Page 1

Epson® SureColor

F6070

User’s Guide

®

Page 2

Copyrights and Trademarks

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Seiko Epson Corporation. The information contained herein is designed only for use with this Epson

printer. Epson is not responsible for any use of this information as applied to other printers.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of accident, misuse, or

abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.)

failure to strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

Seiko Epson Corporation shall not be liable for any damages or problems arising from the use of any options or

any consumable products other than those designated as Original Epson Products or Epson Approved Products

by Seiko Epson Corporation.

Seiko Epson Corporation shall not be held liable for any damage resulting from electromagnetic interference that

occurs from the use of any interface cables other than those designated as Epson Approved Products by Seiko

Epson Corporation.

EPSON, Epson UltraChrome, and SureColor are registered trademarks and EPSON Exceed Your Vision is a

registered logomark of Seiko Epson Corporation.

General Notice: Other product names used herein are for identification purposes only and may be trademarks of

their respective owners. Epson disclaims any and all rights in those marks.

This information is subject to change without notice.

© 2013 Epson America, Inc. 8/13

CPD-38765R1

Copyrights and Trademarks 2

Page 3

Contents

Chapter 1 Introduction

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

When choosing a location for this product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

When setting up this product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

When using this product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

When handling the ink packs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Warnings, Cautions, Important and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Illustrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating System Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Printer Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Slider (chip holder). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Roll Paper Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

LCD Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Realizing High Productivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Ease-of-Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Notes on Usage and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Installation Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Notes When Using the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Notes When Not Using the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Notes on Handling Ink Packs and Ink Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Notes on Handling Paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Using the Supplied Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Contents of the Software CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Starting Epson LFP Remote Panel 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Exiting Epson LFP Remote Panel 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Uninstalling Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Chapter 2 Basic Operations

Loading and Removing the Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Loading Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Cutting Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Removing Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Viewing and Changing Media Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Checking Media Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Adjusting Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Contents 3

Page 4

Replacing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Before Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Saving Optimal Settings for the Current Paper (Print Paper Settings) . . . . . . . . . . . . . . . . . . . . . . . . .39

Custom Paper Setting Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Saving Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Turning Off the Power Using Power Off Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Canceling Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Chapter 3 Using the Control Panel Menu

Menu Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

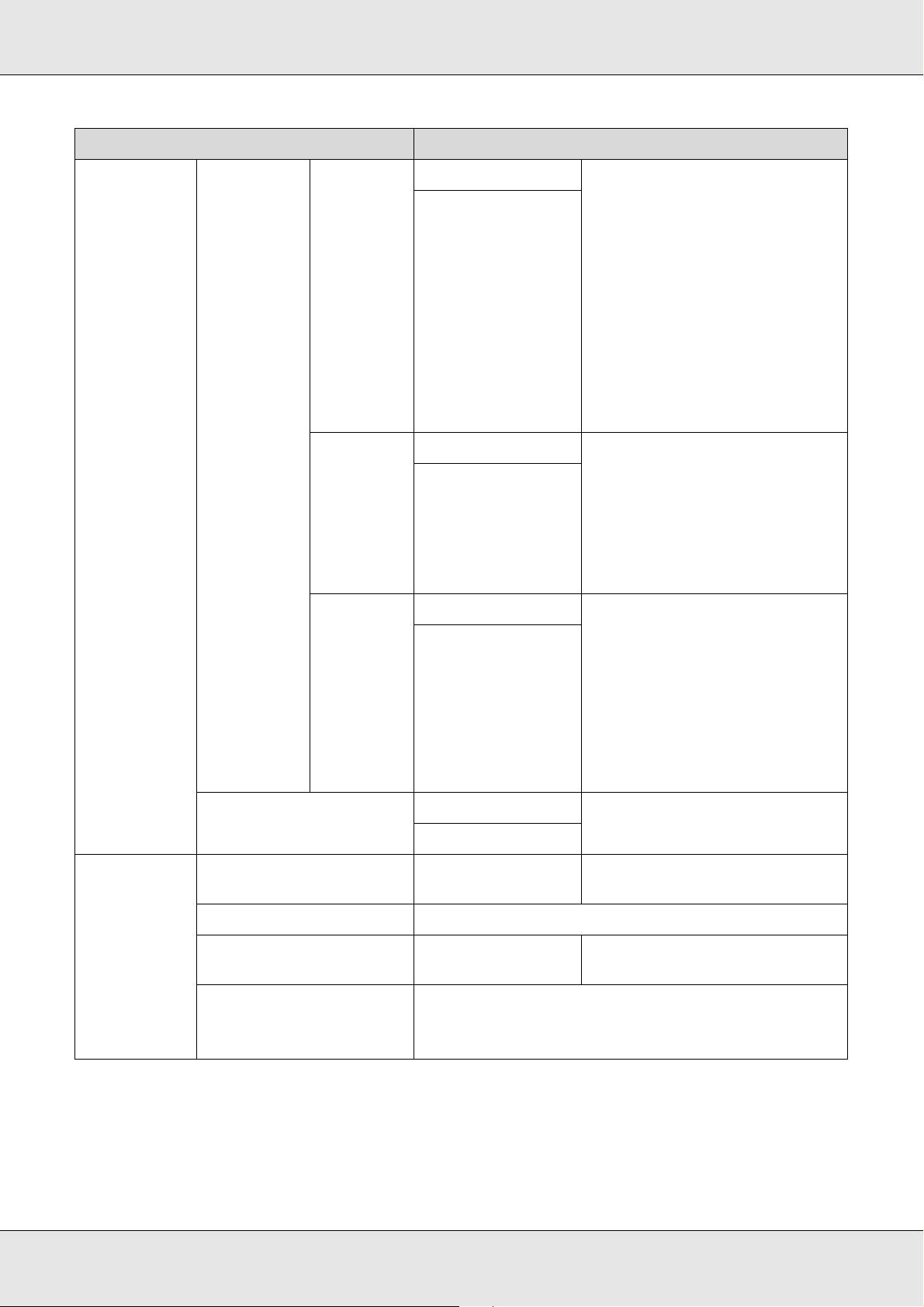

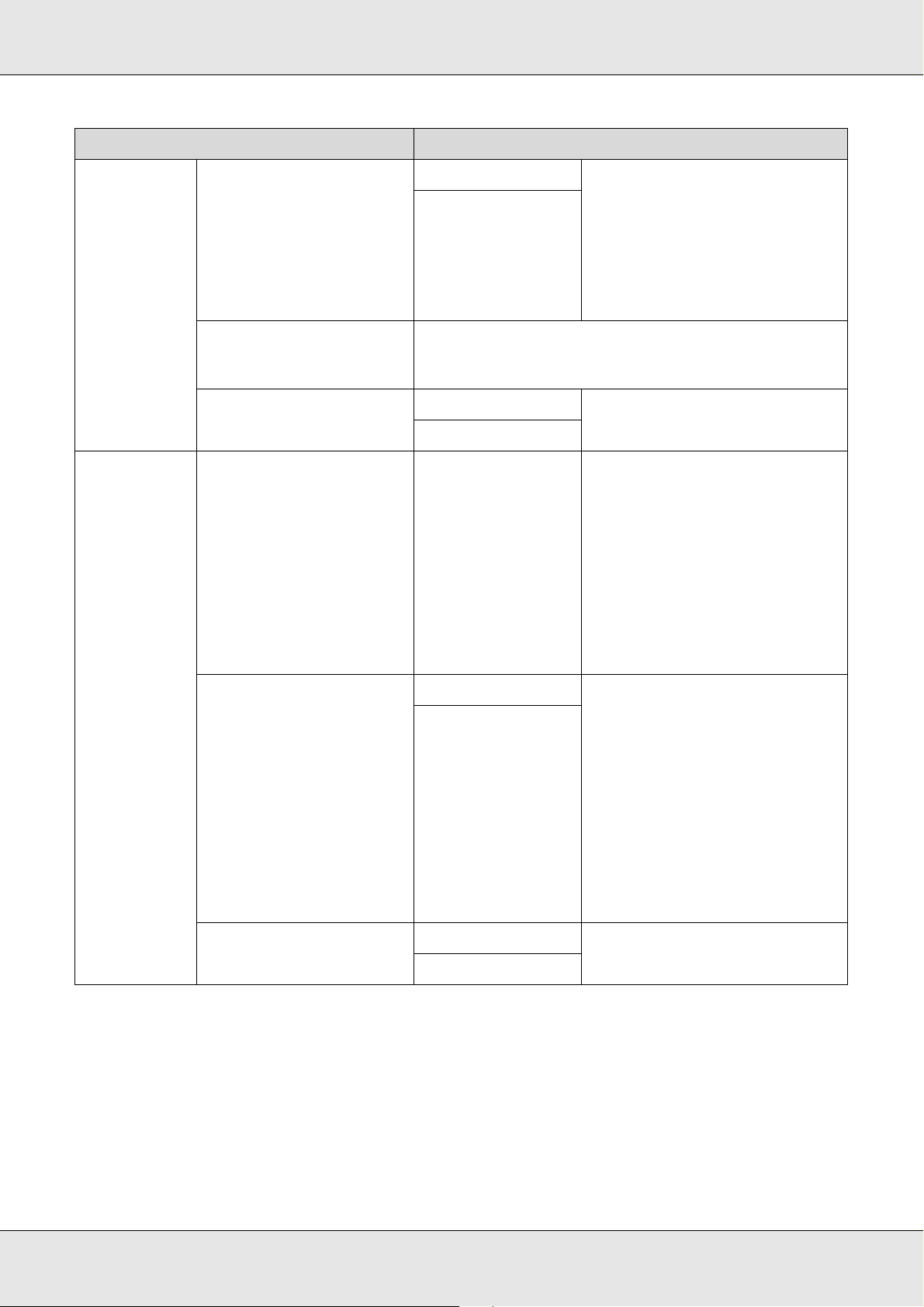

Menu List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Menu Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Print Queues Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Paper Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Chapter 4 Maintenance

Adjusting the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Checking for Clogged Nozzles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Cleaning the Print Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Minimizing Print Misalignments (Head Alignment). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Replacing and Refilling Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Time Period for Chip Unit Replacements and Ink Refills. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Procedure for Chip Unit Replacement and Ink Refills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Replacing Maintenance Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Replacing the Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Disposal of Used Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Parts That Are Periodically Replaced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Cleaning the Outside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Cleaning the Inside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Chapter 5 Problem Solver

What to Do When a Message Is Displayed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

When a Maintenance Call/Service Call Occurs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

You cannot print (because the printer does not work) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Contents 4

Page 5

The printer sounds like it is printing, but nothing prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

The prints are not what you expected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Feeding or ejecting problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Appendix A Options and Information

Options and Consumable Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Supported Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Moving and Transporting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Moving the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Specifications Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Standards and Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

FCC Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Appendix B Where To Get Help

Contacting Epson Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Appendix C Software License Terms

Open Source Software Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Bonjour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Other Software Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Info-ZIP copyright and license . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Contents 5

Page 6

Chapter 1

Introduction

Important Safety Instructions

Read all of these instructions before using the printer. Also be sure to follow all warnings

and instructions marked on the printer.

When choosing a location for this product

O Place this product on a flat, stable surface that is larger than this product. This product

will not operate properly if it is tilted or at an angle.

O Avoid places subject to rapid changes in temperature and humidity. Also keep it away

from direct sunlight, strong light, or heat sources.

O Avoid places subject to shocks and vibrations.

O Keep this product away from dusty areas.

O Place this product near a wall outlet where the plug can be easily unplugged.

When setting up this product

O Do not block or cover the openings in this product’s cabinet.

O Do not insert objects through the slots. Take care not to spill liquid on this product.

O This product’s power cord is for use with this product only. Use with other equipment

may result in fire or electric shock.

O Connect all equipment to properly grounded power outlets. Avoid using outlets on the

same circuit as copiers or air control systems that regularly switch on and off.

O Avoid electrical outlets controlled by wall switches or automatic timers.

O Keep the entire computer system away from potential sources of electromagnetic

interference, such as loudspeakers or the base units of cordless telephones.

O Use only the type of power source indicated on the product’s label.

Introduction 6

Page 7

O Use only the power cord that comes with this product. Use of another cord may result

in fire or electric shock.

O Do not use a damaged or frayed power cord.

O If you use an extension cord with this product, make sure the total ampere rating of the

devices plugged into the extension cord does not exceed the cord’s ampere rating.

Also, make sure the total ampere rating of all devices plugged into the wall outlet does

not exceed the wall outlet’s ampere rating.

O Do not attempt to service this product yourself.

O Unplug this product and refer servicing to qualified service personnel under the

following conditions: The power cord or plug is damaged; liquid has entered the

product; the product has been dropped or the cabinet damaged; the product does not

operate normally or exhibits a distinct change in performance.

O If damage occurs to the plug, replace the cord set or consult a qualified electrician. If

there are fuses in the plug, make sure you replace them with fuses of the correct size

and rating.

When using this product

O Do not put your hand inside this product.

O Do not move the print head by hand; otherwise you may damage this product.

O Always turn the product off using the Power button on the control panel. When this

button is pressed, the Power light flashes briefly then goes off. Do not unplug the power

cord or turn off the product until the Power light stops flashing.

When handling the ink packs

O Keep ink packs out of the reach of children and do not drink the ink.

O Wear protective eyewear and gloves when refilling ink tanks.

O Should ink contact your skin or enter your eyes or mouth, immediately take the

following actions:

If fluid adheres to your skin, immediately wash it off using large volumes of soapy water.

Consult a physician if the skin appears irritated or is discolored.

If fluid enters your eyes, rinse immediately with water. Failure to observe this precaution

could result in bloodshot eyes or mild inflammation.

Introduction 7

Page 8

If swallowed, induce vomiting and consult a physician immediately.

The lithium batteries in this product contain Perchlorate Material - special handling may

apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate.

Warnings, Cautions, Important and Notes

Warning:

Warnings must be followed to avoid serious bodily injury.

w

Caution:

c

Important:

Note:

Illustrations

The illustrations in this manual may differ slightly from the actual objects they are intended

to represent.

Cautions must be followed to avoid damage to this

product or bodily injury.

Important must be followed to avoid damage to this

product.

Notes contain useful or additional information on the

operation of this product.

Operating System Versions

In this documentation, the following abbreviations are used.

Windows refers to Windows® 8, Windows 7, Windows Vista®, Windows XP.

O Windows 8 refers to Windows 8, Windows 8 Pro, and Windows 8 Enterprise.

O Windows 7 refers to Windows 7 Home Basic, Windows 7 Home Premium, Windows 7

Professional, and Windows 7 Ultimate.

O Windows Vista refers to Windows Vista Home Basic Edition, Windows Vista Home

Premium Edition, Windows Vista Business Edition, Windows Vista Enterprise Edition,

and Windows Vista Ultimate Edition.

Introduction 8

Page 9

O Windows XP refers to Windows XP Home Edition, Windows XP Professional x64

Edition, and Windows XP Professional.

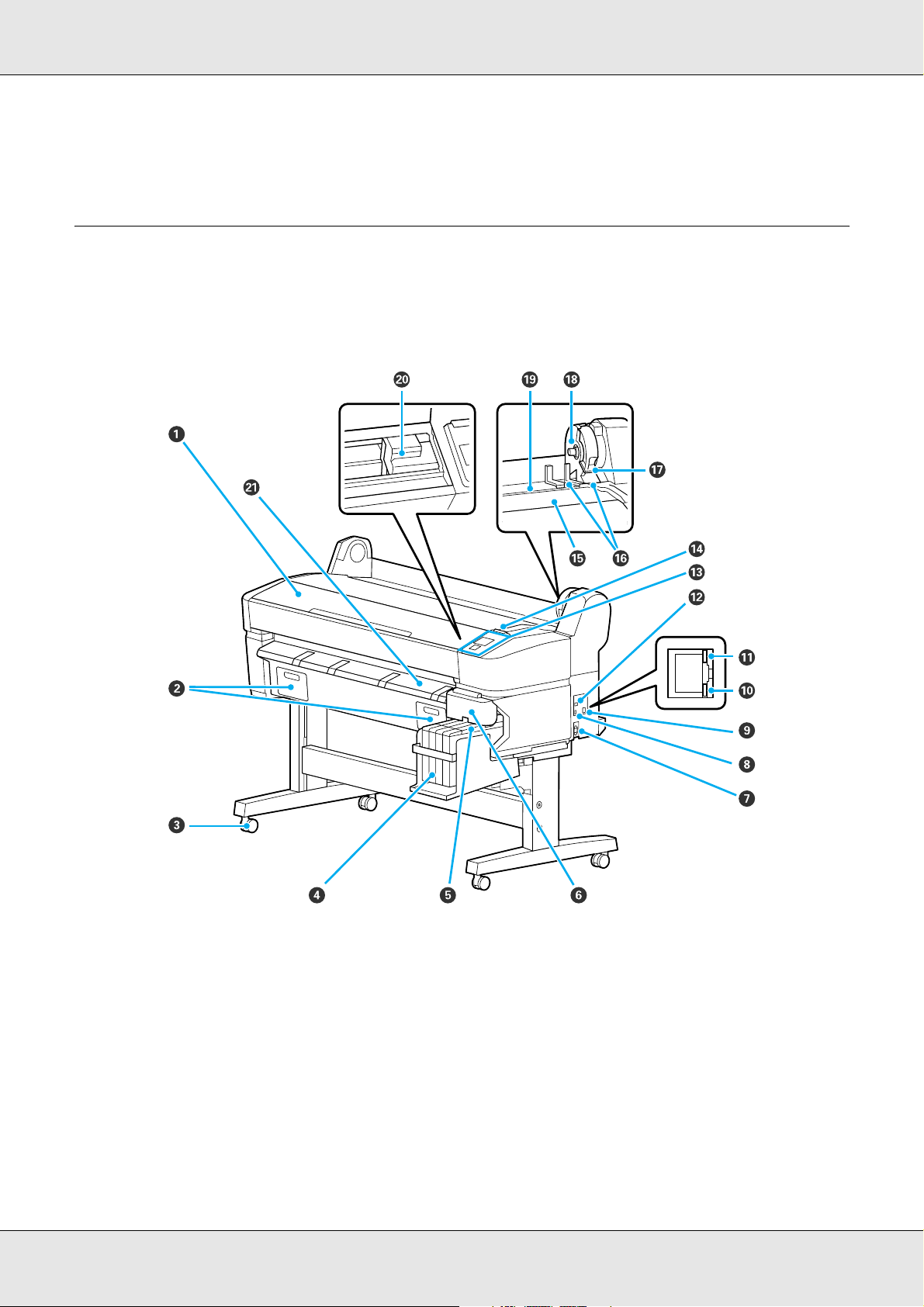

Printer Parts

Front

Printer cover

1

Open this cover when cleaning the printer or clearing jams.

Maintenance box covers

2

Open these covers when replacing the maintenance box.

See “Replacing Maintenance Boxes” on page 74.

Casters

3

There are two casters on each leg. The casters are normally kept locked once the printer is

in place.

Introduction 9

Page 10

Ink tanks

4

Hold ink used for printing.

Slider (chip holder)

5

See “Slider (chip holder)” on page 11.

Side cover

6

Open the side cover to remove the slider for chip unit replacement. Always close the side

cover securely after inserting the slider.

7 AC inlet

Connect the supplied power cable here.

Option port

8

No options are currently available for the printer.

LAN port

9

Connects the LAN cable.

Data light

10

The network connection status and data reception are indicated by a lit or flashing light.

On : Connected.

Flashing : Receiving data.

Status light

11

The color indicates the network transmission speed.

Off : 10Base-T

Red : 100Base-T

Green : 1000Base-T

USB port

12

Connect the USB cable here.

Control panel

13

See “Control Panel” on page 13.

Alert lamp

14

This lamp lights or flashes when an error occurs.

Lights or

flashes

Off : No error.

: An error has occurred. How the lamp lights or flashes varies with the type of error.

The control panel displays a description of the error.

Roll rest

15

When loading roll paper, place it on this rest and attach the roll paper adapters.

See “Loading Roll Paper” on page 27.

Introduction 10

Page 11

Adapter guides

16

Guides for attaching roll paper. Move the roll along these guides to attach it to the adapter

holder.

See “Loading Roll Paper” on page 27.

Roll lock lever

17

A lever that locks roll paper in place after the roll is attached to the adapter holder.

Adapter holder

18

The roll paper adapter is placed in this holder after the roll paper is attached.

Paper slot

19

The slot through which roll paper and single sheets are fed during printing.

Feed single sheets one at a time.

Print head

20

Fires ink via high density nozzles while moving left and right to print.

Paper output (eject) guide

21

Guides paper as it is ejected.

Slider (chip holder)

Slider

1

Attach the chip unit included with the ink pack before refilling the ink.

Ink inlet cover

2

Open this cover to refill the ink tank.

3 Chip unit

The unit that includes an IC chip. This is included with the ink pack.

Introduction 11

Page 12

Roll Paper Adapter

Use the supplied roll paper adapter when loading roll paper onto the printer.

See “Loading Roll Paper” on page 27.

Adapter lock lever

1

Lift to unlock, lower to lock. Unlock when attaching roll paper to the adapter, lock once the

roll is attached.

Size lever

2

Position according to the size of the roll core.

Introduction 12

Page 13

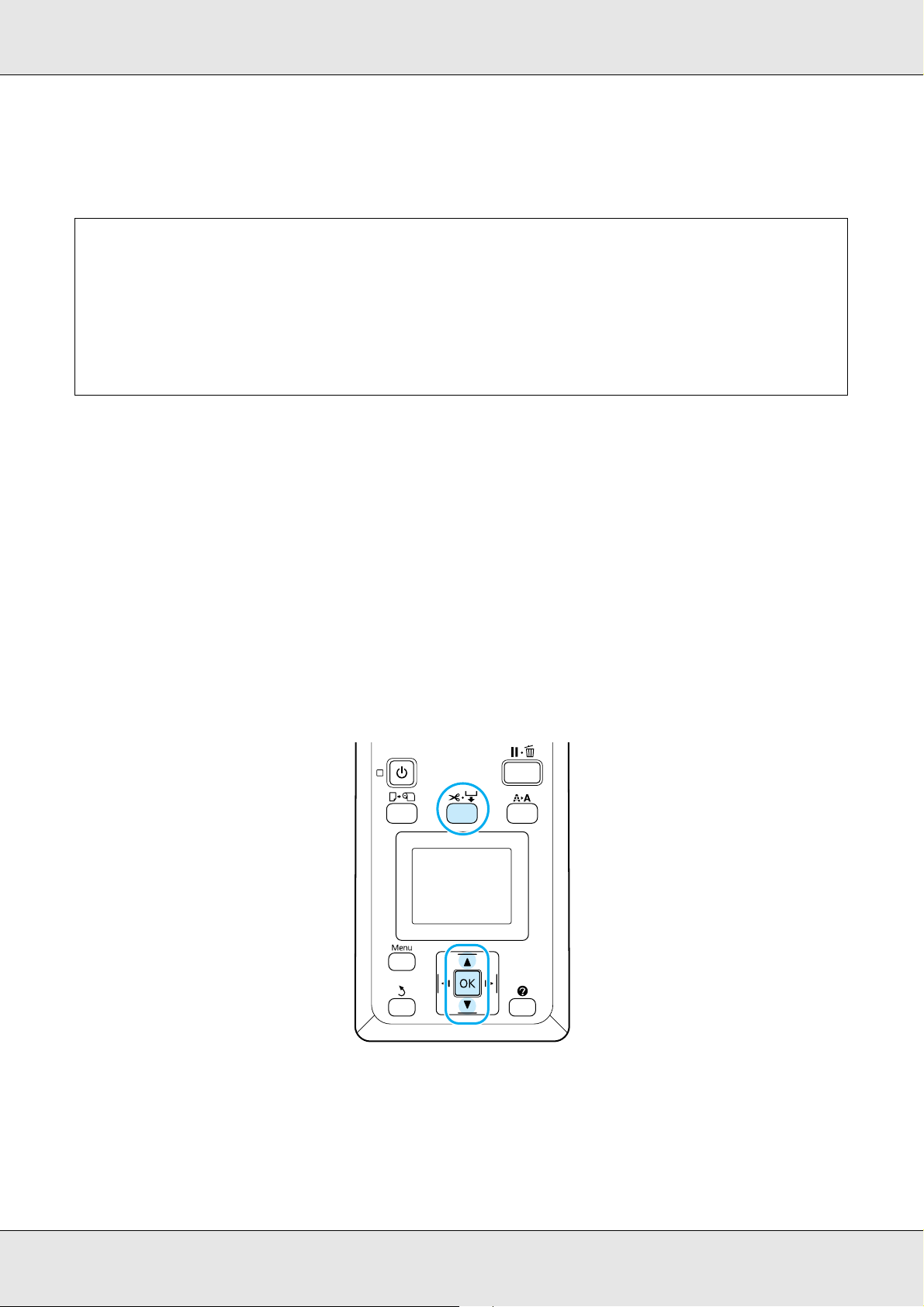

Control Panel

P button (Power button)

1

Turns the power on and off.

P light (Power light)

2

The printer’s operational status is indicated by a lit or flashing light.

On : The power is on.

Flashing : The printer is receiving data or cleaning the print head or performing other

operations in the course of being shut down.

Off : The power is off.

( button (Load/Remove Paper button)

3

Pressing this button displays the Load/Remove Paper menu. Instructions for loading or

removing the paper can be displayed by highlighting either Remove Paper or the type of

paper currently loaded and then pressing the OK button. Follow the on-screen instructions

to load or remove the paper.

Screen

4

Displays the printer’s status, menus, error messages, and so on.

See “LCD Screen” on page 15.

Introduction 13

Page 14

Menu button

5

Displays the menu for the tab currently selected in the display.

See “Using the Control Panel Menu” on page 48.

y button (Back button)

6

If menus are displayed, pressing this button takes you up one level in the menu hierarchy.

See “Menu Operations” on page 48.

l/r buttons (Left/Right buttons)

7

O Use these buttons to select tabs. The selected tab is highlighted and the content of the

info display area updated for the selected tab.

See “LCD Screen” on page 15.

O If menus are displayed, these buttons can be used to position the cursor or to delete

characters when entering text for items such as Setting Name or IP Address.

u/d buttons (Up/Down buttons)

8

When menus are displayed, these buttons can be used to highlight items or options.

See “Menu Operations” on page 48.

Z button

9

O Displays the menu for the tab currently selected in the display.

See “Using the Control Panel Menu” on page 48.

O When menus are displayed and an item is highlighted, pressing this button displays the

sub-menu for the highlighted item.

O If pressed while a parameter is selected from the Menu, the parameter is set or

executed.

10

11

12

button (Help button)

Displays the information area in the

" button (Maintenance button)

Displays the Maintenance menu, which is used for nozzle checks and head cleaning.

See “Adjusting the Print Head” on page 62.

B tab.

W button (Pause/Cancel button)

O The printer enters pause status if this is pressed while printing. To release the pause status,

press the W button again, or select Pause Cancel on the screen and then press the OK

button. To cancel print jobs being processed, select Job Cancel on the screen and then

press the OK button.

O Pressing this button while a menu or help is displayed closes the menu or help and returns

the printer to ready status.

Introduction 14

Page 15

) button (Feed/Cut Media button)

13

O This button is used to manually cut roll paper using the built-in cutter.

See “Manual cut method” on page 32.

O If printing is not currently in progress and the printer is loaded with roll paper, you can

feed paper ahead by pressing first this button and then the d button. Press the u button

to rewind. Keep the d button pressed to feed the paper up to 9.8 feet (3 m). Keep the

u button pressed to rewind the paper up to 7.9 inches (20 cm).

When the u button is used to rewind roll paper, the paper will pause when the end of

the roll reaches the starting print position. Release the button and then press it again to

resume.

LCD Screen

Message

1

Displays the printer’s status, operation, and error messages.

See “What to Do When a Message Is Displayed” on page 83.

Introduction 15

Page 16

Tabs/Info Display Area

2

The tab/info display area contains the six tabs listed below.

Use the l r buttons to select a tab.

Information on the selected tab appears in the info display area.

, The Print Queues Tab

This tab displays print job status and can be used to access the Print Queues menu.

The Info Display Area

The print queues tab info display area shows the name of the current print job.

Pressing the OK or Menu button when this tab is selected displays the Print Queues

menu.

. The Paper Tab

This tab shows the type of paper in the printer and can be used to access the Paper

menu.

The Info Display Area

The paper tab info display area shows the Source and Media Type. When roll paper is

used, it also shows the roll width. In addition, when On is selected for Roll Paper

Remaining, it shows the amount of roll paper remaining. When the length remaining

drops below the value selected for Remaining Alert, a icon appears above the tab

icon and an alert like that shown below is displayed to warn that the printer is nearing

the end of the roll.

Pressing the OK or Menu button when this tab is selected displays the Paper menu.

See “Paper Menu” on page 52.

The Ink Tab

The ink tab displays the status of the chip unit.

The Info Display Area

The display changes as follows whenever an error is detected in an installed chip unit.

Normal Warning or Error

1 Status indicators

The chip unit status is indicated as follows.

No error. Ready to print.

An error occurred. Check the message on the screen, and clear the error.

The chip unit could not be recognized or it is not compatible with the

printer. Or, the slider is not locked.

Check the message on the screen

Introduction 16

Page 17

The chip unit requires replacement. Replace the chip unit with one from

a new ink pack.

As it gets closer to time to replace the chip unit, a icon will begin to

flash.

2 Ink color codes

BK Black

YYellow

MMagenta

CCyan

The Maintenance Tab

-

The maintenance tab shows the status of the maintenance boxes and is used to display

the Maintenance menu.

The Info Display Area

The maintenance tab info display area shows maintenance box status and the

approximate amount of space remaining in the maintenance box. The icons change

as follows to show errors or to warn when the maintenance box is nearing the end of its

service life.

Normal Warning or Error

1

1 Status indicators

Maintenance box status is indicated as follows.

No error. The height of the indicator corresponds to the amount of space

remaining.

The maintenance box is nearing the end of its service life. Make sure you

have a new maintenance box.

The maintenance box is at the end of its service life. Replace the

maintenance box with a new one.

Pressing the OK or Menu button when this tab is selected displays the Maintenance

menu.

See “Maintenance Menu” on page 55.

The Setup Tab

/

The setup tab displays the IP address and menus for various settings.

The Info Display Area

The setup tab info display area shows the IP address currently assigned, if any.

Pressing the OK or Menu button when this tab is selected displays the Setup menu.

See “Setup Menu” on page 56.

Introduction 17

Page 18

Features

The main features of this printer are described below.

Realizing High Productivity

High-speed printing

The speed of the print head and paper feed have been increased for faster printing.

The printer is equipped with a high-speed rotary cutter for quick cutting, significantly

increasing productivity.

Improved operability with an easy to see and use color screen

Designed for intuitive operation, the large, brightly-lit, color LCD display is easy to

understand and easy to use.

The large display offers detailed, easy-to-understand error messages and illustrated

guides to loading paper.

See “LCD Screen” on page 15.

Checking current operating status even from afar thanks to an alert lamp

Errors are immediately obvious even at a distance, thanks to the large, highly visible alert

lamp. This helps prevent any wasted time when printing has stopped due to running out of

ink or paper.

High-capacity ink tanks included

The printer includes high-capacity ink tanks for high productivity. We also offer 1000 ml

high-capacity ink packs for ink refill. This eliminates the need for frequent troublesome ink

cartridge replacements.

Ease-of-Use

Spindle-free roll paper adapter makes loading roll paper a snap

The lack of a spindle makes it possible to load and remove roll paper even in environments

where space is at a premium.

To load roll paper, simply place it on the roll rest and attach roll paper adapters to both

ends.

See “Loading Roll Paper” on page 27.

Introduction 18

Page 19

Easy maintenance

Roll paper and all replacements, including ink refills, maintenance boxes, and cutter, are

installed from the front, allowing the printer to be placed against a wall. The printer does not

have to be moved to allow rear access.

Notes on Usage and Storage

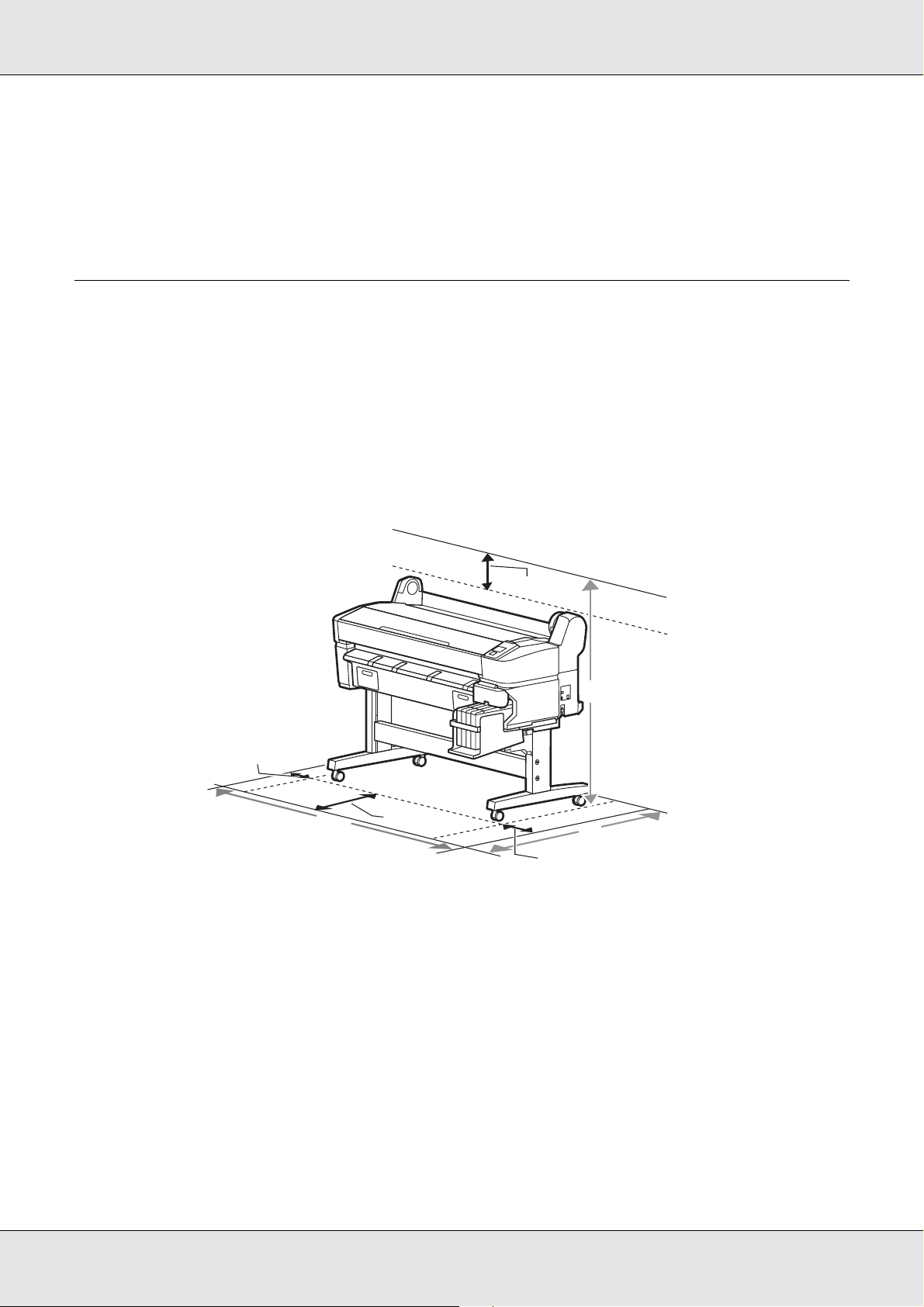

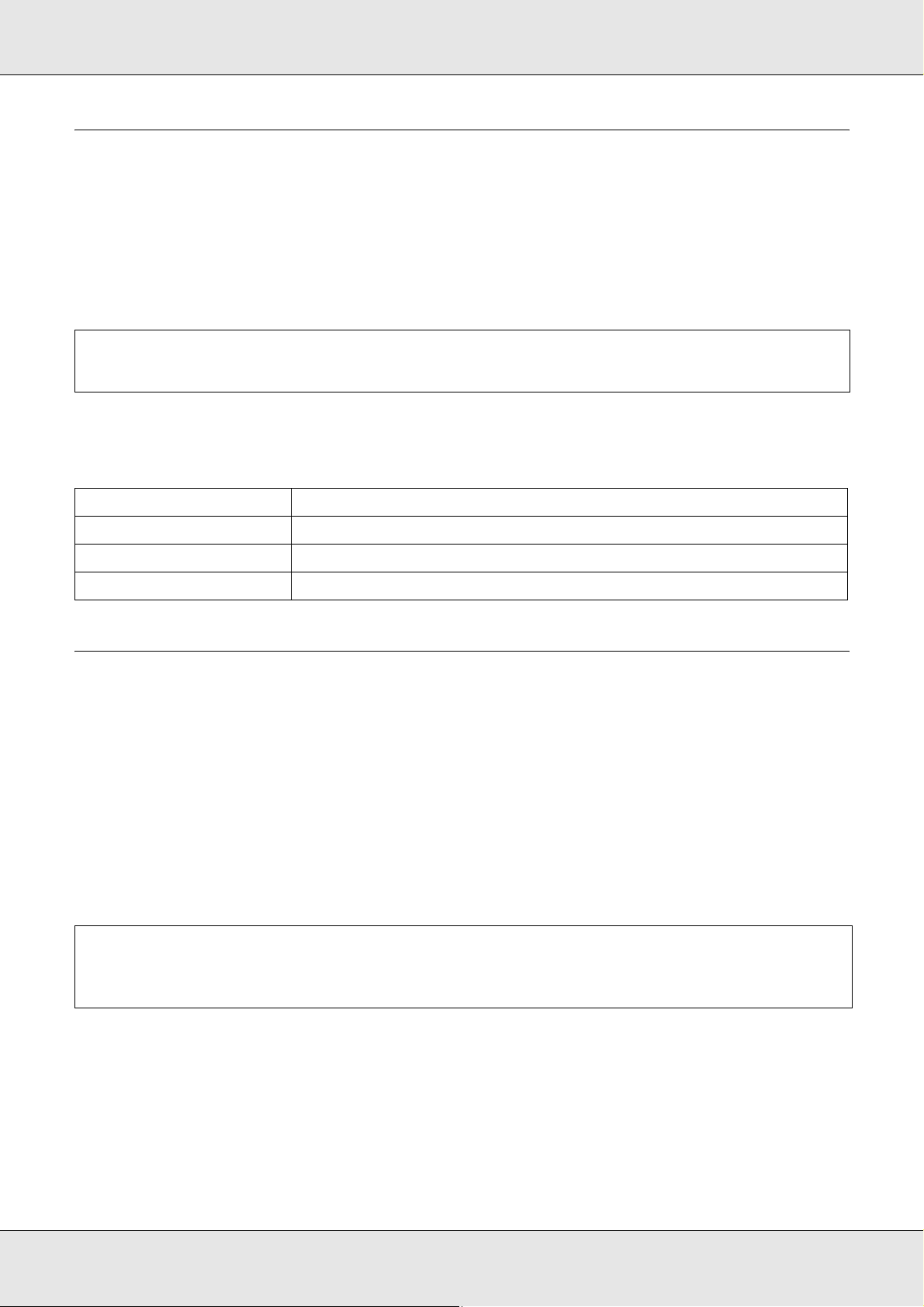

Installation Space

Make sure that you secure the following space, clear of any other objects, so that paper

ejection and consumable replacement are not obstructed.

See “Specifications Table” on page 96 for the external dimensions of the printer.

5.9 in.

(150 mm)

0.4 in. (10 mm)

50.3 in. (1278 mm)

7

0

i

n

(

1

7

6

23.6 in.

(600 mm)

.

8

m

m

)

55.6 in. (1413 mm)

5.9 in. (150 mm)

Introduction 19

Page 20

Notes When Using the Printer

Note the following points when using this printer to avoid breakdowns, malfunctions, and

print quality decline.

O When using the printer, observe the operating temperature and humidity range

described in the “Specifications Table”. See “Specifications Table” on page 96.

Even when the conditions above are met, you may not be able to print properly if the

environmental conditions are not suitable for the paper. Be sure to use the printer in an

environment where the paper’s requirements are met. For more details, see the

documentation supplied with the paper.

Also, when operating in dry areas, air conditioned environment, or under direct sunlight,

maintain the appropriate humidity.

O Do not install the printer next to heat sources or directly in the path of air from a

ventilator or air conditioner. Failure to observe this precaution could result in the print

head nozzles drying and clogging.

O The print head may not be capped (i.e., may not move to the right side) if an error

occurs and the printer is turned off without first resolving the error. Capping is a function

for automatically covering the print head with a cap (lid) to prevent the print head from

drying out. In this case, turn on the power and wait a while until capping is performed

automatically.

O When the power is on, do not remove the power plug or cut the power at the breaker.

The print head may not be capped properly. In this case, turn on the power and wait a

while until capping is performed automatically.

O Even when the printer is not in use, some ink will be consumed by head cleaning and

other maintenance operations needed to keep the print head in good condition.

Notes When Not Using the Printer

If you are not using it, note the following points when storing the printer. If it is not stored

correctly, you may not be able to print properly the next time it is used.

O If you do not print for a long time, the print head nozzles may become clogged. Turn the

printer on at least once every two weeks to prevent the print head from clogging.

When the printer is turned on, head cleaning is performed automatically. Do not turn the

printer off until cleaning is complete.

Leaving the printer for too long without turning it on may result in a malfunction. Repair

work for such malfunction will be charged.

Introduction 20

Page 21

O If you will not be using the printer for more than 2 weeks, maintenance must be

performed by a service engineer before and after this period. This maintenance work

will be charged.

Note that even if proper maintenance has been done before leaving the printer for a

long time, repair may be necessary when doing maintenance for reusing the printer,

depending on the period and conditions of storage. In such a case, the repair work will

also be charged.

O The roller may leave an impression on paper that is left in the printer. This can also

cause wavy or curled paper resulting in paper feeding problems, or the print head could

be scratched. Remove any paper when storing or not using the printer.

O Store the printer after confirming that the print head has been capped (the print head is

positioned at the far right). If the print head is left uncapped for a long time, the print

quality may decline.

Note:

If the print head is not capped, turn the printer on, and then turn it off.

O To prevent the accumulation of dust and other foreign matter in the printer, close all

covers before placing it in storage.

If the printer will be not be used for an extended period, protect it with an anti-static cloth

or other cover.

The print head nozzles are very small, and they can become clogged easily if fine dust

gets on the print head, and you may not be able to print properly.

O When turned on after an extended period of disuse, the printer may automatically

perform head cleaning to ensure print quality.

Head cleaning will end after about 10 to 15 minutes.

Notes on Handling Ink Packs and Ink Tanks

Note the following points when handling ink packs and ink tanks.

O Do not remove the ink tanks.

Ink tanks are calibrated when installed. Removing them can harm quality and

functionality.

O Store ink packs at room temperature out of direct sunlight.

Introduction 21

Page 22

O To ensure print quality, use all the ink in the ink pack before one of the following

(whichever comes first):

The date printed on the ink pack

25 days from the day that the ink tank was refilled from the ink pack

O If the ink pack has been stored in a cold location for a long period of time, keep at room

temperature for at least 4 hours before using.

O When refilling the ink in an ink tank, be sure to use all the ink in the ink pack at once.

O Refill the ink tank as soon as possible after opening the ink pack.

O Do not place any objects on top of the ink tanks.

Notes on Handling Paper

Note the following points when handling and storing the paper. If the paper is not in good

condition, print quality may decline.

Check the documentation supplied with each paper.

O Do not fold the paper or scratch the surface of the paper.

O Avoid touching the printable surface of the paper with your bare hands. Moisture and

oils from your hands can affect print quality.

O Handle paper by the edges. We recommend wearing cotton gloves.

O Do not wet the paper.

O Avoid locations that are subject to direct sunlight, excessive heat, or humidity.

O Remove roll paper that is not in use from the printer. Rewind it correctly and then store

it in the original packaging that came with the roll paper. If you leave the roll paper in the

printer for a long time, its quality may decline.

Notes on handling prints

To maintain long lasting, high quality print results, note the following points.

O Do not rub or scratch the printed surface. If they are rubbed or scratched, the ink may

peel off.

Introduction 22

Page 23

O Do not touch the printed surface; failure to observe this precaution may cause ink to rub

off.

O Make sure the printouts are completely dry before folding of stacking; otherwise, the

color may change where they touch (leaves a mark). These marks will disappear if they

are separated immediately and dried; however, they will remain if not separated.

O Avoid direct sunlight.

Note:

Typically, printouts fade over time (color distortion) due to the effects of light and various

constituents in the air. But if care is taken in how these items are stored, you can help reduce

discoloration.

The colors of printed materials appear different under different lighting conditions (light

sources

sources.

* Light sources include sunlight, fluorescent light, incandescent light, and other types.

*

). The colors of printouts from this printer may also appear different under different light

Using the Supplied Software

Contents of the Software CD

The following applications are available on the supplied software CD. Install as required.

For information about these applications, see the on-line help for the application in

question.

Note:

The included software CD does not contain any printer drivers. A software RIP is required to

print.

Download the latest version of the software from Epson’s website.

Introduction 23

Page 24

Software Name

Epson Driver and Utilities Installs the Epson communications driver (Epson SC-F6000 Series Comm

Driver).

The Epson communications driver is required if the Epson LFP Remote

Panel 2 is to be used to copy paper settings. It is not a printer driver. In

addition, the software RIP may not display printer status if the Epson

communications driver is not installed when the printer is connected to

a computer via USB. See the software RIP documentation for more

information on the status display.

Epson LFP Remote Panel 2 Epson LFP Remote Panel 2 is used to update firmware from a computer

and copy paper settings bank created in the printer’s setup menu to a

computer.

See “Starting Epson LFP Remote Panel 2” on page 24.

EpsonNet Config With this software, you can configure various network settings for the

printer from your computer. This is useful as it allows you to enter

addresses and names using the keyboard.

The documentation is installed with the application.

Starting Epson LFP Remote Panel 2

Launch Epson LFP Remote Panel 2 after confirming that the printer displays Ready.

1. The application can be launched using either of the following two methods.

Double-click the Epson LFP Remote Panel 2 icon on the desktop. The Epson LFP

Remote Panel 2 icon is created when the application is installed.

Click Start > All Programs (or Programs) > Epson LFP Remote Panel 2 > Epson

LFP Remote Panel 2.

2. Click the desired item in the Epson LFP Remote Panel 2 main window.

See Epson LFP Remote Panel 2 help for more information.

Exiting Epson LFP Remote Panel 2

Click Exit in the Epson LFP Remote Panel 2 main window.

Introduction 24

Page 25

Uninstalling Software

To remove the EPson LFP Remote Panel 2 or Epson communications driver, follow the

procedure below.

Important:

O You must log in as an Administrator.

O Enter the Administrator password when prompted and then proceed with the remainder of the

operation.

O Exit any other applications that may be running.

1. Turn off the printer, and unplug the interface cable.

2. Go to the Control Panel and click Uninstall a program from the Programs category.

3. Select the software you want to remove and then click Uninstall/Change (or

Change/Remove or Add/Remove).

Selecting the following deletes the Epson communications drivers.

Epson SC-F6000 Series Comm Driver Printer Uninstall

Select Epson LFP Remote Panel 2 to remove Epson LFP Remote Panel 2.

Introduction 25

Page 26

4. Select the target printer icon, and then click OK.

5. Follow the on-screen instructions to continue.When the delete confirmation message

appears, click Yes.

Restart the computer if you are reinstalling the Epson communications driver.

Introduction 26

Page 27

Chapter 2

Basic Operations

Loading and Removing the Roll Paper

Loading Roll Paper

Load roll paper after attaching the supplied roll paper adapters.

Important:

Insert the paper just before printing. The roller may leave an impression on paper that is left in

the printer.

Note:

The paper that can be used in the printer is detailed in the following section. (See “Supported

Media” on page 94.)

1. Turn on the printer by pressing the P button.

2. Confirm that the adapter holder lock lever is raised.

Basic Operations 27

Page 28

3. Place roll paper on the roll rest on top of the printer.

4. Size the two supplied roll paper adapters to the roll core.

3-inch core

2-inch core

5. Raise the adapter lock lever to release the lock on each of the two roll paper adapters.

Basic Operations 28

Page 29

6. Press the adapters in until they are fully inserted in the roll, with no gaps.

7. Lower the lock levers to lock the adapters in place.

8. Slide the roll paper all the way to the right.

Following the adapter guides, slide the roll slowly back.

Basic Operations 29

Page 30

9. Press the ( button on the control panel. Confirm that Roll Paper is highlighted in the

display and press the OK button.

10.Insert the end of the roll paper in the paper slot and pull it through. Make sure that the

paper is free of slack and that the end is not folded.

Note:

Do not touch the paper where it will be printed. After loading the roll paper, rotate the

roll paper adapters as shown to feed the paper through.

Basic Operations 30

Page 31

11.Lower the roll lock lever.

12.Following the on-screen instructions, press the OK button.

The paper will be fed into the printer.

13.Check the media type.

The printer will display the Paper Type and Roll Paper Remaining settings for the paper

currently selected with the printer. To print at current settings, press the

highlight Keep Settings Above and press the OK button. To change settings, highlight

Change Settings and press the OK button. See “Viewing and Changing Media

Settings” on page 36.

Cutting Roll Paper

Either of the following two methods can be used to cut roll paper after printing.

O Auto Cut:

Cut the roll paper after printing each page automatically using the built-in cutter.

d/u buttons to

Basic Operations 31

Page 32

O Manual cut:

Press the ) button to cut the paper using the built-in cutter. A cutline is printed for

manual cutting and can be used as a guide when cutting paper using the built-in cutter.

Note:

O It may take a while to cut the roll paper.

O Some of the roll paper may not be cut using the built-in cutter. Use a commercially available

cutter to cut the paper. Follow the steps below when using a third-party cutter.

Press the ) button. Keep the d button pressed to feed the paper so that the cut location

is below the paper eject guide. Cut the paper using scissors or a third-party cutter.

Setting method

Use the l/r buttons in the control panel to select the / tab and press the OK or Menu

button. The Setup menu will be displayed; select Printer Setup > Roll Paper Setup> Auto

Cut > On and press the OK button. For manual cutting, select Off. The default setting is

On. See “Setup Menu” on page 56 for more information.

Manual cut method

If Auto Cut is turned off, you can cut at any position via the following procedure after

printing is complete.

Buttons that are used in the following settings:

Basic Operations 32

Page 33

Cutting paper manually using the built-in cutter

1. Press the ) button. Viewing the interior of the printer without opening the printer

cover, press the d button to align the cut location with the mark on the right side of

the printer’s interior.

Note:

The minimum length of paper that can be cut with the built-in cutter is fixed at 2.4 to

5 inches (60 to 127 mm) and cannot be changed. If the cutting position is shorter than

the shortest length above, the paper has to be automatically fed to that length; thus

a margin will have to be left. Cut off the margin with a commercially available cutter.

2. Press the OK button.

The paper is cut by the built-in cutter.

Removing Roll Paper

This section describes how to remove and store roll paper after printing. The pressure

rollers may leave impressions on paper that is left in the printer.

Basic Operations 33

Page 34

Buttons that are used in the following settings:

1. Confirm that the printer is ready and press the ( button.

The Load/Remove Paper menu will be displayed.

2. Press the d/u buttons to highlight Remove Paper and press the OK button.

Note:

To calculate Roll Paper Remaining, you must enter the length of the roll paper when the

roll paper is installed. In order to perform accurate remaining roll paper management, we

recommend opening the

you replace the roll paper.

. tab and recording the amount of roll paper remaining when

3. The paper will automatically be rewound.

Once the paper is rewound, the printer will display Press and load paper.

Note:

When the display shows Turn roll paper adapter to wind up roll paper, open the

roll paper cover and rewind the paper by hand.

Basic Operations 34

Page 35

4. Raise the roll lock lever.

5. Holding the paper by the roll adapters, move the roll to the roll rest.

6. Lift the adapter lock levers to release the roll paper adapters.

7. Remove the roll paper adapters.

After rewinding the roll paper carefully, store it in the original package.

Basic Operations 35

Page 36

Viewing and Changing Media Settings

The following is displayed in the control panel after paper is loaded.

Checking Media Settings

The dialog displays the following options for the paper currently loaded in the printer.

Selected Paper Type

The following display indicates what is used as the basis for paper settings.

RIP settings: Printing is performed based on the RIP settings.

XXXXXXXXXXXXXXXXXX: Printing is performed based on paper settings #1 saved in

the printer.

This printer allows you to configure and save various paper settings depending on the

characteristics of the paper used. You can save up to 10 different settings in setting slots 1

through 10.

See “Saving Settings” on page 40.

Remaining Setup

When this option is turned On, the approximate amount of paper remaining is calculated

based on the set paper length and the amount used in printing, and this value is displayed

in the information display area of the . tab. This allows you to check the amount of paper

remaining on-screen before printing, which helps you to determine when you need to

replace the paper. You can also set a threshold value which, when the amount of paper

remaining decreases below this level, will display a warning message.

Basic Operations 36

Page 37

Adjusting Settings

Follow the steps below to change the settings displayed.

Buttons that are used in the following settings:

1. Select an option.

To print at current settings

Press the d/u buttons to highlight Keep Settings Above and press the OK button.

Then proceed to step 6.

To change settings

Press the d/u buttons to highlight Change Settings and press the OK button.

2. Highlight a setting you wish to change and press the OK button.

3. Highlight an option and press the OK button.

4. Press the y button to return to the dialog in step 2.

5. When settings are complete, highlight Exit and press the OK button.

6. If On is selected for Remaining Setup, you will be prompted to enter the length of the

roll. Press the d/u buttons to choose a value between 15 and 3000 feet (or 5.0 and

999.5 m) and press the OK button. Paper length is set in increments of 1 foot (or 0.5 m).

After a short pause the printer will show Ready, indicating that it is ready to print. Transmit

the data to be printed from a computer.

Basic Operations 37

Page 38

Replacing Paper

This section describes how to replace paper. The procedure is displayed on the control

panel screen. Follow these instructions.

Buttons that are used in the following settings:

1. Confirm that the printer is ready and press the ( button.

The Load/Remove Paper menu will be displayed.

2. Press the d/u buttons to select roll paper, and then press the OK button.

Note:

To calculate Roll Paper Remaining, you must enter the length of the roll paper when the

roll paper is installed. In order to perform accurate remaining roll paper management, we

recommend opening the

you replace the roll paper.

. tab and recording the amount of roll paper remaining when

3. The roll rewinds automatically.

Note:

When the display shows Turn roll paper adapter to wind up roll paper, rewind the

paper by hand.

4. Follow the on-screen instructions to load the paper for the next job.

Basic Operations 38

Page 39

Before Printing

Before printing, adjust the paper settings for the characteristics of the paper you are going

to use. Settings are adjusted as follows.

O Select Custom Paper Setting in the printer Paper menu. See “Paper Menu” on page

52.

O LFP Remote Panel 2 can be used to copy from the computer the paper settings you

configured in the printer settings menu.

Note:

O Be sure to check the paper characteristics such as paper tension, ink fixating, or paper

thickness before adjusting the custom paper setting. For the paper's characteristics, check

the paper's documentation or with your local dealer.

O Test the print quality with this printer before purchasing a large amount of paper.

Saving Optimal Settings for the Current Paper (Print Paper Settings)

A variety of paper settings can be optimized for the current paper and stored in the printer.

Once frequently used settings have been stored in a paper setting bank, it can be recalled

to instantly optimize multiple parameters.

The printer offers a total of 10 paper setting banks.

This section describes how to create paper setting banks and the settings that can be

stored.

Custom Paper Setting Details

The following items can be configured in the custom paper settings:

O Select Reference Paper

O Platen Gap

O Detect Paper Thickness

O Paper Feed Adjust

Basic Operations 39

Page 40

O Paper Suction

O Roll Paper Tension

O Remove Skew

O Setting Name

For more information, see “Paper Menu” on page 52.

Saving Settings

Use the following procedure to save paper settings.

Choosing a Custom Paper Setting Bank

1. Confirm that the printer is ready to print.

Press the l/r buttons to open the . tab, then press the Z button.

The Paper menu will be displayed.

2. Press the d/u buttons to highlight Custom Paper Setting and press the Z button.

The Custom Paper Setting menu will be displayed.

3. Press the d/u buttons to select the bank (1 to 10) where you want to save the custom

paper settings, then press the Z button.

The custom paper settings menu for the selected number will be displayed.

Basic Operations 40

Page 41

Note that if you select a number for which settings have already been saved, the old

settings will be overwritten.

Note:

Press the

W button to close the settings menu.

Select Reference Paper

Select the paper type that is the closest in characteristics to the paper you are using.

1. Select Select Reference Paper in the paper settings menu, then press the Z button.

2. Press the d/u buttons to select reference paper, and then press the Z button.

3. Press the d/u buttons to select the paper closest to the one you are using, then press

the Z button.

4. Press the y button twice to return to the paper settings menu.

Platen Gap

Select the platen gap which is the distance between the print head and the paper.

Normally, select Standard. Select a wider setting if printed images are smeared. If, upon

performing head alignment you feel that it is still not completely aligned, select Narrow.

1. Press the d/u buttons on the paper settings menu to highlight Platen Gap and then

press the Z button.

2. Press the d/u buttons to select the target setting value, and then press the Z button.

3. Press the y button to return to the paper settings menu.

Detect Paper Thickness

You can print out a paper thickness detection pattern to determine and set the optimal

paper thickness based on the printout.

1. Press the d/u buttons on the paper settings menu to highlight Detect Paper

Thickness and then press the Z button.

2. Press the Z button to print the paper thickness detection pattern.

3. Press the d/u buttons to select the number of the pattern with the least amount of

discrepancy between the lines in the printout, and then press the Z button to return

the printer to the ready-to-print state.

Basic Operations 41

Page 42

Paper Feed Adjust

If the paper feed amount is not set correctly, banding (horizontal band patterns or

discoloration) may occur. If the banding is not resolved after head cleaning or Head

Alignment is performed, adjust the amount of paper feed correction. This value can be set

in either of the following two ways:

O Pattern

Visually check the printed pattern and enter the correction value.

O Value

Change the value based on the banding observed. The correction value is set as the

ratio in relation to 1 meter (-0.70 to +0.70%).

Printing an Alignment Pattern for Correction

1. Select Custom Paper Setting from the paper menu.

2. Press the d/u buttons to select the bank where you want to save the custom paper

settings, then press the Z button.

3. Press the d/u buttons to highlight Paper Feed Adjust and press the Z button.

4. Select Pattern, and then press the Z button.

5. Press the Z button to print an adjustment pattern.

6. Using a ruler that shows millimeters, measure the distances between the “+” symbols

in the printed adjustment pattern.

Use only the distance between the center symbols or the average of the distances between

the left, center, and right symbols.

7. Press the d/u buttons to enter the measured value and press the Z button to return

the printer to the ready-to-print state.

Basic Operations 42

Page 43

Manually Changing the Value for Adjustment

1. Select Custom Paper Setting from the paper menu.

2. Press the d/u buttons to select the bank where you want to save the custom paper

settings, then press the Z button.

3. Press the d/u buttons to highlight Paper Feed Adjust and press the Z button.

4. Select Value, and then press the Z button.

5. Press the d/u buttons to select the target value, and then press the Z button.

6. Press the y button twice to return to the paper settings menu.

Paper Suction

Choosing too high a value for thin paper will increase the distance between the paper and

the print head, causing print quality to decline or preventing the paper feeding correctly. If

this happens, lower the paper suction.

1. Press the d/u buttons on the paper settings menu to highlight Paper Suction and then

press the Z button.

2. Press the d/u buttons to select the target value, and then press the Z button.

3. Press the y button to return to the paper settings menu.

Roll Paper Tension

Select High or Extra High if the paper wrinkles during printing.

1. Press the d/u buttons on the paper settings menu to highlight Roll Paper Tension and

then press the Z button.

2. Press the d/u buttons to select the target setting value, and then press the Z button.

3. Press the y button to return to the paper settings menu.

Remove Skew

This sets the operation performed to prevent the paper from skewing when it is fed.

1. Press the d/u buttons on the paper settings menu to highlight Remove Skew, and then

press the Z button.

Basic Operations 43

Page 44

2. Press the d/u buttons to select either On to reduce paper skew during feeding, or Off

to disable this feature, then press the Z button.

3. Press the y button to return to the paper settings menu.

Setting Name

You can assign a name to saved custom paper settings. Choose an easy-to-remember

name for quick selection.

1. Press the d/u buttons on the paper settings menu to highlight Setting Name, and then

press the Z button.

2. Enter the setting name.

You can cycle between different character types by pressing the Menu button. The

order is as follows: Uppercase -> Lowercase -> Numbers/Symbols.

Press the d/u buttons to cycle through the characters for the selected character type.

Once the character you want is displayed, press the r button to confirm.

The cursor will then move on to the next input area. Repeat this process until you are

finished.

If you make a mistake, press the l button to delete the previous character.

3. Once you are finished entering the name, press the Z button.

4. Press the y button to return to the paper settings menu.

Basic Operations 44

Page 45

Printable Area

This section describes the printable areas for the printer.

If the margin set in an application is larger than the following setting values, sections

beyond the specified margins are not printed. For example, if 15 mm is selected for the left

and right margins in the printer menus and the document fills the page, the 0.6 in. (15 mm)

at the left and right sides of the page will not be printed.

The gray area in the illustration below shows the printable area.

The arrow in the illustration indicates the direction of the ejected paper.

10 in. to 44 in.

5 in. to

49 ft

Margins for roll paper depend on the option selected for Roll Paper Margin in the menus,

as shown in the following table. For Roll Paper Margin Settings, see “Setup Menu” on

page 56.

The default setting is Normal.

Roll Paper Margin Parameter Margin Values

Normal 1, 3 = 15 mm

2, 4 = 3 mm

Top15 mm/Bottom 15 mm 1, 3 = 15 mm

2, 4 = 3 mm

Top 35 mm/Bottom 15 mm 1 = 35 mm

3 = 15 mm

2, 4 = 3 mm

Basic Operations 45

Page 46

Roll Paper Margin Parameter Margin Values

Top 15 mm/Bottom 150 mm 1 = 15 mm

3 = 150 mm

2, 4 = 3 mm

Top 5mm/Bottom 5mm 1, 3 = 5 mm

2, 4 = 3 mm

15 mm 1, 2, 3, 4, = 15 mm

*

Important:

O Printing is distorted when the trailing edge of the roll paper comes off the core. Make sure the

trailing edge does not come inside the printing area.

O The print size does not change even when the margins are changed.

Turning Off the Power Using Power Off Timer

The printer offers the following two power management options:

O Sleep mode

The printer enters sleep mode when there are no errors, no print jobs being received,

and no control panel or other operations performed. When the printer enters sleep

mode, the control panel’s screen turns off and the internal motors and other parts

switch off to consume less power.

Press the P button to exit sleep mode and return to the normal running state. The delay

before the printer enters sleep mode can be selected from values between 5 and 240

minutes. At default settings, the printer enters sleep mode if no operations are

performed for 15 minutes. The delay can be changed from the Setup menu (see “Setup

Menu” on page 56).

Note:

When the printer enters sleep mode, the control panel’s screen goes blank as if the power

has been turned off, but the P light remains lit.

O Power Off Timer

The printer is equipped with a Power Off Timer option that automatically turns the

printer off if no errors occur, no print jobs are received, and no control panel or other

operations are performed for a set period of time. The delay before the printer turns off

automatically can be selected from values between 1 and 24 hours in increments of 1

hour.

Basic Operations 46

Page 47

At default settings, the printer turns off automatically if no errors occur, no print jobs are

received, and no control panel or other operations are performed for eight hours. Power

Off Timer settings can be adjusted from the Setup menu (see “Setup Menu” on page

56).

About Power Management

You can adjust the time before Power Management is applied. Any increase will affect the

printer’s energy efficiency. Please consider the environment before making any change.

Canceling Printing

Press the W button, select Job Cancel on the screen, and then press the OK button.

The print job is canceled even in the middle of printing. It may take a while before the

printer returns to ready status after canceling a job.

Basic Operations 47

Page 48

Chapter 3

Using the Control Panel Menu

Menu Operations

The steps for displaying the various menus are shown below. The example below shows

the steps for accessing the Paper menu.

* After pressing the OK button to select the highlighted option, press the y button to return to the previous

menu. Press the W button to exit.

Using the Control Panel Menu 48

Page 49

Menu List

The items and options available in the menu are described below. See the reference pages

for more details on each item.

, Print Queues menu

See “Print Queues Menu” on page 52.

Menu item Description

Print Job Log Sheet Press OK to start printing.

. Paper menu

See “Paper Menu” on page 52.

Menu item Description

Load/Remove

Paper

Select Paper

Type

Remove Paper Displays instructions for removing the paper.

Roll Paper Displays instructions for loading the paper.

RIP Settings —

1 to 10 (Paper Settings Number) Lists the names of user-defined custom paper

types.

Using the Control Panel Menu 49

Page 50

Menu item Description

Custom Paper

Setting

XXXXXXXXXX

XXXXXXXXXX

(name of

custom

paper type)

Select

Reference

Paper

Platen Gap Narrow, Standard, Wide, Wider

Detect Paper

Thickness

Paper Feed

Adjust

Paper Suction –4 to 0

Roll Paper

Tension

Remove Skew On, Off

Setting Name 22 characters or less (letters, numbers, and

Photo Paper Displays the

Matte Paper

Plain Paper

Others

No Paper Selected No Paper Selected

Press OK to start printing.

Pattern Press OK to start

Value –0.70 to +0.70%

Normal, High, Extra High

symbols)

Epson-unique paper

name.

printing.

Restore Settings Yes, No

Print Paper List Press OK to start printing.

- Maintenance menu

See “Maintenance Menu” on page 55.

Menu item Description

Nozzle Check Press OK to start printing.

Head

Cleaning

Head

Alignment

Cutter

Maintenance

All nozzles Execute (Light), Execute (Medium), Execute (Heavy)

Selected nozzles Execute (Light), Execute (Medium), Execute (Heavy)

Manual (Uni-D) Press OK to start printing.

Manual (Bi-D)

Adjust Cut Position –3 to 3 mm

Replace Cutter Press OK to start move.

Using the Control Panel Menu 50

Page 51

/ Setup menu

See “Setup Menu” on page 56.

Menu item Description

Printer Setup Roll Paper

Setup

Advanced

Settings

Auto Cut On, Off

Refresh Margin On, Off

Page Line On, Off

Roll Paper

Margin

Roll Paper

Remaining

Remaining Alert 1 to 15 m (4 to 50 ft)

Roll Paper

Tension

Less Head

Scuffing

Drying Time Per

Page

Paper Size

Check

Paper Skew

Check

Normal, Top15 mm/Bottom15 mm, Top

35 mm/Bottom 15 mm, Top 15 mm/Bottom

150 mm, 3 mm, Top 5 mm/Bottom 5 mm, 15 mm

On, Off

Low, Normal, High, Extra High

On, Off

0 to 60 minutes

On, Off

On, Off

Cleaning cycle Off, every 1 to 10 pages

Restore Settings Yes, No

Printer Status Firmware Version xxxxxxx,x.xx,xxxx

Option Status Options are not available for this printer.

2

(XXXXXX ft2)

Gateway

Network

Setup

Power

Settings

Show Total Prints XXXXXXX m

Print Status Sheet Press OK to start printing.

IP Address Setting Auto -

Panel IP Address, Subnet Mask, Default

Print Status Sheet Press OK to start printing.

Restore Settings Yes, No

Sleep Mode 5 to 240 minutes

Power Off Timer Off, 1 to 24 hours

Restore Settings Yes, No

Using the Control Panel Menu 51

Page 52

Menu item Description

Preference Language Lists the supported languages.

Unit: Length m, ft/in

Alert Lamp Setting On, Off

Administrator

Menu

Date And Time MM/DD/YY HH:MM

Time Zone Enter the time difference between GMT and

the current time zone.

Reset All Settings Yes, No

Menu Descriptions

Print Queues Menu

Item Description

Print Job Log Sheet Press the OK button to print the print job log.

Paper Menu

Item Description

Load/Remove Paper Remove

Paper

Roll Paper After you make your selection, press the OK

Select

Paper

Type

RIP Settings Select the paper settings to use for printing.

1 to 10 (Paper Settings

Number)

If RIP Settings is selected, the paper settings set in the software

RIP are used.

Set to a number between 1 and 10 to use the paper settings

set in that slot for printing. To save a group of settings in this

way, use Custom paper Setting

Press the OK button to view instructions for

removing the paper. Follow the on-screen

instructions to remove the paper.

Instructions are not displayed if no paper is

loaded.

button. Follow the on-screen instructions to

load the paper.

If paper is already loaded in the printer, the

instructions for removing the loaded paper

type will be displayed before loading

instructions are shown.

.

Using the Control Panel Menu 52

Page 53

Item Description

Custom

Paper

Setting

XXXXXXXX

XXX

(name of

custom

paper

type)

Select

Reference

Paper

Platen

Gap

Detect

Paper

Thickness

Photo Paper You can select the media type that is the

Matte Paper

Plain Paper

Others

No Paper

Selected

(default)

Narrow Select the platen gap which is the distance

Standard

(Default)

Wide

Wider

Press the OK button to print a pattern to determine the

thickness of the current paper.

Select the pattern number with the least misalignment from

the print results.

closest to the paper you are using.

Select this option if you do not wish to

specify the paper type.

between the print head and the paper.

Normally, select Standard. Select a wider

setting if printed images are smeared. If,

upon performing head alignment you feel

that it is still not completely aligned, select

Narrow.

Using the Control Panel Menu 53

Page 54

Item Description

Custom

Paper

Setting

(Cont’d)

XXXXXXXX

XXX

(name of

custom

paper

type)

(Cont’d)

Paper

Feed

Adjust

Pattern Use this setting if you are unable to resolve

Value

banding issues (horizontal striped lines or

uneven colors) in the standard print area

even after head cleaning or head

alignment.

Pattern Selected

Press the OK button to print an adjustment

pattern. Measure the distances between

the “+” symbols in the printed adjustment

pattern.

Use only the distance between the center

symbols or the average of the distances

between the left, center, and right symbols.

Paper

Suction

After the adjustment pattern is printing, the

length of the pattern will be displayed in the

control panel. Press the u/d buttons to enter

the measured value and press the OK

button.

Value Selected

Choose an adjustment between –0.70 and

+0.70%.

Selecting too small a value causes dark

bands; adjust the amount upward. Similarly,

choosing too large a value causes white

bands; adjust the amount downward.

–4 to 0 It is important to choose the appropriate

amount of suction for the paper used in

order to maintain the correct distance

between the paper and the print head.

Choosing too high a value for thin or soft

paper will increase the distance between

the paper and the print head, causing print

quality to decline or preventing the paper

feeding correctly. If this happens, lower the

paper suction. The suction power is

weakened when the parameter is lowered.

Using the Control Panel Menu 54

Page 55

Item Description

Custom

Paper

Setting

(Cont’d)

Print Paper List Press the OK button to print a list of custom paper settings.

XXXXXXXX

XXX

(name of

custom

paper

type)

(Cont’d)

Roll Paper

Tension

Remove

Skew

Setting

Name

Restore

Settings

Normal

(Default)

High

Extra High

On (Default) Select whether to enable (On) or disable

Off

Enter a name of up to 22 characters for custom paper

settings. Choose an easy-to-remember name for quick

selection.

Yes Restore the selected custom paper settings

No

Select High or Extra High if the paper

wrinkles during printing.

(Off) paper skew reduction.

to default values.

Maintenance Menu

Item Description

Nozzle Check Press the OK button to print a nozzle check pattern.

Visually inspect the printed pattern and perform

head cleaning if you notice faint or missing areas.

See “Checking for Clogged Nozzles” on page 63.

Head Cleaning All Nozzles Execute

(Light),

Execute

(Medium),

Execute

(Heavy)

Selected Nozzles Execute

(Light),

Execute

(Medium),

Execute

(Heavy)

Check the number of any patterns

with faint or missing segments and

specify whether you want to perform

cleaning for all nozzles or only for the

rows containing those numbers. All

Nozzles performs head cleaning for all

nozzles. Selected Nozzles allows you to

specify a row or rows of nozzles to

perform head cleaning for.

You can choose between the

following levels for head cleaning:

Execute (Light), Execute (Medium), or

Execute (Heavy). At first, use Execute

(Light). If you still notice any faint or

missing areas, then use Execute

(Medium). If you still notice any faint or

missing areas, then use Execute

(Heavy).

See “Cleaning the Print Head” on

page 64.

Using the Control Panel Menu 55

Page 56

Item Description

Head Alignment Manual (Uni-D) If print results are grainy or out of focus, perform head

Manual (Bi-D)

alignment to realign the print head. See “Minimizing

Print Misalignments (Head Alignment)” on page 65.

Cutter

Maintenance

Adjust Cut Position –3 to 3 mm The cut position can be adjusted in

increments of 0.2 mm.

Replace Cutter Moves the cutter to the replacement position so it

can be replaced. Press the OK button to move the

cutter to the replacement position. The paper must

be removed before the cutter can be replaced.

Remove the paper before proceeding. See

“Replacing the Cutter” on page 76.

Setup Menu

Selecting Administrator Menu displays a password prompt. No password is entered at

shipment; press the OK button to proceed. If the administrator password has been

changed, enter the administrator password.

Item Description

Printer Setup Roll Paper

Setup

Auto Cut On (Default) Choose On to automatically cut

Off

roll paper using the built-in cutter

as each page is printed, Off to

disable auto paper cutting.

Refresh

Margin

On (Default) If On is selected during

Off

borderless printing, the printer will

automatically trim the leading

edge to remove any ink stains

that may have been left by the

previous copy; to disable this

feature, choose Off. However,

borderless printing is not

guaranteed on this printer.

Using the Control Panel Menu 56

Page 57

Item Description