Page 1

®

Color ink jet printer

EPSON Stylus COLOR 440/640/740

TM-SC4/6/740

Page 2

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

PREF ACE

This manual describes basic functions, theory of electrical and mechanical operations, and maintenance and repair procedures of the Stylus COLOR

440, 640, and 740. The instructions and procedures included herein are intended for experienced repair technicians, and attention should be given to

the precautions on the following pages.

Revision Date

st

1

Release November 1998

ii

Page 3

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to prov ide reaso nable prote ction agains t harmful inter fe rence in a residential in stallation. T his equipmen t generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

and telev is ion reception. However, there is no guarante e th at int erference will not occur in a particul ar installatio n. If t his equipment does cause

interfere nc e to radio an d t elevision rec eption, wh ic h c an be determined by turning the eq uipment of f an d on, the use r is enc ouraged to try to

correct th e interferenc e by one or more of the fol low ing measures:

Reorient or relocate th e receiving antenna.

Increase the separation between the equipment and receiver.

Connec t the equipm ent into an out let on a circuit di fferent from th at to wh ic h t he receiver is c onnected.

Consult t he dealer or an experien c ed radio/TV t ec hnician for help.

WARNING

The conn ec t ion of a non-shielded equipmen t in te rf ac e cable to th is equipment w ill invalidate t he FCC Certification of this device and may cause

interference levels that exceed the limits established by the FCC for this equipment. It is the responsibility of the user to obtain and use a shielded

equipment interfa c e c able with this device. If this equipmen t has m ore than on e int erface con nector, do n ot leave cables c onnected to unus ed

interfaces.

Changes or modifica t ions not expr es s ly approved b y the m anufactur er c ould void the user's authority to op erate the printer.

FOR CANADIAN USERS

This Clas s B digital appa rat us meets all requirem ents of the Ca nadian Interf erence-Causing Equipment R egulations.

Cet appa reil numériq ue de la class e B respecte to ut es les exigenc es du Règlement sur le ma t eriel brouilleur du Cana da.

iii

Page 4

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

COPYRIGHT NOTICE

All rights r eser ved. No part of thi s p ublica ti o n may be rep roduce d, sto red i n a re tr i eval system, or transmitted in any form o r by any means, electronic,

mechan ic al, photocopy ing, recording, or otherwise, with out the writte n permissi on of Epson Am erica, Inc. No patent liabilit y is assumed with respect

to use of the inf ormation co nt ained herein. Neithe r is any liability assumed for damages res ulting from th e use of the information c ontained herein.

While eve ry precaution has been tak en in the pre paration of th is book, Epso n America, Inc., assumes no responsibility for errors and omissions.

Neither E ps on America, I nc . , n or it s af fi liat es shall be liable to the purchaser of th is product or th ird parties for dam ages, losses, costs, or expenses

incurred by purchaser or third parties as a result of: accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to

this produ c t.

Epson America, Inc., shal l no t be l i abl e agai nst any damage s or p roble ms ari si n g fro m the u se of a ny op ti ons or a ny consumable products other than

those designated a s O riginal EPSON Produ c ts or EPSON -Approved Products by Seiko Epson Corpor at ion.

TRADEMARKS

EPSON and ESC/ P are registe red trademarks and ESC / P 2, EPSON FX-880, and EPSON F X-1180 are tradem ark s of Seiko Epson

Corporat ion. Epson C onnection is a s erv ic e mark of Ep s on America, In c .

General Notice:

EPSON dis c laims any a nd all rights in t hos e marks.

Copyrigh t © 1998 Epso n America, Inc .

20770 Madrona Av enue

Torrance , CA 90509-2842

Other product name s us ed herein are for identif ic at ion purpos es only and may be trademark s of t heir respect iv e c om panies.

iv

Page 5

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

PRECAUTIONS

Precaut ionary notat ions throughout the te xt are categorized with re s pect to: (1) pers onal injury and (2) dam age to equipment.

W ARNING

CAUTION

Always obs erve the precautions lis t ed below when performing repair and maintenance pr oc edures.

Signals a precaution which, if ignored, could result in se rious or fata l personal inj ury . Great cauti on s hould be ex erc is ed in

performing a procedure preceded by a WARNING.

Signals a precaution which, if ignored, could result in damage to equipmen t.

WARNING

1. Always dis c onnect the product from both the pow er source and the host co m puter before performing any maintenance or repair procedure.

2. No work sh ould be perfo rm ed on the un it by persons unf am iliar with bas ic s af et y m easures dic t at ed for all elect ronics technicians in their line of

work.

3. In performing testin g described in this manu al, do not connec t t he unit to a pow er s ource until instructed t o do so. When the po w er s upply cable

must be co nnected, use extreme ca ut ion in working on the po w er s upply and o th er electronic c om ponents.

CAUTION

1. Repairs o n EPSON pr oducts should be perfo m ed only by an EPSON-certified repair technic ian.

2. Make certain that the source voltage is the same as the rated voltage listed on the serial number/rating plate. If the EPSON product has a primary

AC rating different from the available power source, do not connect it to the power source.

3. Always ve rif y th at th e EPSON pr oduct has be en disconnected from t he power source before removing or replac ing printed circ uit boards or

individual chips.

4. To protect se ns it iv e microproc essors an d ot he circuitr y, us e static discharge equipment, su c h as anti-static wr is t st raps, when a c c es s ing interna l

components.

5. Replace ma lf unctioning c om ponents only with thos e c om ponents rec ommended by the ma nuf acturer; in tr oduction of sec ond-sour c e ICs or other

nonappr ov ed components may damage the product and void an y a pplicable EP SON warranty.

v

Page 6

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

vi

Page 7

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

Table of Contents

1. Product Description

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cut Sheets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Transparencies, Glossy Paper . . . . . . . . . . . . . . . . . 9

Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Card Stock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjust Lever Setting (PG Adjust Lever). . . . . . . . . . . 12

Ink Cartridge Specifications . . . . . . . . . . . . . . . . . . . . . . . 13

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . 15

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Safety Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CE Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parallel Interface (Forward Channel). . . . . . . . . . . . . . . . 17

Parallel Interface (Reverse Channel). . . . . . . . . . . . . . . . 19

Host Data Transfer Timeout Prevention . . . . . . . . . . 22

Interface Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Serial Interface (Stylus COLOR 740 only) . . . . . . . . . . . . 23

USB Interface (Stylus COLOR 740 only). . . . . . . . . . 23

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Indicators (LEDs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control Panel Functions. . . . . . . . . . . . . . . . . . . . . . . . . . 25

LED Indicators and Printer States . . . . . . . . . . . . . . . . . . 26

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Ink Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Paper Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 7

Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

No Ink Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Maintenance Request . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Fatal Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Printer Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Initialization Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Main Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 0

Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

C206 MAIN-B Board (Stylus COLOR 440). . . . . . . . . . . .31

C256 MAIN Board (Stylus COLOR 640) . . . . . . . . . . . . . 31

C257 MAIN Board (Stylus COLOR 740) . . . . . . . . . . . . . 32

Power Supply Board

C206 PSB/PSE (Stylus COLOR 440 and 640)

C257 PSB/PSE (Stylus COLOR 740) . . . . . . . . . . . .32

C206 PNL Board (Stylus COLOR 440 and 640) . . . . . . .33

C209 PNL Board (Stylus COLOR 740) . . . . . . . . . . . . . .33

2. Operating Principles

Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Printing Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Carriage Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Platen Gap and Parallelism Adjustment Mechanisms . . . 39

Carriage Lock Mechanism . . . . . . . . . . . . . . . . . . . . . . . .40

Paper Feed Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Paper Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

ASF transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Automatic Sheet Feeder (ASF) . . . . . . . . . . . . . . . . .42

Paper Feed Mechanism. . . . . . . . . . . . . . . . . . . . . . .43

Ink System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

vii

Page 8

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

Head Cleaning Operations . . . . . . . . . . . . . . . . . . . . 44

Pump Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Capping Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 47

Electronic Circuit Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Power Supply Operation . . . . . . . . . . . . . . . . . . . . . . 49

Main Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Gate Array. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Reset Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Power-Off Timer Circuit. . . . . . . . . . . . . . . . . . . . . . . 58

Sensor Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Printhead Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Paper Feed (PF) Motor Driver. . . . . . . . . . . . . . . . . . 63

Carriage (CR) Motor Drive Circuit . . . . . . . . . . . . . . . 64

3. Troubleshooting

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Component Test Specifications . . . . . . . . . . . . . . . . . . . . 68

Unit Level Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . 71

Printer Does Not Turn On . . . . . . . . . . . . . . . . . . . . . . . . 71

Error Indicated by LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . 72

Printing Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Paper Not Feeding Correctly . . . . . . . . . . . . . . . . . . . . . . 73

Control Panel Operation is Abnormal. . . . . . . . . . . . . . . . 73

Unit Repair of the Power Supply Board . . . . . . . . . . . . . . . 74

Unit Repair of the Main Board. . . . . . . . . . . . . . . . . . . . . . . 77

Repair of the Printer Mechanism. . . . . . . . . . . . . . . . . . . . . 82

4. Disasse mbly and Assembly

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Precautions for Disassembling the Printer. . . . . . . . . . . . 86

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Specification for Screws. . . . . . . . . . . . . . . . . . . . . . . . . .88

Service Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Disassembly Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Removing the Housing. . . . . . . . . . . . . . . . . . . . . . . . . . .91

Removing the Board Assembly . . . . . . . . . . . . . . . . . . . . 92

Removing the Front Panels . . . . . . . . . . . . . . . . . . . . . . .94

Disassembling the Printer Mechanism. . . . . . . . . . . . . . .95

Removing the Printhead . . . . . . . . . . . . . . . . . . . . . .95

Removing the Waste Ink Pad Assembly . . . . . . . . . .98

Removing the Pump and Capping Assemblies . . . . .99

Removing the CR Motor . . . . . . . . . . . . . . . . . . . . . .102

Removing the PF Motor. . . . . . . . . . . . . . . . . . . . . . .103

Removing the ASF Assembly . . . . . . . . . . . . . . . . . .105

Removing the Carriage Assembly . . . . . . . . . . . . . . .109

Removing the Paper Feed and Paper Eject Roller

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Removing the PE Sensor. . . . . . . . . . . . . . . . . . . . . .113

Removing the HP Sensor . . . . . . . . . . . . . . . . . . . . .114

5. Adjustments

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Adjustment Tools Required . . . . . . . . . . . . . . . . . . . . . . .117

Choosing the Correct Adjustment Program. . . . . . . .117

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Parallelism Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . .118

Using the Adjustment Program . . . . . . . . . . . . . . . . . . . .120

Operating Environment . . . . . . . . . . . . . . . . . . . . . . .120

Starting the Adjustment Program . . . . . . . . . . . . . . . .120

viii

Page 9

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

Entering the Main Menu. . . . . . . . . . . . . . . . . . . . . . . 121

Initial Ink Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Head Cleaning Operation . . . . . . . . . . . . . . . . . . . . . 126

Protection Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Market Destination Check . . . . . . . . . . . . . . . . . . . . . 129

Head Voltage ID Input. . . . . . . . . . . . . . . . . . . . . . . . 131

Head Angle Adjustment. . . . . . . . . . . . . . . . . . . . . . . 133

Bi-D Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Printing the A4 Check Pattern . . . . . . . . . . . . . . . . . . 138

6. Maintenance

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Corrective Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Printhead Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Maintenance Request . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

7. Appendix

Connector Summary (Stylus COLOR 440 and 640). . . . . . 147

Connector Summary (Stylus COLOR 740). . . . . . . . . . . . . 151

EEPROM Address Map (Stylus COLOR 440 and 640). . . . 155

EEPROM Address Map (Stylus COLOR 740) . . . . . . . . . . . 159

Circuit Board Component Layouts. . . . . . . . . . . . . . . . . . . 1 64

Exploded Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

ix

Page 10

PRODUCT DESCRIPTION

Page 11

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

(

(

q

y

gh-q

g

g

y

y

y

g (cy

)

y

y

g

g

(

)

g

y

y

y

q

y

)

y

(

y

(

y

(

g

g

y

y

y

(

y

g

y

y

y

St

1.1 Features

The EPSON Stylus COLOR 440/640 /7 40 printers are highperformance, low-cost printers desi

SOHO) market. The Stylus COLO R 440 has the sa m e print quality

720 × 720 dpi) as the Stylus ProXL; the Stylus COLOR 640 and Stylus

COLOR 740 have the same print

COLOR 60 0 and St

The main features of these printers are:

Hi

uality color print in

Hi

h resolut ion:

St

lus COLO R 440—720 (H) x 720 (V) dpi

lus COLO R 640—1440 (H) X 720 (V) dpi

St

St

lus COLO R 740—1440 (H) X 720 (V) dpi

Standard four-color printin

Stylus COLOR 440—Black: 64 nozzles; CMY: 21 nozzles

lus COLOR 640: Black: 64 nozzles; CMY: 32 nozzles

St

lus COLO R 740: Black: 144 nozzles ; C M Y: 48 nozzles

St

Tradition al printin

bandin

lus COLOR 800.

and new Microweave printing that eliminates

ned for the small office/home office

uality (1440 × 720) as the Stylus

an, magenta, yellow, an d black

Compact size

Li

Acous tic noise

One combined printhead for black and color

lus COLOR 740: 200 cps

The print er’s head dr iv e f re

that is twice as fast as t hat of the St

models

St

155 mm) H

St

157 mm) H

St

6.2”

ht-weight

Wei

St

St

St

.

lus COLOR 440: 16.9” (429 mm) W x 9” (231 mm) D x 6.1”

lus COLOR 640: 16.9” (429 mm) W x 9: (231 mm) D x 6.2”

lus COLOR 740: 16.9” (429 mm) W x 10.3” (261 mm) D) x

157 mm) H

ht: 11.5 lbs. (5.2 Kg)

lus COLOR 440: Approximately 45 dB

lus COLOR 640: Approximately 47 dB

lus COLOR 740: Approximately 47 dB

uency, 14.4 KHz, allows printing

lus COLOR (true of all three

Built-in aut o s heet feeder

Holds 100 cut-sheets

Holds 10 e nv elopes

Holds 10 transparencies

Holds 65 sheets of spec ial paper

Hi

h-speed printing

St

lus COLO R 440: 200 cps at 10 c pi

lus COLO R 640: 200 cps in N ormal mode, 400 cps in Dr af t

St

mode

55 g/m2

Bidirectional parallel interface

three models

Additional interfac es:

St

lus COLOR 740: USB

Operatin

St

St

environm ents:

lus COLOR 440 and 640: Windows onl

lus COLOR 740: Windows and Macintosh

IEEE-1284 level 1 device) for all

2

Page 12

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

Fonts:

All three m odels: Stan dard and NLS P

Stylus COLO R 740: 5 scalab le fonts

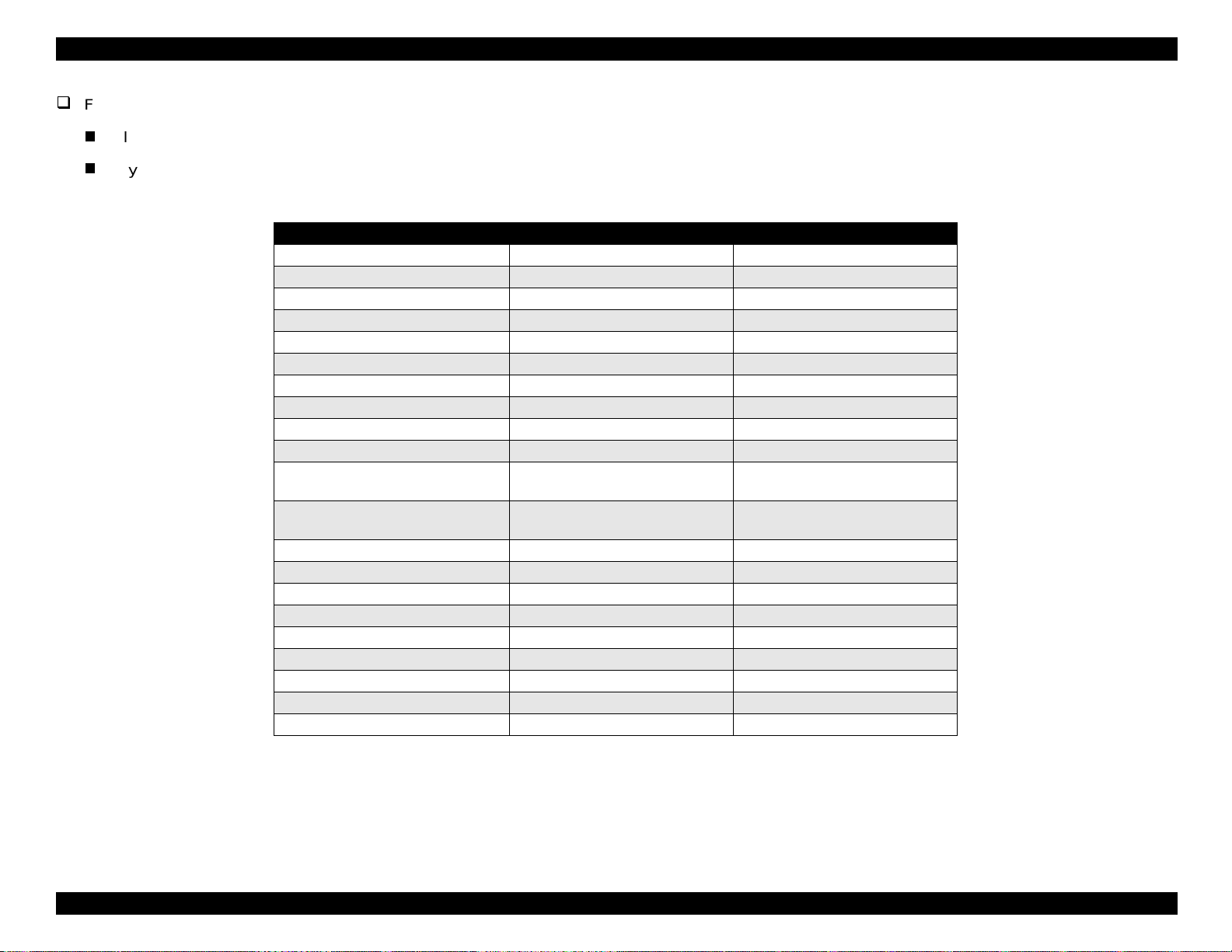

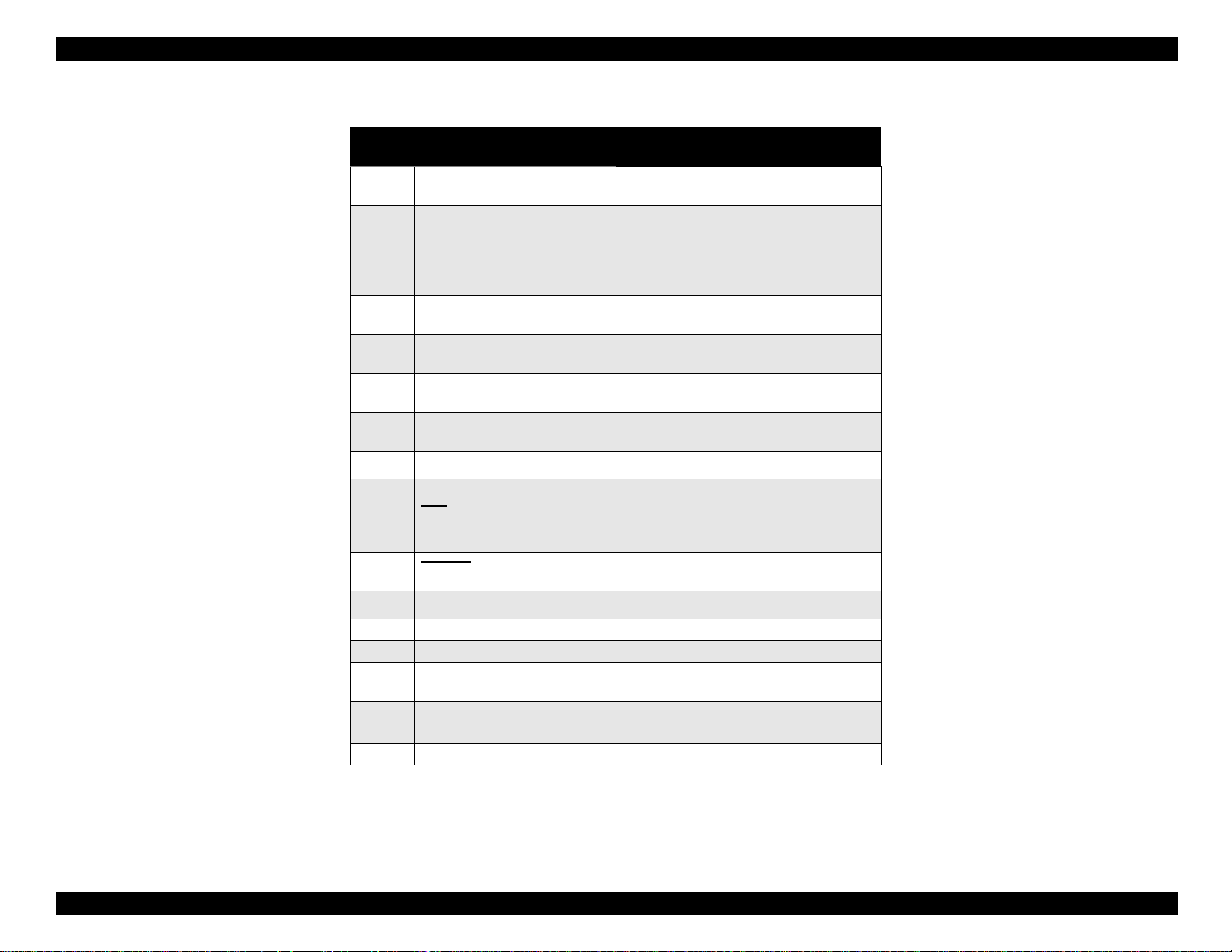

Table 1-1. Consumables Available for Stylus Color 440/640/740

Items Codes Remarks

Black ink cartridge S020189 Stylus Color 740

Black ink cartr idge S020187 Stylus Color 440, 640

CMY ink cartridge S020191 Stylus Color 440, 640, 740

EPSON 360 dpi ink jet paper S041025 Size: A4 (200 sheets )

EPSON 360 dpi ink jet paper S041059 Size: A4 (100 sheets)

EPSON 360 dpi ink jet paper S041060 Size: Letter (100 sheets)

Photo quality ink jet paper S041026 Size: A4 (200 sheets)

Photo quality ink jet paper S041061 Size: A4 (100 sheets )

Photo quality ink jet paper S041062 Size: Letter

Photo quality ink jet paper S041067 Size: Legal

Photo quality glossy paper (new

release)

Photo quality glossy paper (new

release)

Photo quality glossy film S041071 Size: A4

Photo quality glossy film S041124 Size: Letter

Photo quality glossy film S041107 Size: A6

Ink jet transparencies S041063 Size: A4

Ink jet transparencies S041064 Size: Letter

Photo quality ink jet cards S041054 Size: A6

Photo quality ink jet cards S041121 Size: 5 x 8 inches

Photo quality ink jet cards S041122 Size: 8 x 10 inches

Photo quality self-adhesive sheets S041106 Size: A4

S041126 Size: A4

S041124 Size: Letter

3

Page 13

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

g

y

j

)

g

g

g

y

)

y

)

y

)

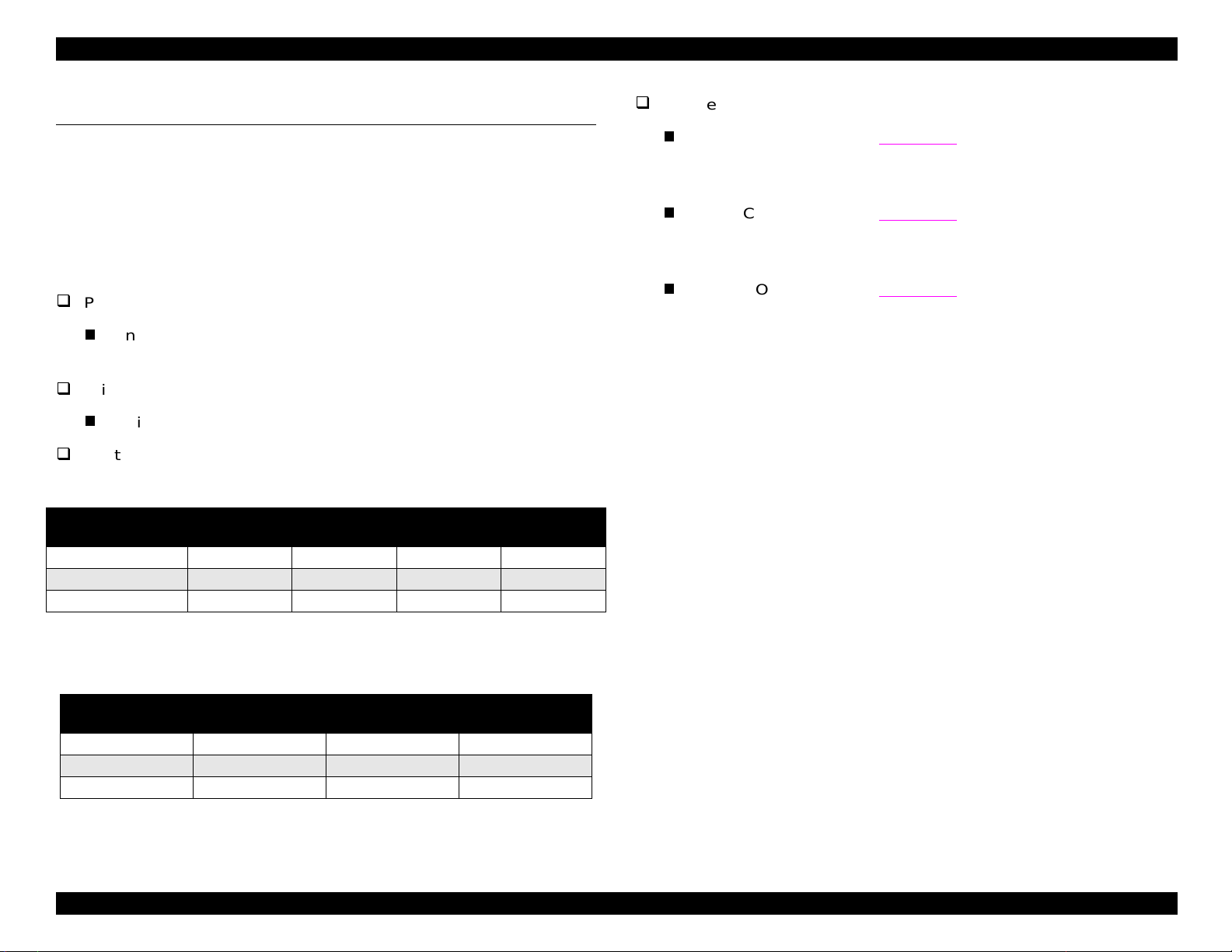

1.2 Specifications

Nozzle Confi

urations:

This section provide s th e f ollowing information for all three printers:

printin

settin

specifica t ions, reliabilit

specifica ti ons , paper specif ic ations, pri nt able area, a djust lever

s, ink cartridge specific at ions, enviro nm ental conditions, el ec t ric

statistics, safety approvals, and CE marking.

1.2.1 Printing Specifications

Print method

On-demand ink

color heads

Print direc t ion

Bidirecti onal with lo

Print spee d/ Printable co lum ns

Table 1-2. Character Mode Speed

Model Name

Stylus COLOR 440 10 80 200 CPS —

Stylus COLOR 640 10 80 200 CPS 400 CPS

Stylus COLOR 740 10 80 200 CPS —

et (MACH type; one unit c om bining black an d

ic seekin

Character

Pitch

Printable

Columns

LQ Speed Draft Speed

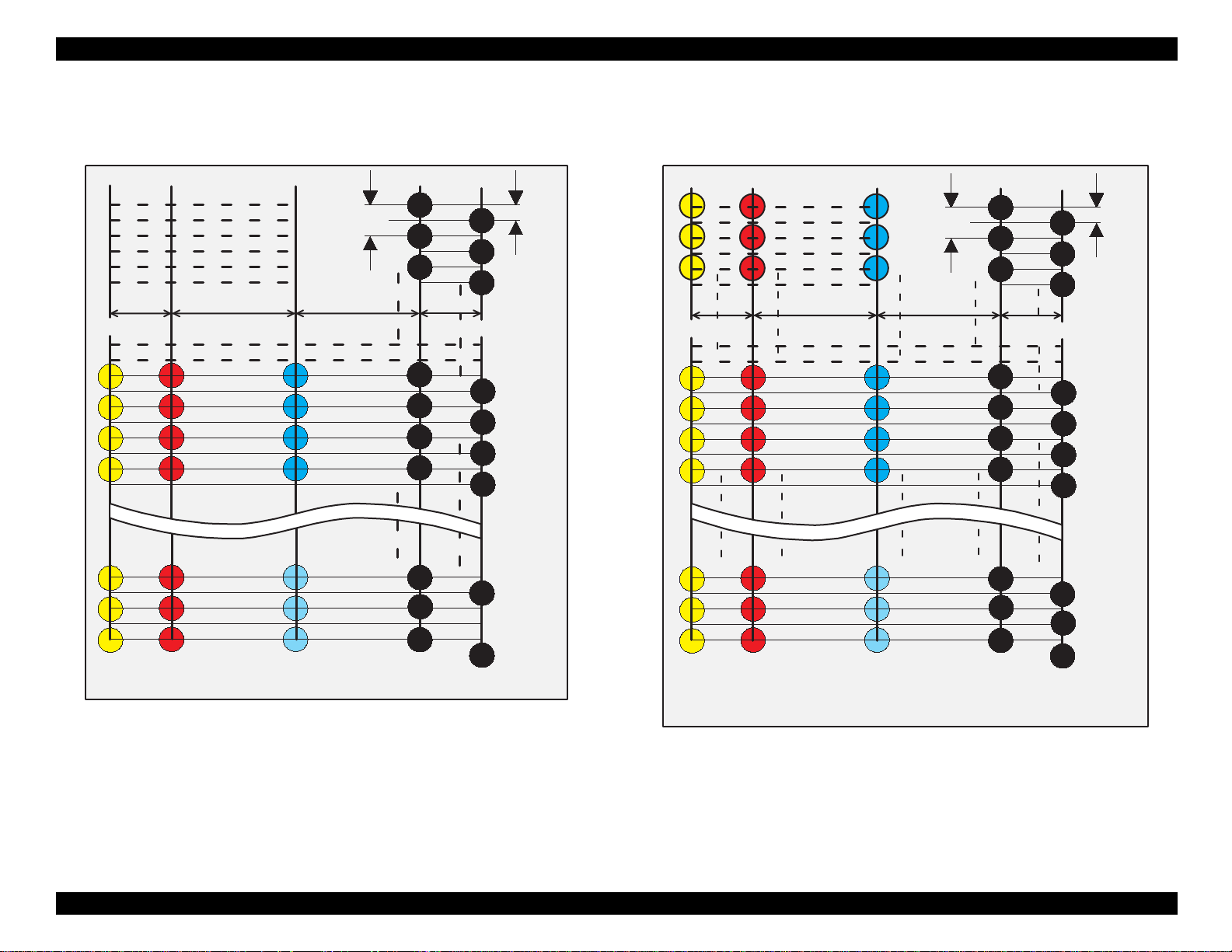

lus COLOR 440 (see Figure 1-1):

St

Black— 64 nozzles

×

Color—21 nozzles

St

lus COLOR 640 (see Figure 1-2):

3 (CMY

Black— 64 nozzles

×

Color—32 nozzles

St

lus COLOR 740 (see Figure 1-3):

3 (CMY

Black— 144 nozzles

Color—48 nozzles × 3 (CMY

Table 1-3. Graphic Mode Speed

Horizontal

Resolution

180 dpi 8.26 1488 20 IPS

360 dpi 8.26 2976 20 IPS

720 dpi 8.26 5952 20 IPS

Printable Area Available dots CR Sp eed

4

Page 14

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

Y1

Y2

Y3

Y4

Y19

Y20

Y21

M 1

M 2

M 3

M 4

M 19

M 20

M 21

#1

90DPI

#3

#5

10.16 mm2.2578 mm

7.9022 mm

C1

C2

C3

C4

C19

C20

C21

#23

#25

#27

#29

#59

#61

#63

#2

#4

#6

2.2578 mm

#24

#26

#60

#62

#64

180DPI

Y1

Y2

Y3

2.2578 mm

Y12

Y13

Y14

Y15

Y30

Y31

Y32

M1

M2

M3

10.16 mm

M12

M13

M14

M15

M30

M31

M32

C1

C2

C3

7.9022 mm

C12

C13

C14

C15

C30

C31

C32

90DPI

#1

#3

#5

#23

#25

#27

#29

#59

#61

#63

#2

#4

#6

2.2578 mm

#24

#26

#60

#62

#64

180DPI

(Y)

(M)

(C)

(B2)

(B1)

Figure 1-1. Nozzle Configuration for the Stylus COLOR 440

(Y)

(M)

(C)

(B2)

(B1)

Figure 1-2. Nozzle Configuration for the Stylus COLOR 640

5

Page 15

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

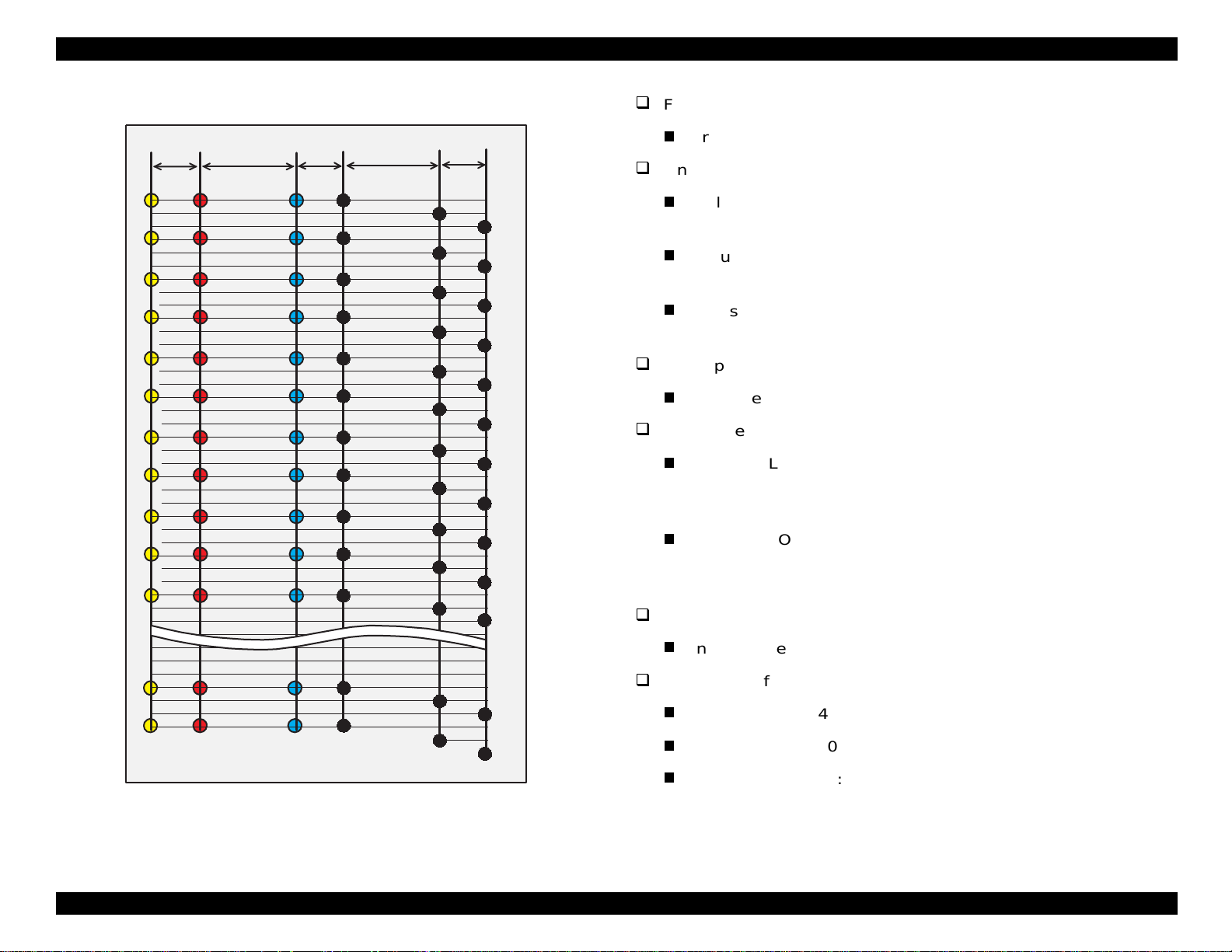

(

)

g

y

y

y

y)

y

(

(

y

g

(

y

g

)

y

y

y

Feed method

32/360"

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

112/360"

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

32/360"

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

112/360"

#1

#4

#7

#10

#13

#16

#19

#22

#25

#28

#31

32/360"

#2

#5

#8

#11

#14

#17

#20

#23

#26

#29

#32

#3

#6

#9

#12

#15

#18

#21

#23

#26

#29

#32

Line spac in

Paper path

Feed speed

Ink suppl

Friction feed with the ASF

St

lus COLOR 440: 1/6 inch, or programmab le in units of 1/360

Automatic Sheet Feeder

inch

St

lus COLOR 640: 1/6 inch, or programmab le in units of 1/360

inch

St

lus COLOR 740: 1/6 inch, or programmab le in units of 1/360

inch

Cut-sheets: ASF (top entr

lus COLOR 440 and 640:

St

190 ms per 1/3-inch

2.0 in/sec

lus COLOR 740

St

50.8 mm/sec), continuous

110 ms, advancin

4.5 in/sec

114.3 mm/sec), continuous

8.5-mm) increme nt advance

in 0.4-inch (10.16-mm) increm ents

#47

#48

Ink cartrid

#47

#48

(M)(Y)

#47

#48

(C)

(B1)

#139

#142

(B2)

#140

#143

(B3)

#141

#144

Input da ta buffer

St

lus COLOR 440: 10 Kb

St

lus COLOR 640: 32 Kb

St

lus COLOR 740: 64 Kb

es (Black an d C M Y

Figure 1-3. Nozzle Configuration for the Stylus COLOR 740

6

Page 16

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

y

y

g

y

(

(

g

y

y

y

(

)

(

)

y

(

(

(

Paper capacit

Size: Index card to L e

Thickness: Less than 8 mm

Paper capacit

Photo Paper, Iron-On Cool Pee l

Character tables:

St

lus COLO R 440 and 640

PC437

of input tra

: 100 cut sheets

10 envelopes

65 sheets of c oated pape r

65 sheets of c oated pape r

lossy sheets or sheets of EPSON Photo

20

Paper

30 transparency sheets

30 index cards

1 sheet of an

Transfer Paper, Pho to St ic k ers ,

Gloss

Film, Self Ad hesive Paper

US, Standard Europe

al

360 dpi)

720 dpi)

of the follow ing: Panoramic

St

lus COLOR 740

Standard version: 11 charac t er t ables

Italic, PC437

PC860

US Standard, Europe), PC850 (Multilingual),

Portuguese), PC861 (Iceland ic), PC863

Canadian-French), PC865 (Nordic), Abicomp, BRASC I I,

Roman 8, IS O Latin 1

NLSP v ers ion: 30 charac t er t ables

Italic, PC437, PC437 Greek , P C 850, PC852, PC 853,

PC855, PC857, PC860, PC861, PC865, PC866, ISO8859-7,

ISO Lat in 1T , PC 774, Esto nia, ISO8859-2, PC866-LAT,

PC866UKR, PC AR864, PC APTEC, PC708, PC720,

Hebrew7

*

, Hebrew8*, PC862

*

NOTE: Character t ables mark ed with an asterisk are not av ailable for

selection in the default setting mode.

PC850

Multilingual

NOTE: Thes e c haracter se ts are not available for selection in th e

default set t ing mode.

7

Page 17

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

y

y

y

g

(

)

)

)

)

y

y

(

g

(

)

)

)

)

(

)

(

)

(

)

)

T

pefaces

1.2.2.1 Cut Sheets

lus COLO R 440 and 640

St

Bitmap LQ fo nt : EPSON Courier 10 cpi

lus COLO R 740

St

Bitmap LQ fo nt s :

EPSON R om an 10 cpi, 12 cpi, 15 cpi, Pro portional

EPSON Sans Serif 10 cpi, 12 cpi, 15 cpi, Pro portional

EPSON C ourier 10 cpi, 12 cpi, 15 cpi

EPSON Presti

e 10 cpi, 12 cpi, 15 cpi

EPSON Sc ript 10 cpi, 12 cpi , 15 cp i

Scalable f onts:

EPSON Roman 10.5 pt.; 8 to 32 pt.

2 pt. increments

EPSON Sans Serif 10.5 pt.; 8 to 32 pt. (2 pt. increments

EPSON Roman T 10.5 pt.; 8 to 32 pt. (2 pt. increments

EPSON Sans Serif H 10. 5pt.; 8 to 32 pt. (2 pt. increments

NOTE: Each t yp ef ace has 4 va riat ions: Normal, Bold, Italic, and Bold

Italic.

Control codes

St

lus COLO R 440 and 640

ESC/P raster

EPSON remote commands

Sizes

Letter: Width 8 .5 ”

Le

al: Width 8.5”

216 mm) x Length 11.0” (279 mm)

216 mm) x Length 14.0” (356 mm

Statement: Width 5 .5 ” (139.7 mm) x Length 8.5” (216 mm

Exclusiv e: Width 7.5” (190.5 mm) x Length 10” (254 mm

A4: Width 8.3” (210 mm) x Length 11.7” (297 mm

B5: Width 7.2”

182 mm) x Length 10.1” (257 mm

Thickness

0.003”

0.08 mm) to 0.004” (0.11 mm

Weight

17 lb

64 g/m

2

to 24 lb (90 g/m

2

Quality

EPSON paper, bon d paper, or PPC

St

lus COLO R 740

ESC/P2 and ESC/P raster

EPSON remote commands

1.2.2 Paper Specifications

This section describes the printable area and types of p aper th at c an be

used with t hes e printers.

8

Page 18

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

(

)

)

(

)

(

)

)

)

(

)

(

)

)

(

)

)

)

)

(

)

1.2.2.2 Transparencies, Glossy Paper

Sizes

Letter: Width 8.5”

216 mm) x Length 11.0” (279 mm

A4: W idth 8.3” (210 mm) x Length 11.7” (297 mm

Thickness

0.003”

0.075 mm) to 0.0033 ” (0.085 mm

NOTE: Printing on transparencie s is available only at normal

temperatures.

1.2.2.3 Envelopes

Sizes

No.10 Width 9.5”

DL Width 8.7” (220 mm) x Length 4.3” (110 mm

C6 Width 6.4” (162 mm) x Length 4.5” (114 mm

Thickness

241 mm) x Length 4.13” (104.88 mm

1.2.2.4 Card Stock

Sizes

5 x 8” card: Width 5.0”

8 x 10” car d: Width 8.0 ” (203 mm) x Length 10.0” (254 mm

A6 card: Width 4.1” (105 mm) x Length 5.8” (148 mm

A5 card: Width 5.8” (148 mm) x Length 8.3” (210 mm

Thickness

Less than 0.0091”

0.23 mm

127 mm) x Length 8.0” (203 mm

0.006”

0.16 mm) to 0.02” (0.52 mm

Weight

12 lb

45 g/m

2

to 20 lb (75 g/m

2

Quality or Paper Type

Bond paper envelopes, plain paper envelopes, or air mail envelopes

NOTES:

1. Printing on enve lopes is avail able only at normal temp eratures.

2. Load the longer side of the envelop e horizontally.

9

Page 19

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

g

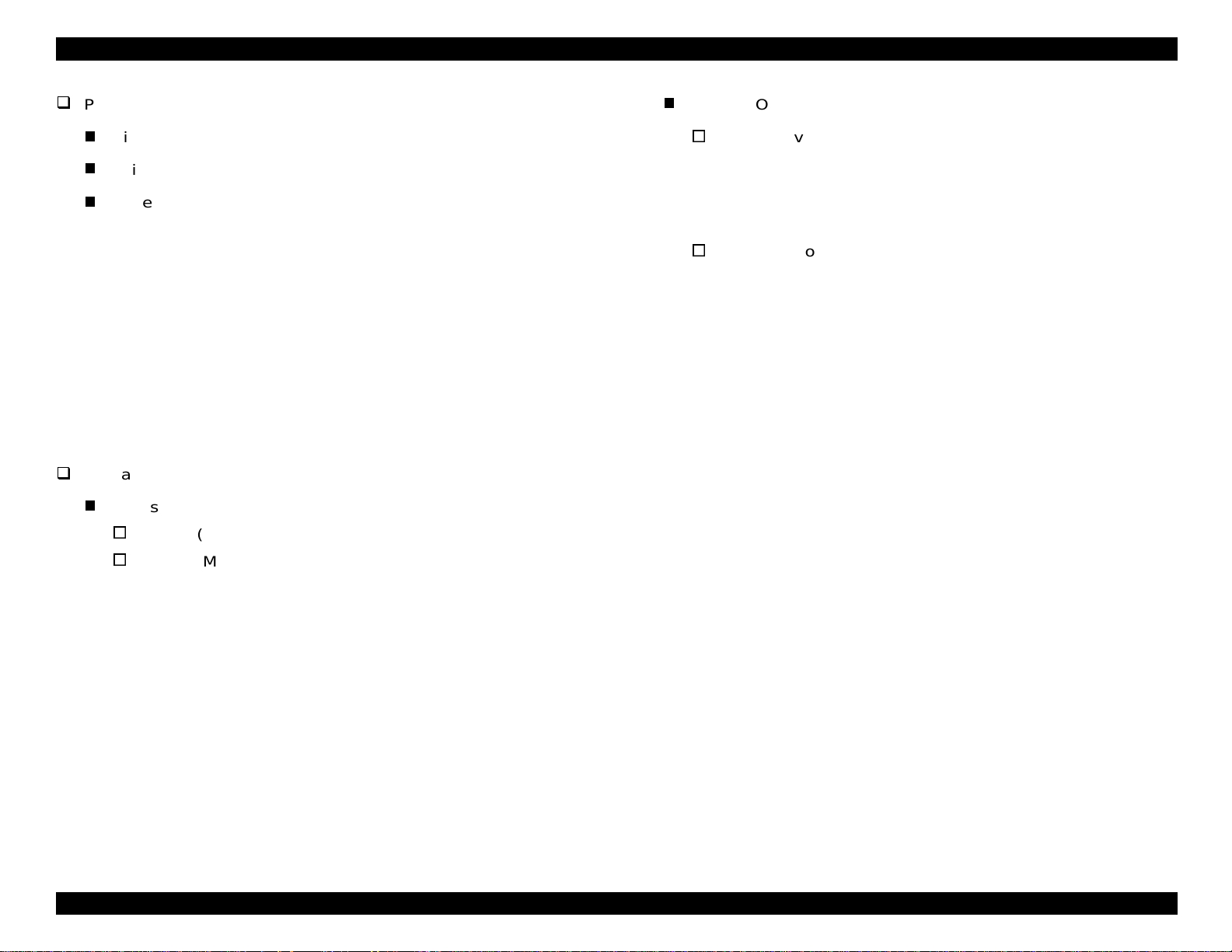

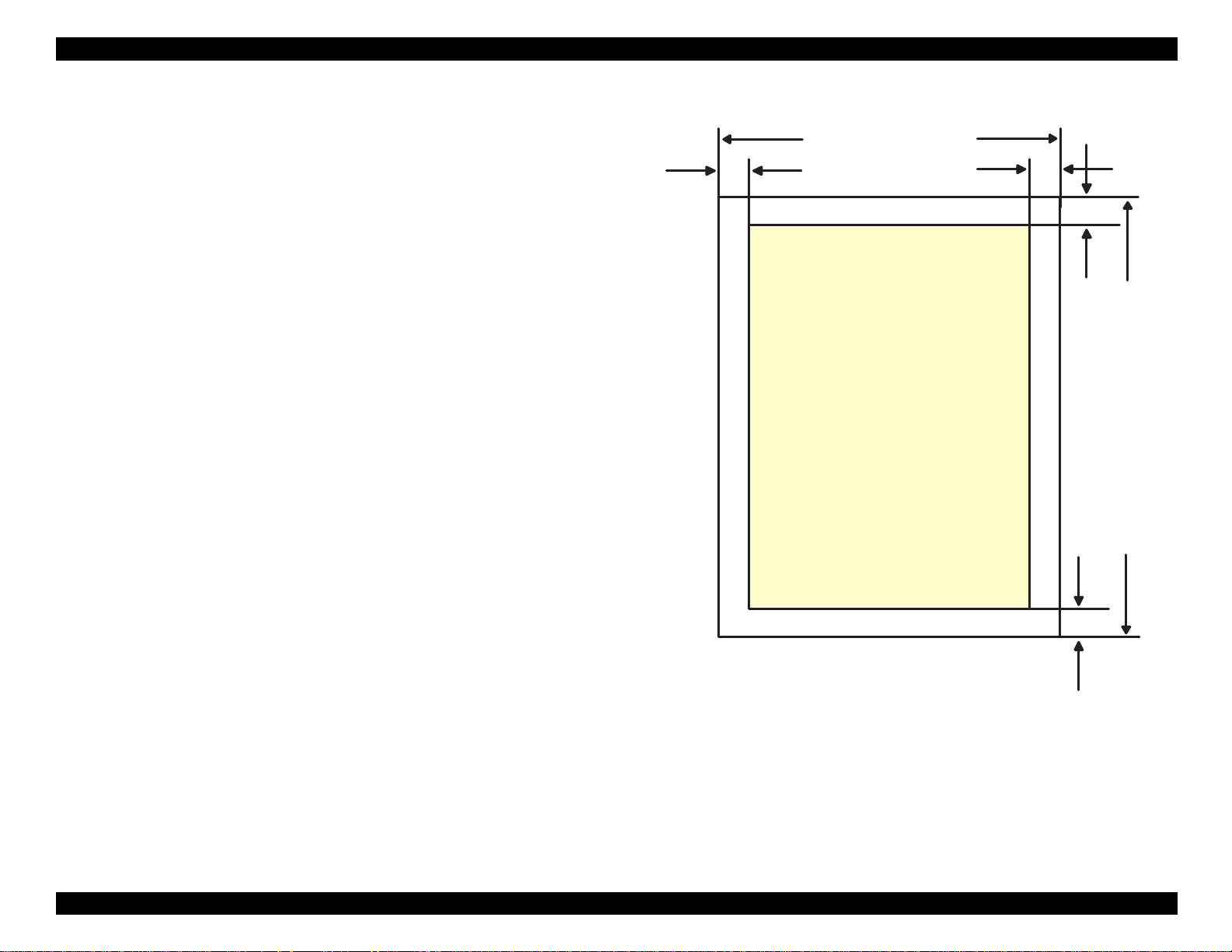

1.2.3 Printable Are a

Cut Sheets

ure 1- 4 in th e right column and the tables on the following page show

Fi

printable areas in character mo de and raster

NOTE: Charac t er mode is su pported on ly by th e St y lus COLOR 740.

raphics mode.

LM

PW

Printable

Area

RM

TM

PL

BM

Figure 1-4. Printable Area for Cut Sheets

10

Page 20

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

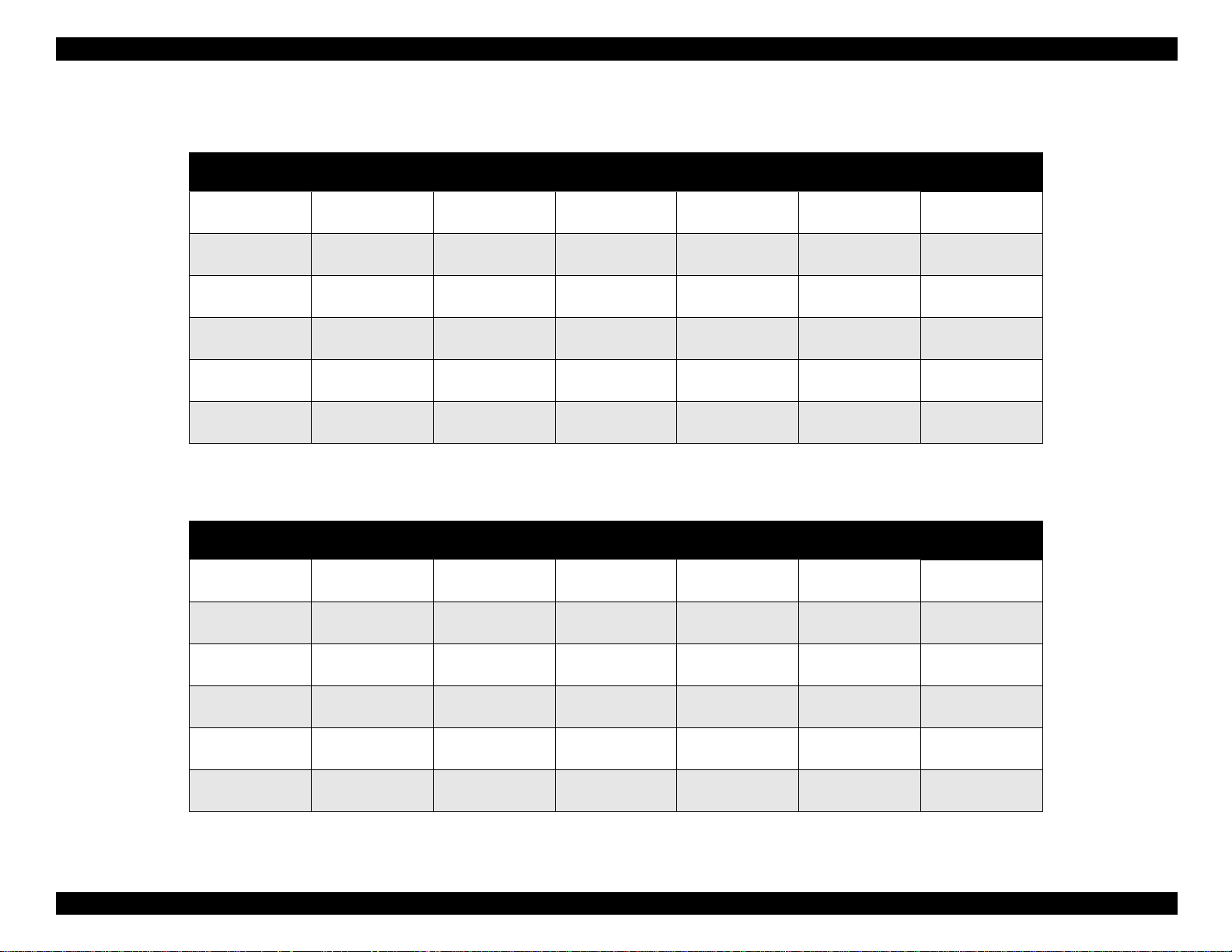

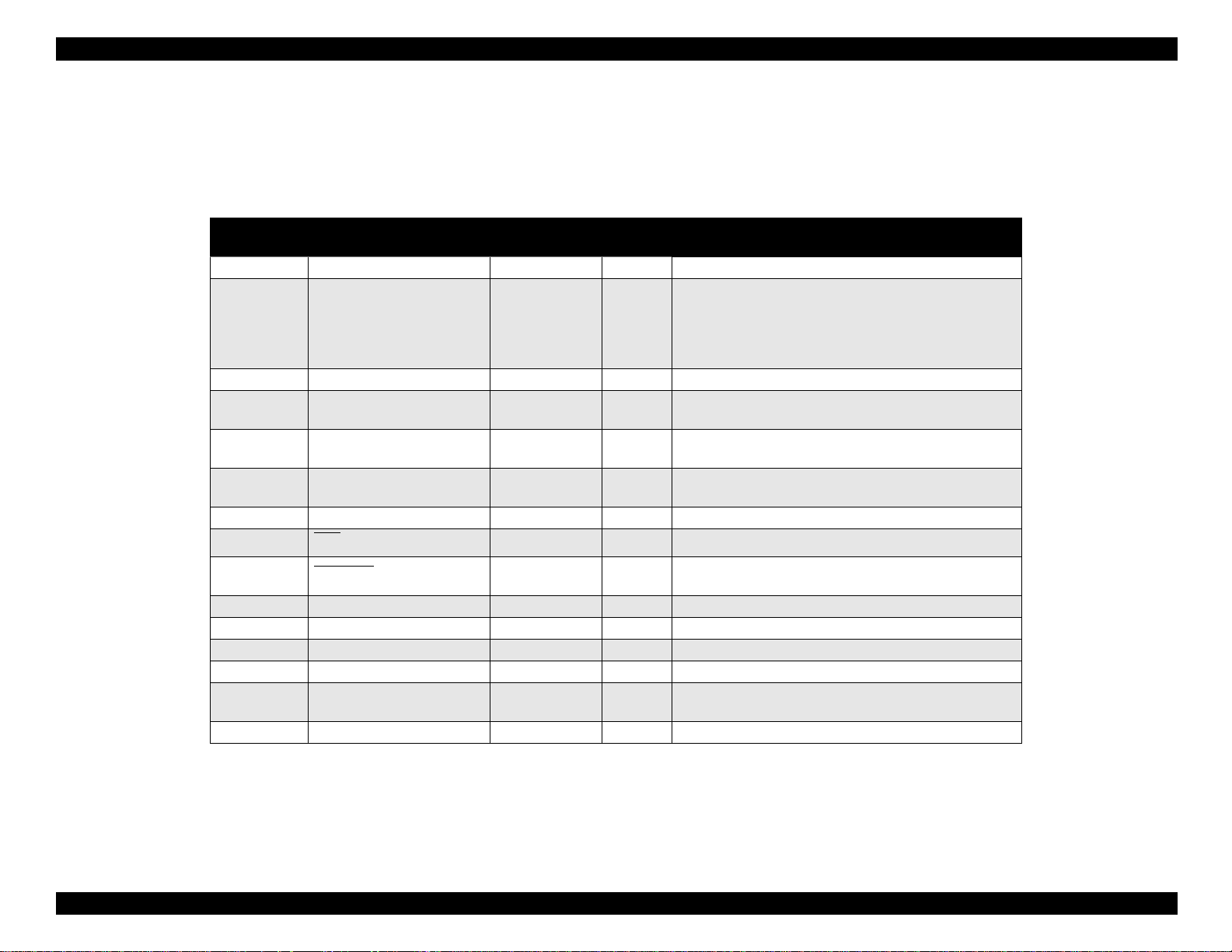

Table 1-4. Raster Graphics Mode

Paper Size PW (Typical

Paper Width)

A4 8.3” (210 mm) 11.7” (297 mm) 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

Letter 8.5” (216 mm) 11.0” (279 mm) 0.12” (3 mm) 0.35” (9 mm) 0.12” (3 mm)

B5 7.2” (182 mm) 10.1” (257 mm) 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

Legal 8.5” (216 mm) 14.0” (356 mm) 0.12” (3 mm) 0.35” (9 mm) 0.12” (3 mm)

Statement 5.5” (139.7 mm) 8.5” (21 6 mm) 0.12” (3 mm) 0.12” (3 mm) 0.l2” (3 mm)

Executive 7.5” (190.5 mm) 10”(254 mm) 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

PL (Typical

Paper Length)

LM (Minimum

Left Margin)

RM (Minimum

Right Margin)

TM (Minimum

Top Margin

BM (Minimum

Bottom Margin)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

Table 1-5. Character Mode (Stylus COLOR 740 only)

Paper Size PW (Typical

Paper Width)

A4 8.3” (210 mm) 11.7” (297 mm) 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

Letter 8.5” (216 mm) 11.0” (279 mm) 0.12” (3 mm) 0.35” (9 mm) 0.12” (3 mm)

B5 7.2” (182 mm) 10.1” (257 mm) 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

Legal 8.5” (216 mm 14.0” (356 mm) 0.12” (3 mm) 0.35” (9 mm) 0.12” (3 mm)

Statement 5.5” (139.7 mm) 8.5” (216 mm) 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

Executive 7.5” (190.5 mm) 10” (254 mm) 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

PL (Typical

Paper Length)

LM (Minimum

Left Margin)

RM (Minimum

Right Margin)

TM (Minimum

Top Margin)

BM (Minimum

Bottom Margin)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

11

Page 21

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

y

y

(

g

Envelopes

Table 1-6 and Figure 1-5 show t he printable area for envelopes.

Table 1-6. Printable Area for Envelopes

Envelope

Size

#10 0.12” (3 mm) 1.10” (28 mm) 0.12” (3 mm)

DL 0.12” (3 mm) 0.28” (7 mm) 0.12” (3 mm)

C6 0.12” (3 mm) 0.12” (3 mm) 0.12” (3 mm)

LM (Minimum

Left Margin)

LM

RM (Minimum

Right Margin)

TM (Minimum

Top Margin)

BM (Minimum

Bottom Margin)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

0.54” (14 mm)

0.12” (3 mm)

RM

Printable

Area

TM

BM

1.2.3.1 Adjust Lever Setting (PG Adjust Lever)

The adjust lever (blue) on the right side under the printer cover needs to

be set to the proper position for the paper

If

ou find th at th e paper wrin k les during printing, or if smudges appear

on the paper, move the lever to the + position

ardless of paper type.

re

Table 1-7. Adjust Lever Setting

Lever Position Clearance between head and platen

Plus position 1.04 mm

Zero position 1.74 mm (+0.7 mm)

NOTE: A lw ays return th e adjust leve r to th e z ero position af t er you

finish printing. Leaving the lever in the plus position may cause

poor pri nt ing in the next printout.

ou pri nt on. (See Tabl e 1 -7.)

toward the rear),

Figure 1-5. Printable Area for Envelopes

12

Page 22

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

18.3

38.5

51.2

19.8

52.7

27.8

52.7

38.5

51.2

26.3

18.3

38.5

51.2

19.8

52.7

for S tylus C olor 440, 640

for S tylus C olor 740

1.2.4 Ink Cartridge Specifications

Black Ink Cartridge

Table 1-8. Black Ink Cartridge Specifications

Items Specifications

Type Exclusive EPSON ink cart ridges designed for the Stylus COLOR

440, 640, and 740

Print c apa c ity • Stylus COLOR 440 and 640

-540 pages / letter or A4 (ISO/IEC 10561 Letter Patt ern at

360 dpi)

Cartridge life 2 years (sealed in package) / 6 months (out of package)

Environmental

conditions

Dimensions •

Weight Cartridge plus ink: 1.06 oz (30 g)

• Stylus COLOR 740

- 900 pages / letter or A4 (ISO/IEC 10561 Letter Pattern at

360 dpi)

• Temperature

- Storage: -4 to 104 °F (-20 to 40 °C)

1 month at 104 °F (40 °C)

- Packing stora ge: -22 to 104 °F (-30 to 40 °C)

1 month at 104 °F (40 °C)

- Transit: -22 to 140 °F (-30 to 60 °C)

1 month at 104 °F (40 °C)

120 hours at 140 °F (60 °C)

• Humidity

5% to 85% (without condensation)

Note:

Ink freezes bel ow 27 °F (-3 °C) but it thaws and is usable after 3

hours at 77 °F (25 °C).

Stylus COLOR 440 and 640

0.78” W × 2.1” D × 1.52” H (19.8 mm W × 52.7 mm D ×

38.5 mm H)

Stylus COLOR 740

•

1.09” W × 2.1” D × 1.5” H (27.8 mm W × 52.7 mm D ×

38.5 mm H)

Total ink: 0.58 oz +/- 0. 02 oz (16. 4 +/-0.5 g)

Consumable ink weight: more than 0.43 oz (12.1 g)

Figure 1-6. Black Ink Cartridge Dimensions (units in mm)

13

Page 23

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

Color Ink Cartridge

Table 1-9. Color Ink Cartridge Specifications

Items Specifications

Type Cartridge especially designed for the Stylus COLOR 440, 640

and 740

Colors Cyan, Magenta, Yellow (CMY)

Print capacity 300 pages / A4 (360 dpi, 5% duty each color)

Cartridge life 2 years (sealed in package) / 6 months (out of package)

Environmental

conditions

• Temperature

- Storage: -4 to 104 °F (-20 to 40 °C)

1 month at 104 °F (40 °C)

- Packing storage: -22 to 104 °F (-30 °C to 40 °C)

1 month at 104 °F (40 °C)

- Transit: -22 to 140 °F (-30 °C to 60 °C)

1 month at 104 °F (40 °C)

120 hours at 140 °F (60 °C)

•Humidity

5% to 85% (without condensation)

Note:

Ink freezes below 27 °F (-3 °C), but it thaws and i s usable after 3

hours at 77 °F (25 °C).

• Dimensions

×

1.7” W

2.1” D × 1.5” H (42.9 mm W × 52.7 mm D ×

38.5 mm H)

Weight Cartridge plus ink: 2.36 oz (67 g)

Total ink: 0.45 oz +/- 0. 02 oz (12. 8 +/-0.5 g)

Consumable ink weight: mo re than 0.34 oz (9.6 g)

52.7

42.9

41.4

43.2

51.2

38.5

Figure 1-7. Color Ink Cartridge Dimensions (units in mm)

14

Page 24

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

g

y

g

(

)

g

g

g

g

g

)

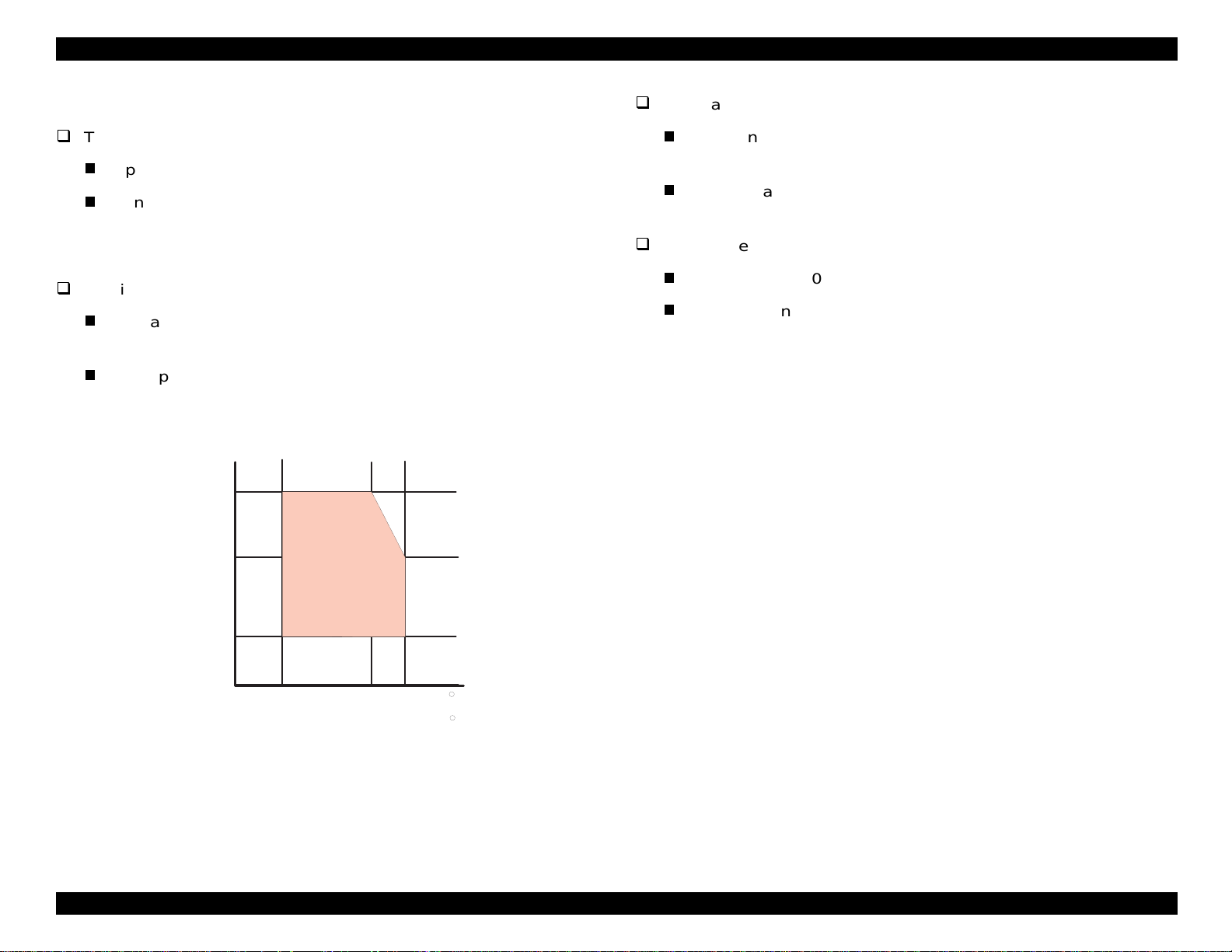

1.2.5 Environmental Conditions

Resistance to shock

Temperature

Operatin

Non-operatin

: 50 to 95 °F (10 to 35 °C) (See Figure 1-8.)

:-4 °F to 140 °F (-20 to 60 °C) in shipme nt

containe r

NOTE: 1 month at 104 °F (40 °C) an d 120 hour s a t 1 40 °F (60 °C)

Humidit

Operatin

: 20% to 80% RH without condensation

See Figure 1-8.

Non-operatin

shippin

: 5% to 85% RH without condensation and in

container

Hum idity

(% R H )

80%

55%

20%

G uaranteed

A re a

Operatin

: 1 G, within 1 ms

X, Y, and Z directions

Non-operatin

: 2 G, within 2 ms

X, Y, and Z directions, in shipment c ontainer

Resistance to vibration

Operating:0.15 G

Non-operatin

:0.50 G

NOTES: 1. When the printer is not in operation , ma k e s ure that the

printhead is capped.

2. During transport, make s ure the printhead is capped and

the ink cartridges are installed.

3. If you notice that the printhead is not capped while power

is off, turn power on (in k ca rt ridges should be installed).

After the printhead has moved to the capping position,

turn pow er off again.

4. Ink freezes under 27 °F (-3 °C), but thaws and becomes

usable again after 3 hours at 77 °F (25 °C).

10 27

50

35

80 95

( C

( F )

Figure 1-8. Temperature / Humidity of Range

15

Page 25

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

g

q

q

(

)

)

(

)

(

)

g

g

q

q

(

)

)

(

)

(

)

)

)

)

y

y

y

)

g

1.2.6 Electrical Specifications

120 V Versi o n

Rated volta

Input volta

Rated fre

Input fre

Rated current: 0.4 A

Power co ns um ption: Approxim ately 16 W (ISO/IEC 10561

Insulation resistan c e: 10M ohms minimum

Dielectric s tr ength: 1000 VAC rms for 1 minute or 1200 VAC rms

220 to 240V Version

Rated volta

Input volta

Rated fre

Input fre

Rated current: 0.2 A

Power co ns um ption: Approxim ately 16 W (ISO/IEC 10561

Insulation resistan c e: 10M ohms minimum

Dielectric s tr ength: 1500 VAC rms for 1 minute

e: 120 VAC

e range: 99 to 132 VAC

uency range: 50 to 60 Hz

uency range: 49.5 to 60.5 Hz

maximum 0.5 A

Letter patt ern

between AC line and chassis, 500 VDC

for 1 second

e: 220 to 24 0 VAC

e range: 19 8 t o 264 VAC

uency range: 50 to 60 Hz

uency range: 49.5 to 60.5 Hz

maximum 0.3 A

Letter patt ern

500 VDC bet w een AC line and chassis

betwee n AC line and cha s s is

; ENERGY STAR-c ompliant

between AC line and chassis

; ENERGY STAR-c ompliant

1.2.7 Reliability

Total Print Volume

Stylus COLO R 440: 10,000 pages (A4, Letter

Stylus COLO R 640: 25,000 pages (A4, Letter

Stylus COLO R 740: 75,000 pages (A4, Letter

Printhead Life

Stylus COLOR 440: 2x109 dots/nozzle

St

lus COLOR 640: 2x109 dots/nozzle

lus COLOR 740: 4x109 dots/nozzle

St

1.2.8 Sa fe ty App r ov als

120 V Version

Safety standards UL1950 with D3

CSA22.2 No.950 with D3

EMI FCC part 15 subpart B class B

CSA C108.8 class B

220 to 240 V Version

Safet

EMI EN55022 (CISPR Pub.22) class B

standard s EN 60950 (VDE, NEMKO

AS/NZS 3548 class B

1.2.9 CE Ma rk in g

220 to 240 V Version

Low Volt a

EMC Directive 89/336/EEC: EN55022 Class B

e Directiv e 73/23/EEC :EN60950

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

16

Page 26

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

y

(

g

g

g

g

(

)

(

)

j

g

g

g

1.3 Interface Specifications

A parallel int erf ace is standard on all th ree printers.

1.3.1 Parallel Interface (Forward Channel)

Transmission mode

Synchronization

Handshaking

Signal level

Adaptable connector

The BUSY si

h, and rem ains high until the s e s ignals ret urn to their inac t iv e s t at e.

hi

The BUSY si

Durin

When the input data buffer is full

When the INIT

nal is set high before setting either ER R OR low or PE

nal is HIGH at these times:

data entry

8-bit parallel, IEEE-1284 compatibilit

STROBE pu lse

BUSY and ACKLG

TTL-com patible le ve l

57-30360

signal is LOW , or during hardware initializat ion

Amphenol) or equivalent

signals

mode

Table 1-10

assi

line is used and the return side is connected to the GND si

on the follo w ing page shows the signal and connector pin

nments for the parallel interface. With these signals, a twiste d pair

nal.

NOTE: The forward channel is the mode used to send ordinary da ta ,

such as w hen a print com m and is sent fr om t he compute r t o

the print er.

When the re is a printer erro r

The ERROR signal is LOW w hen the printer is in one of th e f ollowing

states.

The PE si

Printer hardware error

Paper-o ut error

PaperInk-out error

am error

nal is HIGH during a paper-out error.

fatal err or

See ERROR signal

17

Page 27

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

Table 1-10. Signal and Connector Pin Assignments for the Parallel Interface

Pin No.

1STROBE

2 to 9

10 ACKNLG

11 BUSY 29 Out

12 PE 28 Out

13 SLCT 28 Out

14 AFXT

31 INIT 30 In

32 ERROR

36 SLIN 30 In Not used.

18 Logic-H — Out Pulled up to +5 V via 3.9K ohm resistor.

35 +5V — Out Pulled up to +5 V via 3.3K ohm resistor.

17

16,33,

19 to 30

15,34 NC — — Not connected.

Signal

Name

DAT A0 t o

DAT A7

Chassis

GND

GND — — Signal ground.

Notes: In and Out refer to the direction of signa l f low f rom the printer’s poi nt of view.

An overscore above a signal name means that the signal is active LOW.

Return

GND Pin

19 In

20 to 27 In

28 Out

30 In Not used.

29 Out

— — Chassis ground.

In/Out Functional Descri ption

The strobe pulse. Data is re ad in at the

falling edge of this pulse.

The DATA0 through DATA7 signals

represent data bits 0 thr ough 7. Each

signal is at a HIGH level when dat a is

logical 1, and at a LOW level when data

is logical 0.

This signal is a negative pulse indicating

that the printer can agai n accept data.

A HIGH signal indicates that the printer

cannot receive data.

A HIGH signal indicates a paper-out

error.

Always HIGH when the printer is

powered on.

The falling edge of a negati ve pulse or a

LOW signal on this line causes the

printer to initialize . Mini mum 50

is necessary.

A LOW signal indicates a printer error

condition.

µ

s pulse

18

Page 28

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

(

y

y

q

g

1.3.2 Parallel Interface (Reverse Channel)

Transmission mode:

Synchronization:

Handshaking:

Data transmission timing:

Signal level:

Adaptable connector:

Extensi b ili ty r eq u est:

IEEE-1284 nibble m ode

Refer to th e IE EE-1284 s pecification

Refer to th e IE EE-1284 s pecification

Refer to th e IE EE-1284 s pecification

IEEE-1284 level 1 device

TTL-compatible level

57-30360

Amphenol) or equivalent

The printe r responds af f irm ativel

the extens ibilit

request values are 00H or

04H, which means:

00H: Request nibb le m ode reverse

channel t ransfer.

04H: Re

uest device ID; return data

usin

nibble mode reverse

channel t ransfer.

when

NOTE: The printer se nds followin g device ID string when requested.

Table 1-11. Details of Device ID

00H 3CH Contents

MGF EPSON Manufacturer

CMD ESCPL2, BDC Command system

Stylus COLOR 440

MDL

CLS PRINTER Class

Stylus COLOR 640

Stylus COLOR 740

Model name

NOTES: 1. [00H] denotes a hexadecimal value of zero.

2. The MDL value depends on the EEPROM setting. The

model name can be c hanged by ch anging an address in

the EEPR OM.

19

Page 29

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

Table 1-12 shows pin as s ignments for the reverse channel. (Reverse

channel is th e m ode in which all data is tra ns f erred from th e printer to

the comput er.) For these signals, a twist ed pair line is us ed, and the

return sid e is co nnected to th e s i

nal GND .

Table 1-12. Pin Assignments for Reverse Channel

Pin No. Signal Name

1 HostClk 19 In Host clock signal.

2 to 9 Data0 to Data7 20 to 27 In

10 PrtClk 28 Out Printer clock signal.

11 PtrBusy, Data Bit-3,7 29 Out

12 AckData Req, DataBit-2,6 28 Out

13 Xflag, DataBit-1,5 28 Out

14 HostBusy 30 In Host busy signal.

31 INIT 30 In

32 DataAvail

36 1284-Active 30 In 1284 Active Signal

18 Logic-H — Out Pulled up to +5 V via 3.9K ohm resistor.

35 +5 V — Out Pulled up to +5 V via 3.3K ohm resisto r.

17 Chassis GND — — Chassis ground.

16,33, 19 to

30

15,34 NC — — Not connected.

Notes: In/Out ref ers to the direction of signal flow from the printer’s point of view.

An overscore above a signal name means that signal is active LOW.

GND — —

, DataBit-0,4 29 Out

Return GND

Pin

In/Out Functional Description

The DATA0 through DATA7 signals represent data

bits 0 through 7. Each signal is at HIGH level when

data is logical 1, and at a LOW level when data is

logical 0. These signal s are used to transfer th e 1284

extensibility request valu es to the printer.

Printer busy signal and reverse channel tra nsfer data

bit 3 or 7.

Acknowledge data request signal and revers e channel

transfer data bit 2 or 6.

X-flag signa l and reverse channel tran sfer data bit 1 or

5.

Not used.

Data available signal and reverse channel tr ansfer

data bit 0 or 4.

Signal ground.

20

Page 30

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

(

y

g

g

g

y

g

g

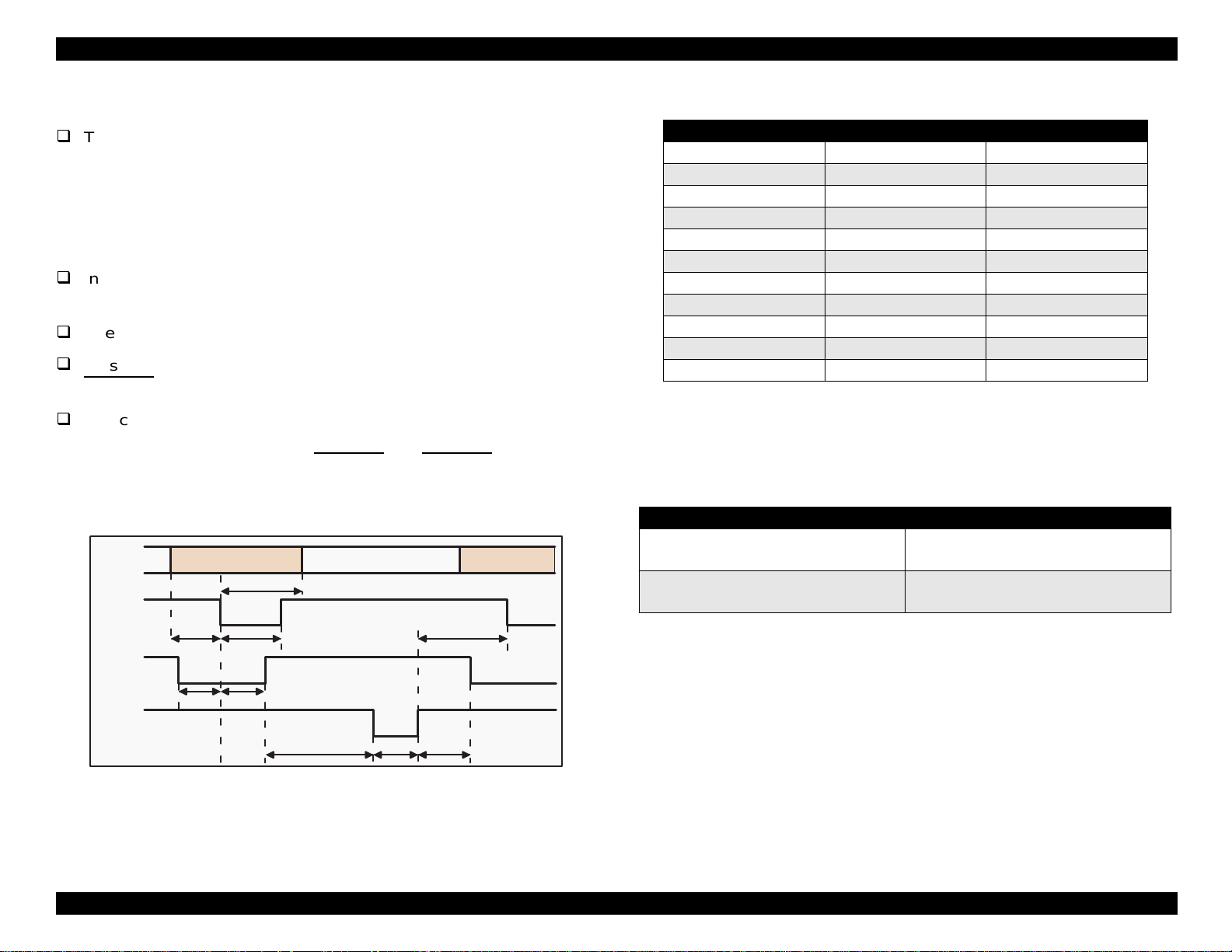

The following are general notes on the parallel interface:

The Return GND Pin c olumn in Tables 1-10 an d 1-12 indica t es a

twisted pair return, and is used for all control si

nals exce pt Logic-H,

+5 V, Chassis GND, and NC. The return side is connected to GND

pins 16, 33 , and 19 to 30) in the twisted pair retu rn. Since thes e

cables are s hielded,

connectin

Interface conditions are based on TTL lo

them to Chassis GND in both the printer and computer.

should be less than 0.2

See Fi

Be sure to perform data transmission onl

ACKNLG

You can perform a print t es t wi th out usin

ure 1-9 for the transmission timing of each signal.

and BUSY s ignals are LOW.

the 8-bit da t a s i

code and connect them to the ACKNLG

Data

/STROBE

Tsetup

BUSY

ou can reduce electrostatic noise by

ic levels. Rise and fall ti mes

µ

s.

after conf irm ing that the

external equipment. Set

nals (pins 20 th rough 27) to the appro priate word

and STRO BE signals.

Byte Data n

Thold

Tstrb

Byte Data n+1

Tnext

Maximum and Minimum Timing for Data Transmission

Parameter Minimum Maximum

tsetup 500ns —

thold 500ns —

tstb 500ns —

tready 0 —

tbusy — 500ns

tt-out* — 120ns

tt-in** — 200ns

treply 0 —

tack 500ns 10us

tnbusy 0 —

tnext 0 —

* Rise and fall time of every output signal.

** Rise and fall time of every input signal. Typical timing for the tack

paramete r is s how n in Table 1 -14 below.

Table 1-14. Typical Tack Timing

Parallel Interface Mode Typical Tack Timing

µ

2

High speed

Normal speed

s (Stylus COLOR 440 and 640)

µ

s (Stylus COLOR 740)

1

4µs (Stylus COLOR 440 and 640)

µ

s (Stylus COLOR740)

3

/ACKNLG

Tready Tbusy

Treply

Tack Tnbusy

Figure 1-9. Data Transmission Timing for the Forward Channel

Table 1-13.

21

Page 31

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

(

y

y

y

y

y

g

(Sty

g

y

g

g

g

q

g

g

g

g

The following tables show typical input and output signal levels for the

interface

IEEE-1284 lev el 1 devi c e). Signal levels are based o n T T L

standards.

Table 1-15. Typical Output Signal Characteristics

Parameters Minimum Maximum

Voltag e -0.5 V 5.5 V

Current 0.32 mA

when V

Capacitance — 50 pF

= 2.4 V

out

when V

12 mA

= 0.4 V

out

Table 1-16. Typical Input Signal Characteristics

Parameters Minimum Maximum

Voltage 0.8 V 2.0 V

Current 0.32 mA

when V

Capacitance — 50 pF

= 2.0 V

in

12 mA

when V

= 0.8 V

in

NOTE: The input and output signals are active-h igh; the logic lev el is

conside red HIGH at 3. 0 v olt s or m ore and LOW at 2.0 V or

less. The receiver shall provide an impedance equivalent to

7.5K ohm to ground.

1.3.2.1 Host Data Transfer Timeout Prevention

1.3.2.2 Interface Selection

Manual Selection:

One of two interfac es ca n be selecte d t hrou

mode.

Automatic Selection

lus COLO R 740 only):

Automatic interface selection is enabled in the default settin

In automatic interfac e se lection mod e, the printer is initialized to the

idle state when it is po w ered on. The printer sca ns t he interface s to

determ ine which int erf ace receiv es data first, then selects th at

interfa ce fo r fu rt her data trans m ission. When the ho st s to ps data

transfer and the pri nt er is in stand-b

for several seconds, the

printer ret urns to the idle s t at e. T he process is repeated ea ch ti m e

the print er is powered o n.

The follo w ing notes explain how the selection of one interface affects

the cond it ion of other int erfaces:

When an interface ot her than the parallel inte rf ac e is selected,

the parallel interface

set to LOW, blockin

response from the 1284 Active si

for the host, which re

oes into the BUSY state. The LH signal is

the power supply and preventing a

nal. This makes it necessary

uires reverse tr ansfer of data, to ch eck the

LH state.

h the default setting

mode.

Generally, hosts abandon data transfer to peripherals when a peripheral

is BUSY continuousl

time-out, the printer receives data ver

even if it is bu s

buffer dro ps under several hundred b

BUSY con t inuousl

for dozens of seconds. To prevent this kind of

slowly, several bytes per minute,

. This slo w down starts wh en the remainder of the input

tes. In add it ion, the printe r is

when the inp ut buffer is full.

When an interface other than the serial interface is selected, the

serial interface sets the DTR si

When th e printer is init ialized or returned to the idle state, th e

paralle l int erface

sets the DTR si

the Main St at us Re

oes into th e ready state. The serial interf ace

nal SPACE (LOW) and reset s th e of f -line bit of

ister (MNSTS) to an optio nal interface .

nal MARK.

22

Page 32

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

y

y

y

y

(

)

g

(

)

Pin #1

Pin #2

Pin #3

Pin #4

1.3.3 Serial Interface (Stylus COLOR 740 only)

Standard

Synchronization

Bit rate

Handshaking

Word format

Connector

Cable

Table 1-17. Connector Pin Assignments for the Serial Interface

Pin No. Signal Name I/O Functional Description

1 SCLK Out Synchronous clock signal

2 CTS In Cl ear to send

3 TXD- Out Transmit data (-)

4 SG In Signal ground

5 RXD- I n Receive data (-)

6 TXD+ Out Balanced transmit data (+)

7 DTR Out Data terminal ready

8 RXD+ In Balanced recei ve data (+)

RS-423 c ompatible

S

nchronous

Approximatel

1800 Kb ps

X-ON/X-OFF, DTR protocol

Data Bit= 8 bit s

Parit

Bit= None

Start Bit= 1 bit

Stop Bit= 1 bit

8-pin mini-circular c onnector

Apple S

recommended

stem Peripheral-8 Cable

1.3.3.1 USB Interface (Stylus COLOR 740 only)

Standard

Bit rate

Data encoding

Connector

Cable length

Table 1-19. Connector Pin Assignments for the USB Interface

Pin No. Signal Name I/O Functional Description

1VCC —

2 -Data Bi-D Data

3+DataBi-D

4 Ground — Cable ground

Universal Serial Bus Specifications Rev. 1. 0

Universal Serial Bus Device Class Definition

for Printin

Device Version 1.0

12 Mbps

NRZI

USB Series B

2 meters

recommended

Cable power; maximum power

consumption is 100 mA

Data; pulled up to +3.3 V via a 1.5K ohm

resistor

Table 1-18. X-On/X-Off and DTR Status

State Buffer Space X-ON/X-OFF DTR

Busy Less than 3072 bytes Sen d X-OFF code OFF

Ready More than 5120 bytes Send X-ON code ON

Figure 1-10. USB Pin Assignments

23

Page 33

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

y

y

g

g

g

g

g

j

g

g

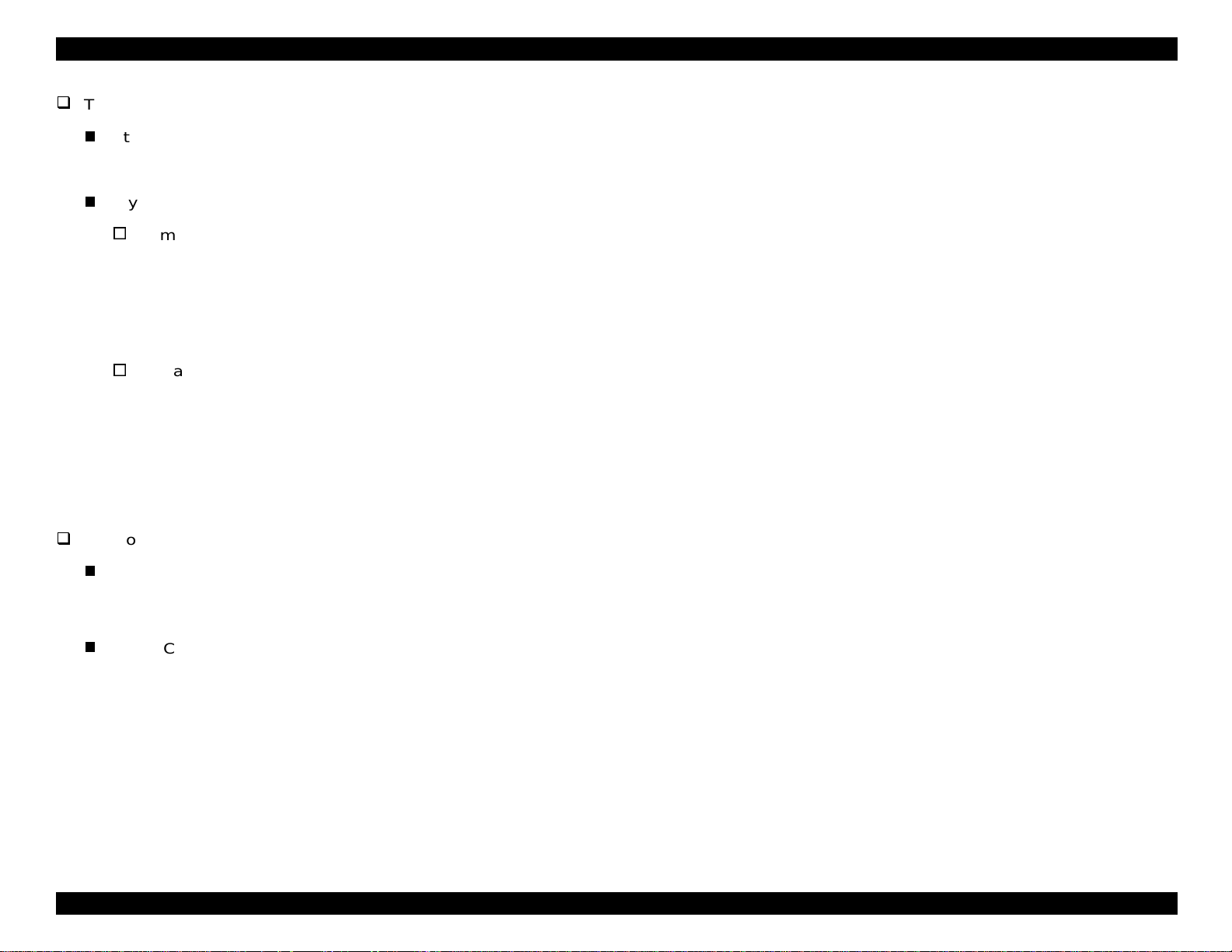

1.4 Control Panel

Since the printer drivers f or t he Stylus COLOR 440, 640, and 740

control man

control bu ttons. Ther e are two non-lock t

button, and four LEDs. Fi

panels.

settings and functions, these printers do not require many

pe buttons, one lock type

ure 1-11 sh ow s t he layout of the co nt rol

Paper Out LED

Ink Out(Bk)LED

Ink Out(CMY)LED

Cleaning Switch

(Ink maintenance)

Load/Eject Switch

Power on Switch

Power LED

Stylus Color 440, 640

1.4.1 Ind ica to r s (LEDs )

(1) Power

hts when the Opera t e s w it c h is ON and AC power is supplied,

Li

and flas hes when the printer is rece iv in

mainte nance oper at ion such as cleanin

(2) Paper Ou t

hts when the printer is out of paper, and flashes w hen there is a

Li

paper

(3) Black Ink Out

Li

ink is low.

(4) Color Ink Out

Li

ink is low.

am.

hts when the black ink ca rt ridge is out of ink, and flashes when

hts when the color ink c art ridge is out of ink , and flashes w hen

data or perf orming a

the printhead.

Stylus Color 740

Figure 1-11. Control Panels

24

Page 34

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

1.4.2 Control Panel Functions

Tables 1- 19 t hrough 1-21 desc ribe control panel fun c tio ns .

Table 1-20. Control Panel Functions

Button Function

Load/Eject

(Hold at least 2

seconds)

Load/Eject

(Press for less than

2 seconds.)

Cleaning

(Hold at least 2

seconds)

Cleaning

(Press for less than

2 seconds)

1. Starts the ink cartridge r eplacement sequence.

1. Loads or ejects the paper.

2. If the cartridge is in the ink change position, ret urns it to the

capping position.

1. Starts the printhead cleani ng sequence.

2. When the printe r is low on ink or out of ink (either cartridge),

starts the ink cartridge replacement sequence.

1. If the carriage is in the ink ca rt ridge ch ange posit ion, return s

it to the capping position.

Table 1-21. Control Panel Functions at Power On

Switch Function

Load/Eject 1. Starts status printing. 1

Cleaning

Load/Eject

+

Cleaning

Stylus COLOR 440 and 640:

Changes the code page. 2

Stylus COLOR 740:

Enters the default setting mode. 3

Enters the EEPROM Reset mode. (The Load/Eject LED

flashes for a few seconds.)

(Used only to clear a maintenance error.)

NOTES: 1. Prints the firmware version, ink counter value, and nozzle

check pattern.

during Normal Printer Use

Table 1-22. Control Panel Functions in the EEPROM Reset Mode

Button Function

Cleaning Resets the EEPROM.

1. After the Load/Eject LED has been flashing for about 2

seconds, press and hold down the Cleaning button for 10

seconds.

Stylus COLOR 440 and 640

After 10 seconds, both the Bl ack Ink Out and Color Ink Out

LEDs come ON simultaneously.

Stylus COLOR 740

After 10 seconds, the Load/Eject, Black Ink Out and Color

Ink Out LEDs all

2. Do one of the fo l lowi n g:

Stylus COLOR 440 and 640

After you confirm that both the Black Ink Out and Color Ink

Out LEDs are ON, release the Cleaning button. The print er

resets certain addresses in the EEPROM as it begins the

initia li zation process.

Stylus COLOR 740

After you confirm that all 3 LEDs are

Cleaning but ton. The prin ter resets certain addresses i n the

EEPROM as it begins the initializati on process.

flash

simultaneously.

flashing

, release the

NOTES: 1. Before you press the Load / Eject button, be sure you are

in EEPROM reset mo de (see Table 1-20)

2. The f ollowing ad dresses are res et in EEPROM Reset

Mode: timer IC (power-off timer), ink counter, and

interfa ce s election (int erf ac e selectio n is res et to Auto)

3. If you repeat the EEPROM reset operation, it reset s the

EEPROM addre sses but does not necessarily initialize

the EEPR OM. Whe th er or not the EEPROM is initialized

depen ds on the power-off time m onitored by the tim er IC.

2. Code pages for th e St y lus COLOR 440 and 640 are not

available.

3. The us er c an use the parameter lis t to se lec t s et t ings for

both the st andard and N LSP version of the Stylus

COLOR 74 0.

25

Page 35

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

1.4.3 LED Indicators and Printer States

Table 1-23 describes t he appearance of the LE D indicators during

various pr int er states. Y ou can use the ta ble below to determine t he

nature of a printer probl em and how to so lv e it .

Table 1-23. Printer Condition and LED Status

Printer State

Power on ————9

Ink sequence mode On — — — 6

Ink cartridge replacement mode Flashing — — — 5

Data processing Flashing — — — 8

Paper out Flashing — — On 4

Paper jam — — — Flashing 3

No ink cartri dge or i n k out (black) — On — — 7

Ink low (black) — Flashing — — 7

No ink cartridge or i nk out (color) — — On — 7

Ink low (color) — — Flashing — 7

Enter EEPROM reset — ON (for 3 seconds) —

Maintenance request Flashing Flashing Flashing Flashing 2

Fatal error Flashing On On Flashing 1

Power Ink Out (Black) Ink Out (Color) Paper Out

Indicator Sta tus

Priority

26

Page 36

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

y

g

(

g

g

g

ging

g

g

y

y

g

g

y

y

g

g

g

y

y

g

(

j

j

j

1.5 Error Conditions

When the error conditions described in the following sections occur, th e

printer stops acceptin

and the Bus

information on the st at us of th e LED indicat ors durin

states.

signal to HIGH , and stops pr int ing. See Sec ti on 1.4.3 fo r

1.5.1 Ink Out

When the printer is almo s t o ut of any color of ink, th e appropriat e Ink

Out indicator

When the printer is out of either ink co lor, it stops pri nt in

appropr iat e I nk Out indicat or remains on. In s ta ll a new ink car tr id

this time.

CAUTION

black or co lor) flashes and the printer k eeps on prin t ing.

Never reinstall an ink cartridge that has been removed

from the printer. Installing an old ink cartridge

interferes with the printer’s ink level detection

capability and may cause serious printing problems.

data, sets the interface ERROR signal to LOW

various err or

and the

e at

2. As lon

cannot ent er the printhead. Howe v er, if an old ink ca rt rid

removed from the printer, an

full

bubbles will form. If thickened ink

the ink pa t h or nozzle and cause ser ious printhead dama

3. Normally, the ink consumption counter is reset when the ink

cartrid

unnecessaril

value, a nd the printer m a

ink cartrid

as the ink ca rt ridge remains ins t alled in the pr int er, air

e is

air entering the cartridge can never be

absorbed into the ink. As a result, the ink w ill t hic k en and

ets into the pri nt head, it can clog

e.

e is removed. If an ink ca rt ridge is removed and reins t alled

, the ink co ns um ption counter will hav e t he wrong

keep printing even though the inksta lled

e is empty. This can damage the printh ead.

1.5.2 Paper Out

When the printer is printing and fails to lo ad a sheet of p aper after all

power-on operat ions

press the Load/E

indicat es a paper out er ror.

including timer clearing) are done, or after you

ect button and the pape r fa ils to load, the print er

1.5.3 Pa pe r Jam

Here’s why:

1. Once the ca rt rid

the printhead, and bubbles that form can prevent the printhead from

dischar

durin

ink itself, si nc e t he ink in the ca rt rid

the production process. However, the ink’s abilit

for onl

installation of a new ink c art ridge can be absorbed in t o th e

about one hour after th e c artridge has been ins t alled.

e has been removed, air enters the ca rt ridge and

ink properly. On the other hand, the air that ente rs

e has been de-aerated during

to absorb air lasts

When th e printer cannot eject a sheet of paper after printing, or when

the Load/ E

indicat es a paper

ect butto n on the contro l panel is press ed, the print er

am error.

27

Page 37

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

g

g

g

g

g

g

g

g

y

g

q

g

y

q

g

g

ge g

g

g

g

q

1.5.4 No Ink Cartridge

The following can be reas ons for the printer to indic at e a No Ink

Cartrid

1. The printe r is bein

e error:

turned on for the first time. This is a normal

conditio n, and the printer clears the error state as s oon as an ink

cartridge is installed.

2. Ink cartrid

occur if the carria

procedure, or if the carria

cartrid

ain correctly, the prin te r c lears the error c ondition.

a

3. There is a problem with the carria

If the error oc c urs when th e ink c artrid

correctl

indicate s a No In k Ca rt rid

e replacement is pe rf orm ed incorr ec t ly. This error m ay

e is moved during the cartridge repla c em ent

e returns to the home position before the

e is installed. When ink cartridge replacem ent is perfo rm ed

e sensor or with the printer itself.

e has been ins t alled

, or if the printe r so m et im es prints no rm ally and sometimes

e error, th e C R se ns or or printe r m ay

need to be repaired.

1.5.5 Maintenance Request

Since 1 c ounter poin t e

followin

EPSON Stylus COLOR 440 420 ml

EPSON Stylus COLOR 640 396 ml

EPSON Stylus COLOR 740 818 ml

:

Printer Maximum Ink Capacity

uals 0.02 m l of ink , ink ca pacity is set at the

CAUTION

When you print the A4 nozzle check pattern after

completing repairs, the print out shows you the cur rent

value of the total ink counter and whether the ink is

discharging properly from all the nozzles. Make sure

that the value of the total ink counter is acceptable. If

the value is too high (if it is close to or gre ate r than t he

maximum value), it may be necessary to clear the

EEPROM and replace the waste ink pad.

1.5.6 Fatal Errors

The follo w ing are fatal er rors :

When t he t ot al quantity of ink released by cleaning and flushing reaches

the threshold value, a maintenance re

stops print in

. You need t o replace the waste ink pad in the prin t er

uest error occurs and the printer

case. A print er counter m onitors the am ount of ink that has been

absorbed by the waste in k pad. The coun t er uses a point system that

corresponds to the amount of ink that has been used. The maximum

capacit

points

EPSON Stylus COLOR 440 21000

EPSON Stylus COLOR 640 19800

EPSON Stylus COLOR 740 40900

of the waste ink pad is set at the following

:

Printer Maximum Counter Points

maximum counter

Carria

carria

belt tension malfunction, not enou

e Contro l Error: This e rror may be cause d by a misaligned

uide shaft, a home position sensor malfunction, a timing

h lubricant on the carriage guide

shaft, or ot her problem s .

CG Access Error: This error occurs if the carria

the ink cart rid

se

uence.

e replacem ent positio n during the replac em ent

e does not move to

28

Page 38

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

y

(

g

(a)

(b)

(c)

(d)

y

g

g

(a)

(b) Ej

(c)

(d)

(e)

g

(a)

(b)

g

g

g

g

g

g

g

g

)

1.6 Pr in te r In itialization

Stylus COLOR 440, 640, and 740 have three kinds of initialization

methods, as described below:

Power-on initialization

Power-on initialization occurs when

printer rec eiv es the cold res et c om mand

Power-on initializat ion performs t he followin

Initializes the printer mechanism.

Clears the input data buf f er.

Clears the print buffe r.

Sets the default values.

Operator initialization

Operator initializat ion occurs when

seconds af t er it was turned off, or when the printer receives th e I N IT

nal (negative pulse) from the parallel interface. Operator initialization

si

performs t he followin

acti ons:

ou turn the pri nt er on, or when the

remote RS command).

actions:

ou turn the printer on less t han 10

1.7 Initialization Settings

The settings below take effect when the Stylus COL OR 440, 640, or

740 are init ialized. If the us er chan

panel bu t to ns , th e D ef ault Settin

settin

s will take effect instead of the facto ry settings.

e position: Page headi ng location fo r c urrent page

Pa

Line spac in

ht margin positio n: 80 lines

Ri

Left mar

Charac t er pitch: 10 cpi

Printin

: 1/6 inch

in position: First line

mode: Text mode (not raster graphics mode

es any settings using the control

mode, or remote commands, those

Caps the printhead.

ects the p aper.

Clears the input data buffer.

Clears the print buffer .

Sets the default values.

Software initialization

Software initializat ion occurs when the prin t er receives the ESC @

command. Software initializat ion performs the followin

Clears the print buffer .

Sets the default values.

actions:

29

Page 39

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

(

g

)

g

)

y

y

)

y

y

y

)

y

y

y

(PF)

y

g

g

1.8 Main Components

The main components of the Stylus COLOR 440, 640, and 740 are

listed below.

the lower h ousin

1) Upper housin

2) Printer m ec hanism

3

4

5

Note that t he bottom of th e printer mec hanism se rv es as

for all three pr int ers.

Main con t rol board

lus COLO R 440: C206 MAIN-B board,

St

C255 MAIN board *

Stylus COLO R 640: C256 MAIN board

lus COLO R 740: C257 MAIN board

St

Power s upply board

lus COLO R 440: C206 PSB /P SE board

St

lus COLO R 640: C206 PSB /P SE board

St

St

lus COLO R 740: C257 PSB /P SE board

Contro l panel board

lus COLO R 440: C206 PNL board

St

St

lus COLO R 640: C206 PNL board

lus COLO R 740: C209 PNL board

St

1.8.1 Printer Mechanism

Like the printer mech anism for ea rlier printers s uc h as the Stylus

COLOR 600, the paper feed

mechanism and the ink pump. However, the ink pump operates onl

when the carria

approp riate direct ion.

Another important f eature is tha t the printhea d is one unit, combinin

both blac k and color ink nozzles.

e is in its home position and the PF motor is turning the

motor drives both the paper feed

* The C255 MAIN board will eventually replace the C206 MAIN-B.

30

Page 40

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

y

g

g

1.8.2 C206 MAIN-B Board (Stylus COLOR 440)

The C206 M AI N -B board co nt rols the operation of the printer

mechanism and data processin

This boar d w ill ev entuall

be replaced by the C255 MAIN board.

The C206 MAIN-B board consists of the following major components:

IC 14(PF)IC 15(C R )

CN6CN7

CN10

IC 7(H ead)

CN8

EEPRO M

(IC 1 1 )

Q 7,Q 9(H ead)

operations for the Stylus COLOR 440.

IC 3 (P -R O M )

CN1

IC 1 (C P U )

IC 2 (A s ic )

B a tt 1

IC 4 (4 M D -R A M )

CN3

CN5

CN4

CN11

1.8.3 C256 MAIN Board (Stylus COLOR 640)

The C25 6 M AIN board c ontrols the operation of t he printer mec hanism

and data processin

of the followin

IC 15(C R )

CN10

IC 7(H ead)

operations fo r t he Stylus COLOR 640. It consists

major components.

IC 14(PF)

CN6CN7

CN8

Q 7,Q 9(H ead)

CN1

IC 1 (C P U )

IC 2 (A s ic )

IC 16(P-R O M )

CN2

B a tt 1

IC 6

IC 5 (4 M D -R A M )

Figure 1-13. C256 MAIN board

CN3

CN5

CN4

CN11

Figure 1-12. C206 MAIN-B board

31

Page 41

EPSON Stylus COLOR 440, 640, and 740 Chapter 1 Product Description

g

g

y

g

(

job)

gging

)

1.8.4 C257 MAIN Board (Stylus COLOR 740)

The C257 M AI N board controls the operation of the printer mec hanism

and data processin

of the follow in

HT1

IC 1 2 IC 1 3

(P F D riv e )

operations for the Stylus COLOR 640. It consists

major compon ents.

IC 14(H ead)

CN9

CN7

IC 1 5

(R e g u la to r)

CN8

IC11(CR)

IC 6 (C G :o n ly fo r N L S P )

IC 3 (P -R O M )

CN3

CN1

B a tt 1

IC 4 IC 5

(4M DRAMx2)

IC 1 (C P U )

IC 2 (A s ic )

IC 7(EEPRO M

CN2

CN3

CN5

CN4

CN11

Figure 1-14. C257 MAIN Board