Epson LQ-1170, LQ-870 Service Manual

EPSON

EPSON TERMINAL PRINTER

LQ-870/1170

4000694

REV.-A

NOTICE

* All rights reserved. Reproduction of any part of this manual in any from

whatsoever without SEIKO EPSON’s express written permission is forbidden.

‘ The contents of this manual are subject to change without notice.

“ All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

* The above notwithstanding SEIKO EPSON can assume no responsibility for any

errors in this manual or the consequences thereof.

@

Copyright 1991 by SEIKO EPSON CORPORATION

Nagano, Japan

-i-

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1 ) personal injury, and 2) damage

to equipment:

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS

OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE EPSON WARRANTY.

/wP

CHIPS AND CIRCUITRY, USE STATIC

- ii –

PREFACE

This manual describes functions, theory of electrical and mechanical

operations, maintenance, and repair of the

The instructions and procedures included herein are intended for the

experienced repair technician,

precautions on the preceding page. The chapters are organized as follows:

and attention should be given to the

LQ-870/l

170.

REV.-A

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Chapter 5 -

Chapter 6 -

‘

The contents of this manual are subject to change without notice.

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer operation.

Includes a step-by-step guide for product disassembly and

assembly.

Includes a step-by-step guide for adjustment.

Provides Epson-approved techniques for troubleshooting.

Describes preventive maintenance techniques and lists

lubricants and adhesives required to service the equipment.

-

iv -

REV.-A

REVISION SHEET

A July 23, 1991

1st issue

~

. . .

:

.

-v-

~<...

. ,.

,,

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATION PRINCIPLES

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6. MAINTENANCE

APPENDIX

DISASSEMBLY AND ASSEMBLY

ADJUSTMENTS

TROUBLESHOOTING

REV.-A

-

vi -

CHAPTER 1

GENERAL DESCRIPTION

REV.-A

FEATURES

1.1

SPECIFICATIONS

1.2

1.2.1

1.2.2

PARALLEL INTERFACE

1.3

1.4

CONTROL PANEL

1.4.1

1.4.2

DIP SWITCHES AND

1.5

1.5.1

1.5.2

OPERATING INSTRUCTIONS

1.6

1.6.1

1.6.2

1.6.3

1.6.4

1.6.5

1.6.6

1.6.7

1.6.8

1.6.9

1.6.10

.....................................................................................@.m...m..mmo.om.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware

Firmware Specifications

Buttons

Indicator Lights

DIP Switches

Jumpers

Self Test

Hexadecimal Dump

Paper-out Detection and Form Override Function ...........1 -21

Error Conditions

Buzzer Operation

Printer Initialization

Default Values

Paper Loading and Ejection

Tear-off Function

Paper-Thickness Lever Operation

Specif

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-3

ications..........................................."""...."..

............................................S.............." 1-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JUMPERs......................................S"..."."."".S"...".".."

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...s...

1-3

1-14

1-16

1-16

1-17

1-18

1-18

1-19

1-20

1-20

. 1-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-21

1-21

1-21

1-22

.

1-22

1-23

1-24

1.6.11

MAIN COMPONENTS

1.7

1.7.1

1.7.2

1.7.3

1.7.4

1.7.5

1.7.6

Printer Protection for Heavy Duty Printing . . . . . . . . . . . . . . . . . . . . . . . .

C060

C060

C060

C060

M-5D1 O/5D60

Housing

1-25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAIN Board (Main Control Circuit Board) .............1 -26

PNL Board (Control Panel Circuit Board) ...............1 -27

PSB/PSE Board (Power Supply Circuit Board) ......1 -27

DRV Board (Head Control Circuit Board)

Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

-i

.................l

1-26

-28

1-28

1-29

REV.-A

LIST OF FIGURES

,:,.,

~

Figure 1-1.

Figure 1-2.

Figure 1-3.

Figure 1-4.

Figure 1-5.

Figure 1-6.

Figure 1-7.

Figure 1-8.

Figure 1-9.

Figure 1-10. Paper-Thickness Lever Positions

Figure 1-11.

Figure 1-12.

Figure 1-13.

Figure 1-14.

Figure 1-15.

Figure 1-16. M-5

Figure 1-17. Housing

Exteror View of the

Pin Configuration

Printable Area for Single-Sheet Paper ..............................1-6

Printable Area for Continuous Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transmission Timing

Control Panel

Self-Test

Hexadecimal Dump

LQ-870/l

C060

C069@NL

C060 PSB/PSE

C060

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

170 Component Layout ....................................1-26

MAIN Board

Board

DRV Board

D10/5D60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LQ-870/l

....................................m.................................l.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board

....................................................................l.28

Printer Mechanism ..................................1-28

170 .....................................1-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...........................................................l.27

1-6

. 1-13

.

1-14

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-16

1-20

1-20

1-24

1-26

1-27

1-29

.,,

(:-.

LIST OF TABLES

Table 1-1.

Table 1-2.

Table 1-3.

Table 1-4.

Table 1-5.

Table 1-6.

Table 1-7.

Table 1-8.

Table 1-9.

Table 1-10.

Table 1-11.

Table 1-12.

Table 1-13.

\

Table 1-14.

Optional Interface Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Units

Specifications for Single-Sheet Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Specifications for Single-Sheet Multi-Part Forms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. l-l

1-2

.

~. ,,

..,.

(Carbonless Duplicating Paper) ............................................1-5

Specifications for Continuous Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications for Envelopes

Specifications for Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing (Text Mode)

Printing (Bit Image Mode)

Character Matrix and Character Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector Pin Assignments and Signal Functions

DIP Switch Set 1

DIP Switch Set 2

International and PC Character Set Selection ...............1 -19

...............................................................l.l O

(SWl).........................................................l.l

(SW2)

................................................l.5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.......l-l

1-5

. 1-5

1-11

1-12

4

8

1-19

Table 1-15.

Table 1-16.

Page Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper-Thickness Lever Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 1-19

1-24

1.1 FEATURES

REV.-A

The

l_Q-870/l

handling and is compatible with The

●

Use of ESC/P 2 control codes

The printer can print fonts in various point sizes and receive and print raster graphic images.

●

Compatibility with LQ and SQ series printers

●

Printing speeds:

300 characters per second

330

cps (draft, 12 cpi)

275

cps (draft, 10 cpi)

110

92

cps (LQ, 10 cpi)

●

Multiple fonts resident in the printer: nine letter quality

Prestige, Script, OCR-B, Script-C, Orator, and Orator-S) and one draft font

●

Clear, easy-to-read printing using standard EPSON fonts

●

Selection of fonts, condensed printing, and the cut-sheet feeder (C SF) bin using control panel buttons

Advanced paper handling

●

Continuous paper:

Three ways to insert continuous paper, using the front, bottom, or rear paper entrance

Auto

Ability to use continuous paper without removing the cut-sheet feeder

Ability to use the standard tractor in three positions (two push tractor positions and one pull tractor

position)

Single-sheet paper:

Two ways to insert single-sheet paper, using the front or top paper entrance

Auto loading

Easy handling of single-sheet paper with the optional cut-sheet feeder

●

●

Optional tractor that can be used to create a push-pull tractor feeding

●

Optional interface cards

170 is a small, light-weight, low-cost printer that provides advanced

LQ-5 10/550. The printer’s main features are:

(CPS)

in high-speed draft mode at 10 characters per inch (cpi)

cps (LQ, 12 cpi)

(LQ) fonts (Roman, Saris Serif, Courier,

backout and auto loading when using the front or rear paper entrance

paper

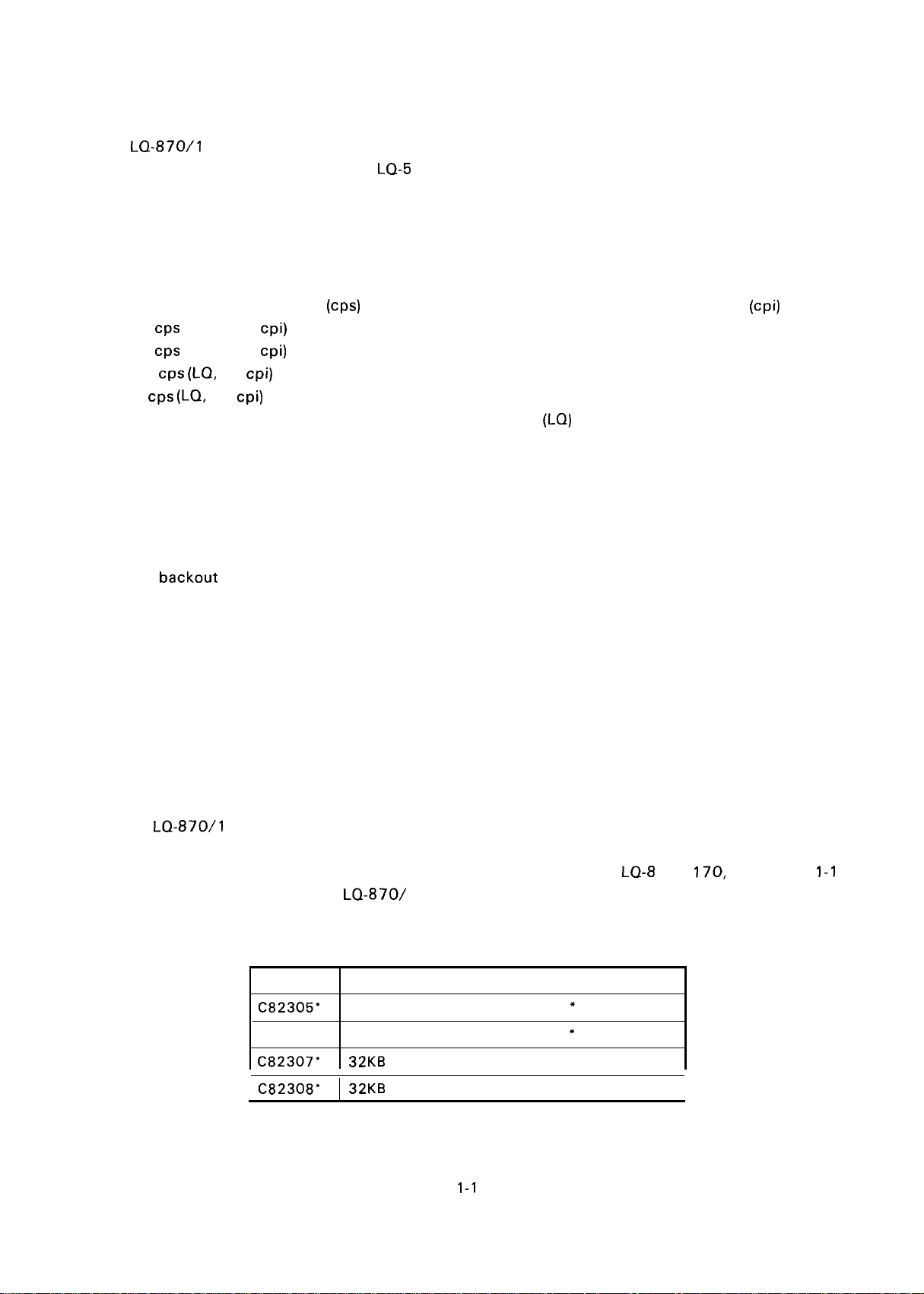

The

LQ-870/l

interface cards ensure compatibility with a wide variety of computers. Table 1-1 Lists the optional

interface cards, Table 1-2 lists the optional units available for the

shows an exterior view of the

170 is equipped with the standard EPSON 8-bit parallel interface. The optional

LQ-870/

Table 1-1 Optional Interface Cards

Model No.

C82305*

C82306”

C82307” 32KB serial interface card (inch screw)

C82308*

Serial interface card (inch screw) ‘ 1

Serial interface card (mini screw)

32KB

1170.

Description

‘ 1

serial interface card (mini screw)

LQ-8 70/1

170,

I

and Figure

1-1

1-1

REV.-A

● The last digit in each part numbers above, represented by an asterisk

country.

‘

I. You cannot use the printer with the following baud rates: 1800,

NOTE: Refer to the “Optional Interface Technical Manual”

interface cards.

Table 1-2. Optional Units for

Model No. Description

C80637’

C80638”

C80020

7753

7768

Model No.

C80639’ I

C80640’

Single-bin

High-capacity cut-sheet feeder

Tractor

Fabric ribbon cartridge

Film ribbon cartridge

Table 1-2-1. Optional Units for LQ-1 170

I

.

.

Single-bin cut-sheet feeder

High-capacity cut-sheet feeder

cut-sheet feeder

Description

for more information on the optional

LQ-870

200, 134.5, 110, or

(’),

varies depending on the

75 bps.

(

~...

“

-w

C80021•

7754

I 7770

● When the last digit in the

depending on the country.

Tractor

I

Fabric ribbon cartridge

]

Film ribbon cartridge

part number above is represented by an asterisk (“), the number varies

I

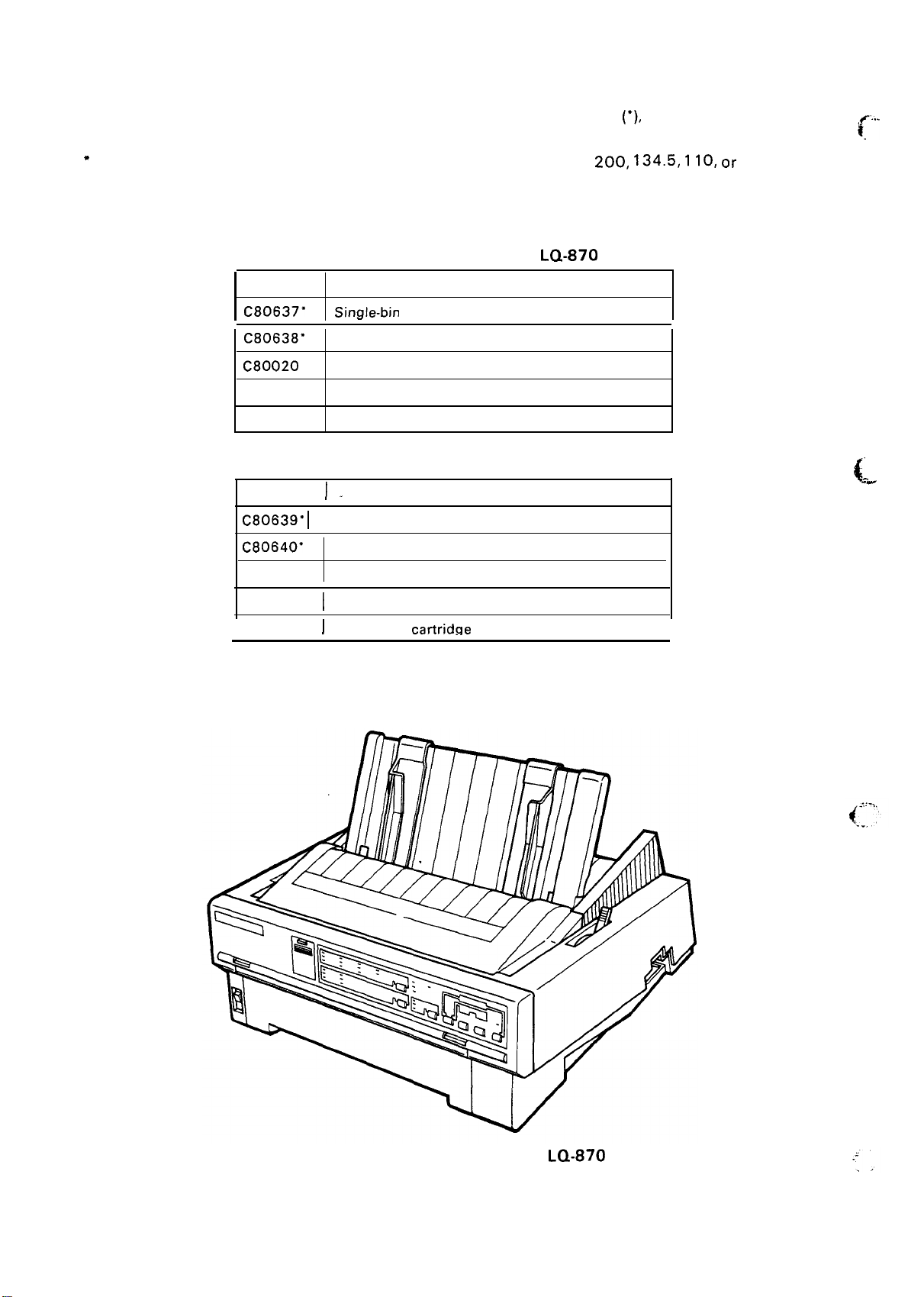

Figure 1-1. Exterior View of the

1-2

LQ-870

1.2 SPECIFICATIONS

REV.-A

This section provides the specifications for the

1.2.1

Hardware Specifications

Printing method

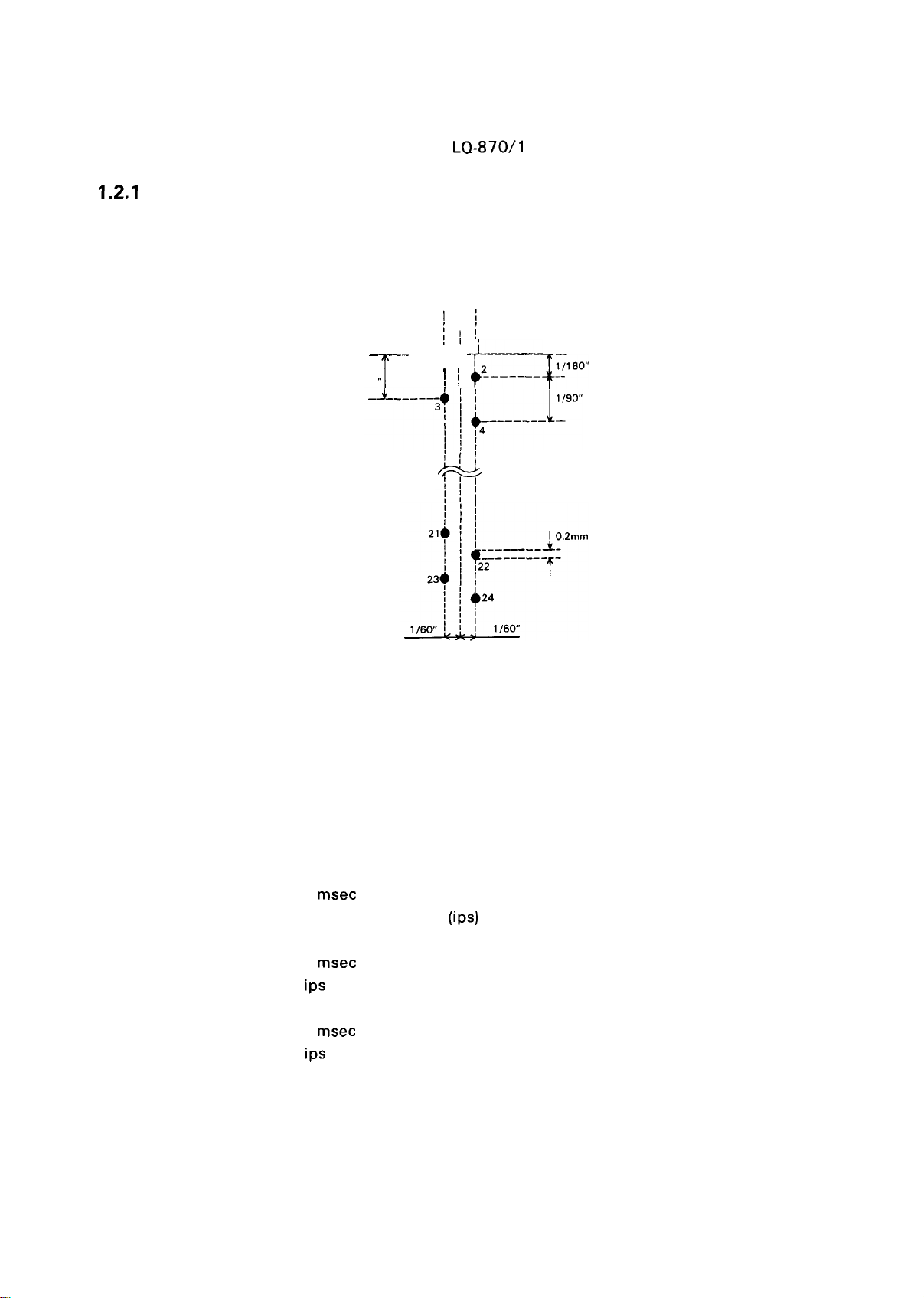

Pin configuration

Serial, impact, dot matrix

24 wires; 12 x 2 staggered, diameter 0.2 mm (.008 in.)

Wires 1 Wires 2

— --—

1 /90”

--’+;

T

LQ-870/l

~j

ili

1,,

-+--------

~ ( +L_J!!””i

170.

-“

Figure 1-2. Pin Configuration

Feeding methods

Line spacing

Paper insertion

Paper feed speed

Friction feeding (front and top paper entrances)

Push tractor feeding (front and rear paper entrances)

Pull tractor feeding (front and bottom paper entrances)

Push-pull tractor feeding (front and rear paper entrances)

1/6 inch, 1/8 inch, or programmable in units of 1/360 inch

Friction feeding: front or top paper entrance

Tractor feeding: front, bottom, or rear paper entrance

Friction feeding without cut-sheet feeder:

59.0

msec for a l/6-inch line feed

3.6 inches per second

Friction feeding with cut-sheet feeder:

62.7

msec for a l/6-inch line feed

3.3

ips during continuous feeding

Tractor feeding:

64.1

msec for a l/6-inch line feed

3.0

ips

during continuous feeding

(ips)

NOTE: Paper handling precautions are listed below.

during continuous feeding

1-3

REV.-A

Friction feeding precautions

● Move the release lever to the FRICTION position.

● Load paper into the front or top paper entrance.

● Do not use continuous paper.

● Do not perform any reverse feeds within the top 8.5 mm (.34 in.) or bottom 22 mm (.87 in.) of

the paper.

. Do not perform reverse feeds greater than 1/6 inch after a paper end is detected.

● Use the paper tension unit.

. Load single-sheet multi-part forms only into the front paper entrance.

. Use only carbonless multi-part forms.

Push tractor feeding precautions

● Move the release lever to the REAR PUSH/FRONT PUSH position.

● Load paper into the rear paper entrance.

. Release the friction-feed mechanism.

● Multi-part forms must be spot pasted beyond the perforation between the sprocket holes.

● Use only carbonless multi-part forms.

● Use the paper tension unit.

● Do not perform reverse feeds greater than 1/6 inch.

. Because paper feeding accuracy cannot be assured after a paper end is detected, do not perform

reverse feeds after a paper, end is detected.

Push-pull tractor feeding precautions

.,

● Move the release lever to the REAR PUSH/FRONT PUSH position.

● Load paper into the front, rear, or bottom paper entrance.

● Release the friction-feed mechanism.

● Remove the paper tension unit and attach the pull tractor.

● Make sure there is no slack in the paper between the platen and the pull tractor.

● Carefully align the pull tractor and push tractor sprockets.

. Paper for multiple copies must be spot pasted beyond the perforation between the sprocket holes.

● Use only carbonless multi-part forms.

● Do not perform reverse feeds greater than 1/6 inch.

● Do not perform reverse feeds after a paper end is detected.

~

.

.:-

Pull tractor feeding precautions

● Move the release lever to the PULL position.

● Load paper into the front or bottom paper entrance.

. Release the friction feed mechanism.

. Remove the paper tension unit and attach the pull tractor.

● Paper for multiple copies must be spot pasted beyond the perforation between the sprocket holes.

● Use only carbonless multi-part forms. ‘

. Do not perform reverse feeds.

Paper specifications

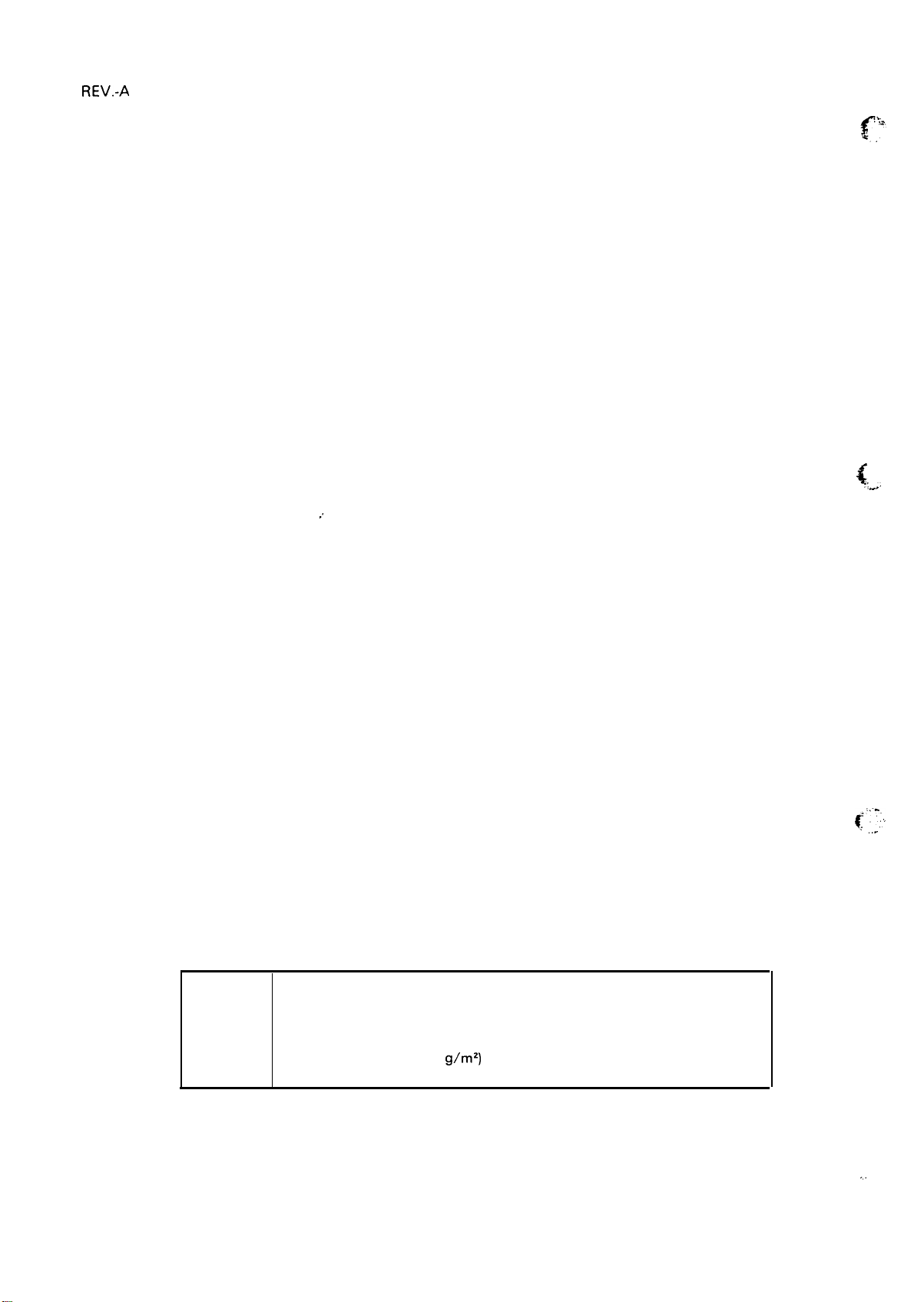

Table 1-3. Specifications for Single-Sheet Paper (80/1 36 column)

Width

Length

Thickness

Weight 14 to 24 lb (52.3 to 90

Quality

See Tables 1-3, 1-4, 1-5, 1-6, and 1-7.

148 to 257/420 mm (5.8 to 10. 1/1 6.5 in.) (top insertion)

182 to 257/364 mm (7.2 to 10. 1/1 4.3 in.) (front insertion)

364 mm (1 4.3 in.), maximum

0.065 to 0.14 mm (0.0025 to 0.0055 in.)

g/m2)

Standard paper (such as photocopier paper)

{::”-.

,,.

.,.

1-4

REV.-A

Table 1-4. Specifications for Single-Sheet Multi-Part Forms (Carbonless) (80/1 36 column)

Width

Length

Thickness

Weight

Quality

Copies

Table 1-5. Specifications for Continuous Paper (80/1 36 column)

Width 101 to 254/406 mm (4.0 to 10.0/16 in.)

Thickness

Weight

Quality

Copies

Size

Thickness

Weight

Quality

Copies

182 to 2 16/364 mm (7.2 to 8.5/1 4.3 in.)

257 to 297 mm (10.7 to 11.7 in.)

0.065 to 0.14 mm (0.0025 to 0.0055 in.) — per sheet

0.12 to 0.64 mm (0.0047 to 0.0256 in.) total

17 to 24 lb (52.3 to 90

12 to 15 lb (40 to 58

Carbonless duplicating paper

Four sheets (one original and three copies)

0.065 to 0.10 mm (0.0025 to 0.0039 in.) single sheet

0.065 to 0.32 mm (0.0025 to 0.012 in.) total

14 to 22 lb (52.3 to 82

12 to 15 lb (40 to 58

Standard paper or carbonless duplicating paper

4 sheets (1 original and 3 copies)

Table 1-6. Specifications for Envelopes

No. 6 = 166 mm x 92 mm (6.53 in. x 3.62 in.)

No. 10 = 240 mm x 104 mm (9.45 in. x 4.09 in.)

0.16 to 0.52 mm (0.0063 to 0.0197 in.)

Differences in thickness within the printing area must be less

than 0.25 mm (0.0098 in.).

12 to 24 lb (45 to 91

Bond paper, standard paper, air mail

Not available

g/m2)

single sheets

g/m2)

each

g/m2) single sheet

g/m2) each

g/m2)

NOTES:

NOTES: ●

Printing on envelopes is available only at normal temperatures.

●

Load envelopes only into the top paper entrance.

●

Keep the longer side of the envelope horizontal when you insert it.

●

Place the left edge of a no. 6 envelope at the sheet guide mark.

●

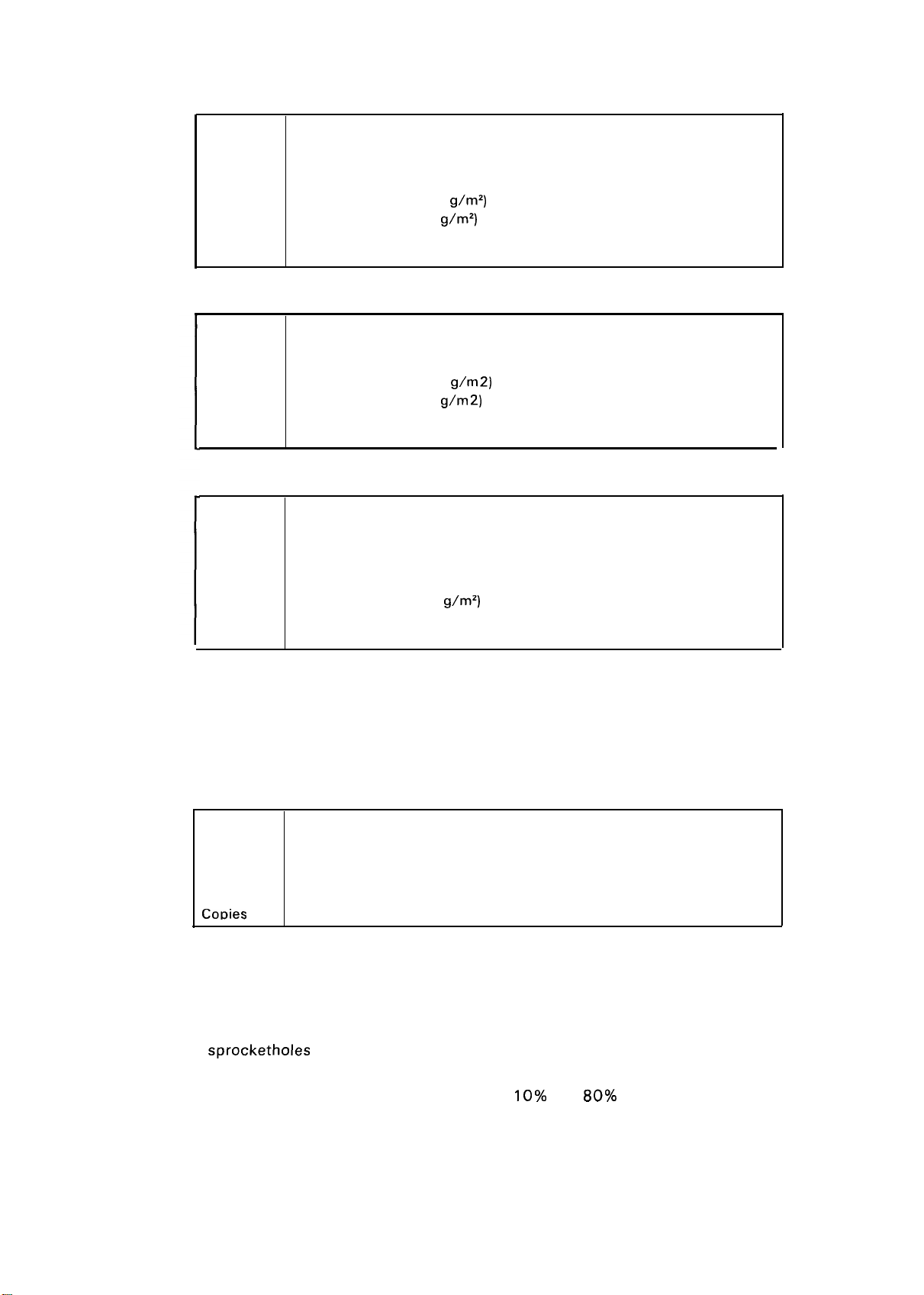

Table 1-7. Specifications for Labels

Label size

Thickness

Co~ies

Printing on labels is available only at normal temperatures.

Only use labels on continuous backing paper with sprocket holes for tractor feeding.

●

Labels with pressure-sensitive paper must be spot pasted beyond the perforation between

●

the

sprocketholes and the total thickness must be less than or equal to 0.3 mm (0.01 18

in.). You can print labels only when the temperature is between 5 and 35 degrees C (4 1

and 95 degrees F) and humidity is between

Examples of labels: Avery continuous form labels and Avery mini-line labels

●

2 1/2 in x 15/16 in.

4 in. x 15/16 in.

4 in. x 7/16 in.

0.07 to 0.09 mm (0.0028 to 0.0031 in.) —for the backing paper

0.16 to 0.19 mm (0.0063 to 0.0075 in.) — total

Not available

10YO

and

80’%0

RH.

1-5

REV.-A

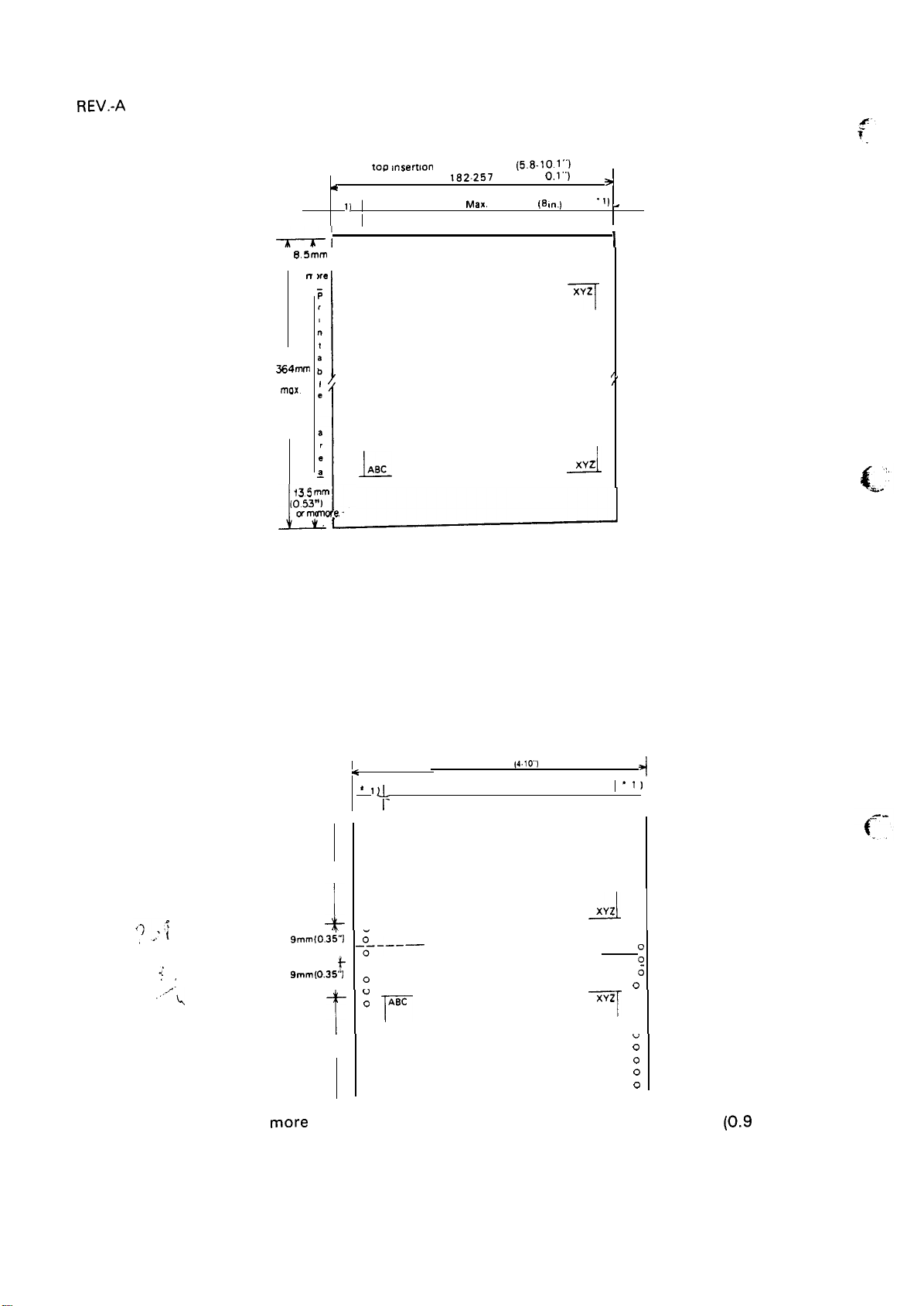

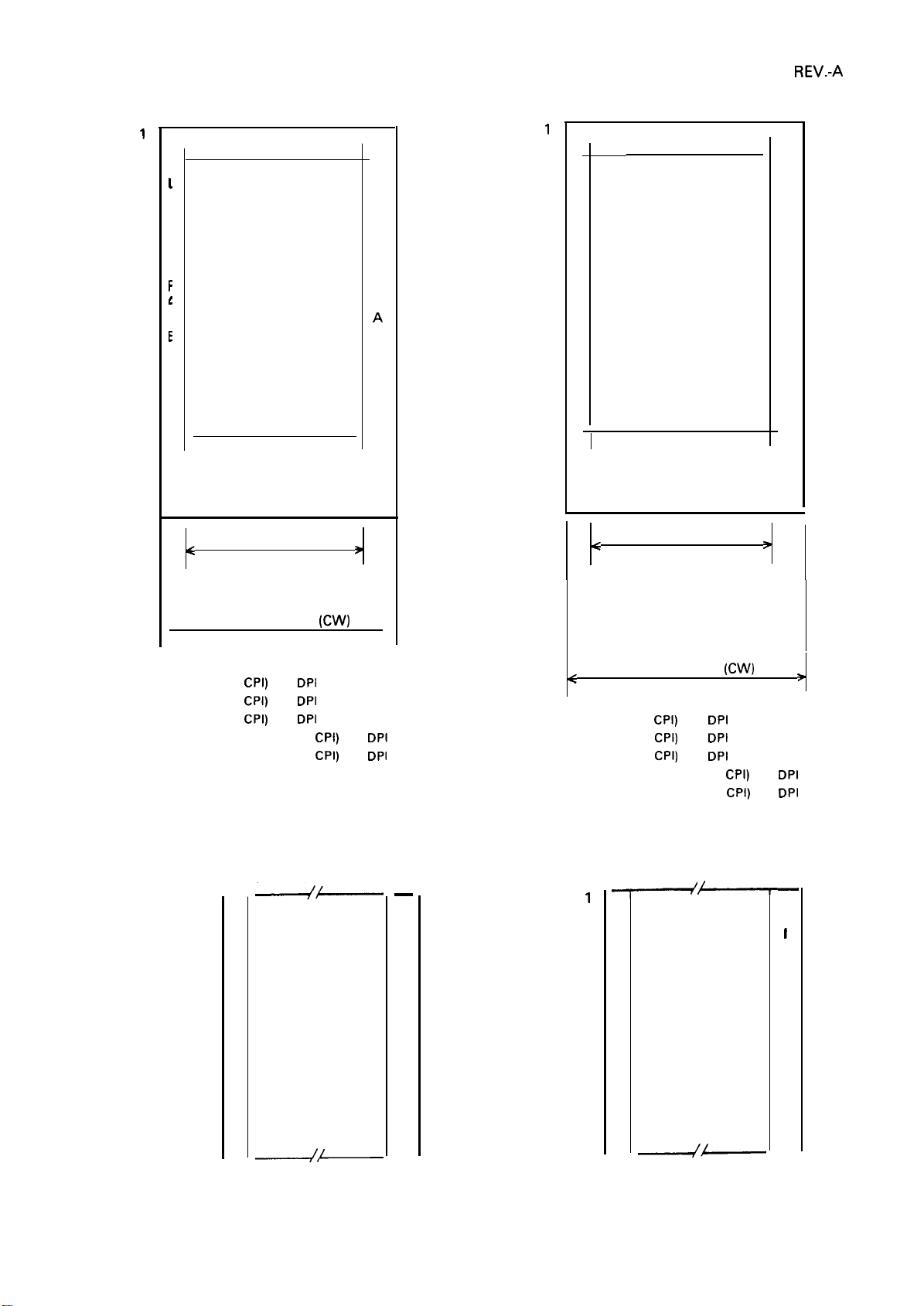

Printable area

See Figures 1-3, 1-4, and 1-5.

&

—a--A

85mm

[033”)

or n

-

364mm

(14 3“)

mox.

—

i3.5

mm

[053”)

w mue

“

1)

I

ABC

T

ABC

L

tog insertton

front insertion

Printable area Max. 203.2 mm [8

148.257 mm

182-257

(5.8.10. 1‘“)

mm (72-1 o 1“)

In.)

XYZ

T

XYZ

J

1

>

“1) >

I

/

,

/

l__J_

‘1) 3.0 mm (O. 12 in.) or more when paper width is less than 229 mm (9 in.).

25 mm (0.9 in.) or more for top insertion or 26 mm (1.0 in.) or more for front insertion when paper

width is 257 mm (1 0.1 in.).

●

For top insertion, paper feeding accuracy cannot be assured within 26 mm (1 .02 in.) from the bottom

edge of the paper.

For front insertion, paper feeding accuracy

bottom edge of the paper.

cannot be assured within 47.0 mm (1 .85 in.) from the

.:

,,

““”-”””k

● 1) 13 mm (0.51 in.)

for rear insertion

Figure 1-3 Printable

<

4 1~

1-

0

0

~

-:----—

+-

1-

0

0

0

0

0

0

.

;

~

u

0

0

0

0

0

0

0

0

ABC

l-’

ABC

r

Printable

area

9mm(0.35”1

“’more

9mm(0.35”1

or more

Printable

area

fnore

or

or

with paper 101 to 241 mm (4 to 9.5 in.) wide. 25 mm

26 mm (1,0 in.) or more for front insertion with paper 254 mm (1 O in.)

Area for Single-Sheet Paper

101.254

mm

(4.10’”)

Printable area

XYZ o

-1

T

----------------

XYZ

o

7

‘1)

‘1

0

0

0

0

0

0

0

0

:

o

o

0

0

v

o

0

0

0

(0.9

in.) or

more

wide.

Figure 1-4 Printable Area for Continuous Paper

1-6

REV.-A

Ink ribbon

Reliability

Printhead life

Safety approvals

Electrical specifications 120 V version

80-column:

Black ribbon cartridge #7753

Film ribbon cartridge #7768

136-column:

Black ribbon cartridge #7754

Film ribbon cartridge #7770

Color Black

Life

Dimensions of ribbon cartridge:

80-column:

293 mm (width) x 34 mm (height) x 72 mm (depth)

11.7 in. (width) x 1.4 in. (height) x 2.9 in. (depth)

136-column:

468.5 mm (width) x 34 mm (height) x 72 mm (depth)

18.4 in. (width) x 1.4 in. (height) x 2.9 in. (depth)

Mean cycles between failures

Mean time between failures

80-column

Mean time between failures (M

136-column

200 million strokes (black ribbon)

100 million strokes (film ribbon)

Safety standards UL1 950 with D3 (U.S. version)

Radio frequency

interference

2 million characters at 48 dots/character (black ribbon)

0.2 million characters at 48 dots/character (film ribbon), 80-column

0.3 million characters at 48 dots/character (film ribbon), 136-column

(RFI)

(MCBF): 5 million lines (excluding printhead)

(MTBF): 4000 power-on hours (POH) at 25% duty,

CBF):

6000 power-on hours (POH) at 25% duty,

CSA22.2#220

EN 60950 (TUV) (European version)

FCC class B (U.S. version)

VDE0871 (self-certification) (European version)

120

Rated voltage

Input voltage range

Rated frequency range 50 to

Input frequency range 49.5 to 60.5 Hz

Rated current

Power consumption

Insulation resistance

VAC

103.5 to 132

60

2.0 A

Approx.58 W (during

test in draft)

10 Megohms minimun (at

500 VDC between AC line

and chassis)

VAC

HZ

self-

1-7

REV.-A

220 to 240 V Rated voltage

version

Environmental conditions

VAC rms for one minute or

Dielectric strength

Input voltage range

Rated frequency range

Input frequency range

Rated current

Power consumption

Insulation resistance

Dielectric strength

,,

Temperature

Humidity

Resistance to shock

1000

1200 VAC rms for one second

(between AC line and chassis)

220 to 240

198 to 264

50 to 60 Hz

49.5 to 60.5 Hz

1.0 A

Approx. 58 W (during self-test in

draft mode at 10

10 Megohms minimum (at 500 VDC

between AC line and chassis)

1250

VAC rms for one minute or

1500

VAC rms for one second

(between AC line and chassis)

5 to 35 degrees C (41 to 95

degrees F), operating

–30 to 65 degrees C (–22 to

149 degrees F), in shipping

container

10 to 80

5 to 85 %

1 G, within 1

2 G, within 1

VAC

VAC

YO RH,

operating

RH,

storage

ms, operating

ms, storage

cpi)

$“”

Q

““

Physical specifications

Resistance to vibration

Weight

.

Dimensions

0.25 G, 55 Hz, maximum, operating

0.50 G, 55 Hz, maximum, storage

80-column:

Approx. 8.8 kg (4.0 lb)

136-column:

Approx. 11.5 kg (5.2 lb)

80-column:

449 mm (width) x 365 mm

(depth) x 171 mm (height)

17.7 in. (width) x 14.7 in.

(depth) x 6 in. (height)

column:

624 mm (width) x 365 mm

(depth) x 171 mm (height)

24.6 in. (width) x 14.7 in. (depth)

x6

in. (height)

136-

1-8

1.2.2 Firmware Specifications

REV.-A

Control codes

Printing direction

Input data buffer

Character code

Character tables

Fonts and pitches

Bit map fonts

Scalable fonts

ESC/PTM

(EPSON standard code for printers)

Bidirectional with logic seeking

8KB, 32KB,

This printer is able to input buffer capacity 8, 32, or

8 bits

italic character table, PC 437, PC 850, PC 860, PC 863, PC 865

(PC indicates character tables for personal computers.)

EPSON Roman

EPSON Saris Serif

EPSON Courier

EPSON

EPSON Script

EPSON Script C

OCR-B

EPSON Orator

EPSON Orator-S

EPSON Draft

EPSON Roman

EPSON Saris Serif

level

Pr@ge

ESC/P

64KB; to change RAM (4A 5A)

2

10, 12, 15, proportional

10, 12, 15, proportional

10, 12,

10, 12

10, 12

proportional

10

10

10

10, 12, 15

8 to 32 pt

8 to 32 pt

64KB

15

Printing modes

It is possible to select and mix the following printing modes, except 15 cpi

condensed, which is not available.

. Print quality (draft or

LQ)

● Character pitch (1 O, 12, 15, or proportional)

● Condensed

. Double-width

. Double-height

● Emphasized

. Double-strike

. Italic

. Underlined

● Double-underlined

● Overscore

● Strike-through

. Outline

● Shadow

1-9

REV.-A

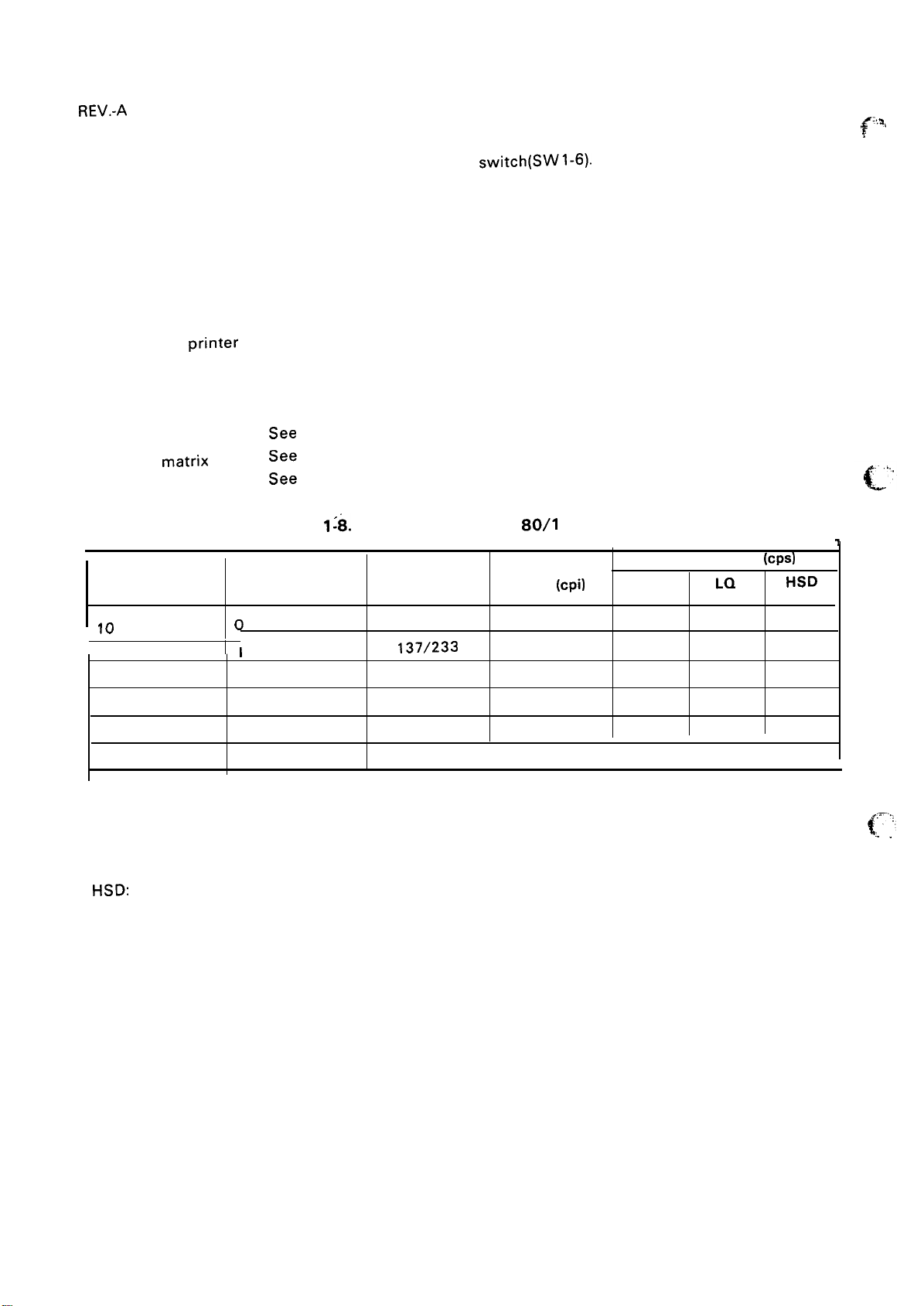

NOTES: High-speed draft is valid when the printer’s status is as follows:

● High-speed draft mode is selected by DIP switch(SVV1-6).

● Emphasized mode is not selected.

● Condensed mode is not selected.

● Draft mode is selected.

● No D/L (download) characters are sent to the printer.

● The horizontal dot space of characters is not set.

● No bit image is sent to the printer.

● Super/subscriPt is not selected.

(The

printer

characters and bit images.)

switches back to normal mode to print emphasized;

condensed, or download

~,.

:5,

printing speed

printing columns

Character

rnatriX

Character size

print Pitch

4A

Iv

I

12

15

cpi:

Cps:

LQ:

HSD:

characters per inch

characters per second

letter quality

high-speed draft

See Tables 1-8 and 1-9.

See Table 1-8.

See

Table 1-10.

See Table 1-10.

Table

1:6.

Printing (Text Mode)

Peinting

.

f)

1

I

0

1

0

1

Printable

Columns

80/1 36

137/233

96/1 64

160/274

120/204

80/1

36-Column

Character

(cpi)

Pitch

10

17.1

12

20

15

Invalid.

Printing Speed

Draft

275

236

330

275

413

(CPS)

LQ

92

HSD

300

157 —

110 —

183 —

138 —

1

~:.:

-.. .

1-1o

REV.-A

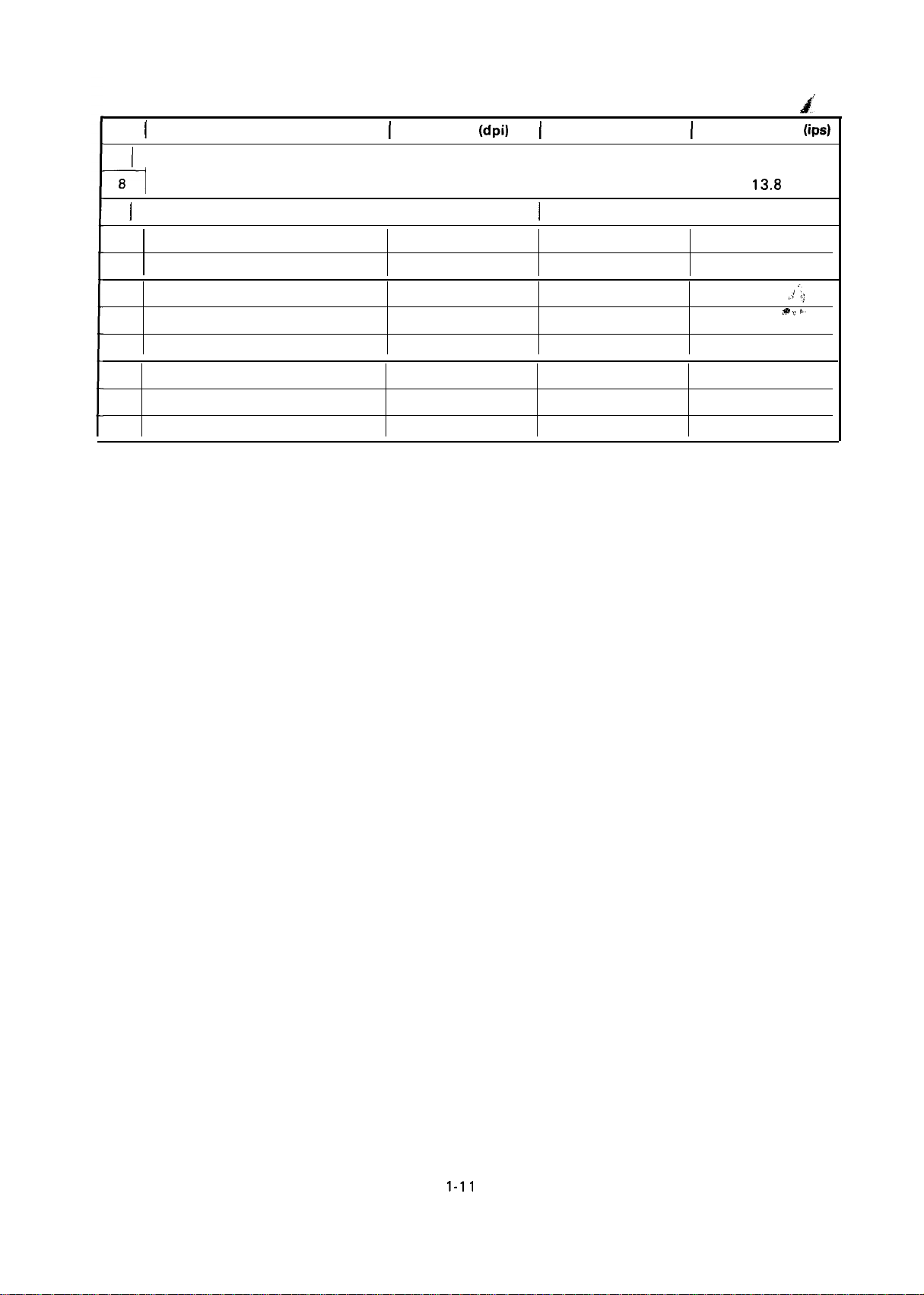

Table 1-9. Printing (Bit Image Mode) 80/1 36-Column

Pins

[

Bit Image Printing Mode

8 I Single-density

8 Dual-density

1

8 ] Double-speed, dual-density

8

Quadruple-density 240

8 CRT graphics 80 640/1 088

8

CRT graphics II

24

Single-density

24

Dual-density

24 CRT graphics II

24

Triple-density

24

Hex-density

dpi:

ips:

dots per inch

inches per second

I

Density

I

I

I

60

120

120

90 720/1 224 18.3

60 480/8 16

120 960/1 632

90

180 1440/2448

360 2880/4896

(dpi)

I

Printable Dots

I

I

1

480/8 16

960/1 632

960/1 632

1920/3264

720/1 224

I

Printing Speed

I

I

I

27.5

13.8

27.5

13.8

13.8

27.5

13.8

18.3

9.2

9.2

*

4;

(ips)

,.! ‘;;

‘“ ‘“”

1-11

REV.-A

printing Mode

High-speed draft, 10 pitch

Draft, 10 pitch

Draft, 12 pitch

Draft, 15 pitch

Draft, 10

Draft, 12 pitch, condensed

LQ,

LQ,

LQ,

LQ,

LQ, 12 pitch, condensed

LQ, proportional

LQ,

LQ,

LQ,

condensed

pitch,

condensed

10 pitch

12 pitch

15 pitch

10 pitch, condensed

proportional, condensed

proportional,

proportional,

super/subscriPt

super/subscriPt,

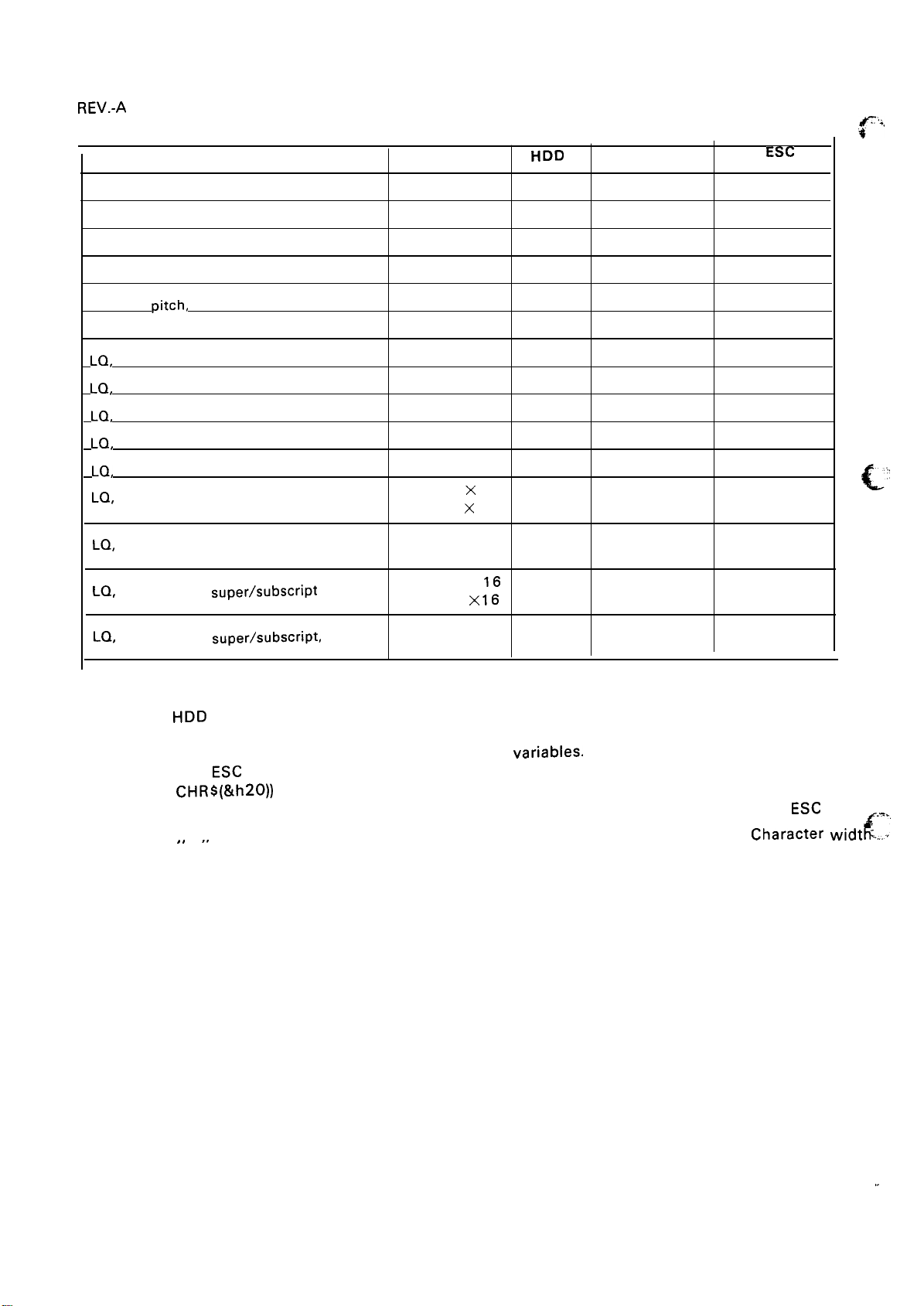

Table 1-10. Character Matrix and Character Size

Face Matrix

7 x 22

9 x 22

9 x 22

7 X 16

—

—

31 x 22

27 X 22

22 X 16

—

—

Max. 37

.

Min. 18

Max. 28 X

Min. 12

—

—

—

X

22

X 22

16

X 16

HDD

90

120

120

120

240

240

360

360

360

360

360

360

360

360

360

360

360

360

360

Character Size

2.0 x 3.1

1.9 x 3.1

1.9 x 3.1

1.0 X 2.3

—120

2.2 x 3.1

1.9 x 3.1

1.6 X 2.3

2.6 X

1.0 x 3.1

1.8 X 2.3

0.7 X 2.3

ESC

Unit

—

120

120

120

—

— 180

— 180

3.1

— 180

—

— 180

—

120

180

180

180

180

180

SP

,<’,,

e

.,.

,

NOTES:

HDD is the horizontal dot density in dots per inch.

●

Face matrix and character size indicate the size

●

depends on the paper, the ribbon, and other

Unit

ESC

●

CHR$(&h20))

the minimum length to be added to the right of the character specified with the

control code.

,, ,,

—

●

becomes half of the noncondensed character width.

sp (which also can be sent as unit followed by the character string

indicates

indicates that printer firmware reshapes the character

of the maximum character. This value

variabIes.

matrix.

ESC

SP

Character width ..-

.%.

<“

1-12

.

REV.-A

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

(Typical draft character)

1

2

3

4

1

5

E

6

F

7

1

8

9

c

.

F

c

.

.

E

Ascender area

R

I

G

H

T

s

P

A

c

E

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

(Typical LQ character)

Ascender area

L

E

F

T

s

P

A

c

E

R

I

G

H

T

s

P

A

c

E

17

18

19

20

21

Descender area

22

23

Descender area

24

&

Face width

9 dots

Character width

(CW)

9

<

(Typical LQ, excluding 15 pitch)

15 pitch and condensed LQ

Face width

29 dots

15 dots for

>

12 dots (10

15 dots (12

16 dots (15

14 dots (condensed 10

12 dots (condensed 12

CPI)

120

DPI

CPI)

180

DPI

CPI)

240

DPI

(Subscript character)

9

10

L

11

E

12

F

13

T

14

15

s

16

P

17

A

18

19

c

20

E

21

22

23

24

—

CPI)

240

DPI

CPI)

240

DPI

—

R

I

G

H

T

s

P

A

c

E

—

Figure 1-5. Character Matrix

<

Character width

36 dots (10

30 dots (12

24 dots (15

21 dots (condensed 10

18 dots (condensed 12

1

2

3

4

5

6

CPI)

360

CPI)

360

CPI)

360

(Subscript character)

-

L’

E

F

T

7

s

8

P

9

10

A

11

c

12

E

13

14

15

16

—

DPI

DPI

DPI

(CW)

CPI)

CPI)

360

360

>

DPI

DPI

—

R

I

G

H

T

s

P

A

c

E

—

1-13

REV.-A

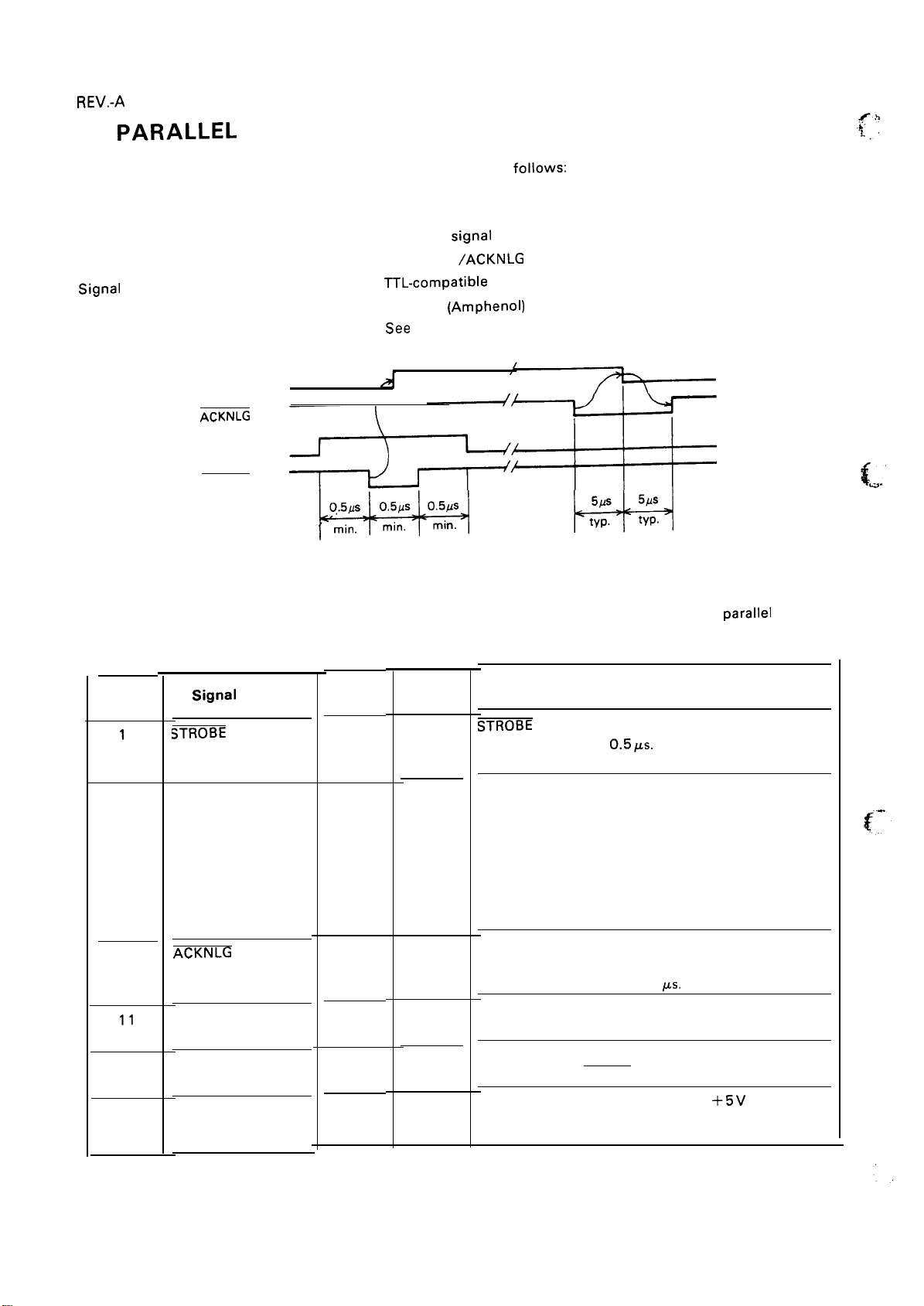

1.3 PARALLEL INTERFACE

The specifications for the printer’s 8-bit parallel

Data format

Synchronization

Handshaking

Signal

level

Adaptable connector

Data transmission timing

BUSy

ACKNLG

DATA

STROBE

interface are as

8-bit parallel

/STROBE

BUSY and

TTL-compatible

57-30360 (AmphenOl) or equivalent

See

A

[

signal

/ACKNLG

Figure 1-6.

w

Figure 1-6. Data Transmission Timing

Table 1-11 provides the connector pin assignments and describes the signal functions of the 8-bit parallel interface.

follows:

signal

/

,

H

c

..ZY

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Signal Name

STROBE

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

DATA 8

ACKNLG

BUSY

PE

SLCT

Table 1-11. Connector Pin Assignments and Signal Functions

Return

Pin No.

19

20

21

22

23

24

25

26

27

28

29

30

—

Dir.

IN

IN

IN

IN

IN

IN

IN

IN

IN

OUT

OUT

OUT

OUT

STROBE pulse to read the input data. Pulse width

must be more than

the falling edge of this signal.

Parallel input data to the printer.

HIGH level means data 1.

LOW level means data O.

This pulse indicates data has been received and

the printer is ready to accept more data. Pulse

width is approximately 11

HIGH indicates the printer cannot accept more

data.

HIGH indicates paper out. This signal is effective

only when the ERROR signal is LOW.

Always

S. SK-ohm resistor.)

HIGH output. (Pulled up to

Function

0.5

#s.

Input data is latched at

KS.

+5 V

through a

1-14

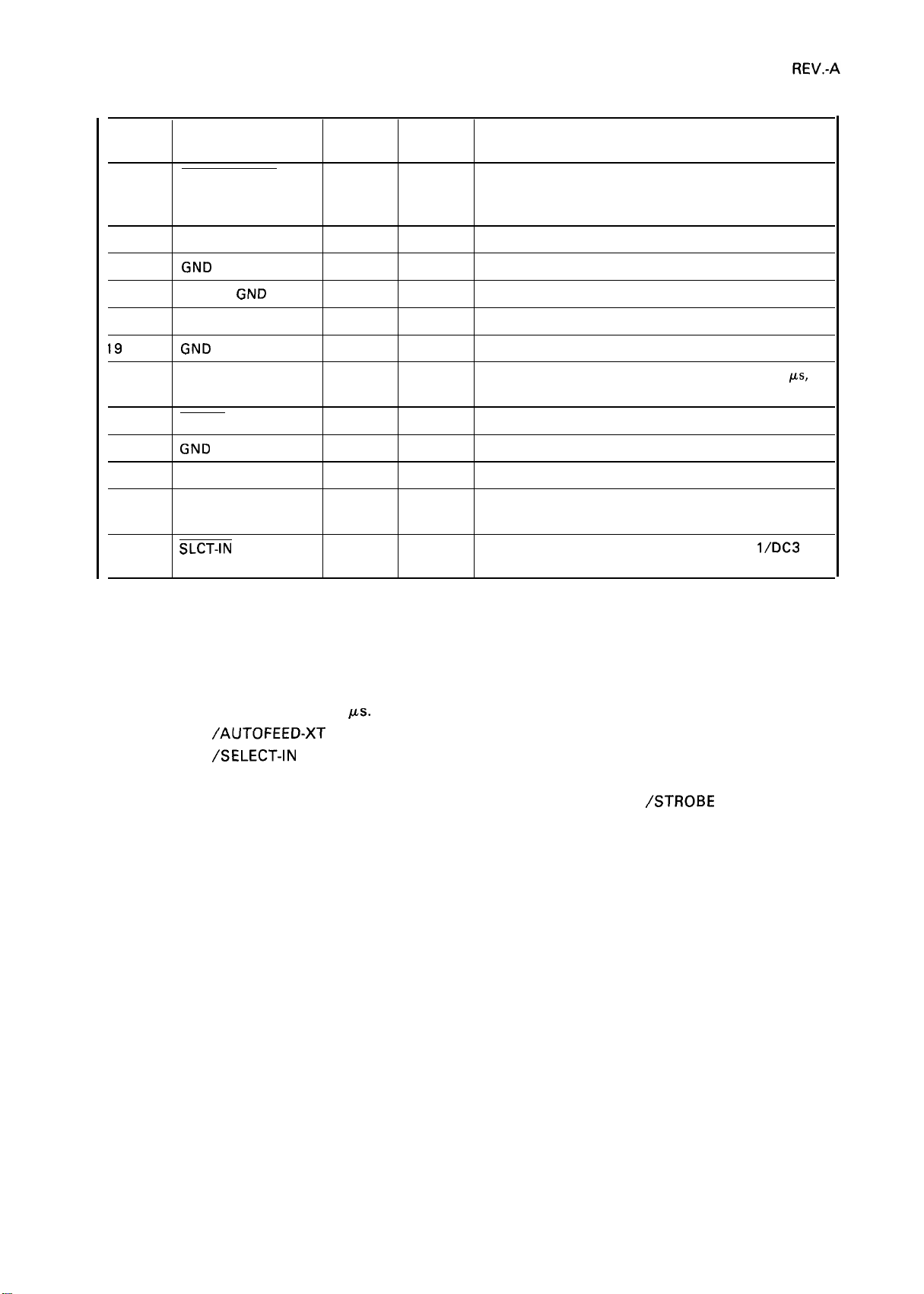

Table 1-11. Connector Pin Assignments and Signal Functions (Cont.)

Pin No. Signal Name

19

to 30

14

15

16

17

18

31

32

33

34

35

36

AUTO FEED-XT

GND

Chassis

GND

I NIT

ERROR

GND

SLCT-IN

GND

Return

Pin No.

—

— —

16

—

—

Dir.

IN

—

IN

OUT

—

OUT

IN

Functional Description

If LOW when the printer is initialized, the printer

automatically performs a line feed upon input of

the CR code (auto LF).

Not used.

Ground for twisted pair grounding.

Chassis ground level of printer.

Not used.

Ground for twisted pair grounding.

Pulse input for printer initialization (width: 50

minimum, active

LOW indicates an error has occurred in the printer.

Ground for twisted pair grounding.

Not used.

Always HIGH. (Pulled up to + 5 V through 3.3 K-ohm

resistor.)

If LOW when the printer is initialized, DC

control is disabled.

LOW).

KS,

l/DC3

NOTES: 1. “Dir.” indicates the direction of the signal flow as viewed from the printer.

2. “Return Pin No.” denotes a twisted pair return line.

3. The cable used must be shielded to prevent noise.

4. All interface conditions are based on TTL levels. Both the rise and fall times of all

must be less than 0.2

5. The

6. The

7. You can perform printing tests, including interface circuit tests, without using external

/AUTOFEED-XT

/SELECT-lN

equipment by setting the DATA 1 through DATA 8 pins to the

signal can be set to LOW using jumper 3.

ws.

signal can be set to LOW using DIP switch 2-4.

\STROBE

signal.

signals

1-15

REV.-A

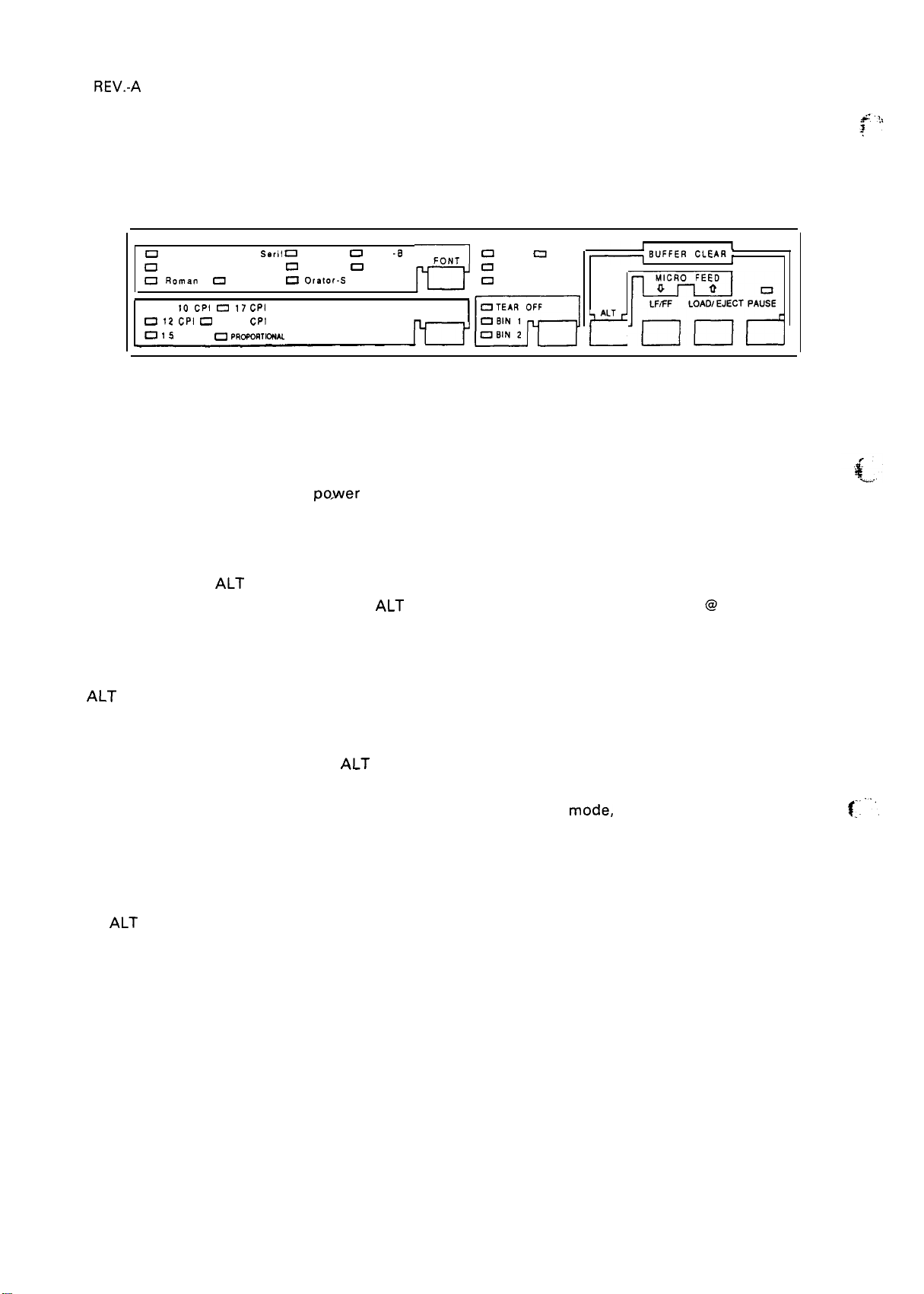

1.4 CONTROL PANEL

There are seven non-lock buttons and 19 indicators on the control panel.

u

DRAFT m Saris. Sefil 0 Script. C 0 OCR

0

Courier O Prestige0 ORATOR U SLOT

u

Roman

m 10

o

!2 CPI n 20 CPI

= 1 S

0

cP1 o 17

C PI 0

Script

cpi

PRCPIXTICNAL

0

1.4.1 Buttons

(1) Operate switch

Use this switch to turn on the

OratOr-S

po,wer supply to the printer.

E

FONT

d

PITCH

0

POWER 0 DATA

0

MULTI. PART

0

PAPER OUT

m

Figure 1-7. Control Panel

-

F

&LncT:Er

MICRO FEED

-

(2) PAUSE button Press this button to toggle the printer between the PAUSE condition (in which there

is no printing or paper feeding and the printer does not accept data) and the RUNNING condition. Press

the PAUSE and

initialization. Pressing the PAUSE and

ALT buttons at the same time to clear the input buffer and perform a software

ALT buttons has the same effect as the ESC @ command.

(3) LINE FEED/FORM FEED button Press this button to perform a line feed. Hold it down to perform a

form feed, whether the printer is in the PAUSE or the RUNNING condition. Press this button and the

ALT button at the same time to use the micro reverse feed function.

(4) LOAD/EJECT button Press this button to load or eject paper. See Section 1.6.8, Paper Loading and

Ejection. Press this button and the

(5)

TEAR OFF/BIN l/BIN 2 button When the printer is in tractor feed mode, press this button to advance {“

continuous paper to the tear-off position. The TEAR OFF indicator light comes on. When the printer is

in friction feed mode, press this button to select bin 1 or bin 2 of the cut-sheet feeder. The indicator

light of the selected bin comes on.

(6)

ALT button Use this button with other buttons to perform a variety of functions.

(7) FONT button Press this button to select a font. Press it again to select the next font. The FONT

indicator light shows the currently selected font.

ALT button at the same time to use the micro forward feed function.

‘“,

(8) CONDENSED button Press this button to select normal or condensed printing.

NOTE: FONT and CONDENSED button selections are stored as defaults and take effect when the printer

is initialized.

1-16

REV.-A

1.4.2 Indicator Lights

(1) OPERATING (green)

Lit when the printer’s operate switch is on and AC power is supplied.

(2) PAUSE (orange)

Lit when the printer is in PAUSE mode. In PAUSE mode, there is no printing or paper feeding and the

printer does not accept data.

(3) TEAR OFF (orange)

Lit when the page is advanced to the tear-off position.

(4) DATA (orange)

Lit when the printer has received data from the host machine.

(5) PAPER OUT (red)

Lit when the paper-out detector detects that there is no paper. See Section 1.6.3, Paper-out Detection

and Form Override Function.

(6) MULTI-PART (green)

Lit when the paper-thickness lever is positioned at the fourth step or higher.

(7) BIN

Lit when bin 1 is selected.

(8) BIN 2 (green)

Lit when bin 2 is selected.

(9) FONT (green) -Draft, Courier, Roman, Saris Serif, Prestige, Script, Script C, Orator, Orator-S, OCR-B

These indicator lights show the currently selected font.

(10) CONDENSED (green)

Lit when condensed mode is selected.

1

(green)

1-17

REV.-A

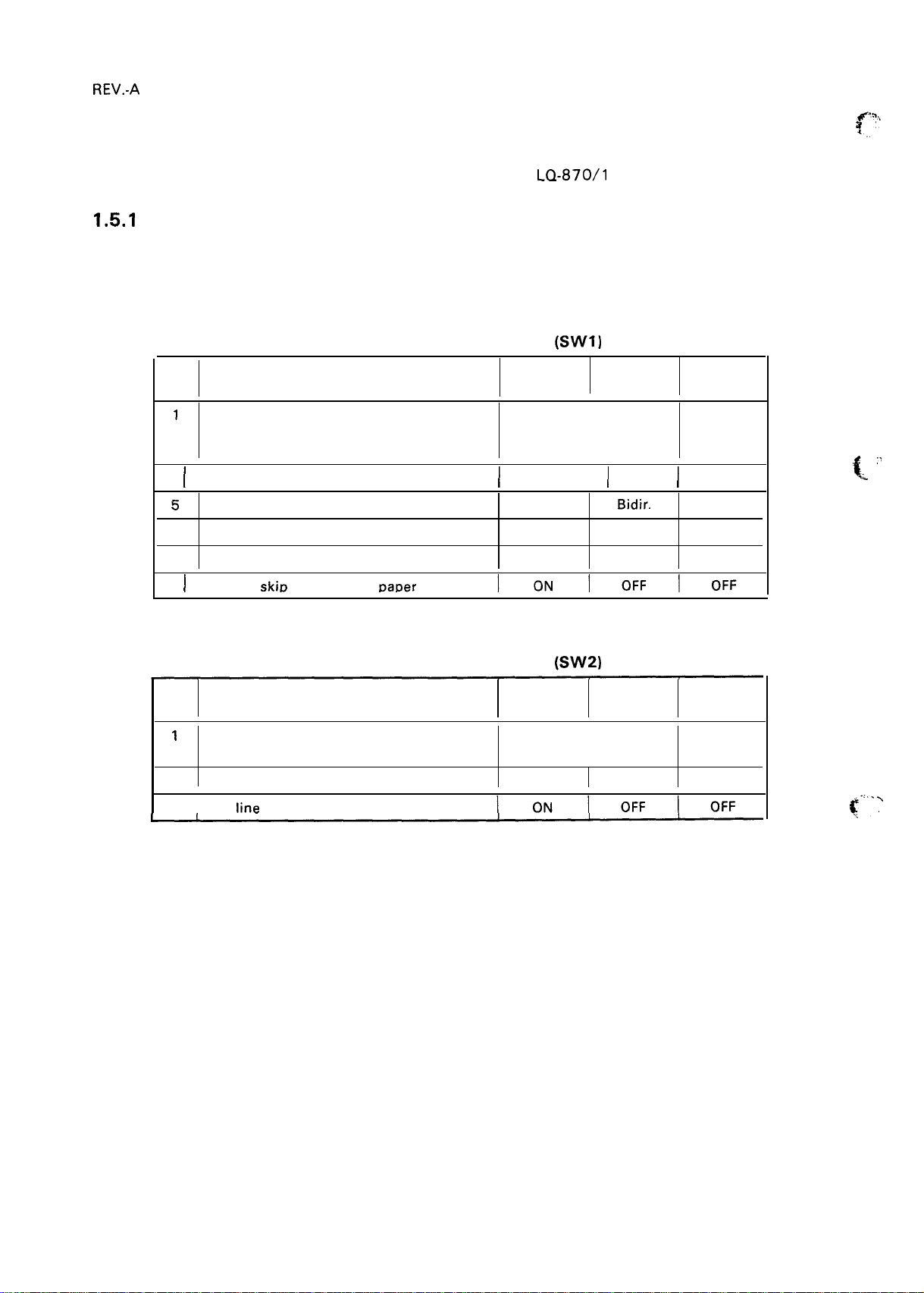

1.5 DIP SWITCHES AND JUMPERS

This section describes the DIP switches

1.5.1

DIP Switches

The printer has two banks of DIP switches located on the control panel. Tables 1-12 through 1-15

describe the functions of the DIP switches. The status of the DIP switches is read only at power-on or

upon receipt of the /l NIT signal.

Table 1-12. DIP Switch Set 1

No.

Description

1

2

International and PC character set selection

3

4 I Character table selection

5

Graphics direction”

High-speed draft mode

6

7

Input buffer

8 I One-inch

SkiI)

continuous

and

jumpers of the

DaDer

LQ-870/l

170.

(SW1)

ON

See Table 1-14.

I

Graphic I Italic I OFF

Unidir.

Invalid

Invalid

OFF

Bidir.

Valid

Valid

Factory

Setting

ON

ON

ON

OFF

OFF

OFF

t

“.

Table 1-13. DIP Switch Set 2

No.

1

Page length of continuous paper

2

3

Auto tear-off

4 I Auto

line

feed

Description

(SW2)

ON

See Table 1-15.

ON

OFF

OFF OFF

Factory

Setting

OFF

OFF

~-. .,

1-18

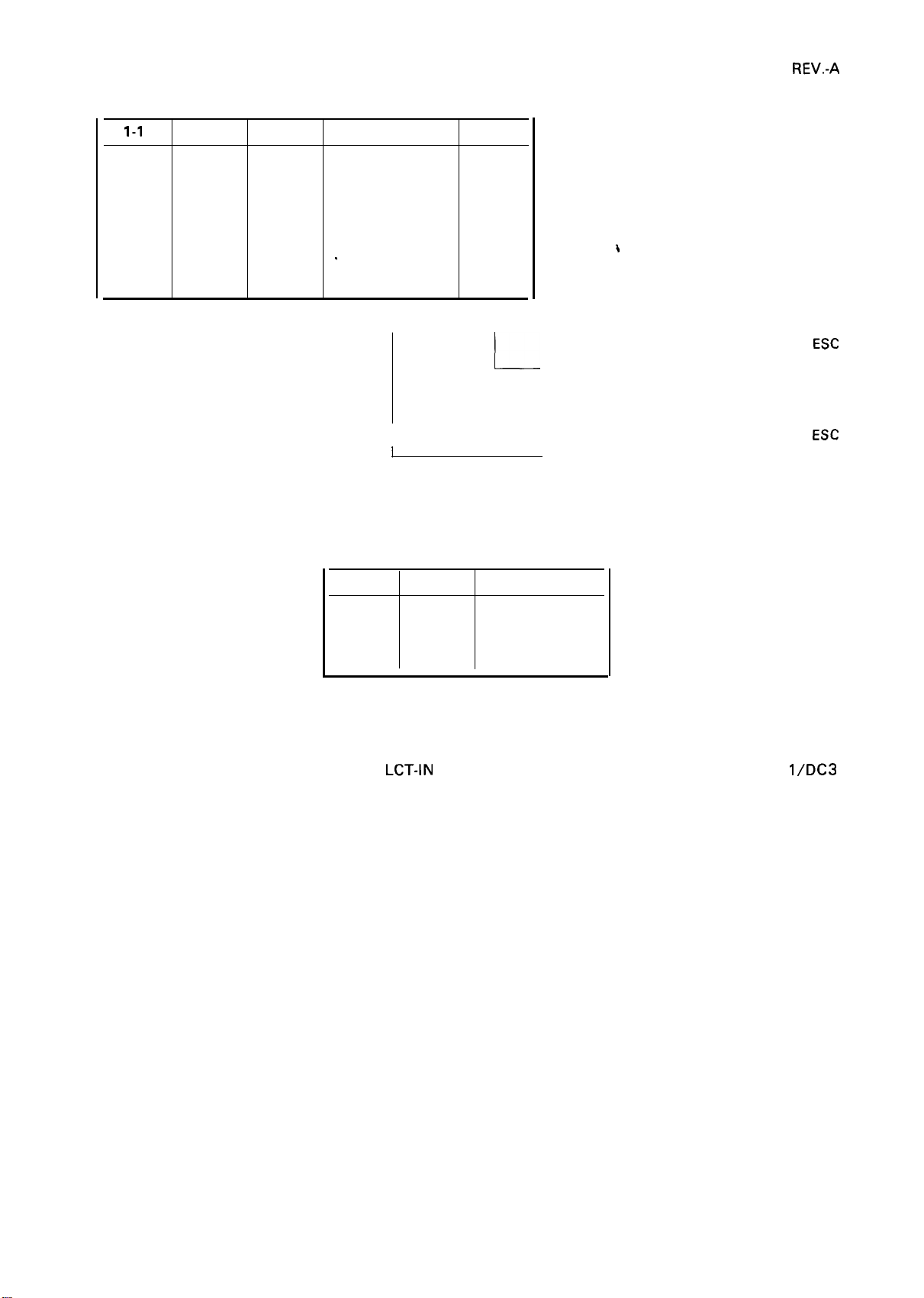

Table 1-14. International and PC Character Set Selection

REV.-A

1-1

ON ON

ON

ON

ON

OFF

OFF

OFF OFF

OFF

1-2

ON

OFF

OFF

ON

ON

OFF

1-3

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Country

Us.

France

Germany 860

U.K.

Denmark 1 865

Sweden

‘

Italy

Spain 1

Pc

437

850

863

(437)

(437)

(437)

I I

I

I

Table 1-15. Page Length

1-

When you turn on DIP switch 1-4 and use

+ O to select the italic character table, the

country setting becomes U.S.

When you turn off DIP switch 1-4 and use

t 1 to select the graphics character table, the

PC setting becomes 437.

ESC

ESC

2-1

OFF

ON

OFF

ON ON

2-2

OFF

OFF

ON

Page Length

11 inches

12 inches

8.5 inches

70/6 inches

1.5.2 Jumpers

If jumper 3 is connected to GND, the /S LCT-lN signal is set to LOW and the printer ignores DC

control.

l/DC3

1-19

REV.-A

1.6 OPERATING INSTRUCTIONS

This section describes the self-test, hexadecimal dump function, error states, printer initialization, and

buzzer operation.

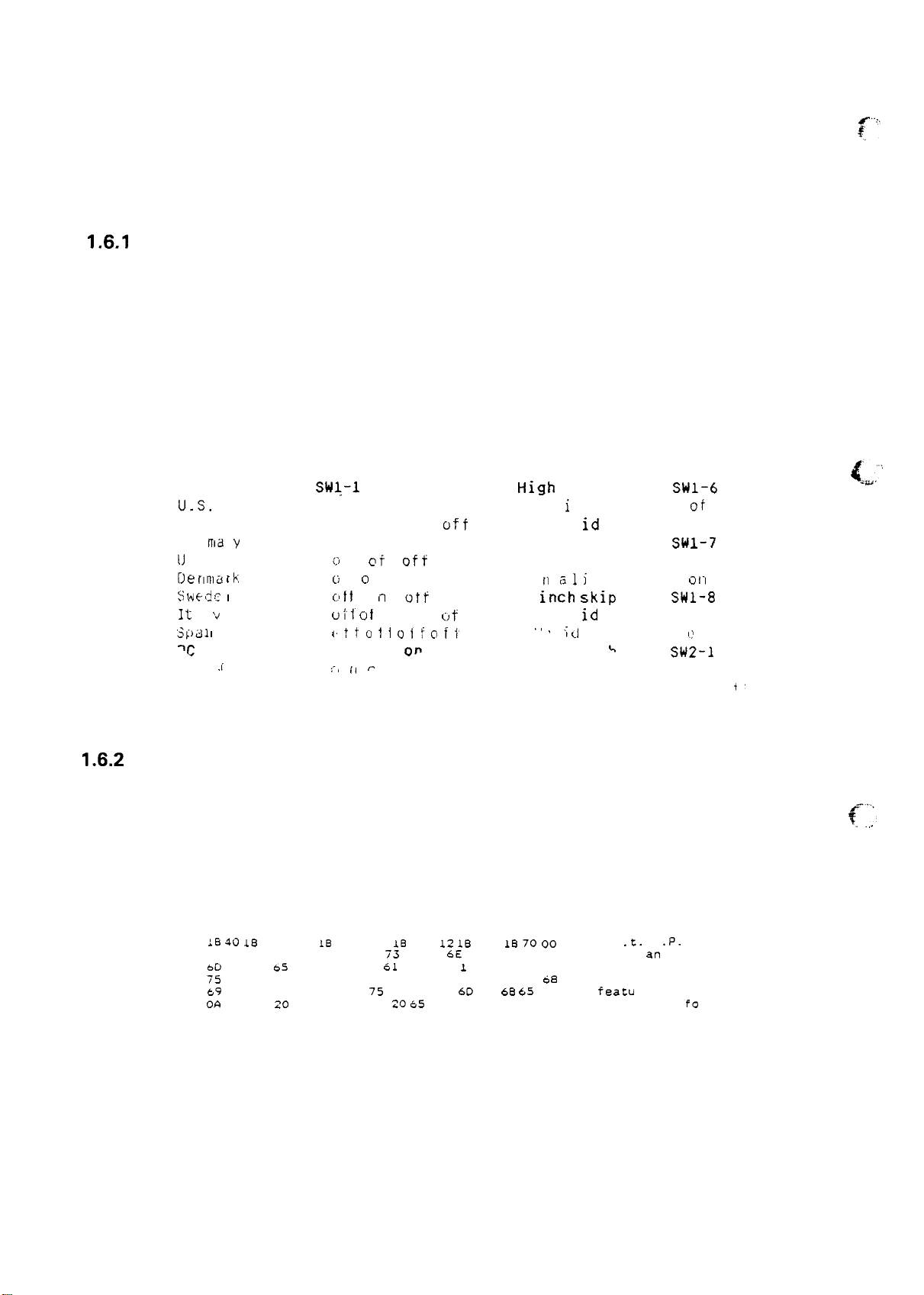

1.6.1

Self-Test

.

To run the self-test in draft mode, turn on the printer while pressing the LOAD/EJECT button. To run

the self-test in LQ mode, turn on the printer while pressing the

LINE FEED/FORM FEED button. You can

press the PAUSE button to stop or start the self test.

When you are satisfied with the self test, press the PAUSE button to stop it and then turn off the printer.

The firmware revision number is printed on the first line of the self-test, followed by the current DIP

switch settings.

Xxxxxx

Country/PC

U.s.

o. . ‘on o n o n

France

Ge r

IBd

n

y () n

U

. h .

r)e

rlnld.

r

k o t f

S (4 & d C

i

I

1 t

a ]

‘J

“s () J 1 I

,

‘c

437 on on on

. . . [ ,

Swl-1

1-2 1-3 1-4

o n o n

off on

(.>

n

of

f

0

n o n

c! t i

o

n

u { t“ o

I t o n

( ~

t t c1 t i o f f o f

:-f

II e

High

off

off

off

Va 1 i d

I rival

of f Receive buffer

off

of f

of f

(It t of t

i)

f f

i’

Valid

I il v

1

inch skip

I

nva 1

,,

,

I ~

speed draft SW1-6

of i

id

on

SW1-7

off

a

1

d

id

i

d

\

o 1“1

SM1-8

off

,,,

, ,

Swz-1 2-2

off off

t’

Figure 1-8. Self-Test

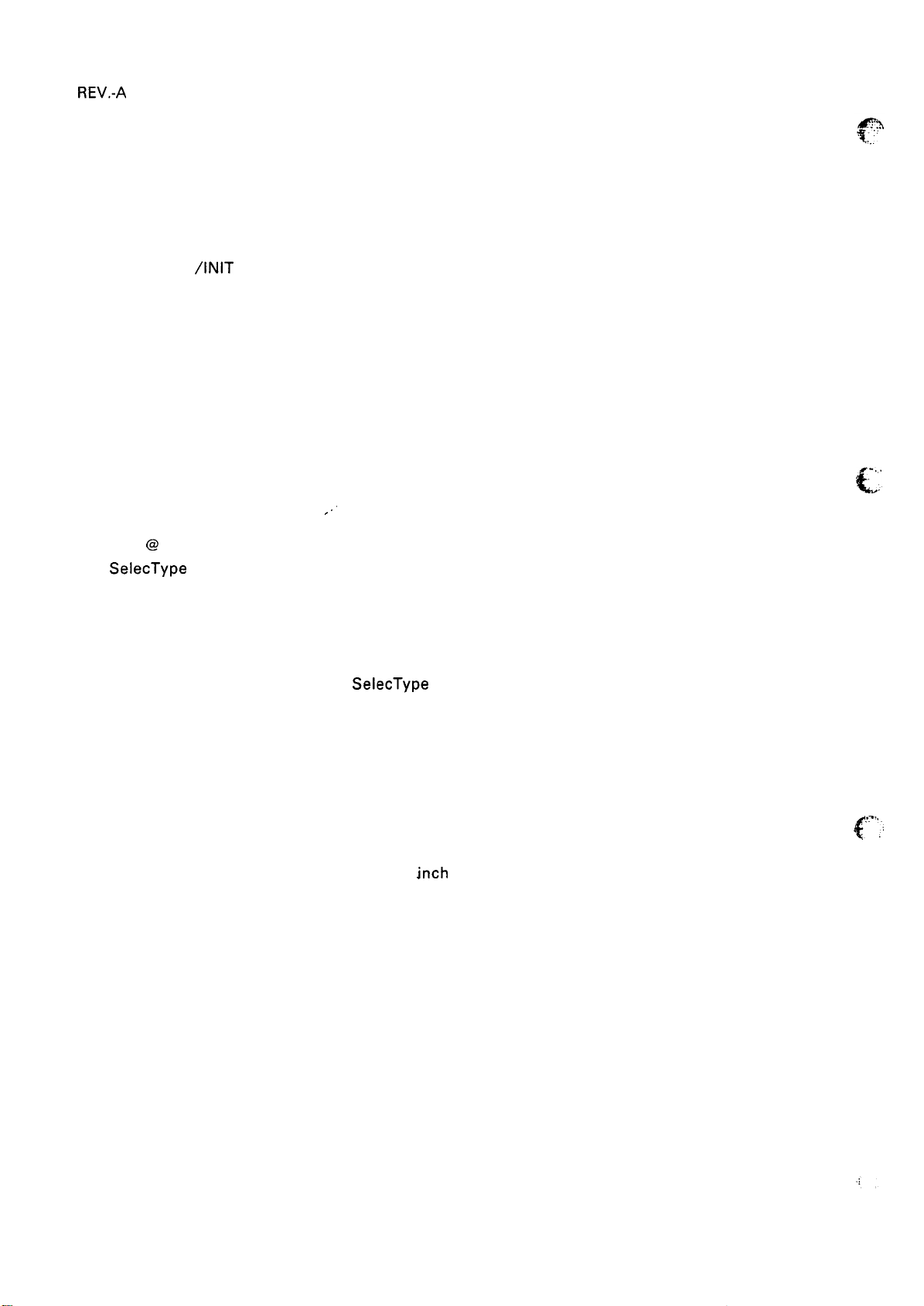

1.6.2

Hexadecimal Dump Function

To enter hexadecimal dump mode, turn on the printer while pressing both the LOAD/EJECT and the

LINE FEED/FORM FEED buttons. In hexadecimal dump mode, the printer prints the hexadecimal

representation of the input data along with the corresponding ASCII characters. This function is useful

for checking the data the printer receives from the host. If input data is a control code instead of a

character code, a period (.) is printed in the ASCII

column,

.@. R.

.t.

.6.

.P.

16 ~~ 16 52 00 IB 74 01 IB 36 12 IB 50 IB 70

20 20 54 68 69 73 20 69

6~

70 6C 65 20 6F 66 20 61 20 64 b 1 74 61 20 64

75

60 70 20 70 72 69 6E 74 6F 75 74 2E 20 54

69

73 20 66 65 61 74 75 72 65 20 6D 61 6B 65 73 is

OA 20 20 20 20 20 69 74 20 65 61 73 79 20 66 6F . i t easy

?3

20 61 6E 20 65 78 b 1

00

68

This is

mple of a data d

ump printout. Th

featu

P.

an

exa

re makes

fo

Figure 1-9. Hexadecimal Dump

~.,

.,,.

1-20

REV.-A

1.6.3 Paper-Out Detection and Form Override Function

The paper-out detector is attached to the printer mechanism. When the paper-out detector senses a

paper end, the printer first performs a form override. If paper loading fails, the BUSY signal goes HIGH,

the PAPER OUT indicator light comes on, the interface PE signal becomes HIGH, the \ERROR signal

becomes LOW, and the printer enters the PAUSE condition.

The form override function ignores the paper out and allows the printer to print additional lines after

a paper out is detected. After you load paper and press the PAUSE button, the printer returns to the

RUNNING condition and printing begins again.

The printer enters the paper-out state only when a paper out is detected after the printer performs a

paper loading operation,

1.6.4 Error Conditions

If any of the following error conditions are detected, the printer automatically enters the PAUSE

condition.

● The home position is not detected at printer mechanism initialization.

● The home position is detected during printing.

. The PAUSE button is pressed and the printer enters the PAUSE condition.

● A paper out is detected after the printer performs a paper loading operation.

If the parallel interface is selected, the following interface signals are output to indicate the error and

to stop data transmission:

● The BUSY signal becomes HIGH.

. The /ERROR signal becomes LOW.

● No

/ACKNLG

pulse is sent.

1.6.5 Buzzer Operation

The buzzer sounds under the following conditions:

● A paper-out error is detected. (The buzzer beeps three times for 0.1 seconds, with 0.1 second

interval s.)

● Abnormal carriage movement is detected. (The buzzer beeps five times for 0.5 seconds, with 0.5

second intervals.)

. A control panel setting is accepted. (The buzzer produces one O. l-second beep.)

1-21

REV.-A

1.6.6 Printer Initialization

There are three types of initialization: hardware, software, and control panel.

(1) Hardware initialization

This type of initialization takes place when you turn on the printer (and the AC power cord is plugged

in) or when the

When the printer is initialized, it performs the following actions:

(a) Initializes the printer mechanism.

(b) Clears the input data buffer.

(c) Clears the downloaded character set.

(d) Clears the print buffer.

(e) Returns the printer settings to their default values.

(2) Software initialization

ANIT

signal is received.

.“

,,

L

.,,

The ESC @ command initializes the printer but does not perform functions (a), (b), and (c) above. The

last

SelecType

(3) Control panel initialization

Pressing the PAUSE and ALT buttons at the same time initializes the printer but does not perform

functions (a) and (c) above. The last

settings still take effect.

SelecType settings still take effect.

1.6.7 Default Values

When the printer is initialized, the following default values take effect:

Page position

Left and right margins

Line spacing

Vertical tabs

Horizontal tabs

Family number of typestyle

Download characters

Character spacing

Printing effects

Condensed printing

Printer condition

The current paper position becomes the top-of-form position.

Released

1/6

jnch

Cleared

Every eight characters (relative)

Last font selected from the control panel

Kept during software initialization Cleared during hardware

initialization

Last setting selected from the control panel

Cleared except condensed printing

Last setting selected from the control panel

RUNNING (not PAUSE)

‘f

,,.7,,

~~$

1-22

Loading...

Loading...