Epson LQ-2070 Service Manual

EPSON TERMINAL PRINTER

LQ-2070

SERVICE MANUAL

EPSON

4006244

NOTICE

• All right reserved. Reproduction of any part of this manual in any form wharsoever without SEIKO EPSON’s express

written permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual. However, should any errors be

detected, SEIKO EPSON would greatly appreciate being informed of them.

• The above notwithstanding SEIKO EPSON can assume no responsibility for any errors in this manual or the

consequences thereof

.

Copyright 1995 by SEIKO EPSON CORPORATION

Nagano, Japan

PRECAUTIONS

Precautionary notations throughout the tect are categorized relative to 1) personal injury, and 2) damage to

equipment:

DANGER Singnals a precaution which, if ignored, could ressult in serious or fatal personal

injury, Great caution should be exercised in performing procedures preceded by

a DANGER headings.

WARNING Singnals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair

/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK

3. WHEN PERFORMING TESTING AS DISCATED WITHIN THIS MANUL, DO NOT CONNECT

THE UNIT TO A POWER SOURCE UNIT INSTRUCTED TO DO SO. WHEN THE POWER

SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLTAGE,

LISTED ON THE SERIAL NUMBER/RATIG PLATE. IF THE EPSON PRODUCT HAS A

PRIMARY-AC RATING DIFERENT FORM THE AVAILABLE POWER SOURCE, DO NOT

CONNECTE IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE m P CHIPS AND CIRCUITRY, USE STATIC

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING

INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENTED BY THE MAANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs

OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID

ANY APPLICABLE EPSON WARRANTY.

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair of

the FX-2170. The instructions and procedures included herein are intended for the experienced repair

technician, and attention should be given to the precautions on the preceding page. The chapters are

organized as follows:

Chapter 1 - Provides a general product overview, Lists specifications, and illustrates the main

components of the printer.

Chapter 2 - Describes the theory of printer operation.

Chapter 3 - Includes a step-by-step guide for product disassembly and assembly.

Chapter 4 - Includes a step-by step guide for addjustement.

Chapter 5 - Provides Epson-approved techniques for troubleshooting.

Chapter 6 - Describes prevetive maintenance techniques.

❇ The contents of this manual are subject to change without notice.

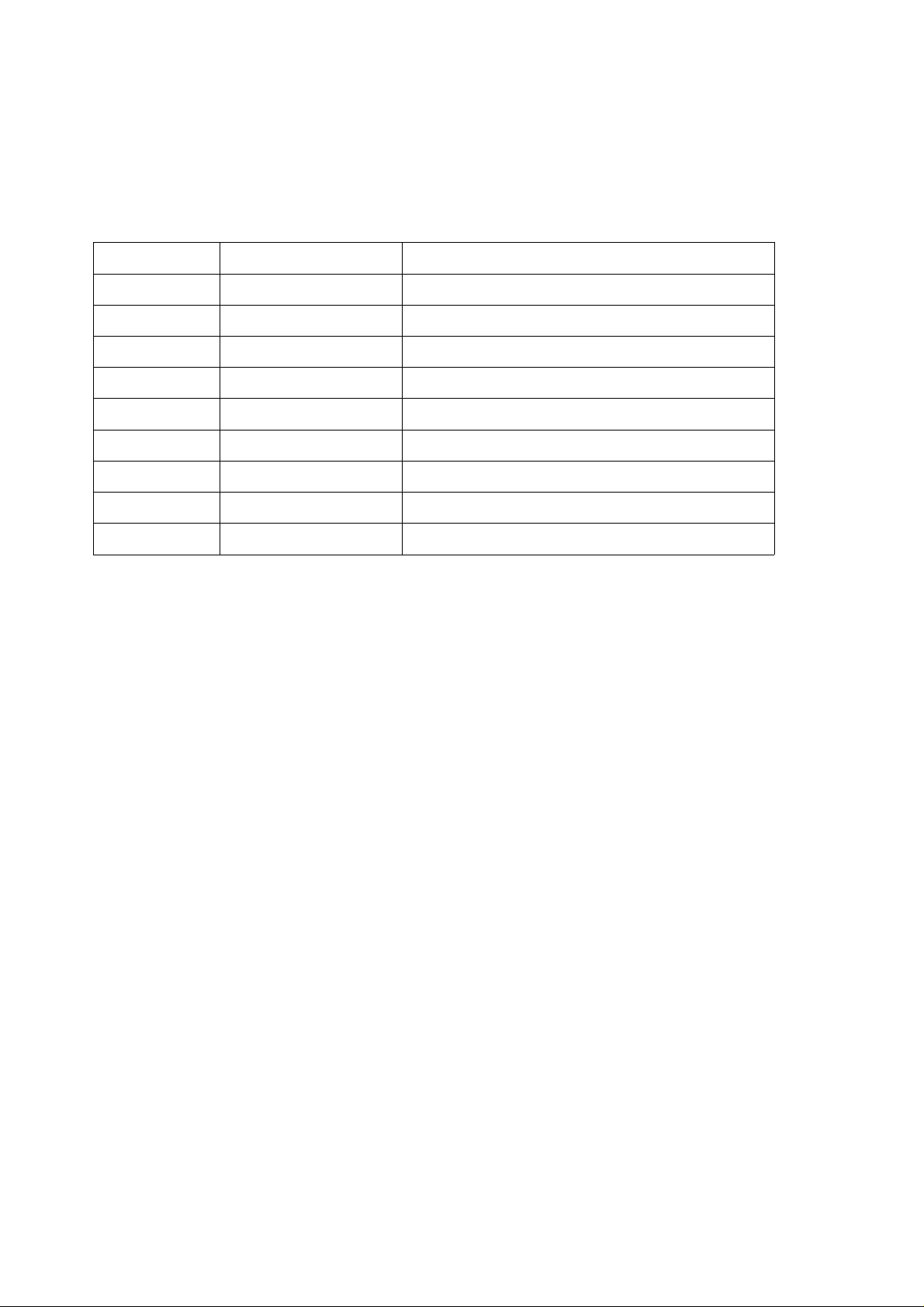

REVISION SHEET

Revision Issued Date Revision Page

Rev. A April 8,1996 1st issued

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATION PRINCIPLES

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENTS

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

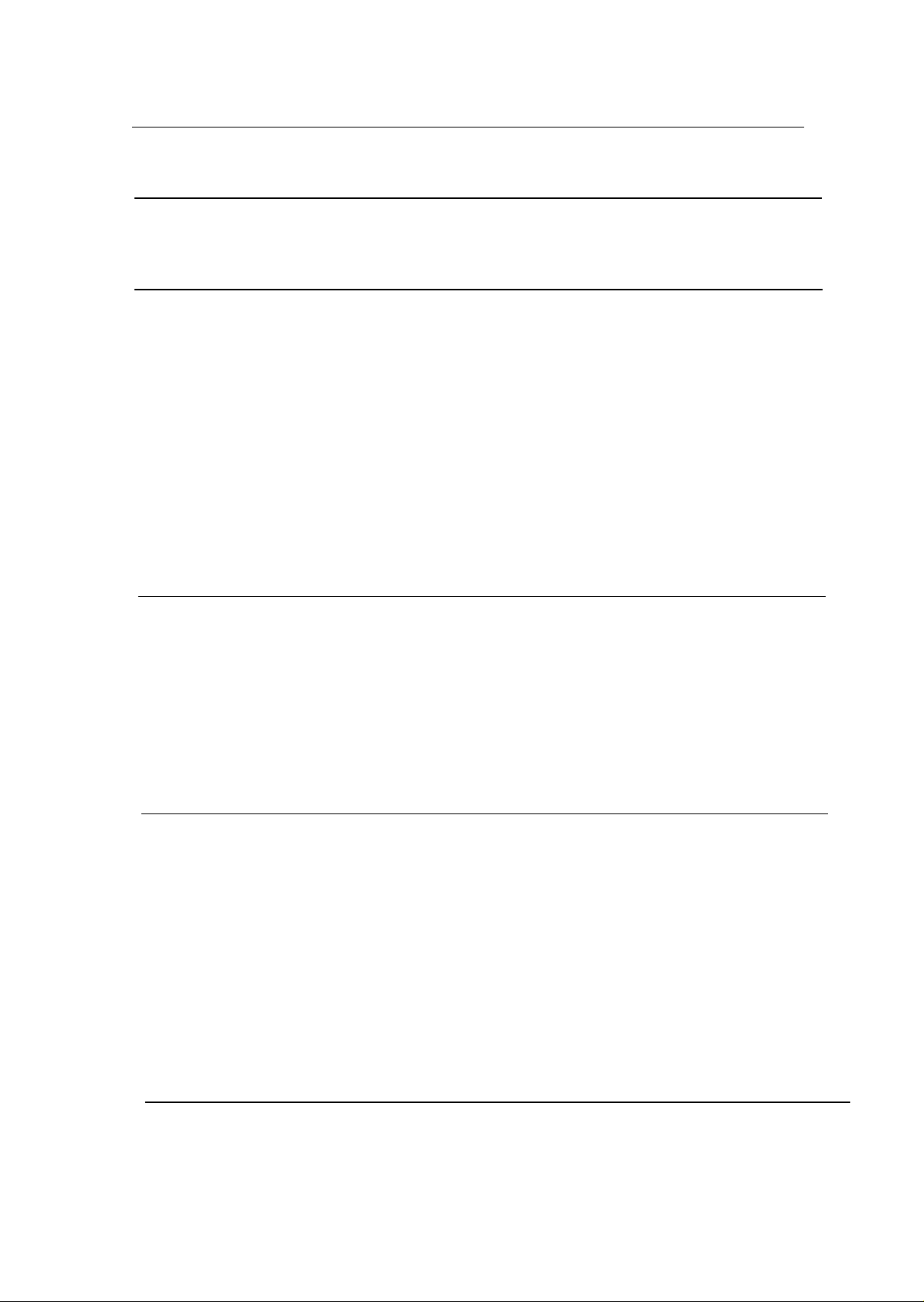

CHAPTER 1 Product Description

Table of Contents

1.1 Specifications

1.1.1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . 1-3

1.2 Hardware Specifications

1.2. I Printing Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.2.2 Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Paper Handling Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-6

1.2.4 Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.2.5 Ribbon Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... ..... 1-16

1.2.6 Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-16

1.2.7 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.2.8 Reliability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .- ...., .. 1-17

1.2.9 Safety Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-17

1.2.10 CE Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-18

1.2.11 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-18

1.2.12 Cut Sheet Feeder Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.3 Firmware Specifications

1.3.1 Control Codes and Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-20

1.3.21nterface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-21

1.3.2.1 Parallel Interface (Forward Channel) . . . . . . . . . . . . . . . . . . . . .. 1-21

1.3.2.2 Parallel interface (Reverse Channel) . . . . . . . . . . . . . . . . . . . . . 1-23

1.3.2.3 Interface Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ..1-24

1.3.2.4 Preventing the Host from Data Time-out . . . . . . . . . . . . . . .....1-24

1.3.3 Paper Handling Firmware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

1.3.4 PaperWidth Sensor Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

. ... .... 1-5

1-1

1-4

1-20

1.4 Operating Instructions

1.4.1 Control Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ..1-29

1.4.2 Status Codes Indicated by the LEDs and Beeper . . . . . . . . . . . . . . .....1-30

1.4.3 Micro Adjustment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-31

1.4.4 TearOff Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-31

1.4.5 Self-test Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-32

1.4.6 Hexadecimal Dump Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..1-32

1.4.7 Default Setting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-33

1.4.8 EEPROM Clear Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-33

1.4.9 Bidirectional Adjustment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

1.4.10 Quiet Mode Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..1-34

1.5 Initialization

1.5.1 Software initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-34

1.5.2 Operation initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-34

1.5.3 Power On initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-34

1-29

1-34

1.6 MAIN COMPONENTS

1.6.1 C186 MAIN Board Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 C166

C165 PNL Board Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.3

1.6.4 Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

1.6.5 Housing Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PSB/PSE

Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-35

1-36

1-36

1-37

1-38

List of Figures

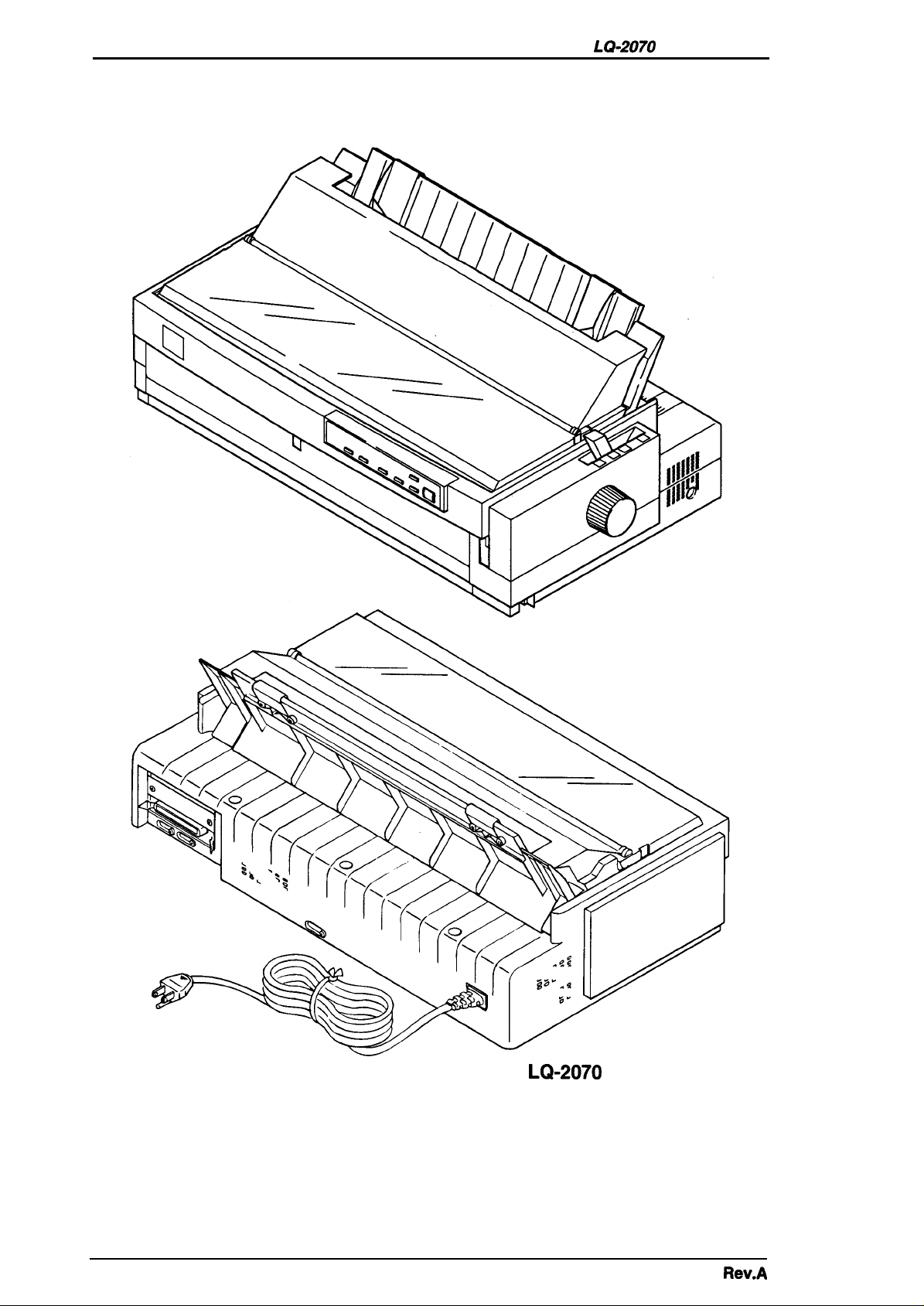

Figure 1-1. Exterior View of the LQ-2070 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

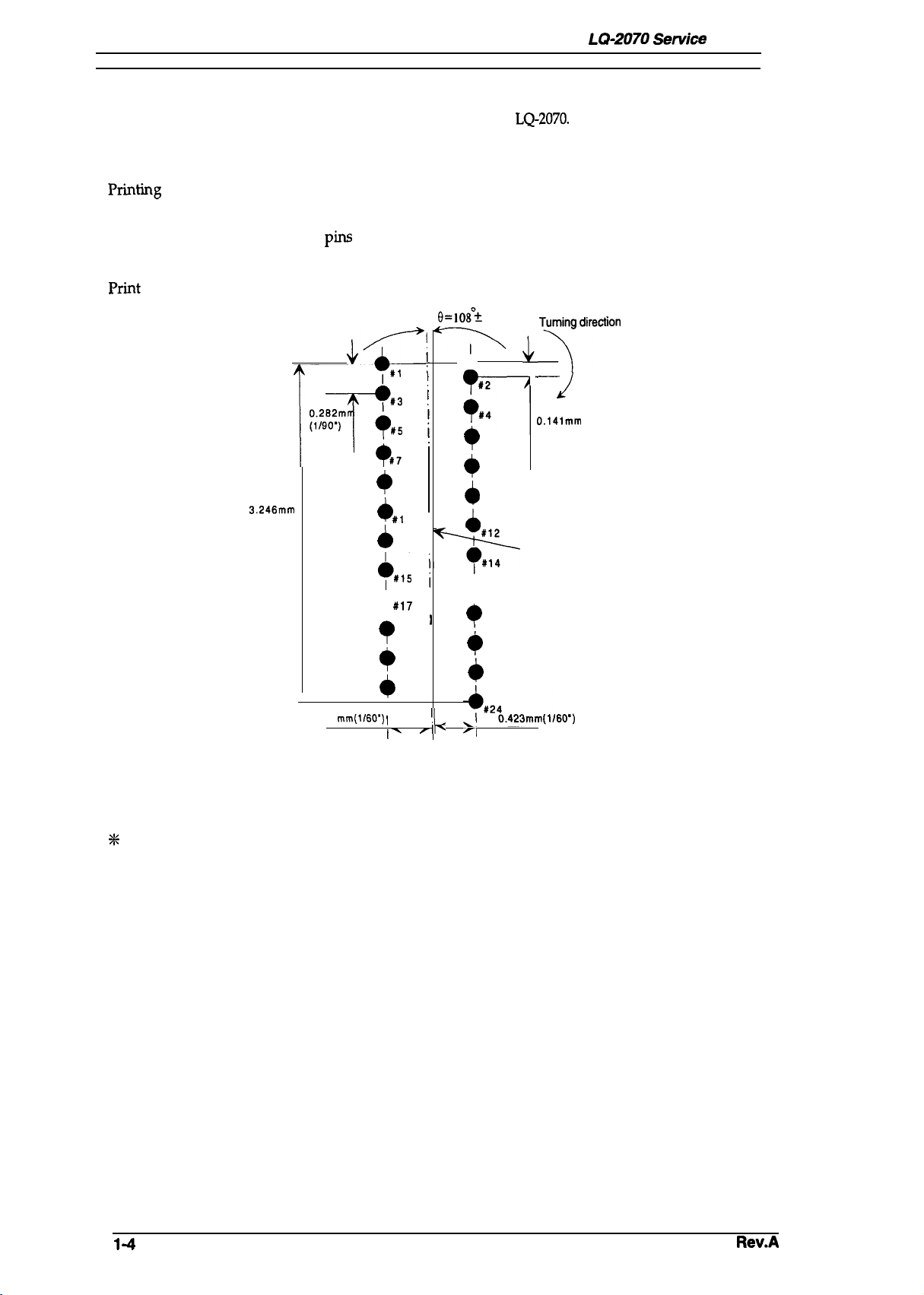

Figure l-2. Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-3. Printable Area for Cut Sheets. . . . . . . . . . . . . . . . . . . . . . . . .“. . . . . . 1-9

Figure 1-4. Printable Area for Envelopes and Card Stock . . . . . . . . . . . . . . . . 1-11

Figure l-5. PrintableAreafor Continuous Paper . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-6. Label Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-7. Printable Area for Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure l-8. Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Figure l-9. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Figure 1-10. Self-test Printout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Figure l-11. Hexadecimal Dump Printout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Figure l-12. Main Components, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Figure l-13. C186MAlN Board Assembly.. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Figure l-14. C166

Figure l-15. C165 PNLBoardAssembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Figure l-16. Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Figure l-17. Housing Assembly . . . . . . . . . . . . . . .

PSB/PSE

Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

.

. . . . . . . . . . . . . . . . . . . . 1-38

List of Tables

Table 1-1. Items Included with the Printer . . . . . . . . . . . . . . . . . . . . . .........1-3

Table 1-2. Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .1-3

“ “ “

Table 1-3. Optional Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

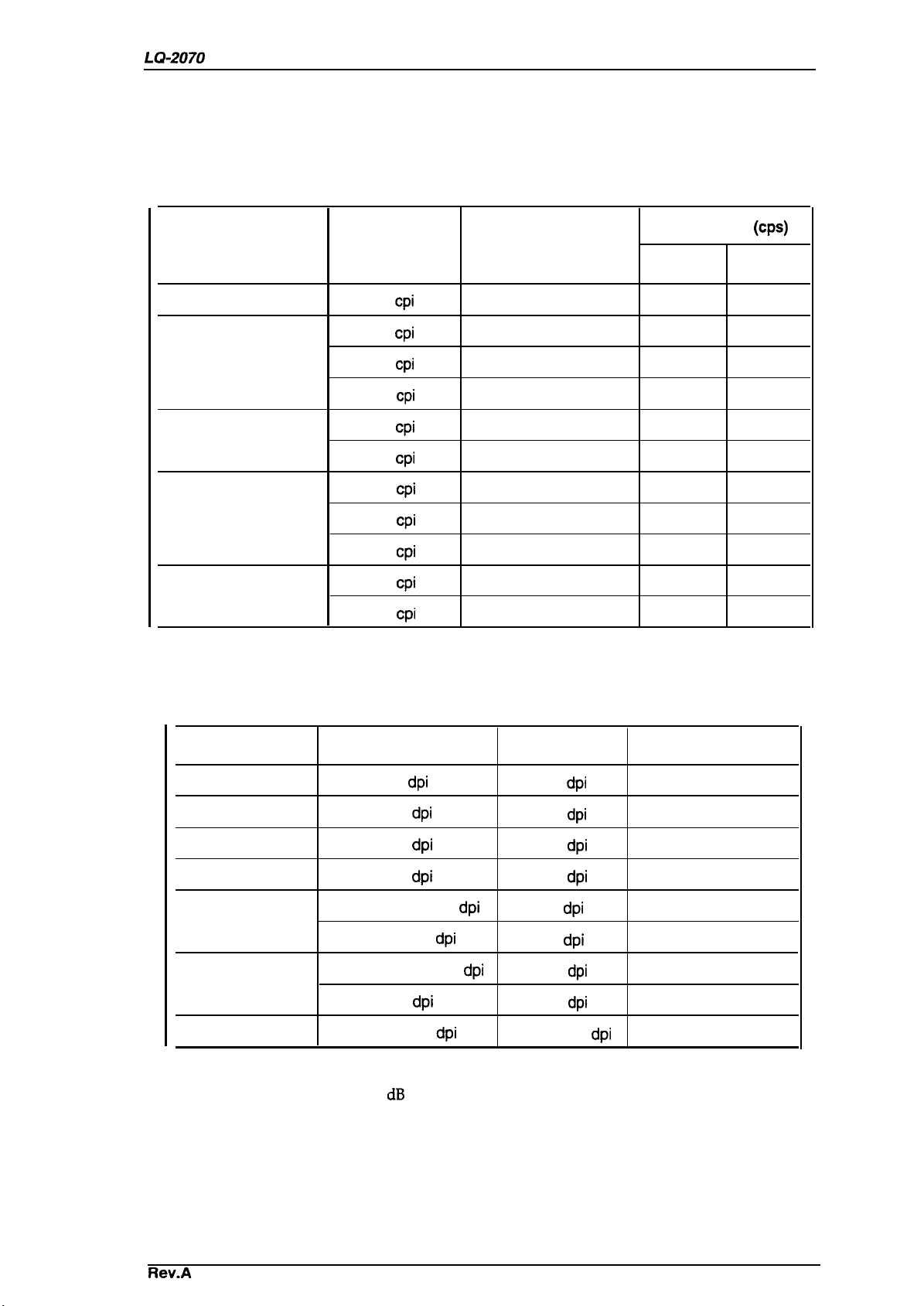

Table l-4. PrintSpeed and Printable Columns . .........................1-5

Table l-5. Print Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .........1-5

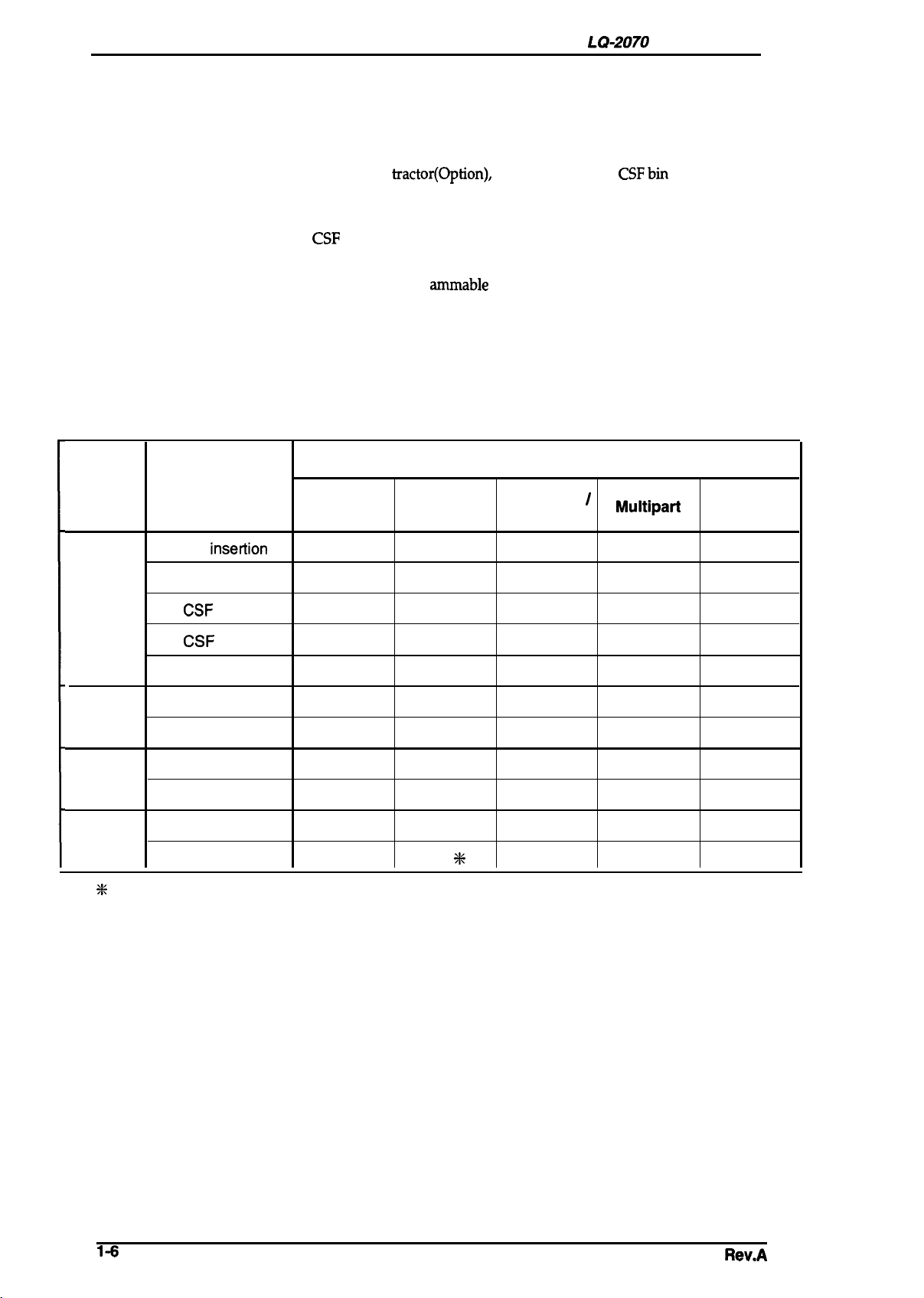

Table 1-6. Paper Path and Paper Types . . . . . . . . . . . . . . . . . . . . . ..........1-6

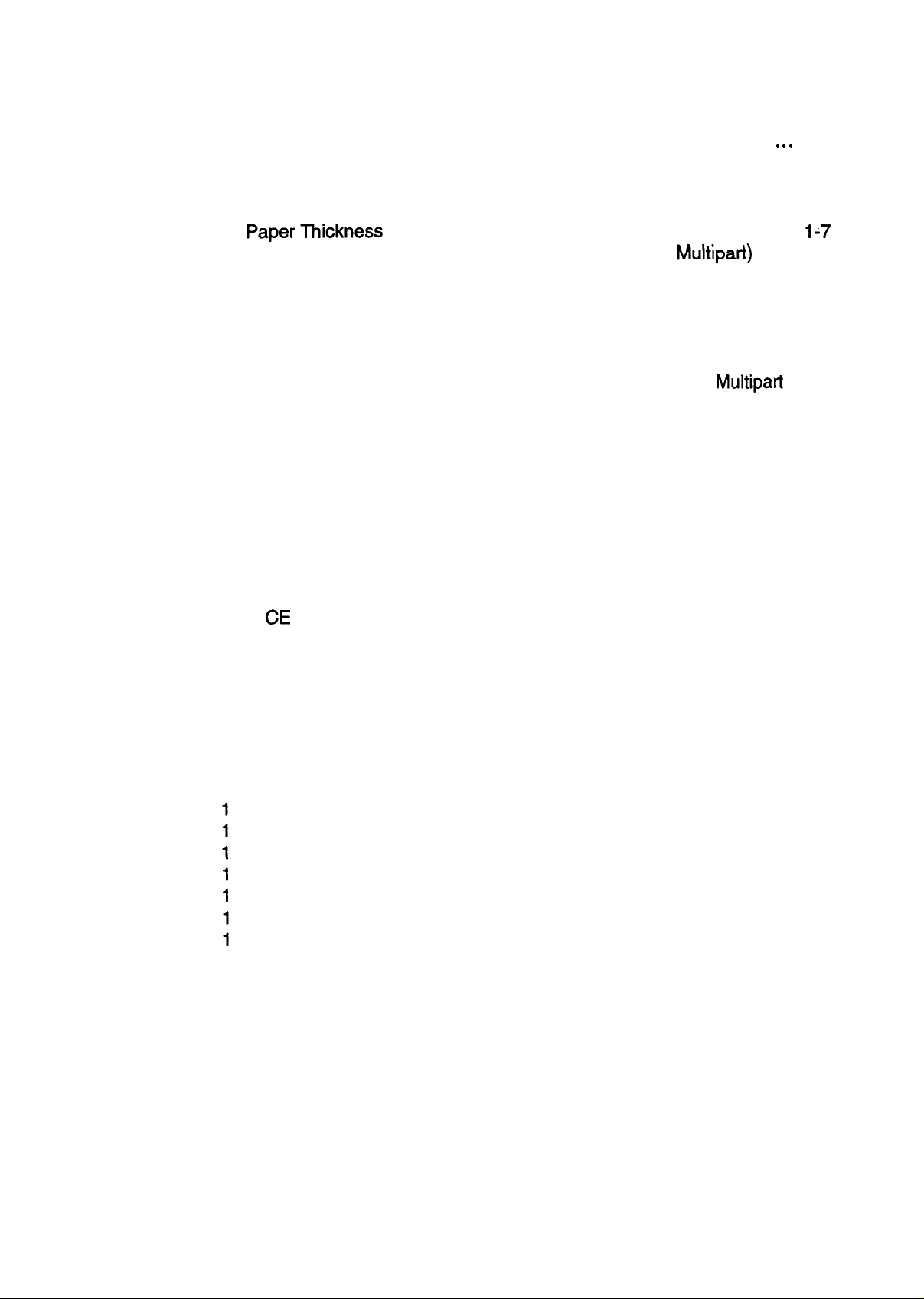

Table l-7.

Table 1-8. Specifications for Cut Sheets (Single Sheet, not

Table 1-9. Specifications for Cut Sheets (Multiparty). . . . . . . . . . . . . . . . . . . . . .. 1-8

Table l-l O. Printable Area for Cut Sheets. . . . . . . . . . . . . . . . . . . . . . . .......1-9

Table l-11. Specifications for Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . .....1-10

Table 1-12. Specifications for Card Stock . . . . . . . . . . . . . . . . . . . . . . . . .....1-10

Table 1-13. Printable Area for Envelopes and Card Stock . . . . . . . . . . . .....1-11

Table 1-14. Specifications for Continuous Paper (Single Sheet and

Table 1-15. Printable Area for Continuous Paper . . . . . . . . . . . . . . . . . . . . .. .1-13

Table 1-16. Specifications for Continuous Paper with Labels . . . . . . . . . .....1-14

Table 1-17. Specifications for Roll Paper. . . . . . . . . . . . . . . . . . . . . . . . . .....1-15

Table 1-18. Printable Area for Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . .....1-15

Table 1-19. Ribbon Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-16

Table 1-20. Electrical Specifications for 120 V Version. . .................1-1 6

Table 1-21. Electrical Specifications for 220/240 V Version . . . . . . . . . . .....1-16

Table 1-22. Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-17

Table 1-23. Reliability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ..1-17

Table 1-24. Safety Information for Printer Models . . . . . . . . . . . . . . . . . . . . .. .1-17

Table 1-25.

Table 1-26. Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-18

Table 1-27. Hopper Capacity. . . . . . . . . . . . . . . . . . . . . . .................1-1 8

Table 1-28. Stacker Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-19

Table 1-29. Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-19

Table 1-30. Character Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-20

Table 1-31. Pin Assignment of Forward Channel . . . . . . . . . . . . . . . . . . . . .. .1-21

Table 1-32. Minimum and Maximum Timings for Data Transmission . . . .....1-22

Table 1-33. Pin Assignments for Reverse Channel. . . . . . . . . . . . . . . . . . . . . .1-23

Table

Table

Table

Table

Table

Table

Table

Table 1-41. Operations in Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . .....1-29

Table l-42. 0perationsat Power On....... . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Table 1-43. Operations for Default Setting Mode. . . . . . . . . . . . . . . . . . . . . .. .1-30

Table l-44. indicators and Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Table 1-45. EEPROM Initialization Settings. . . . . . . . . . . . . . . . . . . . . ... , .. .1-33

PaperThickness

CE

Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .1-18

-34. Paper Handling Sequence 1 . . . . . . . . . . . . . . . . . . . . . . . . . .....1-25

-35. Paper Handling Sequence 2. . . . . . . . . . . . . . . . . . . . . . . . . .....1-25

-36. Paper Handling Sequence 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

-37. Paper Handling Sequence 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

-38. Paper Handling Sequence 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

-39. Paper Handling Sequence 6. . . . . . . . . . . . . . . . . . . . . . . . . .....1-27

-40. PaperWidth SensorOperation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Lever Positions.. . . . . . . . . . . . . . . . . . . . . . . . . . .

Multipart)

Multipatt

.1-3

1’7

. .......1-8

) 1-12

LQ-2070 Sendce Manual

1.1 Specifications

Product Description

These specifications provide statistical information for the

1.1.1.

Features

The

LQ-2070

is a 24pin serial impact dot-matrix printer suitable for the VAR (value addedreseller)

market. The major features of this printer are:

. Print speed

High speed draft

Draft

~Q

●

Feeding method

●

Feeder

●

Paper/media

. Fonts

●

Character tables

Friction feed

Push tractor feed

Push and pull tractor feed

Pull tractor feed

Front push

tractor(option),

Pull tractor (option), roll paper holder (option)

Single sheet, continuous paper,

labels, roll paper

9 LQ and 1 draft bitmap typefaces, 4 Sarable typefaces,

8 barcode fonts

Standard version 11 tables

NLSP version 20 tables

LQ-2070

serial impact dot matrix printer.

(front, rear)

(front, rear)

(front, rear)

(front, rear, bottom)

rear push

&actor,

multipart

300 characters per second

275

CPS

92

cps

at 10 characters per inch (cPi)

(cps)

CSF bin 1 / bin 2 (option)

paper, envelopes, card

●

Input buffer

●

Acoustic noise

●

Reliability

●

Interfaces

64KB

51 dB (A), 1S0 7779 pattern

Total print volume 6 million lines, except

MTBF

Printhead

life

Ribbon life

Bidirectional parallel interface

6000 power on hours

200 million strokes/wire

8 million characters

(IEEE-P1284

printhead

nibble mode supported)

(POH)

Type B I/F Level 2 (option)

. Control codes

. Copy capability

●

Control panel functions

ESC/P2

and IBM 2390/2391 plus emulation

1 original+ 3 copies

Font, Pause, Condensed Pause, Tear off, Bin,

LF/FF,

Adjust, Default Setting

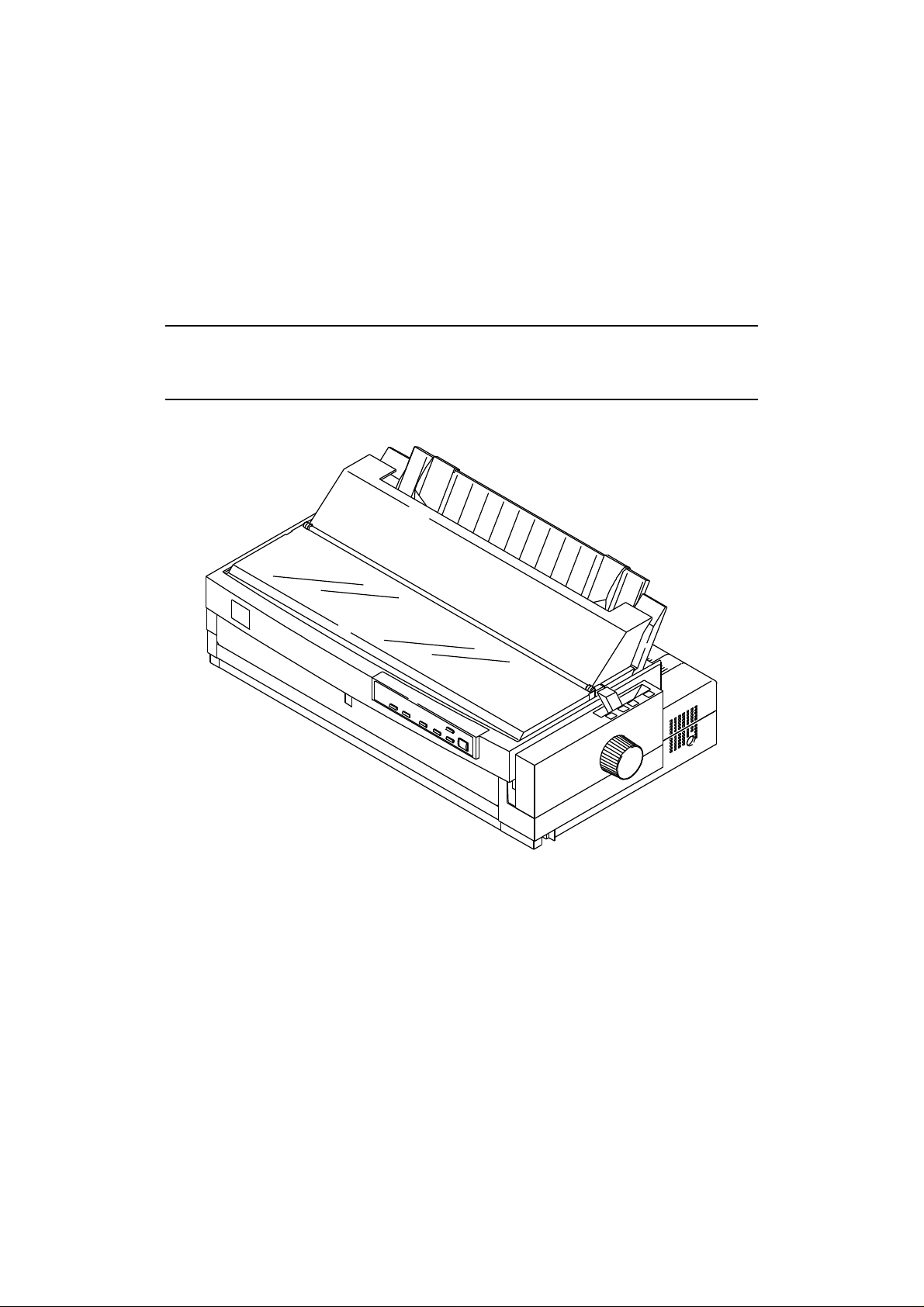

Refer to Figure 1-1 on the next page for an exterior view of the

LQ-2070.

Note: Roll paper is not available on all models and not available in the U.S.

Load/Eject, Micro

Rev.A

1-1

Product Description

LQ-2070 Service Manual

1-2

Figure 1-1 Exterior View of the LQ-2070

Rev.A

LCk2070

Service Manual

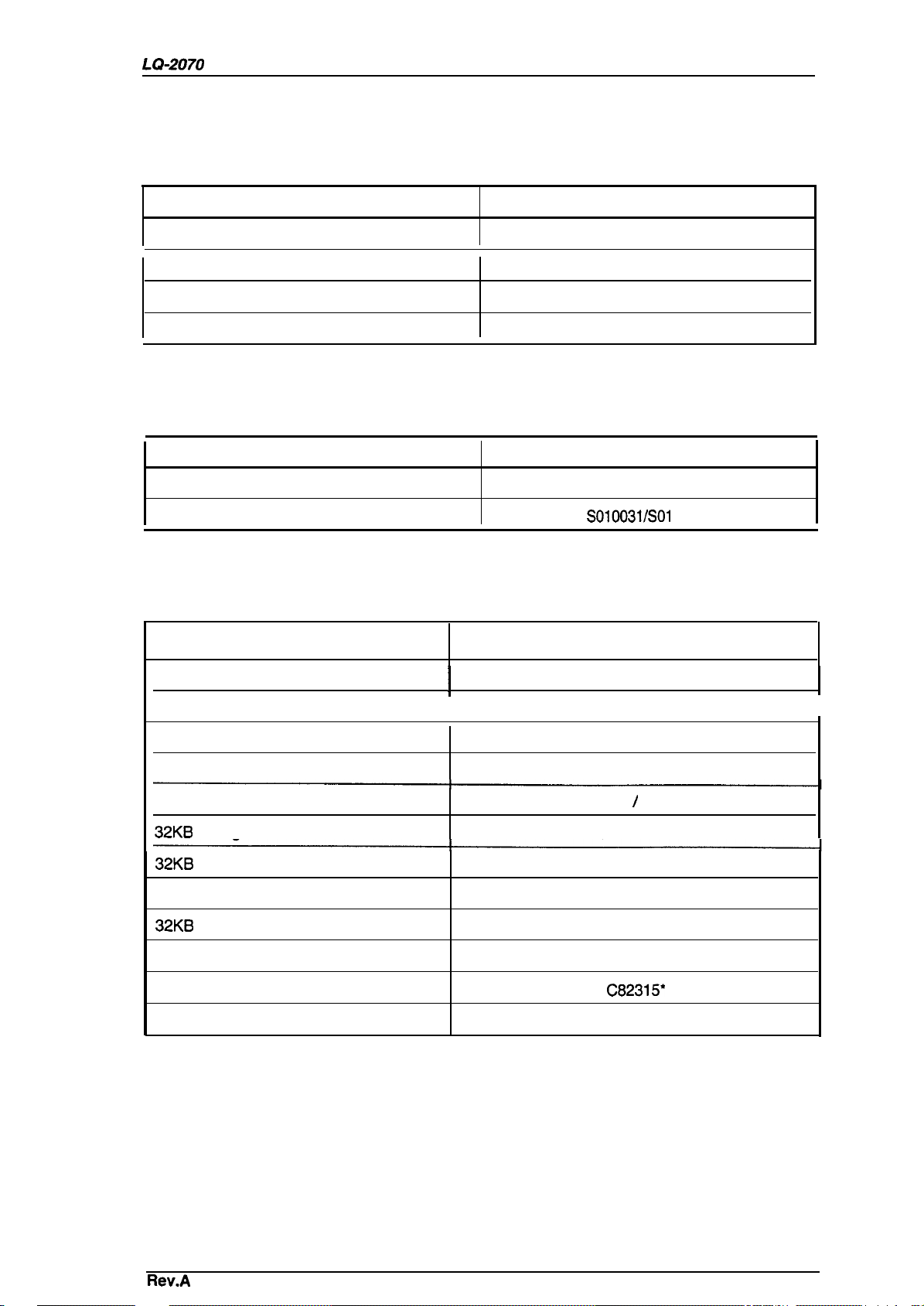

1.1.2. Accessories

●

Items included in the printer

Table 1-1 Items Included with the Printer

Product Description

carton

Quantity

1

1

1

1

User’s guide

Driver diskette

Ribbon cartridge

Power cord

Enclosed

Items

. Consumables

Table 1-2 Consumables

Consumable Item

Ribbon cartridge S015083/S01 5086

Ribbon pack

. Options

Part Number

soloo31/sol

0033

Table 1-3 Optional Units

Unit

Description

High-capacity cut sheet feeder 1 (bin 1)

Second bin cut sheet feeder 2 (bin 2)

Pull tractor unit

Roll paper holder

Serial l/F card

32KB intelligent serial l/F card

32KB intelligent parallel l/F card

Local Talk l/F card

32KB IEEE-488 l/F card

Coax l/F card

Twinax l/F card

Ethernet l/F card

!

I

C80673*

C80674*

C80032*

#831 O

C82305* / C82306*

C82307* / C82308*

C8231O*/C82311•

C82312*

C82313*

C82314*

C82315*

C82331•

* The number represented by an asterisk varies, depending on the country.

Note: Roll paper is not available on all models and not available in the U.S.

I

Rev.A

1-3

Product Description

1.2 Hardware Specifications

This

section provides detailed hardware specifications for the

1.2.1 Printing Method

.

l?rintig

method

. Color

. Number of pins

. Pin arrangement

●

print

Pin diameter

Impact dot matrix

Black

24

pins

12x 2 staggered

0.2 mm (0.0079 inch)

f)=108°*

LQ-2070

Servioe

LQ-2070.

0.2° . ~1I18O')

Manual

3.246mm

(23/180”)

‘:~9Tf

v

0,423

J<!

+

+

b

0,,5

T

T

+

4

mm(l160’) \

1=

#7

#9

#l 1

$13

#l?

#19

#21

#23

>

~

I

>

;

I

I

I

1

I

I

!/

r

1-

~’~gd’re”’on

#2

#4

T

7

#6

+

*

#8

b

#lo

b

#12

#16

T

#18

9

$20

+

+

#22

-l

Figure 1-2. Pin Configuration

—

1

0.141mm

(1/180’)

Head center

$k

The figure above shows the configuration of pins on the paper .

.

Print

direction

Bidirectional, with logic seeking for text, and unidirectional for

graphics. (Bidirectional printing of graphics can be selected with a

printer setting or software command.)

1-4

Rev.A

LQ-2070

Service Manual

1.2.2 Printing Specifications

Product Description

●

Copy capability

●

Print

speed

and printable

Print

Mode

High-speed draft

Draft

Draft condensed

LQ

1 original+ 3copies

columns

Table 1-4 Print Speed and Printable Columns

Character Pitch Printable Columns

Normal

cpi 136

10

10

12

15

17

20

10

12

15

cpi

cpi

cpi

cpi

cpi

cpi

cpi

cpi

136

163

204

233

272

136

163

204

Print Speed

copy

300

275

330 220

413

236

275

92

110

138

(cps)

244

183

275

157

183

61

73

92

LQ Condensed

. Resolution

Print Mode

High-speed draft

Draft condensed

8 pin bit image

24 pin bit image

.

17

cpi

cpi

20

Table 1-5 Print Resolution

Horizontal Density

90

Draft 120

240

LQ

60,80, 90, or 120

60,90, 120, or 180

360

120 or 240

360

dpi

dpi

dpi

dpi

dpi

dpi

233

272

157

183 122

Vertical Density Adjacent Dot Printed?

180

dpi

dpi

180

180

180

60

60

180

180

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

No

No

No

No

Yes

No

Yes

No

105

Raster graphics

●

Acoustic noise

Rev.A

180 or 360

51

dB

dpi

(A), 1S0 7779 pattern

180 or 360

dpi

Yes

1-5

Product Description

1.2.3 Paper Handling Specifications

●

Feeding method

Friction feed

Push tractor feed

Push and pull tractor feed

LQ-2070 Service Manual

(front, rear)

(front, rear)

(front, rear, bottom)

. Feeder

. Paper path

●

Line spacing

●

Feed speed

. Release lever

Lever

Position

Friction

Table 1-6 Paper Path and Paper Types

Paper Entrance

Front

insedion

Rear insertion

CSF

bin 1 OK

Front push

tractor(option),

mar push tractor,

CSFbin

1 /bin 2 (Option)

Pull tractor (Option) and roll paper holder (Option)

Manual insertion

CSF

Tractor

1/6 inch or progr

amrnable

Front or rear in, top out

Rear in, top out

Front, rear, or bottom in, top out

in increments of 1/360 inch.

1/6 inch feed 45 msec

Continuous feed 0.127 m /see ( 5.0 inches/see)

Set the release lever, using the following table.

Paper Types

Single Sheet Labels

OK

OK

NO

NO

NO

Card Stock

Envelopes

OK% OK

OK OK

OK OK

I

Multipart

Roll Paper

NO

NO

NO

CSF

bin 2

Roll paper holder

Rear

tractor

Front

tractor

Full

release

%

This symbol after “OK” means you need to check the paper type before using it with this paper

Push

Push-pull OK

Push

Push-pull OK

Pull (front bottom)

Pull (rear)

OK

NO

OK

OK

OK

OK

NO

NO

OK%

OK%

OK%

OK%

OK

OK

NO

NO

NO

NO

NO

NO

NO

X

NO

NO

NO

OK

OK

OK

OK

OK

OK

path.

NO

OK

NO

NO

NO

NO

NO

NO

1-s

Rev.A

LQ-2070

Service Manual

Product Description

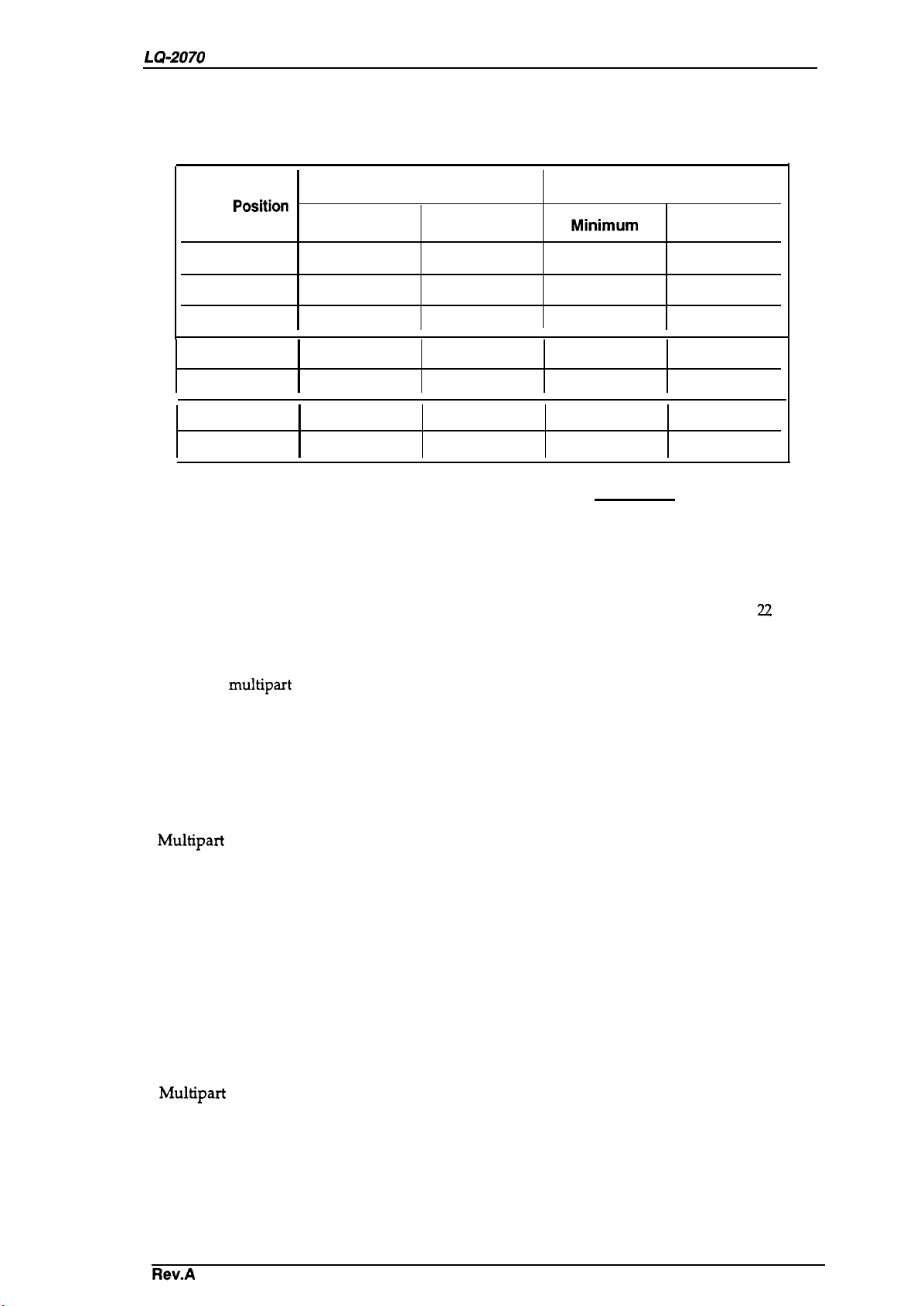

. Paper thickness lever

Table 1-7 Paper Thickness Lever Positions

Lever

Position

o

1

2

3

4

5

6

—–-——— Precautions for Handling Paper

1. Friction feed

Set the paper thickness lever to the appropriate position, as

indicated in the following table.

Paper Thickness ( inches)

Minimum

0.0024

0.0047

0.0075

0.0102

0.0126

0.0142

0.0157

Maximum

0.0047

0.0075

0.0102

0.0126

0.0142

0.0157

0.0205

Paper Thickness (mm)

Minimum

0.065

0.12

0.19

0.26

0.32

0.36

0.40

Maximum

0.12

0.19

0.26

0.32

0.36

0.40

0.52

. Set the release lever to the FRICTION position and install the paper eject assembly

●

Load paper from the front or top entrance.

●

Do not use continuous paper.

. Do not perform any reverse paper feeds within the top 8.5 mm (0.33 inch) and bottom

22

mm

(0.87 inch) area.

. Do not perform reverse feeds greater than 1/6 inch after the paper endhasbeen detected.

● Use the paper-tension unit.

●

Insert the

2.

Push tractor feed

multipart

cut sheet forms only from the front.

. Set the release lever to the REAR PUSH/FRONT PUSH position and install the paper eject

assembly.

●

Load paper from the rear or front entrance.

●

Release the friction feed mechanism.

.

Multipart

● Use the paper-tension unit.

paper must be carbonless.

. Do not perform reverse feeds greater than 1/6 inch.

. Do not perform reverse feeds after the paper end has been detected, because accuracy of

paper feeding cannot be assured.

3.

Pull tractor feed

. Set the release lever to the PULL position.

●

Load paper from the front, rear, or bottom entrance.

(The front or bottom entrance is recommended for thick paper or labels.)

●

Remove the paper eject assembly and attach the pull tractor unit.

. Insert paper from either from the front or bottom.

.

Multipart

paper must be carbonless.

. Do not perform reverse feeds.

Rev.A

1-7

Product Description

4.

Push-pull tractor feed

●

Set the

release lever to the REAR PUSH/FRONT PUSH position.

●

Load paper from the front or rear entrance.

●

Remove the paper eject assembly and attach the pull tractor unit.

●

Remove any slack in the paper between the platen and pull tractor.

LQ-2070 Service Manual

. Precisely adjust the horizontal position of the pull tractor and push tractor.

.

Multipart

paper mustbe carbonless.

. Do not perform reverse feeds greater than 1/6 inch.

. Do not perform reverse feeds after the paper end has been detected.

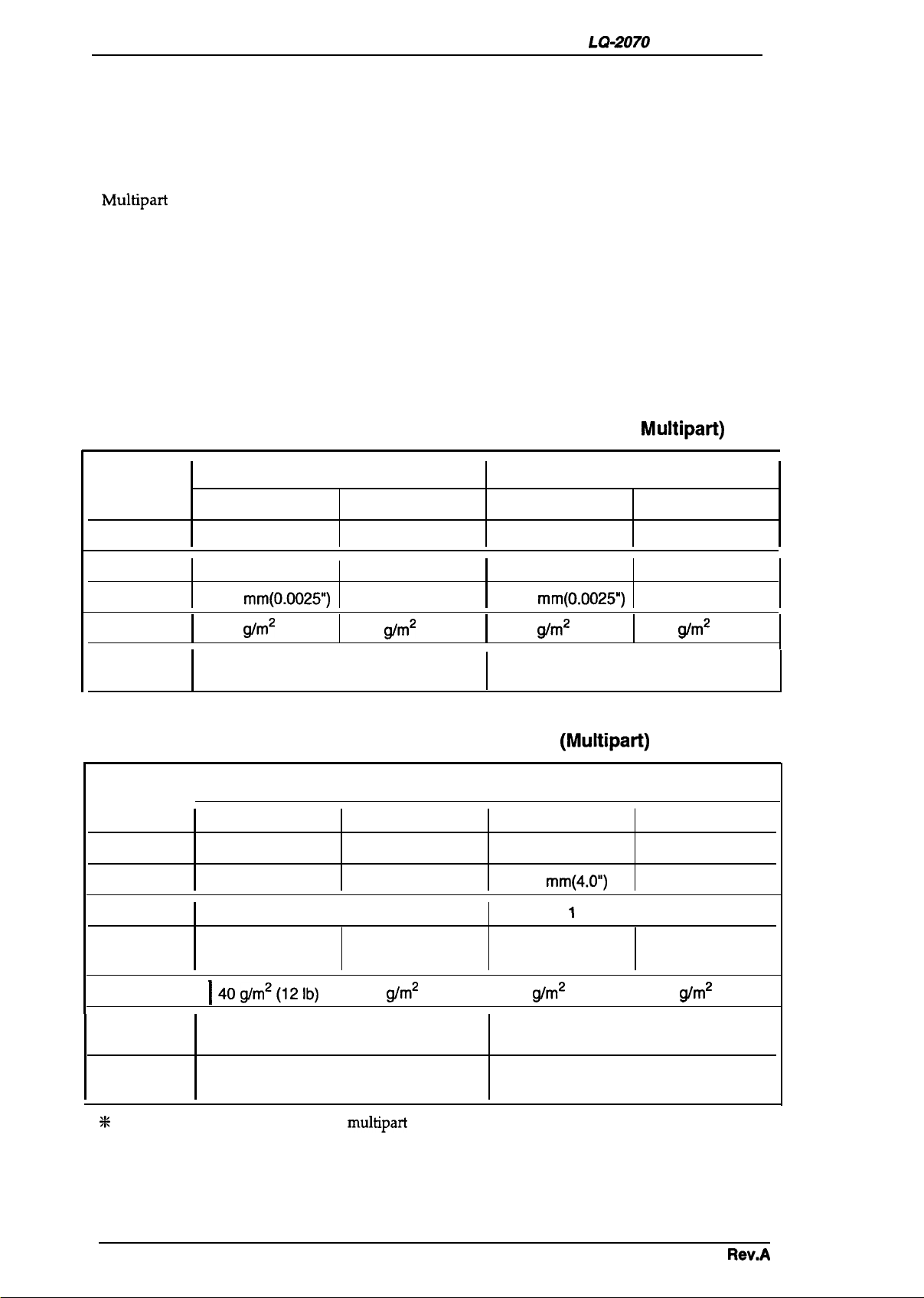

1.2.4 Paper Specifications

This

section describes the printable area and types of paper that can be used in this printer.

Cut Sheets

●

Paper/ media specifications

The following table shows specifications for cut sheets.

Table 1-8 Specifications for Cut Sheets (Single Sheet, Not Multipart)

Rear Entry

(14 lb)

Width

Length

Thickness

Weight 52.3

Quality

101 mm (4.0”) 420 mm (1 6.5”) 101 mm (4.0”)

147 mm (5.8”) 420 mm (16.5”)

0.065

I I

Plain paper, recycled paper.

Not curled, not folded, or not crumpled.

Front Entry

Minimum

mm(O.0025”)

g/m2

(14 lb)

Maximum

0.14 mm (0.0055”)

90

g/m2

(24 lb) 52.3

Minimum

101 mm (4.0”)

0.065

mm(O.0025”)

g/m2

Plain paper, recycled paper.

Not curled, not folded, or not crumpled.

Table 1-9 Specifications for Cut Sheets (Multipart)

I

Front Entry

I

Rear Entry

Maximum

420 mm (16.5”)

420 mm (16.5”)

0.14 mm (0.0055”)

g/m2

90

(24 lb)

Minimum Maximum Minimum Maximum

Width 101 mm (4.0”) 420 mm (1 6.5”)

Length 147 mm (5.8”)

Copies

Total

thickness

Weight% I 40g/m2(121b)

Quality

Binding

%

This weight is for one sheet of the

0.12 mm (0.0047”)

Plain paper, recycled paper.

Not curled, not folded, or not crumpled.

A line of glue at the top or one side of the

form.

1 original+ 3 copies

420 mm (16.5”)

0.32 mm (0.013”)

58

g/m2

I

multipart

(15 lb)

form.

1-8

101 mm (4.0”) 420 mm (16.5”)

101

mm(4.0”)

1

original+ 3 copies

0.12 mm (0.0047”)

40

g/m2

I

Plain paper, recycled paper.

Not curled, not folded, or not crumpled.

A line of glue at the top of the form.

(12 lb)

420 mm (16.5”)

0.32 mm (0.013”)

58

g/m2

I

(15 lb)

Rev.A

LC?-2070

●

Printable area

Service Manual

Product Description

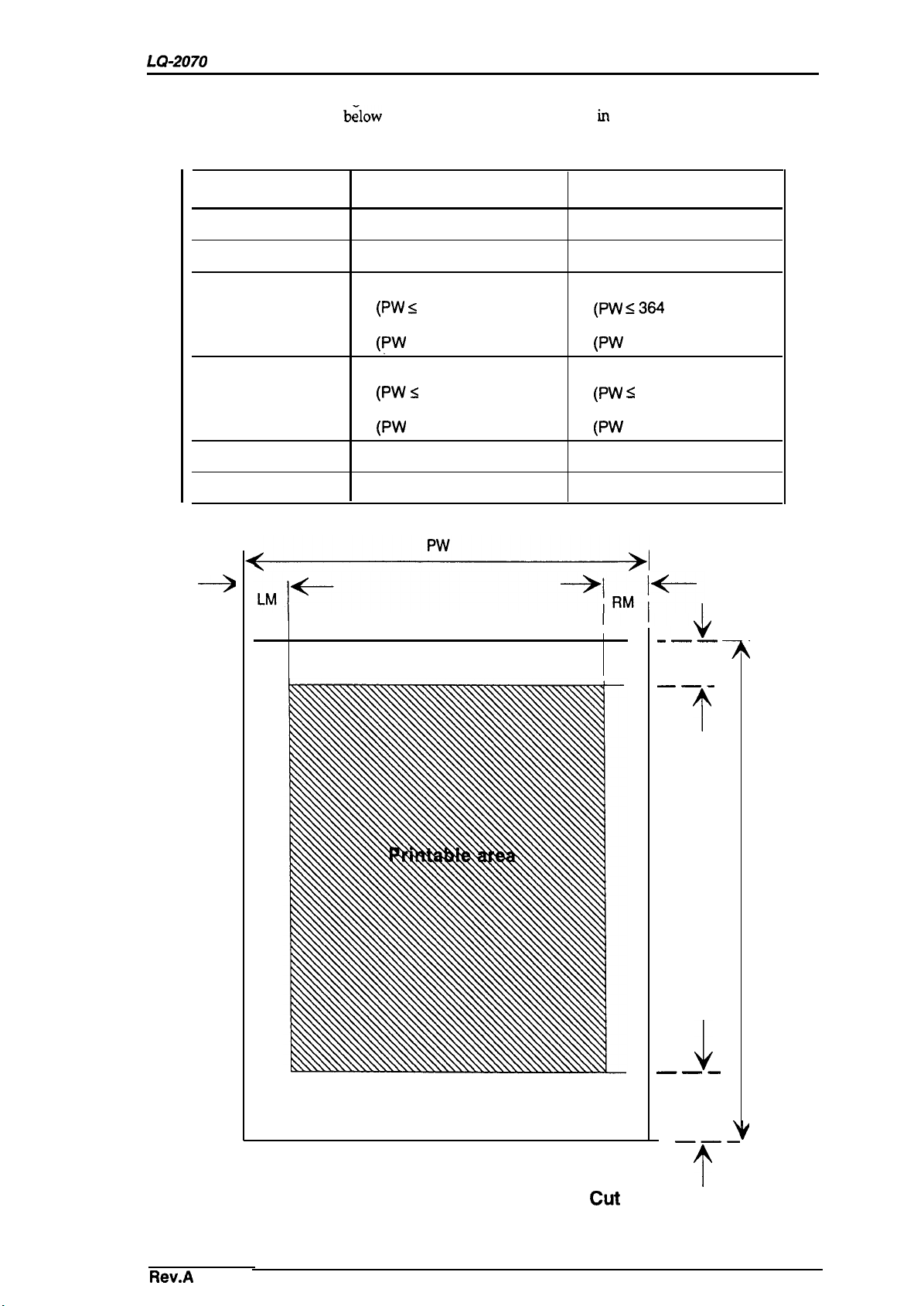

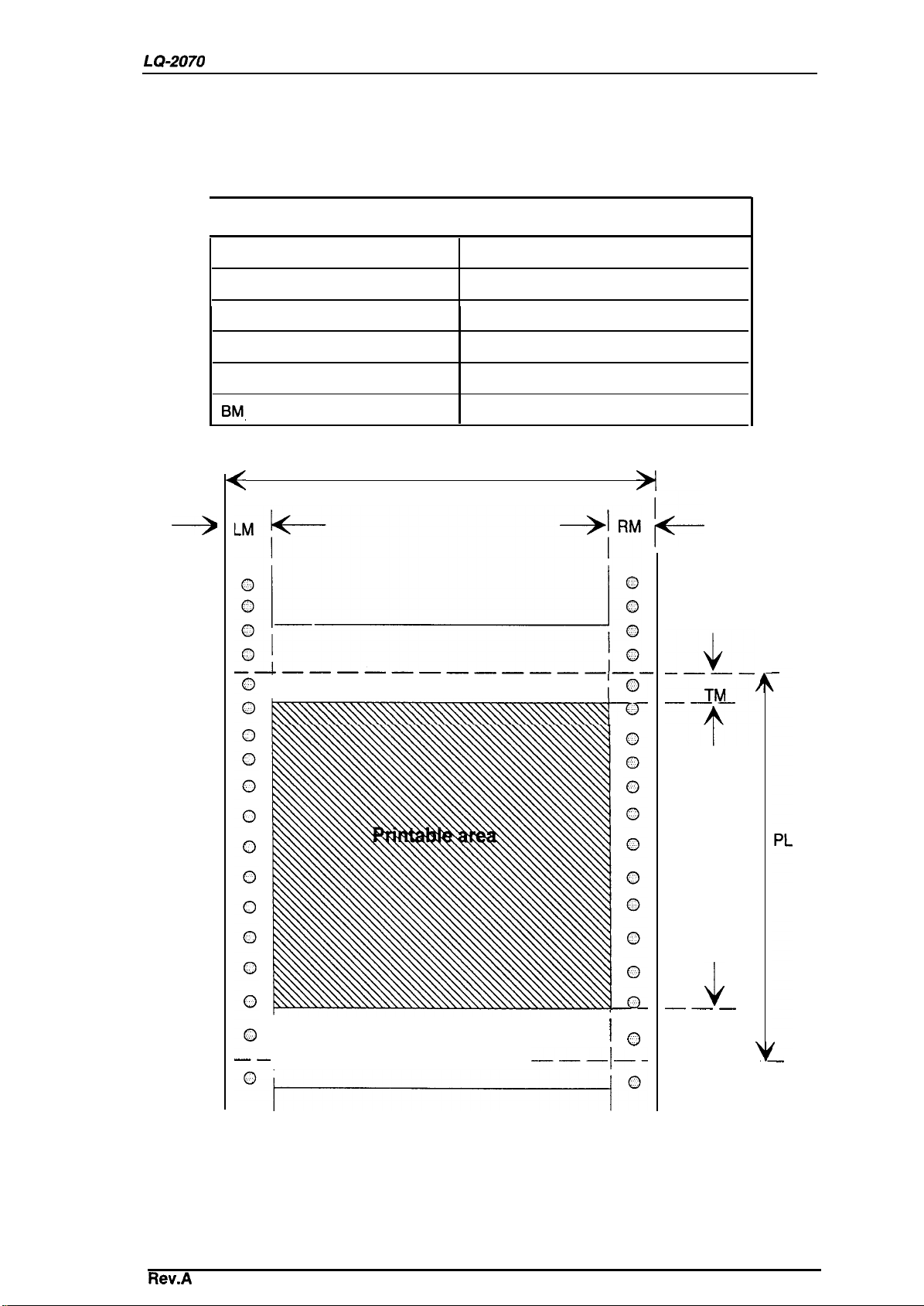

Figure 1-3 shows the printable area for cut sheets. The table

b;low

defines the abbreviations used in the figure.

Table 1-10 Printable Area for Cut Sheets

Abbreviations Single Sheet

PW (width)

PL (length)

LM (left margin) 3 mm (0.12”) or more

RM (right margin)

TM (top margin)

BM (bottom margin) 4.2 mm (0.17”) or more

Refer to Table 1-8.

Refer to Table 1-8.

(PW ~

364

mm (14.33”)) (PW <364

25 mm

(PW

3 mm or more 3 mm or more

(PWs

25 mm (0.98”) or more 25 mm (0.98”) or more

(PW = 420 mm (16.5”))

(0.98”)

= 420 mm (16.5”)) (PW

364 mm (14.33”))

4.2 mm (0.17”) or more

or more

I

Multipart

Refer to Table 1-9.

Refer to Table 1-9.

3 mm (0.1

25 mm (0.98”) or more

(PW S

(PW

4.2 mm (0.17”) or more

4.2 mm (0.1 7“) or more

2“)

or more

mm (14.33”))

= 420 mm (16.5”))

364 mm (14.33”))

= 420 mm (16.5”))

———

7

TM

——-

?

J

———

BM

—

———

PL

t

}

—

Rev.A

Figure 1-3 Printable Area for

cut

Sheets ‘

?

1-9

Product Description

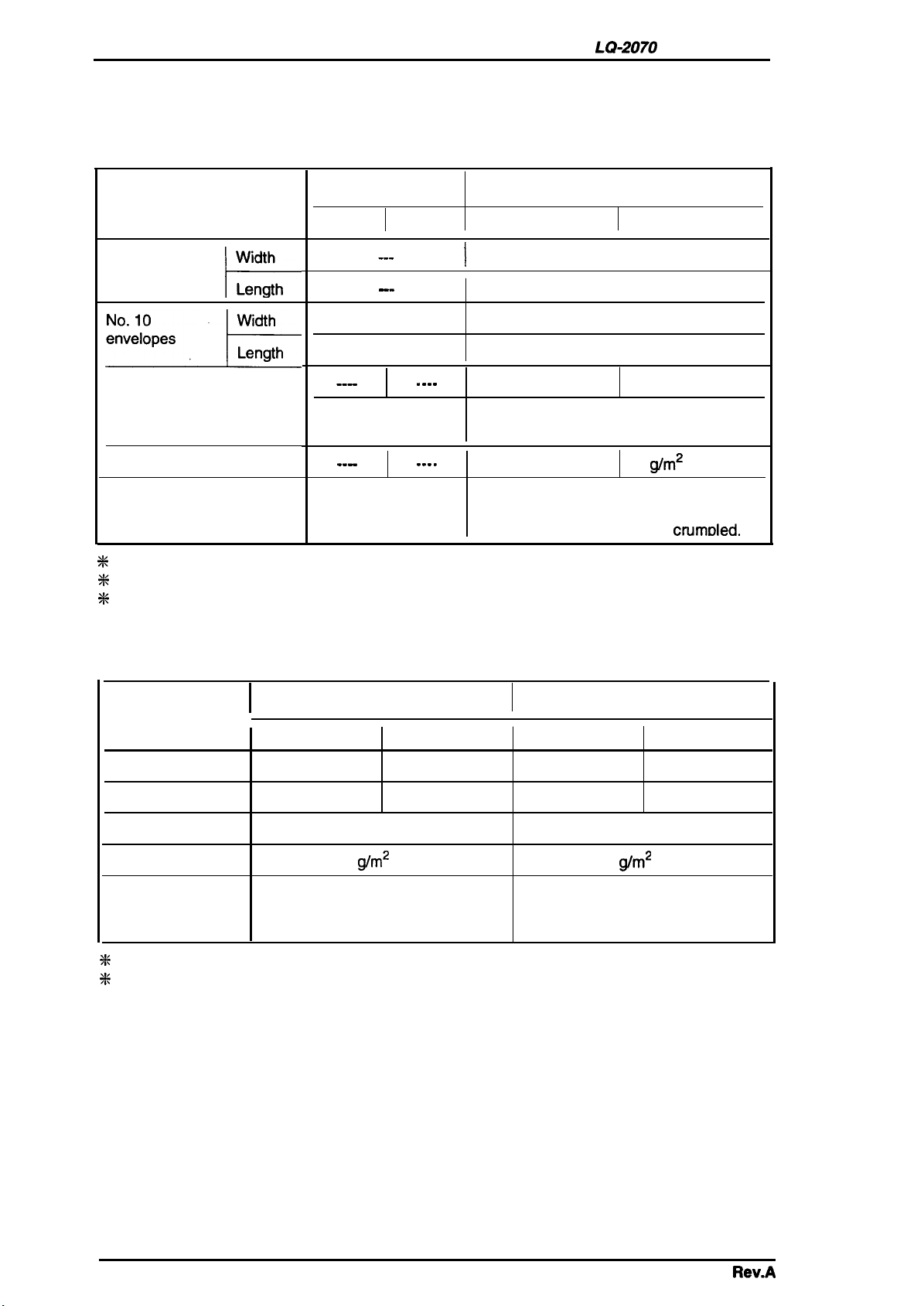

Envelopes and Card Stock

LQ-2070 Service Manual

●

Paper/media specifications

The following tables gives specifications for envelopes and card stock.

Table 1-11 Specifications for Envelopes

Front Entry

Minimum

No. 6

envelopes

Width

Length

*

Minimum

Maximum

---

--

I

---

!!5L_E&

..-

Total thickness

Weight

Quality

%

Printing on envelopes is available only at normal temperatures and humidity.

%

Insert envelopes from the rear entrance only.

---

---

X Insert the longer side of the envelope horizontally.

.-.

. . . .

. . . .

. . . .

0.16

mm (0.0063”)

Differences in thickness in the printable

area must be within 0.25 mm

45g/m2(12

Bond paper, plain paper, or airmail.

No glue at the flap.

Not curled. not folded. or not

Rear Entry

166 mm

(6.5”)

92 mm (3.6”)

240

mm (9.5”)

104 mm (4.1”)

0.52 mm (0.020”)

lb)

91

Maximum

g/m2

(0.0098”).

(24 lb)

C~MDled.

Table 1-12 Specifications for Card Stock

Front Entry

Minimum

Width

Length

Thickness

Weight

Quality Plain paper, recycled paper.

%

Printing on card stock is available only at normal temperatures and humidity.

*

When the longer side of an A6 card is to be inserted horizontally, insert it from the rear entrance.

105 mm (4.13”)

148 mm (5.83”) 148 mm (5.83”)

0.22 mm (0.0087”)

192

g/m2

Not curled, not folded, or not

crumpled.

Maximum

148 mm

(51 lb)

(5.83”)

Minimum

mm (4.1 3“)

105

105 mm (4.13”) 148 mm (5.83”)

Plain paper, recycled paper.

Not curled, not folded, or not

crumpled.

Rear Entry

Maximum

148 mm (5.83”)

0.22 mm (0.0087”)

g/m2

192

(51 lb)

1-1o

Rev.A

LQ-2070 Service Manual

Product Description

●

Printable area

Table 1-13 Printable Area for Envelopes and Card Stock

Abbreviations

PW (width)

PL (length)

LM (left margin)

RM (right margin)

TM (top margin)

BM (bottom margin) .

t

\

-%

\\

The figure below shows the printable area for envelopes and card stock.

Each

~bbreviation

is defined-in the following table.

Envelopes

Refer to Table 1-11.

Refer to Table 1-11.

3 mm (0.1 2“) or more

3 mm (0.12”) or more

4.2 mm (0.17”) or more

4.2

mm (0.17”) or more

Pw

Refer to Table 1-12.

Refer to Table 1-12.

3 mm (0.12”) or more

3 mm (0.12”) or more

4.2 mm (0.17”) or more

4.2 mm (0.1

>1

-

Card Stock

7“)

or more

-–w-

I

TM ‘

———

‘>;

K

LM

,

I

~–

I

Pw

,

–>i RMk+

I

-–#-

>1 ‘

,

.—J—

TM

———

———

BM

.———

?

+

+

Rev.A

+

Figure 1-4 Printable Area for Envelopes and Card Stock

1-11

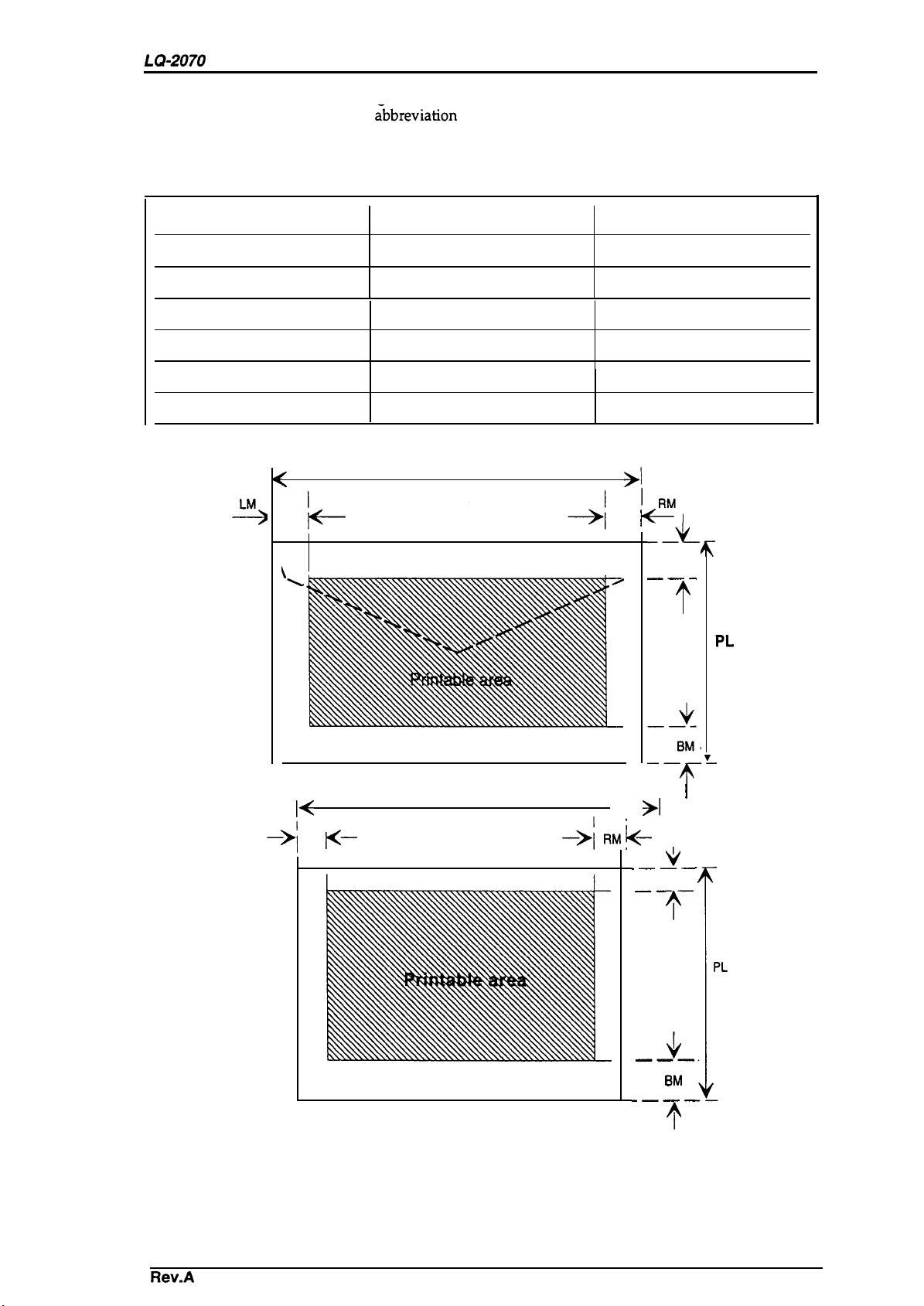

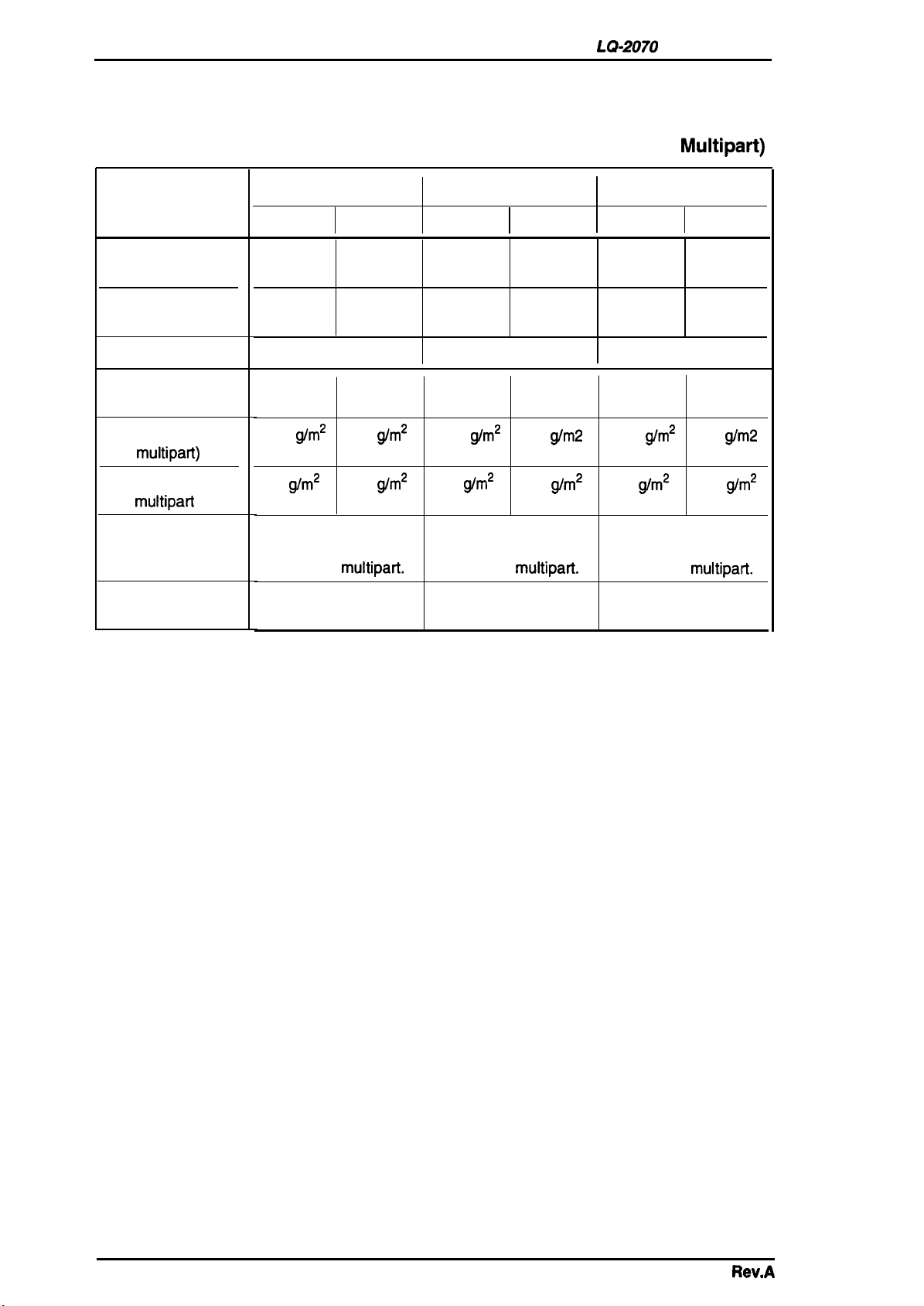

Product Description

Continuous Paper

LQ-2070 Service Manual

●

Paper/media specifications

The following table gives specifications continuous paper.

Table 1-14 Specifications for Continuous Paper (Single Sheet and

Rear Entry Bottom Entry

Minimum

(4.0”)

101 mm

(4.0”)

Maximum

(16”) (4.0”)

559 mm 101 mm

(22”) (4.0”)

Minimum

1 original + 3

0.065 mm

52.3

g/m2

(14 lb)

40

g/m2

(12 lb)

Recycled paper.

Carbonless

0.32 mm

(0.013”)

82

g/m2

0.065 mm

(0.0025”)

52.3

g/m2

(22 lb) (14 lb) (22 lb)

58

g/m2

(15 lb) (12 lb) (15 lb)

multipart.

40

g/m2

Plain paper.

Recycled paper.

Carbonless

Width

Length

Copies

Total thickness

Weight

multipart)

(not

Weight (one sheet

multipart

of a

Types of paper

form)

Front Entry

Minimum Maximum

101 mm

406 mm 101 mm 406 mm 101 mm

(4.0”) (16”)

101

mm

559

mm

(4.0”) (22”)

1 original + 3 copies 1 original+ 3 copies

0.065

mm

(0.0025”)

52.3

g/m2

(14 lb)

40

g/m2

(12 lb)

Plain paper. Plain paper.

Recycled paper.

Carbonless

0.32 mm

(0.013”) (0.0025”)

82

g/m2

(22 lb)

58

g/m2

(15

lb)

multipart.

Multipart)

Maximum

406 mm

(16”)

559 mm

(22”)

copies

0.32

mm

(0.013”)

82

g/m2

58

g/m2

multipart.

Binding

Dots of glue or paper

staples (both sides).

Dots of glue or paper

staples (both sides).

Dots of glue or paper

staples (both sides).

1-12

Rev.A

LQ-2070

Service Manual

Product Description

●

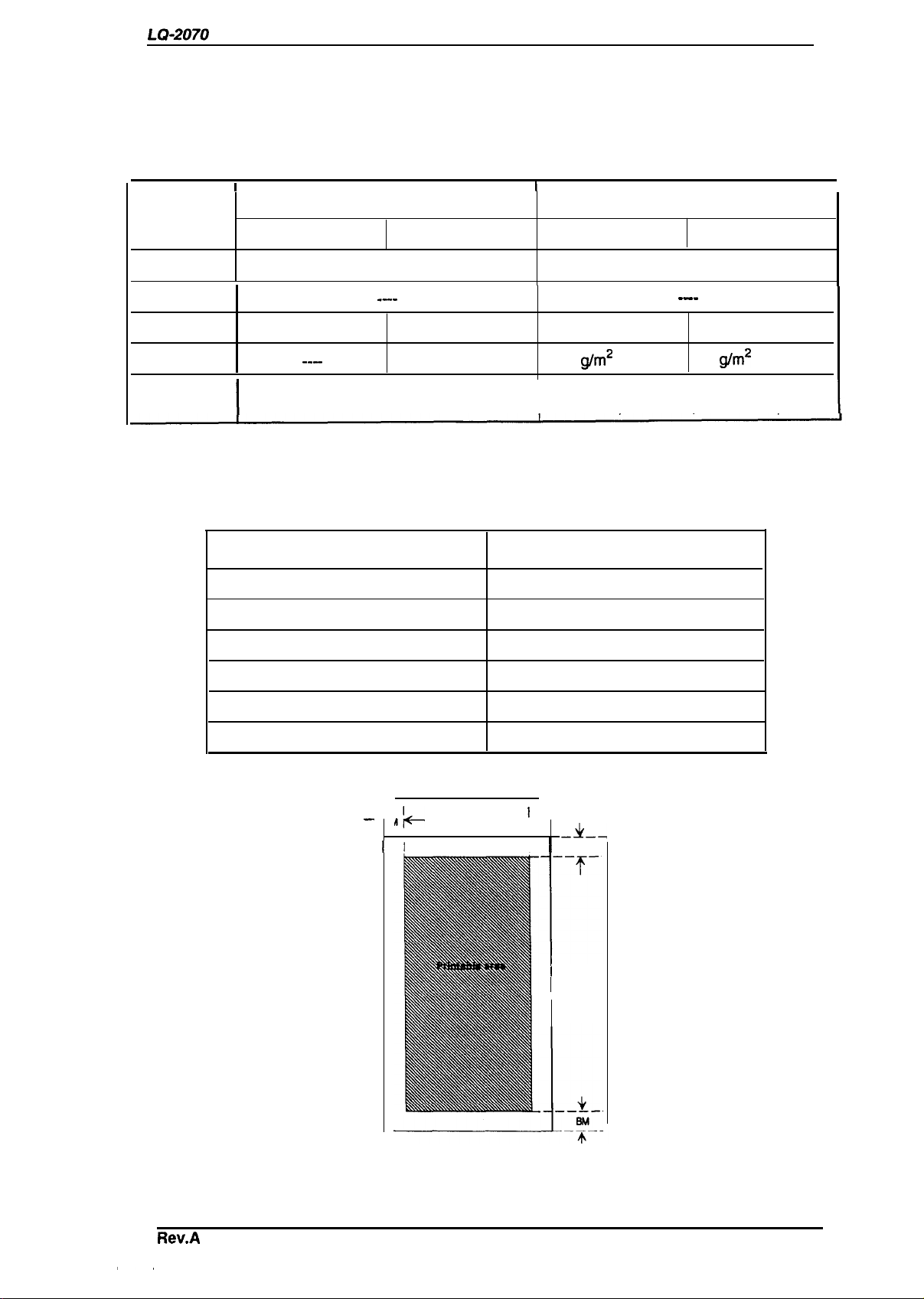

Printable area

I

PW (width)

PL (length)

LM (left margin)

RM (right margin)

TM (top margin) 4.2 mm (0.17”) or more

BM,

The figure below shows the printable area for continuous paper.

Each abbreviation is defined in the following table.

Table 1-15 Printable Area for Continuous Paper

Abbreviations

(bottom margin) 4.2 mm (0.1

<

I

Pw

Continuous Paper

Refer to Table 1-14.

Refer to Table 1-14.

13 mm (0.51”) or more

13 mm (0.51”) or more

7“)

or more

I

I

I

t –––––––––

–––l–-

4

———

I

0

—

BM

)

—

T

Rev.A

Figure 1-5 Printable Area for Continuous Paper

1-13

Product Description

Continuous Paper with Labels

LQ-2070 Service Manuai

●

Paper/media specifications

The following table gives the specifications for continuous paper with

labels.

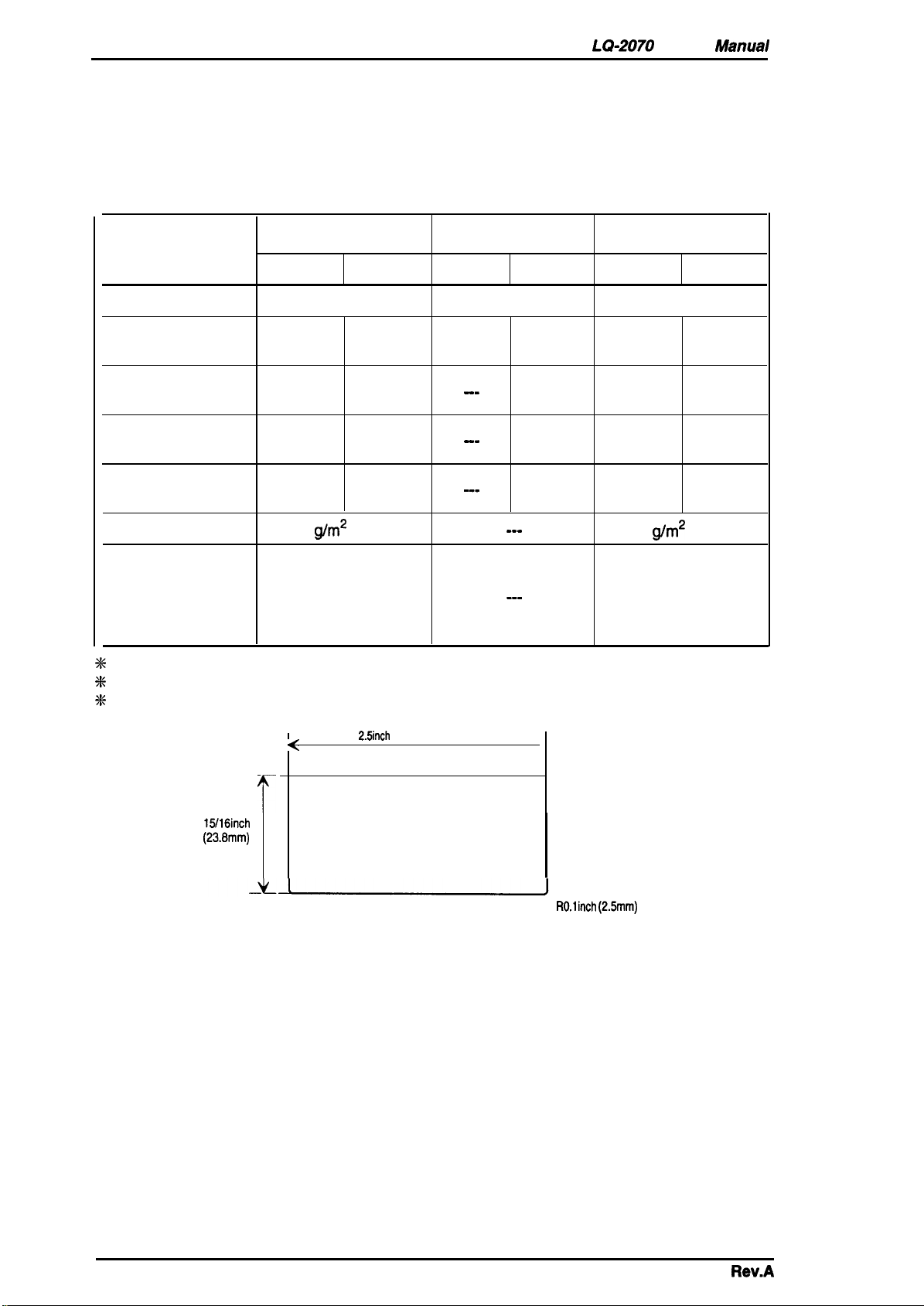

Table 1-16 Specifications for Continuous Paper with Labels

Front Entry

Minimum Maximum

Label size See the figure below

Base sheet width

Base sheet length

(one page)

Base sheet thickness 0.07 mm

Total thickness

Label weight

Quality

101 mm 406 mm

(4.0”) (16”)

101

mm

559 mm 101 mm

(4.0”) (22”)

0.09

g/m2

(0.0035)

0.19 mm

(0.0075”)

(17 lb)

(0,0028”)

0.16 mm

(0.0063”)

68

. A very continuous

form labels

. A very mini-line or

equivalent quality

labels

mm

Rear Entry Bottom Entry

Minimum Maximum Minimum

--

---

. . .

See the figure below

101

mm

(4.0”) (16”)

-..

.-.

--

‘

--

‘

--

‘

(4.0”) (22”)

0.07 mm

(0.0028”) (0.0035”)

0.16 mm 0.19 mm

(0.0063”) (0.0075”)

68

g/m2

. Avery continuous

form labels

. Avery mini-line or

equivalent quality

labels

‘-

‘-

‘--

Maximum

406

mm

559 mm

0.09 mm

(17 lb)

%

Printing on labels is available only at normal temperatures and humidity.

*

The base sheet for the labels must be continuous paper.

%

Continuous paper with labels should be inserted from the front or bottom entrance.

2.5inch

<

—

T

15/16inch

(23.6mm)

min.

(63.5mm) min.

Label

>

RO.linch (2.5mm)

min.

Figure 1-6 Label Size

. Printable size and area

The figure above is the printable size for the labels.

The printable area for the base sheet containing the labels

depends on conditions in Figure 1-5 and Table

-

1-15.

1-14

Rev.A

Lt2-2070

Service Manual

Product Description

Roll Paper

Note: Roll paper is not available in all models, and not available in the U.S.

. Paper/media specifications

Table 1-17 Specifications for Roll Paper

I

Minimum

Width

Length

Thickness

Weight

Quality

●

Printable area

I

---

..-

Table 1-18 Printable Area for Roll Paper

Abbreviations

The following table shows specifications for roll paper.

Front Entry

---

.-.

---

Maximum

---

---

I

Minimum

0.07 mm

52.3

g/m2

Plain paper, recycled paper.

Not curled. not folded, or not crumpled.

Rear Entry

216

(0.0028”)

(14 lb)

mm

.-.

(8.5”)

0.09

82

g/m2

Figure 1-7 gives the printable area for roll paper.

Each abbreviation is defined in the following table.

Roll Paper

Maximum

mm

(0.0035”)

(22 lb)

I

PW (width)

PL (length)

LM

RM

TM 4.2 mm (0.17”) or more

BM

—

&

II

See Table 1-17.

See Table 1-17.

3 mm (0.12”) or more

3

mm

(0.12”) or more

4.2 mm (0.17”) or more

Pw

I

I

1

TM

1

-L-

PL

Figure 1-7 Printable Area for Roll Paper

Rev.A

,,

1-15

Product Description

1.2.5 Ribbon Specifications

Table 1-19 Statistics on the Ribbon

LQ-2070 Service Manuai

Specification

cpi, 48dotcJ

character)

Type

Color

Ribbon life

Dimension

Item

Fabric

Black

8 million characters (draft, 10

506.0 mm (W) x 123.5 mm (D) x 23.0 mm (H)

19.92”

(W)

X

4.86” (D) X .91 “ (H)

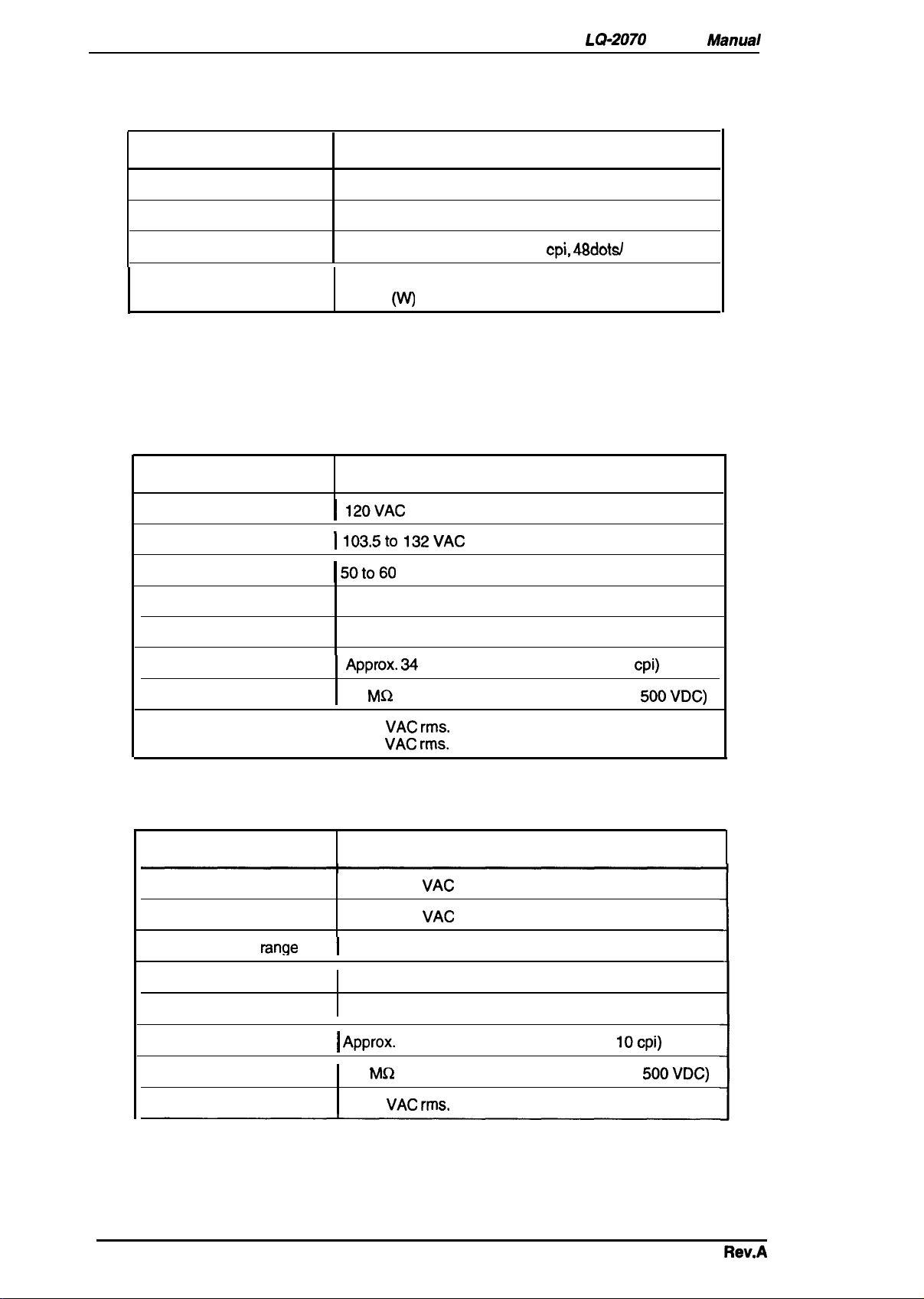

1.2.6 Electrical Specifications

Tables 1-20 and 1-21 provide statistics on electrical ratings and consumption.

Table 1-20 Electrical Specifications for the 120 V Version

Item

Rated voltage

Input voltage range

Rated frequency range

I

120VAC

I

103.5to 132VAC

I 50t060

Hz

Specifications

Input frequency range

Rated current

Power consumption Approx. 34

Insulation resistance

Dielectric strength

49.5 to 60.5 Hz

1.0 A (max. 2.4A)

W (self-test in draft mode at 10

10 MQ min. (between AC line and chassis, 500VDC)

1000 VAC

1200

I

VAC

rms.

1 min. or

rms.

1 sec. (between AC line and chassis)

Table 1-21 Electrical Specifications for the 220/240 V Version

Item

Rated voltage

Input voltage range

Rated frequency

Input frequency range

Rated current

Power consumption

range

220 to 240

198 to 264

I

50to 60 Hz

49.5 to 60.5 Hz

0.5 A (maximum 1.2A)

I Approx.

VAC

VAC

34 W (self-test in draft mode at IOcpi)

Specifications

cpi)

1-16

Insulation resistance

Dielectric strength

10 MQ min. (between AC line and chassis, 500VDC)

1500

VAC rms.

1 min. (between AC line and chassis)

Rev.A

LQ-2070

Service Manual

Product Description

1.2.7 Environmental Conditions

Table 1-22 explains the conditions the printer requires during operation and when not operating,

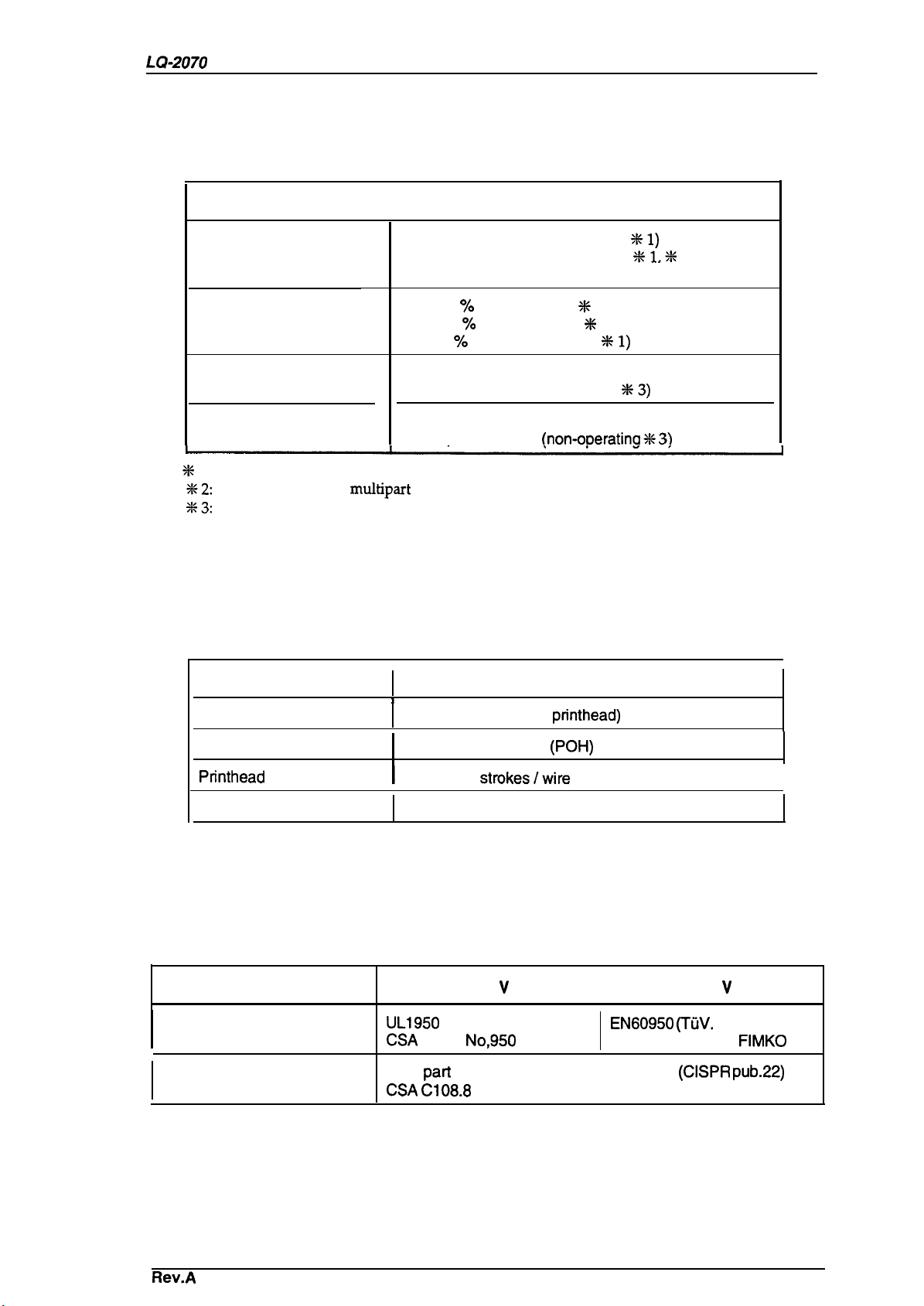

Table 1-22 Environmental Requirements

Item

Temperature

Humidity

Resistance to shack

Resistance to vibration

%

1: Without condensation.

*2:

During printing on

%3:

In shipment container.

multipart

I

5 to 35° C/41 to 95° F ( operating %1)

15to 25° C/59 to 77° F (operating

-30 to 60° C/-22 to 140° F (non-operating)

%

10 to 80

30 to 60

O to 85

1 G, within 1 ms (operating)

2 G, within 2 ms (non-operating %3)

0.25 G, 10 to 55 Hz (operating )

0.50 G, 10 to 55 Hz

RH (operating M 1)

?’o RH (operating

% RH (non-operating %1)

paper, envelopes, card stock, or labels.

Specifications

(non-oDeratina % 3)

1.2.8 Reliability

Table 1-23 gives maximum life and usage specifications.

Table 1-23 Reliability Statistics

X

1,X 2)

X1,X

2)

Item

Specification

1

Total print volume

MTBF

Printhead

Ribbon life

life

6 million lines (except

6000 power on hours

1

I

200 million strakes/wire

8 million characters

printhead)

(POH)

1.2.9 Safety Approvals

Table 1-24 provides information about the safety approvals the printer has met.

Table 1-24 Safety Information for Printer Models

Safety Standards

EMI

120 v

UL1950

CSA

FCC

CSA CI08.8

with D3

C22.2

N0,950

parl 15 subpart B class B EN55022

with D3

I

EN60950 (TuV.

DEMKO, NEMKO,

class B

230

V

SEMKO,

FIMKO

(CISPR pub.22)

I

)

Rev.A

1-17

Product Description

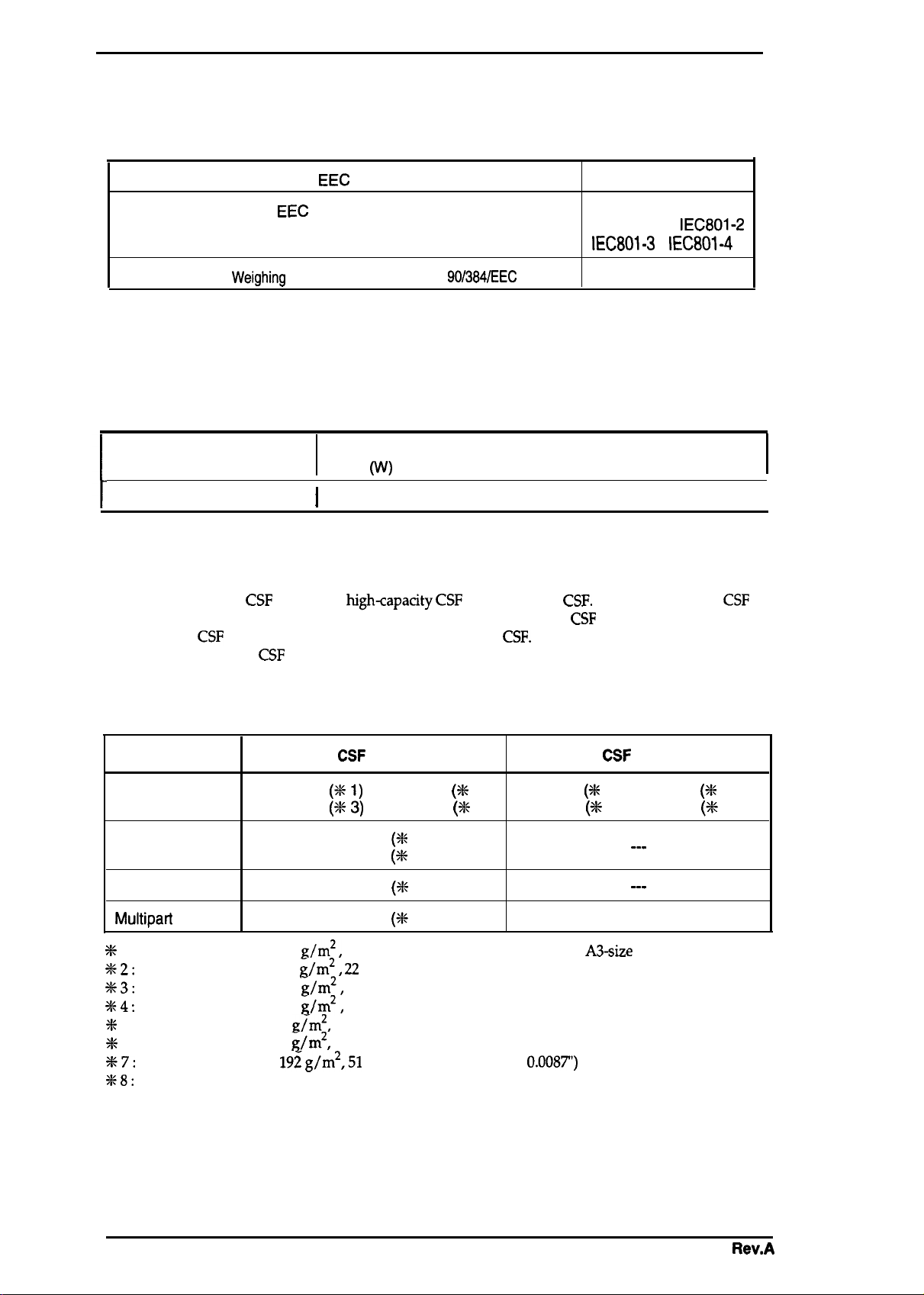

1.2.10 CE Marking

The following table lists CE marking information.

Table 1-25 CE Marking

LQ-2070 Service Manual

Low Voltage Directive 73/23 /

EMC Directive 89/336/

EEC

EEC

EN60950

EN55022 class B

EN50082-1 ,

IEC801-3

Non-Automatic

Weighing

Instruments Directive

90/384/EEC

EN45501

1.2.11 Physical Specifications

Table 1-26 provides printer dimensions and weight.

Table 1-26 Physical Specifications

Dimensions

Weight

639 mm (W) x402 mm (D) x 257 mm (H)

25.16”

(W)

X

16.14” (D) X 10.12” (H)

I

Approx. 13 kg (28.66 lb)

1.2.12 Cut Sheet Feeder Specifications

This printer has two

has special a paper-feed motor to load the paper quickly. The 2nd bin

high-capacity

CSF

specifications for these

CSF

options: a

to allow them to be used as a double bin

CSF

options.

high-capaaty CSF

and a 2nd bin

CSF.

CSF.

The high-capacity

CSF

can be connected to the

The following table provides the

IEC801-2

,

IEC801-4

I

CSF

. Hopper capacity

Table 1-27 Hopper Capacity

CSF

Bin 1

Single sheets

Envelopes

Card stock

Multipart

%

1 : Plain paper (weight: 82

%2:

%3:

*4:

paper

Plain paper (weight: 82

Plain paper (weight: 64

Plain paper (weight: 64

X 5 : Envelopes (weight: 91

~

6: Envelopes (weight: 45

%7:

Card stock (weight:

3+8:

1 original+ 5 copies (thickness: 0.36 mm, 0.0142”)

150 sheets (%1) / 110 sheets (% 2)

185 sheets (%3) / 135 sheets (% 4)

25 sheets (X 5)

(%

30 sheets

50 sheets (% 7)

40 sheets

g/m2,

22 lb) or recycled paper, except for

g/m2, 22

g/m2,

17 lb), except for A3 paper.

g/m2,

17 lb), A3 paper.

g/m2,

24 lb)

g/m2,

12 lb)

192g/m2,51

lb) or recycled paper, A3 paper.

6)

(%

8)

lb; thickness: 0.22 mm,

CSF

Bin 2

50 sheets (~ 1 ) / 50 sheets (% 2)

60 sheets

(~

3) / 60 sheets

-..

-..

---

A3-size

paper.

(3$

4)

O.0087”)

1-18

Rev.A

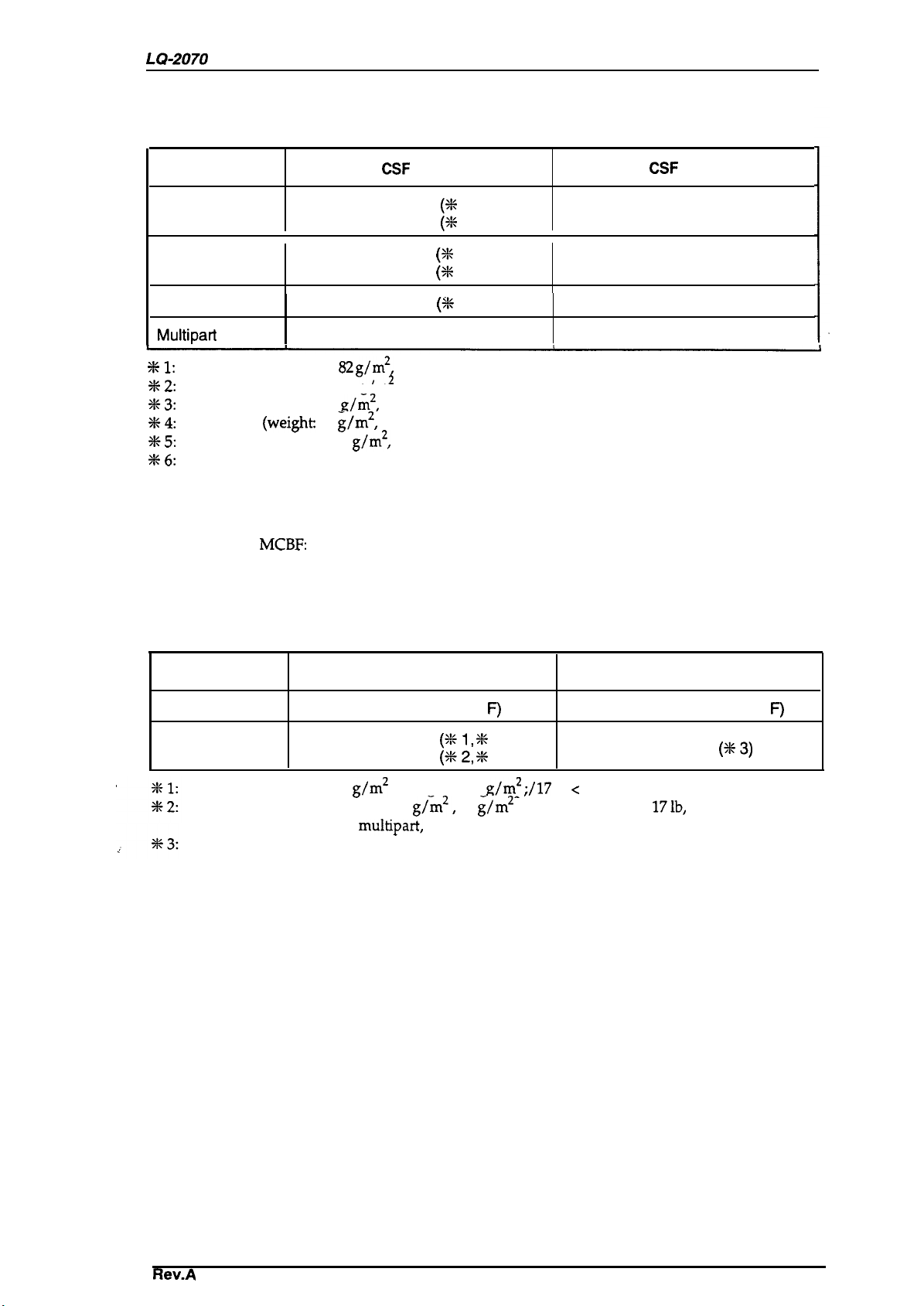

LQ-2070 Service Manual

. Stacker capacity

Table 1-28 Capacity of the Stacker

CSF

Bin 1

Product Description

CSF

Bin 2

Single sheets

Envelopes

Card stock

Multipart

Single sheets (weight: 82

%1:

Single sheets (weight: 82 g/m ,22 lb), A3 paper

*2:

Envelopes (weight: 91

*3:

Envelopes

*4:

Card stock (weight: 192

*5:

1 original+ 5 copies (thickness: 0.36 mm, 0.0142”)

3%6:

(weighti

45

140 sheets

100 sheets

15 sheets

28 sheets

30 sheets (% 5)

36 sheets (3$6)

g/m2i

22 lb), except for A3 paper

g/m2,

24 lb)

g/m2,

12 lb)

g/m2,

51 lb; thickness: 0.22 mm, 0.0087”)

(+$

(~

(%

(%

1)

2)

3)

4)

. Reliability

MCBF:

2 x 105 cycles

. Environmental conditions

Table 1-29 Environmental Conditions

----

----

---... -

Temperature

Humidity

Single sheets (plain, 64

5 to 35° c (41 to 95°

10 to 80% RH (%1, X 3)

30 to 60% RH

g/m2

Single sheets (plain, weight< 64

Single sheets (recycled),

Without condensation

Operating Non Operating

< weight <82

g/m2,

multipart,

envelopes, and card stock

l=)

(%2, X 3)

g/m2 ;/17

82

g/m2

< weight/weight <

–30 to 60° C (-22 to 140°

O to 85% RH

lb e weight <22 lb)

171b,

22 lb < weight)

F)

(%3)

Rev.A

1-19

Product Description

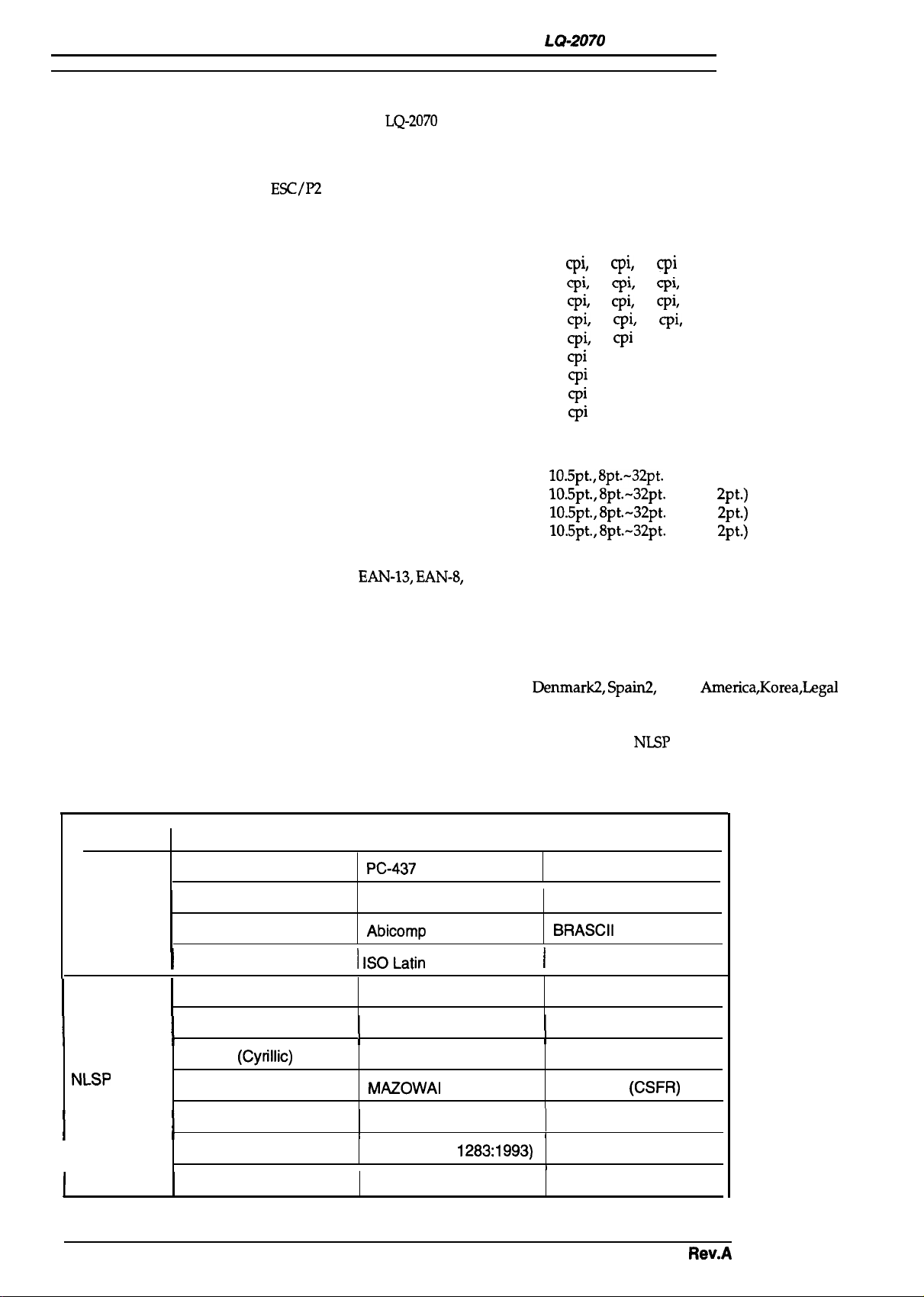

1.3 Firmware Specifications

This

section

1.3.1 Control Codes and Fonts

●

Control codes

provides detailed information about

ESC/P2

and IBM 2390/2391 plus emulations.

LQ-2070

LQ-2070 Service Manual

firmware.

●

Typefaces

●

International character sets

Bitmap fonts

EPSON Draft

EPSON Roman

EPSON Saris Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON OCR-B

EPSON Orator

EPSON Orator-S

EPSON Script C

Scalable font

EPSON Roman

EPSON Saris Serif

EPSON Roman T

EPSON Saris Serif H

Bar code fonts

EAN-13, EAN-8,

Code 128, POSTNET

14 countries

U.S.A., France, Germany, U.K., Denmark 1, Sweden, Italy,

Spain l, Japan, Norway,

10

cpi,

12

cpi,

15

cpi

10

cpi,

12

cpi,

15

cpi,

proportional

10

cpi,

12

cpi,

15

cpi,

proportional

10

cpi,

12

cpi,

15

cpi,

10

cpi,

12

cpi

10

cpi

10

cpi

10

cpi

10

cpi

Proportional

10.5pt., 8pt.-32pt.

10.5pt., 8pt.-32pt.

10.5pt., 8pt.-32pt.

10.5pt., 8pt.-32pt.

(every 2 pt.)

(every

(every

(every

2pt.)

2pt.)

2pt.)

Interleaved 2 of 5, UPC-A, UPC-E, Code 39

Denmark2, Spain2,

Latin

America,Korea,Legal

. Character tables

Version

Standard

Version

I

Roman8

I

NLSP Version

I

I

I

The standard version has 11 character tables and the

character tables, as shown in the following table.

Table 1-30 Character Tables

Italic

PC-860 (Portuguese)

PC-865 (Nordic)

Italic

PC-437 Greek

PC-855

PC-869 (Greek)

ISO 8859-7 (Latin/Greek)

Estonia (Estonia)

PC-866 LAT (Latvia)

(Cynllic)

Character Tables

pC-437

PC-861 (Icelandic)

Abicomp

]

ISOLatin 1

PC- 437

I

PC-852 (East Europe)

I

(U.S., Standard Eur.)

(US, Standard Eur.)

PC-857 (Turkish)

MAZOWAI

(Poland)

ISO Latin IT (Turkish)

I

PC-744(LST

I

PC-864 (Arabic)

1283:1993)

NLSP

PC-850 (Multilingual)

I

PC- 863

BRASCII

I

PC-850 (Multilingual)

I

PC-853 (Turkish)

I

PC-866 (Russian)

Code MJK

Bulgaria (Bulgarian)

d

ISO Latin 2

)

(Canadian-French)

(CSFR)

version has 20

1-20

Rev.A

LQ-2070

Service Manual

Product Description

1.3.2 Interface Specifications

This

printer provides a bidirectional 8-bit parallel interface and a Type B optional interface slot,

standard.

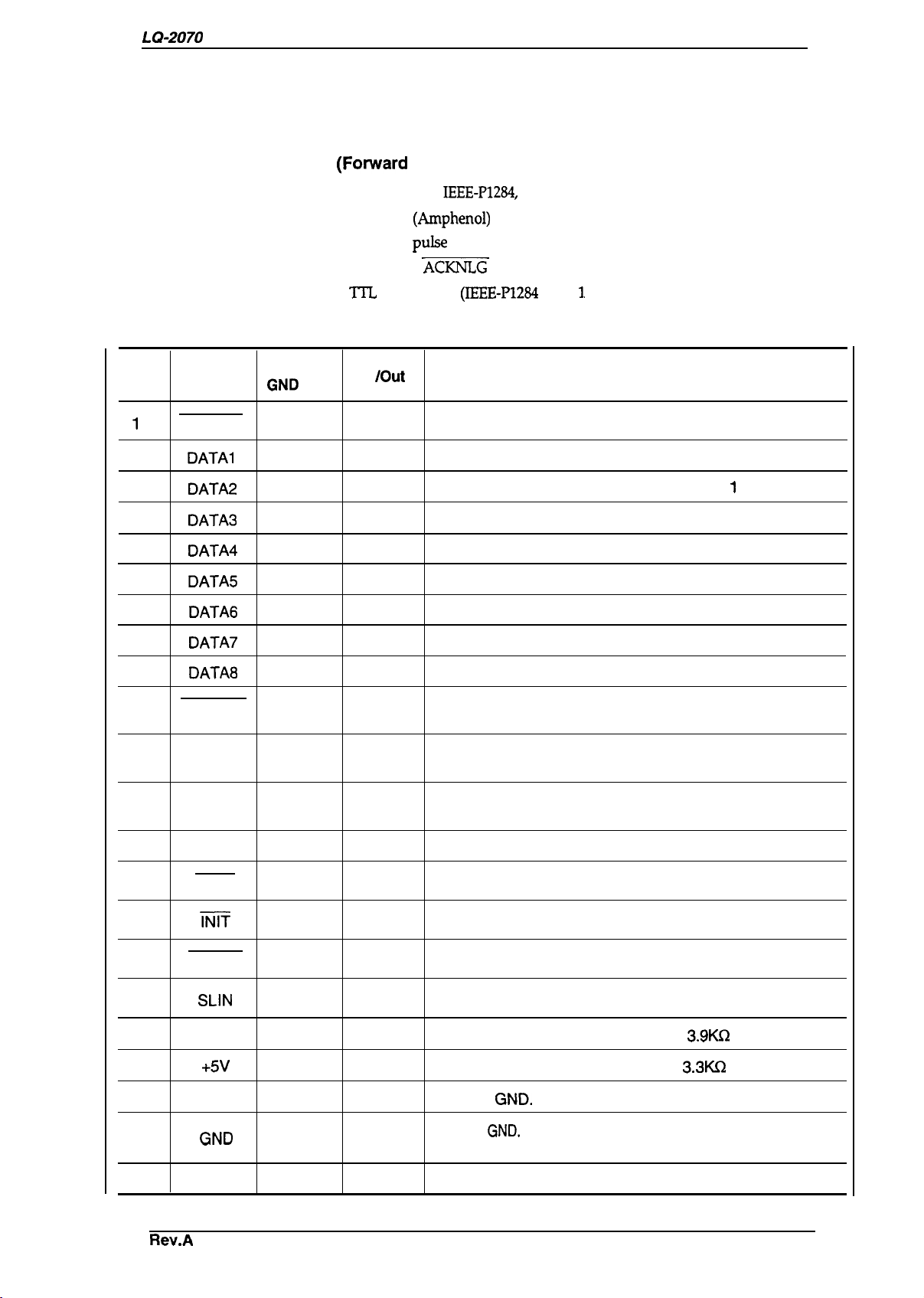

1.3.2.1 Parallel Interface (Fotward Channel)

●

Transmission mode

●

Adaptable connector

●

Synchronization

. Handshaking

●

Signal level

Pin

No.

1

2

3

4 DATA3

5

6

7

Signal

Name

STROBE

DATA1

DATA2

DATA4

DATA5

DATA6

8-bit parallel,

57-30360

STROBE

BUSY and

‘ITL

compatible

IEEE-P1284,

(Amphenol)

P1.lk

ACI@lLG

signals

(IEEE-P1284

compatibility mode

or equivalent

level 1. device)

Table 1-31 Pin Assignments for Forward Channel

Return

GND

pin

19 In

20

21

22

23

24

25

In

IOut

In

In

In

In

In

In

Function Description

Strobe pulse. Input data is latched at falling edge of the signal

Parallel input data to the printer

bit O: LSB

bit

1

bit 2

bit 3

bit 4

bit 5

8

9

10

11

, 12

13

14

31

32

36

18

35

DATA7

DATA8

ACKNLG

BUSY

PE 28

SLCT

AFXT 30

M

ERROR

SLIN

Logic H

+5V

26

27

28

29

28

30

29

30

----

----

In

In

out

out

out

out

In

In

out

In

out

Out

bit 6

bit 7: MSB

This signal (negative pulse) indicates the printer has received

data and is ready to accept more data.

This signal’s HIGH level means the printer is not ready to

accept data.

This signal’s HIGH level means the printer has a paper-out

error.

Always HIGH when the printer is powered on.

Not used.

This signal’s negative pulse initializes printer.

This signal’s LOW level means the printer is in an error state.

Not used.

This line is pulled up to + 5 V through 3.9KQ resistor.

This line is pulled up to +5 V through

3.3KQ resistor.

17

16,33,

19-30

15,34

Chassis ----

GND

NC

Rev.A

----

----

-–-

---

---

Chassis

Signal

GND.

GND.

Not connected.

1-21

Loading...

Loading...