Page 1

®

SERVICE MANUAL

®

All-in-one printer, scanner, and copier

EPSON STYLUS Scan 2000

Page 2

EPSON STYLUS Scan 2000 Revision B

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

2

Page 3

EPSON STYLUS Scan 2000 Revision A

CAUTION

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

W ARNING

Signals a precaution which, if ignored, could result in

damage to equipment.

Signals a precaution which, if ignored, could result

in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME A S THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF

THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER

SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE MADE BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE ICs

OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

3

Page 4

EPSON STYLUS Scan 2000 Revision A

PREFACE

This manual describes basic functions, theory of electrical and

mechanical operations, maintenance and repair procedures of

EPSON STYLUS Scan 2000. The instructions and procedures

CHAPTER 1. “Product Description”

Provides a general overview and specifications of the product.

CHAPTER 2. “Operating Principles”

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. “Troubleshooting”

Provides step-by-step procedures for troubleshooting.

CHAPTER 4. “Disassembly & Assembly”

Describes step-by-step procedures for disassembling and assembling the product.

CHAPTER 5. “Adjustment”

Provides Epson-approved methods for adjustment.

included herein are intended for the experie nced repair technicians,

and attention should be given to the precautions on the preceding

page. The chapters are organized as follows:

CHAPTER 6. “Maintenance”

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

CHAPTER 7. “Appendix”

Provides the following additional information for reference:

• EEPROM Address Map

• Connector Pin Assignment

• Schematics

• Circuit Diagrams

4

Page 5

EPSON STYLUS Scan 2000 Revision A

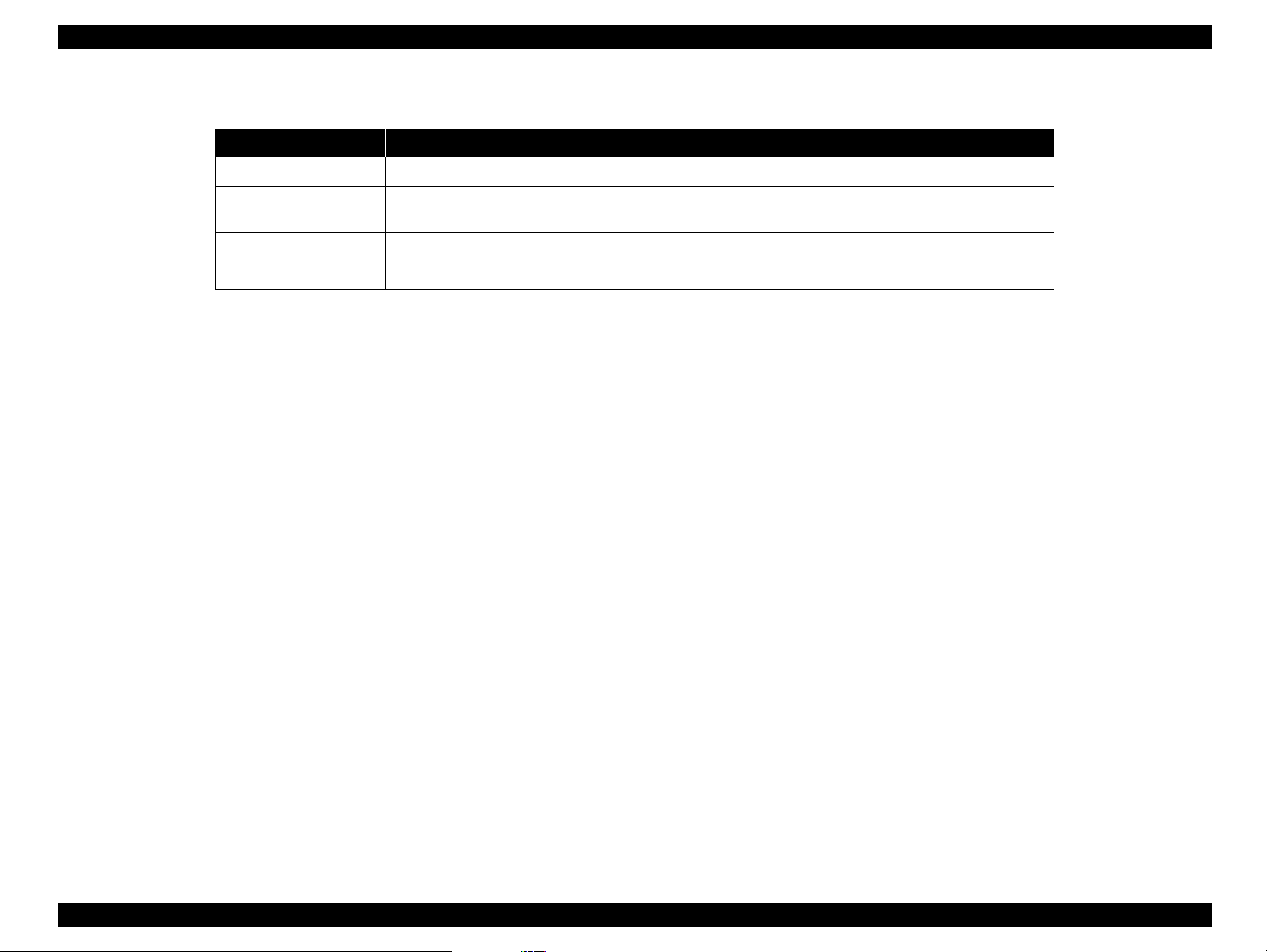

Revision Status

Revision Issued Date Description

Revision A October 4, 1999 Full version

Revision B October 20, 1999

Changed Disassembly and Troubleshooting to account for ASP blue

protective tape, also fixed scanner removal description

5

Page 6

EPSON Stylus Scan 2000 Revision A

Contents

Product Description

Features............................................................. ....... ...... ....... ...... .................. 9

General Specifications ............................................................................... 10

Local copy.............................................................................................. 10

Scan area................................................................................................ 10

Print area................................................................................................ 11

Printer..................................................................................................... 12

Scanner .................................................................................................. 15

Common................................................................................................. 16

Interfaces..................................................................................................... 17

Printer interface ..................................................................................... 17

Scanner interfaces................................................................................. 22

Control Panel............................................................................................... 23

Buttons................................................................................................... 23

Control panel indicates the printer’s condition................................... 25

Initialization............................................................................................ 26

Stylus Scan Errors ...................................................................................... 28

Physical Characteristics.............................................................................. 29

Dimensions............................................................................................ 29

Weight.................................................................................................... 29

External view ......................................................................................... 29

Operating Principles

General........................................................................................................ 31

Printer Mechanism Operation ................................................................... 32

Printing Mechanism.............................................................................. 33

Printing Process..................................................................................... 34

Carriage Mechanism ............................................................................. 35

Paper Feeding Mechanism ................................................................... 37

Ink System ............................................................................................. 42

Pump, Carriage Lock, Head Cleaner Mechanism................................ 43

Scanner Mechanism Operation................................................................. 46

Mechanism ............................................................................................ 46

Local and PC-Centric Copy Principles....................................................... 47

Local copy process................................................................................ 47

PC-Centric copy process....................................................................... 47

Electrical Circuit Operating Principles ...................................................... 49

B101 PSB/PSE Board............................................................................. 50

B101 MAIN Board.................................................................................. 53

Troubleshooting

Unit Level Troubleshooting....................................................................... 57

Printer/Scanner does not operate at power on................................... 58

Error is detected .................................................................................... 59

Failure occurs during printing.............................................................. 59

Printer does not feed paper correctly.................................................. 60

Control panel operation is abnormal................................................... 60

Repair of the Printer Mechanism .............................................................. 61

Troubleshooting the Scanner.................................................................... 65

Scanner Troubleshooting Flowcharts.................................................. 65

Scanner troubleshooting check points................................................ 66

Troubleshooting the Motors and Sensors ............................................... 69

6

Page 7

EPSON Stylus Scan 2000 Revision A

Disassembly & Assembly

Overview ..................................................................................................... 71

Precautions for Disassembling the Printer.......................................... 71

Tools....................................................................................................... 72

Screw Numbering System and Specifications ................................... 73

Service Checks After Repair ................................................................. 74

Disassembly Procedures............................................................................ 76

Removing the Housing ................................................... ...... ................ 77

Removal of printer consumables......................................................... 81

Removing the Circuit Board Tray............... ....... ...... ....... ...... ....... ...... ... 84

Removing the Scanner Mechanism..... ...... ....... ...... ....... ...... ................ 88

Disassembling the Printer Mechanism................................................ 94

Adjustment

Required Adjustments.............................................................................. 108

Adjustment Tools Required................................................................ 110

Printer Adjustment ................................................................................... 110

Printer hardware adjustments............................................................ 111

Using the Service-Adjustment Program................................................. 113

Installing the program......................................................................... 113

Opening the Start-up menu................................................................ 114

Initial Ink Charge Operation................................................................ 119

Bi-D Adjustment .... ...... ...... ....... ....................................... ...... ....... ...... . 120

Head Cleaning Operation.................................................................... 121

Head Voltage ID Input................................. ....... ...... ....... ...... ....... ...... . 122

Head Angular Adjustment .................................................................. 123

Ink draining..................................... ....................................... ....... ...... . 125

Scanner Adjustment................................................................................. 125

Maintenance

Printer-Related Maintenance................................................................... 127

Cleaning .................................................................................................... 128

Exterior................................................................................................. 128

Inside.................................................................................................... 128

Lubrication ................................................................................................ 129

Printer Mechanism .............................................................................. 129

Appendix

Connector Summary................................................................................ 138

Board Connector Summary................................................................ 139

Connector Pin Assignment................................................................. 140

EEPROM Address Map............................................................................. 143

Exploded Diagrams.................................................................................. 148

Parts List.................................................................................................... 155

Component Layout................................................................................... 160

Circuit Diagrams.................................... ...... ....... ...... ....... ...... ....... ...... ...... 165

7

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

EPSON Stylus Scan 2000 Revision A

1.1 Features

The major features of the EPSON Stylus Scan 2000 are:

High Color Print Quality

1440 (H) X 720 (V) dpi printing

Four Color Printing (CMYK)

Traditional and New Microweave

Sheet-fed 300dpi scanning

High quality local copy

One color copy mode Text & Graphics

Two B&W copy modes Black & White, Grayscale

High speed local copy

Color normal mode copy Max. 1.2 PPM

Gray mode copy Max. 1.3 PPM

B/W normal mode copy Max. 3.0 PPM

Two Built-in Interfaces

Bi-directional parallel I/F (IEEE-1284 level 1 device)

USB

Windows/Macintosh exclusive

Copy settings from the computer

Auto Photo Fine

Auto Enlarge

Auto Layout

Background reduction

Installed functions are the same or equivalent to the EPSON Stylus

Color 740 and the GT-2200.

Small footprint 228 x 437 x 279 mm (HWD)

Local copy settings from the control panel

Enlargement 141%

Reduction 93%, 70%

Copy size protection Letter/Half Letter/5 x 8”/Legal

A4/B5/A6

(Copy size protection prevents the printhead from firing ink onto the platen

in cases where the loaded paper size does not match the paper size

selected in the software.)

Built-in Auto Sheet Feeder

Holds 100 cut-sheets (64g/m2)

Holds 10 envelopes

Holds 30 transparency films

Product Description Features 9

Page 10

EPSON Stylus Scan 2000 Revision A

1.2 General Specifications

1.2.1 Local copy

1. Local copy

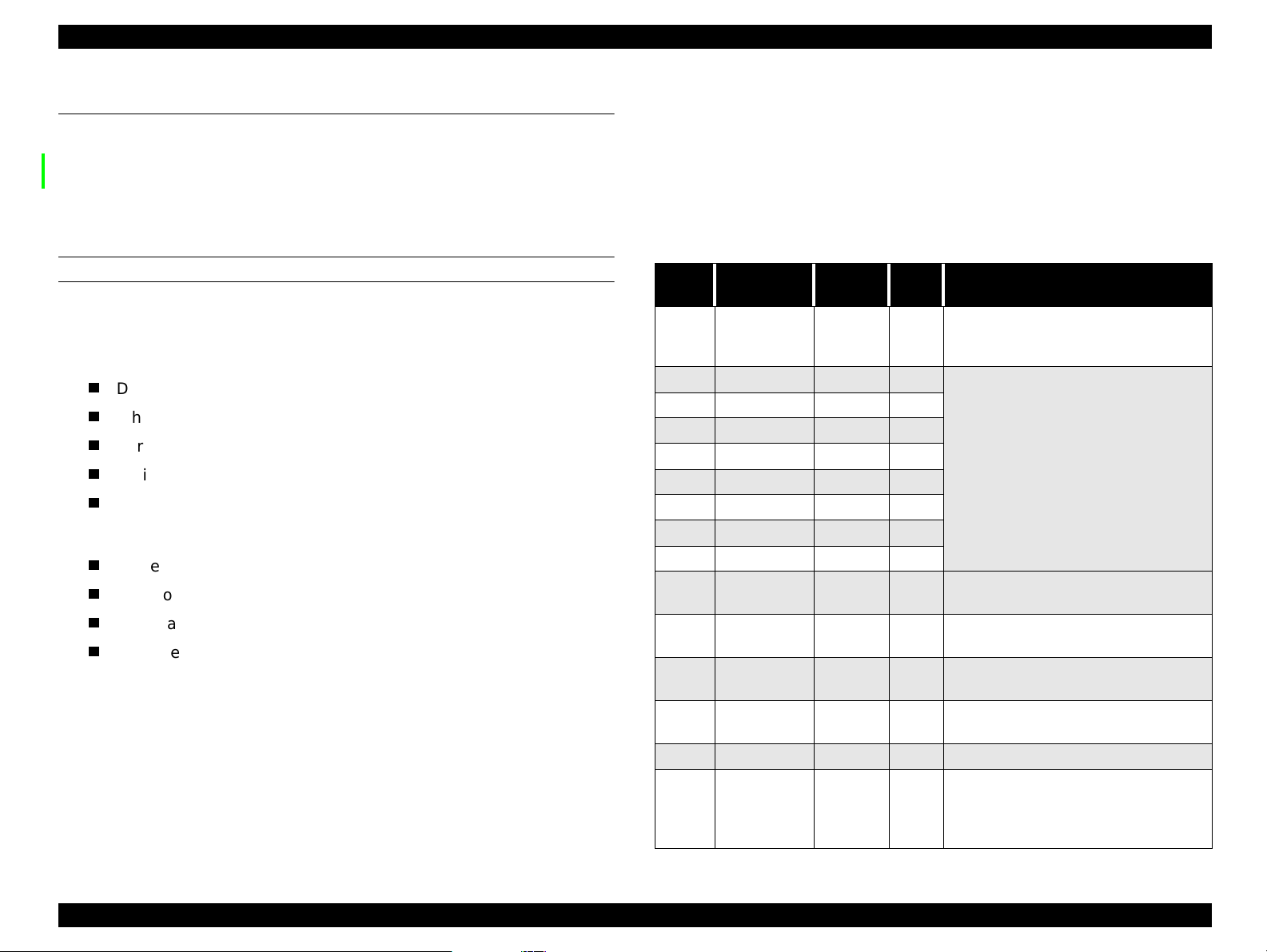

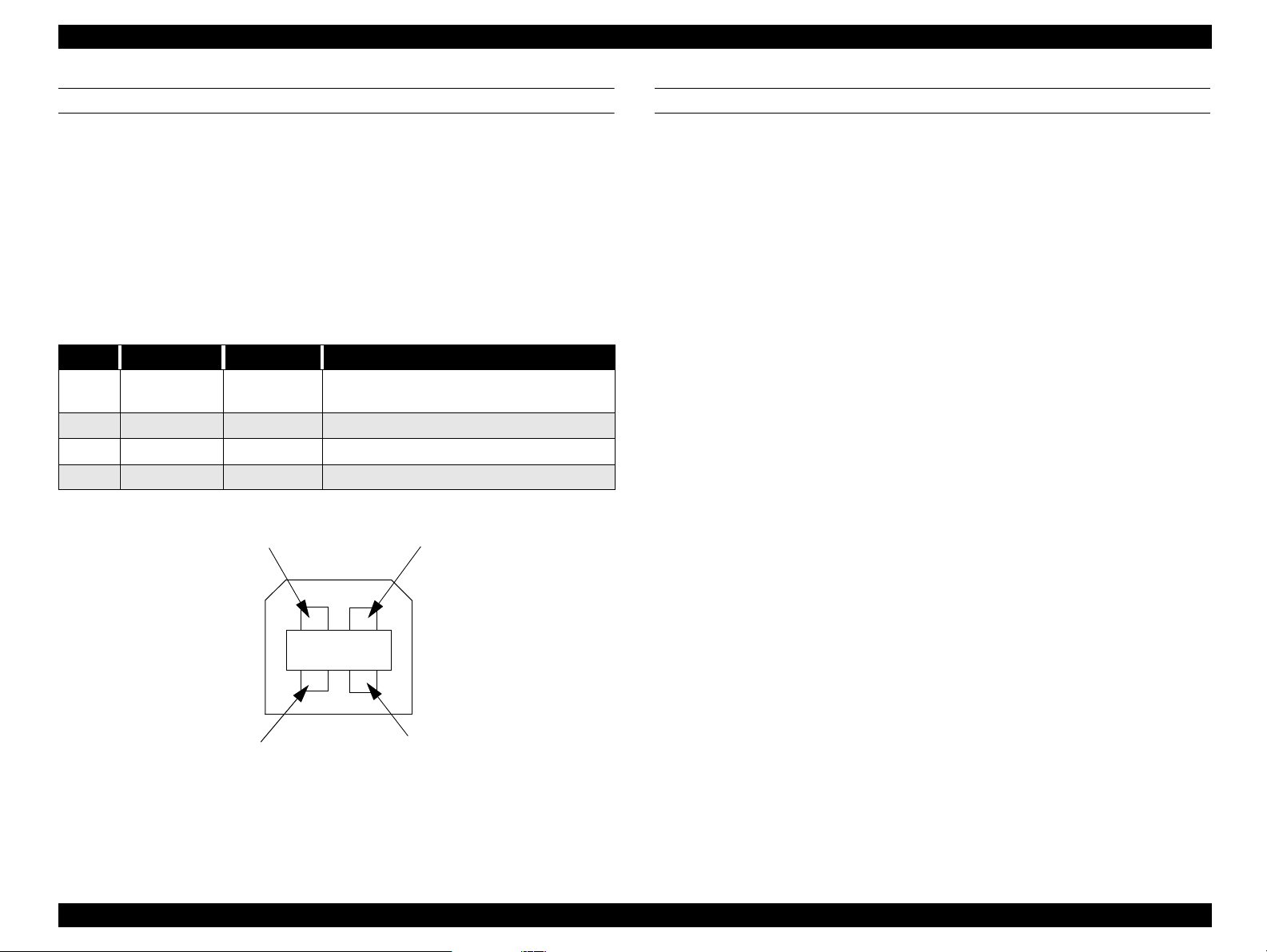

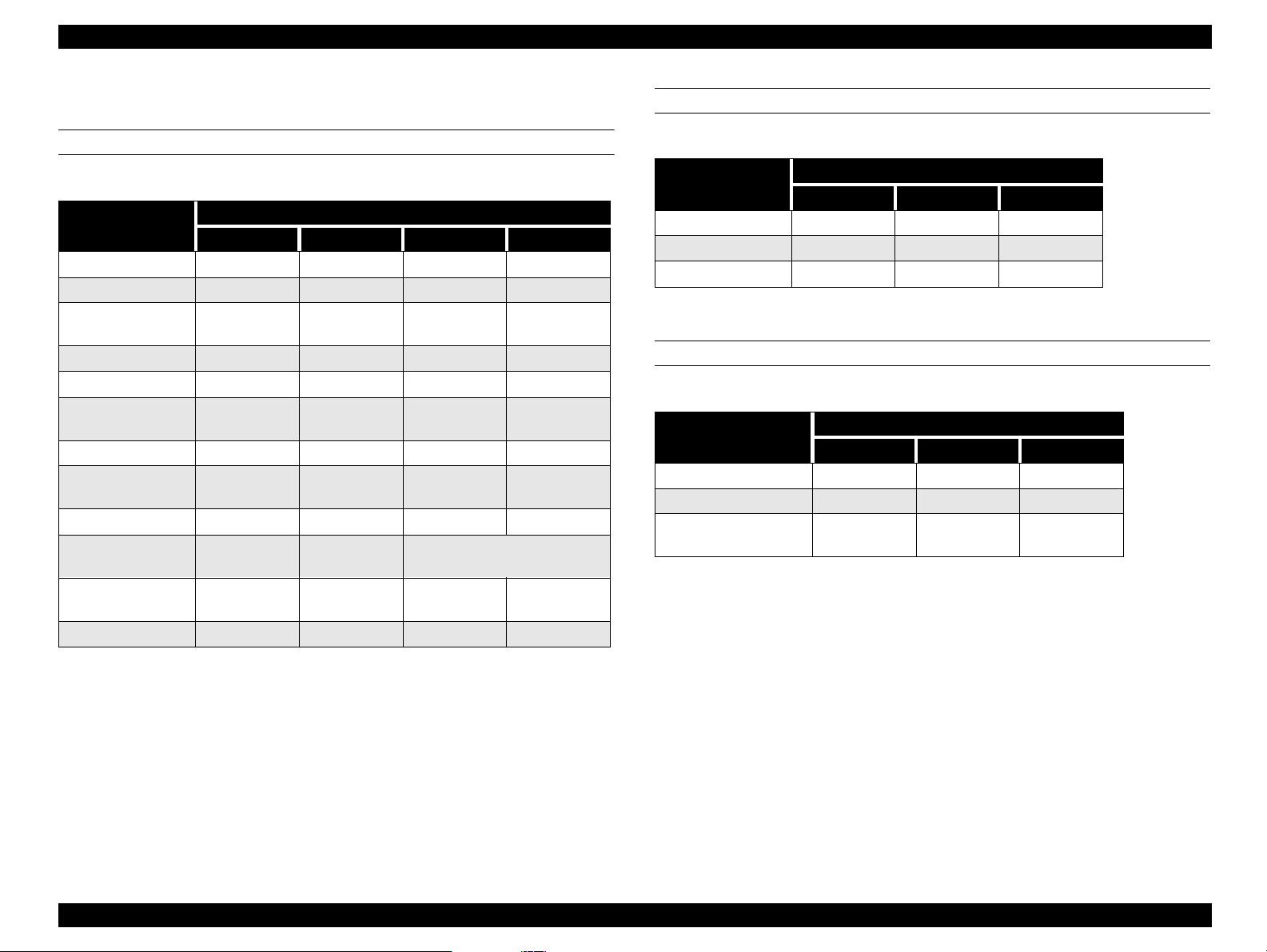

Table 1-1. Local Copy Specifications

Mode

B/W 300x300 Line art 360x360 Off No Bi-D Normal

B/W

Grayscale 300x300 Gray 360x360 On No Bi-D Normal

Text &

Color

Graphics

Output mode = data from the scanner ASIC to the printer

Scan

res.

300x300

2. Enlargement: Default 100%

Enlargement 141%

Reduction 70%, 93%

(not continuous)

3. Copy size Max. copy size 216 x 355.6mm (8.5 x 14inches)

Copy size protection A4/B5/A6 (A-size version)

Output

mode

Full

color

Print

res.

360x360 On No Bi-D Normal

Micro

Weave

Variable

dot

Head

seq.

Media

(Top, bottom, and both sides

need 3mm margins)

Letter/Half Letter/5 x 8”/Legal

(Letter size version)

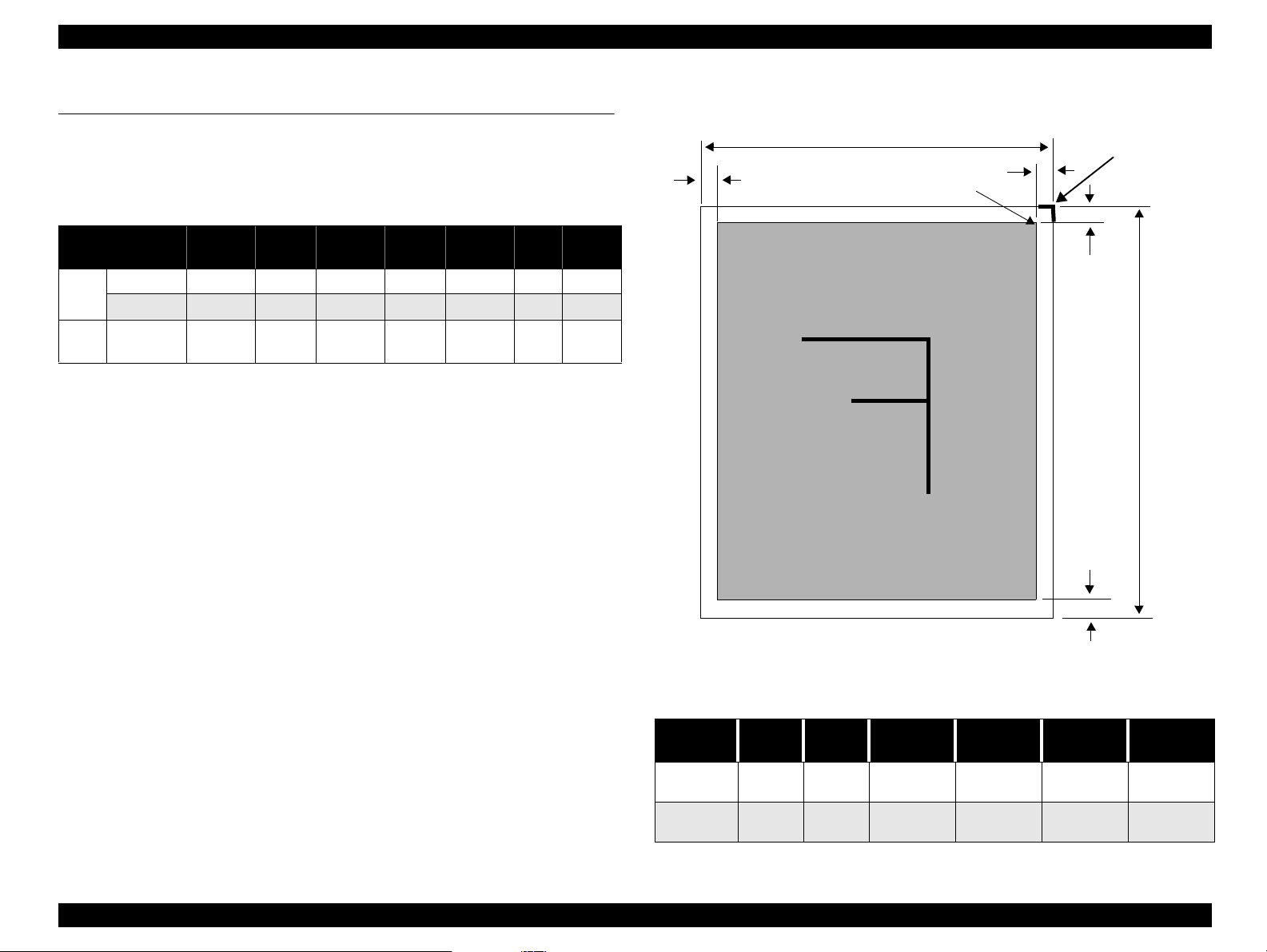

1.2.2 Scan area

LM

PW

Starting scan

position (1st bit)

Scanning Area

RM

TM

Document

edge (scale

edge)

PL

BM

4. Printing paper size Normal paper A4/Letter

Photo paper A4/Letter

Figure 1-1. Scan Area

Table 1-2. Scan Area

Document

size

A4 210mm 297mm

Letter 216mm

PW

(width)PL(length)

355.6mmat least

LM

(left)

at least

3mm

3mm

RM

(right)

at least

3mm

at least

3mm

TM

(top)

at least

3mm

at least

3mm

BM

(bottom)

at least

3mm

at least

3mm

Product Description General Specifications 10

Page 11

EPSON Stylus Scan 2000 Revision A

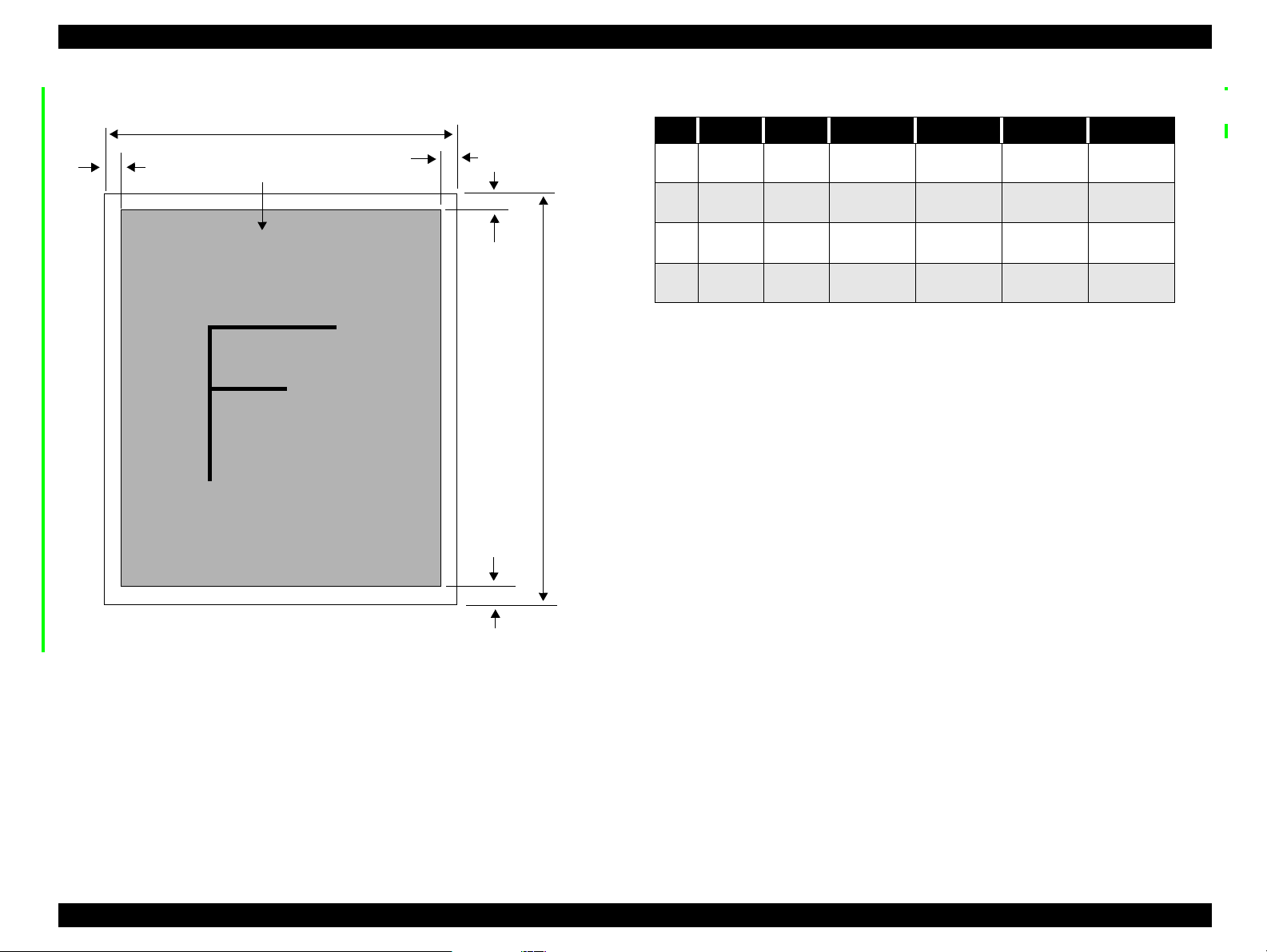

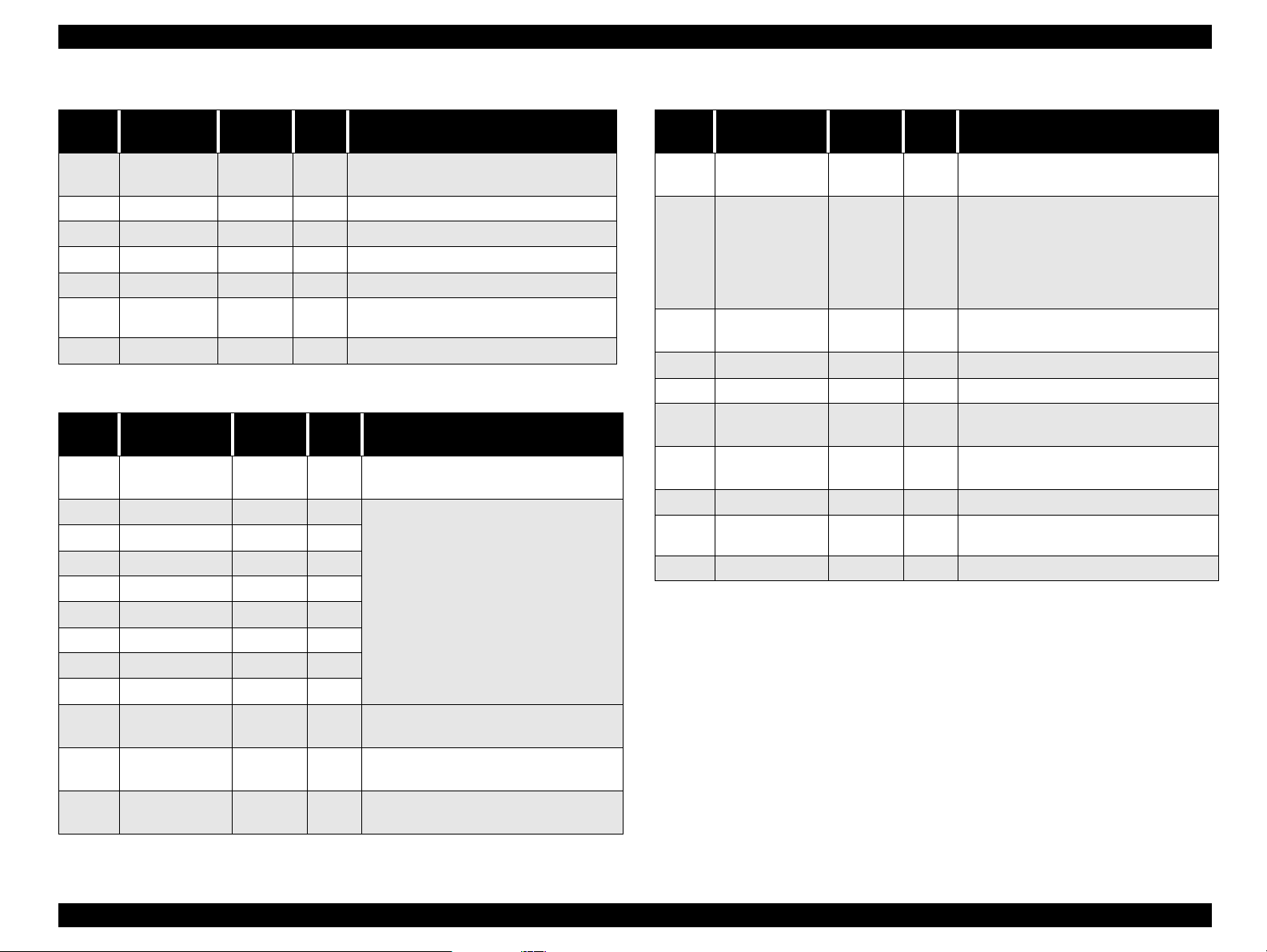

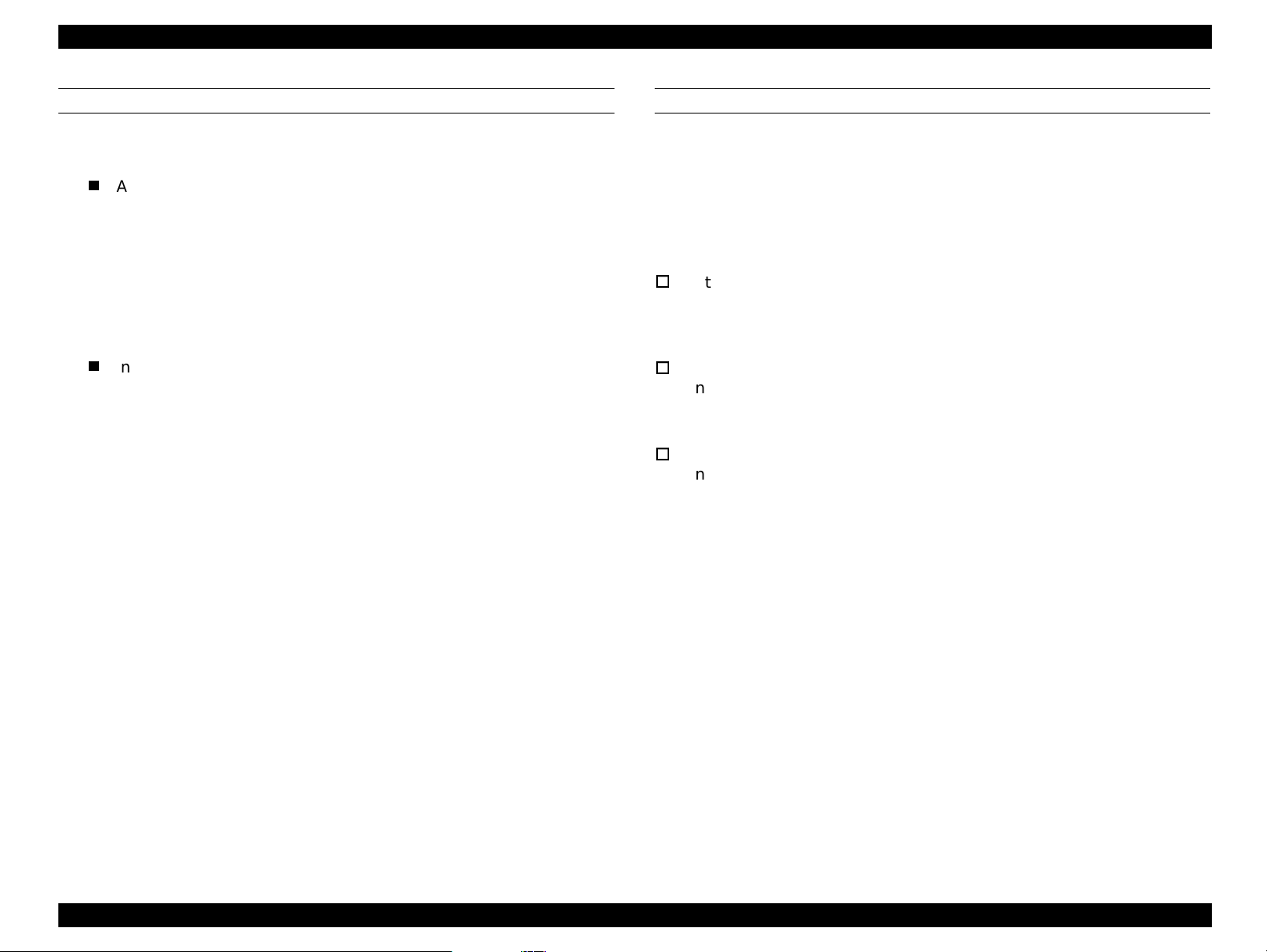

1.2.3 Print area

LM

PW

Paper feed direction

Printable Area

RM

TM

BM

PL

Table 1-3. Print Area

Size PW PL LM RM TM BM

A4 210mm 297mm

Letter 216mm 279mm

B5 182mm 257mm

Legal 216mm 356mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

at least

3mm

Figure 1-2. Print Area

Product Description General Specifications 11

Page 12

EPSON Stylus Scan 2000 Revision A

1.2.4 Printer

PRINTING

Print method Drop On Demand ink jet

Nozzle configuration monochrome 144 nozzles (48 x 3 staggered)

color 48 nozzles each (cyan, magenta, yellow)

Print direction Bi-direction with logic seeking

Print speed & printable columns

Table 1-4. Character mode

Character pitch Printable columns LQ speed

10 CPI (Pica) 80 200 cps

Table 1-5. Raster graphic mode

Horizontal

resolution

180 dpi 8.26 inch 1488 20 IPS

360 dpi 8.26 inch 2976 20 IPS

720 dpi 8.26 inch 5952 20 IPS

Printable area Available dots CR speed

PAPER FEED

1. Feeding method Friction feed with ASF

2. Line spacing 1/6 inch or programmable at 1/360 inch

3. Paper path cut-sheet ASF (front enter, front out)

4. Feed speed 2.36 inch/sec. normal/ continuous

4.5 inch/sec. fast/continuous

CONTROL CODES

ESC/P Raster

EPSON Remote Command

Product Description General Specifications 12

Page 13

EPSON Stylus Scan 2000 Revision A

PAPER

Cut-sheets

size: A4 210(W) x 297mm (L) (8.3 x 11.7”)

Letter 216 x 279mm (8.5 x 11.0”)

B5 182 x 257mm (7.2 x 10.1”)

Legal 216 x 356mm (8.5 x 14.0”)

Statement 139.7 x 215.9mm (5.5 x 8.5”)

Executive 184.2 x 266.7mm (7.25 x 10.5”)

Photo paper 101.6 x 152.4mm (4 x 6”)

thickness: 0.08~0.11mm (0.003~0.004”)

weight: 64g/m

quality: Exclusive paper, bond paper, PPC

OHP sheets, Glossy paper

size: A4 210(W) x 297mm (L) (8.3 x 11.7”)

thickness: 0.075~0.085mm (0.003~0.0033”)

NOTE: Transparency printing is only supported at normal temperature.

Envelopes

size: No.10 241(W) x 104.8mm (H) (9.5 x 4.125”)

thickness: 0.16~0.52mm (0.006~0.02”)

weight: 45g/m

quality: Exclusive paper, bond paper, Air mail

2

~90g/m2 (17~24lb.)

Letter 216 x 279mm (8.5 x 11.0”)

DL 220 x 110mm (8.7 x 4.3”)

C6 162 x 114mm (6.4 x 4.5”)

2

~75g/m2 (12~20lb.)

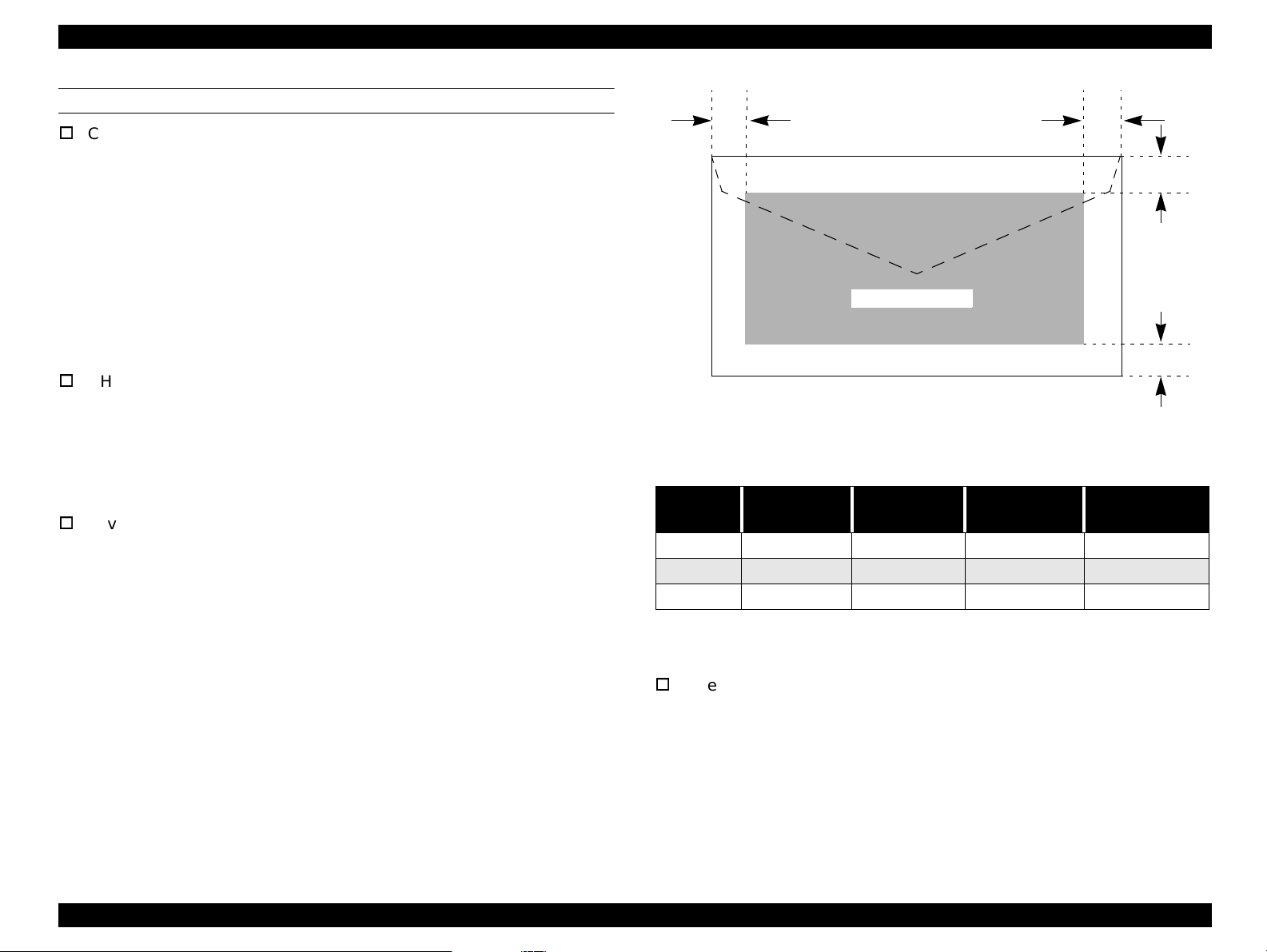

LM

Printable Area

Figure 1-3. Printable Area for Envelopes

Table 1-6. Envelope Margin

Size

#10 3 mm (0.12”) 28 mm (1.10”) 3 mm (0.12”) 14 mm (0.55”)

DL 3 mm (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.55”)

C6 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.55”)

Left Margin

(min.)

NOTE: Envelope printing is only supported at normal temperature.

Load long edge first.

Index cards

size: A6 index 105(W) x 148mm (L) (4.1 x 5.8”)

thickness: less than 0.23mm (0.0091”)

Right Margin

(min.)

Top Margin

(min.)

Bottom Margin

A5 index 148 x 210mm (5.8 x 8.3”)

5x8” index 127 x 203mm (5.0 x 8.0”)

10x8” index 254 x 203mm (10.0 x 8.0”)

(min.)

RM

TM

BM

Product Description General Specifications 13

Page 14

EPSON Stylus Scan 2000 Revision A

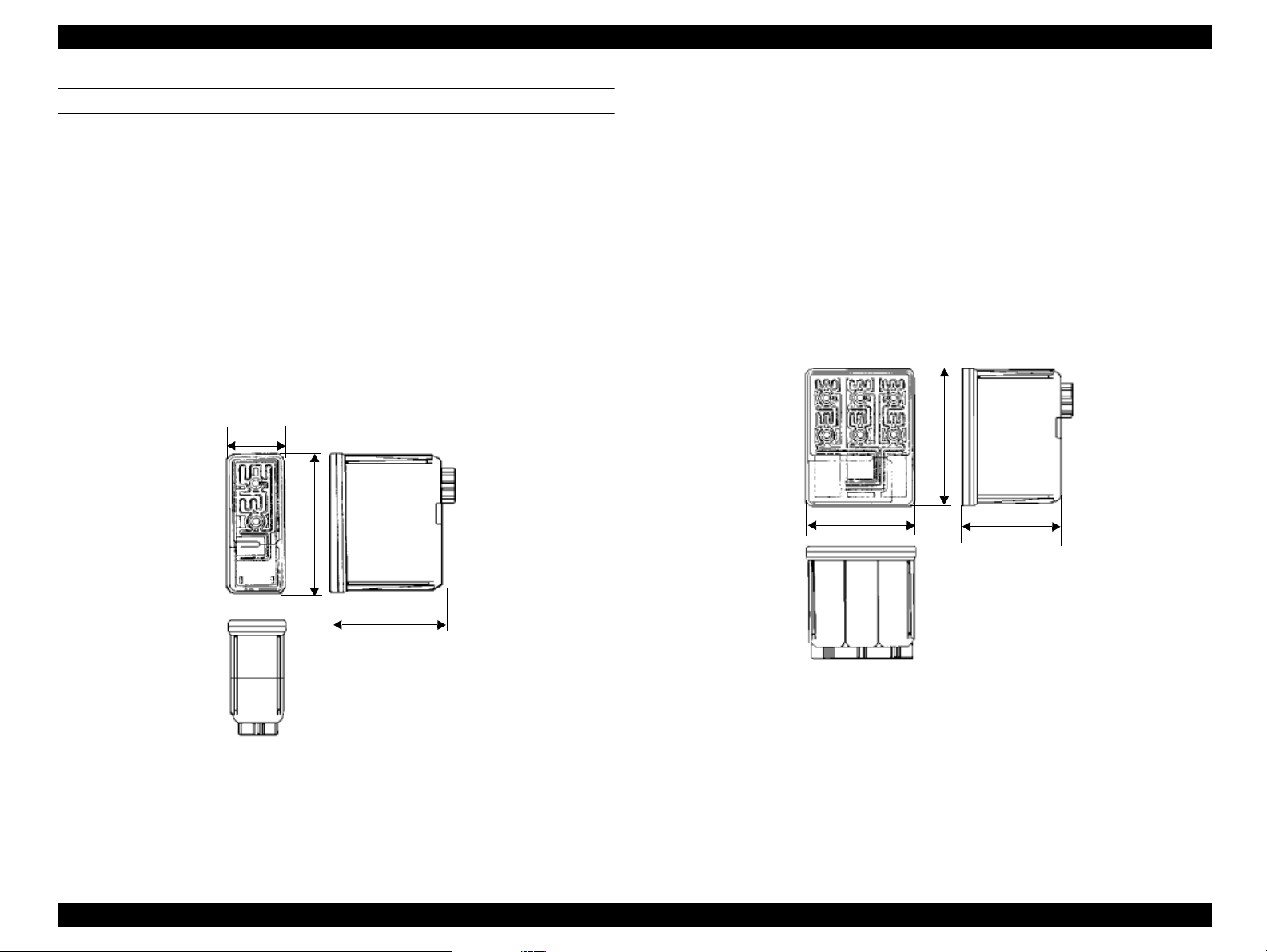

42.9

38.5

52.7

INK

1. Ink cartridge (black)

Type: Exclusive cartridge

Color: Black

Print capacity: 900 p ages/A4 (ISO/IEC 10561 Letter pattern

360dpi)

Ink life: Two years from production date

Storage temperature: -20~40°C (storage, less than a month at 40°C)

-30~40°C (packing storage, less than month at

40°C)

-30~60°C (transit, within 120 hours at 60°C and

within a month at 40°C)

Dimensions: 27.8 (W) x 52.7 (D) x 38.5mm (H)

27.8

52.7

2. Ink cartridge (color)

Type: Exclusive cartridge

Colors: Magenta, cyan, and yellow

Print capacity: 300 pages/A4 (360 dpi, 5% duty each color)

Ink life: Two years from production date

Storage temperature: -20~40°C (storage, less than a month at 40°C)

-30~40°C (packing storage, less than month at

40°C)

-30~60°C (transit, within 120 hours at 60°C and

within a month at 40°C)

Dimensions: 42.9 (W) x 52.7 (D) x 38.5mm (H)

38.5

Figure 1-5. Color Ink Cartridge

NOTE: Ink cartridges are consumable products and cannot by any

means be refilled.

Do not use cartridges that have passed their expiration date.

Figure 1-4. Black Ink Cartridge

Ink will freeze at less than -4°C but can be used after thawing

for three hours at room temperature.

Product Description General Specifications 14

Page 15

EPSON Stylus Scan 2000 Revision A

INPUT DATA BUFFER

64K bytes

1.2.5 Scanner

Product type Sheet-fed color image scanner (without ADF)

Sub scan method Sheet-fed type

Photoelectric d e vice Color CCD line sensor

Max. scan area 8.5 x 14” (216 x 355.6mm)

Max. effective pixels 2550 x 4220 pixels (300dpi)

Scan resolution main = 300dpi and sub = 300dpi

Output resolution 50~4800 dpi (1dpi increments)

Scan speed (300dpi, Draft mode)

Color = 4.25 msec/line

Monochrome (bi-level) = 1.68 msec/line

Color separation By the CCD color filter

Command level ESC/I - B7

Zoom 50~200% (1% increments)

Pixel depth 8 bits/color (input 12 bits/pixel/color,

output 8 bits/pixel/color)

Gamma correction CRT two levels (A,B)

PRINTER three levels (A,B,C)

User defined = one level

Color correction Impact-dot printer

Thermal printer

Ink-jet printer

CRT display

User defined

Brightness Seven levels

Line art Fixed threshold

TET

Digital halftoning AAS

Error diffusion three modes (A,B,C)

(Bi-level, Quad-level) Dither (resident) four modes (A,B,C,D)

Dither (user defined) two modes (A,B)

Interface USB and IEEE1284.4

Light source White cold cathode fluorescent lamp

Product Description General Specifications 15

Page 16

EPSON Stylus Scan 2000 Revision A

1.2.6 Common

ELECTRICAL SPECIFICATIONS

Rated voltage AC 120V

AC 220~240V

Input voltage AC 99~132V

AC 198~264V

Rated current 0.6A (AC 120V model)

0.4A (AC 220-240V model)

Rated frequency range 50~60 Hz

Input frequency range 49.5~60.5 Hz

Power consumption Approx. 29W (local copy printing)

Insulation resistance 10M

SAFETY, EMC

Safety UL1950 (UL)

EMC FCC Part15 Subpart B Class B

Ω

at 500V DC

(between AC line and chassis)

CSA C22.2 No. 950 (CSA)

EN60950 (VDE)

CSA C108.8 Class B

AS/NZS3548 Class B

ENVIRONMENTAL CONDITIONS

Temperature 10~35°C (operating, see figure below)

-20~60°C (non-operating, in packaging)

One month at 40°C

120 hours at 60°C

Humidity 20~80% RH (operating, without condensation, see

figure below)

5~85% RH (non-operating, in packaging without

condensation)

90

80

70

60

Humidity (%)

50

40

30

20

10

10

20

27 30 35

40

Temperature (°C)

Figure 1-6. Environment

CE Marking

Low voltage directive 73/23/EEC EN60950

Resistance to shock 1 G, within one ms (operating)

2 G, within two ms (non-op e rating, in packaging)

EMC Directive 89/336/EEC EN55022 Class B

EN61000-3-2

EN61000-3-3

Resistance to vibration0.15G (operating)

0.50G (non-operating, in packaging)

EN50082-1

IEC 801-2/801-3/801-4

RELIABILITY

Main unit Life 75,000 pages

Lamp Life 15,000 hours

Product Description General Specifications 16

Page 17

EPSON Stylus Scan 2000 Revision A

1.3 Interfaces

This section is divided into printer and scanner interface specifications. See the

following section for printer interface details or see “Scanner interfaces” on

page 22 for scanner interface details.

1.3.1 Printer interface

PARALLEL

BUSY signal is set high before setting either -ERROR low or PE high, and held

high until all these signals return to their inactive state.

BUSY signal is at high level in the following cases:

During data entry (see data transmission timing)

When input data buffer is full

During -INIT signal is at low level or during hardware initialization

During printer error (see -ERROR signal)

When the parallel interface is not selected

ERROR signal is at low level when the printer is in one of the following states:

Printer hardware error (fatal error)

Paper-out error

Paper-jam error

Ink-out error

PE signal is at high level during paper-out error.

1. Specifications

Transmission mode 8 bit parallel, IEEE-1284 ECP compatibility/nibble

mode

Synchronization Refer to the IEEE-1284 specification

Handshaking Refer to the IEEE-1284 specification

Packet Refer to the IEEE-P1284.4 Standard for Data Delivery

and Logical Channels for IEEE Std. 1284 Interface

(Draft D1.50)

Signal level TTL compatible level (IEEE-1284 Level 1 device)

Data trans. timing Refer to the IEEE-1284 specification

2. Connector pin assignment and signals

Table 1-7. Forward channel pin assignments and signals

Pin # Signal Name

1 -STROBE 19 In

2 DATA0 20 In

3 DATA1 21 In

4 DATA2 22 In

5 DATA3 23 In

6 DATA4 24 In

7 DATA5 25 In

8 DATA6 26 In

9 DATA7 27 In

10 -ACKNLG 28 Out

11 BUSY 29 Out

12 PE 28 Out

13 SLCT 28 Out

14 -AFXT 30 In Not used

31 -INIT 30 In

Return

GND pin

In/Out Description

The strobe pulse. Read-in data is

preformed at the falling edge of this

pulse.

The DATA0 through DATA7 signals

represent data bits 0 to 7, respectively.

Each signal is high when data is logical

1 and low when data is logical 0.

A negative signal that indicates the

printer is ready to accept data

A high signal that indicates the printer

is not ready and cannot receive data

A high signal indicates a paper-out

error

Always at high level when the printer

is on

The falling edge of a negative pulse or

a low signal on this line causes the

printer to initialize. Minimum 50us

pulse necessary.

Product Description Interfaces 17

Page 18

EPSON Stylus Scan 2000 Revision A

Table 1-7. Forward channel pin assignments and signals

Pin # Signal Name

32 -ERROR 29 Out

36 -SLIN 30 In Not used

18 Logic H - Out Pulled up to +5V via 3.9KΩ resistor

35 +5V - Out Pulled up to +5V via 3.3KΩ resistor

17 Chassis GND - - Chassis GND

16, 33

19-30

15,34 NC - - Not connected.

GND - - Signal GND

Return

GND pin

In/Out Description

A low signal indicates a printer error

condition

Table 1-8. Reverse channel pin assignments and signals

Pin # Signal Name

1 HostClk 19 In

2 DATA0 20 In

3 DATA1 21 In

4 DATA2 22 In

5 DATA3 23 In

6 DATA4 24 In

7 DATA5 25 In

8 DATA6 26 In

9 DATA7 27 In

10 PeriphClk 28 Out

11 PeriphAck 29 Out

12 nAckReverse 28 Out

Return

GND pin

In/Out Description

Data or address information

transferred from host to product.

The DATA0 through DATA7 signals

represent data bits 0 to 7,

respectively. Each signal is high

when data is logical 1 and low when

data is logical 0.

These signals are use d to trans fer the

1284 extensibility request values to

the printer.

Data transferred from product to

host.

Printer busy signal and reverse

channel transfer data bit 3 or 7

Printer goes to Low and approves

nReverseRequest

Table 1-8. Reverse channel pin assignments and signals

Pin # Signal Name

13 Xflag 28 Out

14 HostAck 30 In

nReverseReque

31

st

32 nPeriphRequest 29 Out This signal produces a host interrupt.

36 1284-Active 30 In 1284 active signal, High in ECP mode.

18 Periph-Logic H - Out

35 +5V - Out

17 Chassis GND - - Chassis GND

16, 33

19-30

15,34 NC - - Not connected.

GND - - Signal GND

3. Data trans. timing Refer to the IEEE-1284 specification and the

following.

Return

GND pin

30 In

In/Out Description

X-flag signal and reverse channel

transfer data bit 1 or 5

Host uses this signal for flow control

in reverse direction. Also this signal

offers the data bit 9 that is used to

judge whether the data or command

will be sent on the data signal in

forward direction.

This signal goes low to cha nge to the

reverse channel.

Always high. Pulled up to +5V via

3.9KΩ resistor

Always high. Pulled up to +5V via

1.0KΩ resistor

Product Description Interfaces 18

Page 19

EPSON Stylus Scan 2000 Revision A

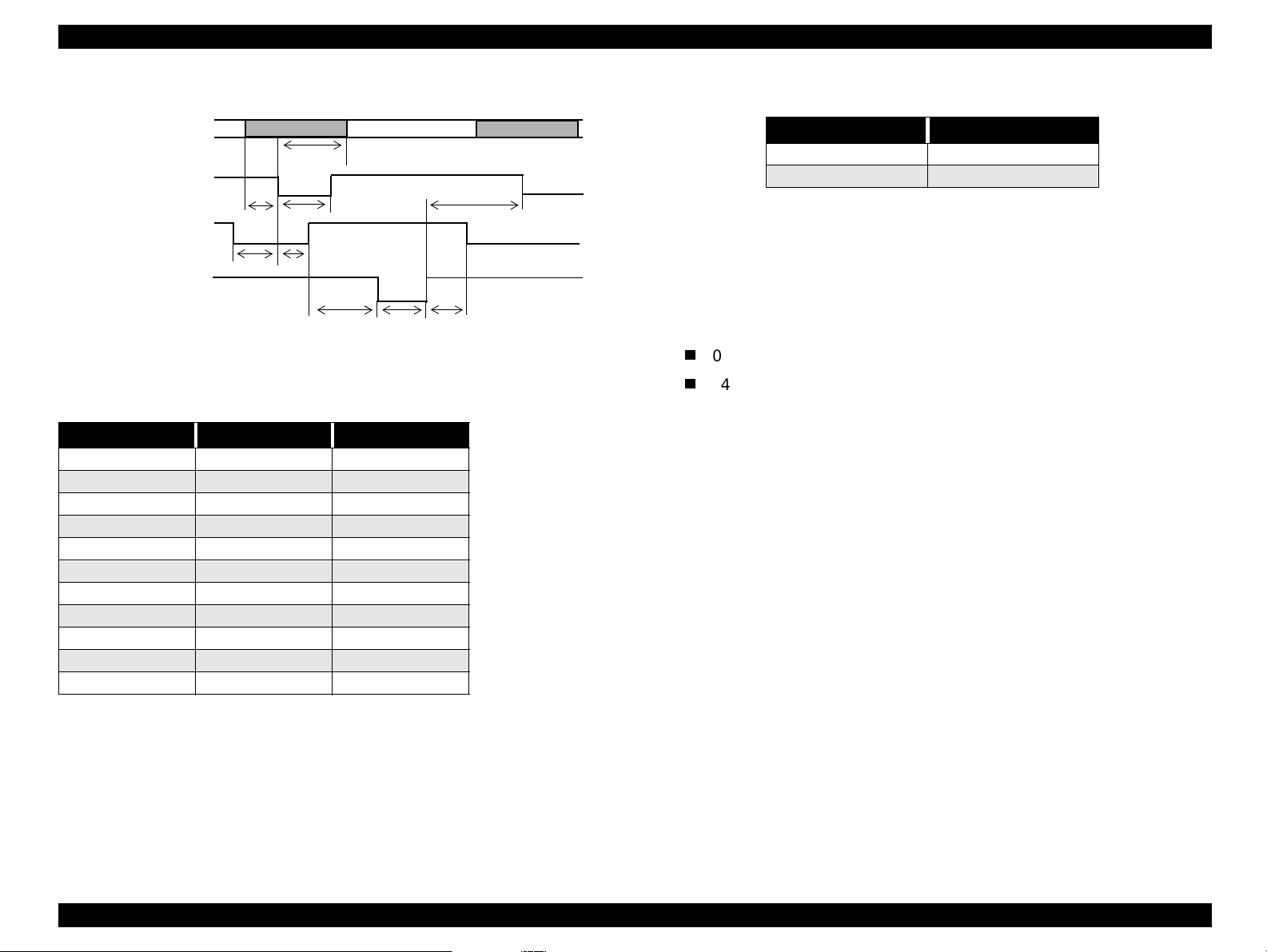

Table 1-10. Typical tack time

DATA

-STROBE

BUSY

-ACKNLG

ready

t

setup

t

data byte n

hold

t

t

busy

stb

t

data byte n +

next

t

Parallel I/F mode Time required

High speed 1 us

Normal speed 3 us

* The Logic H signal goes low, 2.0 V or less, when the printer is turned off and

goes high, 3.0 V or more, when the printer is turned on. The receiver shall

provide an impedance equivalent to 7.5 KΩ to ground.

4. Extensibility Request:

reply

t

Figure 1-7. Data Transmission Timing

Table 1-9. Data transmission times

Parameter Minimum Maximum

tsetup 500 ns -

thold 500 ns -

tstb 500 ns -

tready 0 -

tbusy - 500 ns

tt-out* - 120 ns

tt-in** - 200 ns

treply 0 -

tack 500 ns 10 us

tnbusy 0 -

tnext 0 -

* Rise and fall time of every output signal

** Rise and fall time of every input signal

ack

t

nbusy

t

The printer responds affirmatively when the extensibility request values are

00H or 04H, which mean

00H Request nibble mode reverse channel transfer

04H Request Device ID;

Return data using nibble mode reverse channel transfer

Device ID:

The printer sends the following device ID string when it is requested.

IEEE 1284.4 is enabled,

[00H][5EH]

MFG:EPSON;

CMD:ESCPL2,BDC,D4,SPC;

MDL:Stylus[SP]Scan[SP]2000;

CLS:PRINTER

DES:EPSON[SP]Stylus[SP]Scan[SP]2000;

Note: (1)[00H] denotes a hexadecimal value of zero

(2)MDL value depends on the EEPROM setting.

Product Description Interfaces 19

Page 20

EPSON Stylus Scan 2000 Revision A

USB

Standard :based on

“Universal Serial Bus Specifications Revision 1.0”

“Universal Serial Bus Device Class Definition for

Printing Devices Version 1.0”

Bit rate :12Mbps (Full speed device)

Data encoding :NRZI

Adaptable connector :USB series B

Suggested cable length :2 meters

Table 1-11. USB connector pin assignments and signals

Pin no. Signal name In/Out Description

1 VCC 2 -Data bi-directional data

3 +Data bi-directional data, pull up to +3.3V via 1.5K Ω resistor

4 Ground - Cable ground

Pin #2

Cable power, max. power consumption is

100mA

Pin #1

PREVENTING DATA TRANSFER TIME-OUTS

Generally, hosts abandon data transfer to peripherals when a perip heral is in

the busy state for dozens of seconds continuously. To prevent hosts from

entering this kind of time-out period, the printer slows down the data reception

rate to around several bytes per minute, even if the printer is in the busy state.

This slowdown starts when the remaining open buffer area decreases to

several hundred bytes. The Stylus Scan enters a continuous busy state if the

input buffer becomes full.

Pin #3

Pin #4

Figure 1-8. USB Pins

Product Description Interfaces 20

Page 21

EPSON Stylus Scan 2000 Revision A

INTERFACE SELECTION

The Stylus Scan has two built-in interfaces; the USB and parallel interfaces.

The interface in use is selected automatically.

Automatic selection

When the Stylus Scan is turned on, it initializes and then goes into an idle

state. During this idle period the printer scans the interfaces for incoming

data. The interface that receives data first is selected.

When the host stops transferring data and the printer is in the stand-by

state for a certain amount of time, the printer returns to the idle state. As

long as the host sends data or the printer interface is in the busy state, the

interface selection does not change.

Interface status and selection

When the parallel interface is not selected, the interface goes into the busy

state. When the printer initializes or returns to th e idle state, the parallel

interface goes into the ready state. Be aware that an interrupt signal such

as the -INIT signal only takes effect on the parallel in ter face when the

parallel interface is selected.

IEEE1284.4 PROTOCOL

The packet protocol described by IEEE1284.4 standard allows a device to

carry on multiple exchanges or conversations which contain data and/or

control information with another device at the same time across a single pointto-point link. The protocol is not, however, a device control language. It does

provide basic transport-level flow control and multiplexing services. The

multiplexed logical channels are independent of each other and blocking of one

has no effect on the others. The protocol operates over IEEE1284.

Automatic Selection

An initial state is compatible interface and starts IEEE1284.4

communication when magic strings (1284.4 synchronous commands)

are received.

On

An initial state is IEEE1284.4 communication and data that received it

by the time it is able to take synchronization by magic string (1284.4

synchronous commands) is discarded.

Off

An initial state is compatible interface and never starts IEEE1284.4

communication even if magic strings (1284.4 synchronous commands)

are received.

Product Description Interfaces 21

Page 22

EPSON Stylus Scan 2000 Revision A

1.3.2 Scanner interfaces

PARALLEL

1. Specification

Transmission mode 8 bit parallel, IEEE-1284 ECP (Compatibility/Nibble)

mode

Synchronization Refer to the IEEE-1284 specification

Handshaking Refer to the IEEE-1284 specification

Packet Refer to the IEEE P1284.4 Standard for Data Delivery

and Logical Channels for IEEE Std. 1284 Interface

(Draft D1.50)

Refer to the IEEE 1284.4 specification

Signal level TTL compatible level (IEEE-1284 Level 1 device)

Data trans. timing Refer to the IEEE-1284 specification

2. Connector pin assignments

Refer to the IEEE-1284 specification

USB

Any items not included in this spec ificati on shall be in compliance with the

Universal Serial Bus Specification Revision 1.0

Configuration - the scanner supports the following configurations

Table 1-12. USB Configuration

Element Description

Full Speed Mode (12Mbit/s)

Class: Vendor-specific

Subclass: Vendor-specific

Device

Configuration

Interface

Endpoint

String Descriptor

Protocol: Vendor-specific

Vendor ID: 0x04B8 (Seiko Epson Corp.)

Product ID: 0x0105

Number of possible configurations: 1

Number of interfaces supported by this configuration: 1

Characteristics: Self-powered (Re mote wake-up feature not

supported)

Max. power consumption from VBUS: 2mA (5V)

No alternate setting

Number of endpoints used by this interface (excluding

endpoint 0):2

Class: Vendor specific

Subclass: Vendor specific

Protocol: Vendor specific

Bulk IN transfer

Max. data transfer size: 64 bytes

Bulk OUT transfer

Max. data transfer size: 64 bytes

Language ID: English, US

1: iManufacturer “EPSON”

2: iProduct “Scanner Stylus Scan 2000”

Requests

The scanner must support almost all standard device requests. The

scanner does not support vendor specific requests.

Some requests and descriptors depend on the configuration (endpoint

number) of each USB device. Therefore this specification recommends the

configuration where Endpoint 1 is Bulk IN endpoint and Endpoint 2 is OUT

endpoint.

Product Description Interfaces 22

Page 23

EPSON Stylus Scan 2000 Revision A

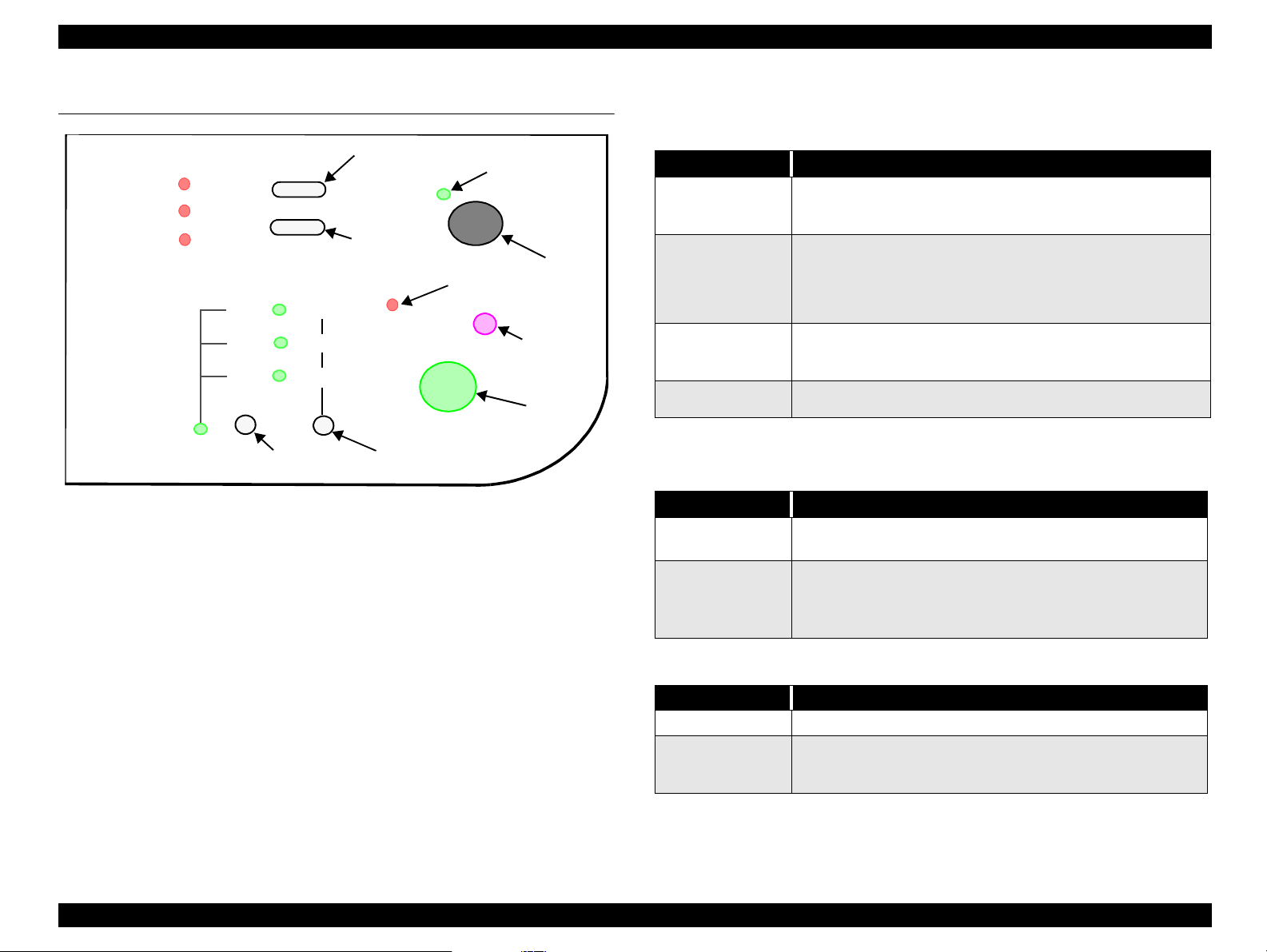

1.4 Control Panel

Paper Error

Black Ink

Maintenance

Color Ink

Maintenance

141

93%

70%

Enlarge/

Reduce

LED

Enlarge/Reduce

Selector

Figure 1-9. Control Panel

Paper Load/Eject

Ink

Maintenance

Scanner Error LED

Color

Bk Grayscale

Bk Text

Copy Mode

Selector

Operate LED

Power

button

Stop/Clear

button

Copy

button

1.4.1 Buttons

Table 1-13. Normal button functions

Button Function

• Loads or ejects paper

Load/Eject

Load/Eject

(pushed for two*

seconds)

Cleaning

(pushed for two*

seconds)

Cleaning

* The user’s guides state three seconds.

Button Function

Load/Eject

Load/Eject

+

Cleaning

• If the carriage is at the ink cartridge installation position,

returns the carriage back to the home position

• Starts the ink cartridge replacement sequence (not

available during printing). The carriage mo ves to the black

ink cartridge installation position first, and then to the

color ink cartridge installation position when pushed a

second time.

• Starts the printhead cleaning cycle.

• If the printer is in the “Ink Low” or “Ink Out” condition,

starts the ink cartridge replacement sequence.

• Returns the carriage from the ink cartridge replacement

position to the home position.

Table 1-14. Power-on button functions

Prints a status sheet that includes firmware version, ink

counter, and nozzle check patterns.

Enters the special-settings mode (see table below), which

remains active for three seconds. If neither the Load/Eject

nor Cleaning button is pushed in that three seconds, norma l

initialization begins.

Table 1-15. Special settings mode

Button Function

Load/Eject Resets the real-time counter (power-off time) in EEPROM

Cleaning

(hold for ten

seconds)

Resets the waste ink overflow counter

Product Description Control Panel 23

Page 24

EPSON Stylus Scan 2000 Revision A

COPY BUTTON

Table 1-16. Copy button functions

Button Function

Operate • Sets Local Copy Mode as the default.

• Stops the current copy job and ejects the paper during

Stop/Clear

Copy • The default setting for copying is

Copy Mode

Enlarge/Reduce

copying.

• Ejects paper during paper loading.

•Selects

• First press = LED shows current status

• Multiple presses (within 5 sec.s) = moves up one setting

each time

• Example

First time = Black Text LED activated (default)

Second time = Grayscale LED activated

Third time = Color Text & Graph LED activated

Fourth time = Black Text LED activated

• Selects reduce or enlarge

• Default = 100%

• First press = LED shows current status

• Multiple presses (within 5 sec.s) = moves up one setting

each time

• Example

First time = Enlarge/Reduce LED only (100%) activated

(default)

Second time = Enlarge/Reduce and 70% LEDs activated

Third time = Enlarge/Reduce and 93% LEDs activated

Fourth time = Enlarge/Reduce and 141% LEDs activated

Fifth time = Enlarge/Reduce LED only (100%) activated

Grayscale, Black Text,

B & W

Color (Text & Graphics)

or

and

100%

Table 1-17. Power-on functions for the Copy button

Button Function

Copy

Stop/Clear Changes printout paper size during copying (see below).

Prints a status sheet including firmware version and paper

size.

To change the printout paper size during copying, press the Stop/Clear button

until the appropriate indicator combination activates, as described below.

Table 1-18. Changing printout paper sizes during local copying

Paper size

Scanner Error Color Grayscale B lack Text

A4 on on off off

Letter on off off on

Control Panel Indicators

Product Description Control Panel 24

Page 25

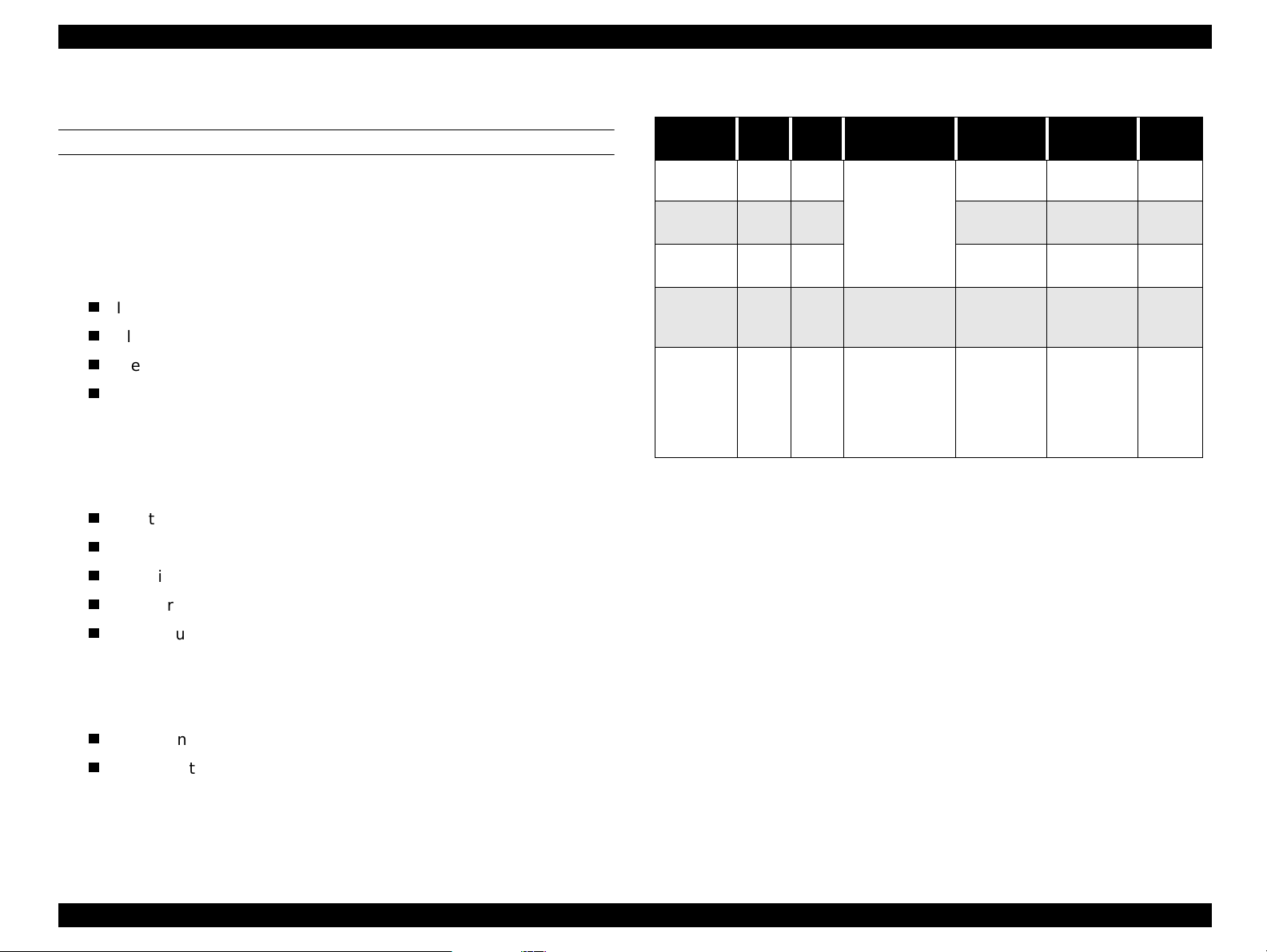

EPSON Stylus Scan 2000 Revision A

1.4.2 Control panel indicates the printer’s condition

PRINTER

Table 1-19. Printer Condition

Printer status

Printing Flashing - - Ink charging Flashing - - Ink cartridge

replacement mode

Paper Out Flashing - - On

Paper jam - Off Off Flashing

No ink cartridge/

ink end black

Ink low black - Flashing - No ink cartridge/

ink end color

Ink low color - - Flashing Enter EEPROM and

Timer IC reset

Maintenance

request

Fatal error Flashing On On Flashing

Power Ink Out (BK) Ink Out (C) Paper Out

Flashing - - -

- On - -

- - On -

- On

Flashing Flashing On On

Indicators

On

(one second only)

SCANNER

Table 1-20. Scanner Condition

Scanner status

Power Error Priority

Lamp warming up Flashing - 1

Fatal error - On 1

Paper jam - On 2

“-” = does not matter

Indicators

LOCAL COPY

Table 1-21. Copy Status

Scanner status

Power on On - 3

Copying Fla sh ing - 2

Scanner/Printer error

Paper jam

“-” = does not matter

Power Error Priority

-On1

Indicators

“-” = does not matter

Product Description Control Panel 25

Page 26

EPSON Stylus Scan 2000 Revision A

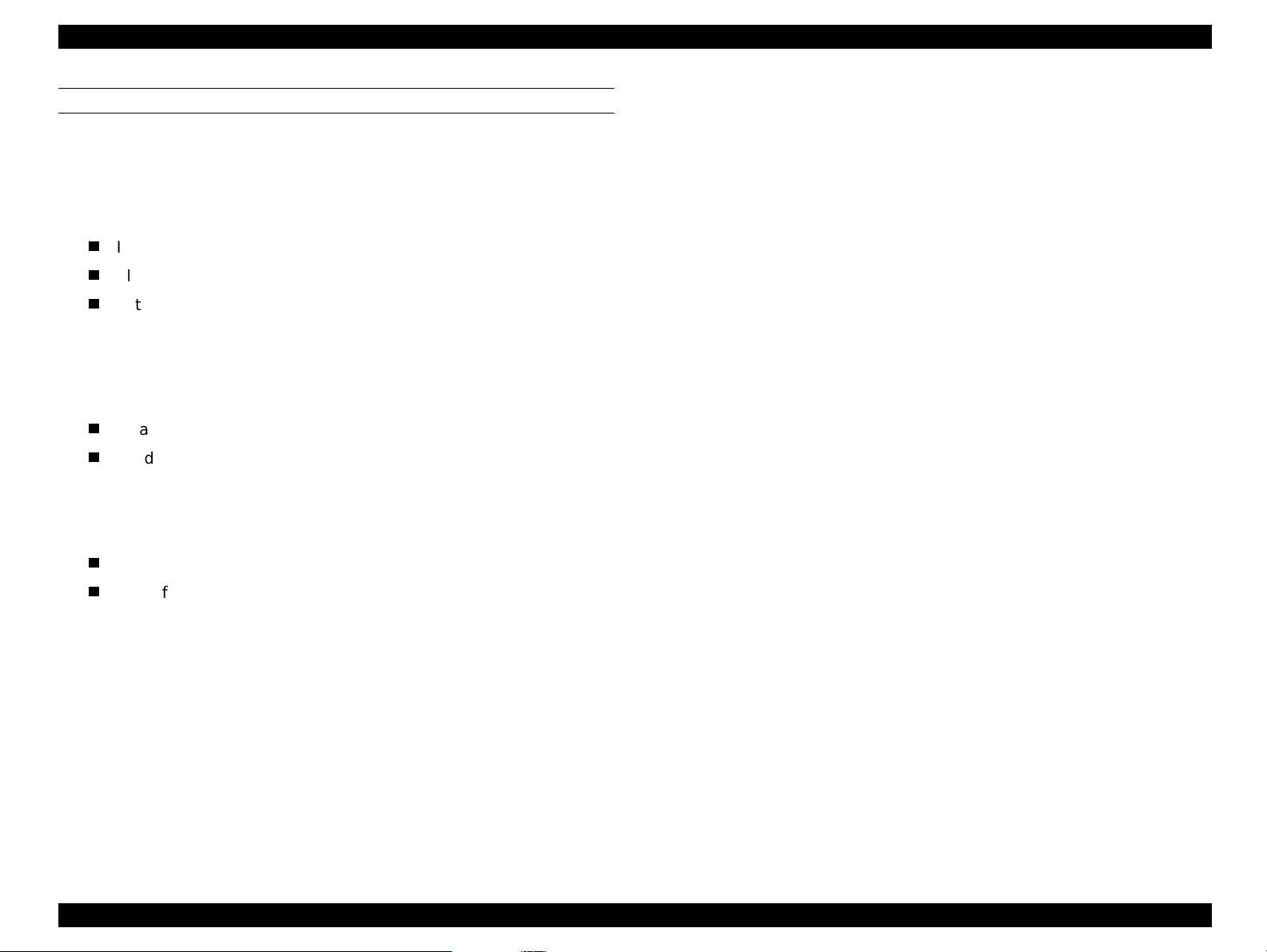

1.4.3 Initialization

PRINTER

There are three initialization methods.

1. Power-on (hardware) initialization

The printer initializes when turned on or when it recognizes the cold-reset

command (remote RS command).

When the printer initializes, the following action s are p erformed.

Initialize printer mechanism

Clear input data buffer

Clear print buffer

Set default values

2. Operator initialization

The printer initializes when turn ed on, or when the p rinter recogn izes the -

INIT signal (negative pulse) from the parallel interface.

When the printer initializes, the following action s are p erformed.

Cap the printhead

Eject paper

Operation

Power on Valid Valid

Panel

Reset

Initialize by

command

STOP Valid -

CLEAR - Valid

Operat

StandbyController

ing

Valid Valid

Valid Valid

Table 1-22. Initialization

Scanner

process

Set the local

copy setting to

default

Stop copying

Setting remains

as is

• Setting

mode:

default

• Copy mode:

Multi-copies

volume 1

process

H/W

initialization

Controller

initialization

S/W

initialization

Cancel Eject paper

Printer

process

H/W

initialization

Panel

initialization

S/W

initialization

Restart

-

-

-

Copy

button

Clear input data buffer

Clear print buffer

Set default values

3. Software initialization

The ESC@ command also initializes the printer.

When the printer initializes, the following action s are p erformed.

Clear print buffer

Set default values

Product Description Control Panel 26

Page 27

EPSON Stylus Scan 2000 Revision A

SCANNER

There are three initialization methods.

1. Hardware initialization

The scanner initializes when turned on.

When the scanner initializes, the following actions are performed.

Initialize scanner mechanism

Clear input/output data buffer

Set default values

2. Operator initialization

The scanner initializes when it recognizes the -INIT signal (negative pulse)

from the parallel interface.

When the scanner initializes, the following actions are performed.

Clear input/output data buffer

Set default values

3. Software initialization

The ESC@ command also initializes the scanner.

When the scanner initializes, the following actions are performed.

Clear input/output data buffer

Set default values

Product Description Control Panel 27

Page 28

EPSON Stylus Scan 2000 Revision A

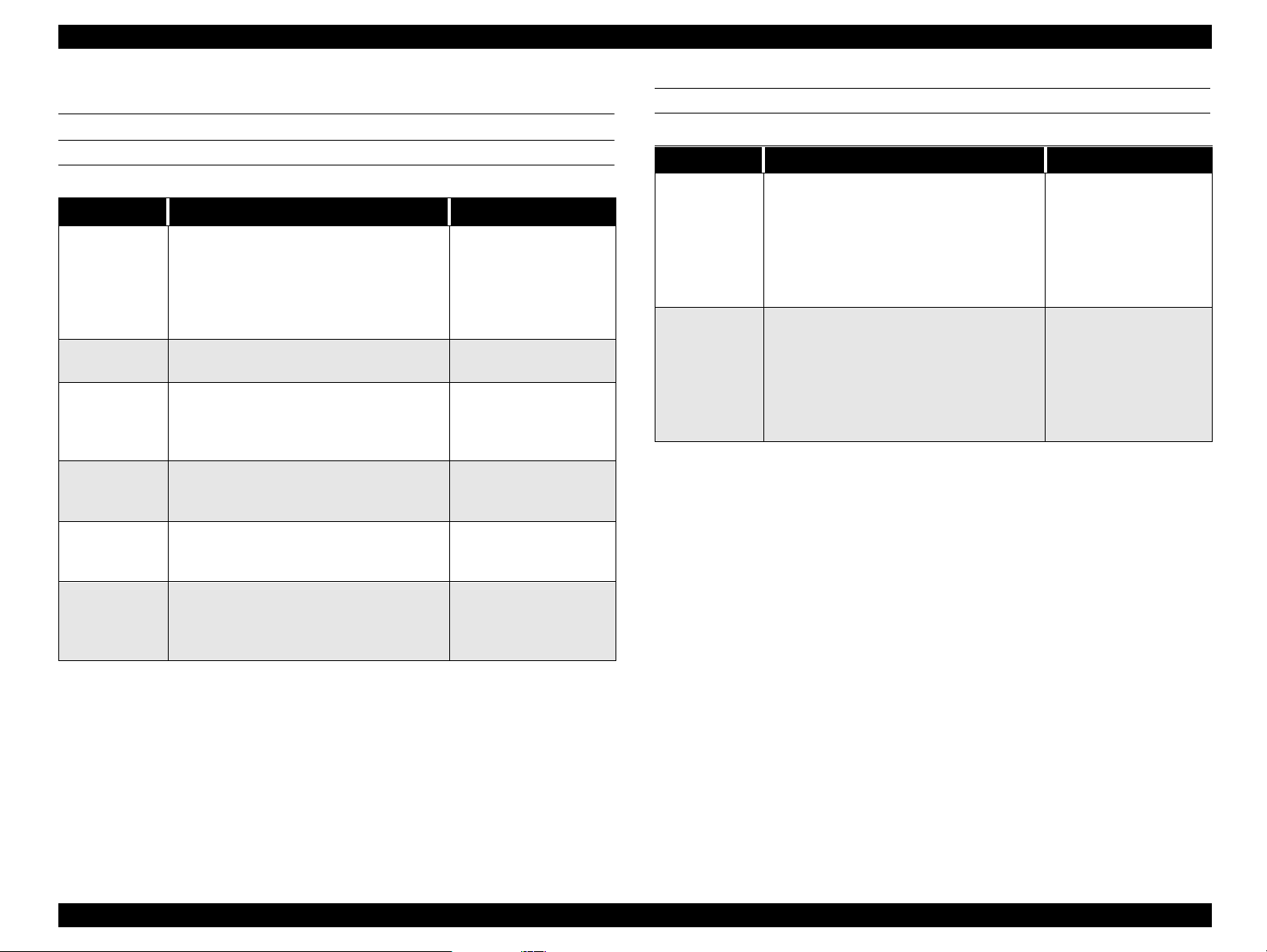

1.5 Stylus Scan Errors

PRINTER

Table 1-23. Printer Related Errors

Error Cause Solution

When one or more ink cartridges are

almost empty, the printer e nters the l ow-

Ink out

Paper out

Paper jam

No ink

cartridge

Maintenance

request

Fatal error

ink state and continues printing.

When the cartridge is complete ly empty ,

the printer indicates a n i nk-o ut e rro r an d

stops printing.

If the printer fails to properly load paper,

it indicates a paper-out error.

If the printer fails to properly eject paper,

it indicates a paper jam.

If the printer detects that one of the ink

cartridges is not installed, it indicates a

no-ink-cartridge error.

When the total amount of waste ink

reaches the limit, the printer indicates a

maintenance request and stops printing.

A carriage control or CG access error has

occurred.

Install a new ink

cartridge.

Load paper and press

the Load/Eject button.

Press the Load/Eject

button. If this does not

clear the error, remove

the paper by hand.

Install a new ink

cartridge.

Replace the waste ink

pads.

Turn off the Stylus

Scan and turn it back

on. If the error does not

clear, service.

SCANNER

Table 1-24. Scanner Related Errors

Error Cause Solution

Fatal error

Command

error

• The lamp is broken.

• System breakdown.

• Scanner fails to eject the document.

• (Disposition)

Unidentified command detected.

(Disposition)

The scanner sent a NACK signal and is

waiting for the next command. If an

incorrect command or parameter is

received, it is disregarded and the

previous value is maintained.

Turn off the Stylus

Scan and turn it back

on. If the error does not

clear, service.

Turn off the lamp and

stop operation. Set bit 7

of the status byte.??

Send a correct

command to clear the

error.

NOTE: Do not re-install used ink cartridges. Doing so confuses the ink-

level detection function and may cause a serious problem in the

printhead.

Product Description Stylus Scan Errors 28

Page 29

EPSON Stylus Scan 2000 Revision A

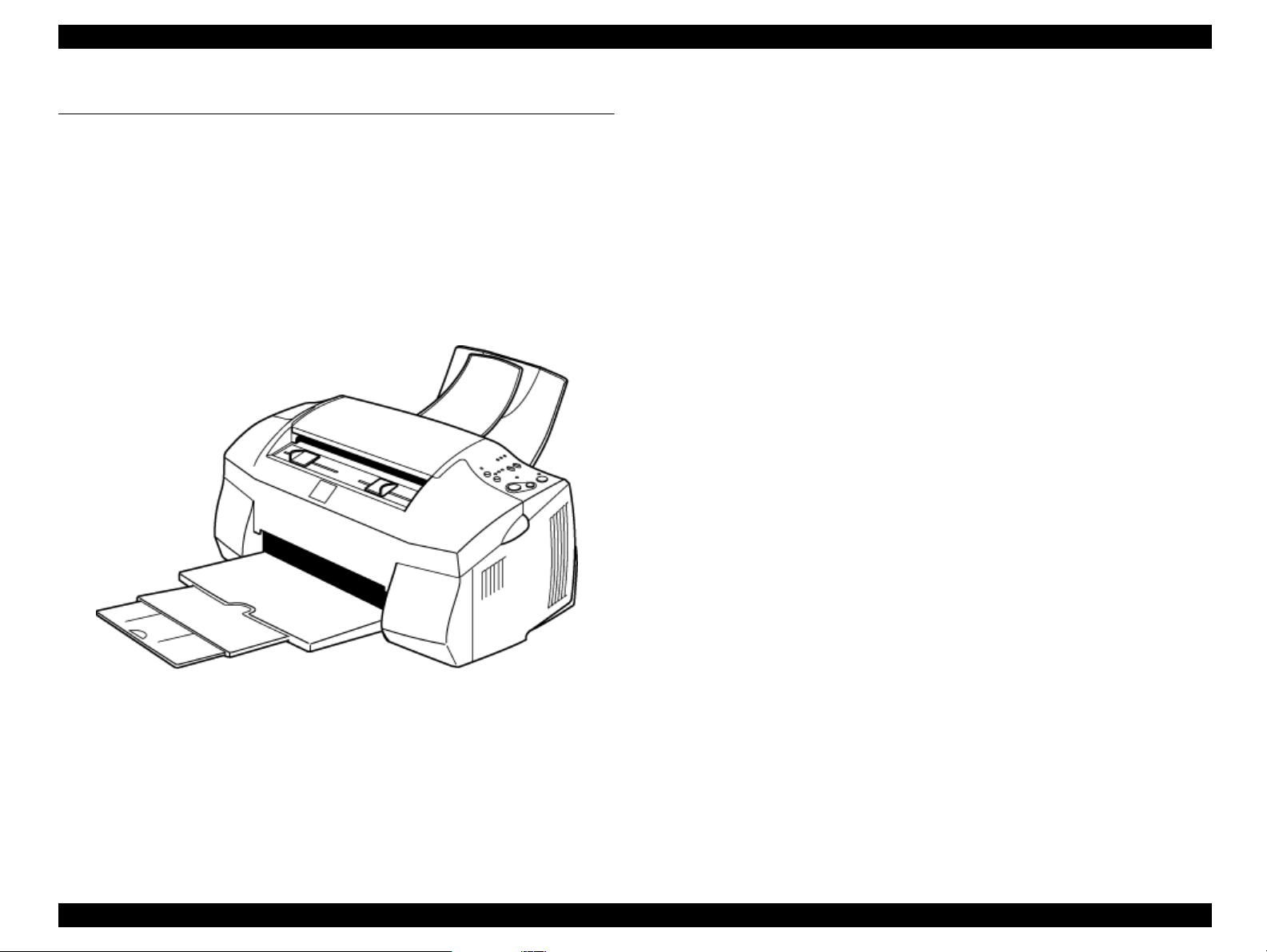

1.6 Physical Characteristics

1.6.1 Dimensions

228 x 437 x 279 mm (HWD)

1.6.2 Weight

7.5 Kg

1.6.3 External view

Figure 1-10. EPSON Stylus Scan 2000

Product Description Physical Characteristics 29

Page 30

OPERATING PRINCIPLES

CHAPTER

2

Page 31

EPSON Stylus Scan 2000 Revision A

2.1 General

The main components of the EPSON Stylus Scan 2000 are the printer

mechanism, scanner mechanism, and the following electronic boards;

Main: B101 Main Board

Power Supply: B101 PSB/PSE Board

Panel: B101 PNL Board

Operating Principles General 31

Page 32

EPSON Stylus Scan 2000 Revision A

2.2 Printer Mechanism Operation

Like previous EPSON Ink Jet printers such as the Stylus Color 740, the printer

mechanism of the EPSON Stylus Scan 2000 does not have an exclusive

mechanism to switch from paper feeding to pumping and back. Instead, this

control is done by the rotational direction of the paper feed/pump motor and

also depends on the position of the carriage.

The printhead combines the b lack and CMY heads in one un it. The following

indicate the nozzle configurations of these 3 models.

Black Nozzles: 144 nozzles (120 dpi x 3 rows in staggered)

CMY Nozzles: 48 nozzles/colors (120 dpi x 1 row)

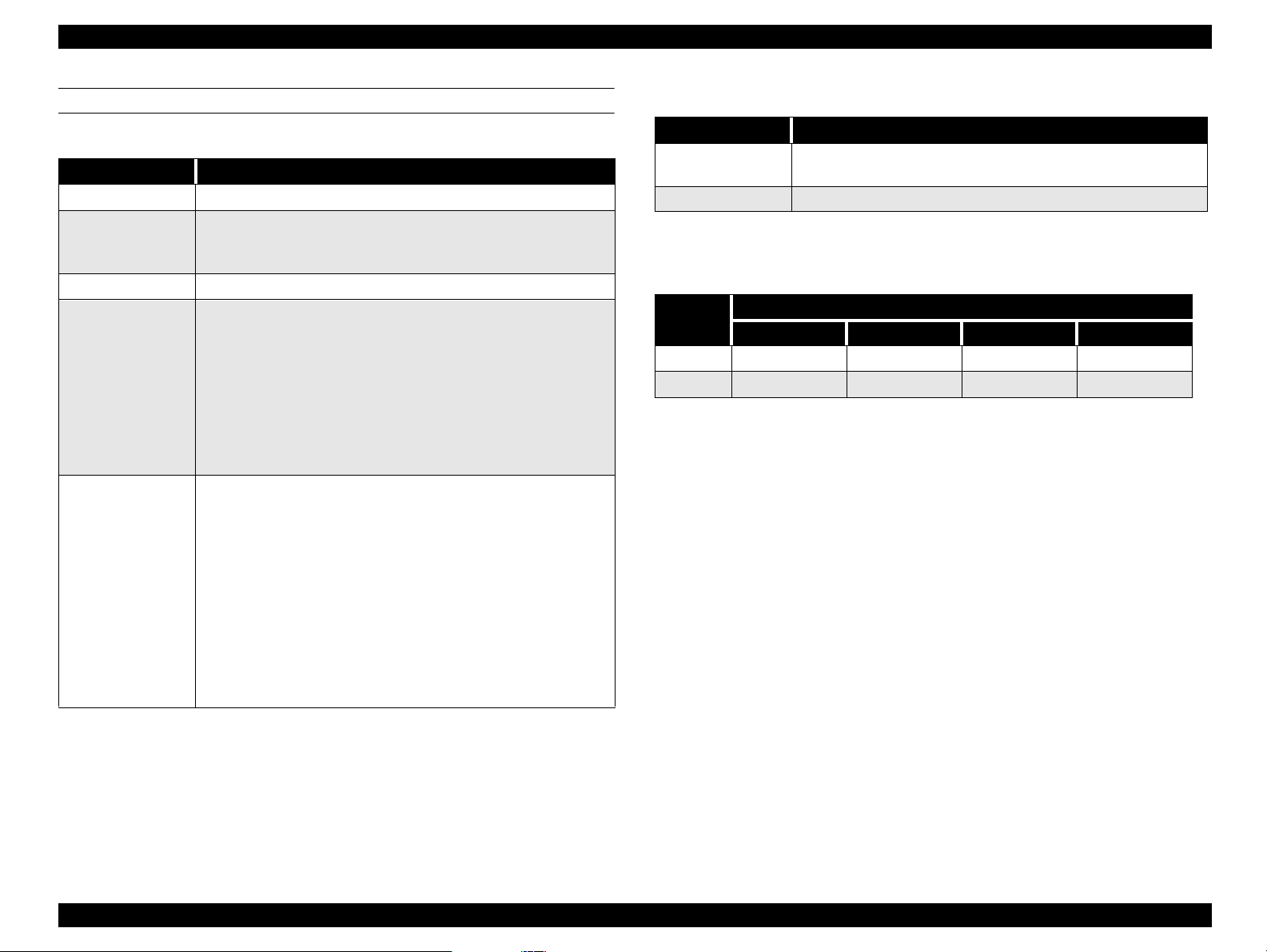

Table 2-1. Motor Types and Corresponding Functions

Motor Type Function

CR Motor Stepping Used to drive the carriage. page 35

• Drives the ASF to feed paper into

paper path

• Drives paper feed rollers at variable

PF Motor Stepping

speeds

• Drives the CR Lock lever (as

described on page 40)

• Drives pump unit to absorb ink

For details

see

page 37

PF motor

pinion

Intermittent

gear

PF Motor

Flushing section

Star wheel

Disengage flag

Black I/C sensor

CMY I/C sensor

Carriage unit

Printhead

(one unit)

Timing belt

Cap unit

Pump unit

Disengage

lever

73.6 Gear/Precision Gear

ASF

sensor

Detector

wheel

Loading

shaft

Loading

rollers

PE sensor

Carriage HP

sensor flag

Carriage HP

sensor

Figure 2-1 in the in the right column shows the outline of the printer

mechanism.

CR guide shaft

PF roller

CR Motor

PG lever

Figure 2-1. Printer Mechanism Block Diagram

Operating Principles Printer Mechanism Operation 32

Page 33

EPSON Stylus Scan 2000 Revision A

2.2.1 Printing Mechanism

The basic principles of the printhead are the same as previous models; DropOn-Demand type MACH head method.

You need to manually input the drive-voltage code (printed on top of the

printhead) for the multi-layer piezo electric element. Input this value every time

you replace the printhead, MAIN board, or printer mechanism.

The main parts of the printhead and carriage are described below.

PZT

PZT is an abbreviation of Piezo Electric Element . The print signal is sent

from the PSB/PSE board through the driver board on the

and to the PZT. Then, the appropriate PZT squeezes the cavity, forcing

the ink stored in the cavity out through the nozzle. This process is

described in more detail on the next page.

Ink cavity

Ink flows from the ink cartridge, through the filter, and to the ink cavity

where it is stored until one of the PZT units forces it out through the

nozzles.

Nozzle Plate

The bottom surface of the printhead which contains nozzle holes to

direct ejected ink toward the paper below. See the next page.

Filter

When the ink cartridge is installed, if any dirt or dust around the

cartridge needles is absorbed into the inside of the printhead, there is a

large possibility that the nozzles will clog. Clogged nozzles can be

detected by alignment failure and dot-missing problems. To prevent

these kinds of problems, a filter is set below the cartridge needle and

ink flows through the filter on its way to the ink cavity.

printhead

unit

Nozzle selector

Board

I/C Out

sensor

actuator

Needle

Ink cartridge

PZT

(Piezo)

unit

Nozzle

plate

Figure 2-2.

I/C Out sensor actuator

The I/C Out sensor detects whether or not an ink cartridge is installed

according to the position of the I/C Out sensor actuator. When a

cartridge is installed, the actuator is pushed down, which turns the

shaft that is connected to the act uator. The fl ag at the other end of t he

shaft activates the I/C Out sensor when the cartridge is fully in place.

Printhead

Ink cavity

Sectional Drawing

Filter

See the next page for more details on the nozzle s e lector board and the ink

ejecting process.

Operating Principles Printer Mechanism Operation 33

Page 34

EPSON Stylus Scan 2000 Revision A

Ejecting State:

2.2.2 Printing Process

The following figures show sectio nal drawing s of th e printh ead in the n ormal

and ejecting states.

Normal State:

1.

When no print signal is outpu t, the PZT is in the normal, standby, state.

2.

When a print signal is sent from the MAIN board, the IC (Nozzle Selector)

located on the printhead unit receives the data in 1-byte units. The Nozzle

Selector then sends the voltage signal on to the appropriate PZT. Due to

the physical properties of the PZT, electrical signals cause the PZT to

change shape. When the PZT changes shape, it squeezes the ink cavity,

ejecting ink out through the nozzles.

Ink course

Piezo unit

Nozzles

Figure 2-3. Printhead Normal State

Cavity

Nozzle plate

surface

Figure 2-4. Printhead Ejecting State

Operating Principles Printer Mechanism Operation 34

Page 35

EPSON Stylus Scan 2000 Revision A

Rotor

1

2

3

4

A

/A

B

/B

2.2.3 Carriage Mechanism

The carriage mechanism moves the carriage back and forth according to the

drive from the carriage motor. See Figure 2-6 on the next page.

The carriage motor is a 4-phase, 200-pole, stepping motor and is driven by 2-2

phase, 1-2 phase, Double 1-2 phase, 2-Double 1-2 phase, and 4-Double 1-2

phase drives. This stepping moto r allows the carriage to move freely to fixed

positions where necessary operations such as ink absorption can be

performed. The following tables show carriage the motor specifications and

motor controls.

Table 2-2. Carriage Motor Specifications

Items Description

Motor type 4-Phase/200-pole Stepping motor

Drive voltage Range 42VDC ± 5%

Internal coil resistance

Control method Bi-Polar Drive

Table 2-3. Phase drive

7.8 Ohms ± 10%(per phase under 25 °C

environment)

Table 2-4. CR Motor Control at Each Mode

Printing mode

High Speed Skip 340 4080

Normal Printing 200 2400

Capping 80 960

Wiping 40 480

Cap (Valve

Release)

Withdrawal of cap 5 60

Drive Speed

[CPS]

20 240

Drive frequency

[PPS]

Drive method

Double1-2, 2-2,1-2

phase drive*

Double 1-2, 2-2 phase

drive

2-Double 1-2, 2-2

phase drive

2-Double 1-2, 2-2

phase drive

4-Double 1-2, 2-2

phase drive

4-Double 1-2, 2-2

phase drive

Phase Drive inch/pulse mm/pulse

2-2 1/120 0.212

1-2 1/240 0.106

Double 1-2 1/480 0.053

2-Double 1-2 1/960 0.026

4-Double 1-2 1/1920 0.013

Figure 2-5. CR Motor Internal Circuit Diagram

Operating Principles Printer Mechanism Operation 35

Page 36

EPSON Stylus Scan 2000 Revision A

PLATEN GAP LEVER

Carriage

motor

Rear (thick

paper) position

Parallelism

adjust

lever

Paper feed

roller

Paper eject

rollers

Timing

belt

Paper guide

(front)

Home position

sensor

Carriage

unit

Forward

(normal)

position

Platen Gap

lever

Figure 2-6. Carriage Mechanism with platen gap lever (Top view)

As shown in Figure 2-6, the Platen Gap lever can be moved forward or back to

adjust for the thickness of the paper. The PG lever is connected to the carriage

guide shaft, which raises or lowers the carriage depending on the PG lever

position. The nozzle surface remains parallel to the paper in either position

thanks to a tilt adjustment mechanism. Also, the two parallelism-adjustment

levers, one mounted on each side of the carriage guide shaft, adjust the

parallelism between the platen and shaft when the shaft is installed in the

factory. This precise adjustm e nt is necessary to make sure the gap between

the platen surface and the printhead surface is 1.04 mm in the normal position

or 1.74 mm in the thick-paper position.

Operating Principles Printer Mechanism Operation 36

Page 37

EPSON Stylus Scan 2000 Revision A

Rotor

1

2

3

4

A

/A

B

/B

2.2.4 Paper Feeding Mechanism

The paper feeding process begins at the ASF, continues through the PF roller,

and ends at the paper eject roller (and star-wheel gear).

The ASF unit, which is common with the Stylus COLOR 740 printers, is driven

by the PF motor (stepping motor). Torque sent from this motor switches

between the ASF unit and pump/PF roller depending on the position of the

disengage lever (described later).

In the EPSON Stylus Scan 2000, a four-phase hybrid type pulse motor is used

in the PF motor as a motive power of the paper mechanism. The torque is sent

at 2-Double 1-2, Double 1-2, 1-2, and 2-2 phase drives. This motor drives the

paper-feeding mechanism as well as the pump mechanism which is necessary

for printhead cleaning. By using this pulse motor, it becomes possible to use

variable drive levels for many purposes, such as paper feed, slight paper feed,

and high or low speed absorption of pump operations. The following table

shows PF motor specifications.

Table 2-5. PF Motor Specifications

Item Description

Motor type 4-phase/200-pole Stepping motor

Drive voltage 42VDC ± 5%

Coil Resistance

8.8 Ohm ± 10%(per 1 phase under 25°C

environment)

Table 2-6. Phase drive

Phase Drive Inch/pulse mm/pulse

2-2 1/720 0.035

1-2 1/1440 0.018

Double 1-2 1/2880 0.0088

2-Double 1-2 1/5760 0.0044

Figure 2-7. PF Motor Internal Circuit Diagram

Control method Bi-Polar Drive

Phase drive 1-2, 2-2, Double 1-2, 2-Double 1-2

Operating Principles Printer Mechanism Operation 37

Page 38

EPSON Stylus Scan 2000 Revision A

Table 2-7. Print Modes and Drive Methods

Printing mode

High Speed Skip 340 4080

Normal Printing 200 2400

Capping 80 960

Wiping 40 480

Cap (Valve

Release)

Withdrawal of cap 5 60

Drive Speed

[CPS]

20 240

Drive frequency

[PPS]

Drive method

Double 1-2, 2-2,1-2

phase drive*

Double 1-2, 2-2 phase

drive

2-Double 1-2, 2-2

phase drive

2-Double1-2, 2-2 phase

drive

4-Double1-2, 2-2 phase

drive

4-Double 1-2, 2-2

phase drive

Drive from the PF motor is sent to the P F rollers and paper eject rollers as

described below.

To the PF rollers:

PF motor pinion gear (CCW rotation)

To the eject rollers:

PF motor pinion gear (CCW rotation)

(13.5, 30.8)

NOTE:

Above CCW rotation is mentioned viewing from the PF motor pinion

gear side.

→

Spur gear (28) → Paper eject rollers

→

Gear 73.6 → PF rollers

→

Gear 73.6 → Combination gear

Figure 2-8 shows a paper feeding mechanism block diagram, which includes

the parts along the PF motor drive-transmission paths.

Gear

73.6

Combination

Gear13.5,30.8

Paper Eject Roller

PF motor

Gear 28

PF Roller

Star Wheel Assy.

Figure 2-8. Paper Feeding Mechanism (Top View)

The printer feeds paper from the ASF (when the PE sensor located near the

carriage motor detects paper is loaded) through the paper path and stops

feeding when the paper’s leading edge reaches the halfway point of the front

paper guide. To correct for any misfeeding, the paper is fed back toward the

ASF a predetermined number of steps and then it is fed forward again until it

reaches the top-of-form position.

Once the printer starts printing, it advances paper using the PF rollers and

subrollers until it reaches the last 14mm of the paper, when it advances the

paper using the star wheel gear and paper eject rollers.

Torque sent from the ASF/Pump motor to the ASF unit via the disengage

mechanism is used for the following operation.

Operating Principles Printer Mechanism Operation 38

Page 39

EPSON Stylus Scan 2000 Revision A

MULTI-FEED PREVENTION MECHANISM

Like the Stylus COLOR 740 ASF, the ASF built in the Stylus Scan has the

multiple-paper-feeding-prevention mechanism to provide accurate and

consistent paper feeding. This mechanism prevents a sheet of paper from

falling from the paper set position in to the paper path. A paper return lever

in the mechanism pushes paper that may have fallen off back onto the

hopper. After this motion is completed, the LD roller starts loading paper .

The multiple-paper-feeding-prevention operation is described in the

following steps.

1. When the printer power is turned on, the ASF/Pump motor rotates

counterclockwise to detect ASF home position. Then the motor rotates

clockwise specified steps to set the LD roller and paper return lever to their

proper positions. (See “Standby State” in Figure 2-9.)

2. When the paper loading signal is sent from the PC or the Load/Eject button

is pressed, the PF motor turn s counterclockwise to let the LD roller load

paper. (See “Paper Pick Up State” in Figure 2-9.)

3. Due to the design of the ASF, the LD roller loses friction on the paper and

stops at the point where the paper is fed by the PF roller. (See “PF Roller

Paper Feed State” in Figure 2-9.)

4. When the next print signal is sent or the Load/Eject button is again

pressed, the PF motor rotates clockwise a specified number of steps to set

the LD roller and the paper return lever in place. (See “Standby State” in

Figure 2-9.)

NOTE: If no print signal is sent for a predetermined number of

seconds in step 4, the LD roller and the paper return lever

automatically return to the standby state.

Figure 2-9. Multiple Paper Loading Prevention Mechanism (right side view)

Operating Principles Printer Mechanism Operation 39

Page 40

EPSON Stylus Scan 2000 Revision A

SMALLER TRAILING-EDGE MARGIN

Like the Stylus COLOR 740, this model uses a new design to allow printing up

to the last 3mm by changing the design and position of the star-wheel gear.

The star-wheel gear assembly has been shifted 5 degrees from directly on top

of the eject rollers towards the front paper guide. This change suppresses the

tailing edge of the paper so that the old minimu m margin of 14mm has been

reduced to only 3mm.

Old Feeding

Method

Paper

New Feeding

Method (from

COLOR 740)

Star wheel

Assembly

Eject rollers

Moved to a 5

degree angle

Printhead Support roller

Platen

3mm bottom margin

may contact printhead

PF roller

CARRIAGE LOCK MECHANISM

The carriage lock mechanism prevents the carriage from being left at an

uncapped position for a long time which can occur due to user mistakes,

physical shock, vibration during transport, and so on. The CR lock mechanism

is driven by the stepping PF motor. See Table 2-5, “PF Motor Specifications,”

on page 37 for motor specifications.

The PF motor controls the CR lock mechanism as well as the PF mechanism

depending on the direction of the PF motor rotation. The CR lock mechanism is

located at the right end of the paper eject roller.

Top view

Bushing 6

Pump Planetary

Lever

CR Lock

Lever

Right-side view

Carriage

Paper Eject

roller

Middle frame

Pump

Planetary

Lever Guide

Figure 2-11. CR Lock Mechanism

While the PF motor drive is used for paper feeding (PF motor rotation = CCW),

This area remains

stable

the CR Lock Lever is set under the Paper Eject Frame. But the CR Lock lever

rises up and locks the carriage when the PF motor rotates CW.

Figure 2-10. 3mm improved margin (viewed from right side)

Operating Principles Printer Mechanism Operation 40

Page 41

EPSON Stylus Scan 2000 Revision A

The PF motor drive is sent to the CR Lock lever via the Paper Eject roller.

PF Motor pinion gear (CW rotation)

Gear 28

→

Paper Eject Roller

→

CR Lock Lever

→

Gear 73.6

→

Combination gear

→

If the carriage is left uncapped for a long time, ink on the printhead surface

gradually thickens and may clog the nozzles. In some cases, the nozzles may

be so thoroughly clogged that they cannot be cleared even after performing

multiple cleaning operation s.

To prevent clogged nozzles, the printer caps and locks the carriage in the

following conditions.

Power off sequence:

When power is turned off, even during printing, the printer caps and

locks the carriage at the end of the power-off sequence.

Power on sequence:

When power is turned on, the printer automatically performs an

automatic (power-on) cleaning cycle and then caps and locks the

carriage.

NOTE: The power-on cleaning cycle is an automatic head cleaning

sequence that is performed every time the power is turned on.

The timer IC, which is powered by the lithium battery,

measures the length of time the printer has been off. The

printer selects and performs the appropriate cleaning

operation according to the length of time it has been off.

PAPER PICK UP OPERATION

When the Load/Eject switch is pressed or printing order is inp ut, the carriage

unit moves until the left edge and collides with paper pick up trigger lever.

When the carriage collides with this trigger level, a planetary gear located on

the same axis is also pushed at the same time and conveys the motive power

on the platen to the adjoining gear line side for ASF drive.

Gear 34/

ASF roller

drive gear

Combination

gear 16,40.8

Paper pickup

trigger lever

Gear 36/

Eject roller

drive gear

Combination

G 12.4,28/

Eject roller

transmission

gear

PF motor

Spur 23.2/ASF

roller

transmission

gear

Gear 73.6

pinion gear

Combination G

16,21.6/Platen roller

transmission gear

Figure 2-12. Paper Pickup Mechanism

Paper eject sequence:

When the Load/Eject button is pressed, the printer ejects any paper in

the paper path. If no print data is received at this time, the printer caps

and locks the carriage and then enters the standby mode.

However, if no paper is in the paper path when the Load/Eject is

pressed, the printer loads a sheet and does not lock the carriage.

PF motor torque is always transmitted to the CR lock lever side, but the

operation of the CR lock mechanism varies depending on the rotation direction

of the motor.

Clockwise = sets the carriage lock lever

Counterclockwise= releases the carriage lock lever

Operating Principles Printer Mechanism Operation 41

Page 42

EPSON Stylus Scan 2000 Revision A

2.2.5 Ink System

Ink system mechanism consists of 1) cap mechanism, 2) pump mechanism, 3)

carriage lock mechanism, 4) waste ink absorber and 5) ink sequence. Out of

these mechanisms, 1) to 4) are physical mechanism and parts which are

mounted on the printer mechanism and 5) the ink sequence is performed

automatically by the firmware. The EPSON Stylus Scan 2000 has no engage/

disengage mechanism, meaning the pump and platen are always at work when

the PF motor operates. The figures below show printhead positions when the

ink system and various ink-pumping sequences are performed.

Eject roller

drive gear

PF roller drive

gear

Carriage lock

lever

Cleaner blade

A

B

Figure 2-14. Major Ink Sequence Positions on Carriage

Printable Area

2976 dots (360-dpi)

C

A. ASF Pick-up position

B. Flushing

C. Wiping/rubbing position

D. Flushing position

E. Ink Discharge position

F. Cap cleaning position

E

D

F

Eject roller

transmission

gear

PF (pump)

motor pinion

gear

Pump roller

Cap unit

Figure 2-13. Ink System Mechanism

Operating Principles Printer Mechanism Operation 42

Page 43

EPSON Stylus Scan 2000 Revision A

2.2.6 Pump, Carriage Lock, Head Cleaner Mechanism

n the EPSON Stylus Scan 2000, there is no switch or mechanism to switch

between the ink pump and paper feed operations. Therefore, whenever the

paper feed/pump motor rotates, the pump-drive roller inside the pump unit

rotates. However, the rotational direction of the rollers determines whether or

not the pump sucks ink. Also, even if the pump rotates in the ink-absorption

direction, ink is not abso rbed if the carriage is in the false-absorption position.

Figure 2-13 shows process of conveying motive power to the pump drive

roller.

The process of conveying the motive power to the paper eject roller is shown

in Figure 2-15. This motive power is conveyed to Gear C through Gear B. The

lever that drives Gear C, the carriage lock, and the head-cleaner mechanism is

shown separately but it is constructed as one unit. Since the engagement of

these parts depends on the tension of the compression spring, if the lever is

burdened, only Gear C and the pump roller rotate and no more motive power is

conveyed to the lever part.

Axis of

Paper

eject

roller

Gear C

Gear A

Gear B

Compression

spring

Pump drive

roller

Figure 2-15. Pump Mechanism Power Transmission Process

The table below shows PF/Pump motor rotational direction and pump system

operation.

Operating Principles Printer Mechanism Operation 43

Page 44

EPSON Stylus Scan 2000 Revision A

Table 2-8. Pump Motor Rotation and Operation

PF motor pinion gear rotation

(looking at gear surface)

Clockwise (CW)

forward rotation

Counterclockwise (CCW)

backward rotation

1) Release the tubes

2) Disengage Head Cleaner

3) Disengage carriage lock

1) Squeeze tubes to pump ink

2) Engage Head cleaner

3) Engage carriage lock

Refer to Figure 2-16 in the right column which shows the pump operations at

clockwise and counterclockwise rotation.

During ink-absorptive operations such as cleaning and flushing (but not during

normal printing), ink drains from the ink cartridge to the waste-ink pads

through the cap. During printing and flushing, ink is fired out of the nozzles by

the PZT. But during absorption operations the head is capped and ink is sucked

off the nozzle plate by the force of the vacuum created by the pump drive and

the PZT does not move.

Counter-Clockwise

Revolution

Pump unit operation

Clockwise

Revolution

Table 2-9. Pumping modes

Pump Mode Revolutions Absorption

Low speed 0.38rev/second 0.06m l/s ec ond

Regular

absorption

High speed 2.6rev/second 0.4ml/second

Super high speed 3.38rev/second 0.54ml/second

1.3 rev/second 0.2ml/second

Tube squeezed

Tube released

Figure 2-16. Pump Roller Rotation and it’s Operation

Operating Principles Printer Mechanism Operation 44

Page 45

EPSON Stylus Scan 2000 Revision A

2.2.6.1 Cap Mechanism

The cap mechanism prevents ink from thickening and sticking on the head

surface when the printer is not in operation and it also plays a part in cleaning

the printhead. During the power-off sequence, the printhead moves to the right

where the head surface and cap come into contact, and the head surface

contacts the rubber frame of the cap surface until the power is turned back on.

An absorber pad is spread in the cap and can hold a certain amount of ink

which is absorbed from the head without draining it to the waste ink pad. Also,

below the absorber pad, there are two valves that control the adhesion

pressure between the head and cap surface. There is also one exit and tube to

drain ink to the waste ink pads.

Position A

When the carriage is out of the HP (for example in the printable area or paper

feed position), the valves on the cap mechanism stay in Position A (closed) as

shown to the right.

Position B

When the carriage returns to the right, it catches the carriage flag on the cap

mechanism. This raises the cap to meet the head surface. This position is used

for head cleaning because the valves are still closed but the rubber around the

cap traps air, so when the pump sucks air away from the cap, a vacuum is

created and ink is sucked away from the head surface. Ink absorption and

slight ink absorption are performed in Position B.

Position C

By moving the carriage a little further to the right, the frame flag on the cap

mechanism contacts the frame and the air valve opens. When the carriage is in

this position and the pump sucks air, no ink is absorbed from the head surface

but ink left in the absorber pad in the cap is drained.

Position A Positions B and C

Carriage flag

Ink Eject Valve

Negative Pressure

Valve

Closed-

valve state

Open-valve

Frame

flag

Figure 2-17. Cap mechanism and valve operation

state

Operating Principles Printer Mechanism Operation 45

Page 46

EPSON Stylus Scan 2000 Revision A

2.3 Scanner Mechanism Operation

2.3.1 Mechanism

The figure below describes how the light reflected off the document passes

through the lens and reaches the CCD and how the CCD reproduce an image.

The CCD reads the light, converts lig ht into various analog data according to

the strength of the light, and sends this various analog data to the MAIN

board. The analog data received by the MAIN board is converted into digital

data, and after being processed, the digital data is sent to the host.

Cooling Cathode

Fluorescence Lamp

Analog

Signal

Lens

CCD

MAIN

Board

Figure 2-18. Scanner Operating Principle

Digital

Signal

Host

R

CCD

G

B

CDS

CDS

CDS

PGA

PGA

PGA

CCD Signal Processor

MUX

ADC

Digital

Signal

OUT