Page 1

EPSON TERMINAL PRINTER

LQ-860/1060

TECHNICAL MANUAL

Page 2

NOTICE

‘

All rights reserved. Reproduction of any part of this manual in any form

whatsoever without SEIKO EPSON’s express written permission is forbidden.

‘ The contents of this manual are subject to change without notice.

“ All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

“

The above notwithstanding SEIKO EPSON can assume no responsibility for any

errors in this manual or the consequences thereof.

@

Copyright 1989 by SEIKO EPSON CORPORATION

Nagano,

Japan

-i-

Page 3

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury, and 2) damage

to equipment:

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2.

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

ON

THE

VOLTAGE, LISTED

UCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

3.

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4.

IN ORDER TO PROTECT SENSITIVE

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE

SE:RIAL

EPSC)N

NUMBER/RATING PLATE. IF THE EPSON PROD-

pP CHIPS AND CIRCUITRY, USE STATIC

WARRANTY.

- ii -

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical

operations, maintenance, and repair of

The instructions and procedures included herein are intended for the

experienced repair technician,

precautions on the preceding page. The chapters are organized as follows:

and attention should be given to the

the LQ-860/l 060.

REV.-A

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Chapter 5 -

Chapter 6 -

‘ The contents

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer operation.

Discusses the options

Includes a step-by-step

assembly, and adjustment.

Provides Epson-approved techniques for troubleshooting.

Describes preventive maintenance techniques and lists

lubricants and adhesives required to service the equipment.

of this manual are subject to change without notice.

guide for product disassembly,

-

iv -

Page 5

REVISION TABLE

REVISION DATE ISSUED

=)=

CHANGE DOCUMENT

I

I

1st issue

I

I

-v-

Page 6

REV.-A

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2.

CHAPTER 3. OPTIONAL EQUIPMENTS

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

OPERATING PRINCIPLES

DISASSEMBLY, ASSEMBLY,

TROUBLESHOOTING

MAINTENANCE

APPENDIX

AND ADJUSTMENT

-

vi –

Page 7

CHAPTER 1

GENERAL DESCRIPTION

1.1

FEATURES-=M~.”H..H..-M..M .-.~..H.H”.UM.-.-.~.M.-.-Ho

1.2

SPECIFICATIONS

1.2.1 Hardware Specifications”... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Firmware Specifications

1.3

INTERFACE OVERVIEW -----

1.3.1 8-Bit Parallel interface Specifications

1.3.2 RS-232C Serial interface Specifications

1.4

DIP SWITCH

1.4.1 DIP Switch Settings

1.4.2 Jumper Settings

1.5

SELF-TEST OPERATION

1.6

HEXADECIMAL DUMP FUNCTION

1.7

PRINTER INITIALIZATION

1.7.1 Hardware Initialization

1.7.2 Software Initialization

1.7.3 Default Values-

1.8

BUZZER OPERATION AND ERROR CONDITIONS

1.8.1 Buzzer Operation

1.8.2 Error Conditions

1.9

MAIN COMPONENTS

1.9.1 Printer Mechanism

1.9.1.1 Printer Mechanism Features

1.9.1.2 Paper Feed Operations

1.9.2 JUNMMBoard (Main Board)

1.9.3 MONPS/MONPSE Board (Power Supply Circuit Board)

1.9.4 Control Panel

.fl.-..-~..-.~.~.-..-..-tiuu.

-.-.-ti.m.-.o.tito.-.tim.-.ti

C.~..~-..-..M~MU.6fiM-H..fi.-

ANDJUMPERSETTINGS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-..”~..-.m.M..-.-.-.H.H.fiH..~--.H.-.-.H...-M-..-.fi.mo.H

..H.=..MM-~.-.H.-.M.-.-.~.-.

~.-.-..~.-.H.H.-.-..-H.M----

.~~.~..~.~..--..H.u.uH.-.H.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

~-..-.-.~H.-...o..M.H.M

...~.-...H---.-.H.-.-.-..-H.-

-.~..-.~.M..M-..-..-M.-..M...~~..~-.~..~.H.M.-.~.-.H.M.-

...=..~.-.~.~..f~.-~...~-.~..-

...-.’fi..-.=.HH.H...-M-.H.H-.

...H.-..Hu..-.H.--.-..~.-M----

.-M-.H.~.M.H.u.H.H.M.-H.H.. M--..H.-29.-1-29

‘iHu.o.u..-ttio.-.--.-.-tio.-

---------------------------

-.-.H.,,-.-.-.MHHM.HH.M.-H. M-1-16

,MH...H..-.-...H.M

-----

H.M..~.MH-.-.-H.Hl-.oH-.Hl

---------------------------

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.~~.~.-..-~-.-.-~”~.-.=.-.l

.m-.fi.-fifHM-.HM-.ml-13

.~.~-.~.=.~~~..~~~..~.l-21

.~.~.~.~.~-.~.~-.~-l.2222

-.-uu..-H-.H.H.~--.ul-24

.~~.H.--M.H.-H.~.M.l-24

-..-.---..--.-.--.--.-..1-24

H.H.H-.-.-H.-..-..HH.M.1-25

.-.-u.H..~H-.-H.u.-25.l-25

..--M..-~.~.~~.l~.-l-27

...-.---.-.Hu.-.M1..1-1

. ..........................1-3

.-.~--.~.~-.~’~-..l-9

-..-1-13

-.~.~~-.-19l9

M-.H.u.-M.1.2323

H.”~-.-.~.HH.H-.-l-24

-----------

-.-.1-27

...............1-28

.-.-.~-.~..~1.-~l-3o

.~.-l-3

.1-25

REV.-A

1-19

-26

-31

l-i

Page 8

REV.-A

LIST OF FIGURES

Figure 1-1.

Figure 1-2.

LQ-860/1060

Printheacf

Exterior Views

Pin Configuration

Figure 1-3. Cut Sheet Paper Printable Area

Figure 1-4.

Fanfold Paper Printable Area

Figure 1-5. Head Adjustment Lever Positioning

Figure 1-6. Character Matrix

‘s..”....””””.”””””””””””””””””””””””””

““”””””””””””””””””””””””””””””””””””””

-.--”-””””””””””””””””””””””””””””””””

““”””-””””””””””””””””””””””””””””””””

.“”.””H””””.”-.”.””””””.”””””o”””””.”.

““”””””””””””””””””””””””””””””””””””””

““””””””””””””””””””””””””””””””””””l-1

Figure 1-7. 8-Bit Parallel interface Data Transmission Timing

Figure 1-8.

Figure 1-9.

Figure 1-10. Serial Data Transmission Timing

Figure 1-11. Serial Interface Connector

Figure 1-12. Self-Test Printing

Figure 1-13. Hexadecimal Dump

Figure 1-14.

Figure 1-15. Model-5810/5860 Printer Mechanism

Figure 1-16. JUNMM Board

Figure 1-17. MONPS Board

Figure 1-18. Control Panel

36 Pin Printer Side

tinnector”-””.”-”..””””.

c.”.”””.”.”””.””””.”.””.”””””.”.””0”.

RS-232Clnterface Handshaking,”-””.-”.”””...””..” .“”.”””””.....-”””””””””.”””.”.””.1-1

““””””.””””””””””””””””””””””””””””””””

‘.””””.”””””””.”””””””””””””””’””””””””

.......””””””””””””””””””””””””””””””””

““”””””””””””””””””””””””””””’”””””l-22

List”.””.”-””””.””-”....”..”.”.”””.”” ““”””””””.”.”.””-””””””””s””.”1-23

LQ-860/1060

Component Locations

“-00”.””..00”.””.o.o””-””.”””-””cc”””.”

OOC..””.....””””””..O”.....””””..””U”.

Do.....”..-”.”-.-...”..”....”....”....”

.......................””....”.........l-29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

““”””””””””””””””””””l-1

““”””””””””””””””””””””l-3

““”””””””””””””””l-5

s“”..””.”””.””4”””””1-6

““””””””””””l-7

1

.....”.”””””””””””””””””””””1-13

.“”1-13

6

““”””””””””””1-17

““”””””””””””””””””””1-17

.“s””..””1-26

“..-..1-27

.......................................l-30

.-’.,

.~:.

.,.

l-ii

.,. .

,:.:

Page 9

LIST OF TABLES

REV.-A

Table 1-1.

Table 1-2.

Table 1-3.

Table 1-4.

Table 1-5.

Table 1-6.

Table 1-7.

Table 1-8.

Table 1-9.

Table 1-10. Environmental Conditions

Table l-11. Printing Mode

Table 1-12. Character Matrix and Character Size

Table 1-13. 8-bit Parallel l/F Connector Pin Assignments

Table l-14. Select/Deselect Control

Table l-15. Serial Interface Handshaking

Table l-16.

Table l-17.

Table l-18.

Table l-19.

Table l-20.

Table l-21.

Table l-22.

Table l-23.

Table l-24.

Optional Units

Optional Interface

Line Feed Speeds

Cut Sheet Paper Specified Conditions

Continuous Paper Specified Conditions

Lever Adjustment..””...’”””.”

Ribbon Cartridge Specification

Dimensions and Weight

Electrical Specifications

RS-232CSerial l/F Connector Pin Assignments

DIP Switch

International Character Set Designation

DlPSwitch2

Interface Selection

Baud Rate Selection

Jumper Setting

Self-Test Operation

Hexadecimal Dump Operation

........ ’......., . . . . . . . . .......... O..... ”... ””..’”

Bc~ards

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

lSettings

Settings

~...-..f~o..~...-~H”..ti.tio.H”

~.~.-.-..~~..-..-.~~..~--.oH

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-..-.~..~.~..uH”-..-.uH”-o-

-.....m.oo”-”m’ti”-”ti-””o-”ti”-

-.-.-.-..--.-.”-.--”-”--”-

““””.”””””-------”------s-”-”--”””””-”””

-..~-...--..-....-tio-o.H.-HM

-....-.~..-.~.M..--.-.o-.uM”

.~.-..-..-~..-.Hu..-.~”-H”su.

.-.-...--..-.-.-.-.-..--.-””

.~.-.oH-.H..co”u”.”u-H”ti”M” --”-”1-12

..~~...-.-.~.~.-..ti-.ti.M.ti’o

...---.-..M.M.-.H”~.M”MCOCO -oH”-o-”HM”u1-16

.~.~~..-..~.-.~.~.-..-..-”..-

................””..””.”””””””””””””””” ““””””1-19

.-.-.~.~...-~..M.n”MM-.n”M.” --”-”~-”~””~~”~-”-l-20

..-.-.~...-.ti.ti..-..ti-ti.uo

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

““””””””””””””””””””””””””

““~-~”~”--”~”~””fll-2

‘--””-””-””-”””””--””””-1-7

“-””~~”~-””~1-7

-“”u”-~”u”M-”H.H”M”l-8

-“Mu.-”o-u”uc-.1.8-8

-.--.-”---”-”-”-1-8

. .................”..”””.””””””””””””””””

......-.....”...””.”””””””””””””””””1-1

“-””-~”~”~”-~-”-l-15

........-””””...”.-””-”””s””””.””1-18

“-~”~”-”-”~”~”--”~”l-l9

“~”~~””-”---”~”~~”~”1”202o

““~~~””-”--”-”-”-~”-”l-2o

-.~.~”-.~”~”-~”~”~”-~”~””l-2

. ““”.””.”.”-”.””””””1-23

““”

””l-2

“-”-”1-4

“-”-””1-5

“l-lo

1-22

1-4

4

1

l-iii

Page 10

1.1 FEATURES

REV.-A

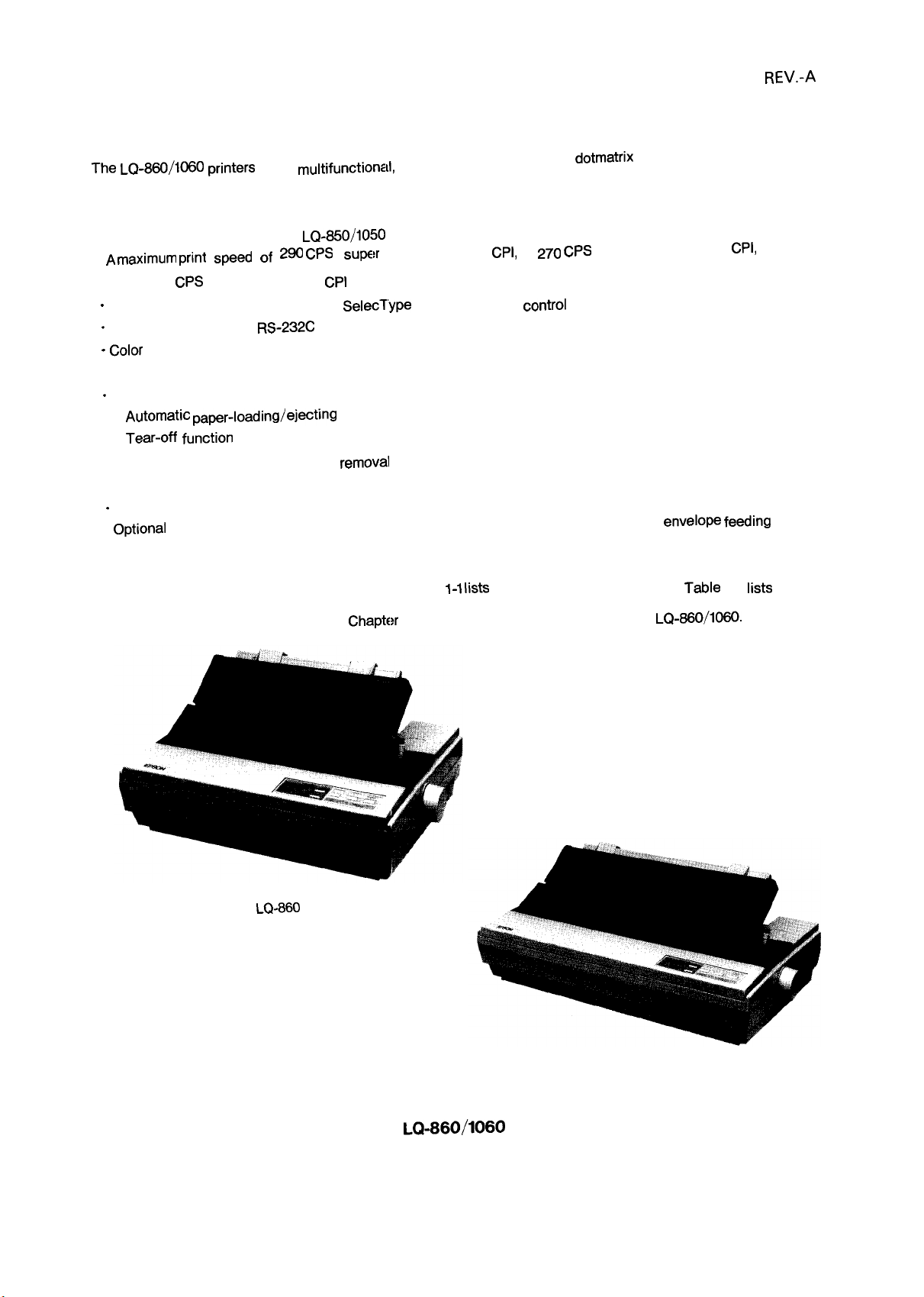

The

LQ-860/1080

features of the these printers

. Upward compatibility with the LQ-850/1050

. ~

maximum print

and of 90

o

Direct selection of font and pitch in

.

Both 8-bit parallel and

.

Color

printing capability

. Push and (optional) pull tractor feeding

.

Advanced paper handling:

AUtomatiC paper-loadin9/ejectin9

Tear-off

Printing of fanfold paper without

. Low-noise acoustics

.

Optional interface for the EPSON 8100 series

.

Optional

capability

Figure 1-1 shows exterior views of the printers,

the optional interface boards (refer to

printerS

speed of 290

CPS

in LQ mode at 12

funCtiOn

low-priced,

are

multifunction~ll,

are:

cps

in super

CPI

SelecT’YPe

RS-232C

single-bin and double-bin

serial interfaces

function

removal

Chapt[?r

24-pin printhead, impact

draft mode at

feature from the

of the cut sheet feeder (option)

Table

3 for more detailed information) for the LQ-8W106O.

10

CPI,

of

contrOl

cut sheet feeders which contains

1-1 lists

optional units available, and

dotmatrix

270 Cps

panel

printers. The main

in draft mode at 12

enveloPe feedin9

Table

CP1’

1-2

lists

LQ-860

Figure 1-1.

LQ-860/1060

1-1

LQ-106O

Exterior Views

Page 11

REV.-A

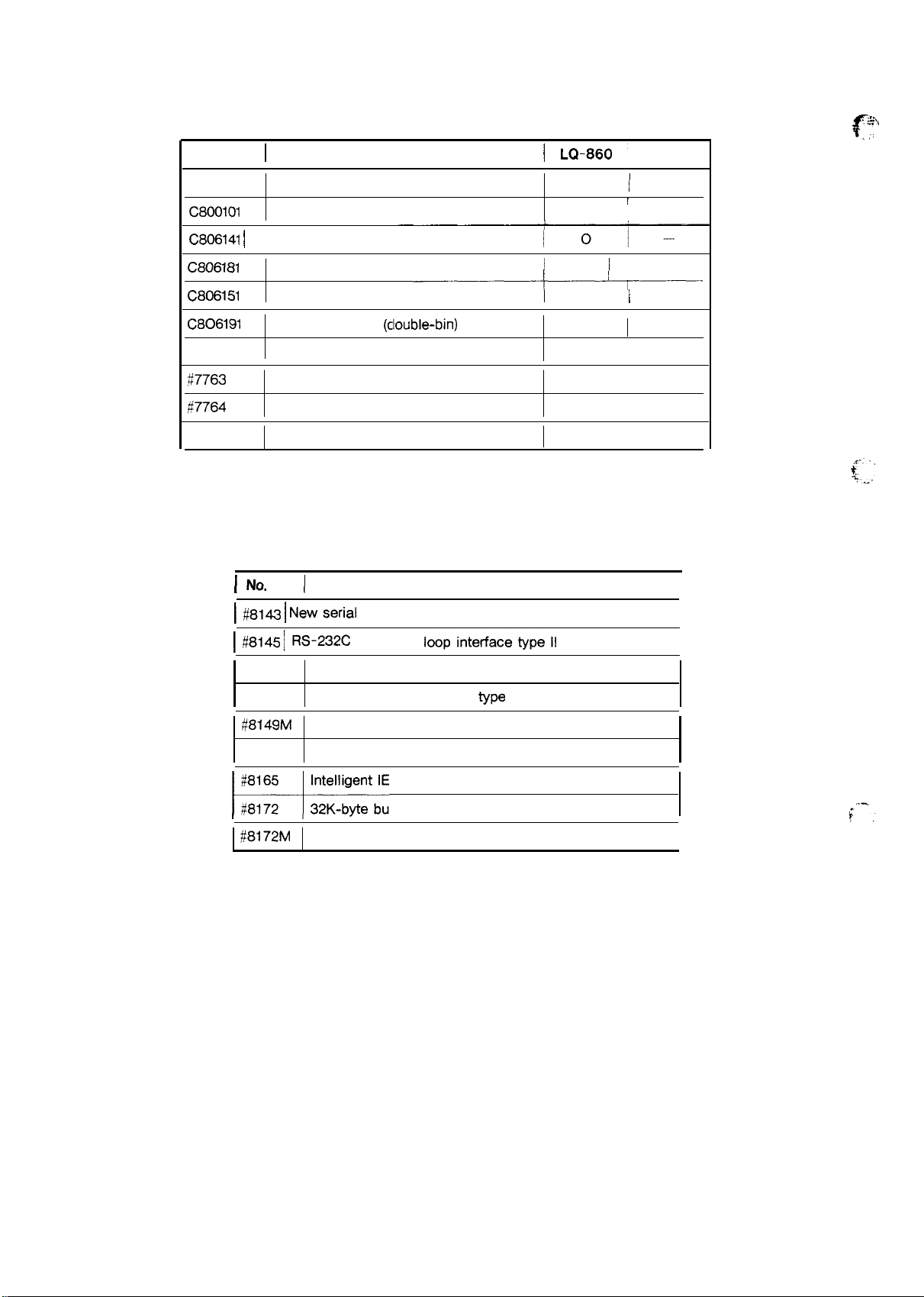

No.

C800071

C800101

I

Pull tractor unit

Pull tractor unit

Table 1-1. Optional Units

Name

I LQ-8601 LQ-106O

o

~

–

!

o

.+

.-. ,

r.

.,. .

C806141 I

C806181

C806151

C806191

#7762

87763

ff7764

#7407

Cut sheet feeder (single-bin)

Cut sheet feeder (single-bin)

Cut sheet feeder (double-bin)

Cut sheet feeder

Ribbon cartridge (black)

Ribbon cartridge (color)

Ribbon cartridge (film)

Multi font module

Table 1-2. Optional Interface Boards

I

No.

/

1#8143 I

1#8145

Newserial interface

IRS-232C current loopinterfacetypell

#8148

Intelligent serial interface

~

(clouble-bin)

Name

- ! 0

I

o

—

;

–

o

o

o

o

o

I

I

I

#8149

#8149M

#8161

l=-+---

#8172M

Intelligent serial interface

Intelligent serial interface type Ill

IEEE-488 interface

Intelligent IEEE-488 interface

32K-byte buffer parallel interface

128K-buffer parallel interface

type

II

I

1-2

Page 12

REV.-A

1.2 SPECIFICATIONS

This section describes the specifications for the printer without the Identity Module option.

Specifications not affected by firmware (hardware specifications) are the same whether or not the Identity

Module is installed.

1.2.1 Hardware Specifications

Printing Method

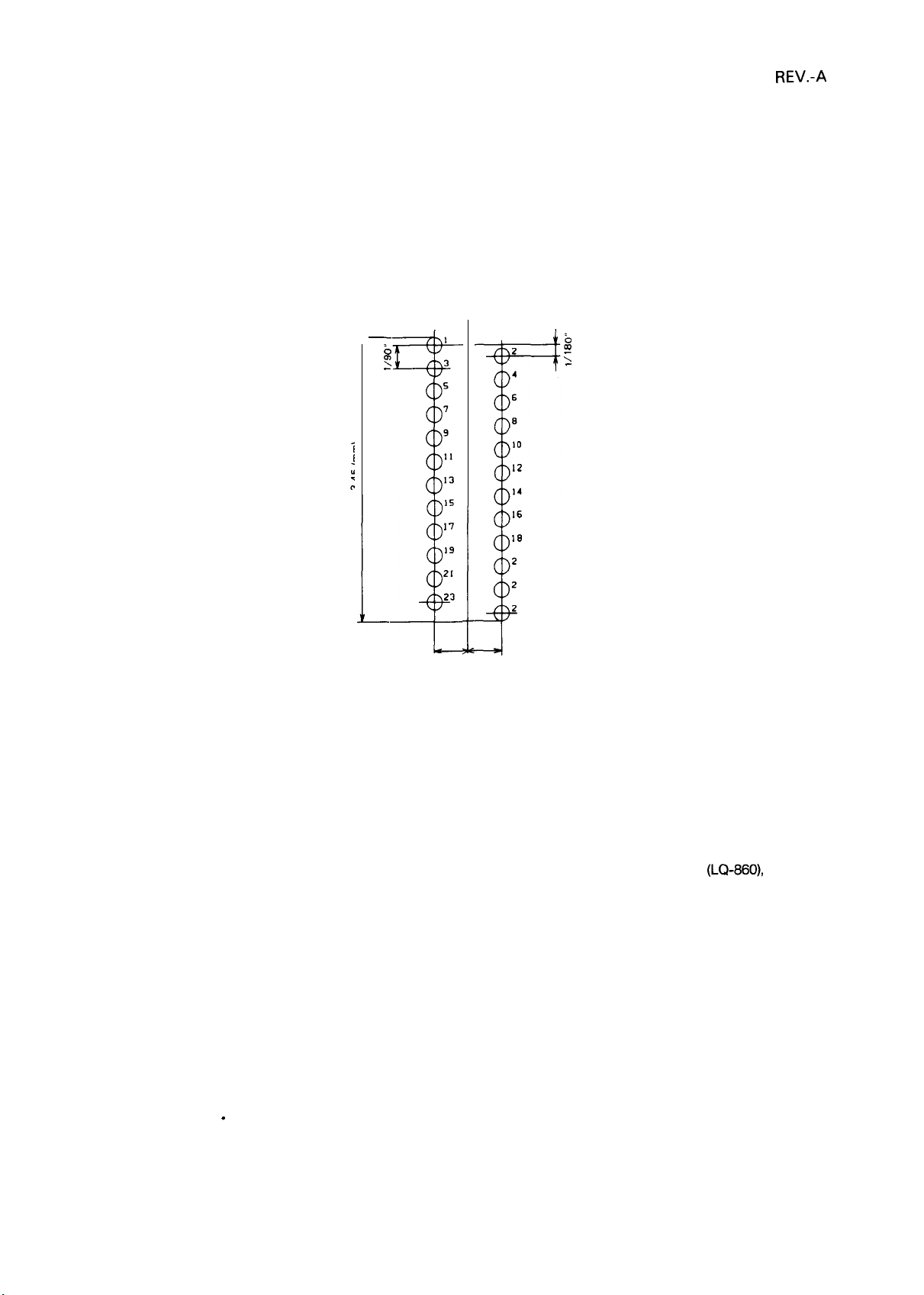

Pin Configuration

Serial, impact dot matrix

See Figure ‘I-2 (12x2 staggered, diameter: 0.2 mm).

—

0

y

-dz-

[~

Figure 1-2. Printhead Pin Configuration

I

3

15

r

17

19

21

23

[

“ 1/60”

‘ i/60’

o

m

T

4

6

8

10

12

14

16

18

20

22

24

Feeding Method

NOTES :

1. When using friction feed :

2. When using tractor feed:

Friction feed

Tractor feed (push: standard, pull : optional)

Adjust the paper release lever at rear position.

Use the paper tension unit.

Do not use continuous paper.

Do not use a single sheet paper shorter than 182 mm or longer than 257 mm

364 mm (LQ-106O).

Do not perform any reverse paper feed operations within the top 8.5 mm and bottom 22

mm area of the paper.

Do not perform reverse feed beyond than 1/6 “ after the paper end has been detected.

Do not use multi-part single sheet forms.

. Multiple copies for printing must be finished by pasting them together at the line or dots.

. Copy paper must be a carbonless multi-part paper.

a) When using push tractor feed:

. Adjust the paper release lever at center position.

“

Use the paper tension unit.

(LQ-860),

1-3

Page 13

REV.-A

“

Do not perform reverse feeding for more than 1/6 “.

“

Because accuracy of paper feed cannot be assured, do not perform reverse feeding

after the paper end has been detected.

b) When using pull tractor feed :

“

Adjust the paper release lever at front position.

“

Remove the paper tension unit and mount the pull tractor unit.

o

Use the paper path when a single sheet is inserted.

WV I

1~1 I

c) ‘A’’---

Adjust the paper release lever at front position.

Remove the paper tension unit and mount the pull tractor unit.

Do not loosen the paper between the platen and the pull sprocket.

Precisely the horizontal position of the pull sprocket and push tractor.

Do not perform reverse feeding for more than 1/6”.

Do not perform reverse feeding after the paper end has been detected.

U~ll Iy ~UW l-~Ull 11

“

“-’--

-’

‘-L

-’‘“ ‘---”-”

cX,LUl IGC7J

‘---A

.

“

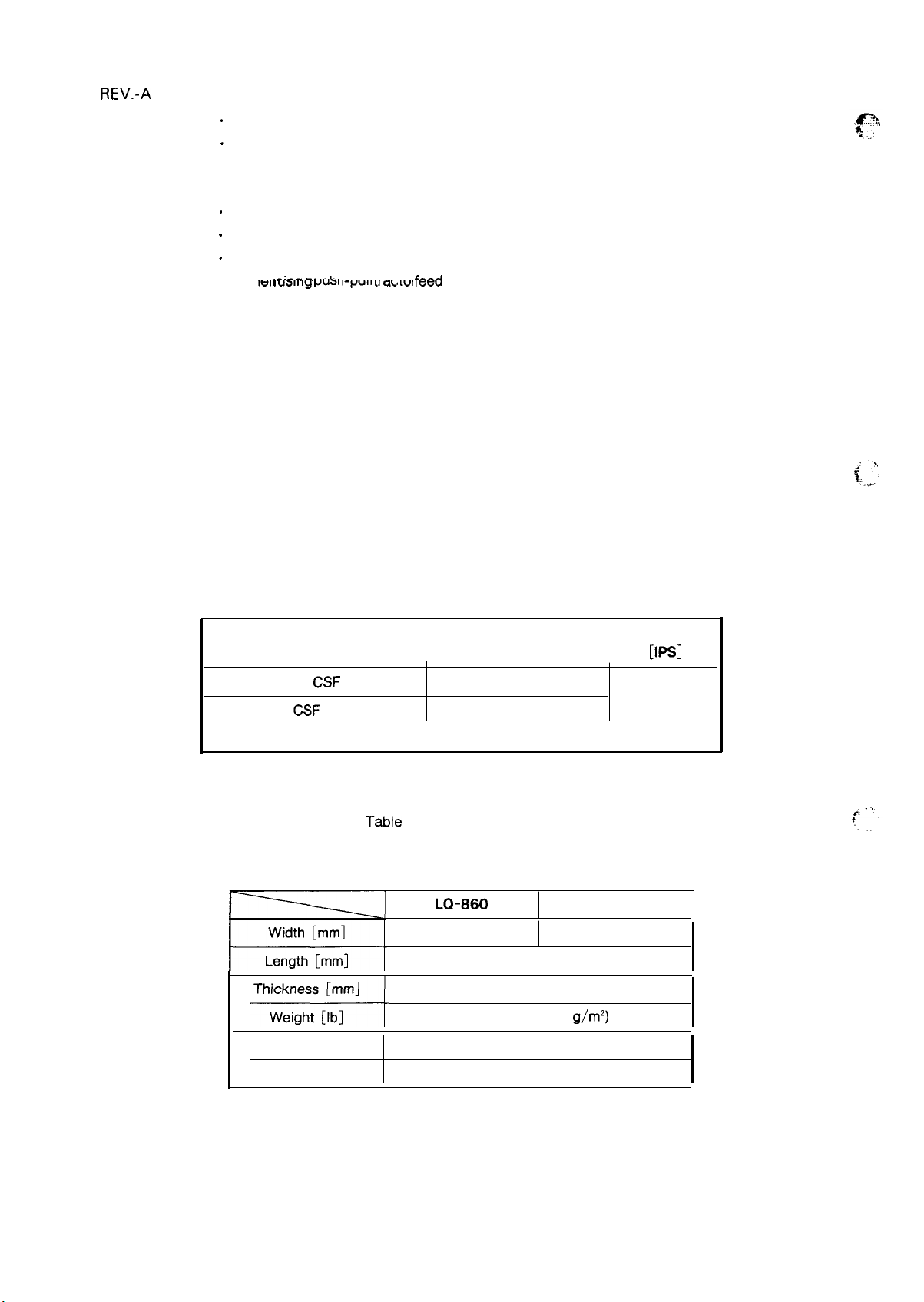

Paper Loading Directions

Line Spacing

Line Feed Speed

Feeding Method

Friction without

Friction with

Tractor

Paper specifications

Cut sheet paper

Inserted from the rear side

1/6” or programmable (min. 1/360”)

See Table 1-3.

Table 1-3. Line Feed Speeds

1 /6” line spacing

[ins/line]

CSF

CSF

I

Refer to

Table 1-4. Cut Sheet Paper Specified Conditions

Table

1-4.

LQ-860

182-257 (7.2 -10.1 “) 182-364 (7.2- 14.3”)

56.4

67.3

64.1

Continuous

I

I

LQ-106O

IIPS]

3.1

1

l--=%-l

*

Quality

Copies

182-364 (7.2-14.3”)

0.065-0.10 (0.0025-0.004”)

14-22 (52-82

Plain paper

Not available

1-4

9/m2)

Page 14

REV.-A

Continuous paper

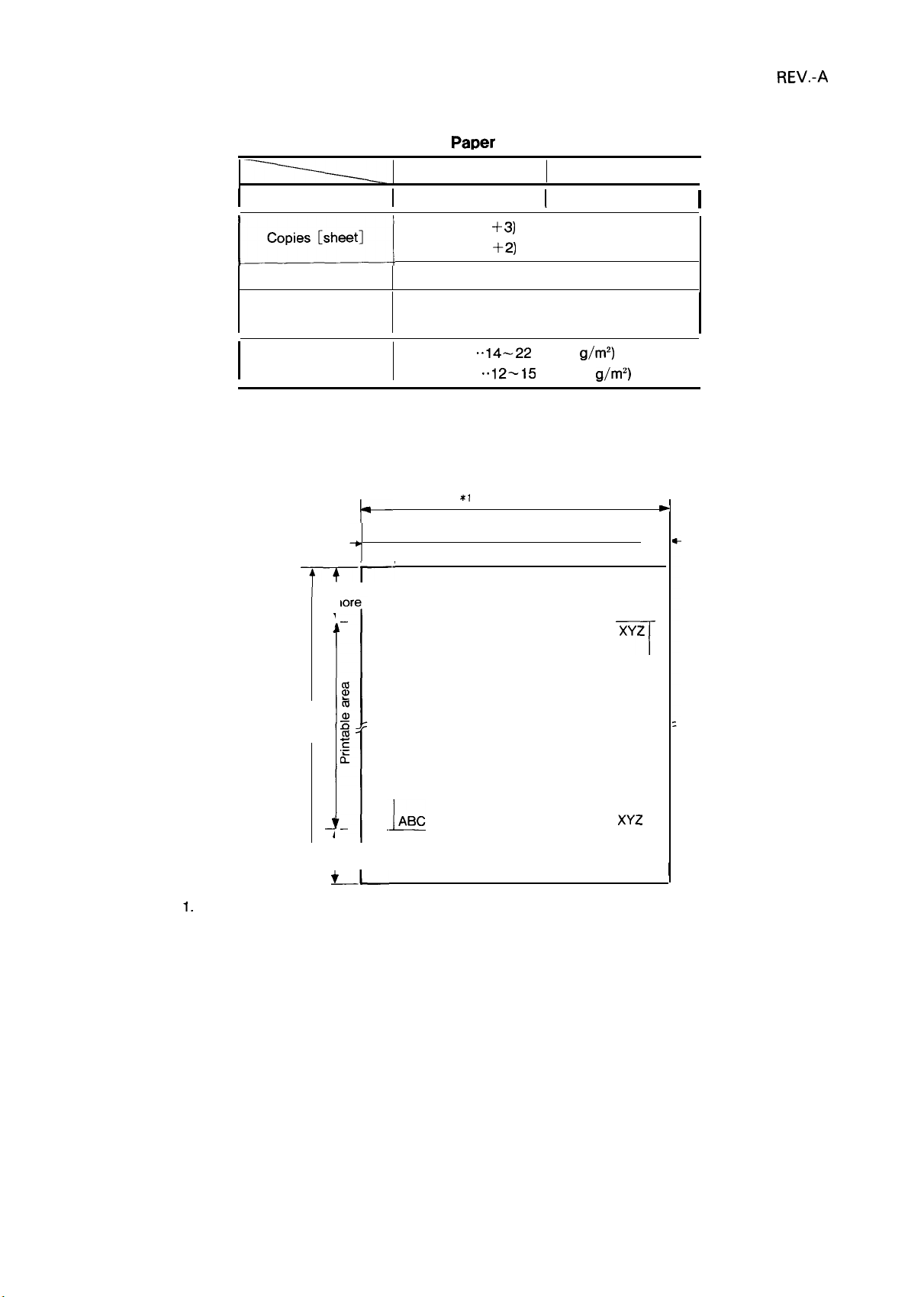

Printable Area

Cut sheet paper

Refer to Table 1-5.

Table 1-5. Continuous Paper Specified Conditions

I

Width [mm]

LQ-860

I

101-254 (4.0-10.0”) I 101-408 (4.0-16.0”)

4 (1 original

3 (1 original

+3)

+2)

1

at normal temperature

at all temperature range

H

Quality

Total Thickness

[mm]

Weight [lb]

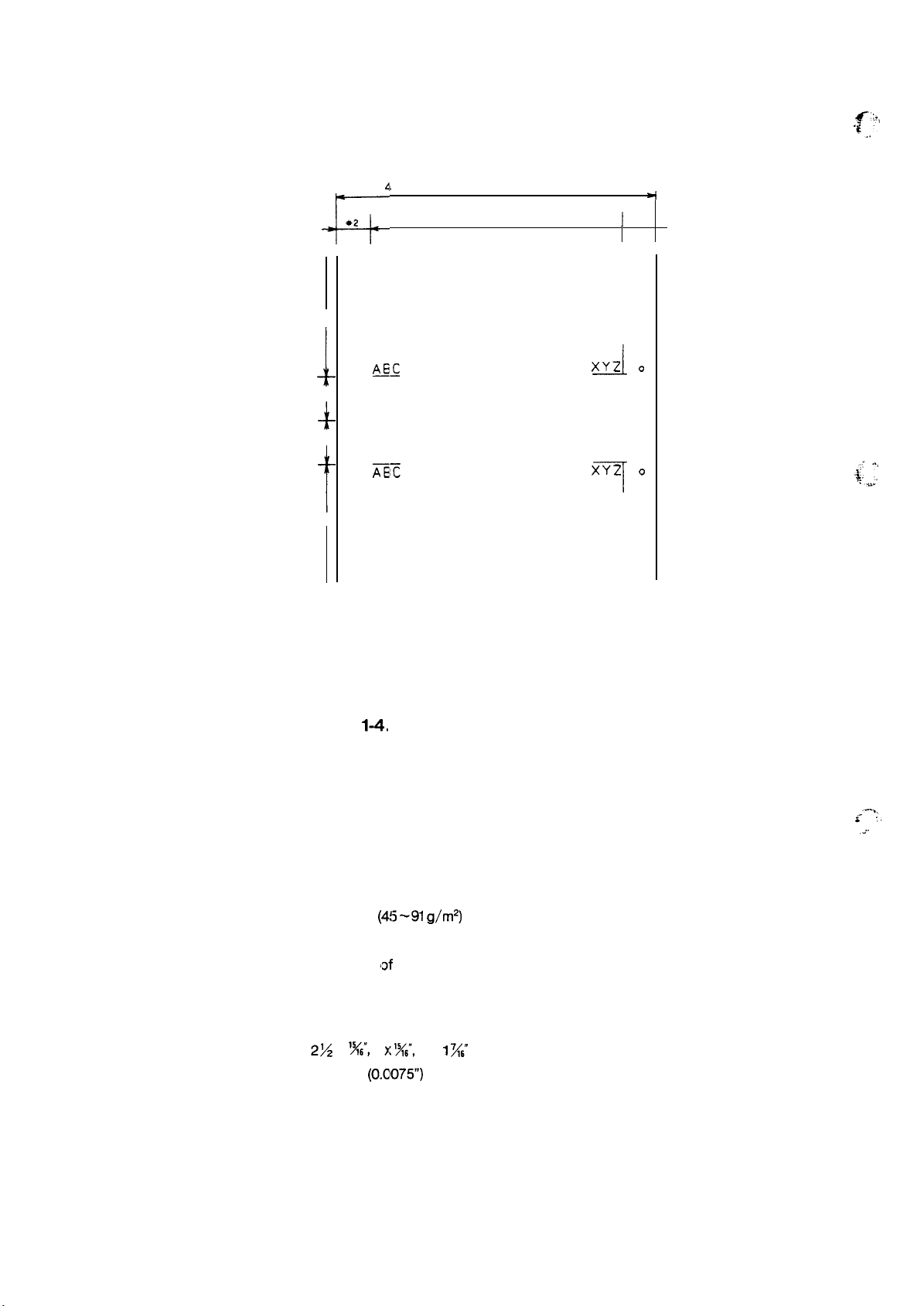

See Figure 1-3.

i

--TY’

0.33”, 8.5 mm

I

or

I

I

—

I

t-

*3

i

0.085-0.32 (0.0025-0.01 2“)

1 sheet”

4 sheets” ””12-15 (40-58.2

7.2–10.1 *1 (14.4)”, 182–257 (364) mm

=

ABC

‘r

Plain paper

.”14-22

(52-82

Printable area

LQ-I 060

g/m2)

g/m2)

for each

XYZ

T

I

I

I

m

*3

—

NOTES :

7.2–14.3”,

182–364 mm

1

7

0.53”, 13.5 mm

or more

+L

1-

Values in the parentheses apply to the LQ-106O.

1.

2.

Printing is possible for approximately 42 mm after the bottom edge of a page has been

detected. Thus, the value 13,5 mm (lowest print position) is given for reference only. Paper

feed accuracy cannot be assured in the area approximately 22 mm (0.87”) from the bottom

edge of the page.

3.

0.12”, 3.0 mm or more when the 12”, 305 mm or less width paper is used. 0.58”, 15 mm or

more when the 13” width paper is used.

Figure 1-3. Cut Sheet Paper Printable Area

ABC

.J-

XYZ

-1

I

1-5

Page 15

REV.-A

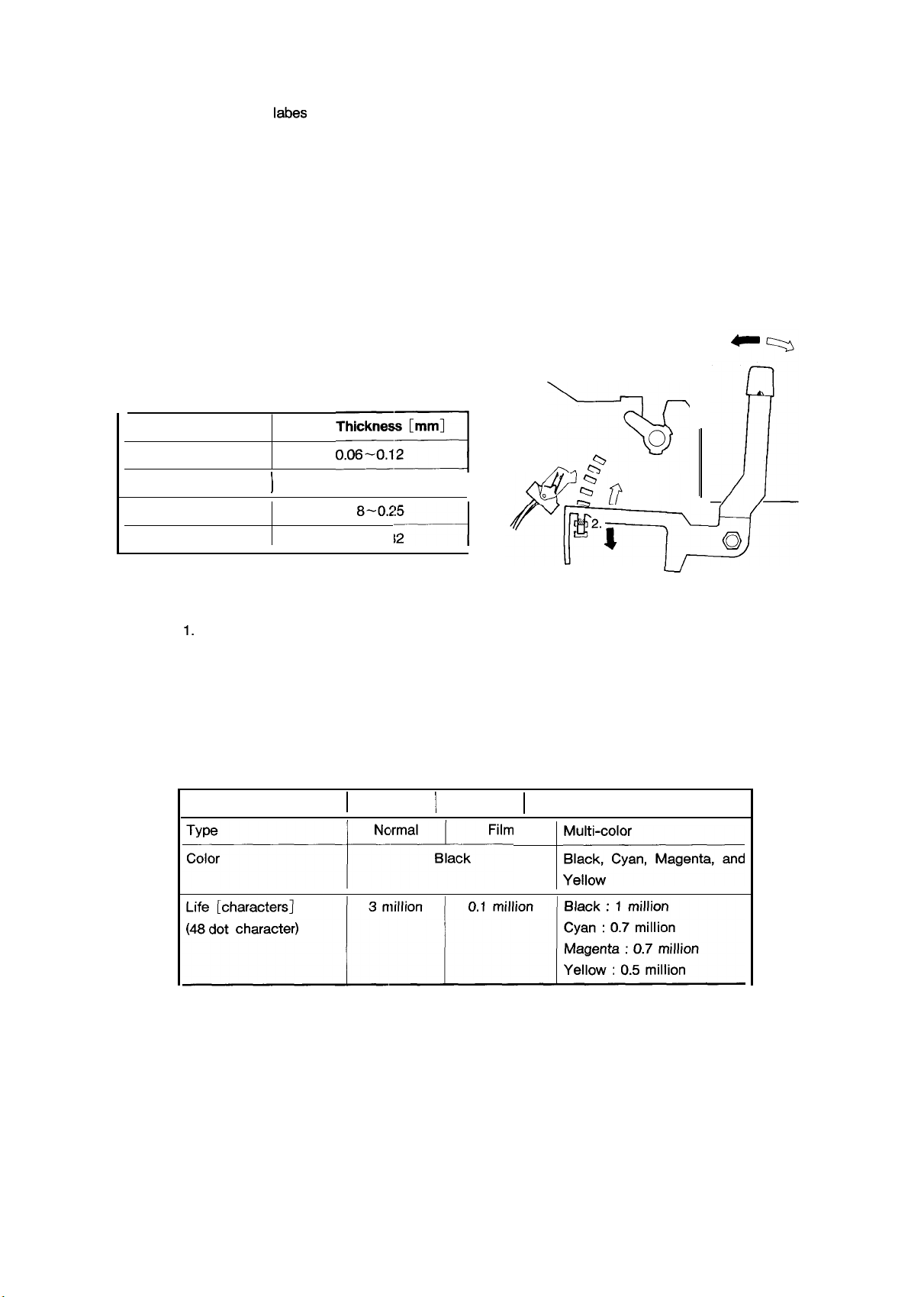

Fanfold (continuous) paper

0.35”, 9 mm

or more

0.35”, 9 mm

or more

See Figure 1-4.

*2

&

0

0

0

Printable

area

Printable

area

0

0

0

0

o

i

o

0

0

+

0

0

0

o

o

0

t

0

0

0

0

4!

- 10*1(1 6)”, 101

AE&

L

-------

AE~

T

0

- 254 (406)

Printable area

-----—.—-----------——

mm

XYZ

i

X’fz

I

0

T

4

*2

0

0

0

0

0

0

0

0

0

0

o

0

0

o

0

0

0

0

0

0

0

NOTES :

1. Values in the parentheses are apply to LQ-106O.

2. 0.47”, 12 mm or more when the 101 to 242 mm, 4 to 9.5” (101 to 378 mm, 4 to 14.9”) width

paper is used. 0.98”, 25 mm or more when the 254 mm, 10”, (381 to 406 mm, 15 to 16”) width

paper is used.

Figure

14.

Fanfold Paper Printable Area

Envelopes

Size

Quality

Thickness

NOTES :

Weight

NOTES :

Differences in thickness within printing area must be less than 0.25 mm (0.0098”).

1. Envelope printing is only available at normal temperature.

2. Keep the longer side

No. 6 (166 x 92 mm), No. 10 (240 x 104 mm)

Bond paper, xerographic copier paper, airmail paper

0.16-0.52 mm (0.0063-0.0197”)

12-24 lb (4!5-91

of

g/m2)

the envelope horizontally at setting.

3. Set the left of No. 6 envelope at the setting mark of the sheet guide.

Label

2% X

1%’s”,

4 x

%“,

4 X 1

Size

Thickness 0.19 mm

(0.C075”)

%“

max.

NOTES: Thickness excluding the base paper must be less than or equal to 0.12 mm (0.0075”).

.-..

f ;,

,-,,

1-6

Page 16

REV.-A

NOTES :

Lever Adjustment

1. Printing of

2. Labels must be fanfold.

3. Labels with pressure-sensitive paper must be jointed by pasting along the dots or lines, and

the total thickness must be less than or equal to 0.3 mm (0.0118”) to be printed out under

conditions that must be between 5 to 35-C and 10 to 80°/0 RH.

4. Examples of Iavels: AVERY CONTINUOUS FORM LABELS

Table 1-6. Lever Adjustment

Lever Position

2nd

3nd

4th

5th

Iabes

is only available at normal temperature.

AVERY MINI-LINE LABELS

See Figure 1-5 and l-able 1-6.

Paper Thickness

0.06-0.1:1

I

0.13-0.17

0.1

8-0.:!5

0.26-0.32

[mm]

I

+

~

NOTES :

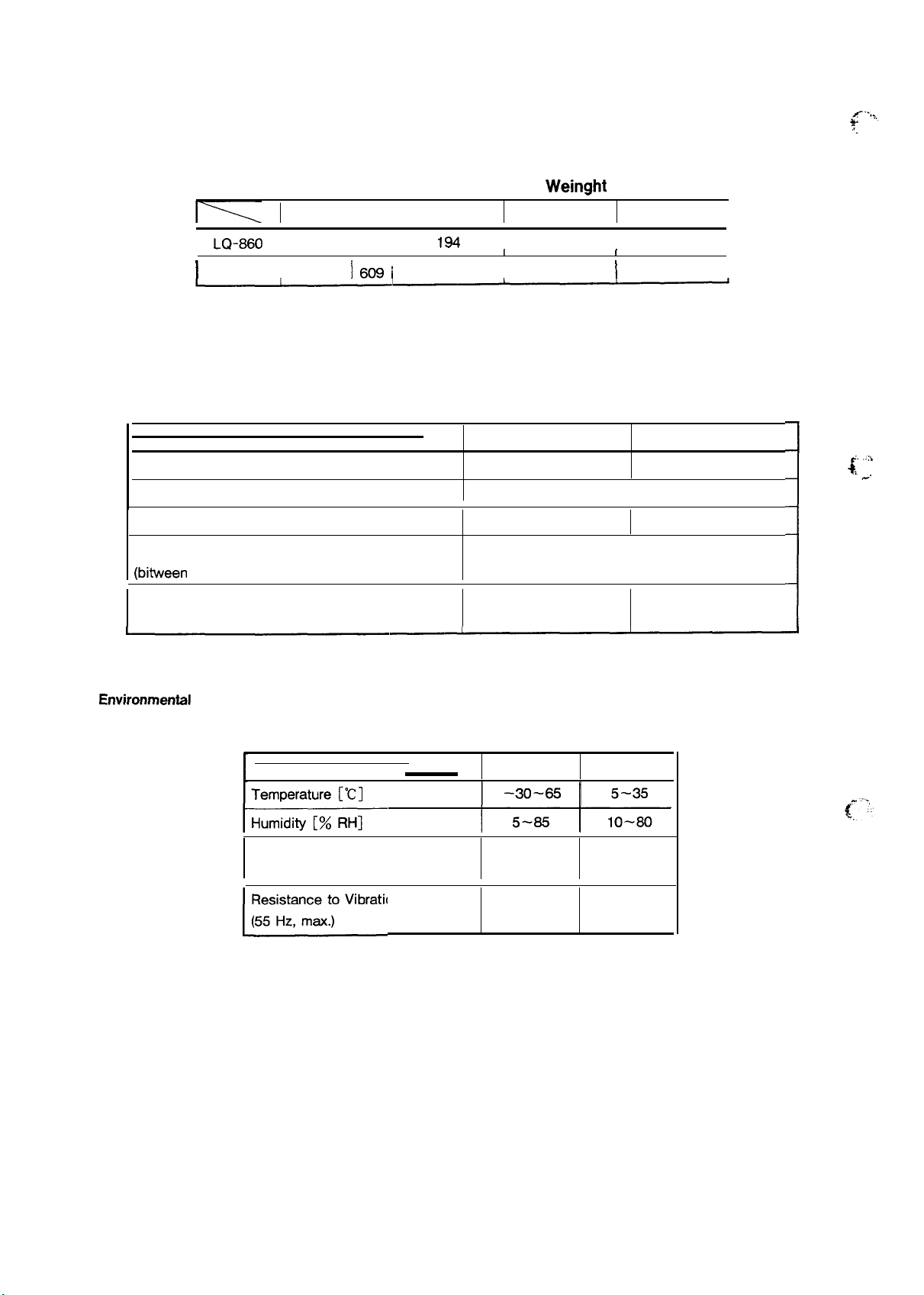

Ribbon Cartridge

1.

2.

Ribbon Model No.

w%k’i’m

u

Figure 1-5. Head Adjustment Lever Positioning

When printing density becomes lighter, set the head adjustment lever one position lower.

When using thicker paper than shown in the above table, set the head adjustment lever to

the 6th or higher appropriate position by performing the self-test operation.

See Table 1-7.

Table 1-7. Ribbon Cartridge Specification

I

#7762 I #7764 I #7763

:ii:;:nMagenta7and

1-7

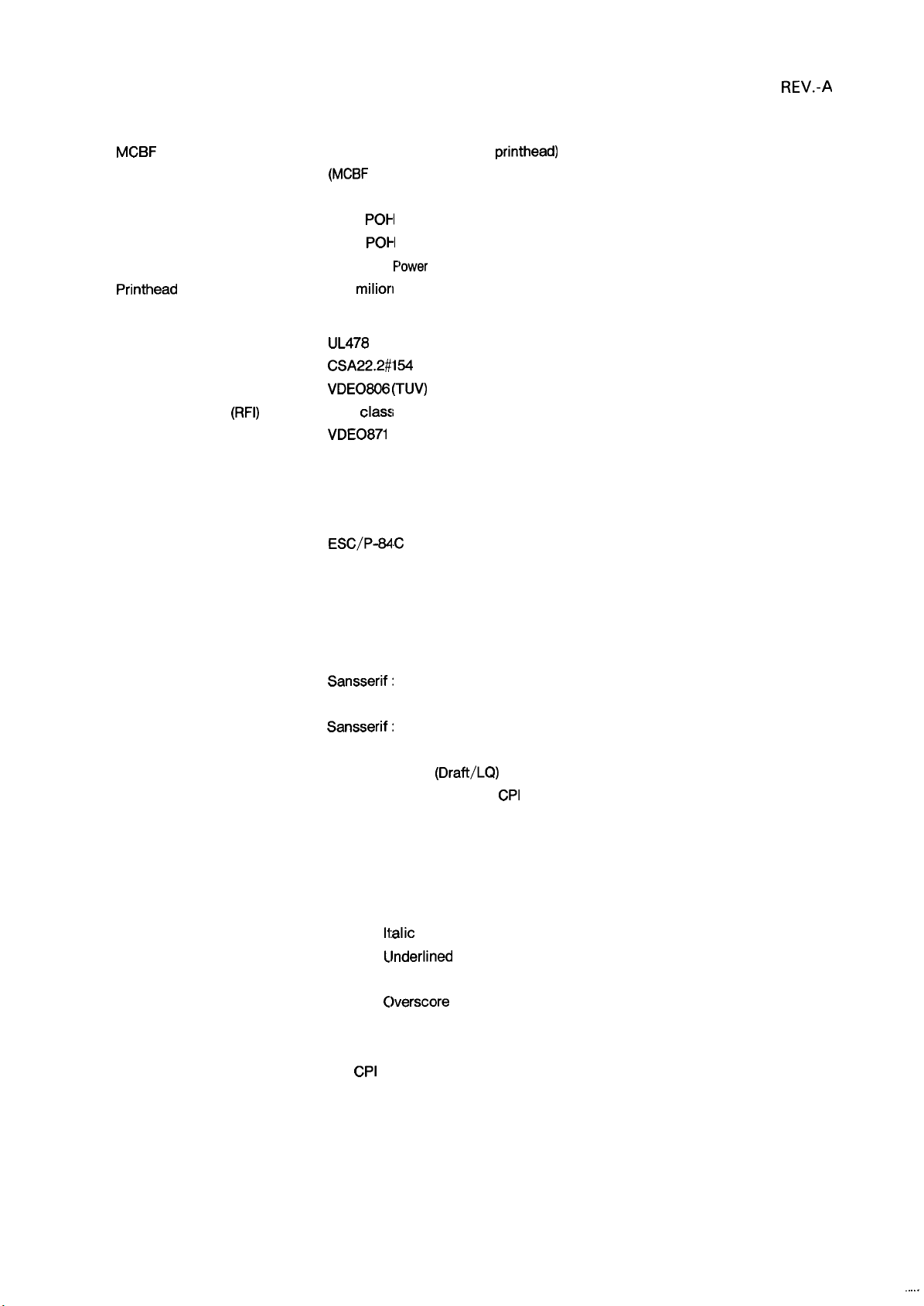

Page 17

REV.-A

Dimensions

Weight

I LQ-860 I

I

I

LQ-106O

See Table 1-8 (Details are shown in Figures A-36 and A-39.)

See Table 1-8.

I

NOTE : Excluding paper feed knob and sheet guide.

Electrical Specifications

Voltage [V AC]

Frequency Range [Hz]

Rating Current [A]

Insulation Resistance [M ohm] min.

Oitween

AC line and chassis)

See Table 1-9.

Table 1-8. Dimensions and Weinght

Width [mm]

469

I 609 i

Height [mm]

194

194

Depth [mm]

399

I

I

399

I

Table 1-9. Electrical Specifications

100-120 V Version

108-132

2

Weight [Kg]

I

1

I

220-240 V Version

49.5 -60.5

10

10

13

198-264

I

I

I

I

~. .:,,

“

-,

1

Dielectric Strength [V AC, rms]

(1 minute, between AC line and chassis)

Conditions Refer to Table 1-10.

Table 1-10. Environmental Conditions

I

Resistance

(within 1 ms)

Resistance to Vibration [G]

to shock [G]

L@_

1250

Storage

2

0.50

3750

Operating

(“;,

1

0.25

1-8

Page 18

Reliability

. . . . .

REV.-A

MCBF

MTBF

LQ-860 :

LQ-106O :

Printhead

Safety

life

Approvals

Safety standards

Radio Frequency

(RFI)

Interference

1.2.2 Firmware Specifications

Control Code

Printing Direction

Input Data Buffer

Character Code

Character Set

Family

Font

Printing Mode

NOTES :

A condensed mode for 15

0

/0)

0

/0)

printhead)

5 million lines (excluding

(MCBF . . .

4000

6000

(POH . . . .

200

UL478

Mean Cycles Between Failure)

POFI

(duty 25

POI-I

(duty 25

F)ower

On Hours)

milion

strokes/wire

(U.S.A. version)

CSA22.2#f54

VDE0806 (TUV)

FCC

class

(European version)

B (U.S.A. version)

VDE0871 (self-certification)

(Europe version)

ESC/P-84C

Bidirectional with logic seeking

6 K-byte or none ( DIP SW 1-8 selectable)

8 bits

96 ASCII, 14 international, and 1 Legal charactersets

Roman:

Sansserif:

Roman:

Sansserif:

Draft:

Printing quality

Character pitch (10, 12, 15

No. O

No. 1

10, 12, 15, Proportional

10, 12, 15, Proportional

10, 12, 15

(Draft/LQ)

CPI

or Proportional)

Condensed

Double-width

Double-height

Emphasized

Double-strike

It:alic

Lhderlined

Double-underlined

C)verscore

Strike-through

Shadow/Outline

CPI

characters is not available.

Print Speed

Print Columns

Refer to l-able 1-11.

Refer to l-able 1-11.

1-9

Page 19

REV.-A

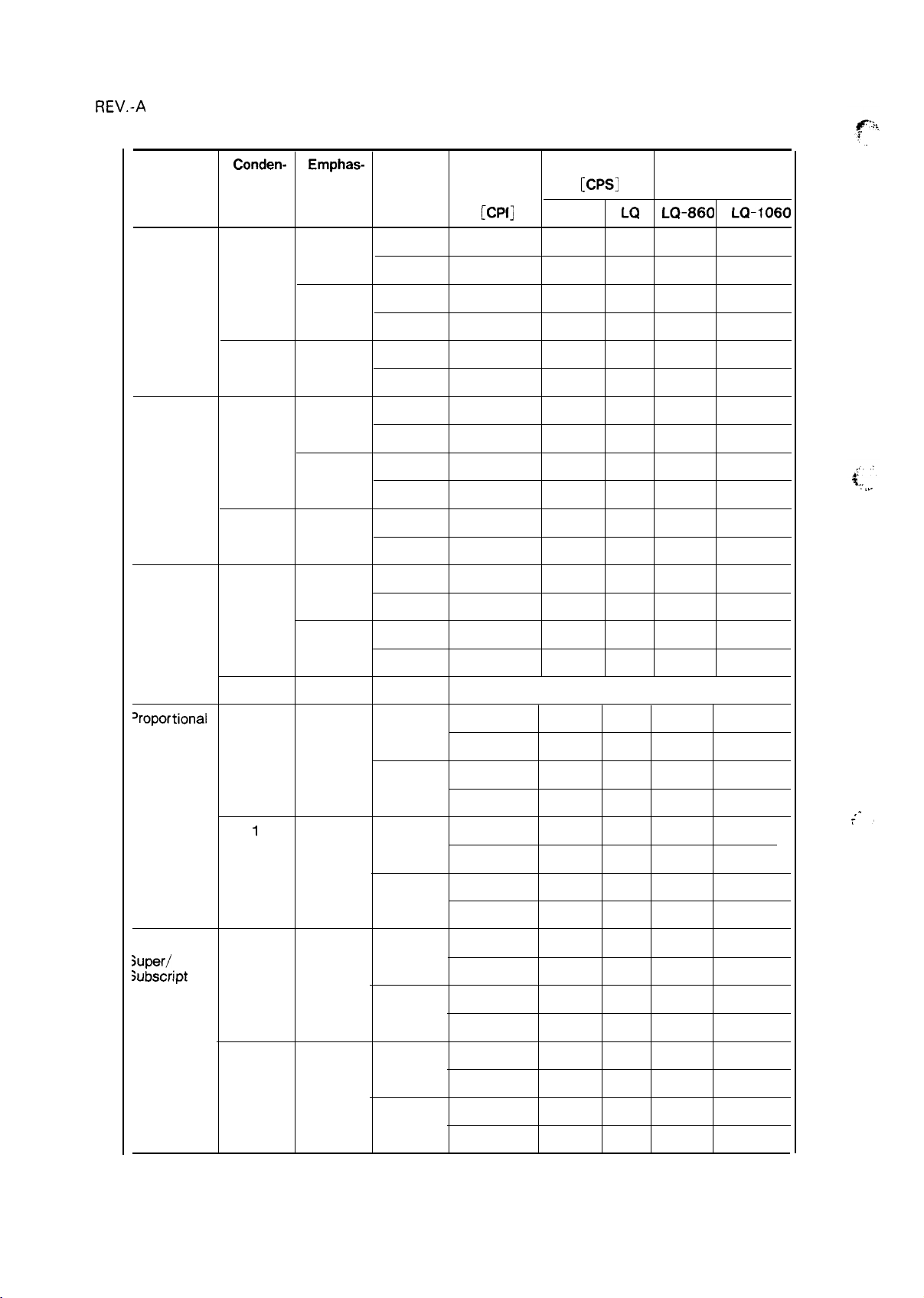

Table 1-11. Printing Mode

10

12

15

Print

Pitch

Conden- Emphas- Double

sed

0 0

ized

Width

0

1

1

0

1

1

x

o

1

0

0 0

1

1

0

1

1

x

o

1

0 0 0

1

Character

Pitch

[cPI]

10

5

10

5

17.1

8.5

12

6

12

6 68

20 225

10 113

15

15

Printing Speed

Printable Columns

[CPS]

Draft

225”’

113

113

56

193

LQ

LQ-860 LQ-1060

75

38

75

38

129

96 64

270 90 96

135

135

45

90

45

150

75

338

169

113 120

56

80

40

80

40

137

69

48

96

48

160

80

60

136

68

136

68

233

117

164

82

164

82

272

136

204

102

%oporticmal

‘proportional

Super/

subscript

1

0

1

1

o

x

x

x

o

7,5

7.5

8.6 64

20

1

4.3

10

1

x

o

17.1

40

1

8.6

20

o

x

o

12.8

30

1

6.4

15

1

x o

25.7

60

1

12.8

30

169 113

84

56

Ignored

—

150

32

—

—

—

—

75

129 Max. 137

300

64

150

—

96 Max. 103

225

—

—

–

—

—

—

48 Max. 51

113

193

450

96

225

120

60

204

102

Max. 69 Max. 117

Min. 160

Min. 272

Max. 34 Max. 59

Min. 80

Min. 136

Max. 233

Min. 320

Max. 69

Min. 160

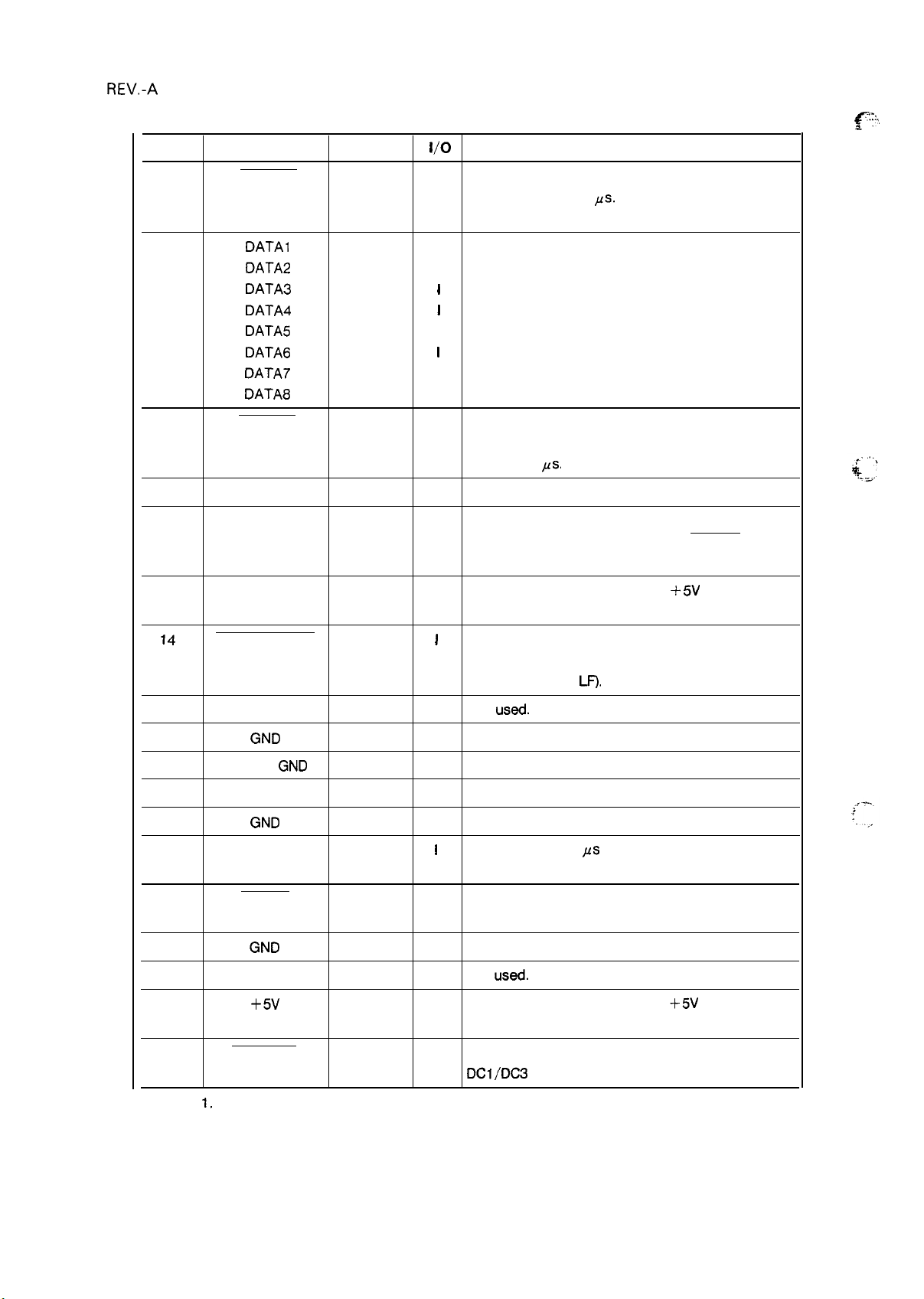

Min. 544

Max. 117

Min. 272

Max. 175

Min. 240

Min. 408

Max. 87

Min. 120 Min. 204

Max. 206

Max. 349

Min. 480 Min. 816

Max. 103

Min. 240

Max. 175

Min. 408

—

.

.

r’

,

1-10

Page 20

*

1 :

290

CPS

NOTES : 1.

at super draft printing (DIP SVV

Max. means the value when

Min. means the value when

2.

“

—“ means that LQ character set is automatically selected when proportional pitch is

3.

1-6

is off).

t:he

maximum width characters are printed.

the

minimum width characters are printed.

specified.

REV.-A

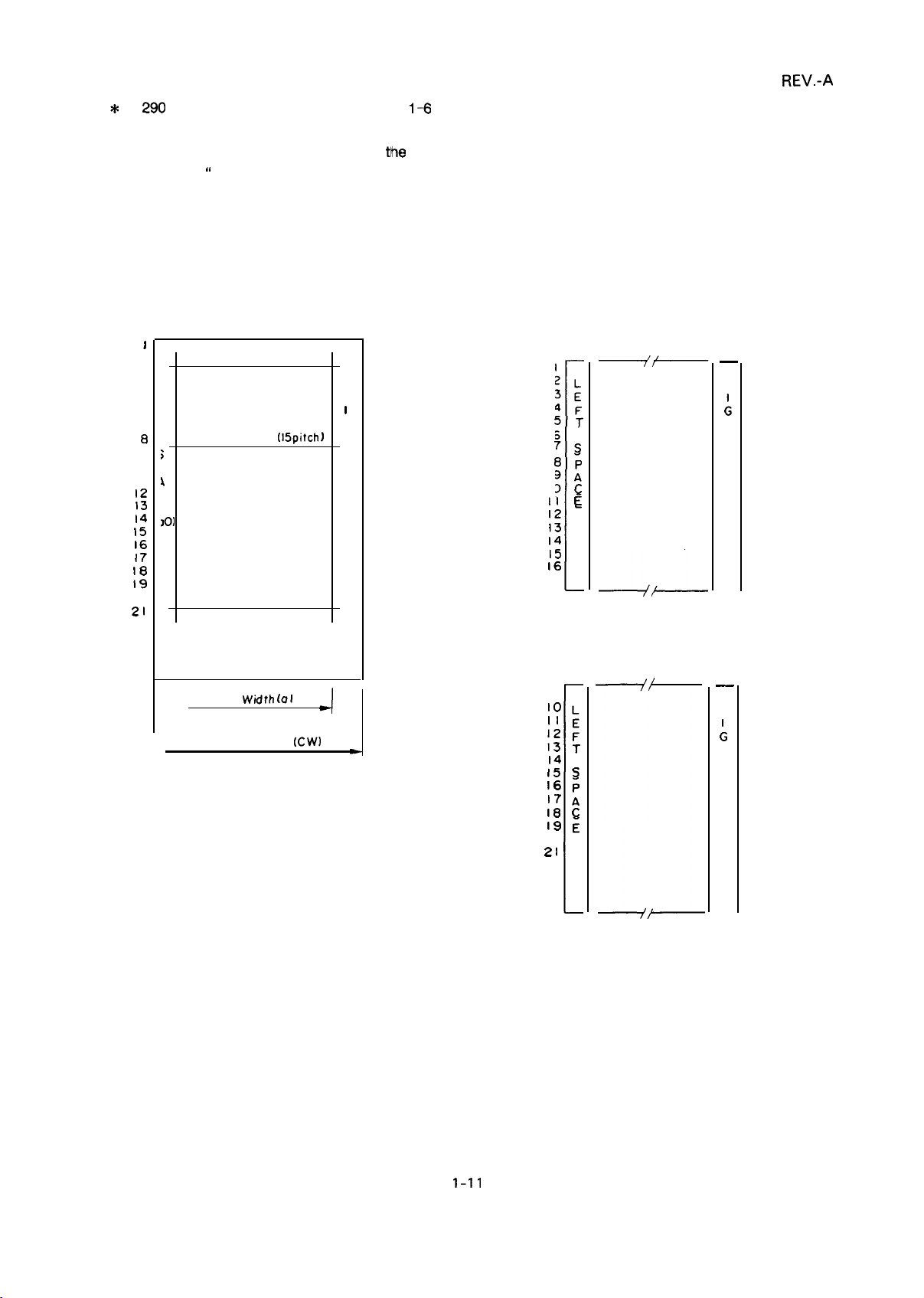

Character Matrix

(Normal Character)

1

2

3

4

5

6

7

r

Ascender Area

8

9

;

>

10

II

i

.

12

,

13

14

10.

15

16

/7

18

19

20

21

22

23

24

Descender Area

Character Width

Ascender Area

(15pitch )

Face

Width (al

See Figure 1-6 and Table 1-12.

R

I

G

H

T

s

P

A

c

E

(a

2

)

(CW)

J

(Superscript Character)

Pin Nos. 17 to 24 are not used when superscript

printing.

—

2L

3E

4F

5T

6

7s

Eip

9A

10

c

II E

12

13

14

15

16

[

(Subscript Character)

Pin Nos. 1 to 8 are not used when subscript printing

9

10

L

II

E

12

F

13

T

14

15 s

16

p

17

A

18 c

19

E

20

21

22

23

24

[

R

A

H

T

s

P

A

c

E

—

—

R

;

H

T

s

P

A

c

E

—

Figure 1-6. Character

1-11

Matrix

Page 21

REV.-A

Character Size See Table I-12.

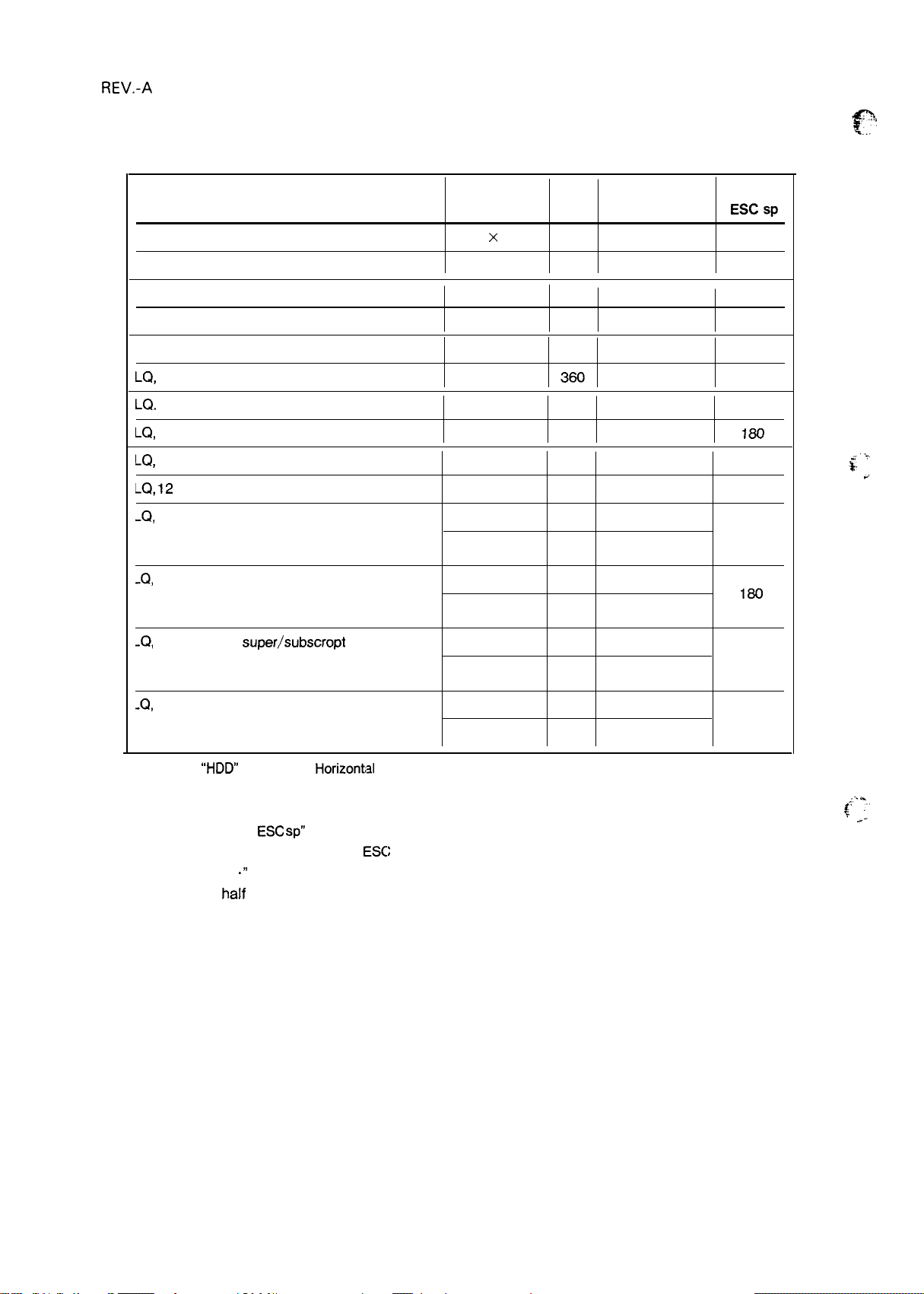

Table 1-12. Character Matrix and Character Size

Printing Mode

DRAFT, 10 pitch

DRAFT, 12 pitch

DRAFT, 15 pitch

DRAFT, 10 pitch, condensed

DRAFT, 12 pitch, condensed

LQ,

10 pitch

LQ.

12 pitch

LQ,

15 pitch

LQ,

10 pitch, condensed

LQ, 12

pitch, condensed

-Q, proportional

.Q, proportional, condensed

Face Matrix

9 X 23

9 X 23

9

X 16

. . .

. . .

29X 23

29X 23

15X 16

. . .

. . .

max. 37X 23

min. 18X 23

. . .

. . .

HDD

120

120

120 1.0 X 2.3 120

240

240

360 2.0x 3.2

360

360

360

360

360 2.6X 3.2

360

360

360

Character Size

H. XV. (mm)

1.9x 3.2

1.9x 3.2

. . .

. . .

2.0 x3.2

1.0X 2.3

. . .

. . .

1.0x 3.2

. . .

. . .

Unit

ESC

120

120

120

120

180

180

180

180

180

180

180

Sp

: .:.,

P

.

.-,:. . .. .

.

*

“=-.

+

.Q, proportional,

-Q,

proportional, super/subscript, condensed

NOTES : 1.

2.

3.

4.

super/subscropt

“HDD”

means the

“Face matrix” and “character size” indicate the size of maximum characters and this value

will be changed condition of paper, ribbon, and etc.

“Unit

ESC SP”

can be specified with

“.. .“ indicated that the character matrix is reformed by firmware. Character width becomes

haJf

of a non-condensed character.

Horizontid

indicates the minimum length which is added to the right of the character that

max. 28X 16

min. 12x 16

. . .

. . .

360

360 0.7X 2.3

360

360

1.8x 2.3

. . .

. . .

dot density, and the “Unit” shows the number

ESC)

sp control code.

160

180

of dots per inch.

... %

.,.

f ‘“’

.“”

1-12

Page 22

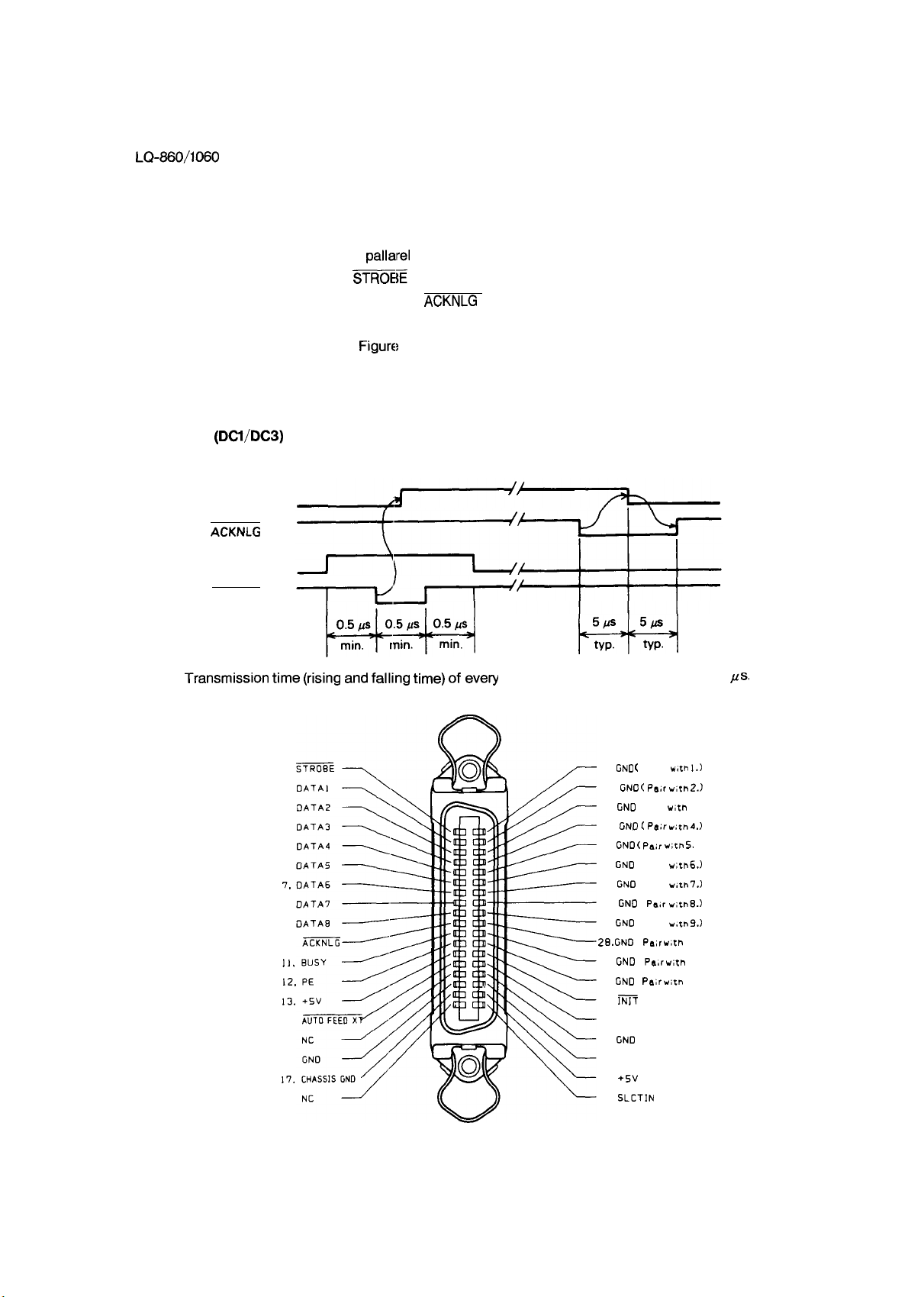

1.3 INTERFACE OVERVIEW

The LQ-860/1060 has both 8-bit parallel interface and RS-232C serial interface as standard. They can be

selected by DIP switches 2-3 and

2-4 respectively. (This detail of DIP switch settings, refer to Table 1-20.)

REV.-A

1.3.1 8-bit Parallel

Data Transmission

Interface

Mode

Synchronization

Hand Shaking

Logic Level

Data Transmission Timing

Adaptable Connector

Connector Pin Assignment

Select/Deselect

(DC1/DC3)

Control

BUSY

ACKNLG

DATA

STROBE

Specifications

8-bit

pallarel

By

STROB=

By BUSY and

pulse

ACKNLG

(either or both)

TTL compatible

See

Figure

1-7.

57-30360 (AMPHENOL) or equivalent

(See Figure 1-8.)

Refer to Table 1-13.

Refer to Table 1-14.

~**,~

w

NOTES :

Transmission time (rising and falling time) of evev

input signal must be less than 0.2

Figure 1-7. 8-bit Parallel Interface Data Transmission Timing

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

I 1.

12.

13.

I 4.

15.

16.

17.

18.

19.

GNO (

Pair

GNO (

20.

21.

GND

( Pair

G?4D [ Pair

22.

GND (

23.

24.

GND

( Pair w;th6.)

25.

GND

( Pair w;th7.)

26.

GNO

(

GNO

( Pair w,th9.)

27.

28. GNO

(

29.

GNO

(

30.

GNO

(

31.

~T

32. ERROR

33.

GNO

34. NC

35.

+5V

36.

5LCTIN

witn 1.)

Pair

w;th2.)

with

3.)

w;ti14.)

Pair

w;tn5. )

Pair “:t~s.)

Pair with

10. )

Pair w;th

I 1.)

Pair w;tn

12. )

IAS.

Figure 1-8. 36-Pin Printer Side Connector

1-13

Page 23

Table 1-13. 8-bit Parallel l/F Connector Pin Assignments

f’;’.

Pin No.

1

2

3

4

5

Signal

STROBE

DATA1

DATA2

DATA3

DATA4 23

6 DATA5

7

8

DATA6

DATA?

9 DATA8

10 ACKNLG

11

BUSY

12

13

SLCT

PE

Return

19

20

21

22

24

25

26

27

28

29

30

—

1/0

I

Strobe pulse to read the input data. Pulse width must

be more than 0.5

Description

,US.

input data is latched after

falling edge of this signal.

Parallel input data to the printer.

I

“HIGH” level means data “1”.

I

“LOW” level means data “O”.

I

I

I

I

I

I

This pulse indicates data are received and the

0

printer is ready to accept next data. Pulse width is

approx. 11

“HIGH” indicates printer can not accept data.

0

“HIGH’ ’indicates paper-out.

0

/s.

This signal is effective only when ERROR signal is

“LOW”.

+5V

Always “HIGH”. (Pulled up to

o

through 3.3 K

ohms resistor.)

14

15

16

17

18

19 to 30

31

32

33

34

35

36

AUTOFEED-XT –

NC

GND

Chassis

GND

NC

GND

INIT

ERROR

GND

NC

+5V

SLECT-IN

—

—

—

16

.

—

—

—

—

—

—

If this signal is “LOW” when the printer is initialized,

I

a line feed is automatically performed by input of

“CR” code (Auto

—

Not

USed.

—

Ground for twisted-pair.

—

Printer chassis ground.

—

Not used.

—

Ground for twisted-pair.

Pulse (width : 50

i

LF).

,US

min., active “LOW”) input for

printer initialization.

0

“LOW indicates that some error has occurred in the

printer.

.

Ground for twisted-pair.

—

Not

USed.

+5V

Always “HIGH”. (Pulled up to

o

through 3.3 K

ohms resistor.)

If the signal is “LOW” when printer is initialized, the

I

DC1/DC3

control is disabled.

NOTES :

“Direction” of signal flow is as viewed from the printer.

1.

2.

“Return” denotes “TWISTED PAIR RETURN” and is to be connected at signal ground level.

1-14

Page 24

REV.-A

As to the wiring for the interface, be sure to use a twisted-pair cable for each signal and

never fail to connect the return side. To prevent noise, cables should be shielded and

connected to the chassis of the host computer and the printer.

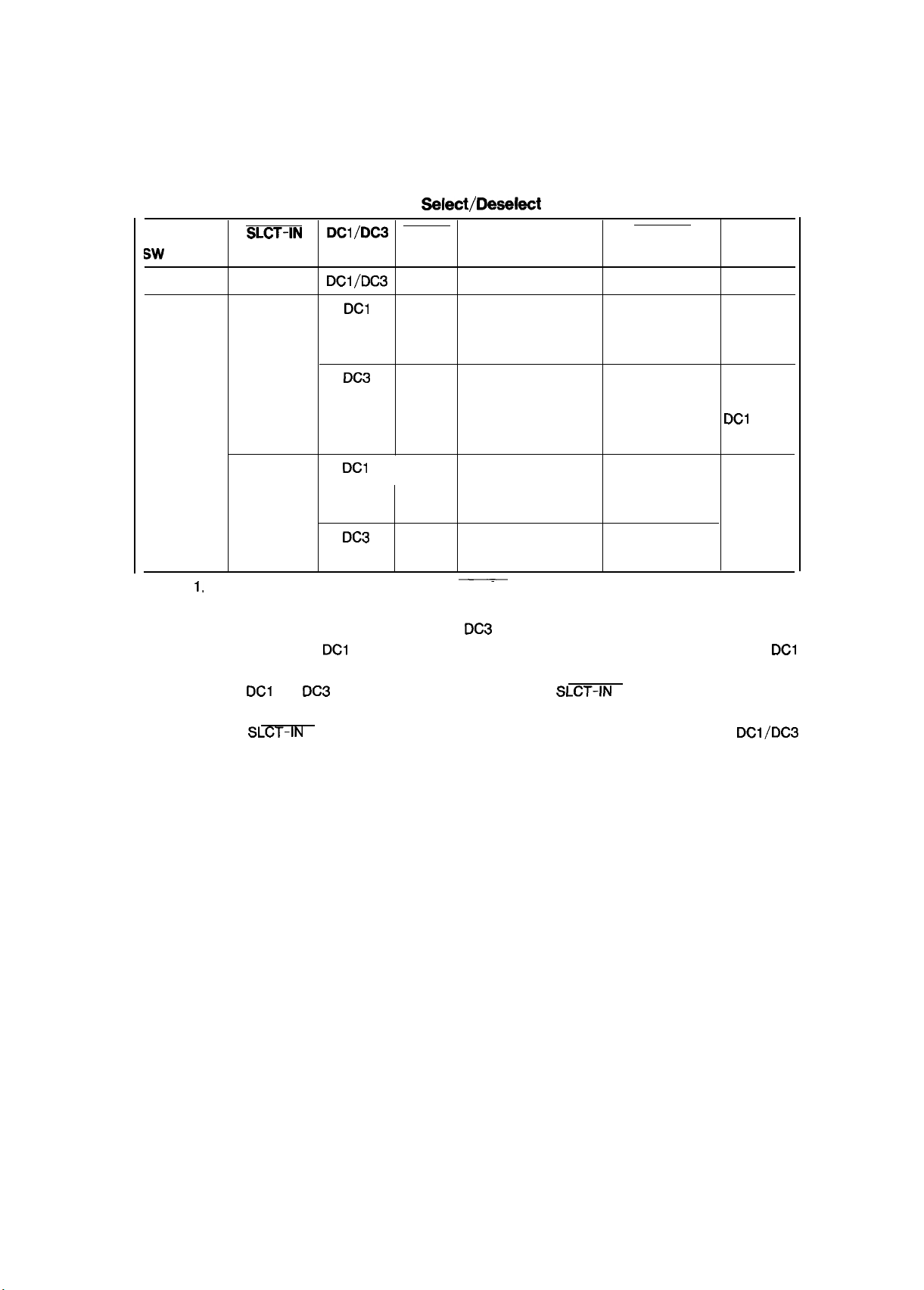

Table 1-14. Select/Deaelect Control

ON-LINE

Sw

OFF-LINE

ON-LINE

SLCT-IN

HIGH/LOW

HIGH

LOW

DCI /DC3

DCI

/DC3

DC1

DC3

DC1

DC3

ERROR

LOW

HIGH

HIGH

HIGH

HIGH

HIGH

LOW/HIGH (During

data entry)

LOW/HIGH (During

data entry)

LOW/HIGH (During

data entry)

LOW/HIGH (During

data entry)

-

BUSY

NOTES : 1. In Table 1-14, it is assumed that no ERROR status exists other than

OFF-LINE mode.

2. Once the printer is deselected by the

state until the

is received.)

3. The

DC1

and

No. 36 when the parallel interface unit is used) is HIGH and the printer is initialized.

4. The

SLCT-IN signal is “LOW” when the printer is initialized. At this time the DC1/DC3

printer select/deselect control is invalidated, and these control codes are ignored.

DC1

code is input. (In the deselected state, input data is ignored until

DC3

codes are enabled only when the SLCT-IN signal (Input Connecter Pin

DC3

code, the printer will not revert to the selected

ACKNLG DATA

No pulse

Pulse output after

entry

Pulse output after

entry

Pulse output after

entry

Pulse output after

entry

that attributable to the

ENTRY

Disable

Enable

(Normal

Process)

Enable

(Waits

DC1

. See

NOTE 2)

Enable

(Normal

Process)

DC1

1-15

Page 25

REV.-A

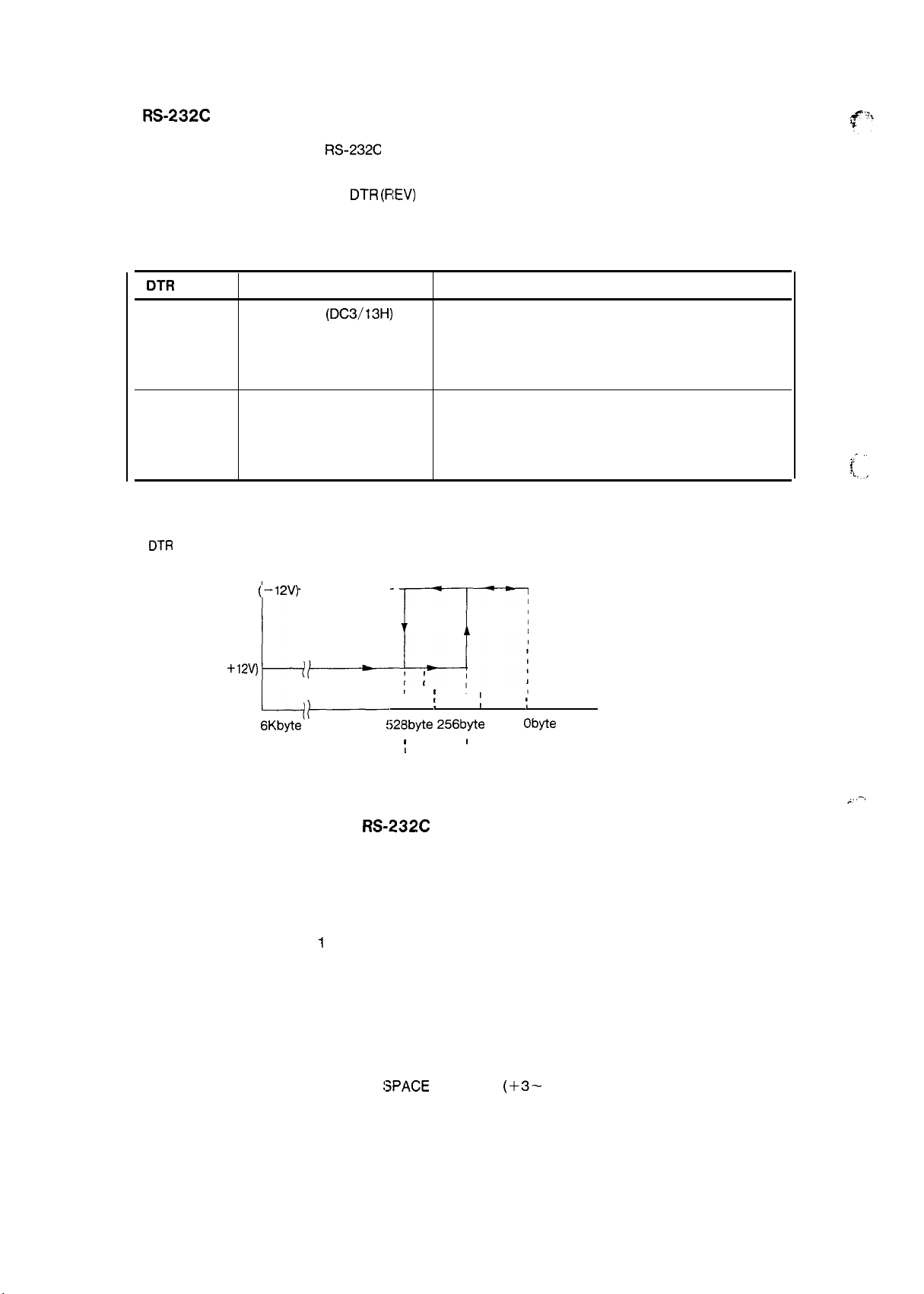

1.3.2 RS-232C Serial Interface Specifications

Data Transmission Mode RS-232C serial

Synchronization

Handshaking

Asynchronous

(By

DTR (FIEV)

(Refer to Table 1-15 and Figure 1-9.)

Table 1-15. Serial Interface Handshaking

signal or X-ON/OFF Protocol

DTR

Signal

MARK

SPACE

DTR

(REV) Signal

MARK

SPASE (

+12V)

X-ON/OFF protocol

X-OFF (DC3/13H)

X-ON (DC1/11 H)

I

(–12V)

-----------

~,

~

6Kbyte

~

When the number of bytes remaining in the input buffer

reaches 256 or less, the signal level goes to MARK, or

and X-OFF code is sent to the host computer. This

indicates that the printer is not ready to receive data.

When the number of bytes remaining in the input buffer

reaches 528 or more, the signal level goes to SPACE, or

an X-ON code is sent to the host computer. This indicates that the priter is ready to receive data.

Eq

:

,

1

!j28byte 256byte

1

[

X-ON X-OFF

:

1

1

1

[

:

Obyte

Description

Input Buffer Vacant Area

X-ON/X-OFF Protocol

Word Length

Start bit:

Data bits:

Parity:

Stop bits:

Bit Rate

Logic Level

Figure 1-9. RS-232C Interface Handshaking

1

8

Odd, Even, or none

1 bit or more

300, 1200, 9600, or 19200 BPS

EIA level, IMARK: logical 1 (–3- –27 V)

!SPACE

: logical O

1-16

(+3-

+27 V)

>,. ,-,

Page 26

REV.-A

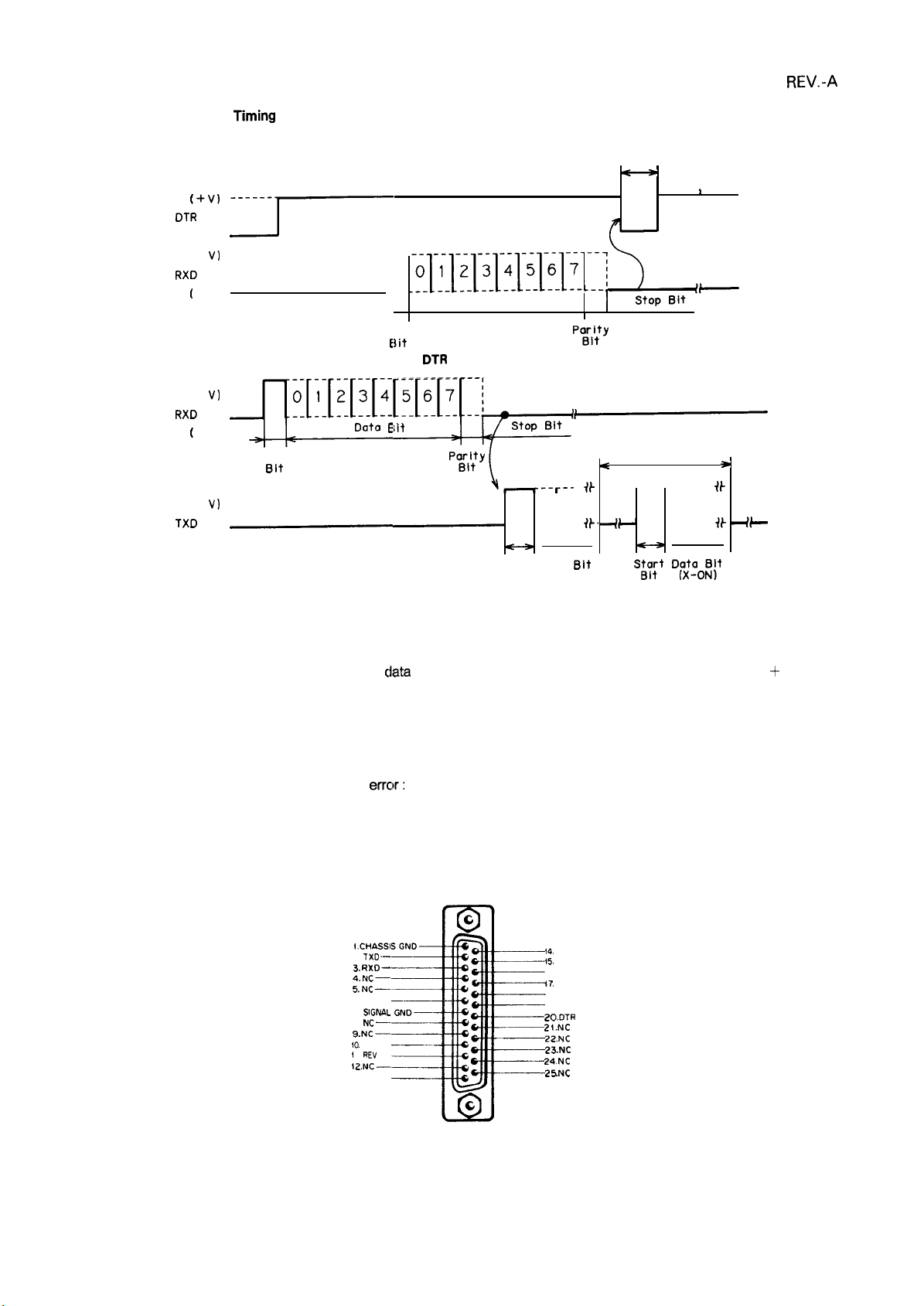

Data Transmission

[

+V)

DTR

r

( – VI

( +

v]

RXD

--------------------y

(

-v)

( +

v]

[

-v)

( +

v)

g:F[<[[[iFEE3

RXD

TXD

( -v]

Timing

Start

Blt

See Figure 1-10.

:!S!12131:15-FF

Start

Elit

Elit

Data

+

x-ON/X-OFF

DTR

Handshake

P\ri~y

Data Bit

,+apB,+/—

--- --

Start Data

Bit (X-OFF)

Protocol

-- --

[[

::;

P~rlty

4

i~

if

4+

Bit

‘T”

~

s

‘T “

-- --

–

-- --

.[[’

S;;;t D~t:OB;t

ik

IF

*

4+

NOTES :

1. The value of “T” varies according to the input data.

2. The word structure of serial

1 or more stop bits.

Error Detection

Connector

Connector Pin Assignments

clata

is 1 start bit + 8 data bits+ parity (Odd, Even, or none)

Figure 1-10. Serial Data Transmission Timing

errcr:

Parity

Overrun error:

Framing error: Ignored

D-SUB 25-pin connector (See Figure 1-11.)

Refer to Table 1-16.

LCHASSI

2.

TxD-—

3.RXD—

4,NC—

5.NC—

6.Nc-—-

7.

SGNAL

8. Nc—-

9.NC—

tO.

NC —

I

l,

REv

—

f2.NC—

13. NC —-

“x” is printed.

Ignored

t4.

NC

i5.

NC

16. NC

17,

NC

16 NC

19. NC

20.QTR

21.NC

22.NC

23.NC

24.NC

25NC

+

Figure 1-11. Serial Interface Connector

1-17

Page 27

REV.-A

Table 1-16. RS-232C Serial l/F Connector Pin Assignments

Pin No.

2

20

11

3

7

1

Signal

TXD

DTR

REV (=2nd RTS) o Same as

RXD

SIGNAL

CHASSIS

GND

GND

Dir.

o

o

I

–

–

Transmit data.

Indicates when printer is ready to receive data. “MARK”

level

indictes

Receive data.

Signal (Logic) ground level.

Printer chassis ground.

printer is not ready to receive data.

DTR.

NOTE : “Direction” of signal flow is as viewed from the printer.

Description

1-18

f ‘:,

.,

Page 28

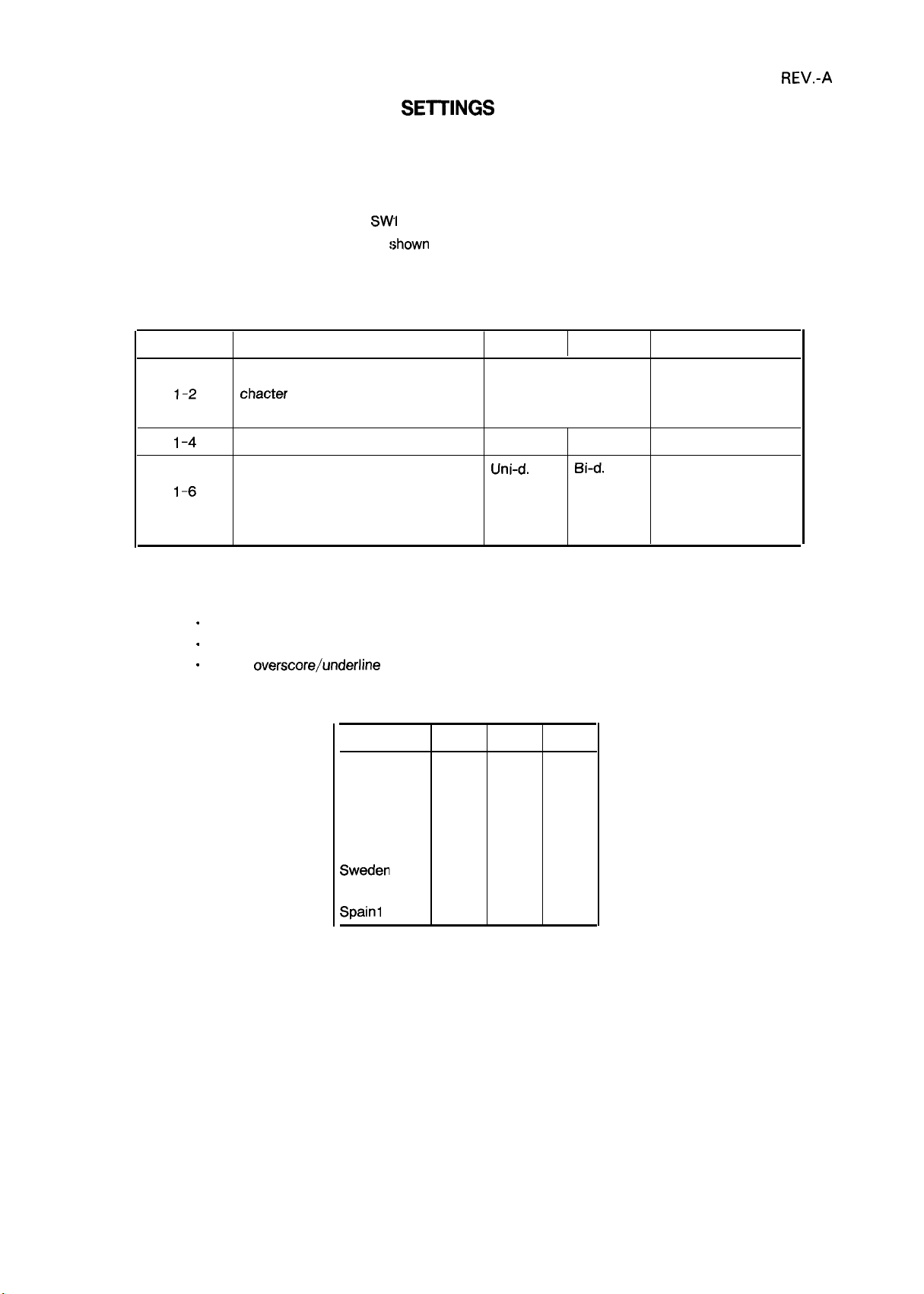

1.4 DIP SWITCH AND JUMPER SEITINGS

This section describes DIP switch settings and jumper settings on the JUNMM board.

1.4.1 DIP Switch Settings

REV.-A

The DIP switches that users can set are

the control panel, and have the functions as

DIP switches are read only when the printer power on or an INIT signal is input.)

SW”I

and SW2. These switches are positioned at the left side of

:>hown

in Tables 1-17 through 1-21, (note that the status of the

Table “I-17. DIP Switch 1 Settings

DIP SW.

1-1

1-2

International

chacter

set

Function

ON

See Table 1-18.

OFF

1-3

1-4

1-5

1-6

1-7

1-8

* 1 : “

Graphic print” means follows

a) Bit image printing

b) Multi pass printing

Code table select

Graphic print direction”’

Super draft

CSF mode

Input buffer

“

30 dots graphics

“

Double height character

o

Double

overscore/underline

Graphic

Uni-d.

off

Valid

None

. Orator/Orator-S font

. Double-strike

. Violet, Orange, Green color printing

Italic

Bi-d. OFF

On

Invalid

6K-byte

Factory Setting

ON

ON

ON

OFF

OFF

OFF

OFF

Table 1-18. International Character Set Designation

Country

U. S. A.

France ON ON OFF

Germany ON

U. K.

Demarkl

Sweden

Italy OFF OFF

Spainl

1-1

ON ON

ON OFF OFF

OFF ON

OFF ON OFF

OFF

1-2 1-3

ON

OFF

OFF OFF

ON

ON

ON

NOTE : The above settings can be changed to any country’s characters set by inputting ESC R control

codes.

1-19

Page 29

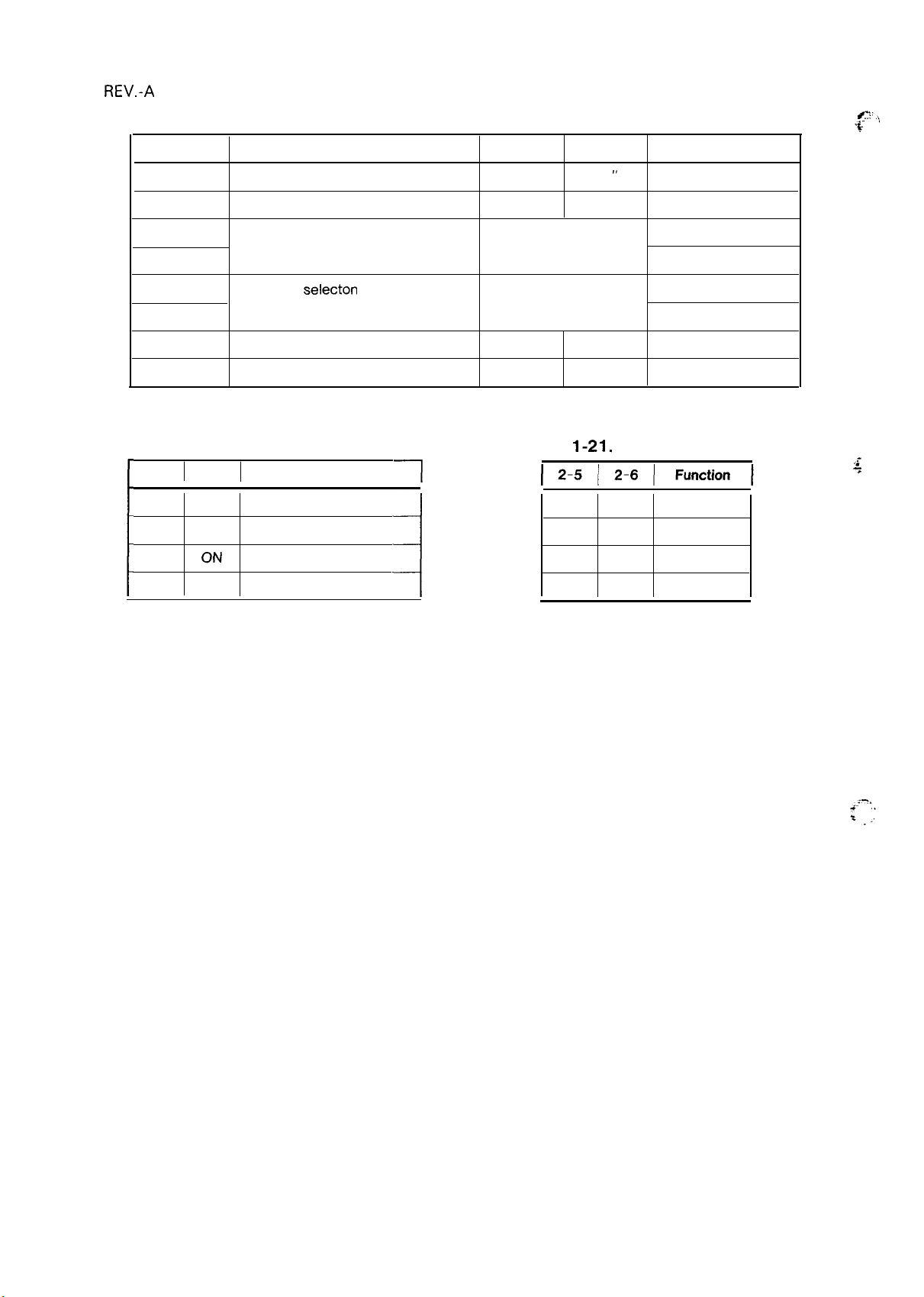

REV.-A

DIP SW.

Function

Table 1-19. DIP Switch 2 Settings

ON OFF

Factory Setting

q

‘g

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

Page length

1“ skip-over perforation

Interface selection

Baud rate

Auto fear-off mode

Auto LF

selecton

Table 1-20. Interface Selection

2-3

OFF

ON

OFF

ON

2-4

OFF

OFF

ON

Function

8-bit Parallel

Serial, Even parity

ON

Serial, Odd parity

Serial, None parity

19,200

9,600

1,200

300

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

.*-

-%

12”

Valid Invalid

See Table 1-20.

See Table 1-21.

Valid Invalid

Valid

Table

11

“

Invalid

1-21.

Baud Rate Selection

1

OFF

ON

OFF

1

ON ON

OFF

OFF

ON

1-20

Page 30

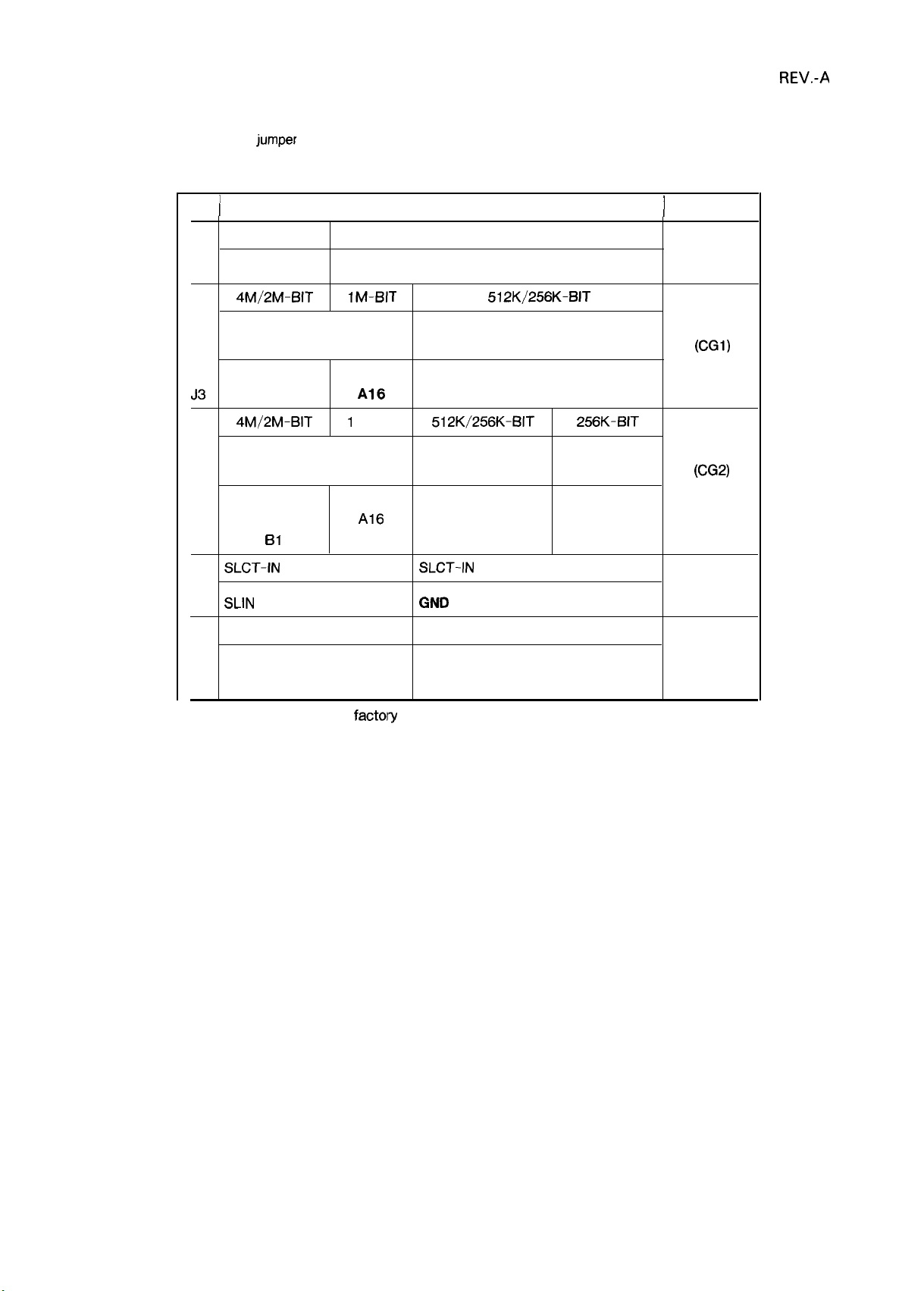

1.4.2 Jumper Settings

REV.-A

Table 1-22 shows the

No.

/

JI

4M/2M-BIT IM-BIT

J2

J3

4M/2M-BIT

J4

J5

J6

SLCT-IN inable

jumper

settings.

Table 1-22. Jumper Settings

Type

27256 27512

256

MASK-ROM

B4

RD

MASK-ROM

B4

RD

B1 B1

A16

1

M-BIT’

A16

+5 +5

+5 +5 +5

SLCT-IN disable

512

512K/256K-BIT

512K/256K-BIT

ROM

RD RD

B2

ROM

RD

256K-BIT

RAM

WR

)

Location

6A

3A

(CG1)

4A

(CG2)

J7

SLIN

LQ-860

J8

Close

J9

Open

NOTE : Bold indicates the

factotw

GND

LQ-106O

Open

Open

settings.

1-21

Page 31

REV.-A

1.5 SELF-TEST OPERATION

The LQ-860/1060 printer has the following self-test operation. The control ROM version No. and the DIP

switch settings also printout when the self-test is performed.

Table 1-23 lists the self-test operating instructions and Figure 1-12 shows the self-test printing.

Table 1-23. Self-Test Operation

Type-face

Draft

,-

Lu

Start

Turn the power ON while

pressing the LINE FEED switch.

Turn the power ON While

pressing the FORM FEED switch.

Push the ON LINE switch, and turn the

power OFF.

Draft mode

!

“

#$%&

f

“

#$%&

‘ ( )*+ , -

“ #$%&‘ ( )*+, -. /C)12345676g : ; ~ =

‘ ( )*+ , –

#$%&

‘ (

$%&

=

& “ ( )*+, -- /0123456789: ;

‘

( )*+, -. /0123456789: ;

()*+,

)*+,

)x+,

‘ ( )*+, -

‘ (

)%+

,-.

/0123; 456789 --

-./,oI234567B9,

-./olz3456789:;

*+,-./ol234567~9:

+ -

High-speed draft mode

/n17745A7RQ..

!“#$%&”(

)*+,

“’#$%&’()*+,-.

‘-’#$%&”()*+,-.

#S%&”(j*+=-./O123456789:

$%&”(j*t>–.

%&”c)*+,–-/0lZ5ASA78g:

A“()*+,–-/012W%T89-

“()*+,–.,/o1234+

()*+,–-/ol23456T8S ::<=?

)*+,--jo~~~456789: ;<=>?@ABCDEFGHIJKLMNC)PQRSTLJ

*+.–./olZ34s698’9

+.

-

/f1177A<A7FlQ-

. /0123456789: ; < =

. /01 23456789: ; <

-. /01.23456789

.

/012’ 3456789 : ;

: ; <

< = >?@

.,<

< =

=

>

<

<=>?@~BCDEFGHIJKLMNopQRST

;

<=>?@ABcDEFGHIJKLMNOP9RSTL

-

,<=>?@A6CDEFGHIJKLMNOPQRSTUV

=>91aQ

<

RCITFI=C14T.TKI

-./Ol23Zi56789:

=>?@ABCDEFGHIJKLMNOpc

>?@~8CDEFGl_i

=>?@46cDEFGti1JKLP

>?@~BcDEFGH IJKLM~

=

>~@~BCDEFGHIJKLmNC

ABcDEFGH

>~@ABCDEFGH IJKLMNOPQR

?@AB cD E

FGH I

IJ

J K

MNnDC)!2qTllVk

;<=>?@6BCDEFGHIJKL

/0123456789: ;<=>?@ABC0EFGHIJKLtIt

/0123456789:

!01234567EW: :<=>

;<=>?@iM3CDEFGHIJKLMN4

;<=>?@A8COEffiHIJKLMN0

?@~~C~~f=GHIJKLMN~p

;~=>~@ABCDEffil+lJKLM~

-.<=>~@~mDEffitilJK~~

<6789: ;<=>

-<

-

?@

ABCDE FC; H13KLMNOPQRS

‘?@ABCOEFGtilJKLMNOPQRST

:;<=>?@A~DE~HIJK~~sTuv

=>~~r2RCIlFFFiHT.TK

I MN(~PC)f?STllVW

LMN

stop

IJKL

KLMNOF

() PQR:

L(2

mode

!“#$%&)

!“#$%&y( )*+,-#

“#$%&’( )*+,-./Ol23456789

#$%&’ ()*+,

$%&’(

%&’ ()*+,

&’()*+,

‘(

()*+,-.

)*+,

*+,-./Ol23456789

.+.-.

(

)x+,-./OI23456789

/0123456789

:

;<=>?@ABCDEFGHIJK’

:;<=>?@ABcDEFGHIJKLI

:;<=>?@ABCDEFGHIJKLMl

-./ol23456789

)*+, -./Ol23456789:

-./Ol23456789:

-./Ol23456789

:;<=>?@ABCDEFGHIJKLMNi

;<=>?@ABCDEFGHIJKLMNO]

;<=>?@ABCDEFGHIJKLMNOPt

: ;<=>?@ABCDEFGHIJKLMNOPQl

)*+,-./ol23456789: ;<=>?@ABCDEFGHIJKLMNOPQRl

/0123456789:;

-./ol23456789: ;<=>?@ABCDEFGHIJKLMNOPQRSTI

/0123456789:

<=>?@ABCDEFGHIJKLMNOPQRS’

:

;<=>?@ABCDEFGHIJKLMNOPQRSTLP

:<=>?@ARC~RFRHTJKTIMNOPORSTlrV~

Figure l-12. Self-Test Printing

1-22

Page 32

1.6 HEXADECIMAL DUMP FUNCTION

In hexadecimal dump mode, the printer prints out the data it receives in hexadecimal format. The printer

prints a column of 16 hexadecimal values, followed by a column containing the 16 corresponding ASCII

characters. If there is no corresponding printable character for a value (e.g., a control code, such as a

carriage return or line feed), a period (.) is printed in the ASCII column in the position of the code.

Each line of the dump contains 16 values, printed in the order they were received, and

(less than 16 values on the final line) can be printed by operating the ON LINE switch. Table 1-24 shows

the hexadecimal dump operation and Figure

Figure 1-13. Hexadecimal Dump List

Table 1-24. Hexadecimal Dump Operation

1-13

shows printout of the operation.

any remaining data

REV.-A

IR.mction

Hexadecimal

dump mode FORM FEED switches.

Data Dump Mode

31 2E 31 20 46 45 41 54 55 52 45 53 OD

54 68 65 20 4C 51 2D 38 35 30 2F 31 30 35 30 20

70 72 69 6E 74 65 72 73 20

74 69 66 75 6E 63 74 69 6F 6E 61

2D 70 69 6E 20 70 72 69 6E 74 68 65 61 64 2C 20

69 6D 70 61 63 74 20 64 6F 74 2D

72 69 78 20 70 72 69 6E 74

65

20 6D 61 69 6E 20 66 65 61 74 75 72 65 73 20 e main features

6F 66 20 74 68 65 20 74 68 65 73 65 20 70 72 69 of

6E 74 65 72 73 20 61 72 65

20 55 70 77 61 72 64 20 63 6F 60 70

69 6C 69 74 79

51 2D 38 30 30 2F 31 30 30 30 OD

6D 61 78 69 6D 75 6D 20 70 72 69 6E 74 20 73 70

65 65 64 20 6F 66 20 32 36 34 20 43 50 53 20 69

6E 20 64 72 61 66 74 20 6D 6F 64 65 20

I

Turn the power on while pressing both the LINE FEED and

2G

77 69 74 68 20 74 68 65 20 4C i 1 i ty

Operation

0/4

00

Ofl

61

72 65 20 6D 75 6C

6C 2C 20 32 34

OD 0#1

65

72 73 2E 20 54 68 rix printers. Th

3G

20 OD 09 OD OA 2E

OA

6D 61 74 impact dot- . . mat

61

74 69 62

2E 20 41 20 Q-800/1000. . .

61

74 20

I

Turn the power off.

1.1 FEATURES. . . .

The

printers are mul

tifunctional,

-pin print head.

nters are: . . . . .

Upward

maximum print sp

eed of 264 CPS

n draft mode at

stop

LQ-850/

the these

compatib

with

I

I

1050

24

pri

the L

A

i

Figure 1-13. Hexadecimal Dump List

1-23

Page 33

REV.-A

1.7 PRINTER INITIALIZATION

There are two initialization methods: hardware initialization and software initialization.

1.7.1 Hardware Initialization

This type of initialization occurs when printer power is turned on or when the printer receives the INIT signal

from the host via the 8-bit parallel interface.

When printer is initialized in this way, it

. Initializes printer mechanism

- Clears downloaded character set

. Clears the input data buffer

. Clears the print buffer

. Sets printer selections to their default values

perfc)rms

the following actions :

#-:;,,

x,

1.7.2 Software Initialization

This type of initialization occurs when the printer receives command

When the printer is initialized in this way, it

. Clears the print buffer

. Sets printer selections to their default values.

performes

the following actions :

1.7.3 Default Values

The printer’s default values are as follows:

Page Position

Left and Right Margin

Line Spacing

Vertical Tab Position

Horizontal Tab Position

VFU Channel

Family Number of Type Style

Downloaded Characters

Justification

Character Per Inch

Bit Image Mode Assignment

Color

Preset paper position becomes top of form position

Released

1/6”

Cleared

Every 8 characters (relative)

Channel O

Last selected font by the control panel

Deselected: Software initialization

Cleared:

Left justification

Last selected pitch by the control panel

ESC

ESC *3

Black

K =

t+ardware

ESC

*O,

initialization

ESC

L =

ESC xl, ESC

(ESC @)

via software.

Y =

ESC *2, ESC

. ,-..

4..,

Z =

1-24

Page 34

REV.-A

1.8

BUZZER OPERATION AND ERROR CONDITIONS

REV.-A

This section describes the buzzer operation

and

error conditions of the printer.

1.8.1 Buzzer Opeartion

The buzzer ring as follows:

● When a BEL code is sent to the printer, the buzzer sounds for 0.5 seconds

● When an error has

. Carriage mechanism trouble

o

Color select mechanism trouble

.

C.G.

ROM error

Sounds 5 times (rings for 0.5

. Paper end

Sounds 3 times (rings for 0.1

● When a panel setting is accepted, the buzzer sounds for 0.1 seconds

(Refer to Section 1.9.4 for

occured

sescmds

seccmds

firther

information concerning control panel settings.)

with 0.5 seconds interval.)

with 0.1 second interval.)

1.8.2 Error Conditions

If any of the following errors occur, the printer automatically enters the OFF-LINE mode.

“

Carriage and color home positions are not detected at printer mechanism initialization.

. Home position is detected during printing.

. The OFF-LINE switch is pressed, causing the printer to enter OFF-LINE mode.

“

A paper-out signal is detected and formes-override is finished.

. A paper-out signal is detected after the printer has performed a paper loading operation with the cut

sheet feeder enabled.

For information concerning the status of the interface signals, refer to Table 1-14.

1-25

Page 35

REV.-A

1.9 MAIN COMPONENTS

The LQ-860/1060 printer includes the

. Model-5810/5860 printer

“

JUNMM board (main board)

. MONPS/MONPSE board (power supply

“

Control panel (JUNPNL-W board)

Figure 1-14 shows the

Fan Unit

\

M

lodel-5810

PI

‘inter

Mechanism

machanism

LQ-860/1060 component locations.

following major subassemblies:

MONPS/MONPSE

board,

120V and 220/240V versions)

Board

JUNMM

Board

I

Control Panel

‘%.::,,’

Model-5860

Printer Mechanism .

LQ-860

LQ-106O

,. .,

~:

Figure 1-14.

LQ-860/1060

1-26

Component Locations

Page 36

1.9.1 Printer Mechanism

REV.-A

This section describes features and paper feed operations of the printer

machanism.

1.9.1.1 Printer Mechanism Features

The printer mechanism is composed of three stepper motors

select/ribbon feed, a 24-pin printhead, five sensors (home position, paper end,

and color position sensors), and metal frames.

used in carriage move, paper feed, and color

friction/traCtOr,

platen gap,

Model-5810

Model-5860

Figure 1-15. Model-5810/5860

Printer Mechanism

1-27

Page 37

REV.-A

1.9.1.2 Paper Feed Operations

Paper Loading and Paper Ejection

The paper release lever has a disengage capability for the optional pull tractor unit’s drive mechanism.

Therefore, these printers provide some improved paper handling functions that can be performed by using

a combination of the paper release lever and LOAD/EJECT switch on the control panel.

Single Sheet Loading and Ejection

To load a sheet of paper, adjust the paper release lever at friction feed position, place the page along the

sheet guide, and press the LOAD/EJECT switch. This loads the paper at the top-of-form position. If

LOAD/ EJECT switch is pressed after paper has been loaded, it causes the paper to be ejected.

Continuous Paper Loading and Ejection (Back Out)

To load continuous paper, adjust the paper release lever at tractor feed position, and insert the paper into

the push tractor. Pressing the LOAD/EJECl- switch loads the paper automatically to the top-of-form

position. If LOAD/EJECT switch is pressed after the continuous paper has been loaded, the printer ejects

the paper backward to the push tractor.

times, since reverce feed is performed on a page-by-page basis.

The MULTI-PART LED blinks only after the paper has been loaded and the ON LINE switch has been

pressed. After ON-LINE has been pressed, the user can adjust the paper loading position for the next sheet

loaded into the printer and the top-of-form position for the currently loaded sheet. Pressing the FORM FEED

switch advances the paper forward continuously for as long as the switch is held down, and pressing the

LINE FEED switch moves the paper in reverse.

Moving the paper with these switches is called “Top-Of-Form adjust”. After the paper has been adjusted

in this way, the printer uses that position as the loading position for each subsequent page. When the

printer is initialized, the loading position for a, single sheet returns to the default value.

To,back

out several pages, press the LOAD/EJECT switch several

f!,,

“+.

‘-..

g:

‘u.

Tear-Off Function

The paper is advanced to the tear-off position by pressing the TEAR OFF switch or auto tear-off function

(depend on DIP SW 2-7 setting) when the tractor feed is selected. Auto tear-off function is enabled and the

paper release lever is at the tractor position, the paper will be fed to the tear-off position automatically if

the input data buffer is empty and the printer is ON-LINE. At this time, MULTI-PART LED will blink to

indicate that the FORM FEED and LINE FEED switches can be used for forward and

backword

micro feed

adjustment. Using the micro feed, adjust the paper to meet the tear-off edge. Once the tear-off position is

set, the setting remains valid even after the printer is turned off, reset or initialized. If subsequent data is

input to the printer, the paper will be released to the original position automatically and printing will start.

[f

the ON LINE switch is pressed (printer becomes OFF LINE) while the paper is advanced to the tear-off

position, then the paper will be released to the original position.

Tear-off function is also valid in the cut sheet feeder mode when the tractor feed is selected.

1-28

Page 38

1.9.2 JUNMM Board (Main Board)

REV.-A

Figure 1-16 shows the

operation of

the

printer.

Driver circuits for the motors, sensors, and printhead are also included on this board. Other main

JUNMM

Gate Array

Memory

board are:

IC

“

EO5A1OAA (8B)

o E05A24GA

“ E05A02LA

(5A)

(2A)

IC

“ EP-ROM (6A)”””””””””””””.”Used

“

MASK-ROM (3A)

o PS-RAM

“

ST-RAM*’

x

1 : The data is held by the lithium battery while power is turned off.

Universal

“ S17300A

(5A)

(7A).”””.”.””””””.”UK-bit

IC

.................. Carriage motor driver

(1A)

JUNMM

.............. Memory management unit

............&bit

............ ”..

board, which contains a 8-bit one chip CPU

(MMU) IC

parallel

Printhead

for program 256K-bit

I/F’,

port expansion

data control

IC

..........,.Used for character generator, IM-bit

...............256K-bit

IC

IC

~PD78213

(4B) to control the

ICS

on the

S17

‘300A

\

MASK-ROM (C.

E05A02LA

\

G.)

PS-RAM

\

(’jpu

I

EP-ROM

/

ST-RAM

EO5A1OAA

Lithium Battery

/

E05A24GA

Figure 1-16.

JUNMM

1-29

Board

Page 39

REV.-A

1.9.3 MONPS/MONPSE Board (Power Supply Circuit Board)

The power supply circuit board is located on one of two boards, the MONPS for 120 V AC operation and

the MONPSE for 220/240 V operation. The basic construction of the two board is the same: each board

contains a power switch, fuses, line filter circuit, and switching regulator circuit. Compactness of the

circuitly

is made possible by use of a

DC-to-13C

converter.

.{

‘“

... ,

Figure 1-17.

MONPS Board

!.

~.

.

1-30

Page 40

REV.-A

1.9.4 Control Panel

[n

the control panel, seven switches and seventeen LEDs, as shown in Figure 1-18. The functions of the

switches and indicators are given immediately below the illustration.

Figure 1-18. Control Panel

ON LINE Switch

This switch toggles the printer between ON-LINE and OFF-LINE modes. The printer is automatically set to

ON-LINE mode and becomes ready

and the printer becomes BUSY.

at power on. If the printer is set to OFF-LINE mode, printing is stopped

FORM FEED Switch

Pressing this switch

next top-of-form position. This switch is also used as the micro forward adjust, refer to Section 1.9.1.2 for

details.

once while the printer is in the OFF-LINE mode advances the paper vertically to the

LINE FEED Switch

Pressing this switch within 0.5 seconds

line at a time. And pressing more than 0.5 seconds performs continuous feeding until this switch is

released.

This switch is also used as the micro reverse adjust, refer to Section 1.9.1.2 for details.

while the printer is in the OFF-LINE state advances the paper one

LOAD/EJECT Switch

Pressing this switch loads or ejects the paper. Details of the paper loading and ejection process are

described in Section 1.9.1.2.

is

When this switch

pressed in the CSF mode and ON-LINE state, printer beeps once (pi) and selects bin

1, or beeps twice (Pi-, pi-) and selects bin 2 alternately.

FONT Switch

Pressing this switch selects a font, and continuing to press the switch for more than 0.5

the next font, sequentially. The FONT indicator lights beside the currently selected font.

seconds select

1-31

Page 41

REV.-A

PITCH Switch

Pressing this switch selects the character pitch, and continuing to press the switch for

seconds select the next character pitch,

The PITCH indicator lights beside the currently selected character pitch to confirm its status.

seq~lencially.

more than 0.5

NOTE : Settings by FONT and PITCH switches are stored as defaults. So that the last FONT, PITCH

settings becomes effective when the printer is initialized.

TEAR OFF Switch

Advance the paper to the tear-off position. This switch is only effective in the tractor feed.

This switch is effective in both of ON-LINE and OFF-LINE states, refer to Section 1.9.1.2 for details.

POWER LED (Green)

Lights when power is ON.

READY LED (Green)

Lights when printer can receive the data.

:$,

.’

.-.

’

PAPER OUT LED (Red)

Lights when the paper is end.

ON LINE LED (Green)

Lights in the ON-LINE mode.

MULTI-PART LED (Orange)

Lights

FONT (DRAFT, ROMAN, SANS SERIF, SLOT A, SLOT B)

These

selected using the FONT switch, and the indicator beside either SLOT A or SLOT B will be lit. If no font

module is installed in the slot when the FONT switch is pressed, SLOT A and SLOT B selections will be

skipped.

PITCH (1OCPI,

These

when the head adjustment lever is set for 4th or higher.

LEDs

(Orange)

LEDs

indicate the currently selected font. If slots A and B contain font

12CPI, 15CPI, 17CPI,

LEDs

indicate the currently selected character pitch.

20CPI, PROPORTIONAL)

LEDs

modules, they each may be

(Orange)

TEAR OFF LED (Orange)

This indicator the paper is advanced to a tear off position.

,,.. “;

1-32

Page 42

CHAPTER 2

OPERATING PRINCIPLES

REV.-A

2.1 GENERAL

2.1.1 Connector Descriptions

2.1.2 Printer Mechanism Operations

2.2 POWER SUPPLY CIRCUIT OPERATION

2.2.1 MONPS/MONPSE Boards

2.2.2 Input Filter Circuit

2.2.3 Rectifier, Smoothing, and Surge-Suppression Circuit

2.2.4 Main Switching Circuit

2.2.5 +35 V Voltage

2.2.6 Over Voltage Protection Circuit

2.2.7 +5 V Switching Regulator Circuit

2.2.8 +12 V Half-Wave

2.3 CONTROL CIRCUIT BOARD

2.3.1 Reset Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2.1 Printing Mechanism

2.1.2.2 Carriage Movement Mechanism

2.1.2.3 Ribbon Feed,/Color Select Mechanism

2.1.2.4 Paper Feed Mechanism

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4.1 Circuit Operation

Regurator Circuit

2.2.7.1 Activation

2.2.7.2 Voltage Regulator Circuit

2.2.7.3

Soff Start

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rec:tifier-Smoothing

(JUNMM BOARD)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(MONPS/MONPSE

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

●

. . . . . . . . . . . . . . . . . . . . . . . . .

●

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

board) ● 0.000 .”osoooo”oo02-17

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-2

2-3

2-6

2-8

2-13

2-17

2-19

2-19

2-20

2-20

2-23

.

2-24

2-25

2-25

2-25

2-26

2-27

2-28

2-29

2.3.1.1 Vx (Drive System Pull-up) Voltage Supply

2.3.1.2 Power

2.3.1.3 Font/Identity Module Installation and Removal Reset”* ””* ”**** ””**

2.3.1.4 ST-RAM (7A) Battery Backup Circuit

2.3.2 Interface

2.3.2.1 8-Bit Parallel Interface

2.3.2.2

2.3.3 Control Panel Interface Circuit

2.3.3.1 LED Drive Section

RC-232C Serial Interface

ON/C)FF

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circufi*.**”””* ”*-”-c-o*e*2-29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. i

2-30

”*2-31

2-33

2-34

2-34

2-38

2-41

2-42

Page 43

REV.-A

2.3.3.2 Switch Status Read Section

2.3.4 State Detection and Sensor Signal Input Circuits

2.3.4.1 Reference Voltage Supply Circuit

2.3.4.2 35 V Line Voltage Detection Circuit

2.3.4.3

2.3.4.4

2.3.4.5 CR HP Sensor Circuit

2.3.4.6 CS Sensor Circuit

2.3.4.7 PG Sensor Circuit

2.3.4.8 PE Sensor Circuit

2.3.4.9 F/T Sensor Circuit

Printhead Control and Drive Circuit

2.3.5

2.3.5.1 Relationship Between Paper Thickness and Print Mode ”...* ...562-56

2.3.5.2 Relationship Between

2.3.6 CR Motor Control and Drive Circuit

2.3.6.1 Reference Voltage Generation Circuit

2.3.6.2 CR Motor Drive Circuit

2.3.6.3 CR Motor Control

2.3.7 PF Motor Control and Drive Circuit

2.3.7.1 PF Motor Drive Circuit

2.3.7.2 PF Motor Phase Switching Timing

CS/RF Motor Control and Drive Circuit

2.3.8

2.3.8.1

2.3.8.2

VR1/VR2 Reading Circuit

Printhead

+35 V Line Voltage

CS/RF Motor Drive Circuit

CS/RF Motor Phase Switching Timing

Temperature Detection Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printhead Drive Pulse Width and

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .