Page 1

EPSON TERMINAL PRINTER

LX-1050+

SERVICE MANUAL

EPSON

,’

4003283

,,

Page 2

NOTICE

All

rights

reserved.

Reproduction of any part of this manual in any form whatsoever without

SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure theaccuracyof the contents of this

manuaI.

However, should

any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for any errors in this

manual or the consequence thereof.

Epson and Epson

General Notice: Other product names used herein are for

ESC/P

are registered trademark of Seiko Epson Corporation.

identication

purposes only and maybe

trademarks of their respective campanies.

@

Copyright 1994 by

SEIKO EPSON CORPORATION

Nagano, Japan

-i-

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal

damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/

maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

inju~

and 2)

DANGER

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

2.

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

3.

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLT-

2.

AGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO

NOT CONNECT IT TO THE POWER SOURCE.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM

3.

THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4.

IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

5.

BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

ICS

OR OTHER

- ii -

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of LX-105O+.

The instructions and procedures included herein are intended for the experience repair technician, and

attention should be given to the precautions on the preceding page. The chapters are organized as

follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

-

iv -

Page 5

REVISION SHEET

Revision Issue Date

A

Rev.

May 18, 1994

Revision Page

1st

issue

-v-

Page 6

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

DISASSEMBLY AND ASSEMBLY

ADJUSTMENTS

TROUBLESHOOTING

MAINTENANCE

- vi -

Page 7

Chapter 1

General Description

Table of Contents

FEATURES

1.1

1.2 SPECIFICATIONS

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.2.6

1.2.7

1.2.8

1.2.9

1.3 INTERFACE OVERVIEW

1.3.1 Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.3.2 Optional Interface #8143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4 PRINTER OPERATIONS

1.4.1

1.4.2

1.4.3

1.4.4

1.4.5

1.4.6

1.4.7

Printing Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Handling Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ink Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reliability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Approval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

SelecType Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

MicroAdjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Panel Operational Power ON....... . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

DIP Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Buzzer Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

EEPROM Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1-1

1-3

1-3

1-5

1-5

1-7

1-7

1-7

1-7

1-7

1-7

1-8

1-1o

1.5 MAIN COMPONENTS

1.5.1 TAMA Main Control Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.5.2

1.5.3 Printer Mechanism

Figure 1-1. Exterior View of the LX-105O+. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Figure l-2. Pin Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Figure 1-3. Printable Area - Cut Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure l-4. PrintableArea -Continuous Paper. . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure l-5. Adjust Lever Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure l-6. Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure l-7. Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Figure l-8.

Figure 1-9.

Figure 1-11. Printer Mechanism

TAa Filter Unit... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

(M-3D60). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

List

TAMA Board Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

TAa Filter Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

of Figures

(M-3D60) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1-15

Page 8

List of Tables

Table 1-1. Options for

Table 1-2. Print Speed and Printable Columns . . . . . . . . . . . . . . . . . . . . . . . . .

Table l-3.

Table

Table

Table

Table

Table

Table

Table

CharacterTables.

-4. Adjust Lever Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-5. Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-6. Connector PinAssignments and Signal Functions. . . . . . . . . . . . . . 1-8

-7. Settings

for DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

-8. International Character Set Selection . . . . . . . . . . . . . . . . . . . . . . . 1-12

-9. Character Table Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-lO. Page Length Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LX-105O+

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

l-s

I-A

1-6

1-7

1-13

1-13

Page 9

LX-105O+

Service Manual

1.1 FEATURES

The

LX-105O+

are:

The LX-105O+ has

Standard version:

India version:

Russian version:

Latin version:

South Europe version:

c1

Command compatible with following printers.

Standard, Latin, and South Europe version: with

Russian and India version:

Q

Printing speeds:

200

240

40

48

Ci

PC table support as follows.

Standard version:

India version:

Russian version:

Latin version:

South Europe version:

Two built-in

c1

c1

Input buffer size is as follows.

Standard, Latin, and South Europe version: 4Kbytes

Russian and India version:

L1

Optional EPSON TYPE-A interface

is a small, light-weight, low-cost, advanced paper handling printer. Its main features

versions. Different parts are Program ROM version only.

four

ROM version SOxxxx

ROM version Slxxxx

cps

(draft 10

cps

(draft 12

cps (NLQ

cps (NLQ

ROM version S2

ROM version S3xxxx

ROM version S4xxxx

cpi)

cpi)

10

cpi)

12

cpi)

Italic,

PC437, PC850, PC860, PC863,

Italic,

PC437

Italic,

PC437, PC866, PC855,

Italic,

PC437, PC852,

Italic,

PC437, PC857,

NLQ

(Near Letter Quality) fonts (Roman and Saris Serif)

XXXX

with FX-1OOO

MAZOVIA, codeMJK

1S0 Latin IT,

IK bytes

LX-105O

Bulgaria

PC865

PC437

Greek,

General Description

PC869,

1S0 8859-7

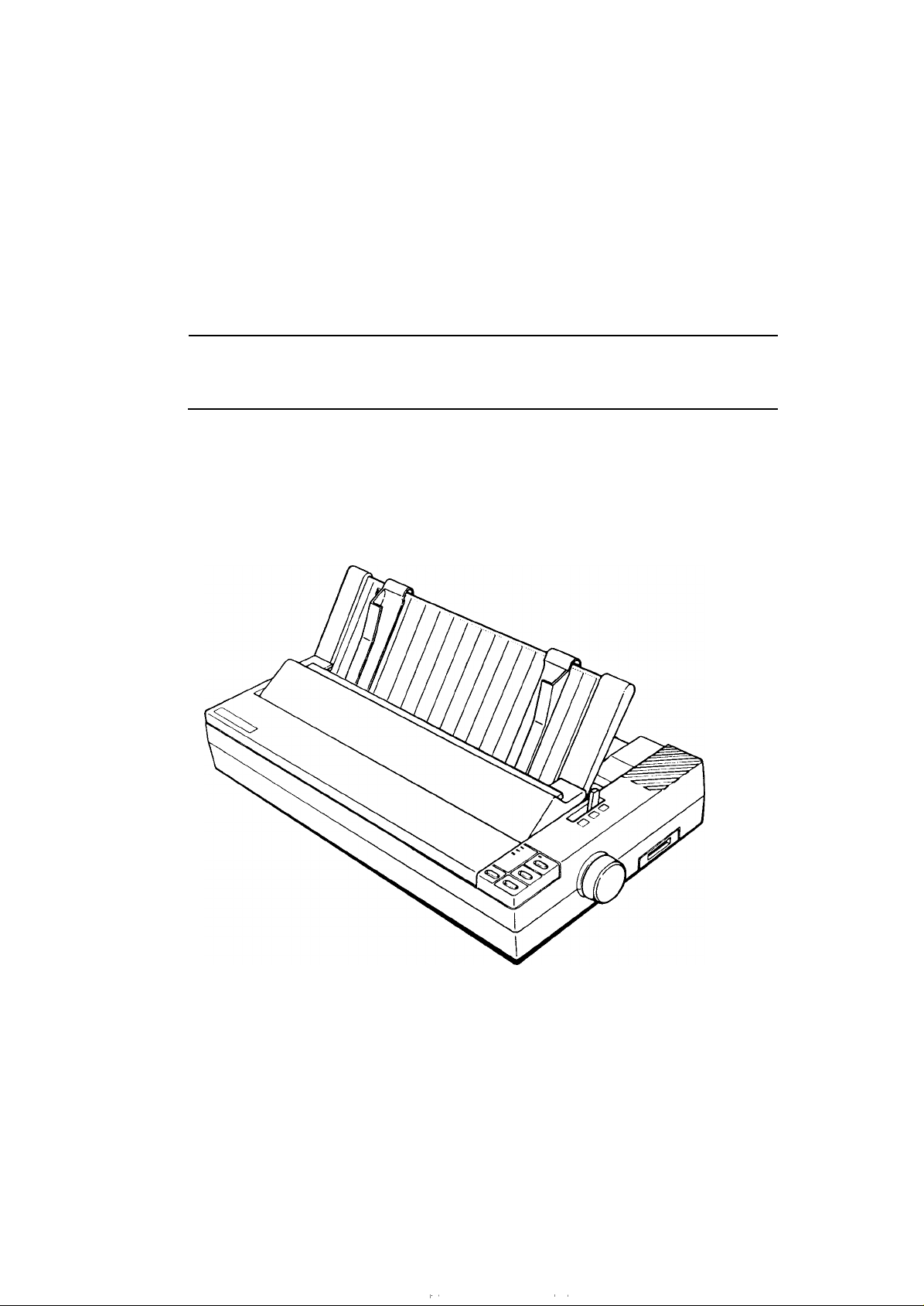

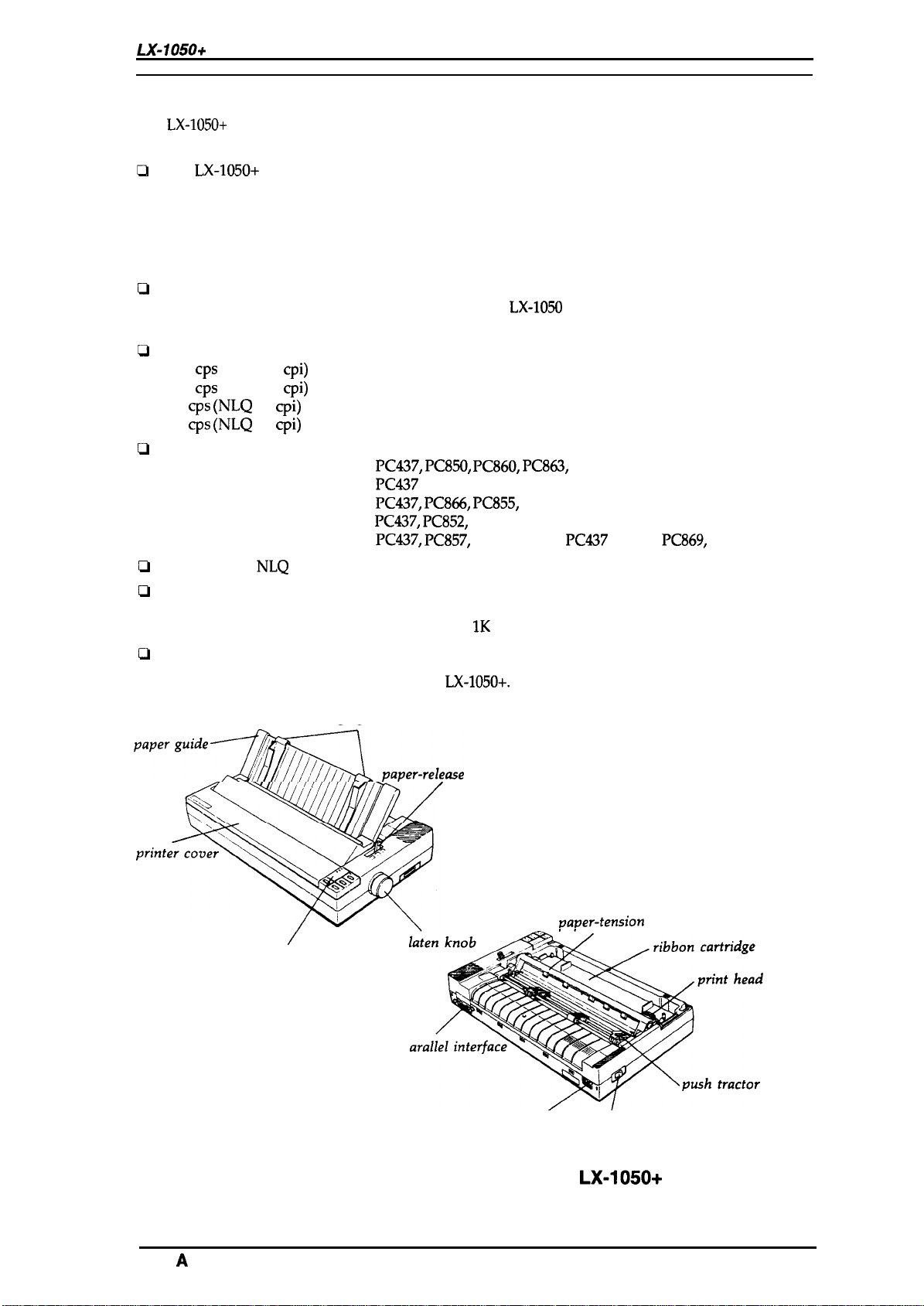

Figure 1-1 shows the an exterior view of the

edge guides

‘aperguideSp.per-re,e.e

/

control panel

P

P

LX-105O+.

lever

AC inlet’

vaver-tension

/

power switch

unit

Rev.

Figure 1-1. Exterior View of the

A

LX-105O+

1-1

Page 10

General Description

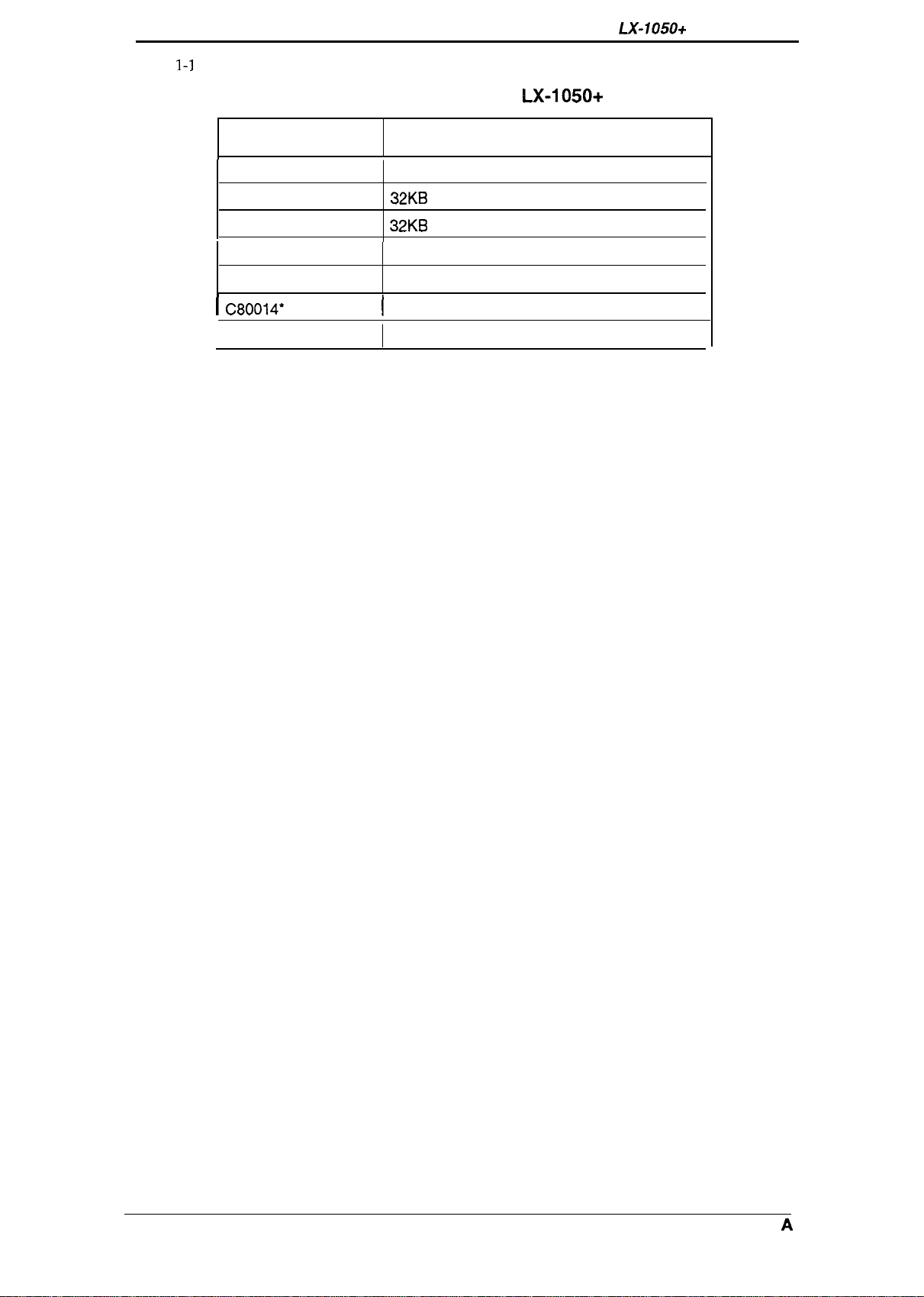

Table

1-1

lists the optional units available

for the LX-1050+.

LX-105O+

Service Manual

Table 1-1. Options for

Cat. No. Description

8143 New Serial Interface Board

C82302*/C82304*

C82303*

8165

C80624* Single Bin Cut Sheet Feeder

i C80014*

8755

32KB Serial Interface

32KB Parallel Interface

IEEE-488 Interface Board

[

PullTractorUnit

Ribbon Cartridge

LX-105O+

1-2

Rev. A

Page 11

LX-105O+ Service Manual

1.2 SPECIFICATIONS

This section provides detailed statistics for this printer.

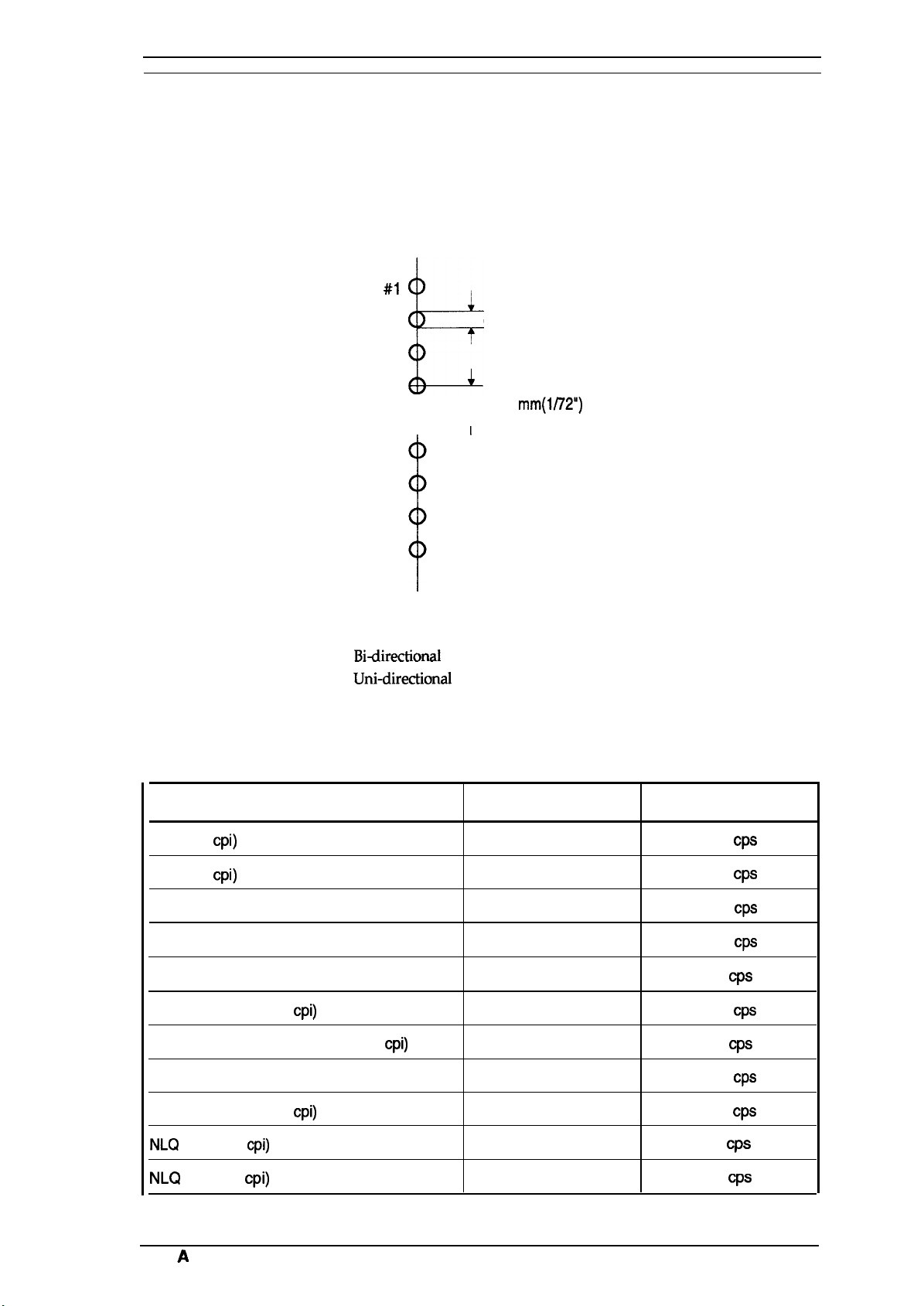

1.2.1 Printing Specification

General Description

Printing Method:

Pin Configuration: 9 wires (diameter 0.29rnm)

Serial, impact, dot matrix

#1

I

0.29

0.35

mm

mm(l/72”)

#2

#3

b

#4

#5

&--=-

#8

#7

#8

#9

Figure 1-2.

Pin Configuration

Print direction:

Print speed:

Printable columns

Bi-directional

Uni-directional

See Table 1-2.

See Table 1-2.

Table 1-2. Print Speed and Printable Columns

Type of Letters

Pica (10

Elite (12

Double-width pica

Emphasized pica

Double-width emphasized pica

Condensed pica (17

Double-width condensed pica (17

Double-width elite

cpi)

cpi)

cpi)

cpi)

printing with logical seeking (Text mode)

(left to right) printing (Bit image mode)

Printable Columns

136

163

68

136

68

233

115

81

Print Speed

200

Cps

240

CpS

100

Cps

100

Cps

50

Cps

171

Cps

86

Cps

120

Cps

Condensed elite (20

NLQ

NLQ

Rev.

pica (1 O

elite (12

A

cpi)

cpi)

cpi)

272

136

163

200

40

48

Cps

Cps

CpS

1-3

Page 12

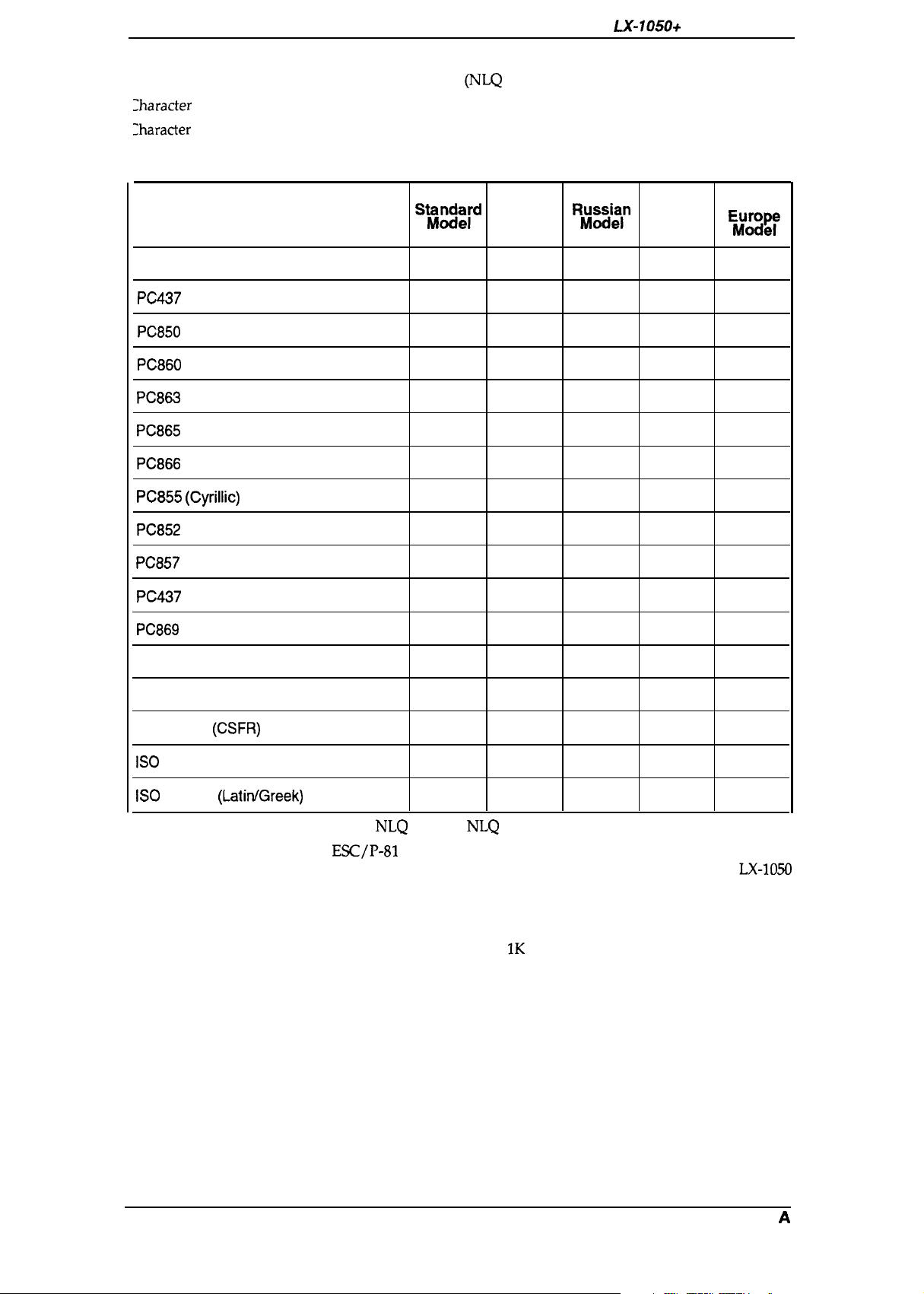

General Description

lot matrix format:

Ytaracter

~haracter

sets:

tables:

9 X 9

Text mode (Draft)

18X 20 Text mode

(NLQ

13 international character sets

See Table 1-3.

Table 1-3. Character Tables

LX-105O+

Service Manual

Character Table

ITALIC

PC437

(US/ Standard Europe)

PC850

(Multilingual)

PC860

(Portuguese)

PC863

(Canadian-French)

PC865

(Nordic)

PC866

(Russian)

PC855 (Cyrillic)

PC852

(East Europe)

PC857

(Turkish)

PC437

Greek

PC869

(Greek)

SW)ck[d

o

o

o

o

o

o

x x

x x

x x x

x x x x

x x x x

India

Model Model

0 0 0

0 0 0

x x

x

x x x

x

l?~su~ln

x

x x

o

o

x x x x

Latin

x

x

x

x

o x

South

E$;mg~

0

0

x

x

x

x

x

x

o

o

o

Bulgaria

MAZOVIA (Poland)

Code MJK

ISO

Latin IT (Turkish)

ISO

8859-7

(CSFR)

(LatitiGreek)

Font:

Control code:

Input buffer:

x

x

x

Saris Serif

o

x

x

x x

x x

x

o x

o x

x

o

o

Draft,

NLQ

x

x x

x

x

x x

Roman,

NLQ

Esc/P-81

Standard, Latin, and South Europe model compatible with

LX-105O

India and Russian model compatible with FX-1OOO (except IBM

mode)

Standard, Latin, and South Europe model: 4K bytes

India and Russian model: IK bytes

1-4

Rev. A

Page 13

LX-105O+ Service Manual

1.2.2

Paper Handling Specification

General Description

Line spacing:

Line feed speed:

Paper feed method:

Paper insertion:

1.2.3 Paper

Useable paper:

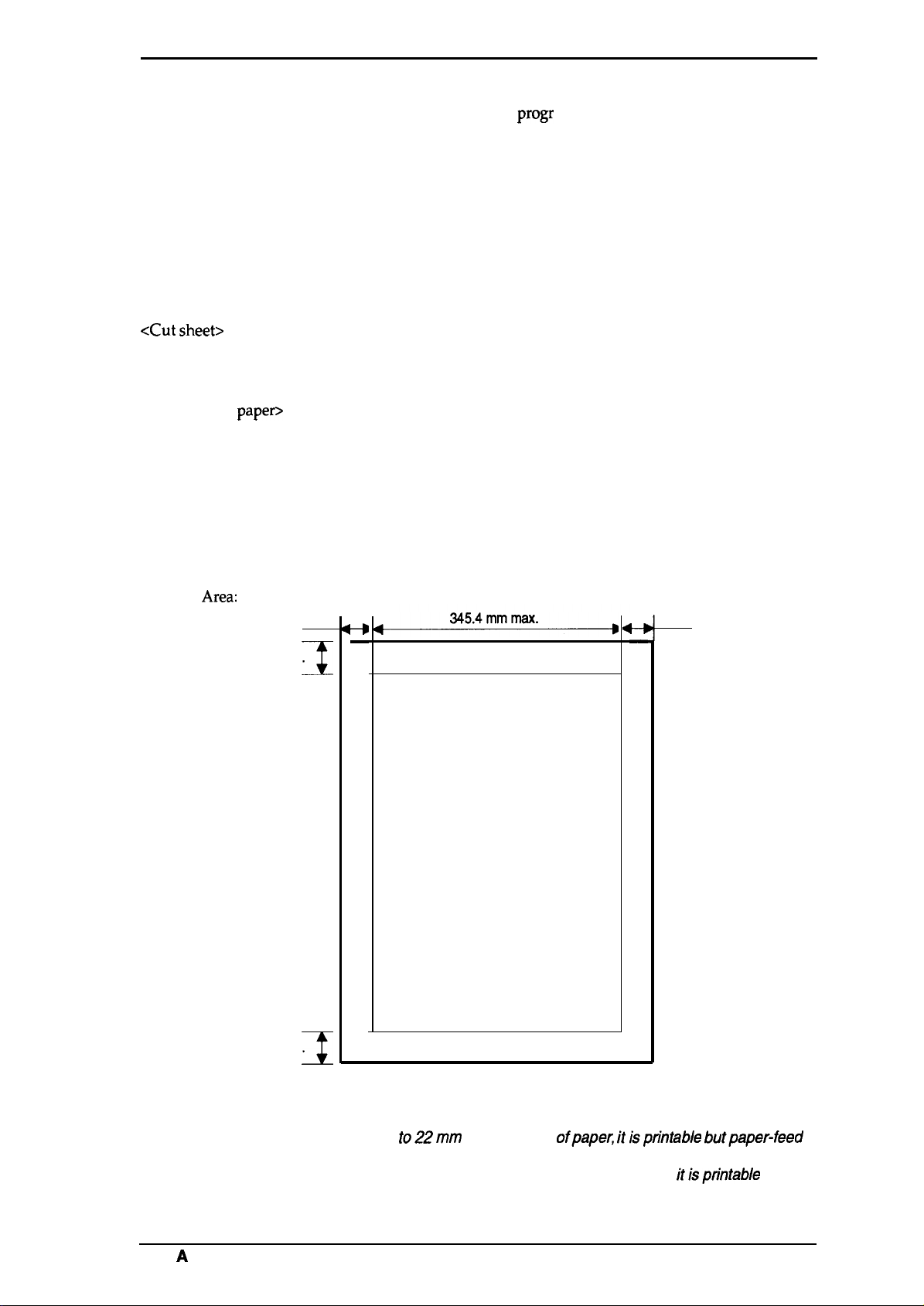

<Cut sheet>

<Continuous

<Envelope>

<Label>

Printing

Area:

Specification

paper>

3

22 mm min.

Note 1

mm min.

I

1/6 inch or 1/8 inch, or

Approximately 95 ms (1/6 inch line feed)

Approximately 75 ms (1/6 inch in page feed)

Friction feed

Tractor feed (push tractor: standard, pull tractor: optional)

Rear

Width: 182 to 364 mm (4 to 14.3 inch)

Length: 182 to 364 mm (4 to 14.3 inch)

Thickness: 0.065 to 0.14 mm (0.0025 to 0.055 inch)

Weight: 45 to 78 Kg (14 to 24 lb)

Width: 101 to 406.4 mm (4 to 16 inch)

Copies: 3 sheets (1 original 2 copies)

Total thickness: 0.065 to 0.25 mm (0.0025 to 0.010 inch)

Weight: 45 to 70 Kg (14 to 22 lb)

34 to 50 Kg (12 to 15 lb)-- copy paper

Size: No. 6 (166X 92 mm), No.1O (240X 104 mm)

Total thickness: 0.16 to 0.52 mm (0.0063 to 0.0197 inch)

Weight: 39 to 78 Kg (12 to 24 lb)

Size: 63.5 X23.8 mm (2.5 inch X 15/16 inch)

Cut sheet

-#

—

Printable area

progr

ammable in units of 1/216 inch

3

mm min.

t--i

—

Notes:

Rev.

22 mm min.

Note 2

I

Figure 1-3. Printable Area - Cut Sheet

1. In the

2. In the area from 13.5 mm to 22mm from the bottom of the paper, itisptintable but

A

area from

is not assured.

paper-feed is not assured.

8.5

mm

to22mm

from the top ofpapec itisprintable butpaper-feed

1-s

Page 14

General Description

LX-105O+ Service Manual

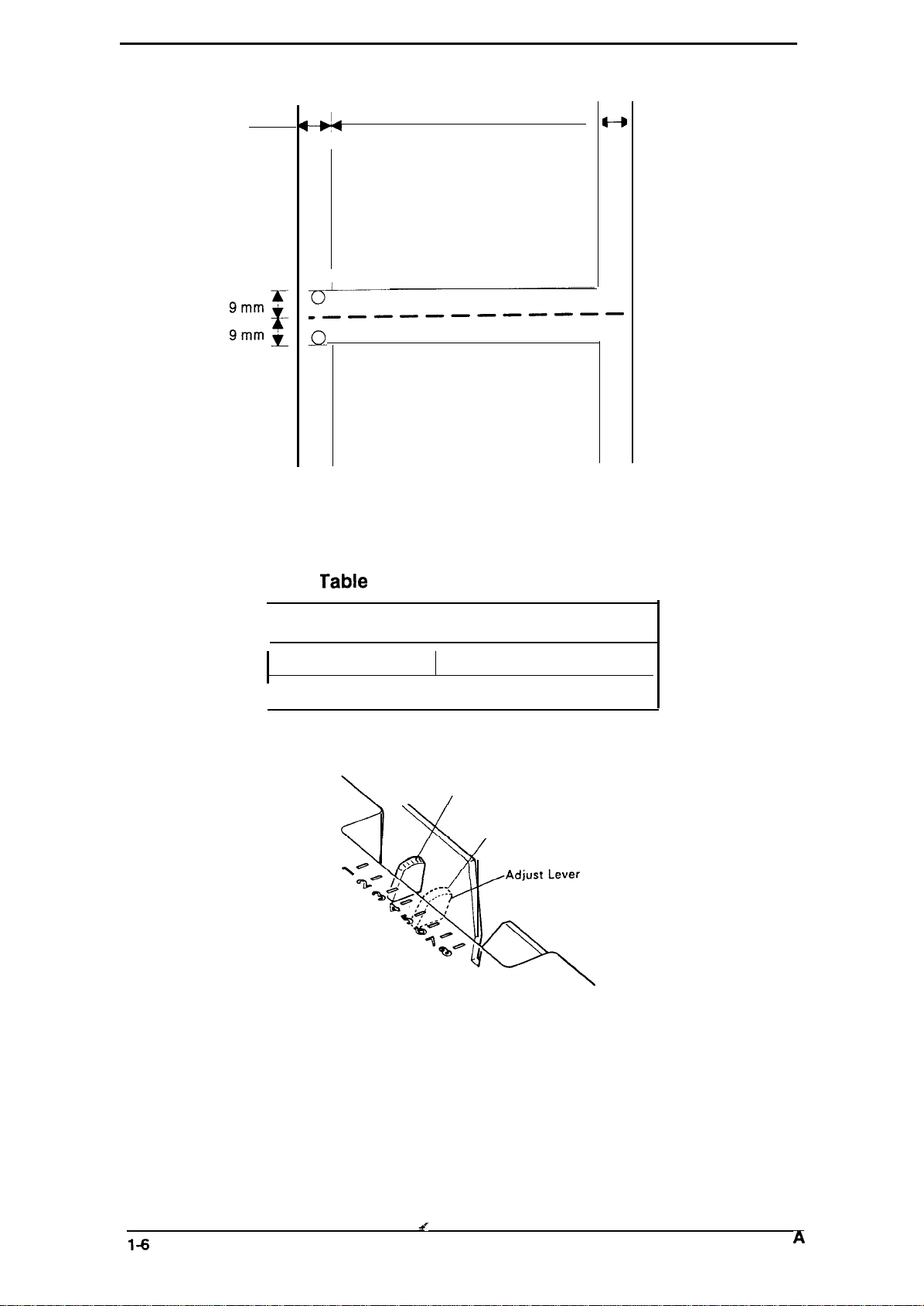

Continuous paper

13 mm min.

Figure 1-4. Printable Area - Continuous Paper

Adjust lever settings

I

345.4

mm max.

➤

4---D

13 mm min.

I

o

Printable area

0

0

0

.————————————

c1

0

0

0

The adjust lever must be set to the proper position for the paper

thickness.

o

0

0

0

0

n

u

0

0

0

Table

Lever position

I

2nd step

I

1-4. Adjust Lever Settings

Paper Thickness

0.06 to 0.18 mm

0.19 to 0.25

2’nd position

4’th position

3rd step

\@

I

I

I

mm

1-6

Figure 1-5. Adjust Lever Position

s?

Rev.

A

Page 15

LX-105O+

Service

Manual

1.2.4 Ink Ribbon

General Description

Type:

Color:

Reliability:

#8755 Ribbon Cartridge

Black

3 million characters at 14 dots/character

1.2.5 Environmental Conditions

Temperature:

Humidity:

Resistance to shock:

Resistance to vibration:

-30 to60“C - Storage

5to35“C - Operation

5 to 85

10to801%0

2 G, 1 ms - Storage

1 G, 1 ms - Operation

0.50 G (55 Hz max.) - Storage

0.25 G (55 Hz max.) - Operation

YO RH

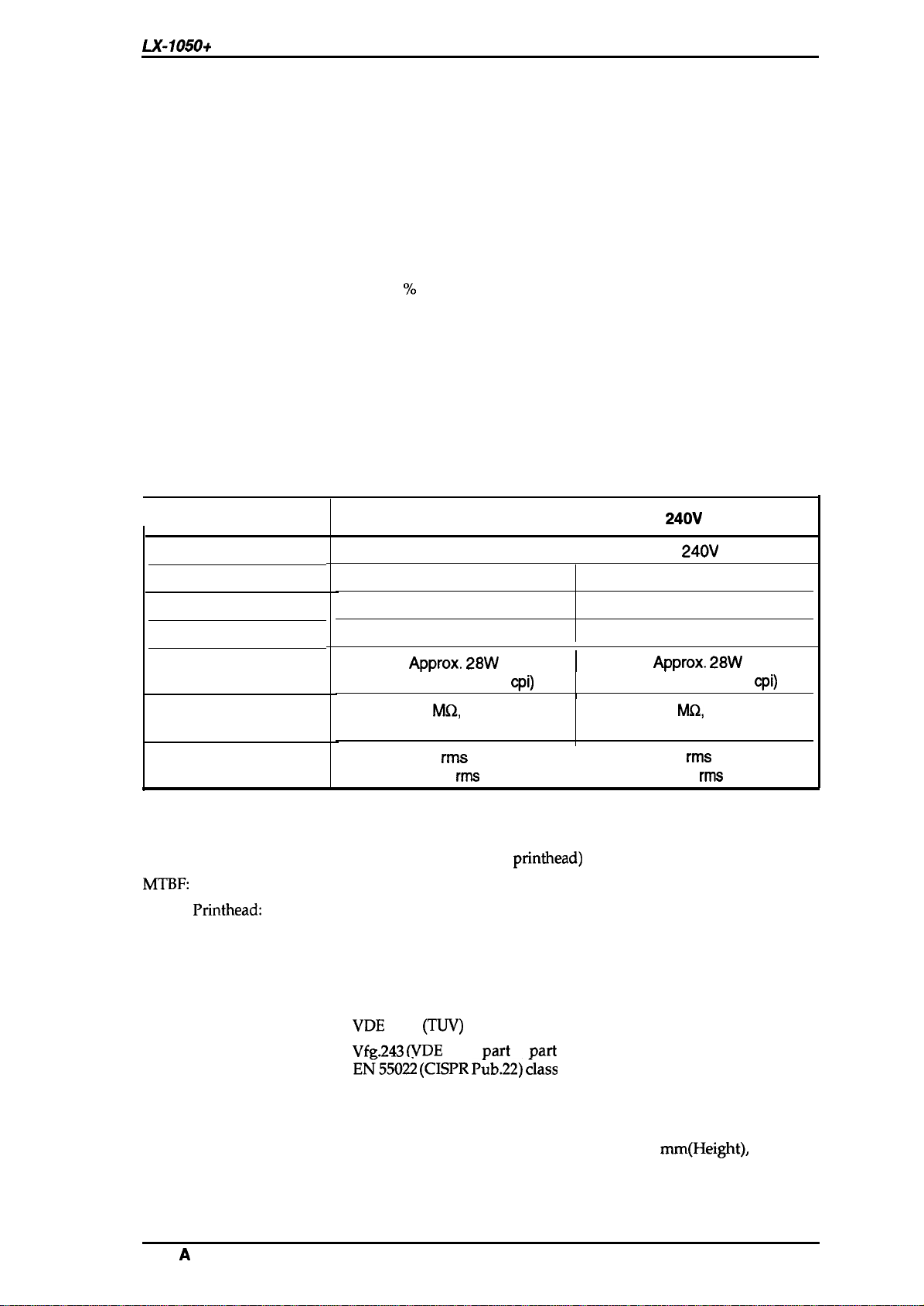

1.2.6 Electrical Specifications

Table 1-5. Electrical Specifications

I

Rated voltage

Input voltage range

Rated frequency range

Input frequency range

Power consumption

Insulation resistance

Item

(between AC line and chassis)

120V Version

103.5

49.5 to 60.5 Hz

Approx. 28W

(Self test in draft 10

(no

condensation) - Storage

RH

(no

condensation) - Operation

120 V AC

to 132V

50 to 60 Hz

10

M(2,

min.

cpi)

220-

240V

I

I

I

1

(between AC line and chassis)

220-

49.5 to 60.5 Hz

Approx. 28W

(Self test in draft 10

Version

240V

AC

198 to 264V

50 to 60 Hz

10

MQ,

min.

cpi)

Dielectric strength

AC 1000 V

or AC 1200 V

1.2.7 Reliability

MCBF:

MTBF:

Life of

Printhead:

3 million lines (except

6000 POH

200 million strokes/wire

1.2.8 Safety Approval

Safety Standards:

RFI:

UL4785th(U.S. version)

CSA22.2 #220. (U.S. version)

VDE

0806

VfR.243 (VDE

E~550~ (CISPR P~b.22) ~lass

1.2.9 Physical Specifications

Dimensions

Weight

619.3 mm (Width)

excluding knobs

8.80 Kg

rms

1 minute

rms

1 second

printhead)

(TIN)

(European version)

0878

Part

3,

x 339 mm

I

Part

30)

B”

(Depth) x 141

AC

1250

V

rms

or AC 1500 V

mm(Height),

1 minute

rms

1 second

Rev.

A

Page 16

General Description

1.3 INTERFACE OVERVIEW

The

LX-105O+

■

■

is equipped with the following external interfaces;

Centronics parallel interface

Optional Type A interface

LX-105O+

Service Manual

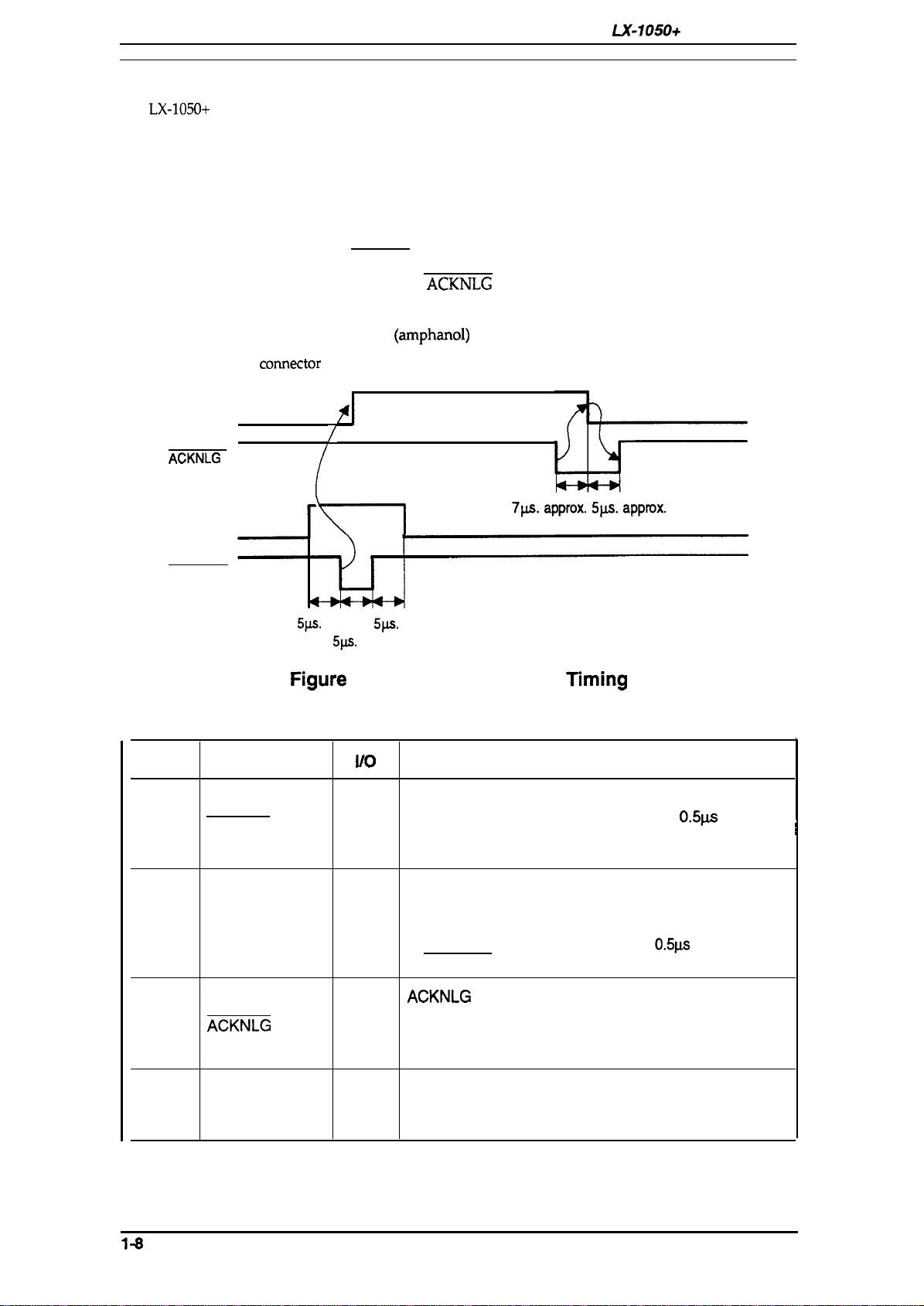

1.3.1

Parallel InterFace

Data Format

Synchronization

Handshaking

Signal Level

Adaptable Connector

Table 1-6 shows the

BUSY

ACKNLG

DATA

STROBE

comector

8-bit parallel

By STROBE pulse

By BUSY and

ACKNLG

signal

Ill-compatible

57-30360

(arnphanol)

or equivalent

pin assignments and signal functions of the parallel interface.

$1

/

5ps.

\

min.

5ps.

5w.

min.

min.

7p.a. approx. 5ps. approx.

Pin No.

1

2-9

10

11

Figure

Table 1-6. Connector Pin Assignments and Signal Functions

Signal Name

STROBE

1-6. Data Transmission

1/0

The STROBE pulse is used to read data from the host

computer. The pulse width must be

I

Normally, it is HIGH, and data is latched with rising

Timing

Description

0.5p.s

edge of this signal.

DATA 1-8 are parallel data bits. When one of these

signals is HIGH, the data bits is 1; when LOW, the data

bits is O. The most significant bit ( MSB) is data 8. The

DATA 1-8

I

signal state must be maintained for

0.5ps

on either side

of STROBE signal’s active edge.

ACKNLG

ACKNLG

approximately 10P.s. This signal goes LOW upon the

o

completion of data reception, to indicates that the printer

is an acknowledge pulse with a width of

is ready to receive further data.

The BUSY signal informs the host computer of the

o

BUSY

printer’s status. When this signal is HIGH, the printer

cannot accept further data.

or more.

~i

1-8

Rev. A

Page 17

LX-105O+

Sewice Manual

General Description

Table 1-6. Connector Pin Assignments

—. . .

Pin No.

12

13

14

15

16

17

18

19-30

31

Signal Name

PE

SLCT

AUTO FEED XT

NC

GND Signal ground

CHASSIS

GND

NC

GND Twisted-pair return signal ground.

INIT

1/0

o

o

1

.

I

This signal indicates whether paper is available in the

printer or not. A HIGH level indicates a no paper

condition.

pulled up to +5V though

If this signal is set to LOW, the printer automatically

performs one line feed upon receipt of a CR (carriage

return) code.

Not

USSd.

Chassis ground.

Not

USSd.

If this signal goes LOW, the printer is initialized. The

pulse width of this signal must be

. -. . — . .

and

Signal Functions (Cont.)

Description

3.3KQ

resistor in the

50p.s

or more.

.- . .

print,er.

,

32

33

34

ERROR

o

GND Signal ground.

NC

35 +5V

36

Notes:

IN

A// interface conditions are based on

must be

The AUTO FEED-XT signal can be set LOW by DIP

The SELECT IN signal can be set LOW by jumper 1.

/ess than

0.2 p.s.

I

SLCT

1.3.2 Optional Interface #8143

The

LX-105O+

Tyep:

Synchronization:

Protocol:

Transfer speed:

can use the non-intelligent serial interface board #8143.

RS-232C

Asynchronous start-stop system

Start bit: 1 bit

Stop bit: 1 bit or more

Data length: 7 or 8 bits

Parity:

X-ON/X-OFF or DTR control

75,110,134.5,150,200, 300,600,1200,1800,2400, 4800, and 9600

This signal goes LOW if the printer:

-

has a fatal error.

- runs out of paper.

- off line.

Not

Used

Pulled up to +5 V through 3.3

The

DC1/DC3

code is only valid when this signal is

KQ

HIGH.

7ZL

/eve/s. Both the rise

sw”tch

andfa//

2-4.

or current loop

Odd, Even or none

resistor in the printer.

times of all signals

Rev.

A

1-0

Page 18

General Description

LX-105O+ Service Manual

1.4 PRINTER OPERATIONS

This section describes the basic operations of the printer.

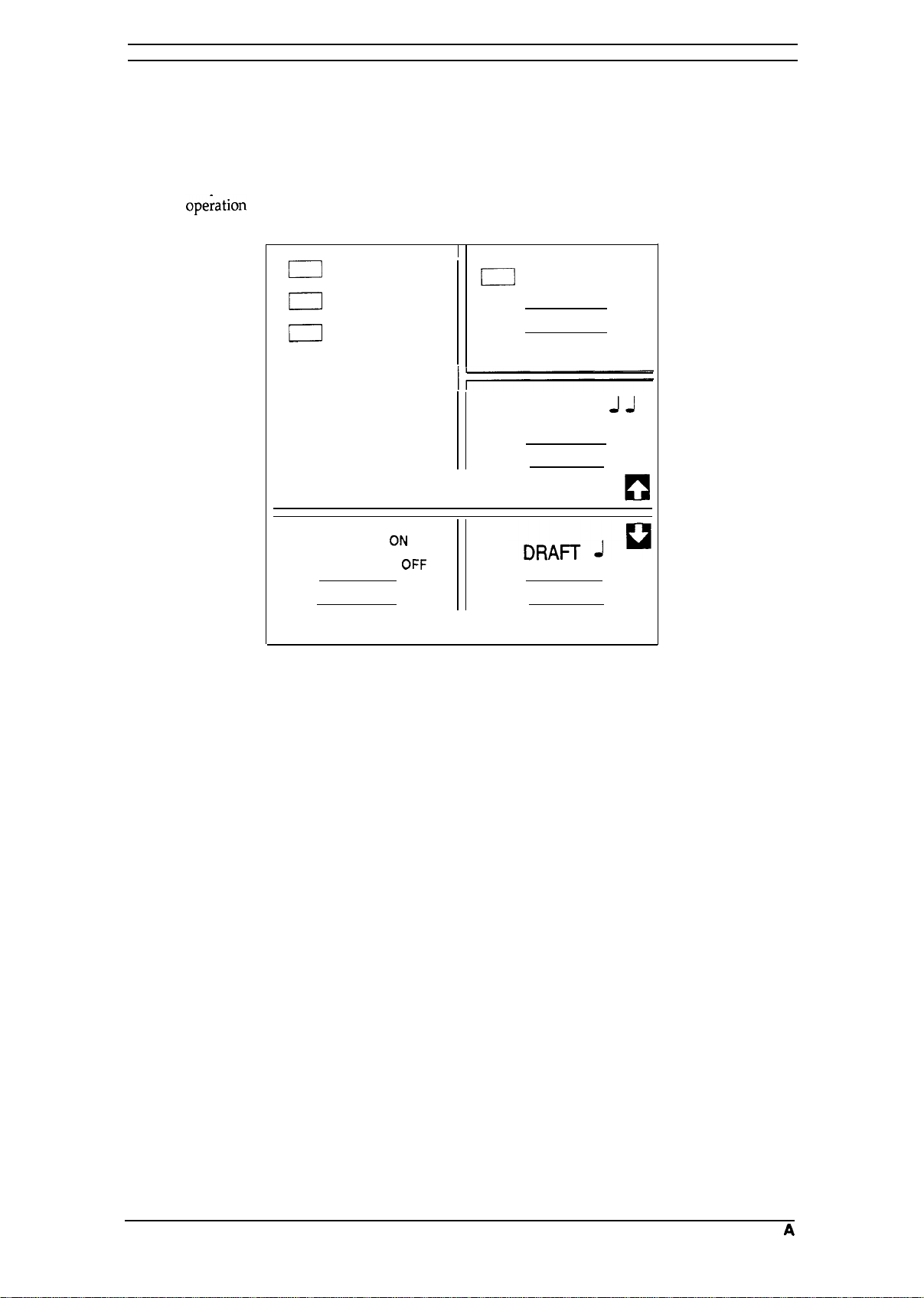

1.4.1 Control Panel

The control panel of this printer contains four non-lock type push buttons and four LED indicators

for easy

[Buttons]

ope;ation

of the various printer function.

D

POWER

D

READY

m

PAPER

OUT

0

ON LINE

OFF LINE

ON LINE:

FORM FEED:

LINE FEED:

LOAD/EJECT:

CONDENSED

LOAD/EJECT

ON

OFf=

J

J J

II

I I

II

NLQ

ROMAN

SANS SERIF J J J

FORM FEED

LINE FEED

JJ

~

Figure 1-7. Control Panel

Switches printer status between on line and offline.

When the

or to advance continuous paper to the top of the next page.

When the printer is off line, press this button to advance the paper one line,

or hold it down to advance the paper continuously.

This button is used to feed the paper to the loading position, or to eject paper

that is already loaded. Paper is ejected forward if the paper-release lever is

set to the single-sheet position, or is ejected backward (removed from the

paper path) if the release lever is set to the continuous paper position.

printer is off line, press this button to eject a single sheet of paper

[Indicators]

POWER:

READY:

PAPER OUT:

ON LINE:

1-10

On when the power switch is on and power is supplied.

On when the printer is ready to accept input data. Flickers while data is

printed.

On when the printer is out of paper or when continuous paper ia in a

standby position. The printer also beeps when it is out of paper.

On when the printer is on line and ready to accept data from the computer.

When this indicator is blinking, the micro-adjustment feature can be used.

Rev.

A

Page 19

LX-105O+ Service Manual

,!

General Description

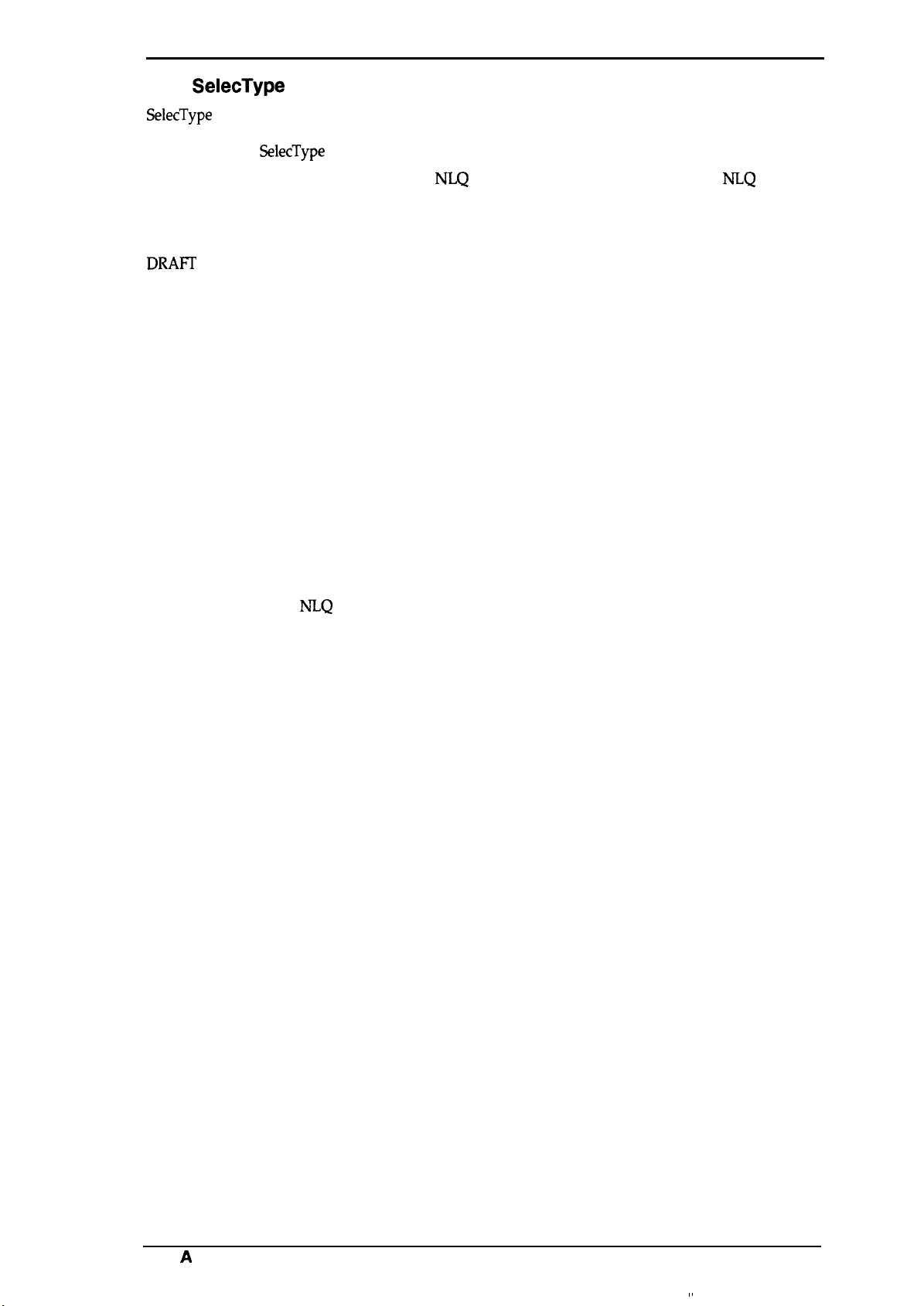

1.4.2

SelecType

selection of Draft, Roman, or Saris Serif fonts and selection of normal printing or condensed

printing modes.

To select Roman or Saris Serif, press the

pressed. When it sounds twice, the Roman font is selected. When it sounds three times, the Saris

Serif font is selected.

To select the Draft font, press the DRAFT button. The buzzer will sound once, indicating that the

DRAFT

To set for condensed printing when the printer is in the print mode, press the CONDENSED button

once (the buzzer will sound once), and the printer will enter the condensed print mode.

To cancel condensed printing, press the CONDENSED button again. After you press the button,

the buzzer sounds twice to tell you that condensed printing is canceled.

SelecType

allows the user to choose fonts and the printing mode easily. This function provides for

font is selected.

Functions

SelecType

is effective only when the printer is ON LINE and not printing.

NLQ

button. A buzzer sounds when the

NLQ

button is

1.4.3 Micro Adjustment

By pressing the FORM FEED or LINE FEED buttons immediately after loading paper or when

using the tear-off feature, you can make tine adjustment to the loading and tear-off positions.

1.4.4 Panel Operation at Power ON

The following functions can be activated at power on by holding down the specified button on the

control panel.

Self-test mode:

Hex Dump mode:

To begin printing the self-test in the Draft mode, turn the printer ON while

pressing the LINE-FEED button. To begin printing the self-test using the

NLQ

mode (Near Letter Quality), press FORM FEED and hold it down, then

turn the printer power ON.

Self-test printing can be stopped or started by pressing ON-LINE (ON-LINE

indicator is not lit). To finish the self-test, stop the printing by pressing the

ON-LINE switch then turn OFF the printer power.

The firmware revision number is printed as the first line of the self-test, and

subsequently, current DIP switch settings are printed.

The printer enters the HEX-DUMP mode when it is powered on while the

LINE-FEED and FORM-FEED buttons are pressed down.

In the HEX-DUMP mode, the hexadecimal representation of the input data is

printed out, along with corresponding ASCII characters. This function is

valuable for checking the data the printer has received from the host. If input

data is a control code rather than a character code, a period (.) is printed in

the ASCII column.

Rev.

A

1-11

Page 20

General Description

L.X-1050+

Service Manual

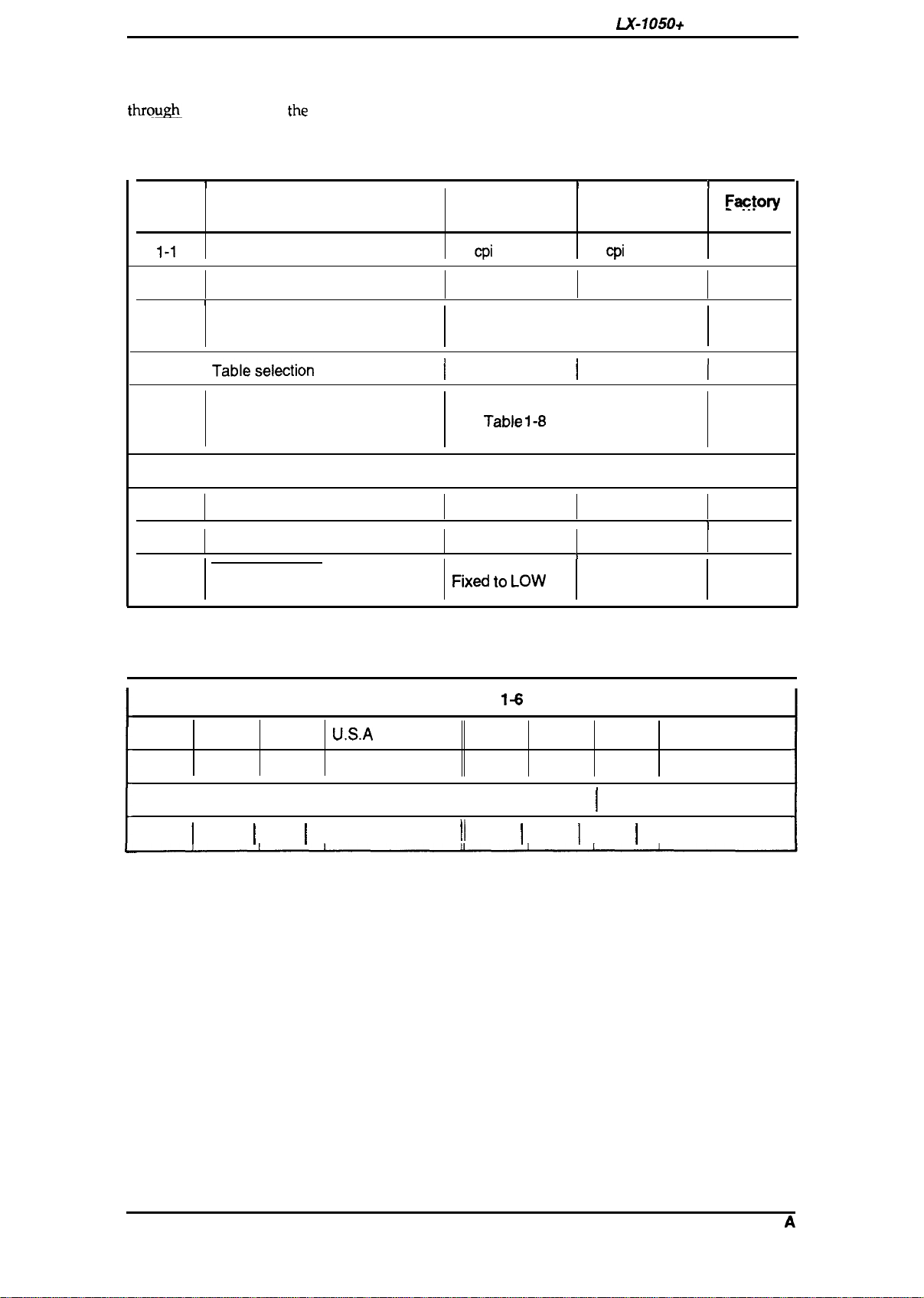

1.4.5 DIP Switch Settings

The two DIP switches are located on the side of the printer and function as shown in Tables 1-7

throum

the

1-10. Note

INIT signal.

that

the

status of the DIP switches is read only at power on or upon receipt of

Table 1-7. Settings for DIP Switch

SW No.

1-1

I

Character

Description

Pitch

I

12

cpi

ON

I

10

cpi

OFF

I

Faoto~

Settings

OFF

1-2

Shape of Zero

1

1-3

1-4

1-5 I

1-6

1-7

1-8 ON

2-1

2-2

Page length

Tableselection

Character table selection

Short tear-off Invalid

Cut sheet feeder control

I

2-3

Skip over perforation 1 inch

0

1

See Table 1-10.

I

Graphics

See Table

1-8

Valid

I I

1

2-4

AUTO FEED XT signal internally

fixed or not

Fixd t. Low

0

I

Italics

or 1-9.

Valid

Invalid

None

I

Depends on

external signal

I

I

OFF

I

I

1

Table 1-8. International Character Set Selection (DIP SW 1-5: OFF)

1+

Sw 1-6 Sw 1-7 Sw 1-8

Country Sw

Sw 1-7 Sw 1-8 Country

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

ON ON ON

ON ON

ON

OFF ON Germany

I

ON I OFF

OFF

I

OFF

U.S.A

France

I

U.K.

OFF

OFF

OFF

II

II

OFF I OFF I OFF I Spain

ON ON

ON

OFF I ON

I

OFF Sweden

Denmark

Italy

1-12

Rev.

A

Page 21

LX-105O+

Service

Manual

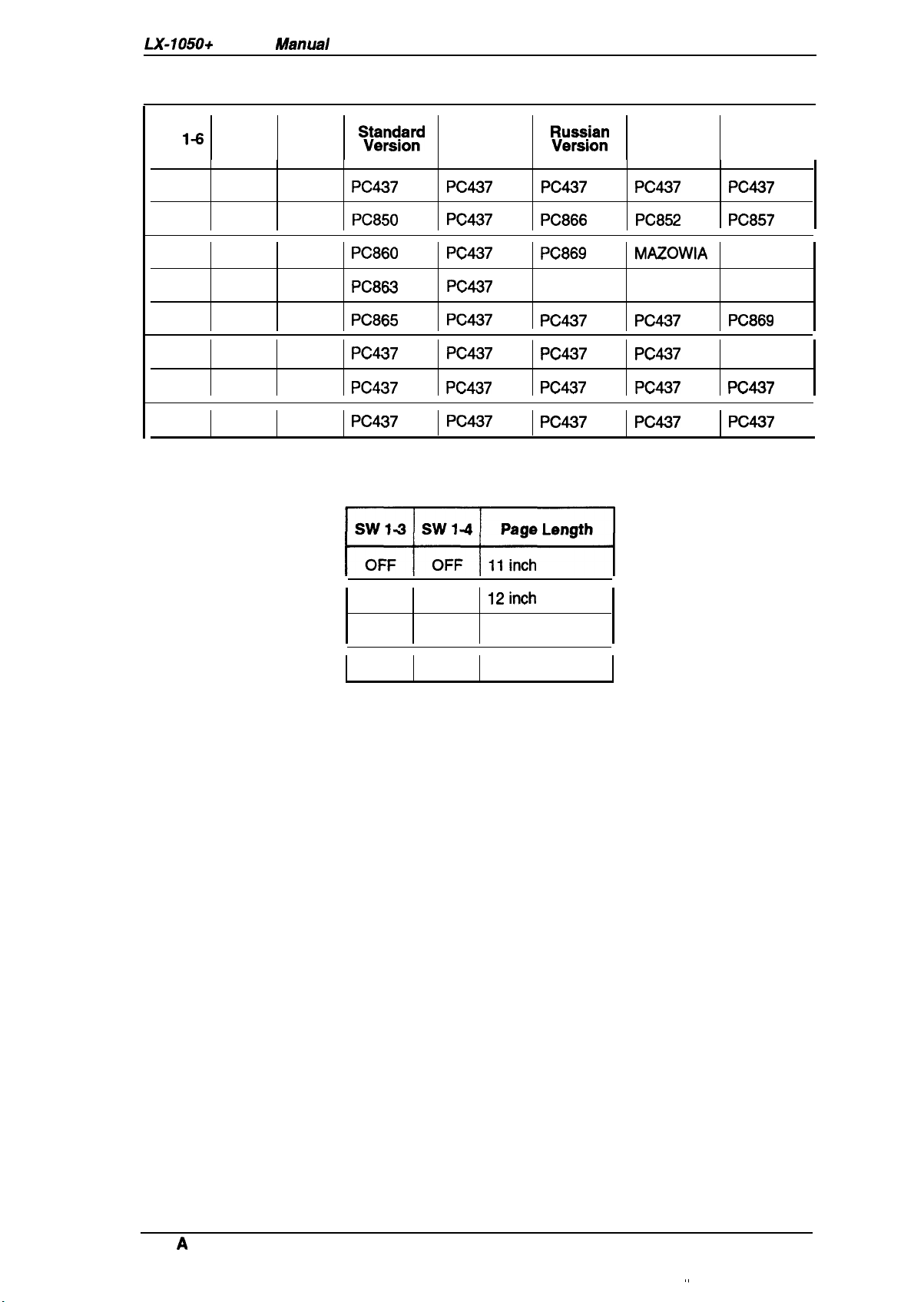

Table 1-9. Character Table Selection (DIP SW 1-5: ON)

General Description

Sw

1-6

Sw 1-7

ON ON ON

ON ON

ON

ON

OFF ON ON

OFF

OFF

OFF

OFF

OFF

ON

OFF ON

OFF

Sw 1-8

OFF

ON

OFF

OFF

OFF

~:pj:;d

PC437 PC437

PC850 PC437

PC860 PC437

PC863 PC437

PC865 PC437

PC437 PC437

PC437 PC437

PC437 PC437

Table

1-10. Page Length Selection

w

India

version

:?:/::

PC437

PC866

PC869

Bulgaria

PC437 PC437 PC869

PC437 PC437 1S088597

PC437 PC437 PC437

PC437 PC437 PC437

Latin

Version

PC437 PC437

PC852

MAZOWIA

Code MJK PC437G.

South

Europe

Version

PC857

ISO Lat. IT

I

I

ON

OFF

ON ON

OFF

ON

12inch

8.5 inch

70/6

inch

Rev.

A

,,

1-13

Page 22

General Description

1.4.6 Buzzer Operation

The

buzzer sounds under the following conditions:

LX-105O+

Service Manual

BEL

code:

Carriage trouble:

PaperQut:

Abnormal voltage:

Incorrect

SRAM:

Incorrect RAMinside CPU:

Recognition of panel

The buzzer sounds for 0.1 second when a

Beeps 6 times, pausing briefly after 3rd beep.

Beeps 20 times, pausing briefly after every 4 beeps.

Beeps 5 times, pausing after every beep.

Beeps 8 times, pausing briefly after every 2 beeps.

Beeps indefinitely until power OFF.

Beeps 1 or 2 or 3 times in setting print mode.

operation:

Factory setting:

Beeps once when the value under micro-adjusting is equal to the

factory-set value.

Sheet ejection failure

(in

CSF

mode):

Illegal paper release/

unrelease:

Beeps 20 times, pausing briefly after every 4 beeps.

Beeps continuously when the paper release lever is changed when

the paper is in the paper path.

Beeps until the lever is changed again or the paper is completely out

of the path.

1.4.7

This printer has

EEPROM

Reset

EEPROM,

it memorized SelecType settings, position of continuous paper, and

bi-directional printing adjustment value.

main board replacement,

The

EEPROM

is cleared, when the printer power on while FF and LOAD/EJECT switches are

EEPROM

replacement, or printer mechanism replacement.

pressed.

EEPROM

BEL

code is input.

reset operations are only required after the

1-14

Rev.

A

Page 23

LX-105O+

,,

Service Manual

1.5 MAIN COMPONENTS

Ganeral

Description

The main

components

of the

LX-105O+

printers are designed for easy removal and replacement to

maintain/repair the printers.

The main components are:

Cl TAMA

D

TAPNL-W control panel: Control panel.

Cl

TAa filter unit: Transformer and filter board.

D M-3D60:

board: Main control board. The CPU on this board controls all main functions.

Printer mechanism.

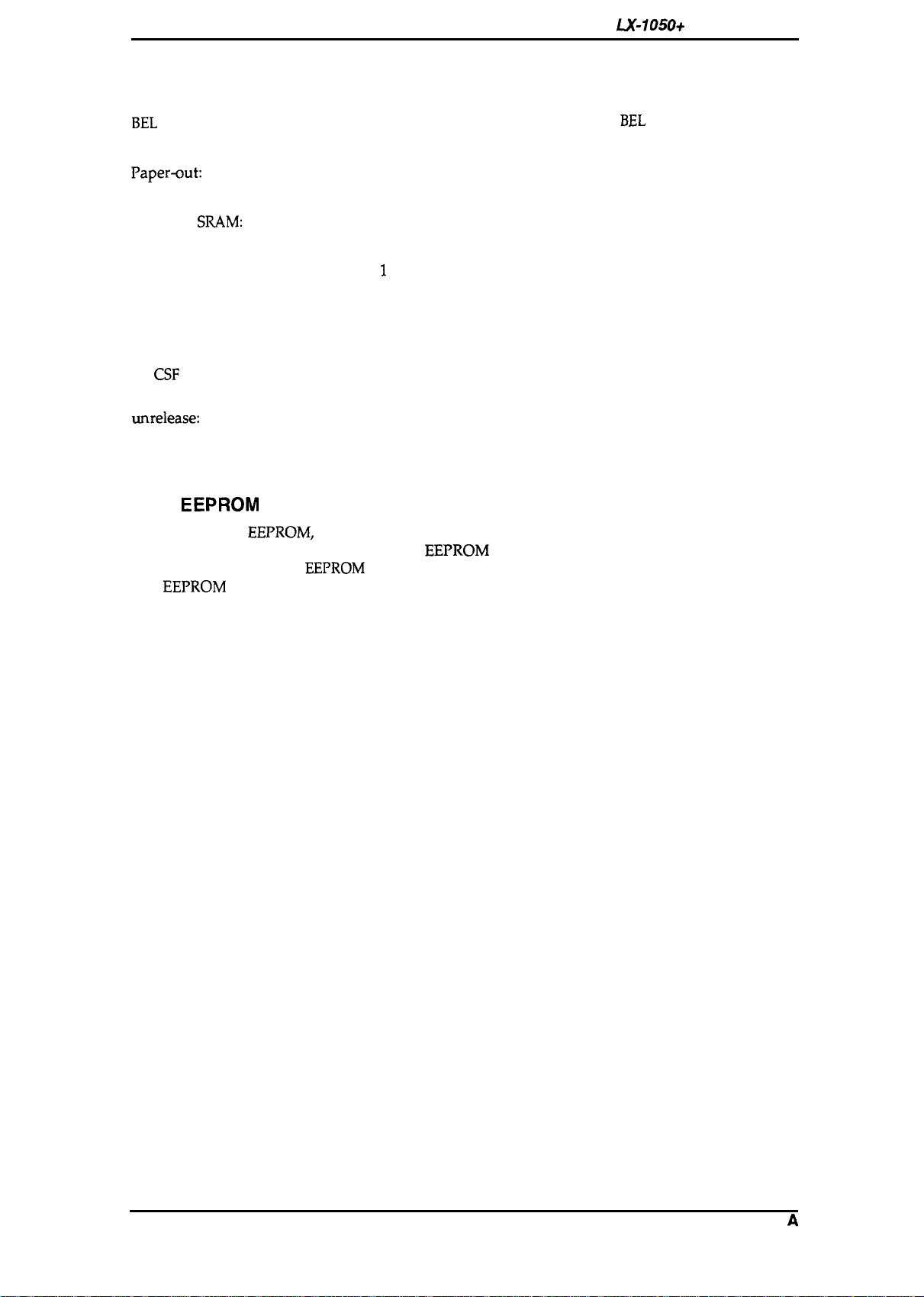

1.5.1 TAMA Main Control Board

The

TAMA

board is the main controller of this printer. It takes charge of interfacing with the host

computer and processing of received print data, as well as control of the whole printer mechanism.

This-board consists of the following components.

CPU

(2C):

Gate-array

Program ROM

RAM

EEPROM

(3B):

(3C):

(3D):

(lC):

CR Motor driver (1A): SLA7020M

8-bit CPU (PPD781OHG)

15 MHz operation clock

E05A30

Includes the following functions:

- MMU (Memory Management Unit)

-

IFU

(Interface Control Unit)

- PCU (1/0 Port Control Unit)

- Head control unit

256

Kbit

EPROM or mask ROM

64

Kbit

PS RAM

256 bit

EEPROM

GA

E05A30(3B)

“ PROM(3C)

“ RAM(3D)

-

CPU(2C)

-

EEPROM(l

SLA7020M(1A)

Figure 1-8. TAMA Board Component Layout

C)

Rev.

A

1-15

Page 24

General Description

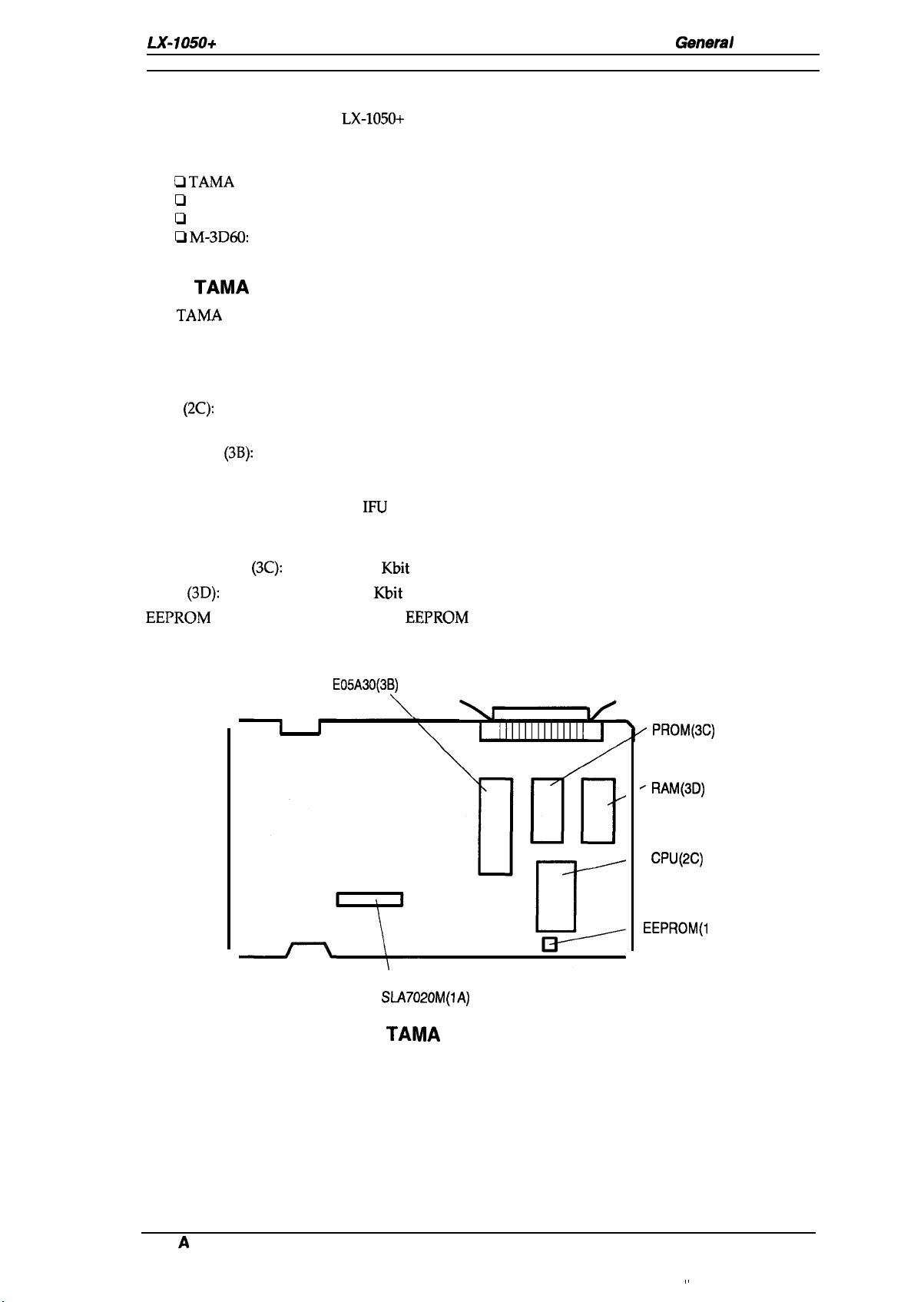

TAa

1.5.2

The

TAa

Filter Unit

filter unit contains a power cord

(120V

Version) or AC inlet

switch, fuse filter circuit, and power transformer.

LX-105O+

(220/240V

Service Manual

Version), power

120V Version

Figure 1-9. TAa Filter Unit

1.5.3 Printer Mechanism (M-3D60)

The

M-3D60

components include:

Carriage motor

Carriage mechanism

Paper feed motor

Paper feed mechanism

Ribbon feed mechanism

Printhead

Sensors

printer mechanism was developed specifically for the

220/240V Version

LX-105O+

printer. Its

1-16

Figure 1-10. Printer Mechanism (M-3D60)

Rev. A

Page 25

Chapter 2 Operating Principles

Table of Contents

2.1 OVERVIEW

2.2 OPERATING PRINCIPLES OF THE PRINTER MECHANISM

2.2.1 Printhead Printing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Carriage Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2.1 Home Position Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.3 Paper Feed Mechanism Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3.1 PaperEndSensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.3.2 Release Sensor.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.4 Ribbon Advance Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3 OPERATING PRINCIPLES OF THE ELECTRICAL

2.3.1 Operating Principles of the Power Supply Circuit . . . . . . . . . . . . . . . . . . 2-8

2.3.2 Operating Principles of the Main Control Circuit . . . . . . . . . . . . . . . . . . . 2-9

2.3.2.1

2.3.2.2

2.3.2.3

2.3.2.4

2.3.2.5

2.3.2.6

2.3.2.7

Reset Circuits.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Carriage Motor Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Paper Feed Motor Drive Circuit. . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Printhead Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Host Interface.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

EEPROM

Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

CIRCUITRIES

2-1

2-1

2-8

List of

Figure 2-1

Figure 2-2

Figure 2-3. Carriage Drive

Figure2-4. Home Position Sensor Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-5. Friction Feed Operation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-6. Tractor Feed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-7. Paper End Sensor Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-8. Release Sensor Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure2-9. Ribbon Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-10. Power Supply Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure2-11. Main Control Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure2-12. Data Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-13. Reset Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-14

Figure 2-15

Figure 2-16

Figure 2-17

Figure 2-18

Figure 2-19

Block Diagram of the Printer Mechanism . . . . . . . . . . . . . . . . . . . . 2-1

Printhead-Printing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

M~chanism

Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Carriage Drive Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . 2-11

Paper Feed Motor Drive Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Printhead Drive Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . 2-13

Host Interface.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

EEPROM

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Figures

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Page 26

List

of Tables

Table 2-1. Ribbon-Feed Gear Train. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

.

Table 2-2. Voltage Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-3.

Table 2-4. Phase-Excitation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functionsofthe

Main

ICand Circutis

. . . . . . . . . . . . . . . . . . . . . . . 2-10

2-8

2-11

Page 27

LX-105O+

Service Manual

Operating Principles

2.1 OVERVIEW

This section describes the operating principles of the printer mechanism and the electrical circuits

of the

LX-105O+.

2.2

OPERATING PRINCIPLES OF THE PRINTER MECHANISM

The

LX-105O+

carriage drive mechanism, and various sensors. The figure below shows a block diagram of the

printer mechanism.

printer mechanism is composed of the

printhead

unit, paper feed mechanism,

Printhead

Q

. . . . . . . . . . . . . . . .

Phase

v

Stepper Motor

Carriage Drive

I

1160nlStep

or

ll120*lStep

CR HOME

A

carnage

Home

1

Phase

v

Stepper Motor

Paper

Feed

I

11216

’lStep

I

PE

A

Paper End

1

Figure 2-1. Block Diagram of the Printer Mechanism

RELEASE

FRICTIOtV

TRACTOR

Release

Lever

Position

Rev.

A

2-1

Page 28

Operating Principles

,,

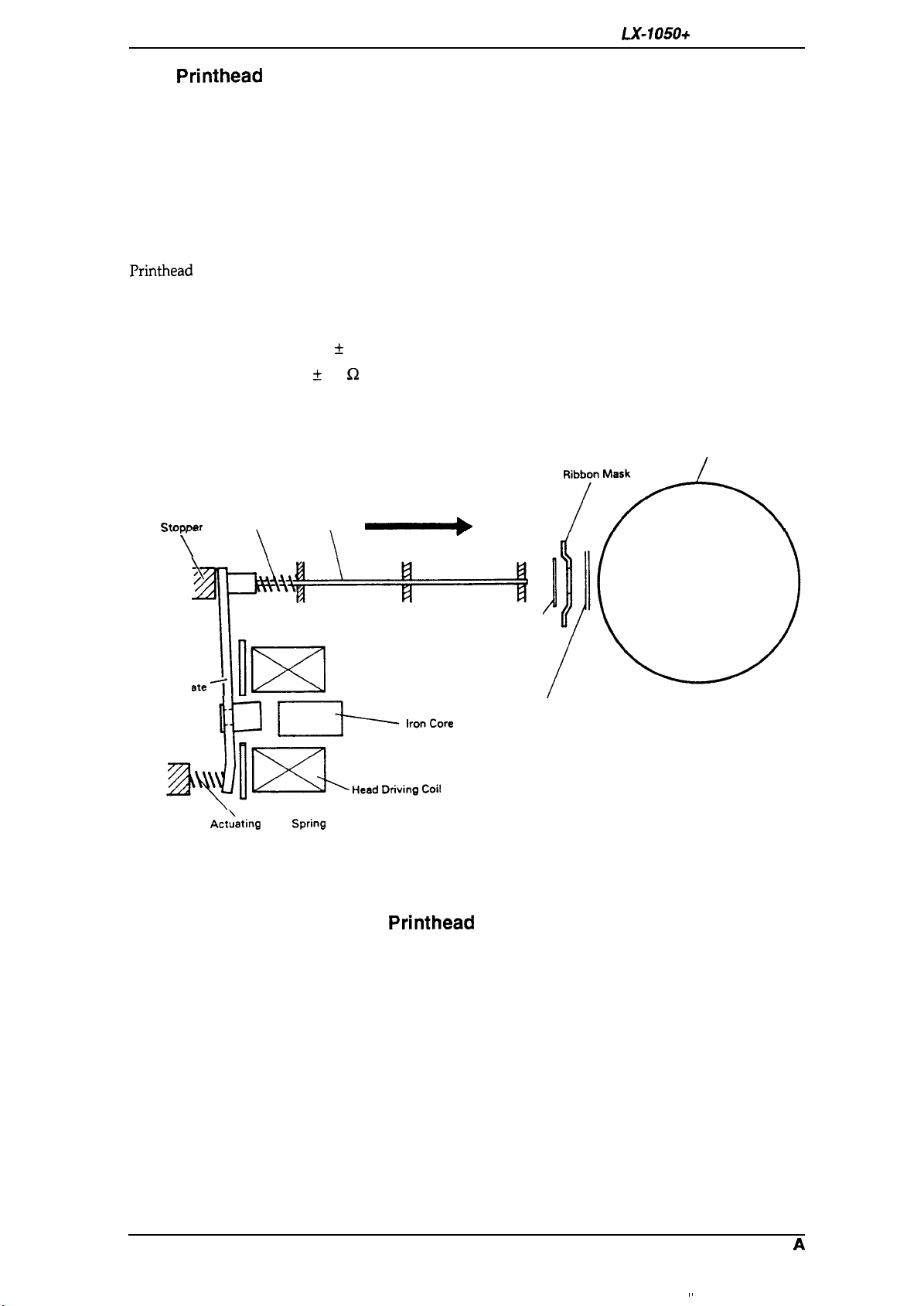

2.2.1 Printhead Printing Operation

The dot-wire operation during printing is as follows. When the head-driving coil for a dot wire is

energized, the actuating plate, which is engaged to one end of the dot wire, is attracted to the iron

core, and drives the dot wire toward the platen. The dot wire forcefully pushes both ribbon and

paper against the platen, causing a dot to be printed.

When the head-driving coil is deenergized, the actuating plate spring causes the actuating plate to

return to its initial position. After striking the platen, the dot wire also returns to its initial position,

partly in response to the impact energy, and partly as a result of the wire-resetting spring. The dot

wire then remains engaged to the actuating plate until it is driven again.

LX-105O+

Service Manual

Printhead

Solenoids:

Wire Diameter:

Drive Voltage:

Coil Resistance:

specifications areas follows:

Wire Resetting Spring

Stnnner

.-.

-r

F-

\

‘4P+—+1

Actuating Plate

~

T

9 solenoids

0.29 mm

24 VDC * 10Yo

19.2 ~ 1.0

Dot Wire

\

\

\

fi2

\

at 25° C

Ilxl

cl--k-e

/

Ribbon

Platen

‘7”*

Paper

~~l~HeadDrivin9Coi,

!’

Act;ating plate

SPrin9

Figure 2-2. Printhead Printing Operation

2-2

Rev.

A

Page 29

LX-1050+ Service Manual

2.2.2 Carriage Drive Mechanism

Operating Principles

The carriage mechanism includes the

and the platen.

The timing belt is connected to the bottom of the carriage. The belt is driven by the carriage motor

and moved via the beltdriven pulley. The

unit is moved right and left along the carriage guide shaft and plate.

Carriage motor specifications are as follows:

Type:

Drive Voltage:

Coil Resistance:

Current Driving:

4-phase, 48-pole step motor

24 V

k

MY/o

11 G2

k

77.

0.36 A *

0.28 A

Holding: 0.09 A

IO%(Typical)

* IO%(Typical)

at

25°C

printhead,

f IWO

the carriage, the timing belt, the carriage motor,

printhead

(Draft Printing)

(NLQ Printing)

-%’”

is mounted on the carriage, and the entire

Left

.carr-

Figure 2-3.

2.2.2.1

Following figure shows the home position sensor. The sensor switch is ON when

the home position.

Home

Position Sensor

Carriage Drive

Mechanism

the carriage is at

Rev.

Figure 2-4. Home Position Sensor Mechanism

A

2-3

Page 30

Operating Principles

LX-105O+

Service Manual

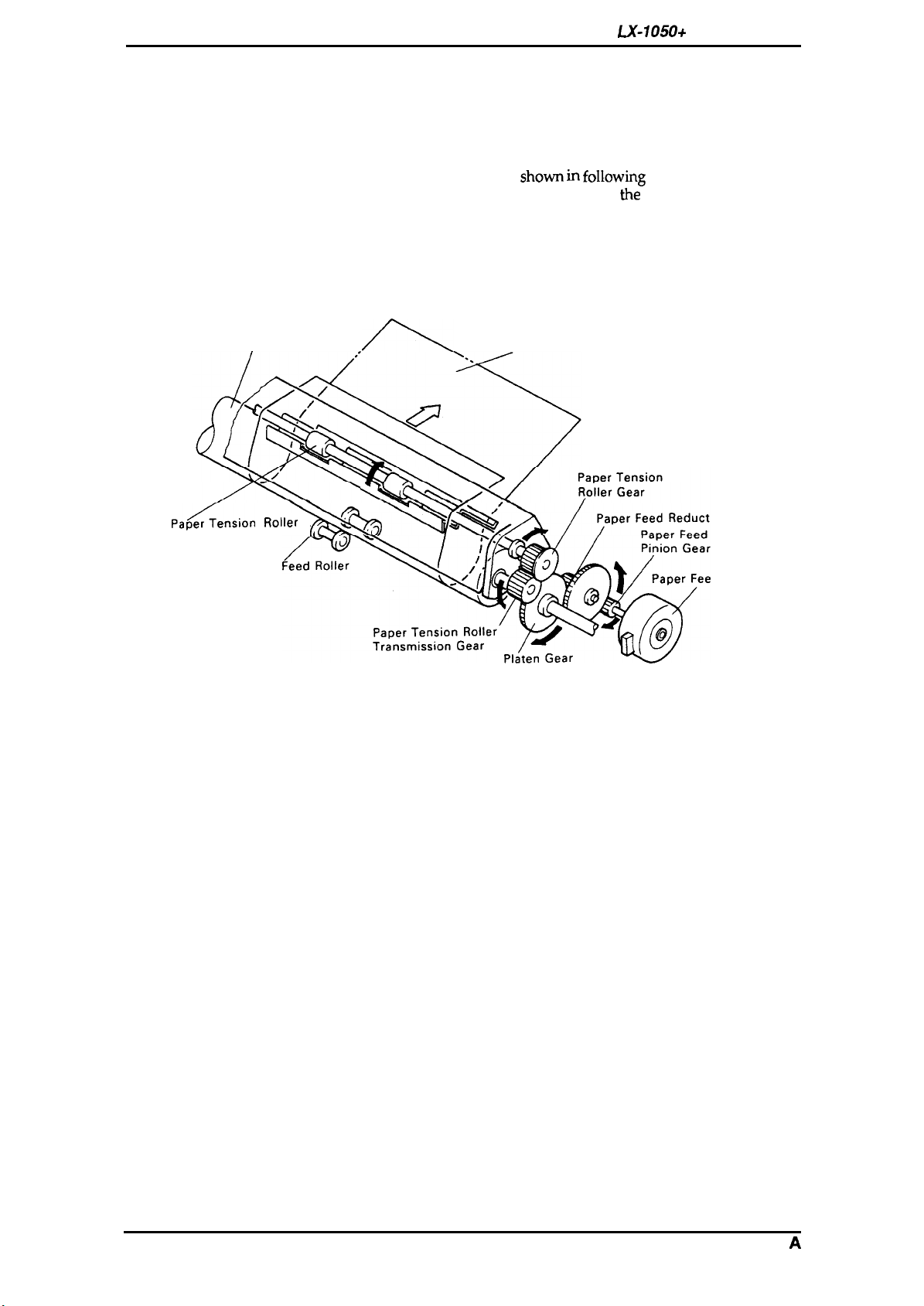

2.2.3 Paper Feed Mechanism Operation

Friction feeding is used for cut sheets, and push tractor feeding is used for fanfold paper.

Friction-Feed Operation

The paper is held against the platen by paper-feed rollers. The paper-feed motor rotates the platen

gear, via the paper-feed reduction gear, in the direction

friction between the paper-feed rollers and the platen, the rotation of

paper to be fed. The feeding direction is indicated by the arrow in the Figure.

The paper is held against the platen by the spring force of the paper-feed rollers, and can be

released by shifting the paper-release lever forward.

shown in following

the

platen gear causes the

figure. Because of the

Platen

,ap~en,ion

Paper

,O,,er

paper (Cut Sheet)

p

,(

Figure 2-5. Friction Feed Operation

ion Gear

Motor

d Motor

2-4

Rev.

A

Page 31

LX-105O+

Push Tractor Feed Operation

Service

Manual

Operating Principles

When the push tractor unit is used, the paper is set such that its holes mesh with the tractor pins

along the tractor belt. The paper feed motor is driven and, via the pinion on the motor shaft, rotates

the gears in the direction shown in following figure, rotating the tractor belts. This causes the paper

advances in the direction indicated by the arrow. When push tractor feeding is used, the pressure

of the paper feed rollers against the platen is released by moving the paper release lever to its

forward setting.

ear

Figure 2-6. Tractor

Paper-feed motor specifications are as follows:

Type:

Drive Voltage:

Coil Resistance:

Phase Excitation:

Current:

4phase, 48-pole step motor

VDC *

24

40 ohms*

10Yo

79!.

at 25°C

2-2 phase

Maximum, 1.1A (Rush Current, 26.4

Driving: 0.30 A (Typ., 480

Holding: 0.06 A

*20 rnA

Driving Frequency: 480

pps,

PPS

Feed Operation

VDC)

24

VDC)

Gear

Motor

Rev.

A

2-5

Page 32

Operating Principles

2.2.3.1 Paper End Sensor

LX-105O+ Service Manual

Following figure show the paper end sensor. This sensor switch is ON when no paper is in place

(e.g., when the paper supply

has run out.).

Paper

~

2

“Paper present”

Figure 2-7. Paper End Sensor Mechanism

2.2.3.2 Release Sensor

The release sensor senses the position of the release lever in order to detect whether tractor feed or

friction feed is in effect.

24

Fric/ion/Tractor Sensor

Figure 2-8. Release Sensor Mechanism

Rev.

A

Page 33

LX-105O+

Service Manual

Operating Principles

2.2.4 Ribbon Advance Mechanism

The ribbon-feed mechanism consists of the ribbon cartridge and the ribbon-feed section. The

ribbondriving

gear is always driven counterclockwise (regardless of the timing belt direction) via

the gear trains shown in following table.

Table 2-1. Ribbon-Feed Gear Train

I

Direction of Carriage

Movement

1

Gear Linkage

Left to right (arrow

Left to right (arrow

e)

d)

~ Ribbon-drivin9

Beltdriven

-

Platen gear (4) -

gear

pulley- Platen gear (1) - Platen gear(3)

Ribbondriving

gear

Following figure shows the ribbon-feed mechanism. The inked ribbon is held in the cartridge case

Beltdriven pulley-+ Platen gear (1) ~ Platen gear(2)

between the ribbon-feed and the ribbon-pressure roller mounted on the ribbon-driving gear.

The

ribbon configuration is such that the ribbon can feed endlessly.

The

ribbondriving

gear drives the rollers, which causes the ribbon to be fed.

To prevent ribbon slack, a ribbon-breaking spring is attached at the exit of the cartridge case. A

ribbon mask is installed to prevent the ribbon from staining the paper.

G

b’

Ribbon

Ribbon Feed Roller

‘ress”re ‘O’’er\ >

Ribbon Transmission Gear

P,ane;:’;ar

Ribbon Driving Gear

‘\

&

-

m%’d

-&-

“H

.

\\\

Figure 2-9. Ribbon Feed Mechanism

Breaking

Sp;ing

Carriage

Rev.

A

2-7

,,

Page 34

Operating Principles

LX-105O+ Service Manual

2.3 OPERATING PRINCIPLES OF THE ELECTRICAL

This section describes principles of electrical

circuitries.

CIRCUITRIES

2.3.1 Operating Principles of the Power Supply Circuit

The electrical power required by this mechanism is developed using the

combines a filter and a power transformer) and the

T14NfA

board. The Ac input passes first

through the filter circuit, where line noise is removed, and is then set to the transformer, where it is

stepped down into two separate voltages: AC 26V and AC

the power circuits on the

required for operation.

TAMA

board, which converts the power to the DC voltages (see below)

12C.

The transformer output is sent to

TAa Fiher

Unit (which

Table 2-2. Voltage Applications

Voltage

+5

VDC

+24

VDC

Logic circuit voltage

Holding voltage for paper feed motor

Others

Carriage

Paper-feed motor drive voltage

Printhead

motor drive voltage

drive voltage

Purpose

I

AC IN

o--

*

+12

I

VDC

TAa Filter Unit

Voltage

for the optional l/F

I

TAMA

I

Full-wave

rectifier regulator

and circuit

smoothing

circuit

—

Full-wave

rectifier

and

smoothing

circuit

Filter

Circuit

Step-

down

Trans-

former

——1

26

12

VAC

I

VAC

I

~1

,1

Figure 2-10. Power Supply Circuit Block Diagram

Board

+24

VDC

+24

VDC

regulator

circuit

+

+24

VDC

+

+5

VDC

+12

VDC

➤

2-8

Rev.

A

Page 35

LX-105O+

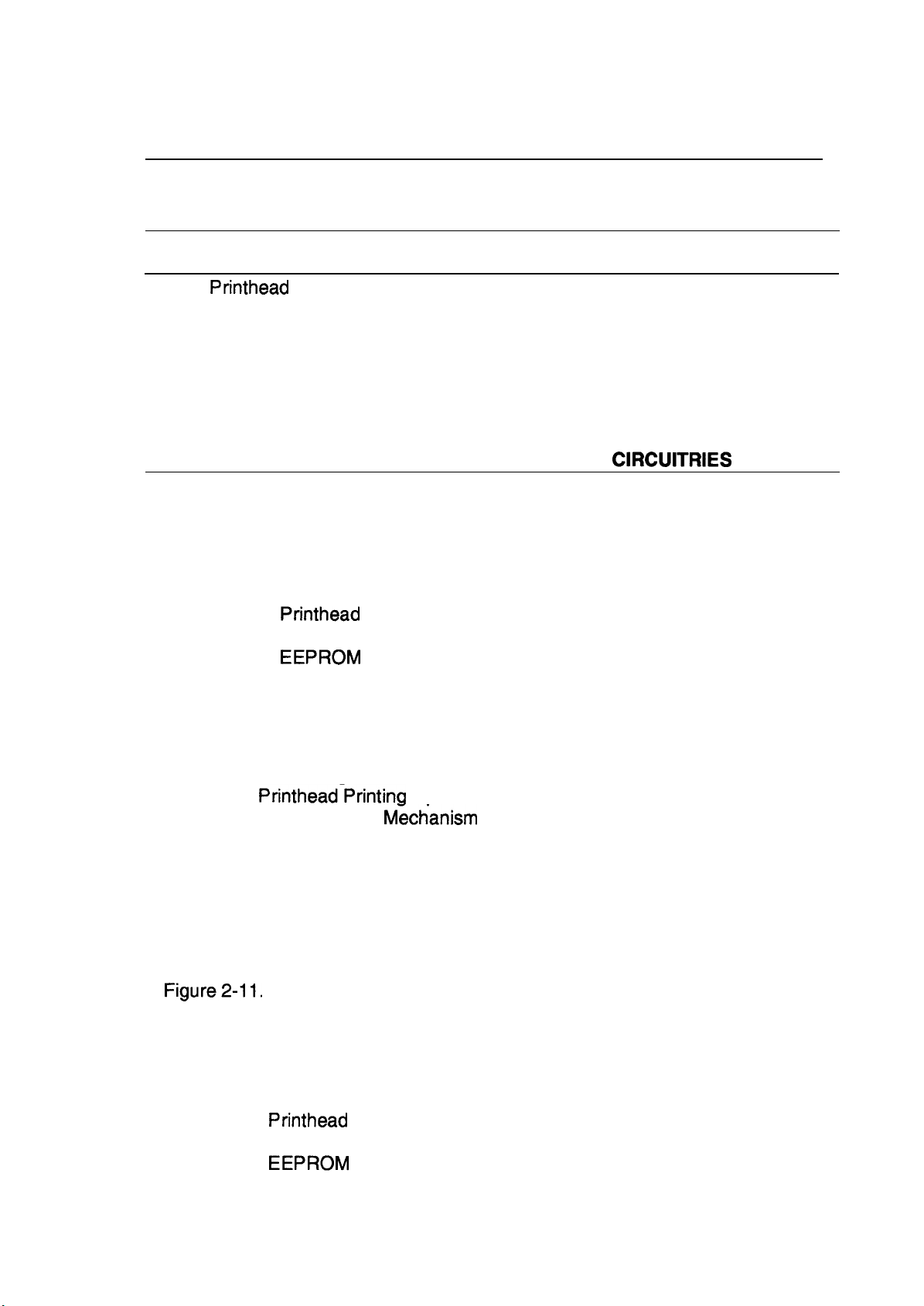

2.3.2 Operating Principles of the Main Control Circuit

Service Manual

Operating Principles

The printer CPU is an 8-bit CPU

components of the printer. The

that control the assignment of the memory and 1/0 areas.

CPU

vPD781OHG

(2C)

~D7810HG

E05A30

gate array contains various memory management functions

running at 15 MHz. It oversees control of all the

Bm

~c”’””’

E05A30

(3B)

I

CR

motor

driver

EIE

E

Control Panel

Parallel l/F

m

Figure 2-11. Main Control Circuit Block Diagram

Table 2-3 lists the functions of the components and circuits of the printer. The CPU converts the

print data sent from the host computer to image data (the print image). The image data is then

loaded to RAM. Each line of data is processed sequentially. The CPU transfers the print data to the

printhead

length of this pulse corresponds to the pnnthead drive voltage. The head drive circuit then outputs

the-head drive signal.

drive circuit. The CPU sends the

-

Print

Host

Computer

tl

Data

+24V

Printhead

line

L

Drive

printhead

CPU

Data Input

Print Data

Convertor

I

drive pulse to the

1

Image Data

Transfer

printhead

RAM

Input

●

Buffer

—

Image

+

Buffer

—

drive circuit. The

Rev.

L?ap’nthead

Figure 2-12. Data Flow

A

II

2-9

Page 36

Operating Principles

Table 2-3. Functions of the Main IC and Circuits

LX-105O+

Service Manual

IC

and Circuits

vPD781

OHG

E05A30

ROM

RAM

EEPROM

Looation

2C

3B

3C

3D

Ic

Functions

Receives data from the host computer and loads the data to the

input buffer in RAM. Expands the input data held in the buffer to

create image data. Loads this image data to the image buffer in

RAM. Transfers the image data to the

controls various parts of the printer mechanism, such as the

motors.

The gate array

1. Parallel l/F

2. Address decoder

3. Data address multiplexer

4. PF motor control

5. CR motor control

6. Control panel LED drive

7.

Printhead

This ROM memory program and fonts.

This RAM is used as an input data buffer and image buffer for

expanding data, and as working area for the program.

The

EEPROM

paper position.

E05A30

drive

has a 256-bit memory, and remembers the current

functions areas follows

oontrol

printhead

drive circuit. Also

The paper feed motor drive circuit drives the paper feed motor.

Paper feed motor

drive circuit

Carriage motor

drive circuit

2.3.2.1 Reset Circuit

11-tis

circuit generates the signal that initializes the printer, and is made by monitoring the +5 and

+24V

voltages when the power is switched ON and OFF.

The reset signal line is

+5V4

—

—

comect

The paper feed motor is a 4 phase-step motor. The rotation of the

motor (position and speed) is controlled by outputting the phase

switching signal by the

The carriage motor drive circuit drives the carriage motor. The

carriage motor is a 4 phase-step motor. The rotation of the motor

(position and speed) is controlled by outputting the phase

switching signal by the

to the CPU and gate array 3B.

c15

A1015

R57

10K

)

E05A30

E05A30

MA165

gate array.

gate array.

R83

47K

RESET

2-1o

+

+2J?!-P’

MA4036-M

Figure 2-13. Reset Circuit

k

h

I

ZD2

R82

2.2K

KIT

C18

&

Rev.

A

Page 37

LX-105O+ Service Manual

Operating Principles

2.3.2.2

Following figure shows the sensor circuit in block diagram. The

home position. The

A/D convertor senses

2.3.2.3

Following figure shows a block diagram of the carriage motor drive circuit. In this circuit, the phase

switching for the carnage motor is directly executed not by the CPU, but by the gate array

which acts on the basis of the CPU phase data. SLA7020M drives the carriage motor with a

stabilized stabilized current.

Sensor Circuit

PA1

senses paper end. The

+24V

line voltage.

HOME

PE

RELEASE

+24V

line

Carriage Motor Drive

PA2

senses release lever position. The

PAO

PA1

PM

AN5

Figure 2-14. Sensor Circuit

CPU

uPD7810HG

(2C)

PAO

of CPU port senses carriage

AN5

of CPU

(3B),

The excitation system is determined by the firmware and is executed in accordance with the

carriage speed, as shown in Table 2-4.

1

SLA

7020M

( 1A)

b

CPU

L

PD78 10HG

(2 c)

GA

E05A30

(3B)

Phase” Data

M

o

Figure 2-15. Carriage Drive Circuit Block Diagram

Table 2-4. Phase-Excitation Method

Rev. A

Drive Mode Excitation Type

Mode 1

Mode 2 2-2 phase

Mode 3 1-2 phase

Mode

I

4 1-2

2-2

phase

phase

Drive Frequency Type

1200

pps

900

pps

1200

pps

pps

900

2-11

Page 38

Operating Principles

LX-1050+ Service Manual

2.3.2.4 Paper Feed Motor Drive Circuit

The

paper-feed motor drive circuit is shown in

motor which can utilize 2-2 phase excitation. When the paper-feed signal

following figure. me

paper-feed motor is a step

PC2

is set to HIGH, Q20

and Q16 are turned on, and +24 V is supplied to the motor. When the paper-feed motor is not

driven, +5 V is supplied, via resistor

R42

and diode D6, to hold the motor.

The paper feed motor is a 48-pole step motor and is

open-loop

controlled. When 2-2 phase

excitation is used to drive the motor, each step feeds the paper a distance of l/216th inch.

CPU

rffPD78

(2C)

I

EO:\O

(3 B)

10HG

PC2

PFA

PFB

PFC

PFD

19

8

9

10

11

RI 16

33K

R87 3.3K

VAVAV

R89 3.3K

VAVAV

R86 3.3K

v

VAV

R88 3.3K

Vhvf

R45

5.6K

I?44

5.6K

R36

3.3K

+24V

A

,

+5V

A

12

8

11

7

PFCOM

PFCOM

PF A

PF B

PF C

PF D

GP

Figure 2-16. Paper Feed Motor Drive Circuit

Page 39

LX-105O+ Service Manual

Operating Principles

2.3.2.5

Gate array

the head-wire drive pulses from gate array

V line).

The

to the

Print data is expanded in the image buffer as dot patterns. The CPU outputs the dot patterns to the

E05A30.

The data for pins 1 through 8 of the

The data for pin 9 of the

After data latching, the pnnthead drive pulse width signal FIRE is output from the CPU’s event

counter. When the signal is LOW, the gate array will be open, so that the data from

HD9

The drive pulse width is adjusted using CPU port PC6.

CPU

/U PD78 10HG

(2C)

Printhead

E05A30

E05A30

will be output.

gate array includes circuitry to interface the CPU and the

printhead

is used as an 8-bit + l-bit data latch. The CPU determines the pulse width for

in the following sequence:

Drive Circuit

printhead

is latched by

EO%30

(3 B)

E05A30

printhead

by monitoring the

printhead.

is latched by HDl trough

HD9

of the

E05A30.

Printhead

Drive

Circuit

printhead

The data is output

HD8

of the

drive power (+24

E05A30.

HD1

through

Print herd

L

--N

DATA

--N

-1/

FIRE

●

--l/

Figure 2-17. Printhead Drive Circuit Block Diagram

Rev.

A

2-13

Page 40

Operating Principles

2.3.2.6 Host Interface

LX-105O+

Service Manual

The host

interface circuit is

shown in following figure. STROBE

pulses

from the host computer pass

through the low-pass filter, consisting of R72 and C12, and flow into the STROBE terminal.

These pulses latch the parallel data and set the BUSY signal HIGH, so that subsequent data transfer

is inhibited.

At this time, the CPU, by reading address

OCO02H,

can detect whether the data from the computer

are latched in the gate array.

When the CPU determines that data have been latched, it proceeds to read the data. After the data

have been read, the gate array automatically resets its busy signal.

z

-1

2

u

u

a

-a

z<

I

V&

0

0

0

N

- t-i 0

r)

- .

x x%x

m

m m m

!+&1+

-

I+

m *

w!sw w

a

n

0

i-

,

N

10

K

K

K

k

4.

0

&

w

m

1-

0n0

a

P

0

UC-)

Zz

~

ua

:11111%11

H-M

o

:

n

t’i+

Lnu-lmm

CDlnlo(n

-----<<<<

Zzzz

Inlnmln

ID

WUJW

----

<<<<

Zzzz

2-14

Figure 2-18. Host Interface

Rev.

A

Page 41

LX-105O+

Service Manual

Operating Principles

2.3.2.7

The

EEPROM

EEPROM

Circuit

stores in its memory the current feed position of continuously fed paper, as well as

the current panel settings. This memory is retained even after power is shut off.

EEPROM

can memorize the current position of continuously fed paper, so that this information can

be maintained even if power goes off.

Following figure shows the

EEPROM

is selected when CPU port

be sent is set in CPU

CPU port PC4’S

The

EEPROM

clock:

receives commands to indicate whether to read or write data,

EEPROM

Dort

PB1, and is fed bit-by-bit to the

Data are read,

circuit. Note that this is external to the CPU’s memory space.

PC5

goes HIGH. Once

bit-by-bitjin

line with falling clock pulses.

EEPROM

EEPROM

has been selected, the data to

in line with rising pulses from

and to indicate

addresses.

CPU

K

PD78 10HG

(2C)

10

PB 1

9

PBO

22

PC5

.

21

PC4

777

ER59256

( 1 c)

7

TEST

DI

DO

Cs

CLK

3

4

‘

2

R1

19

33K

T

RI 20

33K

-.

Figure 2-19.

EEPROM

Circuit

Rev.

A

2-15

Page 42

Chapter 3 Disassembly and Assembly

Table of Contents

3.1 GENERAL REPAIR INFORMATION

3.2 DISASSEMBLY AND ASSEMBLY

3.2.1

3.2.2 Removal of Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.3 Removal of Circuit Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.4 Removal of Printer Mechanism . .“. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2.5 Disassembly of Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Printhead Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.2.1 Upper Casing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.2.2 Control Panel Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.3.1

3.2.3.2

3.2.5.1

3.2.5.2

3.2.5.3

3.2.5.4

3.2.5.5

3.2.5.6

3.2.5.7

3.2.5.8

3.2.5.9

TAMA Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

TA-a Filter Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Removal ofCarriage Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Removal

RemovalofPlaten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

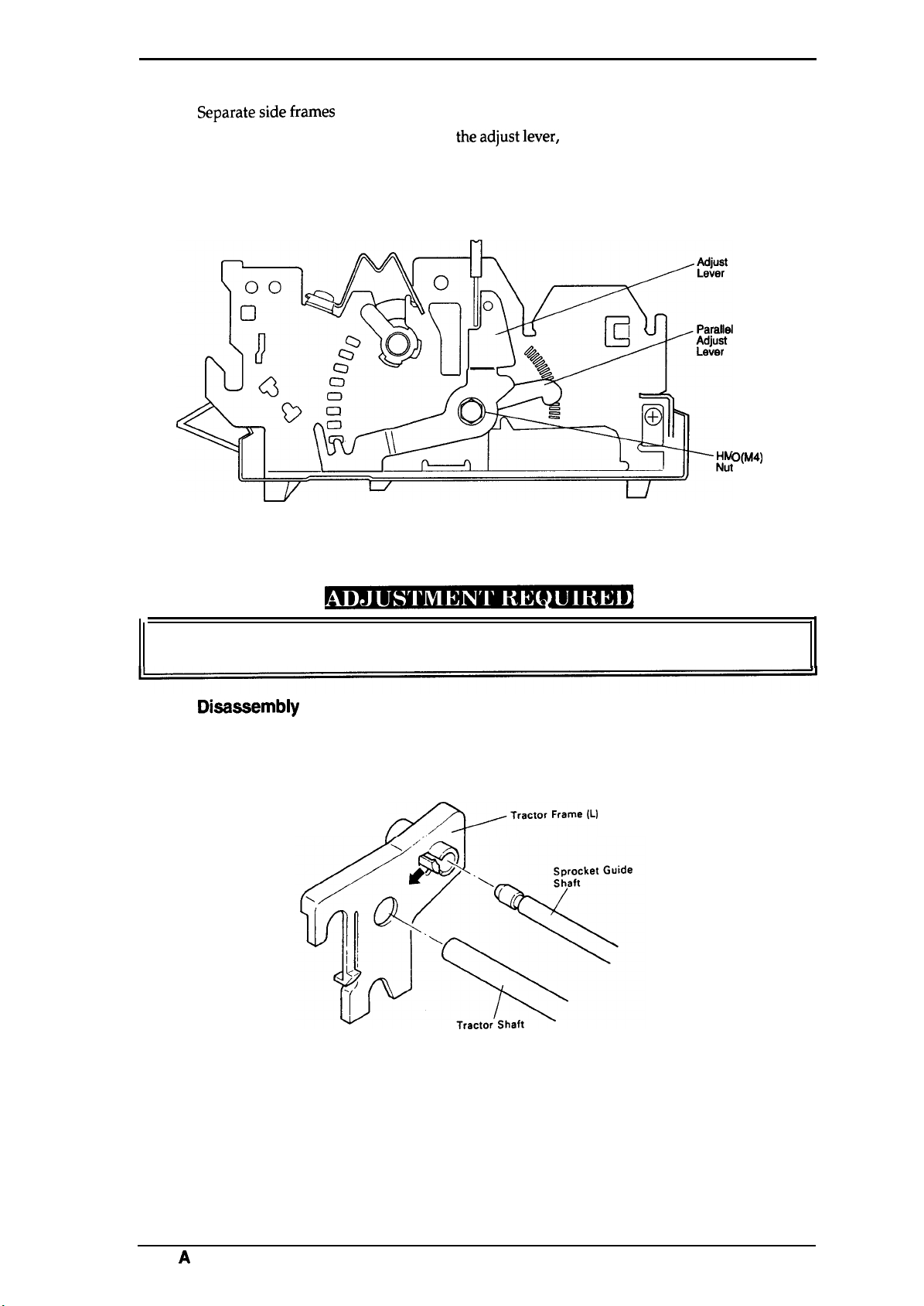

Removal ofFrame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Removal ofPaperFeed Motor . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Removal ofPaperEndSensor . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Removal of Paper Guide Plate . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Removal

Disassembly

ofHome

ofCarriage.

Position Sensor.. . . . . . . . . . . . . . . . . . . . . 3-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

ofTractorUnit

. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-1

3-2

Figure 3-1,

Figure 3-2.

Figure 3-3.

Figure 3-4.

Figure 3-5.

Figure 3-6.

Figure 3-7.

Figure 3-8.

Figure 3-9.

Figure 3-10.

Figure 3-11.

Figure 3-12.

Figure 3-13.

Figure 3-14.

Figure 3-15.

Figure 3-16.

Figure 3-17.

Figure 3-18.

Figure 3-19.

Figure 3-20.

Figure 3-21.

Figure 3-22.

Figure 3-23.

Figure 3-24.

List of Figures

PaperTension Unit Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Printhead Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Push Tractor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Upper Casing Removal -1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Upper Casing Removal -2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

FFC.

Control Panel

Control Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

TAMA Board Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

TA-a Filter Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Printer Mechanism Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Carriage Motor Mounting Plate Removal . . . . . . . . . . . . . . . . . . . 3-9

Carriage Motor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Home-Position Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Crescent Ring Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Platen Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Head Cable Holderand

Helical Spring Hook. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Release Lever Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Release Lever Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Separation of Tractor Disengage Cam . . . . . . . . . . . . . . . . . . . . 3-14

Bottom Viewof Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . 3-14

Separate of Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Paper Feed Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Paper EndSensorRemoval . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

FFC

Removal . . . . . . . . . . . . . . . . . . . . 3-12

Page 43

Figure 3-25. Paper Guide Plate Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Figure3-26.

Figure 3-27. Tractor Frame l-Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Figure 3-28. Extraction

Figure 3-25. Tractor Phase Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust

l_everRernoval

ofTractorunti

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3-17’

S-18

List of Tables

Table 3-1. Repair Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-2. Measuring Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3-1

Page 44

LX-105O+

Service Manual

3.1 GENERAL REPAIR INFORMATION

Disassembly and Assembly

This chapter describes the procedures for

of the

LX-105O+.

Prior to beginning any of these procedures, be certain that the AC power cord is

disconnected.

To help prevent hands jiotn being cut by the printer mechanism or sharp plate edges, wear

gloves when performing these procedures.

The printer mechanism, boards, and other parts are sometimes held in place with plastic

clips rather than screws. Be

Tables 3-1 and 3-2 list tools and measuring instruments recommended for carrying out disassembly

and repair.

carefil

removin~

not to damage these clips when removing them.

replacins and adjusting the main components

Table 3-1. Repair Tools

Description Part No.

Round-nose pliers

B7404OO1OO

Nipper

Tweezers

Electric soldering iron

E-ring holder #2.5

E-ring holder #5

PhiliDs

screwdriver No. 2

Screwdriver No. O

Thickness gauge set (#F518)

6740500100

B641OOO1OO

I

B7402OO1OO

6740800400

6740800700

I

6743800200

6743800300

1

B776702201

I

I

I

I

Table 3-2. Measuring Instruments

Description

Oscilloscope

Muttimeter

To ensure optimal performance of the printer, be sure, following reassembly and adjustment, to

lubricate, apply adhesive, clean, and maintain, according to the procedures described in Chapter 6.

I

I

I

Rev. A

3-1

Page 45

Disassembly and Assembly

3.2 DISASSEMBLY AND ASSEMBLY

LX-105O+

Service Manual

This section details the disassembly procedures for the

LX-105O+.

As a rule, reassembly is

performed by simply reversing the procedures; a number of special notes, however, are provided

under the heading “Notes for Reassembly.” When a disassembly or reassembly procedure requires

that an adjustment be performed, the adjustment is described under the heading, “Required

Adjustment.” Be sure to perform these adjustments as indicated.

Be sure that you have read Section 4.1, “General Repair Information,” before performing

disassembly.

Be sure that paper and ribbon cartridge are removed before disassembly.

The disassembly procedure detailed below is in the following sequence: (1) removal of the

printhead,

(2) removal of the casings, (3) removal of the circuit boards, (4) removal of the printer

mechanism unit, and (5) disassembly of the printer mechanism.

3.2.1 Printhead Removal

[Step

[Step

Remove the printer cover, and confirm that paper and ribbon cartridge have been

1]

removed.

Open the cover of the paper tension unit.

2]

paper TensIon

/

[“

I

[

Prlnthead

Pli4en

Figure 3-1. Paper Tension Unit Cover

I

3-2

Rev. A

Page 46

LX-105O+

[Step

3]

Unlock the two levers securing the

Service Manual

lift and remove the

P

printhead.

printhead

to

thecarnage

Disassembly and Assembly

bypulhngthemdown. Then

Levers

[Step

Figure 3-2.

4]

Disconnect the head cable from

Printhead

Removal

theconnector ontheprinthead.

Rev.

A

3-3

Page 47

Disassembly and Assembly

3.2.2 Removal of Casing

This section details the procedure for removing the upper casing and the control panel.

3.2.2.1 Upper Casing Removal

LX-105O+

Service Manual

[Step 1]

[Step

2]

Remove the sheet guide unit, printer cover, paper tension unit, and paper feed knob.

Pull in the two notches securing the push tractor to the printer mechanism, and remove

the push tractor from the printer mechanism.

[Step

[Step

Figure 3-3. Push Tractor Removal

3]

Remove the two

Insert a standard screwdriver into each of the two holes at the front of the upper

4]

and gently push (See figure 3-4) to unlock the notches.

u

c“’”’’’”

C.B.B-tite

The notch can be

unlocked

it in the direction

shain by the

arrow using

the screwdriver

(M4 x 25) screws securing the upper case.

Lower

Case

Guide

\~

\

[“<l

I

w

by pushing

CBB(M4 X 25)

6

v

.1

Upper

Case

Notch

msing,

3-4

Figure 3-4. Upper Casing Removal -1

Rev.

A

Page 48

LX-105O+ Service Manual

[Step

5]

While lifting the upper casing,

CN3 on the

TAMA

discomect

the cable of the control panel from connector

board. Then remove the upper casing.

Disassembly and Assembly

Figure 3-5. Upper Casing

NOTE FOR REASSEMBLY:

Before reassembling the upper

Control Panel and

TAMA

board in such a way that it can be connected to the Panel Cable Sailed

Plate.

Figure 3-6. Control

casin&

prepare the

Removai

FFC

(Flat Flexible Cable) that connects the

-2

Control

Panel

Panei FFC

Rev.

A

3-5

Page 49

Disassembly and Assembly

LX-105O+

Service Manual

3.2.2.2

Control Panel Removal

[Step 1] Remove the upper casing (as described in the previous section).

[step

2]

Turn the upper casing over, push in the two notches on the casing that are securing the

control panel to it, and remove the control panel.

anel

Figure 3-7. Control Panel Removal

3-6

Rev. A

Page 50

LX-105O+

Service Manual

3.2.3 Removal of Circuit Boards

This

section describes the procedure for removing the

TAMA

3.2.3.1

Board Removal

TAMA

Disassembly and Assembly

Board and the TA-a filter unit.

[Step 1]

Do not pull roughly on the connectors, or you may damage the board. Remove them by

pulling gently while at the same time holding the board.

[Step 2]

[Step 3]

CN9

Remove the upper casing (See section 3.2.2.1). The following connectors on the

board, which are connecting it to external components, should be disconnected:

CN5, CN6, CN7, CN8 FFC

Remove the two C.B.Btite

grand rink which are securing the TAMAboard to the base plate and the lower casing.

Loosen the four bent tabs on the lower casing which are securing it to the

Then

remove the

TAMA

(Flexible Flat Cable), and CN9.

(P2) (M3

board.

CBS(0)(M3X8)

x 6) screws, the

C.B.S-tite

(0)

(M3

x 8) screw, and

TAMA

~TAMA

8oard

board.

TAMA

—-

CN4,

CN8

CN7

I

CN6 CN5 CN4

Be

carefil

them or to cause damage to components on the

When the

Section 4.2

not to bend the tabs toofar. Also, when pushing the tabs, be careful not to break

TM

board is replaced, perform the following adjustment.

BI-DIRECTIONAL

I

Figure 3-8.

\

TAMA

PRIN7TNG ALIGNMENTADJUSZ7WENT

Board

TM

Removal

board.

Rev. A

3-7

Page 51

Disassembly and Assembly

LX-1050+ Service Manual

3.2.3.2

[Step 1]

[Step

2]

[Step

3]

[Step 4]

TA-a Filter Unit Removal

Remove the upper casing (See section 3.2.2.1).

Disconnect connector