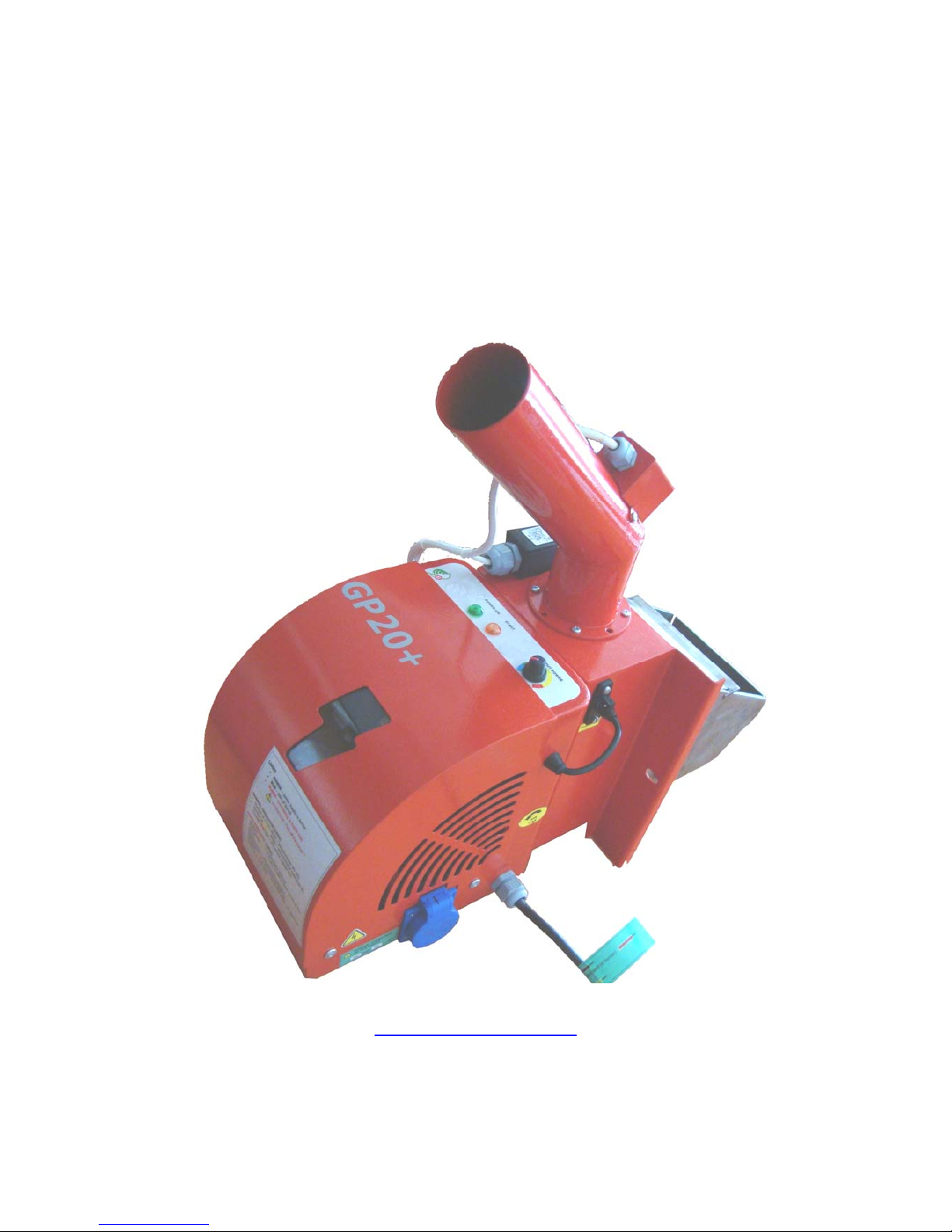

Erato GP20+ Instruction Manual

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 1/50

Instruction manual

for installation and operation of

Automatic pellet burner

ERATO GP20+

http://www.erato.bg

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 2/50

Thank You for buying our product – automatic pellet burner „ERATO GP20+”.

This manual will help You to use and maintain the unit properly.

ATTENTION!

IN INTEREST OF YOUR PERSONAL SECURITY IT IS

NECESSARY TO READ THOROUGHLY AND CAREFULLY THIS

INSTRUCTION MANUAL BEFORE PROCEEDING WITH ANY

ACTIONS WITH THE BURNER – INSTALLATING, CONNECTING,

OPERATING, ETC. IN CASE THAT REQUIREMENTS, DEPICTED IN

THIS MANUAL ARE NOT SATISFIED, FAILURE OF THE UNIT

COULD BE EXPECTED, OR EVEN FATAL CONSEQUENCES, FOR

WHICH ERATO COMPANY DOES NOT TAKE RESPONSIBILITY.

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 3/50

Table of contents

Page

1. Automatic pellet burner “ERATO GP20+” – description and

advantages............................................................................................................5

The burner could utilize following types of fuel ...........................................5

The unit is equipped with................................................................................5

The burner is equipped with ........................................................................... 6

Advantages of the burner................................................................................6

2. Automatic pellet burner “ERATO GP 20+” technical data ....................8

Table 2.1 Thermal and technical data of automatic pellet burner “ERATO

GP20+”, utilizing wood pellets..........................................................................8

Table 2.2 Dimensions and technical data of automatic pellet burner “ERATO

GP20+” ..............................................................................................................9

Table 2.3 Recommended solid biomass fuel properties – wood pellets...........9

Table 2.4. Pellets classification, considering their physical properties..........10

3. Description of the construction of automatic pellet burner “ERATO

GP20+”...............................................................................................................11

3.1. Main properties....................................................................................11

3.2. Specific design measures in order to increase the safety operation of

the burner.......................................................................................................14

4. Installation of automatic pellet burner.....................................................15

4.1. Some basic requirements for correct installation of automatic pellet

burner “ERATO GP20+” are.......................................................................15

4.2. Installation of the burner....................................................................15

4.3. Overall and attachment dimensions of the burner’s main unit......16

4.4. Arrangement and installation of the pellet burner’s modules........18

5. Initial steps and starting of pellet burner “ERATO GP20+”................20

5.1. Basic fuel requirements.......................................................................20

5.2. Staring automatic pellet burner “ERATO GP 20+”........................20

5.2.1. Interface control board of automatic pellet burner “ERATO

GP20+” ........................................................................................................21

5.2.2. Automatic pellet burner power supply.......................................21

5.2.3. Switching on the burner...............................................................22

5.2.4. Burner’s operating algorithm .....................................................24

5.2.5. Operating control parameters of the burner.............................26

• Description of LED indication (positioned on the control board of

the unit):......................................................................................................26

Table 5.1. Description of the operating parameters of the burner’s control

board.................................................................................................................28

5.2.6. Adjustment process of the burner, according to the heat

demand of a consumer...............................................................................30

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 4/50

5.2.7. Nominal thermal load of the burner...........................................31

5.3. Adjustment of the thermal capacity of the burner...........................32

5.3.1. Decreasing thermal capacity of the burner................................32

5.3.2. Increasing thermal capacity of the burner.................................32

5.4. Stopping the pellet burner..................................................................33

5.5. Turning the burner OFF.....................................................................33

• Emergency burner stop .......................................................................34

5.6. Showing and teaching the end user about the maintenance and

adjustment procedures of the burner..........................................................35

5.7. Safety and unexpected risks ...............................................................35

5.8. Operation faults and repairing procedures ......................................36

Table 5.3. Automatic pellet burner faults and repair procedures....................42

Table 5.4. Detailed description of control board’s alarm mode indications...43

5.9. Automatic pellet burner “ERATO GP20+” warranty form

completion.......................................................................................................44

5.10. Actions, after the burner is not in exploitation anymore.............44

6. Electrical scheme of automatic pellet burner “ERATO GP20+”..........44

QUALITY CERTIFICATE .............................................................................46

WARRANTY FORM........................................................................................47

WARRANTY CONDITIONS..........................................................................48

WARRANTY SERVICE PROCEDURES LIST...........................................49

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 5/50

1. Automatic pellet burner “ERATO GP20+” – description and advantages

“ERATO GP20+” is automatic pellet burner, which utilizes wood pellets.

The burner is designed to be installed on already operating heating boilers or

other equipment, thus allowing fuel switch procedure to a renewable energy

sources - biomass. The installed burner operates on wood pellets and the

thermal energy, resulting from the intensive combustion process is directed

to the heat exchange surfaces of a boiler or another thermal consumer.

The burner could utilize following types of fuel

• Wood pellets, having diameter 6 and 8 mm, categorized in the range

of: A, AB, B (according to the methodology, developed for pellets

properties estimation in ERATO company);

• Pre-dried pits (from cherries for example);

• Fuel mixture – pellets and pits (for example mixture ratio could be

50% - 50%);

• Other solid biomass based pellets, but these fuels need testing and

approval in ERATO company laboratory;

The unit is equipped with

• adjustable operating module, which controls the functions of the unit

and is adjustable to the specific needs of a heating system;

• auger, which transports fuel from a bunker to the main unit;

• fresh air supplying fan, equipped with a Hall sensor, which returns

information to the control unit;

• electric heater, which ignites the fuel;

• combustion chamber, which gives environment for efficient

combustion process;

• removable grate of the combustion chamber, allowing easy access and

ash cleaning;

• photosensor, which gives information for the status of the combustion

process to the control unit and allows dynamic operation of the burner;

• interface panel, equipped with light indicators;

• the control board is equipped with led indicator for indicating the

status of adjustable parameters index value;

• a variable potentiometer, which allows easy thermal capacity

adjustment;

• a position switch, which confirms that the burner is installed properly

and could work safely;

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 6/50

The burner is equipped with

• automatic fuel ignition system;

• automatic fuel transport system – from bunker to the combustion chamber

of the main unit;

• safety system, which blocks its operation if the main unit is not installed

properly;

• safety system, which blocks its operation in case that at any circumstances

the fuel delivery pipe is preheated above certain temperature safety level;

• photosensor, which allows dynamic monitoring of the combustion process

status;

• transition system, which modulated the air supply fan operation at ignition

process;

Advantages of the burner

• the burner automatically utilizes renewable energy source – biomass,

which makes it environmental friendly and does not contribute to the

global warming and pollution;

• the burner is installed in order to apply the so called fuel switch process

for appliances, utilizing fossil fuels – diesel, natural gas, LPG, coal;

• the burner’s design allows easy installation on manual fed boilers – such

as those, designed for coal, wood logs. The heating system and the

boiler/equipment however need minor redesign and reconstruction in

order to allow such fuel switch process;

• the resulting heat energy, based on organized combustion process of

renewable energy source - biomass, is less influenced by the global trend

of the energy sources and as result the price is competitive, compared to

price of the popular energy sources;

• the burner operates automatically and achieves operation comfort,

delivered by operating of fossil fuel burners – working with liquid and

gaseous fuel, which permits remote control by programmable room

thermostat;

• the burner’s control unit is equipped with automatic fuel ignition

procedure;

• automatic operation of the burner allows variable thermal load adjustment

and economic operation of the heating system, which guarantees optimal

thermal comfort and reduced fuel consumption;

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 7/50

• simplified installation procedure and initial adjustment, which guarantees

faster assembly and unified approach;

• opportunity to utilize biomass, pellet shaped as well as other dried nuts,

according the appropriate fuel table;

• high efficiency;

• low pollutant emissions;

• automatic fuel transport from a bunker, built according to the local units

arrangement and need of the client (the bunker is not part of the burner

equipment delivery);

• simplified maintenance and service;

• minimal operating costs;

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 8/50

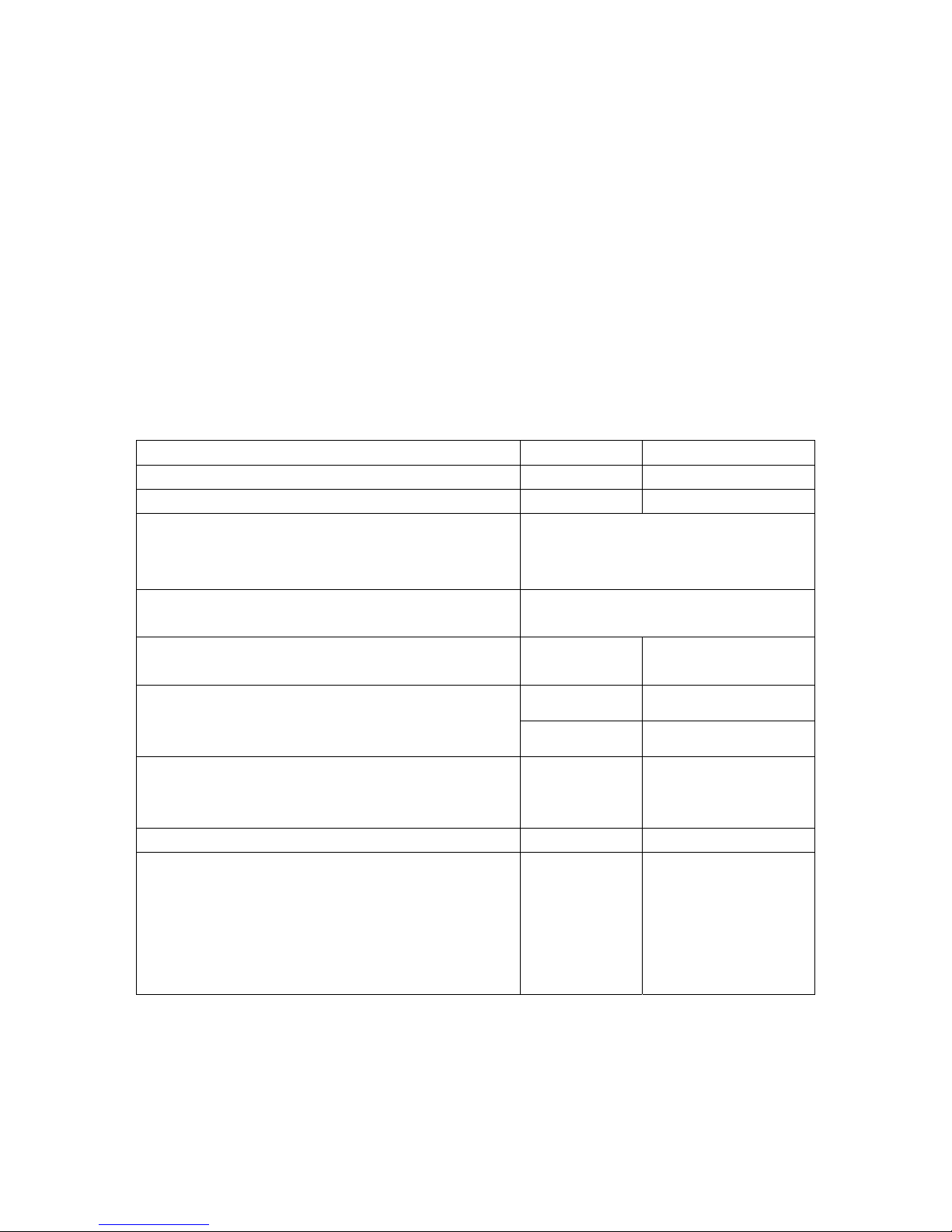

2. Automatic pellet burner “ERATO GP 20+” technical data

2.1. Thermal and technical data of automatic pellet burner “ERATO

GP20+”, utilizing wood pellets are given in Table 2.1;

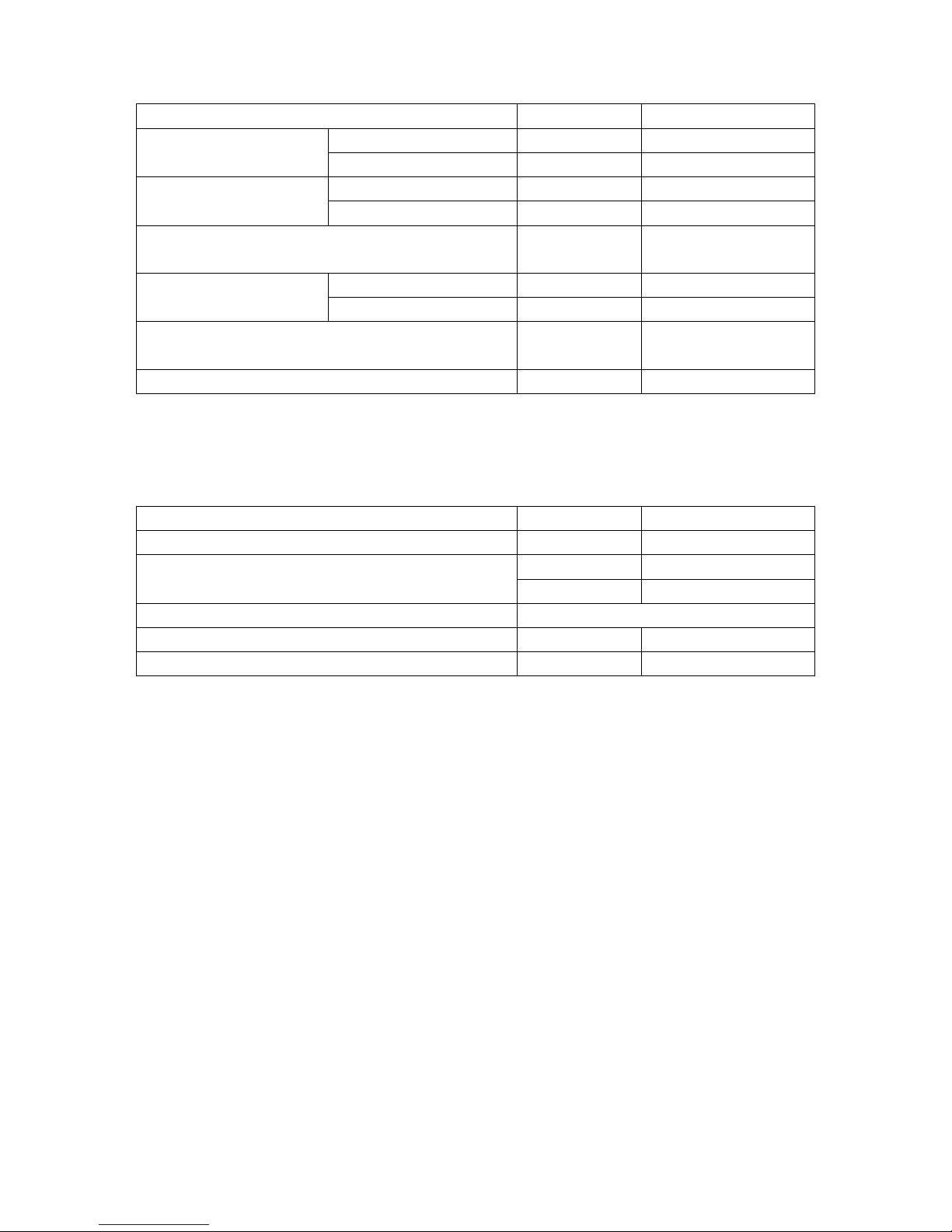

2.2. Dimensions and technical data of automatic pellet burner “ERATO

GP20+” are given in Table 2.2;

2.3. Recommended solid biomass fuel properties – wood pellets, are

given in Table 2.3;

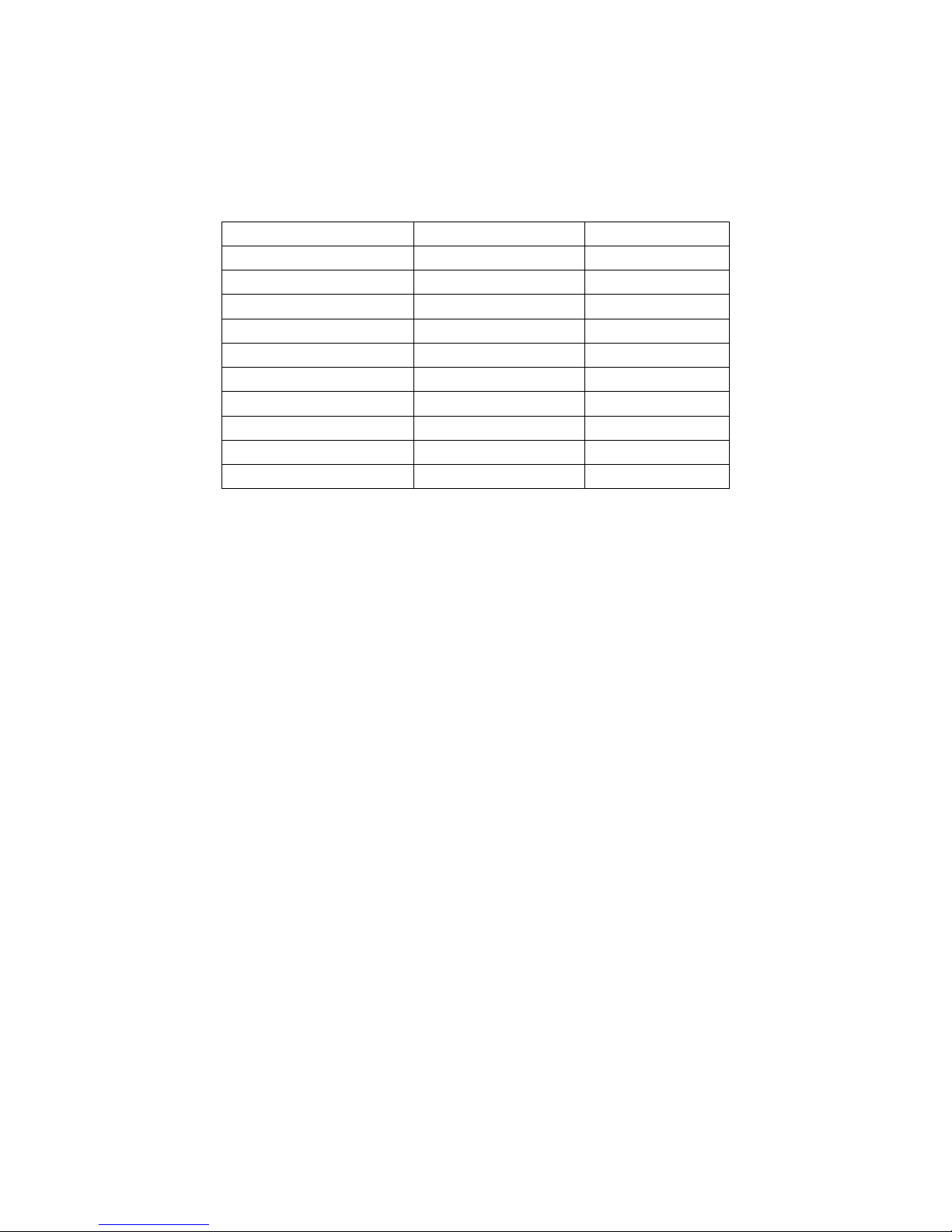

2.4. Pellets classification, considering their physical properties (based

on fuel proximate analysis) are shown in Table 2.4;

Parameter Dimension Value

Nominal thermal capacity kW 32

Thermal capacity operation range kW 5 – 32

Utilized solid fuel

• Wood pellets;

• Pre-dried cherry nuts;

• Other dried nuts;

Utilized pellets, complying ERATO

classification methodology

A,AB,B

Wood pellets fuel consumption rate at

nominal thermal capacity

kg/h 6.8

kg/h

55 – 65

Fresh air flow rate, required for effective

combustion process and boiler operation

m

3

/h

50 - 60

Averaged wood pellets consumption rate

(the unit is operating in a popular heating

system)

kg/h 5.0

Air excess ratio λ 1.6 – 1.8

Solid fuel residue ash The quantity

depends on the ash

contents in the raw

fuel, as well as

operating

conditions

Table 2.1 Thermal and technical data of automatic pellet burner “ERATO

GP20+”, utilizing wood pellets

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 9/50

Parameter Dimension Value

main module kg 18

Weight

fuel transport auger kg 14

main module mm 250 х 570 х 530 Overall dimension of

the unit (WxDxH)

fuel transport auger mm 220x1890x110

Power supply -

1PEN ; 50Hz;

230V;

at nominal load 0.2 A Power consumption

rate

at ignition 4.5 A

Electrical capacity

VA <100 + 1100 (at

ignition process)

Electric protection - IP20

Table 2.2 Dimensions and technical data of automatic pellet burner “ERATO

GP20+”

Parameter Dimension Value

Pellet’s characteristic size mm 6 – 8

MJ/kg >17.2 Recommended fuel net calorific value

kWh/kg >4.7

Wood pellets category

A, AB, B

Ash content % See Table 2.4.

Moisture content % Max. 8 – 10%

Table 2.3 Recommended solid biomass fuel properties – wood pellets

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 10/50

Classification of wood pellets, considering their physical properties (based on

fuel proximate analysis) – according to fuel evaluation method, developed and

applied in ERATO company is show on the following table.

Pellet’s category A

d

DU

A %6.0≤

d

A %0.97≥DU

AB

%6.0≤

d

A

%0.97

<

DU

B %0.16.0 ≤<

d

A %0.97≥DU

BC %0.16.0 ≤<

d

A %0.97

<

DU

C %0.2%0.1 ≤<

d

A

%0.97≥DU

CD %0.2%0.1 ≤<

d

A %0.97

<

DU

D %0.3%0.2 ≤<

d

A %0.97≥DU

DE %0.3%0.2 ≤<

d

A

%0.97

<

DU

E %0.3>

d

A %0.97≥DU

EF %0.3>

d

A %0.97

<

DU

Table 2.4. Pellets classification, considering their physical properties

where :

A

d

– ash contents, dry basis, [%];

DU – mechanical durability, [%];

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 11/50

3. Description of the construction of automatic pellet burner “ERATO

GP20+”

3.1. Main properties

The burner consists of the following elements/modules:

• The basis part of the pellet burner is the main unit, which consists of:

• Combustion chamber, which forms combustion domain and

optimal environment for solid biomass combustion, is designed of

high quality stainless steel;

• Grate of the combustion chamber, which could be easily

detached and reveals access for ash removal;

• Air duct, which uniformly distributes the airflow and ensures safe

cooling of the elements of the burner;

• Electric heater, which heats and ignites the fuel. The heater is

positioned beneath the inclined plate of the grate in the combustion

chamber;

• Air supply fan, equipped with Hall sensor for rotation speed

monitoring;

• Photosensor, which monitors the intensity/presence of the

combustion process, installed aside of the combustion chamber for

easy access and cleaning;

• Alarm thermo-probe, which stops and blocks burner operation in

case of “back fire” process in the fuel delivery pipe;

• On-position switch (safety sensor), which stops and blocks the

burner operation if it is detached from the appliance- heat energy

consumer;

• Control board, which monitors and controls the operation of the

burner and indicates its status;

• Transport auger connector, which realizes power supply to the

electric motor of the auger;

• Interface panel, which is equipped with light indicators and

thermal capacity control gauge;

• Transparent window, though which the operation of the control

board could be checked without removing the cover and any

interventions;

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 12/50

• Electrically driven (external for the main unit) fuel transport auger,

which extracts the solid fuel from the bunker and delivers pellets to the

main unit, according to the operating mode of the burner. The transport

auger consists of electric gear-motor, a transport pipe with one end in the

fuel hopper and the other end is side opened and delivers fuel to the main

unit though a aperture;

• Flexible hose, which is made o f specific semitransparent thermal resistant

material (in case of combustion process it does not emit toxic substances

and does not sustain combustion process), which connects the transport

auger and the main module;

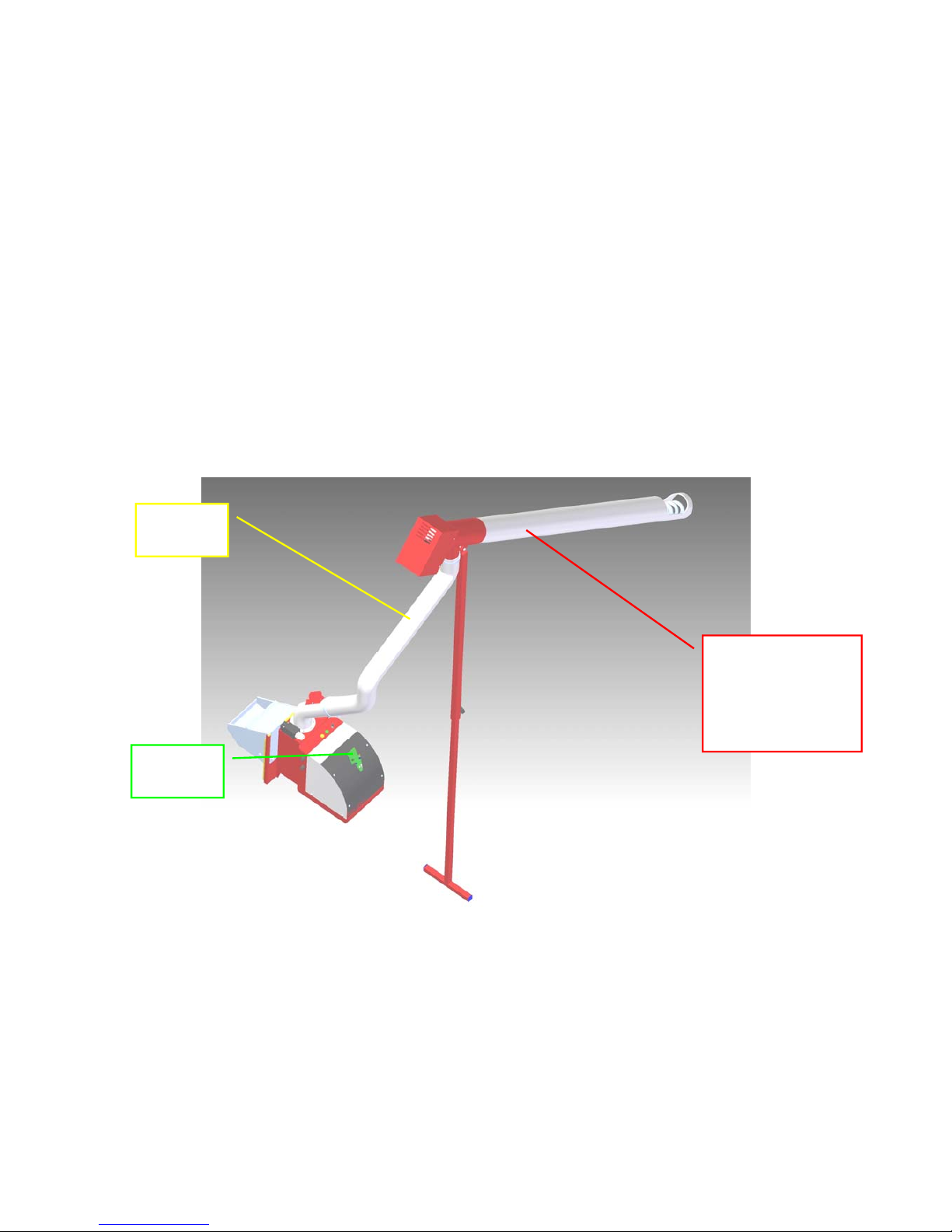

The main modules of the pellet burner and their arrangement are shown of the

following figure.

Figure 3.1 Arrangement of the modules of the pellet burner (top view);

Elements and modules of the main unit are shown on figure 3.2 and figure 3.3.

Main unit

Fuel transport

auger (from the

bunker to the main

unit)

Flexible

pipe

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 13/50

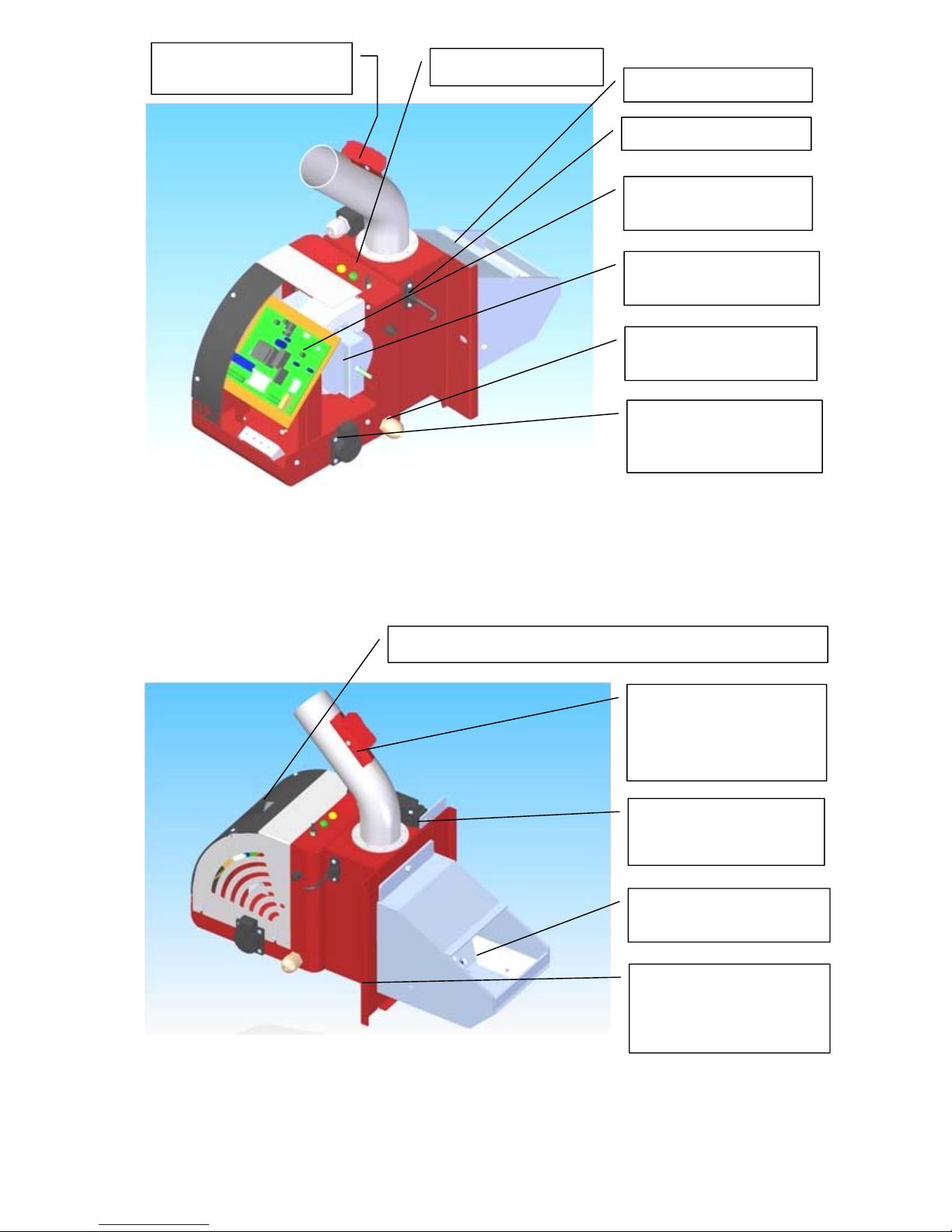

Figure 3.2 Section view of the elements of the main unit of the burner;

Figure 3.3 Side view of the main unit of the burner;

Combustion chamber

Photosensor

Power supply cable

Auger power supply

plug

Control board of the

burner

Interface panel

Flap and air supply fan

“Back fire” safety alarm

thermo-

p

robe

Fuel delivery pipe and

“back fire” safety

thermo-probe

Grate of the combustion

chamber

“L” shaped element and

on-position safety

Installation flange for

attaching the main

module to a consumer

unit

Control board monitoring transparent window

Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 14/50

3.2. Specific design measures in order to increase the safety operation of

the burner

• The ignition and the combustion process is monitored by microprocessor

control board;

• The ignition process is monitored and in case that the fuel is not ignited

for some reason, after certain number of ignition trials, the operation of

the burner is stopped and alarm mode is indicated;

• In case that fuel is consumed from the hopper, than after the defined

number of ignition trials the burner will go out in stop mode and alarm is

indicated as well;

• The flexible hose, which connects the fuel transport auger with the main

unit, is transparent and is made of specific heat resistant material;

• Information stickers are applied, indicating certain precautions measures

and correct operation of the unit;

• The burner is equipped with safety elements, which are involved in back

fire protection system:

o Free falling duct, which practically interrupts the fuel flow between

the transport auger and the main module. This duct is

approximately 250mm long. Beside that, the fuel auger is

connected to the main unit by a flexible hose, which does not

contain fuel. The grate of the burner is however charged with

controlled amount of fuel, which is utilized at controlled

combustion process and possibility of back fire is strongly reduced;

o Sensor of “back fire” alarm thermo-probe, which is positioned on

the fuel delivery pipe of the main unit, activates at surface

temperature levels above 90 – 95

o

C. In case of alarm thermo-probe

activation, the main unit and the fuel transport auger are stopped

and switched to alarm mode. This mode is indicated by appropriate

signals of the LEDs on the control board of the main unit. The

alarm mode is not automatically deactivated and needs manual

restarting. The cause of the alarm situation should be clarified and

precaution measures should be taken before restarting the burner

(performed by switching OFF and back ON the main power

supply).

Loading...

Loading...