Page 1

6(59,&(0$18$/

3LQ,PSDFW'RW3ULQWHU

EPSON FX-880

®

4008484

Page 2

NOTICE

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However,

should any errors be deteced, SEIKO EPSON would greatly appreciate being informed of

them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for

any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may

be trademarks or registered trademarks of their respective owners. EPSON

disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2)

damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could r esult in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POW ER SOURCE AND PERIPHERAL

DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIER WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED

VOLTAGE, LISTED ON T HE SERIAL NUMBER/RATING PLATE. I F THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAI LABLE POW ER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations,

maintenance and repair procedures of FX880. The instructions and procedures included herein

are intended for the experienced repair technicians, and attention should be given to the

precautions on the preceding page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved lubricants and

adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Page 5

REVISION STATUS

Rev. Date Page(s) Contents

A 1997/09/30 All First release

Page 6

TABLE OF CONTENTS

PRODUCT SPECIFICATION

1.1 SPECIFICATION .................................................................................. 1-1

1.2 OPERATION.........................................................................................1-7

1.2.1 Control panel ................................................................................................ 1-7

1.2.2 Switches........................................................................................................ 1-7

1.2.2.1 Usual Operation..................................................................................1-7

1.2.2.2 Operations at Power-on...................................................................... 1-8

1.2.3 Indicators ( LEDs )........................................................................................ 1-9

1.2.4 Buzzer............................................................................................................ 1-9

1.2.5 Default setting mode 1............................................................................... 1-10

1.2.5.1 Setting Method.................................................................................. 1-10

1.2.5.2 Setting Items.....................................................................................1-10

1.2.6 Default Setting Mode 2............................................................................... 1-11

1.2.6.1 Setting Items..................................................................................... 1-11

1.2.7 EEPROM Clear Function............................................................................ 1-12

1.2.8 Bi-D Adjustment.......................................................................................... 1-13

OPERATING PRICIPLES

2.1 MAIN COMPONENTS..........................................................................2-1

2.1.1 C229MAIN Board........................................................................................... 2-1

2.1.2 C229PSB/PSE Board.................................................................................... 2-1

2.2 PRINTER MECHANISM.......................................................................2-2

2.2.1 Printhead....................................................................................................... 2-2

2.2.2 Paper Feed Mechanism................................................................................ 2-2

2.2.3 Carriage Movement Mechanism.................................................................. 2-2

2.2.4 Tractor Feed Mechanism ............................................................................. 2-2

2.2.5 Platen Gap Adjustment Mechanism............................................................ 2-2

2.2.6 Ribbon Feed Mechanism ............................................................................. 2-2

2.3 CIRCUIT OPERATION......................................................................... 2-4

2.3.1 C229PSB/PSE Power Supply Circuit .......................................................... 2-4

2.3.2 C229MAIN Board Circuit .............................................................................. 2-5

Page 7

TROUBLESHOOTING

3.1 OVERVIEW ..........................................................................................3-1

3.1.1 Main Component Checking Point ............................................................... 3-1

3.1.2 Error............................................................................................................... 3-3

3.2 UNIT LEVEL TROUBLESHOOTING....................................................3-4

3.3 UNIT REPAIRING OF THE POWER SUPPLY BOARD .....................3-11

3.4 UNIT REPAIRING OF THE MAIN BOARD......................................... 3-13

3.5 REPAIRING THE PRINTER MECHANISM......................................... 3-16

DISASSEMBLY AND ASSEMBLY

4.1 OVERVIEW ..........................................................................................4-1

4.1.1 Disassembly Precautions........................................................................... 4-1

4.1.2 Tools and Instruments................................................................................. 4-1

4.1.3 Service Check After Repair.......................................................................... 4-2

4.1.4 Abbreviations for Small Parts...................................................................... 4-3

4.2 DISASSEMBLY AND ASSEMBLY....................................................... 4-4

4.2.1 Printhead Removal....................................................................................... 4-5

4.2.2 HP (Home Position) Detector Removal....................................................... 4-6

4.2.3 Pre-disassembly Procedures ...................................................................... 4-7

4.2.4 Upper Housing Removal.............................................................................. 4-8

4.2.5 C229MAIN Board Removal........................................................................... 4-9

4.2.6 C229PSB/PSE Board Removal.................................................................. 4-11

4.2.7 ROM Removal ............................................................................................. 4-12

4.2.8 Platen Removal........................................................................................... 4-13

4.2.9 Printer Mechanism Removal...................................................................... 4-14

4.2.10 Printer Mechanism Disassembly............................................................. 4-15

4.2.10.1 CR Motor Removal.......................................................................... 4-15

4.2.10.2 PF Motor Removal.......................................................................... 4-16

4.2.10.3 PF Gear Train Disassembly............................................................ 4-17

4.2.10.4 PG (Platen Gap) Detector Removal................................................ 4-18

4.2.10.5 Release Detector Removal............................................................. 4-18

4.2.10.6 Front PE (Paper End) Detector Removal........................................ 4-19

4.2.10.7 Rear PE Detector Removal............................................................. 4-19

4.2.10.8 Carriage Assembly Removal........................................................... 4-20

4.2.10.9 Rear Paper Guide Assembly Removal............................................ 4-21

4.2.10.10 Ribbon Drive (RD) Assembly Removal......................................... 4-22

Page 8

ADJUSTMENT

5.1 ADJUSTMENT OVERVIEW ................................................................. 5-1

5.1.1 Required Adjustment ................................................................................... 5-1

5.1.2 Adjustment Tools ......................................................................................... 5-1

5.2 ADJUSTMENT AND RESETTING THE PRINTER............................... 5-2

5.2.1 Platen Gap Adjustment ................................................................................ 5-2

5.2.2 Factory Setting.............................................................................................. 5-4

5.2.3 Bi-D Adjustment............................................................................................ 5-6

MAINTENANCE

6.1 PREVENTIVE MAINTENANCE............................................................6-1

6.2 LUBRICATION ..................................................................................... 6-2

APPENDIX

7.1 CONNECTOR SUMMARY ................................................................... 7-1

7.2 COMPONENT LAYOUT....................................................................... 7-6

7.3 EXPLODED DIAGRAM ........................................................................ 7-9

7.4 DIMENSION AND WEIGHT................................................................ 7-11

7.5 CIRCUIT DIAGRAM ...........................................................................7-12

Page 9

CHAPTER

PRODUCT SPECIFICATION

1

Page 10

FX-880 Service Manual

Chapter 1 Product Description

1.1 SPECIFICATION

The FX-880 is a small hoot, 9 pins serial impact dot m atrix printer. The main specif icat ion is as

follows;

HARDWARE SPECIFICATIONS

Print method 9 pins Impact dot matrix

Print pin arrangement 9 ´ 1

Print pin diagrams 0.29 mm ( 0.0114 inch )

RESOLUTION

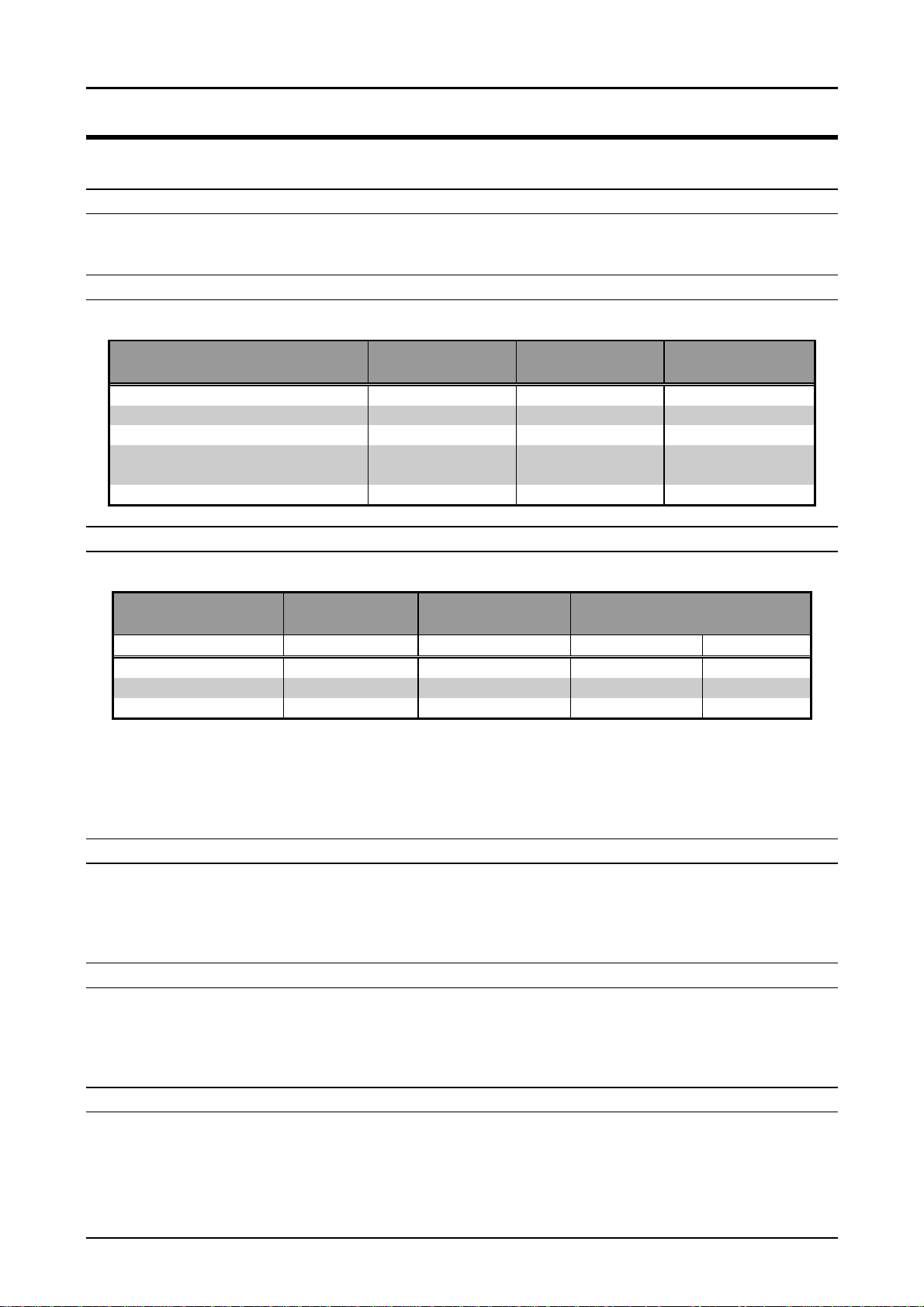

Table 1-1. Resolution ( dpi )

Printing mode Horizontal

density

High speed draft 90 72 No

Draft 120 72 No

NLQ 240 144 No

Bit image 60, 72, 80, 90 or

120

120 or 240 72 No

PRINTING SPEED

Table 1-2. Printing Speed (cps)

Printing mode Character

pitch

High speed Draft 10cpi 80 410 345

Draft 10cpi 80 310 260

NLQ 10cpi 80 78 65

l When the power supply voltage drops to the lower limit, the pr inter stops printing once and

then starts to print rest dat a on that line again more slowly than before.

l When the head temperature rises to the upper limit, the print er st ops pr inting once. If the

head temperature falls down to t he nor m al level, it begins to print again mo r e slowly than

before.

Printable

column

Vertical density Adjacent dot

print

72 Yes

Printing speed

Normal Copy

FEEDING METHOD

Friction feed Front, Rear

Push tractor feed Front, Rear

Push & Pull tractor feed Front, Rear

Pull tractor feed Front, Rear, Bottom

FEED SPEED

Normal mode 62 ms 1/6 inch feed

0.127MPS ( 5.0 IPS) continuos feeding

Copy mode 83 ms 1/6 inch feeding

0.078MPS (3.1 IPS) continuos feed

FEEDER

Front push tractor

Rear push tractor

CSF ( Option, bin1 / bin2 )

Pull tractor ( Option )

Roll paper holder ( Option )

Rev. A

1-1

Page 11

FX-880 Service Manual

2

Chapter 1 Product Description

PAPER / MEDIA

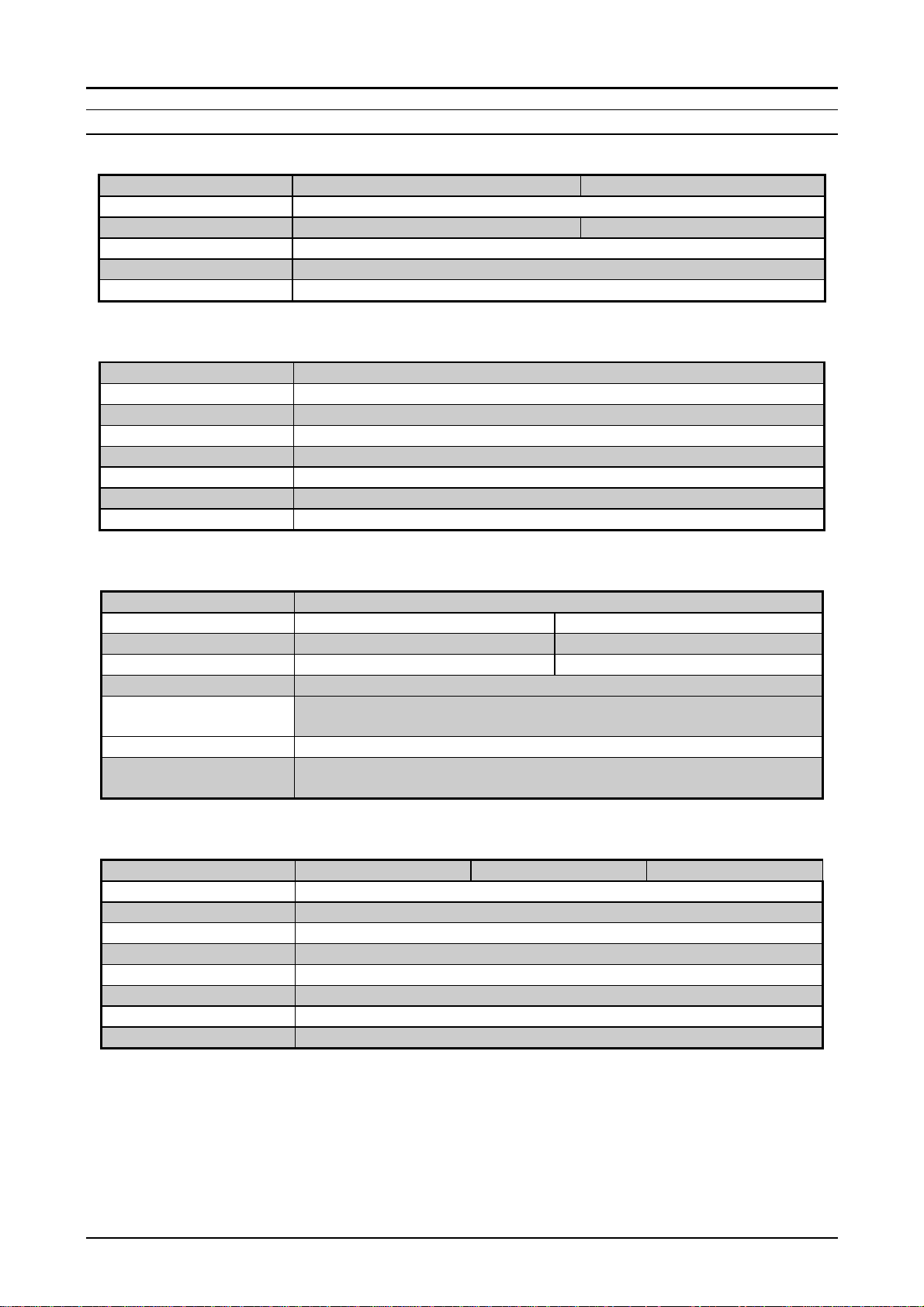

Table 1-3. Cut Sheet

Insertion Front entry Rear entry

Width 148 ~ 257mm ( 5.8 ~ 10.1”)

Length 182 ~ 364mm ( 7.2 ~ 14.3” ) 92 ~ 364mm ( 3.6 ~ 14.3”)

Thickness 0.065 ~ 0.14mm ( 0.0025~ 0. 0055” )

Weight 52 ~ 90g/m2 (14 ~ 24 lb)

Quality Plain paper, Reclaimed paper *, not curled, not folded, not cr um pled

Table 1-4. Cut Sheet ( Multi-Part )

Insertion Front entry

Width 182 ~ 257mm ( 7.2 ~ 10.1” )

Length 182 ~ 364mm ( 7.2 ~ 14.3” )

Copies 1(original) + 5

Total thickness 0.12 ~ 0.46mm ( 0.0047 ~ 0.018” )

Weight 40 ~ 58g/m2 ( 12 ~ 15 lb)

Quality Plain paper, Reclaimed paper, not curled, not folded, not crumpled

Jointing Line glue at the top or one side of form

Table 1-5. Envelope

Insertion Rear entry only

Envelope No.6 No.10

Width 165mm ( 6.5” ) 241mm ( 9.5” )

Length 92mm ( 3.6” ) 105mm ( 4.1” )

Total thickness 0.16 ~ 0.52mm ( 0.0063 ~ 0.020” )

The difference of thickness at the printable area is within 0.25m m

( 0.0098” )

Weight 45 ~ 90g/m2 ( 12 ~ 24 lb )

Quality BOND paper, plain paper, air mail, no glue at a flap, not curled, not

folded, not crumpled

Table 1-6 Continuous Paper ( Single Sheet and Multi-Part )

Insertion Front entry Rear entry Bottom entry

Width 101. 6 ~ 254m m ( 4 ~ 10” )

Length 101.6 ~ 558.8mm ( 4 22” )

Copies 1(original) + 5

Total thickness 0.065 ~0.46mm ( 0.0025 ~ 0.018” )

Weight 52 ~ 82g/m2 ( 14 ~ 22 lb )

Weig ht ( multi part) 40 ~ 58g/m2 ( 12 ~ 15 lb )

Quality Plain paper, Reclaimed paper, carbon less mult i part paper

Jointing Point g lue or bot h sides paper staple

Rev. A

1-

Page 12

FX-880 Service Manual

3

Chapter 1 Product Description

Table 1-7. Continuous Paper wit h Label s

Insertion Front entry Bottom entry

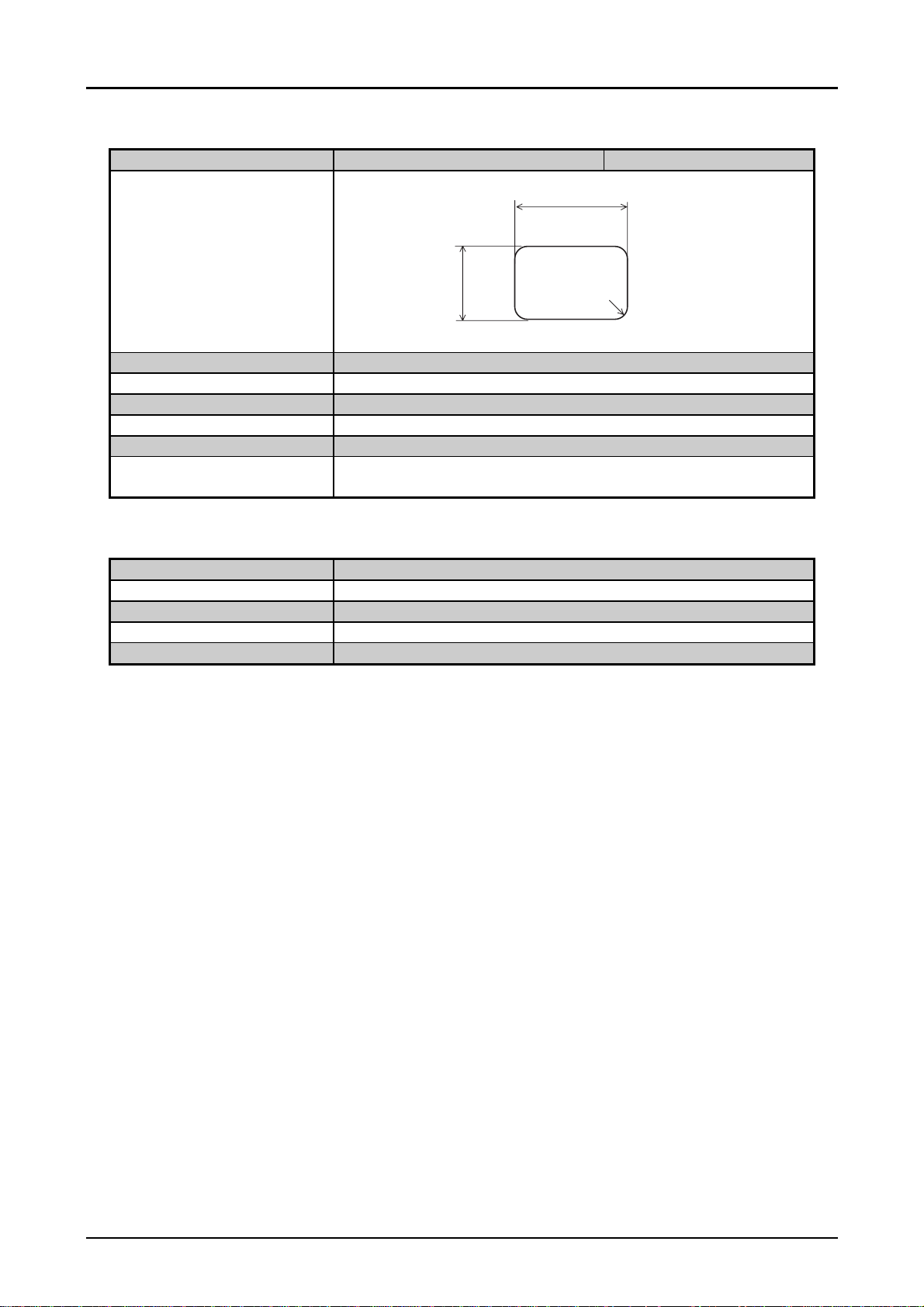

Label size See the figure below;

63.5m m (2.5")

Label

23.8m m ( 15/16" )

R 2.5m m ( 0.1" )

Figure 1-1. Label

Base sheet width 101.6 ~ 254.0mm ( 4 ~ 10” )

Base sheet length 101.6 ~ 558.8mm ( 4 ~ 22” )

Base sheet thickness 0.07 ~ 0.09mm ( 0.0028 ~ 0.0035” )

Total thickness 0.16 ~ 0.19mm ( 0.0063 ~ 0.0075” )

Label weight 68g/m2 (17 lb)

Quality A very continuous form labels, a very mini-line labels or the

same quality labels

Table 1-8. Roll Paper

Insertion Rear entry

Width 216mm ( 8.5” )

Thickness 0.07 ~ 0.09mm ( 8.5” )

Weight 52 ~ 82g/m2 ( 14 ~ 22 lb )

Quality Plain paper, not curled, not folded, not crumpled

Rev. A

1-

Page 13

FX-880 Service Manual

4

Chapter 1 Product Description

TYPEFACE

Bit map Font EPSON Draf t 10cpi, 12cpi, 15cpi

EPSON Roman 10cpi, 12cpi, 15cpi, Proportional

EPSON Sans Serif 10cpi, 12cpi, 15cpi, Proportional

Bar code fonts EAN-13, EAN-8, I nterleaved 2 of 5, UPC-A, UPC-E, Code 39,

Code 128, POSTNET

CHARACTER TABLES

Standard version 11 tables

NLSP version 19 tables

INPUT BUFFER

0 Kbytes / 32 Kbytes

ELECTRICAL SPECIFICATION

120 V version

Rated voltage AC 120 V

Input voltage range AC 103.5 to 132 V

Rated frequency range 50 to 60 Hz

Input frequency range 49.5 to 60.5 Hz

Rated current 0.7 A ( Max. 1.6 A )

Power consumption Approx. 34 W ( ISO/IEC10561 Letter pattern)

Insulation resistance Min. 10 MW ( between AC line and chassis)

Dielectric strength AC 1000 V rms 1 min. or AC 1200 V rms 1 sec.(between AC line and

chassis)

230 V version

Rated voltage AC 220 to 240 V

Input voltage range AC 198 to 264 V

Rated frequency range 50 to 60 Hz

Input frequency range 49.5 to 60.5 Hz

Rated current 0.4 A ( Max. 0.9 A )

Power consumption Approx. 34 W ( ISO/IEC10561 Letter pattern)

Energy Star compliant

Insulation resistance Min. 10 M W ( between AC line and chassis)

Dielectric strength AC 1000 V rms 1 min. or

AC 1200 V rms 1 sec. ( between AC line and chassis)

Rev. A

1-

Page 14

FX-880 Service Manual

5

Chapter 1 Product Description

ACOUSTIC NOISE

55 dB(A) ( ISO 7779 patt er n )

ENVIRONMENTAL CONDITION

Temperature 5 to 35 °C ( Operating )

-30 to 60 °C ( Non-operating)

Humidity 10 to 80 % ( Operating without condensation )

0 to 85 % ( Non-operation without condensation)

RELIABILITY

Total print volume 6.5 million lines ( Except Print head)

MTBF (4000 POH )

Print head life approx. 100 million characters

RIBBON CARTRIDGE

Type Fabric

Color Black

Ribbon life Approx. 3 million characters ( Draft 10 cpi, 14 dot / chr. )

SAFETY APPROVALS

120 V version

Safety standards UL 1950 CSA C22.2 No. 950

EMI FCC part 15 subpart B class B, CSA C108.8 class B

230 V version

Safety standards EN60950 ( VDE, NEMKO )

EMI EN55022 ( CISRP pub.22 ) class B

AS/NSZ.3548 class B

CE MARKING

230 V version

Low Voltage Directive 73/23/EEC

EN60950

EMC Directive 89/336/EEC EN55022 class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

INTERFACE

Bi-directional parallel Interface ( IEEE-1284 nibble mode supported )

Type-B I/F level 2 ( Option )

CONTROL CODE

ESC/P

IBM 2380 Plus emulation

PHYSICAL SPECIFICATIONS

Dimensions 415mm( W ) ´ 350mm ( D ) ´ 154mm ( H )

Weig ht Approx. 7.6 kg

Rev. A

1-

Page 15

Chapter 1 Product Description

6

CONSUMPTION & OPTIONS

Table 1-9. Consumable & Option

Consumption Code No.

Ribbon cartridge #8750

Ribbon pack #8758

Options

High capacity cut sheet feeder ( Bin1 ) C80638*

Single bin cut sheet feeder ( Bin 2 ) C80637*

Pull tractor unit C80020*

Roll paper holder #8310

Front paper guide C81402*

Front sheet guide C81400*

Serial Interface card C82305* / C82306*

32KB intelligent serial Interface card C82307* / C82308*

32KB intelligent Interface card C82310* / C82311*

Local Talk I/F card C82312*

32KB IEEE-1284 I/F card C82313*

Coax I/F card C82314*

Twinax I/F card C82315*

IEEE-1284 parallel I/F card C82345*

Ethernet I/F card C82347*

“*”: According to each destination.

FX-880 Service Manual

Figure 1-2. Exterior View of the FX-880

Rev. A

1-

Page 16

FX-880 Service Manual

7

Chapter 1 Product Description

1.2 OPERATION

This section describes the operations equipped with this print er.

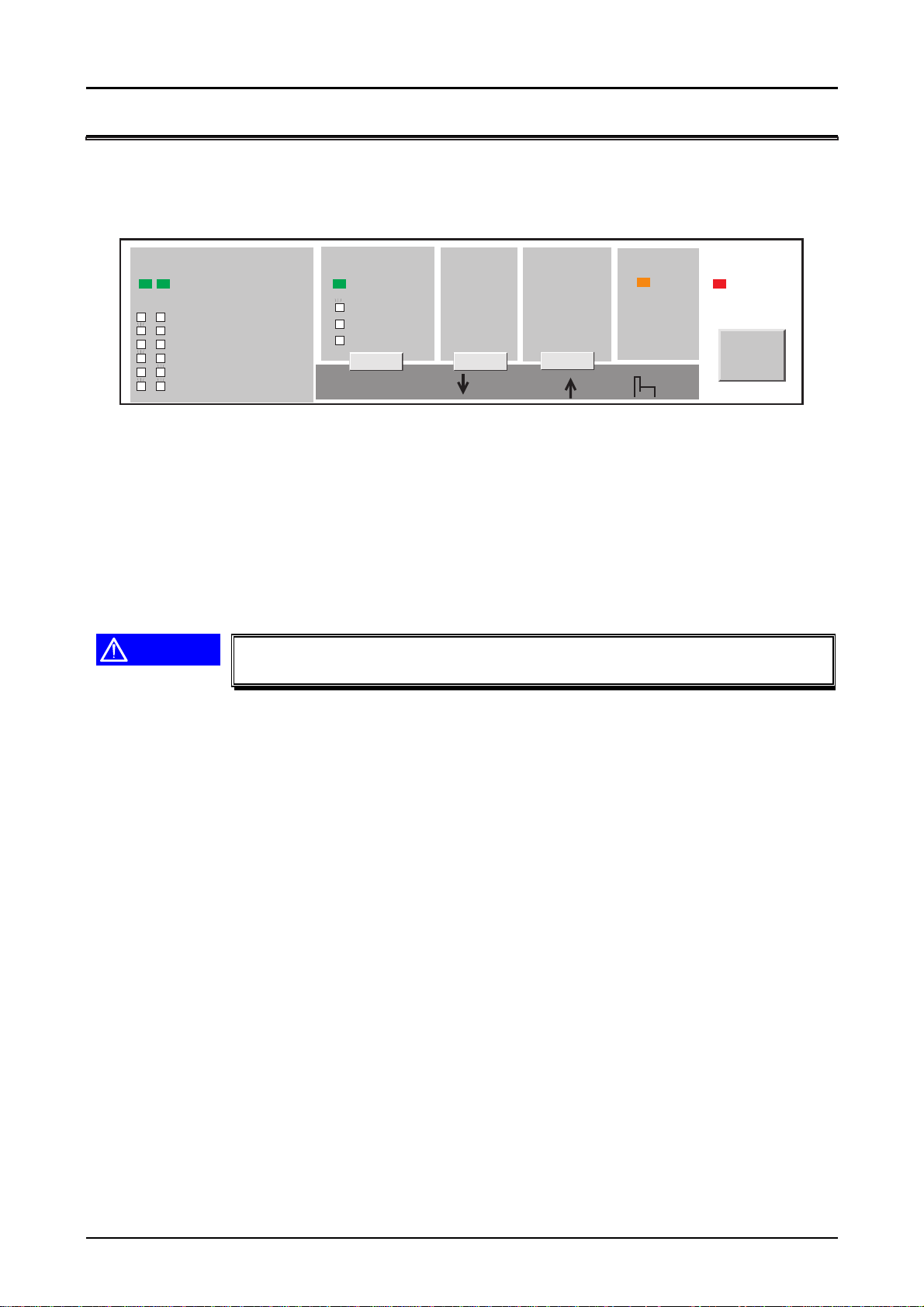

1.2.1 Control panel

The control panel of this print er consist s of 5 switches and 5 LEDs, as shown below;

Font

Draft

D raft C ondensed

Rom an

R om an C ondensed

Sans serif

Sans serif C ondensed

T e a r O ff/B in

Tear off

Bin1

Bin2

LF/FF

M icro A djust

Load/Eject

Pause

3sec

Paper O ut

O perate

Figure 1-3. Panel Operation Outline

1.2.2 Switches

1.2.2.1 Usual Operation

In the normal mode, pressing panel switches executes the following functions;

Operate

(1)

This switch turns the printer on and off it is the secondary switch in the power supply circuit.

CAUTION

Unplug the power cable from the AC Inlet when connecting/

disconnecting the Interface cable to/from t he pri nt er.

Pause

(2)

This switch alternates printer activity between printing and non-printing states.

If this button is held down for over 3 seconds when the printer is in t he non-printing status, the

Micro Adjust function and Font selection are enabled. If it is pressed again, these function are

disabled.

Load/Eject

(3)

- Loads the paper when the printer is out of paper .

- Ejects the paper to the paper par k.

LF/FF

(4)

- Feeds a line if pressed shortly.

- Feeds the continuos paper or eject the cut sheet .

Tear Off

(5)

Advances the continuos paper to the Tear-OFF posit ion. If it is pressed again, the paper is

moved to the TOF position.

Bin

(6)

Selects the CSF bin number when the CSF is used.

Font

(7)

Selects the font fr om t he list on the panel when the Micro Adjust function is enabled.

Micro Adjust

(8)

The Micro Adjust switch is available in the Micro Adjust mode.

Micro switch executes micro feed forward or backward by 1/216 inch one by one.

The TOF adjustment is enabled in t he TOF position after loading t he paper, and the Tear-off

adjustment is enable in the Tear-off position.

Rev. A

1-

Page 17

FX-880 Service Manual

8

Chapter 1 Product Description

1.2.2.2 Operations at Power-on

Pressing the specified switch (switches) while turning on the pr int er enables the following special

functions:

1. Self test

- Switches :

Function: Executes the printing LQ self t est printing.

- Switch:

Function: Executes the Draft self t est printing.

2. Data dum p m ode

Switches :

Function: Executes the data dump function.

3. Clearing the line counter value for the r ibbon life in the EEPROM

Switches:

Function: Clears the line counter value stored in the EEPROM.

4. Bi-D adj ust m ent

Switches:

Function: Executes the Bi-D adjustment.

Load / Eject

LF / FF

Load / Eject

Tear-off / Bin

Pause

turning on the printer.

switch, while turning on the printer.

while turning on the printer.

LF / FF

and

and

switches at same time while turning on the printer.

Pause

at same time while turning on the printer.

Rev. A

1-

Page 18

FX-880 Service Manual

9

Chapter 1 Product Description

1.2.3 Indicators ( LEDs )

This printer has the following indicators to indicate its current condition as shown in the table below:

Pause ( Orange )

1.

Comes On when the printer is paused, and goes Off when the printer is not paused.

Blinks when the Micro adjust function and the Font selection are enabled or the printhead is in

the overheated condition.

Paper Out ( Red )

2.

Comes On when the printer is in the Paper out condition.

Blinks when the paper eject error has occurred .

Tear Off / Bin ( Green )

3.

Blinks when the continuos paper is in the tear off position.

Comes On when the CSF Bin1 is selected, and goes Off when the CSF Bin2 is selected.

Font ( Green )

4.

Indicates the font selections.

Table 1-10. LED Status

Pause

Paper out error

Release lever error

Paper eject warning

Head hot warning

Micro adjust & Font selection

Tear off

Bin selection

Font selection According as

Fatal error Blinks Blinks Blink s Blinks

Printer status

Font Tear-Off /

Bin

¾¾

¾ ¾

¾¾

¾ ¾

¾¾

¾ ¾

¾

¾

font

selection

According as

paper path

According as

bin selection

¾¾¾

Pause Paper Out

On

On On

On

On Blinks

Blinks Blinks

Blinks

¾¾

¾ ¾

1.2.4 Buzzer

This printer has the buzzer to indicate its current condition with the following indications:

Table 1-11. Buzzer Status

¾

¾

¾

Printer status Beep sounds

Paper out error

Release lever error – – – – –

Paper eject warning

Illegal panel operation

Note: The symbols used in the table represents t he f ollowing:

“ Ÿ ” = A beep sounds for approximately 100 ms with the interval of appr oxim at ely 100 m s .

“ – “ = A beep sounds for approximately 500ms wit h t he interval of approximately 100ms.

Rev. A

ŸŸŸ

ŸŸŸ

Ÿ

1-

Page 19

FX-880 Service Manual

0

Chapter 1 Product Description

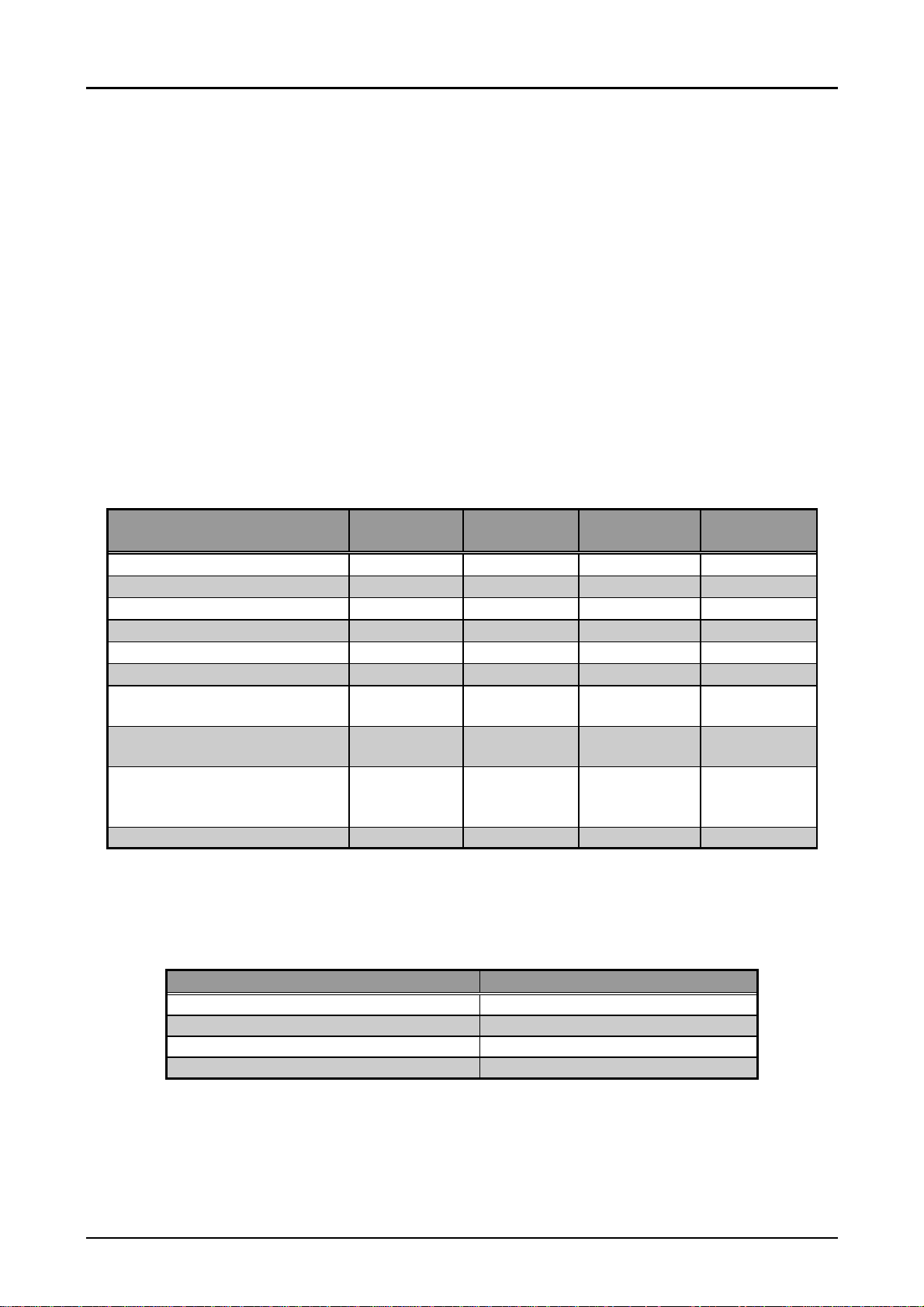

1.2.5 Default setting mode 1

You can change some parameters that t he pr inter refers to at pr int er initialization.

1.2.5.1 Setting Method

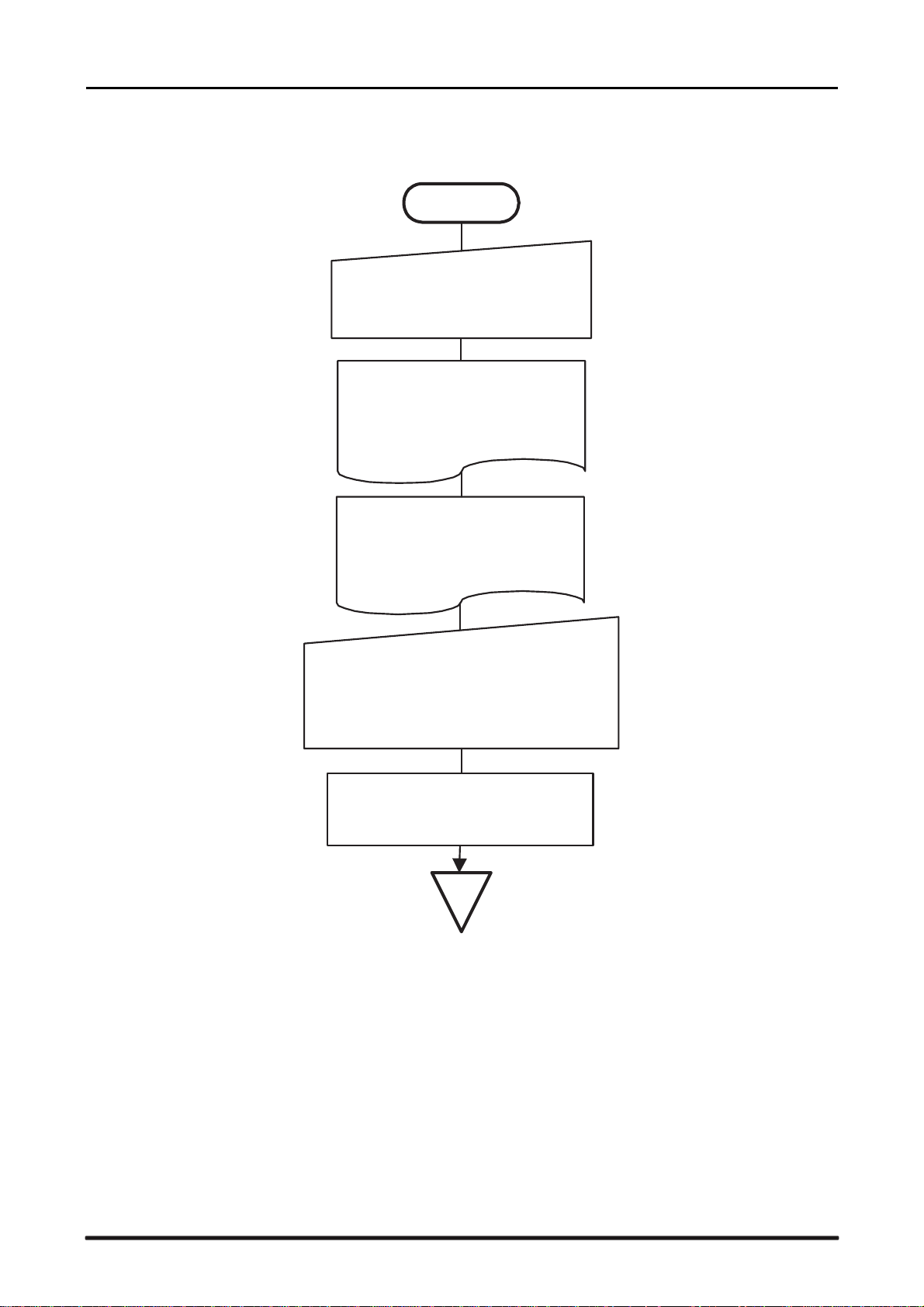

Refer to the following f lowchart for the default sett ing mode 1.

START

H o ld in g d o w n

Language selection sheet

Push down

Select the m enu, select m ethod and

current setting are printed.

Tear off/ B in

tu rn o n th e p rin te r.

C hange the language?

NO

Tear off/ B in

s w itc h ,

YES

sw itch.

Push down

select the aim ed language.

Lo ad/E ject

s w itc h to

R e fe rrin g to th e F o n t a n d T e a r o ff/ B in

LED s, push

sele ct the m enu .

R eferring to the Pause and Paper

O u t L E D s , p u s h

Tear off/B in

to change the setting value.

Finish?

T u rn th e p rin te r o ff to s a v e th e

settings.

s w itc h to

Load /Eject

END

sw itch

Figure 1-4. Flowchart f or Def aul t Setting Mode 1

1.2.5.2 Setting Items

Setting values available for the default set ting mode including factory sett ings are as shown in the

following table:

Table 1-12. Setting Values Available for Default Setting Mode 1

Items Setting values

(BOLD font : factory setting)

Skip over perforation

Auto tear off

Auto line feed

Print direction

I/F mode

Auto I/F wait time

Software

0 slash

High speed draft

Input buffer

Buzzer

Auto CR ( IBM 2380 Plus )*1

IBM character table

Bi-D

Auto

, Parallel, Option

0 sec

1

ESC/P

table 2

Off

On,

Off

On,

Off

On,

, Uni-D

., 30 sec.

, IBM 2380 Plus

0

, Ø

On

, Off

On

, Off

On

, Off

Off

On,

, table 1

( IBM 2380 Plus )*1

*1: This setting is effective when the I BM 2380 Plus em ulat ion is select ed only.

Rev. A

1-1

Page 20

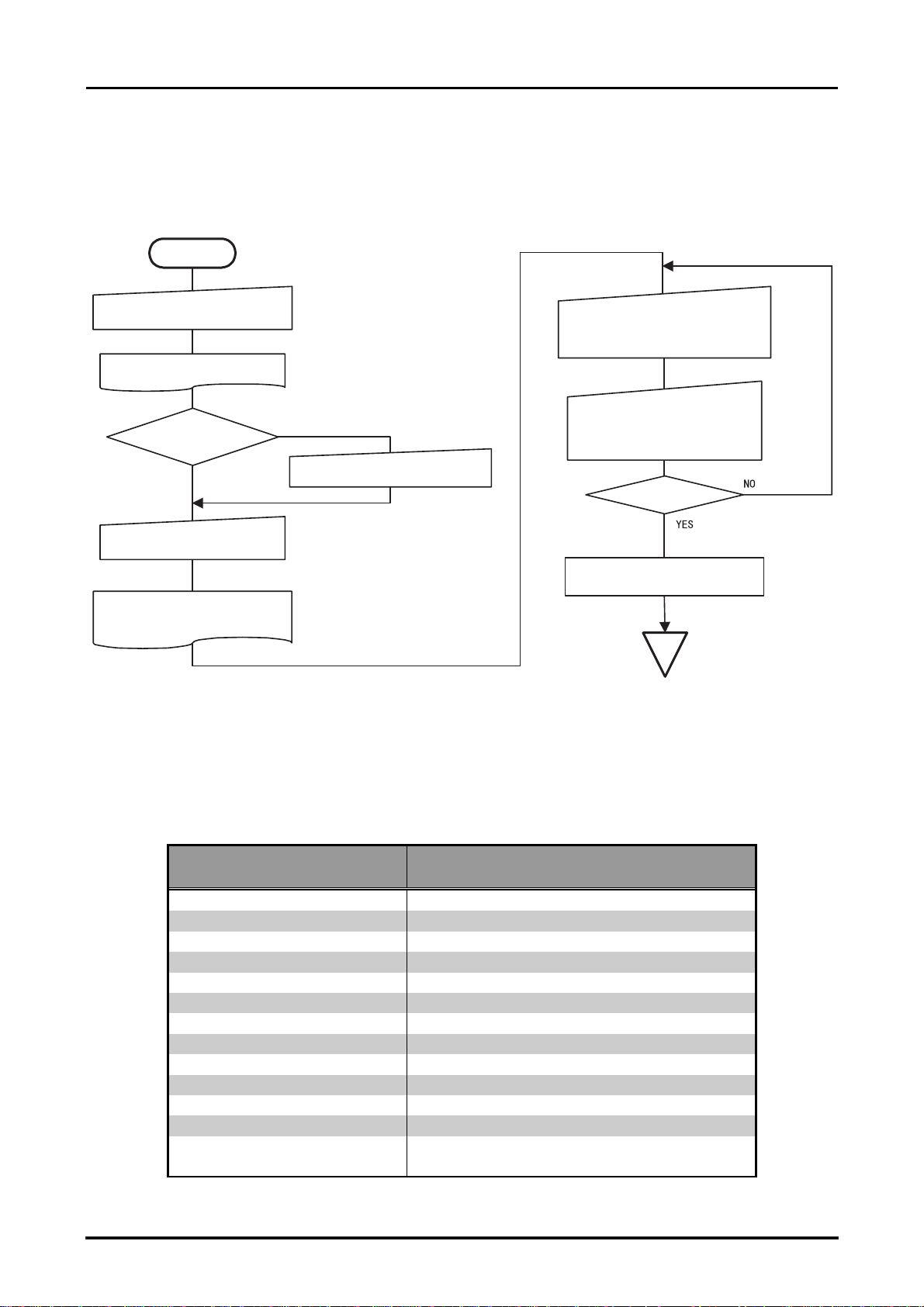

1.2.6 Default Setting Mode 2

Refer to the following f lowchart for the default sett ing mode 2.

START

FX-880 Service Manual

Chapter 1 Product Description

H o ld in g d o w n

LF/FF

s w itc h e s , tu r n th e p rin te r o n .

Language selection sheet

C hange the language?

Push down

Select the m enu and the m ethod,

and the current settings are printed.

Tear off/ B in

NO

Tear off/ Bin

and

YES

sw itch.

Figure 1-5. Flowchart f or Def aul t setting mode 2

Push down

select the aim ed language.

Lo ad/E ject

s w itc h to

R eferring to the Font and Tear

o ff/ B in L E D s , p u s h

sw itch to se le ct the m e nu.

R eferring to the P ause and Paper

O u t L E D s , p u s h

to change the setting value.

T u rn th e p rin te r o ff to s a v e th e

Load /Eject

Finish?

settin gs.

END

Tear off/Bin

sw itch

1.2.6.1 Setting Items

Setting values available for the default set ting mode including factory sett ings are as shown in the

following table:

Table 1-13. Setting Values Available for Default Setting Mode 2

Items Setti ng values (BO LD f ont : factory setting)

Page length for front tractor 3 inch, 3.5 inch, 4 inch, 5.5 inch, 6 inch, 7 inch, 8 inch, 8. 5 inch,

11 inch

Page length for rear tractor 3 inch, 3.5 inch, 4 inch, 5.5 inch, 6 inch, 7 inch, 8 inch, 8.5 inch,

11 inch

Character table Standard version:

Italic,

Abicomp, Roman 8, ISO Latin 1

NLSP version:

Italic,

PC857, PC866, PC869, MAZOW IA, Code MJK, ISO 8859-7,

ISO Latin 1T, Bulgar ia, PC774, Estonia, ISO 8859-2, PC866

LAT.

International character set for

Italic table

Italic U.S.A.

Denmark 1, Italic Sweden, It alic Italy, Italic Spain 1

, 70/6 inch, 12 inch, 14 inch, 17 inch

, 70/6 inch, 12 inch, 14 inch, 17 inch

PC437

PC437

, PC850, PC860, PC863, PC865, PC861, BRASCII,

, PC850, PC437 Greek, PC 853, PC855, PC852,

, Italic France, Italic Germany, Italic U.K., Italic

Rev. A

1-11

Page 21

FX-880 Service Manual

2

Chapter 1 Product Description

1.2.7 EEPROM Clear Function

You can change some parameters into the factory settings to perform panel operation easily.

Pressing

default settings into the factory settings:

Tear off / Bin

Table 1-14. Cleared Items and Values on EEPROM (Standard M odel)

Character table selection PC437

Page length for rear tractor 11 inch

Page length for front tractor 11 inch

Page length for CSF bin 1 22 inch

Page length for CSF bin 2 22 inch

TOF adjustment value for rear tractor 8.5 mm

TOF adjustment value for front tractor 8.5 mm

TOF adjustment value for CSF bin 1 8.5 mm

TOF adjustment value for CSF bin 2 8.5 mm

TOF adjustment value for rear manual insertion 8.5 mm

TOF adjustment Value f or front manual insertion 8.5 mm

Bottom margin for rear tractor 11 inch

Bottom margin for front tractor 11 inch

Font Selection Draft 10 cpi

Print direction setting Bi-D

I/F mode selection Auto

Auto I/F waiting time setting 10 sec.

Auto line feed Off

Auto tear off Off

Skip over perforation Off

High speed draft On

Input buffer On

Software ESC/P

0 slash Off

Buzzer On

Auto CR Off

Tear-off adj ustment value 0

Manual insertion time 2 or 3 sec.

Tear-off wait time 3 sec.

I/F timing data BUSY timing data

TOF minimum value 4.2 mm

Paper edge length 0

Paper length for rear m anual insertion 22 inch

Paper length for front manual insertion 22 inch

sub number for customization Standard

Load / Eject

and

switches at same time while turning on the printer turns the

Item Value

Rev. A

1-1

Page 22

3

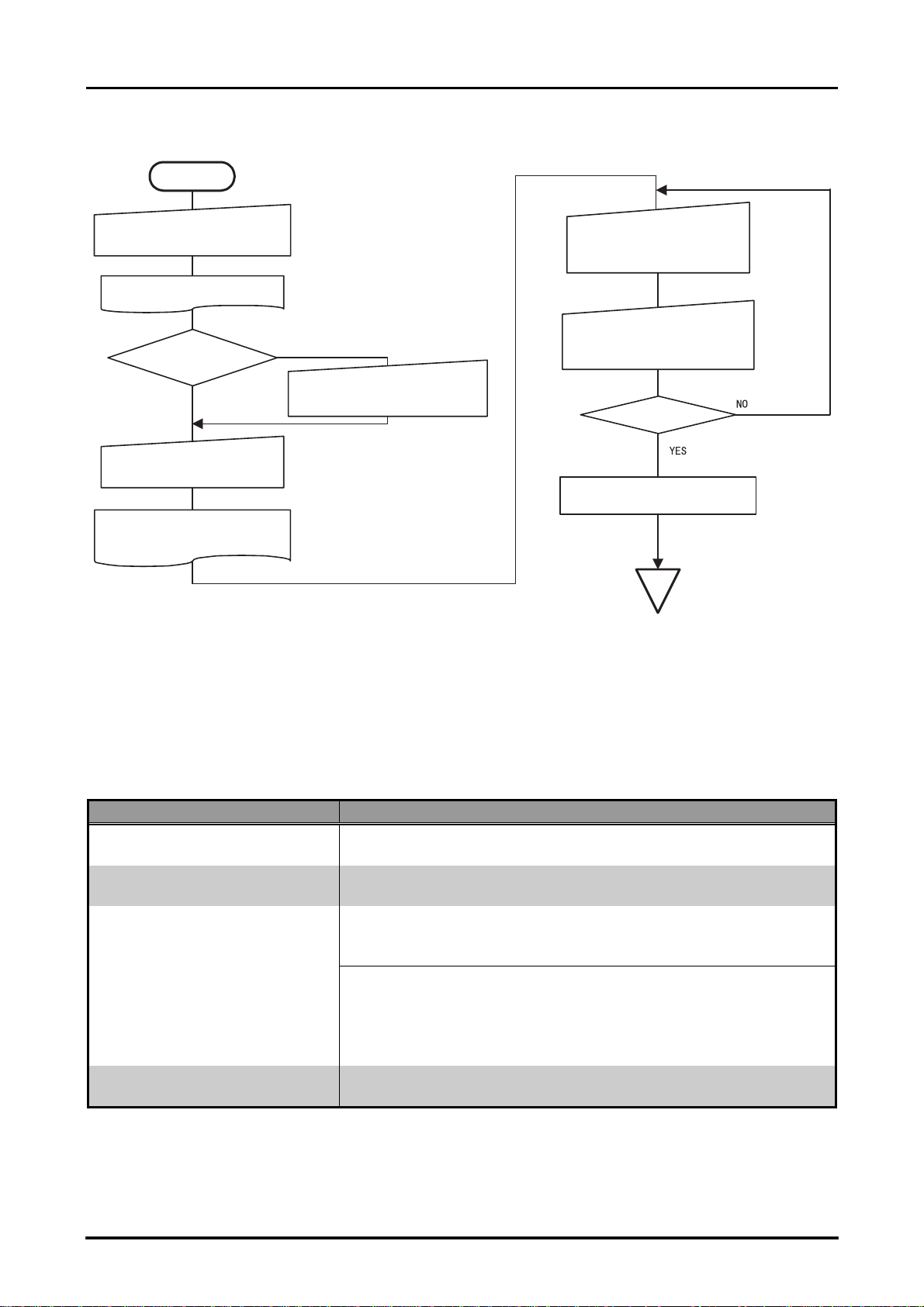

1.2.8 Bi-D Adjustment

Refer to the following f lowchart for the Bi-D adjustment.

START

FX-880 Service Manual

Chapter 1 Product Description

H o ld in g d o w n

the printer on, and the first

alignm ent patter is printed along

w ith th e g u id e fo r th e a d ju s tm e n t.

[S te p A ]

S e le c t th e n u m b e r fo r th e m o s t

closely aligned pattern by

pressing the LF/FF sw itch and

Load/E ject sw itches.

[S te p B ]

Fix the selected num ber by

p re s s in g T e a r O ff/B in s w itc h , a n d

the next alignm ent patter is

printed.

R epeat S teps A and B until finishing the

a d ju s tm e n t fo r th e fo llo w in g m o d e s :

1 . H ig h s p e e d d ra ft m o d e

2 . D ra ft m o d e

3 . N L Q m o d e

Pause sw itch,

tu rn

T u rn th e p rin te r o ff, a n d th e n e w

settings are stored in the non-volitile

memory.

END

Figure 1-6 . Bi-D Adjustment flowchart

Rev. A

1-1

Page 23

&+$37(5

OPERATING PRICIPLES

Page 24

FX-880 Service Manual

Chapter

2 Operating Principles

2.1 MAIN COMPONENTS

This printer is divided into several main components for easy removal and repair. The main

components are :

z C229MAIN : Control board

z C229PSB/PSE : Power supply board

z C229PNL : Operation panel board

z M-3J10 : Printer mechanism

z Housing : Upper case, Lower case, Rear sheet guide, Knob, Printer cover

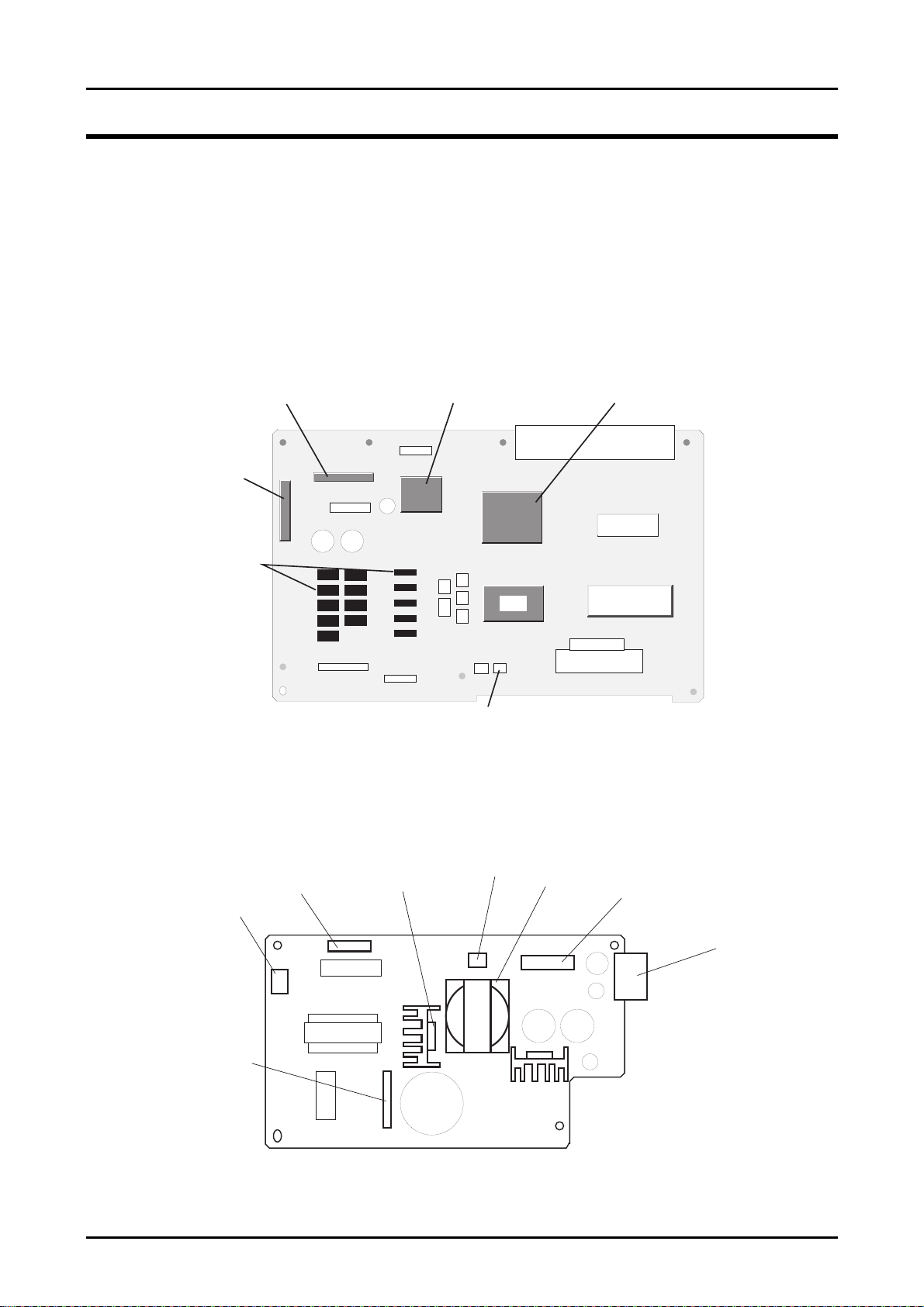

2.1.1 C229MAIN Board

The C229MAIN board consists of CPU TMP96C141AF (IC3), gate array E05B50 (IC2), EEPROM

AT93C46 (IC4), 1/4M PSRAM (IC5), 2/4M PROM (IC7), driver elements, and so on.

P F M o to r D riv e r IC

CN3

Print H ead D river

C R M o to r D r iv e IC G a te a rra y

CPU

EEPRO M

E05B 50

PSRAM

PRO M

Figure 2-1 . C229MAIN Component

2.1.2 C229PSB/PSE Board

The C229 PSB/PSE power supply board consists of Transformer, Switching FET, Regulator IC,

Diode bridge, Fuse, Photo-coupler, and so on.

Fuse

CN1

Switching FET

Photo-coupler

Transform er

R e g u la to r IC

Rev. A

CN2

D iode B ridge

Figure 2-2. C229PSB/PSE Component

2-1

Page 25

FX-880 Service Manual

2

Chapter

2 Operating Principles

2.2 PRINTER MECHANISM

This printer mechanism consists of Printhead, Paper feed mechanism, Carriage movement

mechanism, Tractor feed mechanism, Platen gap adjustment mechanism, Ribbon feed

mechanism, PF motor, CR motor, detectors, and so on.

2.2.1 Printhead

The printhead prints data from the control board on paper using the ink ribbon. The printhead is

mounted on the carriage unit.

2.2.2 Paper Feed Mechanism

The paper feed mechanism picks up paper and transports it to the printhead, then ejects it step by

step or continuously driven by the PF motor. PF motor drives the paper feed mechanism gears

and the platen roller. The top of form and paper out condition are detected by front and rear PE

detector, respectively.

2.2.3 Carriage Movement Mechanism

The carriage movement mechanism carries the carriage unit left and right along the CR guide

shaft and mechanism frame and stops it at any position for printing. It is driven by the torque sent

from the CR motor via the timing belt. Home position is detected by the HP (home position)

detector at power on and CR motor phase changing timing.

2.2.4 Tractor Feed Mechanism

The tractor feed mechanism feeds continuous paper to the printhead and ejects it. The torque

from the PF motor is transferred to the tractor unit via the release mechanism in the paper feed

mechanism. The release mechanism switches the PF motor torque between cut sheet feeding and

continuous paper feeding by the release lever. This printer is equipped with several tractor feeding

methods (front / rear push tractor feeding, front / rear push & pull tractor feeding and front / rear

pull tractor feeding), which is selected according to the tractor unit setting positions and the lever

positions. The tractor detector detects the release lever setting position in cut sheet feeding or

continuous paper feeding.

2.2.5 Platen Gap Adjustment Mechanism

The platen gap (the gap between the platen and the printhead) adjustment mechanism consists of

CR guide shaft, parallelism adjustment bushing, PG adjust lever and PG detector. PG adjust lever

is attached to the left side of the CR guide shaft. The bushings are attached to the both sides of

the frame. As the both sides part of CR guide shaft is eccentric toward external form of it,

printhead approaches or recedes from the platen roller to turn the PG lever forward or backward.

PG detector detects PG lever position. If the lever is set 2nd and more position, the printer gets

into copy mode.

2.2.6 Ribbon Feed Mechanism

The CR motor drives the ribbon feed mechanism via the timing belt. The ribbon feed mechanism

has the sun and planetary gear system. No matter the carriage unit is driven left and right, the ink

ribbon is driven in one direction.

Rev. A

2-

Page 26

Chapter

3

FX-880 Service Manual

2 Operating Principles

Tractor

Front P E detector

Rear PE DEtector

P a ra lle lis m B u s h in g

Platen R oller

P rinthead

C R G uide S haft

R elease Lever

R elease D etector

P F M o to r

P a ra lle lis m B u s h in g

R ibbon Feed M echanism

PG Adjust Lever

Carriage Unit

HP Detector

Tim ing Belt

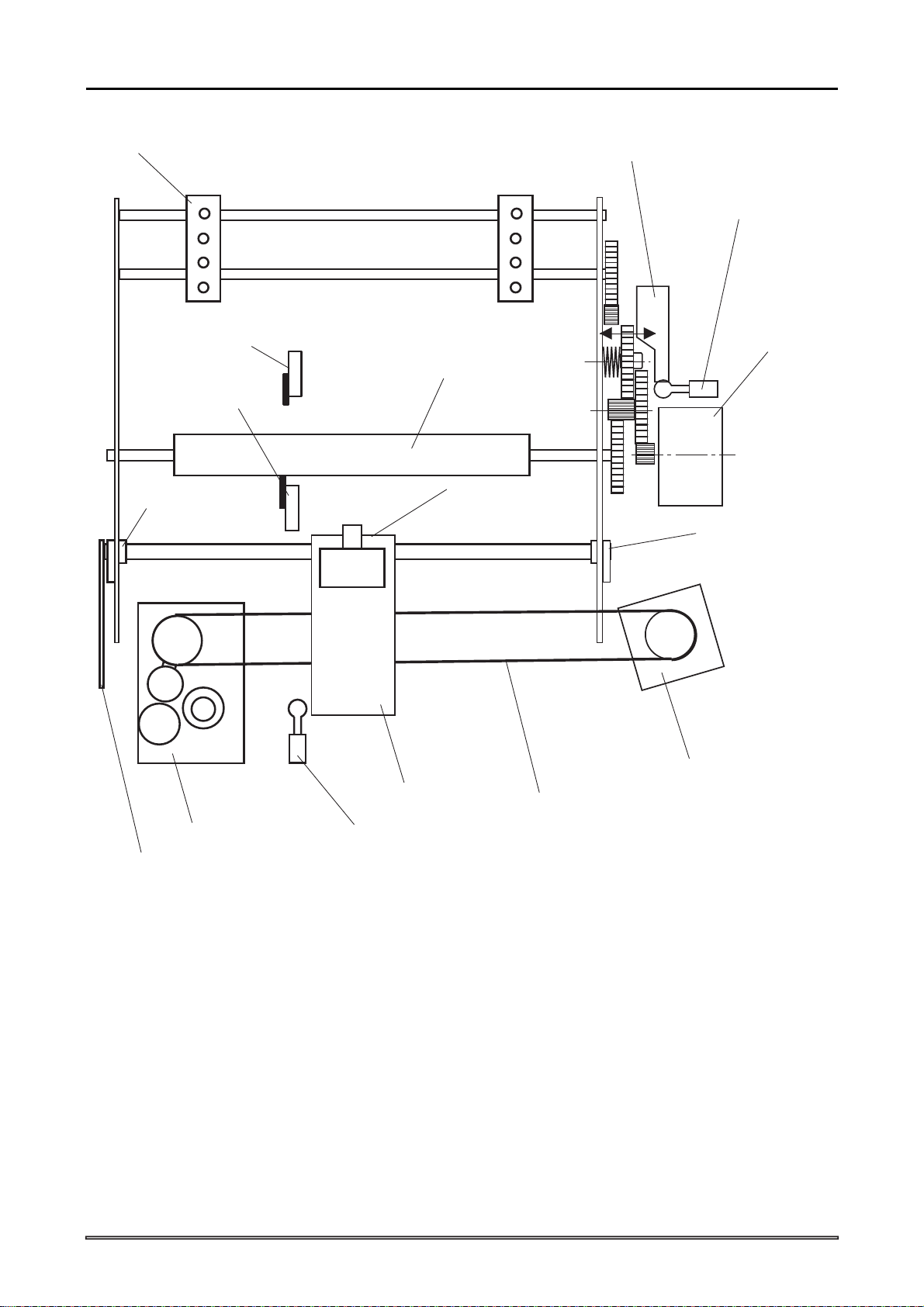

Figure 2-3. Printer Mechanis Outline

CR Motor

Rev. A

2-

Page 27

FX-880 Service Manual

4

Chapter

2 Operating Principles

2.3 CIRCUIT OPERATION

2.3.1 C229PSB/PSE Power Supply Circuit

This printer can be powered by either of two power supply boards: the C229PSB (120V) board or

the C229PSE (230V) board. The function of these two boards is the same , except for a difference

in the primary circuitry. The power supply outputs the DC current necessary to drive the printer

control circuit and drive the mechanism. The input voltages and fuse ratings for these boards are

as shown in the following table:

Table 2-1. Input Voltage and Fuse Rating

Board Input Voltage Fuse F1 Rating

C229PSB 85-138VAC 4A, 125V or 250V

C229PSE 187-276VAC T2.0AH, 250V

The power supply circuit outputs voltages used to drive the various control circuits and the

mechanism, as shown in the following table:

Table 2-2. Output Voltages and Applications

Output Voltage Applications

5V•}5% 0.7A

Logic lines

(Type-B I/F output is included.) Detectors

Panel Switches & LEDs

35V•}6% 0.8A

CR Motor

PF Motor

Printhead

The power supply circuit consists of the line filter circuit, ZC-RCC (Zero-Cross Ringing Choke

Converter) switching circuit and 5V chopper regulator IC. The AC voltage is first input to the line

filter circuit for higher harmonics absorption, then input to the switching circuit and transformed to

+35VDC. +5VDC is generated from +DC35V by the regulator IC. The over current / voltage

protection circuit is also designed on the board.

The power switch is set in the secondary circuit that is controlled by the signal PSC from the

control panel.

AC Line

In p u t

Line F ilter

ZC-RCC Switching Regulator

- O ver C urrent protection

- O ver V oltage protection

R e g u la to r IC

+35V D C

+5VD C

PSC

Figure 2-4. Power Supply Circuit Block Diagram

Rev. A

2-

Page 28

FX-880 Service Manual

5

Chapter

2 Operating Principles

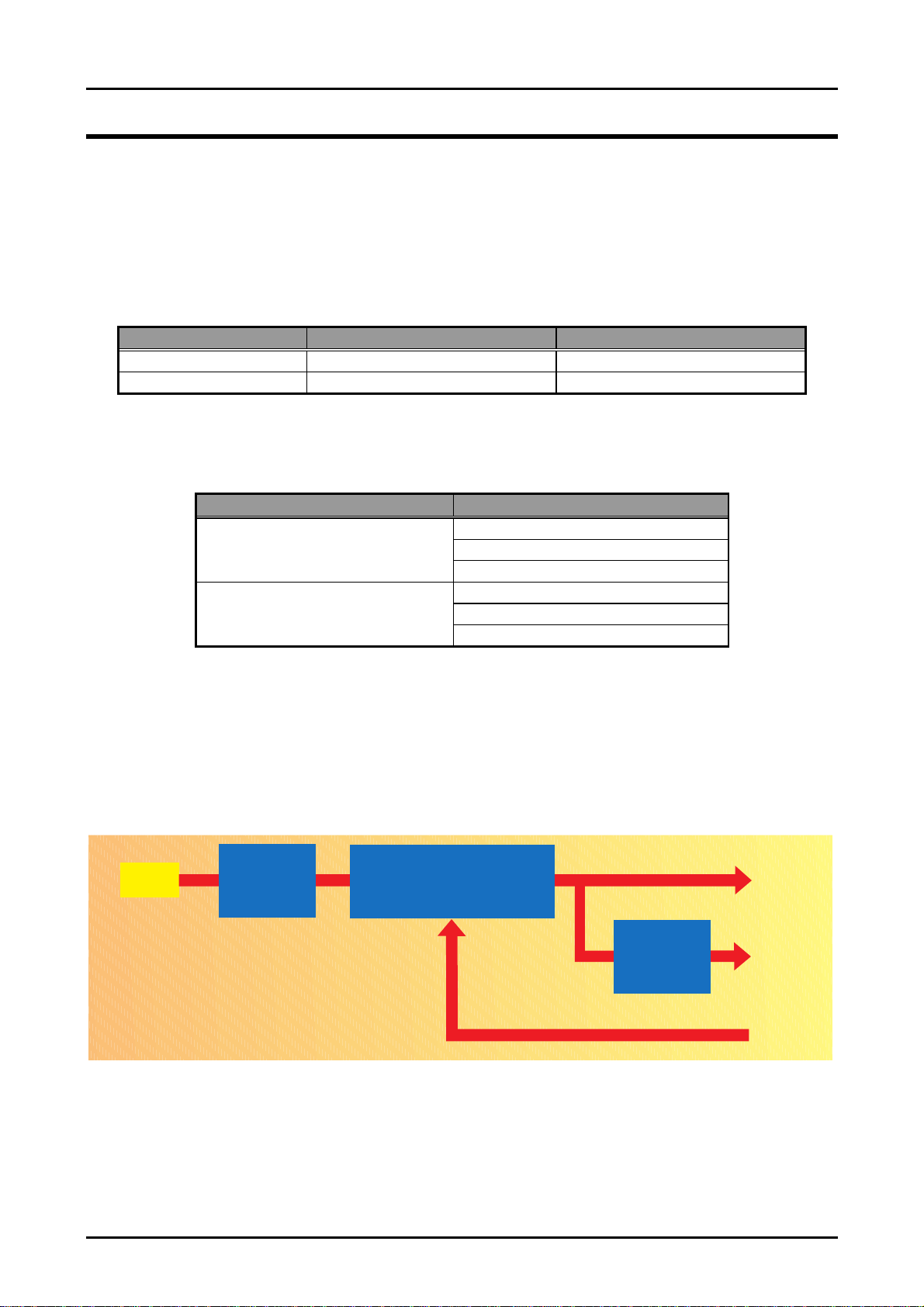

2.3.2 C229MAIN Board Circuit

The C229MAIN board is the control circuit board of this printer. This board consists of several IC

chips and drivers, as shown in the table below:

Table 2-3. Function of the Main IC

Element Location Function

TMP96C141AF IC3 16 bit CPU runs at 14.47MHz

- Main controller

- Detectors control

- CR Motor Control

E05B50 IC2 Gate array : System Controller

- Parallel I/F control

- Option Type-B I/F control

- Panel Switch, LED control

- Printhead Control

- PF Motor Control

- CR Motor Current control

PST594E IC1 Reset IC : Hardware reset function

AT93C46 IC4 EEPROM :

System control data (Market, TTL threshold, Bi-D setting, Page

length, TOF, etc.) containing

PSRAM IC5 1M/4M bit

- Buffer and Working area of CPU & Gate array

ROM IC7 2/4M bit EPROM/ Mask ROM

- Control program containing

SLA7024M IC8 CR Motor driver

A2917SEB IC11 PF Motor driver

Comparator IC12 Power-off signal sensing

O peration

Panel

P a ra lle l I/F

Type-B I/F

(O ption)

PF Motor

Driver

P rinthead

Head Driver

G.A.

E 05B 50

(IC 2 )

CR Motor

Driver

Therm istor

CG

Addres/DATA Bus

PSRAM

ROM

R e s e t IC

EEPRO M

CPU

TM P 96C 01A F

(IC 3 )

+35V D etector

P G D e te c to r

Rear

PE Detector

Front

PE Detector

HP Detector

R elease

Lever D etector

Figure 2-5 . C229MAIN Board Circuit Block Diagram

Rev. A

2-

Page 29

FX-880 Service Manual

6

Chapter

2 Operating Principles

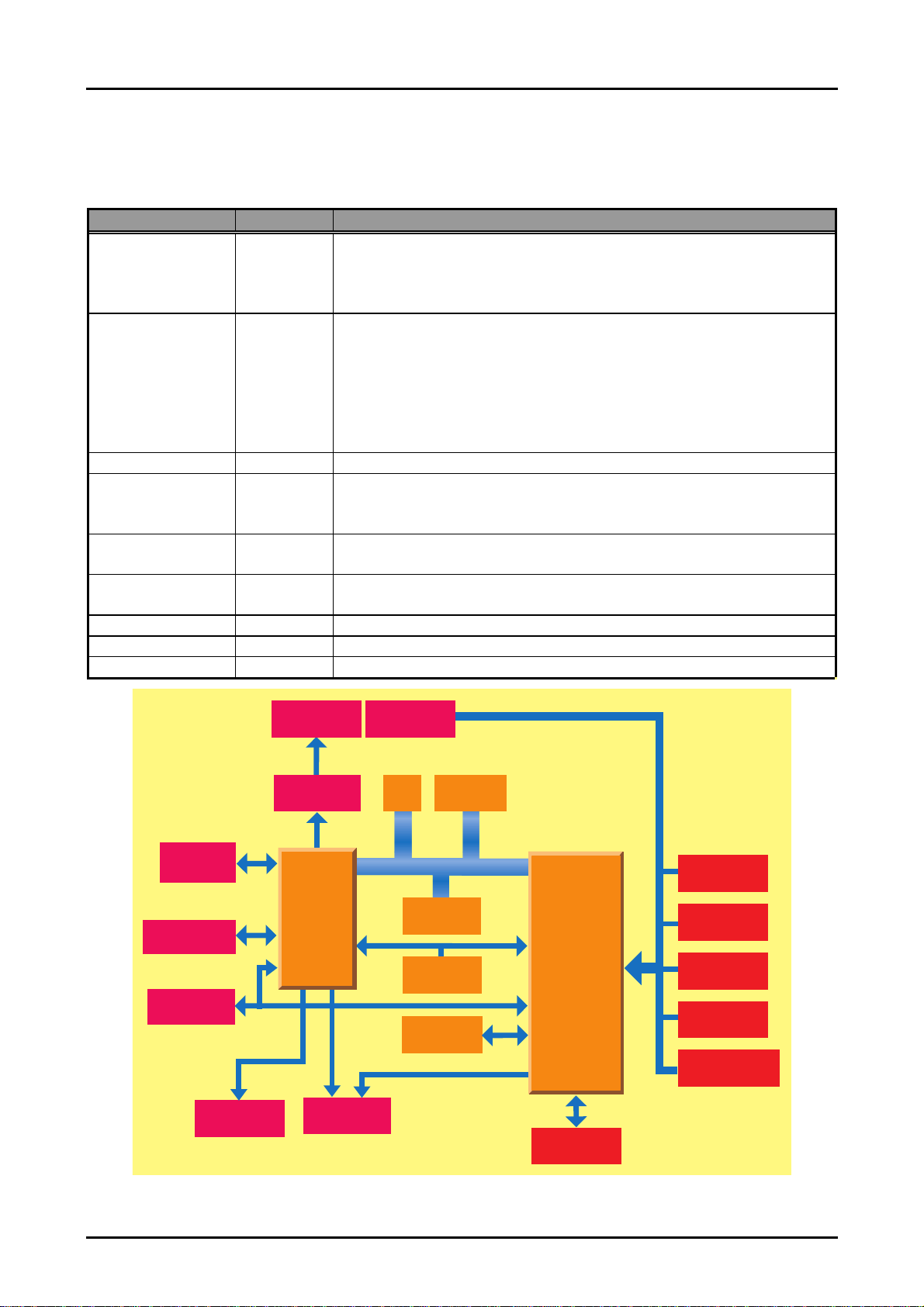

The data from the host computer is stored in the input buffer once, then converted into image data

and transmitted to the printhead through the gate array, as shown in the figure below:

H ost com puter

Print data

conversion

Im age data

tra n s fe r

CPU

D a ta la tc h

and

data output

Gate array

Figure 2-6. Data Flow

Input buffer

Im age buffer

RAM

Printhead driver

circuit

Rev. A

2-

Page 30

TROUBLESHOOTING

&+$37(5

Page 31

FX-880 Service Manual

Chapter

3 Troubleshooting

3.1 OVERVIEW

The printer may exhibit different symptoms for the same problem, which makes troubleshooting

more difficult. This section, however, provides simple and effective ways to facilitate

troubleshooting. The following flowchart illustrates the main steps of the troubleshooting process.

START

Unit Level Tr oubl es hoo ting

Unit Repair of the

C229PSB/PSE Board

Unit Repair of the

C229MAIN Board

Assembly and Adjustment

END

Unit Repair of

M-3J10 Mechanism

Figure 3-1. Troubleshooting Process Flowchart

3.1.1 Main Component Checking Point

The following components can be checked by a simple measurement equipment such as a multimeter, etc.) easily.

Table 3-1. Motor Coil Resistance Test Points

Motor

Connector

Number

PF Motor

(CN8)

CR Motor

(CN9)

Rev. A

Test Pin

Number

(Set Meter to Ohms. Disconnect

Test Method

Motor from Main Board and check it

with Printer Power off.)

1 and3, 2 and 4 Place one lead on pin 1 (pin2) and the

other lead on pin3 (pin 4) each of the

test pins to check the two motor phases.

Common pin : 5,

Test pins : 1, 2, 3

and 4

Place one lead on pin 5 and the other

lead on each of the 4 test pins to check

the two motor phase.

Meter Reading

16.0

Ω ± 10%

(at 25°C par one

phase)

2. 7 Ω ± 10%

(at 25°C par one

phase)

3-1

Page 32

2

Table 3-2. Printhead Solenoid Resistance

FX-880 Service Manual

Chapter

3 Troubleshooting

Part Test Pin

Number

(See the figure

berlow.)

Printhead

Common pin C1 :

Test pin 1, 4

Common pin C2 :

Test pin 8

Common pin C3 :

Test pin 2, 6

Common pin C4 :

Test pin 5, 9

Common pin C5 :

Test pin 3, 7

Test Method

(Set Meter to Ohms. Disconnect

Motor from Main Board and check it

with Printer Power off.)

For example, place one lead on pin C1 and

the other lead on Test pin 1 to check #1 pin

Printhead solenoid. The test pin num ber is

just match with the printhead solenoid (dot

wire) number.

Printhead Connenctor

Specifications

8.19 ± 0.8Ω (at 25°C)

Printhead

2

6

C1

C2

4

View A

C5

8

9

1

T

T

3

5

7

Printhead Connenctor

C4

C3

Figure 3-2. Printhead Connector Pin Alignment

Table 3-3. Printhead Driver Test Pint

Transistor Numbers Test Method

(Set meter to diodes. Check

power off.)

Q2, Q3, Q4, Q5, Q6,Q7, Q8,

Q9, Q10

Check from base to collector,

and check from base to

emitter. Reverse leads and test

again.

Q11,Q12, Q13, Q14, Q15,

Q16, Q17, Q18, Q19, Q20

A

Meter Reading

Not open and not shorted from

base to collector, base to

emitter.

Rev. A

3-

Page 33

3

Table 3-4 Detector Test Point

FX-880 Service Manual

Chapter

3 Troubleshooting

Detector Connector

Number

HP Detector

(CN4)

Front PE Detector

(CN6)

Release Lever Detector

(CN10)

PG Detector

(CN11)

Printhead thermistor Place one lead on pin T and the

(Set Meter to Ohms. Check the

Place one lead on pin 1 and the

other lead on pin 2, and toggle the

detector actuator.

Place one lead on pin 1 and the

other lead on pin 2, and toggle the

detector actuator.

Place one lead on pin 1 and the

other lead on pin 2, and toggle the

detector actuator.

Place one lead on pin 1 and the

other lead on pin 2, and move the

detector actuator from -0 to 6.

other lead on other pin T to check

the resistance.(Refer to Fig.3-2.)

Test Method

Printer power off.)

Meter Reading

Meter should toggle between

open and short. (LOW: within

CR Home position.)

Meter should toggle between

open and short. (HIGH:

paper is installed in the

printer.)

Meter should toggle between

open and short. (HIGH:

Friction Feed mode.)

Meter should toggle between

open and short.

(HIGH: PG -1 ~ 3.)

Approx. 14KΩ (at 17°C)

3.1.2 Error

As this printer checks its condition by itself at power-on, when it finds any trouble, it indicates it

with error indication buzzer and LEDs. The error Indications and countermeasures are shown in

the table below:

Error LED Status Buzzer Cause Disposition

Paper out error Paper Out: On

Pause: On

Release lever

error

Fatal error All LEDs : Blink

Note: Symbols used in the table represent the following:

“∗” : A beep sounds for approx. 100 ms with the interval of approx. 100ms.

“-“ : A beep sounds for approx. 500 ms with the interval of approx. 100ms.

Pause: ON

***

-----

The printer fails to load

paper.

The release lever is set

to a wrong position.

The carriage unit gets

into out of control or

power supply voltage

becomes incorrect.

Set paper to the

printer correctly.

Set the release

lever to the

correct position.

Turn off the

printer once and

turn it back on.

Rev. A

3-

Page 34

FX-880 Service Manual

4

Chapter

3 Troubleshooting

3.2 UNIT LEVEL TROUBLESHOOTING

You may be able to Identify the defective unit just from the symptom displayed. The table below

provides the symptoms for a number of failures, so that you can easily Identify the problem. Once

the problem has been identified, refer to the flowchart listed In the right-hand column of the table

below to determine the case of the problem.

Table 3-5. Symptoms and Problems

Symptom Problem See Page

Printer fails to operate

when power is on.

Abnormal carriage

operation at power on.

Printing is faulty during

self-test, but carriage

operation is normal.

Abnormal paper

feeding

Abnormal control panel

operation

Data sent by the host

computer is printed

incorrectly

z Carriage dose not move.

z Control panel indicator LEDs do not light.

z Carriage moves away from the home position at

power on.

z Carriage returns to home position correctly, but the

printer then fails to enter the READY mode.

z No printing at all.

z Faulty printing some of the dots are not printing.

The printer prints but feeds paper Incorrectly.

When the LF/FF switch is pressed, no paper is fed.

z Carriage operates normally at power on, and self-

test is executed correctly, but data is not printed.

z Data from the computer is printed incorrectly.

3-5

3-6

3-7

3-8

3-9

3-10

The repair procedure flowcharts use the following symbols:

START

Start

Preocessing

Forwarding to

another items

END

Decision

Figure 3-3. Symbols Used in the Flowcharts

Branching

Return to the

Start of the item

END

Rev. A

3-

Page 35

5

1. Printer fails to operate when power is on.

START

FX-880 Service Manual

Chapter

3 Troubleshooting

Is AC input voltage normal?

120V version: 85 - 138V

230V version: 187 - 276V

YES

Are the fuses F1 on

C229PSB/PSE bl own?

NO

Measure the +35V line at pin 7

or 8 of CN2 on C229PSB/PSE.

Is output voltage

normal?

YES

Measure t he +5V line at pin 3 or 4

of CN2 on C229PSB/PS E.

NO

NO

YES

Use the correct AC input voltage.

No fluctuation from AC voltage range is

NO

Is the ne w f use also blow n w h en

power is turned on again?

permitted.

Replace the fuse.

YES

Replace the C229

PSB/PSE.

Rev. A

Is output voltage

normal?

YES

Verify each motor and printhead solenoid

resistance,referring to Table 3-1 and Table 3-2.

Are the resistance

normal?

YES

Replace the C229MAIN.

NO

NO

END

Figure 3-4. Flowchart (1)

Replace the C229

PSB/PSE.

Replace the applied

unit.

3-

Page 36

6

2. Abnormal carriage operation at power on.

START

FX-880 Service Manual

Chapter

3 Troubleshooting

Are all c onnectors connecting the

C229MAIN board and printer

mechanism?

YES

Dose the carriage move

to the home position?

YES

Replace the C229MAIN Board.

NO

NO

Reinsert the connectors correctly.

NO

Is the fault solved?

YES

END

See the troubleshooting for

Printer Mechanism.

NO

Is the fault solved?

Rev. A

YES

END

END

Figure 3-5. Flowchart (2)

3-

Page 37

Chapter

7

g

j

g

g

g

g

j

y

3. Printing is faulty during self-test, but carriage operation is normal.

START

FX-880 Service Manual

3 Troubleshooting

Is AC input voltage normal?

120V version: 85 - 138V.

230V version: 187 - 276V.

YES

Holding down the LF/FF or

Load/E

printer to start self test printin

Is the vertical

YES

ect switch, turn on the

Is printin

executed?

line ali

Is any dot

missin

YES

ned?

YES

?

NO

NO

NO

NO

.

Perform the Bi-D

ad

ustment.

Is the fault solv ed?

END

Use the correct AC input v ol tage.

No fluctuation from AC v ol ta

permitted.

Are all connectors connec ting the

C229MAIN board and printer

mechanism?

YES

NO

YES

e range is

Reinsert the connectors correctly.

NO

NO

Is the fault solv ed?

YES

END

Rev. A

YES

Verify FFCs are properly inserted

and have continuit

defective, replace t he pri nthead.

Is the fault solv ed?

. If they are not

NO

YES

END

Adjust the Platen Gap.

Replace the C229MAIN

board.

END

Figure 3-6. Flowchart (3)

3-

Page 38

8

4. Abnormal paper feeding

START

FX-880 Service Manual

Chapter

3 Troubleshooting

Is the paper loaded

correctly?

YES

Is the connector CN5

or CN6 connected

correctly?

YES

Dose the platen knob rotate

smoothly when it is turned

manually at power off?

YES

Replace the

C229MAIN board.

NO

NO

Load the paper

correctly.

Reinsert the connector

CN5 or CN6 correctly.

NO

Is the fault

solved?

YES

END

NO

Refer to the

troubleshooting for

Printer Mechanism.

Rev. A

NO

Replace the

C229MAIN board.

Is the fault

solved?

YES

Is the fault

solved?

NO

YES

Refer to the

troubleshooting of

Printer Mechanism.

END END END

Figure 3-7. Flowchart (4)

3-

Page 39

9

5. Abnormal control panel operation

START

FX-880 Service Manual

Chapter

3 Troubleshooting

Do the switches

have clicks?

YES

Is the fault

solved?

YES

NO

Replace the Operation Panel.

NO

Replace the C229MAIN board.

NO

Is the fault

solved?

YES

Verify t ha t t he harnes s for the operation

panel is properly inserted and have

continuity . I f it is connected, replac e t he

harness.

END

END

END

Figure 3-8. Flowchart (5)

Rev. A

3-

Page 40

0

6. Data sent by the host computer is printed incorrectly.

START

Execute the printer self test.

FX-880 Service Manual

Chapter

3 Troubleshooting

Dose the self test print

normally?

YES

Verify the default setting.

Is the interface

cable connected

correctly?

YES

Replace the

C229MAIN

board.

NO

Refer to the other

troubleshooting items.

NO

Replace the interface cable.

NO

Is the fault sol ved?

YES

END

Rev. A

Is the fault sol ved?

YES

END

NO

Increase the setting position of

the paper thickness lever.

Is the fault sol ved?

YES

END

Figure 3-9. Flowchart (6)

NO

Adjust the platen gap.

(Refer to chapter 4.)

3-1

Page 41

FX-880 Service Manual

Chapter

3 Troubleshooting

3.3 UNIT REPAIRING OF THE POWER SUPPLY BOARD

This section is necessary only for servicers who repair to the component level. Servicers who

perform only board replacement can ignore this section.

The table below lets you troubleshoot problems with the power supply board (C229PSB/PSE). The

table provides various symptoms, likely cases, and checkpoints. Checkpoints include waveforms,

resistance, and other value to be checked to evaluate the operation of each component.

Table 3-6. Repair of the C229PSB/PSE

Condition Cause Checkpoint Solution

Symptom

Fuse F1 is

blown.

Transformer

(T1) is open.

Verify whether the fuse is blown or

not.

Verify the coil of transformer by a

multimeter.

Verify the waveform at drain of Q1.

Replace the

C229PSB/

PSE board.

Replace the

C229PSB/

PSE board.

The printer

dose not

operate at

all.

+35V line is

defective.

Switching

FET (Q1) is

defective.

Q2 or Q3 is

defective.

Replace the

C229PSB/PS

E board.

Figure 3-10. Drain of Q1

Verify the waveform at corrector of

Q2 or Q3.

Replace the

C229PSB/

PSE board.

Rev. A

Figure 3-11. Corrector of Q2/Q3

3-11

Page 42

2

Symptom

FX-880 Service Manual

Chapter

Table 3-7. Repair of the C229PSB/PSE (continued)

Condition Cause Checkpoint Solution

Verify the waveform at pin 5 or 7 of

PC1.

+35V line is

defective.

PC1 is

defective.

Figure 3-12. Waveform of PC1

3 Troubleshooting

Replace the

C229PSB/

PSE board.

The printer

dose not

operate at

all.

+5V line is

defective.

Regulator IC

(IC51) is

defective.

Verify the waveform at pin 5 of IC51.

Replace the

C229PSB/

PSE board.

Figure 3-13. OSC of IC51

Verify the waveform at pin 9 or 10 of

IC51.

Replace the

C229PSB/

PSE board.

Figure 3-14. Output of IC51

Rev. A

3-1

Page 43

FX-880 Service Manual

3

Chapter

3 Troubleshooting

3.4 UNIT REPAIRING OF THE MAIN BOARD

This section is necessary only for servicers who repair to the component level. Servicers who

perform only board replacement can ignore this section.

The table below lets you troubleshoot problems with the main board (C229MAIN). The table

provides various symptoms, likely cases, and checkpoints. Checkpoints include waveforms,

resistance, and other value to be checked to evaluate the operation of each component.

Table 3-8. Repair of the C229MAIN

Condition Cause Checkpoint Solution

Symptom

Verify the voltage waveforms for the

+5VDC line (IC1, pin 3) and for the

reset signal (IC1, pin 1) when the

power is on.

The printer

dose not

operate at

all.

The CPU

dose not

operate.

The reset

circuit is not

operational.

Selection

control ROM

is abnormal

5V line

Replace the

C229MAIN

board.

/RESET

Figure 3-15. Reset Signal

Verify the signal at pin 22, IC7 or pin

30, IC6 which changes between

HIGH and LOW.

Replace the

C229MAIN

board.

Figure 3-16. Chip Select Signal for

Program ROM

Rev. A

3-1

Page 44

4

Symptom

The printer

dose not

operate at

all.

FX-880 Service Manual

Chapter

3 Troubleshooting

Table 3-9. Repair of the C229MAIN (continued)

Condition Cause Checkpoint Solution

Verify the oscillator signal at pin 26

or 27 of the CPU (IC3).

Replace the

The CPU

dose not

The CPU is

defective.

C229MAIN

board.

operate.

The carriage

operates

abnormally.

The carriage

dose not

operate at

all.

IC8 is

defective.

Figure 3-17. Clock Signal of CPU

Verify the CR motor phase control

signals at pin 5, 6, 16,17, and motor

drive signals at pin 1, 8, 11, 18 of

IC8.

Pin 5 of IC8

Pin 1, of IC8

Figure 3-18.

CR Motor Control Signal

Replace the

C229MAIN

board.

Rev. A

3-1

Page 45

5

Symptom

FX-880 Service Manual

Chapter

3 Troubleshooting

Table 3-10. Repair of the C229MAIN (continued)

Condition Cause Checkpoint Solution

Verify the PF motor phase control

signals at pin 1, 2, 23, 24, and

motor drive signals at pin 3, 6, 18,

21 of IC11.

The paper

feeds

abnormally.

Self test

printing is

abnormal.

The paper

dose not

feed at all.

The self test

printing is

not executed

or a

particular dot

is not

printed.

IC 11 is

defective.

Any

transistor of

Q2 - Q10 is

defective.

Pin 1 of IC11

Pin 3 of IC 8

Figure 3-19.

PF Motor Control Signal

Verify the printhead drive signal at

the corrector and base of Q2 - Q11

BASE of Q5

CORRECTOR of Q5

Replace the

C229MAIN

board.

Replace the

C229MAIN

board.

Figure 3-20.

Pritnhead Drive Signal

Any

transistor

from Q11 to

Q25 is

-

Replace the

C229MAIN

board.

defective.

Data from

the host

computer is

printed

incorrectly.

Rev. A

Data

corruption

occurs when

the interface

is used.

IC2 or CPU

is defective. -

Replace

C229MAIN

board.

3-1

Page 46

6

3.5 REPAIRING THE PRINTER MECHANISM

FX-880 Service Manual

Chapter

3 Troubleshooting

For detailed procedures for replacing or adjusting matter, refer to Chapter 4,

Assembly

try find other potential causes.

Problem: The CR motor fails to operate.

The CR motor fails to

drive the timing belt

after power on.

Problem: The carriage dose not operate when power on (after carriage has been centered

The CR motor rotates,

but the carriage dose

not move.

The carriage moves to

the left slightly, then

stops.

The carriage moves to

the left or right end,

then stops.

Problem: Self test printing is not executed.

The carriage moves,

but dose not print.

and Chapter 5,

Symptom Cause Checkpoint Solution

prior to power on manually).

adjustments

Table 3-11. Repairing the Printer Mechanism

Foreign substances

are lodged in the

mechanism.

The CR motor is

defective.

The belt drive or

driven pulley is

defective.

The timing belt is

defective.

The carriage

movement is not

smooth.

The HP detector is

defective.

The printhead FFC

common wires are

disconnected.

The printhead is

defective.

. If a problem or symptom occurs, refer to following tables to

Manually move the

timing belt to see if the

motor can rotate freely.

Measure the motor coil

resistance. It should be

about 16 ohms. If the

coil is shorted, also

verify CR motor driver

IC8 on the main board.

Verify the pulleys which

are broken or worn.

Verify the timing belt is

set correctly to the

carriage.

Verify whether the timing

belt is broken or not.

Verify whether the

carriage moves

smoothly when move

manually.

Verify the HP detector

by multi meter.

Verify whether FFC is

set or not to the

printhead or the main

board.

Measure the printhead

coil resistance. It should

be about 8 ohms. If the

printhead is shorted,

also verify the drivers on

the main board.

Disassembly and

Remove the

foreign substance.

Replace the CR

motor (and main

board, if

necessary).

Replace the

pulleys.

Reset the belt to

the carriage.

Replace the belt.

Clean and

lubricate the CR

guide shaft or

frame. Otherwise,

replace the CR

motor.

Replace the HP

detector.

Set the FFC to the

printhead or the

main board

correctly.

Replace the

printhead, (and

drivers , if

necessary).

Rev. A

3-1

Page 47

FX-880 Service Manual

7

Chapter

Table 3-12. Repairing the Printer Mechanism (continued)

Symptom Cause Checkpoint Solution

Problem: Self test printing is not executed.

A particular dot is

missing.

The printing is too

light, or the print

density is not

uniform.

Problem: Paper feed is abnormal.

Printing is performed

but the paper is not

fed or is fed

uniformly. The PF motor dose

Problem: The ribbon is abnormal.

The ribbon is not

turning.

The ribbon feed

properly only when

the carriage moves

in one direction (i.e.,

it fails to feed when

the carriage moves

in the other

direction).

The printhead is

defective.

The printhead is

defective.

The platen gap is

properly adjusted.

Foreign substances

are lodged in the

paper path.

not drive the

mechanism.

The PF motor is

defective.

The ribbon cartridge is

defective.

Foreign substances

are caught in the

gears.

The planetary gear in

the ribbon drive gears

is defective.

Measure the printhead coil

resistance. It should be

about 8 ohms. If the

printhead is shorted, also

verify the drivers on the

main board.

Verify whether head wire is

born or not.

Verify whether head wire is

born or not.

Set the gap adjustment

lever to the first position,

and check the platen gap.

The correct PG is 0.365 ±

0.015.

Verify the paper path

whether any foreign

substance is put on.

Verify the mechanism

whether any foreign

substance is put on.

Measure the motor coil

resistance. It should be

about 16 ohms. If the motor

is shorted, also verify the

drivers on the main board.

Remove the ribbon

cartridge, verify to rotate its

knob manually, and to see if

the ribbon feeds normally.

Verify whether the RD

ratchet rotates when the

carriage is moved manually

toward left and right.

Move the carriage manually:

verify whether the ribbon

feed gears turns in reverse

and engages the gear.

3 Troubleshooting

Replace the

printhead, (and

drivers , if

necessary).

Replace the

printhead.

Replace the

printhead.

Adjust the platen

gap. Refer to

Chapter 5.

Remove any

foreign

substance.

Remove any

foreign

substance.

Replace the PF

motor, (and

drivers , if

necessary).

Replace the

ribbon cartridge.

Remove any

foreign

substances.

Otherwise,

replace the ribbon

feed mechanism.

Replace the

ribbon feed

mechanism.

Rev. A

3-1

Page 48

FX-880 Service Manual

8

Chapter

Table 3-13. Repairing the Printer Mechanism (continued)

Symptom Cause Checkpoint Solution

Problem: Paper becomes stained with ink.

Ink stains appear on

printed areas.

Problem: Printing continues after the paper ends or when no paper is loaded.

Printing continues

past the end of the

page.

The ribbon mask is

positioned incorrectly.

The platen gap is not

adjusted correctly.

The PE detector is

defective.

Make sure the ribbon

mask is in the correct

position.

Set the gap adjustment

lever to the first position,

and verify the platen

gap. The correct platen

gap is 0.365±0.015.

Check if the PE detector

is bad.

3 Troubleshooting

Reinstall the ribbon

mask.

Adjust the platen

gap. Refer to the

chapter 5

Adjustment

Replace the PE

detector.

.

Rev. A

3-1

Page 49

CHAPTER

DISASSEMBLY AND ASSEMBLY

Page 50

FX-880 Service Manual

Chapter

4 DISASSEMBLY AND ASSEMBLY

4.1 OVERVIEW

This section describes various points to note when disassembling and assembling the printer.

Unless otherwise specified, disassembled units or components can be re-assembled by reversing

the disassembly procedure. Therefore, no assembly procedures are included in this section.

Precautions for any disassembly or assembly procedure are described under the heading

CHECK POINT

“

heading “

ADJUSTEMNTS

4.1.1 Disassembly Precautions

Follow the precautions below when disassembling the printer.

”. Any adjustments required after disassembling the units are described under the

”.

WARNING

CAUTION

Before disassembling, assembling or adjusting the printer,

disconnect the power supply cable from the AC power socket.

Failure to do cause personal injury.

Be careful with the printhead when you handle it, as it may be very

hot just after printing.

Do not touch the heat sink attached to the switching FET (Q1) on the

power supply board, just after power off as it may be very hot.

Never touch the heat sink attaches to the switching FET (Q1) while at

AC power cable is connected to the AC outlet, as it is not electrically

isolated.

To maintain efficient printer operation:

Use only the recommended tools for maintenance work.

Use only the recommended lubrications and adhesives (See Chapter

6.)

Adjust the printer only in the manner described in this manual.

4.1.2 Tools and Instruments

The table below lists the tools and the instruments required for disassembling, assembling or

adjusting the printer. Use only tools that meets these specifications.

Table 4-1 . Tool and Instrument List

Name Specification EPSON Part No.

Phillips Screwdriver No.2 B743800200

Phillips Screwdriver No.1 B743800100

Box Driver 7.0mm Diagonal B741700200

Tweezers

Round-nose pliers

Thickness gage

Soldering iron

E-Ring holder Size: #6 B740800800

Multi-Meter OHM/Voltage/Current

Oscilloscope Min. 50MHz

Note) All tools and instruments listed above are commercially available.

Rev. A

B741000100

B740400100

B776702201

B740200100

4-1

Page 51

FX-880 Service Manual

2

Chapter

4 DISASSEMBLY AND ASSEMBLY

4.1.3 Service Check After Repair

After completing repair of the product, use the check list shown below, to verify status of repaired

product and all the repair work performed before returning the product to the users. This list can

be as a record of all service work performed with the product.

Table 4-2. Repair Status Check List

Category Component Item to Check Status

Printer

Mechanism

Operation Self-Test Was the self-test printing

Adjustment Platen-Gap Is the gap adjusted correctly?

ROM Version Latest version = Checked, OK

Packing Ribbon Cartridge Has the ribbon cartridge been

Printhead Are all wires print properly? Checked, OK

Not necessary

Carriage

Mechanism

Paper Feed

Mechanism

Paper Path Do all types of paper advance

Ribbon Mask Is the ribbon mask free of

On-line Test Was the on-line printing

Bi-D Alignment Is the Bi-Directional alignment

Attachments Have all relevant attachments

Dose the carriage move

smoothly?

z Noisy

z Any dirt or excessive oil?

Is the CR motor at the normal

temperature? (Not too hot?)

Does paper advance smoothly?

z Noisy?

z Paper is jamming?

Is the PF motor at the normal

temperature? (Not too hot?)

smoothly?

Is the tractor feeding paper

smoothly?

Are all paper paths clear of

obstructions?

Is the plate free of damage? Checked, OK

damage?

successful?

successful?

(PG = 0.38 ± 0.02mm )

made properly?

removed from the printer?

been packed together with the

printer?

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Not necessary

Checked, OK

Not necessary

Checked, OK

Not necessary

Rev. A

4-

Page 52

FX-880 Service Manual

3

Chapter

4 DISASSEMBLY AND ASSEMBLY

4.1.4 Abbreviations for Small Parts

The table below lists the abbreviations used in this manual for small parts, such as screws and

washers, etc.

Table 4-3. Abbreviations and Screw Type

Abbreviation Description

CB Screw

CBS Screw

CBB Screw

CBP Screw

CP Screw

CB(O) Screw

Head Body Washer

Top Side

C

ross-

recessed

Bind-head S-tight Outside toothed

C

ross-recessed Bind-head Screw

C

ross-recessed Bind-head S-tight Screw

C

ross-recessed Bind-head B-tight Screw

C

ross-recessed Bind-head P-tight Screw

C

ross-recessed Pan-head Screw

C

ross-recessed Bind-head Screw with Outside toothed

lock washer

Table 4-4. Screw Types and Abbreviations

(assembled)

lock washer

Pan-head B-tight

P-tight

Rev. A

4-

Page 53

FX-880 Service Manual

4

Chapter

4 DISASSEMBLY AND ASSEMBLY

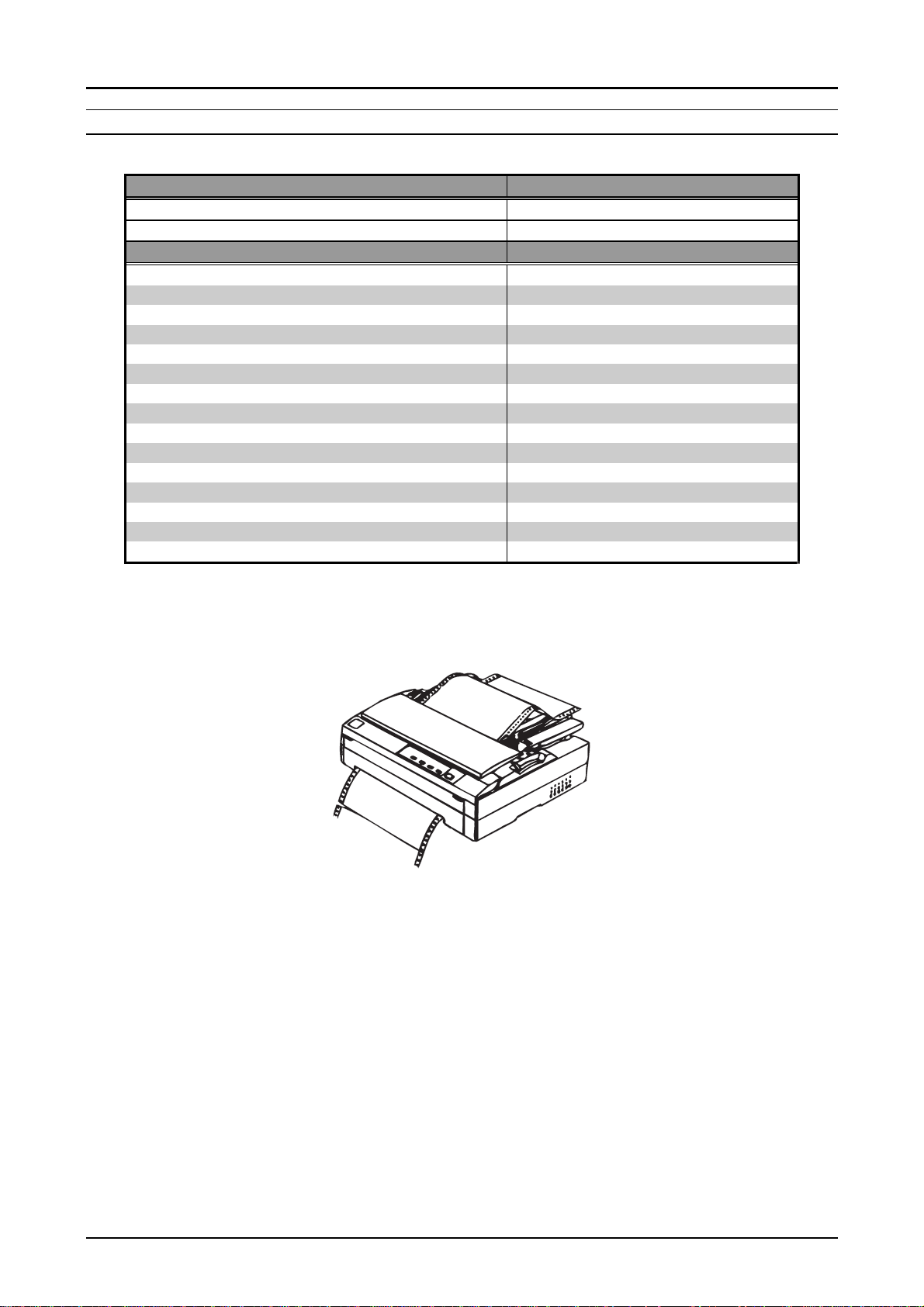

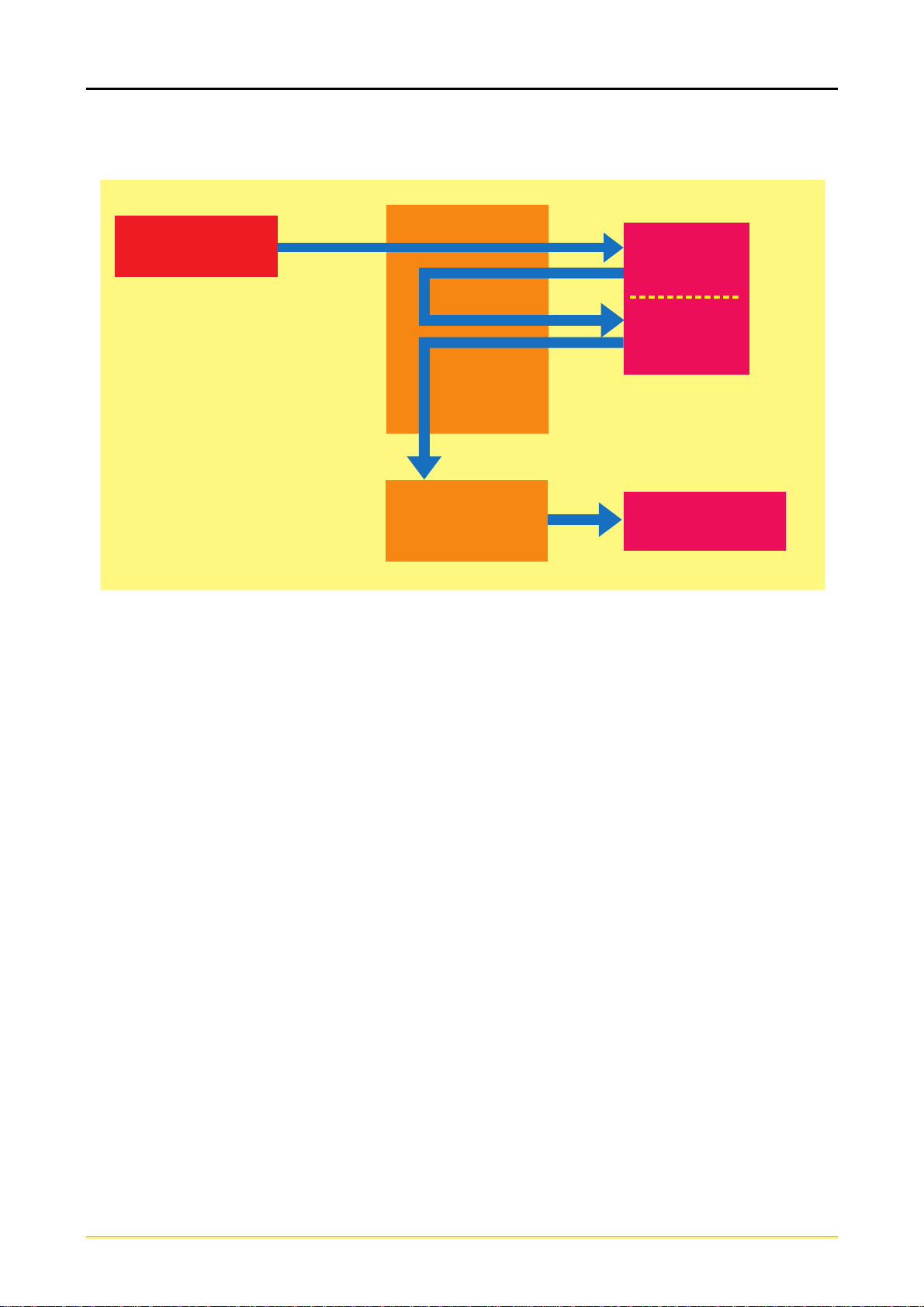

4.2 DISASSEMBLY AND ASSEMBLY

This section provides the disassembly procedures. The basic order for disassembly is shown in

the flowchart below. The exploded diagrams are also provided in the APPENDIX. Refer to them to

see how components are engaged each other if necessary.

Main Compornents Disassembly

START

Pre-disassembly

Procedures

Upper Housing Removal

Printer Mechanism

Removal

Printhead Removal

HP Detector Removal

C229MAIN Board

C229PSB/PSE Board

Platen Removal

ROM Replacemant

Printer Mechanism Disassembly

START

Carriage Assembly

Removal

Removal

Ribbon Drive

Assembly Removal

Removal

Figure 4-1. Disassembly Flowchart

PF Motor RemovalCR Motor Removal

PF Gear Train Removal

Rear Paper Guide

Assembly Removal

PG Detector

Removal

Release Detector

Removal

Front PE Detector

Removal

Rear PE Detector

Removal

Rev. A

4-

Page 54

FX-880 Service Manual

5

Chapter

4 DISASSEMBLY AND ASSEMBLY

4.2.1 Printhead Removal

1. Remove the top cover.

2. Remove 2 CBS (M3 × 8) screws attaching the printhead to the carriage assembly.

3. Disconnect the head FFC from the printhead and remove it.

WARNING

$'-8670(17

Before disassembling or assembling the printhead, disconnect the

power supply cable from the AC power socket. Failure to do cause

personal injury.

Be careful with the printer when you handle it, as it may be very hot

just after printing.

After replace the printhead, perform the platen gap adjustment. (Refer

to Chapter 5.)

Printhead

Head FFC

Figure 4-2. Printhead Removal

Rev. A

4-

Page 55

FX-880 Service Manual

6