Page 1

Chapter 2

Operating Principles

2.1 OVERVIEW...............................................................................................................1

2.1.1 Printer Mechanism .................................................................................................................... 1

2.1.1.1 Printing Mechanism...................................................................................................... 2

2.1.1.1.1 Printing Process................................................................................................3

2.1.1.1.2 Printing Method.................................................................................................4

2.1.1.2 Carriage Mechanism .................................................................................................... 7

2.1.1.2.1 Paper Gap Adjust Mechanism ........................................................................ 10

2.1.1.3 Paper Feed Mechanism and Pump Mechanism.........................................................11

2.1.1.4 Ink System.................................................................................................................. 14

2.1.1.4.1 Pump Mechanism ........................................................................................... 15

2.1.1.4.2 Cap Mechanism.............................................................................................. 17

2.2 Electrical Circuit Operating Principles................................................................18

2.2.1 C206 PSB/PSE Power Supply Board ..................................................................................... 19

2.2.2 C206 MAIN Board..................................................................................................................... 21

2.2.2.1 Reset Circuits............................................................................................................. 23

2.2.2.2 Sensor Circuits........................................................................................................... 24

2.2.2.3 EEPROM Control Circuits .......................................................................................... 25

2.2.2.4 Timer Circuit............................................................................................................... 26

2.2.2.5 DRAM Control ............................................................................................................ 26

2.2.2.6 Print Head Control Circuit........................................................................................... 27

2.2.2.7 PF (Pump) Motor Drive Circuit ................................................................................... 30

2.2.2.8 CR Motor Drive Circuit ............................................................................................... 31

Page 2

Chapter2 Operating Principles

2.1 OVERVIEW

This section describes Printer Mechanism, electric circuit board (C206 PSB/PSE, C206 Main, C206PNL

board) of Stylus Color 400.

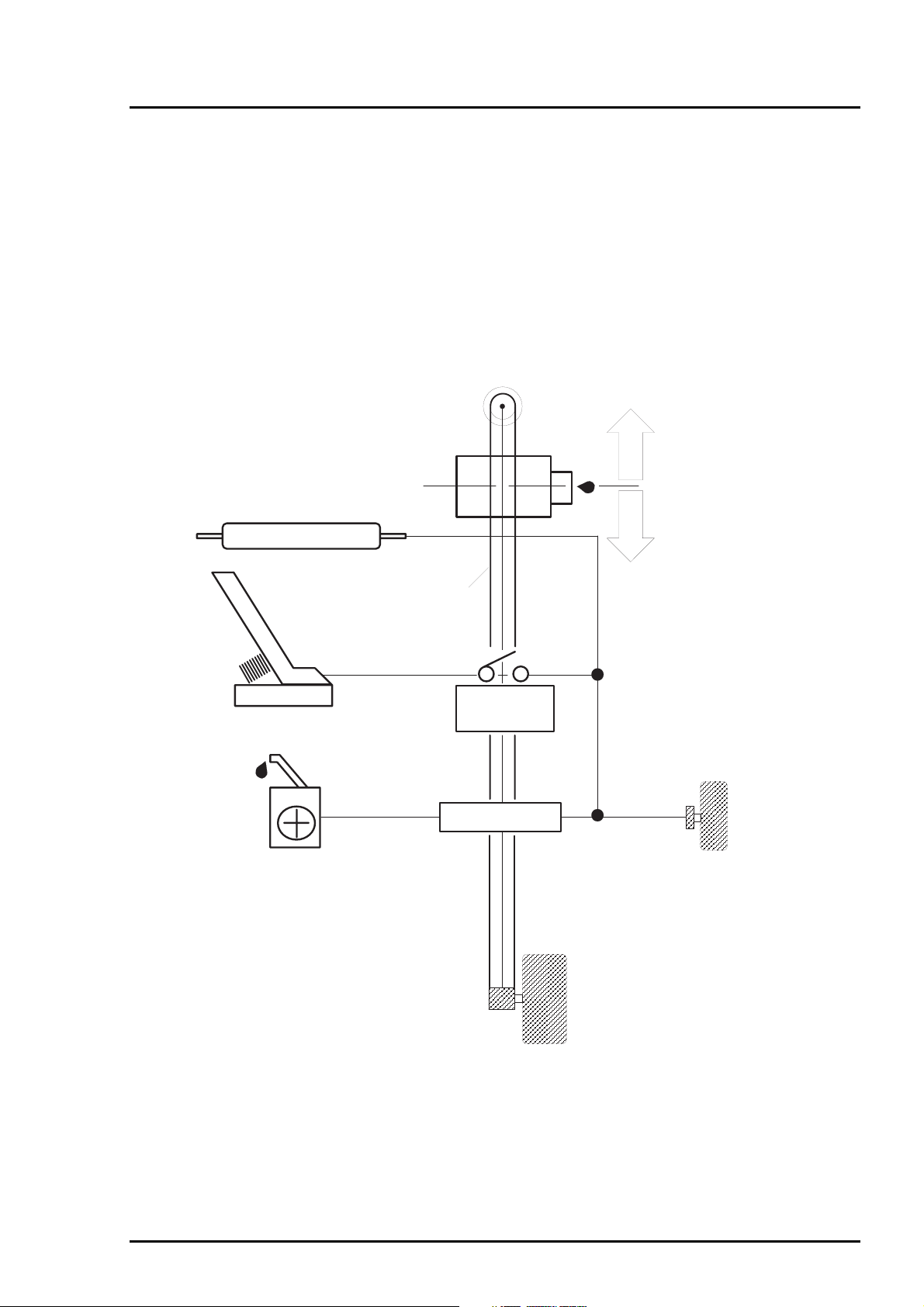

2.1.1 Printer Mechanism

Unlike previous EPSON Ink Jet printers, printer mechanism of Stylus Color 400 does not have exclusive

mechanism to change over paper feeding and Pumping operation. In stead, this control is done by the

turning direction of paper feed/pump motor and position of carriage at that time. Also, unlike previous print

heads, print head of this printer became one unit combined with black and CMY head. Black head has

64 nozzles, 180 dpi(vertical direction) and CMY head has 21 nozzles, 90 dpi (vertical direction). Also,

since these print head is driven by frequency 14.4Khz, this printer can print double resolution(1440

dpi/100-dpi) than Stylus Color. Following figure2-1 shows outline of printer mechanism.

Carriage Unit

(Prinr Head Unit)

Platen Drive Mechanism

Paper Pickup Mechanism

Pump Drive Mechanism

Timing Belt

Paper Pick Up

Trigger Lever

Pumping Position

Paper Feed Motor

Rev.A

Carriage Motor

Figure 2-1. Stylus Color 400 Printer Mechanism Block Diagram

2-1

Page 3

EPSON Stylus Color 400 Service Manual

2

As major printer mechanisms in the figure 2-1, there are four major mechanisms as they are listed below.

1) Printing mechanism 2) Carriage unit 3) Paper pick up mechanism4) Pump drive mechanism

2.1.1.1 Printing Mechanism

Basic principles of the print head which plays major role of printing mechanism is the same as previous

models; on demand type MACH head method, but there is some difference in the resolution. (Refer to

figure1-1) Also, unlike Stylus Color IIs, 820, 200 automatic correction type, in order to fix the dispersion of

mufti layer piezo electric element which is used for driving each nozzles, it is necessary to input the VH

value written on the side of print head by using exclusive program when you replace print head, control

board, or the printer mechanism.(However, there are no resistor array to decide the VH voltage on the

main control board.) Following explains print head.

PZT

PZT is an abbreviation of Piezo Electric Element. Print signal from C206 board is sent through the

driver board on the print head unit and to the PZT . Then, the PZT pushes the top cavity which has

ink stored, and make the ink discharge from each nozzle located on the nozzle plate.

Cavity Set

Ink which is absorbed from ink cartridge go through the filter and will be stored temporarily in this

tank, which is called “cavity” until PZT is driven.

Nozzle Plate

The board with nozzle holes on the printer head surface is called Nozzle Plate.

Filter

When the ink cartridge is installed, if any dirt or dust around the cartridge needles are

absorbed into the head inside, there is a great possibility of causing nozzle clog and

disturbance of ink flow and finally causing alignment failure and dot-missing. In order to

prevent this, filter is set at cartridge needle below and ink is once filtered here.

Printhead driver board

Ink Cartridge Sensor

Actuator

Cartridge needle

(Ink Cartridge)

PZT

Ink Supply Tube

Cavity set

Nozzle Plate

Figure 2-2. Print Head Sectional Drawing

2-

Filter

Rev.A

Page 4

Chapter2 Operating Principles

3

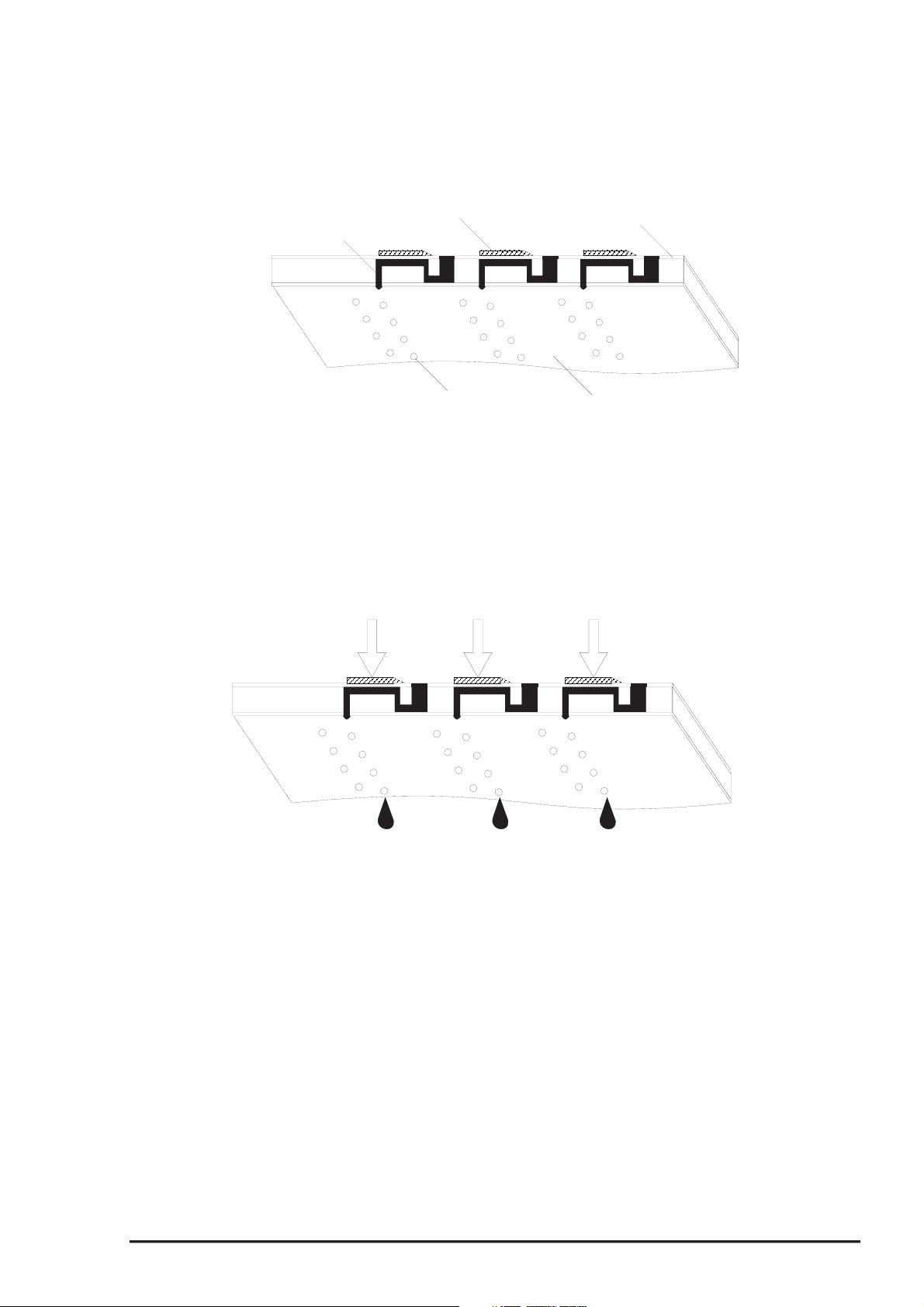

2.1.1.1.1 Printing Process

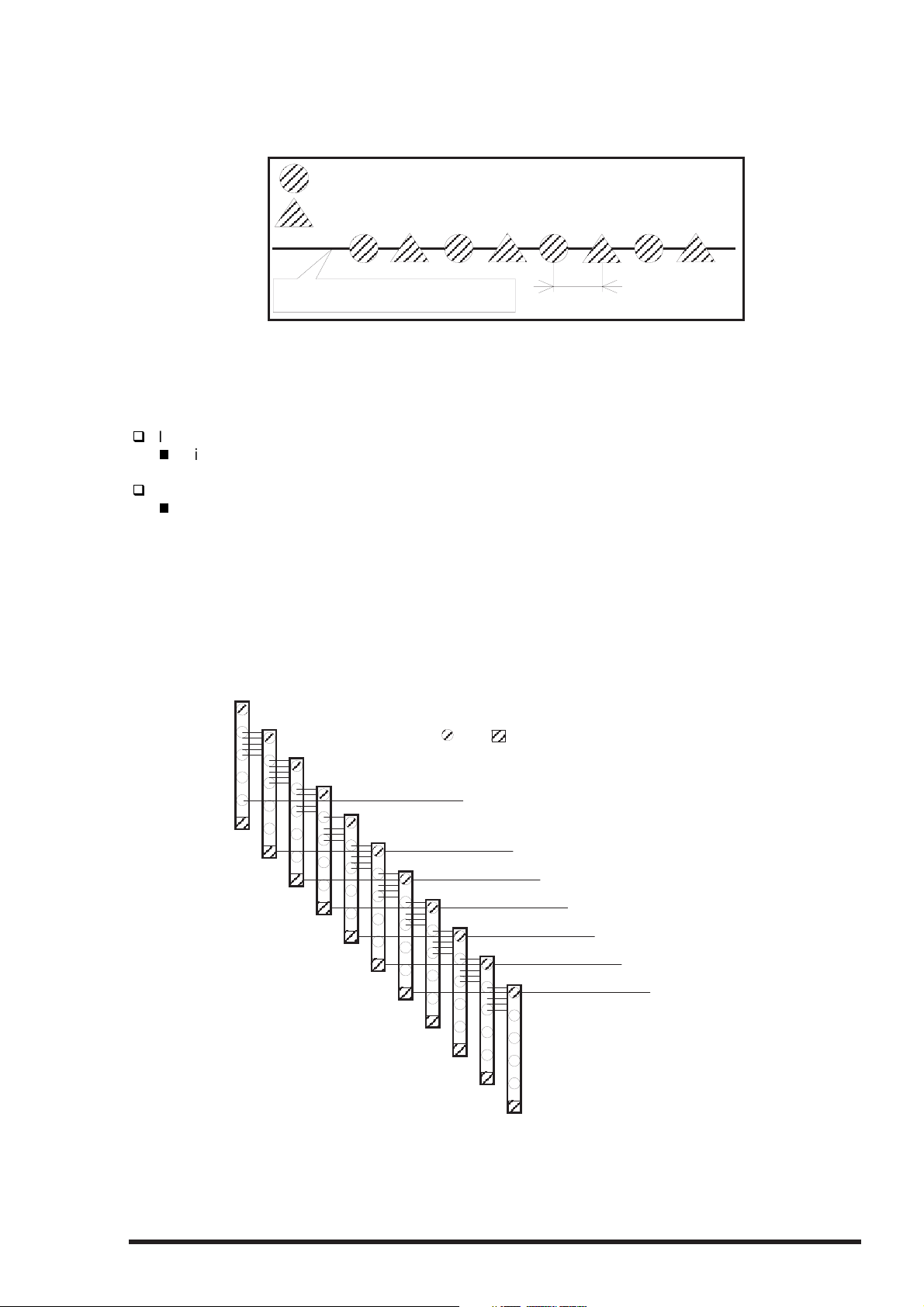

Following figures indicate the sectional drawing of normal state and ejecting state of the print head.

(1) Normal State:

When the print signal is not output, PTZ also does not move in the waiting state(normal state).

PZT

Cavity

Ink Course

Nozzle

Figure 2-3. Print Head Normal State

(2) Ejecting State:

When the print signal is output from the C206 main board, IC(IR2C72C:Nozzle Selector) located

on the Print head unit latches the data once by 1-byte unit. Appropriate PZT latched by nozzle

selector is pushed into the cavity by applying common voltage from the C206 main board.

By this operation, ink that is stored in the cavity pops out from nozzles.

Nozzle Plate

Figure 2-4. Print Head Ejecting State

Rev.A

2-

Page 5

EPSON Stylus Color 400 Service Manual

4

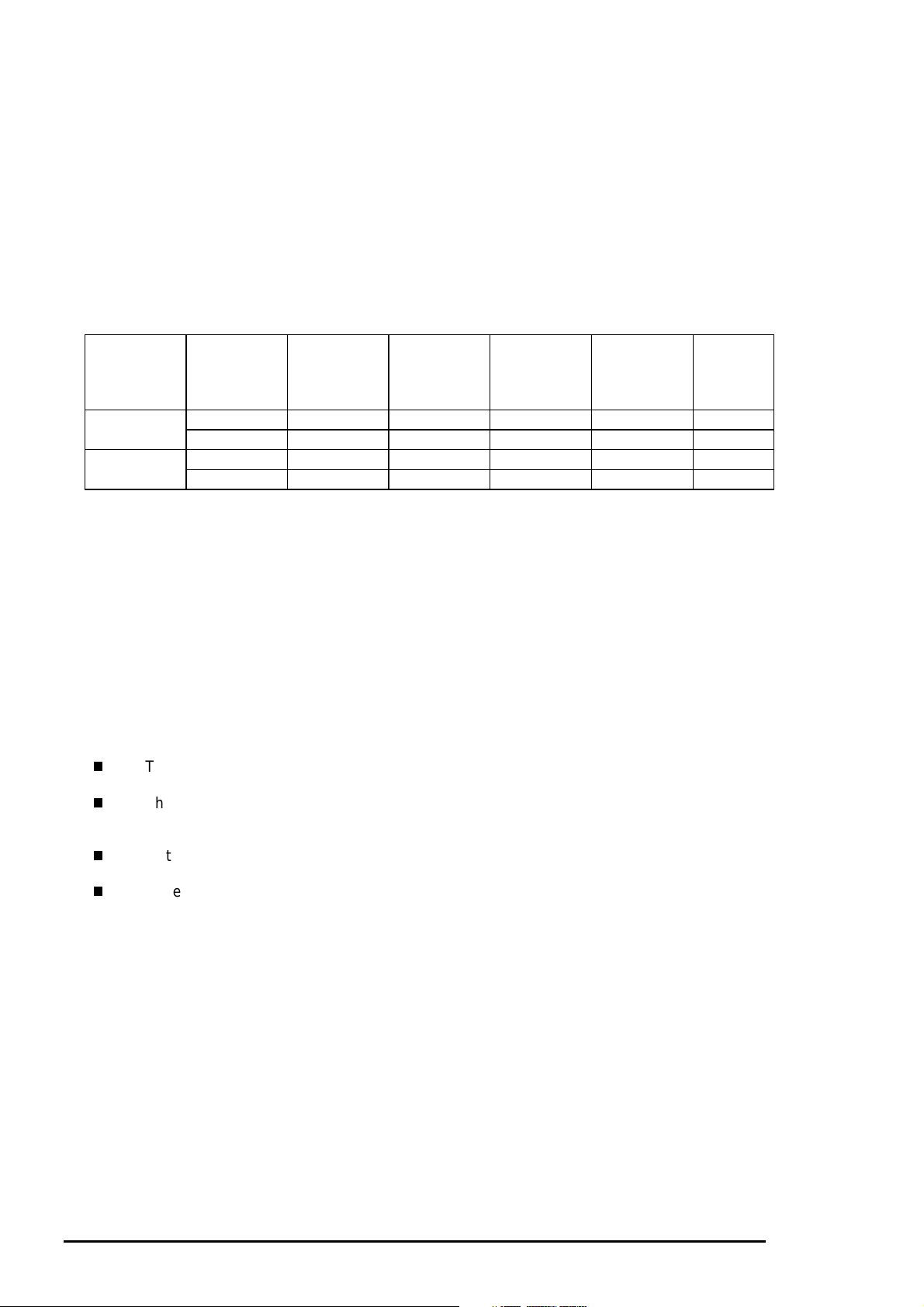

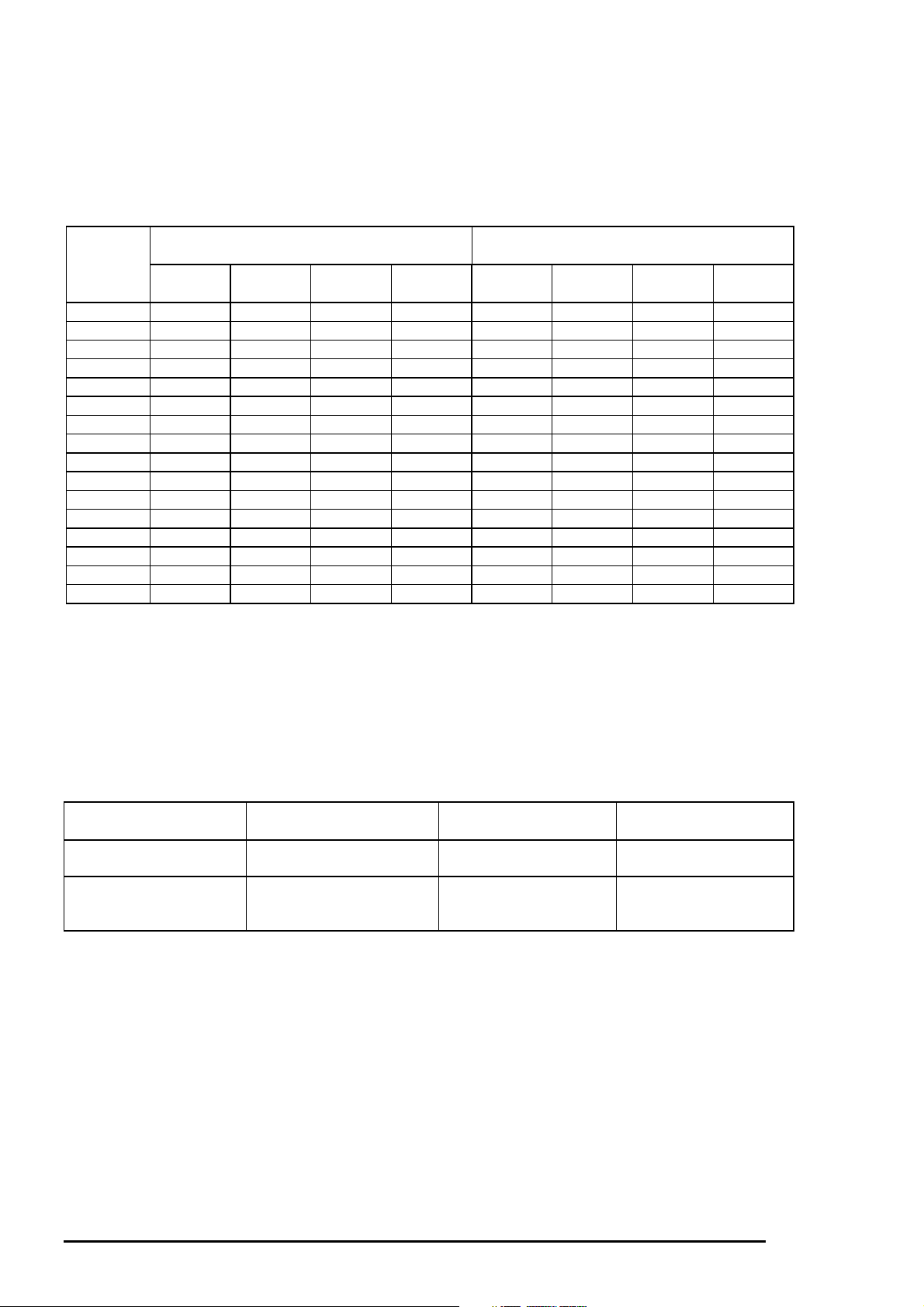

2.1.1.1.2 Printing Method

This section explains printing method of actual printing such as printing text at various resolution

select/printing mode and graphics printing. In order to prevent white or color banding which are peculiar

problem of ink-jet, new Micro-Weave functions are added to the previous Micro-Weave function.

The number of nozzles and printing mode according to the selected resolution are used separately by a

user. The table below shows relation between selected resolution and printing mode.

1) Full Overlap Micro-Weave

2) Part Line Overlap Micro-Weave

3) Micro-Weave: (same as previous control)

Table 2-1. Resolution and Printing mode

Vertical

direction

[dpi]

Printing

mode

Paper feed

pitch

[inch]

Forward

Overlap-

Nozzle

Non

Overlap-

Nozzle

Backward

Overlap-

Nozzle

Not used

Nozzle

360 FOL M/W 15/360

M/W 31/360 ---

720 FOL M/W 15/720

POL M/W 29/720

Note1:

M/W means Micro-Weave.

Note2:

Note3: POL means Part line Overlap Micro- Weave.

Note4:

Following explains operation outlines of new Micro-Weave functions listed above.

[1. Full Overlap Micro-Weave]

In order to print one line at horizontal direction, this printing method is designed to complete a printing

pattern by two-pass carriage operation with two different types of dot. When this two different types of dot

pass one same line twice, it does not print the same dot twice.

FOL means Full Overlap Micro-Weave.

Forward Overlap-Nozzle and backward Overlap -Nozzle are described in the [1.Full Overlap

Mirco-Weave] and [2.Part line Overlap Micro-Weave] below.

The nozzles whose configuration completely match to the black and CMY nozzle are used.

(Usually Micro-Weave type)

Therefore, all nozzles in case of CMY nozzle and #1∼#63 nozzles in the B2 line in case of

black head are its objects. (B1 line is not used at Micro-Weave. Refer to figure1-1 for detail of

nozzle configuration.)

Out of these 4 color nozzle objects, the number of all nozzles which are going to be used are

divided equally into 2 groups.

Paper feeding will be done as many as each number of nozzles which are divided into two

groups and the same number of dots.(for example, if there are two 10-nozzle groups during

360-dpi printing at longitudinal direction, paper feeding of 10/360-inch becomes available.)

At this time, two groups perform Micro-Weave individually and particular lines are passed by

two different nozzles.

#16∼#30

#16∼#30

#30∼#32 #4∼#29 #1∼#3

---

#1∼#31

---

#1∼#15 #31∼#32

--- #32

#1∼#15 #31∼#32

---

Note1)

2-

These nozzles which are divided into two groups must be set and divided in order to

be a pair of odd and even number.

Rev.A

Page 6

Chapter2 Operating Principles

5

Note2)

Two groups which are divided according to each elements will be divided either even dot or

odd dot when particular lines(level direction line) are formed and eventually, these lines will be

completed at selected resolution. Following is a conceptual figure when full overlap microweave orms a particular line.

Nozzle No.#9

Condition: 360-dpi printing

Nozzle: Total 10 nozzle/each color

Nozzle No.#4

Particular line(Completed line)

Figure 2-5. Full Overlap Micro-Weave

Note 3)

If the line which is about to be printed is even line:

If the line which is about to be printed is odd line:

[2.Part Line Overlap Micro-Weave]

This printing method is to perform Micro-Weave printing, overlapping a part of nozzles which are

used for printing. As a result, a part of raster which is overlapped consists of different browse with

different nozzles. The figure below shows 1-line Overlap at 5-dot sending as an example with

explanation on the next page.

The way firmware decides which nozzle becomes even dot or odd dot is determined

as it is described below.

First dot prints odd dot lines and 2nd dot prints even dot lines.

1st dot prints even dot lines and 2nd dot prints odd dot lines. Eventually, horizontal resolution

will be the same resolution as selected one.

360-dpi

Pass1

#1

#2

#3

#4

#5

#6

2

Note1: The paper feed pitch is 5/360-dpi in this figure.

Note2: Mark of and mean overlap nozzle.

3

4

5

6

Raster 1

Raster 10

7

8

9

10

11

Figure 2-6. Part line Overlap Micro-Weave

Rev.A

2-

Page 7

EPSON Stylus Color 400 Service Manual

6

The difference between Full-Overlap Micro-Weave and Part line Overlap Micro-Weave are following;

Full-Overlap Micro-Weave:

Printing is performed, judging if nozzles are even or odd dot by 2 different dots with all

different rasters.

Part line Overlap Micro-Weave:

After particular nozzles(only#1, and #6 in the figure2-7) are determined as overlap nozzles,

even or odd dot will be determined like Full-overlap Micro-Weave does.

(Forward Overlap Nozzle is determined as even and backward nozzle is odd.)

Also, nozzles other than particular nozzles can print at even and odd dot just by one

nozzle.

1) Overlap Nozzle : Head drive frequency is driven half of the ordinal one like 2)

below.

2) Nozzle other than Overlap nozzle : Head drive frequency is twice as much as overlap nozzle.

Usually, the firmware changes over automatically these full overlap Micro-Weave, Part line Overlap

Micro-Weave, and ordinal Micro-weave according to the selection of resolution. Also, when these three

printing modes are performed by the Stylus Color 400, the printer performs top and bottom margin

process in order to control the overprinting volume as little as possible.

2-

Rev.A

Page 8

Chapter2 Operating Principles

7

2.1.1.2 Carriage Mechanism

Carriage mechanism is to drive the carriage with print head mounted from left to right or vice versa.

The carriage drive motor in this printer is a 4-phase, 200-pole, stepping motor and is driven by

1-2phase, 2-2phase and W1-2phase drive method. This stepping motor allows the carriage to

move freely to the particular positions which is necessary for various operation, such as paper feeding,

ink absorbing, flashing, ink exchange and cleaning operations. The tables below shows carriage motor

specifications and motor controls at each mode.

Table 2-2. Carriage Motor Specification

Item Description

Motor type 4-phase/200-pole Stepping motor

Drive voltage Range

Internal coi l resistance

Driving speed(frequency) range[csp(pps)]

Control method Bi-Pola Drive

Table 2-3. Motor Control at Each Mode

Mode Driving speed

[CSP]

High speed skip 340 4080 W1-2, 2-2,1-2phase drive*

Printing(Normal) 200 2400 W1-2phase drive

Printing(SLQ) 100 1200 W1-2phase drive

Capping 80 960 W1-2phase drive

Wiping 40 480 W1-2phase drive

Cap(valve release) 20 240 W1-2phase drive

Withdrawal of cap 5 60 W1-2phase drive

42VDC ± 5%

7.8 Ohms ± 10%(per phase under 25 °C

environment)

5(60)∼340(4080)

Drive frequency

[PPS]

Drive method

*Note 1):

Acceleration 1 mode → Acceleration 2 mode → Deceleration 1 mode → Deceleration 2 mode

The reason why plural drive methods exist is that following some sequences described below

exist in the each mode and stable carriage operation and printing are performed individually

by different drive methods. This drive method is especially necessary for high speed skip.

A

/A

C206 MAIN Board

Rotor

Connecter CN6

B

/B

Figure 2-7. CR(PF) Motor Internal Block Diagram

Rev.A

2-

Page 9

EPSON Stylus Color 400 Service Manual

8

The table below shows W1-2 phase drive sequence at each steps when the rotor of carriage motor

makes one rotation. In the Stylus Color 400, in addition to a function that printing is performed with W1-2

drive phase, high speed skip mode which is a function to skip over the blank from the end of the printing

data to the next data starting point with high seed can be also performed by 2-2 and 1-2 phase drive.

W1-2 phase requires 4 times as much steps as 2-2 phase drive, calculating 2-2 phase as standard.

By using this method, it becomes possible to supply constant stable torque to the motor. As a result, it

also became difficult to be influenced by vibration from the printer mechanism during printing.

Table 2-4. Motor Drive Sequence(W1-2 phase drive)

Sequence

Number

Phase a 10a l1a Current

0010+2/3010+2/3

1001+1/3000+1

2X110000+1

3101-1/3000+1

4110-2/3010+2/3

5100-1X01+1/3

6100-11110

7100-1101-1/3

8110-2/3110-2/3

9101-1/3100-1

10X110100-1

11001+1/3100-1

12010+2/3110-2/3

13000+1101-1/3

14000+1X110

15000+1001+2/3

Phase A Phase B

Phase b 10b l1b Current

Duty

Duty

This W1-2 phase drive (or 2W1-2 phase drive) is called Micro-step and is attached with so called

2/3 • Vref or 1/3 • Vref factor, compared with drive current value (Vref100%) which is supplied at 2-2phase

drive. This Micro-Step allows the rotor to have delicate rotation. In the 2-2 phase drive method, it is usually

required to take 4-step sequence in order to rotate the rotor once. However, in case of W1-2 phase, it is

required to take 16-step sequence(in the table 2-4, sequence 0∼15) which is 4 times more than 2-2 phase

method to do that. Also, in case of 2W1-2 phase drive which can be seen in the Stylus Color etc., it takes

2-step to rotate the rotor once. The table below shows relation of rotation direction of rotor and carriage

proceeding direction.

Table 2-5. Relationship Between Rotor Direction and Carriage Operation

Carriage proceeding

direction

HP→80 column direction

80 column→HP direction

Rotation direction of

Rotor

Looking from rotor output

side, clockwise direction

Looking from rotor output

side, counterclockwise

direction

Drive method Proceeding order of

sequence

2-2, 1-2, W1-2 phase

2-2, 1-2, W1-2 phase

Sequence No.0→15

Sequence No.15→0

2-

Rev.A

Page 10

Chapter2 Operating Principles

9

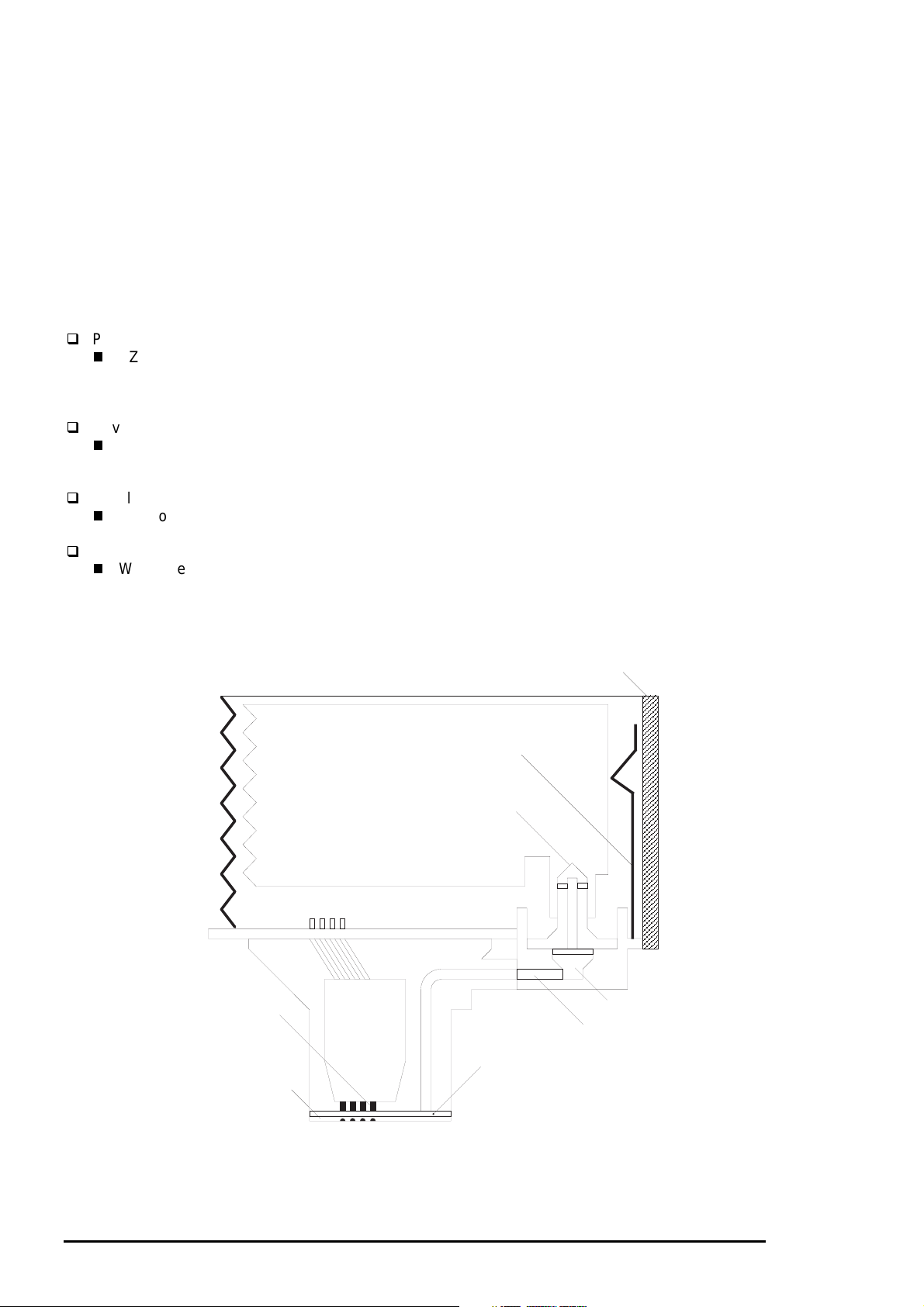

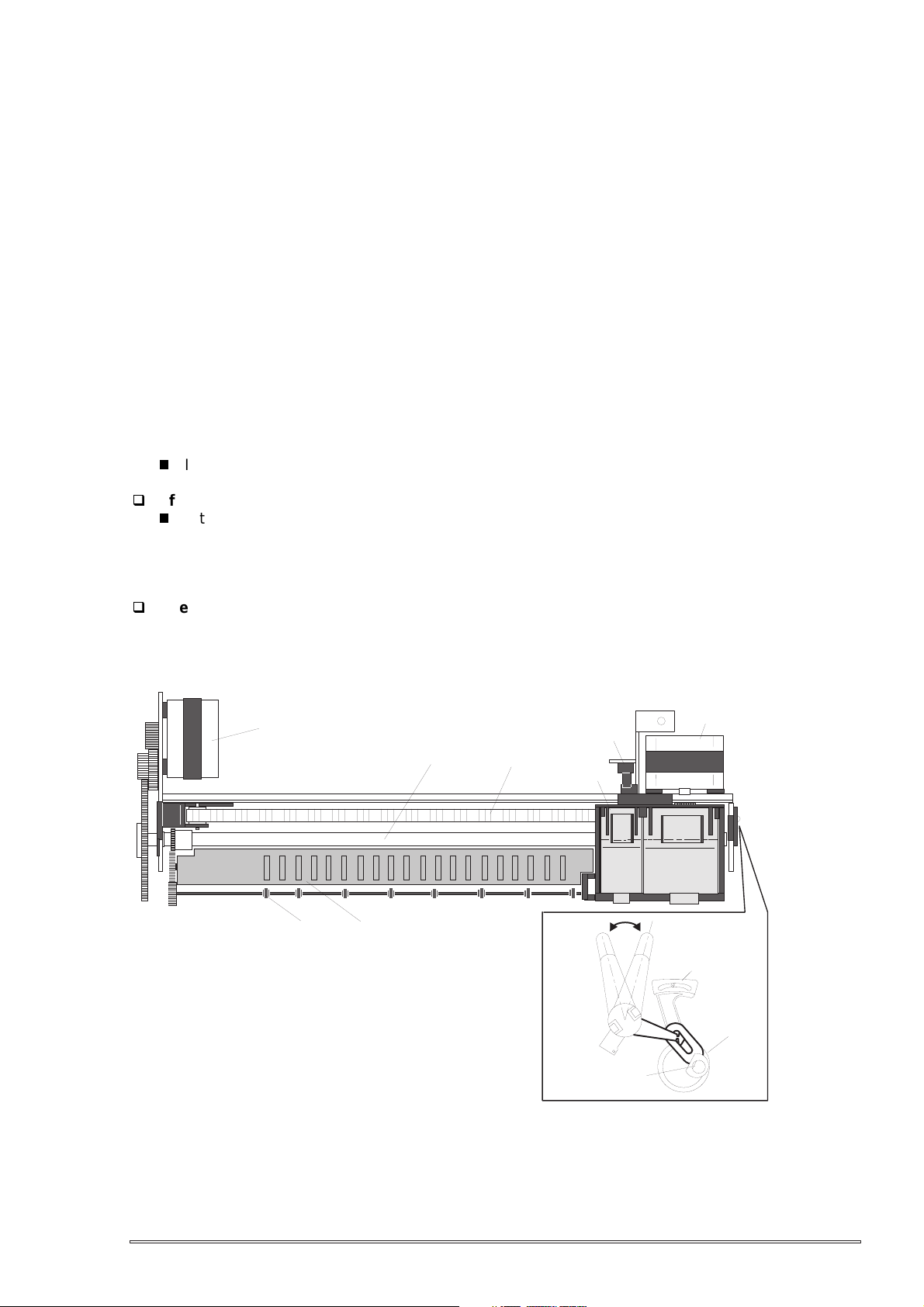

The figure below shows the carriage mechanism. The print head as a core of the printing mechanism is

stored in the carriage unit. This print head keeps the tilt of print head in flexible and adjustable structure by

moving the adjustment lever up and down by the tilt adjustment mechanism. (Refer to chapter 4 for more

details) Also, parallelism adjustment lever is mounted on the left and right side of carriage guide shaft and

it adjusts parallelism degree between platen and shaft when this shaft is installed to the printer

mechanism.

After this adjustment is completed and operate PG adjustment lever, it becomes possible to change the

space between the platen surface and the print head surface into 2 phases; either 1.1mm to 1.8mm. It is

possible to vary the space between platen surface and print head by rotating the axis of carriage guide

shaft which itself is decentralized, with the operation of PG lever. This is the mechanism that user can

adjust the appropriate PG value by himself according to the paper thickness or any other environmental

conditions such as paper curl.

Carriage lock mechanism is to prevent the carriage from being left at uncap position for a long time

because of vibration during the printer transport or mishandling by the users. If the carriage is left at uncap

position and uncap state of the print head for long time, an ink on the print head surface gradually

becomes viscosity. As a result, the nozzle will be unable to discharge an ink. To make matters worse, the

holes(crater) of nozzle may be completely clogged by the viscosity ink and it may not be able to return to

the normal condition just by cleaning operation. In order to prevent this, printer goes to carriage lock state

at the following conditions.

After Power OFF operation:

If the power is turned off on the way of printing or any other performance, carriage lock will be

performed in the end after completing initialize operation.

After power ON operation:

After power is turned on and automatic P-On Cleaning is performed, then carriage lock will be

performed. P-On Cleaning is an automatic head cleaning that is performed when the power is

turned on. The timer IC always calculates printer’s power OFF time by the power of lithium battery

mounted on the C206 main board. P-on cleaning function automatically selects the cleaning level

according to the time which the printer is not in used.

After Eject the paper:

After Load/Eject button is pressed and the paper is ejected, if the data is not input, the printer

performs carriage lock and goes to standby state. However, if the paper is loaded to the printer

inside by Load/Eject button, the printer does not perform carriage lock operation.

Paper Feed Motor

Eject Roller

Paper guide(Front)

Carriage home position Sensor

PF Roller

Timing Belt

Carriage Unit

Front Side

Figure 2-8. Carriage Mechanism Top (Viewing)

Carriage Motor

Rear Side

Parallelism

Adjust Lever

Fixing Bush

Carriage

Guide Shaft

Rev.A

2-

Page 11

EPSON Stylus Color 400 Service Manual

0

2.1.1.2.1 Paper Gap Adjust Mechanism

This mechanism can be set by the users and can prevent various problems related to low image density

or print with any dirt by changing the positions of PG lever according to the paper types.

Table 2-6. Platen Gap Adjust Lever Setting

Paper Lever position PG adjustment value

Normal paper,

Coated paper

Envelopes Rear 0.9mm

It is a major premise that parallel adjustment is done correctly for the space between head and platen

(PG adjustment value above) which can be changed by platen gap adjustment.

Parallel adjustment should be done when the serviceman mounts the carriage guide shaft on the printer

mechanism during the production process or repair service. In the adjustment, the space between

parallel adjustment lever and gage should be 1.04 mm.

Front 0 mm

(1.1mm between head and platen)

(2.0mm between head and platen)

2-1

Rev.A

Page 12

Chapter2 Operating Principles

2.1.1.3 Paper Feed Mechanism and Pump Mechanism

Mechanisms that send the paper in the hopper to inside the printer and perform constant paper

feed in order to perform printing on the sent paper are called paper feed mechanism as generic name.

In the Stylus Color 400, 4-phase, 200-pole hybrid type pulse motor is used in the PF motor as a motive

power of the paper mechanism and driving is done at 2-2 and 1-2 phase drive method. This motor is

not only used as a power source for paper feed mechanism but also used as power source of pump

mechanism which is necessary for print head cleaning. By using this pulse motor, it becomes possible

to use high speed driver or intermittent drive for the various paper feeds and pump operations such as

paper feed, slight paper feed, high and low speed absorption of pump operations. Following tables(Table

2-7 and 2-8) show PF motor specifications and control method at each mode.

Table 2-7. PF Motor Specification

Item Description

Motor type 4-phase/200-pole Stepping motor

Drive voltage

Coil Resistance

Drive frequency [csp(pps)] 400-4320Hz

Control method Bi-Pola Drive

Table 2-8. Motor Control Method at Each Mode

Mode Drive Method Drive Frequency

Paper feed A 2-2 phase 4320 231

Slight paper feed 1-2 phase 400 2500

Slight paper feed 1-2 phase 2400 417

High speed attraction of pump 2-2 phase 4100 243

Low speed attraction of pump 1-2 phase 1800 555

Low speed paper feed 1-2 phase 1200 833

Paper feed B 2-2 phase 3400 294

Paper feed C 1-2 phase 4000 250

Ordinal absorption of pump 1-2 phase 4100 243

42VDC ± 5%

7.8 Ohms ± 10%(per 1 phase under

25°C environment)

Pulse Space

[Hz]

(µs)

Following tables show 1-2phase drive method at PF motor drive and each drive sequence at 2-2phase

drive method.

Table 2-9. 1-2 Phase Drive Method

Step No. Clockwise Counter clockwise

Phase A Phase B Phase A Phase B

1 +2/3 +2/3 +2/3 +2/3

0+1+10

2 -2/3 +2/3 +2/3 -2/3

-1 0 0 -1

3 -2/3 -2/3 -2/3 -2/3

0-1-10

4 +2/3 -2/3 -2/3 +2/3

+1 0 0 +1

Table 2-10. Drive Sequence at 2-2 Phase Drive

Step No. Clockwise(CW) Counter clockwise(CCW)

AB A B

1 +2/3 +2/3 +2/3 +2/3

2 -2/3 +2/3 +2/3 -2/3

3 -2/3 -2/3 -2/3 -2/3

4 +2/3 -2/3 -2/3 +2/3

Rev.A

2-11

Page 13

EPSON Stylus Color 400 Service Manual

2

Papers on the ASF (auto-sheet-feeder) supplied by the user are carried to the printer inside by paper

pick up sequence. Unlike the previous models, ASF of Stylus Color 400 has mufti feed prevention

mechanism. Following explains this function and figure below shows its mechanism.

[1. Multi feed prevention mechanism]

When the Load/Eject button is pressed, reversed rotation of PF motor is performed.

The return lever resets papers which are already in the out of stand by position in the stand by position

and make it possible to perform stable paper feeding by picking up the paper again.

Pintch Roller

D-Cut Roller

CAM

Hopper

Hopper spring

2)

1)

2)

Pad spring

Return Lever

[Standby state]

Figure 2-9. Multi Paper Feed Prevention Mechanism

Following explains process of multi feed prevention step by step. Refer to the figure above and confirm

its operation.

[Step 1]

[Step 2]

[Step 3]

[Step 4]

When the load/Eject switch is pressed or printing order is input from the PC, PF motor rotates

counterclockwise and makes the CAM rotate towards direction of 1 in the figure above.

When the CAM covers the notch by the return lever, that position is considered as home

position, being monitored by ASF sensor.

When the CAM rotates toward 1 in the figure above, the return lever is pushed by the notch

of CAM and falls towards 2. At this time, the return lever moves to direction 3 by this

motion, and push down the pad which is waiting in the below part. At this time, friction of

pinch roller and pad will be canceled.

The papers which are out of stand by position by the previous paper feed motion are

returned to the paper stand by position by flip over strength of return lever. After this,

PF motor rotates clockwise and the printer goes to pick up sequence.

[Returning state]

2-1

Rev.A

Page 14

Chapter2 Operating Principles

3

In the paper pick up mechanism of Stylus Color 400, same mechanism as Stylus Color IIs/820

are applied. This mechanism changes adjoined lines of gear by colliding trigger lever with carriage unit

and convey the motive power on the platen to the ASF side(paper roller). The figure below

shows mechanism with explanation.

[2. Paper pick up mechanism]

When the Load/Eject switch is pressed or printing order is input, the carriage unit moves until

the left edge and collides with paper pick up trigger lever. When the carriage collides with this trigger

level, a planetary gear located on the same axis is also pushed at the same time and conveys

the motive power on the platen to the adjoined gear line side for ASF drive.

Paper Pick Up

ASF Roller Drive Gear

Planetary Gear

Trigger Lever

Eject Roller Drive Gear

Eject Roller

Transmission Gear

PF Motor Pinion Gear

ASF Roller Transmission Gear

Platen Roller Drive Gear

Platen Roller Transmission Gear

Figure 2-10. Paper Pick Up Mechanism

[3. Paper feed mechanism]

After papers in the ASF receive controls from pick up and multi feed prevention mechanism, they are

sent to the printer inside. The papers picked up by paper roller in the ASF goes to between platen

and roller support. Also, the eject roller pushes out the paper completely until the end and the roller

support drops the paper in the eject tray. The eject roller is driven with an eject paper notched roller as

pair where is located on the paper eject roller. Paper eject notched roller solves the deflection of paper

that is in the between platen eject notched roller and paper eject roller and always keep a certain space

between print head and paper surface. The figure below shows the paper feed mechanism.

Paper

Eject Notched Roller

Support Roller

Eject Roller

PF Roller

Figure 2-11. Paper Feed Mechanism

Rev.A

2-1

Page 15

EPSON Stylus Color 400 Service Manual

4

2.1.1.4 Ink System

Ink system mechanism consists of 1)cap mechanism, 2)pump mechanism, 3)carriage lock

mechanism, 4)waste ink absorber and 5)ink sequence. Out of these mechanism, from 1) to 4)

are physical mechanism and parts which are mounted on the printer mechanism and 5) ink

sequence is performed automatically by firmware. Also, unlike previous models, since

Stylus Color 400 has no engage/disengage mechanism to change over pump mechanism and

paper feed mechanism, it is one of the major characteristics that pump and platen are always

at work whenever the PF motor is driven. The figure below shows head positions when the ink

system and various ink sequence are performed.

Platen Drive Gear

Eject Roller Drive Gear

Eject Roller

Trasmission Gear

Head Cleaner

Carriage Lock

PF(Pump) Motor Pinion

Pump Roller

Figure 2-12.Ink System Mechanism

2975 dot

Cap Unit

CRHP

ABCDEFGH

Figure2-13. Major Ink Sequence Position on the Carriage Mechanism

2-1

Rev.A

Page 16

Chapter2 Operating Principles

5

2.1.1.4.1 Pump Mechanism

In the Stylus Color 400, there is no switch or mechanism to change over the pump/paper feed

mechanism. Therefore, whenever the paper feed/pump motor rotate, pump drive roller in the pump unit

inside rotates. However, ink absorption/non ink absorption are separated by the roller rotational direction.

Also, even if the pump driver rotates toward ink absorption and the carriage position is in the false

absorption position, only driving in the pump mechanism is performed and actual ink attraction is not

done. The figure below shows process of conveying motive power to the pump drive roller.

Gear A

Axis of Paper Eject Roller

Gear B

Gear C

Actually, these parts

are one unit.

Compression

Spring

Pump Drive Roller

Figure 2-14. Pump Mechanism Power Transmission Process

The process of conveying the motive power to the paper eject roller by rotating the pinion of PF motor

is descried in figure 2-12. This motive power is conveyed to the Gear C through the Gear B.

In the figure above, although the lever in order to drive Gear C, carriage lock, head cleaner mechanism

is shown separately, it is c onstructed as one unit. Since the engagement of thes e two parts depends on

the tension of the compression spring, if the lever is burdened, only Gear C and pump roller rotate and no

more motive power is conveyed to the lever part.

Rev.A

2-1

Page 17

EPSON Stylus Color 400 Service Manual

6

The table below shows PF/Pump motor rotational direction and pump system operation.

Table 2-11. Relationship Between Pump Motor Rotation and Pump Operation

PF/Pump motor rotational direction Pump unit operation

Clockwise(CW)

forward rotation

Counterclockwise(CCW)

backward rotation

The figure below shows the pump operation at clockwise and counterclockwise rotation.

1)Release from the Pump pressure welding

2)Head cleaner reset

3)Carriage lock reset

1)Rotation towards pump pressure welding

2)Head cleaner set

3)Carriage lock set

CW Rotation

Tube pressured

Figure 2-15. Pump Roller Rotation and it’s Operation

In the ink absorptive operation such as cleaning, flushing and initial ink charge except for printing

operation, ink in the ink cartridge drains to the waste ink absorber(pad) through the cap by the pump unit

drive. In case of printing and flashing drive, ink is popped out by the PZT in the print head, but in case of

absorptive operation such as cleaning and initial ink charge, ink absorption is performed

only by the pump drive without PZT drive after the head surface is adhered to the cap.

The next page explains cap mechanism and relation between printer operation and cap.

CCW Rotation

Tube released

2-1

Rev.A

Page 18

Chapter2 Operating Principles

7

2.1.1.4.2 Cap Mechanism

In the cap mechanism, in order to prevent ink from being thickened on the head surface, it is controlled

that the head surface stays adherent to the rubber frame of the cap surface when the power is off.

The absorber is spread in the cap and can hold a certain amount of ink which is absorbed from the

head without draining it to the waste ink pad. Also, in the bottom of absorber, there are two valves in order

to control adhesion of head and cap surface, and one exit to drain ink to the waste ink pad.

A

Flag for Carriage

Ink Eject Valve

Negative pressure

release valve

Valve

Close state

B

Release state

Flag for frame

Head surface and

cap are adhered

each other.

Actual and false

absorptions.

During cleaning, initial ink

charge, and right flushing.etc.

Ink absorption in

the cap.

During left flushing and paper

feeding,etc.

Figure 2-16. Cap Mechanism Operation Principle

If the carriage is out of HP(in this case, in the printable area or paper feed position), the valves on the

cap mechanism stays in the position A in the figure above and are always closed. In this condition,

the carriage collides with flag, actual ink absorption and slight ink absorption are performed.

Also, by moving the carriage to further right side and colliding the flag for opening the valves with

the frame, negative pressure is released in the state that head surface and cap are adhered. This

makes it possible for ink on the nozzle plate surface to be ready for leaving from the cap in the stable

condition.

Rev.A

2-1

Page 19

EPSON Stylus Color 400 Service Manual

8

2.2 Electrical Circuit Operating Principles

Stylus Color 400 contains the following four electric circuit boards.

C206 PSB/PSE board

C206 Main board

Head Driver board

C206 PNL board

C206 PSB/PSE, C206 board are explained in this section. The head drive board is installed in the head

unit on the carriage. The figure below shows major connection of the 3 boards and their roles.

AC100V

RCC Switching Regulator

(C206 PSB/PSE Board)

CR Motor

PF MOTOR

(Pump Motor)

+5 V DC

+42 V DC

C206 Main Control Board

(C206 Main Board)

+5 V DC

+42 V DC

PE Sensor

BCO/CCO Sensor

INK END Sensor

(Firm Wear)

ASF Lever

Position Sensor

2-1

Thermistor

Print Head

Head Drive Board

Figure 2-17. Electric Circuit of Stylus Color 400

Rev.A

Page 20

Chapter2 Operating Principles

9

2.2.1 C206 PSB/PSE Power Supply Board

C206 PSB/PSE board is a power supply board with a RCC switching regulator, which generates +42VDC

for drive part and +5VDC for logic part to drive the printer. One of the major characteristic of this board is

that the same secondary switch is used as Stylus Color series printer. By using this switch, the following

difference can be seen as superficial phenomena compared with products applied with primary switch

method, such as Stylus Color IIs, II and Stylus 800/1000 series printer. The table 2-12 below shows

application of voltages generated by C206 PSB/PSE board.

1) Even if the switch is turned off during the middle of printer operation, since the driving

power is turned off after the carriage goes back to the carriage lock position,

the possibility of clogging ink nozzle will be decreased.

2) If the switch is turned off when the papers in the printer are still being carried except for

the papers in the hopper, the same operation mentioned above is performed and the

driving power is turned off after the paper is completely ejected.

Table 2-12. Application of DC Voltage

Voltages Application

+42VDC

+5VDC

CR Motor

PF/Pump Motor

Head driving power supply

Power supply for logic control

System control signal

Sensor circuit power supply voltage

LED panel drive power supply

Nozzle selector control signal power supply voltage

Figure 2-18 shows block diagram of C206 PSB/PSE board. The process from the input of AC100V to the

output of 42 V DC and 5 V is explained below.

1) Regardless of the state of power switch(On or OFF), the voltage is always applied in the primary

side of the power supply board from the moment or at the state that AC-plug is plugged in.

At this time, F1 plays a role of preventing AC100V from coming into the F1.

L1 and R1-R2 also prevent high harmonic wave noise generated in the RC circuit filter which consist

of C1∼C4 and R1∼R2 from going out, and eliminate the noise from outside here.

2

2) The AC is full-wave rectified by diode bridge DB1, and converted to

electrolytic capacitor C11.

3) The pressured up direct current makes Q1 On through the starting resistor R31 and starts the primary

side of the circuit.

4) When the primary side is On state, the energy(current) led by the electromagnetic induction through

the trans (T1) does not flow to the secondary side since the diode(D51) on the secondary side

is installed in the opposite direction.

5) When the energy which is charged in the trans is reaching the saturated state, the voltage which

makes the Q1 On becomes weak gradually. At the point that this voltage drops at the

certain voltage, C13 absorbs the current in the opposite direction and Q1 is quickly shut off by

the resulting sharp drop.

6) When the primary side is turned off, the energy charged in the T1 is opened according to the

diode(D51) direction which is installed on the secondary side. Basically, 42 V DC is output

by these circuit operations and the number of T1 spiral coil .

x AC in voltage by smoothing

7) +5VDC is generated by pressured down this +42VDC as power supply. IC51 pressures down the

+42VDC and generates precise +5VDC by chopping off the output, forming the standard santooth

wave form by the outer RC integration circuit.

Rev.A

2-1

Page 21

EPSON Stylus Color 400 Service Manual

0

DB1 C11

Full Wave

Rectifier circuit

L1,R1-R2 C1-C4

Filter Circuit

F1

Prevention of

current flow

Q1

Q2,Q3,

Smoothing

circuit

Main switching

circuit

Q31,PC1

Feedback

circuit

T1

D51

T

R

A

N

S

PC1

Photo coupler

C51

Smoothing

circuit

C84,Q84

Power OFF

Delay circuit

ZD81-86,

ZD51

+42V constant

voltage control

circuit

+42V overvoltage

protection circuit

ZD52,87

+5V generation

(IC51)

circuit

ZD53

+5V overvoltage

protection circuit

+42VDC

+5VDC

PSO Signal

AC100V

Figure 2-18. C206 PSB/PSE Board Block Diagram

The C206 PSB/PSE board has various control circuits to stop output if malfunction on the power supply

board, on the main board or on the duty of printer mechanism happen. Following explains each control

and protection circuits.

1) +42V Line Constant Voltage Control Circuit:

The output level of the +42V line is monitored by a detection circuit consisting of seven Zener diodes.

This circuit prevents voltage from dropping for constant output voltage.

2) +5V Line Over voltage Protection Circuit:

This protection circuit is in the same line as +42V over voltage protection circuit is located. The output

voltage level of the +5V line is monitored by a Zener diode. This circuit shuts down the circuit

operation forcefully when the voltage level exceeds +9V.

3) +42VDC Line Over voltage Circuit:

This circuit is in the same line as +5V line over voltage protection circuit is located. The output level is

monitored by two Zener diodes. If the voltage level exceeds +48VDC, this circuit stops circuit

operation forcefully.

4) +5V Line Constant Voltage/Constant Current Control Circuit:

The output current is monitored by a +5VDC generation switching control IC(IC51), which also

monitors the output voltage. This information is input to the internal comparator and stabilizes +5V

line. Also, operation of the secondary side switch is explained below.

1) When the power is turned on, Q1 repeats ON/OFF automatically along with the increase and

decrease of energy on the trans coil at the primary side. While the power is being on, PSC

signal is input to the power supply board from the C206 main board.

2) This signal turns Q84 on and it becomes possible to discharge energy between 8-9 of T1.

At this time, even if the power is turned off, the electrolytic capacitor keeps Q84 on for a while.

By this electrolytic capacitor, output is hold at least 30 seconds even after the power is turned off.

This time helps the printer to complete the P-Off operation.

2-2

Rev.A

Page 22

Chapter2 Operating Principles

2.2.2 C206 MAIN Board

Various DC voltage generated on the C206 PSB/PSE board is added various signals in order to drive the

printer function on the C206 main board, and the drive of CR/PF(Pump) motor and printing head is

performed. This control board consists of system part and drive part. In the system part, there are

formation and controls of various signals in order to drive the CR/PF(pump) motor, sequence control

by input from the sensor circuit, and also output of signal to select appropriate nozzle for the printing

head. On the other hand, the drive part has constant current drive by the driver IC for the CR/PF(pump)

motor drive and trapezoidal wave form circuit for head drive.

C206 Main Board

PROM4M

(IC3:EPROM)

M5M411664

(IC4:D-RAM)

System

DRAM Control

Head Temperature

From A

From B

From B

TPM 95C061

(IC1:CPU)

SN75LBC775

(IC16 Transceiver)

H8D2813D

(IC6)

LB1845

(IC14)

LB1845

(IC15)

Timer (IC5)

E05B44

(IC2: Gate Array)

EEPROM (IC11)

Print Head

Carriage Motor

PF(Pump) Motor

CR/PF Motor Drive

Panel I/F

Head Common Drive

Power

to B

to A

Centornics I/F

Serial I/F

Sensor Circuit

Figure 2-19. C206 Main Control Board Block Diagram

[CPU]

The C206 main board is controlled by a 16-bit CPU(TMP95C061AF) running at 25Mhz. Gate array

manages most of controls and monitors. Likewise the Stylus Color, the D-RAM is applied for RAM

which is used as work area for receiving data and developing the data and CPU manages its control

such as CE, RAS/CAS controls.

[Gate Array]

E05B44 controls following functions.

Motor control : Each motor performs data transmission(W1-2 phase) that motives

Micro-Step.

Head voltage control: In the ink jet printers, drive voltage wave form(trapezoidal wave form)

in order to drive PZT is formed in the various shapes according to the

types of the printers.

Therefore, it is necessary to form appropriate drive form for each head.

Head voltage control forms necessary wave form for each control

signals and outputs them.

EEPROM control: The correction value to eliminate the error of each printers at the

production process is installed in the fixed address of IC.

When the power is turned off, the contents set by users is

written instantly, and is red to the RAM when the power is turned on.

Sensor Data: The sensor detects information at the various conditions, which is

necessary for the printer operation. The gate array recognizes

signals and changes over to the next control.

Rev.A

2-21

Page 23

EPSON Stylus Color 400 Service Manual

2

Timer Data: The timer IC that uses lithium battery as power source monitors how long

the power is off. When the power is turned on, it is changed to appropriate

cleaning level according to the time that the power is off.

Serial Data: The gate array receives serial data through the transceiver IC.

Parallel I/F control: With the use of IEEE1284 Nibble mode, it became possible not only to

receive the data from the host but also to return various information which

the printer possesses to the host.

[Common Driver IC]

The trapezoidal wave form circuit for head drive is became to HIC from the previous discreate structure.

Because of this, it is not necessary to adjust the adjustable VR on the board during production process.

Various electric charge/discharge control signals are all processed in the HIC.

[CR/PF Motor Drive Circuit]

Constant current drive is performed by the HIC. Out of this, only CR Motor is controlled for Micro-Step

control and HIC becomes poss ible to flow the appropriate current value at each steps. ( PF Motor has

only 1-2, 2-2phase drive method). Also, bipolar drive is performed on the 4 cables individually. Following

pages explain each major control circuit.

2-2

Rev.A

Page 24

Chapter2 Operating Principles

3

2.2.2.1 Reset Circuits

The reset circuit prevents the CPU from running away, which is caused by the unstable voltage in the

logic line during the power ON/OFF operation. Also, this circuit monitors level of power voltage at the over

loading or malfunction on the circuit and manages the printer to operate normally, keeping the damage to

the printer minimum during the abnormal situations. On the C206 main board, 2 ICs are mounted ; IC for

monitoring the voltage level (logic line) and IC for monitoring the voltage level (power line) and both

are monitored by the gate array and CPU.

The figure below shows reset circuit block diagram with explanation on the next page.

+5V

+5V

+42V

R10

R6

PST592D

(IC8)

TMP95C061

(IC1)

15

P84

10

/NMI

M51955B

(IC9)

2

IN

4

GND

Vout

NRES

Vcc

GND

P85

/RESET

1

2

3

4

16

30

NC8

VCC

OUT

NC5

C47

8

7

6

5

+5V

174

R1

R138

E05B44

(IC2)

/RESET

Figure 2-20. Reset Circuit Block Diagram

[PST592(IC8)]

The actual operation of the circuit is to keep outputting Low signal until +5V line goes up to +4.2V

when the power is on, and to cancel the reset signal with output of High signal when the voltage goes up

more than 4.2V.

[M51955(IC9)]

This IC also performs as monitor on the power line same as the reset IC for logic described above.

High/Low is judged at the 33.2V.

[Relation between IC8 and IC9]

Reset signal which is low and output by IC9 is input to the CPU and gate array and system reset operation

is performed. Also, this signal is detected on the IC9(IC for reset monitor, power line) and outputs the

same Low signal towards CPU/NMI terminal by being input to NC5.

Rev.A

2-2

Page 25

EPSON Stylus Color 400 Service Manual

4

2.2.2.2 Sensor Circuits

The following sensor circuits are mounted in the Stylus Color 400 and selects appropriate operations

based on the returned information.

ASF Sensor: An ASF sensor detects the position of return lever when the power is

(Photo) turned on, and causes the paper to be picked up by the pick up roller

from the normal initial condition. (Refer to section 2.1.1.3 for detail.)

PE Sensor: A PE sensor determines if there is paper in the printer. Based on the

(Photo) signal form this sensor, a particular paper edge treatment such as

Micro-weave printing is performed.

HP Sensor: A HP sensor detects the carriage home position.

(Photo) It is used for managing printing position and cleaning, etc.

Thermistor Sensor: A thermistor sensor keeps stable printing quality, changing PZT drive

voltage(VH) slightly according to changes of environmental

temperature.

Cartridge Sensors: Cartridge sensors are built into the Bk, CMY cartridge on the carriage

unit respectively to determine if the cartridge is installed or not when it

is exchanged or the power is turned on. In case of Stylus Color 400,

the counter is reset at every time the cartridge is removed.

The figure below shows sensor circuit. Out of the data such as EPW with IEEE 1284 Nibble mode

to be returned to the host, the data to indicate ink consumption is calculated and managed by the

counter of the firmware. Therefore, it is omitted here.

TMP95C061

(IC1)

+5V

E05B44

(IC2)

Vref

AGND

AN0

SW8

SW7

SW6

SW5

SW4

18

17

20

CCO(198)

BCO(200)

PE(202)

HP(204)

ASF(206)

3

THM

CN8

+5V

CCO

BCO

+5V

2

1

CN8

+5V

3

PEV

2

1

3

2

1

3

2

1

CN4

CN5

CN11

GND

3

PE

HPV

2

GND

HP

1

ASFV

GND

ASF

Figure 2-21. Sensor Circuit Block Diagram

2-2

Rev.A

Page 26

Chapter2 Operating Principles

5

2.2.2.3 EEPROM Control Circuits

The EEPROM of Stylus Color 400 has following contents. Gate array E05B44(IC2) controls operations of

reading data when the power is on and writing data when the power is off.

Ink consumption(Bk, CMY)

CL counter(Various cleaning operations that are previously done are memorized)

Destination information

Information of various adjustment values(Bi-D, VH voltage, etc.)

CPSI pass word

Other various setting values by the user

EEPROM is connected to the Gate array by 4 lines and performs following functions.

The figure below shows EEPROM control circuit.

CS : Chip selection signal

CK : Data synchronism clock pulse

DI : Data writing line(serial data) at power off.

DO : Data reading line(serial data) at power on.

+5V

93C46(IC11)

8

VCC

CS

CK

1

127

2

128

ECS

ECK

E05B44(IC2)

3

6

ORG

5

GND

Figure 2-22. EEPROM Circuit Block Diagram

DI

DO

126

EDO

4

125

EDI

Rev.A

2-2

Page 27

EPSON Stylus Color 400 Service Manual

6

2.2.2.4 Timer Circuit

The lithium battery is mounted on the C206 main board and calculates how long the printer is not used.

The timer IC(IC5) starts counting with oscillation motivated by the CR1 using this battery as a power

source. The figure below shows connection of the Timer circuit.

+5V

D7

D1

BAT1

CR1

8

VDD

2

XOUT

3

XIN

4

VSS

S-3510ANFJ

(IC5)

CS

/SCK

SIO

+5V

Figure 2-23. Timer Circuit Block Diagram

The followings explain about operation of this circuit.

When the printer is on, power is supplied to the Timer IC by applying +5V quickly through

the D1.

This power is also used for the power to oscillate the outer CR1. The oscillation wave form is

input to XIN terminal.

Since the oscillation wave form of CR1 is analog wave form, it is processed into the

pulse form in the Timer IC.

When the printer is turned on, the Timer IC outputs power off time as serial data to the gate

array.

Once the printer is turned off, 3VDC of BAT1(lithium battery) is supplied as power source for

he Timer IC through D7.

Since +5V at the power on is higher than +3V of the lithium battery, the power is not being

consumed from the lithium battery.

1

6

7

123

122

121

124

TCE

TIO

TCLK

TDATA

E05B44(IC2)

2.2.2.5 DRAM Control

In the Dynamic RAM control, output and formation of CAS and RAS control signals become necessary

in addition to the output of CS signal. The CPU TMP95C061AF not only controls that but also perform

the output of CS signal of P-ROM. Refresh timing is performed in the CAS Before RAS.

2-2

Rev.A

Page 28

Chapter2 Operating Principles

7

2.2.2.6 Print Head Control Circuit

The print head control circuit of Stylus Color 400 has following characteristics.

Common wave form circuit became one HIC.

Slight vibration mode is added.(when the CR motor is accelerating)

High speed drive 14.4Khz (trapezoidal wave form

Big Nozzle configuration (resolution in the vertical direction)90dpi

(However, black nozzle is 2 lines structure)

Also, Stylus Color 400 does not have Micro-dot control as dot shooting control, but there are two types;

Normal-dot and Normal dot-2dot. Normal-dot-2dot was called Dual Firing in the Stylus Color IIs/820.

These setting/change are controlled automatically by setting of the printer driver that is determined

by the user. The followings are required conditions to perform the normal-dot 2-dot.

At the OHP sheet setting (360X360 dpi)

At the ordinary paper and resolution 360X360 dpi setting

The control circuit is considered as 2 divided parts; 1) trapezoidal wave form generation circuit

(common drive circuit) to drive PZT in the head, and 2) Nozzle-selector drive circuit to determine

which nozzle should be used. The Nozzle-Selector is attached to the head unit just like the previous

models. The common drive circuit is sumed as one HIC and mounted on the C206 main board.

E05B44

(IC2)

CHG

KC1

ND1

ND2

MD1

MD2

DATA

DATA

/STB

CLK

Figure 2-24. Print Head Control Circuit Block Diagram

[Common drive circuit]

+5V

+42V

F1

VM

VCC

CHG

KC1

ND1

ND2

MD1

MD2

DATA

DATA

/STB

CLK

H8D2813D

(IC6)

CTC

DTB

GND1

GND2

19

20

21

CN8

16

17

18

The shape of trapezoidal wave form will be different according to the printing operation, slight vibrations at

the non-printing nozzle and waiting condition. However, IC6(H8D2813) generates all wave forms as drive

wave forms by resistance(electric) welding control of common voltage drive control signal that is output

from the IC2(E05B44) in the figure above.

Table 2-13. Specifications of H8D2813 Operation

Item Contents

Drive Power Voltage

42 ± 5 %

Starts supplying after 5V rises and be stabilized./ Stops

supplying before +5V drops.

Final drive element

Operation at the Reset

2SC3746(for charging), 2SA1469(for discharging)

Off on the both charging and discharging sides.

Supplies drive power source.

This common voltage trapezoidal wave form can be observed anytime after the +5V rises even if there is

printing data or not. (Q7:3-pin,Q9:3-pin and GND on the C206 main board)

Rev.A

2-2

Page 29

EPSON Stylus Color 400 Service Manual

8

[Nozzle Selector Drive Circuit]

In order to motivate the print head to carry out printing, it is necessary to transmit the printing data to the

appropriate nozzles, which becomes direct signals to drive PZT. This data transmission is performed

by the serial method, however the data output for each black and CMY head is transmitted by the parallel

method. The figure below shows data transmission circuit.

CN8

VH

COM

Gate Array

E05B43(IC2)

NCHG

CLK

SI1

SI2

LAT

THM

U101

IR2C72C

SI0(for black)

SI1(for colr)

SCLK

LAT

XCHG

COM

Color Data

Latch

VHV

VD1/2

Black Data

Latch

Black Nozzle

Color Nozzle

Figure 2-25. Nozzle Selector Circuit Block Diagram

CLK(Clock) pulse considered as source of serial communication is commonly used for both black and

CMY. The serial data transmits data as 64-Clock unit, synchronizing with this pulse. After the data

transmission of 64-Clock is completed, LAT(Latch) signal is activated and is hold temporarily in the

IR2C72C. At this time, since the number of nozzle for Color head is fewer(21-nozzle) and different from

the ones for black head, 0 is transmitted forcefully for the data for 43 nozzle (64-21=43).

2-2

Rev.A

Page 30

Chapter2 Operating Principles

9

After the data transmission by the nozzle selector(IR2C72C) is completed and a certain time passes,

trapezoidal wave form generated by the common drive circuit once sends electric current to the PZT

for the proper nozzles which are determined in the nozzle selector circuit. This motivates PZT and

ejects the ink in the cavity. The figure below shows normal dot data transmission timing in order to form

1 dot.

Figure 2-26. Timing Chart at the Generation of Normal Dot

Rev.A

2-2

Page 31

EPSON Stylus Color 400 Service Manual

0

2.2.2.7 PF (Pump) Motor Drive Circuit

IC15(LB1845) is used for driving PF(Pump) motor. In the IC, Bi-pola drive PWM current control type

is performed, making it possible to provide stable current to each phase of motor.

Also, it makes possible to change over the reference voltage as drive current settings by making

3 combinations(100%, 66% and 33%), using 4 current setting ports(input). (Refer to 2.1.1.3 for motor

and details about sequence) However, firmware does not drive Micro-step in the Stylus Color 400.

The figure below shows connection diagram of PF(Pump) motor drive circuit.

+42V

Figure 2-27. Connection Diagram of PF(Pump) Motor Drive Circuit

Unlike using Uni-Pola drive, there is no c able for GND in the m otor s ince Bi-Pola drive is perf orm ed in the

PF motor.(Refer to figure2-10 since carriage motor interior connection diagram has the same connection

as the PF motor’s phase connection. This helps to understand the reason why the direction of

current is controlled freely in each phase by the combinations of high/low control signals.

The current control is performed by output port(46∼49 pin) of E05B44(IC2), its outer resistance

circuit and driver IC(LB1845). First, firmware possesses 16 ways of current values as current table

out of combinations made by 5 resistance which are connected to the output ports(46∼49 pin) in the

gate array. On the other hand, signals which are output by combination of these resistance’s on/off

are input in the 26 and 17 pins. HIC is driven at the same standard voltage for each A and B phase.

Actual on/off control to send electricity through the motor is performed by the process that SEN1 and

SEN2 terminals (2 and 13 pin) detect the input signal from the gate array which is monitored by the

interior comparator, confirm the current that actually flew the phase as current value again and

perform the feed back to the on/off. The figure below shows relation between input signal to the

driver IC and motor control.

+42V

R4

Ra

Rb

+5V

If feeds back the current

RS

that actually flew in the

coil to the comparator.

Note:

In case of PM motor,

same reference voltage

is input to UDN2917 for

both phase A and B, but

differet reference voltage

is set individually for

phase A and B, in case of

CR motor.

E05B44(IC2)

Gate Array

R1

R2 R3

It varies load resistance

by the control signal and

changes the ratio of partial

pressure.

UDN2917(IC14,IC15)

Figure 2-28.Motor Drive

2-3

Rev.A

Page 32

Chapter2 Operating Principles

2.2.2.8 CR Motor Drive Circuit

In the CR motor, the same LB1845(IC15) as the PF motor has is used. In the IC, Bi-pola drive PWM

current control type is performed, making it possible to provide stable current to each phase of motor.

Also, it makes possible to change over the reference voltage as drive current settings by making

3 combinations(100%, 66% and 33%), using 4 current setting ports(input). (Refer to 2.1.1.3 for motor

and details about sequence) However, firmware performs Micro-step driving in the Stylus Color 400.

The figure below shows carriage motor drive circuit.

+42V

E05B44(IC2)

MTBV0-MTBV4

MTAV0-MTAV4

CRA0

CRA1

CRB0

CRB1

CRAPH

CRBPH

75

76

72

73

77

74

Current decision

resistor

LB1845(IC15)

22

IO1

23

I11

21

IO2

20

I12

25

PH1

18

PH2

Vref1

Vref2

SENS1

E1

SENS2

E2

OUT1A

OUT1B

OUT2A

OUT2B

7

6

9

8

CRA

CR/A

CRB

CR/B

Figure 2-29. Connection Diagram CR Motor Drive Circuit

Unlike using Uni-Pola drive, there is no cable for GND in the motor since Bi-Pola drive is performed in the

CR motor.(Refer to figure2-10 since carriage motor interior connection diagram has the same connection

as the PF motor’s phase connection. This helps to understand the reason why the direction of

current is controlled freely in each phase by the combinations of high/low control signals.

The current control is performed by output port(46∼49 pin) of E05B44(IC2), its outer resistance

circuit and driver IC(LB1845). First, 10 resistance which are connected to the output port(60∼61pin,

63∼70pin) of the gate array divide each current values of phase A and B in the CR motor.

The firmware possesses 16 different ways of current values individually as current table out of

combinations made by 5 resistance which are connected to the output ports(46∼49 pin) in the gate array.

On the other hand, signals which are output by combination of these resistance’s on/off are input

independently in the 26 and 17 pins. HIC is driven at the different standard voltage for each phase A and

B.

Actual on/off control to send electricity through the motor is performed by the process that SEN1 and

SEN2 terminals (2 and 13 pin) detect the input signal from the gate array which is monitored by the

interior comparator, confirm the current that actually flew the phase as current value again and

perform the feed back to the on/off. (Refer to figure 3-31 since it is same as the one of PF motor)

Rev.A

2-31

Loading...

Loading...