Epson Stylus C110, Stylus C120, Stylus D120 Service Manual. Parts Catalog

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus C110/C120/D120

SEIJ07-001

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2007 SEIKO EPSON CORPORATION.

Imaging Products CS, PL & Environmental Management

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO

SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED

CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR

OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN USING COMPRESSED AIR PRODUCTS; SUCH AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF SUCH

PRODUCTS CONTAINING FLAMMABLE GAS IS PROHIBITED.

About This Manual

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Exploded Diagram

• Parts List

• Circuit Diagrams

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Indicates that a particular task must be carried out according to a certain

standard after disassembly and before re-assembly, otherwise the

quality of the components in question may be adversely affected.

Revision Status

Revision Date of Issue Description

A August 9, 2007 First Release

B September 21, 2007 Chapter 1

• 1.2.1 Basic Specifications (p. 10) : Note about a special nozzle of each color on the Printhead is added.

• 1.2.3 Supported Paper (p. 12) : Note about nominal weight is added.

Chapter 2

• 2.1.2 Motors & Sensors (p. 22) : Note about a special nozzle of each color on the Printhead is added.

• 2.2.1 Printhead (p. 23) : Note about a special nozzle of each color on the Printhead is added.

Chapter 4

• 4.1.2 Tools (p. 70) : The Upper Case Opener is added.

• 4.3.4 Upper Housing/Cover Open Sensor (p. 74) : CheckPoint of removing the Right Front Cover is added.

EPSON Stylus C110/C120/D120 Revision B

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features.................................................................................................................. 9

1.2 Printing Specifications......................................................................................... 10

1.2.1 Basic Specifications.................................................................................... 10

1.2.2 Print Mode .................................................................................................. 10

1.2.3 Supported Paper.......................................................................................... 12

1.2.4 Printing Area............................................................................................... 14

1.2.5 Ink Cartridge............................................................................................... 14

1.3 Interface............................................................................................................... 15

1.4 General Specifications......................................................................................... 15

1.4.1 Electrical Specifications ............................................................................. 15

1.4.2 Environmental Conditions .......................................................................... 16

1.4.3 Durability.................................................................................................... 16

1.4.4 Acoustic Noise............................................................................................ 16

1.4.5 Safety Approvals (Safety standards/EMI) .................................................. 16

1.5 Operation Buttons & Indicators (LEDs).............................................................. 17

1.5.1 Operation Buttons....................................................................................... 17

1.5.2 Indicators (LEDs) ....................................................................................... 17

1.5.3 Operation Buttons & LEDs Functions........................................................ 17

1.5.4 Errors & Remedies ..................................................................................... 19

Chapter 2 OPERATING PRINCIPLE

2.1 Overview ............................................................................................................. 21

2.1.1 Printer Mechanism...................................................................................... 21

2.1.2 Motors & Sensors ....................................................................................... 22

2.2 Printer Mechanism Operating Principles ............................................................ 23

2.2.1 Printhead..................................................................................................... 23

2.2.2 Carriage Mechanism................................................................................... 25

2.2.3 Paper Loading/Paper Feed Mechanism ...................................................... 26

2.2.4 Ink System Mechanism .............................................................................. 31

2.2.5 Ink Sequence............................................................................................... 34

2.3 Electrical Circuit Operating Principles................................................................ 35

2.3.1 Power Supply Board................................................................................... 35

2.3.2 C687 Main Board ....................................................................................... 36

Chapter 3 TROUBLESHOOTING

3.1 Overview ............................................................................................................. 43

3.1.1 Specified Tools ........................................................................................... 43

3.1.2 Preliminary Checks..................................................................................... 43

3.2 Troubleshooting................................................................................................... 44

3.2.1 Motor and Sensor Troubleshooting ............................................................ 44

3.2.2 Error Indications and Fault Occurrence Causes ......................................... 45

3.2.3 Superficial Phenomenon-Based Troubleshooting ...................................... 63

6

EPSON Stylus C110/C120/D120 Revision B

Chapter 4 DISASSEMBLY/ASSEMBLY

4.1 Overview ............................................................................................................. 70

4.1.1 Precautions.................................................................................................. 70

4.1.2 Tools ........................................................................................................... 70

4.1.3 Work Completion Check ............................................................................ 71

4.2 Disassembly Procedures...................................................................................... 72

4.3 Removing Housing.............................................................................................. 73

4.3.1 Paper Support Assy..................................................................................... 73

4.3.2 Stacker Assy. .............................................................................................. 73

4.3.3 Cover Printer............................................................................................... 74

4.3.4 Upper Housing/Cover Open Sensor ........................................................... 74

4.4 Removing Board.................................................................................................. 76

4.4.1 Main Board Unit/Left Frame ...................................................................... 76

4.4.2 Panel Unit ................................................................................................... 79

4.4.3 Power Supply Unit...................................................................................... 81

4.5 Disassembling Printer Mechanism ...................................................................... 82

4.5.1 Removing Printer Mechanism (Lower Housing) ....................................... 82

4.5.2 Printhead ..................................................................................................... 83

4.5.3 CR Scale ..................................................................................................... 85

4.5.4 Hopper ........................................................................................................ 86

4.5.5 Front Frame/Right Frame ........................................................................... 87

4.5.6 Star Wheel Holder Assy. ............................................................................ 88

4.5.7 EJ Roller ..................................................................................................... 89

4.5.8 PF Encoder Sensor...................................................................................... 90

4.5.9 PF Scale ...................................................................................................... 91

4.5.10 PF Motor................................................................................................... 91

4.5.11 CR Motor .................................................................................................. 93

4.5.12 Main Frame Assy...................................................................................... 95

4.5.13 CR Unit..................................................................................................... 97

4.5.14 Upper Paper Guide ................................................................................... 99

4.5.15 ASF Unit................................................................................................... 99

4.5.16 Ink System Unit ...................................................................................... 101

4.5.17 Front Paper Guide................................................................................... 104

4.5.18 PF Roller................................................................................................. 105

4.5.19 Waste Ink Pads ....................................................................................... 106

Chapter 5 ADJUSTMENT

5.1 Adjustment Items and Overview....................................................................... 108

5.1.1 Servicing Adjustment Item List................................................................ 108

5.1.2 Required Adjustments .............................................................................. 110

5.2 Using the Adjustment Program ......................................................................... 112

5.2.1 TOP Margin Adjustment .......................................................................... 112

5.2.2 First Dot Position Adjustment .................................................................. 112

5.2.3 Head Angular Adjustment........................................................................ 113

5.2.4 Bi-D Adjustment....................................................................................... 113

5.2.5 PF Adjustment .......................................................................................... 114

5.2.6 PF Band Adjustment................................................................................. 115

Chapter 6 MAINTENANCE

6.1 Overview ........................................................................................................... 117

6.1.1 Cleaning.................................................................................................... 117

6.1.2 Service Maintenance................................................................................. 117

6.1.3 Lubrication................................................................................................ 118

Chapter 7 APPENDIX

7.1 Exploded Diagram / Parts List .......................................................................... 123

7.2 Electrical Circuits .............................................................................................. 123

7

PRODUCT DESCRIPTION

CHAPTER

1

EPSON Stylus C110/C120/D120 Revision B

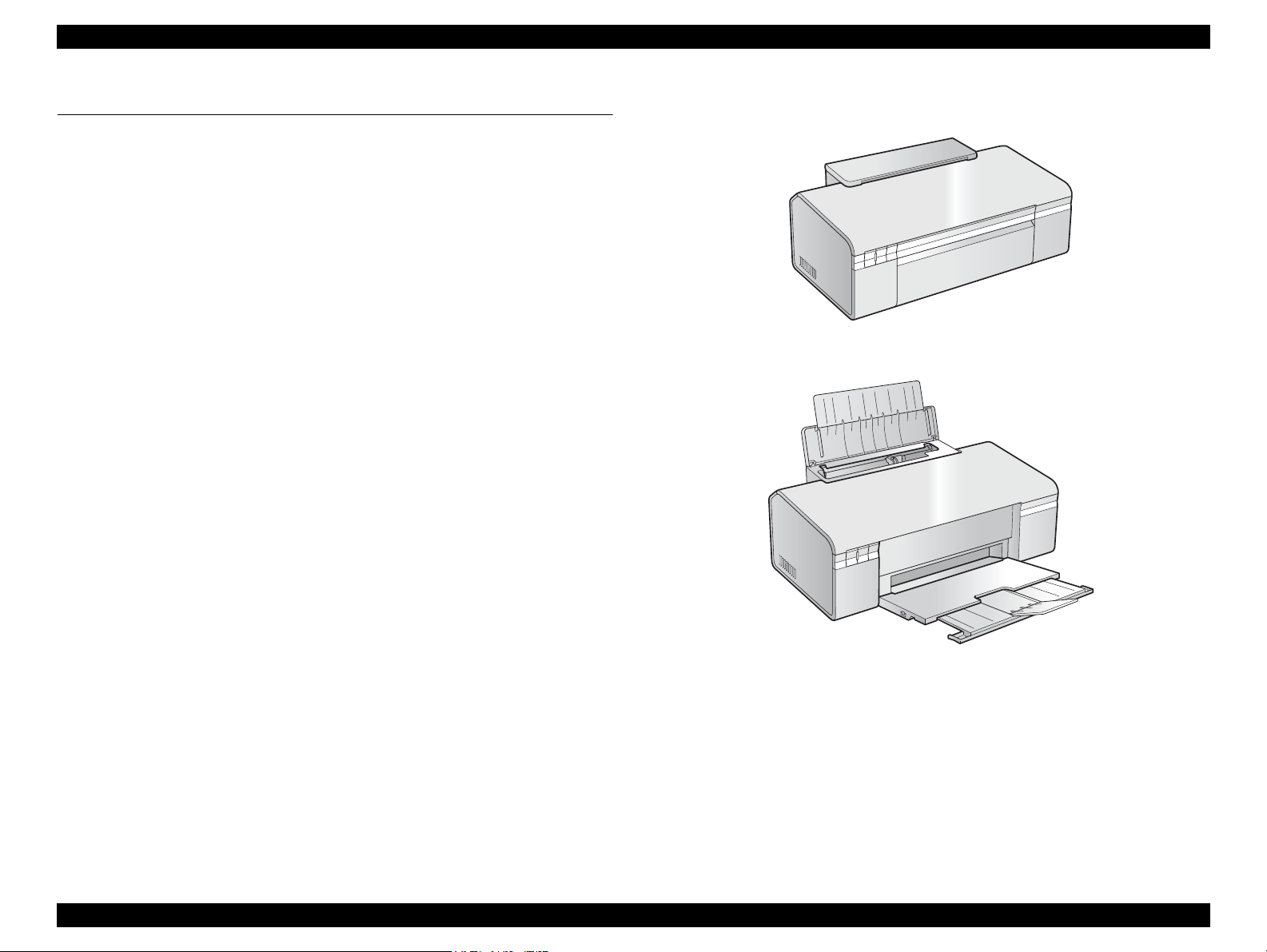

Paper Support & Stacker are Closed

Paper Support & Stacker are Opened

1.1 Features

EPSON Stylus C110/C120/D120 are single-function color ink-jet printers.

The main features are;

High speed & High quality

Maximum print resolution: SMGA 5760 (H) x 1440 (V) dpi

Newly developed F3-3 Mach Turbo II Printhead achieves higher black&white

print speed than ever.

Installs two black ink cartridges as standard.

Newly developed pigment ink is employed.

Borderless printing on specified EPSON brand paper is available.

Control panel

Simple design with three buttons and three indicators (LED).

Dimensions

Dimensions: 435 mm (W) x 240 mm (D) x 161 mm (H)

(Paper support and stacker are closed. Rubber feet are excluded)

Weight: 3.9 kg (without ink cartridges)

Figure 1-1. External View

PRODUCT DESCRIPTION Features 9

EPSON Stylus C110/C120/D120 Revision B

1.2 Printing Specifications

1.2.1 Basic Specifications

Table 1-1. Printer Specifications

Item Specifications

Print method On-demand ink jet

Nozzle configuration Black:180 nozzles x 2

Color: 60 nozzles x 3 (Cyan, Magenta, Yellow)*

Print direction Bi-directional minimum distance printing (logic seeking)

Print resolution Horizontal x Vertical (dpi)

• 360 x 180 • 720 x 720

• 360 x 360 • 1440 x 720

• 360 x 720 • SMGA 5760 x 1440 (1440 x 1440)

Control code • ESC/P Raster command

• EPSON Remote command

Input buffer size T.B.D. Kbytes

Paper feed method Friction feed, using one ASF (Auto Sheet Feeder)

Paper path Top feed, front out

Paper feed rates T.B.D. mm/sec (at 25.4 mm feed)

PF interval Programmable in 0.01764 mm (1/1440 inch) steps

Note * : The No.1 nozzle of each color is used only for executing flushing, and is not used for

printing.Refer to “ 2.2.1 Printhead ” (p.23)

1.2.2 Print Mode

Media

• Plain paper

• Premium Bright

White Paper (EAI)

• Premium Ink Jet

Plain papers (others)

• Ultra Premium

Glossy Photo Paper

(EAI)

• Ultra Glossy Photo

Paper (others)

• Premium Photo Paper

Glossy (EAI)

• Premium Glossy

Photo Paper (others)

• Photo Paper Glossy

(EAI)

• Glossy Photo Paper

(others)

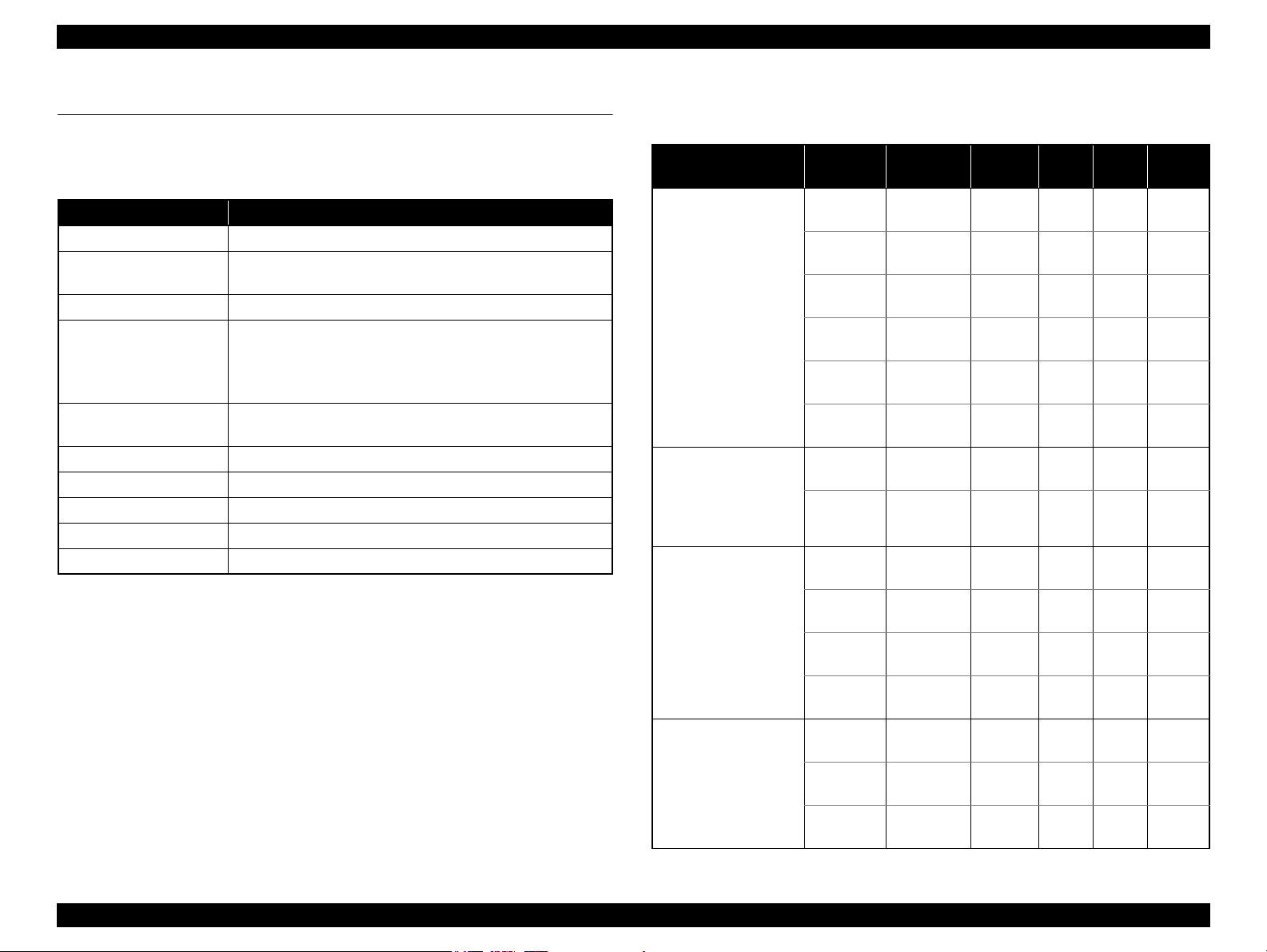

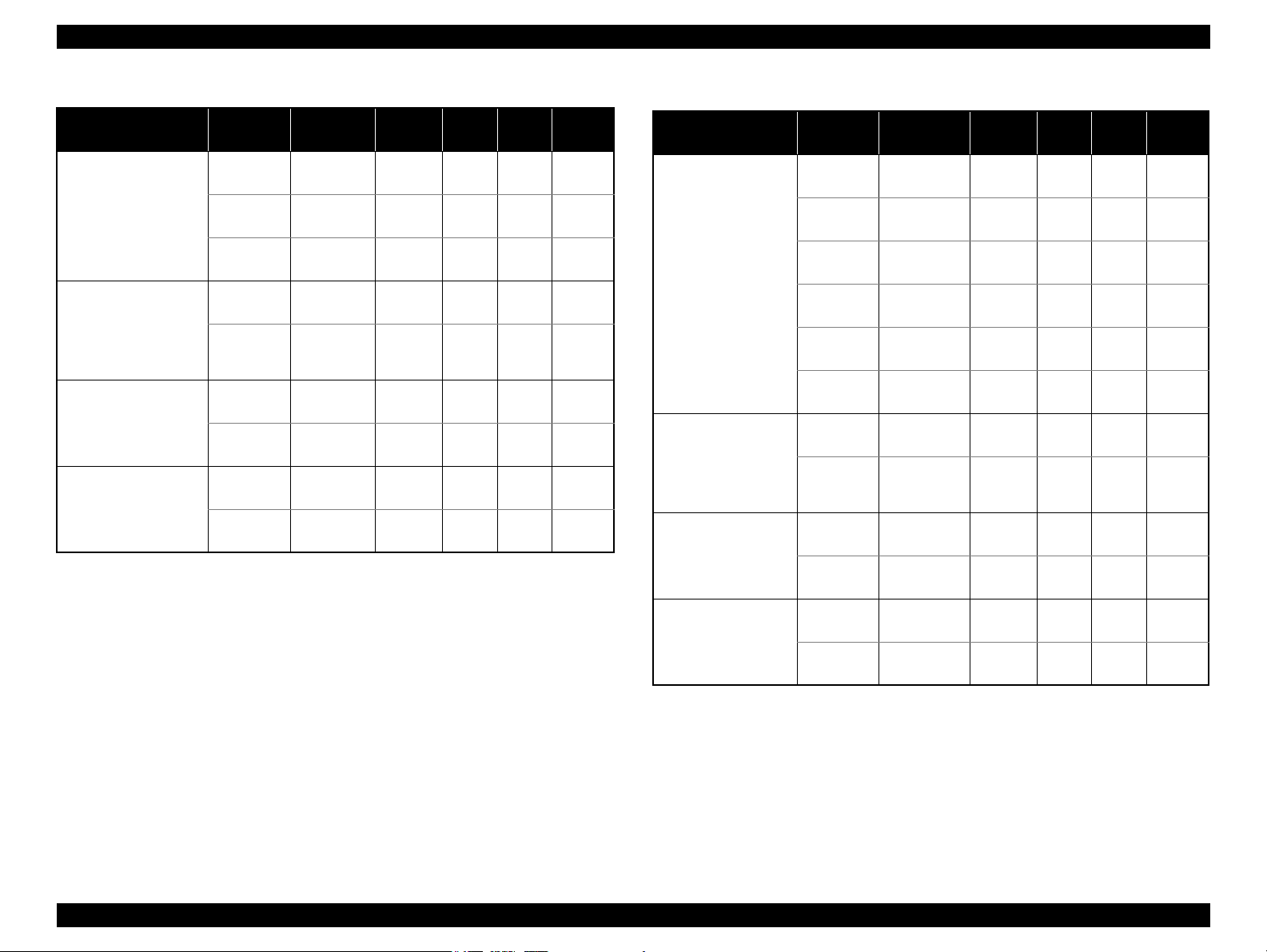

Table 1-2. Print Mode (Color)

Print

Mode

Draft 1 360x180

Draft 2 360x180

Normal 2 360x360

Normal 3 360x360

Fine 360x720

Photo 2 720x720

Best Photo 1440x720

Photo RPM 1440x1440

Fine 360x720

Photo 1 720x720

Best Photo 1440x720

Photo RPM 1440x1440

Fine 360x720

Photo 1 720x720

Best Photo 1440x720

Resolution

(H x V) dpi

Dot Size

(cps)

(400cps)

(400cps)

VSD1

(320cps)

VSD1

(320cps)

VSD2

(245cps)

VSD3

(245cps)

VSD3

(245cps)

VSD3

(245cps)

VSD2

(245cps)

VSD2

(245cps)

VSD3

(245cps)

VSD3

(245cps)

VSD2

(245cps)

VSD2

(245cps)

VSD3

(245cps)

Eco

Eco

Bi-d

Micro

Weave

ON OFF N/A

ON OFF N/A

ON OFF N/A

ON ON N/A

ON ON N/A

ON ON N/A

ON ON OK

ON ON OK

ON ON OK

ON ON OK

ON ON OK

ON ON OK

ON ON OK

ON ON OK

ON ON OK

Border-

less

PRODUCT DESCRIPTION Printing Specifications 10

EPSON Stylus C110/C120/D120 Revision B

Table 1-2. Print Mode (Color)

Media

• Premium Photo Paper

Semi-Gloss (EAI)

• Premium Semigloss

Photo Paper (others)

• Premium

Presentation Paper

Matte (EAI)

• Matte Paper Heavyweight (others)

• Photo Quality Inkjet

Paper* (others)

• Envelope

Note * : Not supported in EAI.

Print

Mode

Photo 1 720x720

Best Photo 1440x720

Photo 1 720x720

Best Photo 1440x720

Photo 1 720x720

Best Photo 1440x720

Normal 2 360x360

Resolution

(H x V) dpi

Fine 360x720

Fine 360x720

Dot Size

(cps)

VSD2

(245cps)

VSD2

(245cps)

VSD3

(245cps)

VSD2

(245cps)

VSD3

(245cps)

VSD2

(245cps)

VSD3

(245cps)

VSD1

(320cps)

VSD2

(245cps)

Bi-d

OFF OFF N/A

OFF ON N/A

Micro

Weave

ON ON OK

ON ON OK

ON ON OK

ON ON OK

ON ON OK

ON ON N/A

ON ON N/A

Border-

less

Media

• Plain paper

• Premium Bright

White Paper (EAI)

• Premium Inkjet

Plain Paper (others)

• Premium

Presentation Paper

Matte (EAI)

• Matte Paper Heavyweight (others)

• Photo Quality Inkjet

Paper* (others)

• Envelope

Table 1-3. Print Mode (Monochrome)

Print

Mode

Draft 3 360x360

Draft 4 360x360

Normal 1 360x360

Normal 3 360x360

Fine 360x720

Photo 2 720x720

Photo 1 720x720

Best Photo 1440x720

Photo 1 720x720

Best Photo 1440x720

Normal 1 360x360

Fine 360x720

Resolution

(H x V) dpi

Dot Size

(cps)

Eco

(400cps)

Eco

(400cps)

VSD1

(320cps)

VSD1

(320cps)

VSD2

(245cps)

VSD3

(245cps)

VSD2

(245cps)

VSD3

(245cps)

VSD2

(245cps)

VSD3

(245cps)

VSD1

(320cps)

VSD2

(245cps)

Bi-d

OFF OFF N/A

OFF ON N/A

Micro

Weave

ON OFF N/A

ON OFF N/A

ON OFF N/A

ON ON N/A

ON ON OK

ON ON N/A

ON ON OK

ON ON OK

ON ON N/A

ON ON N/A

Border-

less

Note * : Not supported in EAI

PRODUCT DESCRIPTION Printing Specifications 11

EPSON Stylus C110/C120/D120 Revision B

1.2.3 Supported Paper

The table below lists the paper type and sizes supported by the printer. The Supported paper type and sizes vary depending on destinations (between EAI, EUR, and Asia).

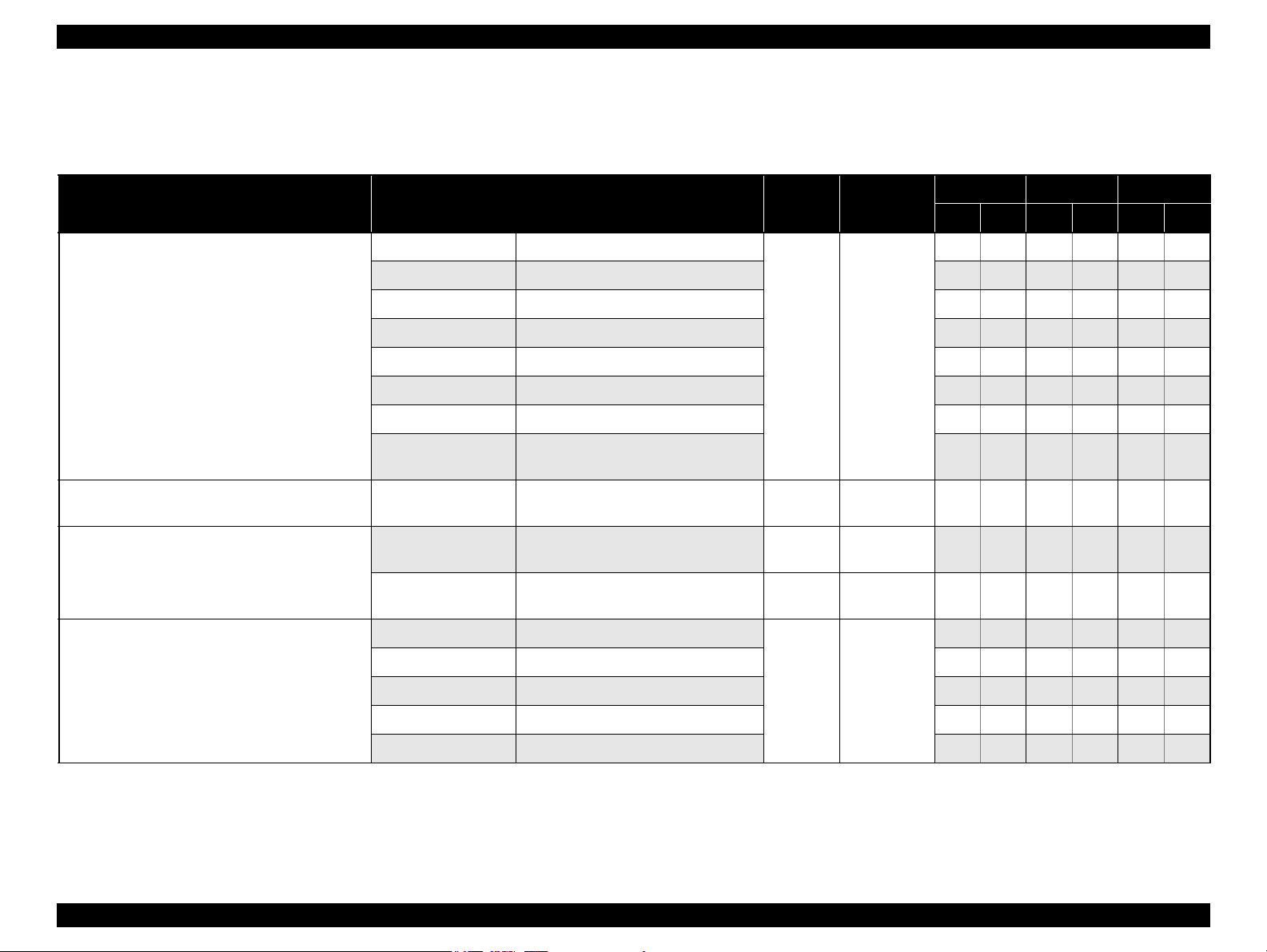

Table 1-4. Supported Paper

Paper Name Paper Size

Thickness

(mm)

Legal 215.9 x 355.6 mm (8.5”x14”)

Letter 215.9 x 279.4 mm (8.5”x11”) Y - Y - Y -

A4 210 x 297 mm (8.3”x11.7”) Y - Y - Y -

B5 182 x 257 mm (7.2”x10.1”) - - Y - Y -

Plain paper

A5 148 x 210 mm (5.8”x8.3”) - - Y - Y -

0.08-0.11

Half Letter 139.7 x 215.9 mm (5.5"x8.5”) Y - - - - -

A6 105 x 148 mm (4.2”x5.8”) Y - Y - Y -

User Defined

89 x 127- 329 x 1117.6 mm

(3.56”x 5.08” - 13.16”x44.7”)

Premium Inkjet Plain Paper A4 210 x 297 mm (8.3”x11.7”) 0.11

Letter 215.9 x 279.4 mm (8.5”x11”) 0.11

Premium Bright White Paper (EAI)

Bright White Inkjet Paper (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) 0.13

Letter 215.9 x 279.4 mm (8.5”x11”)

Weight

64-90 g/m

(17-24 lb.)

80 g/m

(21 lb.)

90 g/m

(24 lb.)

92.5 g/m

(25 lb.)

EAI EUR Asia

*1

*2

P

B

*1

P

Y - Y - Y -

2

Y - Y - Y -

2

- - Y - Y -

2

Y - - - - -

2

- - Y - Y -

Y Y - - - -

*2

*1

B

P

*2

B

A4 210 x 297 mm (8.3”x11.7”) - Y Y Y Y Y

Ultra Premium Glossy Photo Paper (EAI)*

Ultra Glossy Photo Paper (Euro, Asia)*

8” x 10” 203.2 x 254 mm Y Y - - - -

0.30

290 g/m

(77 lb.)

2

5” x 7” 127 x 178 mm Y Y Y Y - -

4” x 6” 101.6 x 152.4 mm Y Y Y Y Y Y

PRODUCT DESCRIPTION Printing Specifications 12

EPSON Stylus C110/C120/D120 Revision B

C A U T I O N

Table 1-4. Supported Paper

Paper Name Paper Size

Thickness

(mm)

Letter 215.9 x 279.4 mm (8.5”x11”)

A4 210 x 297 mm (8.3”x11.7”) Y Y Y Y Y Y

Premium Photo Paper Glossy (EAI)

Premium Glossy Photo Paper (Euro, Asia)

8” x 10” 203.2 x 254 mm Y Y - - - -

0.27

5” x 7” 127 x 178 mm Y Y Y Y Y Y

4" x 6

"

101.6 x 152.4 mm Y Y Y Y Y Y

16:9 wide 101.6 x 180.6 mm Y Y Y Y Y Y

Letter 215.9 x 279.4 mm (8.5”x11”)

Photo Paper Glossy (EAI)

Glossy Photo Paper (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) Y Y Y Y Y Y

0.25

5” x 7” 127 x 178 mm - - Y Y - -

4” x 6” 101.6 x 152.4 mm Y Y Y Y Y Y

Letter 215.9 x 279.4 mm (8.5”x11”)

Premium Photo Paper Semi-Gloss (EAI)

Premium Semigloss Photo Paper (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) - - Y Y Y Y

0.27

4” x 6” 101.6 x 152.4 mm Y Y Y Y Y Y

Letter 215.9 x 279.4 mm (8.5”x11”)

Premium Presentation Paper Matte (EAI)

Matte Paper-Heavyweight (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) Y Y Y Y Y Y

0.23

8” x 10” 203.2 x 254 mm Y Y - - - -

Photo Quality Inkjet Paper A4 210 x 297 mm (8.3”x11.7”) 0.13

Weight

255 g/m

(68 lb.)

258 g/m

(68 lb.)

250 g/m

(66 lb.)

167 g/m

(44 lb.)

102 g/m

(27 lb.)

EAI EUR Asia

*1

*2

P

B

*1

P

B

Y Y - - - -

2

Y Y - - - -

2

Y Y - - - -

2

Y Y - - - -

2

2

- - Y - Y -

*2

*1

P

*2

B

#10 104.8 x 241.3 mm (4.125”x9.5”)

Envelopes

#DL 110 x 220 mm - - Y - Y -

#C6 114 x 162 mm - - Y - Y -

Note *1 : “Y” in the “P” column stands for “the paper type/size is Supported”.

*2 : “Y” in the “B” column stands for “Borderless printing is available”.

Note * : The nominal weight is 300 g/m

2

PRODUCT DESCRIPTION Printing Specifications 13

Note * :

Y - Y - Y -

-

75-100 g/m

(20-27 lb.)

2

Make sure the paper is not wrinkled, fluffed, torn, or folded.

The curve of paper must be 5 mm or below.

When printing on an envelope, be sure the flap is folded neatly.

Do not use the adhesive envelopes.

Do not use double envelopes and cellophane window envelopes.

EPSON Stylus C110/C120/D120 Revision B

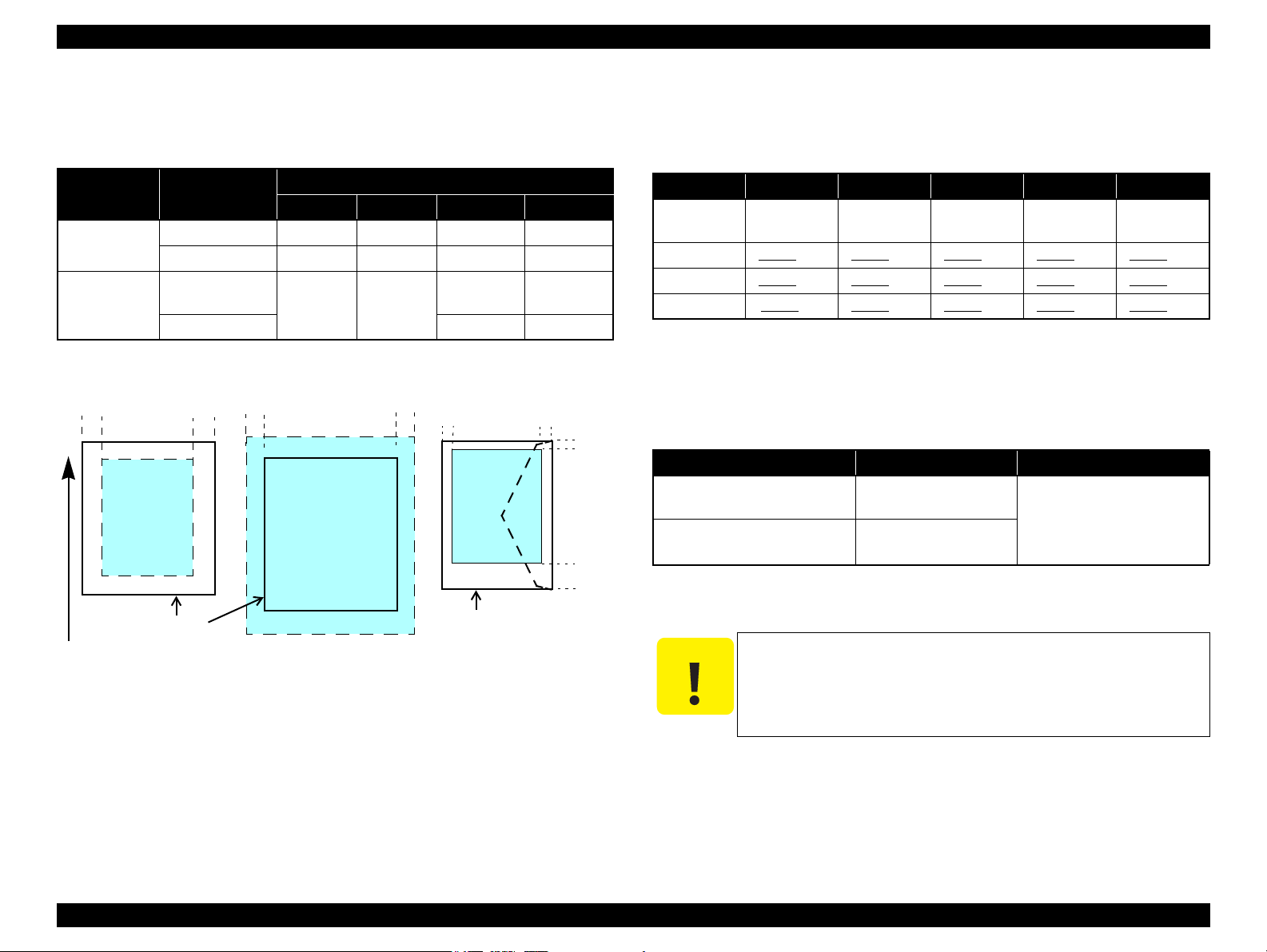

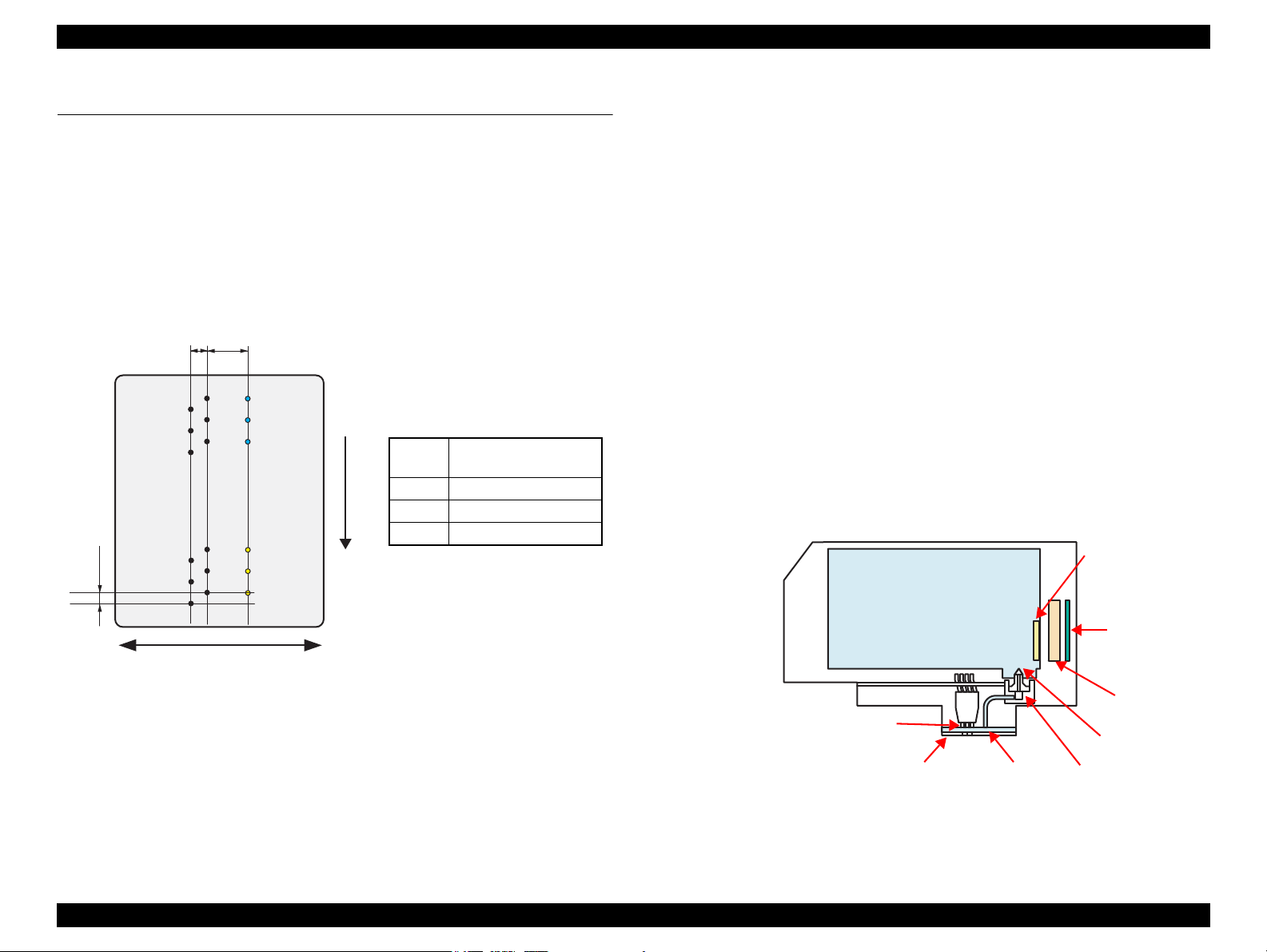

Print Area

LM RM

TM

BM

BM

Cut Sheet (Standard)

Cut Sheet (Borderless)

Paper SIze

LM

RM

TM

BM

Print Area

LM

RM

Print Area

Envelope

Paper Size

TM

Paper Feed Direction

C A U T I O N

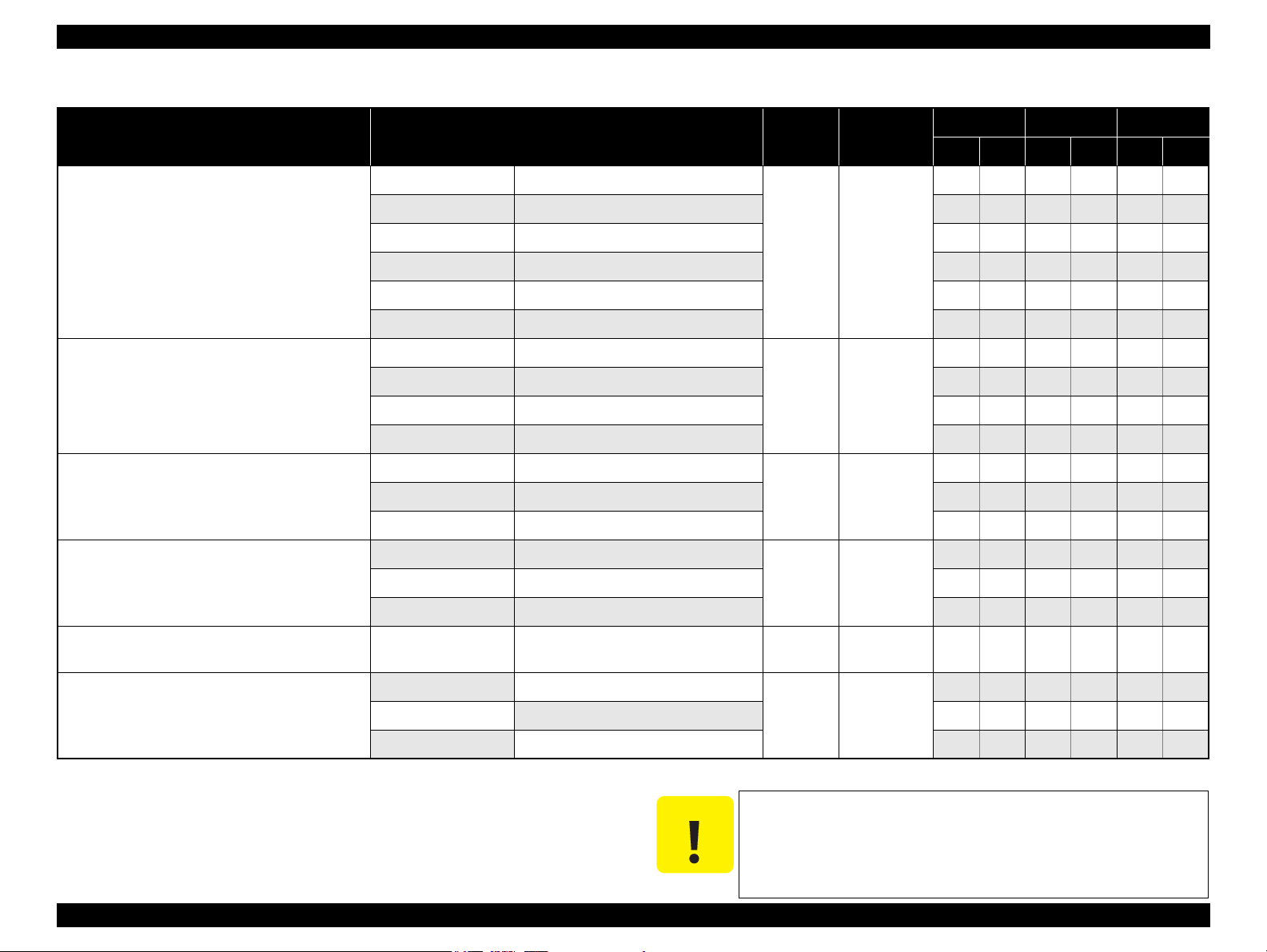

1.2.4 Printing Area

The printing area for this printer is shown below.

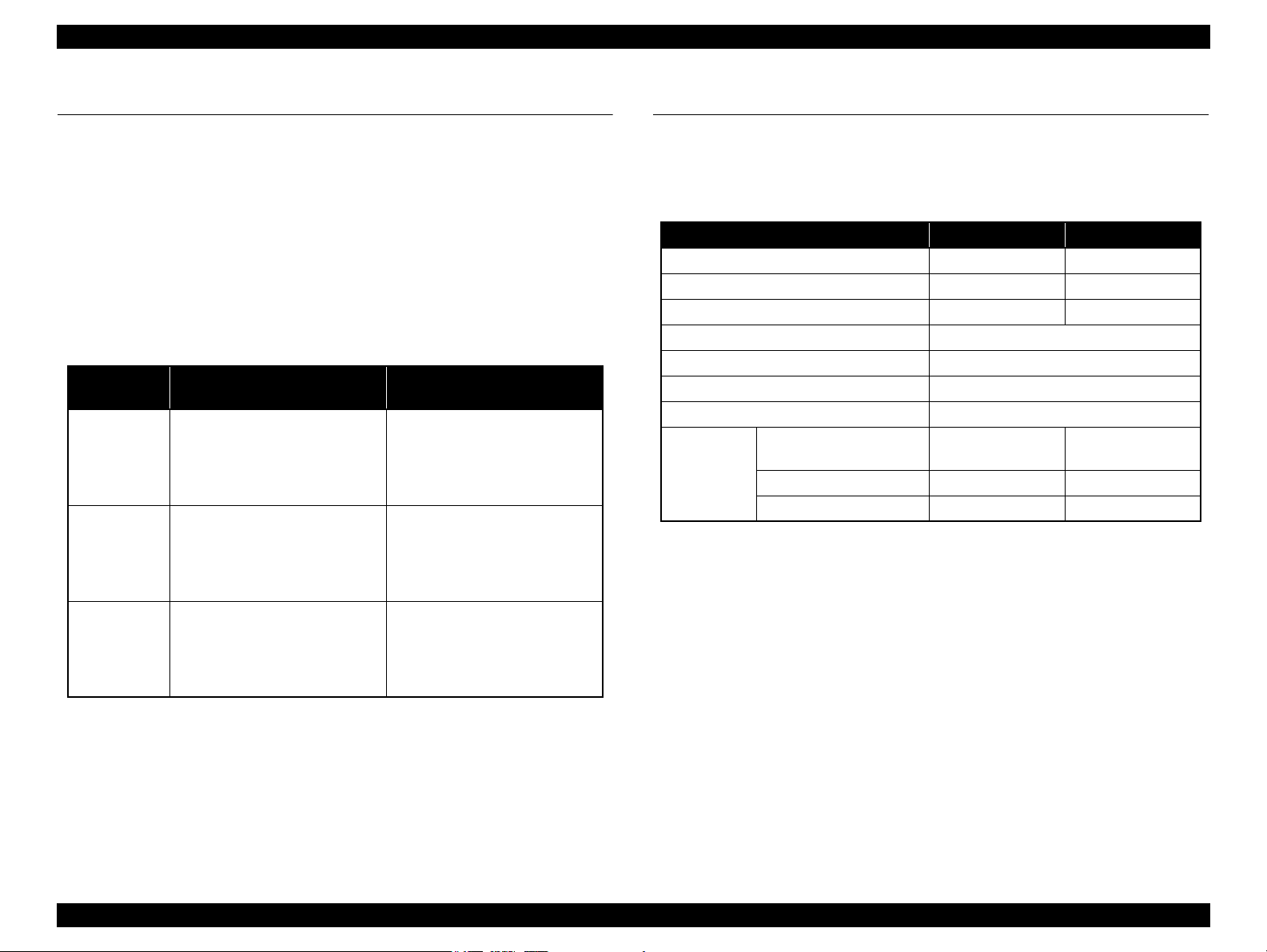

Table 1-5. Printing Area (Margins)

Print Mode Paper Size

Standard print

Borderless

print

Note * : The margins for Borderless print are margins that bleed off the edges of paper.

Any size 3 mm 3 mm 3 mm 3 mm

Envelope 5 mm 5 mm 3 mm 20 mm

A4/Letter to

5” x 7”

4” x 6” 2.3 mm* 3.39 mm*

Left Right Top Bottom

2.54 mm* 2.54 mm*

Margin

2.3 mm* 3.67 mm*

1.2.5 Ink Cartridge

The product numbers of the EPSON ink cartridges for this printer are shown below.

Table 1-6. Product No. of Ink Cartridges

Color EAI Latin Euro CISMEA Asia

Black T0681 (S) T0731H (S)

Cyan T0692 (3S) T0732 (3S) T0712 (3S) T0732 (3S) T0732 (3S)

Magenta T0693 (3S) T0733 (3S) T0713 (3S) T0733 (3S) T0733 (3S)

Yellow T0694 (3S) T0734 (3S) T0714 (3S) T0734 (3S) T0734 (3S)

Note * : Not supported for EHK.

T0711H (S)

T0711 (2S)

Shelf life

Two years from production date (if unopened), six months after opening package.

Storage Temperature

Table 1-7. Storage Temperature

Situation Storage Temperature Limit

When stored in individual boxes

When installed in main unit

-20 oC to 40 oC

(-4oF to 104oF)

-20 oC to 40 oC

(-4oF to 104oF)

T0731H (S)

T0731 (2S)

1 month max. at 40 oC (104oF)

T0731H (S)*

T0731 (2S)

PRODUCT DESCRIPTION Printing Specifications 14

Figure 1-2. Printing Area

Dimension

12.7 mm (W) x 68 mm (D) x 47 mm (H)

The ink cartridge cannot be refilled.

Do not use expired ink cartridges.

The ink in the ink cartridge freezes at -16 °C (3.2 oF). It takes

about three hours under 25 °C (77

becomes usable.

o

F) until the ink thaws and

EPSON Stylus C110/C120/D120 Revision B

1.3 Interface

The printer has a USB interface of the following specification.

Standards

“Universal Serial Bus Specifications Revision 2.0”

“Universal Serial Bus Device Class Definition for Printing Devices Version 1.1”

Transfer rate: 480 Mbps (High Speed Device)

Data format: NRZI

Compatible connector: USB Series B

Recommended cable length: 2 [m] or less

Table 1-8. Device ID

Product

Name

Stylus C120

Stylus D120

Stylus C110

When IEEE 1284.4 is Enabled When IEEE 1284.4 is Disabled

MFG:EPSON;

CMD:ESCPL2,BDC,D4,D4PX;

MDL:Stylus[SP]C120;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]C120;

MFG:EPSON;

CMD:ESCPL2,BDC,D4,D4PX;

MDL:Stylus[SP]D120;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]D120;

MFG:EPSON;

CMD:ESCPL2,BDC,D4,D4PX;

MDL:Stylus[SP]C110;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]C110;

MFG:EPSON;

CMD:ESCPL2,BDC;

MDL:Stylus[SP]C120;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]C120;

MFG:EPSON;

CMD:ESCPL2,BDC;

MDL:Stylus[SP]D120;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]D120;

MFG:EPSON;

CMD:ESCPL2,BDC;

MDL:Stylus[SP]C110;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]C110;

1.4 General Specifications

1.4.1 Electrical Specifications

Primary power input

Rated power supply voltage 100 to 120 VAC 220 to 240 VAC

Input voltage range 90 to 132 VAC 198 to 264 VAC

Rated current 0.6 A 0.3 A

Rated frequency 50 to 60 Hz

Input frequency range 49.5 to 60.5 Hz

Insulation resistance 3000 V (for one minute)

Energy conservation International Energy Star Program compliant

Power

consumption

Note : If the printer is not operated for more than three minutes, the printer shifts into the

standby mode and reduces the current to the motor to conserve power.

Table 1-9. Primary Power Specifications

Item 100-120 V model 220-240 V model

Printing

(ISO10561 Letter Pattern)

Sleep mode 2.0 W 2.0 W

Standby mode (power-off) 0.2 W 0.4 W

15 W 15 W

PRODUCT DESCRIPTION Interface 15

EPSON Stylus C110/C120/D120 Revision B

C A U T I O N

10/50

27/80

35/9520/68

Temperature (°C/°F)

20

30

40

50

90

80

70

60

Humidity (%)

30/86 40/104

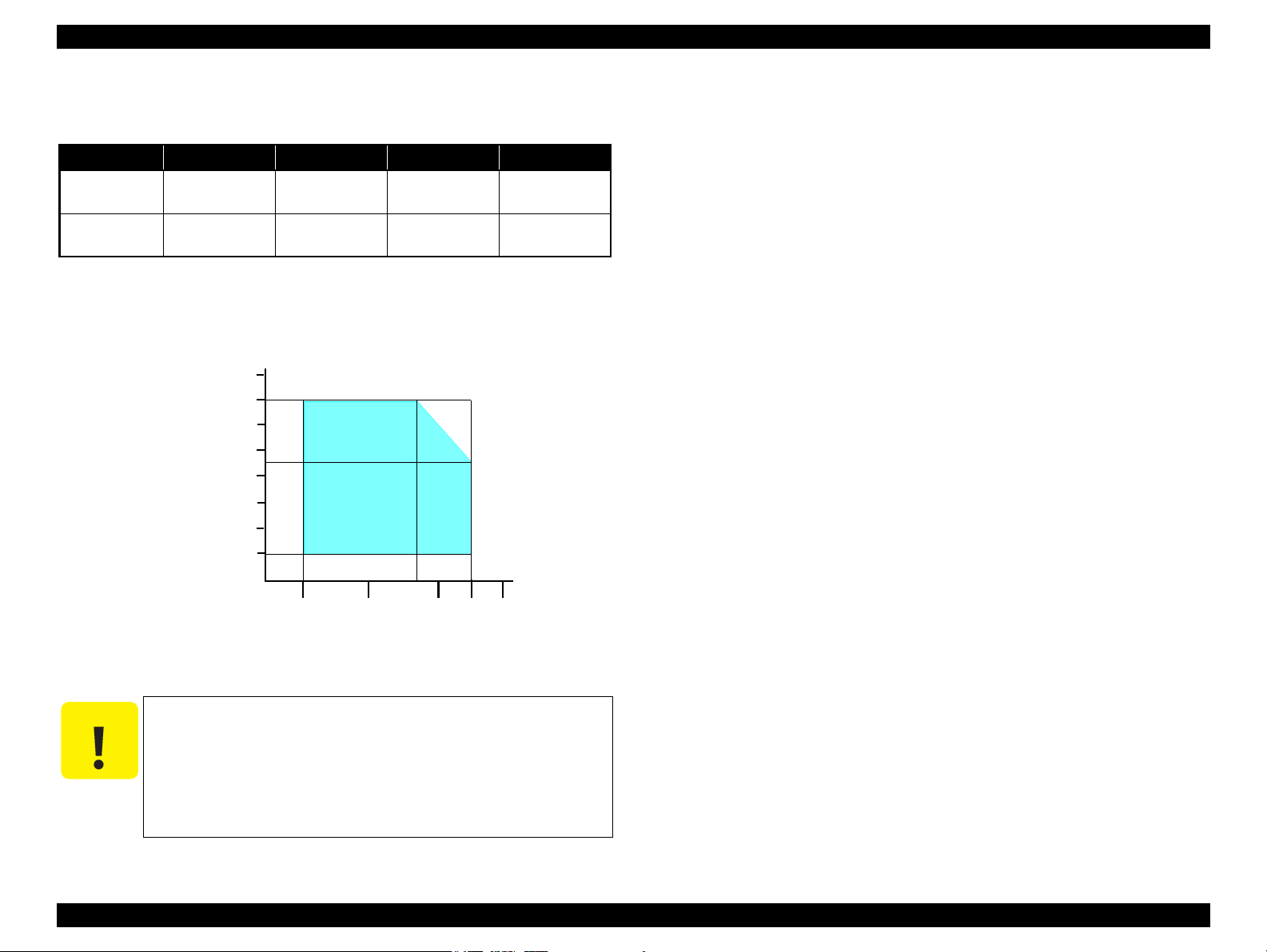

1.4.2 Environmental Conditions

Table 1-10. Environmental Conditions

°F)

*1

3

Humidity

20 to 80%

Condition Temperature

Operating

Storage

(unpacked)

Note *1 : The combined Temperature and Humidity conditions must be within the blue-shaded

range in

*2 : No condensation

*3 : Must be less than 1 month at 40°C.

10 to 35°C

(50 to 95

-20 to 40°C*

(-4°F to 104°F)

Fig.1-3.

Figure 1-3. Temperature/Humidity Range

When returning the repaired printer to the customer, make sure

the Printhead is covered with the cap and the ink cartridge is

installed.

If the Printhead is not covered with the cap when the printer is

off, turn on the printer with the ink cartridge installed, make

sure the Printhead is covered with the cap, and then turn the

printer off.

5 to 85%

*1,2

Shock Vibration

1G

(1 msec or less)

2G

(2 msec or less)

10

10

0.15G,

to 55Hz

0.50G,

to 55Hz

1.4.3 Durability

Total print life: Black 20,000 pages (A4, 3.5% duty),

Color 10,000 pages (A4, ISOFDC24712),

or five years which ever comes first

Printhead: Six billions shots (per nozzle) or five years which ever comes

first

1.4.4 Acoustic Noise

Max. 55dB (when printing from PC, on A4, in default mode)

1.4.5 Safety Approvals (Safety standards/EMI)

USA UL60950-1

FCC Part15 Subpart B Class B

Canada CSA No.60950-1

CAN/CSA-CEI/IEC CISPR 22 Class B

Mexico NOM-019-SCFI-1998

Taiwan CNS13438 Class B

CNS14336

EU EN60950-1

EN55022 Class B

EN61000-3-2, EN61000-3-3

EN55024

Germany EN60950-1

Russia GOST-R (IEC60950-1, CISPR 22)

Singapore IEC60950-1

Korea K60950-1

KN22 Class B

KN61000-4-2/-3/-4/-5/-6/-11

China GB4943

GB9254 Class B, GB17625.1

Argentina IEC60950-1

Australia AS/NZS CISPR22 Class B

PRODUCT DESCRIPTION General Specifications 16

EPSON Stylus C110/C120/D120 Revision B

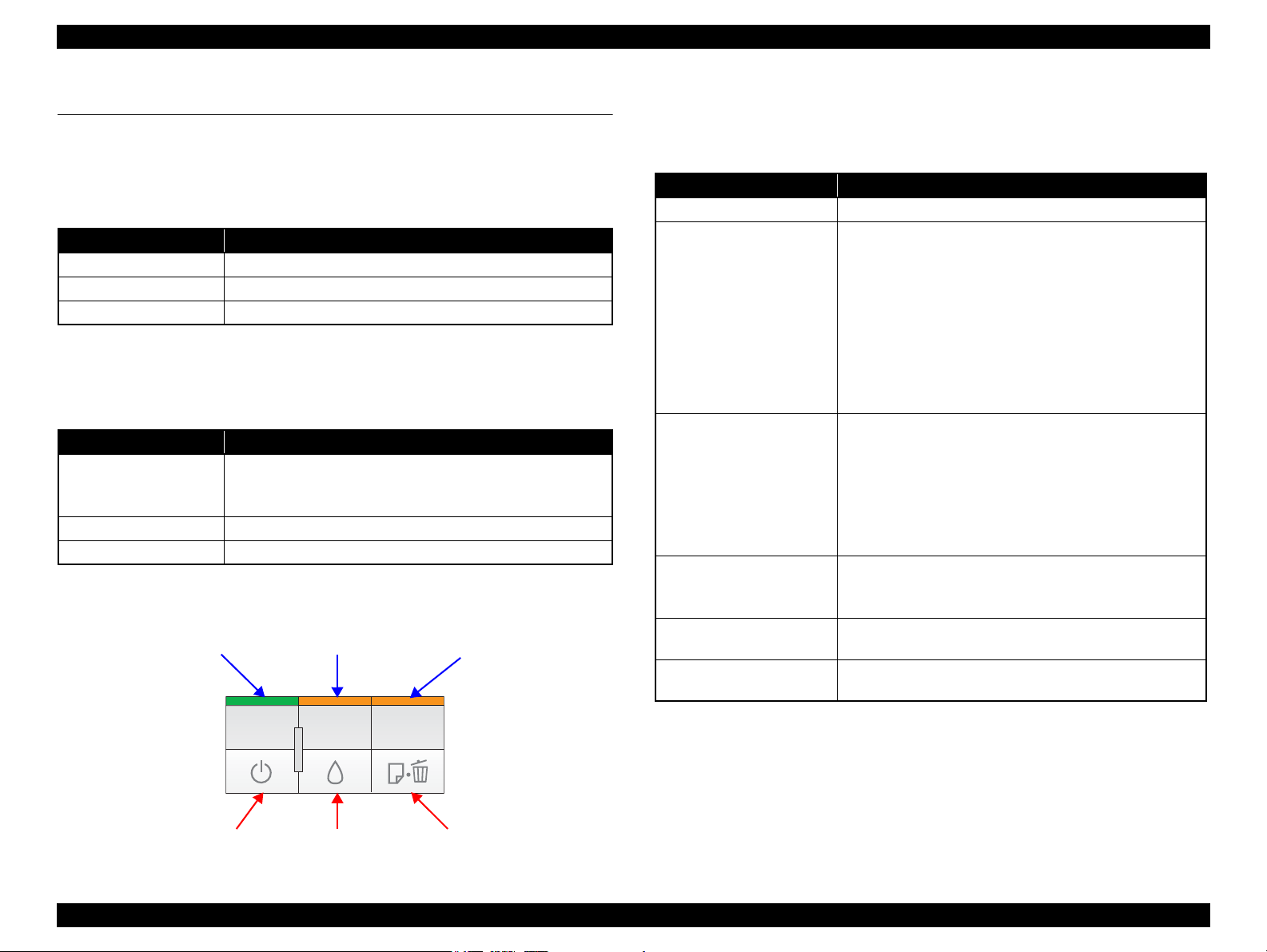

Power Button Paper ButtonInk Button

Power LED Paper LEDInk LED

1.5 Operation Buttons & Indicators (LEDs)

1.5.1 Operation Buttons

The printer has the following three operation buttons.

Table 1-11. Operation Buttons

Button Function

Power Turns the power ON/OFF.

Ink Runs a sequence of ink cartridge replacement or cleaning.

Paper Feeds or ejects paper.

1.5.2 Indicators (LEDs)

Three indicators (LEDs) are provided to indicate settings or printer status.

Table 1-12. Indicators (LEDs)

LED Function

Lights at power-on.

Power LED (green)

Ink LED (orange)*

Paper LED (orange)*

Note *1 : The Ink LED and Paper LED stay OFF when printing from PC.

*2 : See Table 1-14 “Indicators (LEDs) Function” for the LED status at error occurrence.

1

Flashes during some sequence is in progress.

Flashes at high speed during power-OFF sequence.

Lights or flashes when an ink-related error occurs.*

1

Lights or flashes when an paper-related error occurs.*

2

1.5.3 Operation Buttons & LEDs Functions

Detailed information on the buttons and LEDs functions are listed below.

Table 1-13. Operation Button Functions

Button Function

Power • Turns the power ON/OFF

• Runs a sequence of ink cartridge replacement. The carriage

moves to set the ink cartridge to the position for

replacement.

• Moves the carriage to the ink check position when ink level

Ink

Paper

2

Ink

(when held for three seconds

or longer)

Power + Paper *

(combination)

Power + Ink *

(combination)

1

2

low, ink out, or no ink cartridge error has occurred.

• When an ink cartridge is at the ink check position, moves

the carriage to set the cartridge to the position for

replacement, or to the ink check position.

• When an ink cartridge is at the ink replacement position,

moves the carriage to the home position.

• Feeds or ejects paper.

• Recovers from a multi-feed error and resumes the print job.

• Feeds paper that is loaded on the tray when a no-paper error

has occurred.

• Ejects a jammed paper when a paper jam error has

occurred.

• Cancels the print job during printing.

• Runs a head cleaning.

• Runs a sequence of ink cartridge replacement when ink

level low, ink out, or no ink cartridge error has occurred.

•Prints a nozzle check pattern.*

• Forcefully turns the power OFF.

3

Note 1: First press the Paper button and then Power button. The printer will turn On and print

the nozzle check pattern.

2: First press the Power button and then Ink button. Hold them for seven seconds.

3: The nozzle check pattern printed by the printer is shown in Figure 1-5.

Figure 1-4. Buttons & LEDs

PRODUCT DESCRIPTION Operation Buttons & Indicators (LEDs) 17

EPSON Stylus C110/C120/D120 Revision B

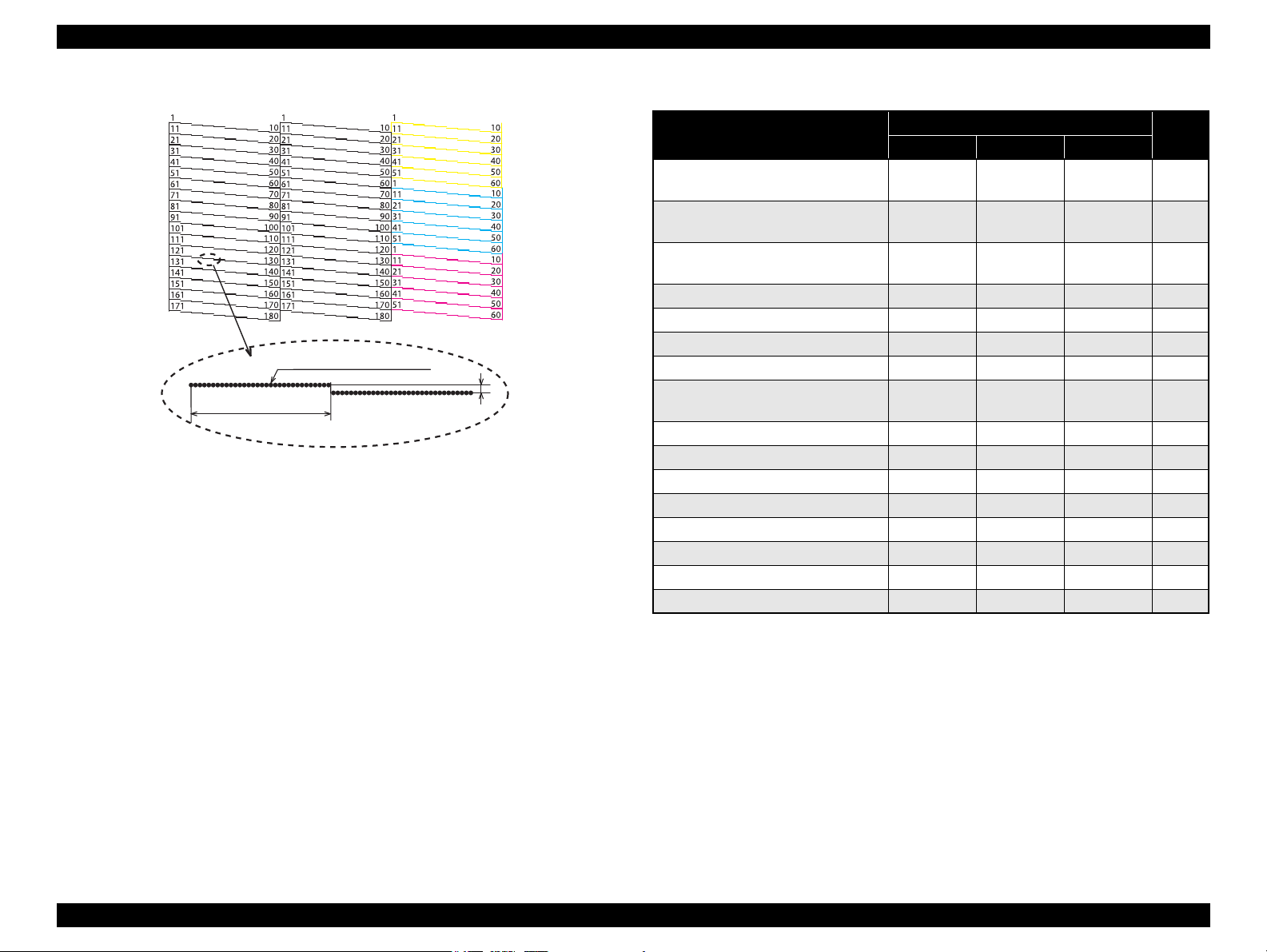

360 dpi VSD1

0.142 mm (1/180 inch)

32 dots

Note : The numbers shown in the figure are nozzle numbers. They are not printed on

an actual nozzle check pattern.

Table 1-14. Indicators (LEDs) Function

Figure 1-5. Nozzle Check Pattern

Printer Status

Powering off

Power Ink Paper

Flashes at

high speed

Fatal error OFF

Maintenance request OFF

Indicators (LEDs)

OFF OFF 1

Flashes at

high speed

Flashes at

high speed

Flashes

alternately 2

alternately 1

Flashes

Paper jam -- -- Flashes 5

Multi-feed error -- -- ON 6

No paper error -- -- ON 6

Cover open error -- Flashes 2 Flashes 2 6

Ink cartridge replacement is in

progress

Flashes -- -- 7

Ink sequence is in progress Flashes -- -- 8

CSIC error -- ON -- 9

No ink cartridge error or ink-out error -- ON -- 9

During feeding or ejecting paper Flashes -- -- 10

Data processing Flashes -- -- 10

Ink level low error -- Flashes -- 11

Power ON ON -- -- 12

Reset request*

2

ON ON ON -

Pri-

ority*

2

3

1

Note : --: No change

Flash: Repeats turning On and Off every 1.25 seconds.

Flash 2: Repeats On for 0.5 seconds, Off for 0.5 seconds,

On for 0.5 seconds, and Off for 1.0 second.

Flash at high speed: Repeats turning On and Off every 0.5 seconds.

Flashes alternately 1: same as the “Flash”

Flashes alternately 2: Repeats turning Off and On every 1.25 seconds.

Note *1 : When two or more errors occur at the same time, the one with higher priority will be

PRODUCT DESCRIPTION Operation Buttons & Indicators (LEDs) 18

indicated.

*2 : All LEDs light for 0.2 seconds when a reset request is received.

EPSON Stylus C110/C120/D120 Revision B

1.5.4 Errors & Remedies

Error Description Remedies

Fatal error A mechanical error has occurred.

Maintenance request

Paper jam A paper jam has occurred.

No paper Failed to feed paper.

Multi-feed

Ink-out The cartridge has run out of ink. Replace the ink cartridge.

No ink cartridge Ink cartridge(s) was not detected. Replace the ink cartridge.

Wrong ink cartridge

Note : For more information on the remedies, see “ 3.2.2 Error Indications and Fault Occurrence

Causes ” (p.45).

Waste ink pads need to be

replaced.

Multiple sheets of paper were fed

at the same time.

Incorrect ink cartridge(s) was

detected.

Turn the power Off and back it

On.

Replace the waste ink pads and

reset the counter.

Remove the jammed paper and

press the Paper button.

Load paper correctly and press

the Paper button.

Press the Paper button to eject the

multiple sheets.

Replace the ink cartridge.

PRODUCT DESCRIPTION Operation Buttons & Indicators (LEDs) 19

OPERATING PRINCIPLE

CHAPTER

2

EPSON Stylus C110/C120/D120 Revision B

Compression

Spring

LD Roller

Retard Roller

Clutch

Mechanism

PE Sensor

PF Motor

Ink System

Carriage

Unit

CR Encoder

Sensor

PF Roller

Timing Belt

EJ Roller

Star Wheel

Roller

PF ScalePF Encoder Sensor

CR Motor

Cover Open

Sensor

Change Lever

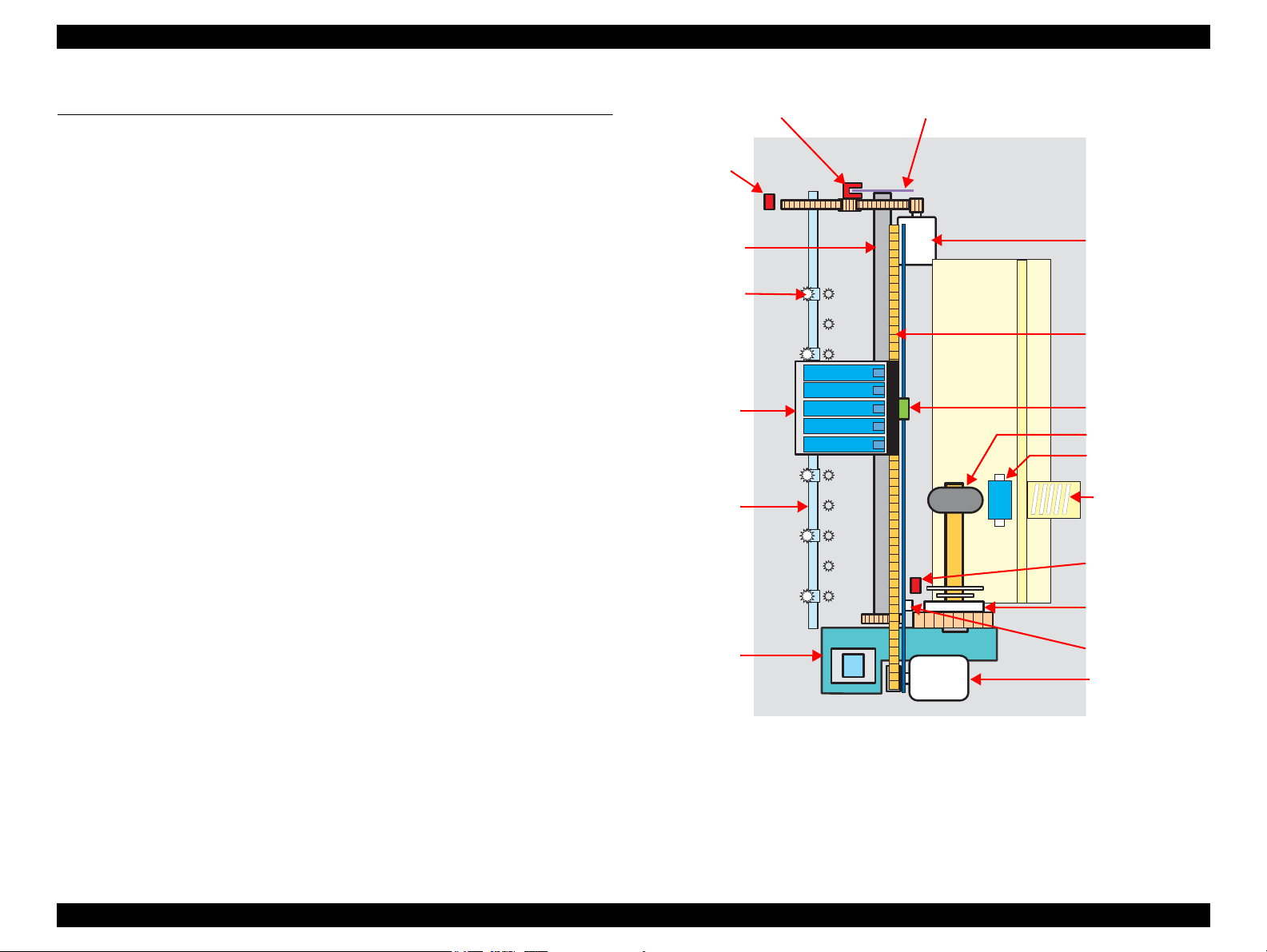

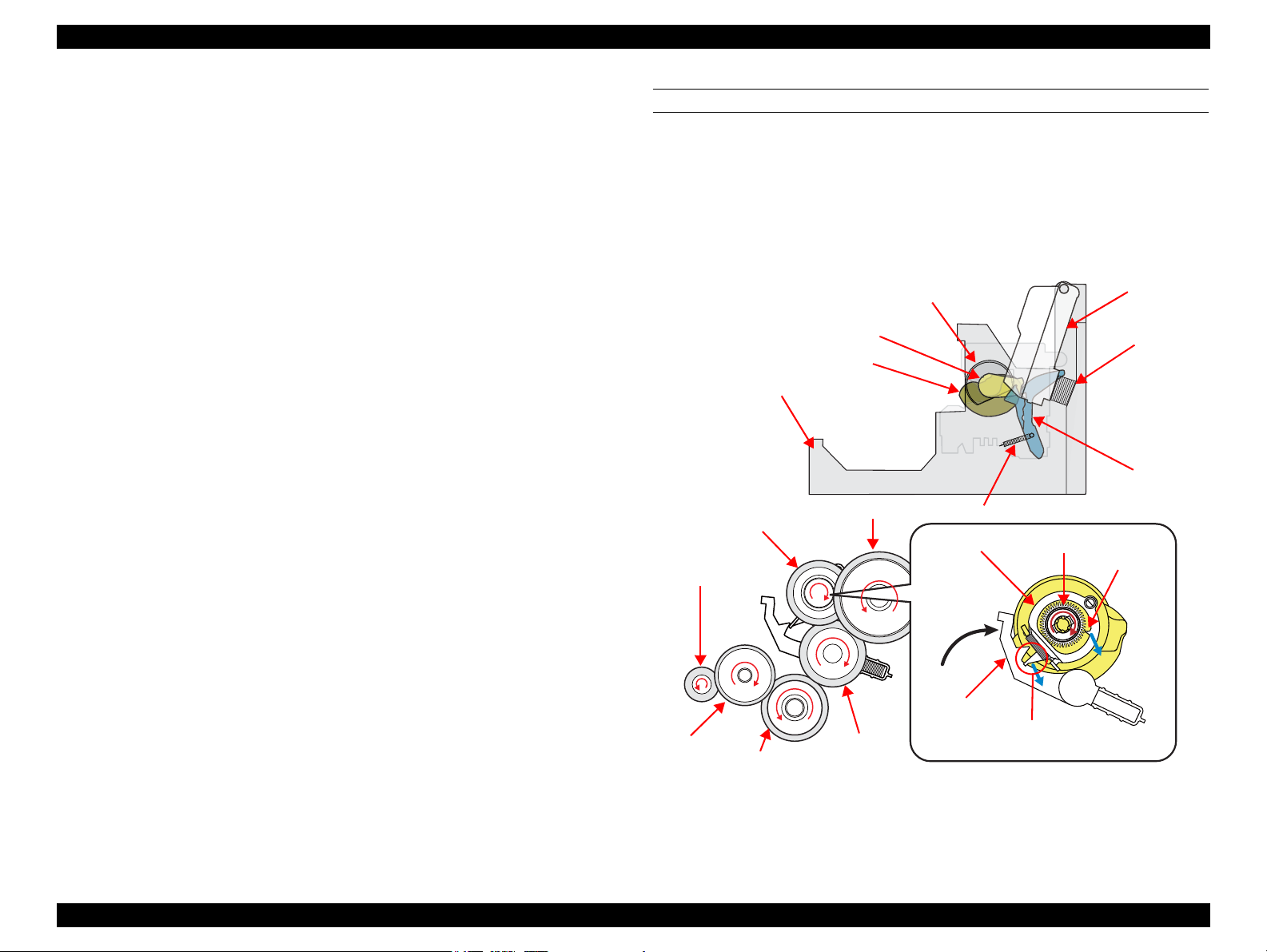

2.1 Overview

This section describes the operating principles of the Printer Mechanism and Electrical

Circuit Boards of Stylus C110/C120/D120.

Stylus C110/C120/D120 employs a newly developed printer mechanism. The

following sections explain about the major components of the new printer mechanism.

2.1.1 Printer Mechanism

Stylus C110/C120/D120 printer mechanism consists of printhead, carriage mechanism,

paper loading mechanism, paper feed mechanism, and ink system.

As the conventional models, Stylus C110/C120/D120 is equipped with two DC

motors; one is used to drive the paper loading, paper feed mechanisms, and the pump

mechanism that includes the carriage lock mechanism, and another one is used to drive

the carriage mechanism. A paper is fed from the rear ASF unit by means of the LD

roller and Retard roller and ejected to the front tray.

OPERATING PRINCIPLE Overview 21

Figure 2-1. Printer Mechanism block diagram

EPSON Stylus C110/C120/D120 Revision B

CR Motor

PF Motor

CR Encoder Sensor

PF Encoder Sensor

CR Contact Module

PE Sensor

Printhead

Cover Open Sensor

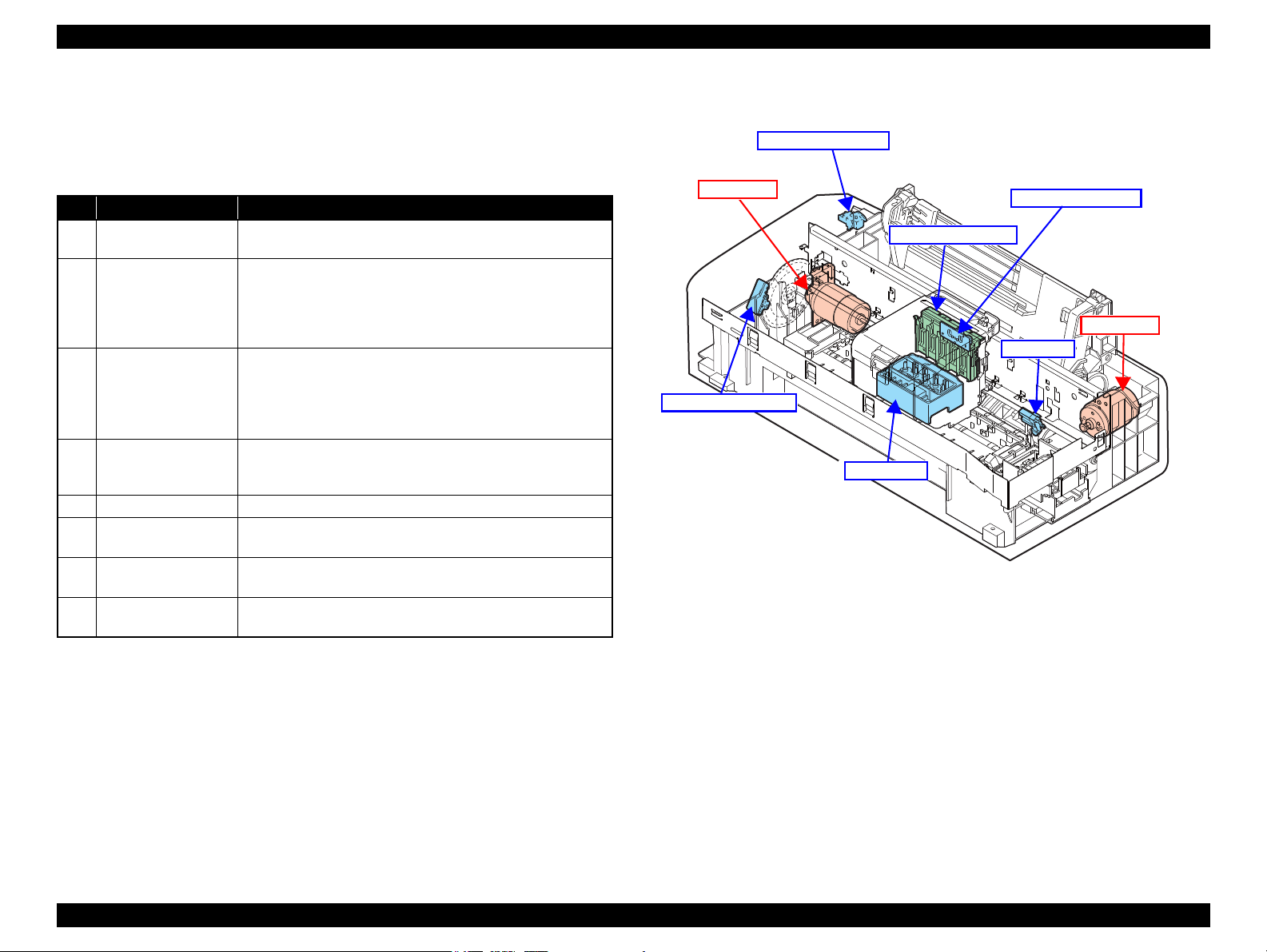

2.1.2 Motors & Sensors

Stylus C110/C120/D120 printer mechanism is equipped with the following printhead,

motors and sensors.

No. Name Specification

1 Printhead

2 CR Motor

3 PF Motor

4 PE Sensor

5 CR contact module CSIC board

6 CR Encoder Sensor

7 PF Encoder Sensor

8 Cover Open Sensor

Figure 2-3 shows their locations.

Table 2-1. List of Motors & Sensors

F3-3 MACH Turbo2 head

(Black: 180 nozzles x 2, Color: 180 nozzles (60 nozzles* x 3 colors) x 1

Type: DC motor

Drive voltage: 42VDC +/- 5% (DRV IC voltage)

Characteristics: Coil resistance: 22.7Ω +/- 10%

Inductance: 15.9mH (1KHz)

Drive method: PWM, constant-current chopping

Type: DC motor

Drive voltage: 42VDC +/- 5% (DRV IC voltage)

Characteristics: Coil resistance: 21.2Ω +/- 10%

Inductance: 17.2 mH (1kHz)

Drive method: PWM, constant-current chopping

Purpose: Detection of paper top and bottom edge, for control to set

paper at the print start position

Type: Photo interrupter

Type: Photo interrupter

Resolution: 180 pulse/inch

Type: Photo interrupter

Resolution: 180 pulse/inch

Purpose: Detection of open/close status of the printer cover

Type: Mechanical contact

Figure 2-2. Motors & Sensors in Printer Mechanism

Note " * " : The No.1 nozzle of each color is used only for executing flushing, and is not used for

printing.

OPERATING PRINCIPLE Overview 22

EPSON Stylus C110/C120/D120 Revision B

2.258

(64/720inch)

A column B column C column

C#3

C#2

C#1

5.644

(160/720inch)

0.071

(1/360inch)

Carriage movement direction

Paper feed direction

C#180

C#179

C#178

B#3

B#2

B#1

B#180

B#179

B#178

A#3

A#2

A#1

A#180

A#179

A#178

* #1,#61 and #121 nozzles of C column are

used only for flushing, and are not used

for printing.

Black

A column: #1 to #180

B column: #1 to #180

Yellow C column*: #1 to C#60

Magenta C column*: #61 to C#120

Cyan C column*: #121 to C#180

CR Contact

Module

Ink Supply Needle

Ink Cartridge

Ink Cavity

PZT

Nozzle Plate

CSIC Memory Chip

Electric poles

for CSIC

*Head ID is stored in EEPROM

on the main board.

Filter

2.2 Printer Mechanism Operating Principles

2.2.1 Printhead

F3-3 Mach Turbo2 type printhead is employed, which produces variable sized dot and

economy dot. The printhead configuration is as follows.

Nozzle configuration

Black: 180 nozzles x 2

Color: 180 nozzles x 1 (cyan, magenta, yellow)

The nozzle layout as seen from behind the printhead is shown below.

Therefore, whenever the printhead, main board, or the printer mechanism must be

replaced with a new one, the Head ID of the new printhead needs to be written into the

EEPROM using the Adjustment Program. The printer generates appropriate PZT drive

voltage based on the Head ID information.

Following explains the basic components of the printhead.

PZT

PZT is an abbreviation of Piezo Electric Element. Based on the drive waveform

generated on the main board, the PZT selected by the nozzle selector IC on the

printhead pushes the top of the ink cavity, which has ink stored, to eject the ink

from each nozzle on the nozzle plate.

Nozzle Plate

The plate with nozzle holes on the printhead surface is called Nozzle Plate.

Filter

This filter is located beneath the ink supply needle which supply ink to the

printhead from the ink cartridge. The filter is preventing dirt or dust from getting

into the printhead. Any dirt or dust may interrupt normal ink flow or can cause

nozzle clog adversely affecting the print quality.

Ink Cavity

The ink absorbed from the ink cartridge goes through the filter and then is stored

temporarily in this tank called “ink cavity” until PZT is driven.

The basic operating principles of the printhead, which plays a major role in printing,

are the same as the previous printer; on-demand method which uses PZT (Piezo

Electric Element). In order to reduce unit-to-unit variation in ink droplet size, the

printhead has its own Head ID (10-digits code for Stylus C110/C120/D120) which

corrects PZT drive voltage for the printhead.

OPERATING PRINCIPLE Printer Mechanism Operating Principles 23

Figure 2-3. Nozzle Layout

Figure 2-4. Printhead Mechanism

EPSON Stylus C110/C120/D120 Revision B

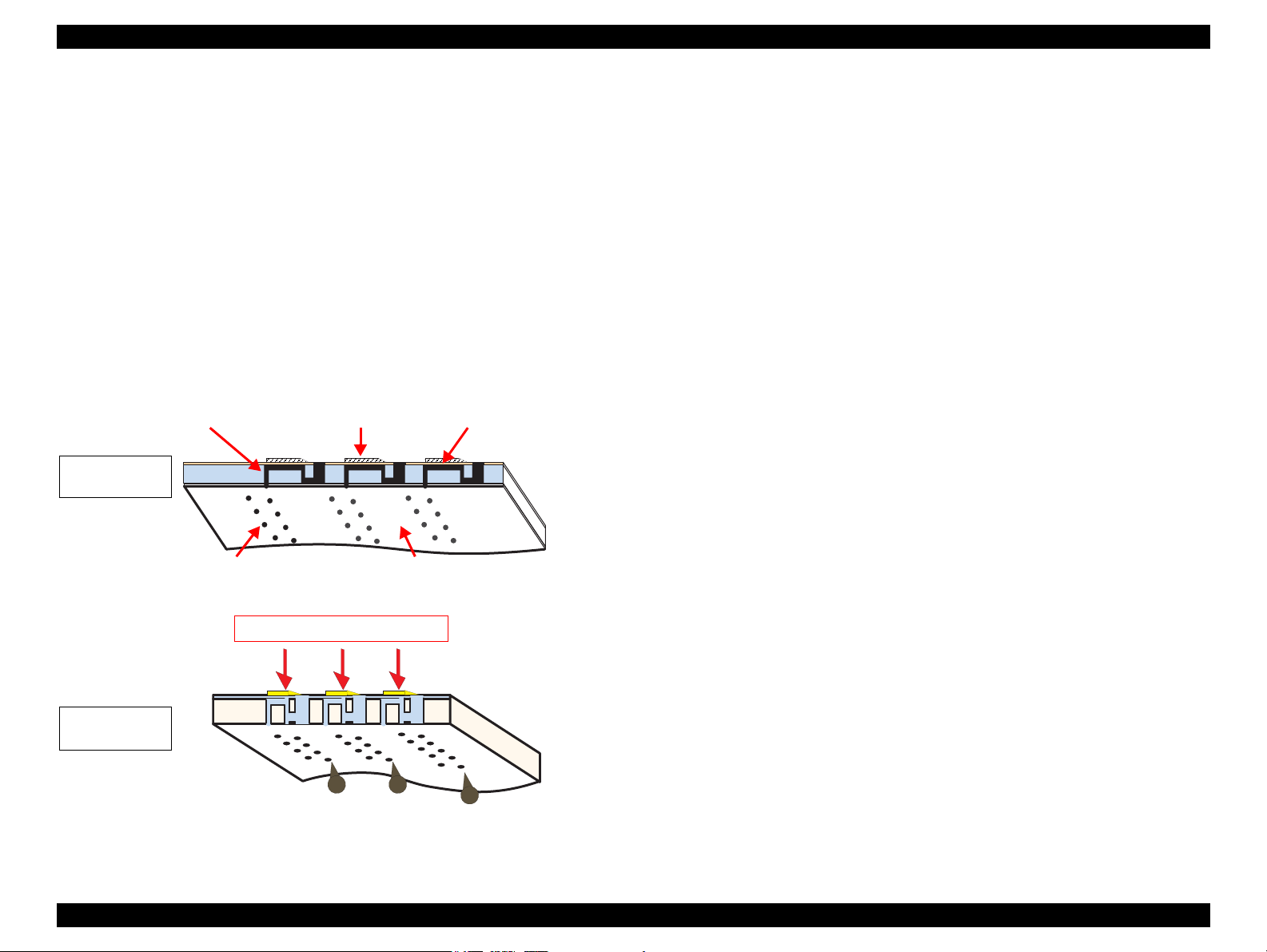

Ink path PZT Ink Cavity

Nozzle Nozzle Plate

PZT drive voltage is applied

When not

firing ink drop

When firing

ink drop

2.2.1.1 Printing Process

This section explains how the printhead of the on-demand inkjet printer fires ink drop

from each of the nozzles.

1. When not firing ink drop

When the printing signal is not output from the C687 main board, or the PZT drive

voltage is not applied, the PZT does not change its shape. Therefore, the PZT does

not push the ink cavity. The ink pressure inside the ink cavity is kept normal. (refer

to

Figure 2-5 (p.24) “When not firing ink drop”)

2. When firing ink drop

When the print signal is output from C687 main board, the nozzle selector IC

provided on the printhead transmits the data in 1-byte unit. Based on the drive

voltage generated on the main board, the PZT selected by the nozzle selector IC

pushes the top of the ink cavity. By this operation, the ink stored in the ink cavity

is ejected from nozzles. (refer to

Figure 2-5 (p.24) “When firing ink drop”)

2.2.1.2 Printing Method

Stylus C110/C120/D120 offers printing with variable sized dot or printing with

economy sized dot.

Variable dot mode

This mode is developed to improve the print quality on Epson designated paper.

Three sizes of dot; micro, middle, and large are automatically selected and used

for printing according to the print data, basically the same as conventional models.

Superior quality can be achieved on the Epson paper.

Economy dot mode

Fixed larger dot is used for printing in economy mode, which enables fast printing

with lower resolutions.

OPERATING PRINCIPLE Printer Mechanism Operating Principles 24

Figure 2-5. How to Fire Ink Drop

EPSON Stylus C110/C120/D120 Revision B

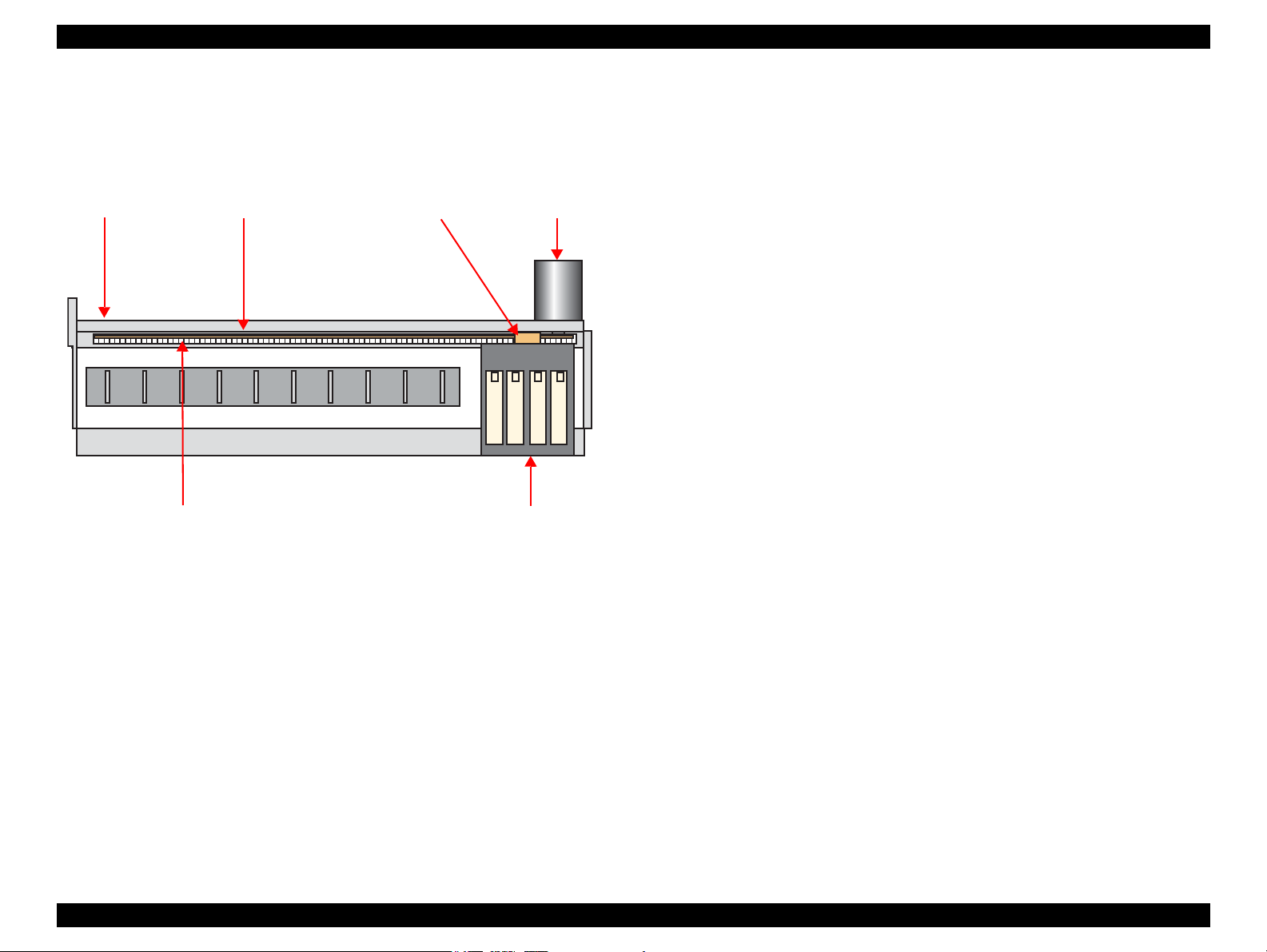

Carriage Unit

Main Frame

Timing Belt

CR Scale CR Encoder Sensor CR Motor

2.2.2 Carriage Mechanism

The carriage mechanism components include the carriage unit (including printhead,

CR encoder sensor), CR motor, timing belt, and CR scale.

The operating principles of the carriage mechanism are described below.

Figure 2-6. Carriage Mechanism

2.2.2.1 CR Motor Control

This printer employs closed-loop control, via the CR motor and an encoder, to control

the carriage speed and position. Since the CR motor is DC motor, the printer controls

the motor in the following methods in order to ensure stable print quality.

Heat control

The heat control over the CR motor is carried out based on the electrical

characteristic of the motor such as torque constants, coil resistance and power

supply voltages.

the CR mechanical load is in the initial state and saved into the EEPROM.

According to the variations measured in the sequence, the voltage is corrected to

make the drive current value constant reducing an individual difference.

CR measurement sequence

To set the appropriate drive voltage for the CR motor in accordance with variation

of the CR motor mechanical load, the printer runs a CR measurement sequence

and stores the measured data into the EEPROM at power-on or in an ink cartridge

replacement sequence. A fatal error occurs if the printer detects that too much load

is applied to the CR motor.

The above control and sequences enable to correct the drive voltage for the CR motor

based on the mechanical load and the electrical characteristic of the motor. According

to the corrected drive voltage, heating value of the motor is calculated. The printer

automatically provides wait time per CR path during printing when the predetermined

heating value is reached.

2.2.2.2 Carriage Home Position Detection

As the previous model, the carriage home position is detected by the CR motor drive

electric current and carriage speed/position signals sent from the CR encoder. The

detection sequence performed at power-on is described below.

1. Drives the CR motor to move the carriage until it contacts with the right

frame, and then stops the CR motor. The carriage position is set as a position

specified number of counts rightward from the home position.

2. Moves the carriage again to the carriage lock position to check the lock for

proper operation.

3. The printer starts to monitor the carriage position through the CR encoder.

The printer causes a fatal error if too much load on the CR motor is detected due to

obstruction on the carriage path or if no carriage position information is obtained due to

CR encoder or CR scale failure.

CR motor drive dispersion measurement sequence

Variations in torque constant, coil resistance and power supply voltage of the

motor are measured in a CR motor drive dispersion measurement sequence when

OPERATING PRINCIPLE Printer Mechanism Operating Principles 25

EPSON Stylus C110/C120/D120 Revision B

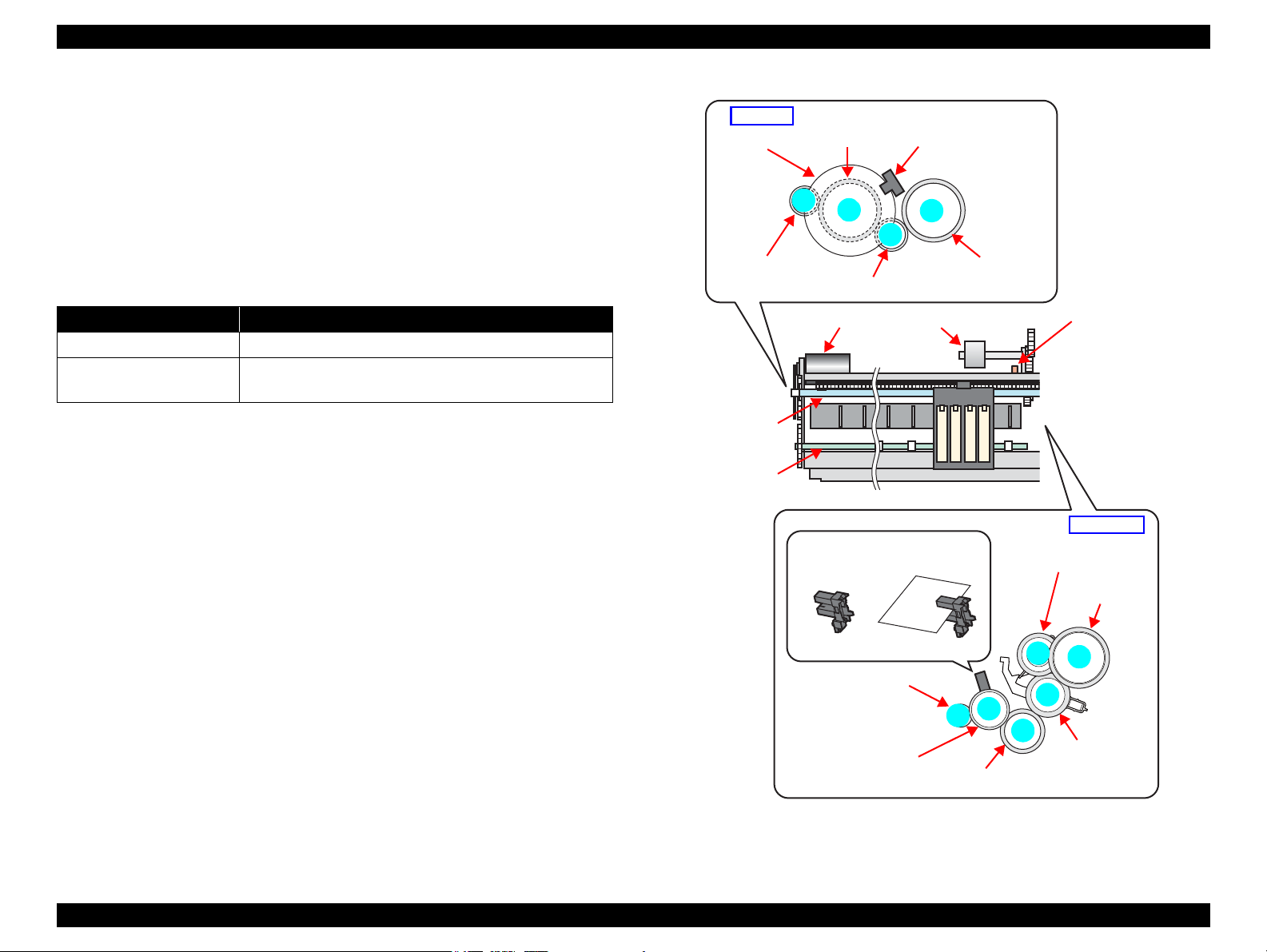

1

2

3

4

2

3

4

5

6

7

PF Motor

Pinion Gear

PF Scale

Spur Gear A

(PF Roller)

PF Encoder Sensor

Transmission Gear

Spur Gear B

EJ Roller

Left side

Right side

Spur Gear C

(PF Roller)

Combination Gear A

Combination Gear B

(Pump Unit)

Combination

Gear C

(Change Lever)

Combination

Gear D

Combination Gear E

(LD Roller/Clutch)

PE Sensor

Low signal

<No Paper> <Detects Paper>

High signal

PF Motor

LD Roller PE Sensor

PF Roller

EJ Roller

2.2.3 Paper Loading/Paper Feed Mechanism

The paper loading/feed mechanism are driven and controlled by the PF motor (DC

motor) and the PF encoder.

The PF motor drive force is transmitted to the LD roller and the PF roller via the gears

in the mechanism. In the loading mechanism, paper is fed to the PF roller from the ASF

unit, and the feed mechanism transports the paper during printing and ejects it.

The rotational direction of the PF motor switches between the loading and feed

operations as shown in the table below.

Table 2-2. Rotational Direction of PF Motor & ASF Operations

Rotational Direction* Operations

Clockwise • Releases the change lever from the clutch mechanism.

Counterclockwise

Note " * " : Rotational direction of the PF motor pinion gear as seen from the left side of the

printer.

Figure 2-7 shows how the PF motor drive is transmitted to the LD roller and the PF

roller. (The numbers in the figure indicate the sequence of the drive transmission.)

• Feeds a paper into the printer and transports it.

• Locks the clutch mechanism with the change lever.

The PE sensor detects the paper top and bottom edges during the loading and feeding

operations. When the sensor could not detect the top edge of paper during the loading

operation, the printer causes a paper out error. And when the sensor could not detect

the bottom edge of paper during feeding operation, the printer causes a paper jam error.

For more details on the errors, see

OPERATING PRINCIPLE Printer Mechanism Operating Principles 26

Chapter 3 "TROUBLESHOOTING" (p42).

Figure 2-7. Paper Loading/Feed Mechanism

EPSON Stylus C110/C120/D120 Revision B

Compression

Spring

Paper Back Lever

Hopper

LD Roller

Hopper Release Cam

Paper Back Lever Cam

Extension Spring

Clutch

Clutch Gear

Clutch Lever

Clutch Lock

Tab

Change Lever

Spur Gear C

(PF Roller)

Base Frame

Combination

Gear A

Combination

Gear B

(Pump Unit)

Combination

Gear C

(Change Lever)

Combination Gear D

Combination Gear E

(LD Roller/Clutch)

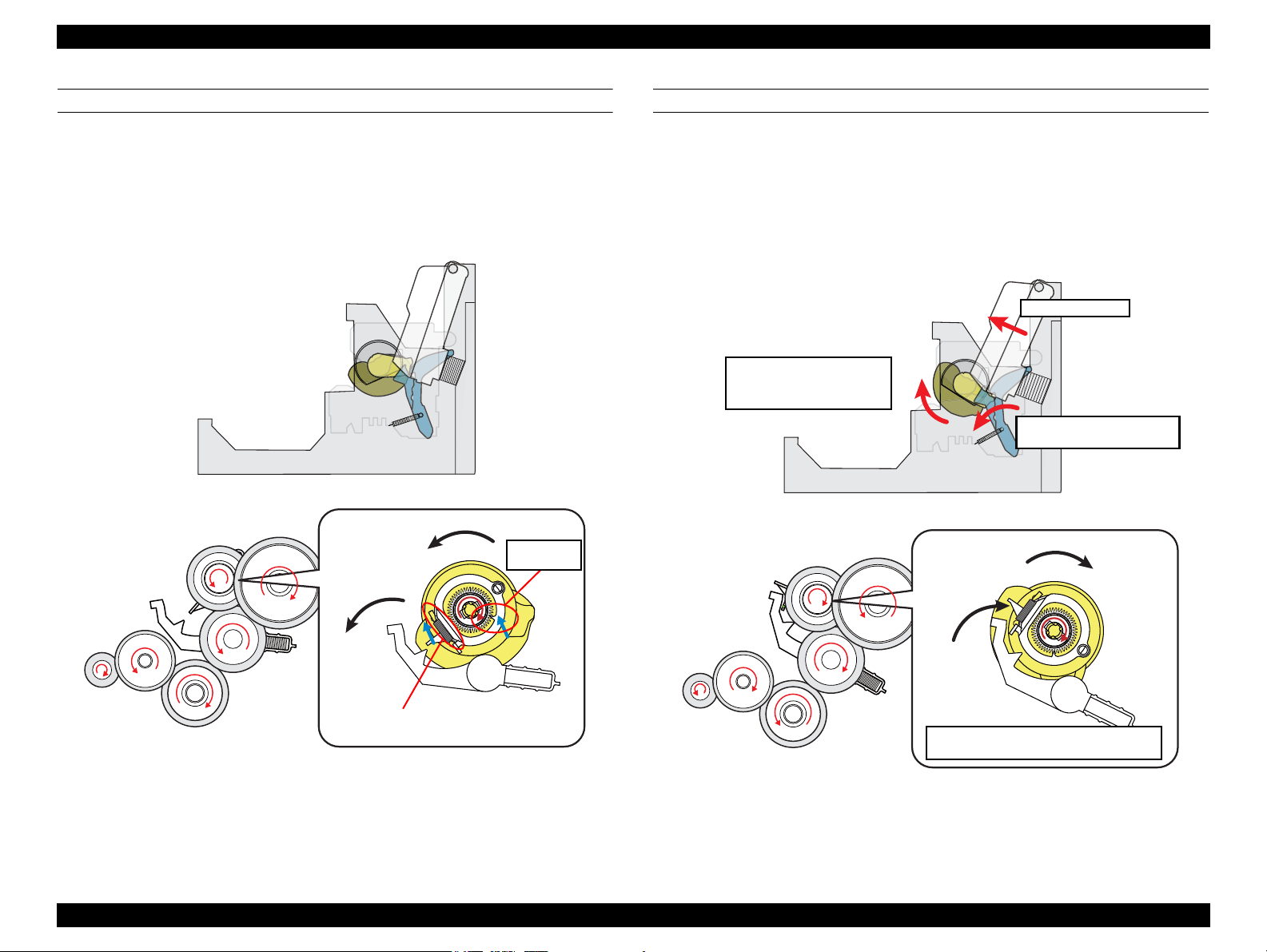

2.2.3.1 Paper Loading Mechanism (ASF Unit)

The paper loading mechanism loads paper from the ASF unit and feeds paper to the PF

roller. The ASF unit includes the hopper, change lever, LD roller shaft, and clutch

mechanism.

The change lever and the clutch mechanism play an important role in the paper loading

operation as described below.

1. ASF home position detection function

The change lever and the clutch mechanism are used to detect the ASF home

position.

The counterclockwise rotation of the PF motor brings the change lever to engage

with the clutch mechanism. The ASF home position is detected by the engagement

of the change lever at the beginning of the paper loading operation. At this time,

paper is not fed to the PF roller because the PF motor drive force is not yet

transmitted to the LD roller shaft.

2. Paper loading function

When the change lever is disengaged from the clutch mechanism by the

counterclockwise rotation of the PF motor pinion gear, the printer changes to the

paper loading state from the ASF home position detection state. The PF motor

drive force is transmitted to the LD roller, and paper is fed from the ASF unit.

The rotation of the two cams on the LD roller feeds paper into the printer.

Larger cam: moves the hopper

Smaller cam: moves the paper back lever

STEP1: ASF HOME POSITION

The counterclockwise rotation of the PF motor pinion gear (as seen from the left of the

printer) causes the change lever to push down on the clutch lever, and the clutch lock

tab is disengaged from the clutch gear as shown in

Figure 2-8. This cuts the PF motor

drive transmission to the LD roller shaft, and the shaft does not move at all. At the

same time, the hopper is pushed down by the two cams on the LD roller shaft, and the

paper back lever is set at the position to prevent paper from being fed. The “ASF home

position” indicates all of the above statuses.

When the first sheet of paper has been fed, the second sheet is returned to the standby

position by the hopper and the paper back lever, which are moved by the cams.

The following sections explain the paper loading sequence and operations of each

components.

OPERATING PRINCIPLE Printer Mechanism Operating Principles 27

Figure 2-8. ASF Home Position

EPSON Stylus C110/C120/D120 Revision B

Extension Spring

Clutch lock

tab engages

PF Motor drive is transmitted to LD

Roller and paper is fed

Paper Back Lever goes to

standby position

Hopper pops up

Paper Back Lever Cam and

Hopper Release Cam rotate

together with LD Roller

STEP2: RELEASING CLUTCH LEVER TO DRIVE LD ROLLER

When the PF motor pinion gear starts clockwise rotation (as seen from the left side),

the change lever is moved toward the front of the printer to release the clutch lever.

This causes the clutch to engage with the gear by being pulled by the extension spring.

The clutch gear engages with the clutch lock tab and the PF motor drive force is now

can be transmitted to the LD roller shaft.

STEP3: FEEDING PAPER FROM ASF

After the engagement of the clutch, the PF motor pinion gear starts counterclockwise

rotation (as seen from the left side) and the drive force is transmitted to the LD roller

shaft via the clutch lock tab and the clutch gear. When the LD roller starts to rotate, the

paper back lever is returned to its standby position, and the hopper is released from the

cams by being pushed by the spring. This causes a sheet of paper to be caught between

the hopper and the LD roller, and the further rotation of the LD roller feeds the paper

into the printer.

Figure 2-9. Releasing Clutch Lever

Figure 2-10. Feeding Paper from ASF

OPERATING PRINCIPLE Printer Mechanism Operating Principles 28

EPSON Stylus C110/C120/D120 Revision B

Clutch lever is locked again by change

lever to shut off PF motor drive force.

Paper Back Lever

snaps back

Hopper is pushed down

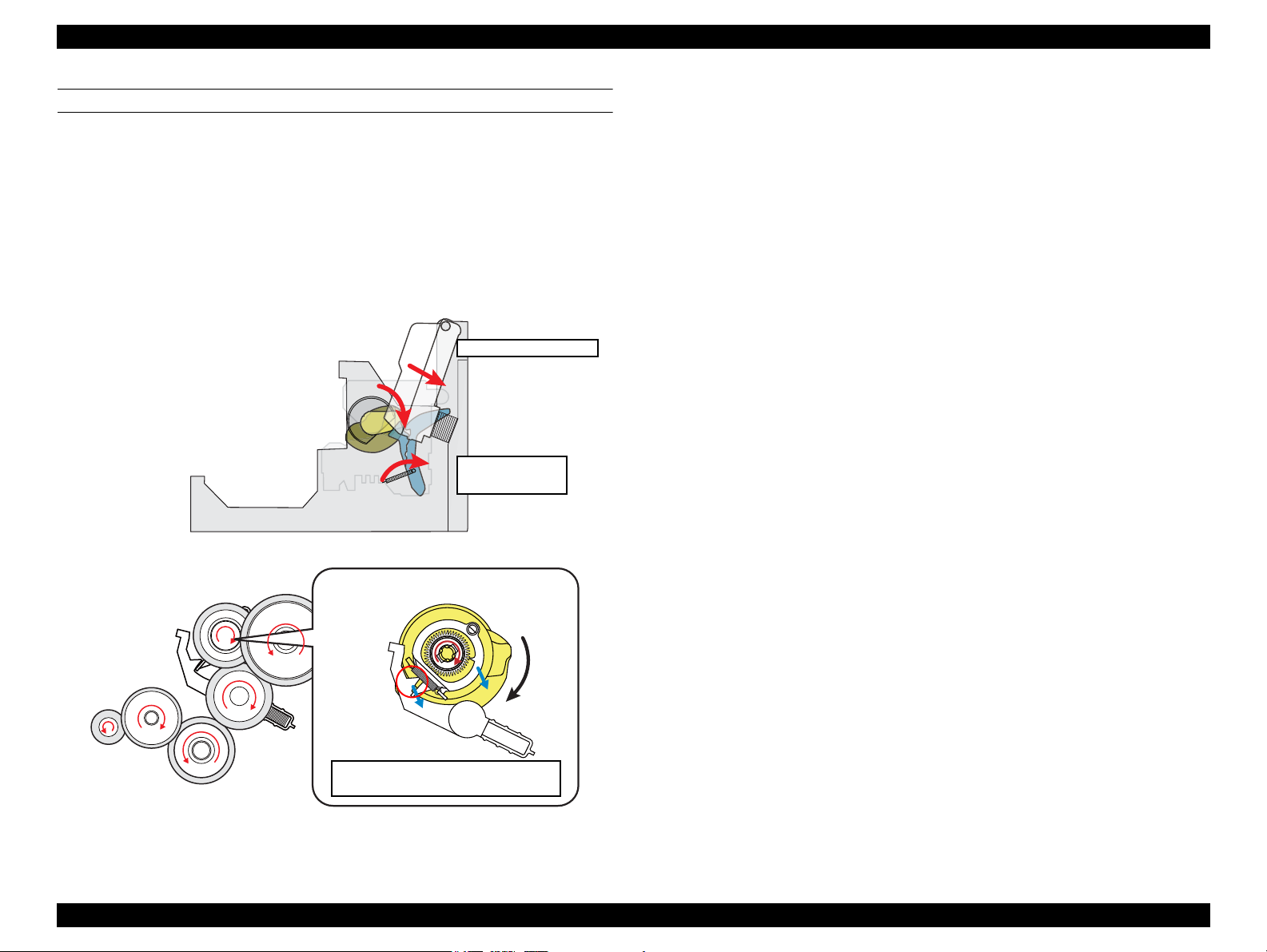

STEP4: ENDING PAPER LOADING OPERATION

Continuous counterclockwise rotation of the LD roller (as seen from the left side) feeds

paper to the PF roller. The LD roller rotation causes the hopper release cam and the

paper back lever cam to push down the hopper and the paper back lever respectively.

The paper back lever returns paper to the standby position to prevent multiple sheets of

paper from being fed at once.

When the LD roller and the clutch reach the ASF home position shown in “Step1” on

the previous page, the clutch lever is locked again by the change lever. This causes the

PF motor drive force not to be transmitted to the paper loading mechanism and to be

transmitted only to the paper feeding mechanism.

Figure 2-11. Ending Paper Loading Operation

OPERATING PRINCIPLE Printer Mechanism Operating Principles 29

EPSON Stylus C110/C120/D120 Revision B

Left side

PF Motor

PF Roller

PF Motor Drive Transmission Path (as seen from the left side of the printer)

• PF motor pinion gear (CCW) → Spur gear A (PF roller) (CW) → Transmission gear (CCW) → Spur gear B (EJ roller) (CW)

PF Motor

Pinion Gear

PF Scale

Spur Gear A

(PF Roller)

Spur Gear B

EJ Roller

PF Encoder Sensor

Transmission Gear

Star Wheel Roller

EJ Roller

Paper Guide Roller

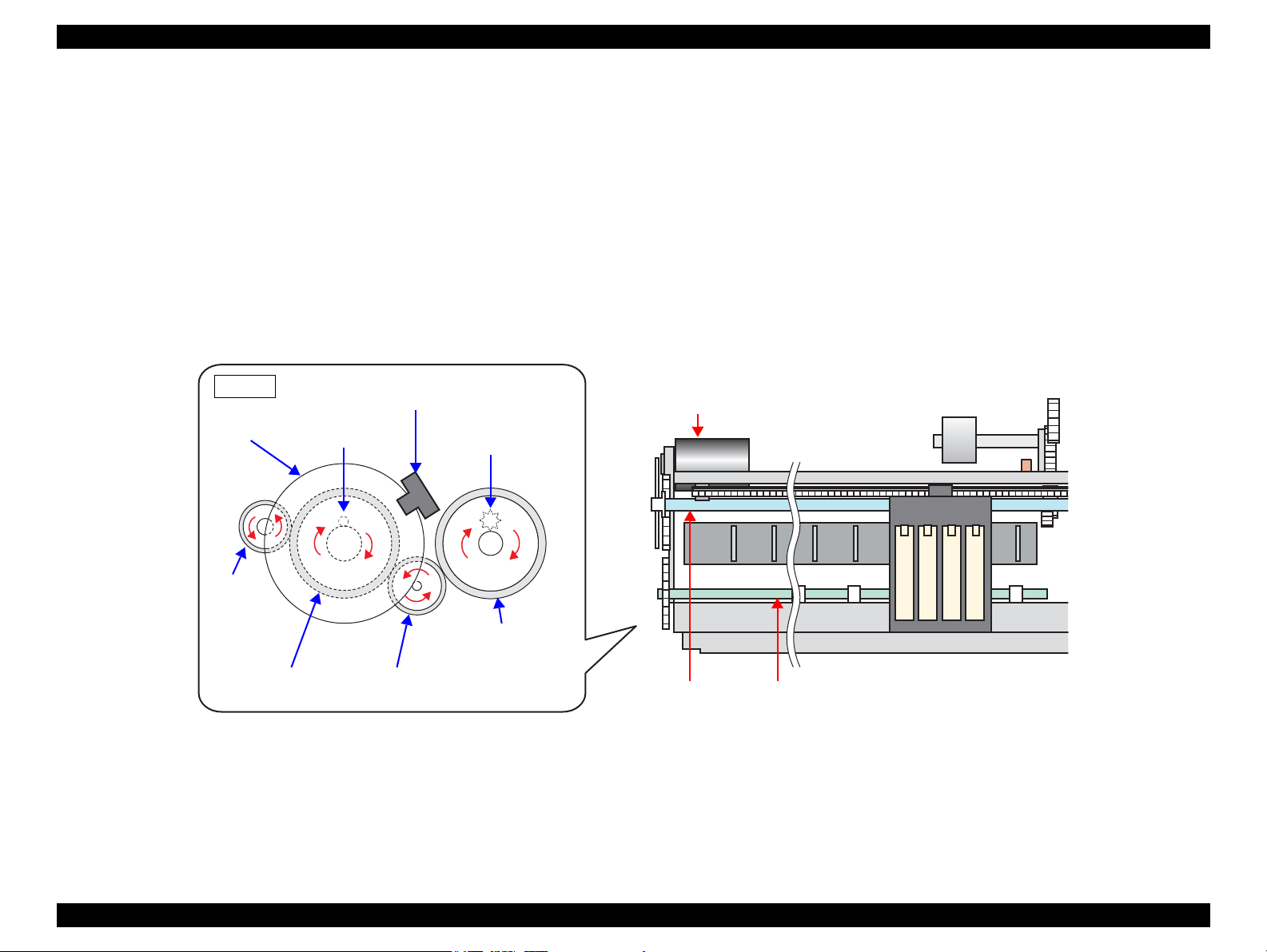

2.2.3.2 Paper Feed Mechanism

The major components of the paper feed mechanism are the PF motor, PF roller, EJ

roller, PE sensor, PF encoder sensor, and PF scale. The sheet of paper fed from the

ASF unit is nipped between two rollers to be transported during printing and to be

ejected.

1. The first two rollers used for feeding the paper are the PF roller and the paper

guide roller mounted on the upper paper guide unit. The PF motor drive force is

transmitted to the paper guide roller via the PF roller.

2. The next two rollers are the EJ roller and the star wheel roller mounted on the Star

Wheel Holder Assy. The PF motor drive force is transmitted to the star wheel

roller via the EJ roller.

The figure below shows how the PF motor pinion gear drive force is transmitted to the

PF roller, EJ roller, paper guide roller and the star wheel roller.

When the PF motor pinion gear starts counterclockwise rotation (as seen from the left

side), the sheet of paper fed from the ASF unit to the PF roller is transported and

ejected from the printer by the PF roller/paper guide roller combination and the EJ

roller/star wheel roller combination.

Figure 2-12. Paper Feed Mechanism

OPERATING PRINCIPLE Printer Mechanism Operating Principles 30

Loading...

Loading...