Page 1

Epson

Robots

G-Series

The Epson G-series SCARA :

Greater performance – higher productivity

Epson

Robots

G-Series

Page 2

2 | Epson Robots G-Series

The Epson G-series SCARA :

Greater performance – higher productivity

With the G-series, Epson introduces their latest SCARA generation to the market.

At present, the complete range comprises of 168 versions with reaches of between 450 to 1,000 millimetres and a load capacity of up to 20 kg. Equipped with

the Epson Smart-Motion Technology, the G-Scaras work much faster than their

predecessors, offering signicantly enlarged working range. All this is topped up

with the usual high precision and reliability.

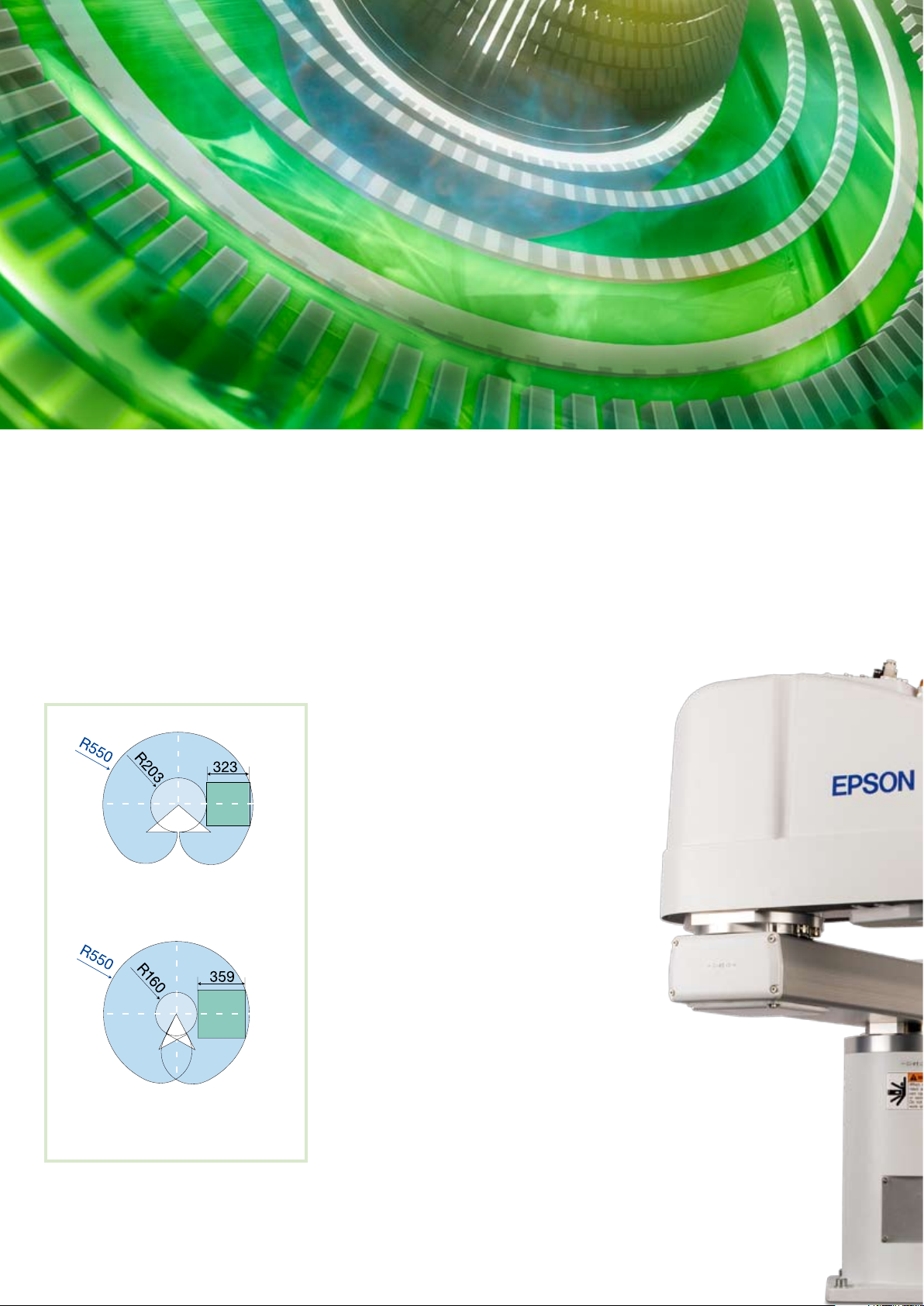

The working range of the G-series

is 23 % larger.

Next to a considerable improvement in the

Z axis speed, the range of movement has

also been increased again. The speed and

the load capacity of the G-series robots

has been increased by 20 to 100 percent

compared to previous models. Thanks to

Epson E2S-551S

the improved motor management, they are

also able to carry out very fast operations

accurately with greater extensions.

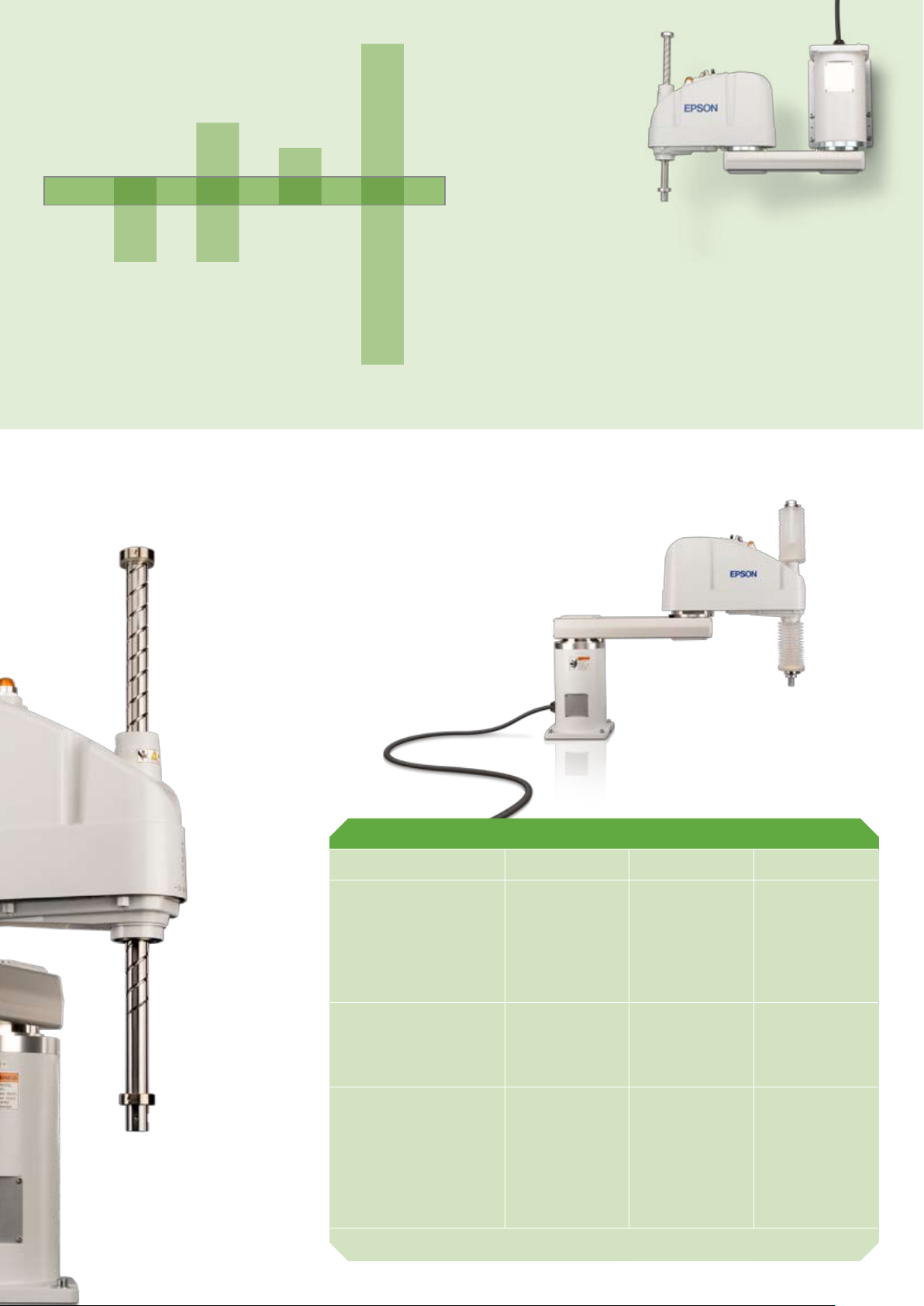

All robot arms of the G-series are available

as standard, cleanroom class 10 / ISO 4

or IP54/65 congurations. Each model can

be selected between a pedestal, wall or

ceiling mount.

(1)

Together with the compact control system

RC180 and the image processing Smart

Epson G6-551S

Comparison of the working ranges

(1)

Class 10 according to US FED STD 209E (old), ISO 4 according to ISO 14644-1.

Vision, the G-series provides great

performance and high ease of use.

Page 3

Epson Robots G-Series | 3

Name syntax

G

6

10

20

45

55

65

85

A0

1

3 or 4

D

DR

DW

S

SR

SW

P

PR

PW

C

CR

CW

= Example:

payload up to 6kg,

650mm reach,

320mm Z-axis,

Standard Wall mounting

= G6-653SW

G6-653SW

Category Reach

1. + 2. Arm

Z-axis

lenght

Version

IP65-Ver sion

G10-854P

G-Series

G6 G10 G20

G20-A04S

Payload (nom./max.) 3 / 6 kg 5 / 10 kg 10 / 20 kg

Reach 1. + 2. Arm

450 mm 45

550 mm 55

650 mm 65

850 mm 85

1.000 mm A0

Z-axis length (¹

180 mm 1

320 mm 3

420 mm 4

Versions

Standard S

Wall mount W

Celling mount R

Cleanroom/ESD C

IP54 P

IP65 P

1)

The usable Z-axis length is shortened by 30 mm for clean-room and IP54 / IP65 machines.

)

•

•

•

–

–

•

•

–

•

•

•

•

•

•

–

–

•

•

–

•

–

•

•

•

•

•

•

•

–

–

•

•

•

–

•

•

•

•

•

•

•

Page 4

A1

C

A

B

A1

A2

A2

D

E

A3

F

A4

A4

H

G

H

G

I J

K

4 | Epson Robots G-Series

Pedestal mount

Celling mount

Wall mount

G6-553C

Page 5

Epson Robots G-Series | 5

G6 - 45 x G6 - 55 x G6 - 65 x G10 - 65 x G10 - 85 x G20 - 85 x G20 - A0 x

Payload nom./max. (kg) 3/6 5/10 10/20

Reach (mm) 450 550 650 650 850 850 1,000

Repeat accuracy + / –

Axes 1+2 (mm)

Axis 3 (mm)

Axis 4 (°)

Max. Speed + / –

Axes 1+2 (mm / s)

Axis 3 (mm / s)

Axis 4 (° / s)

Moment of inertia

nom./max.

(kg m² )

6,440

± 0.015

± 0.010

± 0.005

7,170

1,100 / 2,350

2,400

0.01 / 0.12

7,900

± 0.025

± 0.010

± 0.005

8,900

1,100 / 2,350

2,400

0.02 / 0.25

11,000

11,000

± 0.025

± 0.010

± 0.005

1,100 / 2,350

1,700

0.05 / 0.45

Ø Z-Axis outer/inner (mm) 20/14 25/18 25/18

Insertion force

(1)

Z-Axis

(N)

Working area

A (mm)

B (mm)

C (mm)

A1 (°)

A2 (°)

Z-stroke

A3 (mm)

A4 (°)

150

502

450

134.8

± 152

± 142

for clean-room and IP54 / 65)

602

550

161.2

± 152

± 147.5

180 / 330 (150 / 300

702

650

232

± 152

± 147.5

705.5

650

212.4

± 152

± 152.5

180 / 420 (150 / 390

for clean-room and IP54 / 65)

± 360

250

± 360

905.5

850

207.8

± 152

± 151

250

905.5

850

207.8

± 152

± 151

180 / 420 (150 / 390

for clean-room and IP54 / 65)

1,055.5

1.000

307

± 152

± 152.5

± 360

11,500

Dimensions

D (mm)

E (mm)

F (mm)

G (mm)

H (hole centre distance) (mm)

309.5

299

684 / 834

180

150 x150

372

393.5

813.5 / 1,053.5

240

200 x 200

372

393.5

813.5 / 1,053.5

240

200 x 200

I (mm) 200 300 400 250 450 450 600

J (mm)

K (mm)

Weight

Pedestal mount (kg)

Ceiling mount (kg)

Wall mount (kg)

User cabling

Electrical

Pneumatic

Ambient conditions

Temperature

Humidity

Design of Manipulator

Mounting

Cleanroom & ESD

IP Protection class

27

27

29

250

4–Ø11

400

4–Ø16

27

27

29

28

28

29.5

46

46

51

24 wires ( 15 pin + 9 pin D-Sub)

4 (2x Ø 4mm und 2x Ø 6mm)

5 – 40°C

10 – 80%, non-condensing

Pedastal mount, Ceiling mount, Wall mount

Cleanroom class 10 respectively ISO 4

Standard / IP54 / IP65

48

48

53

400

4–Ø16

48

48

53

(2)

50

50

55

Security reference CE Declaration of Conformity, Safety Class 3

Controller Epson RC180

¹) Shorttime higher values are allowed. 2) Class 10 US FED STD 209E (old), ISO 4 ISO 14644-1.

Page 6

6 | Epson Robots G-Series

Epson RC180 Robot control system

The Epson RC180 control system is small and compact featuring the diversity

and reliability that is typical for products originating from Epson.

The programming of the Epson RC180 control system is intuitive and powerful.

This is achieved by an external computer and programmes can therefore

be created comfortably from your desktop. Furthermore, the control system

offers full network capability – an ideal requirement for larger projects that are

administered by several developers. The programming environment is available

in German, English and French.

Page 7

Epson Robots G-Series | 7

Scope of delivery G-Series / RC180 Controller

• 1x Manipulator

• Power cable 3m

• Signal cable 3m

• Emergency-Off plug

• Dummy connector for optional device connection

• Plug for standard I/O 50-pin Sub-D

• Epson RC+ 5.x CD

• Safety manual

• Manuals on CD:

– Controller system

– Manipulator

– Programming

– User Guide

Dimensions (WxDxH in mm) 302 x 170.5 x 275

CPU Intel Celeron, in stand-alone version

Memory 128 MB Flash RAM, 128 KB battery buffered SRAM

Programming enviroment Epson RC+

Program language Epson SPEL+

Program options VB-Guide, Epson Vision

Inputs /outputs 24 / 16, expandable up to 152 /144

Program Max. 4MB Code, corresponds to approx. 200 K program steps

Points Up to 1,000 points per point le

Interfaces 2x USB for connecting up a PC and USB stick,

Ethernet, 24/16 Standard I/O.

Optional available:

RS-232C, Fieldbus-Slave (Probus/CC-Link/Devicenet) Ethernet-IP, up to 152/144 I/O’s

upgradeable

Main connection 230/240 Volt , single phase

Consumption 1,300 VA, depending on the manipulator connected to it

Weight 7 kg

Ambient temperature 5 – 40 °C

Humidity 20 - 80%, non condensing

Page 8

Epson Smart Vision

Great solutions at fair prices. Whenever compact, exible and cost effective

solutions are required for product recognition, quality assurance or other “visual”

tasks, the new vision system Epson Smart Vision for Epson RC180 controller

shows its strenghts.

The Epson Smart Vision convinces

through its simple operation, straightforward installation. Thanks to the

seamless Vision Editor integration into

the robot programming environment

SC300 (Fixed Camera) SC300M (Mobile Camera)

Resolution (pixel) 640 x 480 640 x 480

Sensor Type

Lens Type CS Mount CS Mount

Mounting Options Fixed Camera Mobile Camera (Mobile head for

Mobile Camera Head Cable

Communications Interface Ethernet 10/100 Ethernet 10/100

Image Operation Tools Open, Close, Erode, Dilate, Sharpen,

Vision Tools Geometric Search, Polar Search,

Other Vision Tools Frames, Lines, Points, Histogram,

Robot/Camera Calibrations

Dimensions (mm) 154.13 (L) x 48.26 (H) x 60.05 (W) Main Body: 150.19 (L) x 51.31 (H) x

Weight (kg) 0.435 Main Body: 0.435

Ambient Temperature 0 – 45 °C 0 – 45 °C

Power Consumption 375 mA @ 24V DC (9W typical) 375 mA @ 24V DC (9W typical)

Connectors RJ45 for Power; RJ45 for Ethernet RJ45 for Power; RJ45 for Ethernet

Certifications FCC Class A; CE Class A; RoHS

¼” Progressive Scan with Square Pixels

NA 5 Meter (Camera Link)

Smooth, Flip, etc.

Normalized Correlation, Blob Analysis,

Edge Finder, etc.

Statistics …

Mobile, Fixed Upward, Fixed Downward

(all wizard based)

Compliant

and the powerful geometry tools, the

programming is exceptionally intuitive.

Two camera versions (stationary and

mobile) provide the necessary freedom for the system conception.

¼” Progressive Scan with Square Pixels

mounting on end of robot arm)

Open, Close, Erode, Dilate, Sharpen,

Smooth, Flip, etc.

Geometric Search, Polar Search,

Normalized Correlation, Blob Analysis,

Edge Finder, etc.

Frames, Lines, Points, Histogram,

Statistics …

Mobile, Fixed Upward, Fixed Downward

(all wizard based)

60.55 (W) Mobile Head: 44.25 (L) x

48.77 (H) x 68.17 (W)

Mobile Head: 0.185

FCC Class A; CE Class A; RoHS

Compliant

EPSON DEUTSCHLAND GmbH

Otto-Hahn-Straße 4

40670 Meerbusch

Tel.: +49 (0) 2159 / 538 1391

Fax: +49 (0) 2159 / 538 3170

E-Mail: robot.infos@epson.de

This brochure is subject to alterations; we are not responsible for any printing errors;

we retain the right to make procedural modifications without giving prior notice.

www.epson.de/robots

Loading...

Loading...