Page 1

FX-870/1170

SERVICE MANUAL

Printed on Recycled Paper.

@

I

Revision Level

®

I

EPSON

Page 2

FCC Compliance Statement

For American Users

This equipment has been tested and found to comply with limits for a Class B digital device pursuant to Part

15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio or television

reception. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television reception, which can be determined by turning the

equipment on and off, the user is encouraged to try to correct the interference by one or more of the following

measures:

l

Reorient or relocate the receiving antenna.

l

Increase the separation between the equipment and the receiver.

l

Connect the equipment into an outlet on a circuit different from the one connected to the receiver.

For Canadian Users

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital apparatus as

set out in the radio interference regulations of the Canadian Department of Communications.

Le present appareil numcrique n’cmet pas de bruits radkklectrique d&passant lea limites applicables aux

appareils numcriques de Classe B prescrites dans le rkglement sur le brouillage radioGctriques tdictk par le

Minis&e des Communications du Canada.

The connection of a non-shielded equipment interface cable to this equipment will invalidate the FCC

Certification of this device and may cause interference levels which exceed the limits established by the FCC

for this equipment. It is the responsibility of the user to obtain and use a shielded equipment interface cable

with this device. If this equipment has more than one interface connector, do not leave the cables connected

to unused interfaces.

Changes or modifications not expressly approved by the manufacturer could void the user’s authority to

operate the equipment.

ii

Epson

f%87W1170

Page 3

-

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electric, mechanical, photocopying, recording, or otherwise, without

the written permission of Epson America, Inc.

information contained herein. Neither is any liability assumed for damages resulting from the use of the

information contained herein. While every precaution has been taken in the preparation of this book, Epson

America, Inc., assumes no responsibility for errors and omissions.

Neither Epson America, Inc., nor its affiliates shall be liable to the purchaser of this product or third parties

for damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse,

or abuse of this product or unauthorized modifications, repairs, or alterations to this product.

Epson America, Inc., shall not be liable against any damages or problems arising from the use of any options

or any consumable products other than those designated as Original Epson Products or Epson Approved

Products by Seiko Epson Corporation.

Copyright Notice

No patent liability is assumed with respect to use of the

Trademarks

Epson@ is a registered trademark of Seiko Epson Corporation.

F’X-870 and PX-1170 are trademarks of Seiko Epson Corporation.

IBM@ and IBM PC@ are registered trademarks of International Business Machines Corporation.

Copyright © 1992 Epson America, Inc.

Epson America, Inc.

20770 Madrona Avenue, Torrance, CA 90509

Epson

FX-87W1170

...

III

Page 4

Precautions

Precautionary notations throughout the text are categorized relative to 1) personal injury, and 2)

damage to equipment.

WARNING

CAUTION

The precautionary measures itemized below should always be observed when performing repair/

maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by a

WARNING heading.

Signals a precaution which, if ignored, could result in damage to equipment.

WARNING

1.

Always disconnect the product from both the power source and the host

computer before performing any maintenance or repair procedure.

2.

No work should be performed on the unit by persons unfamiliar with

basic safety measures as dictated for all electronics technicians in their

line of work.

3.

When performing testing as dictated within this manual, do not connect

the unit to a power source until instructed to do so. When the power

supply cable must be connected, use extreme caution in working on the

power supply and other electronic components.

CAUTION

1.

Repairs on Epson products should be performed only by an Epson certified repair technician.

2. Make certain that the source voltage is the same as the rated voltage

listed on the serial number/rating plate. If the Epson product has a

primary AC rating different from the available power source, do not

connect it to the power source.

3.

Always verify that the Epson product has been disconnected from the

power source before removing or replacing printed circuit boards and/or

individual chips.

4.

In order to protect sensitive pP chip and circuitry, use static discharge

equipment, such as anti-static wrist straps, when accessing internal

components.

5.

Replace malfunctioning components only with those components recom-

mended by the manufacturer; introduction of second-source ICs or other

nonapproved components may damage the product and void any applicable Epson warranty.

Epson

0(-870/l

170

Page 5

How to Use this Manual

This manual contains the information that a service provider needs to support the Epson

FX-870/1170 printer.

0

It provides general information and specifications for the printer.

0

It tells you how to set up and configure the printer at a customer site.

.

If you encounter problems, the manual explains how to troubleshoot the printer, based

on the symptoms you are experiencing.

0

Once you have isolated the problem, the manual shows you how to take the printer

apart to remove any faulty component and replace it.

.

Then, the text describes how to adjust the printer.

l

The manual also provides a detailed discussion of the theory of operation.

.

There are schematics, circuit diagrams, exploded diagrams, and an index at the back of

the manual for quick reference.

The paragraphs below describe the contents of this manual in further detail.

1 Printer Features

Chapter 1 contains printer specifications, answers to a list of likely questions that customers may ask the servicer, an explanation and tables of control panel settings, and a brief

description of the major printer components.

2 Installation and Setup Procedures

This section lists site requirements for the printer. It describes how to unpack the printer,

connect it, power it up, and test it.

The text describes the printer interfaces, and gives

signal tables and serial cable configurations. Finally, this section tells you what the customer needs to do to avoid problems and achieve maximum printer life.

3 Troubleshooting

This section begins with quick reference tables for the printer’s test points. The chapter

also provides an explanation of what each error code means, flowcharts that walk you

through the troubleshooting of various problems, an illustration of connector locations, and

illustrations of sensor locations.

You can use the set of troubleshooting tables and flowcharts to isolate the problem as far as

possible.

If you encounter problems using

Epson ESC/P control codes and symbol sets. There are tips for graphics handling and an

explanation of how to read hex dump printouts.

software,

the

!Z’roubZeshooting section lists supported

Epson

FX-87W1170

Page 6

4 Disassembly/Assembly

This chapter lists the tools you need and gives the recommended procedure for removing

and replacing components.

5 Adjustments, Maintenance, and Lubrication

This chapter provides instructions for performing the platen gap adjustment and the

bidirectional adjustment procedure.

and an illustration of the points at which the printer needs to be lubricated after repair of

the mechanism.

There is also a description of the lubricants required

6 Principles of operation

The

Principles of Operation

printhead function, carriage movement, paper feeding, and

provides details about how printer components function mechanically and electronically.

At the end of the chapter, there is a section for dealers outside the U.S. who need to replace

individual components on the circuit boards.

section explains the theory

of

printer operation, including

ribbon

feeding. The chapter

7 Reference Materials

The Reference Materials section contains pin assignment tables, board layout diagrams,

circuit diagrams, and schematics.

Index

The index tells you where to find key words

and

phrases in the manual.

vi

EptmnFX-870/1170

Page 7

Handy Numbers for U.S. Dealers

Epson Customer Resource Center

Epson Faxback System (310) 782-4214

Epson Bulletin Board System

(800) 922-8911

(310) 782-4531

Numbers and Addresses

for Dealers Outside the U.S.

Epson Canada, Ltd.

95 Mural Street

Richmond Hill, Ontario

;htp

Epson Do Brazil

Av. Pedroso De Morais

631,5th

Pinheiros, Sao

;lgne:

Epson Argentina S.A.

Avenida Del Libertador

498,

1001 Buenos Aires

Phone: (541) 394-2439

Fax: (541) 322-4637

(800) GO-EPSON

.

.

(416) 881-5765

Floor

PauIoSP/O5419

(55) ( 11) 813-3044

,

.

(55) (11) 210-9290

Piso

12

LAB

3G3

Brazil

Epson Latin America, Inc.

6100 Blue Lagoon Drive

Floor 2, Suite 220

Miami FL 33126

Phone:

Fax: (305) 265-0097

Epson Chile S.A.

Avenida Costanera Andres Bello 2287

Providencia, Santiago, Chile

Phone:

Fax:

Epson Costa Rica

Apartado

San Jose, Costa Rica

Phone:

Fax:

(305) 265-0092

(562) 232-4661

(562) 233-3197

1076-2050

(506) 34-6666

(506) 25-5709

Epson Mexico S.A. De C.V.

Av. Ejercito

6

Piso

Col.

Condigo Postal 11510, Mexico, D.F.

;hp

.

.

Epson

FX-8700

NacionaI

PaIamas

(525) 395-9944

(525) 395-9499

170

No. 904

Polanco

Epson Venezuela S.A.

Edif.

Epson - La Urbina

Caracas, Venezuela

Phone:

Fax:

(582) 241-0433

(582) 241-4561

vii

Page 8

Contents

Contents

Chapter 1

Options

Hardware Specifications

Firmware Specifications

Interfaces

Control Panel

Default Settings

Self-Test

Hexadecimal Dump

Paper-out Detection

Auto Tear-off

Buffer-full Printing

Thermal Protection

High-Duty Printing

Sheet Loading and Sheet Ejection

Adjust Lever Operation

Printer Initialization

-

Buzzer

Main Components

Commonly Asked Questions and Answers

.................................................................................

................................................................................................

..........................................................................................

..................................................................................................

...........................................................................................

.....................................................................................................

Printer Features

...........................................................................

.........................................................................

......................................................................................

................................................................................

................................................................................

.................................................................................

.................................................................................

................................................................................

.........................................................

..........................................................................

..............................................................................

...................................................................................

............................................

1-3

1-3

1-12

1-13

1-17

1-20

1-22

1-23

1-24

1-24

1-24

1-24

1-24

1-24

1-25

1-26

1-27

1-28

1-33

Chapter 2

Site Requirements

Removing the Packing Materials

The Correct Power On Sequence

Running the Self-Test

Connecting Printer Cables

Checking the Printer with the Computer

Tips to Increase Printer Life

Chapter 3

Test Points

Error Codes

Problem Isolation

Connector Locations

Sensor Locations

Hex Quick Reference Table for ESC/P Commands

Hex Quick Reference Table for IBM Commands

................................................................................................

...............................................................................................

Installation and Setup Procedures

....................................................................................

.............................................................

..............................................................

..............................................................................

.......................................................................

................................................

....................................................................

Troubleshooting

.....................................................................................

...............................................................................

.....................................................................................

...............................

...................................

2-1

2-1

2-1

2-2

2-2

2-3

2-4

3-1

3-5

3-6

3-18

3-19

3-21

3-23

Epson FX-870.0 170

ix

Page 9

Contents

Chapter 4

Precautions

Tools

Service Checks After Repair

Screw Specifications

Notes for Unit Removal and Installation

Items to Remove Before Disassembling the Printer

Removing the Panel Unit

Removing the Printhead

Removing the Upper Housing Assembly

Removing the Printer Mechanism

.......................................................................................................

.............................................................................................

Chapter 5

Disassembly and Assembly

..................................................................

...............................................................................

..............................................

.............................

.......................................................................

........................................................................

...............................................

.........................................................

Adjustments, Maintenance, and

Lubrication

Adjusting the Printer Mechanism

Bidirectional Alignment Adjustment

Preventive Maintenance

Lubrication

...............................................................................................

..........................................................................

...........................................................

.......................................................

4-1

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

5-1

5-3

5-5

5-5

Chapter 6

Printer Mechanism Operation

Power Supply Operation

Control Circuit Operation

Chapter 7

Connector Summary

Circuit Diagrams

Circuit Board Component Layouts

Outline Drawings

Principles of Operation

.................................................................

........................................................................

......................................................................

Reference Materials

................................................................................

......................................................................................

........................................................

...................................................................................

6-1

6-19

6-22

7-1

7-5

7-10

7-13

X

Epson FX-870/1170

Page 10

Chapter 1

Printer Features

Printer Features

Options..

Hardware

Firmware Specifications

Interfaces.

Control Panel

Default

Self-Test

Hexadecimal Dump

Paper-out Detection

Auto Tear-off

Buffer-full Printing

Thermal Protection

High-Duty Printing

Sheet Loading and Sheet Ejection

Adjust Lever Operation

Printer

Buzzer

Main Components

....................................................................................................

Specifications..

Printing Method

Paper Handling

Precautions for Paper Handling

Paper Specifications

Printable Area ..................................................................................

Ribbon Cartridge

Electrical Specifications

Environmental Conditions

Reliability .......................................................................................

Safety Approvals

Print Control

Input Data Buffer

................................................................................................

Parallel Interface

Optional Interfaces

Buttons

Micro Feed Function

Bin Selection for the Cut Sheet Feeder

Paper Ejection

Indicators

Settings..

Power On Default Settings

...................................................................................................

Initialization

.....................................................................................................

..................................................................................

..........................................................................................

...........................................................................................

.......................................................................................

....................................................................................

...........................................................................................

...................................................................................

.........................................................................

...............................................................................

................................................................................

............................................

.........................................................................

...........................................................................

.................................................................

.............................................................

............................................................................

..........................................................................

..........................................................................

...........................................................................

........................................................................

............................................................

...............................

......................................................................

............................................................

................................................................................

................................................................................

.................................................................................

.................................................................................

................................................................................

.........................................................

..........................................................................

..............................................................................

1-3

1-3

1-3

1-4

1-5

1-6

1-8

1-10

1-11

1-11

1-11

1-12

1-12

1-12

1-13

1-13

1-13

1-16

1-17

1-17

1-18

1-19

1-19

1-20

1-20

1-22

1-22

1-23

1-24

1-24

1-24

1-24

1-24

1-24

1-25

1-26

1-27

1-28

Epson

FX-870/1170

1-i

Page 11

Printer Features

C094 MAIN Board Assembly (Main Control Board)

C094 PNL Board Assembly (Control Panel Circuit Board)

C076 PSB Board Assembly (Power Supply Circuit Board)

Printer Mechanism

Housing Assembly

Commonly Asked Questions and Answers

........................................................................

.........................................................................

............................................

................. 1-29

................... 1-30

.................. 1-30

1-31

1-32

1-33

List of Figures

....

......

......

1-2

1-3

1-8

1-9

1-10

1-14

1-17

1-23

1-23

1-25

1-28

1-29

1-30

1-30

1-31

1-32

Figure 1-1.

Figure 1-2. Pin Configuration

Figure 1-3.

Figure 1-4.

Figure 1-5.

Figure 1-6.

Figure 1-7. Control Panel

Figure 1-8. Self-Test Printout

Figure 1-9. Hexadecimal Dump Printout

Figure 1-10. Lever Positions

Figure 1-11. Main Components

Figure 1-12. C094 MAlN Board Assembly (Main Control Circuit Board).

Figure 1-13. C094 PNL Board Assembly (Control Panel Circuit Board).

Figure 1-14. C076 PSB Board Assembly (Power Supply Circuit Board).

Figure 1-15. Printer Mechanism

Figure 1-16. Housing Assembly

External View of FX-870/1170

................................................................

Printable Area for Cut Sheets

Printable Area for Continuous Paper

Printable Area for Roll Paper

Data Transmission Timing

...................................................................

..............................................................

..................................................................

.............................................................

...........................................................

.............................................................

............................................

............................................

.................................

..........................................

...............................................

............................................

1-ii

List of Tables

Table 1-1. Line Feed Speed (1 line = l/6”)

Table 1-2.

Table 1-3.

Table 1-4.

Table 1-5. Specifications for Envelopes

Table 1-6.

Table 1-7.

Table 1-8.

Table 1-9. Environmental Conditions

Table 1-10.

Table 1-11. Printable Columns

Table 1-12. Print Speed

Table 1-13.

Specifications for Cut Sheets (Standard Paper)

Specifications for Cut Sheets

(Carbonless Duplicating Paper)

Specifications for Continuous Paper

Specifications for Labels

Specifications

Electrical Specifications for

Character Size and Pitch

Connector Pin Assignments and Signal Functions..

for Roll Paper

..........................................................

......................................................................

.........................................

.............................................

...................................................

.............................................

120 V Model

..............................................

................................................

............... 1-6

........................................

.................................

.......................

1-11

1-11

1-12

1-12

1-13

......

1-14

Epson FX-870/1170

1-4

1-6

1-7

1-7

1-7

1-8

Page 12

Printer Features

Table 1-14. Optional Interface ...........................................................

Table 1-15. Identifying Errors Using the LEDs

Table 1-16. Group 1 Features

............................................................

Table 1-17. Group 2 Features (ESC/P Mode)

Table 1-18. Group 2 Features (IBM Mode)

Table 1-19. Group 3 Features (Power-on Settings)

Table 1-20. Lever Positions

Table 1-21. Buzzer Functions

................................................................ 1-25

.............................................................

................................

.....................................

........................................

........................... 1-22

1-16

l-19

1-20

1-21

1-22

1-27

Epson FX-870/1170

1 -iii

Page 13

Printer Features

1

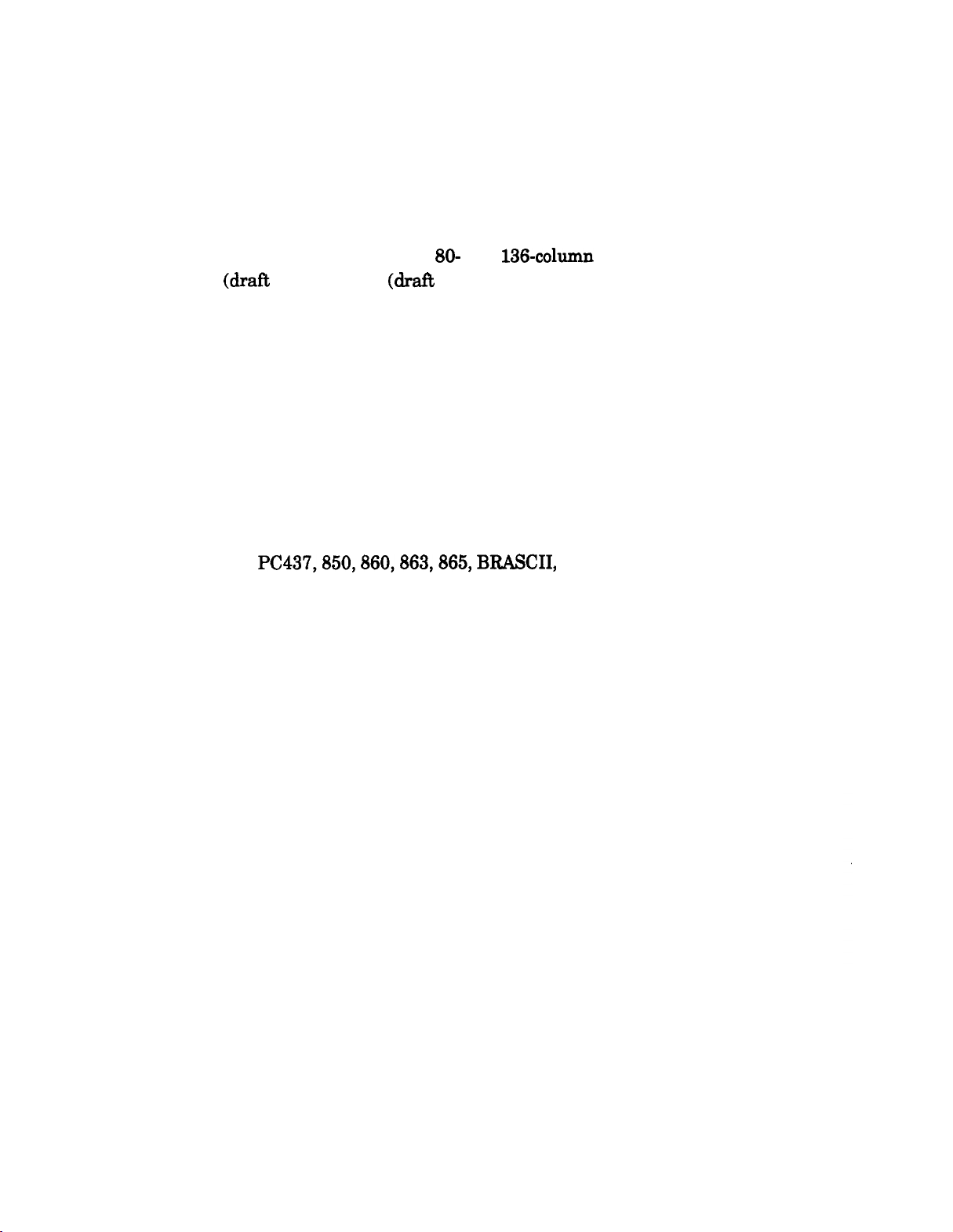

The FX-870/1170 combines advanced firmware, reliability, and affordability in a

single light-weight unit. The major features of this printer are:

l

Upward compatibility with the FX-850/1050 and the FX-86e/286e

l

380 cps (high-speed draft for both 80- and 136-column models)

l

285 cps

l

Advanced paper handling

(draft

pica), 342 cps

(draft

elite)

Continuous paper

3 paths for insertion (front/bottom/rear)

Dual paper park and auto load (front/rear)

The standard tractor unit can be set to 3 positions (2 push and 1 pull)

Continuous paper can be used without removing the cut-sheet feeder (CSF)

Cut sheets

2 paths for insertion (top/optional front)

Auto loading

l

24KB input buffer

l

8 character tables

(Italic,

l

A default setting mode replaces DIP switches for setting default values

l

Type B optional I/F boards can be installed

PC437,850,860,863,865, BRASCII,

and Abicomp)

Figure l-l on the next page shows an exterior view of the FX-870 and FX-1170.

EpsonFX-870/1170

1-1

Page 14

Printer Features

80-column model

1-2

136-column model

Figure 1-1. External View of the FX-870/1170

Epson FX-870/1170

Page 15

options

Printer Features

C806371

C806391

C806381

C806401

C800201

C800211

C814001

C814011

C823051

C823071

C823101

C823141

C823151

#8750

#8755

#8758

#8310

Single-bin cut-sheet feeder (80-column)

Single-bin cut-sheet feeder (136-column)

High-capacity cut-sheet feeder (80-column)

High-capacity cut-sheet feeder (136-column)

Tractor unit (80-column)

Tractor unit (136-column)

Front sheet guide (80-column)

Front sheet guide (136-column)

Serial I/F card (Type B)

32KB intelligent serial I/F card (Type B)

32KB intelligent parallel I/F card (Type B)

Coax interface (Type B)

Twinax interface (Type B)

Fabric ribbon cartridge (80-column)

Fabric ribbon cartridge (136-column)

Fabric ribbon sub cartridge

Roll paper holder (only for 80-column model)

Hardware Specifications

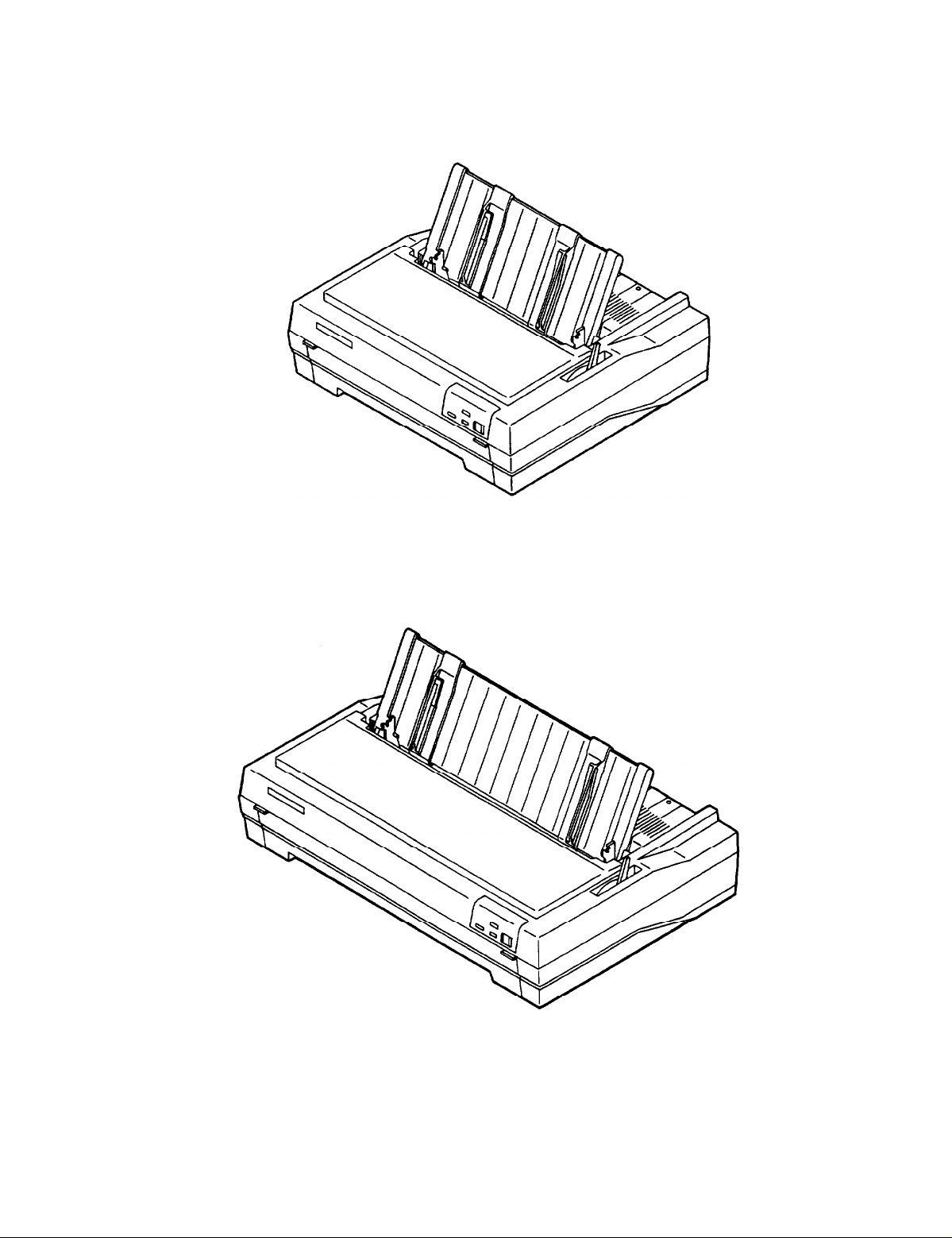

Printing Method

Printing method:

Pin configuration:

Impact dot matrix

9 wires

wire

#’ &

2+---

3 ‘----___

0

44

(diameter 0.29 mm)

--

0.35 mm

5

(l/72”)

Epson

M-870/1

170

Figure 1-2. Pin Configuration

1-3

Page 16

Printer Features

Dot matrix:

9 x 7 matrix (high-speed draft)

9 x 9 matrix

18

x 23 matrix

(drafk)

(NLQ)

Paper Handling

Feeding methods: Friction feed (front/top)

Push tractor feed (front/rear)

pull tractor feed (front/rear/bottom)

Push-pull tractor feed (front/rear)

Method to use for each type of paper:

Fanfold: Tractor feed

Cut sheets:

Envelopes:

Labels:

Rdk

Line spacing:

Friction feed

Friction feed

Tractor feed

Friction feed

l/6”,

L/B”,

or programmable

(l/216”,

minimum)

Thin:

Thick:

Table l-l. Line Feed Speed (1 line = l/@?

Single line feed

Type of paper

Thin

Thick

ms ms

Fanfold paper

Single sheet (manual)

Cut sheet (CSF)

77

69 77

71

85

77

Thin paper is less than or equal to 0.007 inches (0.18 mm).

Thick paper is more than 0.007 inches (0.18 mm).

Continuous feeding

Thin

ms (ips)

55

(3.0)

45 (3.7)

48 (3.5)

Thick

ms (ips)

66 (2.5)

55

(3.0)

55

(3.0)

1-4

Epson

FX-8700170

Page 17

Printer Features

Precautions for Handling Paper

Friction feed

l

Set the release lever to the FRICTION position.

l

Load the paper from the front or top entrance.

l

Do not use continuous paper.

l

Do not perform any reverse paper feeds within the top 0.34” (8.5 mm) area and

bottom 0.88” (22 mm) area.

l

Do not perform reverse feeds greater than

detected.

l

Use the paper-tension unit.

l

Insert multi-part cut-sheet forms only from the front.

Push tractor feed

l

Set the release lever to the REAR PUSH/FRONT PUSH position.

l

Load the paper from the rear or front entrance.

l

Release the friction feed mechanism.

l

Multi-part paper must be carbonless.

l

Use the paper-tension unit.

l

Do not perform reverse feeds greater than

l

Do not perform reverse feeding after the paper end has been detected, because

accuracy of paper feed cannot be assured.

l/6”

after the paper end has been

l/6”.

Pull tractor feed

l

Set the release lever to the PULL position.

l

Load the paper from the front, rear, or bottom entrance.

(The front or bottom entrance is recommended for thick paper or labels.)

l

Release the friction feed mechanism.

l

Remove the paper-tension unit and attach the pull tractor unit.

l

Insert paper from either front or bottom.

l

Multi-part paper must be carbonless.

l

Do not perform reverse feeds.

Push-pull tractor feed

l

Set the release lever to the REAR PUSH/FRONT PUSH position.

l

Load the paper from the front or rear entrance.

. Release the friction feed mechanism.

l

Remove the paper-tension unit and attach the pull tractor unit.

l

Remove any slack in the paper between the platen and the pu11 tractor.

l

Precisely adjust the horizontal position of the pull tractor and push tractor.

l

Multi-part paper must be carbonless.

l

Do not perform reverse feeds greater than l/6”.

l

Do not perform reverse feeds after the paper end has been detected.

Epson FX-870/1170

1-5

Page 18

Printer Features

Paper Specifications

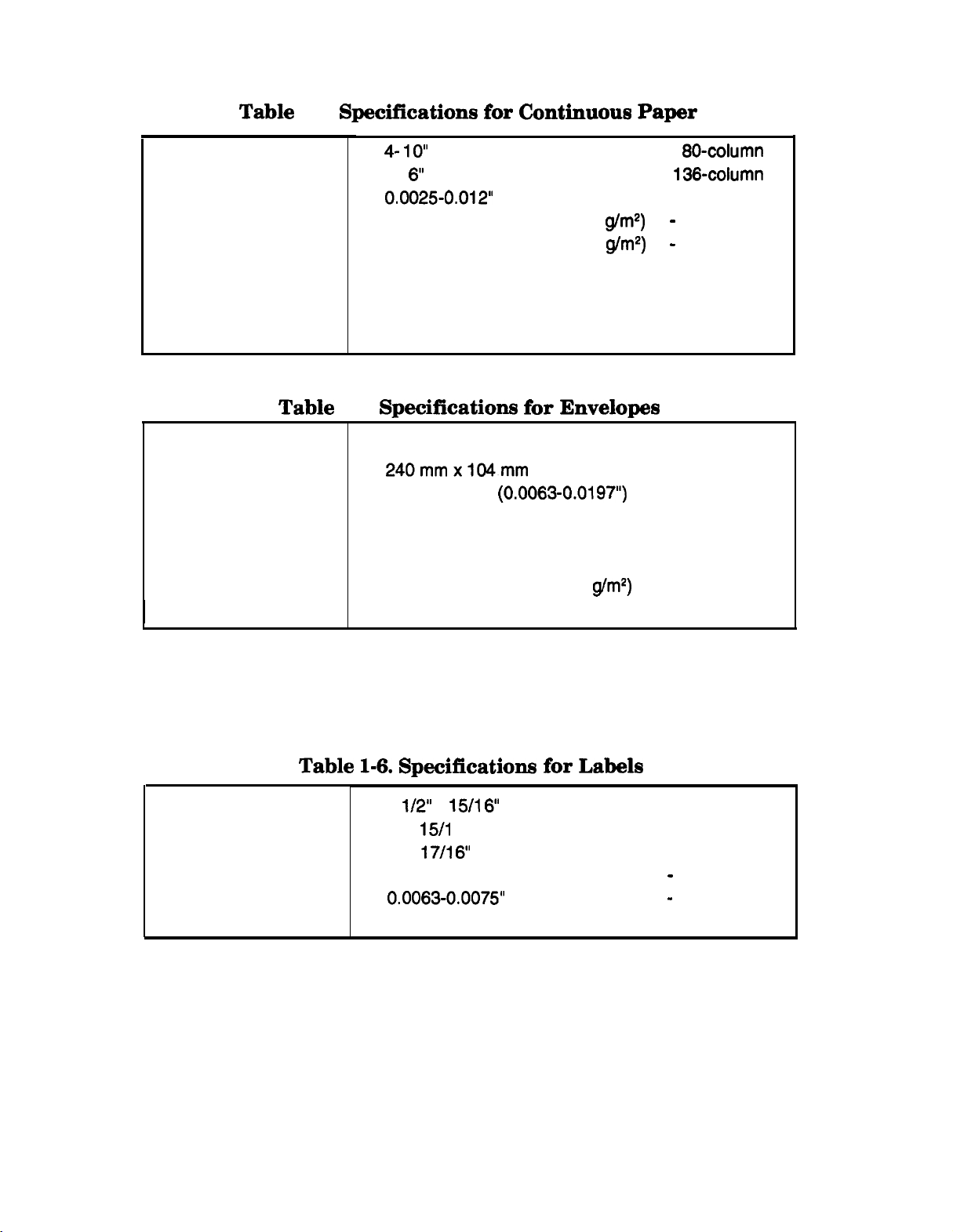

See Tables 1-2, 1-3, 1-4, 1-5, 1-6, and 1-7.

Normal Environmental Conditions

Recycled paper, envelopes, and labels require normal environmental conditions,

which are the following:

Temperature:

Humidity:

Table 1-2.

Width

top insertion

front insertion

Length

Thickness

Weight

Quality

59-68”F(15-25°C)

30 - 60 %

RI-I

Specifications for Cut Sheets (Standard Paper)

5.8-l 0.1” (148-257 mm) 80-column

5.8-l 6.5” (148-420 mm)

7.2-10.1”

7.2-14.3” (182-364 mm)

Up to 14.3” (364 mm)

0.0025-0.0055” (0.065-0.14 mm)

14-24 lb (45-78 kg) (52.3-90

Standard copier paper

Recycled paper (at normal temperature and

humidity levels)

(182-257 mm)

136~column

80-column

136~column

g/m*)

Table 1-3. Specifications for Cut Sheets

(Carbonless Duplicating Paper)

1-6

Width

front insertion

Length

Quality

Thickness

Weight

Copies

7.2-10.1”

7.2-l 4.3” (182-364 mm)

Up to 11.7” (297 mm) 80-column

Up to 14.3” (364 mm)

Carbonless duplicating paper

0.0047-0.0086”

12-15 lb (34-50 kg) (40-58

4 sheets (1 original + 3 copies) maximum

(182-257 mm)

(0.12-0.22 mm)

g/m*) -

Epson

80-column

136~column

136~column

each

FX-870/1170

Page 19

Printer Features

Table

Width

Thickness

Weight

Quality

Copies

Size No. 6

Thickness

Weight

~

Quality

1-4.

Table

No. 10

Specifications for Continuous Paper

4- 10”

(101-254 mm) 80-column

4-l 6” (101-406 mm)

0.0025-0.012”

14-22 lb (45-70 kg) (52.3-82

12-l 5 lb (34-50 kg) (40-58.2

Standard or carbonless duplicating paper

Recycled paper (at normal temperature and

humidity levels)

4 sheets (1 original + 3 copies) maximum

1-5.

Specifications for Envelopes

166 mm x 92 mm

240mmxlO4mm

0.16-0.52 mm

Differences in thickness within the printing

area must be less than 0.0098”

(0.25 mm).

12-24 lb (39-78 kg) (45-91

Bond paper, copier paper, airmail

(0.065-0.32 mm)

(0.0063-0.0197”)

g/m*)- single sheet

g/m*)- each

g/m*)

136~column

Notes: 1. Envelopes must be inserted from the top.

2.

Keep the longer side of the envelope horizontal during insertion.

3.

Set the left edge of a No. 6 envelope at the sheet guide setting mark.

4.

Do not feed envelopes with the standard-capacity cut-sheet feeder.

Table 1-6. Specifications for Labels

Size

Thickness

Quality Standard paper

Notes: 1. Labels must be fanfold.

2. Example of labels: Avery continuous form or mini-line labels.

3. Labels should be used with the pull tractor (front, bottom) or the front

push tractor.

4. Do not perform reverse feeds at any time (including by hand).

5. Remove labels from the paper path when not in use.

6. Label printing is possible only at normal temperature and humidity levels.

2

l/2”

x

15/l 6”

4” x 15/l 6”

4” x

17/l 6”

0.0028-0.0031” (0.07-0.09 mm)

0.0063-0.0075”

(0.16-0.19 mm)

-

base paper

-

total

Epson FX-87011170

1-7

Page 20

Printer Features

Note:

Roll paper is available optionally only for the 80-column model, and its diameter

must not exceed 5” (127 mm).

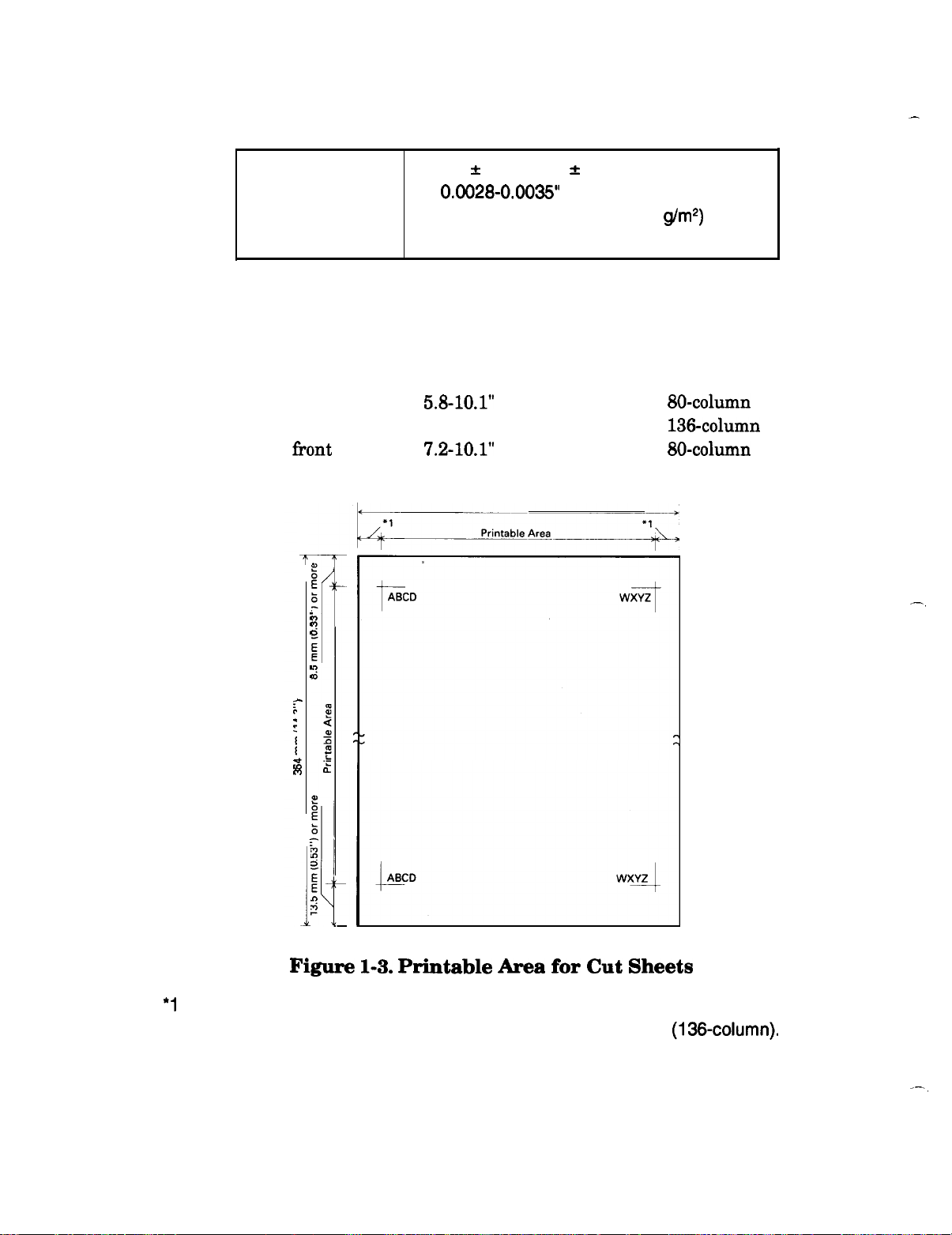

Printable

Cut sheets

Table 1-7. Specifications for Roll Paper

Size

Thickness 0.0028-0.0035”

Weight

Quality

Area

top insertion 5.8-10.1”

fkont

insertion

8.5 f 0.12” (216 A 3 mm)

(0.07-0.09 mm)

14-22 lb (45-70 kg) (52.3-82

Standard paper

(148-257 mm):

5.8-16.5” (148-420 mm):

7.2-10.1”

7.2-14.3” (182-364 mm):

(182-257 mm):

T

-

g/m*)

80-column

136-column

80-column

136-column

1

‘

:

-

?

J

m

1

Figure 1-3. Printable Area for Cut Sheets

*l

0.12” (3.0 mm) or more when the paper width is less than 14.3’ (364 mm).

0.9” (25 mm) or more when the paper width is 16.5” (420 mm)

3.0 mm (0.12”) or more (80-column).

Note:

Paper feed accuracy cannot be assured within 0.94” (24 mm) from the bottom

edge of the paper (for top insertion) or from within 1.9” (48.5 mm) from the

bottom edge of the paper (for front insertion).

(136column).

-,

--_

1-8

Epson FX-8700170

Page 21

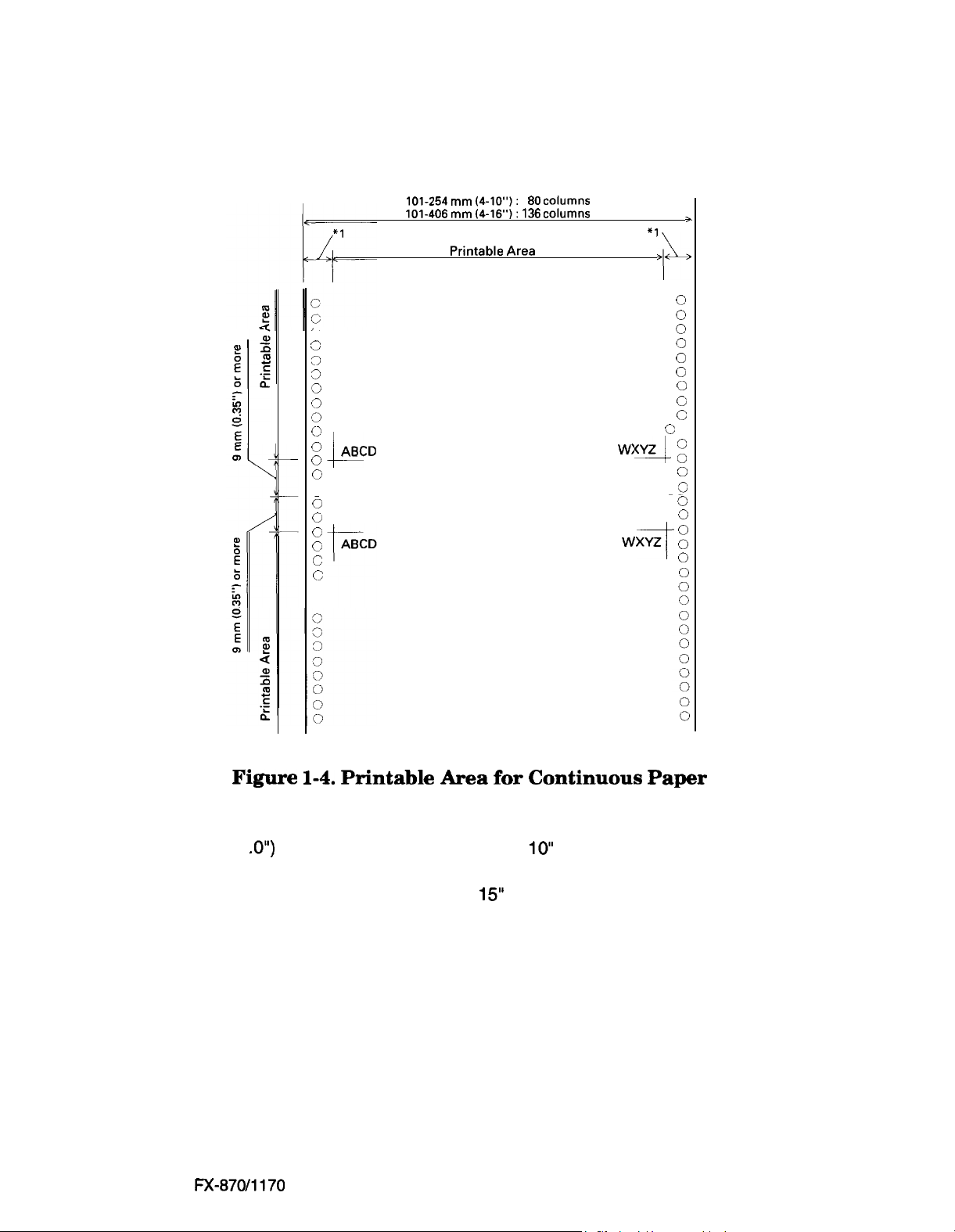

Continuous paper

Printer Features

80

Area

136

columns

columns

*1

>L+

c

WXYZ

J

WXYZ g

I

>

0

0

0

0

0

0

0

G

c

g

0

-0

0

0

0

0

0

101-254mm(4-10"):

101-406mm(4-16"):

Printable

c

c

0

3

0

0

0

<I

0

ABCD

0

c

0

0

0

0

0

0

C

c

Figure 1-4. Printable Area for Continuous Paper

l

1

13 mm (0.51”) or more when the paper width is 4” to 9.5” (101 mm to 241 mm).

25 mm (1

13 mm (0.51”) or more when the paper width is 4” to 14.87” (101 mm to 377.8 mm).

25 mm or more when the paper width is

(136 columns).

Epson

FX-870/1170

,O”)

or more when the paper width is

15”

lo”

(254 mm) (80 columns).

to 16” (381 mm to 406 mm)

1-9

Page 22

Printer Features

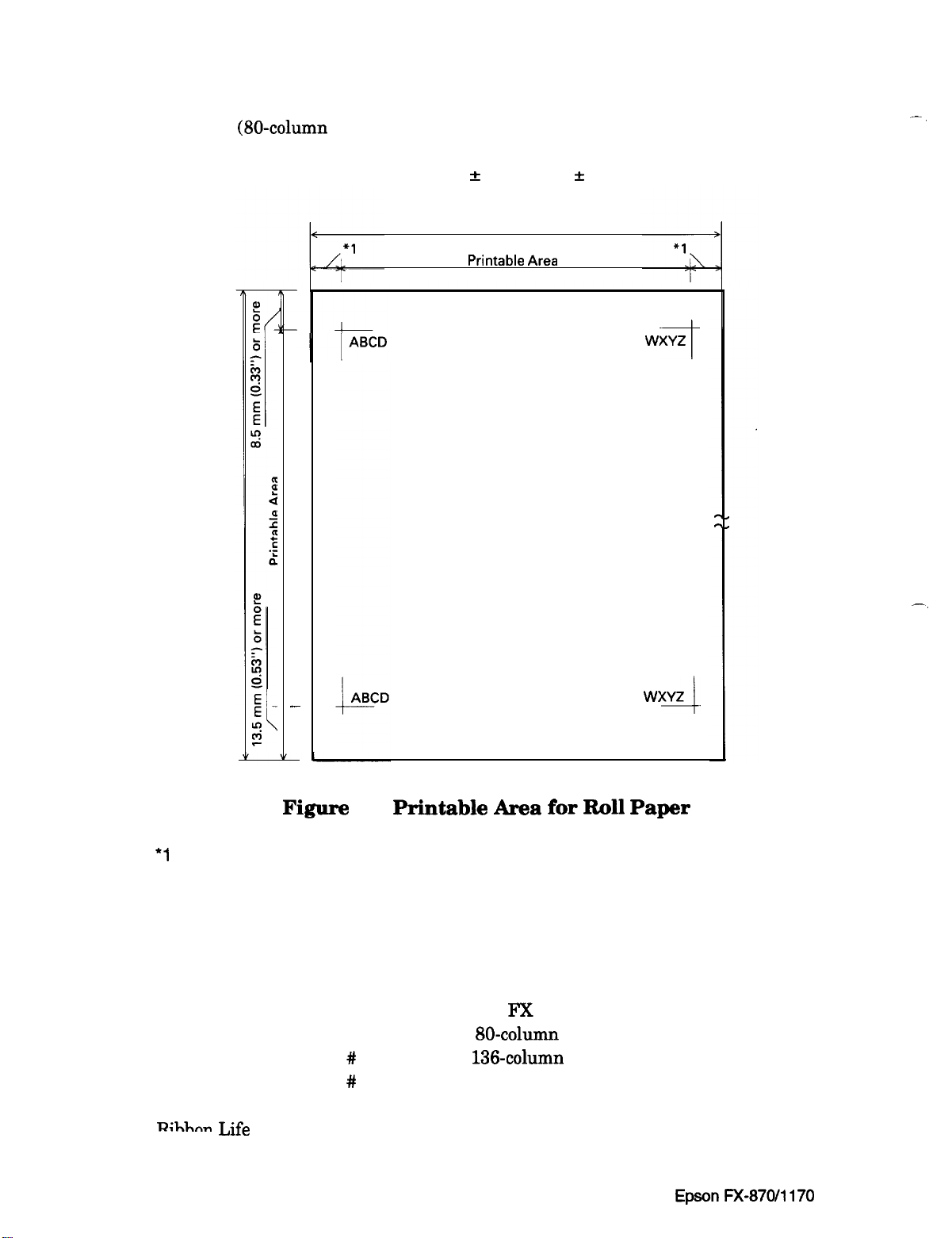

Roll paper (80-column model only)

top insertion

-_

216 2 3 mm (8.5 2 0.12”)

Printable Area

WXYZ

t

-

Figure

*I

0.12” (3.0 mm) or more

Note:

Ribbon Cartridge

Ribbon

Color

Whhnn Life

Paper feed accuracy cannot be assured within 24 mm (0.94”) from the bottom

edge of the paper (top insertion only).

Cartridge type (same as

WXYZ

J

1-5.

Printable Area for Roll Paper

F’X

series)

# 8750

#

8755(M)

#

8758

80-column

136~column

Subcartridge

model

model

Black

3 million characters (at 14 dots/character)

-,

1-10

EpsonFX-870/1170

Page 23

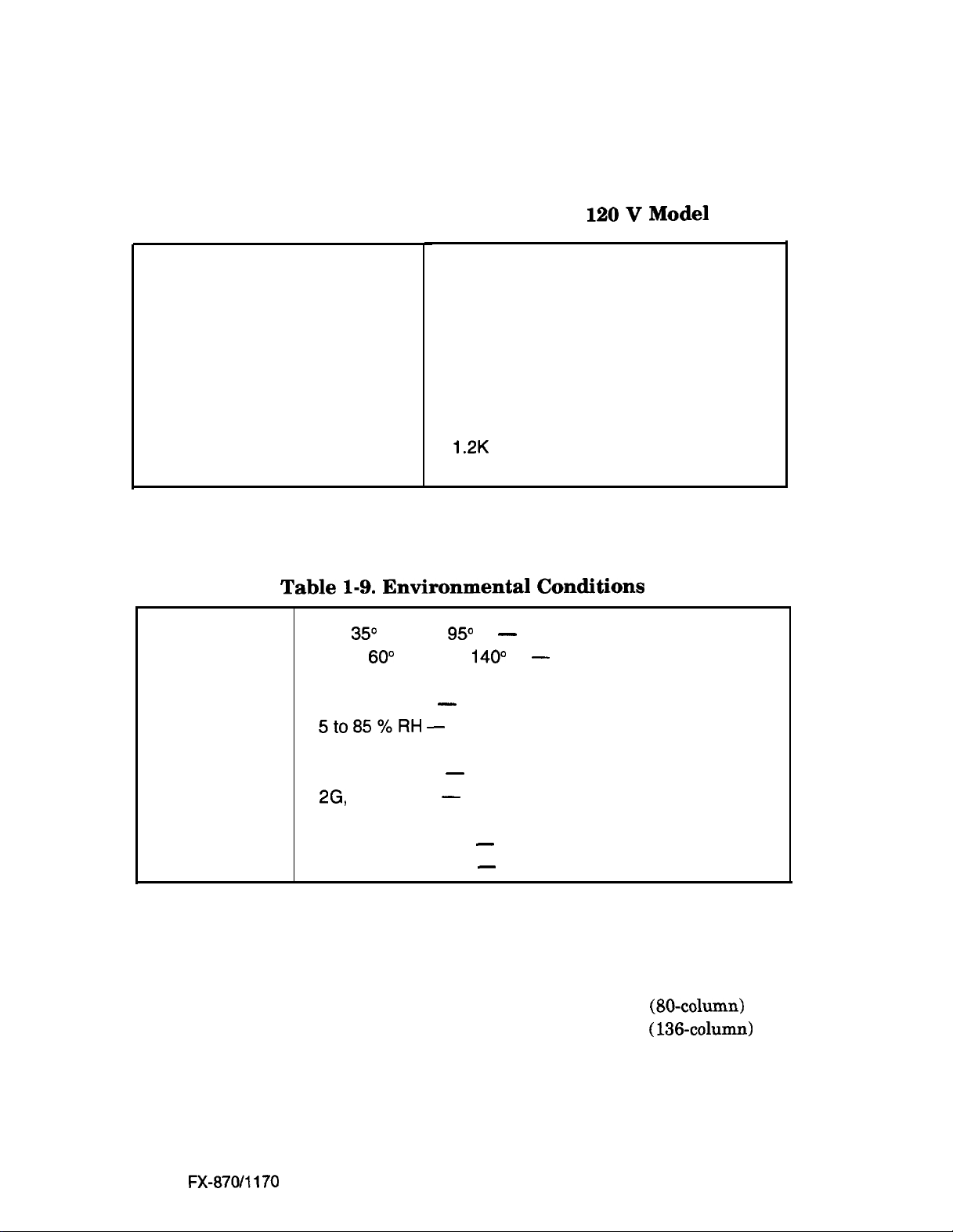

Electrical Specifications

See Table l-8.

Printer Features

Table 1-8. Electrical Specifications for

Rated voltage

Input voltage range

Rated frequency range

.

Environmental Conditions

Input frequency range

Rated current

Power consumption

Dielectric strength

Table 1-9. Environmental Conditions

5 to

350

Temperature

-30 to

C (41 to

60”

120 VAC

103.5132 VAC

50-60 Hz

49560.5 Hz

1.8 A

Approx. 45 W ( 80 columns)

Approx. 45 W (136 columns)

(Self-test in draft mode, 10 cpi)

1.2K

(Between AC line and chassis)

95”

C (-22 to

120

V

Model

VAC rms, 1 second

F) - operating

140”

F) - in shipment container

Humidity

Resistance

to shock

Resistance

to vibration

Reliability

MCBF

MTBF (expected value)

Printhead Life

10 to 80 % RH - operating

5to85%RH

1 G, within 1 ms - operating

2G,

0.25 G, 55 Hz max. - operating

0.50 G, 55 Hz max. - non-operating

-

non-operating

within 1 ms - non-operating

5 million lines (excluding a printhead)

(MCBF: Mean Cycles Between Failures)

4000 power on hours (duty cycle 25%)

6000 power on hours (duty cycle 25%)

(MTBF: Mean Time Between Failures)

100 million characters (14 dots/character)

(80~column)

(136-column)

Epson

FX-870/1170

1-11

Page 24

Printer Features

Safety Approvals

Safety standards

RF1

*

UL1950

CSA!z2.2#220

FCC class B

with D3

Firmware Specifications

Print Control

Printing direction

Text mode

Bit image mode Unidirectional printing

Character sets ASCII characters

ESC/P mode

IBM mode

Bidirectional printing with logic seeking.

(Unidirectional printing can be specified by software.)

-

Italic, PC

-

PC 473,865 (PC = Personal Computer character table

Fonts:

437,850,860,863,

Draft, NLQ Roman, NLQ Sans serif

865, BRASCII, Abicomp

)

-

Table l-10. Character Size and Pitch

Type of letters

Pica

Condensed

Elite

Condensed elite

80-column

Pica

Condensed

Elite

Condensed elite

Width

[mm1

2.1

1.05

1.7

0.85

Height

[mm1

3.1

3.1

3.1

3.1

Character pitch

2.54

1.48

2.11‘ (12 cpi)

1.27 (20 cpi)

Table l-11. Printable Columns

Type of letters

model

80

137

96

160 272

Printable columns

136-column

model

136

233

163

[mm1

(10 cpi)

(17

cpi)

[cpi]

1-12

Epson FX-8700170

Page 25

Notes:

Printer Features

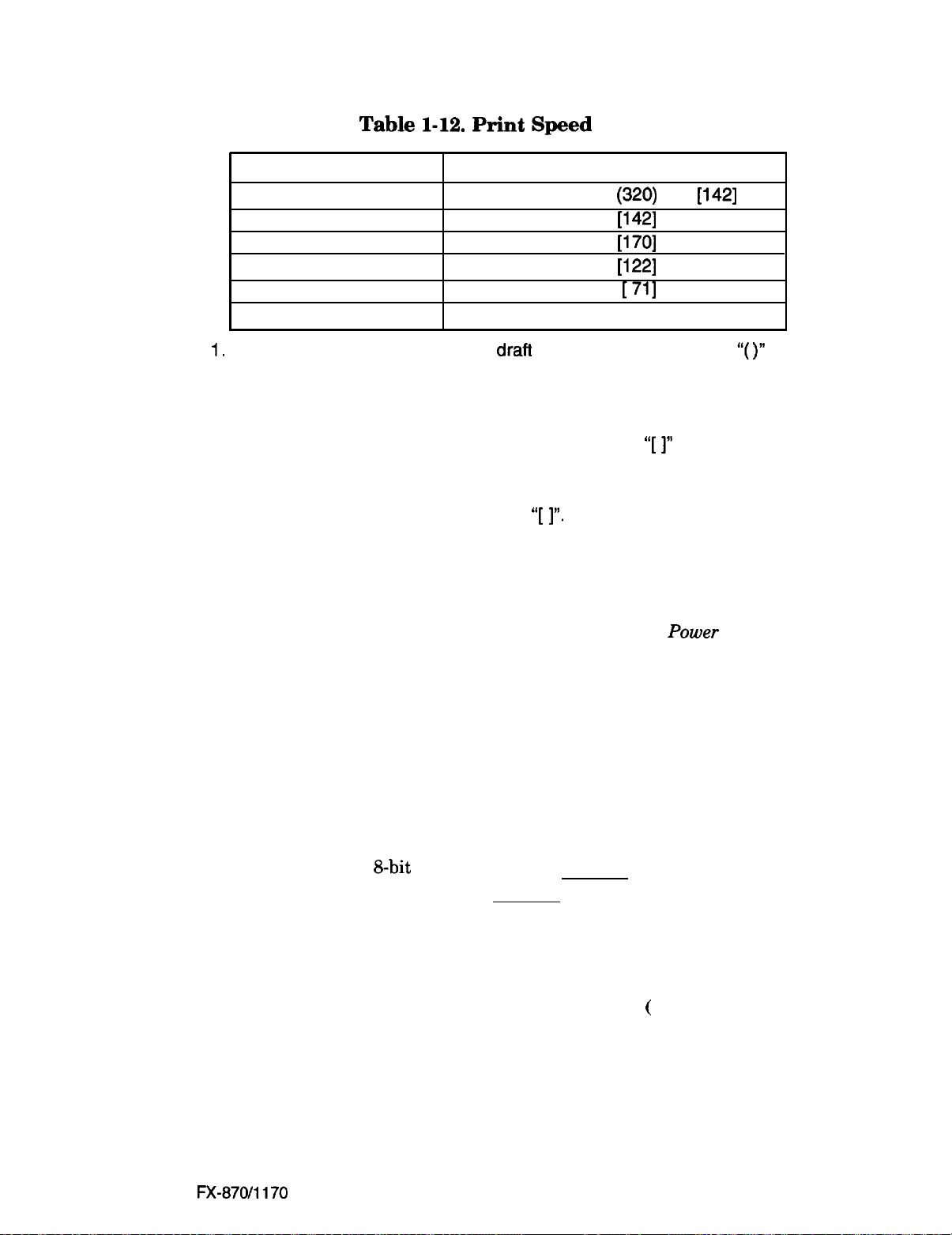

Table 1-12. Print Speed

Type of letters Print speed [cps]

High-speed draft

Draft pica

Draft elite

Condensed draft pica

Emphasized draft pica

NLQ normal pica

1.

The printing speed for high-speed drafl is reduced to the value in

thick paper (over 0.007 inches or 0.18 mm).

2. The printing speed for high-speed draft is reduced to the value of “draft

pica” when any graphic character is in the line.

3. The printing speed for draft is reduced to the value in

character is in the line.

4. The speed for high-duty printing is reduced to approximately half of each

speed, except for the printing speed in “[

380

285

342

243

142

57

I”.

(320)

ii421

[1701

v221

1711

‘I[ I”

11421

‘I( )”

with

when any italic

Input Data Buffer

24K or OK bytes (selectable with power on default settings;

Settings,

later in this chapter.)

see Pouter On Default

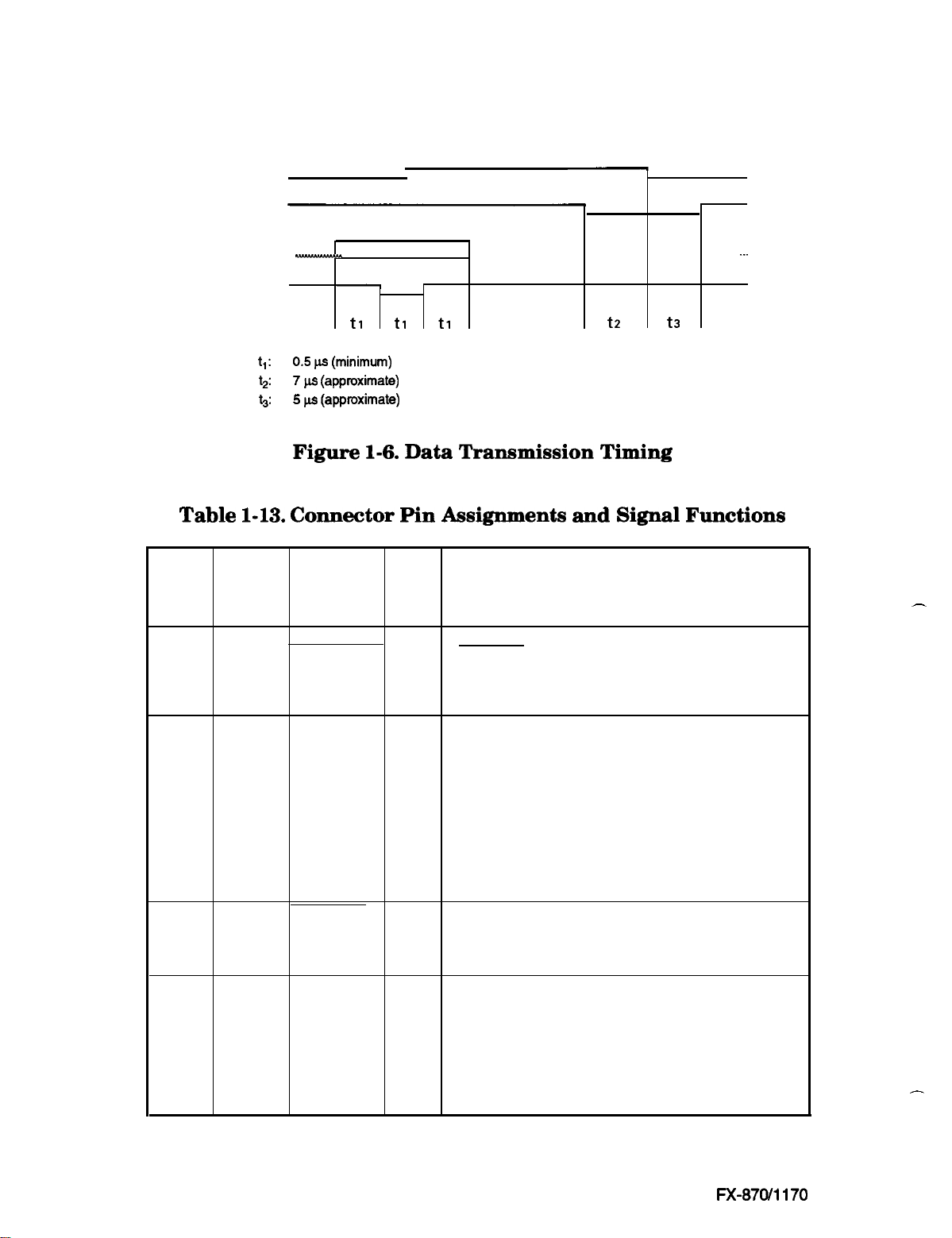

Interfaces

This printer has a built-in, 8-bit Centronics parallel interface.

Parallel Interface

Data transmission mode

Synchronization

Handshaking

Logic level

Connector plug

It is recommended that the interface cable be as short as possible

maximum).

&bit

parallel

Controlled by external STROBE pulse.

Controlled by ACKNLG and BUSY signals.

TTL-compatible

57-30360 (Amphenol) or equivalent

(

10 feet or 3 meters,

Epson

FX-870/1170

1-13

Page 26

Printer Features

BUSY

ACKNLG

DATA

STROBE

t,:

t2:7 w

5:

p

0.5 p-s

(minimum)

(approximate)

5 w

(approximate)

-

t1

I

t1

. . . .

t1

. . . . . . . . . . . .

t2 t3

Figure 1-6. Data Transmission Timing

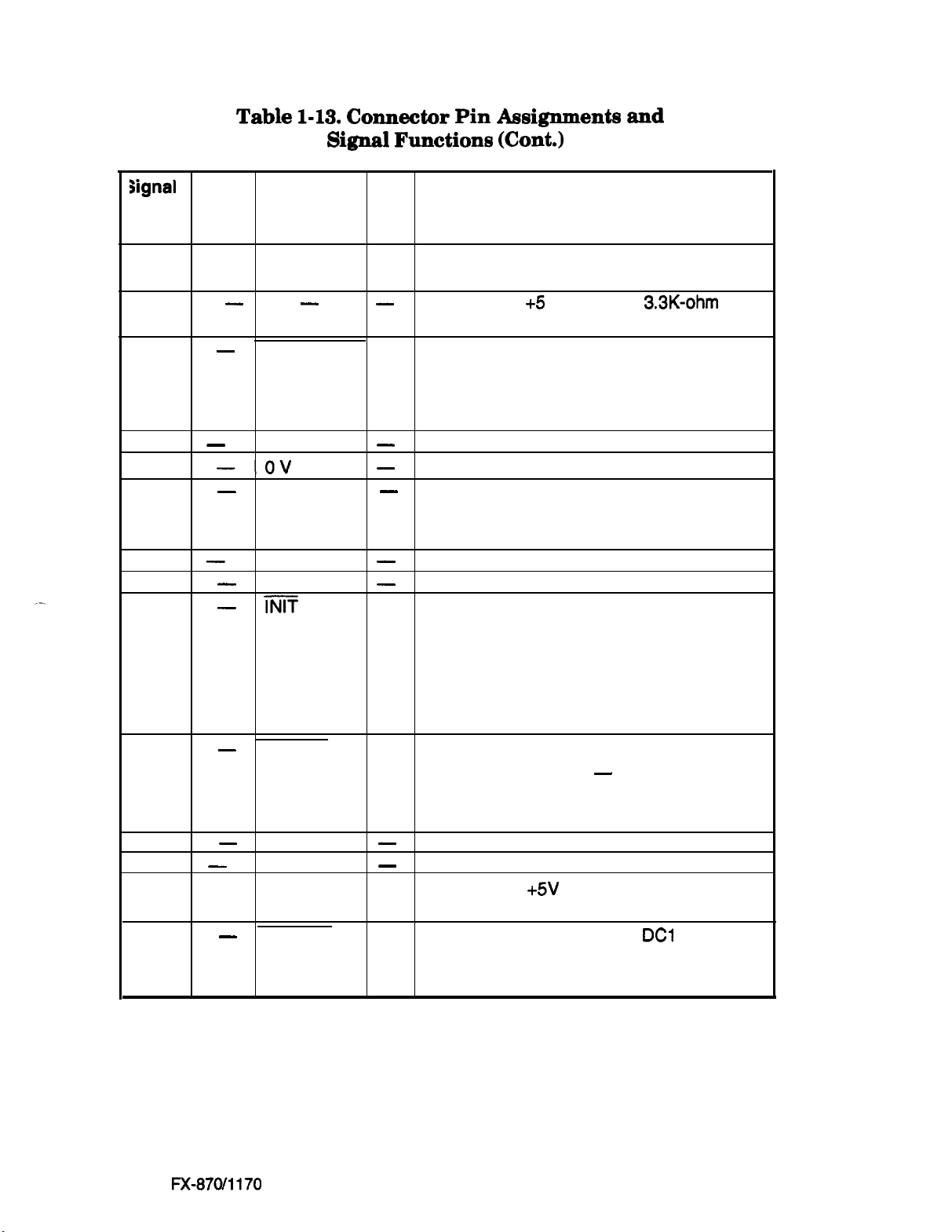

Table 1-13. Connector Pin Assignments and Signal Functions

Signal Return

Pin

No. No.

Pin

Signal

Name

Dir.

Description

-.-

-

1

2

3

4

5

6

7

8

9

10

11

19

20

21

22

23

24

25

26

27

STROBE In

DATA 1 In

DATA2 In

DATA3 In

DATA4 In

DATA5 In

DATA6 In

DATA7 In

DATA8 In

28 ACKNLG

29

BUSY

out

out

STROBE pulse to read data in. Pulse

width must be more than 0.5 us at

receiving terminal.

These signals represent the 1st to 8th

bits of parallel data, respectively. Each

signal is HIGH when data is a logical 1

and LOW when a logical 0.

Approx. 12 us pulse. LOW indicates that

data has been received and that the

printer is ready to accept more data.

A HIGH signal indicates that the printer

cannot receive more data. The signal

becomes HIGH in the following cases:

1. During data entry

2. During input buffer full

3. During printer error status

-

1-14

Epson

FX-870/1170

Page 27

Table 1-13. Connector Pin Assignments and

Signal Functions (Cont.)

signal

Return

30

Pin

30 PE

-

-0V

-

-

-

-

-

-

Signal

Name

AUTO FEED In

XT

CHASSIS

GND

GND

im

ERROR Out

GND

SLCT IN In

Pin

No. No.

12

13 - -

14

15 - NC

16

17

18 - NC

9

to

31

32

33

34 - NC

35 --

36

Printer Features

Dir.

Out A HIGH signal indicates that the printer

is out of paper.

-

-

-

-

-

-

In

-

-

-

Pulled up to +5 V through a

resistor.

When this signal is LOW, paper is

automatically fed one line upon receipt of

a CR code. (This signal level can be set

LOW by default.)

Not used.

Logic GND level.

Printer chassis GND.

In the printer, the chassis GND and the

logic GND are short-circuited.

Not used.

Twisted-pair return signal GND level.

When the level of this signal becomes

LOW, the printer controller is reset to its

initial state and the print buffer is cleared.

This signal is normally at the HIGH level,

and its pulse width must be more than

50 us at the receiving terminal.

The level of this signal becomes LOW

when the printer is in

1. Paper-out status

2. Error status

Twisted-pair return signal GND level.

Not used.

Pulled up to +5V through a 3.3 K-ohm

resistor.

The data between DC3 and

when this signal is HIGH. (The level of

this signal is factory set to LOW.)

Description

.

3.3K-ohm

-

DC1

is invalid

Notes:

Epson

FX-870/1170

1. Direction of signal flow is as viewed from the printer.

2. Return means twisted pair return and is to be connected at signal ground

level.

Be sure to use a twisted-pair cable for each signal, and always complete the

3.

connection on the return side. To prevent noise effectively, these cables

1-15

Page 28

Printer Features

should be shielded and connected to the chassis of the host computer and

the printer, respectively.

4. All interface conditions are based on TTL level. Both the rise and fall times

of each signal must be less than 0.2 us.

5. Data transfers must not be carried out by ignoring the ACKNLG or BUSY

signal. (Data transfers to this printer can be carried out only after confirming the ACKNLG signal or when the level of the BUSY signal is LOW.)

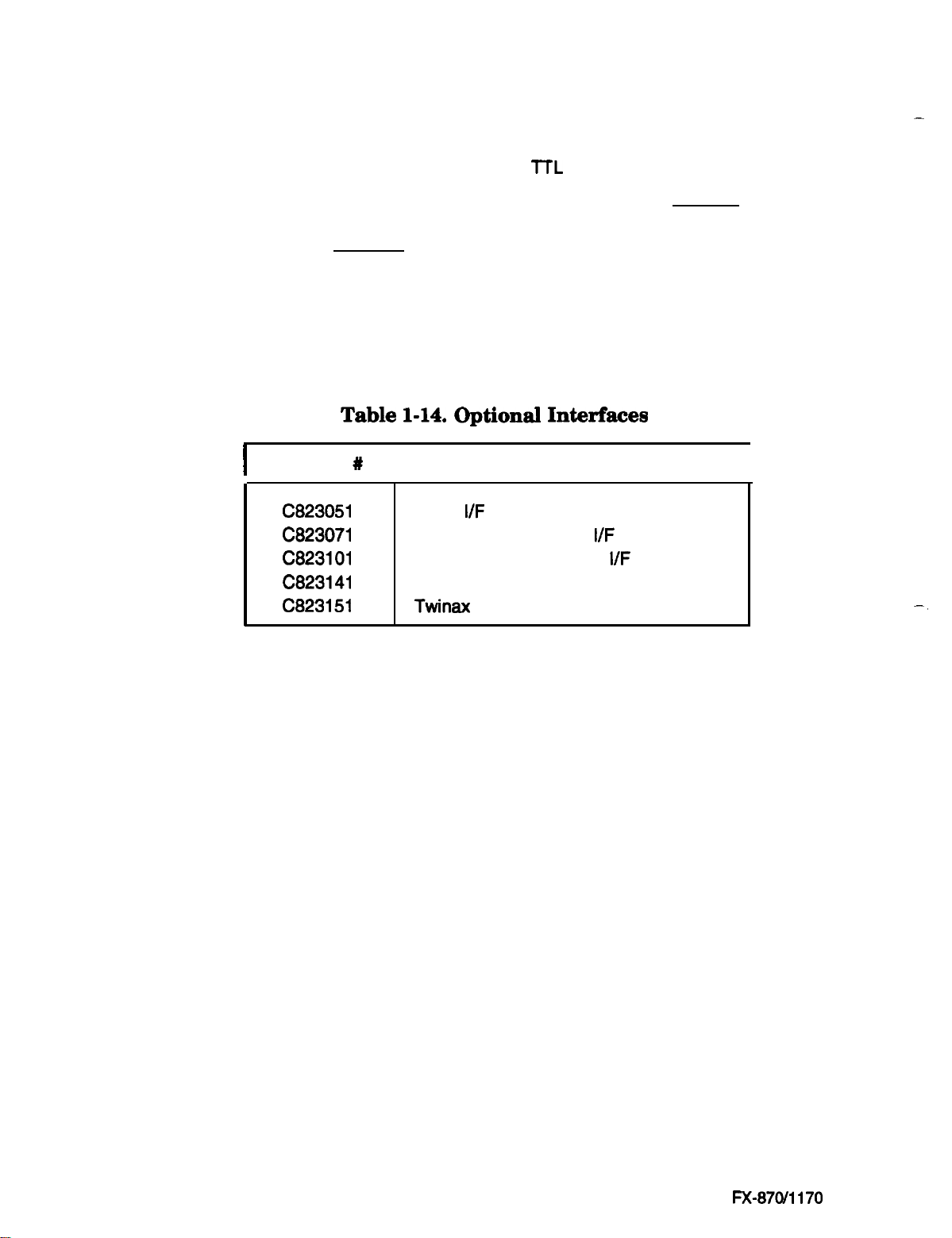

Optional Interfaces

The following interface cards can be used for this printer:

Table 1-14. Optional Interfaces

I

Catalog

C823051

C823071

C823101

C823141

C823151

W

I

Serial

32KB intelligent serial

32KB intelligent parallel

Coax interface (Type B)

Twinax interface (Type B)

I/F

card (Type B)

Interface

I/F

card (Type B)

I/F

card (Type B)

-

I

-_

1-16

Epson

FX-870/1170

Page 29

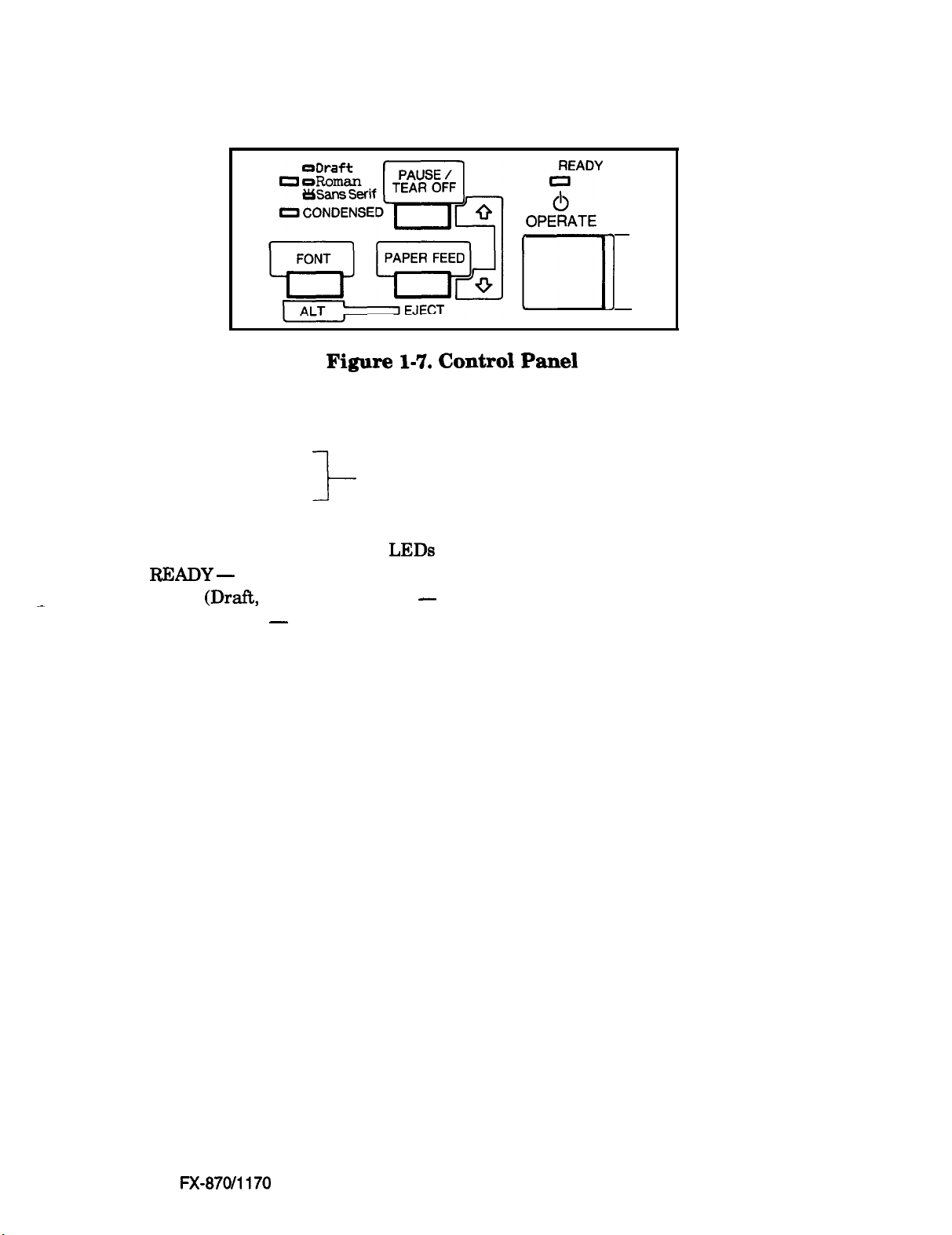

Control Panel

Buttons

OPERATE

PAUSE/TEAR OFF

PAPER FEED

FONT

,,

OPL,,

Figure 1-7. Control Panel

1 lock type button

I-

(non-lock push-type buttons)

Printer Features

READY

3

Indicators

READY -

-

FONT (Draft, Roman, Sans serif) - (green)

(green)

LEDs

CONDENSED - (green)

Buttons

PAUSE

l

When there is data in the input buffer:

Selects printing or pause alternately.

l

When there is no data in the input buffer:

Advances continuous paper to tear-off position after the printer has printed

received data and is ready to receive more print data.

PAPER FEED

l

When there is paper in the paper path:

Advances the paper line by line, using the current line spacing setting while the

printer is ready to print or paused by PAUSE button.

Holding down the button for

about 1 second advances the paper to the next top-of-form (TOF) position.

all

l

When there is no paper in the paper path:

Loads continuous paper inserted in the push tractor or cut sheets in the CSF after

the printer has detected the paper out.

Epson

FX-870/1170

1-17

Page 30

Printer Features

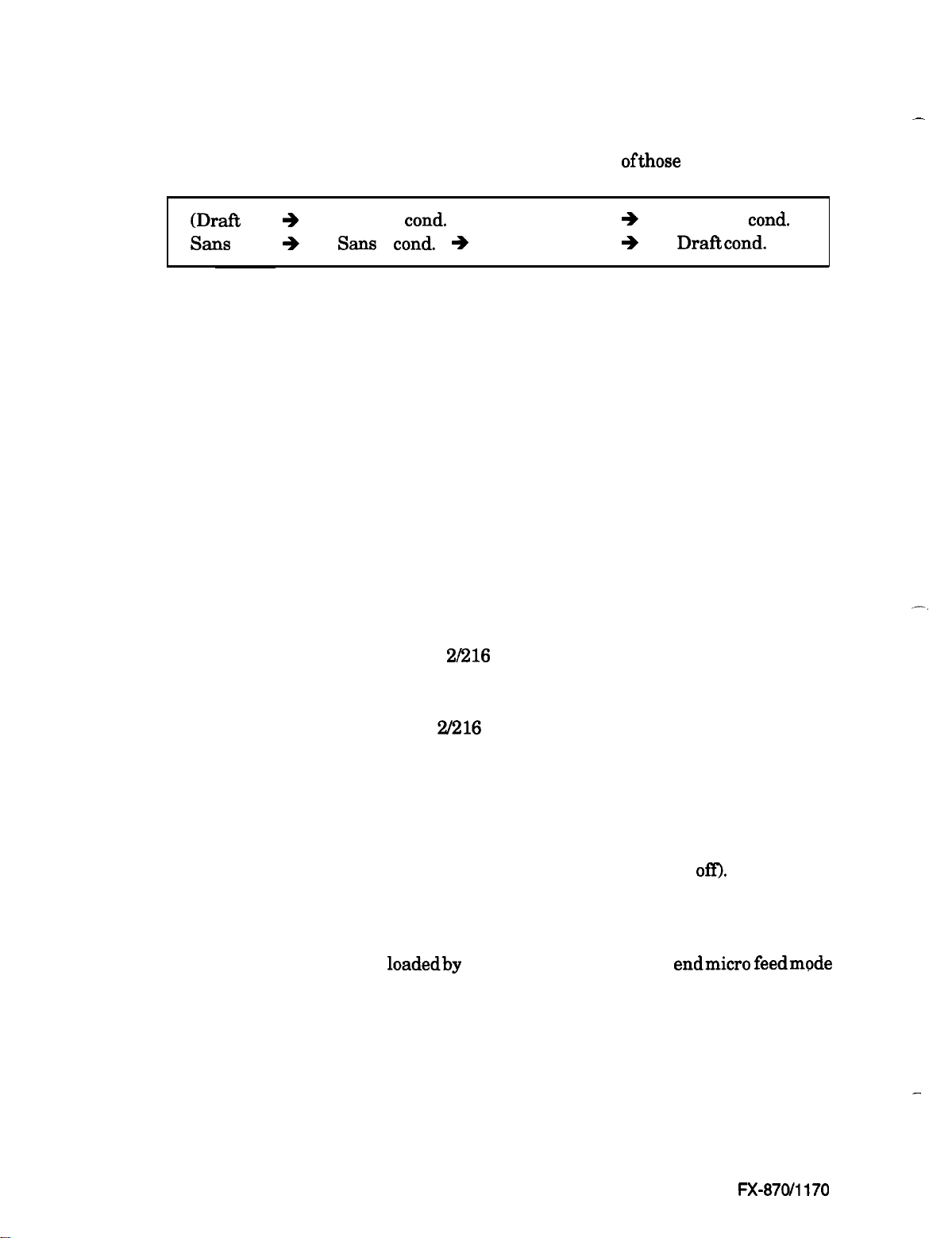

FONT (ALT)

Selects NLQ Roman, NLQ Sans serif, Draft, and condensed

(DraR

Sam

serif

+

*

Draft

Sam cond. +

cond.

3 Roman

Draft

ofthose

+

+

3 fonts in rotation:

Roman

Draft

cond.

cond.

3

. ...)

(The factory setting is Draft, uncondensed font.) The selection is executed when the

button is released and is stored in non-volatile memory.

Micro Feed Function

l

When paper is in the paper path:

1.

Press the PAUSE button to stop printing.

2.

Hold down the FONT (ALT) button and press the PAUSE button to enter the

micro feed mode.

3.

The FONT and CONDENSED lights blink alternately to indicate that the

printer is in micro feed mode.

-

l

In micro feed mode:

PAUSE

Advances the paper forward by 2/216 inch per step.

PAPER FEED

Moves the paper backward by 2/216 inch per step.

Depending on the time when the micro feed is activated, it will micro-adjust the

following positions:

l

the loading position (immediately after paper is loaded in the printer).

l

the tear-off position (when paper has been advanced for tear

l

the current print position (this position is not stored in memory).

off).

The adjustedloading and tear-off positions are stored in non-volatile memory (except

for the position of cut sheets

loadedby

manual insertion). You can

endmicro feedmode

by pressing the FONT button again. The printer exits this mode automatically when

any data arrives from the host computer.

1-18

Epson

-

FX-870/1170

Page 31

Printer Features

Bin Selection for the Cut Sheet Feeder

l

When there is no paper in the paper path:

Holding down the FONT (ALT) button while pressing PAUSE or PAPER FEED

alternates bin selection if a double-bin cut-sheet feeder is attached and friction feed

is selected.

Paper Ejection

Holding down the FONT (ALT) button and pressing PAPER FEED ejects a cut-sheet

forward or feeds continuous paper backward to the paper park position.

Indicators

READY

Ready to print:

Tear-off

Pause: Blinking (50% duty)

Paper error:

Head hot:

ON

Blinking (75% duty)

Blinking (25% duty)

Blinking (25% duty)

FONT

Draft:

OFF

NLQ Roman: ON

NLQ Sans serif:

Blinking

CONDENSED

Normal pitch: OFF

Condensed pitch: ON

When an error occurs, the READY, FONT, and CONDENSED

LEDs

combination to identify the error.

Table

I

Blinking simultaneously

Blinking simultaneously very quickly

Blinking sequentially in the clockwise direction

All on

Blinking in the counter-clockwise direction

1-15.

All indicators

Identification

of

Errors Using the LEDs

Error

Fatal error

Incorrect RAM

High voltage error

Low vottage error

Head thermistor open circuit error

are used in

Epson

FX-870/1170

1-19

Page 32

Printer Features

Default Settings

You can set certain default parameters to be used at printer initialization.

the parameters shown in

1.

Turn on the printer while pressing the FONT button. The printer beeps once and

prints the current default settings on the paper loaded in the paper path.

2. Press FONT to select a parameter. The FONT and CONDENSED

on, off, or blink to show the current parameter selected.

as necessary, until the LEDs indicate the setting to be changed. (See Table l-16.)

3. Press PAUSE to change the setting. The READY LED shows your selection.

4. Repeat this procedure for any Group 1 feature you want to change. (After you set

the feature

Table 1-16.)

5. When all the settings are as you want

are stored in non-volatile memory.

at

the

Table l-16, Group 1 Features,

bottom

of Table 1-16, the printer returns to the first feature in

them,

follow the steps below:

Press FONT as many times

turn off the printer. The settings

To change

LEDs

turn

-.

FONT

LED

OFF

OFF

ON

ON

BLINKS

BLINKS

BLINKS

COND.

LED

ON

BLINKS

OFF

BLINKS

OFF

ON

BLINKS

Table l-16. Group 1’Features

Feature

Emulation

Character pitch

Page length

Skip over perforation

Zero face

Auto tear-off

Auto LF with CR

ESC/P OFF

IBM Proprinter ON

Pica OFF

Elite ON

11 inch

12 inch

8.5 inch

70/6 inch (A4)

No skip

Skip 1 inch

Setting

READY

LED

OFF

ON

BLINKS

BLINKS

FAST

OFF

ON

Note: The factory setting is that the READY LED is OFF for all features.

1-20

Epson

FX-870/1170

Page 33

Printer Features

To change the settings shown in

Table l-18, Group 2 Features

1.

Turn on the printer while pressing the FONT and PAUSE buttons. The printer

beeps once and prints the current character table for either ESC/P or IBM mode

on the paper loaded in the paper path.

2. Press the FONT button to select the character table. The FONT, CONDENSED,

and BEADY

button as many times as necessary until the FONT, CONDENSED, and BEADY

LEDs

indicate the character set you want.

3. Turn off the printer. The settings are stored in non-volatile memory.

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

LEDs

Table

OFF

OFF

ON

ON

ON

BLINKS

BLINKS

BLINKS

OFF

OFF

OFF

ON

ON

ON

BLINK

turn on, off, or blink to show your selection. Press the FONT

1-17.

BLINKS

OFF

BLINKS

OFF

BLINKS

OFF

BLINKS

OFF

BLINK

OFF

Table 1-17, Group 2 Features

(7BM

mode),

follow the steps below:

(ESC/P

Group 2 Features (ESC/P Mode)

Character Table

ON

ON

ON

ON

ON

Italic

Character table

U.S. (standard setting)

France

Germany

U.K.

Denmark

Sweden

Italy

Spain

PC437

PC850

PC860

PC863

PC865

BRASCI

Abicomp

mode),

I

or in

I

Note:

Epson

When the character table PCxxx is selected, that is assigned as the table

selected by the,ESC tl command. Then ESC tl and ESC 6 are set as defaults.

(Codes 80-9FH are printable characters.)

FX-870/1170

1-21

Page 34

Printer Features

Table l-18. Group 2 Features (IBM Mode)

FONT COND. READY

LED

OFF

OFF

LED

OFF ON

OFF BLINKS

OFF ON

[

OFF 1 ON 1 ON

1.

Notes:

For table

1,

codes

LED

OFF

80-9FH

Character table PC437 (table 1) (standard)

are control codes. (ESC 7 is set.)

Character Table

PC437 (table 2)

PC865 (table

PC865 (table 2)

1)

For table 2, codes 80-9FH are printable characters. (ESC 6 is set.)

2. The character tables for ESC/P mode and IBM mode

aresaved

independently

in non-volatile memory.

Power On Default Settings

The printer also lets you change some of its power on parameters.

settings shown

in Table 1-19, Group 3 Features (Power On Settings),

below.

1.

Turn on the printer while pressing the PAUSE and PAPER FEED buttons.

2.

After

a few seconds, press the buttons indicatedin Table 1-19 to change parameters.

To change the

follow the steps

Table 1-19. Group 3 Features (Power-on Settings)

Button

PAUSE

PAPER FEED

FONT

Notes:

1. Auto CR moves the next print position to the left margin when a LF or the

2.‘~‘isonebeep,and‘*~

3. The printer automatically becomes ready to print after the selection.

Feature

Input buffer

Draft printing speed

Auto CR

valid p 0) or invalid

high p 0) or normal

valid p 0) or invalid

T

standard (factory) setting

ESC J code is sent.

’

is two beeps. If no operation is executed within a

few seconds, the printer exits the power on selection mode with five beeps

l l l l

(

0).

The selected value is stored in non-volatile memory.

Betting

p)

p)

p)

Self-Test

Press PAPER FEED while turning on the printer to put it in self-test mode. To stop

the self-test, turn off the printer. (The control panel is still operational in self-test

mode for paper handling and font selection.) When pages are printed

from

the cut-

-

1-22

Epson FX-870/1170

Page 35

Printer Features

sheet feeder (CSF), the first sheet is used for scaling the sheet length. Then, the

maximum number of printable lines is printed in the bottom line of the sheet and

saved in non-volatile memory as the default page length. Page lengths are saved

individually when a dual-bin CSF is in use.

The self test prints out the following:

l

Maximum printable lines (only on cut sheets

l

Firmware version

l

Current default settings

l

Short help messages for control panel operation

l

A pattern of characters, as shown below.

t%om

the CSF)

Figure

l-8.

Self-Test Printout

Hexadecimal Dump

Press the PAUSE button while turning on the printer to put it in hexadecimal dump

mode. In this mode, the printer prints out the hexadecimal format for received data,

along with the corresponding ASCII characters. This function is useful to check

received data from the host.

printer prints a period (.) in the ASCII column.

See Tables 3-10 and 3- 11 for a hex listing of the commands acceptable to this printer.

Figure

If a received code is not a printable ASCII character, the

1-9.

Hexadecimal Dump Printout

Epson

FX-870/1170

1-23

Page 36

Printer Features

Paper-out Detection

If the paper-out sensor detects a paper out, the printer automatically enters a pause

condition after feeding or printing several lines. When a paper-out is detected, load

new paper properly and set the printer ready to print by pressing the PAUSE button.

Auto

Tear-off

When the release lever is set to one of the tractor positions, paper advances to the tear-

off position automatically, if the input buffer is empty and paper is at the top-of-form

position (as long as the printer receives no additional data after receiving a form feed).

If it receives new data, the printer reverse feeds paper to its original position and

starts printing. This function can be disabled in the default setting mode.

Buffer Full Printing

The printer stores received data in the input data buffer, and prints it when it

encounters a print command (CR) or when the buffer becomes full.

Thermal Protection

When the thermistor detects that printhead temperature exceeds

printer stops printing to protect the printhead from overheating.

180”

F

(82”

C), the

High-Duty Printing

When the +35 V monitor circuit determines that printing duty is too heavy for the

power supply because the line voltage has dropped, the printer stops printing until

the voltage recovers.

It then continues printing the rest of the document at halfspeed.

Sheet Loading and Sheet Ejection

The release lever engages or disengages the tractor unit drive mechanism. The lever’s

operation provides improved paper-handling functions:

l

Automatic cut-sheet loading without the cut-sheet feeder

Move the release lever to the FRICTION position and load a sheet using the paper

guide (top or optional front). A few seconds later, the sheet is automatically loaded

to the top-of-form position, and the printer becomes ready to print.

. Automatic cut-sheet loading and ejection with the cut-sheet feeder

Move the release lever to the FRICTION position, and load a stack of paper into the

cut-sheet feeder hopper. Pressing PAPER FEED loads the sheet to the top-of-form

1-24

Epson FX-870/1170

Page 37

Printer Features

position.

If a paper out is detected before printing starts, the sheet is loaded

automatically to the top-of-form position, without PAPER FEED being pressed.

l

Continuous paper loading and ejection (paper park)

Move the release lever to REAR PUSH/FRONT PUSH position and load paper into

the tractor unit. Press PAPER FEED to load the paper automatically to the top-ofform position.

If a paper-out is detected before printing starts, paper is loaded

automatically to the top-of-form position, without PAPER FEED being pressed.

If the FONT+PAPER FEED buttons are pressed when continuous paper is loaded, the

paper is ejected backward to the paper park position. To feed several pages backward,

repeat this operation several times.

Adjust Lever Operation

You must set the platen gap adjust lever to the proper position (from the 8 steps

available) for the paper thickness.

If this lever is set to position 2 (the 4th step) or

higher, printing speed and paper feeding speed are reduced.

Table l-20. Lever Positions

I Lever Position I

0

(2nd step) 0.0024 -0.0048 inches (0.06- 0.12 mm)

1

(3rd step) 0.0052 -0.0068 inches (0.13- 0.17 mm)

2

(4th step) 0.0072- 0.01 inches (0.18 -0.25 mm)

3

(5th step) 0.0104 -0.0128 inches (0.26- 0.32 mm)

Note:

If printing density is light, set the platen gap adjust lever position one step closer.

Paber

Position 1 (3rd step)

Thickness

I

Lever

Epson

FX-870/1170

Figure l-10. Lever Positions

1-25

Page 38

Printer Features

Printer Initialization

The printer is initialized in the following cases.

l

When the printer is turned on.

l

When the INIT signal or CMREQ (optional

When the printer is initialized, it performs the following functions:

l

The printhead returns to the leftmost position (carriage home).

l

The READY LED lights.

l

The printer clears the print buffer and input data buffer.

l

The line spacing is set to l/6 inch.

l

The page length and skip-over-perforation settings are returned to their default

values.

l

All vertical tab positions are cleared.

l

The horizontal tab positions are set to every 8 columns.

.

The print mode is set to the default value set

non-volatile memory.

I/F )

fkom

is input.

the control panel and stored in

TOF position is reset in the following cases.

. Power on

l

Receipt of the

l Receipt of a software reset command (ESC

INIT signal

or

CMIXEQ

(optional

Q)

. Receipt of a page length command (ESC C)

Note:

The CMREQ signal goes LOW when the command request is sent from the

optional card to the

main

system.

I/F)

1-26

Epson

FX-87CY1170

Page 39

Printer Features

Buzzer

The buzzer beeps for 0.1 second at a time. These beep sounds are combined in various

l

ways, as shown below, to indicate different meanings. In the following table, each

”

”

stands for one beep.

Table 1-21. Buzzer Functions

Status Sound

3EL code

Zarriage

Joltage

trouble

error

0

- -

No beeps.

Sounds when a BEL code is received.

A carriage error has occurred.

(Indicators blink sequentially in the

Description

clockwise direction.)

=atal

error

ncorrect

‘aper

error

No beeps.

memory m w a

0.ae.0ao.0

- - - - -

y

(Indicators blink simultaneously.)

-

RAM

- E*PROM

Continuous paper has run out.

Paper in the CSF has run out.

Paper was not present at the start of a

self-test.

A sheet could not be ejected from the

-.

no

CSF.

Anotherpaperdetectionerroroccurred:

With single-sheet feed selected, no

paper is present.

Continuous paper can’t be loaded.

Paper runs out after the PAPER FEED

button is pressed.

Illegal paper

release/unrelease

-

. . .

(continuously till corrected)

The release lever was changed while

there was paper in the paper path.

Change the lever again or remove the

paper in the path to stop the sound.

Recognition of l

operation

Power-on operation (self test, hex

dump, default setting, or power-on)

CSF bin -1 selected.

Micro feed

”

.

CSF bin -2 selected.

The adjusted value set with micro feed

is the same as the factory setting value

(loading position or tear-off position).

-

. . .

(continuously until button is released)

The micro feed value has reached its

upper or lower limit.

Epson

FX-870/1170

1-27

Page 40

Printer Features

Main Components

The components of the FX-870/1170 are designed for easy removal and replacement

during

l

l

l

l

l

The following figure shows the main components of the FX-870/1170.

maintenance

and repair. The main components are:

C094 MAIN board assembly

C094 PNL board assembly

C076 PSB board assembly

Printer mechanism

Housing assembly

Platen

Gap Adjust Lever

Release Lever

B Board Assembly

IN Board Assembly

1-28

Pril

iter

Mechanism

Figure 1-11. Main Components

Epson FX-870/1170

Page 41

Printer Features

C094 MAIN Board Assembly (Main Control Circuit Board)

Basically, the same board layout is used in both the

column model.

It consists of a

The CPU on this board controls all the main functions of the printer.

TMP90C041F 8-bit

CPU, an

E05A55YA

136~column

model and the

gate array, an

E2PROM,

PSRAM, a MASK ROM, motor drivers, and head drive transistors.

PF MOTOR

CR MOTOR

DRIVER

,,DAld-lfil-l

o”-+q/

1”

CPU

TM,p,),

I;

CTRr”.“’

E2PROM

; MASK ROM

80-

a

I/F

HEAD DRIVE

TRANSISTORS

GAiE

ARRAY

E05A66YA

Figure 1-12. CO94 MAIN Board Assembly

(Main Control Circuit Board)

Epson

FX-870/1170

1-29

Page 42

Printer Features

C094

This

function buttons, and three indicator

PNL Board Assembly (Control Panel Circuit Board)

boardis

the control panel

Figure

ofthe F’X-870/1170,

1-13. CO94

LEDs.

(Control Panel Circuit Board)

consisting of a power button, three

PNL Board Assembly

CO76 PSB Board Assembly (Power Supply Circuit Board)

This board is composed of an input filter circuit, a transforming circuit, a switching

regulator circuit, a rectifying circuit, a smoothing circuit, and various protecting

circuits.

1-30

Figure

(Power Supply Circuit Board)

1-14. CO76

PSB Board Assembly

Epson FX-87011170

Page 43

Printer Features

Printer Mechanism

The printer mechanism consists of a g-pin impact dot head, a carriage mechanism,

a carriage motor, a paper feed mechanism, a paper feed motor, a ribbon feed

mechanism, and various sensors.

136-column

80-column

model

model

Figure l-16. Printer Mechanism

Epson

FX-870/1170

1-31

Page 44

Printer Feature8

Housing Assembly

The printer mechanism and all the boards are contained in a housing assembly that

consists of the upper case and the lower case.

1-32

Figure 1-16. Housing Assembly

Epson FX-870/1170

Page 45

Printer Features

Commonly Asked Questions and Answers

This section contains facts that customers often want to know about this printer.

The question-and-answer format is to make it easier for you to scan through the

information.

1.

2.

3.

4.

5.

What are the FX-870 and FX-1170 printers?

Q.

A.

The FX-870 and FX-1170 printers are the direct

replacements for the

FX-850 and FX-1050 printers.

Q.

What is the rated

A.

380 cps in high-speed draft

print

speed for the FX-870 and the FX 1170?

285 cps in draft pica

342 cps in draft elite

Q.

What printer

A.

l Epson

l

IBM Proprinter (X or XL, for narrow or wide carriage)

Q.

What are the

operating modes

ESC/P

resident fonts are

are built into the FX-870/1170?

in these printers, and are they

scalable?

A.

Draft, Roman, and Sans Serif. The FX-870 and FX-1170 do not support

Epson ESC/P2 scalable fonts.

If the program I am running does not list the FX-870 or FX-1170 as a

Q.

printer selection, what other printer can I select in my software?

A.

6. Q.

A.

Acceptable

driver selections

for Epson mode are listed below in order of

preference:

l FX-850

. EX-800

l FX-86e

l

FX-80+ FX-

l

Epson Printer

l

g-pin

Printer

FX- 1050

EX-1000

FX-286e

lOO+

Acceptable driver selections for IBM mode are listed below:

l

IBM Proprinter (X for narrow carriage or XL for wide carriage)

What is the rated

Ribbon

life of the ribbon and printhead?

3 million characters at 14 dots per character

Printhead 100 million characters at 14 dots per character

Epson

FX-870/1170

1-33

Page 46

Printer Features

7. Q.

A.

Q.

8.

A.

Q.

9.

A.

Q.

10.

Do the FX-870 and FX-1170 use the same

FX-

1050?

Yes.

8750 (fabric) for the FX-870

ribbons as

the FX-850 and

8755 (fabric) for the FX-1170

8758 ribbon only replacement pack

(Never use ribbons for 24-pin printers. To extend printhead life, use only

the Epson ribbons listed above.)

What is the

part number for the printhead?

F031000

If any of the pins in the printhead are shorted, be sure to replace the

main board at the same

What type of interface is built into the

time

as the printhead.

FX-870/1170?

The FX-870 and FX-1170 have the most commonly used interface port:

l

Centronics parallel

The printer also has an additional slot for an Epson Type B interface.

What

is the size of the

input buffer

for the built-in parallel interface?

11.

12.

A.

24K (can be enabled or disabled in the default setting mode)

Q.

What

A.

Q.

A

accessories

FX-870

Part No.

C808371

C803881

c800201

C814001

C823051

c823071

C823101

C823141

c823151

Cl

-9E-A

8310

What

is the

CSF

Single-bin

High-capacity

are available for the FX-870 and FX-1170?

FX-1170

Part No.

C808391

C808401

C800211

C814011

C823051

C823071

C823101

C823141

C823151

Cl

-9E-A

Description

Single bin cut sheet feeder

High-capacity cut sheet feeder

Additional tractor unit

Front sheet guide

Serial interface

32KB serial interface

32KB parallel interface

Coax interface

Twinax interface

Parallel printer cable

Roll paper holder (FX-870 only)

capacity of the optional cut-sheet feeders?

Capacity

50 sheets (no envelopes, multi-part forms, or labels)

150 sheets/25 envelopes (no multi-part forms or labels)

1-34

Epson

-

FX-870/1170

Page 47

13. Q.

A.

14.

Q.

A.

15.

Q.

A.

Printer Features

How

many

paper paths

are there for the FX-870 and FX-1170?

The printers have 4 paper paths:

Top feed

Bottom feed

Rear feed

Front feed

How

is the

tractor

used for feeding with the FX-870/1170?

The FX-870 and FX-1170 come with one tractor, which can be positioned

for three different types of feeding:

Front feed push tractor

Rear feed push tractor

Top-mounted pull tractor