200 lb) /

3 kg (6.6 lb)

2000 x 950 x 1100 mm

(79 x 37.5 x 43.25 in)

97%

3.73 kW (5 hp)

220/440 V, 3 phases, 4 poles

4

Page 5

The EI- 2000 balancing

machine is built for industry

and rotors to 2000 kg , just

like machine rolls, motors

rotors, large crankshafts,

mills and more. The soft

bearing suspensions of

the EI-300 are made of

ultralightweight anti-friction

EI SERIES

BALANCING MACHINES

EI-2000

components.

Characteristics

• Balancing in 1 and 2 planes without trial

weights

• Variable speed with inverter

• Adjustable pulleys

• 3 liberty axis per pedestal

• Easy ajust of the transmission system and

support distance

• So bearing suspension to minimize

friction.

• Axial Supports

• Sealed sensors to avoid corrosion

• Auto-aligned slices

• Easy calibration

Technical Specs

Max symmetric load

Dimensions (L x An x Al)

Weight 200 kg (440 lb)

Maximum rotor diameter 2000 mm (79 in)

Maximum weight per base 1000 kg (2200 lb)

Maximum radial displacement 12 mm (0.5 in)

Maximum sha diameter 228 mm (9 in)

Min / Max distance between

supports

Transmission Flat Belt

Lubrication Type-I (manual)

Precision ±0.01 mm/s

152 mm (6 in) / 1778 mm (70 in)

2000 kg (4400 lb) /

5 kg (11 lb)

2000 x 1320 x 1295 mm

(79 x 52 x 51 in)

Accelerometer Sensitivity 100 mV/g

ISO 2953 Reducción de desbalanceo por sec.

Residual unbalance 2 gmm / 100 kg rotor

Motor caracteristics

Speed inverter Included, 3.73 kW AC (5 hp)

*Using a So Bearing suspension system

220/440 V, 3 fases, 4 polos

3.73 kW (5 hp)

97%

5

Page 6

EI SERIES

BALANCING MACHINES

EI-4500

The EI-4500 balancing

machine responds perfectly

to the needs of industrial

customers that balance mid-

weight rotors.With the “trial

weights” mode or influence

coeicients you can balance

fans, rollers, electric rotors

Characteristics

• Slices with 2 positions

• Elevation screw

• Axial supports

• Flat belt transmission

• 3 liberty axis per pedestal

• 3 flat pulleys for transmission ajust

• Flat drive pulley

• Electric motor

• 2 acelerometers

• 2 channel interface

• Optical sensor with magnetic base

A 1 700 mm / 67.00”

B 1 220 mm / 48.00”

C 2 000 mm / 78.74”

and more.

Technical Specs

Max symmetric load

Dimensions (L x An x Al)

Weight

Maximum rotor diameter

Maximum radial displacement

Maximum sha diameter

Min / Max distance between

supports

Maximum sha diameter

Diameter’s dierence in pivots 50.8 mm (2 in)

Lenght of the bench 2 000 mm (78.75 in)

Lock system Yes (manual operation)

Vibration sensors 2 accelerometers (with 2 pins connectors)

Accelerometer sensitivity 100 mV/g

ISO 2953 Unbalance reduction per sequence

Desequilibrio de Reducción por Secuencia

Transmission Flat Belt with manual tension

Lubrication Tipo I (Manual)

Residual Unbalance 2 gmm / 100 kg rotor

Motor characteristics

177 mm (7 in) / 1,700 mm (67 in)

4 500 kg (10 000 lb) /

10 kg (22 lb)

2 000 x 1 700 x 1 220 mm

(78.74 x 67 x 48 in)

Per base: 78 kg (573.20 lb)

Complete: 600 kg (1 322.78 lb)

1 700 mm (66.929 in)

25.4 mm (1 in)

279.4 mm (11 in)

254 - 1778 mm (10 - 70 in)

7.5 hp (5.6 kW)

220/440 VAC 4 poles

97%

6

Page 7

The EI-6000 balancing

machine is built to be

rugged, repeatable, and

reliabile. With the “trial

weights” mode or influence

coeicients you can balance

fans, rollers, electric rotors

and more.

EI SERIES

BALANCING MACHINES

EI-6000

Characteristics

• Slices with 2 positions

• Elevation screw

• Axial supports

• Flat belt transmission

• 3 flat pulleys for transmission ajust

• Flat drive pulley

• Electric motor

• 2 acelerometers

• 2 channel interface

• Optical sensor with magnetic base

Technical Specs

Max symmetric load

Dimensions (L x An x Al)

Weight

Maximum rotor diameter

Maximum radial displacement

Maximum sha diameter

Min / Max distance between

supports

Shorter distance between

supports

*Using the support for short rotors

Diameter’s dierence in pivots

Lenght of the bench 2 000 mm (78.74 in)

Lock system Yes (mechanic operation)

Vibration sensors

Accelerometer sensitivity 100 mV/g

ISO 2953 Unbalance reduction

per sequence

Transmission

Lubrication Type I (Manual)

Residual Unbalance 2 gmm / 100 kg rotor

Motor characteristics

2 000 x 1 686.3 x 1 371.6 mm

Complete: 1 280 kg (2 825 lb)

6 000 kg (13 228 lb) /

15 kg (33 lb)

(78.74 x 66.4 x 54 in)

Per base: 125 kg (263 lb)

2 000 mm (78.74 in)

25.4 mm (1 in)

320.7 mm (12.625 in)

355.6 - 1 943.1 mm

(14 - 76.5 in)

482.6 - 2 500 mm

(19 - 98.42 in)

76.2 mm (3 in)

2 accelerometers

(with 2 pins connector)

Flat belt with tension

manual

Included, 10 hp (7.45 kW)

220/440 VAC 4 polos

97%

A 1 686.3 mm / 66.40”

B 1 371.6 mm / 54.00”

C 2 000 mm / 78.74”

7

Page 8

Powerful...

Precise..

Performance.

The dynamic

balancing

system

EI SERIES

DigivibeMX M10+

BALANCING MACHINES

DigivibeMX M10 is the most powerful and precise solutions for dynamic

balancing available on the market today. It is built with an intuitive interface

and designed for both novice and for the most demanding users.

DigivibeMX M10 includes:

Balancing without trial weights

Calculator with 12 functions

Balancing Wizard & In-Situ

Balancing without phase

Automatic Balancing Reports

Multi-lingual soware

Excellent precision

With this system you can obtain superior

balancing quality

Quality grad: G 0.4 @ 30 000 rpm

Residual Unbalance: 1g mm/100 Kg

Speed: 0.01 mm/s (ISO 10816)

8

Page 9

EI SERIES

BALANCING MACHINES

Functions and

tools

easy to use

Balancing Tools

2 Polar Graphs Balancing calculator with 12

functions:

Add or remove weight

Separate and combine weights

Trial Weights

Balancing in series ( without trial weights)

Drill depth

Plate size

Residual Unbalance

Quality grade

Balancing report

DigivibeMX M10 includes advanced features like:

Automatic balancing reports:

Runs values separates in tables

Balancing evolution in RMS and filtered

values

FFT spectra

Signal based on time in waterfall format

Polar graphics with vibration phase

Final spectrum

Bode diagram

Frequency response

Soft Bearing

Suspension Mode

9

Page 10

DigivibeMX includes:

EI SERIES

BALANCING MACHINES

2-Channel interface

4-pin connectors (1-A, 1-B, 2) for

24V accelerometers

5-pin connector (Op) for Optical Sensor

Selector button (Ch 1 / Ch 2)

Cable with USB connector (15cm)

Weight 230g

Dimensions (mm): 60(d) x 90(w) x 30(h)

Cables

Calibrator

Accelerometer Laser Optical Sensor

Dinamyc Impact Shock: 50g peak (max

shock 5000g)

Freq. response (+/- 3dB): 0.32 - 13000 Hz

Freq. response (+/- 5%): 2 - 10000 Hz

Sensitivity: 100 mV/g +/- 10%

Transverse sensitivity: < 5%

Power supply: 18-30 V / 3-8 mA

Short-circuit protection

Operation temp.: −10 - 50 °C

Protection grade: IP 67, III

Impact resistance: IEC 60028-27

Standard 2-Pin MIL connector

Magnetic Base

Weight 50g

Stainless steel body

Analogic output / Range: 1 - 5000 Hz

Power and current

supply: 5V , 20 - 30 mA.

Voltage drop: <0.4 V

Short circuit, Reverse Voltage and

Over-Voltage (15V for 1min) protection

Operation distance: up to 15 m

Operating temp: −10 - 50 °C

Storing temp: −40 - 85 °C

Protection grade: IP 67, III

Impact Resistance: IEC 60028-27

Weight 60 g

Nylamid body

So Case &

Magnetic Base

*Only M10 y M30

Installation CD

& User Manual

Soware highlights

Displacement: 0.5 um to 30 mm (0.02 to 1200 mils)

Velocity: 0.002 to 3000 mm/s (0.0001 to 120 in/s)

Acceleration: 0.0001 to 100 G’s PP

Lines of resolution: > 1 000 000

FFT windows: Rectangular, Hanning, Hamming, Flaptop, Blackman, CosSum, Bartlett, Kaiser

Measures: Peak, Peak to Peak, RMS

System requirements

Hardware & Soware Requirements:

Processor 1.6 GHz Minimum

1 GB RAM Minimum

Windows 7 or newer (supports Windows

10

8.1 & Windows 10*)

SVGA Monitor or better

“Touch” mode for touch screen

300 MB free disk space

1 USB 2.0 port

*No available on Windows Mobile or Windows RT.

Page 11

Accessories

The EI Series balancing

machines have a

wide range of optional

accessories and

supplies to improve

perfomrance and

EI SERIES

BALANCING MACHINES

reliability.

Negative Load Support (Optional)

EI-30 EI-300, EI-1000, EI-2000, EI-4500, EI-6000

Accessory required to secure rotors with high vibration levels like crankshas.

Axial

Supports

The axial supports limit axial

displacement.

(Included)

Pulleys Set

(Included)

Transmission

Belt

(Included)

11

Page 12

Service & Support Engineer

1-877-223-4606 /+52 (55) 6280-7654 / 7592-2130

support@erbessd-instruments.com

support@erbessd-reliability.com

Sales

info@erbessd-instruments.com

info@erbessdreliability.com

BUY ONLINE

www.erbessd-instruments.com

www.erbessdreliability.com/

TODAS LAS IMÁGENES CONTENIDAS SON CON FINES ILUSTRATIVOS. EL PRODUCTO PUEDE VARIAR

DEPENDIENDO DE LA VERSIÓN Y/O DE LAS ACTUALIZACIONES QUE SE REALICEN A LOS DISPOSITIVOS

© 2017 ERBESSD INSTRUMENTS S. A. DE C. V.

A-2017.0207.15

Loading...

Loading...