Page 1

Rev.5 EM208C4437F

Robot Controller

RC700 / RC90 Option

PG Motion System

Page 2

Robot Controller RC700 / RC90 Option PG Motion System Rev.5

Page 3

Robot Controller RC700 / RC90 Option

PG Motion System

Rev.5

Copyright 2012-2020 SEIKO EPSON CORPORATION. All rights reserved.

RC700 / RC90 Option PG Motion System Rev.5 i

Page 4

FOREWORD

1. Damage or malfunction caused by improper use which is not described in the manual,

or ca

2. Malfunctions caused by customers’ unauthorized disassembly.

3. Damage due to improper adjustments or unauthorized repair attempts.

4. Damage caused by natural disasters such as earthquake, flood, etc.

1. If the Manipulator or associated equipment is used outside of the usage conditions and

product specifications described in the manuals, this warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this manual

cannot warn the user of all possible hazards.

Thank you for purchasing our robot products.

This manual is intended for the users who setup and program the PG Motion System.

Please thoroughly read this and other related manuals prior to and while using this option.

WARRANTY

The Manipulator and its optional parts are shipped to our customers only after being

subjected to the strictest quality controls, tests, and inspections to certify its compliance

with our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please ask your Regional Sales Office for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

reless use.

Warnings, Cautions, Usage:

ii RC700 / RC90 Option PG Motion System Rev.5

Page 5

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® 8 Operating system

Microsoft® Windows® 10 Operating system

Throughout this manual, Windows 8, and Windows 10 refer to above respective operating

systems. In some cases, Windows refers generically to Windows 8, and Windows 10.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

MANUFACTURER

CONTACT INFORMATION

Contact information is described in “SUPPLIERS” in the first pages of the following

manual:

Robot System Safety and Installation Read this manual first

RC700 / RC90 Option PG Motion System Rev.5 iii

Page 6

Before Reading This Manual

■

Install a separate hardware piece, an emergency stop circuit

that your PG board will be driving (apart from the emergency stop that inputs to

the Controller) to securely stop the robot when an emergency stop occurs. The

emergency stop

processed within the software.

■

Carefully read the manual for the motor drive you are using and follow both the

safety and caution principles

■

Always turn OFF the power before

Controller. Installing or wiring the PG board while the power is ON may result in

electric shock, abnormal operation of the robot system, and/or malfunction of the

Controller and PG board.

■

Use extra caution w

The validity of the data is not completely checked or adjusted. If improper

settings are used, the robot may move unexpectedly. The unexpected

movement of the robot is extremely hazardous and may cause damage to

robot and/or peripheral equipment.

This section describes what you should know before reading this manual.

Safety Precautions

Installation of robots and robotic equipment should only be performed by qualified

personnel in accordance with national and local codes. Please carefully read this manual

and other related manuals before installing the robot system or before connecting cables.

Keep this manual handy for easy access at all times. Please read the Safety chapter in

User’s Guide to understand safety requirements before installing the robot system.

Conventions

Important safety considerations are indicated throughout the manual by the following

symbols. Be sure to read the descriptions shown with each symbol.

This symbol indicates that danger of possible serious

WARNING

This symbol indicates that danger of possible harm to

WARNING

injury or death exists if the associated instructions are

not followed properly.

people caused by electric shock exists if the associated

instructions are not followed properly.

CAUTION

CAUTION

This symbol indicates that a danger of possible harm to

people or physical damage to equipment and facilities

exists if the associated instructions are not followed

properly.

for the motor drive

input at the Pulse Generating Board is designed to be

.

installing or wiring the PG board to the

hen setting PG robot parameter values.

iv RC700 / RC90 Option PG Motion System Rev.5

the

Page 7

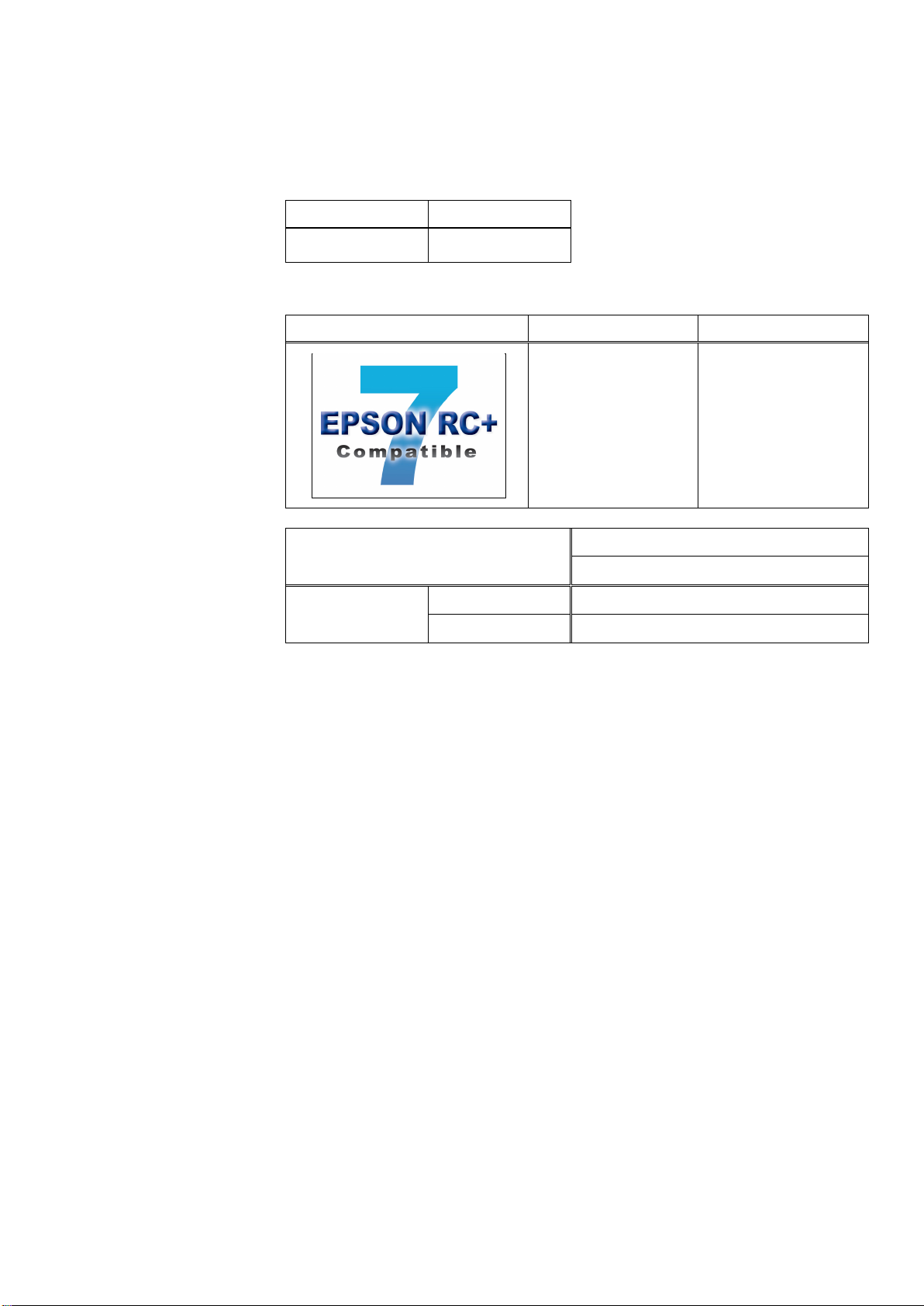

Control System Configuration

Controller

Software

RC90 controller firmware

Ver.7.0.2.0

Before Ver.7.0.1

!!!

Ver.7.0.2 or later

OK

NOTE

NOTE

This option is used with the following combinations of Controllers and software.

TYPE A:

RC700 EPSON RC+ 7.0

TYPE B: Robot Controller RC90 with the following label attached.

Label

EPSON RC+ 7.0

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

7.0.2 or later.

Controller Software

RC90 EPSON RC+ 7.0

This option is not available for Robot Controller RC90 (EPSON RC+ 5.0) without the

label.

Manual PDF for TYPE B is available from EPSON RC+ 7.0 Ver. 7.0.2

RC700 / RC90 Option PG Motion System Rev.5 v

Page 8

vi RC700 / RC90 Option PG Motion System Rev.5

Page 9

Table of Contents

1. Getting Started 1

1.1 Introduction ......................................................................................................... 1

1.2 System Overview ................................................................................................ 1

1.3 How to Setup and Use the System ..................................................................... 2

1.3.1 Hardware Setup Overview ...................................................................... 2

1.3.2 Software Setup Overview ........................................................................ 2

2. Hardware 3

2.1 PG Board Specifications ..................................................................................... 3

2.2 Part Names and Functions ................................................................................. 5

2.2.1 Component Names & Locations ............................................................. 5

2.2.2 DIP Switch Settings ................................................................................. 6

2.2.3 Jumper Settings ...................................................................................... 7

2.2.4 Rotary Switch Settings ............................................................................ 7

2.2.5 LEDs ........................................................................................................ 7

2.2.6 Connectors .............................................................................................. 7

2.2.7 Installation in the Controller..................................................................... 7

2.3 Internal Circuitry .................................................................................................. 8

2.3.1 Signal Functions ...................................................................................... 8

2.3.2 Input Circuit ........................................................................................... 10

2.3.3 Output Circuit ........................................................................................ 11

2.4 Wiring ................................................................................................................ 12

2.4.1 Minimizing Noise Interference ............................................................... 12

2.4.2 Connectors ............................................................................................ 13

2.4.3 PG Board Connector Pin Outs .............................................................. 14

2.4.4 PG Terminal Block Pin Outs ................................................................. 16

2.4.5 Typical Applications............................................................................... 18

2.5 Safety Features ................................................................................................. 19

2.5.1 Typical Application of Emergency Stop Circuit ..................................... 20

3. Software 21

3.1 Creating PG Robots in EPSON RC+ ................................................................ 21

3.2 PG Robot Configuration .................................................................................... 23

3.2.1 PG Robot Parameters Overview ........................................................... 23

3.2.2 PG Parameters ...................................................................................... 24

3.2.3 PG Parameters joint .............................................................................. 25

3.2.4 Backup and Restore Parameter Data ................................................... 30

3.3 [Robot Manger] Configuration ........................................................................... 32

RC700 / RC90 Option PG Motion System Rev.5 vii

Page 10

Table of Contents

3.4 Using PG Robots in EPSON RC+ ..................................................................... 35

4. Calibration Types 38

3.3.1 Overview of [Robot Manager] ................................................................ 32

3.3.2 [Range] ................................................................................................... 33

3.3.3 [Home Config] ........................................................................................ 33

3.3.4 [Mcal Order] ........................................................................................... 34

3.4.1 PG Cartesian Robots ............................................................................. 35

3.4.2 PG Joint Robots ..................................................................................... 35

3.4.3 Tuning .................................................................................................... 35

3.4.4 Motion Commands ................................................................................. 36

3.4.5 SLock and SFree ................................................................................... 36

3.4.6 Dry Run .................................................................................................. 36

3.4.7 PG Signal Status Display ....................................................................... 37

5. Troubleshooting 50

6. Maintenance Parts List 54

viii RC700 / RC90 Option PG Motion System Rev.5

Page 11

1. Getting Started

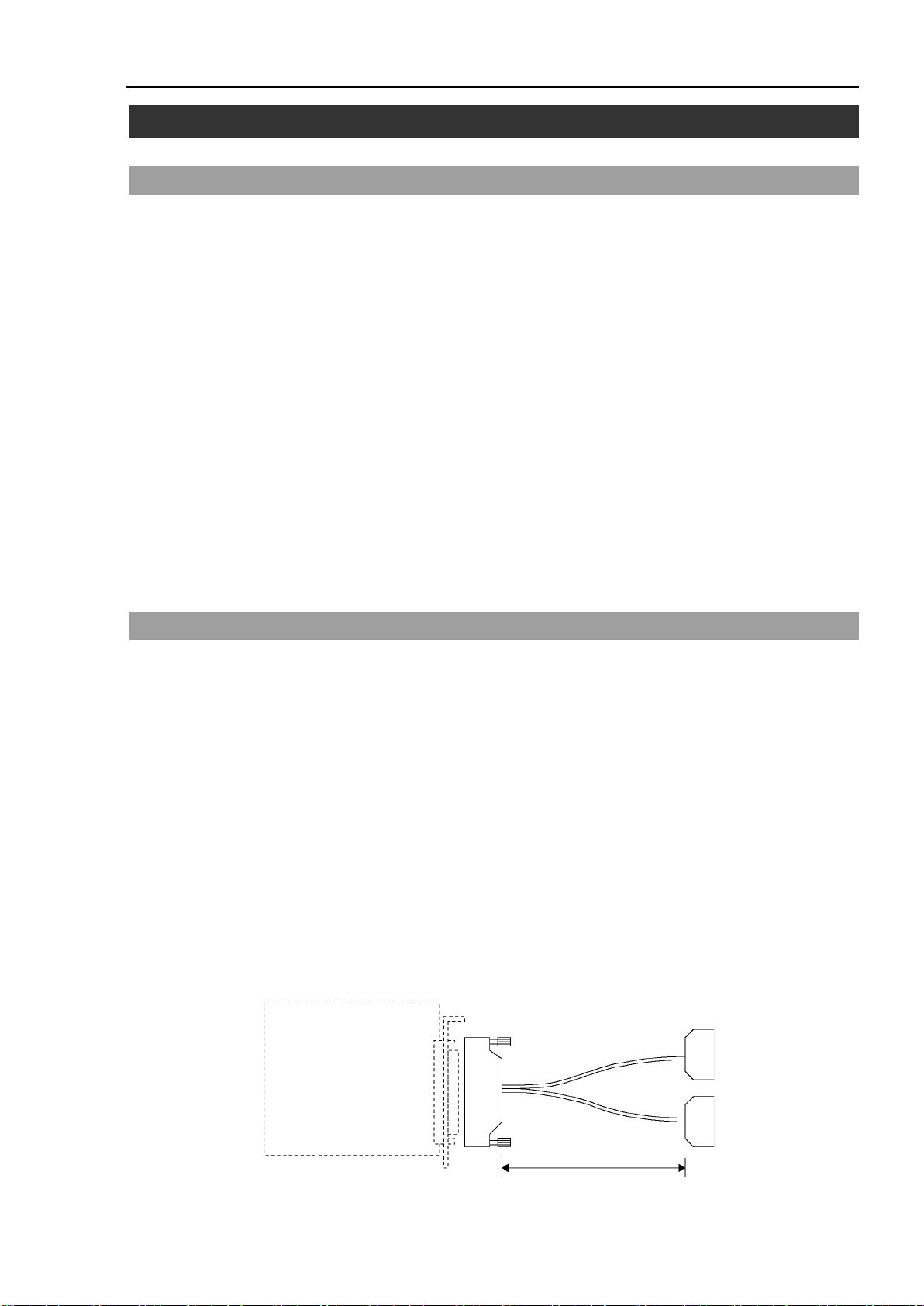

PG board

100 Pin

50 Pin

× 2

57FE-30500-20N (D8)

(DDK)

57FE-30500-20N (D8)

(DDK)

1 m

1.1 Introduction

The PG Motion System option enables you to create robots that use third party drives and

motors. PG robots can coexist with and behave similar to standard robots in the EPSON

RC+ system. Use PG robots to control auxiliary equipment such as XY tables, slides,

rotary axes, etc.

Features include:

One or more PG robots can be used along with standard robots on the same system. (Max.

16 robots in total)

PG robots can be a Cartesian or Joint type.

Both stepper motors and servo motors are supported.

Cartesian type PG robots with 2 or more axes can use Vision Guide.

PG robots are fully integrated into the EPSON RC+ environment and basically operate the

same as standard robots.

Safety features include Emergency Stop, Safeguard, over travel limits, and drive alarm.

1. Getting Started

Before using the PG Motion System option, read through this entire manual.

1.2 System Overview

The PG Motion System is a Robot Controller RC700 / RC90 option that includes a software

component of EPSON RC+ and one or more Pulse Generator boards. The customer

supplies the drives and motors using third party equipment.

The PG Motion System supports up to 4 PG boards for RC700 and 2 PG boards for RC90.

Each board has four channels, which allows a total of sixteen joints for RC700 and eight

joints for RC90. A PG robot can have from 1 to 4 joints for Cartesian coordinate robot, 1

to 7 joints for the Joint type robot.

Included in this package:

Pulse Generator board (hereinafter referred to as PG board)

PG board label (attached only if the PG board is purchased separately)

PG board connector

(Plug:DX40-100P, Cover:DX-100-CV-1 Hirose Electric Co.,Ltd.)

A PG board cable is available as an optional part. This cable is configured as shown

below:

RC700 / RC90 option PG motion system Rev.5 1

Page 12

1. Getting Started

1.3 How to Setup and Use the System

The following sections describe the basic steps on how to setup and use the PG Motion

System.

1.3.1 Hardware Setup Overview

Refer to Chapter 2, Hardware for the following instructions:

(1) Read the entire Hardware chapter and design the PG hardware for your system.

Two examples are provided.

(2) Configure and install one or more PG boards in the Controller.

(3) Wire cables for PG boards and drives.

1.3.2 Software Setup Overview

Refer to Chapter 3, Software for the following instructions:

(1) Create one or more PG robots in the EPSON RC+ system configuration.

(2) Test each PG robot and verify that all safety features are operating properly.

(3) Write SPEL+ software to control PG robots from your EPSON RC+ applications.

2 RC700 / RC90 option PG motion system Rev.5

Page 13

2. Hardware

This chapter describes the PG board hardware including the functions, switch settings, and

internal circuits of the PG board.

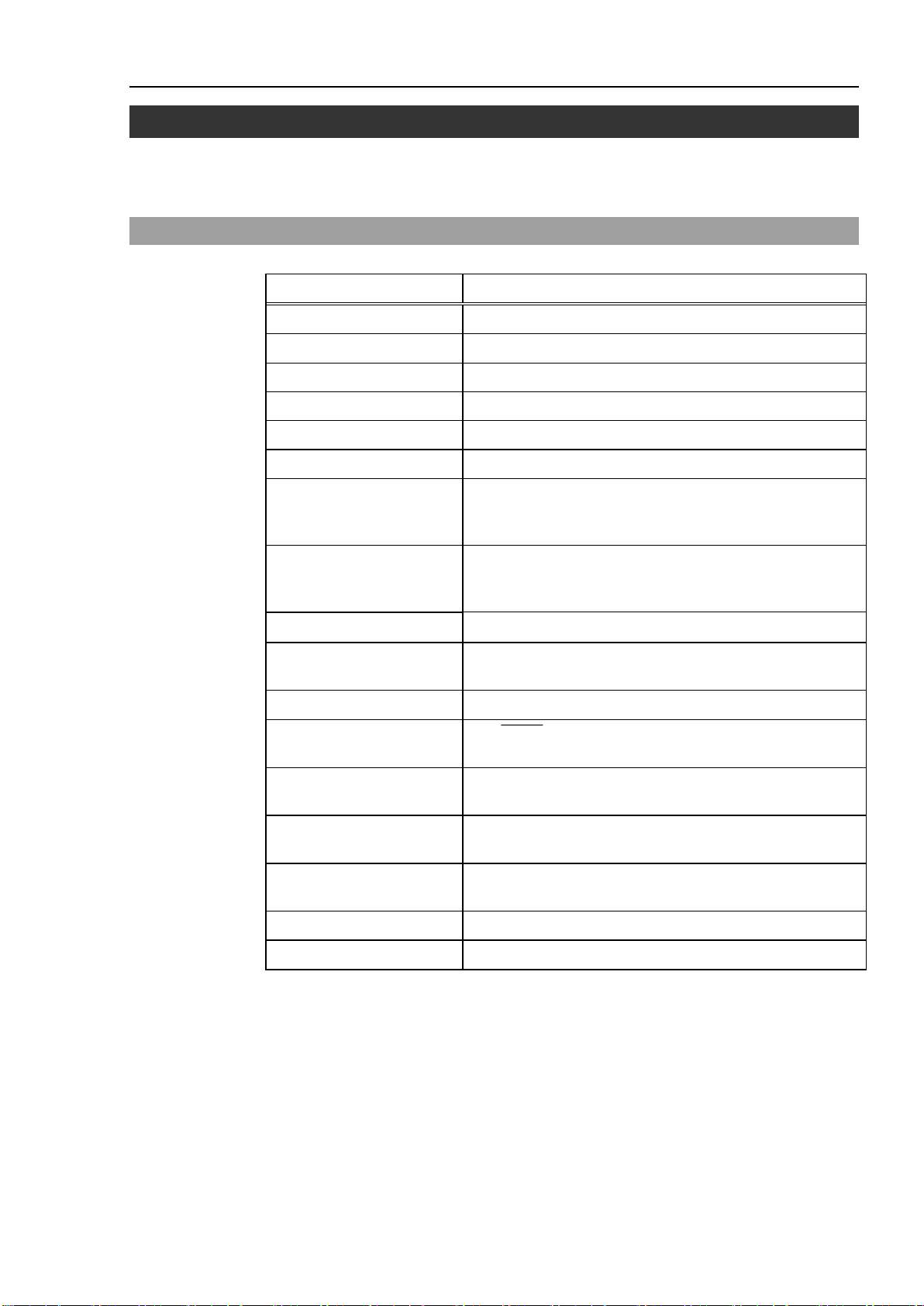

2.1 PG Board Specifications

Item Description

Board Name H756

Compatible Controller RC700 / RC90

Expansion Capability RC700: 4 boards maximum / RC90: 2 boards maximum

Control Axes 4 axes per board

Target Motor Either servo motors or stepper motors can be used.

Output Pulse Rate 0.1 pps to 6.5 Mpps

Speed Setting

2. Hardware

100 steps in the program with the flexible maximum speed

setting. The calibration speed can be programmed

separately from the normal operation speeds.

Acceleration Settings

Arm Travel Range [pulse]

Pulse Output Type

Rotating Direction Programmable in the software.

Positioning Method

Calibration

Stop Function

S-curved

Acceleration/Deceleration

Continuous Rotation Selectable in software

Relative Quantity Travel Selectable in software

The program provides 100 steps each for Acceleration and

Deceleration. (The maximum acceleration or maximum

deceleration setting can be changed.)

− 2,147,483,647 to 2,147,483,647 (32 bits)

Selectable in software: Pulse / Direction Output Method or

CW / CCW Pulse Output Method

The DEND (detection-end) signal generated from the servo

drive (when a servo drive is used).

Selectable from the seven (7) calibration types in the

software.

The pulse generation to be stopped at the input of either the

limit or alarm signal.

Selectable in software

RC700 / RC90 option PG motion system Rev.5 3

Page 14

2. Hardware

Item Description

Output Signal Counter reset (DRST)signal

Input Signal - Origin signal (ORG). Normally open.

- Near-to-origin signal (NORG). Normally open.

- CW limit signal (CWLM). Normally closed.

- CCW limit signal (CCWLM). Normally closed.

- Alarm signal (ALM)

- Encoder Phase -Z signal (ZORG)

- Detection-end signal (DEND)

Safety Features The following safety features of Robot Controller RC700 /

RC90 are supported:

- Emergency Stop Input

- Safeguard Input

- Enable SW Input

- Low/High Power Mode

Board Address Set by DIP switches on the board.

I/F Connector on the Board DX10A-100S (Hirose Electric Co.,Ltd.)

Power Supply

PG Robot Limitations Refer to the section 3.4 Using PG robots in EPSON RC+

5 V ±5 % 1.0 A (max.)

24 V ±2 V 200 mA (max.)

(from the external power source)

4 RC700 / RC90 option PG motion system Rev.5

Page 15

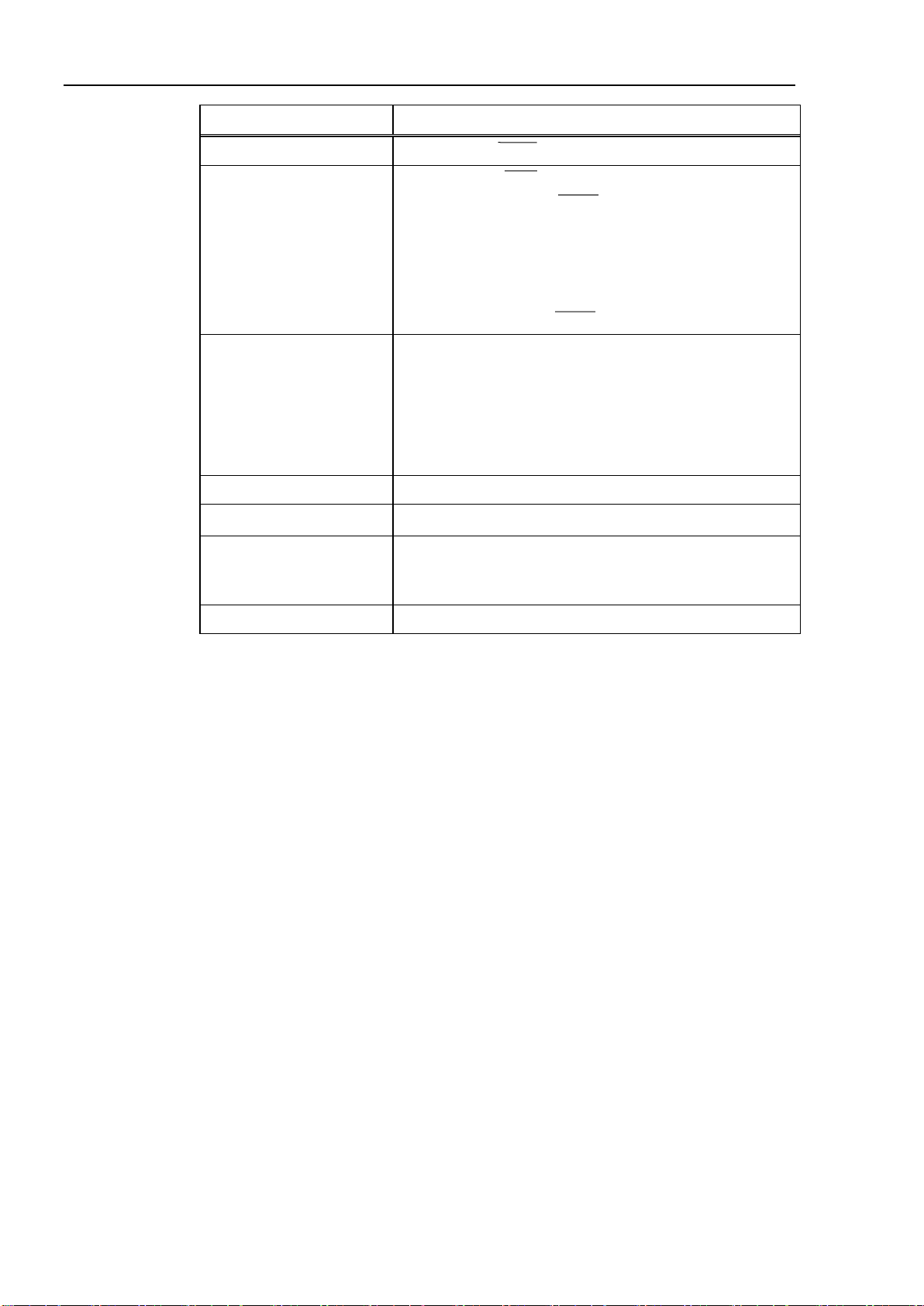

2.2 Part Names and Functions

JP1

CN2

134

130

CN1

CN3

X

Y

S3

S2

S1

2.2.1 Component Names & Locations

2. Hardware

Rotary switch : S1

DIP Switch : S2, S3

LED : X, Y

Jumpers : JP1

Connectors : CN1, CN2, CN3

RC700 / RC90 option PG motion system Rev.5 5

Page 16

2. Hardware

1 2 3 4 1 2 3 4

ON

ON : 0

OFF : 1

DIP switch

S2

DIP switch S3

ON

1 2 3 4 1 2 3 4

ON

ON : 0

OFF : 1

DIP switch S2

DIP switch S3

ON

1 2 3 4 1 2 3 4

ON

ON : 0

DIP switch S2

DIP switch S3

ON

1 2 3 4 1 2 3 4

ON

ON : 0

DIP switch S2

DIP switch S3

ON

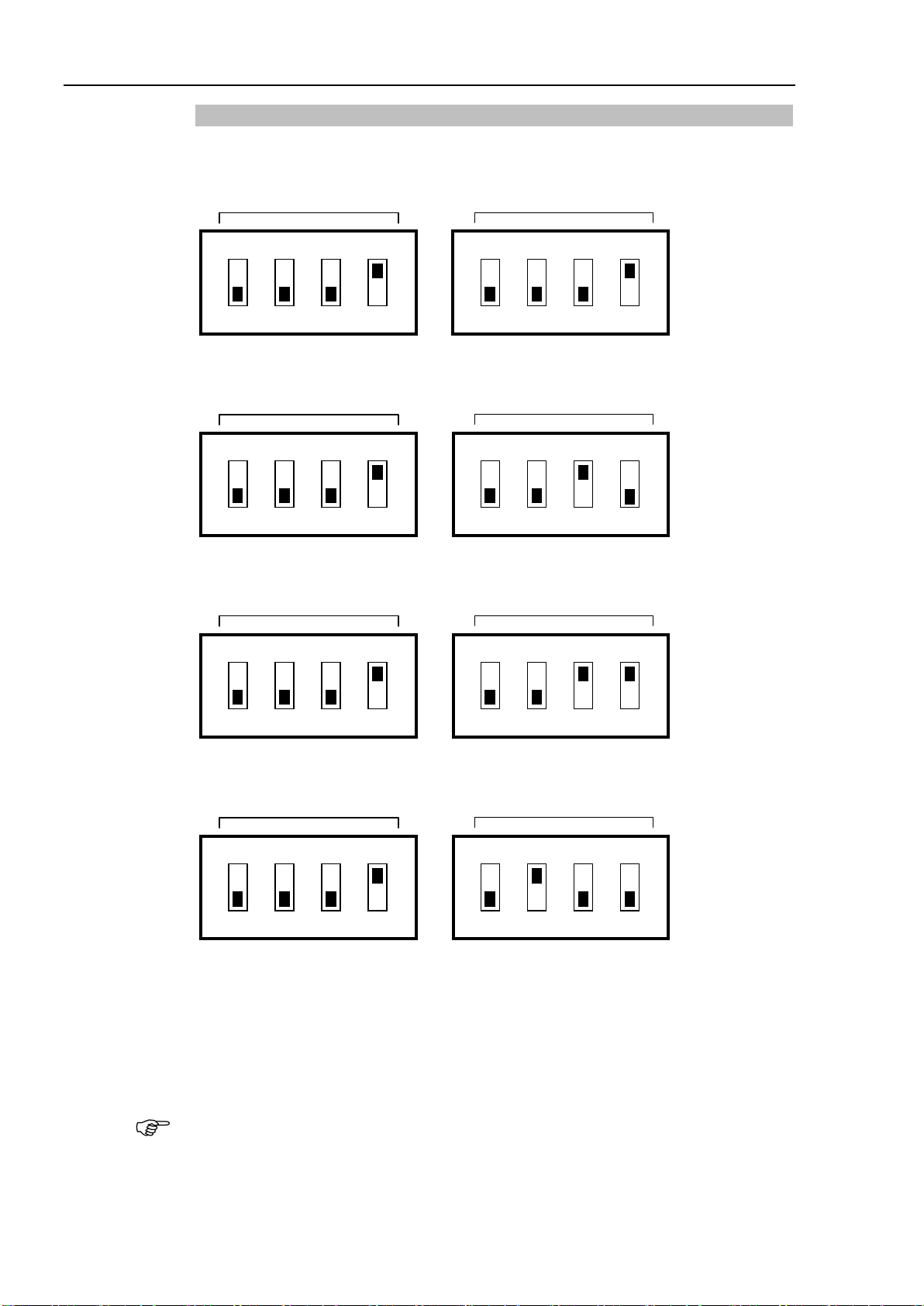

2.2.2 DIP Switch Settings

The board number is set by DIP switch (S2, S3) on the PG board.

The first PG board must be set as shown below:

The second PG board must be set as shown below:

The third PG board must be set as shown below:

OFF : 1

The fourth PG board must be set as shown below:

OFF : 1

If you purchased the PG board alone, apply the provided board number seal to the board

panel before installing to the controller and be sure to keep a written record of the board

number.

If the board has been already installed before shipment, the board number is properly

configured and there is no need of your further configuration.

NOTE

If you use the PG board for the conveyor tracking, use another address for the PG board of

the PG motion system. For example, if the PG board 1 is used for the conveyor tracking,

then use the PG board 2 for the PG motion system.

6 RC700 / RC90 option PG motion system Rev.5

Page 17

2.2.3 Jumper Settings

Do not change the jumper settings. At shipment, it is set as below:

2. Hardware

JP1 : with jumpers

2.2.4 Rotary switch Settings

Do not change the Rotary switch S1 settings. At shipment, it is set as below:

S1 : Position of 1

2.2.5 LEDs

The LEDs on the board are used to monitor the following signals:

X, Y : Inside status of each axis. Turns ON when ready to receive a command.

2.2.6 Connectors

CN1 : Connection for the external devices

(Refer to the section 2.3 Internal Circuitry for further details.)

CN2 : Unused

CN3 : Connector for internal connection

2.2.7 Installation in the Controller

Turn OFF the Controller.

Remove the open slot panel at the front of the Controller. Install the PG board and secure

it with screws. For details, refer to the instruction sheet attached to the board.

Once the board is installed, refer to the section 3.1 Creating PG Robots in EPSON RC+ for

software installation and settings.

RC700 / RC90 option PG motion system Rev.5 7

Page 18

2. Hardware

+COMMON for CWP

2.3 Internal Circuitry

2.3.1 Signal Functions

The table below describes the function of each PG board signal.

Direction Signal Name Function Description

Output +COM

+DRSTCOM

CWP

CWP

CCWP

CCWP

DRST Drive reset signal Outputs a signal to reset the drive's deviation counter.

SVON Servo ON signal Outputs the servo ON signal when connecting the PG board to the

Outputs the +5V power source for the CWP and CCWP signals.

and CCWP

+COMMON for DRST Outputs +5V for DRST signal.

Outputs CW pulses

Outputs CCW pulses

Generates the pulse train for the CW direction when the Pulse

Output parameter is set to CW/CCW.

Generates the pulse train when the Pulse Output parameter is set to

Pulse / Direction.

Generates the pulse train for the CCW direction when the Pulse

Output parameter is set to CW/CCW.

Generates the direction signal when the Pulse Output parameter is

set to Pulse / Direction (clockwise when the CCWP is low).

If the pulse output is put into a rapid stop, the DRST signal = Low is

output for 10 ms.

Must be disconnected when a stepper motor is used.

servo drive. Must be left disconnected when a stepper motor is

used.

The signal is OFF when controller is launched.

It turns OFF automatically when any one of the joints within a

manipulator indicates either a servo error or limit switch related

errors.

8 RC700 / RC90 option PG motion system Rev.5

Page 19

2. Hardware

clockwise (CW) pulses are generated.

Connect to either a photo or magnetic normally open sensor to detect the

Direction

Input CWLM CW (clockwise) Limit

Signal

Name

CCWLM CCW (counter-

NORG Near-to-Origin signal

ORG Origin signal If the motor encoder Z-Phase signal will not be used, connect either a

Function Description

signal

clockwise) Limit signal

Connect to normally closed CW Limit switch.

This signal is accepted only when

When this signal is detected, the pulse generation will be stopped either

gradually or immediately according to the software setting.

Connect to normally closed CCW Limit switch.

This signal is accepted only when counter-clockwise (CCW) pulses are

generated. When this signal is detected, the pulse generation will be

stopped either gradually or immediately according to the software

setting.

proximity of the target origin. Ensure that the proximity sensor is

always used with an origin sensor (either ORG or Z-Phase).

If a mechanical switch is used, you may need to connect a capacitor in

parallel with the switch (0.1μf 50V recommended).

photo or magnetic normally open sensor to detect the target origin.

Leave the ZORG terminal unconnected. The accuracy of calibration or

positioning can be increased and the calibration time can be shortened

by using the origin sensor with a proximity sensor (NORG).

If a mechanical switch is used, you may need to connect a capacitor in

parallel with the switch (0.1μf 50V recommended).

NOTE

+ZORG

-ZORG

DEND Detection (calibration)

ALM Alarm signal Connect the alarm signal from the drive. Generation of pulses will be

Encoder Phase -Z signal Use this terminal if the motor encoder’s Z-Phase is used as an origin

sensor in which case the ORG terminal must be left disconnected.

Connect to the signal from the drive that indicates that positioning is

end signal

complete. Must be left disconnected if a stepper motor is used.

stopped gradually or immediately when this signal is detected. The

alarm logic and the stop mode are defined in the software.

For DEND input, when a servo motor is used, the position complete signal from the drive must be

connected. After a MOVE command is executed, SPEL waits until the DEND input is activated.

When the DEND input is not activated even after waiting for a time specified by a FINE command,

a message "Error 4004: Event waiting error with the Motion Control Module." appears. In case

of this error, it is necessary to exit controller, stop the SPEL Runtime Drivers, then restart controller.

When it is expected that your servo drive does not have an output equivalent to the positioning

completion signal, or that the DEND input is not activated, the DEND input must be connected to

GND. In this case, SPEL does not check that the servo drive's positioning is completed.

Therefore, after the operation command is executed, use the time delay necessary for positioning

to be complete in your application.

RC700 / RC90 option PG motion system Rev.5 9

Page 20

2. Hardware

EXTV

ORG, NORG, DEND, ALM

Board

Drive

+24V

External power supply

ON : 2.5mA or over

OFF : 0.8mA or under

6.8kΩ

EXTV

CWLM / CCWLM

6.8kΩ

Board

Sensor

+24V

External power supply

ON : 2.5mA or over

OFF : 0.8mA or under

The CWLIM and CCWLIM limit switches must be

normally closed. The ORG and NORG switches must

be normally open.

+ZORG

-ZORG

220 Ω

26C31

equivalent

Connect to Line driver RS422 Conforming

+5V

+5V

26C32

equivalent

Board

Drive

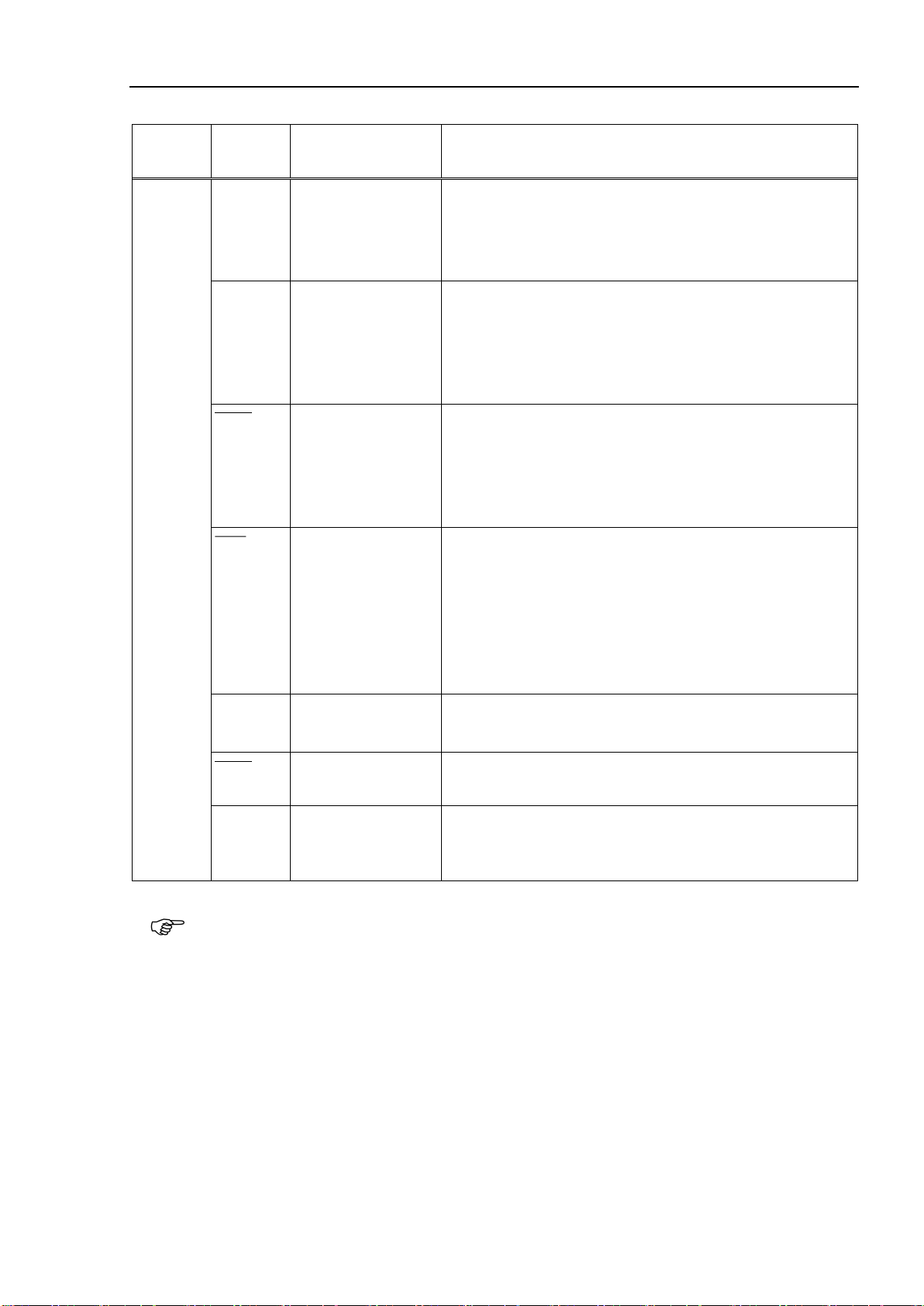

2.3.2 Input Circuit

ORG(Origin), NORG(Near-to-origin), DEND(Detection-end),

ALM(Alarm)

The DEND terminal must be left disconnected if a stepper motor is used.

The input logic of the Alarm signal can be changed in the software.

CWLM(CW Limit), CCWLM(CCW Limit)

ZORG (Encoder Phase -Z) Signal

This terminal must be connected when an Encoder Z Phase signal is used as the origin signal.

10 RC700 / RC90 option PG motion system Rev.5

Page 21

2. Hardware

CWP / CCW P

Line Driver

26C31

equivalent

CWP / CCW P

GND

Max 20mA

+5V

Board

Drive

EXTVGND

EXTV

DRST

+ DRST COM

1.65kΩ

Output Current

Maximum

50 mA

(Vce=under 2 V)

External power

supply

5 V

Board

Drive

150Ω or over

Output Current

Maximum

50 mA

(Vce=under 2 V)

EXTVGND

EXTV

DRST

External power

supply

24 V

+DRSTCOM

1.65kΩ

Board

Drive

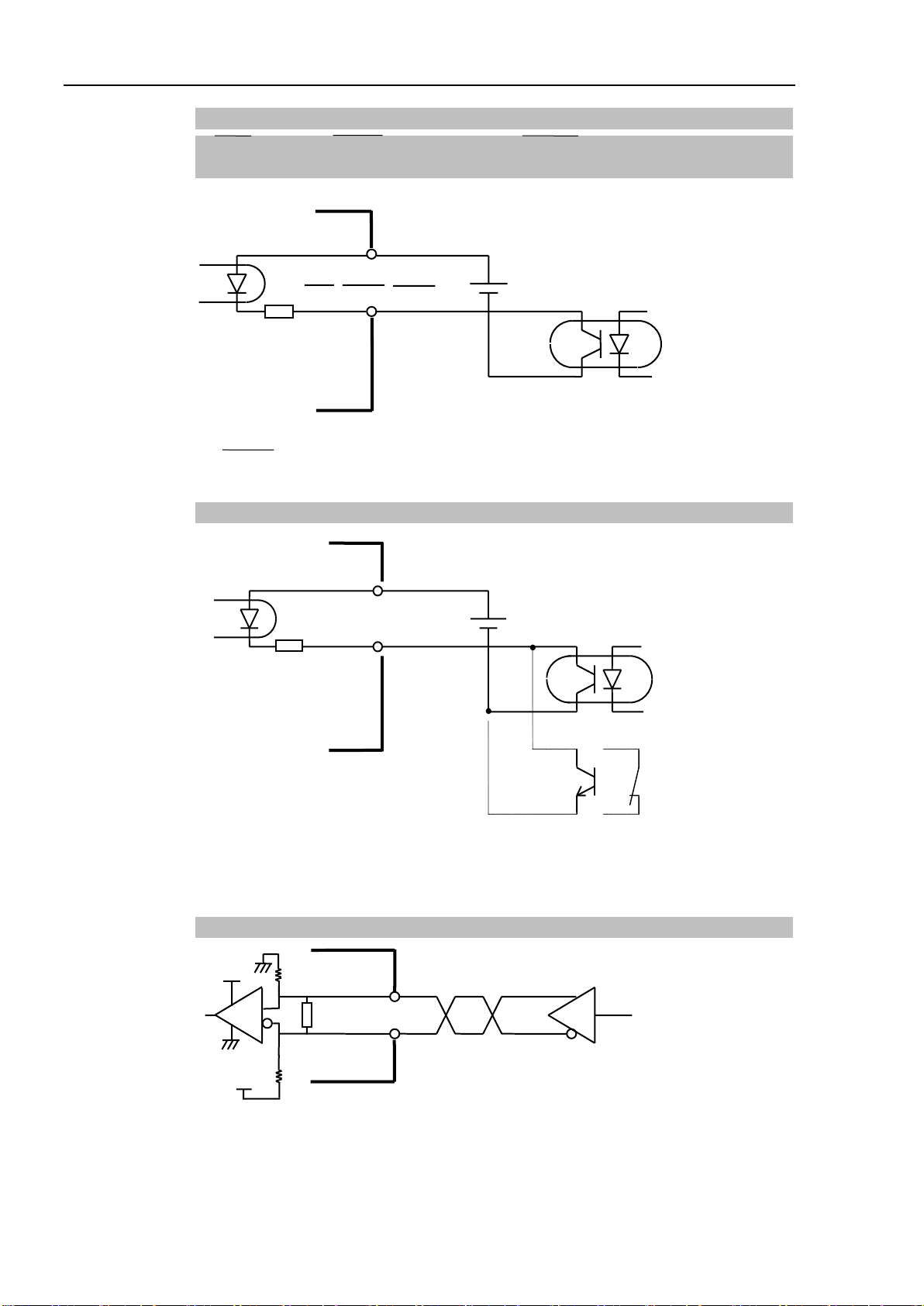

2.3.3 Output Circuit

CWP (CW Pulse Output)/ CCWP (CCW Output) Signals

DRST (Drive Reset)

The DRST terminal does not need to be connected when a stepper motor is used.

When the servo driver counter reset input is +5V interface, refer to the connection example

below.

If the current-limiting resistor of the driver is less than 150Ω, provide an external resistor to

ensure 150Ω or more.

When the servo driver counter reset input is +24V interface, refer to the connection example

below.

RC700 / RC90 option PG motion system Rev.5 11

Page 22

2. Hardware

Output Current

Board

Drive

SVON(Servo ON)

2.4 Wiring

Follow guidelines listed below when connecting a PG board to a drive:

EXTV

SVON

Maximum

70 mA

(Vce=under 2 V)

EXTVGND

R

External power

supply

24 V

2.4.1 Minimizing Noise Interference

Minimize noise interference by using the wiring recommendations as described in the

drive manual.

Use a noise filter on the primary power supply for EXTV/EXTVGND and separate

between the primary and secondary wiring by at least 200mm.

For EXTV/EXTVGND and the instruction signals for using twisted pair (as indicated

in the circuit diagram in the previous “Input and Output Circuits”), be sure to use

twisted pair cables.

Use shielded twisted pair cable for connecting the PG board to the drive.

Follow the drive manual and the manufacturer’s instructions for shielding.

Keep the wiring between the PG board and drive as short as possible (within 1.5 m)

and position them to be separated from possible noise sources as much as possible.

For the load to be used in the controller’s (Control Unit’s) I/O, whether a relay or

solenoid, make sure to use one with surge suppressor. Install a diode (or such) on

the Load L side where there is no surge suppressor.

For such peripheral equipment as a conveyor, switching the rotating direction (start,

forward, reverse) of an AC motor (an induction motor, a 3-phase induction motor,

etc.) requires an appropriate spark suppressor between lines. The closer the

suppressor is to the motor, the more effective the noise suppression.

12 RC700 / RC90 option PG motion system Rev.5

Page 23

2. Hardware

2.4.2 Connectors

The table below lists the connectors on the PG board and the compatible connectors for

wiring:

Receptacle on the Board

Wiring Plug

Connectors

Connector for Wiring to the Cover DX30M-100-CV1

If you are using the optional cable, refer to section 2.4.4 PG Terminal Block Pin Outs later

in this chapter.

DX10A-100S

(manufacturer: Hirose Electric Co., Ltd.)

Individually

pressed-in type

Pressed-in-as-a-whole type

DX30-100P (for AWG#30)

DX30A-100P (for AWG#28)

DX31-100P (for AWG#30)

DX31A-100P (for AWG#28)

Soldered type DX40-100P

RC700 / RC90 option PG motion system Rev.5 13

Page 24

2. Hardware

ply GND for Input

put

+DRST

COM1

+DRST

COM3

2.4.3 PG Board Connector Pin Outs

The pin outs for the PG board connector (DX10A-100S) are shown in the following table.

For details of each signal, refer to section 2.3.1 Signal Functions. If you are using the

optional cable, refer to section 2.4.4 PG Terminal Block Pin Outs later in this chapter.

Pin Dir Signal Description Pin Dir Signal Description

1 In CWLM1 CW limit signal for Axis #1 (*2) 51 In CWLM3 CW limit signal for Axis #3 (*2)

2 In CCWLM1 CCW limit signal for Axis #1 (*2) 52 In CCWLM3 CCW limit signal for Axis #3 (*2)

3 In NORG1 Near-to-origin signal for Axis #1 53 In NORG3 Near-to-origin signal for Axis #3

4 In ORG1 Origin signal for Axis #1 (*1) 54 In ORG3 Origin signal for Axis #3 (*1)

5 In CWLM2 CW limit signal for Axis #2 (*2) 55 In CWLM4 CW limit signal for Axis #4 (*2)

6 In CCWLM2 CCW limit signal for Axis #2 (*2) 56 In CCWLM4 CCW limit signal for Axis #4 (*2)

7 In NORG2 Near-to-origin signal for Axis #2 57 In NORG4 Near-to-origin signal for Axis #4

8 In ORG2 Origin signal for Axis #2 (*1) 58 In ORG4 Origin signal for Axis #4 (*1)

9 − − Not used 59 − − Not used

10 In ALM1 Alarm input signal for Axis #1 60 Out SVON1 Servo ON output signal for Axis #1

11 In ALM2 Alarm input signal for Axis #2 61 Out SVON2 Servo ON output signal for Axis #2

12 In ALM3 Alarm input signal for Axis #3 62 Out SVON3 Servo ON output signal for Axis #3

13 In ALM4 Alarm input signal for Axis #4 63 Out SVON4 Servo ON output signal for Axis #4

14 In EXTV External power supply for Input

circuit

15 In EXTV

16 Out +COM CWP1, CCWP1 +COMMON 66 Out +COM CWP3, CCWP3 +COMMON

17 Out CWP1 CW pulse output signal for Axis #1 67 Out CWP3 CW pulse output signal for Axis #3

18 Out CWP1 Inverted CW pulse output for Axis #1 68 Out CWP3 Inverted CW pulse output for Axis #3

19 Out CCWP1 CCW pulse output for Axis #1 69 Out CCWP3 CCW pulse output for Axis #3

20 Out CCWP1 Inverted CCW pulse output for Axis #1 70 Out CCWP3

21 Out

22 Out DRST1 Drive Reset signal for Axis #1 72 Out DRST3 Drive Reset signal for Axis #3

External power supply for Input

circuit

DRST1 +COMMON 71 Out

64 In EXTVGND External power sup

circuit

65 In EXTVGND

External power supply GND for In

circuit

Inverted CCW pulse output for Axis

#3

DRST3 +COMMON

23 In DEND1 Detection End signal for Axis #1 73 In DEND3 Detection End signal for Axis #3

24 − − Not used 74 − − Not used

25 − − Not used 75 − − Not used

14 RC700 / RC90 option PG motion system Rev.5

Page 25

2. Hardware

-

-

+DRST

COM2

+DRST

COM4

-

-

Pin Dir Signal Description Pin Dir Signal Description

26 − − Not used 76 − − Not used

27 − − Not used 77 − − Not used

28 − − Not used 78 − − Not used

29 In +ZORG1 Encoder Phase +Z signal for Axis #1 79 In +ZORG3 Encoder Phase +Z signal for Axis #3

30 In

31 − − Not used 81 − − Not used

32 Out +COM CWP2, CCWP2 +COMMON 82 Out +COM CWP4, CCWP4 +COMMON

33 Out CWP2 CW pulse output for Axis #2 83 Out CWP4 CW pulse output for Axis #4

34 Out CWP2 Inverted CW pulse output for Axis #2 84 Out CWP4 Inverted CW pulse output for Axis #4

35 Out CCWP2 CCW pulse output for Axis #2 85 Out CCWP4 CCW pulse output for Axis #4

36 Out CCWP2 Inverted CCW pulse output for Axis #2 86 Out CCWP4 Inverted CCW pulse output for Axis #4

37 Out

38 Out DRST2 Drive Reset signal for Axis #2 88 Out DRST4 Drive Reset signal for Axis #4

39 In DEND2 Detection End signal for Axis #2 89 In DEND4 Detection End signal for Axis #4

40 − − Not used 90 − − Not used

41 − − Not used 91 − −

42 − − Not used 92 − −

43 − − Not used 93 − −

44 − − Not used 94 − −

ZORG1

Encoder Phase -Z signal for Axis #1 80 In

DRST2 +COMMON 87 Out

ZORG3

Encoder Phase -Z signal for Axis #3

DRST4 +COMMON

Not used

Not used

Not used

Not used

45 In +ZORG2 Encoder Phase +Z signal for Axis #2 95 In +ZORG4 Encoder Phase +Z signal for Axis #4

46 In

47 − − Not used 97 − −

48 − − Not used 98 − −

49 − − Not used 99 − −

50 − GND Ground 100 − GND Ground

ZORG2 Encoder Phase -Z signal for Axis #2

96 In

ZORG4 Encoder Phase -Z signal for Axis #4

Not used

Not used

Not used

(*1) Leave this terminal disconnected if you use Encoder Z Phase signal as the origin signal when a servo

motor is used.

(*2) When the status of the limit signal is OFF (the photo coupler in the input circuit is OFF), the axis is

deemed to be out of the Permissible Working Range and pulse generation will be stopped. Therefore,

you must connect to an external power source so that the limit signal(s) will remain ON when your system

configuration does not use limit signals.

RC700 / RC90 option PG motion system Rev.5 15

Page 26

2. Hardware

2.4.4 PG Terminal Block Pin Outs

When the optional cable is used, 2 terminal blocks are provided. Pin outs for these terminal

blocks are shown in the following two tables. The pin numbers in parentheses are the pins

on the PG board connector. For details of each signal, refer to the section 2.3.1 Signal

Functions.

Pin Signal Description Pin Signal Description

1 (16) +COM CWP1,CCWP1 +COMMON 26 (32) +COM CWP2, CCWP2 +COMMON

2 (17) CWP1 CW pulse output signal for Axis #1 27 (33) CWP2 CW pulse output for Axis #2

3 (18) CWP1 Inverted CW pulse output for Axis #1 28 (34)

4 (19) CCWP1 CCW pulse output for Axis #1 29 (35) CCWP2 CCW pulse output for Axis #2

5 (20)

6 (21)

7 (22) DRST1 Drive Reset signal for Axis #1 32 (38) DRST2 Drive Reset signal for Axis #2

8 (23) DEND1 Detection End signal for Axis #1 33 (39) DEND2 Detection End signal for Axis #2

9 (24) - Not used 34 (40) - Not used

10 (25) - Not used 35 (41) - Not used

11 (26) - Not used 36 (42) - Not used

12 (27) - Not used 37 (43) - Not used

13 (28) - Not used 38 (44) - Not used

14 (29) +ZORG1 Encoder Phase +Z signal for Axis #1 39 (45) +ZORG2 Encoder Phase +Z signal for Axis #2

15 (30) -ZORG1 Encoder Phase -Z signal for Axis #1 40 (46) -ZORG2 Encoder Phase -Z signal for Axis #2

16 (31) - Not used 41 (47) - Not used

17 (48) - Not used 42 (49) - Not used

18 (9) - Not used 43 (50) GND Ground

19 (60) SVON1 Servo ON output signal for Axis #1 44 (61) SVON2 Servo ON output signal for Axis #2

20 (10) ALM1 Alarm input signal for Axis #1 45 (11) ALM2 Alarm input signal for Axis #2

21 (1) CWLM1 CW limit signal for Axis #1 46 (5) CWLM2 CW limit signal for Axis #2

22 (2) CCWLM1 CCW limit signal for Axis #1 47 (6) CCWLM2 CCW limit signal for Axis #2

23 (3) NORG1 Near-to-origin signal for Axis #1 48 (7) NORG2 Near-to-origin signal for Axis #2

24 (4) ORG1 Origin signal for Axis #1 49 (8) ORG2 Origin signal for Axis #2

25 (14) EXTV

CCWP1

+ DRST

COM1

PG Terminal Block 1

Inverted CCW pulse output for Axis #1 30 (36)

DRST1 +COMMON 31 (37)

External power supply for Input

circuit

50 (64) EXTVGND

CWP2

CCWP2

+ DRST

COM2

Inverted CW pulse output for Axis #2

Inverted CCW pulse output for Axis #2

DRST2 +COMMON

External power supply GND for Input

circuit

16 RC700 / RC90 option PG motion system Rev.5

Page 27

2. Hardware

External power supply GND for

Pin Signal Description Pin Signal Description

1 (66) +COM CWP3, CCWP3 +COMMON 26 (82) +COM CWP4, CCWP4 +COMMON

2 (67) CWP3 CW pulse output signal for Axis #3 27 (83) CWP4 CW pulse output for Axis #4

PG Terminal Block 2

3 (68)

CWP3

Inverted CW pulse output for Axis #3 28 (84)

CWP4

Inverted CW pulse output for Axis #4

4 (69) CCWP3 CCW pulse output for Axis #3 29 (85) CCWP4 CCW pulse output for Axis #4

5 (70)

6 (71)

CCWP3

+ DRST

COM3

Inverted CCW pulse output for Axis #3 30 (86)

DRST3 +COMMON 31 (87)

CCWP4

+ DRST

COM4

Inverted CCW pulse output for Axis #4

DRST4 +COMMON

7 (72) DRST3 Drive Reset signal for Axis #3 32 (88) DRST4 Drive Reset signal for Axis #4

8 (73) DEND3 Detection End signal for Axis #3 33 (89) DEND4 Detection End signal for Axis #4

9 (74) - Not used 34 (90) - Not used

10 (75) - Not used 35 (91) - Not used

11 (76) - Not used 36 (92) - Not used

12 (77) - Not used 37 (93) - Not used

13 (78) - Not used 38 (94) - Not used

14 (79) +ZORG3 Encoder Phase +Z signal for Axis #3 39 (95) +ZORG4 Encoder Phase +Z signal for Axis #4

15 (80) -ZORG3 Encoder Phase -Z signal for Axis #3 40 (96) -ZORG4

Encoder Phase -Z signal for Axis #4

16 (81) - Not used 41 (97) - Not used

17 (98) - Not used 42 (99) - Not used

18 (59) - Not used 43 (100) GND Ground

19 (62)

SVON3

Servo ON output signal for Axis #3 44 (63)

SVON4

Servo ON output signal for Axis #4

20 (12) ALM3 Alarm input signal for Axis #3 45 (13) ALM4 Alarm input signal for Axis #4

21 (51) CWLM3 CW limit signal for Axis #3 46 (55) CWLM4 CW limit signal for Axis #4

22 (52) CCWLM3 CCW limit signal for Axis #3 47 (56) CCWLM4 CCW limit signal for Axis #4

23 (53) NORG3 Near-to-origin signal for Axis #3 48 (57) NORG4 Near-to-origin signal for Axis #4

24 (54) ORG3 Origin signal for Axis #3 49 (58) ORG4 Origin signal for Axis #4

25 (15) EXTV External power supply for Input circuit 50 (65) EXTVGND

RC700 / RC90 option PG motion system Rev.5 17

Input circuit

Page 28

2. Hardware

Command pulse input

Command pulse input

Deviation counter clear

150Ω or more *2

(For 5V spec *1)

Servo ON

(For 24V spec)

Detection End output

Alarm output

Z phase output

Signal ground

Motor driver

External power source

*1 : For the 24V spec input circuit

on the driver side, refer to

2.3.3. Output Circuit - DRST.

*2 : If the current limiting resistance

of input circuit on the driver

side is 150Ω or less, ensure

more than 150Ω with the

external resistor.

+DRST

COM

2.4.5 Typical Applications

Example of connection with the servo motor driver

18 RC700 / RC90 option PG motion system Rev.5

Page 29

Stop generating pulse gradually (by decelerating) or rapidly.

stop function is supported only by the software.

Emergency stop must also be supported in hardware also.

Make sure to install an additional circuit for the purpose of

at the input of Emergency Stop

.

2.5 Safety Features

The PG Motion System supports the same safety features as for standard robots. The

following table describes how each system safety feature is supported for PG robots.

Safety Features Supported Function on the PG Board

Emergency Stop Input

Safety Door Input The function of this input is same as for a standard robot.

High/Low Power Mode The function of this mode is same as for a standard robot.

2. Hardware

You may select either of the two patterns in the software. This

emergency

stopping the motor physically in case of emergency. Refer to

the sample circuit diagram on the next page in which the motor

drive power is turned OFF

signal to the Controller. For more details, refer to the Robot

Controller manual.

The acceleration/deceleration is set as follows for the Low

Power and High Power state respectively:

Low Power : Acceleration and deceleration will be limited

The acceleration and deceleration value of

default are fixed as follows:

Acceleration : 10%

Deceleration : 5%

High Power : The maximum speed, acceleration and

deceleration will be operable at the set-up

maximum value in the software.

Enable Switch Input The function of this input is same as for a standard robot.

Mode Switch Input The function of this input is same as for a standard robot.

For more Safety Features, refer to the Robot Controller manual or the Safety Chapter in the

EPSON RC+ User’s Guide.

RC700 / RC90 option PG motion system Rev.5 19

Page 30

2. Hardware

External +24 V

Fuse

1A or less

External +24 V GND

External +24 V

AC Power

Source

Noise

Filter

Circuit

Breaker

External safety relay

(Simple Chart)

RC700

/ RC90

CAUTION

■

Always take anti-surge measures for coils (electromagnetic contactors, relays,

etc.) or contacts. If anti

flow. The reverse current may cause damage to peripheral equipment.

2.5.1 Typical Application of Emergency Stop Circuit

Connecting external safety relay

-surge measures are not taken, a reverse current may

20 RC700 / RC90 option PG motion system Rev.5

Page 31

3. Software

This chapter describes the software setup to use the PG Motion System.

3.1 Creating PG Robots in EPSON RC+

The PG Motion System can control up to four axes per PG board, so there can be from one

to four PG robots per board, depending on the number of axes per robot.

3. Software

NOTE

If you are also using PG boards for Conveyor Tracking in the same system, those boards are

only used for conveyor tracking encoders. PG boards used for the PG Motion System are

used separately, but are enumerated in the system along with the PG boards used for

conveyor tracking. If you add a PG board to the system for use with the motion system

and there is already one or more boards used for conveyor tracking, then the PG board #

will be the next board after the conveyor tracking PG boards. For example, if you add 1

PG board for conveyor tracking, and then add a board for PG motion, that board will be #2.

To create a PG robot in EPSON RC+, follow these steps:

Turn on the Controller and launch EPSON RC+.

(1)

(2) Select [Setup] - [System Configuration]-[Robots].

(3)

Click the

button. The Add New Robot dialog will be displayed. Enter the

Add

name of the robot and serial number. Select PG motion system.

RC700 / RC90 option PG motion system Rev.5 21

Page 32

3. Software

Select PG board A, Robot Type, and the number of joints used on the robot.

(4)

For the Cartesian coordinate robot, select “Cartesian”.

For the Joint type robot, select “Joint”.

In case of the Joint type robot with more than 5 joints, select also “PG board B”.

(5) Click the OK and reboot the controller.

(6) After the controller is rebooted, a PG robot is added to EPSON RC+.

22 RC700 / RC90 option PG motion system Rev.5

Page 33

3.2 PG Robot Configuration

■

Set

If

unexpected movement of the

damage to the

Once a PG robot has been added to the system, you must configure it for the PG Robot

Configuration.

3.2.1 PG Robot Parameters Overview

To configure parameters for a PG robot:

Start EPSON RC+.

(1)

(2) Select [Setup]-[System Configuration]-[Robot].

(3) Select a PG parameter of the PG robot you want to edit the setting.

3. Software

(4) Follow the instruction in 3.2.3 PG Parameter and follows to change the parameter

settings.

Click

PG robot parameters with extra caution.

parameters are set improperly, the robot may move unexpectedly. The

CAUTION

Apply

to save the new settings.

robot is extremely hazardous and may cause

robot and / or peripheral equipment.

RC700 / RC90 option PG motion system Rev.5 23

Page 34

3. Software

3.2.2 PG Parameters

This dialog allows you to configure the parameters for the new robot. If you already

have a data file from a previously created PG robot, click OK to accept default

parameters, then use the Load Parameters button to load the data file.

If you have a PG robot data file previously created

Load the data file by following the instruction in the section 3.2.4 Backup and Restore

Parameter Data.

If you don't have a data file, then proceed to the following sections to configure the

PG robot parameters.

If you don’t have a data file

Set the PG robot parameter in the dialog shown below.

User Model Name

Name the model of the manipulator here. You may create your own type-name using a

maximum of 32 alphanumeric characters.

The User Model Name entered here will appear as the robot type in Robot Configuration.

The User Model Name does not affect robot operation.

Model Version

This indicates the data version in a 4-digit hexadecimal number. This information does

not affect robot operation. The version number is for your own use to indicate different

versions of robots using the same User Model Name.

Home Speed

This parameter sets the speed when Home is executed, specified by percentage of

maximum speed. The value must be an integer in the range of 1 to 100.

Home Accel

This parameter sets the acceleration when HOME is executed, specified by percentage of

maximum acceleration. The value must be an integer in the range of 1 to 100.

Mcal Speed

This parameter sets the speed when MCAL is executed, specified by percentage of

maximum speed. The value must be an integer in the range of 1 to 100.

24 RC700 / RC90 option PG motion system Rev.5

Page 35

3. Software

NOTE

Mcal Accel

This parameter sets the acceleration when MCAL is executed, specified by percentage of

maximum acceleration. The value must be an integer in the range of 1 to 100.

Specify this parameter so that MCAL is completed within 120 seconds.

If the calibration of each joint is not completed within 120 seconds during MCAL execution,

then error 4083: MCAL did not complete in time will occur.

3.2.3 PG parameter Joint

RC700 / RC90 option PG motion system Rev.5 25

Page 36

3. Software

Alarm Logic

The ALM input logic is defined as follows when you select either Active High or Active

Low from the drop-down list:

Active High

Active Low

The alarm status is active when the input at the ALM input terminal is

at High Active.

The alarm status is active when the input at the ALM input terminal is

at Low Active.

Cal Direction

This setting defines the direction for the joint to move when calibrating the mechanical

origin:

Normal

Reverse

The joint moves in the normal direction during calibration of the

mechanical origin.

The joint moves in the reverse direction during calibration of the

mechanical origin.

Cal Jog Delay

The Jog Delay sets the delay (in msec) per pulse for the low speed, pulse-by-pulse

operation during signal detection.

The value must be an integer in the range of 0 to 1275 and a multiple of 5 (msec).

Cal Limit Delay

The Limit Delay sets the time duration (in msec) before reverse motion starts after either

the CCW or CW Limit is detected during calibration.

The value must be an integer in the range of 0 to 1275 and a multiple of 5 (msec).

Cal Org Detect Speed

This is the speed for detecting the sensor edge in pulses/sec.

The value must be an integer in the range of 1 to 65535.

Cal Scan Delay

The Scan Delay sets the time duration (in msec) before reverse motion starts after the stop

command is input during calibration.

The value must be an integer in the range of 0 to 1275 and a multiple of 5 (msec).

Cal Type ORG

The Calibration Type specifies the calibration method used to calibrate the mechanical

origin. There are seven calibration types 0, 1, 2, 3, 4, 5 and 10. For details of each

type, refer to 4. Calibration Types.

26 RC700 / RC90 option PG motion system Rev.5

Page 37

3. Software

the motion commands for

are

Clear MCal

The check on this box clears the existing MCAL records when either MOTOR OFF or

SFREE is executed. Execution of either MOTOR OFF or SFREE necessitates

execution of MCAL after the motor is let go of servo by either of these commands.

False

True

The MCAL records will not be cleared when either MOTOR OFF or SFREE is

executed. If it is a stepping motor that is driving the joint, this box must be left

unchecked.

The MCAL records will be cleared when either MOTOR OFF or SFREE is

executed. Execution of either MOTOR OFF or SFREE necessitates execution of

MCAL after the motor is let go of servo by either of those commands. If it is a

servo motor connected to the SVON output that is driving the joint, this box must

be checked.

Continuous Motion

Enables the continuous rotation in the any direction. This is used in the rotary table or

other controls. This is for only the Joint type robots.

Disabled Continuous operation is not enabled (Default)

Continuous operation is enabled

If the continuous operation is enabled, normal absolute position

Abled

management is not executed. In addition, only

the continuous rotation (PG_Scan, PG_SlowStop, PG_FastStop)

enabled and the manipulator will not move with other motion commands.

PG_Scan 0 : Continuous motion in CW direction.

Default Horder

When Home (a command to move to the user-defined home position) is executed, each

joint will be moved to the -defined home position in the order as specified by the Horder

command.

When the user clicks Default button in the Tool | Robot manager | Home Config, these

values will be used.

For the details, refer to 3.3.3 [Home Config].

Default MCORDR

When MCAL (calibration to the home position) is executed, each joint will be calibrated

to the mechanical home position in the order as specified by the MCORDR command.

When you click Default button in the Tool | Robot manager | Mcal Order, these values

will be used.

For the details, refer to 3.3.4 [Mcal Order].

RC700 / RC90 option PG motion system Rev.5 27

Page 38

3. Software

Initial Pulse Width

Use this parameter to control the initial pulse width to prevent power swing at the stepper

motor. The value in the range of 1 to 8388607.

Limit Stop Mode

This specifies how the robot will be stopped when a limit signal is turned OFF. Select

from the drop-down list box either Rapid Stop (stop immediately) or Decel Stop

(gradually decelerate to stop).

Margin Pulses

During the calibration without the acceleration or deceleration, when the calibration

signal is detected, the arm stops after moving for the part of margin pulses in the traveling

direction. This is used to prevent the false detection by the origin signal chattering or

hunting. The value must be an integer in the range of 1 to 65535.

Max Accel, Max Decel Max, Speed

These correspond with the SPEL+ commands SPEED 100, and ACCEL 100, 100, whose

values are percentages.

maximum speed [pulse/sec] Real value from 0.1 to 6553400.0

maximum acceleration [pulse/sec2]

Real value from 200.0 to 400000000.0

maximum deceleration [pulse/sec2]

Max Range, Min Range

This is the default working range for the robot. The value must be a signed integer in

the range of −2147483648 to 2147483647.

When the user clicks Default button in the Tool | Robot manager | Range, these values

will be used.

For the details, refer to 3.3.2 [Range].

Motor Type

Specifies the target motor type. Select either Servo or Stepper.

If Servo is selected, the following signals will become effective: Positioning Output of

the servo drive (DEND), Counter Reset Input (DRST) and Servo ON (SVON).

Origin Pulses

Specifies the pulse position after the calibration. The specified pulse value is the

position at where the arm is after the calibration with MCal. The value must be a

positive / negative integer.

Physical / Logical Pulses

Set the relation of the direction of the motor rotation and the pulse values (coordinate

values) in SPEL+. Select Same or Reverse from the drop-down list.

Same As physical encoder values increase, SPEL+ pulse values increase.

Reverse As physical encoder values increase, SPEL+ pulse values decrease.

28 RC700 / RC90 option PG motion system Rev.5

Page 39

3. Software

For this setting, the pulse signal is generated from the CWP output

For this setting, the pulse in + (CW) direction is generated from the

When the relative motion is enabled, normal absolute position management

is not executed. The point data for the motion command is considered as

degrees

from the current position.

Pulse Output

Select the pulse output type from the drop-down list to match to the motor drive’s

specification:

Pulse / Direction

CW / CCW

while the Direction signal will be generated from the CCWP output.

The direction will be + (CW) when CCWP is low, and – (CCW)

when CCWP is high.

CWP terminal while the pulse in – (CCW) direction will be generated

from the CCWP terminal.

Reduction Ratio Joint, Reduction Ratio Pulses

This defines the number of pulses that correspond with the travel distance in millimeters

or degrees.

This sets the pulse number to the reduction ratio pulse, travel distance (angle) to the

reduction ratio joint.

Input range is an integer from 1.0 ~ 1000000.0.

Relative Motion

This enables the relative rotary motion in any directions. This is used to control such as

the rotary index. This is for only the Joint type robots.

Disabled Relative motion is not enabled (Default)

Relative motion is enabled

Abled

SCurve

This sets the acceleration speed curve to Straight or S-curve Acceleration/Deceleration.

Disabled Straight Acceleration/Deceleration (Default)

Abled

Z Joint

Specify the joint designated as Z-joint (vertical operation joint) when the JUMP command

is executed in SPEL+. For Cartesian robots, the Z joint is fixed at joint #3.

the relative travel amount from the current position.

Go XY(100, 0, 0, 0) ‘ Moves 100 mm or 100

S-curve Acceleration/Deceleration

In the S-curve Acceleration/Deceleration, it creates an

acceleration/decelerat

ion curve which changes the speed smoothly.

Also, it can prevent the triangle drive in small distance motions.

RC700 / RC90 option PG motion system Rev.5 29

Page 40

3. Software

3.2.4 Backup and Restore Parameter Data

After creating a PG robot, you can save its parameter data in a file. This file can be used

as a backup, and can also be used to create PG robots on other systems.

To backup PG robot parameter data:

(1) Select System Configuration from the Setup menu.

(2) Select the Robot from the System Configuration.

(3) Select the desired PG robot from the list of Robot, and then select a PG parameter.

(4) Click the <Save>button.

(5) Browse to the desired location and enter the desired filename.

(6) Click the <Save>button.

30 RC700 / RC90 option PG motion system Rev.5

Page 41

3. Software

To restore PG robot parameter data:

(1) Select System Configuration from the Setup menu.

(2) Select the Robot from the System Configuration

(3) Select the desired PG robot from the list of Robot, and then select a PG parameter.

(4) Click the <Load>button.

(5) Browse to the desired location and select the desired filename.

(6) Click the <Open> button. The parameters are now loaded.

RC700 / RC90 option PG motion system Rev.5 31

Page 42

3. Software

3.3 [Robot Manager] Configuration

After the PG robot parameter configuration is completed, now you need to set the parameters

in the [Robot Manager].

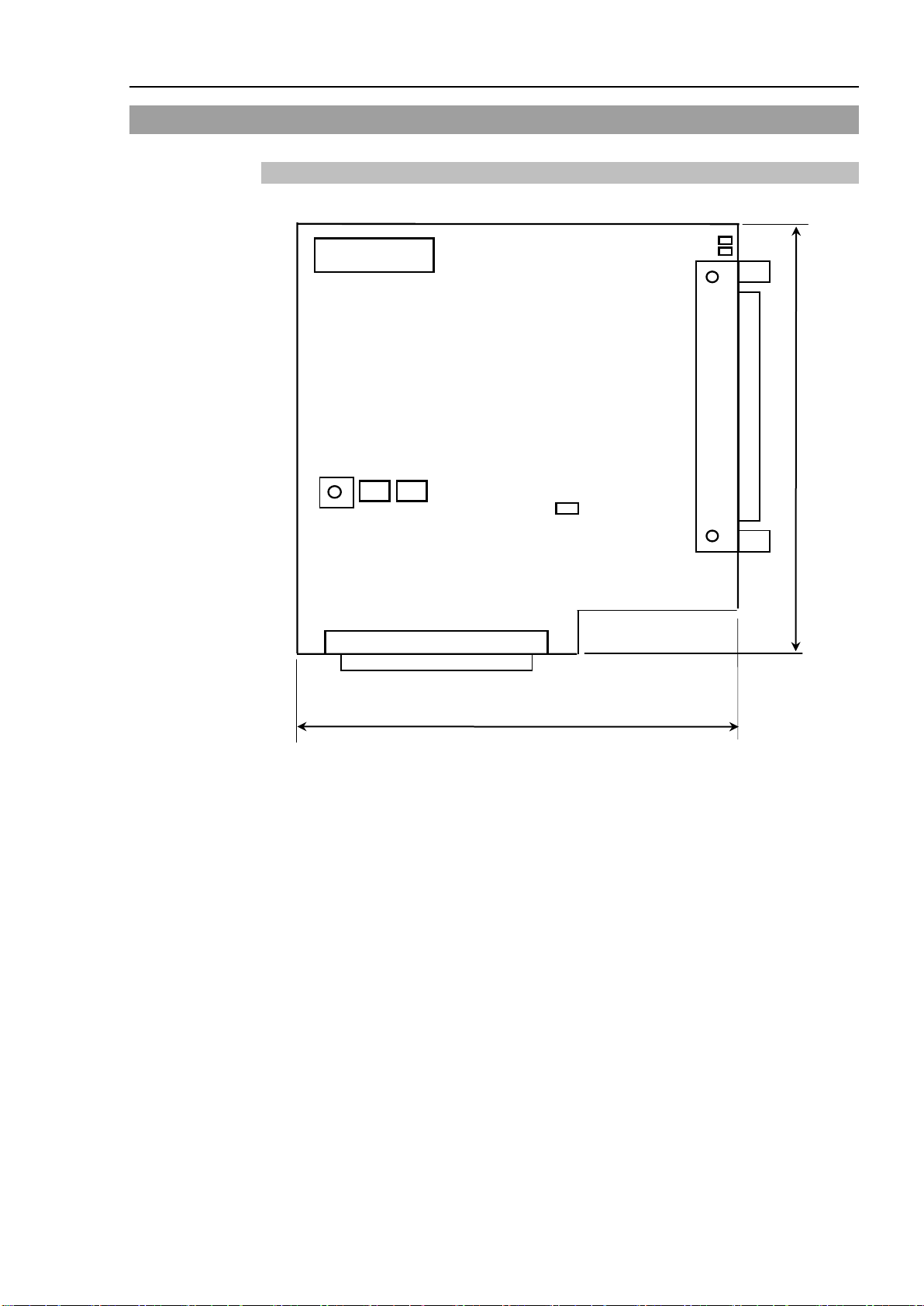

3.3.1 Overview of [Robot Manager]

This is used to control the robot motors and power, jog robots, teach points, and view/edit

several parameters for the robot.

For the details, refer to EPSON RC+ Users Guide: 5.11.1 [Robot Manager Command]

(Tools Menu).

This section describes an instruction for the PG robot parameter setting.

How to edit the [Robot Manager]

(1) Start the EPSON RC+.

(2) Select the Robot Manager from the Tools menu.

(3) Follow the instruction in the section 3.3.2 [Range] or later to change the parameters.

(4) Click the <Apply> button and save the new settings.

32 RC700 / RC90 option PG motion system Rev.5

Page 43

3. Software

3.3.2 [Range]

Set the robot motion range. Click the <Default> button if you want to load the default

values set in the section 3.2.3 PG parameter Joint.

For each Joint (J1 through J4), specify the minimum value in the box on your left and the

maximum on the right. The value must be a signed integer in the range of -2147483647

to 2147483647.

3.3.3 [Home Config]

When HOME (a command to move to the user-defined home position) is executed, each

joint will be moved to the user-defined home position in the order as specified by the

HORDR command.

Click the <Default> button if you want to load the default values set in the section 3.2.3 PG

parameter Joint.

RC700 / RC90 option PG motion system Rev.5 33

Page 44

3. Software

NOTE

J1 through J6 represent Joint #1 through Joint #6 respectively and, they are moved to the

user-defined home position in the order as specified by Step 1 through Step 4. In the

illustrated example, the Joint #2 will be moved to the user-defined home position after Joint

#1 is calibrated and moved to the waiting position.

3.3.4 [Mcal Order]

Specify this parameter so that MCAL is completed within 120 seconds.

If the calibration of each joint is not completed within 120 seconds during MCAL execution,

then error 4083, MCAL did not complete in time, will occur.

When MCAL (calibration to the home position) is executed, each joint will be calibrated to

the mechanical home position in the order as specified by the MCORDR command. The

values to be entered here specify the default values for MCORDR.

Click the <Default> button if you want to load the default values set in the section 3.2.3 PG

parameter Joint.

J1 through J6 represent Joint #1 through Joint #6 respectively and they will be calibrated in

the order as specified by Step 1 through Step 4. In the illustrated example, the Joint #2

will be calibrated to the origin position after Joint #1 is calibrated and moved to the origin

position.

34 RC700 / RC90 option PG motion system Rev.5

Page 45

3.4 Using PG Robots in EPSON RC+

Joint #

Joint Name

1 X 2 Y 3 Z 4

U

Joint

J1

J2

J3

J4

J5

J6

J7

Position

CX(Here)

CY(Here)

CZ(Here)

CU(Here)

CV(Here)

CW(Here)

CR(Here)

coordinate

CX(Pn)

CY(Pn)

CZ(Pn)

CU(Pn)

CV(Pn)

CW(Pn)

CR(Pn)

PG robots behave similar to standard robots. You use Robot Control Panel, Jog & Teach,

Point Editor, etc. the same as you would with standard robots.

Refer to the EPSON RC+ User's Guide for details on using the GUI and program

development.

The following sections contain additional information that is specific to PG robots.

3.4.1 PG Cartesian Robots

PG Cartesian robots can be from 1 to 4 joints. The joint names are shown in the table

below.

3. Software

Current

Point

Joint #3, if used, is fixed as the Z joint. You cannot set which joint is the Z joint for a PG

Cartesian robot.

Vision Guide supports Cartesian robots with 2 or more joints.

PG Cartesian robots support Arm, Tool, and Local.

PG Joint robots do not have an XY coordinate system.

Vision Guide does not support Joint robots (since there is no XY coordinate system).

PG Joint robots do not support Arm, Tool, and Local.

The table below shows the functions used to retrieve coordinates for joint robots.

Normally, for Joint robots, use Agl and PAgl functions. However, you can also use the

CX, CY, CZ, CU functions, as shown.

Agl(1)

PAgl(Pn, 1)

3.4.2 PG Joint Robots

Agl(2)

PAgl(Pn, 2)

Agl(3)

PAgl(Pn, 3)

Agl(4)

PAgl(Pn, 4)

Agl(5)

PAgl(Pn, 5)

Agl(6)

PAgl(Pn, 6)

Agl(7)

PAgl(Pn, 7)

3.4.3 Tuning

Tuning for PG robot drives is handled by the third party motor drive. Refer to the drive

manufacturer's instructions on how to tune the drive. EPSON RC+ does not provide any

commands for tuning the drive. However, if the drive can be controlled from a DLL, it is

possible to execute DLL functions from a SPEL+ program.

RC700 / RC90 option PG motion system Rev.5 35

Page 46

3. Software

3.4.4 Motion Commands

PTP (point to point) motion commands are supported for PG robots. These include Go,

TGo (Cartesian only), and Jump.

Joint motion is not synchronized for PG robots. When a motion command using more than

one joint is executed, the joints do not complete their motion at the same time.

CP motion (linear interpolated) commands are not supported. These include Move,

TMove, Arc, and Curve.

The Jump motion command is supported for PG robots that have a Z joint.

PASS operation with CP ON is not continuous. A PASS operation cannot be continued to

the next operation as one smooth continuous motion in which an action to the first PASS

operation/command slows down to move into another action in accelerating motion.

Attempting a PASS operation via CP ON command will only operate the manipulator by

one motion at a time.

3.4.5 SLock and SFree

Connecting the servo drive to the SVON signal enables servo excitation control via the

SLock and SFree commands. However, MCal must be executed before servos can be set

to free. (This is because the manipulator is possibly out of position while at servo-free.)

In order to ensure MCal execution, set as follows in the software: Enable the [Clear MCal]

in the Configuration dialog | System the Robot.

When you execute a manipulator motion command without executing MCal command, error

message “Error 4014: MCAL has not completed.” is displayed.

The stepper motor itself is not capable of controlling excitation, and normally, the SVON

output signal cannot be used. However, by executing SFree, the manipulator can be

operated in a pseudo servo-free state when the motor is actually engaged. When you

execute SFree, make sure to execute SLock in order to restore the excitation state.

3.4.6 Dry Run

PG robots are not directly supported in Dry Run. For PG robots to be used, the PG board

hardware must exist on the system. If you enable Dry Run in EPSON RC+, the PG robots

will continue to operate from the hardware.

36 RC700 / RC90 option PG motion system Rev.5

Page 47

3. Software

3.4.7 PG Signal Status Display

Input and output status of the PG board can be displayed on the EPSON RC+ GUI.

When the PG robot is selected, open the [I/O Monitor] of the EPSON RC and select [PG

Status] tab.

The [PG Status] tab cannot be displayed in the [I/O Monitor] in the Operator mode.

DRIVE signal turns “On” while the pulse waveform is output. It does not represent the

status of the pulse waveform itself.

RC700 / RC90 option PG motion system Rev.5 37

Page 48

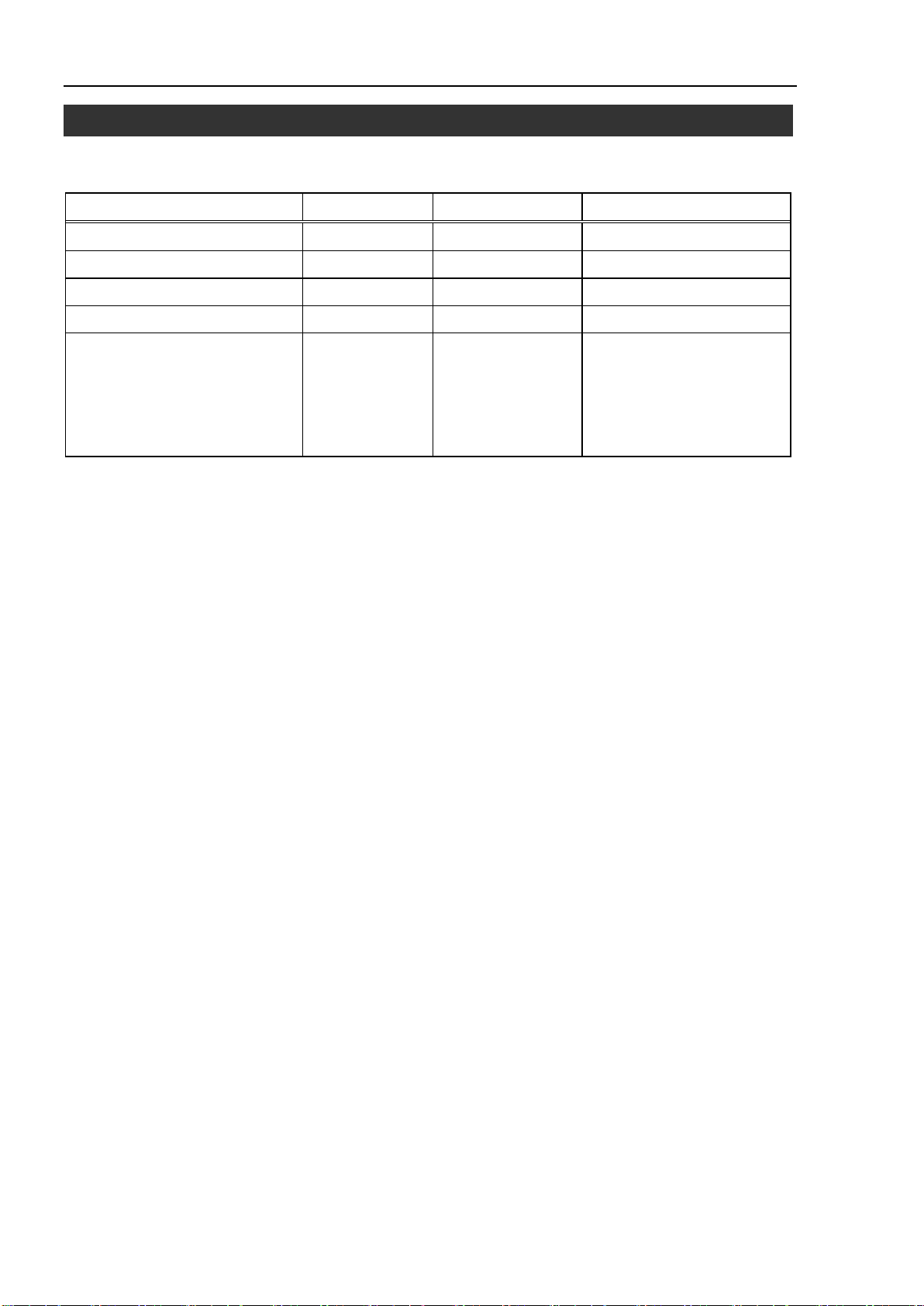

4. Calibration Types

Standard Number

4. Calibration Types

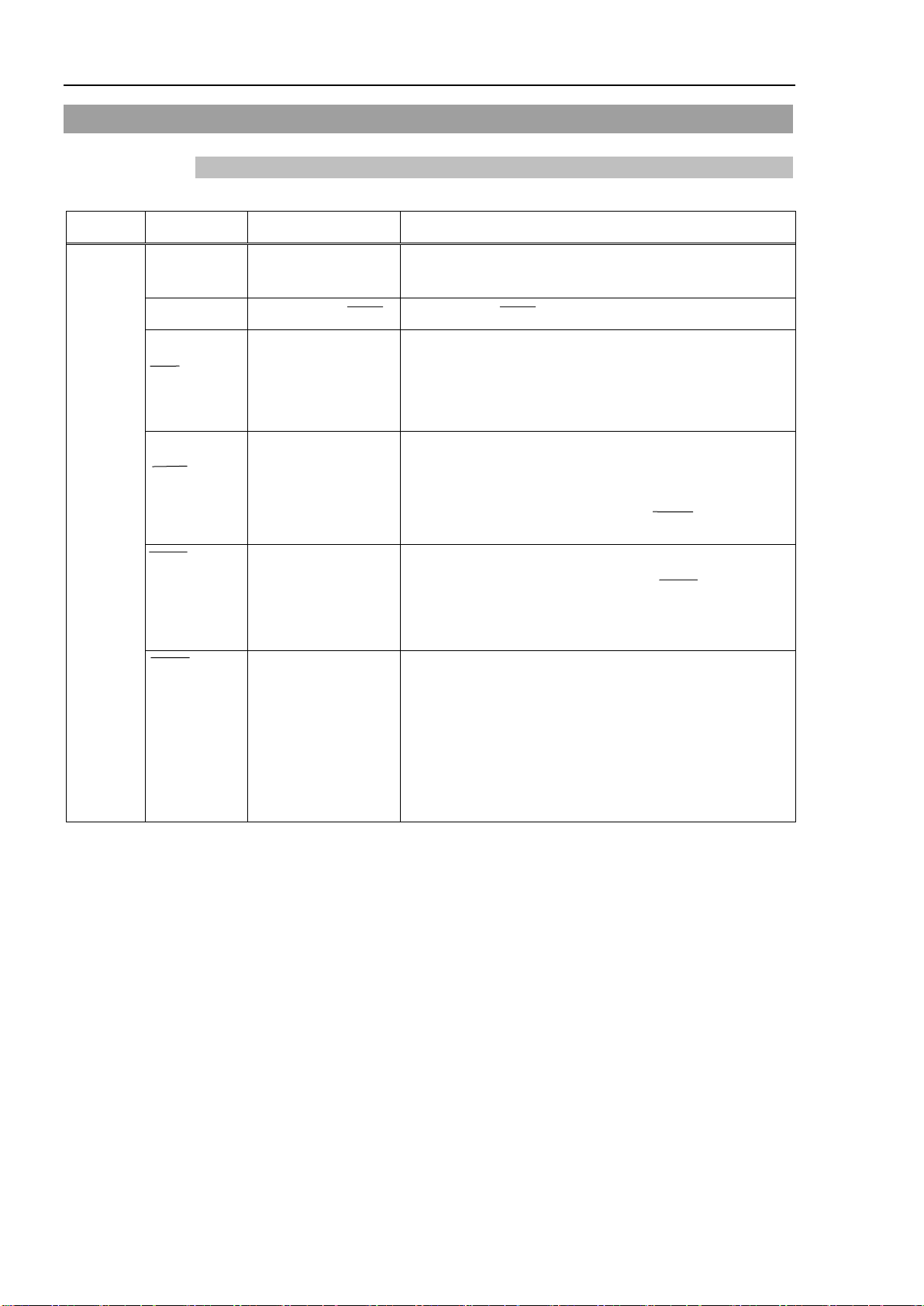

The table below lists the seven Calibration Types. These calibration types determine

how the mechanical origin is determined during MCal.

Cal

Number of

Type

0 1 OFF 2 C Shorter

1 1 ON 2 C Shorter

2 1 OFF 4 B Longer

3 1 ON 4 B Longer

4 2 OFF 4 or 5 A Longest

5 2 ON 4 or 5 A Longest

10 2 ON 2 C Shortest

sensors

*1: A is highest accuracy followed by B and then C.

*2: Complete the calibration of each joint within 120 seconds.

Sensor Status when

calibration is complete

of Steps

Accuracy

Calibration

*1

Time

*2

38 RC700 / RC90 option PG motion system Rev.5

Page 49

4. Calibration Types

The arrow indicates the two types of operation speed as follows:

Run at the speed as specified in the MCAL tab of the PG Robot

Configuration dialog.

Run at the speed as specified in the Origin Edge Detect Speed in

the Calibration tab of the PG Robot Configuration dialog.

The following symbols marked next to (Pause) in the illustration indicates the

duration of time to pause as follows:

or The starting position of the search for the mechanical origin.

Pause

The position for the calibration to complete. (A target origin)

The accelerating or decelerating motion in the direction of arrow

while detecting signals. (Dotted Line indicates a motion to return

to the origin from outside the Permissible Working Range.)

The motion without acceleration or deceleration in the direction of

arrow while detecting signals.

The motion in the slow speed pulse by pulse in the direction of

arrow while detecting signals.

Calibration Sequence per Calibration Type

The following conventions and symbols are used in the Calibration Sequence diagram in

the following pages:

LD Pause for delay time as specified in

the PG Robot Configuration dialog.

SD Pause for delay time as specified in

the PG Robot Configuration dialog.

JD Pause for delay time as specified in

PG Robot Configuration dialog.

RC700 / RC90 option PG motion system Rev.5 39

Limit Delay

Scan Delay

Jog Delay

on Calibration tab of

on Calibration tab of

on Calibration tab of the

Page 50

4. Calibration Types

Cal Type 0 ORG pulse width : 1 msec or over

Cal Type 1 ORG pulse width : 1 msec or over

Cal Type 2 ORG pulse width : 1 msec or over

Cal Type 3 ORG pulse width : 1 msec or over

Cal Type 4 NORG pulse width : 1 msec or over

The interval between the NORG signal edge and ORG signal edge:

5 msec or over

+ZORG/-ZORG pulse width : 10 µsec or over (when a servo motor

is used.)

Cal Type 5 NORG pulse width : 1 msec or over

The interval between the NORG signal edge and ORG signal edge:

5 msec or ove

r

+ZORG/-ZORG pulse width : 10 µsec or over (when a servo motor

is used)

Cal Type 10 NORG Signal width : 1 msec or over

The interval between the NORG signal edge and ORG signal edge

must be sufficient to enable the robot to stop by deceleration.

Whichever Calibration Type is specified, wiring must be done in such a way to prevent

chattering. Also, the following signal conditions must be satisfied:

40 RC700 / RC90 option PG motion system Rev.5

Page 51

4. Calibration Types

<1

<2>

<3>

<4>

<1> <2

When the starting position is in the range of A above. (Operation: 2 steps)

target origin

Working Range

CW (CCW)

Calibration Type 0

For Calibration Type 0, calibration is accomplished using one sensor. Place the sensor

closer to the CCW Limit position. Configure the sensor to detect the ORG signal edge

( ↑ ) in the CW direction.

CCW (CW)

Limit Position

ORG

CW LIMIT

CCW LIMIT

CW (CCW) direction CCW (CW) direction

Limit Position

C

>

When the starting position is in the range of B above. (Operation: 4 steps)

>

LD

When the starting position is in the range of C above. (Operation: 3 steps)

C B A

SD

SD

SD

<1>

<2>

<3>

NOTE

The above motion direction is subject to and affected by the Direction parameter in the

System Configuration | Robot. The directions shown above without parentheses indicate

the motion direction when Normal is selected while those marked in parentheses indicate

the motion direction when Reverse is selected.

RC700 / RC90 option PG motion system Rev.5 41

SD

SD

Page 52

4. Calibration Types

LD

SD

<1>

<2>

When the starting position is in the range of B above. (Operation: 4 steps)

SD

<3>

<4>

SD

<1>

<2>

When the starting position is in the range of A above. (Operation: 2 steps)

SD

<1>

<2>

When the starting position is in the range of C above. (Operation: 3 steps)

SD

<3>

A

CCW (CW)

Limit Position

target origin

ORG

CW LIMIT

CCW LIMIT

CW (CCW)

Limit Position

Working Range

CW (CCW) direction

CCW (CW) direction

C

C B

Calibration Type 1

For Calibration Type 1, calibration is accomplished using one sensor. Place the sensor

closer to the CCW Limit position. Configure the sensor to detect the ORG signal edge

( ↓ ) in the CCW direction.

The above motion direction is subject to and affected by the Direction parameter in the

System Configuration | Robot. The directions shown above without parentheses indicate

the motion direction when Normal is selected while those marked in parentheses indicate

the motion direction when Reverse is selected.

42 RC700 / RC90 option PG motion system Rev.5

Page 53

4. Calibration Types

<1>

<2>

When the starting position is in the range of C above. (Operation: 3 steps)

SD

<3>

JD

JD

SD

<1>

<2>

When the starting position is in the range of A above. (Operation: 4 steps)

<3>

<4>

SD

LD

JD

<1>

<2>

When the starting position is in the range of B above. (Operation: 4 steps)

SD

<3>

<4>

A

CCW (CW)

Limit Position

target origin

ORG

CW LIMIT

CCW LIMIT

CW (CCW)

Limit Position

CW (CCW) direction

Working Range

CCW (CW) direction

C C B

Calibration Type 2

For Calibration Type 2, calibration is accomplished using one sensor. Place the sensor

closer to the CCW Limit position. Configure the sensor to detect the ORG signal edge

( ↑ ) in the CW direction.

NOTE

The above motion direction is subject to and affected by the Direction parameter in the

System Configuration | Robot. The directions shown above without parentheses indicate

the motion direction when Normal is selected while those marked in parentheses indicate

the motion direction when Reverse is selected.

RC700 / RC90 option PG motion system Rev.5 43

Page 54

4. Calibration Types

JD

SD

<1>

<2>

When the starting position is in the range of A above. (Operation: 4 steps)

<3>

<4>

SD

LD

JD

<1>

<2>

When the starting position is in the range of B above. (Operation: 4 steps)

SD

<3>

<4>

<1>

<2>

When the starting position is in the range of C above. (Operation: 3 steps)

SD

<3>

JD

A

CCW (CW)

Limit Position

target origin

ORG

CW LIMIT

CCW LIMIT

CW (CCW)

Limit Position

Working Range

CW (CCW) direction

CCW (CW) direction

C C B

Calibration Type 3

For Calibration Type 3, calibration is accomplished using one sensor. Place the sensor

closer to the CCW Limit position. Configure the sensor to detect the ORG signal edge

( ↓ ) in the CCW direction.

The above motion direction is subject to and affected by the Direction parameter in the

System Configuration | Robot. The directions shown above without parentheses indicate

the motion direction when Normal is selected while those marked in parentheses indicate

the motion direction when Reverse is selected.

44 RC700 / RC90 option PG motion system Rev.5

Page 55

4. Calibration Types

SD

<1>

<2>

When the starting position is in the range of A above. (Operation: 2 steps)

SD

A

CCW (CW)

Limit Position

target origin

NORG

CW LIMIT

CCW LIMIT

CW (CCW)

Limit Position

Roughly positioned

(the first step in this calibration)

Roughly positioned

(the first step in this calibration)

Roughly positioned

(the first step in this calibration)

LD

SD

<1>

<2>

When the starting position is in the range of B above. (Operation: 3 steps)

SD

<3>

<1>

<2>

When the starting position is in the range of C above. (Operation: 2 steps)

SD

SD

Working Range

CW (CCW) direction

CCW (CW) direction

C C B

Calibration Type 4

In Calibration Type 4, calibration is accomplished using two sensors. Use the NORG

signal for rough positioning first. Then, to position more closely, pick up the ORG signal

(if a stepper motor is used) or ZORG signal (if a servo motor is used). Place the NORG

sensor in the direction of CCW Limit Position. Place the ORG sensor on the motor’s

rotation axis and, leave +ZORG disconnected when a stepper motor is used. When a servo

motor is used, connect the +Z Phase of the servo motor to +ZORG and -Z Phase to -ZORG

respectively. Leave ORG disconnected when a servo motor is used. The sequence of

rough positioning in Calibration Type 4 using NORG signal is as follows:

The above motion direction is subject to and affected by the Direction parameter in the

System Configuration | Robot. The directions shown above without parentheses indicate

the motion direction when Normal is selected while those marked in parentheses indicate

the motion direction when Reverse is selected.

RC700 / RC90 option PG motion system Rev.5 45

Page 56

4. Calibration Types

ORG

NORG

JD

ORG = HIGH (sensor: OFF)

when the NORG ( ↑ ) is detected.

JD

SD

ORG = LOW (sensor: ON)

when the NORG ( ↑ ) is detected.

ORG

NORG