Page 1

LQ-1500

SERVICE MANUAL

Printed on Recycled Paper

a9

®

EPSON

Page 2

1.1 Product Overview

1.2 LQ-1500 Interface Overview

1 .3Specifications

1 .4Major Components

2.1

General..

..............................................................................................................................................

2.2 ConnectIon Diagram

2.3 Connector Pin Assignment

Connector on UXMCL circuit board..

2.3.1

Connector on UXDRV circuit board..

2.3.2

Connector on UXPS/PSU 24E circuit board..

2.3.3

2.4

Electrical Circuit

Power circuit

2.4.1

2.4.2 Reset circuit

Sensor circuit..

2.4.3

Carriage motor control circuit..

2.4.4

LF motor control circuit

2.4.5

2.4.6 Head driver circuit

Auto sheet load circuit

2.4.7

Other function..

2.4.8

2.5 Printer Mechanism..

Operation

2.5.1

................................................................................................................................

.....................................................................................................................................

..............................................................................................................................

...........................................................................................................................

..................................................................................................................

.................................................................................................................

...............................................................................................................................

........................................................................................................................

.....................................................................................................................

.........................................

.............................................................................................................................

................................................................................................................................

TABLE OF CONTENTS

CHAPTER 1

GENERAL

...............................................................................................................

CHAPTER 2

PRINCIPLES OF OPERATION

.................................................................................................................

.........................................................................................

.......................................................................................

...........................................................................

.............. 2-13

......................................................................

.............................................................................................................

..............................................................................................................

..............................................................................

...................

1-1

1-1

1-1

1-4

2-1

2-1

2-3

2-3

2-8

2-12

.......... 2-13

2-22

2-22

......

2-26

2-34

2-37

2-39

2-40

2-41

2-41

CHAPTER 3

OPTIONAL EQUIPMENT

3.1 Centronics Compatible Parallel Interface

Introduction

3.1 .1

Specification.. ................................ ..............................

3.1 .2

Operating principal

3.1 .3

Block diagram..

3.1.4

Circuit diagram

3.1 .5

Component layout ...............

3.1 .6

3.2 RS-232C/Current Loop Interface..

lntroductron ............

3.2.1

Specification.. ........

3.2.2

Operating principal ....................................... ....................................................

3.2.3

Block diagram....................................... ..... .............................................................................

3.2.4

Circuit diagram.. ......................... .......... .....

3.2.5

Component layout ....................................................................................................................

3.2.6

3.3 IEEE-488 Interface..

Introduction .......... ........ .............................................................

3.3.1

Specification.. ..... .........

3.3.2

IEEE-488 operatronal parameters.............................

3.3.3

IEEE-488 functional commands .........................................

3.3.4

Block diagram..... .............................. .................

3.3.5

Circuit diagram.. ................................... .......

3 3.6

Component layout ................................

3.3.7

3.4 Single Bin Cut Sheet Feeder (# 8334), Double Bin Cut Sheet Feeder (# 8344)

Introduction ......... ...........................

3.4.1

Specifications.. ..... ........ .......... ...... .................................................

3.4.2

Principle of operation.. ........... ...................................................................

3.4.3

Disassembly and assembly..

3.4.4

Troubleshooting.. .........................................

3.4.5

Preventive maintenance ...... .........................................................................................

3.4.6

.............................................................................................................................

..................................................................................................................

...........................

......... ............................. .........

.,.,.,

..........................................................................................................

...

....... ....................................

...................... ........ ........ .....

...........................................................................................

...................................................... 3-1

...

....

..............................

..............................................................

.................................................................................................. 3-8

...................................

....................................................................................................

...

....

............................................................

..............

.....................................................

...............................................

..........................................................................

....

........

...

..................................................................

....

..............................................................

.............................................................

......................................................................

................................................

....

..............................................

..... .................................................... 3-26

........ ....................................... 3-27

....................................................... 3-29

........................................ 3-42

3-1

3-1

3-4

3-6

.......

3-7

3-9

3-9

..........

3-9

......................

........................ 3-20

..................................... 3-22

.............. 3-32

.................................

.......... ..................

....

........................ 3-36

...........

..........

3-15

3-19

3-21

3-22

3-22

3-31

3-33

3-33

3-34

3-52

3-60

Page 3

CHAPTER 4

DISASSEMBLY/ASSEMBLY AND ADJUSTMENT

4.1

General..

4.2 Tools and Measuring Instruments

4.3 Disassembly and Assembly..

4.3.1 Removal of upper case

4.3.2 Removing the circuit boards..

4.3.3 Removal of Model-3660 printer mechanism..

4.3.4 Removal of fan set UB (head cooling fan).

4.3.5 Removal, installation and adjustmnent

4.3.6 Removal of CPU and ROM.

4.3.7 Adjustment of print alignment (backlash)

4.4 Adjustment.........................

4.4.1 MTS and DTS sensor board adjustment..

4.4.2 H.P. sensor board adjustment

4.4.3 Backlash of the carnage motor and belt driving pulley..

4.4.4 Backlash of the paper feed motor and

............................ ...............................................................................................

...................... ........................ 4-1

........................... 4-6

.............................................. .......................................................

.... ...... .......................................... .....................................................

.......

....

of print head..

paper feeding reduction gear

................................................... ......................................................

...

.................................................

....................................... ........................... .......................

..............................................

.....................................................................

...

...... ........ ........................................................................ 4-9

.....................................................................

..................................................................................

..................................................................................................

............................................................

........... ................................. ......................................................

CHAPTER 5

TROUBLESHOOTING

5.1 Entry of Troubleshooting

5.2 Check-out Procedure

5.3 Unit Repair Flow Chart (UXMCL).

5.4 Unit Repair Flow Chart (UXDRV)

5.5 Unit Repair Flow Chart (UXPS).

5.6 Unit Repair Flow Chart (IUPIF)

......... ................ ..................................................

..... ....... ..... ........ ..........................................

....................

......................

.......... ..... ........................................................................

........ ................................................................................................

...... ....................................................................................................

............................. ......... ....................................................

.,

.,.,

4-1

4-2

4-2

4-3

4-6

4-7

4-10

4-12

4-12

4-1 4

4-15

4-16

5-1

5-4

5-18

5-33

5-40

5-42

CHAPTER 6

MAINTENANCE

6.1

Maintenance

6.1 .1

Cleaning..

6.1 .2 Inspection..

6.2 Lubrication..

6.2.1 Lubricants..

6.2.2 Lubrication requirement

6.2.3 Lubrication

6.2.4 Adhesive application requirements

6.2.5 Adhesive application points..

6.2.6 Lubricants and adhesives list..

....................... ........ ......... ..... ...............................................................................

............

................

.............................

........... ...... ...... .......... ........ ........................................................................

point.. .....................................................................................................................

... ...

................ ...... ........................

...

.... ....

............................................................................................

....

.....................................................................................................

.......................................................................................................

.................................... .......

.............................................

...............................................................................................

...........................................

............. .............................

....

........... ...............................

....

CHAPTER 7

APPENDIX

List of principal IC’s..

Description of principal IC's

Exploded diagram for LQ-1500..

Lubrication and adhesive application points drawing A

Lubrication and adhesive application points drawing B.. ............................................................................

Lubrication and adhesive application points drawing C

UXMCL circuit diagram

Component layout of UXMCL board.

UXDRV circuit diagram..

Component layout of UXDRV board..

UXPS circuit diagram..

Component layout of UXPS board..

PSU 24E circuit diagram..

Component layout of PSU

UXFIL circuit diagram ..................... ..........................................................................................................

II

................. ...... ......................................................................................................

.......

...............................................................................................................................

............................................................................................................................

............................. .................................................................................................

...........................................................................................................................

24E board ........................................................................................................

...

........................................................................................................

................................................................................................................

.............................................................................

..............................................................................

.........................................................................................................

.........................................................................................................

............................................................................................................

6-1

6-1

6-1

6-2

6-2

6-2

6-2

6-3

6-3

6-4

7-1

7-2

7-35

7-36

7-37

7-38

7-39

7-40

7-41

7-42

7-43

7-44

7-45

7-46

7-47

Page 4

INTRODUCTION

This technical manual describes the principle of mechanical and electrical

operations, as well as the maintenance and repair procedures, of the EPSON

LO-1500 Dot Matrix Printer.

Chapters 4 through 6 of the manual deal with the fundamental troubleshooting, maintenance and repair of the LO-1500.

For detail on the disassembly, assembly, troubleshooting and maintenance of

the Model-3660 Printer Mechanism, refer to the separately published “Technical Manual of EPSON Model-3660”.

* The contents of this manual are subject to change without notice

Ill

Page 5

CHAPTER 1

GENERAL

1 .1

Product Overview..

1.2 LQ-1500 Interface Overview

1.3 General Specifications

1 .4

Major Components..

.................................................................................

...........................................................................

...............................................................................

................................................................

1-1

1-1

1-1

1-4

Page 6

1 .1 Product Overview

The LO-1500 is a serial terminal printer, featuring 200 CPS, bi-directional printing (draft pica mode) with

logical seeking capability, and 24 x 24 dot-matrix character formation.

which permit connection of the printer to various computers are optional.

cartridge type, which can be set snugly into the housing.

Should maintenance or repair be required, the printer mechanism and circuit boards of the LQ-1500 are

readily replaceable. The technician can perform maintenance and repair quite easily by referring to this

manual.

All interfaces for the LO-1500

The interface circuit boards are

1.2 LQ-1500 Interface Overview

(1) Centronics-compatible, parallel interface

This standard communication link permits data exchange with many computers without modification

or addition of other peripheral devices.

(2) RS-232C/Current Loop Serial Interface

A 20 mA current loop type, serial interface which permits the printer to receive data at a bit rate

ranging from 75 to 19200 BPS.

(3) IEEE-488 Interface

An optional interface which permits parallel communication between the printer and any computer or

measuring

488-l975.

instrument which is equipped with bus structure conforming the IEEE-488 Std.

1.3 General Specifications

(1 )

Printing Method . . . . . . . . . . . . . . . . . . . . . . . .._......

(2)

Character . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(3) Character Structure

Character

Draft

LO

ProportIonal

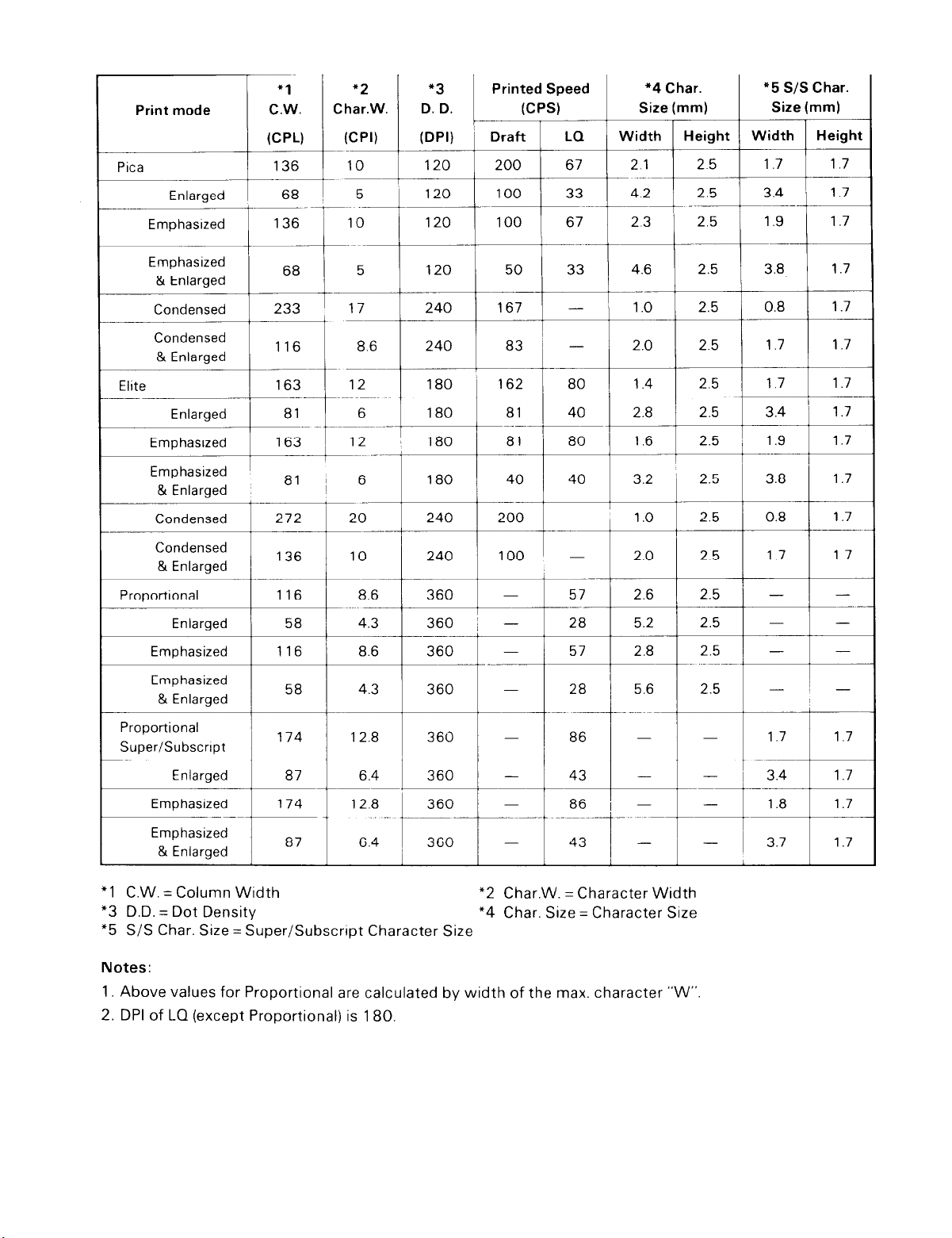

(4) Character Size SeeTable1. on the page 1-3

(5) Column Width..

(6)

Print Speed

(7) Paper Feed

(8) Paper

@

Cut sheet

Paper width ..,,._..........................

Paper thickness .

Weighing .._.............. .

................................ See Table 1. on the page 1 - 3.

........................................

.....................................

Impact dot matrix

1.

Draft

2. Near letter quality (LO)

3. Proportional (standard)

4. Multi-font (with option card)

5. Super/subscript in each above character style. (1 to 4.)

Normal

9x17

font

15 x 17

37x17

See Table 1. on the page 1 - 3.

Friction feed (standard)

Adjustable tractor feed (option)

182 mm to 364 mm

0.06 mm to 0.1 mm

45 kg to 70 kg (52 to 82 g/m*)

font

font

Super/Subscript

7

x

11

font

11

x

11

font

23 x

1 1

font

1-1

Page 7

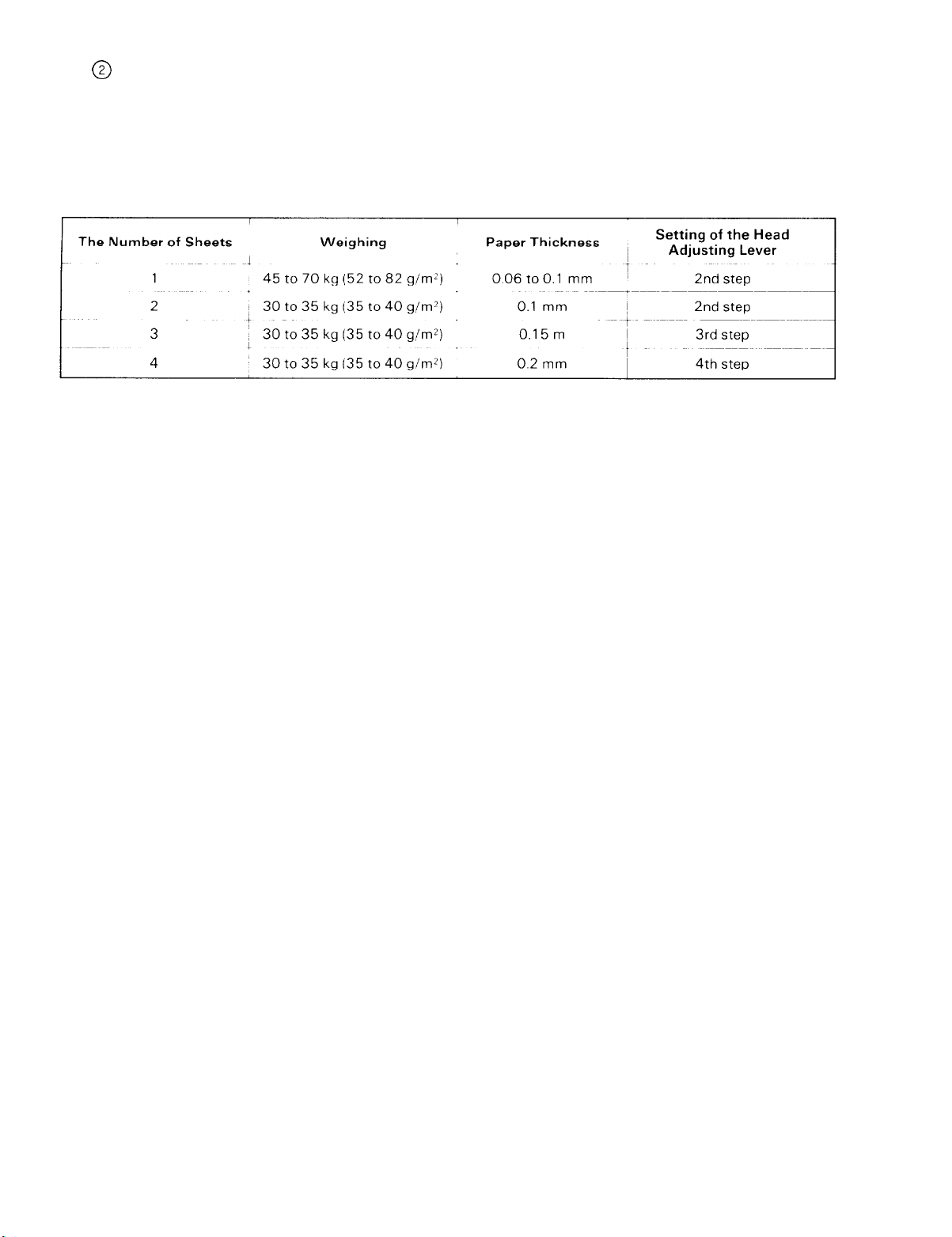

@

Fanfold paper

101

paper width

Copies

Paper thickness and Weight

Notes:

1. Jointing finish of copies should be point or line pasting.

2. Release the friction feed during the tractor feed operation.

3. Set the head adjusting lever as shown in above table.

However, adjust the step setting within range +1 step, depending on print density.

mm to 406 mm

4 sheets max. (include original)

Paper Insertion

(9)

(1 0) Line Spacing

Print Direction................................

(1 1)

(1 2) Line Feed Repeat Rate

Ribbon..

(1 3)

...........................................

...........................

..................................

....................

Rear

1/6”, 1/8” or programmable

Bidirectional printing with logical seeking.

In bit image and double-strike mode, unidirectional printing from

left to right is selected when the power is ON.

Bidirectional printing is also possible using ESC U.

120 ms/line (when 1/6” line feed is performed intermittently)

100 ms/line (when 1/6” line feed is performed continuously)

Exclusive cartridge ribbon (Black)

1-2

Page 8

Table 1

1-3

Page 9

1.4 Major Components

The LQ-1500 consists, in a broad classification, of the following five major components

(I ) Housing

(2) Model-3660 printer mechanism

(3) Control circuit boards

(4) Interface circuit boards

(5) Power supply circuit boards

The housing of the LQ-1500 consists of an upper case and lower case. The lower case is designed to

facilitate mounting of the following components.

Circuitry for the LQ-1500 is located on five different boards: the UXFIL and UXPS/PSU 24E boards which

house the power supply; the UXMCL board, which contains most of the control circuitry; the UXDRV,

which handles print mechanism drive circuitry, and a interface board (IUPIF or IURS or IUIE) which serves

as computer interface.

1-4

Page 10

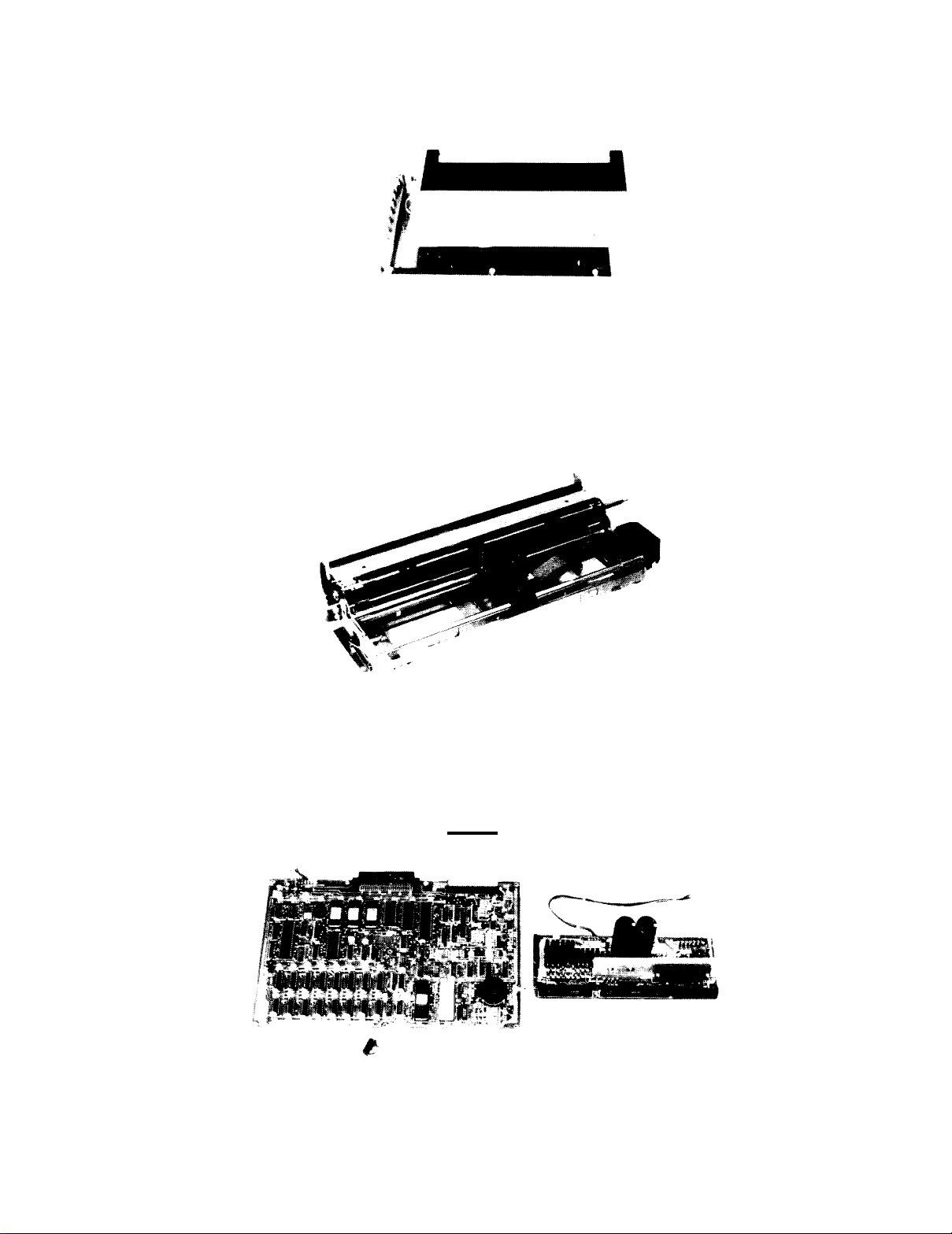

(1) Housing (Fig. 1 .1)

Fig 1 .1 Upper and lower cases

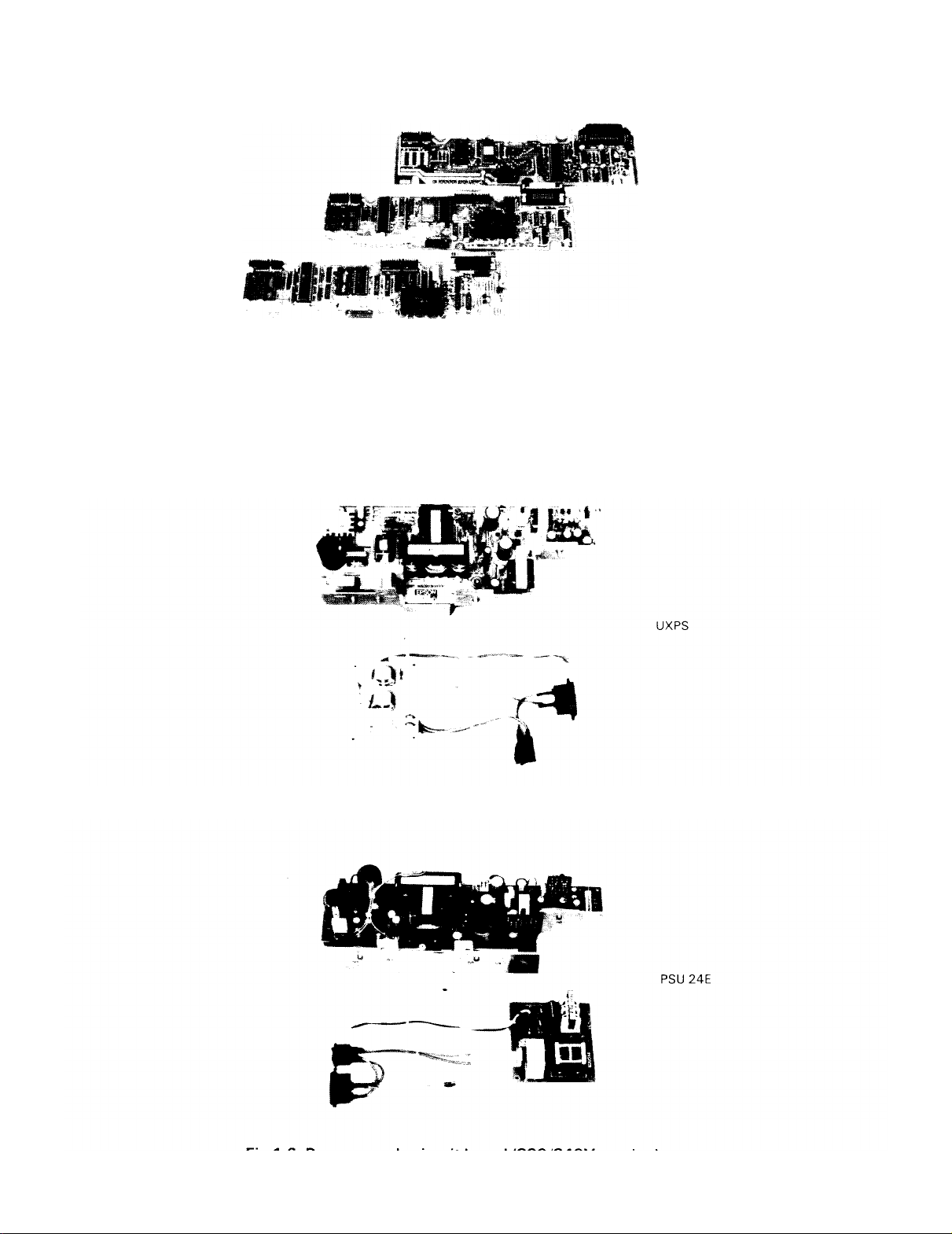

(2) Model-3660 printer mechanism (Fig. 1.2)

The mechanism is an assembly of all the mechanical components including two stepper motors, a print

head, a ribbon feeding mechanism, a carriage assembly, sensors, and a frame section. One stepper

motor operates the print head carriage,

while the other works as the paper feed motor. The

Model-3660 is designed to permit easy maintenance.

‘Fig. 1.2 Model-3660 printer mechanism

(3) Contrl circuit boards (Fig. 1.3)

The control circuit is distributed between two circuit boards, the UXMCL and UXDRV.

The UXMCL circuit board performs the central processing, and the UXDRV circuit board drives the

Model-3660 printer mechanism.

Fig. 1.3 Control circuit boards

1-5

Page 11

(4) Interface circuit boards (Fig. 1 .4)

An interface circuit board exchanges data between the host computer and UXMCL circuit board.

Fig. 1.4 Interface circuit board

(5) Power supply circuit boards (Fig. 1.5)

The power supply circuit of the LQ-1500, consists of two major components, the UXFIL and UXPS/

PSU 24E circuit boards. Both circuit boards are located in the rear righthand corner. The UXPS/PSU

24E circuit board supplies DC +24V, +12V, -12V and +5V to the control circuit and the interface circuit.

Fig 1.5 Power supply circuit board (100/120V version)

Fig 1.6 Power supply circuit board (220/24OV version)

1-6

Page 12

CHAPTER 2

PRINCIPLES OF OPERATlON

....................................................

2.1 General

2.2 Connection

2.3 Connector Pin Assignment

2.3.1 Connector on UXMCL circuit board

2.3.2 Connector on UXDRV circuit board

2.3.3 Connector on UXPS/PSU 24E circuit board..

2.4 Electrical Circuit

2.4.1 Power circuit

2.4.2 Reset circuit

2.4.3 Sensor circuit.. ............................................................................

2.4.4 Carriage motor control circuit..

2.4.5 LF motor control circuit

2.4.6 Head driver circuit.

2.4.7 Auto sheet load circuit

2.4.8 Other function

2.5 Printer Mechanism

2.5.1 Operation

...............................................

Diagram ............................................................................

.................................................................

.........................................

.........................................

.........................

...................................................................................

..............................................................................

................................................................................

................................................

.............................................................

....................................................................

..............................................................

............................................................................

...............................................................................

....................................................................................

2-1

2-1

2-3

2-3

2-8

2-12

2-13

2-13

2-22

2-22

2-26

2-34

2-37

2-39

2-40

2-41

2-41

Page 13

2.1 General

This chapter provides the descriptron of signals at the various connectors electrically interconnecting such

major components as printer mechanism, control circuits, interface circuit, power supply circuit, and control pannel of EPSON LO-1500 Terminal Printer, and explains the operating principles of the various mechanism around the electric circuit of the printer.

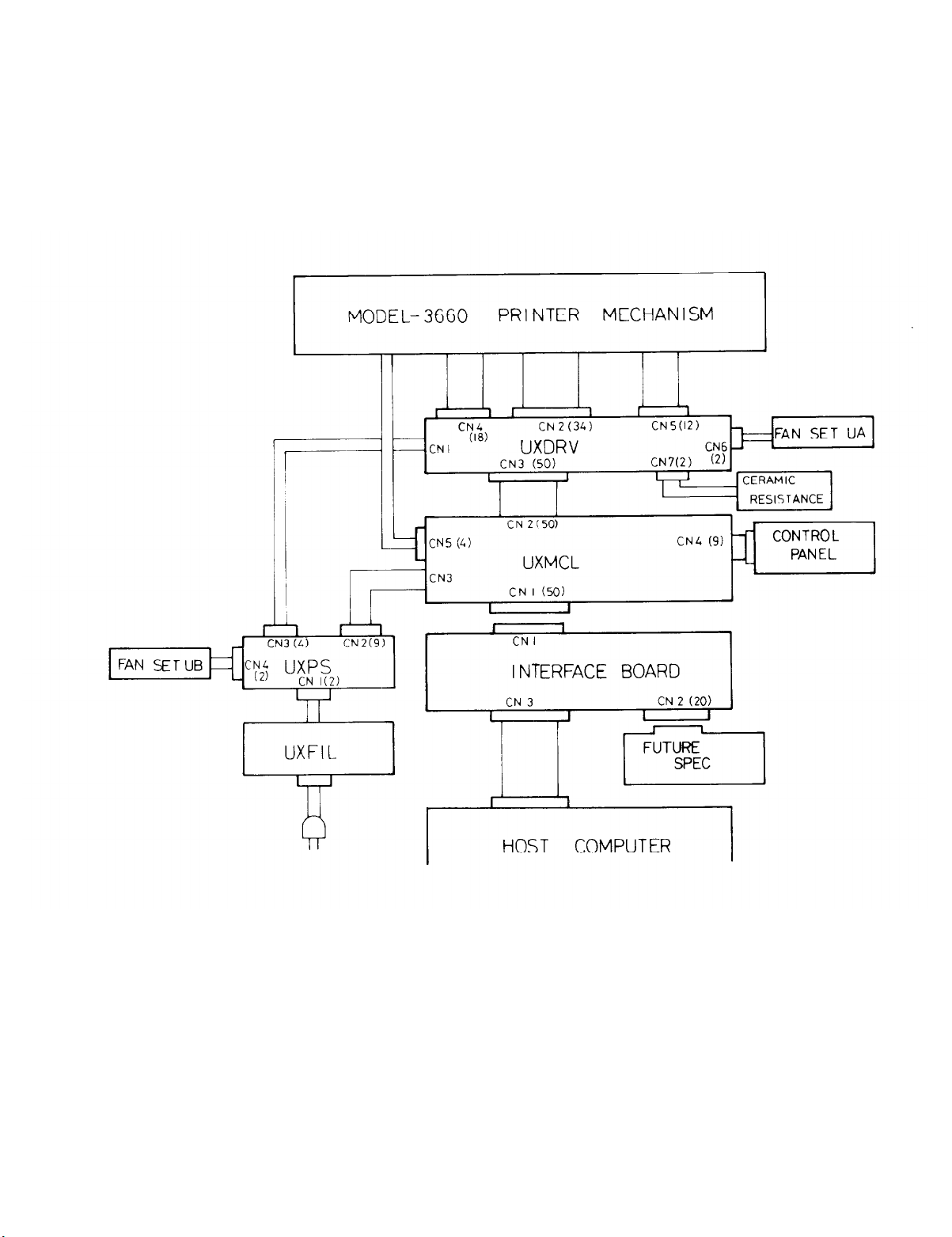

2.2 Connection Diagram (Fig. 2.1)

Fig. 2.1 Connection diagram

2-1

Page 14

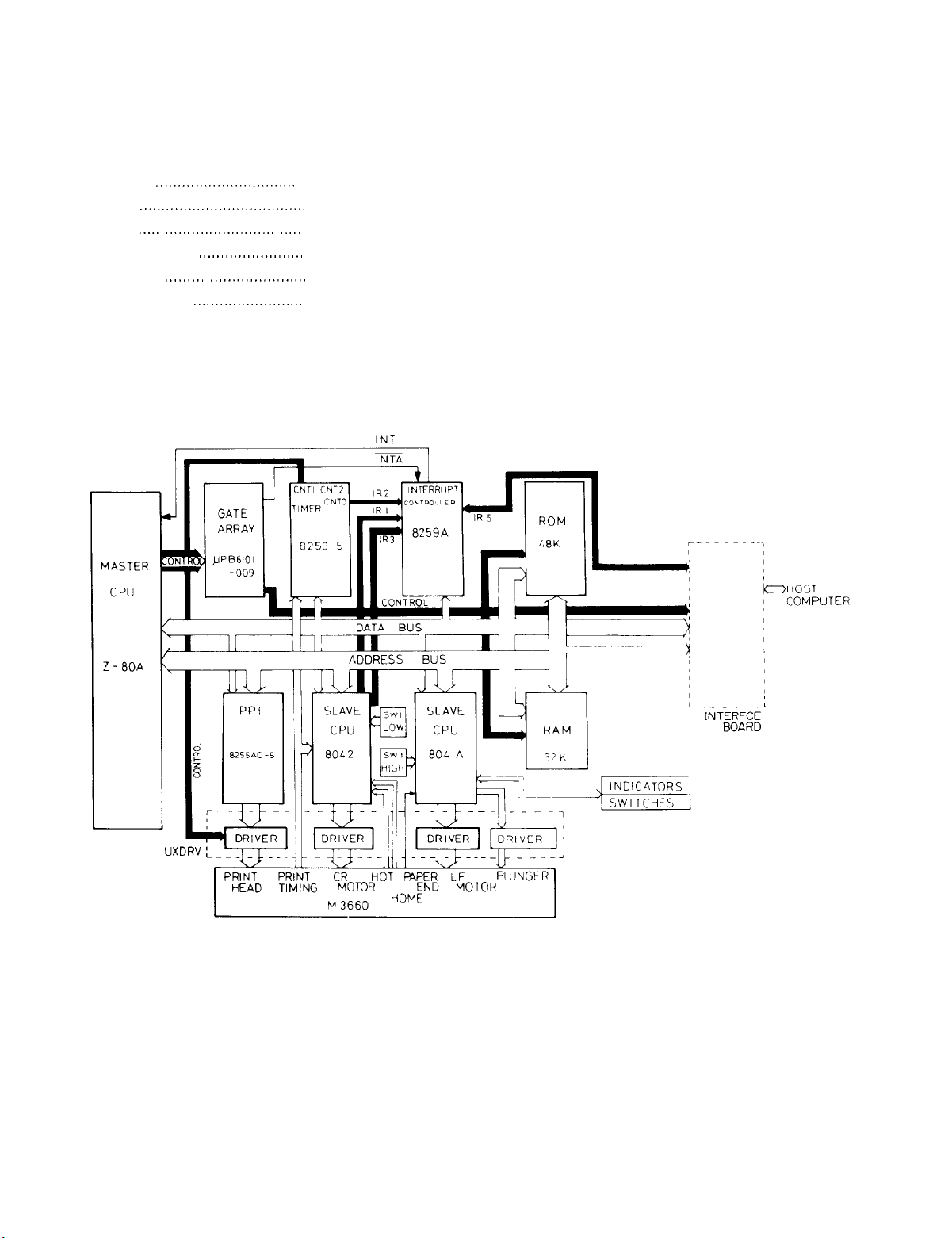

The CPU Z-80A provides overall control of the LQ-1500. In addition the LQ-1500 is supported by two

slave CPUs: the 8042(8742), which controls the carriage motor; the 8041(8741), which controls the

paper feed motor.

Other major LSls include:

8255AC5

,,._,_..,.,_.,........_._......_

Output port for head pin drive data

8259A _..........._....__................... Interrupt controller

8253-5 .___................_................ Timer counter

2764(231 28)

uPD41 6-3

uPB6101 -009

.._._..._.....___....._.

,.,,...,, ,,,,_....,.,,._.,__...

,......._........_.._....

ROM which stores control programs and character patterns

RAM which is used as the input data and print data buffer

Gate array which controls LSls by receiving control signals

from CPU Z-80A

Fig. 2.2 Block diagram

Page 15

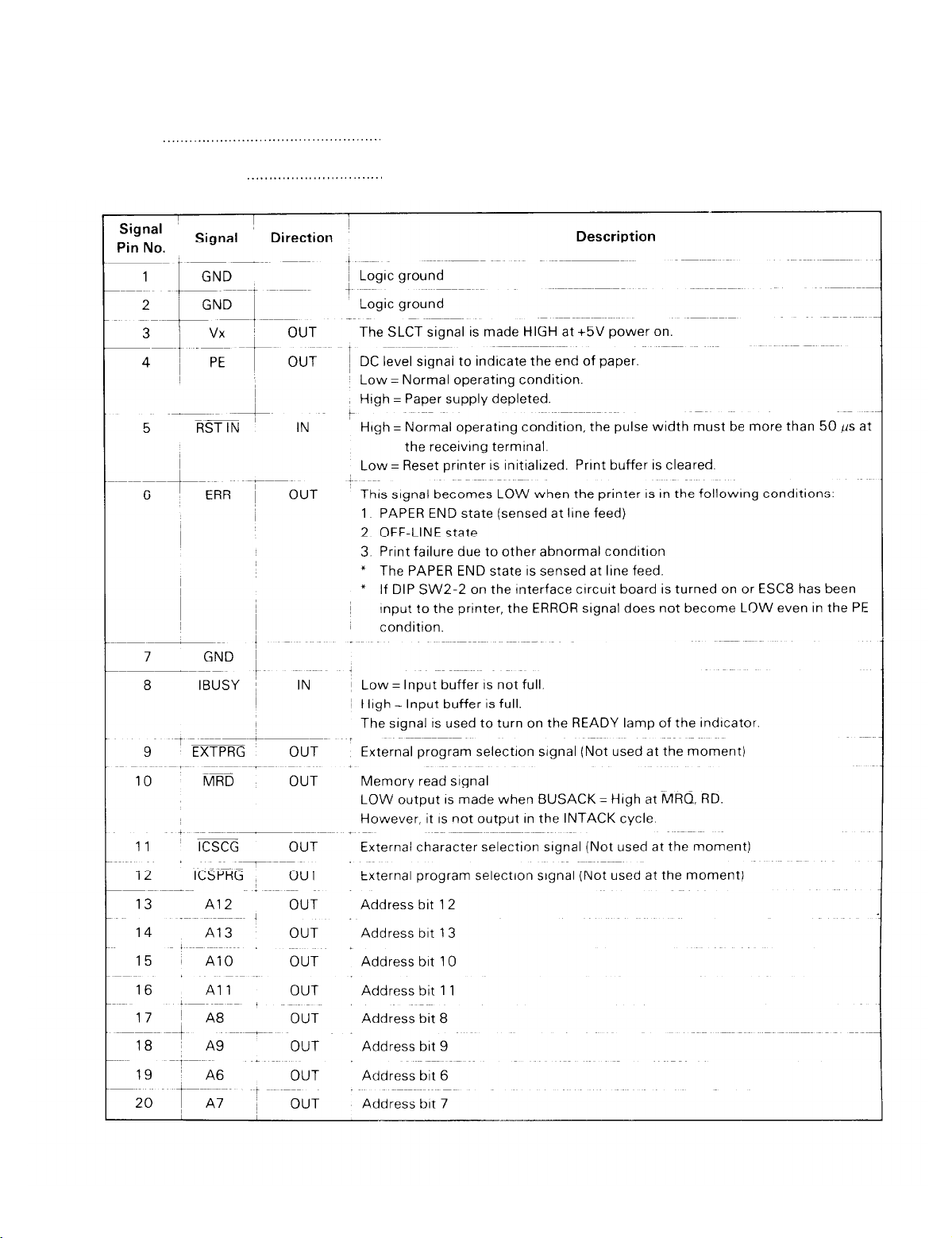

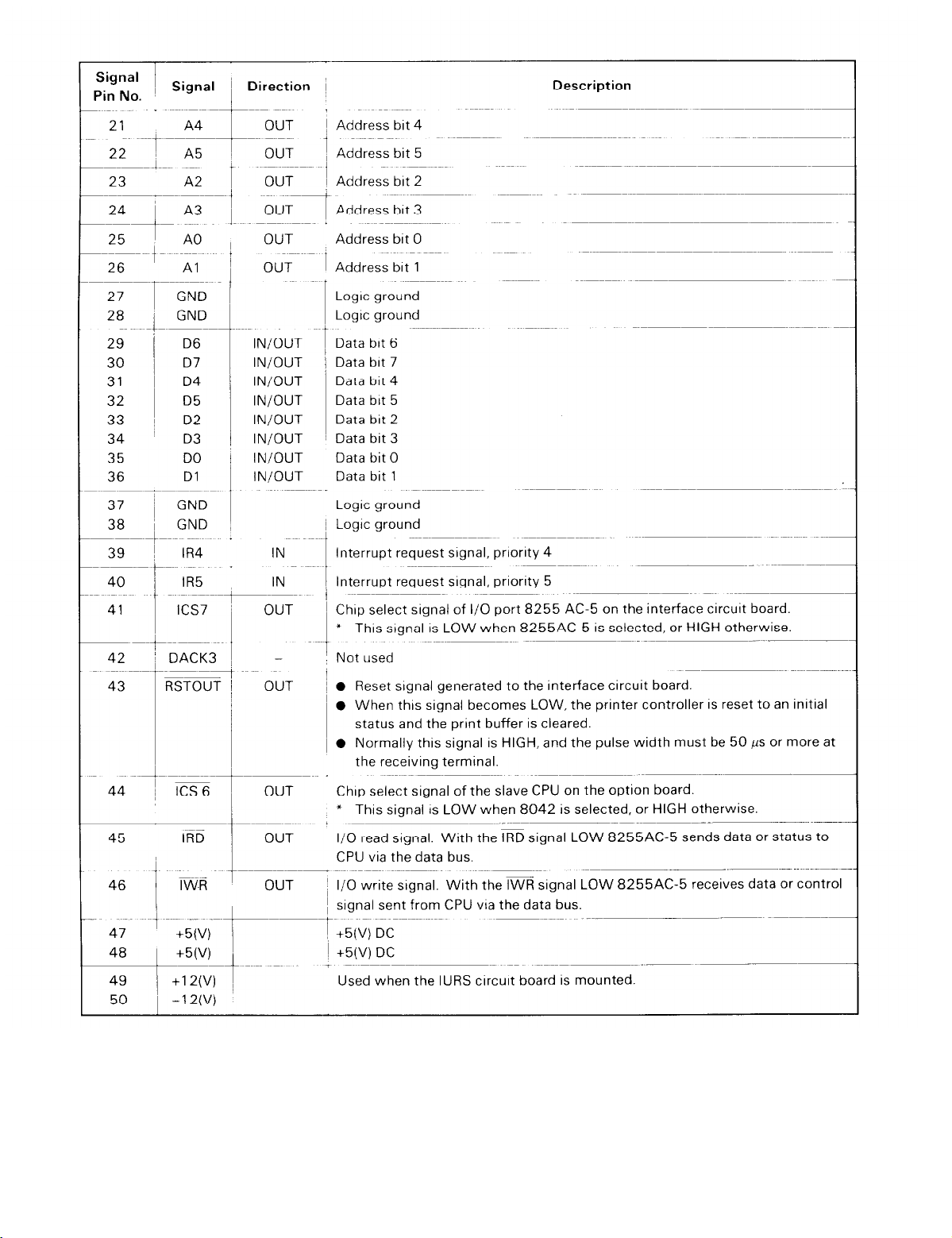

2.3 Connector Pin Assignment

2.3.1 Connector on UXMCL circuit board

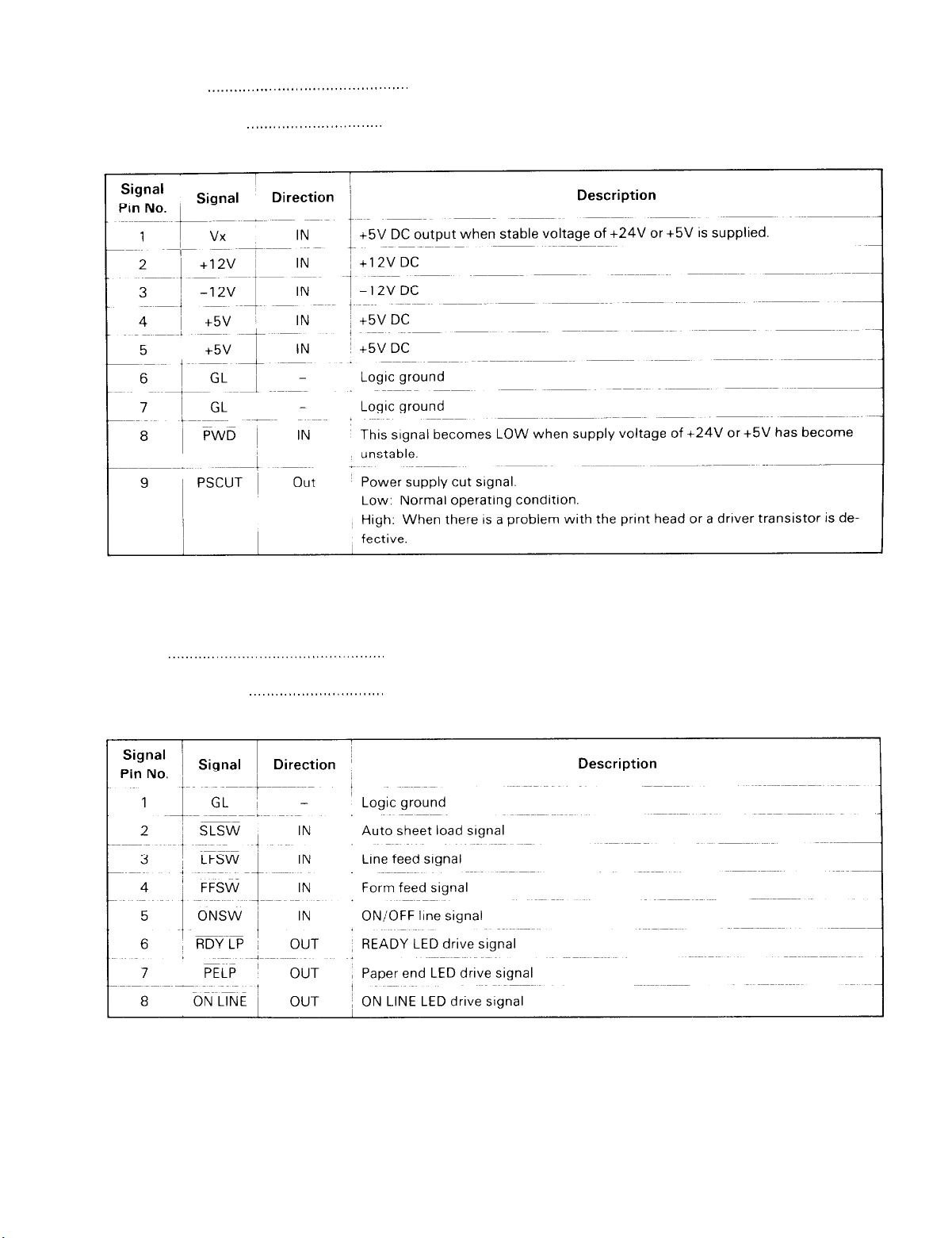

1) Table 2.1 CN1 pin assignment

(a) Use

(b) Number of pins

,,.,.......,,....,.,..,.............._............

._,.,,..._.._...,,,,......_._..

Table 2.1 Pin assignment (CN1 of UXMCL)

Used for data exchange between the main circuit board and the

interface circuit board

50

2-3

Page 16

Note: “Direction” refers to the direction of signal as viewed from the UXMCL circuit board

Page 17

2) Table 2.2 CN2 pin assignment

(a)

Use . . . . . . . . . . . . . . . . . .

(b) Number of pins

.._.........................

Table 2.2 Pin assignment (CN2 of UXMCL)

Data exchange between the main circuit board UXMCL and the

driver circuit board UXDRV.

50

2-5

Page 18

2-6

Page 19

3) Table 2.3 CN3 pin assignment

(a) Use . . . .

(b) Number of pins

..__..................__....,,..._........._..

_,,.._.._.,,,.._._,,..r....__._

Table 2.3 Pin assignment (CN3 of UXMCL)

To supply power from the power supply board UXPS/PSU 24E to

the main circuit board UXMCL.

9

Note: “Direction” refers to the direction of signal as viewed from the UXMCL circuit board.

4) Table 2.4 CN4 pin assignment

(a) Use

,....,,...,.._...__.....__..._,.,,,_.,...._...._..

Signal exchange between the control panel on the UXMCL circuit

board.

(b) Number of pins _...,,...,,_,,,........._...... 8

Table 2.4 Pin assignment (CN4 of UXMCL)

Note: “Direction” refers to the direction of signal as viewed from the UXMCL circuit board.

2-7

Page 20

5) Table 2.5 CN5 pin assignment

(a) Use

___...__....__..._.._.._._..._.__.................

Exchange of head/home position signals between the printer me-

chanism Model-3660 and the main circuit board.

(b)

Number of pins

4

Table 2.5 Pin assignment (CN5 of UXMCL)

Note: “Direction” refers to the direction of signal as viewed from the UXMCL circuit board.

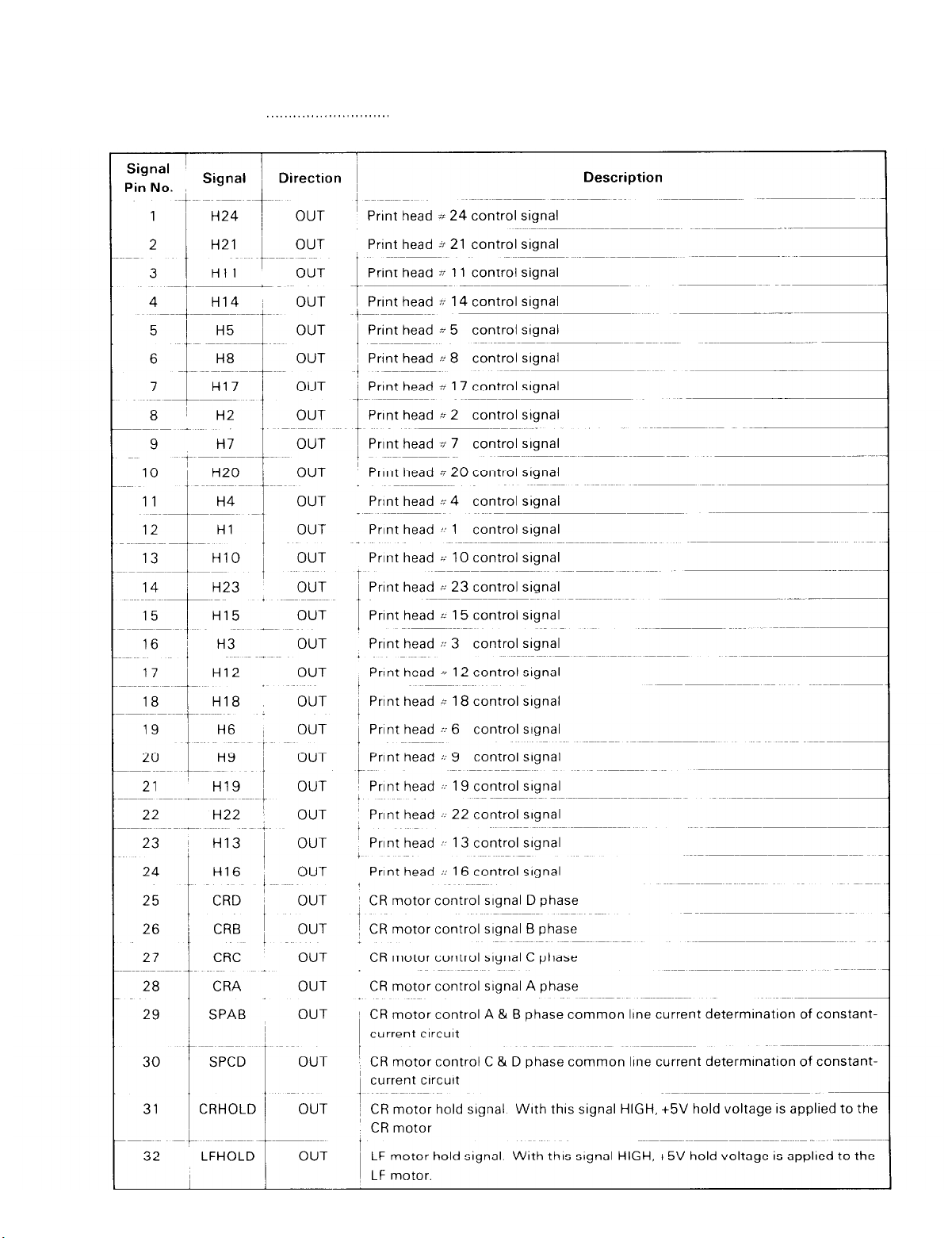

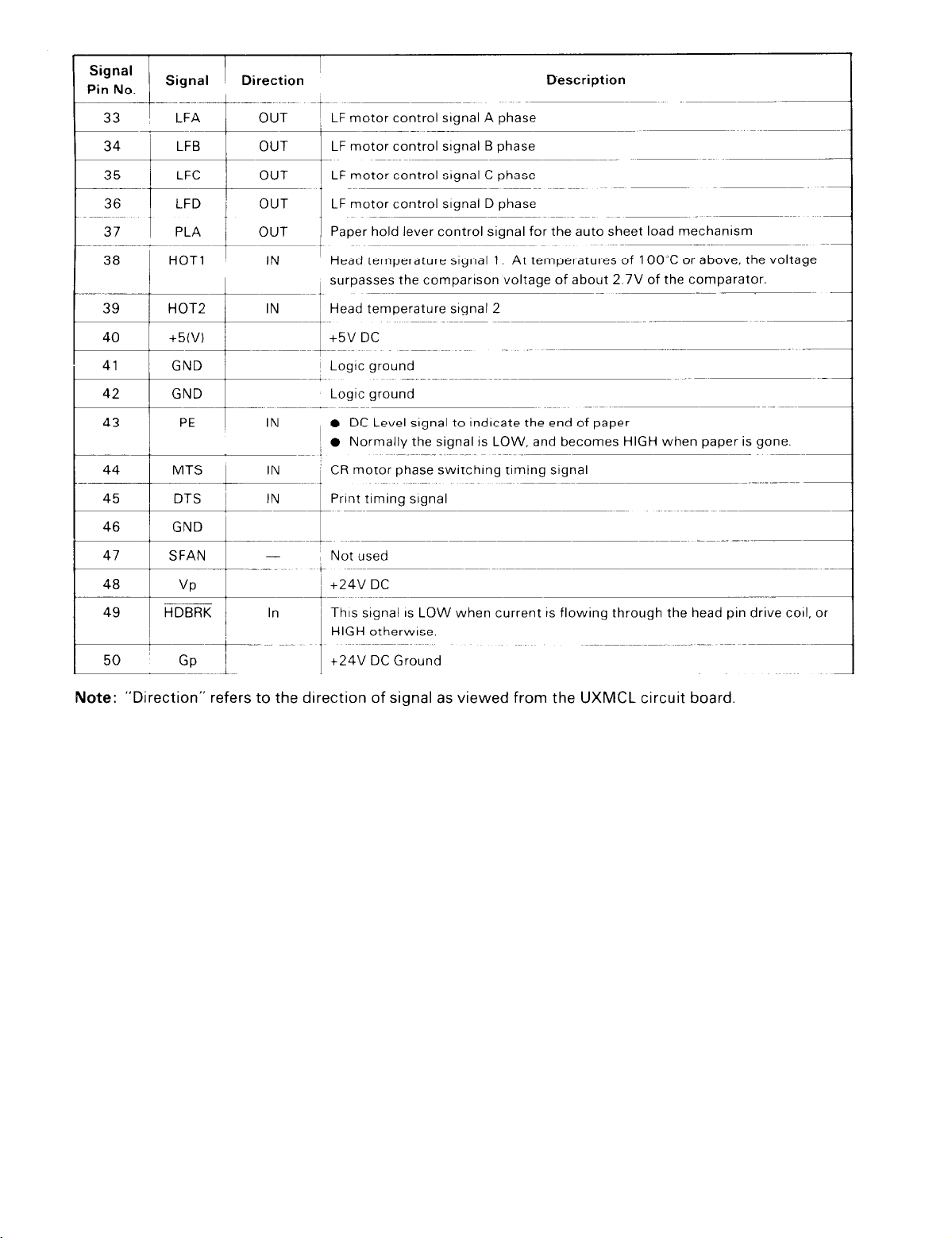

2.3.2 Connector on UXDRV circuit board

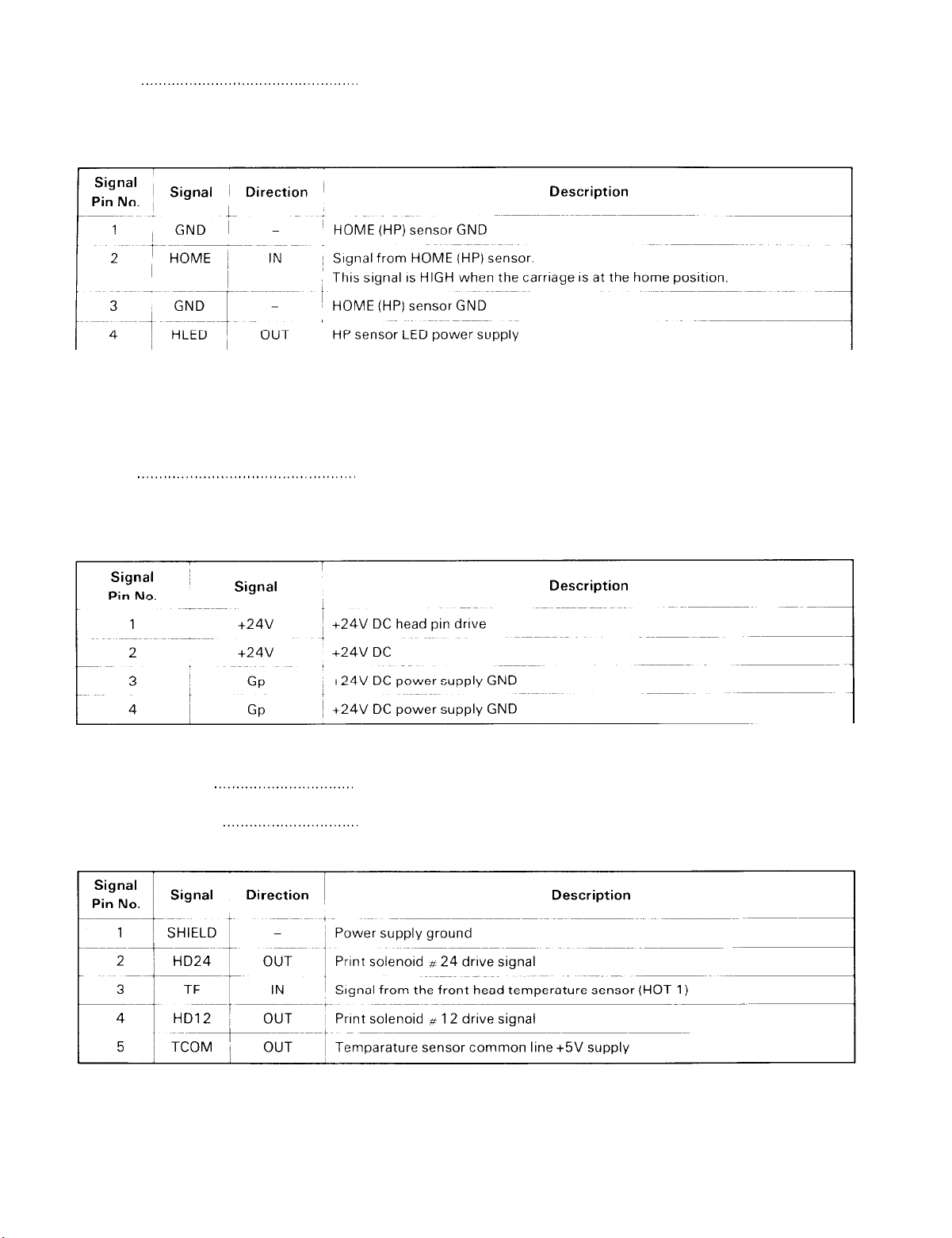

1) Table 2.6 CN1 pin assignment

(a) Use

(b)

._........_.......................................

Number of pins

To supply power from the power supply board UXPS/PSU 24E to

the driver circuit board UXDRV.

4

Table 2.6 Pin assignment (CN1 of UXDRV)

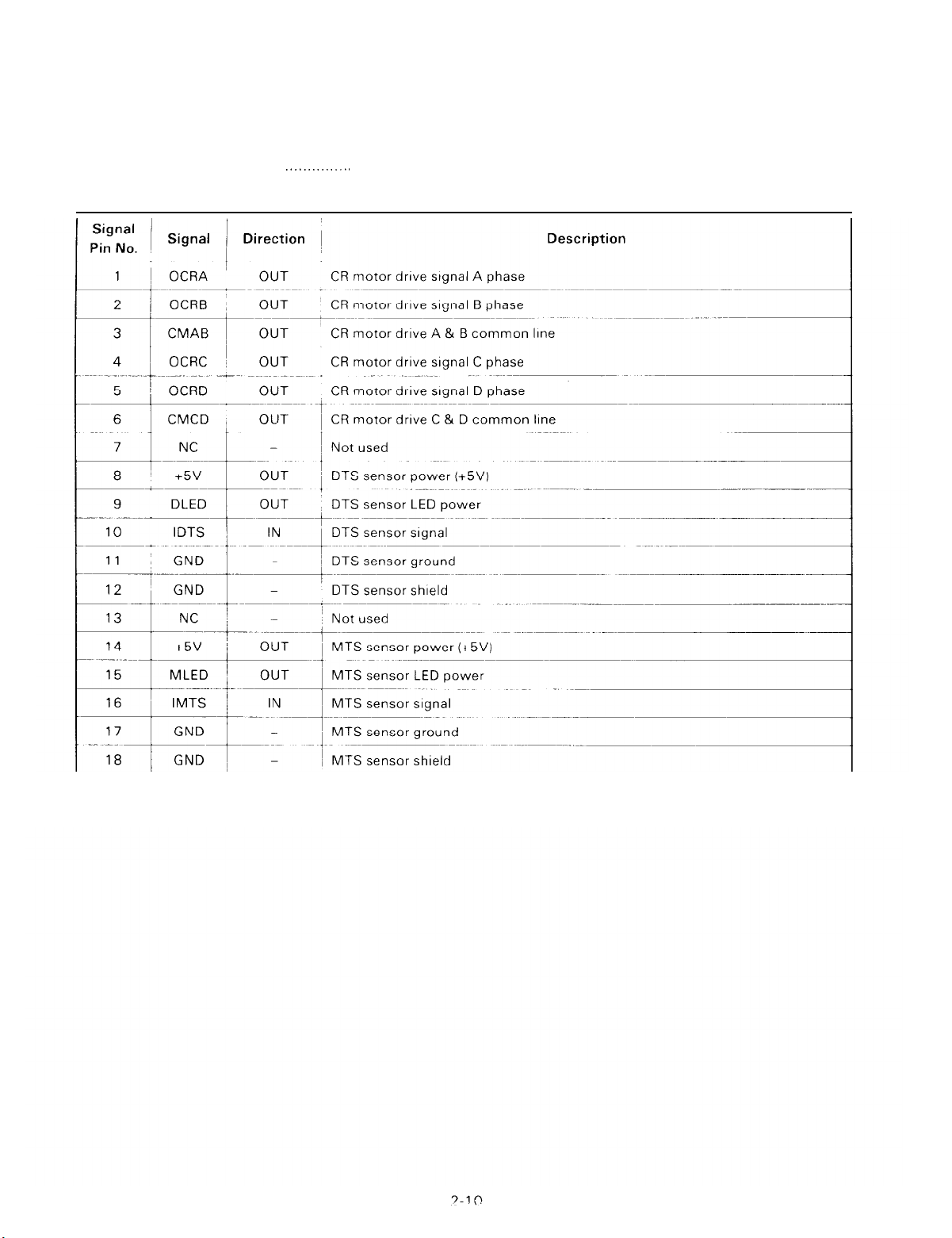

2) Table 2.7 CN2 pin assignment

(a)

Use

(b) Number of pins

.._.._._._...._._......_...._...

__..._._._.._.__..._......_....

Table 2.7 Pin assignment (CN2 of UXDRV)

Data exchange between the driver circuit board and the

Model-3660 printer mechanism.

34

2-8

Page 21

Note: “Direction” refers to the direction of signal as viewed from the UXDRV circuit board.

2-9

Page 22

3) CN3 pin assignment

Refer to Table 2.2.

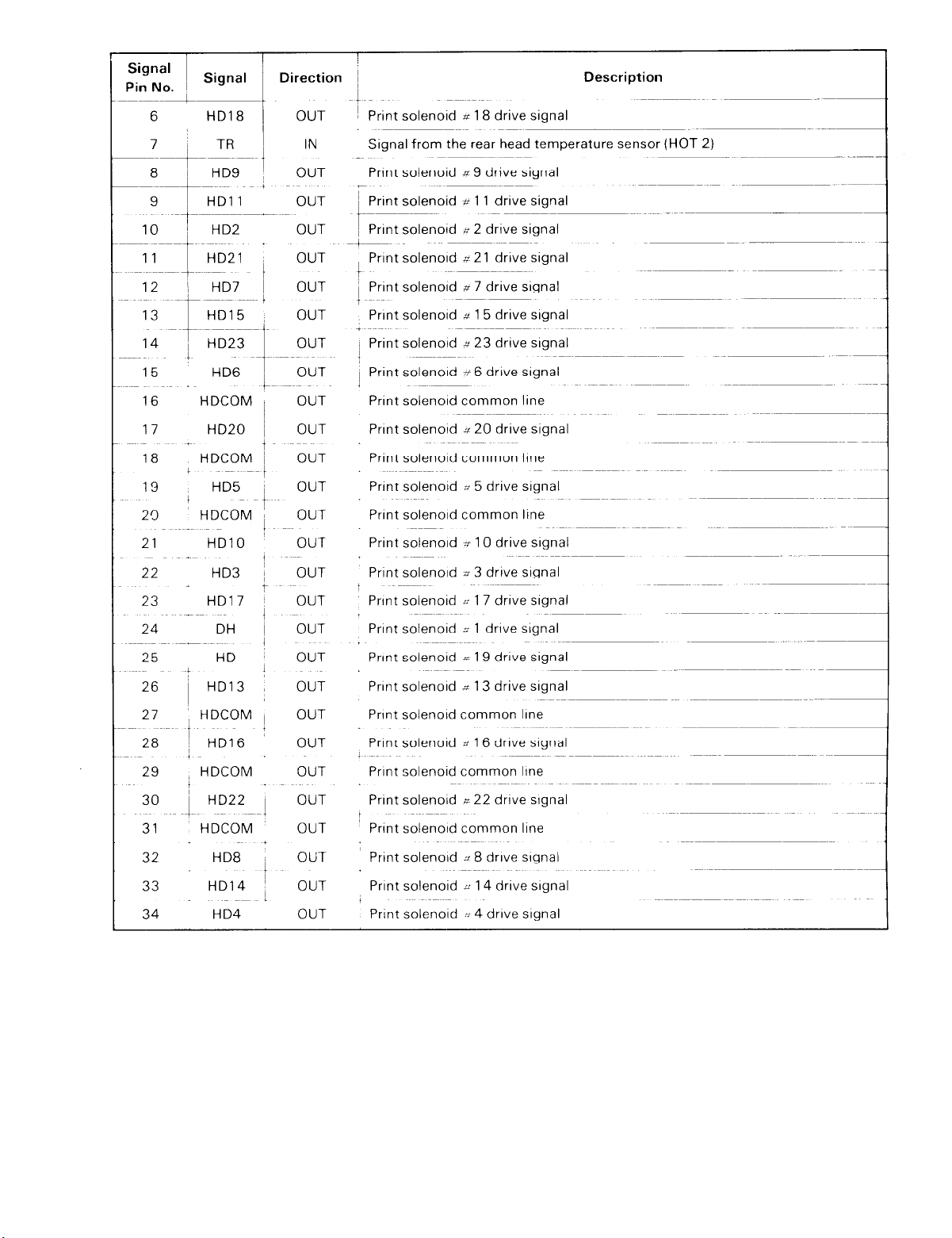

4) Table 2.8 CN4 pin assignment

(a)

Use

Exchange of carriage motor signals between the drive circuit board

and the Model-3660 printer mechanism.

(b)

Number of pins .._............

18

Table 2.8 Pin assignment (CN4 of UXDRV)

Note: “Direction” refers to the direction of signal as viewed from the UXDRV circuit board

Page 23

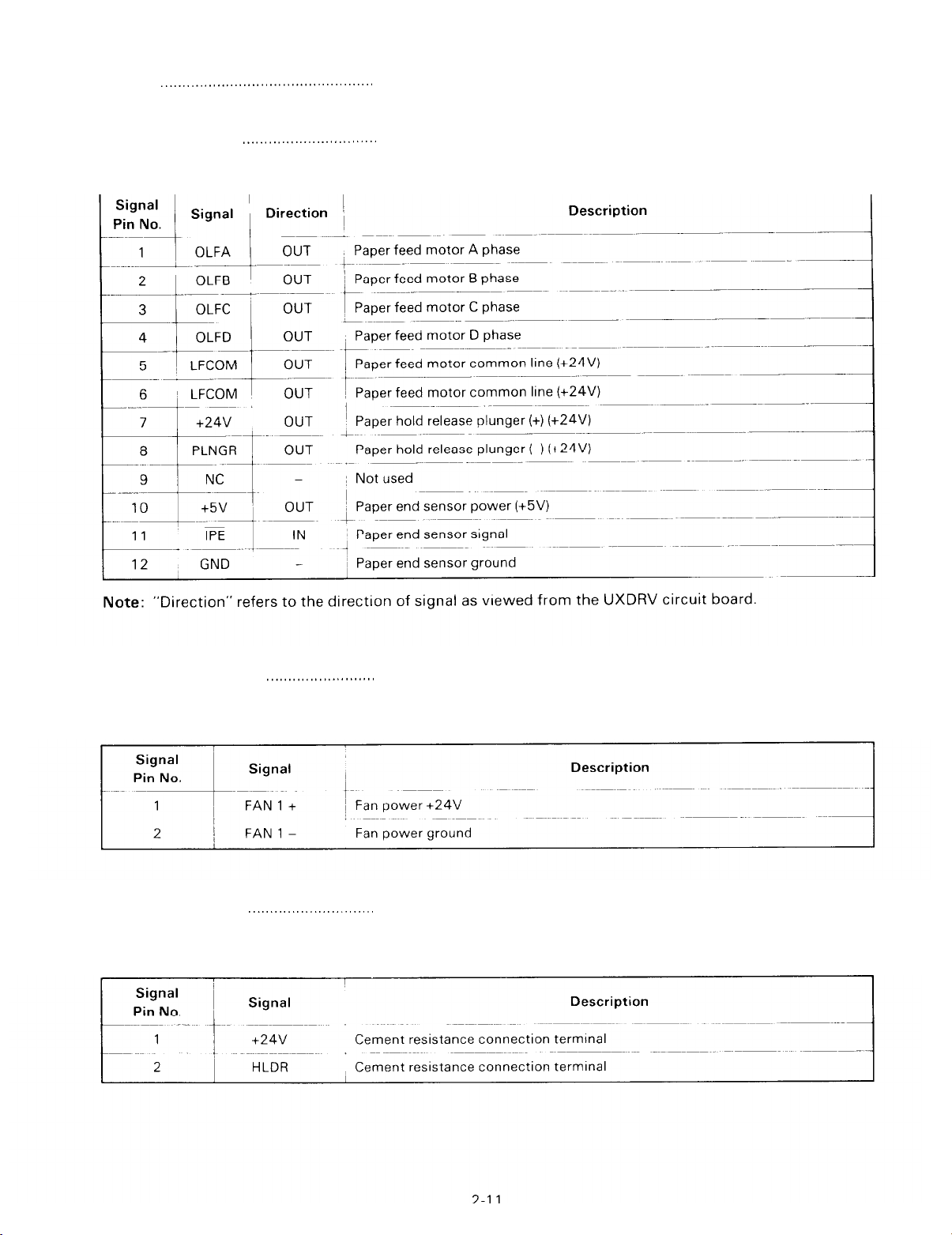

5) Table 2.9 CN5 pin assignment

(a) Use.

(b) Number of pins

.,.,.,,,....,..,.........__......................

,._._........._...__...........

Table 2.9 Pin assignment (CN5 of UXDRV)

Exchange of control signals between the drive circuit board

and the Model-3660 printer mechanism for paper feed motor or

paper hold release plunger.

12

6) Table 2.10 CN6 pin assignment

(a)

Use . . . . . .._.._...................

(b)

Number of pins .._....................

Table 2.10 Pin assignment (CN6 of UXDRV)

7) Table 2.11 CN7 pin assignment

(a)

Use .._.._..._...................

(b) Number of pins

Table 2.11 Pin assignment (CN7 of UXDRV)

To supply power to the fan set UA from the driver circuit board.

2

onnectlon of the driver circuit board and the ceramic resistance

C

2

2-11

Page 24

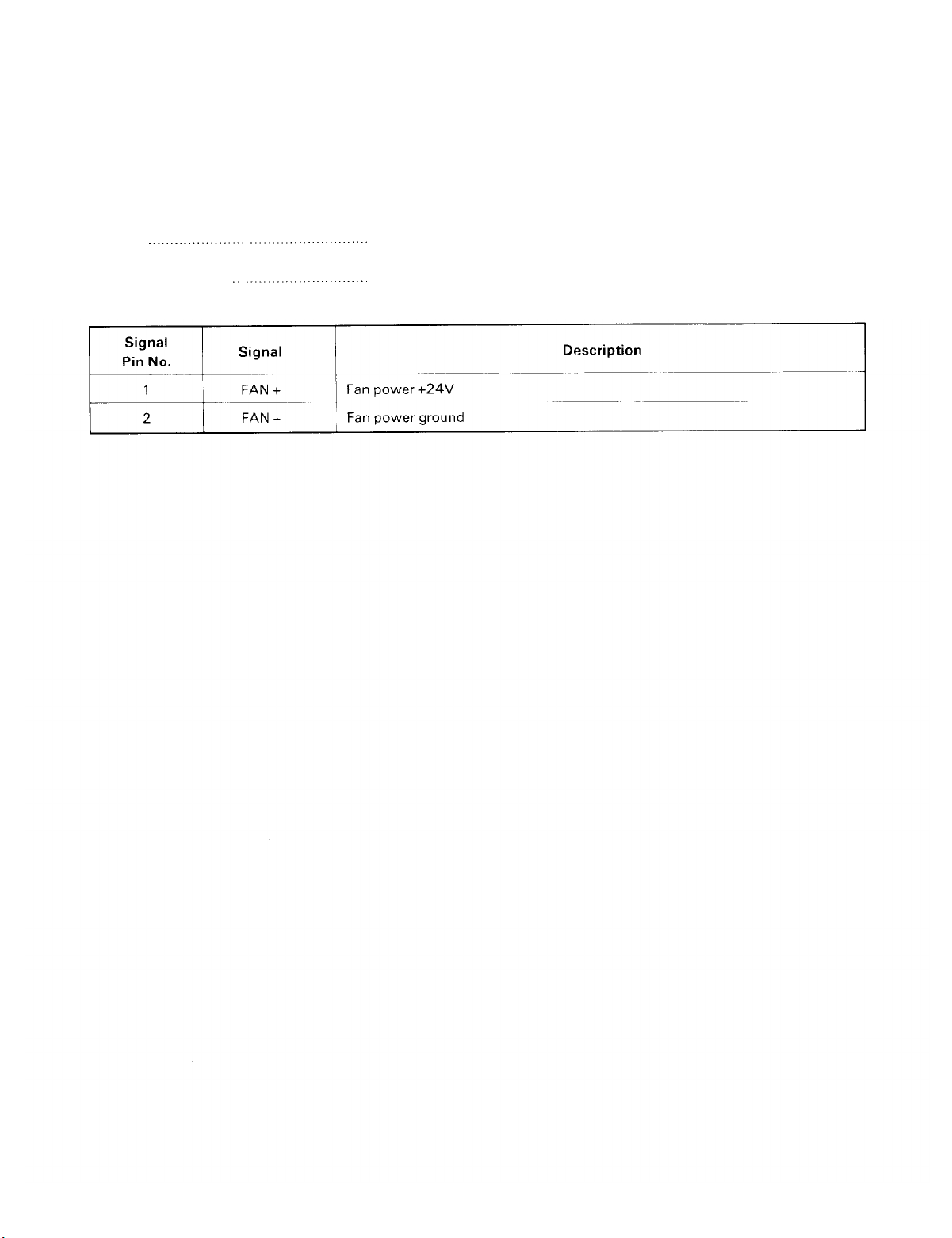

2.3.3 Connector on UXPS/PSU 24E circuit board

1) CN1 pin assignment

AC power is supplied from UXFIL circuit board

2) CN2 pin assignment

Refer to 2.3.1 3) Table 2.3

3) CN3 pin assignment

Refer to 2.3.2 1) Table 2.6

4) Table 2.12 CN4 pin assignment

(a) Use

____..__...,,.,.,..._.._..._._..,..._._..._...,_._

To supply power from the UXPS/PSU 24E circuit board to the fan

set UB.

(b) Number of pins

,.___._..__.,_,,._._..._.._....

2

Table 2.12 Pin assignment (CN4 of UXPS/PSU 24E)

2-12

Page 25

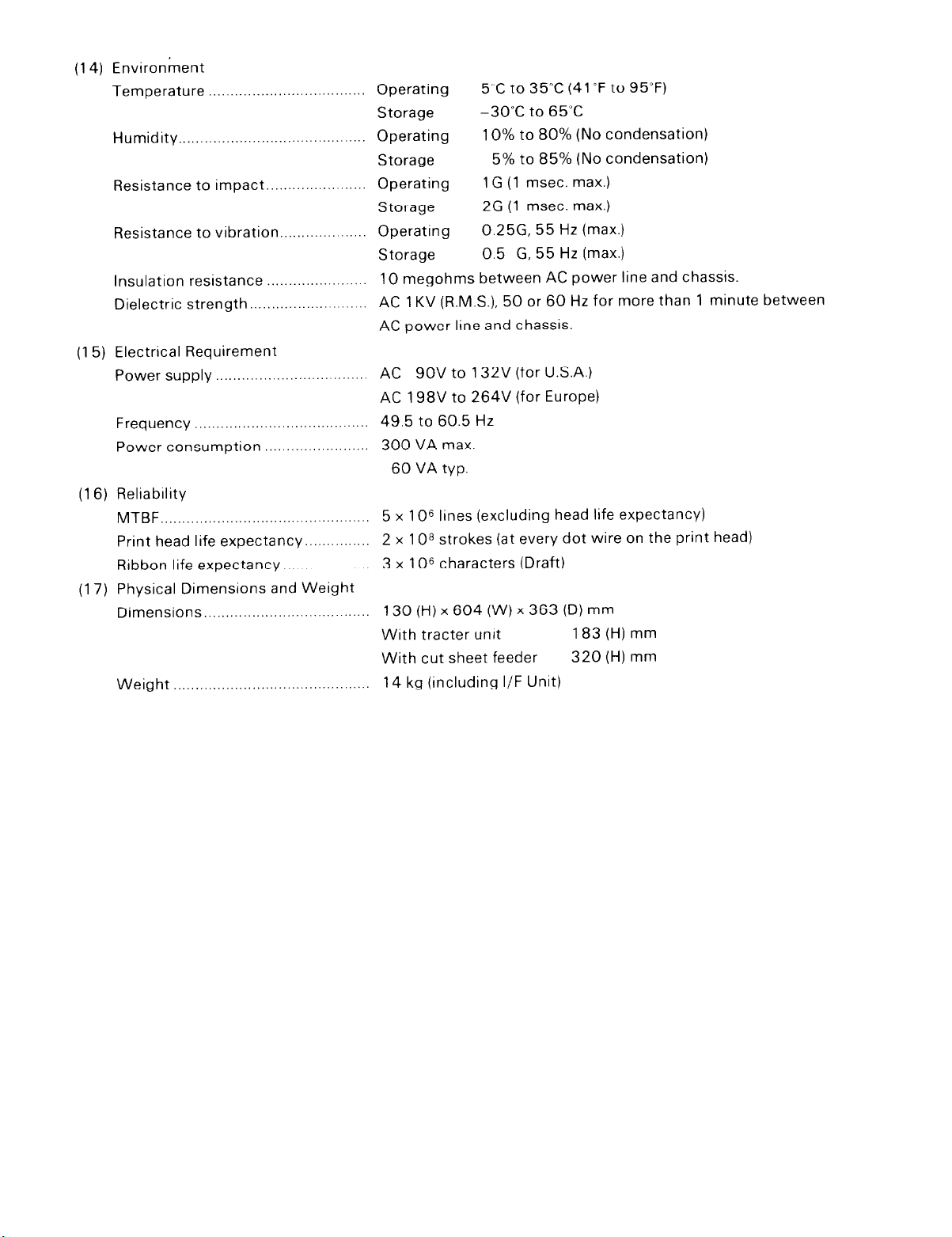

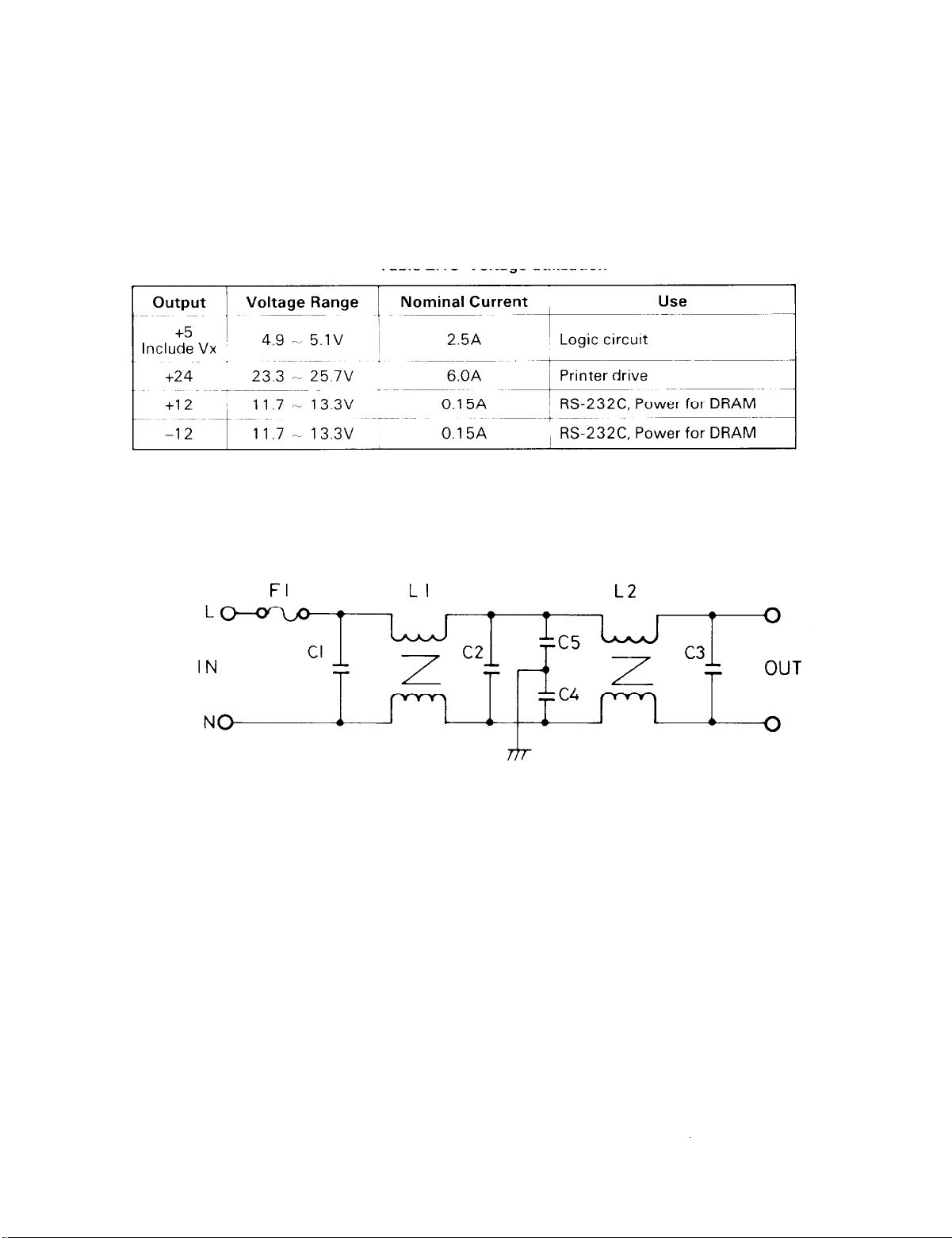

2.4 Electrical Circuits

2.4.1 Power circuit

Overview

The power supply circuit of the LQ-1500 consists of a fuse and filter circuit and power supply circuit.

The output voltages are +5, +12 and -12V for logic circuits and +24V for printer drive.

The power supply circuit, employs a switching power supply system in which the input voltage is directly

rectified for use.

Table 2.13 Voltage utilization

[A] 100V/120V version circuit

1.

Norse filter circuit (100/120V version)

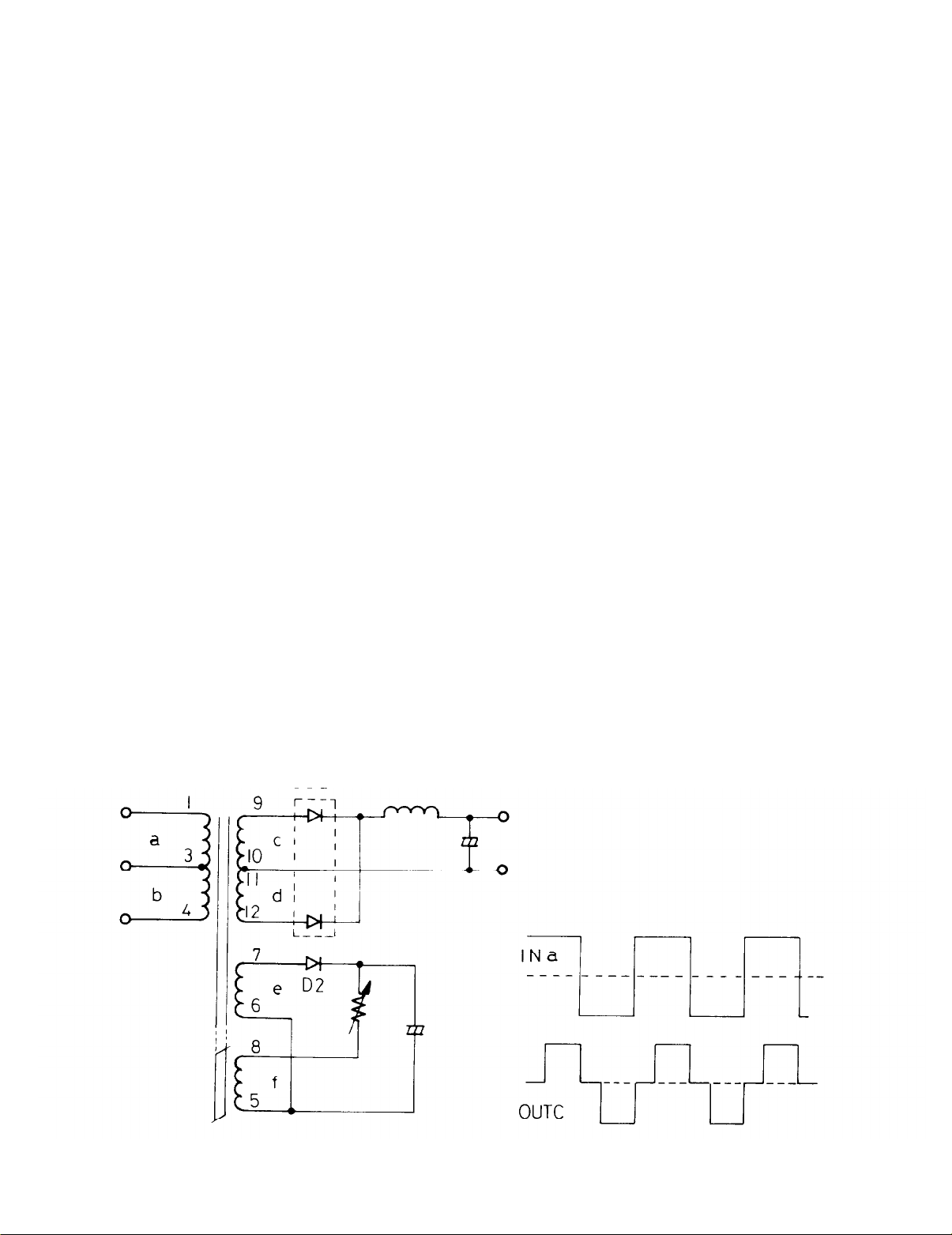

Fig. 2.3 Noise filter circuit

The noise filter circuit IS mounted on the UXFIL board together with the fuse. Incoming AC flows through

the power switch and fuse before being filtered by a noise suppression circuit on the UXFIL board. The

filter circuitry limits electrical interference both to and from the printer.

2-13

Page 26

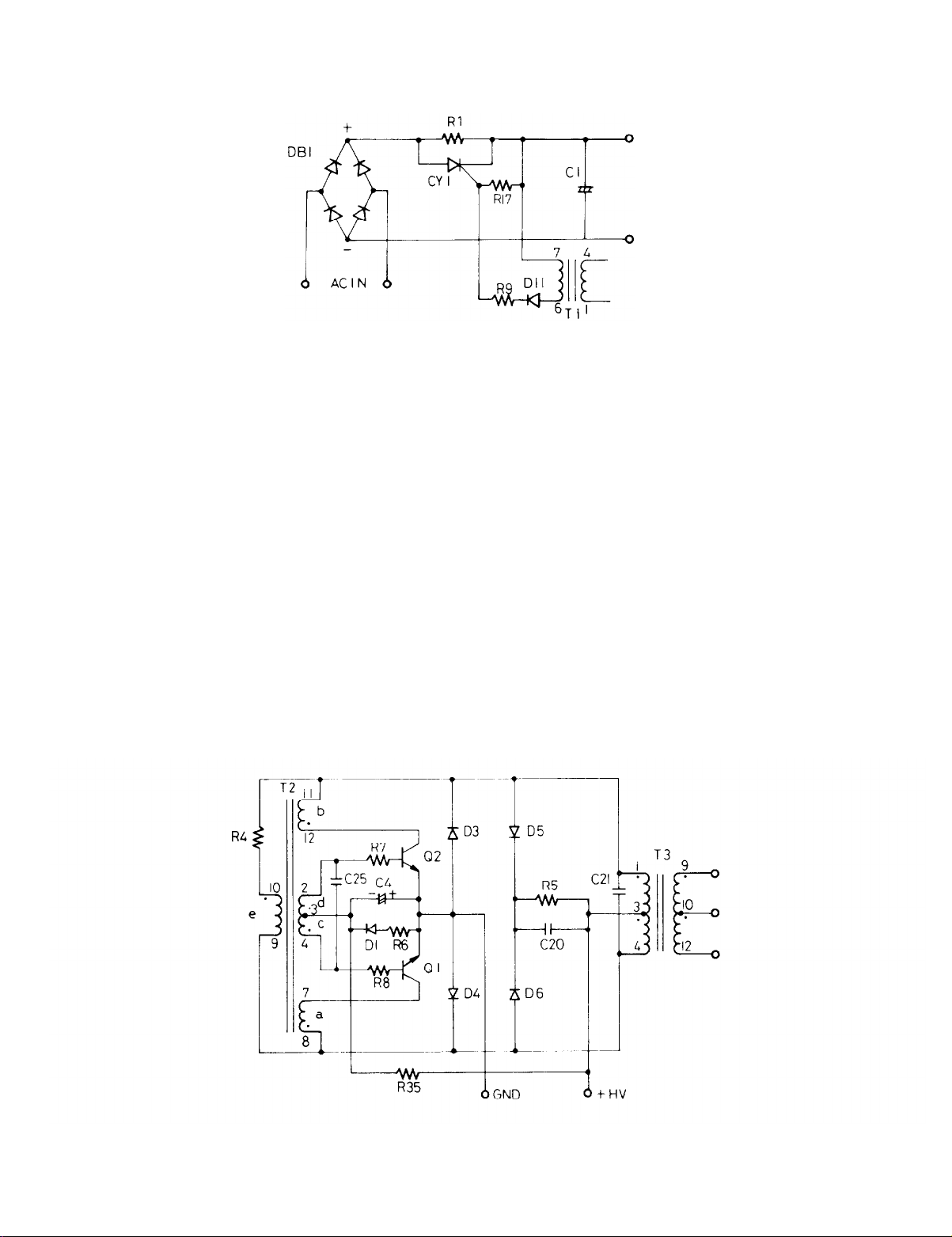

2.

Rectifying circuit and inrush current prevention circuit

(100/120V version)

Fig. 2.4 Rectifying circuit and inrush current prevention circuit

In this power supply system, the AC input is directly rectified by the diode bridge DB1 and the output

voltages are as shown above.

An explosion-proof valve is provided in the upper part of the case of smoothing condenser Cl. If an abnormal voltage is applied to Cl, the explosion-proof valve will open, rendering the part inoperative.

In this power supply system, an inrush current flows at power on. Immediately after power on, when

Cl is not charged, an excessive charging current that may flow can cause the trouble of fuse F1 or

DB1. To prevent it, RI limits the inrush current. In other words, Cl is charged through RI at the time

of power on. With the start of power supply, a voltage is generated at the output of transformer T1,

and this is rectified by D11 and thyristor CY1 IS triggered. Now the thyristor shorts both the ends of

RI, thus completing the action of preventing Inrush current. The thyristor is conducting electricity as

long as the power supply is on.

When the thyristor does not conduct electricity because of some trouble, the power supply remains nor-

mal, but R1 gets heated abnormally. Also, RI may sometimes be disconnected when fuse F1 is blown.

3.

Converter circuit (100/120V version)

Fig. 2.5 Converter circuit

2-14

Page 27

In this circuit, transistors Ql and Q2 alternately supply current to the windings of transformer T3, producing AC voltage as the output. 50/60 Hz input is frequency converted into 20 kHz through the action of

pulse transformer T3. This circuit starts oscillating automatically at about 20 kHz by transformer T2. With

the power supply on, R35 causes the base current to flow and either Q1 or Q2 turns on. Once started, the

base current is supplied from windings a and b, so that the transistor, which has been off, turns on instantly. T2, which is a current transformer, is in a positive feedback connection. 1 /10 of the collector current

from windings c and d as the base current. Oscillation frequency is determind by the length of time it takes

the core of T2 to become magnetically saturated after excitation from windings a and b.

When this occurs, the transistor which has been of opposite polarity is generated at T3.

Winding e adds this voltage to the base current and thus prepares the transistor which has been off, to turn

on. Then oscillation continues, with the trigger voltage from winding e applied to Q1 and Q2 alternately.

R4 limits the current that flows to winding e.

The voltage drop caused by R6 and D1 is smoothed by C4 to produce an inverse bias voltage when Q1 or

Q2 turns off. D3 and D4 are used as the by-pass when part of the magnetic energy is returned to the input

power. D5 and D6 clamp the spike voltage generated by T3 at switching to the DC input voltage via R5

and C20.

The clamp voltage is about twice as large as the DC input voltage. C21 reduces the transitional switching

loss of Q1 and Q2. Q1 and Q2 are parts most liable to develop failure.

Note: When troubleshooting the power supply, Q1 and Q2 should be among the first check points. When

either of these transistors are isolated as a trouble source, both must be replaced. Replacing only

one of the transistors can result in continued problems.

4. Power transformer circuit (100/120V version)

The variable leakage transformer not only performs power transformation by insulating the load from

higher voltage, but also stabilizes the output voltage by controlling the current flow to the control winding.

The VLT raises the DC output voltage by sending DC current into control winding f. From this current, the

VLT outputs a stabilized waveform.

With 20 kHz AC voltage applied to the input windings a and b, the pulse-width controlled AC voltage can

be obtained from the windings c and d. The winding e, which is an auxiliary power source of about 9V, is

used to drive the control winding f.

Fig. 2.6 Power transformer circuit

2-15

Page 28

5.

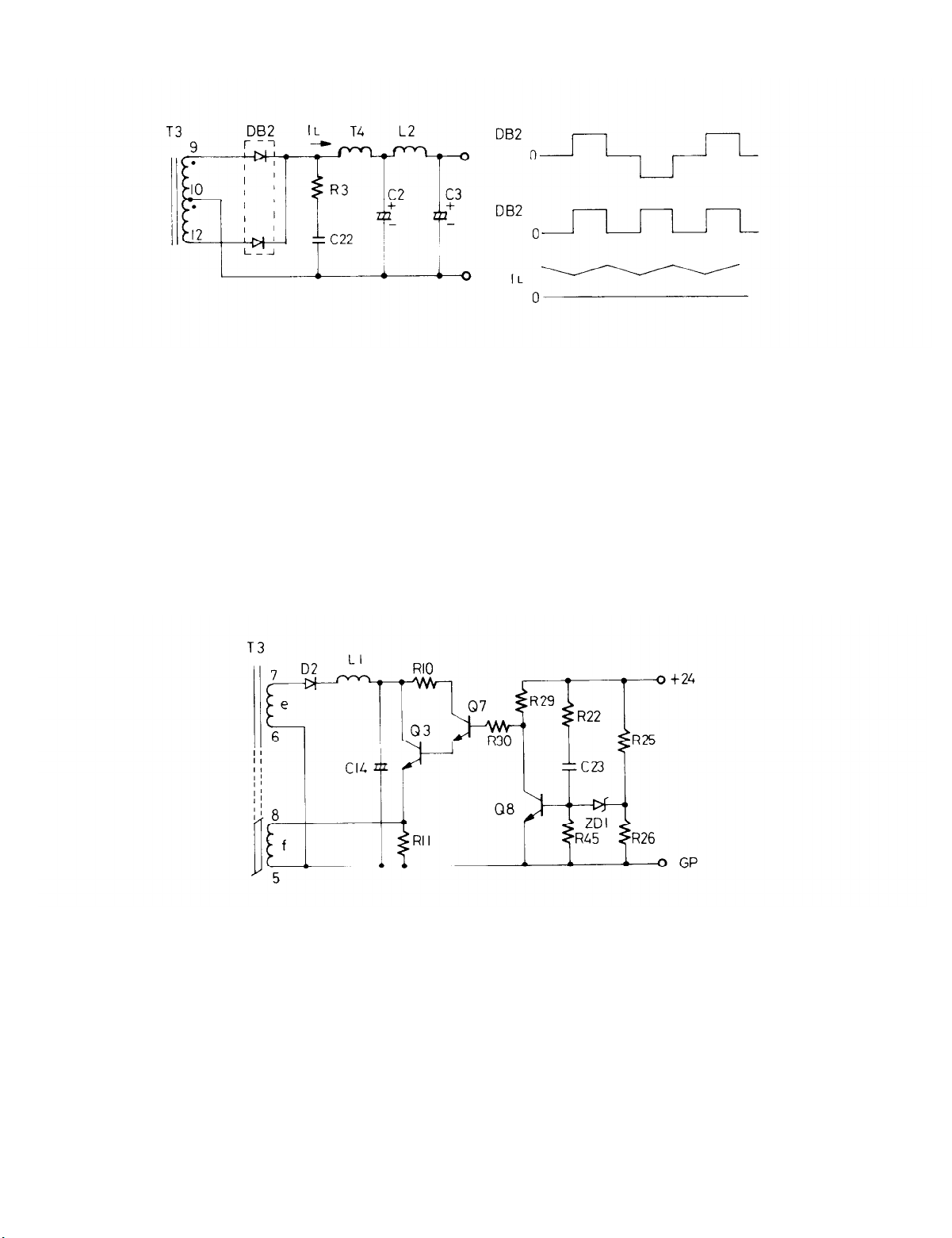

+24V output circuit (100/120V version)

Fig. 2.7 +24V output circuit

The +24V output circuit is capable of supplying an average current of 6A. In this circuit, the pulse-width

controlled voltage from VLT is rectified and smoothed. The output which is a pulse voltage, rectified by

DB2 is smoothed by choke coil T4 and C2, so a continuous load current flows.

T4, excited by the output voltage of DB2, stores magnetic energy. When the current stops flowing from

the VLT, T4 discharges the magentic energy, so the load current flows continuously.

C22 and R3 prevent the spike voltage from occurring as a result of rectification. L2 and C3 constitute a

spike prevention filter.

6. Output control circuit (100/120V version)

Fig. 2.8 Output control circuit

In this circuit, the output voltage is detected and the output is stabilized by controlling the current flowing

to the control winding f of VLT. The current to the control winding is supplied from e, which is the auxiliary

power source, and is driven by Q3 and Q7.

The output voltage is detected by zener diode ZD1 A constant output voltage is maintained which adjusts

the base current of Q7 as assuring a constant current flow to ZD1

If too much current flows to winding f as a result of machine malfunction, the system is short curcuited,

winding f is cut off and output drops below 12V.

R22 and C23 advance the phase so as to maintain a stable output voltage. L1 and C14 constitute and auxiliary power source smoothing filter.

2-16

Page 29

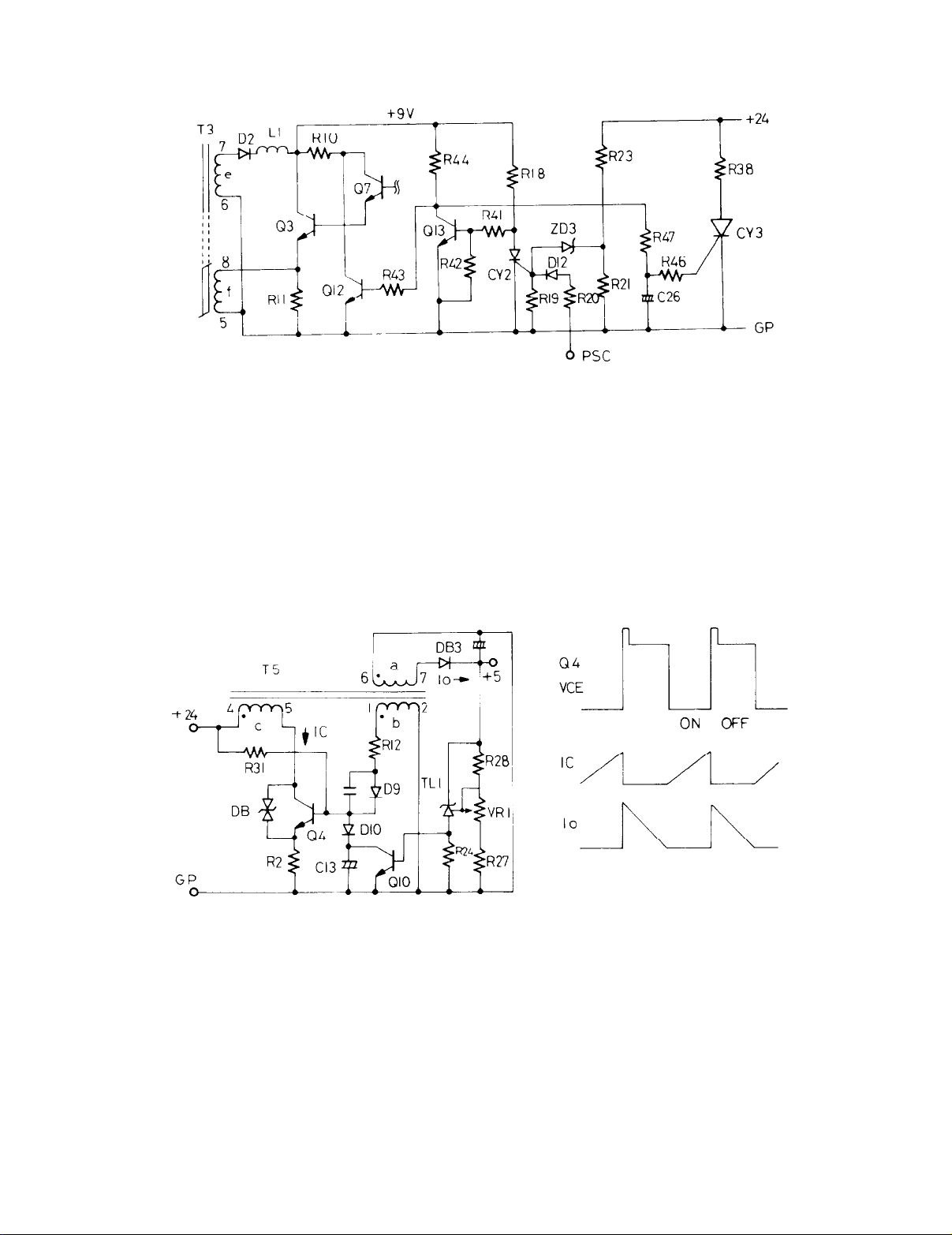

7.

Output cutoff circuit (100/120V version)

Fig. 2.9 Output cutoff circuit

The output cutoff circuit is activated when the PSC signal is input or 30V or more is output as a result of a

malfunction.

When the thyristor CY2 is kept on, Q13 turns on Q12 and stops the base current of Q3, so that power is

not supplied to the control winding of VLT. Then +24V output is shorted by triggering the thyristor CY3.

A PSC signal is output due to failure of a printhead drive transistor.

8. DC-DC converter (100/120V version)

C9-Cll

Fig. 2.10 DC-DC converter circuit

In this circuit, outputs of +5, +I 2 and -12V are produced from +24V.

This circuit starts oscillating automatically at power on.

As the base current flows through R31 and Q4 turns on. With winding c excited, an electromotive force is

generated in winding b. Q4 turns on quickly because positive feedback of the voltage in winding b is made

to the base current of Q4.

With Q4 switched on, the current flowing to winding c continues increasing until it is restricted by the base

current value.

Q4 is turned off quickly by a counterelectromotive force generated in winding b, when increase in collecter

current stops.

2-17

Page 30

The magnetic energy stored in transformer T5 during the ON period is discharged to the load side during

the OFF period. When the magnetic energy is discharged, the counterelectromotive force in winding b is

lost and Q4 starts turning on again. The output is stabilized by controlling the average current flowing to

the winding c.

As +5V output begins to rise, the current flowing into the winding c is reduced, and as it begins to drop, the

current flowing into the winding c is increased. These controls are performed with Q10 shunting the base

current flowing to Q4. The voltage detector TL1 adjusts the base current of Q10 to maintain the +5V output constant.

The oscillation frequency of the circuit lowers with more lead current or rises with less load current.

Under no load, the oscillation becomes intermittent. Normally the circuit operates at about 30 kHz.

D10 and C13 rectify and smooth the base voltage of Q4.

D13, which is a two-way zener diode, clamps the surge voltage generated by T5 to 68V to protect Q4.

VR1 is used to set the +5V output voltage.

9. +5V output circuit (100/120V version)

+5V output is used for the logic circuit.

The current flowing through DB3 charges C9 through 11. The extremely large current value, however

causes a large output voltage ripple which is smoothed by Ls and C12.

10. 12V output circuit (100/120V version)

12V output, which is not stable, is used by RS-232C.

Since the DC-DC converter stabilizes the output by detecting +5V, the output voltage drops to about 5V

when +5V is under no load.

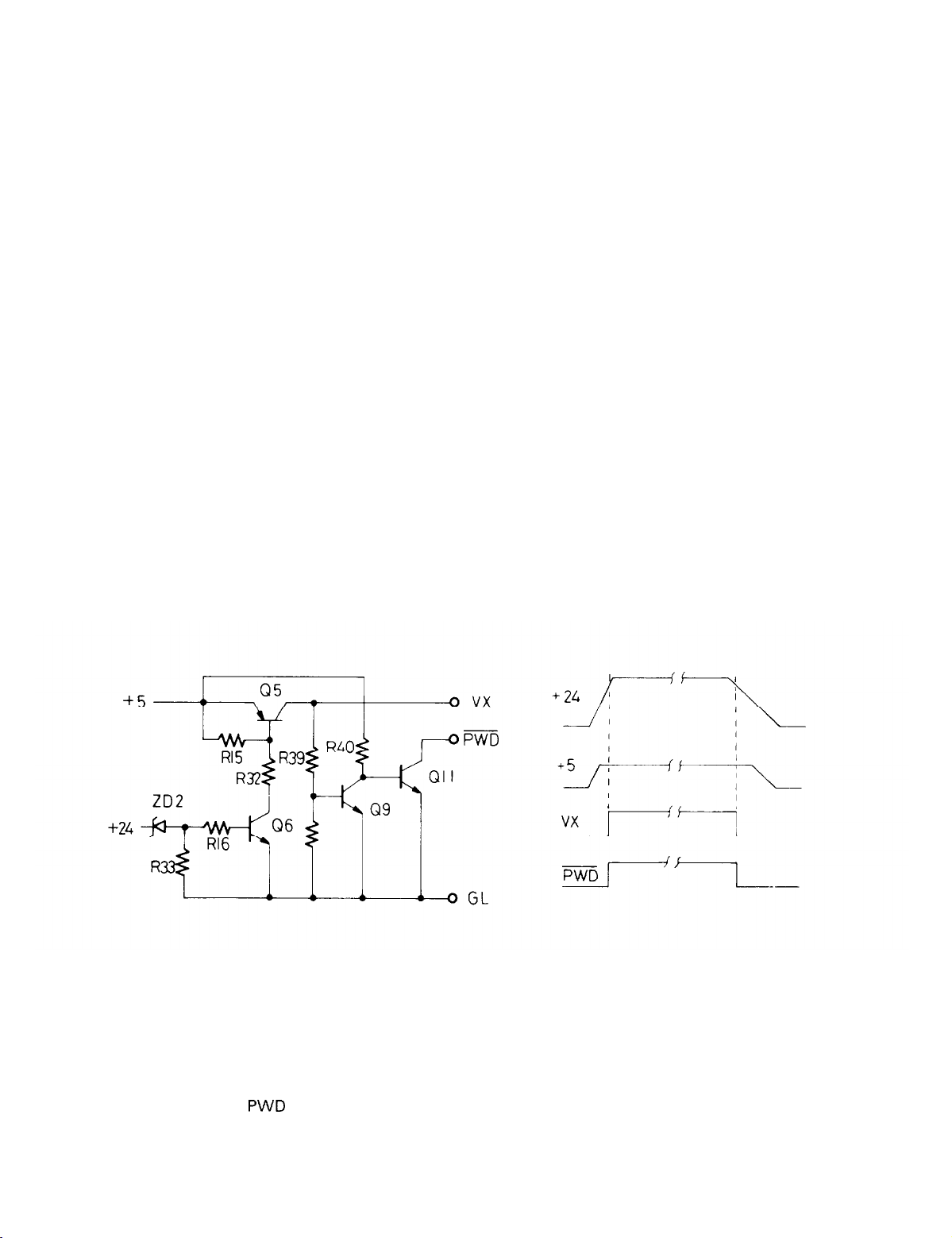

11. Vx. PWD circuit (100/120V version)

Fig. 2.11 Vx. PWD

Vx is output when +5V and +24V voltages become stabilized and is used to prevent the misoperation of the

printer when the power supply is turned on or off.

+5V make from +24V, retains the stable condition longer than +24V. Therefore, Vx is output when the

+24V output is +21 V or above.

A voltage drop on the +24V line due to a power failure or machine malfunction turns Q11 on and triggers

the PWD signal. When PWD is output the CPU is reset and the printer is stopped.

2-18

Page 31

[B] 220/24OV version circuit

1. Noise filter circuit (220/24OV version)

Fig. 2.12 Noise filter circuit

A switching regulator generates noise because of its circuit configuration. Each country

has its own noise

regulations, the circuit configuration, Fig. 2.12, is adopted to meet VDE 0871 class B.

2. Rectifying circuit, inrush current prevention circuit and converter circuit (220/24OV version)

Fig. 2.13 Rectifying and converter circuit

The supply voltage passed through the noise filter circuit is rectified at D101 and smoothed at Cl06 and

Cl 07, providing the mid-point voltage as shown in Fig. 2.13.

R101 and SCR101 form an inrush current prevention circuit. When power is applied, the current is

charged to C106 and C107 via R101 with SCR101 OFF. When the charged voltage rises, the converter

oscillates, SCR101 turns ON and the current path changes from R101 to SCR101 Switching transistors

Tr101 and Tr102 form a symmetric excitation half-bridge type converter which is activated by T101. The

oscillation frequency depends on the saturation of T101. This converter supplies a symmetric pulse voltage to the transformer.

2-19

Page 32

3. Power transformer circuit (220/24OV version)

Fig. 2.14 Power transformer circuit

The transformer

T102,

a variable leakage transformer, has a construction capable of output control.

The pulse voltage input to the primary winding (terminals 1 and 4) is controlled by the DC current flowing

at the control winding (terminals 5 and 8) and is output to the secondary winding (terminals 9 - 12).

As shown in Fig. 2.16, the width of the pulse output to the secondary winding increases as the control current is made larger.

2-20

Page 33

Fig.2.16 Switching regulator circuit

This circuit is formed by a chopper circuit with a power supply of +24V.

As shown in Fig.2.16. when transistor Tr301 turns ON, collector current ic flows, supplying current to the

load.

At the same time, magnetic energy IS being stored in choke coil L (See Ton, Fig. 2.16). If transistor Tr301

turns off, collector current is also cut off. When this occurs, choke coil L maintarns current flow by emitting

the stored magnetic energy In the form of current, supplying the load and flywheel diode D.

Output voltage, Vout, is maintained at a constant level by a control IC, which constantly monitors output,

and switches transistor Tr301 on or off, as required to maintain a constant output.

The relationship between the input and output voltage is expressed as:

T

=-

ON

x Vin

Vout

T

5.

Vx, PWD (Power down) circuit (220/24OV version)

Fig.2.17 Vx, PWD circuit

This circuit compares the

+24V

output with the reference voltage to generate Vx.

The +24V output is divided by R402 and R403. Then, the devided voltage is compared with the reference

voltage obtained by ZD401. When it exceeds 2OV, TR402 turns ON and sends 5V to pin Vx. At

the same time, open collector transistor TR403 turns ON.

This circuit has a slight hysteresis to prevent chattering due to ON/OFF operation.

2-21

Page 34

2.4.2 Reset circuit( Fig. 2.18)

The reset signal is used to reset and start the CPU, causing It to initiate the routine which initializes the processor and associated circuitry.

The reset signal is output only in the following cases:

I) At power on: The signal is output for about 30 ms at the turning on of power.

2) By interface signal: The signal is given while the INIT signal is output from the host computer.

Fig. 2.18 Reset circuit

The reset signal is output at power on when Vx (+5V) is applied to the power on reset circuit, consisting of

RM9, R3 and C4; it is passed on to IC 9B, pin 1, 8B and 8A, which IS the reset signal port initiator.

Time constant of the reset pulse is applied at R69 and C4.

This time constant is approximately 30 ms.

Upon the input of an INIT signal from the interface board, the interface reset (INIT) signal is input to: the

main CPU Z-80A; slave CPUs 8042 and 8041, PPI 8255AC-5; gate array uPB6101-009; and timer

NE555. The INIT signal is output only during the system reset or I/O reset of the host computer that controls the LQ-1500.

If power is off the reset cannot be output.

2.4.3 Sensor circuit

Five sensor circuits (HP, MTS, DTS, PE and HOT1 and 2) monitor status of the printer mechanism and inform the Z80-A CPU as to the mechanism’s operational status at any given time.

1)

Home position sensor circuit (Fig.2.1 9)

Fig. 2.19 HP sensor circuit

Page 35

The home position sensor circuit detects signals defining when the printhead is in or out of the home position. The signal is read when the power switch is turned on or signal INIT is applied to the printer. This circuit also operates at the instruction of carriage return.

When the carrage is out of the home position, phototransistor turns on causing a HIGH output signal to be

emitted to the CPU. At the return of the carriage to the home position, the photocoupler is screened, the

phototransistor is turned off, and the output of HP drops to LOW. The carriage is in the home position, and

it is notified to the 8042. The output signal from the phototransistor is integrated and input to the Schmitt

circuit, which prevents the waveform of the output signal from being disturbed by noise or mechanical vi-

tion.

bra

MTS sensor circuit

2)

Fig. 2.20 MTS sensor circuit

The MTS sensor circuit detects the signal that defines the speed of the head carriage. When the light is

screened by the slit plate (Fig. 2.21) at the photocoupler, the photodiode turns off and HIGH level voltage is

applied to the transistor base of the sensor so that the transistor turns on. As a result, the MTS signal be-

comes LOW. When the light passes through the slit, the photodiode turns on and the transistor of the sensor turns off, so that the MTS signal becomes HIGH.

The period of MTS signal is 860s in the draft mode and 2.52 ms in the letter quality (LQ) mode.

Fig. 2.21 Sensor assembly

2-23

Page 36

3) DTS sensor circuit (Fig.2.22)

Fig. 2.22 DTS sensor circuit

The DTS sensor circuit detects the print timing signal. This signal comes in three pulses in one period of

MTS. As shown in Fig. 2.22, it operates the same way as the MTS sensor circuit.

The timing of DTS signal is 287s in the draft mode and 840s in the letter quality (LQ) mode.

Fig. 2.23 PE sensor circuit

The paper end sensor circuit employs a magnet-electricity conversion system using a Hall IC; output is of

the open collector type. The output signal from the sensor is integrated once and input to the Schmitt circuit, which prevents the waveform of the output signal from being disturbed by noise or mechanical vibration.

When paper has been inserted in the mechanism, the Hall IC is off and pulled up by R63, so that the output

of PE signal is LOW. When the paper is gone, the Hall IC goes on and the collector drops to ground level,

so that the output of PE signal becmes HIGH. The PE signal is applied to T1 (pin 39) of CPU8041 A. It is

possible to render the PE signal Ineffective via a control code or DIP switch setting.

The RE sensor will be ignored and the error signal will not function when DIP switch 2-2 is set or an ESC 8

control code is input. In this mode of operation, although the PE LED goes on, the READY LED remains on

and data can still be received.

* See the operating manual for an explanation of DIP switch settings and use of control codes.

2-24

Page 37

5) Head temperature sensor circuit (Fig. 2.24)

Overheating of the print head during heavy duty printing operation is prevented by the head temperature

sensor circuit.

Fig. 2.24

Head temperature sensor circuit

The head temperature sensor circuit detects the temperature of the print head unit

A fan, situated at home position circulates air, providing a cooling system.

As the temperature of the print head unit reaches approximately 100°C or above, the printing is halted temporarily and the print head unit IS returned to the home position.

A thermistor provided in the print head unit is pulled up to 5V. As the temperature of the unit rises, the resistance decreases and the voltage at the negative terminal (HOT1, HOT2) of the comparator rises higher

than the positive terminal of the comparison voltage.

As the output terminal becomes LOW, Q3 switches from on to off, and the collector level moves from LOW

to HIGH.

2-25

Page 38

2.4.4 Carriage motor control circuit (Figs. 2.25.26)

The control signal of the carriage motor is output from 8042 of the main circuit board. The signal is first

received by the transistor array and then driven by the regulator IC STK6982 (IC2).

The 2-2 phase carriage motor runs in combinations of phases A to D. (See Table 2.14 and Fig. 2.25.)

Fig. 2.25 Motor circuit

The belt, motor sequence for driving the timing belt is shown below.

2-26

Page 39

Fig. 2.26 CR motor drive circuit

2-27

Page 40

The phase changing signal for the carriage motor is output from P20 and P21 of CPU 8042. The control

signal of phases A and B is inverted via the phase inverter, 1 1 C, and used as the control signal of phase C

and phase D, respectively.

Power supply to the carriage motor is monitored by resistances RI and R2 connected to the EAB and ECD

terminals of STK6982, and the outputs of CAB and CCD are controlled in accordance with the reference

voltages S12 and S34 of the comparator inside STK6982. Accordingly, the speed of the carriage motor

can be changed by changing this reference voltage; reference voltage changes depending on whether the

resistances R42 and R43 or R44 and R45, connected to the transistor array by the output of P23 and

P24

of 8042, are selected. Also, ZD4 is provided to prevent counterelectromotive force. Power supply to the

motor is such that switching to high speed can be made by STK6982. The electric energy stored in each

coil is discharged following the end of power supply there, which can cause the breakdown or malfunction

of the elements. To prevent It, the energy produced by the counterelectromotive force is released through

the zener diode.

When the output of P22 of 8042 is HIGH, the HOLD terminal of STK6982 is HIGH. Therefore the common

line is cut off from 24V power supply and, instead, the power is supplied from Vp via the cement resistances D32 and D33. And the current flows through all the phases simultaneously, thus putting the carriage motor in a HOLD state.

Control method:

The Model-3660 carriage drive motor can be stopped at any position by controlling acceleration/

deceleration and the alternation of print direction.

A closed loop control method is used in which the MTS timing signal is fed back to the pulse motor drive

phase switching.

Closed loop control:

The motor phase switching is made by comparing the MTS output from the printer to the control time setting.

When the MTS period, compared with the time setting, IS longer, the CR motor phase switching is made at

the leading edge of MTS. (See Fig. 2.27.)

When the MTS time setting is shorter, MTS is output within the time setting, though the CR motor phase

switching is not made at this time, but after the lapse of the time setting. (See Fig. 2.27.)

2-28

Page 41

(1) Motor bias voltage

The bias voltage for the motor is of two kinds; one for operation use and the other for non-operation use.

Table 2.15 Motor bias voltage

(2) Carriage motor drive signal timing

(a) Acceleration control and constant speed control

For acceleration control and contant speed control, the following time settings (Table 2.16) are available in

the printing speed

(CR

motor speed) modes of1163 pps, 769 pps, 592 pps and 397 pps:

Table 2.16 Speed control table

2-29

Page 42

Table 2.17 Data of decelerate time

Page 43

Fig. 2.29 Deceleration and stop at home position (In case of 1163,769 pps)

Page 44

Fig. 2.30 Acceleration and printing control from position other than home position

Fig. 2.31 Deceleration and stop at home position (In case of 1163, 769 pps)

Page 45

(c) Home Position Seek

Movement of the carriage to home position at printer power on is called the home position (HP) seek.

The CR motor speeds during the home position seek are all in the 1163 pps mode. The following flow

chart exemplifies sequence of HP operational events.

Fig. 2.32 Flow chart of home position seek

2-33

Page 46

(d) Acceleration and printing control from home position:

@

By the control of a) and b) of 12), the carriage is moved from left to right (column 1 to column 80).

In this case, reading to recognize the HP signal is done only in the excitation condition memorized

in v) of d). Accordingly the HP signal read timing is every four MTSs.

@

The print occurs during MTS and thereafter following the MTS where the HIGH of the HP signal is

recognized. The printing occurs during maximum of MTS 816 pulses (DTS2448 pulses).

(e)

Deceleration stop at positions other than home position:

Deceleration control is started from the next MTS (Tm + 1 = T) after the printing of the last dot on the

line (MTS immediately after this if Tm). It is stopped after 18 times of phase switching.

(f)

Acceleration and printing control from positions other than home position:

@

By the control of a) and b) of 12), the carriage is moved in a chosen direction.

@

The printing area is the 19th MTS (TN) and thereafter.

(g) Deceleration and stop at home position

The HP signal is recognized at every MTS during the shift of the carriage from right to left (column 136

to column 1 ), deceleration is started from the next MTS (TM + 1) of the MTS (TM) where the change of

HIGH to LOW of HP signal is recognized, and the CR motor is stopped after 18 phase switches.

(h) Setting of speed control terminals

In each control mode the terminals of 8042 (P23 and P24) in the Fig. 2.26 must be set as follows:

Table 2.18

2.4.5 LF motor control circuit (Fig. 2.34)

The control signal of the 4-phase excitation LF motor (Fig. 2.33) is output from CPU 8041 A on the main

circuit board. This signal is sent to IA to ID inputs of the transistor array HA1 3007. With the input at HIGH

Level, the inside transistor turns on, forming a closed circuit of power supply (+24V): LF motor, diode,

HA1 3007, GND, and the current flows through the coil of the LF motor. The LF motor is thus driven with

the voltage-applied phase switched by turning the transistor on and off inside HA1 3007 by the input signal IA to ID.

The operation mode or the non-operation mode can be selected by the output of P27 of CPU 8041 A.

With this output at HIGH, transistor 029 is off and +5V is supplied to LFCOM via resistance R4 and diode

D31, putting the LF motor in the non-operation mode. With the output of P27 at LOW, on the other hand,

transistor Q29 is on and Vp (+24V) is supplied to LFCOM via D30, putting the LF motor in the operation

mode.

Basically, the belt motor is driven by the 2-2 phase excitation system

Fig. 2.33 LF motor circuit

2-34

Page 47

Fig. 2.34 LF motor drive circuit

(1 ) Motor bias voltage

The bias voltage for the motor is of two types. One for operation use and the other for non-operation use

Table 2.20 Motor bias voltage

(2) Paper feed step motor driven signal timing

Fig. 2.31 shows the time chart for control of the paper feed step motor. The control method is a ramp-up

and ramp-down control. The time settings for this control are as shown in Table 2.21.

This control, however, is not performed when the amount of paper feed is five steps or less. The time set-

ting at this time is constant speed drive of 4.2 ms per step.

(4) Paper feed time

3.3 ms/0.l41 mm

100 ms/4.23 mm (with continuous paper feed)

2-35

Page 48

Fig. 2.35 Paper feed timing chart (In case of N pulse paper feed, N > 5)

Page 49

2.4.6 Head driver circuit (Fig. 2.36)

(1 ) Solenoid driving control

The head has 24 coils and +24V is always supplied to one end of each of the coils. To effect printing with

the coils powered, it is necessary to switch on the driver transistors Q1 to Q24 and bring the voltage at

one end of the relevant COils to the GND (Fig. 2.32).

A sample sequence is as follows.

Print data put on the data bus are output to each port by a total of five control signals, namely, the A0 and

Al signals from the main CPU Z80A, the control signal from Z80A, the RD and WR signals from the gate

array uPB6101-009, producing various timing signals used inside the LQ-1 500, and the chip select signal

from the decoder LS138. The output data is input to the transistor array and produces an open collector

output and is pulled up to Vx by the block resistance RM1 and RM2.

With the port output of 8255AC-5 going LOW, the out terminal of µPA79C is internally disconnected from

the ground and assumes an Open state.

With the port output of 8255AC5 HIGH, the output terminal of µPA79C is internally connected to ground.

The driving pulse width is determined by the output of pin 1 1 of IC 10C. When this output is LOW, Q1 is

on and the power supply Vx is applied to the base as a pulse to turn on Vcc of uPS79C and the driven transistor through Q1. Thus the power is supplied to the solenoid and the head pin is driven.

After the lapse of driving time, as shown in Fig. 2.32, the output of pin 11 of IC 10C goes HIGH, Q1 turns

off and the supply of Vx stops. The driver transistor 2SD1 392 then turns off to stop the solenoid drive.

When the output of pin 1 1 of 10C 1 0C goes HIGH, the output of pin 8 goes HIGH simultaneously and by turn-

rng 04 on, the base charge of the driver transistor is released to the ground through block resistances

RM1,

RM2,

R2 and Q4. This realizes a high-speed switching of the driver transistor.

Voltage applied to print head (VDC)

Fig. 2.36 Applied head voltage and driving time

2-37

Page 50

(2) Counterelectromotive force absorbing circuit

As the power supply to the solenoid is switched on and off at high speed, counterelectromotive force is

produced in the coil. So that the driver transistor is not adversely affected, a diode and a diode array are

provided to each driver transistor (points A, B), and a transistor, resistance, zener diode and electrolytic capacitor (D19, Q27, R6, ZD3, C7) are provided for every 8 driver transisters by wired OR as shown in Fig.

2.37.

As the counterelectromotive force becomes about 44V at point D in the figure, the current flows into the

base of Q27 through R6 and ZD3. Then 027 turns on and the voltage beyond it is fed back to the power

supply Vp via 027.

(3) Protective Circuit

The Voltage at point C in Fig. 2.37 IS at GND level during the solenoid drive and +24V during the non-drive

period. Because of the zener diode ZD3 provided, the current does not flow through the zener diode during

the drive. And the output of pin 15 of 15C becomes open and is pulled up to +5V by R23. During the non-

drive time, the current flows through the zener diode and the output terminal of pin 15 of 15C is internally

connected with ground. The output of pin 2 of 14C on the other hand is internally connected to ground

during the drive sequence and is pulled up to +5V during the non-drive period.

The output of pin 15 of IC 15C and the output of pin 2 of 14C are in wired CR. Consequently, as long as a

normal power is supplied to the solenoid, point E in Fig. 2.37 is always connected to ground. Because voltage Vx is applied to the base of Q2, Q2 remains OFF.

However, if power is continuously supplied due to failure of the driver transistor, point E in Fig. 2.37 goes

HIGH and the base of Q2 lowers to GND. Hence, Q2 turns on, Vx is sent as PSCUT to the power supply circuit, and the power supply circuit, receiving this signal, stops the power supply.

Fig. 2.37 Head driver circuit

Page 51

(4) Driver circuit waveform

Fig. 2.38 Driver current waveform

2.4.7 Auto sheet load circuit

The auto sheet load circuit sets the paper when the sheet load switch is pressed. The operation consists of

the control of the paper hold release lever and the control of the paper feed motor. Refer to 2.4.5 for the

control of the paper feed motor. The CPU 8041 (12D) first checks the OFF-LINE condition when sheet load

switch on the control panel is pressed. Then, if the printer is OFF-LINE, the 8041 determines wheather

paper is set in position. When paper is present, the output of P21 of 8041 goes LOW and the output of pin

10 of IC 15C goes off. Since it is pulled up to 5V by R19, Q30 turns on, the solenoid is driven, and the paper hold lever is released.

In this state, the PF motor is driven at 510 pulses to execute paper feeding. On completion of paper feed,

CPU 8041 brings P21 to high level. Since pin 10 of IC 15C is internally connected to ground, Q30 turns

off, and the base lowers to ground. The solenoid drive is stopped and the paper hold lever turns to the original position. By this control the printing start position is set to about 21 mm from the paper end (print

position of head wire 12). And it is about 19.5 mm at the top of character

Fig. 2.39 Auto sheet load circuit

2-39

Page 52

2.4.8 Other function

Logical seeking (Fig. 2.40)

The logical seeking maximizes operation speed of the bidirectional printer. It does away with the necessity

to start printing from the left end (home position) after each line of printing, but permits printing from any

position after a line feed. Fig. 2.40 shows the sequences of logical seeking.

(a)

When the power switch is turned on, the head carriage, regardless of its position, returns to the left

end, home position in an action of @ to

(b)

Upon receiving print data “EPSON” for a line, the printing is performed in an action of @ to @ with

the head carriage moving to

(c)

The CPU, receiving the next data, analyzes It and determines the acceleration start position of the car-

positior! @.

0.

riage.

(d)

In an action of @ to 0, the carriage is moved to position

@).

Then it goes through acceleration,

printing and deceleration.

(e)

In an action of @ to 0, acceleration and printing are performed. Then the carriage returns to the

home position because in this case the stop position is considered equivalent to the reset position.

Fig. 2.40 Logical seeking

Page 53

2.5 Printer Mechanism (Model-3660)

The Model-3660 printer mechanism features a 24-pin print head and incorporates all of the sophisticated

technology of previously produced EPSON printers.

Operation of the 24-pin print head is supported by the carnage components, including the timing belt, ribbon driving gears, and the carnage motor; the paper feed mechanism, including the platen sprocket assemblies and paper feed motor; and the sensors, which communicate the disposition of the print head and

the paper supply at any given time. The printer mechanism is illustrated in Fig. 2.41.

Fig. 2.41 Appearance of the printer

2.5.1 Operation

2.5.1 1 Sensor mechanism (Signal generating mechanism of Model-3660)

The sensor mechanism is composed of an HP (home positron) sensor, an MTS/DTS sensor, a PE (paper

end) sensor and a print head temperature sensor.

l

The purpose of the HP sensor is to determine the home position of the carriage. The sensor generates

a reference signal for the printing position.

0

The MTS/DTS sensor detects the carnage speed and print timing.

0

The PE sensor detects the presence or absence of paper.

0

The print head temperature sensor detects the internal temperature of the print head. The sensor out-

puts a signal when the print head reaches temperature levels which could damage components.

2-41

Page 54

1) HP (home position) sensor

The HP sensor consists of an HP sensor board and a sensor plate located at the bottom of carriage.

While the sensor plate intercepts the optical axis of the photocoupler, a HIGH signal is emitted (open

collector output).

2) MTS/DTS sensor (print timing signal sensor)

The MTS/DTS sensor consists of an MTS/DTS sensor board and a sensor plate located on the car-

riage motor shaft. When the slit of the sensor plate comes to the predetermined position, an LOW

signal is given (open collector output).

Fig. 2.42 MTS/DTS sensor

3) PE (paper end) sensor

The PE sensor consists of a Hall IC mounted on the PE sensor board and a permanent magnet

mounted on the PE sensor lever. When the printer is out of paper, the magnet touches the Hall IC

and generate a signal.

4) Print head temperature sensor

Two thermistors are built into the print head to detect excessive temperature gains. Their resistance

value aids in maintaining component compatible operating temperatures.

2.5.1.2 Print head assembly

The print head unit mounted on the carriage is moved right and left on the carriage shafts A and B by

the operation of the timing belt. This belt is driven by the timing belt motor assembly through the belt

driving pulley and belt driven pulley.

1) Carriage assembly (Fig. 2.43)

The carriage assembly is moved by the timing belt which is driven by the four phase carriage motor.

Each motor phase produces a movement of the carriage. As the timing belt motor runs, the DTS sig-

nal is generated, and current is also fed through the head driving coil, causing the dot wires to fire.

2-42

Page 55

Fig. 2.43 Carriage mechanism

2) Operation of print head unit (Fig. 2.44)

The movement of a dot wire in printing a dot is as follows:

@

With the current flowing through the head driving coil, the actuator plate is attracted to the iron

core. At this time, the dot wire, which is engaged with the actuator plate, flies out against the

platen assembly.

@

The dot wire thus pushed out strikes at the platen assembly and prints a dot on the paper

through the ribbon

@

On completion of the supply of current to the head driving coil, the actuator plate is caused to re-

turn to its original posltion by the action of the spring. By the impact energy and the force of the

wire return spring, the dot wire is brought back to the original position to engage with the actuator plate and held in readiness.

Fig. 2.44 Print mechanism

2-43

Page 56

3) Correspondence between dot wires and FPC terminals

Fig. 2.45 Printhead connector

2-44

Page 57

2.5.1.3 Paper feeding mechanism

The paper feeding mechanism of the printer comprises two systems: a friction feed system to be used for

cut sheet and a tractor feed system to be used for continuous business form 4 - 16 inches in width.

Each of the two systems have functions such as ordinary feeding and quick feeding. The printer is also

equipped with an auto loading mechanism for setting cut sheet automatically for printing.

1 ) Friction feed system (for cut sheet) (Fig. 2.47)

The paper is held between the platen, the paper feeding rollers and the paper holding rollers. When

the pulse motor rotates, the gears constituting a paper feeding gear train are driven in the directions

of arrows, respectively. Consequently, the paper is frictionally fed by the platen, paper holding

rollers and paper feeding rollers in the direction of the arrow. The paper holding rollers and paper

feeding rollers are pressing the paper against the platen by the action of springs.

The paper can be set free by operating the release lever.

Fig. 2.46 Friction feed mechanism

2-45

Page 58

2) Tractor feed system (for continuous business from 4 - 16 inches in width)

The paper is held on sprocket wheels, some of the sprocket pins being engaged in holes in the paper.

When the pulse motor rotates, the gears in the paper feeding gear train are driven in the directions

of arrows, respectively. Consequently, the paper is driven by the sprocket wheels in the

direction of the arrow.

When the tractor feed system is used, the paper feeding rollers are held apart from the platen by

the action of the release lever.

Fig. 2.47 Tractor (sprocket) feed mechanism

2-46

Page 59

3) Auto loading mechanism

Set a cut sheet between the platen and the paper feeding lever. When the release solenoid is energized, the solenoid shaft, sub paper holding lever and paper holding lever move in the direction of

the arrow respectively to disengage the paper holding roller from the platen. At this point, the pulse

motor (for paper feeding) is driven to feed the paper as specified. When the release solenoid is deenergized, the solenoid shaft, sub paper holding lever and paper holding lever return to their original

positions respectively, causing the cut sheet to be pressed against the platen and set for printing.

Fig. 2.48 Auto loading mechanism

2-47

Page 60

2.5.1.4 Ribbon feeding mechanism (Fig. 2.49)

The ribbon unit consists of a cassette ribbon and a ribbon feeding mechanism. The ribbon feeding me-

chanism is set at the bottom of the carriage.

When the carriage moves to right or left, the ribbon driving pulley is turned by the ribbon driving wire

wound around it so that the ribbon driving gear always turns counterclockwise in the next gear train.

The inked ribbon is housed in the cassette case in an endless state. The inked ribbon between the ribbon

feeding roller and the ribbon pressure roller is fed when the ribbon feeding roller set in the ribbon driving

gear is turned.

A ribbon braking spring is provided at the exit of the cassette case for preventing the ribbon from losing

tension, and a ribbon mask IS provided for protecting the paper from being stained by the inked ribbon.

Fig. 2.49 Ribbon feed mechanism

2-48

Page 61

CHAPTER 3

OPTIONAL EQUIPMENT

Centronics Compatible

3.1

3.1 .1

Overview..

3.1 .2 Specification..

3.1 .3 Operating

3.1 .4 Block diagram..

3.1.5 Circuit diagram..

3.1 .6 Component

RS-232C/Current

3.2

3.2.1 Introduction

3.2.2 Specification..

3.2.3 Operating

3.2.4 Block

3.2.5 Circuit diagram..

3.2.6 Component

IEEE-488

3.3

3.3.1 Introduction

3.3.2 Specification..

diagram..

Interface..

Parallel

...................................................................................

.............................................................................

principal

...........................................................................

.........................................................................

layout..

Interface

Loop

................................................................................

.............................................................................

principal

...........................................................................

.........................................................................

layout..

.............................................................................

................................................................................ 3-22

.............................................................................

interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

....................................................................

....................................................................

.......................................................

....................................................................

....................................................................

3-1

3-1

3-1

3-4

3-6

3-7

3-8

3-9

3-9

3-9

3-15

3-19

3-20

3-21

3-22

3-22

3.3.3 IEEE-488 operational parameters..

3.3.4 IEEE-488 functional commands..

3.3.5 Block diagram..

3.3.6 Circuit diagram

3.3.7 Component layout..

3.4 Single Bin Cut Sheet Feeder (# 8334).

Double Bin Cut Sheet Feeder (# 8344)

3.4.1 Introduction

3.4.2 Specification

3.4.3 Principle of operation..

3.4.4 Disassembly and assembly,

3.4.5 Troubleshooting

3.4.6 Preventive maintenance

...........................................................................

...........................................................................

....................................................................

...

.............................................................................

...............................................................................

..............................................................

..................................................... 3-42

.........................................................................

...........................................................

..........................................

............................................. 3-27

..............................................

3-26

3-29

3-31

3-32

3-33

3-33

3-34

3-36

3-52

3-60

Page 62

3.1 Centronics Compatible Parallel Interface Unit (Cat. No. 7171)

3.1 1 Overview

With the IUPIF interface board, a centronics parallel data from a host computer can be output to and painted dot by the EPSON LQ-1500 terminal printer.

3.1.2 Specification

3.1.2.1 Interface

(1) Data Transmission

(2) Synchronization

(3) Handshaking

(4) Logic level

3.1.2.2 Condition setting on the interface board

These are two DIP switches on the centronics parallel interface board. These switches are set as follows:

(1) DIP switch setting

A. DIP 1

: 8-bit parallel

: Externally supplied STROBE pulses

: ACKNLG or BUSY

: Input data and all interface control signals are TTL compatible.

Table 3.1

B. DIP 2

Table 3.2

Note 1: With this switch ON, the printer does not perform normal operation.

3-1

Page 63

International Character Selection

Table 3.3

3.1.2.3 Pin assignment of interface connector

A. CN1 : This connector communicates with CN1 of the UXMCL board. (Refer to Tab

B. CN2: Future specification

C. CN3: This connectorcommunicates with the host computer.

(1) Number of pins.....36 pins

le 3.1)

Table 3.4 Pin assignment (CN3 of IUPIF)

3-2

Page 64

3.3