Page 1

EPSON

EPSON Stylus Color 600

SERVICE MANUAL

COLOR INK-JET PRINTER

SEIKO EPSON CORPORATION

4007367

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever

without SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for an y e rrors

in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks or registered trademarks of their respective companies.

Copyright ã 1997 by SEIKO EPSON CORPORATION

Nagano, Japan

ii

Page 3

PRECAUTIONS

Precautionar y notations throughout the tex t are categorized rel ative t o 1) personal i njury and 2)

damage to equipment.

WARNING

CAUTION

The precautionary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

WARNING Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

WARNING

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO W ORK SHOULD BE PERFO RMED ON THE UNIT BY PERSONS UNF AMILIAR W ITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL. DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

CAUTION

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VO LT AG E,

LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A

PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DI SCONNECTED FROM T HE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

iii

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance,

and repair of EPSON Stylus Color 600.

The instruct ions and procedur es incl uded herei n are i ntended for the ex peri ence repai r tec hnic ian,

and attention should be given to die precautions on the preceding page. The Chapters are

organized as follows:

CHAPTER 1. GENERAL DESCRIPTION

Prov ides a general product ov erview, l ists specific ations, and illustrates the main components of

the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENT

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides EPSON-approved techniques for troubleshooting.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to

service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and

exploded diagram.

The contents of this manual are subject to change without notice.

iv

Page 5

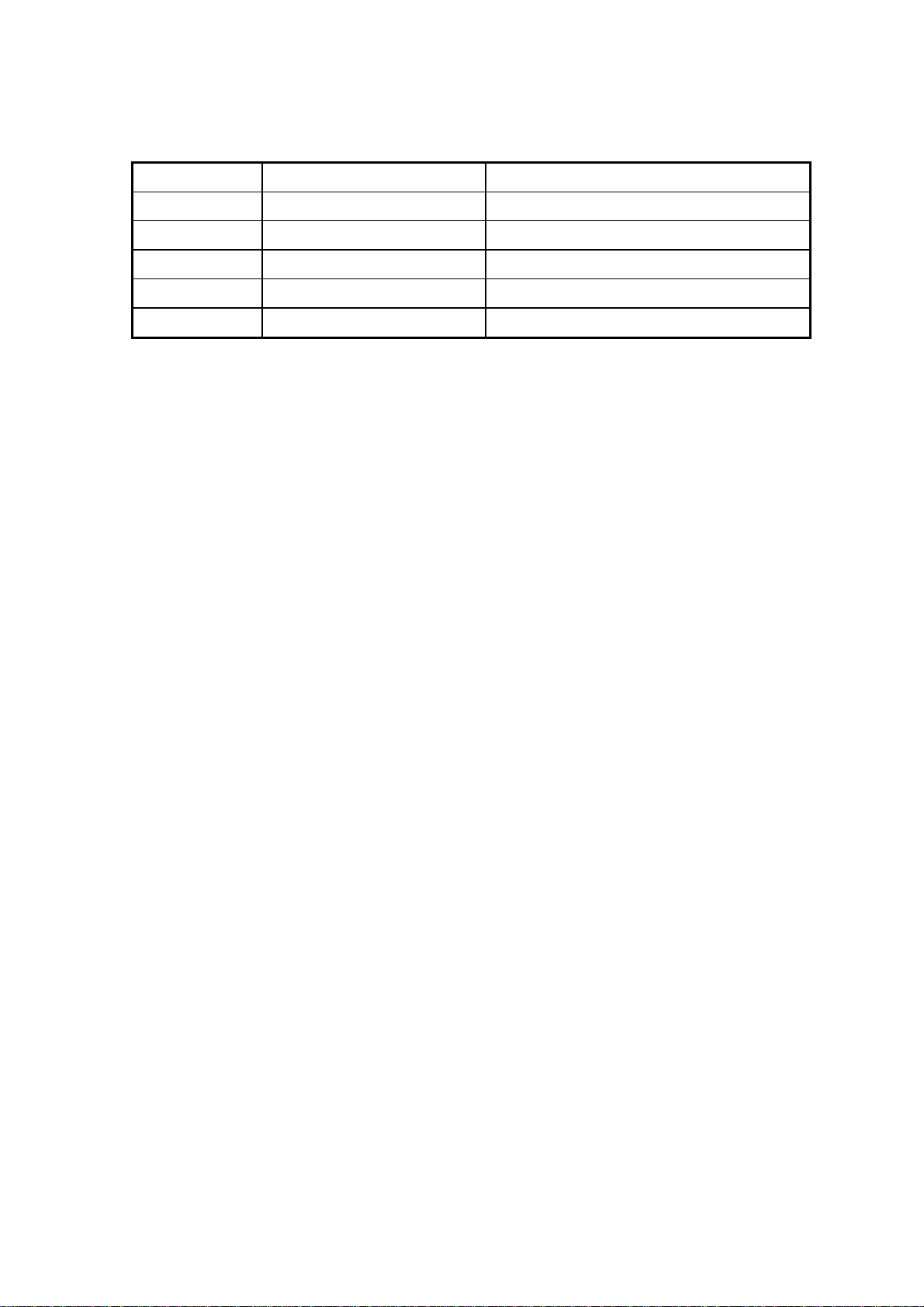

REVISION SHEET

Revision Issued Data Contents

Rev. A First issue

v

Page 6

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENT

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

vi

Page 7

Chapter 1

Product Descriptions

1.1 Features................................................................................................................1-1

1.2 Specifications.......................................................................................................1-2

1.2.1 Printing Specification ....................................................................................................... 1-2

1.2.2 Paper Specification........................................................................................................... 1-5

1.2.2.1 Cut Sheet............................................................................................................. 1-5

1.2.2.2 Transparency Film / Glossy Paper........................................................................ 1-5

1.2.2.3 Envelope.............................................................................................................. 1-5

1.2.2.4 Index Card............................................................................................................ 1-5

1.2.3 Adjust Lever Settings (PG adjust lever)........................................................................... 1-6

1.2.4 Printable Area.................................................................................................................... 1-7

1.2.4.1 Cut Sheet............................................................................................................. 1-7

1.2.4.2 Envelope.............................................................................................................. 1-8

1.2.5 Environmental Condition.................................................................................................. 1-9

1.2.6 Ink Cartridge Specifications............................................................................................1-10

1.2.6.1 Black Ink Cartridge..............................................................................................1-10

1.2.6.2 Color Ink Cartridge ..............................................................................................1-11

1.2.7 Physical Specification .....................................................................................................1-12

1.2.8 Electric Specification.......................................................................................................1-13

1.2.9 Reliability..........................................................................................................................1-13

1.2.10 Safety Approvals............................................................................................................1-13

1.2.11 Acoustic Noise ...............................................................................................................1-13

1.2.12 CE Marking .....................................................................................................................1-13

1.2.13 Printer Language and Emulation ..................................................................................1-14

1.3 Interface..............................................................................................................1-16

1.3.1 Parallel Interface (Forward Channel)...............................................................................1-16

1.3.2 Parallel Interface (Reverse Channel)...............................................................................1-17

1.3.2.1 Prevention Hosts from Data Transfer time-out.....................................................1-19

1.3.3 Serial Interface .................................................................................................................1-20

1.4 Control Panel......................................................................................................1-21

1.4.1 Indicators..........................................................................................................................1-21

1.4.2 Panel Functions ...............................................................................................................1-22

1.4.3 Printer Condition and Panel Status ................................................................................1-23

1.5 Error Status ........................................................................................................1-24

1.5.1 Ink Out ..............................................................................................................................1-24

1.5.2 Paper Out..........................................................................................................................1-24

1.5.3 Paper Jam.........................................................................................................................1-24

1.5.4 No Ink-Cartridge Error......................................................................................................1-25

1.5.5 Maintenance Request.......................................................................................................1-25

1.5.6 Fatal Errors.......................................................................................................................1-25

1.6 Printer Initialization............................................................................................1-26

1.6.1 Initialization Settings.......................................................................................................1-26

1.7 Main Components..............................................................................................1-27

1.7.1 Printer Mechanism...........................................................................................................1-27

1.7.2 C200 MAIN Board .............................................................................................................1-28

1.7.3 C206 PSB/PSE Board.......................................................................................................1-29

1.7.4 C206 PNL Board........................................................................................................... ....1-29

Page 8

Chapter 1 Product Description

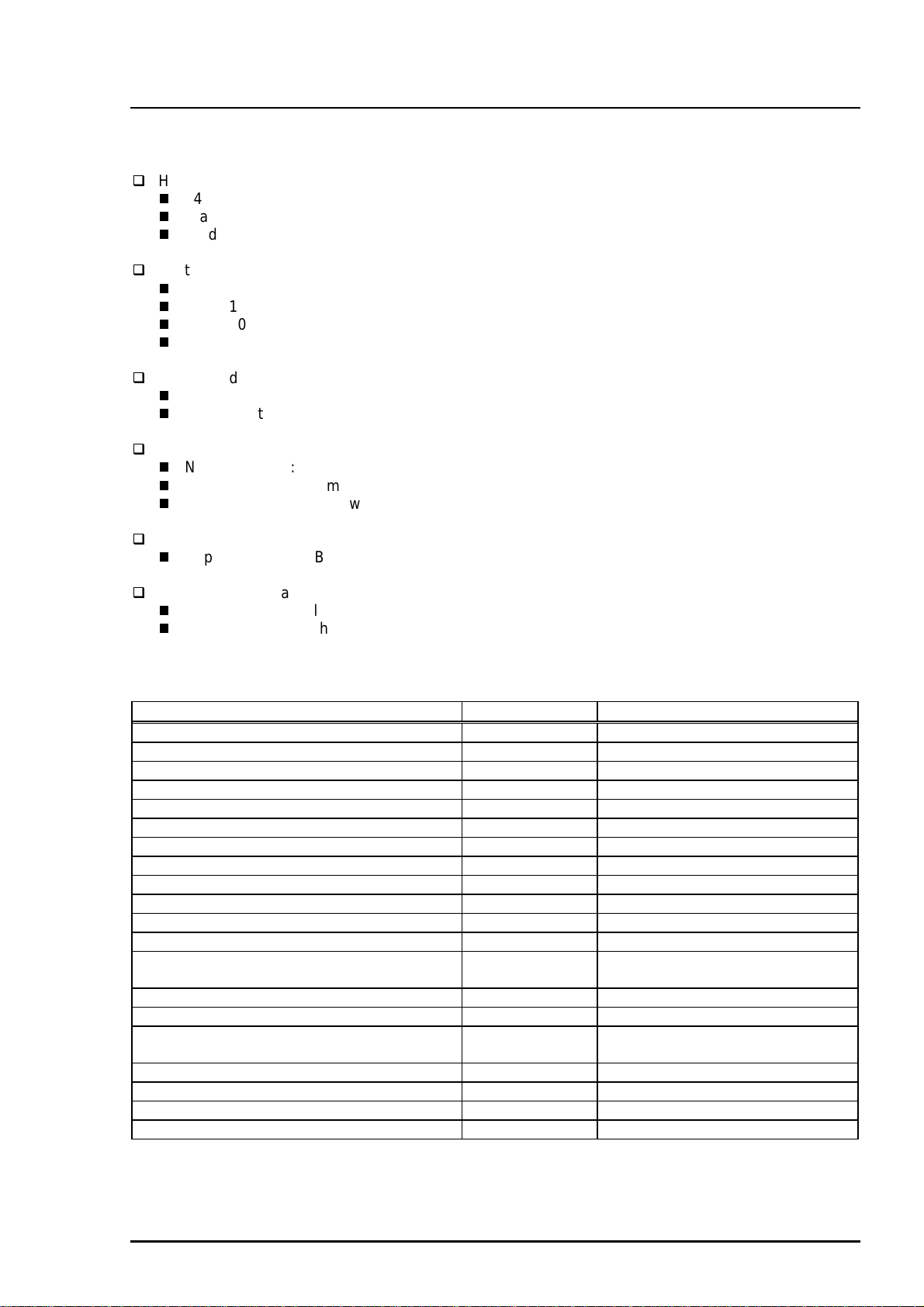

1.1 Features

EPSON Stylus Color 600 is designed for low price for that high performance. The major printer features

are;

High color print quality

1440(H) x 720(V) dpi printing

Standard 4 color printing (CMY+Bk)

Traditional and New Microwave control to eliminate banding

Built-in auto sheet feeder

Holds 100 cut-sheets (64g/‡u)

Holds 10 envelopes

Holds 10 transparency films

Holds 65 special papers

High-speed print

200cps (at LQ/10CPI; No-Draft mode)

By driving the printhead at frequency; 1.44KHz, printing speed is twice faster than Stylus Color.

Compact size

Non-operating : 429mm(W) x 275mm(D) x 168mm(H)

Operating : 429mm(W) x 613mm(D) x 309mm(H)

Weight : 5.2Kg (without cartridge)

Acoustic noise

Approximately 47dB(A)

Two built-in standard I/F

Bi-directional Parallel I/F (IEEE-1284 level 1 device)

Serial I/F (Macintosh-compatible / up to 900Kbps)

The table below shows consumable for EPSON Stylus Color 600.

Table 1-1 Available Consumable

Item Code Remark

Black Ink Cartridge S020093 Color: Black

Color Ink Cartridge S020089 Color: Cyan/Magenta/Yellow

EPSON 360 dpi Ink Jet Paper S041025 Size: A4(200 sheets)

EPSON 360 dpi Ink Jet Paper S041059 Size: A4(100 sheets)

EPSON 360 dpi Ink Jet Paper Product number Size: Letter(100 sheets)

Photo Quality Ink Jet Paper S041026 Size: A4(200 sheets)

Photo Quality Ink Jet Paper S041061 Size: A4(100 sheets)

Photo Quality Ink Jet Paper S041062 Size: Letter

Photo Quality Ink Jet Paper S041067 Size: Legal

Photo Quality Glossy Paper(New Release) S041126 Size: A4

Photo Quality Glossy Paper(New Release) S041124 Size: Letter

Photo Quality Glossy Film S041071 Size: A4

Photo Quality Glossy Film Product

Numbers

Photo Quality Glossy Film S041107 Size: A6

Ink Jet Transparencies S041063 Size: A4

Ink Jet Transparencies Product

Numbers

Photo Quality Ink Jet Card S041054 Size: A6

Photo Quality Ink Jet Card S041121 Size: 5 x 8 inches

Photo Quality Ink Jet Card S041122 Size: 10 x 8 inches

Photo Quality Self Adhesive Sheet S041106 Size: A4

Size: Letter

Size: Letter

Rev. A

1-1

Page 9

EPSON Stylus Color 600

2

1.2 Specifications

This section describes the product specifications for EPSON Stylus Color 600.

1.2.1 Printing Specification

Print method

On-demand color ink jet printing

Nozzle configuration

Black: 64 nozzles (32 nozzles x2 staggered / Nozzle pitch = 180dpi/vertical)

Color: 32 nozzles (per color (CMY) / Nozzle pitch = 90dpi/vertical)

Print Direction

Bi-directional printing with logical seeking for text and graphics

Print Buffer: 32KBytes

Print speed and Printable Columns

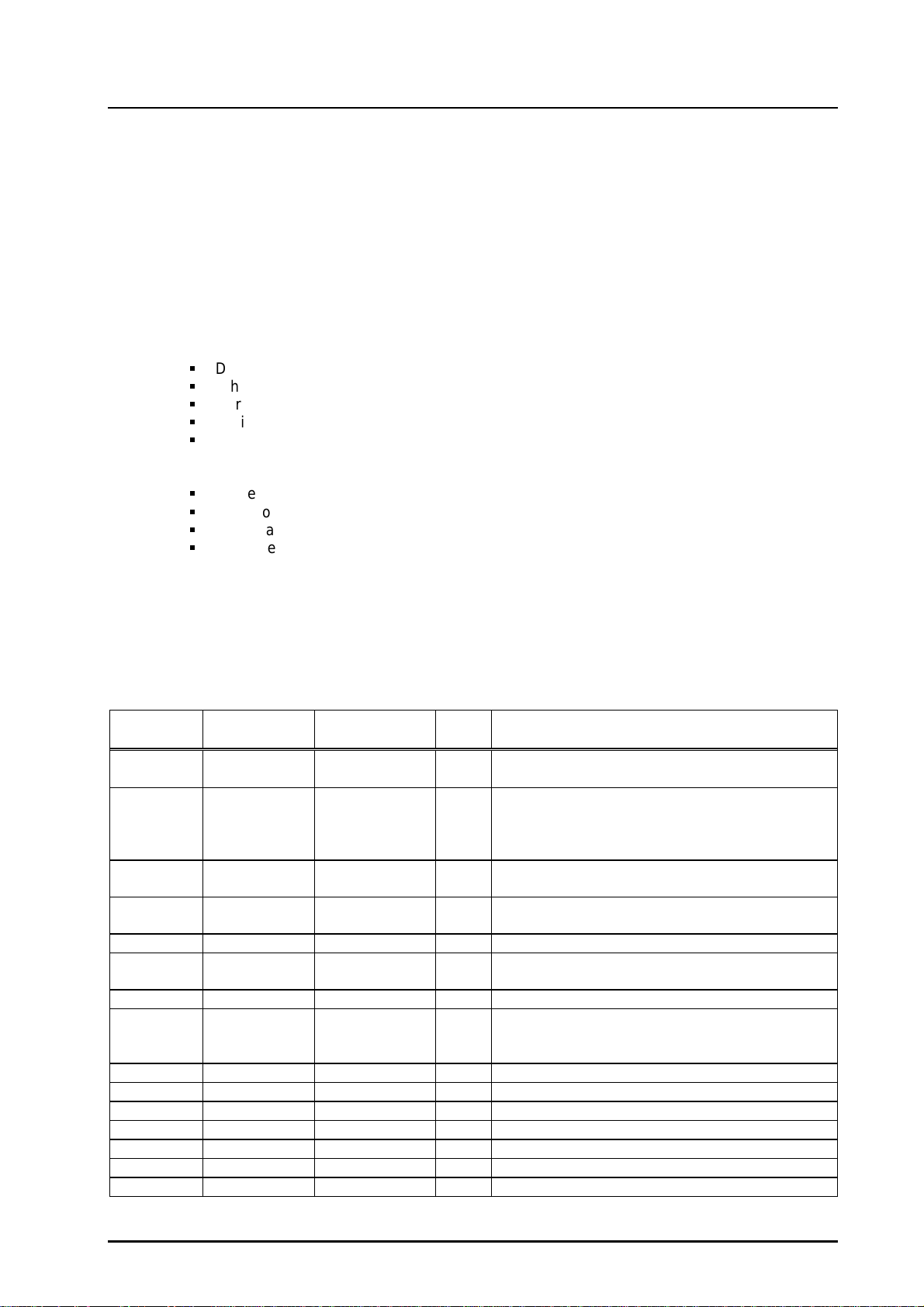

Table 1-2 Print Speed (Text Mode)

Character Pitch Printable

Column

Draft Speed

(CPS)

10 CPI (Pica) 80 400 200

12 CPI (Elite) 96 480 240

15 CPI 120 600 300

17 CPI (Pica Condensed) 137 684 342

20 CPI (Elite Condensed) 160 800 400

Table 1-3 Print Speed (Raster Graphics Mode)

Horizontal Resolution Printable

Available Dot CR Speed

Area

180 dpi 8.26 inch 1488 20

360 dpi 8.26 inch 2976 20

720 dpi 8.26 inch 5952 20

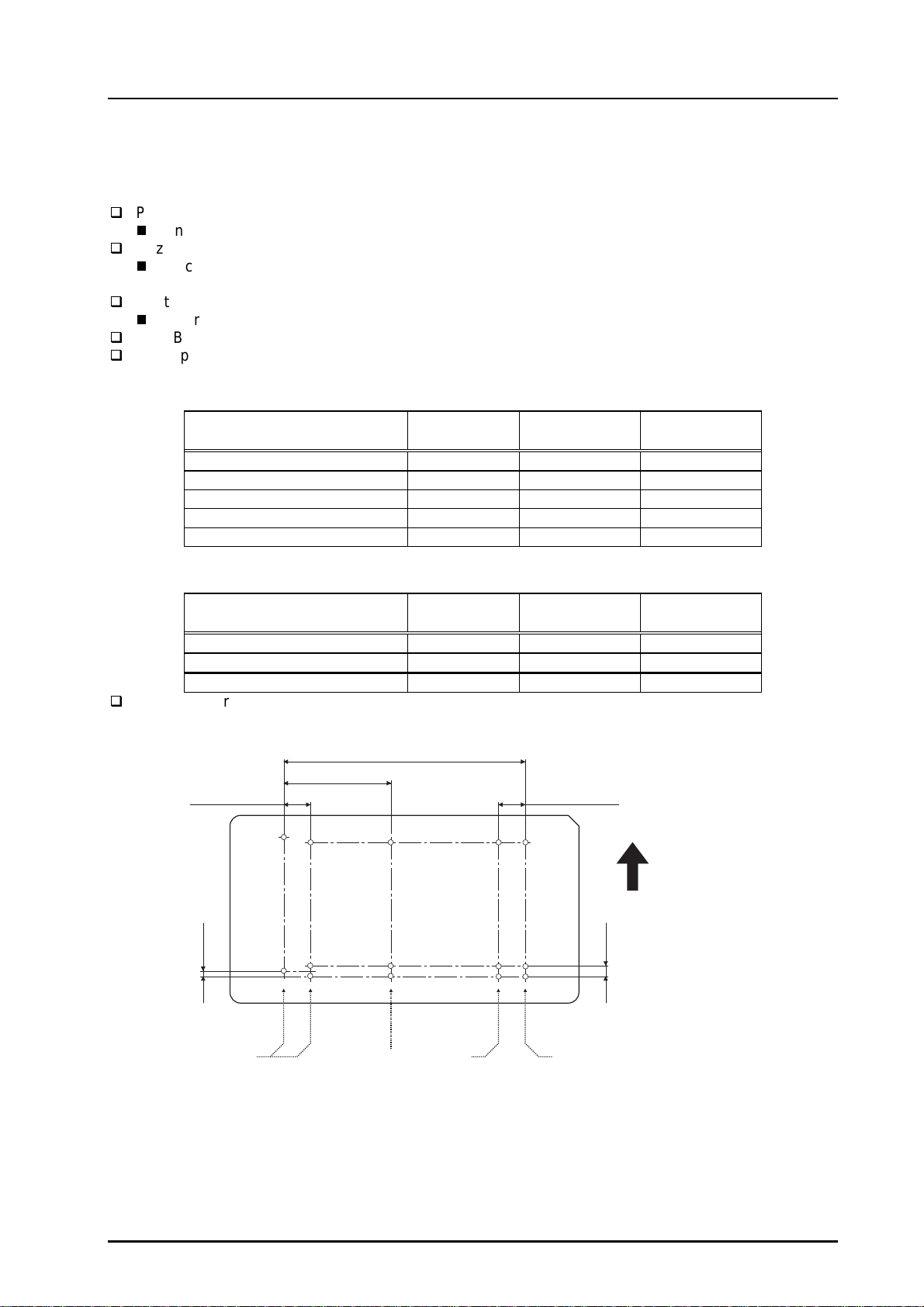

Nozzle arrangement: See figure below.

320/360" (22.5778mm)

144/360" (10.16mm)

32/360" (2.2578mm)

#64

#63

#32 #32 #32

32/360" (2.2578mm)

LQ Speed

(CPS)

(IPS)

Paper feed

direction

180dpi

Black Cyan Magenta Yellow

#3

#2

#1

*Viewed from the back of the head

#1 #1 #1

90dpi

Figure 1-1. Nozzle Layout

1-

Rev. A

Page 10

3

Paper Feeding Method

Friction feed with built in ASF (Auto Sheet Feeder)

Line Spacing

1/6 inch or programmable at 1/360 inch

Paper Path

Top entry (from ASF) only

Feeding Speed

66.6 ms (at 1/6 inch line-feed)

3.0 inch/sec (76.2 mm/sec / at continuous-feed)

ASF Capacity

Size :Index card to Legal

Thickness *1 :Less than 8mm

Paper capacity *2 :Normal cut sheets =100 sheets (64g/m

:Envelops =10

:Coated papers (360dpi) =65

:Coated papers (720dpi) =65

:Glossy papers *3 *4 =30

:Transparency films *4 =30

:Index cards *4 =30

Chapter 1 Product Description

2

)

Notes) *1: Total thickness of paper stack on the ASF.

*2: Those numbers above should be considered as reference. The actual paper accumulation

should be considered first.

*3: Only when the top margin is set for 30mm with A4/Letter size paper, otherwise only one sheet

can be set at a time.

*4: Specified paper must be set at the bottom of stack to ensure proper feeding operation:

Normal paper =Glossy paper, Transparency film

Card Board =Index card

(The one packed with the index card package)

Rev. A

1-

Page 11

EPSON Stylus Color 600

4

Control Code

ESC/P2 and expanded raster graphics code

EPSON Remote command

Character Tables

Legal and 14 international character sets

Standard version: 11 character tables (See Table 1-4 for details)

NLSP version: 19 character tables (See Table 1-4 for details)

Typeface *1

Bit map LQ font: EPSON Roman (10/12/15 CPI, Proportional)

EPSON Sans Serif (10/12/15 CPI, Proportional)

EPSON Courier (10/12/15 CPI)

EPSON Prestige (10/12/15 CPI)

EPSON Script (10/12/15 CPI)

Scaleable font: EPSON Roman (10.5 pt, 8 to 32 pt (every 2 pt))

EPSON Sans Serif (10.5 pt, 8 to 32 pt (every 2 pt))

EPSON Roman T (10.5 pt, 8 to 32 pt (every 2 pt))

EPSON Sans Serif H (10.5 pt, 8 to 32 pt))

Note) *1: Each typeface has four different font style; Normal, Bold, Italic and Bold-Italic.

Table 1-4 Character Table and Typeface

Version Character Table Bit-map Font Scaleable Font

Common EPSON - ;

Roman

Sans Serif

Courier

Prestige

Script

Standard Italic

PC437 (US / Standard Europe)

PC850 (Multilingual)

PC860 (Portuguese)

PC861 (Icelandic)

PC863 (Canadian-French)

PC865 (Nordic)

BRASCII

Abicomp

Roman 8

ISO Latin 1

NLSP Italic

PC437 (US / Standard Europe)

PC850 (Multilingual)

PC437 Greek

PC852 (East Europe)

PC853 (Turkish)

PC855 (Cyrillic)

PC857 (Turkish)

PC866 (Russian)

PC869 (Greek)

MAZOWIA (Poland)

Code MJK (CSFR)

ISO 8859-7 (Latin/Greek)

ISO Latin 1T (Turkish)

Bulgaria (Bulgaria)

PC774

Estonia

ISO 8859-2 (ISO Latin 2)

PC866 LAT

Supported Supported Supported

Supported Supported Supported

Supported Supported Not

EPSON - ;

Roman

Sans Serif

EPSON - ;

Roman T

Sans Serif H

Supported

1-

Rev. A

Page 12

5

1.2.2 Paper Specification

This section describes the types of paper that can be used in this printer.

1.2.2.1 Cut Sheet

[Size]

:A4 [Width 210mm (8.3”) x Length 297mm (11.7”)]

:Letter [Width 216mm (8.5”) x Length 279mm (11.0”)]

:B5 [Width 182mm (7.2”) x Length 257mm (10.1”)]

:Legal [Width 216mm (8.5”) x Length 356mm (14.0”)]

:Half Letter[Width 139.7mm (5.5”) x Length 215.9mm (8.5”)]

:Exclusive [Width 190.5mm (7.5”) x Length 254mm (10”)]

Chapter 1 Product Description

[Thickness]

[Weight]

[Quality]

:0.08mm (0.003”) - 0.11mm (0.004”)

:64g/m

:Exclusive paper, Bond paper, PPC

2

(17Ib.) - 90g/m2 (24Ib.)

1.2.2.2 Transparency Film / Glossy Paper

[Size]

[Thickness]

Note) Transparency printing is only available at normal temperature.

:A4 [Width 210mm (8.3”) x Length 297mm (11.7”)]

:Letter [Width 216mm (8.5”) x Length 279mm (11.0”)]

:A6 [Width 105mm (4.1”) x Length 148mm (5.8”)]

:0.13mm (0.005”) - 0.15mm (0.006”)

:0.17mm (0.007”) - 0.18mm (0.007”) for glossy paper

1.2.2.3 Envelope

[Size]

[Thickness]

[Weight]

[Quality]

: No.10 [Width 241mm (9 1/2”) x Length 104.8mm (4 1/8”)]

: DL [Width 220mm (8.7”) x Length 110mm (4.3”)]

: C6 [Width 162mm (6.4”) x Length 114mm (4.5”)]

: 0.16mm (0.006”) - 0.43mm (0.017”)

: 45g/m

: Bond paper, Plain paper, Air mail

2

(12Ib.) - 75g/m2 (20Ib.)

Note) 1. Envelop printing is only available at normal temperature.

2. Keep the longer side of the envelope horizontally at setting.

1.2.2.4 Index Card

[Size]

[Thickness]

[Weight]

Note) 1. No curled, wrinkled, scuffing or torn paper be used.

2. Set the lever to the proper position according to the paper type you print. (Refer to section

1.2.3 for details)

3. Printing should be performed at room temperature in spite of the paper types.

:A6 Index card [Width 105mm (4.1”) x Length 148mm (5.8”)]

:5x8” Index card [Width 127mm (5.0”) x Length 203mm (8.0”)]

:10x8” Index card [Width 127mm (5.0”) x Length 203mm (8.0”)]

:Less than 0.23mm(0.0091”)

:188g/m

2

Rev. A

1-

Page 13

EPSON Stylus Color 600

6

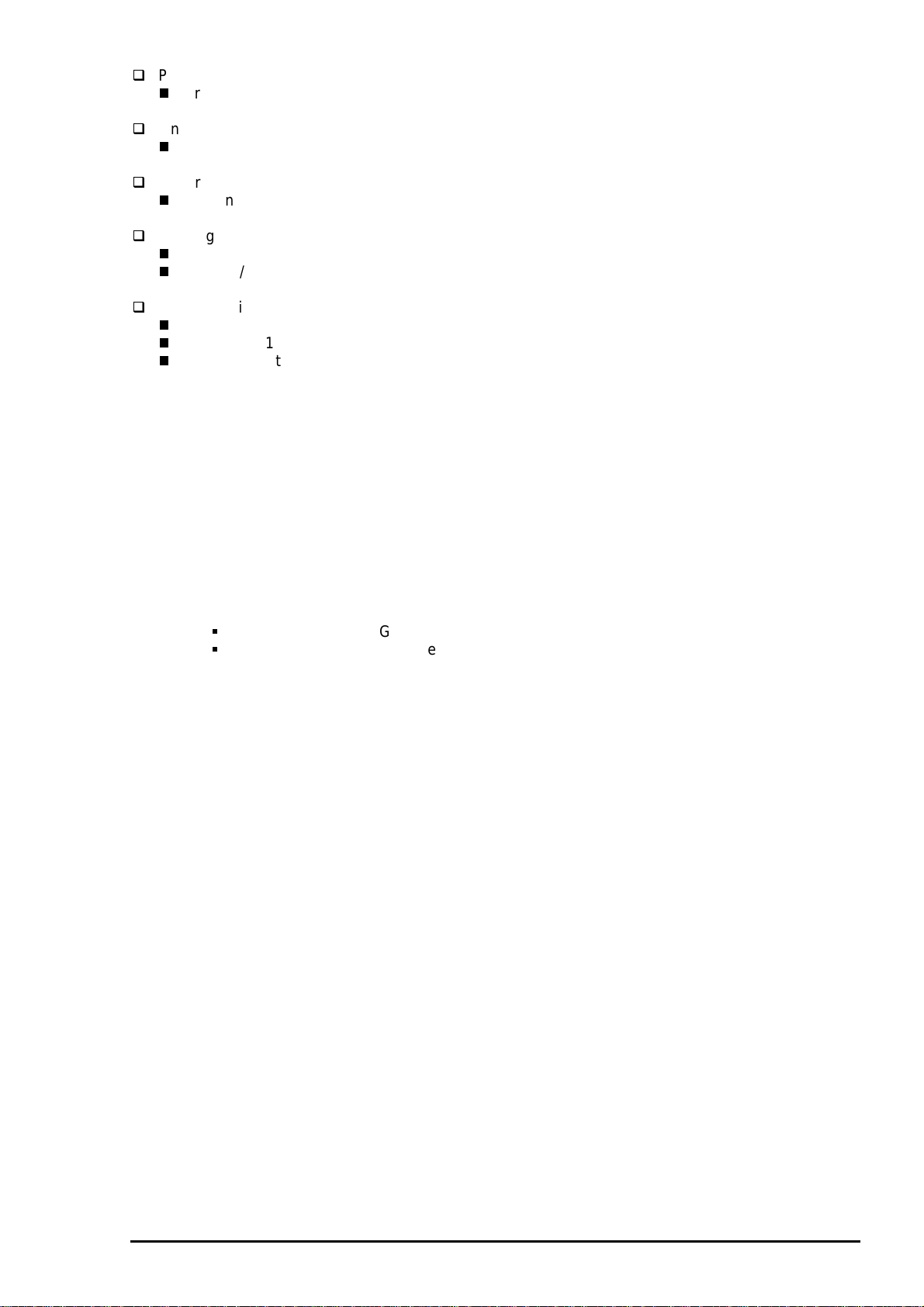

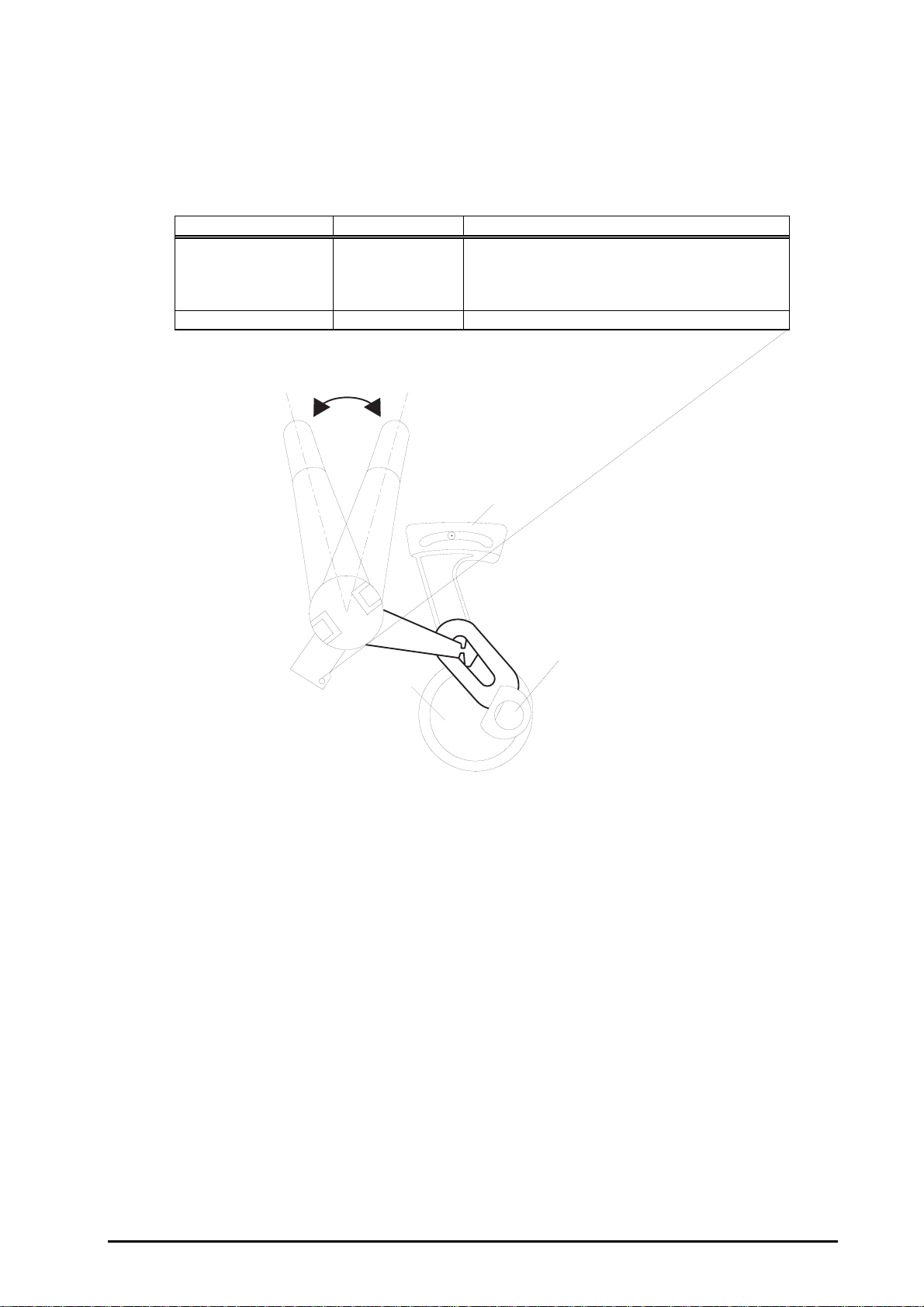

1.2.3 Adjust Lever Settings (PG adjust lever)

The adjust lever located on the right side (blue knob) under the printer cover needs to be set to the

proper position according to the paper you print (Refer to the table below). Also, if there is any dirt

caused by friction on the wavy or wrinkled paper, this can be prevented by changing the lever position to

rear position (marked with “+”) in spite of paper types.

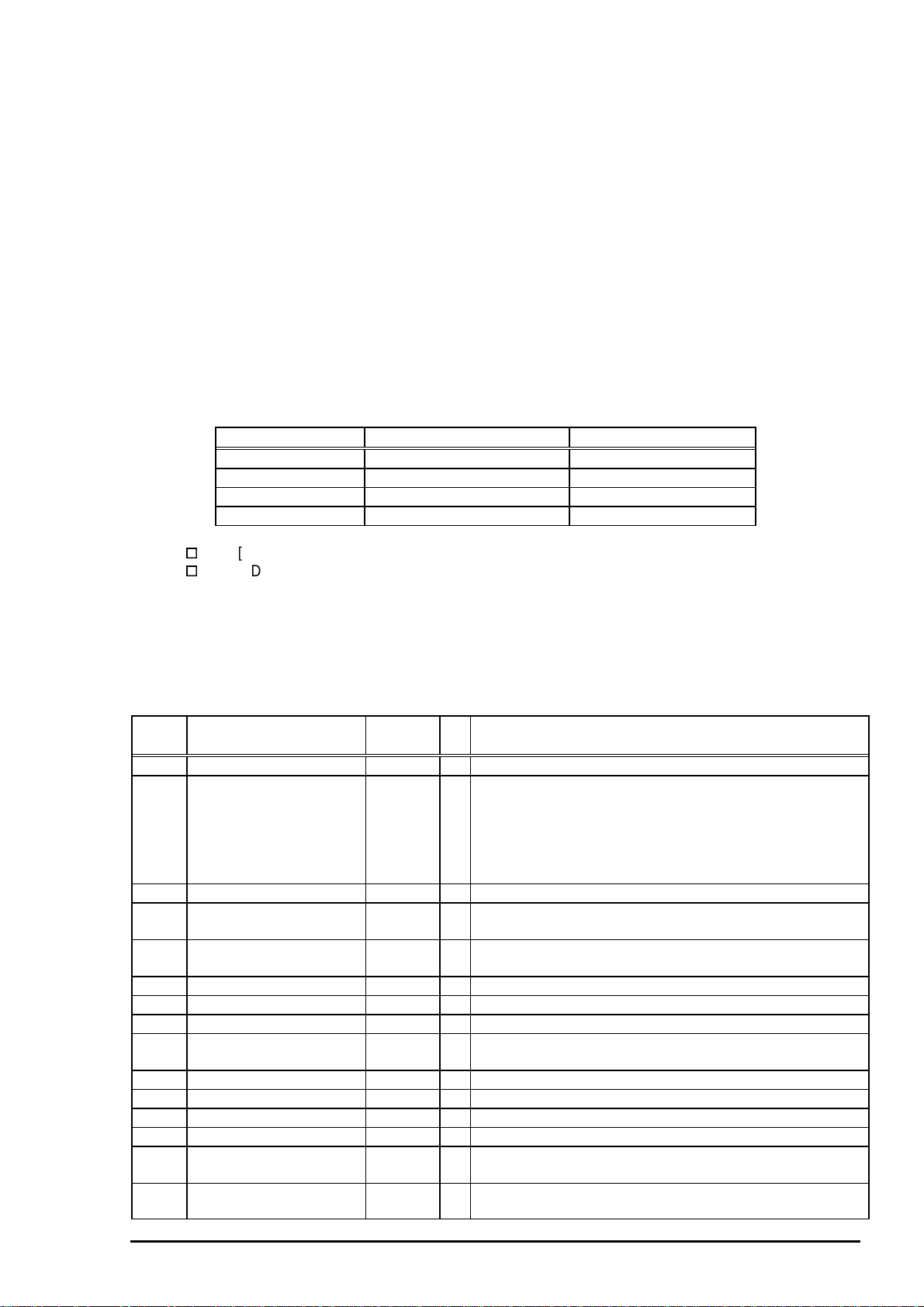

Table 1-5. Adjust Lever Settings

Paper Lever position PG adjustment value

Normal paper,

Coated paper

Transparency film

Label

Envelopes Rear 0.9 mm (2.0mm between head and platen)

Front (Mark "0")

Front 0 mm (1.1mm between head and platen)

+

Rear (Mark "

")

Level adjustment lever

CR Guide Shaft

Bush

Figure 1-2. Adjust Lever Settings

1-

Rev. A

Page 14

Chapter 1 Product Description

7

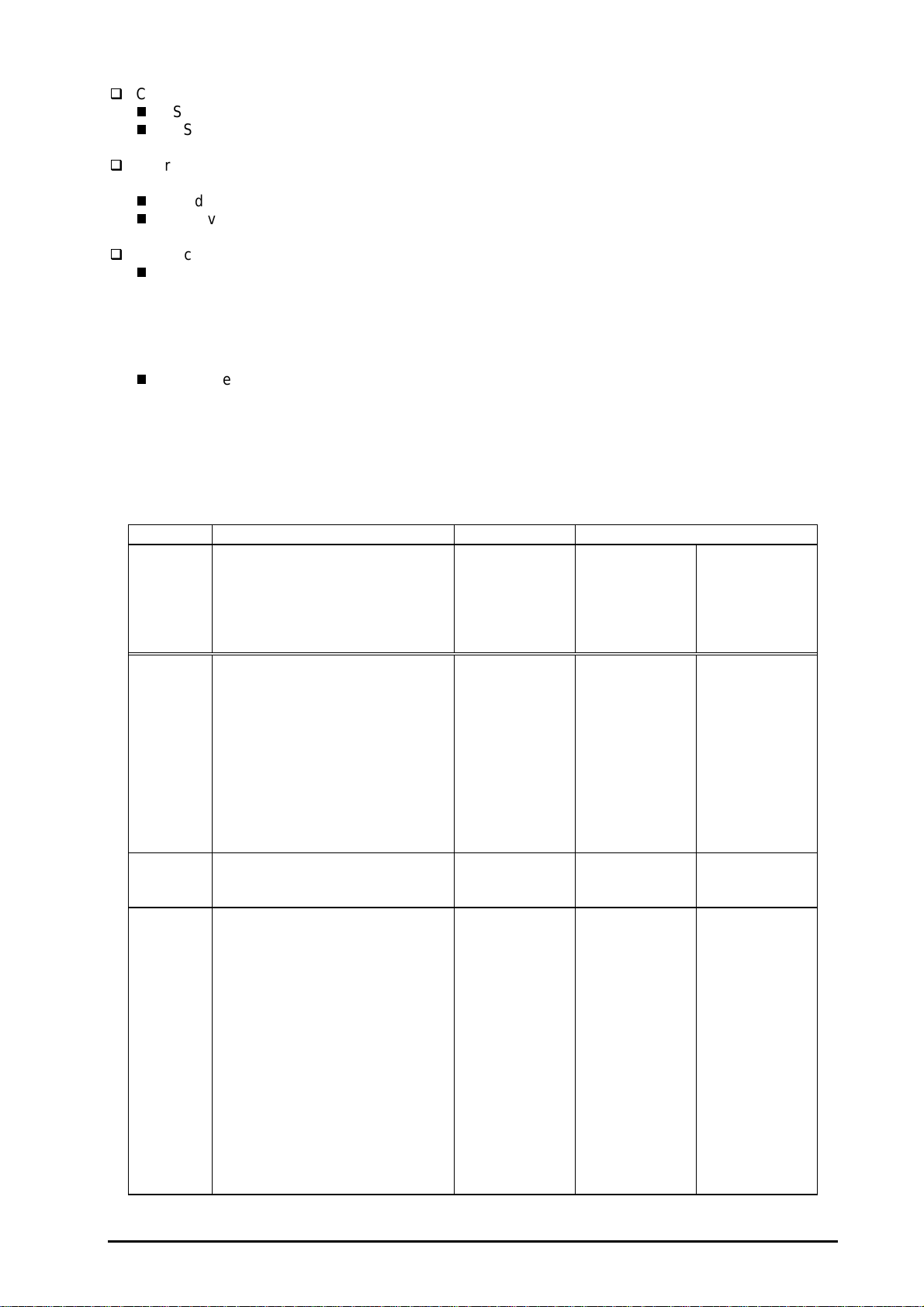

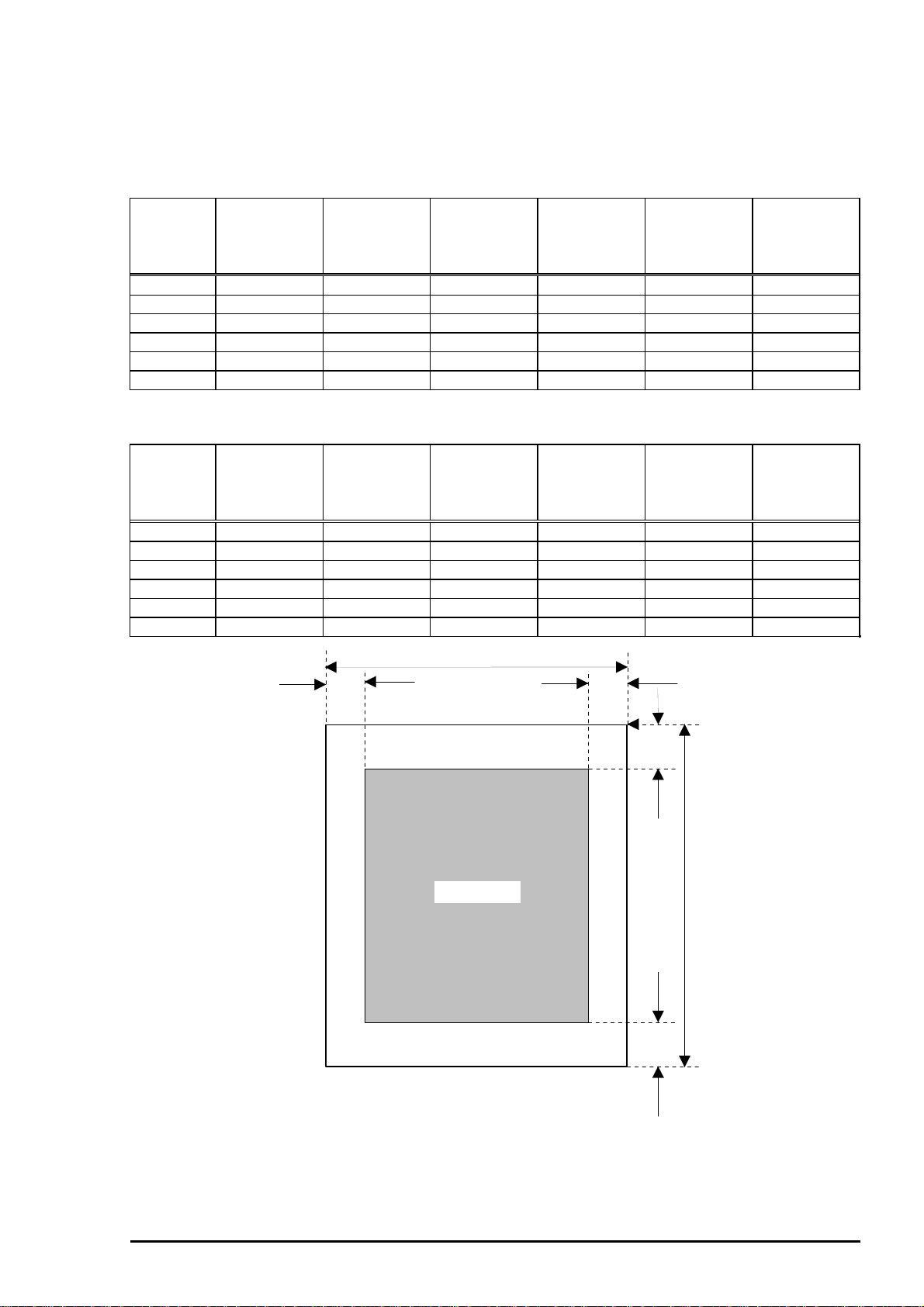

1.2.4 Printable Area

1.2.4.1 Cut Sheet

Following tables show printable areas at Character mode and Raster Graphics mode.

Table 1-6. Character Table

Paper size PW

(Paper width)

(typ.)

PL

(Paper

Length)

(typ.)

LM

(Left margin)

(min.)

RM

(Right

margin)

(min.)

TM

(Top margin)

(min.)

BM

(Bottom

margin)

(min.)

A4 210mm(8.3”) 297mm(11.7”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Letter 216mm(8.5”) 279mm(11.0”) 3mm(0.12”) 9mm(0.35”) 3mm(0.12”) 14mm(0.54”)

B5 182mm(7.2”) 257mm(10.1”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Legal 216mm(8.5”) 356mm(14.0”) 3mm(0.12”) 9mm(0.35”) 3mm(0.12”) 14mm(0.54”)

Statement 139.7mm(5.5”) 215.9mm(8.5”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Executive 190.5mm(7.5”) 254mm(10”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Table 1-7. Raster Graphics Mode

Paper size PW

(Paper width)

(typ.)

PL

(Paper

Length)

(typ.)

LM

Left margin)

(min.)

RM

(Right

margin)

(min.)

TM

(Top margin)

(min.)

BM

(Bottom

margin)

(min.)

A4 210mm(8.3”) 297mm(11.7”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Letter 216mm(8.5”) 279mm(11.0”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

B5 182mm(7.2”) 257mm(10.1”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Legal 216mm(8.5”) 356mm(14.0”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Statement 139.7mm(5.5”) 215.9mm(8.5”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Executive 190.5mm(7.5”) 254mm(10”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

PW

LM RM

Printable Area

Figure 1-3. Printing Area for Cut Sheet

TM

PL

BM

Rev. A

1-

Page 15

EPSON Stylus Color 600

8

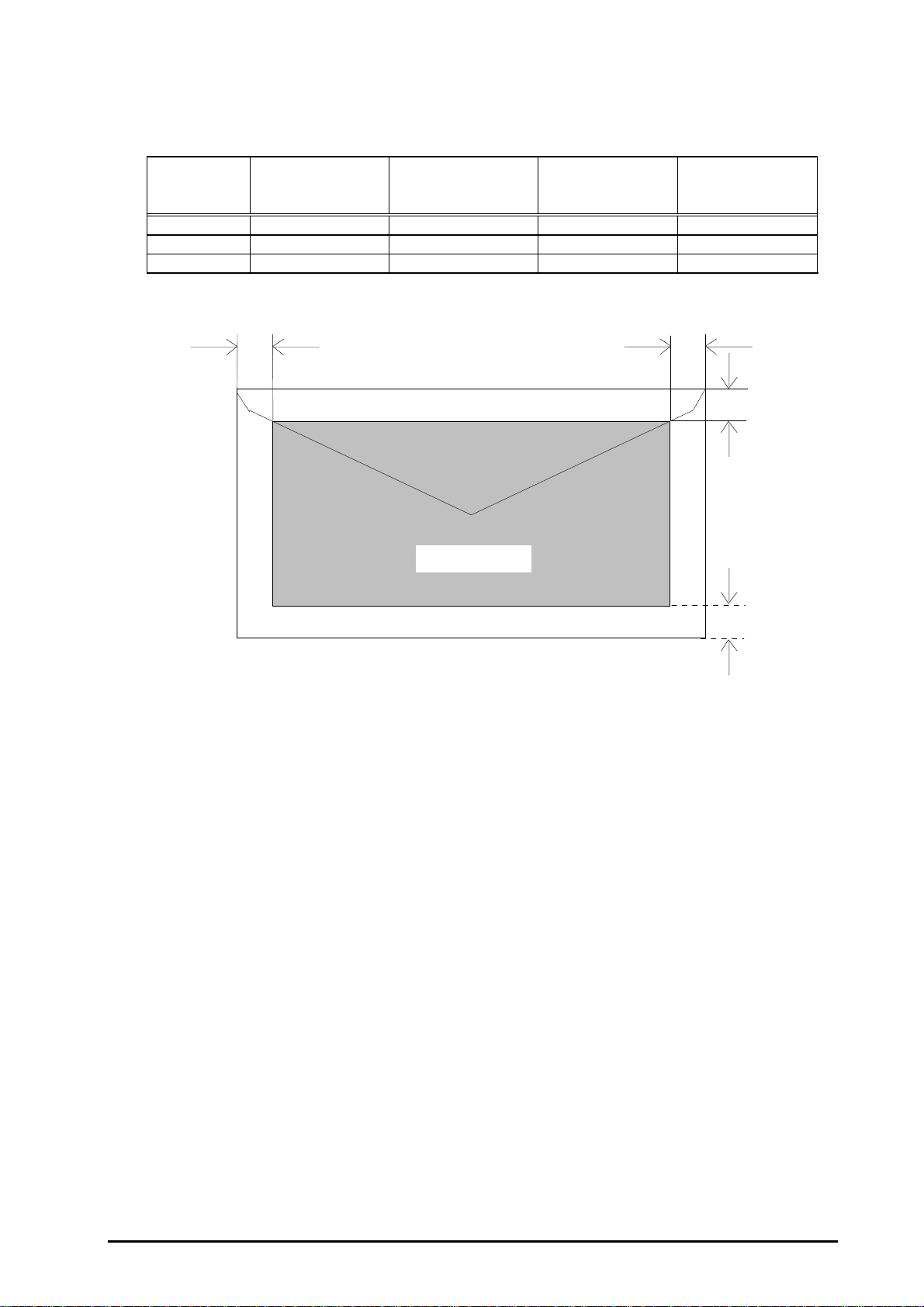

1.2.4.2 Envelope

The table and figure below show the printable area for envelopes.

Table 1-8. Envelope

Paper Size LM

(Left Margin)

(min.)

#10 3mm (0.12”) 28mm (1.10”) 3mm (0.12”) 14mm (0.55”)

DL 3mm (0.12”) 7mm (0.28”) 3mm (0.12”) 14mm (0.55”)

C6 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14mm (0.55”)

LM

RM

(Right Margin)

(min.)

Printable area

TM

(Top Margin)

(min.)

(Bottom Margin)

RM

BM

(min.)

TM

Figure 1-4. Printing Area for Envelope

BM

1-

Rev. A

Page 16

Chapter 1 Product Description

9

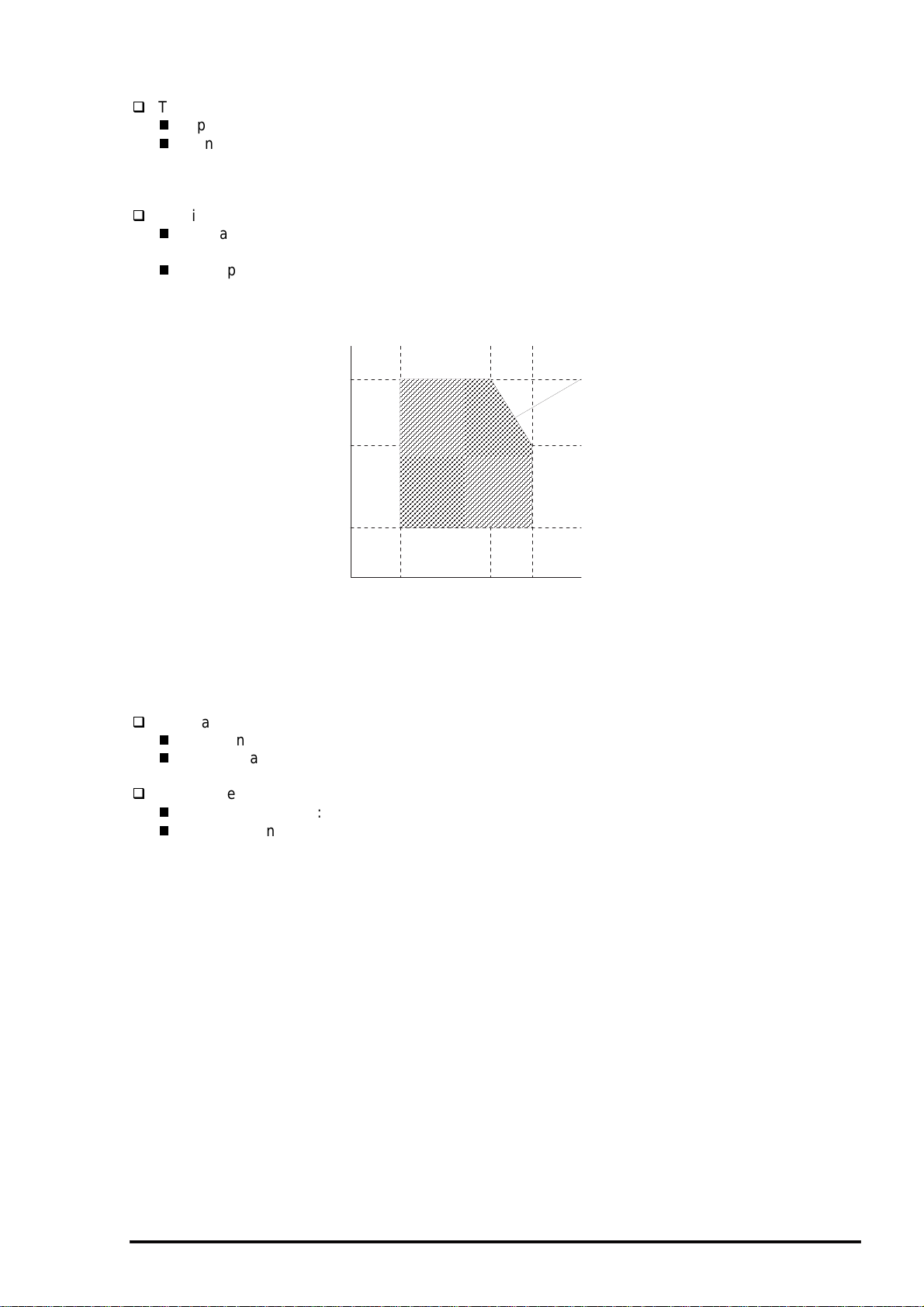

1.2.5 Environmental Condition

Temperature

Operating :10 - 35•• (Refer to the figure below for condition)

Non-operating :-20 - 60•• (with shipment container)

Note) Storage should be within one month at 40°C and 120 hours at 60°C.

Humidity

Operating :20% - 80% RH

(without condensation. Refer to the figure below for condition)

Non-operating :5% - 85% RH

(without condensation and with shipment container)

Humidity

(% RH)

80%

55%

Guaranteed range

20%

10°C

(50°F)

27°C

(80°F)

35°C

(95°F)

°C

(°F)

Figure 1-5. Temperature/Humidity of Range

Resistance to shock

Operating :1G, within 1 ms (X,Y,Z directions)

Non-operating :2G, within 2 ms (X,Y,Z directions/with shipment container)

Resistance to vibration

Operating :0.15G, 10•`55Hz (X,Y,Z directions)

Non-operating :0.50G, 10•`55Hz (X,Y,Z directions/with shipment container)

Note) 1. During non-operating, make sure that the head is capped.

2. During the transport, make sure that the head is capped and ink cartridge is installed to the

printer.

3. If the head is not capped at the power-off state, turn the power on with the ink cartridge

installed and turn off the power after confirming that the head is correctly capped.

4. Ink will be frozen under -4°C environment, however it will be useable after placing it more than

3 hours at 25°C.

Rev. A

1-

Page 17

EPSON Stylus Color 600

0

1.2.6 Ink Cartridge Specifications

1.2.6.1 Black Ink Cartridge

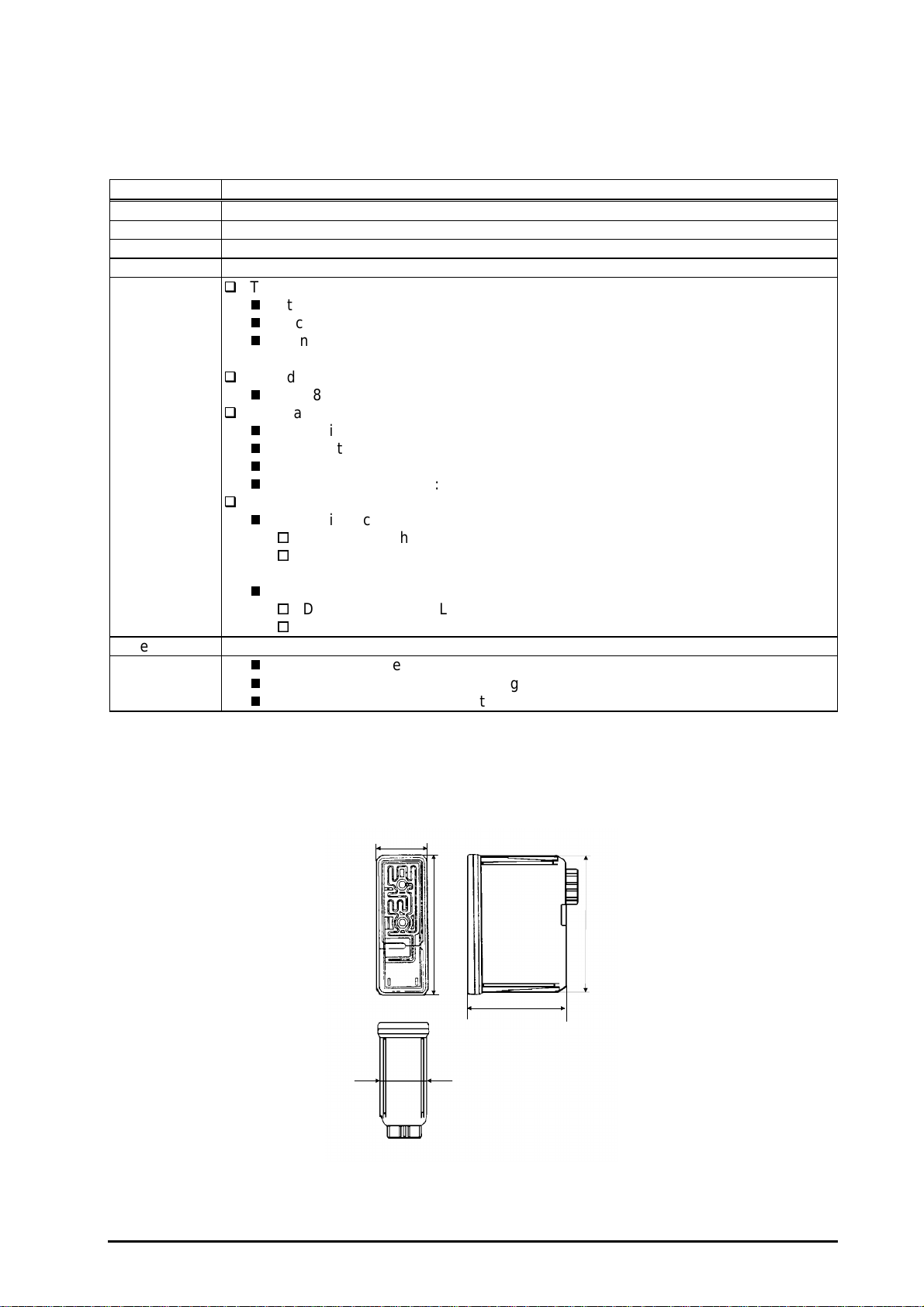

Table 1-9. Black Ink Cartridge Specifications

Item Specifications

Type Black Ink Cartridge (Code: S020093)

Color Black

Print capacity 540 pages / A4 (ISO/IE10561 Letter Pattern at 360 dpi)

Validity 2 years (sealed in package) / 6months(out of package)

Environmental

conditions

Dimension 19.8mm(W) x 52.7(D) x 38.5mm(H)

Weight

Temperature

Storage :-20 - 40°C (within a month at 40°C)

Packing storage :-30 - 40°C (within a month at 40°C)

Transit :-30 - 60°C (within 120 hours at 60°C and within a

month at 40••)

Humidity

5% - 85% (without condensation)

Resistance to vibration

Sealed in package :5 - 55Hz

Acceleration :Less than 29.4m/s (3G)

Direction :X, Y, Z direction

Time :1 hour

Drop

Sealed in package:

Dropping height :Less than 0.80m

Direction :Drop the package facing the bottom, sides and one

edge down.

Out of package:

Dropping height :Less than 1.50m

Frequency :Once

Total ink cartridge :54g

Total ink :16.4•}0.5g (Amount in the ink cartridge)

Consumable ink :More than 12.1g(Useable ink quantity until ink ends)

Note) 1. Ink cartridge can not re-fill, only ink cartridge is prepared for article of consumable.

2. Do not use the ink cartridge which is passed away the ink life.

3. Ink will be frozen under -4••environment, however it will be usual after placing it more than 3

hours at room temperature.

19.8

52.7

38.5

18.3

51.2

Figure 1-6. Ink Cartridge (Black)

1-1

Rev. A

Page 18

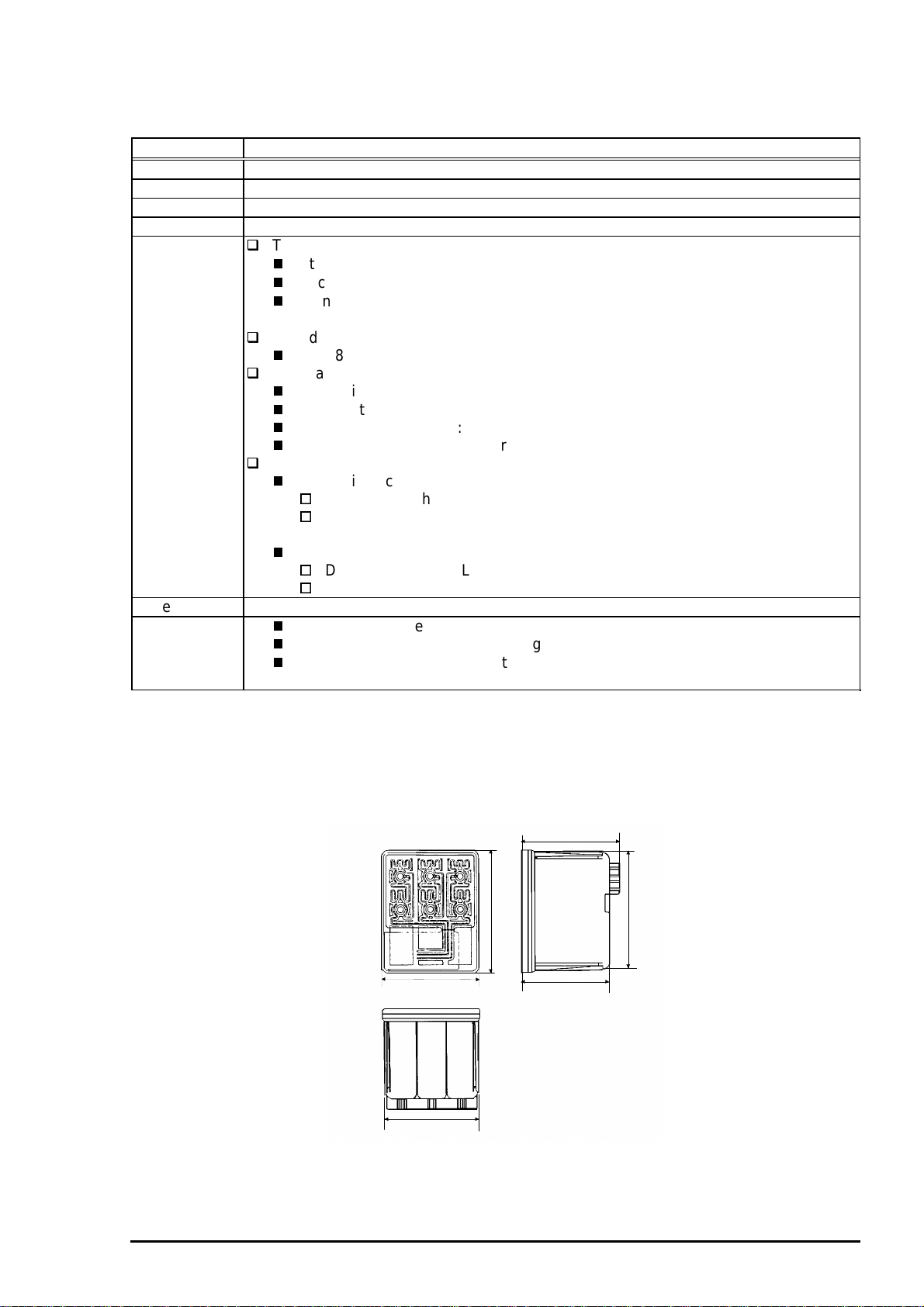

1.2.6.2 Color Ink Cartridge

Table 1-10. Color Ink Cartridge Specification

Item Specifications

Type Color Ink Cartridge(Code: S020089)

Color Magenta/Cyan/Yellow

Print capacity 300 pages / A4 (360 dpi, 5% duty each color)

Validity 2 years (sealed in package) / 6months(out of package)

Environmental

conditions

Dimension 42.9mm(W) x 52.7(D) x 38.5mm(H)

Weight

Temperature

Storage :-20•• - 40•• (within a month at 40••)

Packing storage :-30•• - 40•• (within a month at 40••)

Transit :-30•• - 60•• (within 120 hours at 60••and within a

month at 40••)

Humidity

5% - 85% (without condensation)

Resistance to vibration

Sealed in package :5 - 55Hz

Acceleration :Less than 29.4m/s (3G)

Direction :X, Y, Z direction

Time :1 hour

Drop

Sealed in package :

Dropping height :Less than 0.80m

Direction :Drop the package facing the bottom, sides and one

edge down.

Out of package:

Dropping height :Less than 1.50m

Frequency :Once

Total ink cartridge :68g

Total ink :13.3•}0.5g (Amount in the ink cartridge)

Consumable ink :More than 10.1g/each color (Useable ink quantity until

ink ends)

Chapter 1 Product Description

Note)

1. Ink cartridge can not re-fill, only ink cartridge is prepared for article of consumable.

2. Do not use the ink cartridge which is passed away the ink life.

3. Ink will be frozen under -4••environment, however it will be usual after placing it more than 3

hours at room temperature.

43.2

51.2

42.9

41.4

52.7

38.5

Figure 1-7. Ink Cartridge (Color)

Rev. A

1-11

Page 19

EPSON Stylus Color 600

2

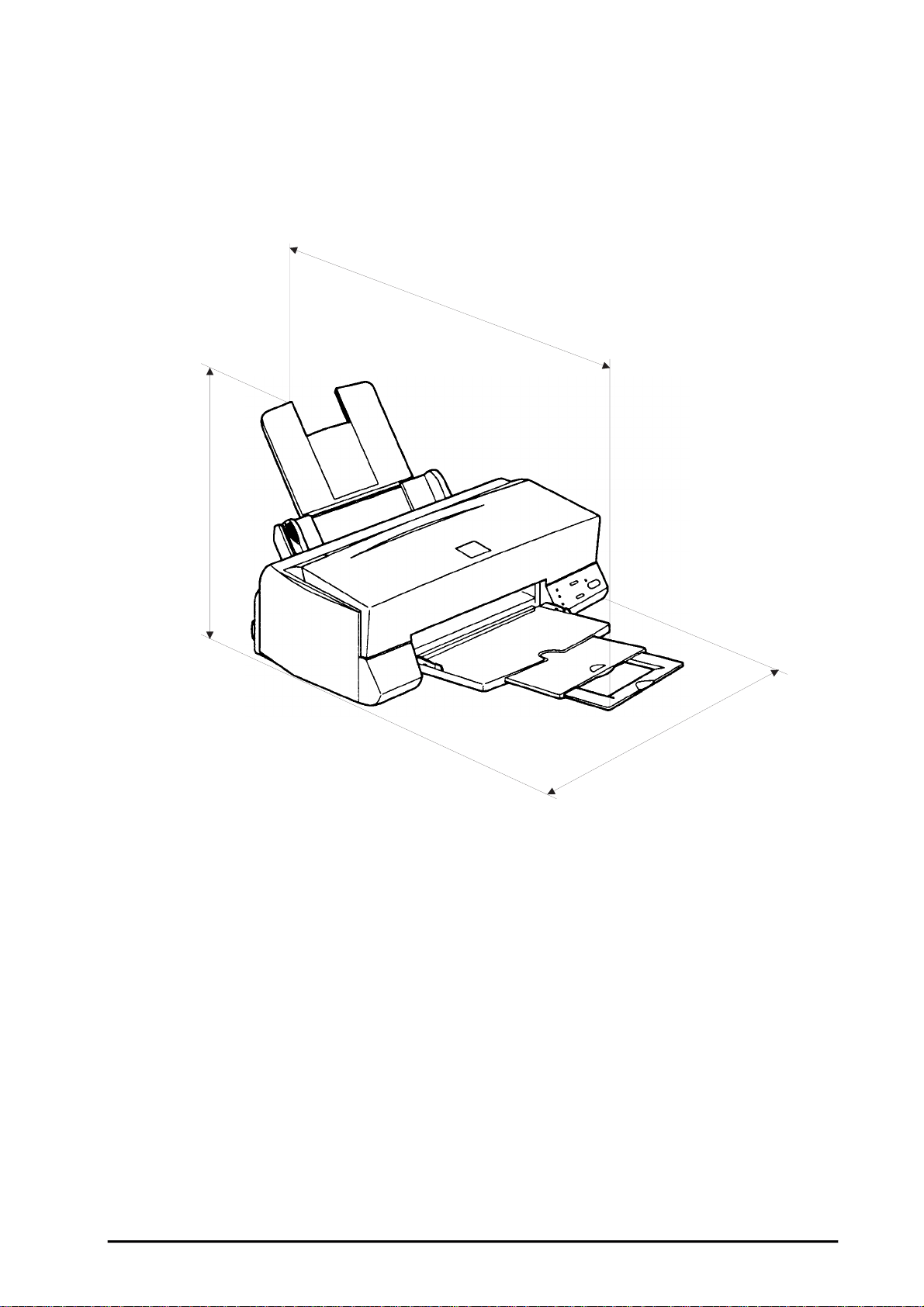

1.2.7 Physical Specification

[Dimension]

[Weight]

309mm

:429mm(W) x 234mm(D) x 162mm(H)

:429mm(W) x 695mm(D) x 309mm(H) with extended stacker and paper support.

:5.2Kg

695mm (Max)

Figure 1-8. Dimension

429mm

1-1

Rev. A

Page 20

3

1.2.8 Electric Specification

[120V] Version

[Rated voltage] :AC120V

[Input voltage range] :AC103.5 - 132V

[Rated frequency range] :50 - 60Hz

[Input frequency range] :49.5•`60.5Hz

[Rated current] :0.4A(Max. 0.5A)

[Power consumption] :Approx.15W(ISO/IEC 10561 Letter pattern)

[Insulation Resistance] :10M ohms min.(between AC line and chassis, DC500V)

[Dielectric strength] :AC1000 V rms. 1 minute or AC1200Vrms. 1 second

(Energy Star compliant)

(between AC line and chassis)

Chapter 1 Product Description

[220•`240V] Version

[Rated voltage] :AC220V - 240V

[Input voltage range] :AC198 - 264V

[Rated frequency range] :50 - 60Hz

[Input frequency range] :49.5 - 60.5Hz

[Rated current] :0.2 A(Max. 0.3A)

[Power consumption] :Approx.15W(ISO/IEC 10561 Letter pattern)

[Insulation Resistance] :10M ohms min.(between AC line and chassis, DC500V)

[Dielectric strength] :AC1500 V rms. 1 minute (between AC line and chassis)

1.2.9 Reliability

Total print volume :10,000 pages(A4, letter)

Print head life :2000 million dots/nozzle

1.2.10 Safety Approvals

[120V version]

Safety standard :UL1950 with D3

EMC :FCC part 15 subpart B class B

(Energy Star compliant)

:CSA22.2 No.950 with D3

:CSA C108.8 class B

[220•`240V]

Safety standard :EN 60950(VDE and NEMKO)

EMC :EN55022(CISPR Pub.22) class B

1.2.11 Acoustic Noise

Noise Level :Approx.45 dB(A) (According to ISO 7779)

1.2.12 CE Marking

[220-240V version]

Low voltage Directive 73/23/EEC :EN60950

EMC Directive 89/336/EEC :EN55022 Class B

:AS/NZS 3548 class B

:EN61000-3-2

:EN61000-3-3

:EN50082-1

:IEC801-2

:IEC801-3

:IEC801-4

Rev. A

1-1

Page 21

EPSON Stylus Color 600

4

1.2.13 Printer Language and Emulation

Printer Language :ESC/P2

:EPSON Remote

ESC/P control codes

General Operation:

Initialize Printer : ESC @

Unidirectional Printing : ESC U

CSF Mode Control : ESC EM

Paper feeding:

Form Feed : FF

Line Feed : LF

Line Spacing : ESC 0, ESC 2, ESC 3, ESC +

Carriage Return : CR

Page format:

Page Length :ESC (C, ESC C, ESC C0

Left / Right Margin :ESC Q, ESC1

Top / Bottom Margin :ESC (c, ESC N, ESC O

Printer position motion:

Horizontal Print Position :ESC $, ESC\

Vertical Print Position :ESC(V, ESC (v

Tab Horizontally :ESC D, HT

Tab Vertically :ESC B, VT

Advance paper :ESC J

Font Selection:

Typeface :ESC k, ESC x

Pitch and Point :ESC X

Pitch :ESC P, ESC M, ESC g, ESC p

Italic Font :ESC 4, ESC 5

Bold Font :ESC E, ESC F

Master Select :ESC!

Font enhancement:

Double-Width :ESC W, DC4, SO

Condensed :DC2, SI

Double-height :ESC w

Double-Strike :ESC G, ESC H

Super / Subscript :ESC T, ESC S

Underline :ESC-

Line / Score :ESC(-

Character Style :ESC q

Spacing:

Intercharacter Space :ESC Space

HMI :ESC c

Define Unit :ESC (U

Character handling:

Character Table :ESC t, ESC (t

International Character :ESC R

User-Defined Characters :ESC %, ESC &, ESC:

Upper Control Codes :ESC 6, ESC7

Print Data as Characters :ESC(^

1-1

Rev. A

Page 22

5

Bit image:

Bit Image :ESC*

Graphics:

Graphics Mode :ESC (G

Raster Graphics :ESC.

Microweave control :ESC (i

Dot size control :ESC (e

Horizontal Position :ESC (\

Printing Speed :ESC(s

Printing mode:

Printing mode :ESC (K

Color:

Printing Color :ESC r, ESC (r

EEPROM control

EEPROM control :ESC

Chapter 1 Product Description

Rev. A

1-1

Page 23

EPSON Stylus Color 600

6

1.3 Interface

This printer provides both parallel and serial interface as standard.

1.3.1 Parallel Interface (Forward Channel)

[Transmission mode]

[Synchronization]

[Handshaking]

[Signal level]

[Adaptable connector]

BUSY signal is set high before setting either/ERROR low or PE high and held high until all these signals

return to their inactive state.

BUSY signal is at high level in the following cases.

During data entry (see Data transmission timing)

When input data buffer is full

During -INIT signal is at low level or during hardware initialization

During printer error (See /ERROR signal)

When the parallel interface is not selected.

ERROR signal is at low level when the printer is in one of the following states.

Printer hardware error (fatal error)

Paper-out error

Paper-jam error

Ink-out error

:8 bit parallel, IEEE-1284 compatibility mode

:By /STROBE pulse

:BY BUSY and /ACKNLG signal

:TTL compatible level

:57-30360 (amphenol) or equivalent

PE signal is at high level during paper-out error.

Table 1-11 shows the signal and connector pin assignments for parallel interface(forward channel*1). In

case of these signals, twist pair line is used and returning side is connected to signal GND (*1). Forward

channel is the mode when the ordinary data such as print data is sent from the PC to the printer.

Table 1-11. Signal and Connector Pin Assignment for Parallel Interface

Pin No. Signal Name Return GND

pin

1 /STROBE 19 In The strobe pulse. Read-in of data is performed at

2-9 DATA0-7 20-27 In The DATA0 through DATA7 signals represent

10 /ACKNLG 28 Out This signal is a negative pulse indicating that the

11 BUSY 29 Out A high signal indicates that the printer cannot

12 PE 28 Out A high signal indicates paper-out error.

13 SLCT 28 Out Always at high level when the printer is powered

14 /AFXT 30 In Not used.

31 /INIT 30 In The falling edge of a negative pulse or a low

32 /ERROR 29 Out A low signal indicates printer error condition.

36 /SLIN 30 In Not used.

18 Logic H - Out Pulled up to +5V via 3.9K ohm resistor.

35 +5V - Out Pulled up to +5V via 3.3K ohm resistor.

17 Chassis GND - - Chassis GND.

16,33,19-30 GND - - Signal GND.

15,34 NC - - Not connected.

I/O Functional Description

the falling edge of this pulse.

data bits 0 to 7, respectively. Each signal is at

high level when data is logical 1 and low level

when data is logical 0.

printer can again accept data.

receive data.

on.

signal on this line causes the printer to initialize.

Minimum 50 us pulse is necessary.

Note) “I/O” refers to the direction of signal flow from the printer’s point of view.

1-1

Rev. A

Page 24

7

1.3.2 Parallel Interface (Reverse Channel)

[Transmission mode]

[Synchronization]

[Handshaking]

[Data transmission timing]

[Signal level]

[Adaptable connector]

[Extensibility request]

Note) The printer sends following device ID string when it is requested.

:IEEE-1284 nibble mode

:Refer to the IEEE-1284 specification

:Refer to the IEEE-1284 specification

:Refer to the IEEE-1284 specification

:IEEE-1284 level 1 device

:TTL compatible level

:57-30360 (amphenol) or equivalent

:The printer responds affirmatively when the extensibility request values

are 00H or 04H, that mean;

00H :Request Nibble Mode Reverse Channel Transfer.

04H :Request device ID; Return Data using Nibble Mode Rev Channel

Transfer.

Table 1-12. Device ID Description

Chapter 1 Product Description

•q

The table below shows pin assignment for reverse channel(*3). In these case of signals, twist pair line is

used and returning side is connected to Signal GND. (*3):Reverse channel is the mode that any data is

transferred from the printer to the PC.

Pin

No.

1 HostClk 19 In Host clock signal.

2-9 Data0-7 20-27 In The DATA0 through DATA7 signals represent data bits 0

10 PrtClk 28 Out Printer clock signal.

11 PtrBusy, Data Bit-3,7 29 Out Printer busy signal and reverse channel transfer data bit

12 AckDataReq, DataBit-2,6 28 Out Acknowledge data request signal and reverse channel

13 Xflag, DataBit-1,5 28 Out X-flag signal and reverse channel transfer data bit 1 or 5.

14 HostBusy 30 In Host busy signal.

31 /INIT 30 In Not used.

32 /DataAvail, DataBit-0,4 29 Out Data available signal and reverse channel transfer data

36 1284-Active 30 In 1284 active signal.

18 Logic-H - Out Pulled up to +5V via 3.9K ohm resister.

35 +5V - Out Pulled up to +5V via 3.3K ohm resister.

17 Chassis GND - - Chassis GND.

16,33

19-30

15, 34 NC - - Not connected.

[00H] denotes a hexadecimal value of zero. MDL value depends on the EEPROM setting.

MDL value depends on the EEPROM setting. Model name can be changed by

changing a certain address in the EEPROM.

Table 1-13. Pin Assignment for Reverse Channel

Signal Name Return

•r •q

00H

MFG EPSON Production Maker

CMD ESCPL2,BDC Command system

MDL Stylus[SP]Color[SP] 600 Model name

CLS PRINTER Class

GND pin

GND - - Signal GND.

•r

3CH

I/O Functional description

to7, respectively.

Each signal is at high level when data is logical 1 and

low level when data is logical 0. These signals are used

to transfer the 1284 extensibility request values to the

printer.

3 or 7.

transfer data bit 2 or 6.

bit 0 or 4.

Contents

Note) “I/O” refers to the direction of signal flow from the printer’s point of view.

Rev. A

1-1

Page 25

EPSON Stylus Color 600

8

Following lists “Notes” when using Parallel Interface.

“

Return GND pin” in the table means twist pair return and is used for all control signals except for

Logic H,+5V, Chassis, GND and NC. In this twist pair return, returning side is connected to

GND (16,33, 19-30 pin) for twist pair return. Also, these cables are shielded wires and it is

effective to connect to each chassis GND in the PC and printer for electrostatic noise.

Conditions for Interface are based on TTL level. Rise and fall time should be within 0.2ms.

Refer to the figure 1-9 for transmission timing of each signals.

Do not perform data transmission ignoring /ACK or BUSY signal. (Perform the data transmission

after confirming that /ACK and BUSY signals are Low.)

It is possible to perform the printing test including interface circuit without using equipment from

outside when 8-bit data signal(20-27 pin) is set to appropriate word code and connect them

forcefully to /ACK and /STRB.

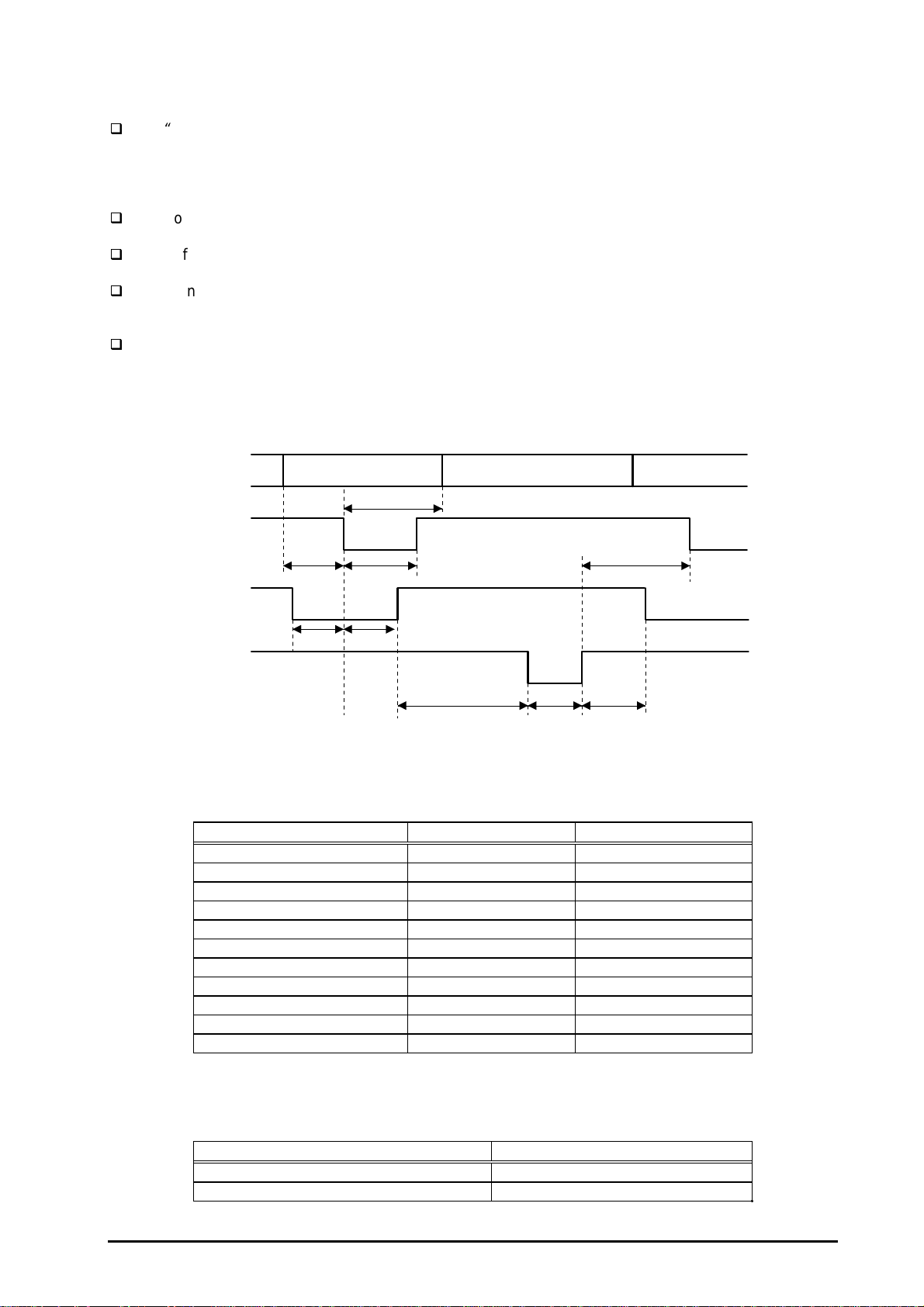

[Data Transmission Timing for Forward Channel]

Data

/STROBE

BUSY

/ACKNLG

Byte Data n Byte Data n+1

Thold

Tsetup

Tstrb

Tready Tbusy

Tnext

Treply

Tack Tnbusy

Figure 1-9. Parallel Interface Timing Chart(Forward Channel)

Table 1-14. Timing Parameters and Value

Parameter Minimum Maximum

tsetup 500ns ---

thold 500ns ---

tstb 500ns ---

tready 0 ---

tbusy --- 500ns

tt-out* --- 120ns

tt-in** --- 200ns

treply 0 ---

tack 500ns 10us

tnbusy 0 ---

tnext 0 ---

Note) *: Rise and fall time of every output signals.

**: Rise and fall time of every input signals.

Table 1-15. Typical Time of Tack

Parallel I/F mode Typical time of tack

High speed 2us

Normal speed 4us

1-1

Rev. A

Page 26

Chapter 1 Product Description

9

[Signal level: TTL compatible (IEEE-1284 level 1 device)]

Table 1-16. Signal Level

Parameter Minimum Maximum Condition

VOH* --- 5.5V

VOL* -0.5V ---

IOH* --- 0.32mA VOH = 2.4V

IOL* --- 12mA VOL = 0.4V

CO --- 50pF

VIH --- 2.0V

VIL 0.8V ---

IIH --- 0.32mA VIH = 2.0V

IIL --- 12mA VIL = 0.8V

CI --- 50pF

Note) *: A low logic level on the Logic H signal is 2.0V or less when the printer is

powered off and this signal is equal or exceeding 3.0V when the printer is

powered on. The receiver shall provide an impedance equivalent to

7.5K ohm to ground.

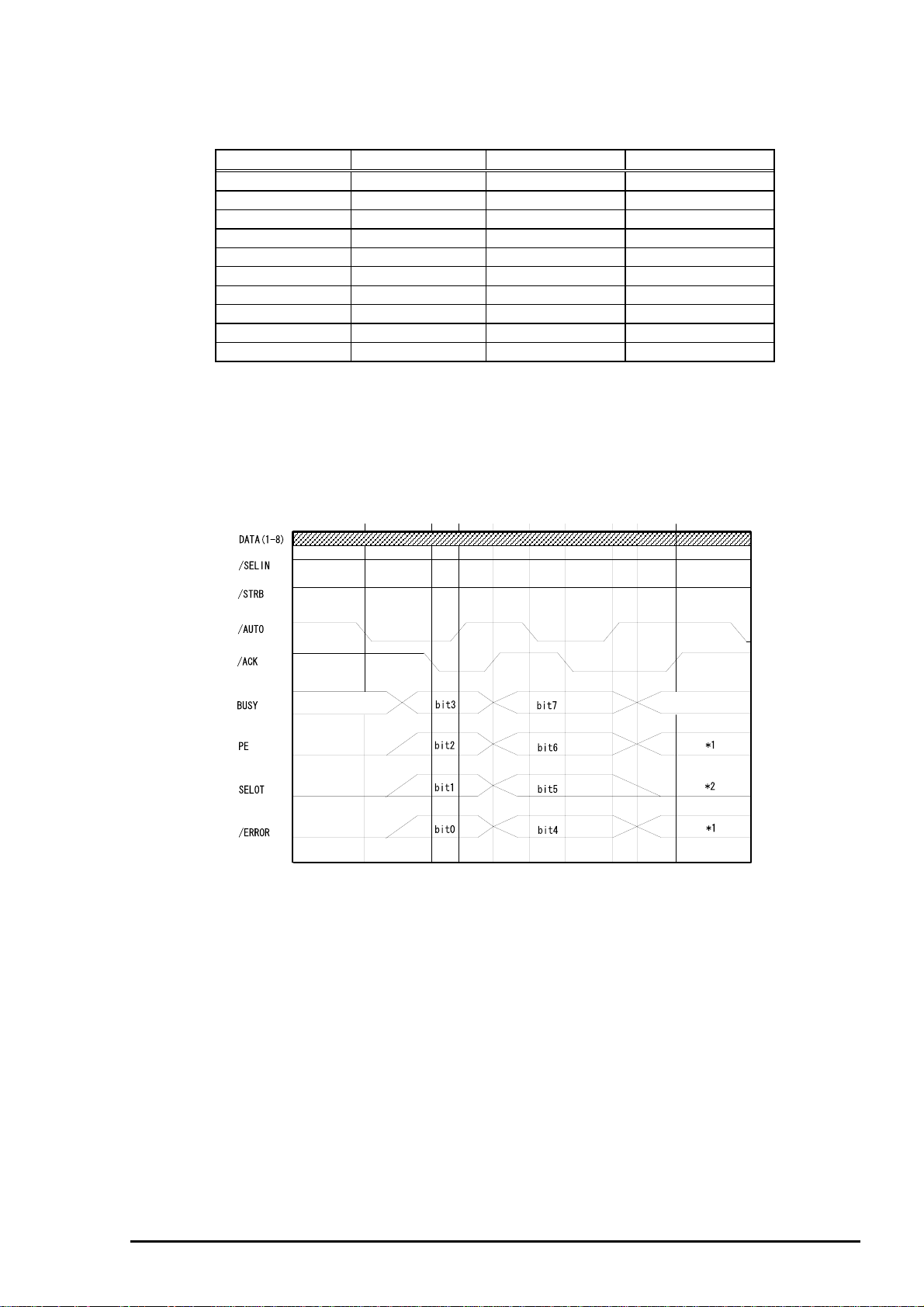

[Data Transmission Timing for Reverse Channel]

The figure below shows timing chart of Parallel Interface Reverse channel.

Virtual Busy Status

Virtual Busy Status

Figure 1-10. Parallel Interface Timing Chart(Reverse Channel)

1.3.2.1 Prevention Hosts from Data Transfer time-out

Generally, hosts abandon data transfer to peripherals when a peripheral is in the busy state for dozens of

seconds continuously. To prevent hosts this kind of time-out, the printer receives data very slowly,

several bytes per minute, even if the printer is in busy state. This showdown is started when the rest of

the input buffer becomes several hundreds of bytes. Finally, the printer is in the busy state continuously

when the input buffer is full.

Rev. A

1-1

Page 27

EPSON Stylus Color 600

0

1.3.3 Serial Interface

[Standard] :Based on RS-423

[Synchronization] :Synchronous

[Bit Rate] :Approx. 900Kbps

[Handshaking] :X-ON/X-OFF, DTR Protocol

[Word Format] :Data Bit = 8 bits

:Parity Bit = None

:Start Bit = 1 bit

:Stop Bit = 1 bit

[Connector] :8-pin mini-circular connector

[Recommended Cable] :Apple System Peripheral-8 Cable

(Part #: M0197)

Table 1-17. Pin Assignment

Pin No. Signal Name I/O Description

1 SCLK O Synchronous clock signal

2 CTS I Clear To Send

3 TXD- O Transmit Data (-)

4 SG I (Signal Ground)

5 RXD- I Receive Data (-)

6 TXD+ O Balanced Transmit Data (+)

7 DTR O Data Terminal Ready

8 RXD+ I Balanced Receive Data (+)

Table 1-18. X-ON/X-OFF and DTR Status

State Buffer Space X-ON/X-OFF DTR

Busy Less than 3072 bytes Send X-OFF code OFF

Ready More than 5120 bytes Send X-ON code ON

1-2

Rev. A

Page 28

Chapter 1 Product Description

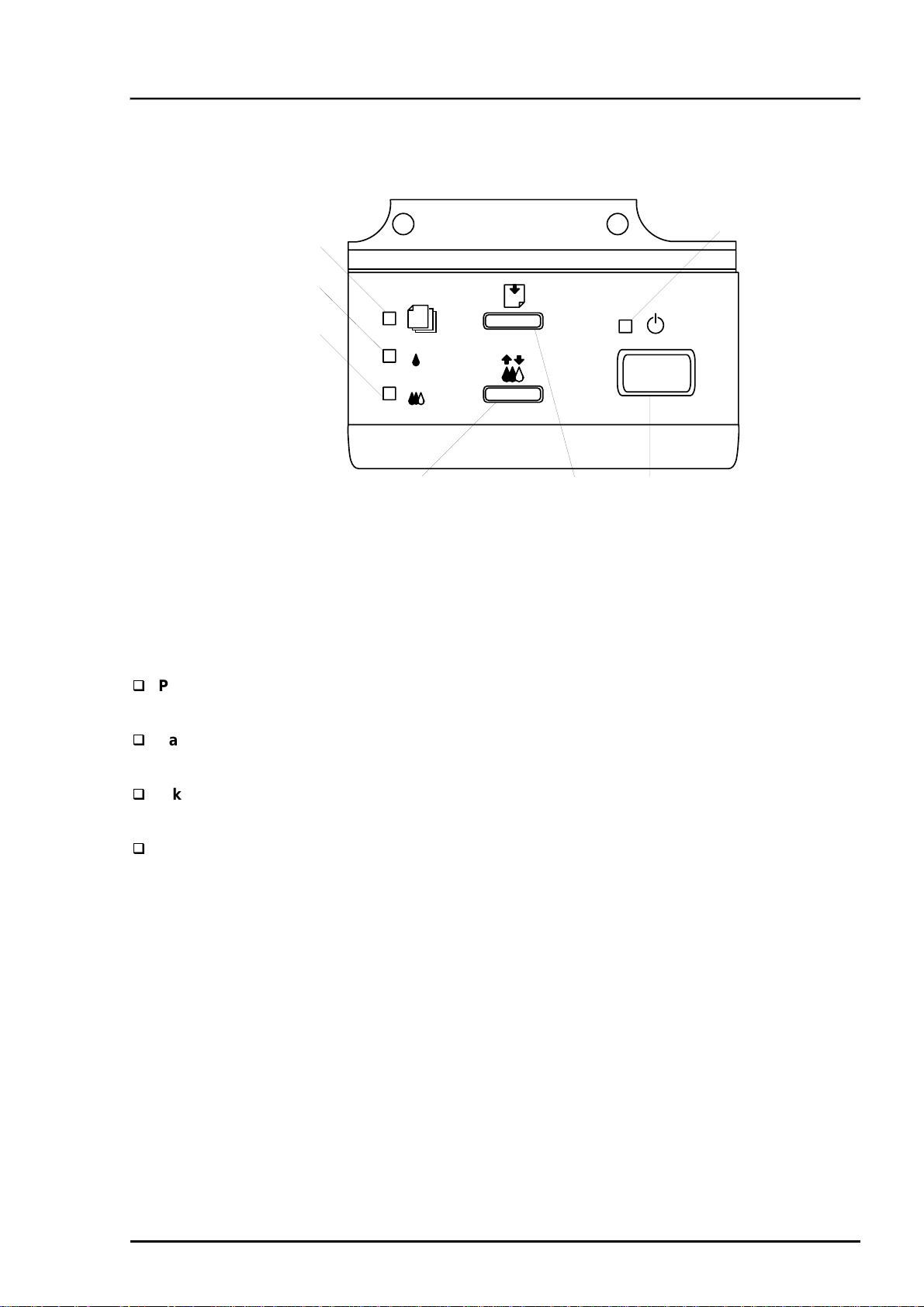

1.4 Control Panel

Since EPSON Stylus Color 600 does not require many buttons since printer driver can start various

settings and motions. Therefore, there are only 2 non-lock type push switches, 1 lock type push switch

and 4 LEDs.

Following figure shows control panel of EPSON Stylus Color 600.

Paper out LED

Ink out(Black)LED

Ink out(CMY)LED

1.4.1 Indicators

Cleaning Switch

(Ink maintenance)

Figure 1-11. Control Panel

Load/Eject switch

Power

Power switch

LED

Power

Lights when the operate switch is “ON”, and AC power is supplied.

Paper out

Lights during the paper-out condition, and blinks during the paper-jam condition.

Ink Out (Black)

Lights during no Black ink condition, and blinks during the Black ink low condition.

Ink Out (Color)

Lights during no Color ink condition, and blinks during the Color ink low condition.

Rev. A

1-21

Page 29

EPSON Stylus Color 600

2

1.4.2 Panel Functions

•q

Panel Functions

Switch Function

Load/Eject

(Pushing within 0.5 seconds*)

Load/Eject

(Pushing for 2 seconds*)

Cleaning

(Pushing for 2 seconds*)

Cleaning

(Pushing within 2 seconds*)

Note) *: 3 seconds is required at the User’s manual.

**: This function is not available in printing status.

***: The time to complete the sequence may vary depending on the printer’s status.

•r

Table 1-19. Panel Function

Loads or Eject the paper.

When the carriage is on the Ink Cartridge change position, return the

carriage from Ink Cartridge change position.

Starts the Ink Cartridge change sequence.**

Moves the carriage to cartridge change position.

Starts the Head Cleaning sequence. ***

In the condition of “Ink Low” or “Ink Out” or “No Ink Cartridge” starts

the Ink Cartridge change sequence.**

When carriage is on the Ink Cartridge change position, return carriage

from Ink Cartridge change position.

•q

Panel Functions with Power ON

Table 1-20. Panel Function with Power ON

Switch Function

Load/Eject

Cleaning

Load/Eject

+

Cleaning

•r

Starts status printings.**

Enter the Default Setting mode

Enters the particular settings mode. (Factory use only.)

To enter the particular settings mode, it is necessary to push

followings switch while Paper Out LED is blinking.(It blinks about 5

seconds)

Note) **: status printings prints firmware version, ink counter, selected code page and nozzle check

patterns.

•q

Particular setting mode

Switch Function

Load/Eject

•r

Table 1-21. Particular Setting Mode

Initialize EEPROM *** and reset Timer IC.

Note) ***: Refer to EEPROM map.

1-2

Rev. A

Page 30

Chapter 1 Product Description

3

By performing a particular setting mode, Maintenance error can be cleared and certain addresses of

EEPROM can also be reset.

[Step 1] Turn the printer on while holding down Load/Eject and Cleaning switches at the same time.

[Step 2] Push the Load/Eject switch while the Paper Out LED is blinking (5 seconds).

Following shows the lists that will be cleared by this performance.

Maintenance Error Clear

(By operating this performance, the Paper Out LED starts blinking.)

Clear the value of Ink Counter

Clear Time IC

Initialization of I/F selection (returns to AUTO)

WARNING

EPSON Stylus Color 600 does not have “EEPROM All Clear” function like other printers. If the

printer does not function well and falls into fatal error condition, replace the main board to see if

the problem is rectified. (Refer to Chapter 4 “Adjustment” when you replace the main board since

some adjustments will be necessary.)

Be sure to replace a waste ink pad in the printer enclosure with a new one after you perform

Maintenance error clear operation.

1.4.3 Printer Condition and Panel Status

The table below shows printer condition and panel status. Since this table shows various error status and

also present printer status, you can judge appropriate repair ways from this table.

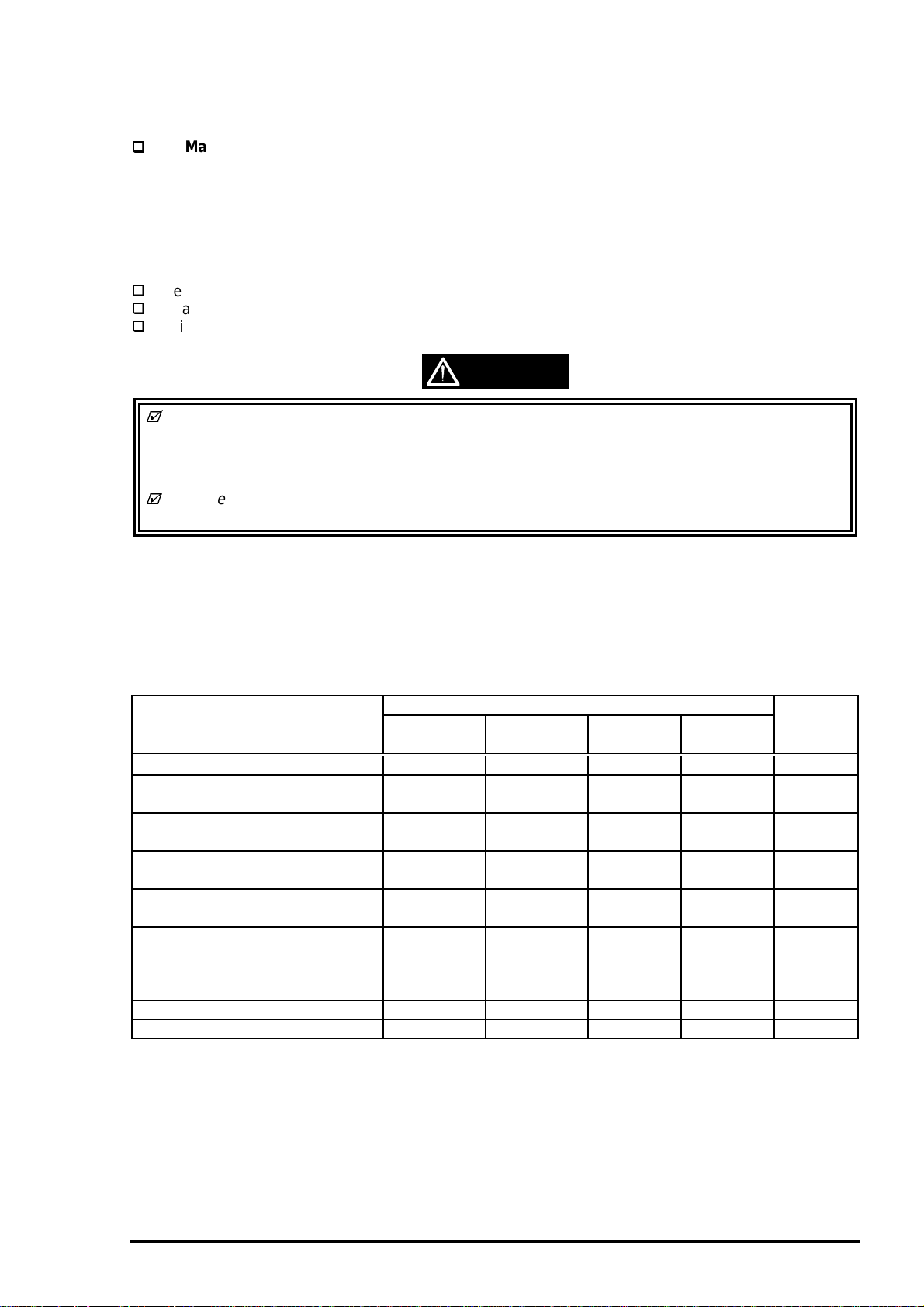

Table 1-22. Printer Condition and Panel Status

Printer status Indicators Priority

Power Ink Out

(Black)

Power on condition On --- --- --- 9

Ink sequence Blink --- --- --- 6

Ink Cartridge change mode Blink --- --- --- 5

Data processing Blink --- --- --- 8

Paper Out --- --- --- On 4

Paper jam condition --- Off Off Blink 3

No Ink cartridge or Ink end(black) --- On --- --- 7

Ink level low(black) --- Blink --- --- 7

No Ink cartridge or Ink end(color) --- --- On --- 7

Ink level low(color) --- --- Blink --- 7

Enter EEPROM and Timer IC reset --- On

(1 second

only)

Maintenance request Blink Blink Blink Blink 2

Fatal error Blink On On Blink 1

Ink Out

(Color)

On

(1 second

only)

Paper Out

On

(1 second

only)

--

Note) “—“ means no changes.

Rev. A

1-2

Page 31

EPSON Stylus Color 600

4

1.5 Error Status

When following status occur, the printer goes to the error status and stops taking data, setting the

/ERROR signal in the interface as “Low”, and Busy signal as “High”. At this time, the printer goes to non

printable status. Refer to section 1.4.2 for more details of LED Panel indicators during the various error

status.

1.5.1 Ink Out

When the printer runs out the most part of the ink of any one color, it warns ink-low and keeps printing.

When the printer runs out the whole ink of any one color, it stops printing and indicates ink-out error.

User is requested to install a new ink-cartridge in this state. An ink-cartridge once taken out should never

be used again. Re-installation of the cartridge not filled fully upsets the ink level detection and may

cause a serious problem in the print head as a result.

WARNING

Never use the ink cartridge once taken out from the printer.

Following explains the reason of the above warning.

After the cartridge is once taken out, airs come in from the ink supply hole located at the top of

cartridge and becomes bubbles, and they are absorbed into the head during printing performance.

Therefore, the head will be unable to discharge the ink properly. Also, inevitable entering of bubbles

when installing a new ink cartridge can be absorbed to ink itself since the ink itself in the cartridge is

deaerated during the production process. However, this absorbing ability can last only about one hour

after the cartridge is installed.

Even after the bubble absorbing ability described above stops, there is no worry about entering

bubbles as long as the ink cartridge is being installed to the printer. However, if the ink cartridge

which does not have absorbing ability any more is once removed from the printer, new coming

bubbles into the cartridge will never disappear naturally. These bubbles may cause not only printing

malfunction but also thickening ink. This thickened ink goes into the head and clogs ink path in the

head or nozzle and may cause serious head damage.

As standard specification for EPSON Stylus Color 600, ink consumption counter is reset when the ink

cartridge is removed. If an ink cartridge is removed and re-installed unnecessarily the value on the

ink consumption monitor which the user can check will be wrong and printer may keep printing

even though the ink cartridge is installed empty. This may cause head damage.

1.5.2 Paper Out

When printer fails to load a sheet after power on operation including timer-cleaning is done and

Load/Eject button on the FF command or operation panel is pressed, it goes paper out error.

1.5.3 Paper Jam

When printer fails to eject a sheet even after feeding motion is completed or Load/Eject button on the FF

command or operation panel is pressed, it goes paper jam error.

1-2

Rev. A

Page 32

5

1.5.4 No Ink-Cartridge Error

Following reasons can be the causes when printer goes this error mode.

Chapter 1 Product Description

according to the ink cartridge exchange operation.)

When the printer is turned on for the first time.

(This is a normal error state and it returns to the normal state after installing an ink cartridge

Ink cartridge exchange operation is done correctly. After the position of carriage is moved by

exchange operation, if the cleaning switch is pushed without installing ink cartridge or if the

carriage returns to the home-position automatically without doing any operation, it is considered

as

handling mistake. However, it returns to normal state by performing ink exchange operation again

and installing cartridge correctly.

If “No ink-cartridge error” appears even after the ink cartridge is installed, the printer must be

something wrong and around the sensor area in the carriage need to be repaired.

If sometimes printer can print normally but also sometimes “No ink-cartridge error” appears, the

printer must be something wrong. (Same reason as above)

1.5.5 Maintenance Request

When the total quantity of ink wasted through the cleanings and flushing reaches to the limit, printer

indicates this error and stops. The absorber in the printer enclosure is needed to be replaced with new

one by a service person. The ink quantity that is absorbed by the absorber (waste ink pad) is monitored

by the software counter as “total ink counter”. This counter is added by point system and absorber’s

maximum ability is set at the following reference value.

29500 X 0.012 ml = Approximately 301ml

However, considering dispersion of ink absorbing quantity and the number of using nozzles, ink total

value is calculated by the following formula.

1-point = 0.0102 ml (the value which is multiplied evaporating rate and 1-dot ink weight 0.02

ml)

29500 = Maximum point number (Maintenance error threshold)

301 X 1.1/63% = 526ml (but up to 532ml can be retained)

WARNING

When you perform self- test after completing repairs, it is possible to check the present value of total

ink counter and ink discharge conditions from all nozzles by performing status printing in the built-in

function. Therefore, make sure that the printer has enough value of total ink counter (if the number is

close to 29500 or not). If there is not enough value, the service man is required to judge if it is

necessary to clear EEPROM after replacing the absorber (waste ink pad) or not. Refer to section

1.3.1 if you need to perform EEPROM Clear.

1.5.6 Fatal Errors

When printer detects fatal errors such as carriage control error or CG access error, it goes to this error

mode. Refer to followings for each error.

Carriage control Error: Parallel adjustment malfunction, Home-position malfunction, Timing belt

tension malfunction, shortage of lubricant on the carriage guide shaft, etc.

CG Access Error: Short circuit, etc.

Rev. A

1-2

Page 33

EPSON Stylus Color 600

6

1.6 Printer Initialization

EPSON Stylus Color 600 has three kinds of initialization methods. Following explains each initialization.

Power-on initialization

This printer is initialized when turning the printer power on, or printer recognized the

cold-reset command (remote RS command). When printer is initialized, following action is

performed.

Initializes printer mechanism.

Clears input data buffer.

Clears print buffer.

Sets default values.

Operator initialization

This printer is initialized when turning the printer power on again within 10 seconds from last

power off, or printer recognize the /INIT signal (negative pulse) of parallel interface. When

the printer is initialized, following action is performed.

Cap the printer head.

Eject a paper.

Clears input data buffer.

Clears print buffer.

Sets default values.

Software initialization

The ESC@ command also initialize the printer. When printer is initialized, following action is

performed.

Clears print buffer.

Sets default values.

1.6.1 Initialization Settings

EPSON Stylus Color 600 initializes following settings when the initialization is performed. Also, if the

user changes the settings in the Panel setting, Default setting or Remote command setting, values or

settings which are possible to be stored are initialized as initialization settings.

Page position :Page heading location as present paper location

Line spacing :1/6 inch

Right margin position :80 lines

Left margin position :first line

Character pitch :10CPI

Printing mode :Text mode (Not Raster graphics mode)

1-2

Rev. A

Page 34

Chapter 1 Product Description

7

1.7 Main Components

EPSON Stylus Color 600 has following major units. Also, it is one of the major characteristics that the

bottom of the Printer mechanism plays the role as lower case at the same time.

Upper case

Printer Mechanism

C200 MAIN Board (Main control circuit board)

C206 PSB/PSE Board (Power supply circuit board)

C206 PNL Board (Control panel circuit board)

1.7.1 Printer Mechanism

Unlike EPSON’s previous ink jet printer mechanisms, one of the major characteristics of EPSON Stylus

Color 600 is that the printer has no Engage/Disengage mechanism in order to change over pump

mechanism and paper feeding mechanism. Instead, however, this change-over control is done by the

distinction between turning direction of PF motor and position of present carriage unit. Also, another

major characteristic is that print head is changed to be one unit combined with black and CMY. Nozzle

configuration for black is 64 nozzles (the nozzle pitch of each column is 90dpi and between two

consecutive nozzles in number (e.g. #1 and #2) is 180dpi). On the other hand, CMY nozzle has 32

nozzles (90dpi) for each color. Following figure shows exterior of mechanism.

CR Motor

Carriage

Rev. A

Control Panel

Hopper

(Exit paper tray)

PF Motor

*ASF is not shown in the above figure.

Figure 1-12. Exterior view of the Printer Mechanism

1-2

Page 35

EPSON Stylus Color 600

8

1.7.2 C200 MAIN Board

The C200 MAIN board controls whole mechanism operations and a data processing operation. Most of

the functions of the circuit are integrated into single ASIC; E05B43YA (IC2) and this makes the board

design very simple and reliable.

IC7

Printhead Driver

IC15

PF Motor Driver

IC14

CR Motor Driver

IC2

ASIC

(E05B43YA)

IC1

CPU

(TMP95C0618F)

IC5

DRAM(4MBit)

IC6

Mask ROM (CG)

Parallel I/F(CN1)

Serial I/F (CN2)

IC3

PROM(4MBit)

Lithium Battery

Figure 1-13. Exterior view of C200 Main Board

1-2

Rev. A

Page 36

Chapter 1 Product Description

9

1.7.3 C206 PSB/PSE Board

The C206 PSB/PSE board is a switching regulator type power supply unit and constantly supplies stable

logic and power voltages to the printer mechanism and the main control board. Also, since this C206

PSB/PSE board has the power switch in the secondly side of the circuit, it is possible to keep supplying

electricity to the C200 MAIN control board for 30 seconds even after the power switch is turned off. Using

this time difference, even when mis-operation is done by the user such as turning off the power during

the middle of printing work, it prevents unexpected trouble with the printhead from occurring, by

transferring the printhead to the cap position before complete shut down. The C206 PSB Board is for

AC100 - 120V input voltage and the C206 PSE Board is for AC220 - 240V input voltage.

FUSE (F1)

AC input (CN1)

Q1

FET (Switching)

Power line to

C200 MAIN/Mechanism

(CN2)

PC1

Photo-coupler

Figure 1-14. Exterior view of C206 PSB Power Supply Board

1.7.4 C206 PNL Board

The C206 PNL board is located in the panel case where is in the right bottom of the front of printer and

consists of 3 switches, 4 LEDs.

Figure 1-15. Exterior view of C206 PNL Board

Rev. A

1-2

Page 37

Chapter 2

Operating Principles

2.1 OVERVIEW............................................................................................................2-1

2.1.1 Printer Mechanism............................................................................................................ 2-1

2.1.1.1 Printing Mec hanism.............................................................................................. 2-2

2.1.1.1.1 Printing Process......................................................................................... 2-3

2.1.1.1.2 Printing Method......................................................................................... 2-4

2.1.1.2 Carriage Mechanism............................................................................................. 2-7

2.1.1.2.1 Platen Gap Adjust Mechanism and P ar allel adjustment M ec hanism..........2-10

2.1.1.3 Paper Feed M ec hanism and Pum p M ec hanism...................................................2-11

2.1.1.4 Ink System ..........................................................................................................2-14

2.1.1.4.1 P ump, Carriage Lock, Head Cleaner M ec hanism......................................2-15

2.1.1.4.2 Cap M ec hanism........................................................................................

2.2 Electrical Circuit Operating Principles.............................................................2-18

2.2.1 C206 PSB/PSE Pow er Board ...........................................................................................2-19

2.2.2 C200 Main Board..............................................................................................................2-21

2.2.2.1 Reset Circuits......................................................................................................2-23

2.2.2.2 Sensor Circuits....................................................................................................2-24

2.2.2.3 EEPROM Cont rol Circuit s....................................................................................2-25

2.2.2.4 Timer Circuit........................................................................................................2-26

2.2.2.5 DRA M Control .....................................................................................................2-26

2.2.2.6 Pri nt Head Control Circuit....................................................................................2-27

2.2.2.7 PF(Pump) Motor Drive Circuit .............................................................................2-30

2.2.2.8 CR Motor Drive Circuit ........................................................................................2-31

2-17

Page 38

Chapter2 Op erat ing Principles

2.1 OVERVIEW

This section describes Printer Mechanism , electric circuit board (C206 PSB, C200 Main, C206PNL

board) of Stylus Color 600.

2.1.1 Printer Mechanism

Unlike previous EPSON Ink Jet printers, printer m echanism of St ylus Color 600 does not have exclusive

mechanism to change over paper f eeding and Pumping operation. In stead, this cont r ol is done by the

turning di r ec tion of paper feed/pump motor and posi tion of c ar r iage at that time. Also, unlike previous print

heads, print head of this pri nter is became one unit com bined with black and CM Y head. Black head has

64 nozzles, 180 dpi( vert ical di r ec tion) and CMY head has 32 nozzles, 90 dpi (verti c al direct ion). Al so, si nc e

these print head i s driven by frequency 14. 4K Hz , this printer can print double resoluti on( 1440 dpi/100-dpi)

than Styl us Col or. Following f igure2-1 shows outline of printer mechanism .

Since the head driv e frequency of Stylus Color was 7.2KHz, it c ould be only 720-dpi printing when it

driven by 100 cps carriage speed. It perf or ms two-pass carriage operati on when Sty lus Color 600

performs the 1440 dpi pri nting towards the horiz ontal line.

Carriage Unit

(Prinr Head Unit)

Platen Drive Mechanism

Paper Pickup Mechanism

Pump Drive Mechanism

Timing Belt

Paper Pick Up

Trigger Lever

Pumping Position

Paper Feed Motor

Carriage Motor

Figure 2-1. Stylus Color 600 Printer Mechan ism Block Diag ram

As major printer m ec hanisms in the figure 2-1, there are four maj or mechanism s as they are listed below.

1) Printing mechanism 2) Carri age unit 3) Paper pick up mechanism 4) Pump drive m ec hanism

Rev. A

2-1

Page 39

EPSON Stylus Color 600

2

2.1.1.1 Printing Mechanism

Basic principles of the print head which plays major r ole of printing mechanism is the same as previous

models; on demand type MACH head method, but there is some difference in the resolution. (Refer to

figure1-1) Also, unlike Stylus Color II, Stylus 820 and Stylus Color 200 autom atic correc tion type, in order to

fix the dispersion of mufti layer piezo electri c element whic h is used for drivi ng eac h noz z les, it is necessary

to input t he V H val ue wri tten on the side of print head by usi ng exclusive program when you replace print

head, control boar d, or the printer mechanism.(However, there are no resistor array for deci de the VH

voltage on the m ain control boar d.) Following explains print head.

PZT

Cavity Set

Nozzle Pl ate

Filter

PZT is an abbreviation of P iezo Electric Element. P r int signal from C200 boar d is sent through

the driver board on the pr int head unit and to the PZT. Then, the PZT pushes the top cavity

which has ink stored, and make the ink discharge from each nozzl e located on the nozz le

plate.

Ink which is absorbed f r om ink car tridge go through the fi lter and will be stored temporarily in

this tank, whic h is called “c avi ty” until PZT is driven.

The board with nozzle holes on the printer head surface is called Nozzle Plate.

When the ink cart r idge is instal led, if any dirt or dust around the cart r idge needles are

absorbed into the head i nsi de, there is a great possibility of causing nozzle clog and

disturbance of ink flow and fi nally causing alignm ent fai lure and dot-missing. In order to

prevent this, filter is set at cart r idge needle below and ink is once fi ltered here.

PZT

Nozzle Plate

Printhead driver board

Ink Cartridge Sensor

Actuator

Cartridge needle

(Ink Cartridge)

Filter

Ink Supply Tube

Cavity set

Figure 2-2. Print Head Sectional Drawing

2-

Rev. A

Page 40

Chapter2 Op erat ing Principles

3

2.1.1.1.1 Printing Process

Following figures i ndicate the sectional drawing of normal state and eject ing state of pr int head.

(1) Normal Stat e:

When the print signal is not output , PTZ al so does not move in the waiti ng state(normal state).

PZT

Cavity

Ink Course

Nozzle

Figure 2-3. Print Head Normal State

(2) Ejecting State:

When the print signal is output from the C200 main boar d, IC(IR2C72C and IR2C73C:Nozzle

Selector) located on the print head unit latches the data once by 1- by te unit. A ppr opr iate PZT latched

by nozzle selector is pushed in to the c avi ty by applying common voltage f r om the C200 m ain

board. By this operation, ink that i s stored in the cavity pops out from noz z les.

Nozzle Plate

Rev. A

Figure 2-4. Print Head Ejecting State

2-

Page 41

EPSON Stylus Color 600

4

2.1.1.1.2 Printing Method

This section explains printing method of ac tual printing such as printing text at var ious resolution

select/printing mode and graphics printing. In or der to prev ent white or color banding which are peculiar

problem of ink- jet, new Micr o- Weave functions are added to the previ ous Micro-W eave function. The

number of nozzles and printing mode ac c or ding to the selected resolution ar e used separately by a user.

The table below shows relati on between selected resoluti on and pr inting mode.

1) Full Overlap Micro-Weave

2) Part Line Overl ap M icro-Weave

3) Micro-Weave: (same as previous control )

Table 2-1. Resolution and Printing mode

Vertical

direction

[dpi]

Printing

mode

Paper feed

pitch

[inch]

Forward

Overlap-

Nozzle

Non

Overlap-

Nozzle

Backward

Overlap-

Nozzle

Not used

Nozzle

360 FOL M/W 15/360

M/W 31/360 ---

720 FOL M/W 15/720

POL M/W 29/720

Note1:

M/W m eans Micro-W eave.

Note2:

Note3:

Note4:

Following explai ns operat ion outlines of new Micro-Weave functions listed above.

[1. Full Overlap Micro-Weave]

In order to print one li ne at horizontal direct ion, thi s printing method is designed to complete a pr inting

pattern by two-pass carriage oper ation with two di fferent types of dot. When t his two diff er ent types of dot

pass one same line twice, it does not print the same dot t wic e.

FOL means Full Overl ap M icro-Weave.

POL means Part line Overl ap M icro- Weave

Forward Overlap-Nozzle and backward Overlap -Nozz le are described i n the [1.Full Overlap

Mirco-Weave] and [2.Par t line O verlap Micro-Weave] below.

The nozzles whose confi gur ation com pletely match to the black and CMY noz z le are used.

(Usually Micro-W eave ty pe)

Therefor e, all nozz les in case of CMY noz z le and #1•`#63 nozzles in t he B 2 line in c ase of

black head are i ts objects. (B1 line is not used at Micro-Weave. Refer t o figure1-1 for detail of

nozzle configuration.)

Out of these 4 color nozzl e objects, the number of all nozzles which are going to be used are

dividedequally into 2 groups.

Paper feeding will be done as many as each number of nozzles which are div ided into t wo

groups and the same number of dots.(for example, if t her e ar e two 10-nozzle groups during

360-dpi printing at l ongitudinal direction, paper feeding of 10/360-inch becomes available. )

At this time, two groups perform M icro-Weave individually and particular lines are passed by

two diff er ent nozzles.

#16•`#30

#16•`#30

#30•`#32 #4•`#29 #1•`#3

.

---

#1•`#31

---

#1•`#15 #31•`#32

--- #32

#1•`#15 #31•`#32

---

Note1)

2-

These nozzles which are divi ded into two groups must be set and di vi ded in order to

be a pair of odd and even number.

Rev. A

Page 42

5

Note2)

Chapter2 Op erat ing Principles

Two groups which are divided acc or ding to each elements will be divided either even dot or

odd dot when particul ar lines(level directi on line) are formed and eventually, these lines will be

completed at selected resol ution. Following is a conceptual f igure when full ov er lap mi c r o-

weave orm s a part icular line.

Nozzle No.#9

Condition: 360-dpi printing

Nozzle: Total 10 nozzle/each color

Nozzle No.#4

Particular line(Completed line)

Figure 2-5. Full Overlap Micro - Weave

Note 3) The way firm ware decides which nozzle becomes even dot or odd dot is determ ined

as it is described below.

If t he line which i s about to be printed is even l ine:

First dot pr ints odd dot lines and 2nd dot prints even dot lines.

If t he line which i s about to be printed is odd line:

1st dot prints even dot l ines and 2nd dot prints odd dot lines. Eventual ly, horizontal resolution

will be the same resolution as selected one.

[2.Part Line Overlap Micro-Weave]

This print ing method is to perfor m Micr o- Weave printing, overlappi ng a par t of nozzles which are

used for printing. As a result , a part of r aster whic h is overlapped consists of differ ent browse with

different nozzl es. The fi gur e below shows 1-line Over lap at 5-dot sending as an example wi th

explanat ion on the next page.

360-dpi

Pass1

#1

#2

#3

#4

#5

#6

2

Note1: The paper feed pitch is 5/360-dpi in this figure.

Note2: Mark of and mean overlap nozzle.

3

4

5

6

Raster 1

Raster 10

7

8

9

10

11

Figure 2-6. Part line Overlap Micro - Weave

Rev. A

2-

Page 43

EPSON Stylus Color 600

6

1) Overlap Nozzle : Head driv e frequency is driven half of the ordinal one like 2)

below.

2) Nozzle other than Overlap nozzle : Head dr iv e frequency is twice as much as overlap nozzle.

Usually, the fir mware changes over automatically these full over lap Micro- Weave, Part line Overl ap

Micro-Weave, and ordinal Micro-weave accordi ng to the selection of resolution. Also, when these three

printi ng modes are perfor med by the St y lus Color 600, the pr inter performs top and bot tom m ar gin

process in order to contr ol the overprint ing v olume as little as possible.

The difference between Ful l-Overlap Micro-W eave and Part line O verlap Micro-Weave are

following;

Full-Overlap Mi cro-Weave:

Printing is perfor med, judging if nozzles are even or odd dot by 2 differ ent dots with all

different rasters.

Part line Overlap M icro-Weave:

After par ticular noz z les(only#1, and #6 in the figure2-7) are deter mined as overlap nozzles,

even or odd dot will be determined like Full-overlap Micro-Weave does.

(Forward Overlap Nozzle is determined as ev en and bac k ward nozzle is odd.)

Also, nozzl es other than particular nozzles can print at even and odd dot j ust by one

nozzle.

2-

Rev. A

Page 44

Chapter2 Op erat ing Principles

7

2.1.1.2 Carriage Mechanism

Carriage m ec hanism is to driv e the carriage wit h pr int head mounted from left to ri ght or v ice versa.

The carriage dr iv e motor i n this printer is a 4-phase, 200-pole, stepping motor and is driven by

1-2phase, 2-2phase and W1- 2phase drive method. T his stepping mot or allows the carriage to

move freely to the particular posi tions which is necessary for various operation, such as paper feeding,

ink absorbing, flashing, ink ex c hange and c leaning operations. The tabl es bel ow shows carriage motor

specifications and m otor control s at eac h mode.

Table 2-2. Carriage Motor Speci f ication

Item Descriptio n

Motor type 4-phase/200-pole Stepping motor

Drive v oltage Range

Internal c oil resistance

Driv ing speed(frequency) range[csp(pps)]

Control method Bi-Pol a Dr iv e

Table 2-3. Motor Control at Each Mode

Mode Driving speed

[CSP]

High speed skip 340 4080 W1-2, 2-2,1-2phase

Printing(Normal) 200 2400 W 1- 2phase drive

Printing(SLQ) 100 1200 W1- 2phase drive

Capping 80 960 W1-2phase drive

Wiping 40 480 W1-2phase drive

Cap(valv e r elease) 20 240 W1-2phase drive

Withdrawal of cap 5 60 W1-2phase dri ve

42VDC •} 5%

7.8 ohms•}10%(per phase under

25••environment)

5(60)•`340(4080)

Drive

frequency

[PPS]

Drive method

drive*

*Note 1):

• Acceleration 1 m ode •¨ • Acceleration 2 mode •¨ • Decelerat ion 1 mode •¨ • Deceleration 2 mode

The reason why plural drive methods exist is that following some sequences described below

exist in the each mode and stable carriage oper ation and printing are performed individually

by different dri ve methods. This drive method is especially necessary for high speed skip.

A

/A

C200 MAIN Board

Rotor

Connecter CN6(CN7)

B

/B

Figure 2-7.CR(PF/Pump) Motor Internal Block Diagram

Rev. A

2-

Page 45

EPSON Stylus Color 600

8

The table below shows W1- 2 phase drive sequence at eac h steps when the rotor of carriage motor

makes one rotation. In the S tylus Color 600, in addition to a func tion that pr inting is performed with W1-2

drive phase, high speed skip m ode whic h is a function to skip over the blank from the end of the print ing

data to the next data starting point wit h high seed can be also perfor med by 2-2 and 1-2 phase drive.

W1- 2 phase requires 4 tim es as muc h steps as 2-2 phase drive, calculating 2-2 phase as standard.

By using this method, it becomes possible to suppl y c onstant stable torque t o the motor. As a result, it

also became di ffi c ult to be i nfluenced by vi br ation f r om the pri nter mechanism during printing.

Table 2-4. Moto r Drive Sequence( W1-2 phase drive)

Sequence

Number

Phase a 10a l1a Current

0010+2/3010+2/3

1001+1/3000+1

2X110000+1

3101-1/3000+1

4110-2/3010+2/3

5100-1X01+1/3

6100-11110

7100-1101-1/3