Page 1

FX-85t3/I05D

TECHNICAL MANUAL

EPSON

Page 2

~...,,

,:

(-’

NOTICE

“ All rights reserved. Reproduction of any part of this manual in any from

whatsoever without

“ The contents of this manual are subject to change without notice.

“ All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected,

being informed of them.

“ The above notwithstanding

errors in this manual or the consequences thereof.

SEIKO EPSON’S express written permission is forbidden.

SEIKO EPSON would greatly appreciate

SEIKO EPSON can assume no responsibility for any

(L

Copyright 1988 by SEIKO EPSON CORPORATION

Na,ga

no, Japan

-i-

(,.

. . . .

”

Page 3

PREFACE

This manual describes functions, theory of electrical and mechanical

FX-

operations, maintenance, and repair of the FX-850 and

The instructions and procedures included herein are intended for the

experienced repair technician, and attention should be given to the

precautions on the preceding page. The chapters are organized as follows:

1050.

REV.-A

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Chapter 5 -

Chapter 6 -

● The contents of this manual are subject to change without notice.

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer operation.

Discusses the options

Includes a step-by-step guide for product disassembly,

assembly, and adjustment.

Provides Epson-approved techniques for troubleshooting.

Describes preventive maintenance techniques and lists

lubricants and adhesives required to service the equipment.

– iv

–

Page 4

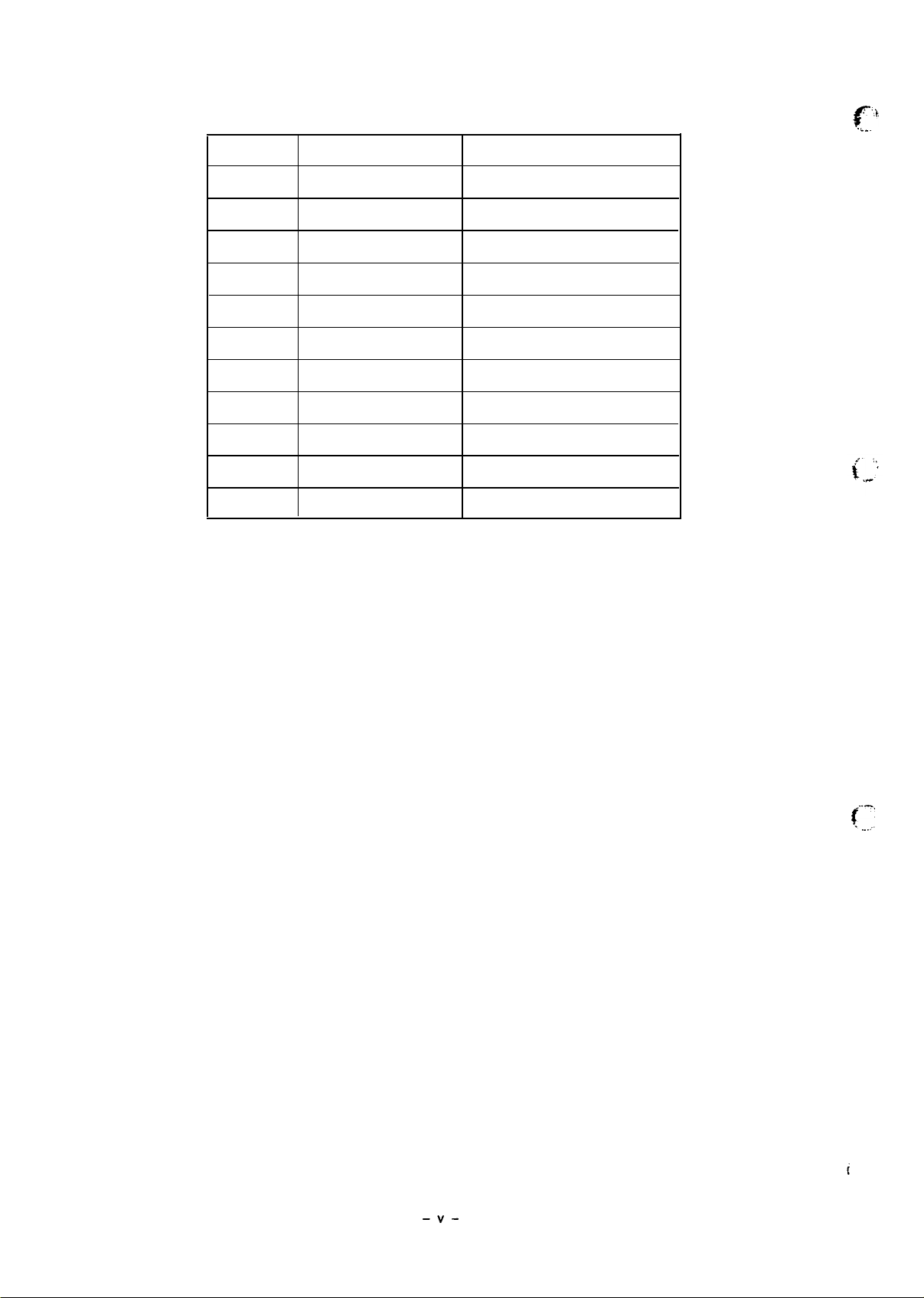

REV.-A

REVISION

REVISION TABLE

DATE ISSUED

CHANGE DOCUMENT

g,},

. .. .

.

A

February 15, 1988

1st issue

-v-

f--;

Page 5

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1 ) personal injury, and 2) damage

to equipment:

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

1.

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL

UCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE EPSON WARRANTY.

NUMBERIRATING PLATE. IF THE EPSON PROD-

jLP

CHIPS AND CIRCUITRY, USE STATIC

- ii -

Page 6

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

REV.-A

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

OPTIONAL EQUIPMENTS

(Intentionally omitted at this time)

DISASSEMBLY, ASSEMBLY, AND ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

–

vi –

Page 7

CHAPTER 1

GENERAL DESCRIPTION

REV.-A

FEATURES

1.1

SPECIFICATIONS

1.2

1.2.1 Hardware Specifications

1.2.1 Firmware Specifications

INTERFACE OVERVIEW

1.3

1.3.1 8-bit Parallel Interface Specifications

DIP SWITCHES AND JUMPER SETTING

1.4

1.4.1 DIP Switch Settings

1.4.2 Jumper Settings

SELF TEST OPERATION

1.5

HEXADECIMAL DUMP FUNCTION

1.6

PRINTER INITIALIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7

1.7.1 Hardware Initialization

1.7.2 Software Initialization

BUZZER OPERATION AND ERROR CONDITIONS ................. 1-22

1.8

1.8.1 Buzzer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.2 Error Conditions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-3

1-3

1-1o

1-12

1-12

1-17

1-17

1-18

1-19

1-20

.

1-21

1-21

1-21

. 1-22

1-22

PAPER HANDLING FUNCTIONS

1.9

1.9.1 Autoloading and

1.9.2 Short Tear-Off Function

1.9.3 Micro-Adjustment Top-of-Form

1.10 PAPER END DETECTION

1.11 MAIN COMPONENTS

1.11.1

1.11.2

1.11.3

1.11.4

1.11.5

Printer Mechanism

PEGX Board (Main Board)

PEBFIL-11

Power Transformer

PGPNL Board (Control Panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Housing

Board (Filter Board) and

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backout Function

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

Figure 1-1.

Exterior Views of the FX-850/1050

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(TOF) Set Function . . 1-23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-23

1-23

1-23

1-24

1-25

1-26

1-27

1-28

1-31

1-1

Figure 1-2.

Printhead Pin Configuration

l-i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3

Page 8

REV.-A

Figure 1-3.

Cut Sheet Paper Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6

.(

“’”

Figure 1-4.

Figure 1-5.

Figure 1-6.

Figure 1-7.

Figure 1-8.

Figure 1-9.

Figure 1-10. Paper End Detection Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Figure 1-11. Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-12.

Figure 1-13.

Figure 1-14. PEGX Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-15.

Figure 1-16. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-17. Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fanfold Paper Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Adjustment Lever Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Data Transmission Timing of 8-bit

Parallel Interface

36-pin 57-30360 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Self-Test Printing

Hexadecimal Dump Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Model-3B10

Model-3B60

PEBFIL-11

(FX-850) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(FX-105O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board and Power Transformer . . . . . . . . . . . . . . . . . . . . . 1-28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7

1-12

1-19

.

1-25

.

1-26

.

1-26

.

1-27

.

1-29

.

1-31

Table 1-1.

Table 1-2.

Table 1-3.

Table 1-4.

Table 1-5.

Table 1-6.

Table 1-7.

Table 1-8.

Table 1-9.

Table 1-10.

Table 1-11.

Table 1-12.

Table 1-13.

Table 1-14.

Table 1-15.

LIST FO TABLES

Optional Units

Optional Interface Boards

Line Feed Speeds

Cut Sheet Paper Specified Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Fanfold Paper Specified Conditions

Roll Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Envelope Specifications

Label Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lever Adjustment

Ribbon Cartridge Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications

Environmental Conditions

Print Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Columns

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1-2

1-4

1-5

.

1-5

1-5

.

1-6

1-8

.

1-9

1-9

1-9

.

1-10

1-11

~-:-,

. . .

Table 1-16.

Table 1-17.

Table 1-18.

Character Size and Pitch

Connector Pin Assignments and

Signal Functions

Printer Select/Deselect Control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11

1-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-16

Page 9

REV.-A

Table 1.19. DIP Switch

Table

1-20. International Character Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Table 1-21.

Table 1-22.

Table 1-23. Self Test Operation

1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch 2 Settings

J1

Setting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................................:...

.......................................S.......SS........."..

. 1-17

1-18

1-18

1-19

Table 1-24. Hexadecimal Dump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1-iii

Page 10

1.1 FEATURES

REV.-A

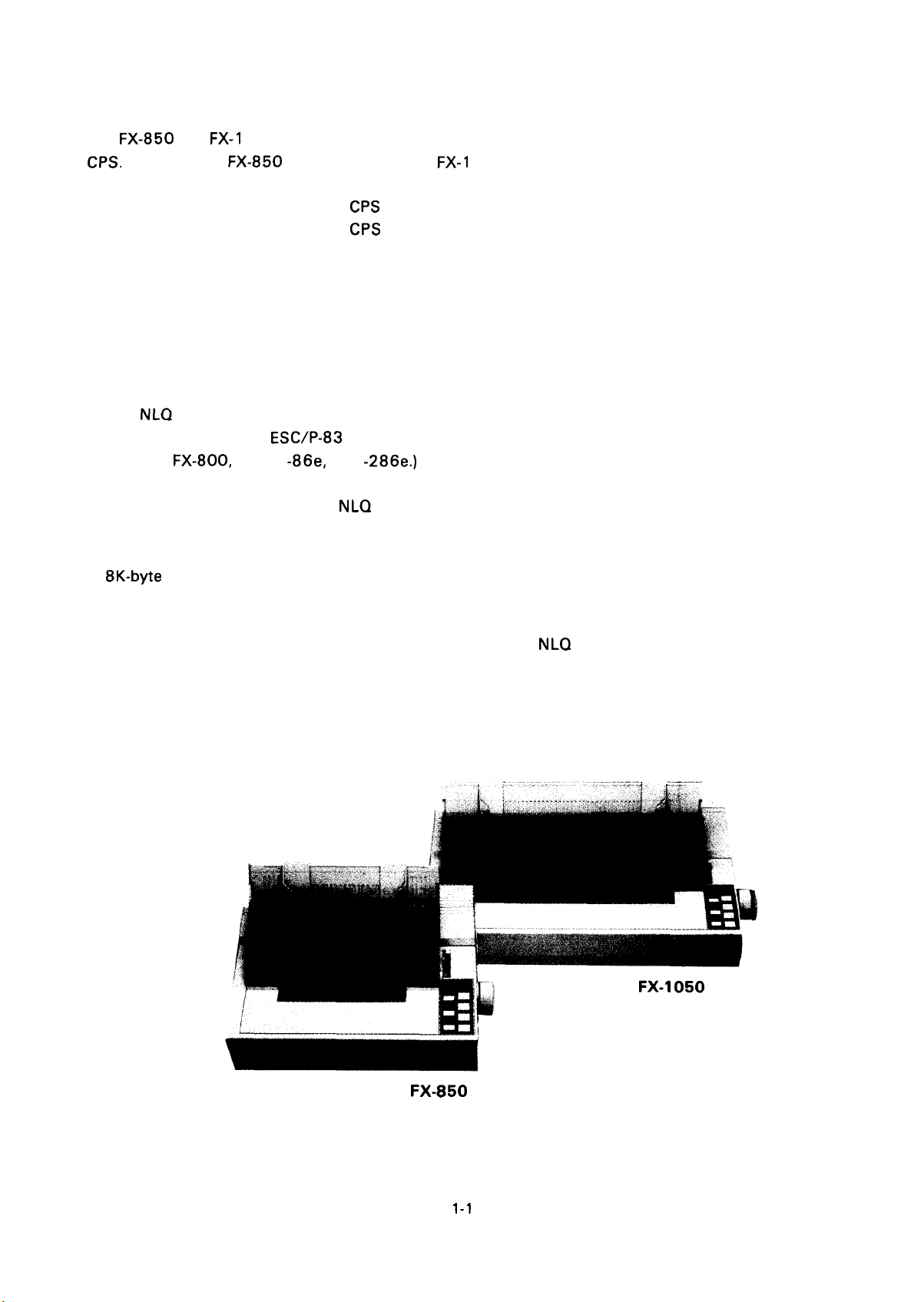

The FX-850 and

CPS.

Either model FX-850 with 80 columns or

to your requirements. The main features are as follows:

Max. printing speed:

●

Advanced paper handling functions: Auto tear-off

●

●

SelecType function (Any print mode can be selected directly from the front panel). Once a mode is

selected, it is stored in the non-volatile memory, and is selected when the printer power is turned

on.

Two

●

●

●

●

●

●

●

●

●

●

NLQ

Printer driver EPSON

such as

Double-height function

Pitch control is possible in the

Since the IBM emulation mode is standard, these printers are IBM-compatible. The IBM characters

are also standard.

8K-byte

Push tractor unit

Printing is possible on envelopes and labels in addition to fan-fold paper, cut sheets, and roll paper.

User-defined characters are supported in both the Draft and

is registered, it is stored in the non-volatile memory and need not be re-registered. The user-defined

character set can only be selected (as a default character set) using the DIP switches.

Compatible with EPSON optional interface board series #81 XX.

input data buffer (Buffering can be disabled.)

FX-1

050 are serial dot matrix 9-pin terminal

FX-1

050 with

264

CPS

(Draft and Elite)

CPS

220

fonts (Roman and Saris-serif) are standard.

ESC/P-83 is standard. (This driver is compatible with the high class models

FX-800, -1000, -86e, and -286e.)

(Draft and Pica)

Auto loading

Auto back-out

Micro adjustment

NLQ

mode. (Pica, elite, proportional modes)

printers that print at a maximum of 264

136 columns can be selected according

NLQ

(Saris-serif) modes. Once a character

FX-850

Figure 1-1. Exterior Views of the FX-850/1050

1-1

Page 11

REV.-A

No.

Table 1-1. Optional Units

Name

FX-850

FX-1

050

#83 10

#731 1

#731 2

#7339

#7340

#8750

#8755 (M)

#8758

#81 XX Optional Interface Board

Roll Paper Holder

Pull Tractor Unit

Pull Tractor Unit

Cut Sheet Feeder (single-bin)

Cut Sheet Feeder (single-bin)

Ribbon Cartridge

Ribbon Cartridge

Ribbon Pack

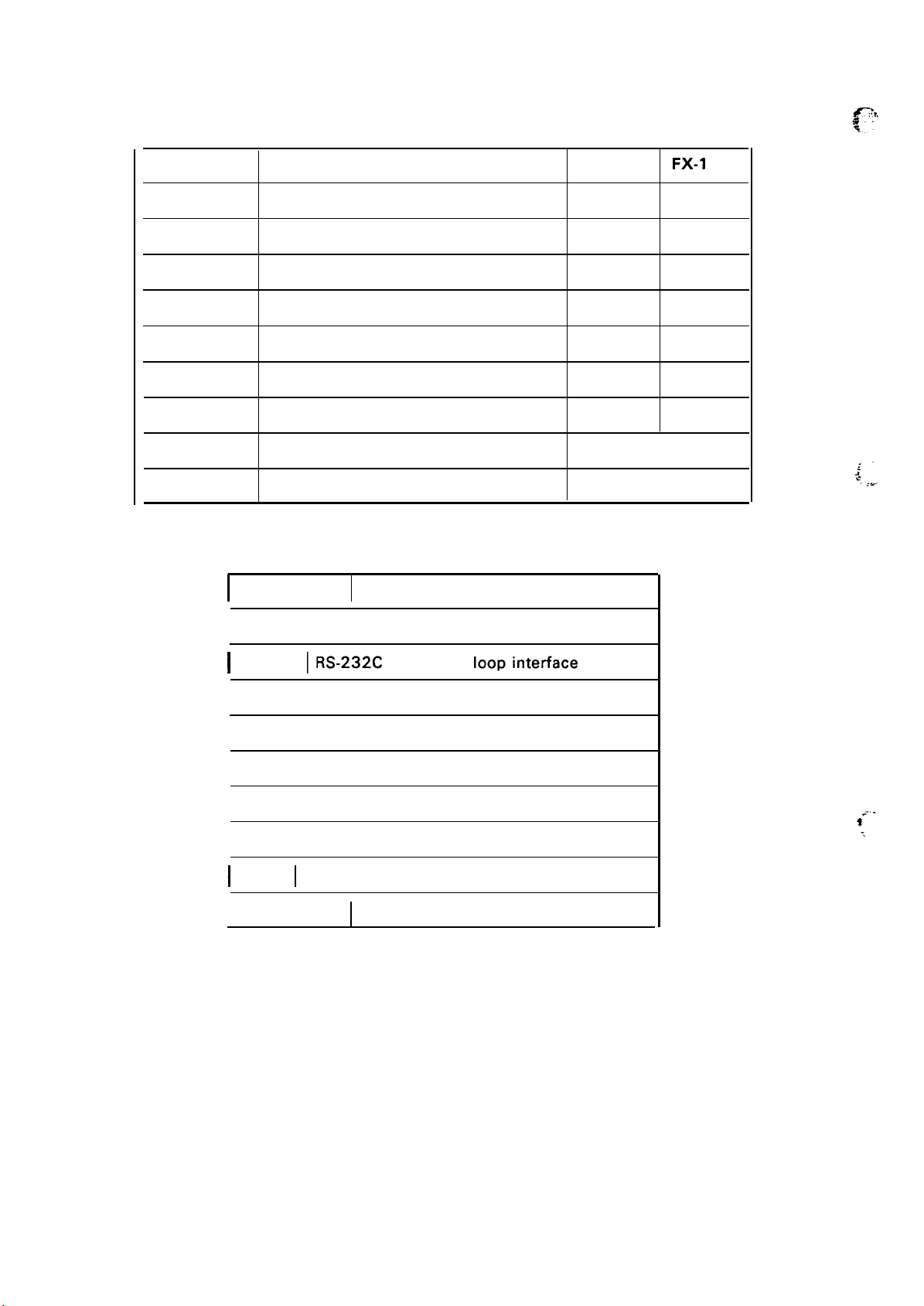

Table 1-2. Optional Interface Boards

No.

#8 143 New serial interface

I

o

o

o

o

o

o

o

o

o

Name

I

#8145

I

I

I

I

I

I

#8172 I 32 K-byte buffer parallel interface

I

IRS-232C

#8 148

#8 149 Intelligent serial interface type II

#8 149M Intelligent serial interface type III

#816 1 IEEE-488 interface

#8 165 Intelligent IEEE-488 interface

#81 72M

current loopinterface type II

Intelligent serial interface

128K-byte buffer parallel interface

-., .

t “’

:.

.

1-2

Page 12

1.2 SPECIFICATIONS

REV.-A

The

FX-850/l

specifications for the printer.

1.2.1 Hardware Specifications

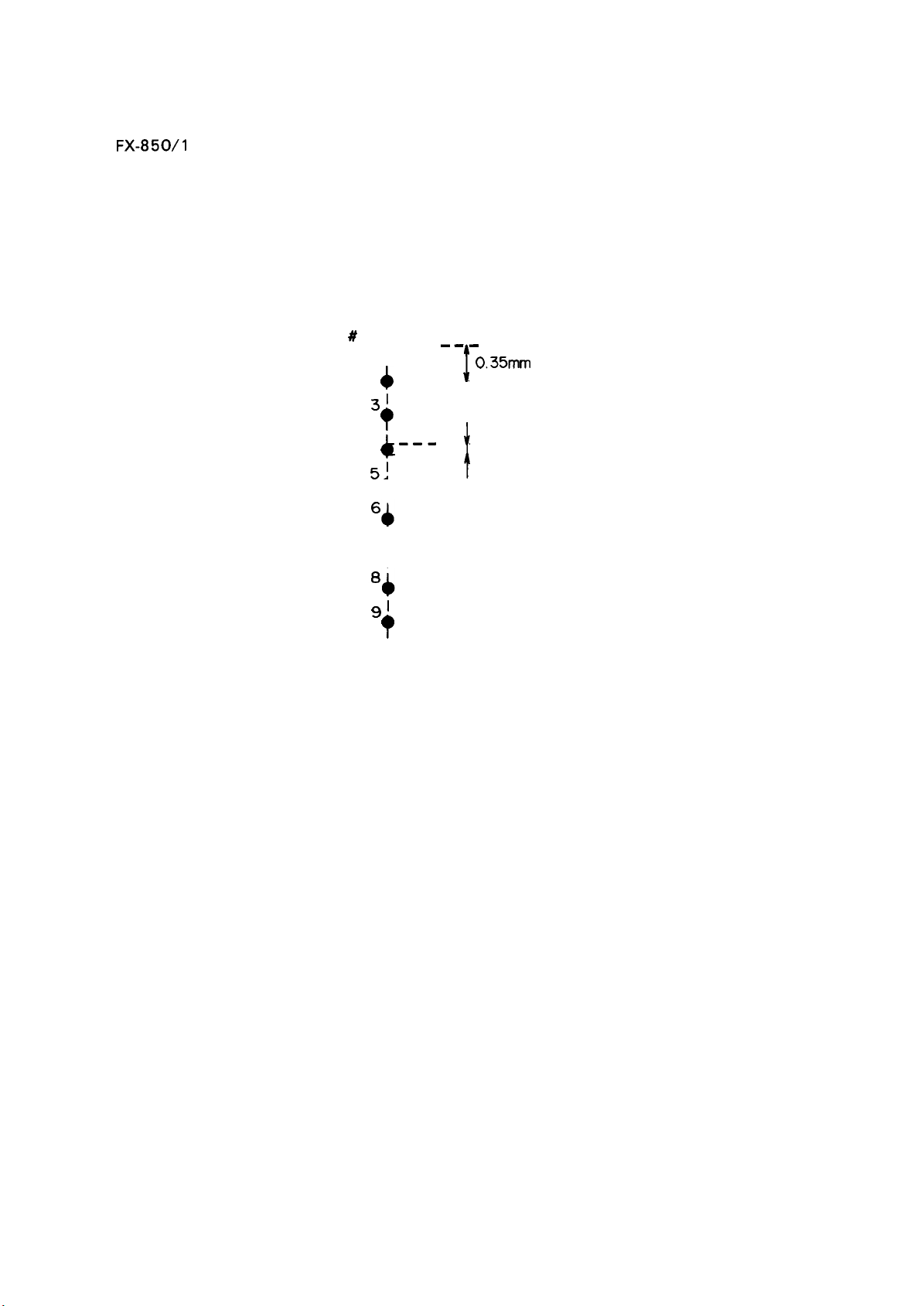

Printing Method

Pin Configuration

050 communicates

Serial, impact dot matrix

See Figure 1-2 (diameter: 0.29 mm).

with a wide variety of host computers. This section describes the

Wires

I

# 1’

2

~1

4

51 ‘

7

t

4

T

4

t

i

t

--— --

––-

--

———

0.35mm ( 1/72” )

I

---

0.29mm

---

---

t

Figure 1-2. Printhead Pin Configuration

Feeding Method

NOTES: 1. When using friction feed:

● Use the paper tension unit.

● Do not use fanfold paper.

● Do not perform reverse feed beyond than 1/6 inches after the paper end has been

detected.

● Do not use multi-part, single-sheet forms.

2. When using tractor feed:

●

Release the friction feed mechanism.

●

Multiple copies for printing must be finished by pasting them together at the line or dots.

●

Copy paper must be a carbonless multi-part paper.

a) When using push tractor feed:

Use the paper tension unit.

●

Friction feed

Tractor feed (push: standard, pull: optional)

~1

?

I

1-3

Page 13

REV.-A

● Do not perform reverse feeding for more than 1/6 inches.

● Because accuracy of paper feed cannot be assured, do not perform reverse feeding ‘

after the paper end has been detected.

b) When using pull tractor feed:

● Remove the paper tension unit and mount the pull tractor unit.

● Use the paper path when a single sheet is inserted.

c) When using push-pull tractor feed:

● Remove the paper tension unit and mount the pull tractor unit.

● Do not loosen the paper between the platen and the pull sprocket.

● -Precisely the horizontal position of the pull sprocket and push tractor.

● Do not perform reverse feeding after the paper end has been detected.

Paper Loading Directions

Fanfold paper

Cut sheet paper

Line Spacing

Line Feed Speed See Table 1-3.

Inserted from the rear side

Inserted from the up side

1/6” or programmable (min.

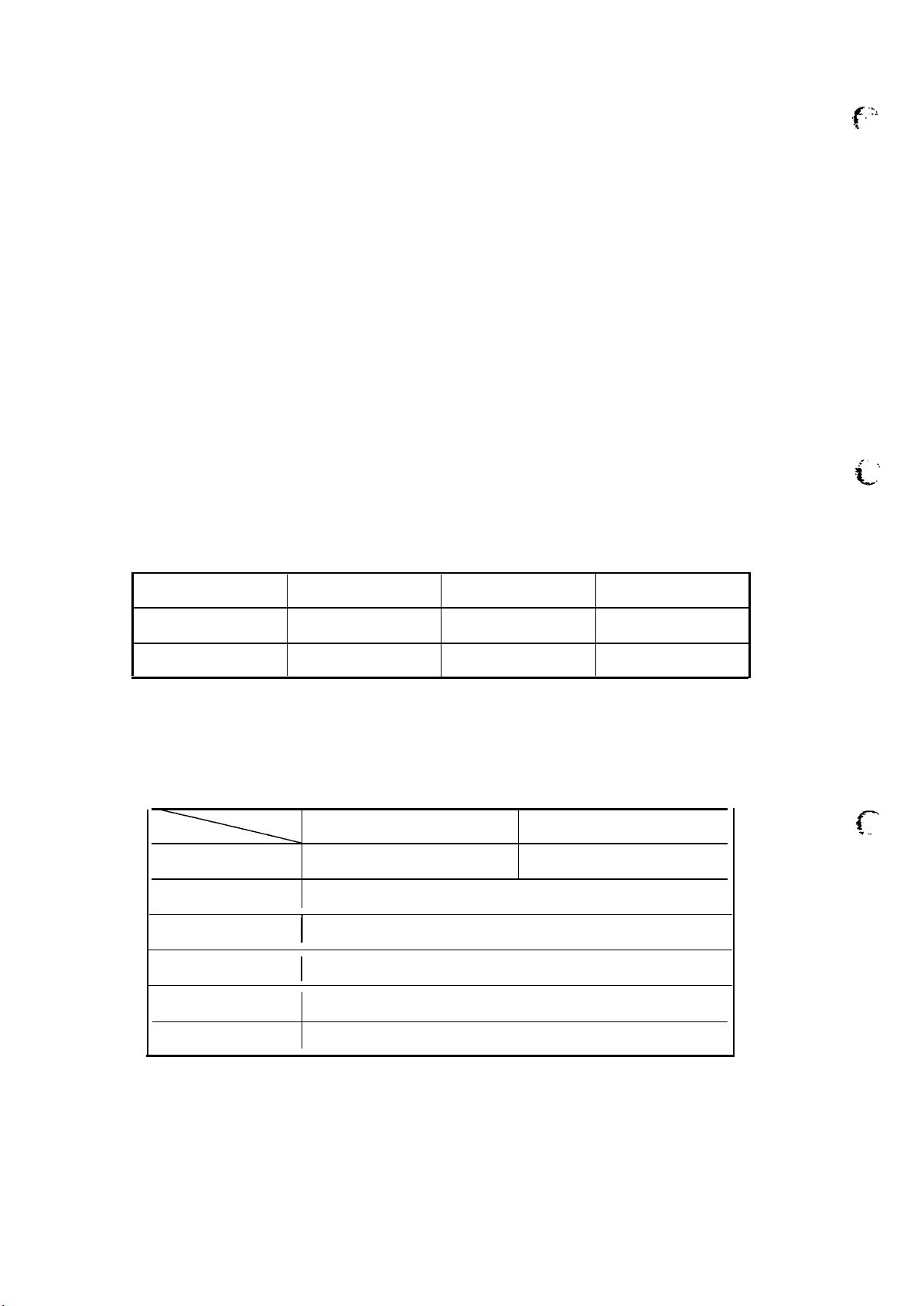

Table 1-3. Line Feed Speeds

f’”

1/2 16“)

Type of Paper Continuous Feed Intermittent Feed Feed Speed

Cut Sheet

Fanfold

Paper Specifications

Cut sheet paper Refer to Table 1-4.

Table 1-4. Cut Sheet Paper Specified Conditions

Width [mm] 182-257 (7.2 - 10.1”) 182-366 (7.2 - 14.4”)

Length

Thickness [mm]

Weight [Kg]

Quality Plain paper

[mm] 182 -

48 ins/line 71 ins/line 3.5 “/see

53 ins/line 76 ins/line

I

I

3.1 “/see

FX-850 FX-1 050

364 (7.2 - 14.3”)

0.065 -

0.10 (0.0025 - 0.004”)

45 - 70 (14 - 22 lb)

f-

..

.

Copies

NOTE: The form overriding mechanism enables printing as close as 13.5 mm from the bottom edge

of the paper. However, paper feed accuracy is not guaranteed within about 22 mm from the

bottom.

Not available

1-4

Page 14

Fanfold

Refer to Table 1-5.

Table 1-5. Fanfold Paper Specified Conditions

Width

Copies

Quality

Total Thickness

Weight

paper

Width

[mm]

[sheet]

[mm]

[Kg]

[mm]

FX-850

- 254 (4.0 - 10.0”) 101 - 406 (4.0 - 16.0”) ~

101

4 (1 original + 3 ) at normal temperature

3 (1 original + 2 ) at all temperature range

Plain paper

0.065 -

Fanfold 45-70 (14 -22 lb)

Multi-part forms 34 - 50 X N (N

Refer to Table 1-6.

Table 1-6. Roll Paper Specifications

I

0.32 (0.0025 -0.01 2“)

s

4)

FX-850

only

FX-1 050

Length

Thickness [mm]

I

Weight [Kg]

Quality

I

Copies

Envelope

Size

Weight

Quality

[mm]

I

I

I

I

Refer to Table 1-7.

Table 1-7. Envelope Specifications

[mm]

[Kg]

Roll diameter not more than 127 mm (5”)

-0.09 (0.0028 - 0.0035”)

0.07

45 - 55

Plain paper

Not available

FX-850/l

166 X 92, 240 X 104

39-

78 (12

Plain, Bond, Air mail

050

-24 lb)

Operating conditions:

Printing must be executed at normal room temperature.

Envelopes must be oriented with the long direction parallel to the carriage.

1-5

Page 15

REV.-A

Label

Refer to Table 1-8.

Table 1-8. Label Specifications

f:,,,

.

Size

Thickness [mm]

Printable Area

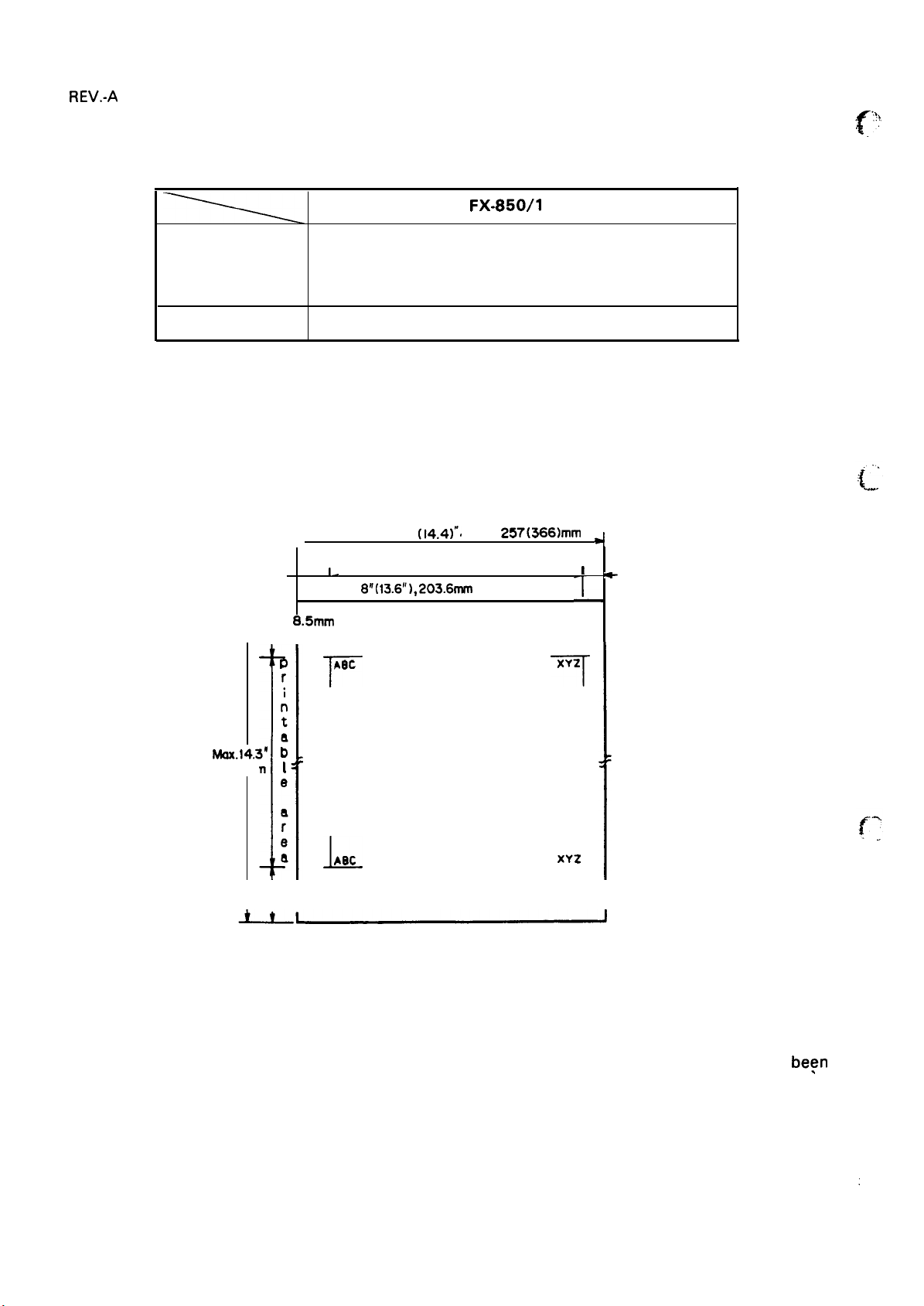

Cut sheet paper

[mm] 63.5 X 2.38 (2.5 X 15/16”),

0.12”, 3rnm

or more

0.33”,

or more

r

MOX.14.3”

364mm

101.6 X 2.38 (4 X 15/1 6“)

101.6 X 36.5 (4 X 1 7/1 6“)

less than 0.19 (0.0075”)

See Figure 1-3.

10.1*’

(14.4)”.

Printable area

D

r

i

n

t

a

b

I

e

1-

8.5mm

72 -

L

8m(13.6’’),203.6mm

Aec

T

FX-850/l

182 - 257(366)mm

(354.4 mm)

050

T

7

XYZ

-1

I

-

0.12”, 3mm

or more

a

r

e

a

:1

0.87”, 22mm

or more

NOTES: 1. Values in the parentheses apply to the FX-105O.

2. Printing is possible for approximately 42 mm after the bottom edge of a page has

detected. Thus, the value 13.5 mm (lowest print position) is given for reference only. Paper

feed accuracy cannot be assured in the area approximately 22 mm (0.87”) from the bottom

edge of the page.

Figure 1-3. Cut Sheet Paper Printable Area

A8C

1-

1-6

XYZ

-1

1

I

be~n

Page 16

REV.-A

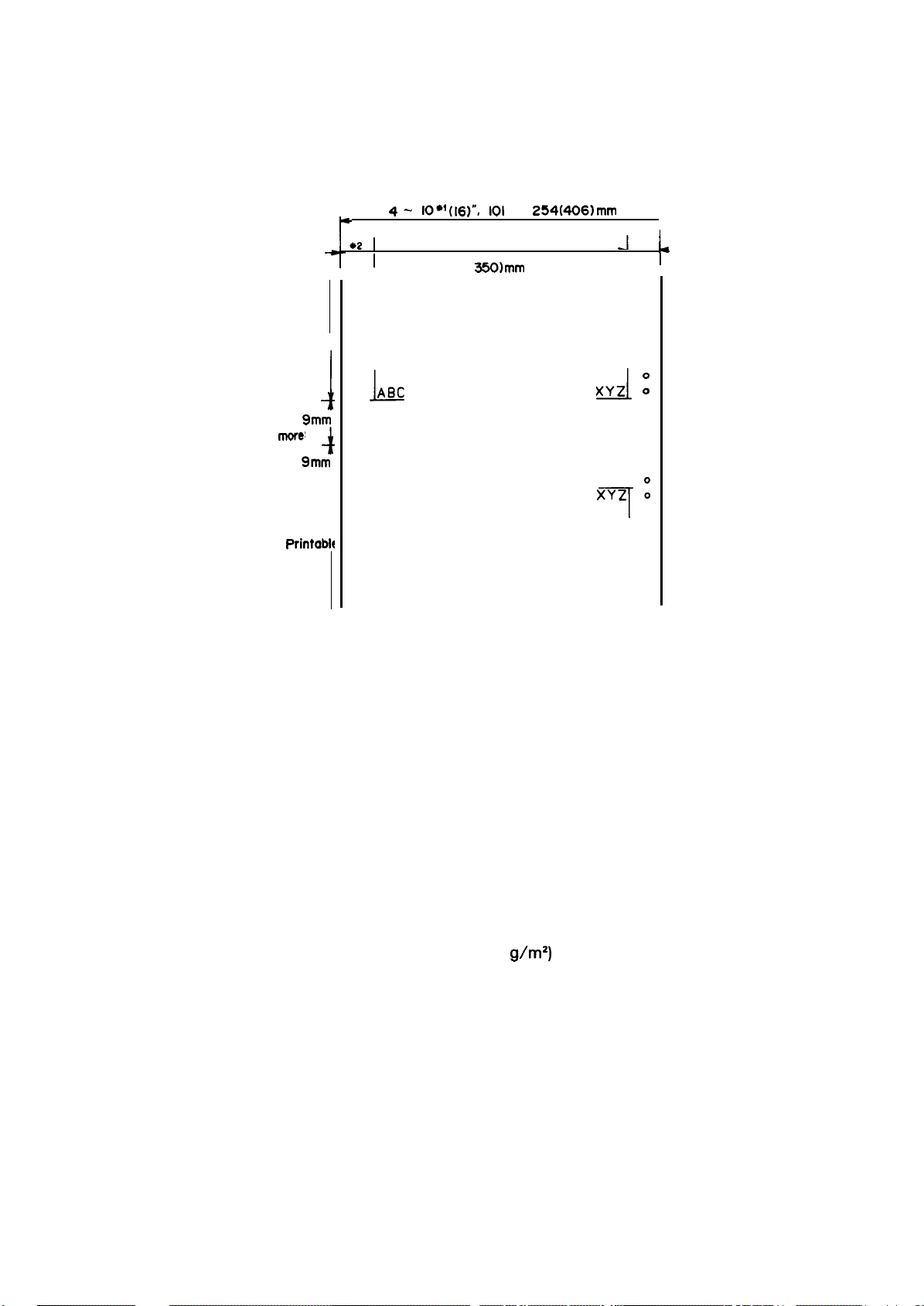

Fanfold paper

Printable

area

0.36”,

or

more!

0.35”,

or more

Printabh

area

See Figure 1-4.

P

1

9mm

4

9mm

4-

*2

o

0

0

0

0

0

0

o ABC

L

o

0

0

---------------------------

o

0

0

o ABC

o

T

o“

i

0

0

0

0

0

10*~(16)”, 101

Printable area

Max. 203.3(

-

350)mm

254(406)mm

,8”(13.8”)

J

XYZ :

J

X’iz :

7

1

*2

~

0

0

0

0

0

0

0

0

0

0

0

0

o

0

0

0

0

0

NOTE: 1. Values in the parentheses apply to FX-105O.

2. 0.47”, 12 mm or more when the 101 to 242 mm (4 to 9.5”) width paper is used.

0.98”, 25 mm or more when the 254 mm (10”) width paper is used.

Figure 1-4. Fanfold Paper Printable Area

Envelopes

Size

Quality

Thickness

No. 6 (166 X 92 mm), No. 10 (240 X 104 mm)

Bond paper, xerographic copier paper, airmail paper

0.16-

0.52 mm (0.0063 -0.01 97”)

NOTE: Differences in thickness within printing area must be less than 0.25 mm (0.0098”).

121

Weight

-241 lb (45 -91

NOTES: 1. Envelope printing is only available at normal temperature.

2. Keep the longer side of the envelope horizontally at setting.

3. Set the left of No. 6 envelope at the setting mark of the sheet guide.

Label

Size

Thickness

2 1/2 X 15/16”, 4 X 15/16”, 4 X 1 7/16”

O.19 mm (0.0075) max.

NOTE: Thickness excluding the base paper must be less than or equal to 0.12 mm (0.0075”).

g\m2)

1-7

Page 17

REV.-A

NOTES: 1.

3.

4.

Printing of labels is only available at

Labels must be fanfold.

2.

Labels with pressure-sensitive paper

and the total thickness must be less

normal temperature.

must be jointed by pasting along the dots or lines,

than or equal to 0.3 mm (O.

under conditions that must be between 5 to 35 “C and 20 to

Examples of labels: AVERY CONTINUOUS FORM LABELS

AVERY MINI-LINE LABELS

11

8“) to be printed out

80Y0

RH.

:!,,

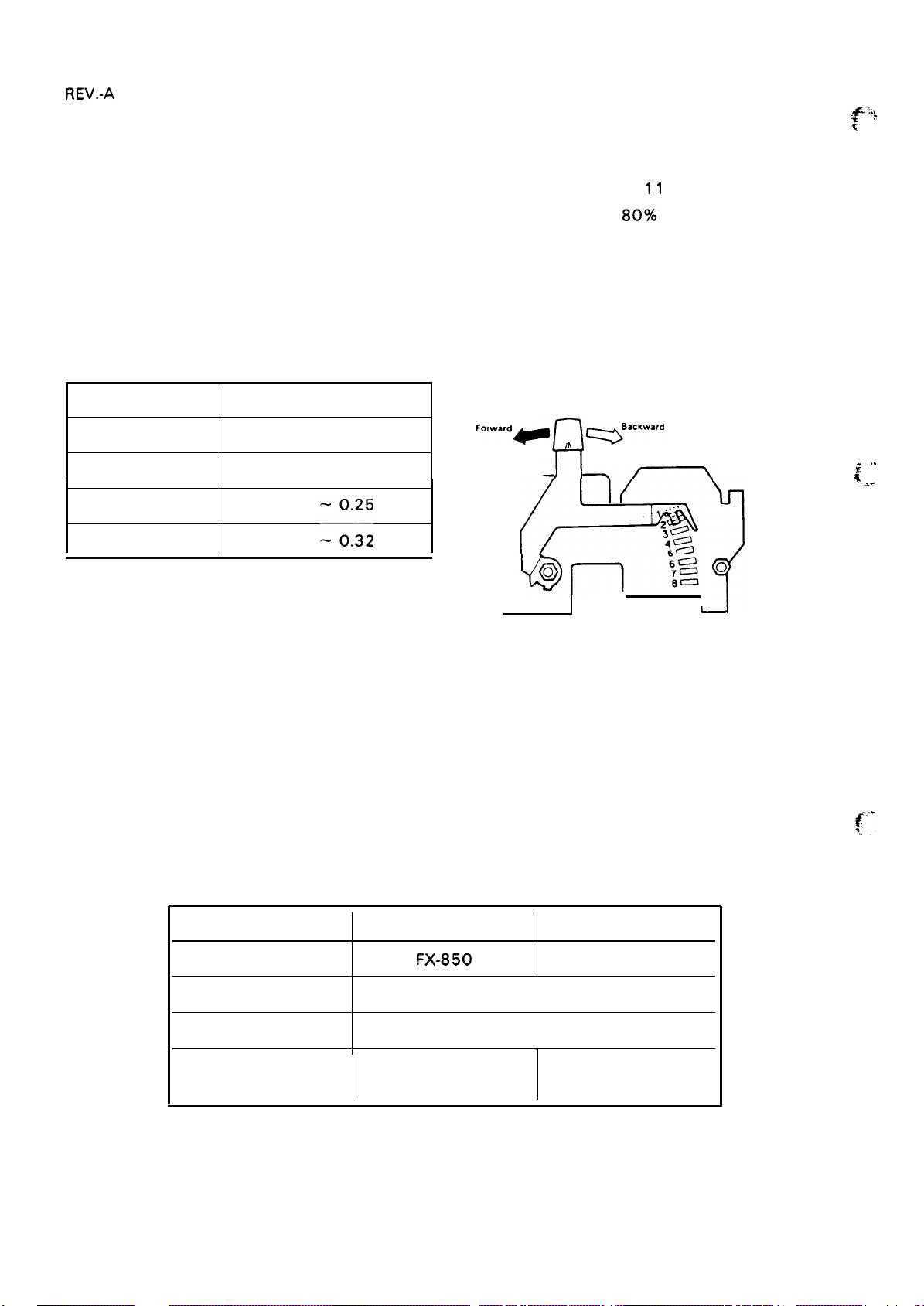

Lever Adjustment

See Figure 1-5 and Table 1-9.

Table 1-9. Lever Adjustment

Lever Position

2nd

3rd

4th

5th

Paper Thickness [mm]

0.06 -0.12

-0.17

o.13

0.18

0.26 .

:::

Head adjustment Lever

‘“’ward-

.fl

(*’

~

q“’’”’”

-~

o

?

~

Figure 1-5.

Head Adjustment Lever

Positioning

NOTES: 1. When printing density becomes lighter, set the head adjustment lever one position lower.

2. When using thicker paper than shown in the above table, set the head adjustment lever

to the 6th or higher appropriate position by performing the self-test operation.

:

.

<=,”

Ribbon Cartridge

Printer

Color

Life

Dimension

(W) X (h) X (d)

See Table 1-10.

Table 1-10. Ribbon

Ribbon Model No.

[characters]

[mm]

Cartridge Specification

#8750

FX-850

3 million (14 dots/character)

293 X 34 X 72

1-8

f-

#8755 (M)

FX-1 050

Black

I

468 X 34 X 78

Page 18

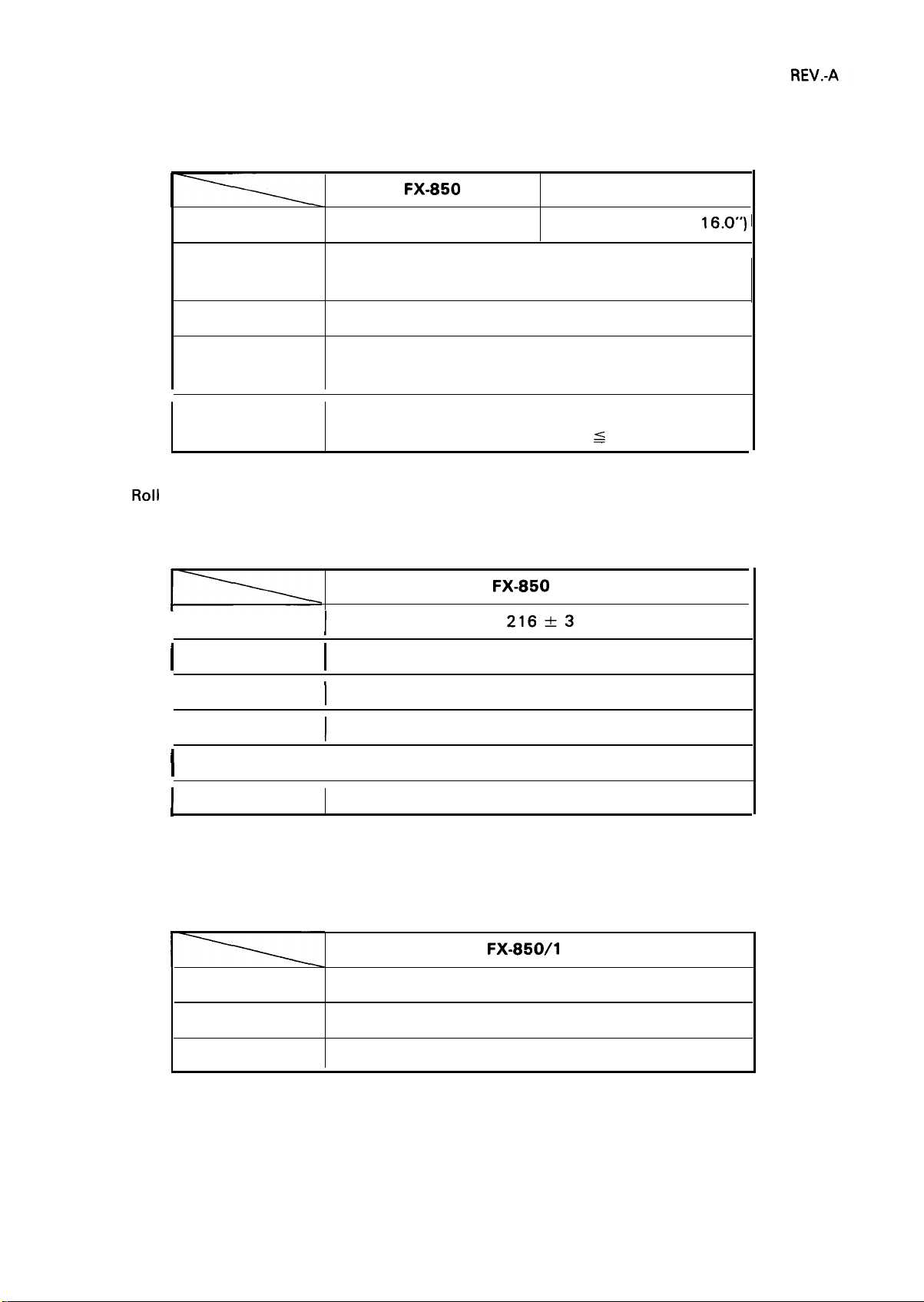

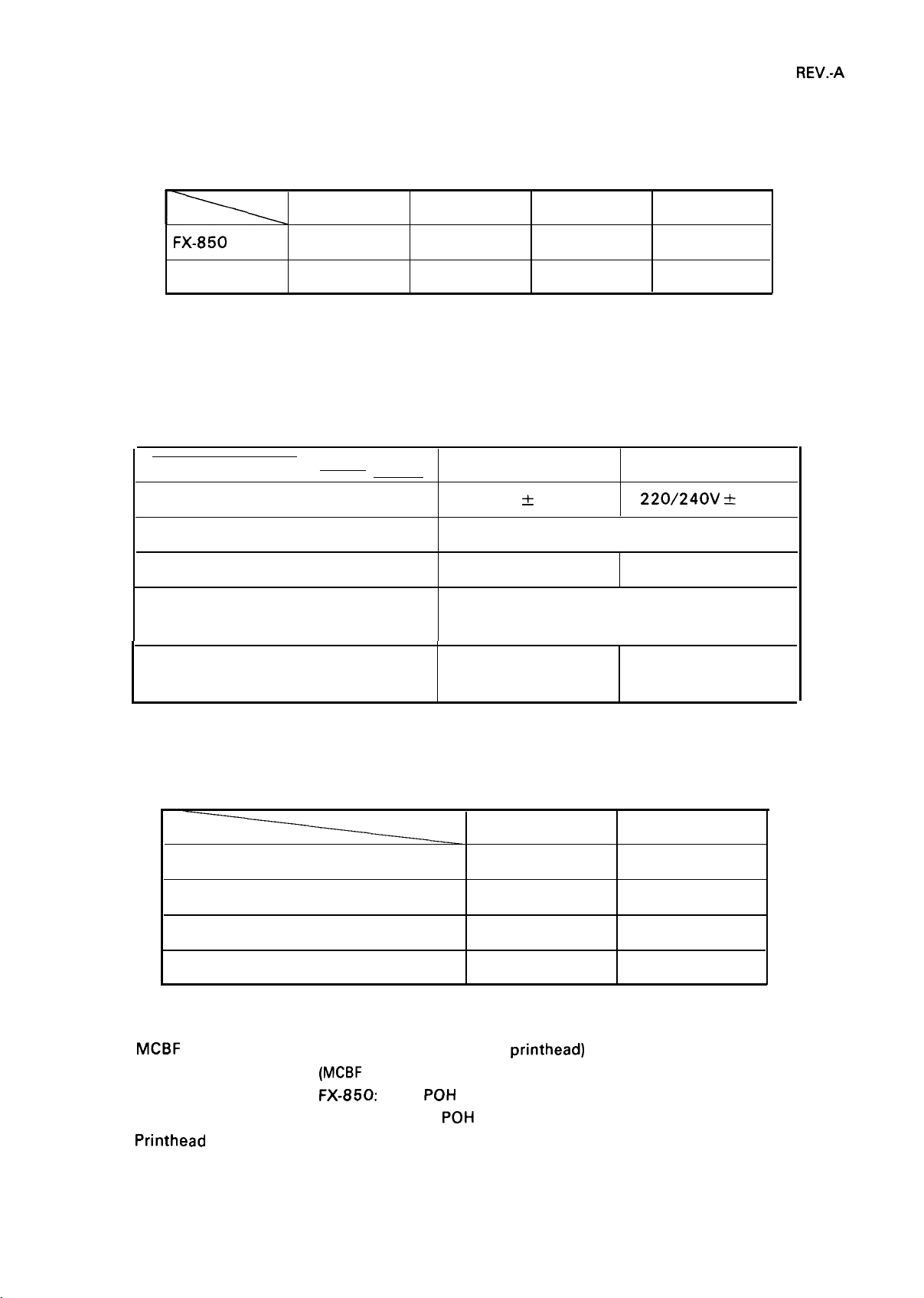

Dimensions

Weight

See Table 1-11 (Details are shown in Figures A-45 and 46.).

See Table 1-11.

Table 1-11. Dimensions and Weight

Width [mm] Height [mm]

FX-850

FX-I 050 605 150

NOTE: Excluding platen knob and paper guide.

Electrical Specifications See Table 1-12.

—

Voltage [V AC]

Frequency range [Hz] 49.5 - 60.5

Rating current [A]

Insulation resistance [M ohm] min.

(between AC line and chassis)

430 150

Table 1-12. Electrical Specifications

Depth [mm]

120 V Version

*

120V

10YO

2

360

360

Weight [Kg]

9.5

12.5

220/240 V Version

220/240V

10

& 10%

1

Dielectric strength [V AC, rms]

(1 minute, between AC line and chassis)

Environmental Conditions

Temperature [“C]

Humidity [% RH]

Resistance to shock [G] (within 1 ms)

Resistance to vibration [G] (55 Hz, max.)

Reliability

MCBF

MTBF

Printhead

life

1250

Refer to Table 1-13.

Table 1-13. Environmental Conditions

Storage

- 60

–30

- 85

5

2

0.50

5 million lines (excluding

(MCBF

. . .

Mean Cycles Between Failure)

FX-850: 4000

FX-105O: 6000

100 million characters (14 dots/character)

POH

(duty 25%)

POH

printhead)

(duty 25%)

1250

Operating

5 -35

10 - 80

1

0.25

I

1-9

Page 19

REV.-A

Safety Approvals

Safety standards

Radio Frequency

Interference

1.2.2

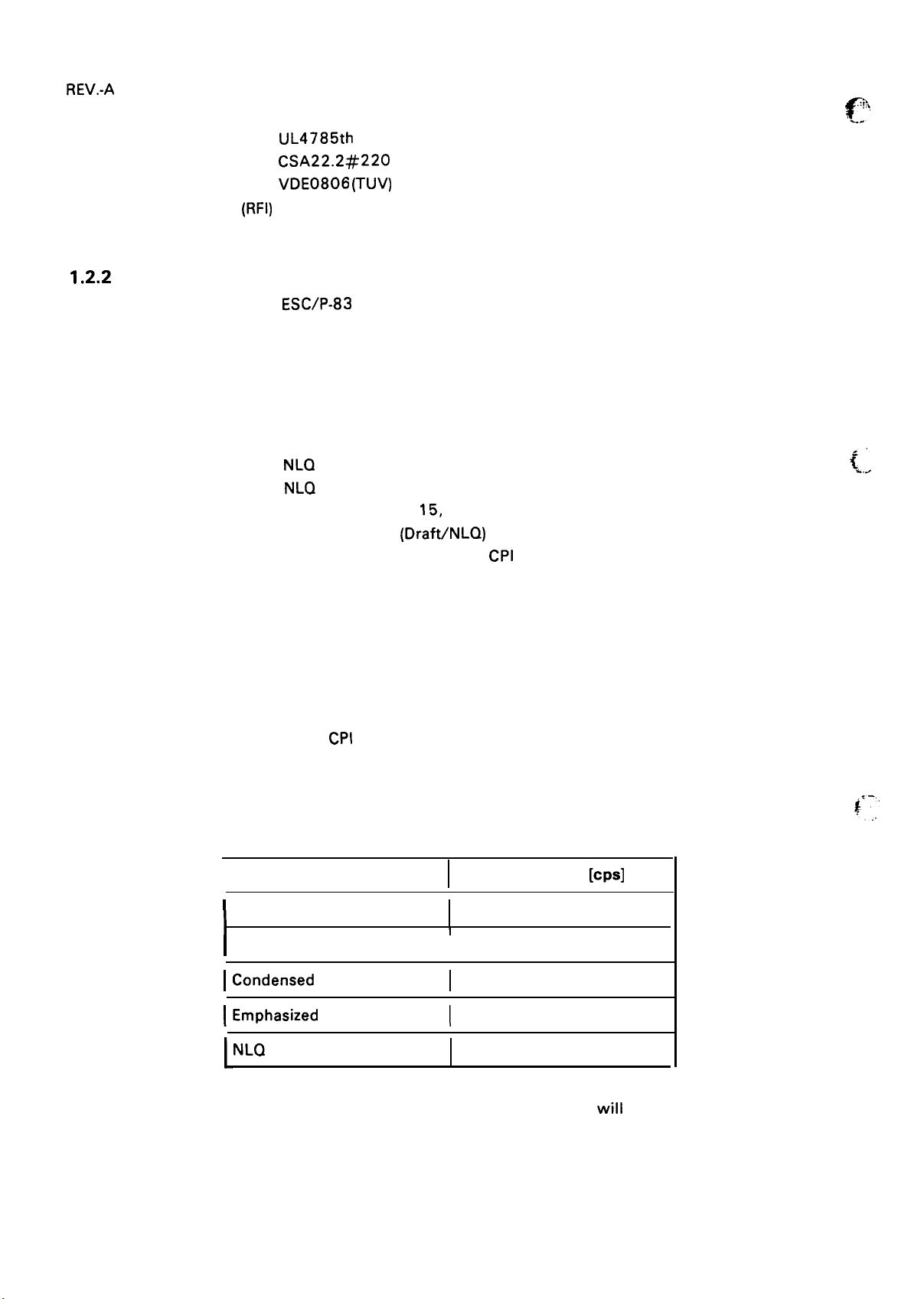

Firmware Specifications

UL4785th (U.S.A. version)

CSA22.2#220

VDE0806

(RFI)

FCC class B (U.S.A. version)

VDE871 (European version)

(TUV)

(European version)

Control Code

Printing Direction

Text

Bit-image

Character Code

Character Set

Font

Printing Mode

NOTE: A condensed mode for 15

ESC/P-83

Bidirectional printing with logic seeking

Unidirectional printing

8 bits

96 ASCII and 13 international character sets

Graphics

NLQ

NLQ

Draft:

Printing quality

Character pitch (10, 12, 15

Roman:

Saris-serif: 10, 12, 15, Proportional

Condensed

Double-width

Double-height

Emphasized

Double-strike

Italic

Underlined

CPI

characters is not available.

10, 12, 15, Proportional

10, 12, 15, Proportional

(Draft/NLQ)

CPI

or Proportional)

Print Speed

I

Draft pica

I

Draft elite

ICondensed draft pica

IEmphasized draft pica

NLQ

NOTE: When any italic character is in the same line, the print speed

the parentheses.

Refer to Table 1-14.

Table 1-14. Print Speed

Type of Letters

normal pica

I

I

I

I

1-10

Print Speed

220 (107)

264 (1 28)

183 (91)

107

45

[CPS]

will be reduced to the value in

Page 20

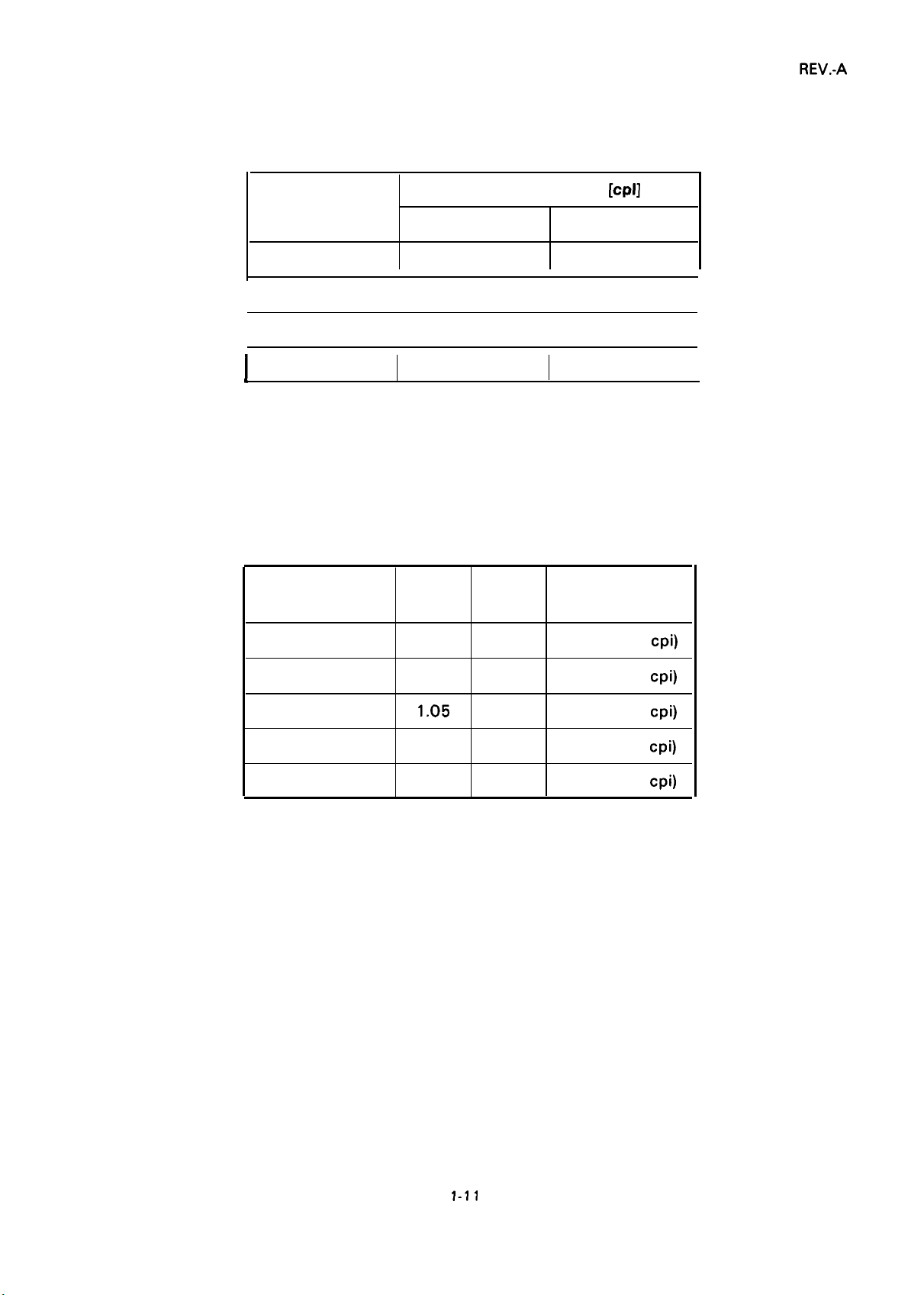

Print Columns

Refer to Table 1-15.

Table 1-15. Print Columns

Printable Columns

Type of Letters

FX-850

Normal

Condensed

I

Elite

I

Condensed elite 160

NOTE: In Condensed mode, printable column is always 137.

(Previous FX series is 132.)

Character Size, Pitch Refer to Table 1-16.

Table 1-16. Character Size and Pitch

Type of Letters

I

I

Width

137

[mm] [mm]

80

96

Height

IcPI]

FX-1 050

136

I

I

Character Pitch

233

163

272

[mm]

I

I

I

Normal

Emphasized

Condensed

Elite 1.7

Condensed elite 0.85

NOTE: Width of Elite character is changed to 1.7 mm from 2.1

mm (not same as normal mode).

2.1

2.1

1.05

3.1

3.1

3.1

3.1

3.1

2.54 (1 O

2.54 (1 O

1.48 (17

2.11 (12

1.27 (20

cpi)

cpi)

cpi)

cpi)

cpi)

1-11

Page 21

REV.-A

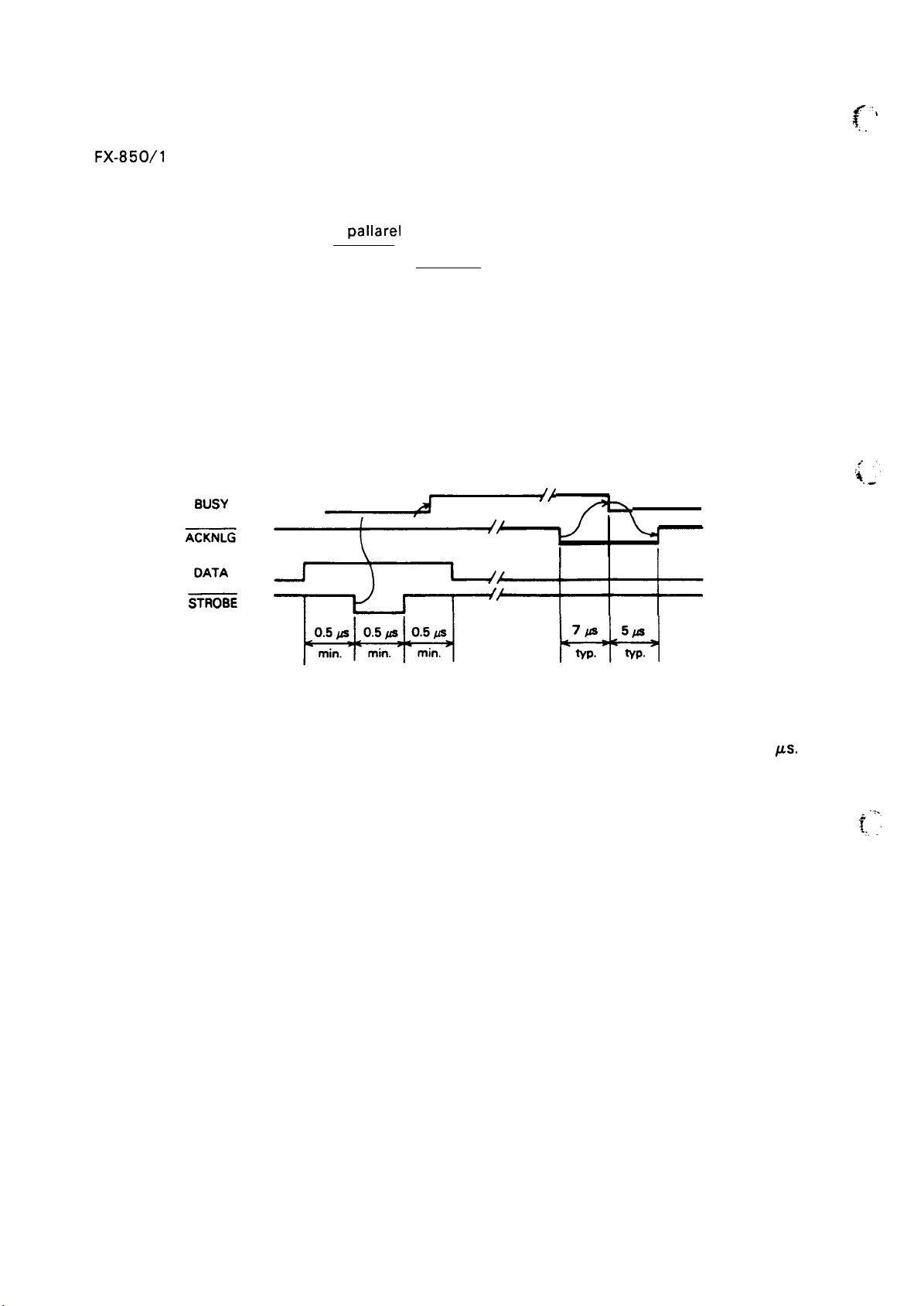

1.3 INTERFACE OVERVIEW

The

FX-850/l

1.3.1 8-bit Parallel Interface Specifications

Data Transmission Mode

Synchronization

Handshaking

Logic Level

Data Transmission Timing

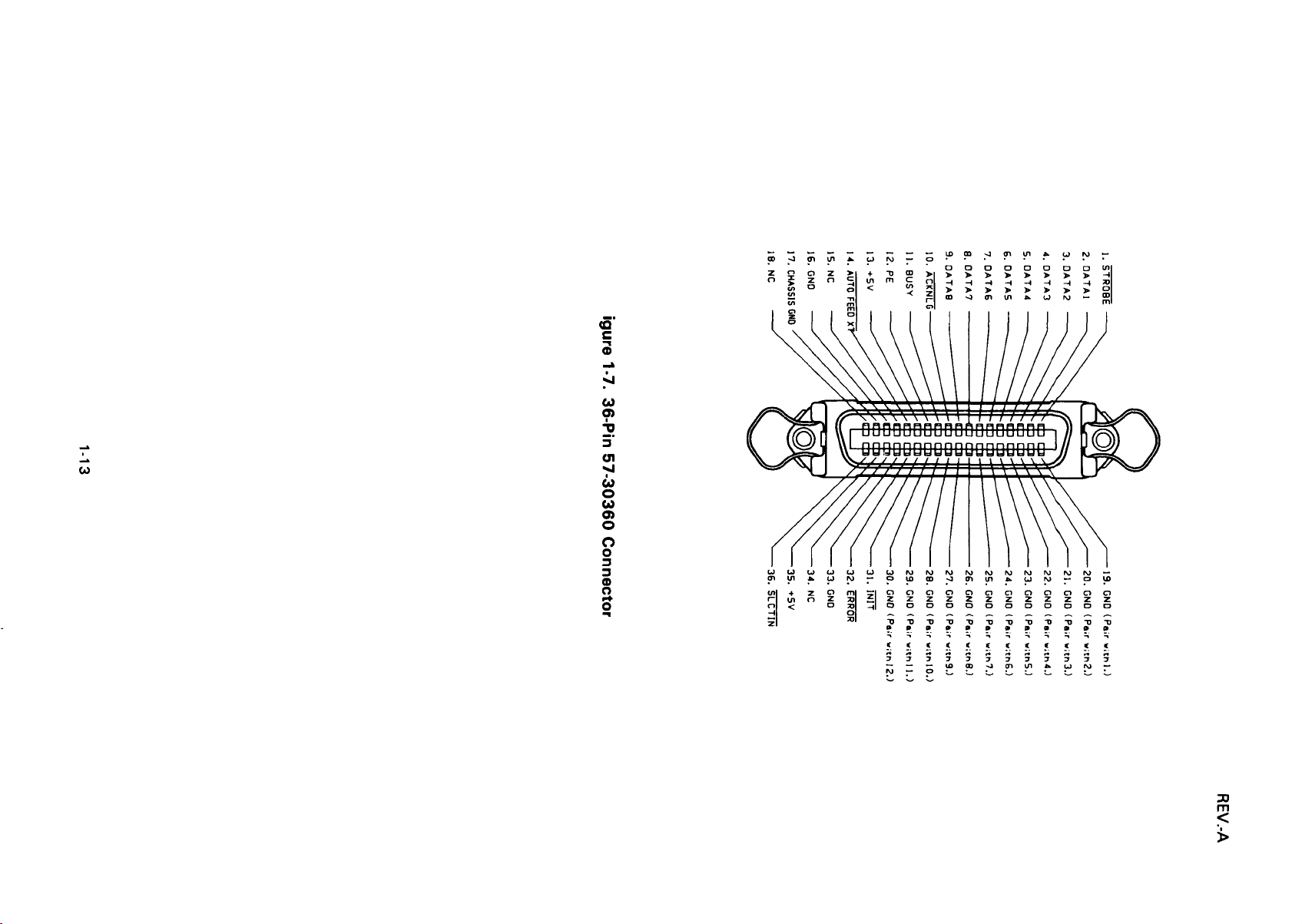

Connector

050 has 8-bit parallel interface as standard.

pallarel

8-bit

By STROBE pulse

By BUSY and ACKNLG (either or both)

TTL compatible

See Figure 1-6.

57-30360 (AMPHENOL) or equivalent

(See Figure 1-7.)

‘“s’

—--J---’

2!-,

=

NOTE: Transmission time (rising and falling time) of every input signal must be less than 0.2

—r—Lrl———ttt—

Figure 1-6. Data Transmission Timing of 8-bit Parallel Interface

ps.

.:.

t,, .

1-12

Page 22

fn

n

-.

s

;

Page 23

REV.-A

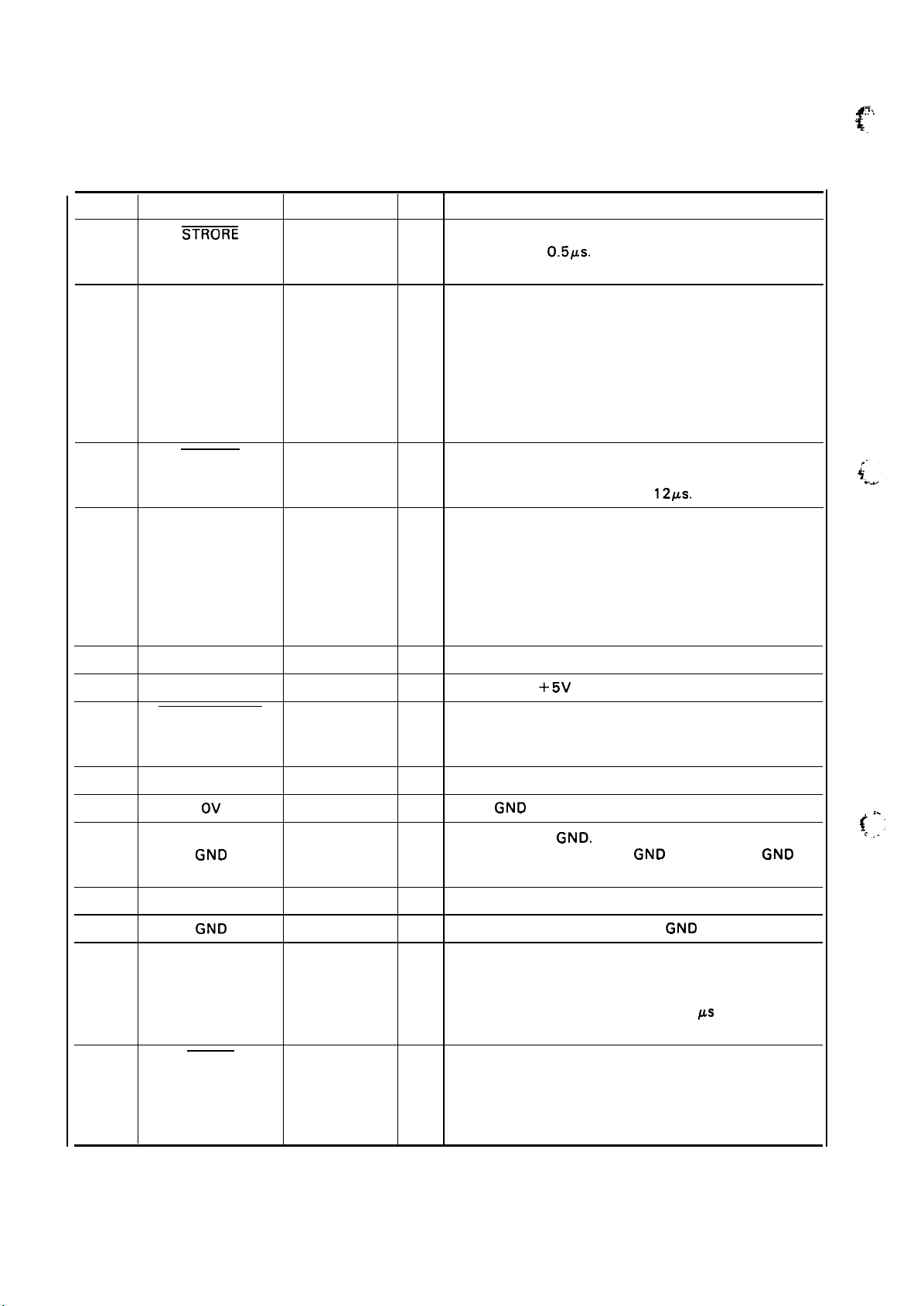

Table 1-17 shows the connector pin assignments and signal functions of the 8-bit parallel interface.

Table 1-17. Connector Pin Assignments and Signal Function

~,.

.., ’

<

Pin No.

1

2

3

4

5

6

7

8

9

10

11

Signal Name

STRORE

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

DATA 8

ACKNLG

BUSY

Return Pin No.

19

20

21

22

23

24

25

26

27

28

29

DIR

Strobe pulse to read the input data.

In

be more than 0.5#s. Input data is latched after falling

edge of this signal.

These signals represent information of the 1st to 8th

In

In

bits of parallel data, respectively. Each signal is at

“HIGH” level when data is logical “1“ and “LOW” when

In

logical “O”.

In

In

In

In

In

out

This pulse indicates data has been received and the

printer is ready to accept more data.

Pulse width is approximately

out

A “HIGH” signal indicates that the printer cannot

receive data.

ing cases:

1. During data entry

2. During printing operation

3. In off-line status

4. During printer error status

Functional Description

Pulse width must

12#s.

The signal becomes “HIGH” in the follow-

19

12

13

14

15

16

17

18

- 30

31

32

PE

AUTO FEED XT

NC

Ov

CHASSIS

GND

NC

GND

INIT

ERROR

30

out

A “HIGH” signal indicates that the printer is out of paper.

Pulled up to

In

With this signal at “LOW”’ level, the paper is automatically fed one line after printing.

(The signal level can be fixed to “LOW”’ with DIP SW 2-4.)

Not used.

Logic

Printer chassis

In the printer, the chassis

isolated from each other.

Not used.

TWISTED-PAIR RETURN signal

In

When the level of this signal become

GND

+5V

through 3.3 K ohms resistor.

level.

GND.

GND

and the logic

GND

level.

“LOW”, the printer

controller is reset to its initial state and the print buffer

is cleared. This signal is normally at “HIGH” level, and

its pulse width must be more than 50 @ at the receiving

terminal.

out

The level of this signal becomes “LOW” when the

printer is in -

1. Paper-out status

2. Off-line status

3. Error status

GND

are

1-14

Page 24

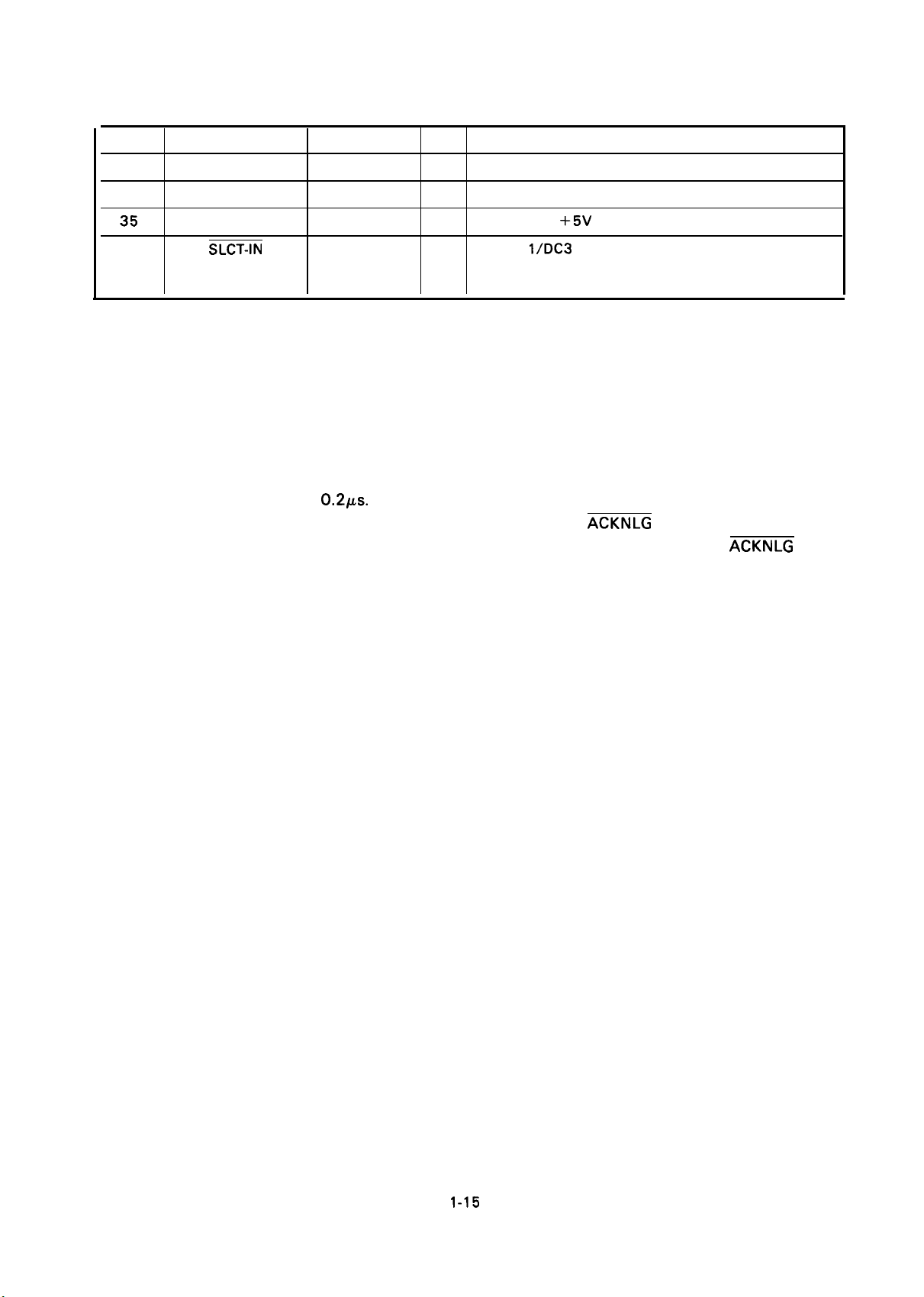

Table 1-17. Connector Pin Assignments and Signal Function (cent’d)

REV.-A

Pin No. Signal Name

33

34

35

36

NOTES: 1.

2.

GND

NC

SLCT-IN

“DIR” refers to the direction of signal flow as viewed from the printer.

“Return” denotes “TWISTED-PAIR RETURN” and is to be connected at signal ground level.

As to the wiring for the interface, be sure to use a twisted-pair cable for each signal and

never fail to complete connection on the Return side. To prevent noise effectively, these

cables should be shielded an connected to the chassis of the host computer and the printer,

respectively.

3.

All interface conditions are based on TTL level. Both the rise and fall times of each signal

must be less than

4.

Data transfer must not be carried out by ignoring the

(Data transfer to this printer can be carried out only after confirming the

or when the level of the BUSY signal is “LOW”.)

Return Pin No.

0.2Ks.

DIR

Functional Description

Same as with Pin No. 19 to 30.

Not used.

Pulled up to

The DC

In

“HIGH” level.

(Internal fixing can be carried out with Jumper- l.)

+5V

through 3.3 K ohms resistor.

l/DC3

code is only valid when this signal is

ACKNLG

or BUSY signal.

ACKNLG

signal

1-15

Page 25

REV.-A

Table 1-18 shows the printer select/deselect (DC

SLCT-IN

input, DC 1

/DC3,

and interface signals.

Table 1-18. Printer Select/Deselect Control

l/DC3)

control, including relations among ON-LINE,

:):>

f

. .

ON-LINE SW

OFF-LINE

ON-LINE HIGH

HIGH/LOW

SLCT-IN

LOW

Dcl/Dc3

DC

l/DC3

DC 1

DC3 HIGH

DC 1

DC3 HIGH

ERROR

LOW HIGH

HIGH

HIGH

LOW\HIGH

(During data

entry)

LOW\HIGH

(During data

entry)

LOW/HIGH

(During data after entry

entry)

LOW/HIGH

(During data

entry)

BUSY

ACKNLG

No pulse Disable

Pulse output

after entry

Pulse output

after entry

Pulse output

Pulse output

after entry

DATA ENTRY

Enable

mal

Enable

(Waits DC1.

See Note 2)

Enable (Nor-

mal

(Nor-

Process)

Process)

NOTES: 1. In the Table 1-18, it is assumed that no ERROR status exists other than that attributable

to OFF-LINE mode.

DC3

2. Once the printer is deselected by the

code, the printer will not revert the selected state

unless the DC 1 code is input again. (In the deselected state, the printer ignores input data

1

until the DC

3. The DC 1 and

code is received.)

DC3

codes are enabled only when the

SLCT-IN

signal (Input Connector No.36

for the parallel interface unit) is HIGH and printer power is initialized.

4. If the

SLCT-IN

signal is LOW when the printer is initialized, DC

l/DC3

printer select/deselect

control is invalidated, and these control codes are ignored.

5. If the

SLCT-IN

signal is HIGH and is not set to LOW by jumper 6 when printer initialized,

the printer starts from the selected (DC 1 ) state.

L

f-:

1-16

Page 26

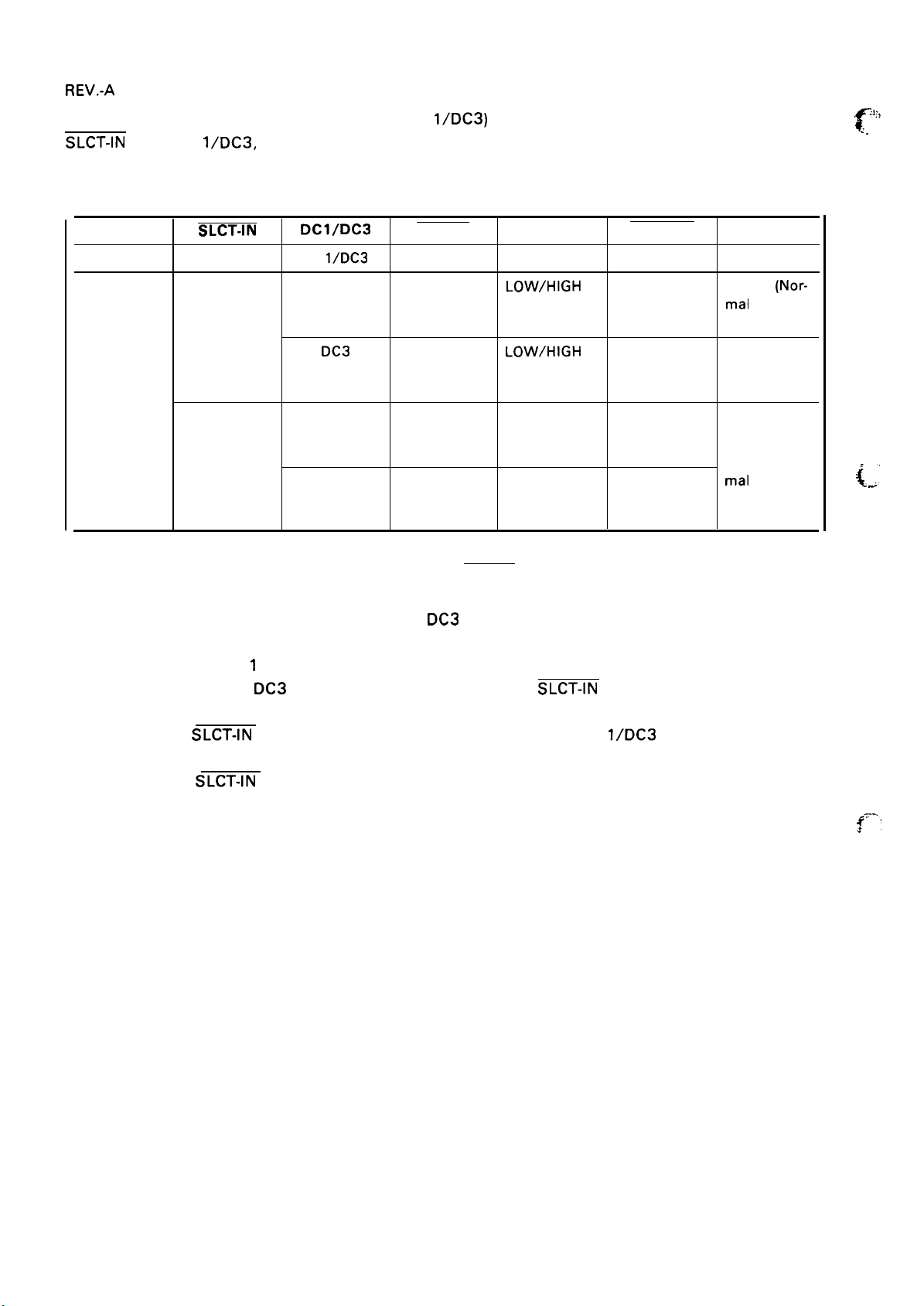

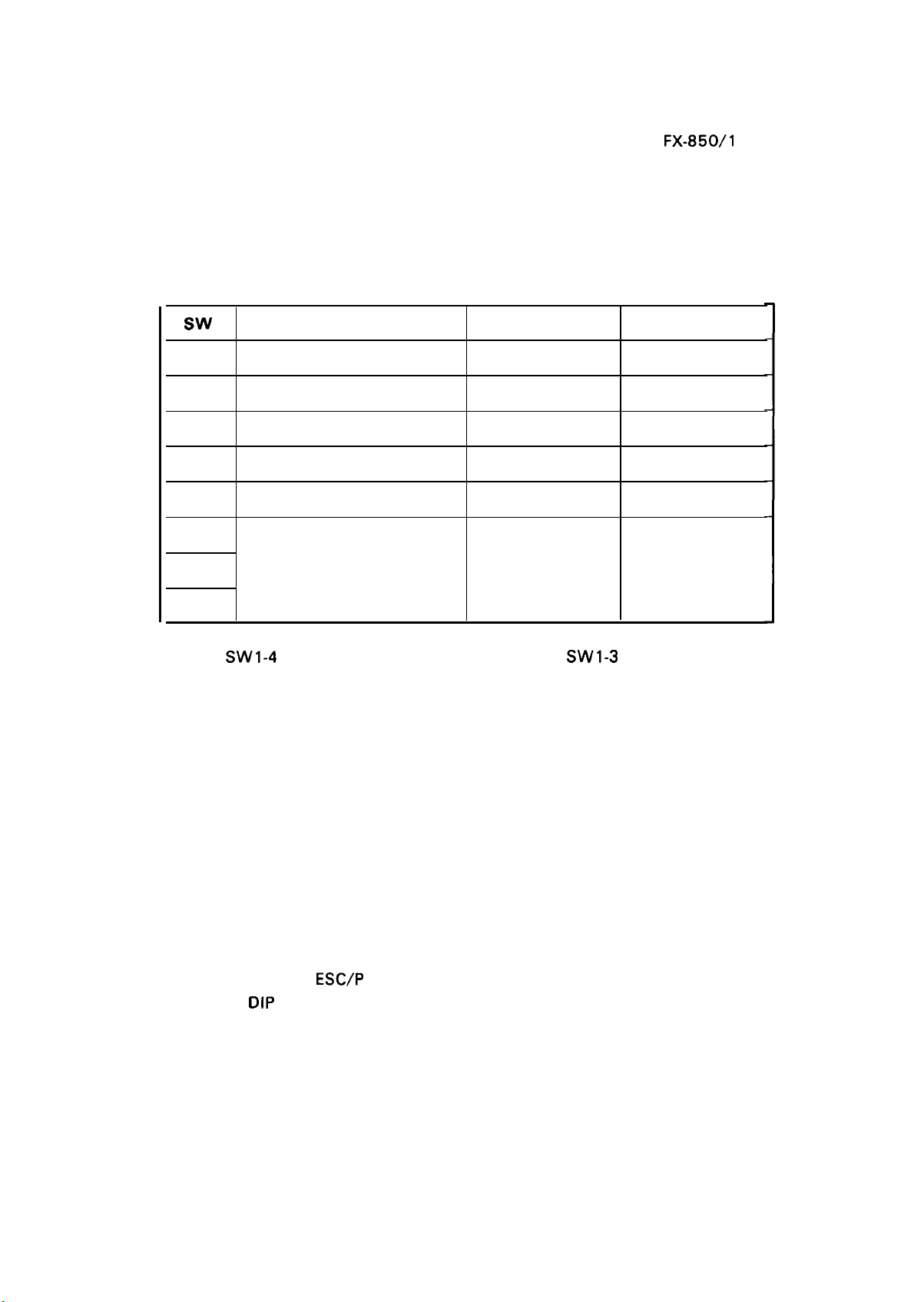

1.4 DIP SWITCHES AND JUMPER SETTINGS

REV.-A

This section describes the DIP switch selections and jumper setting for the

1.4.1 DIP Switch Settings

The DIP switches are located at the right side of the printer. When the printer hardware is initialized,

the following functions are set to the default values shown in the table below.

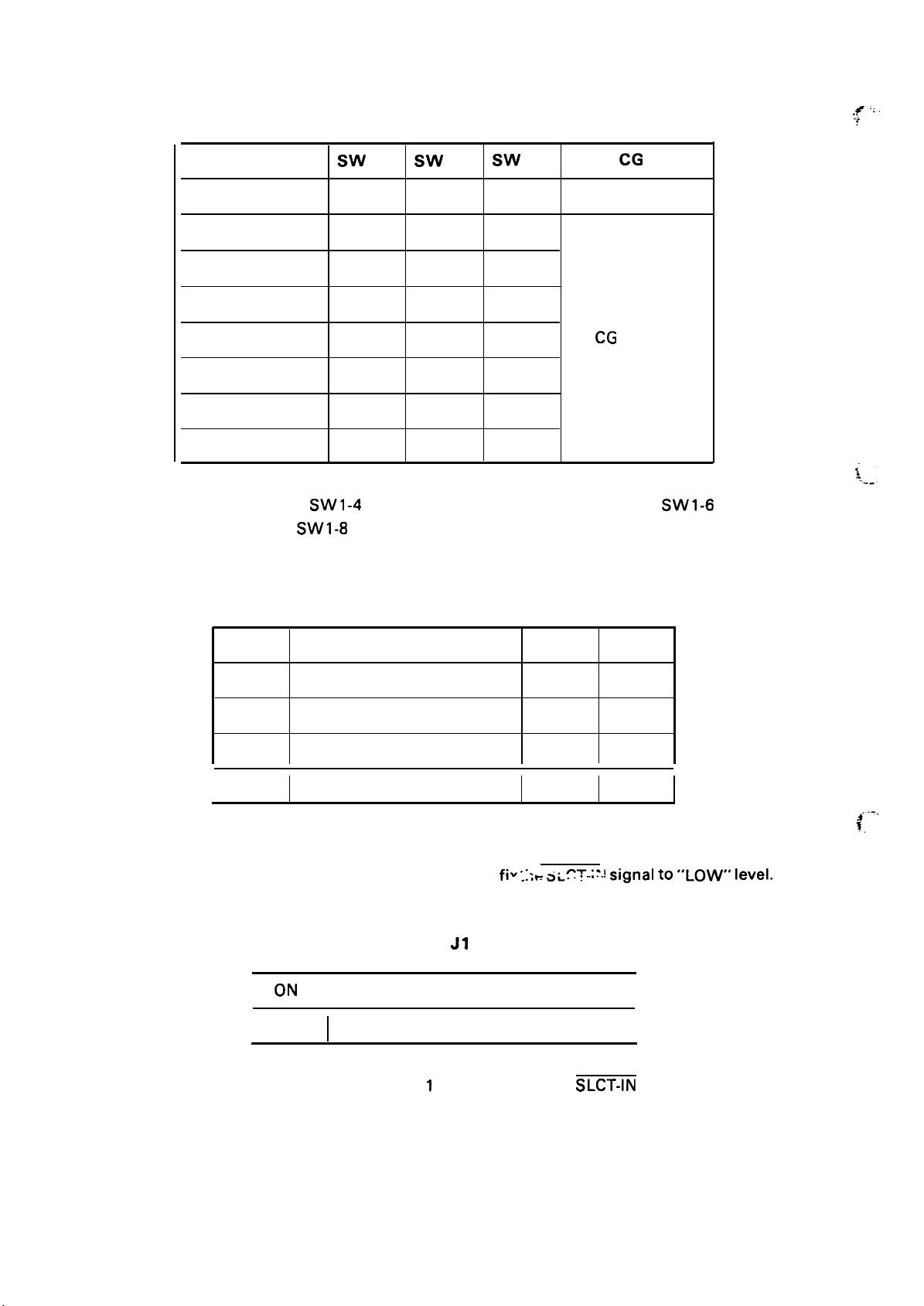

Table 1-19. DIP Switch 1 Settings

WV

1-1

1-2

1-3

1-4

1-5

1-6

1-7

Description

Default character set

Shape of zero

Table select

Protocol mode

Short tear-off mode

International character set

User-defined

Slashed

Graphic

IBM emulation

off

See Table 1-20.

ON

FX-850/l

OFF

ROM

Not slashed

Italic

ES C/P

On

050 printer.

1-8

NOTE:

Default character set

Shape of zero

Protocol mode

When DIP

When DIP switch 1-1 is ON, the user-defined character set will be selected as default.

User-defined characters are maintained in printer memory even when the power is turned off,

so the user-defined character set can be easily selected simply by turning off the power, setting

this switch to ON, and then turning the power on again.

When DIP switch 1-2 is ON, prints

for clearly distinguishing between

When DIP switch 1-4 is ON, printer operates in the IBM emulation mode; when off, printer

operates in the Epson

Functions of

emulation mode.

SW1-4 is on (IBM mode), the function of DIP SW1-3 changes to auto CR ON/OFF.

a stashed zero (0); when OFF, prints open zeros (0).

uppercase O and zero when printing program lists,

ESC/P mode.

DIP

switches 1-6, 1-7, and 1-8 are different when using the printer in the IBM

Useful

etc.

Short Tear-off

When print operation has finished, the short tear-off feature automatically feeds the perforation

of the continuous paper to the tear-off edge of the sheet guide cover so that the user can tear

off the last sheet. When the user resume printing, the paper is fed backward to the loading

position.

1-17

Page 27

REV.-A

Country

Table 1-20. International Character Set

WV

1-6

SW

1-7

SW

1-8

IBM

CG

Table

,,# ,.

.:

USA

France

Germany

UK ON OFF

Denmark

Sweden

Italy

Spain

NOTE: When DIP SW1-4 is on (IBM mode), the functions of DIP SW1-6

through

SW1-8 change to IBM character generator selection.

ON

ON

ON

OFF

OFF ON

OFF OFF ON

OFF

Table 1-21. DIP Switch 2 Settings

ON

ON

OFF

ON ON

OFF

ON

OFF

ON

OFF

OFF

OFF

CG Table 1

CG

Table 2

Sw

2-1

2-2 Cut sheet feeder mode

2-3

2-4

I

1.4.2 Jumper Setting

The jumper J 1 is located on the main board and it can

I

I

NOTE: If the jumper J 1 is connected, the

Page length

1 -inch skip over perforation

Auto line feed

ON

OFF

signal is fixed to LOW, and DC 1 /DC3 printer

select control is ignored.

Description

Table 1-22. J1 Setting

Fix to “LOW”

Depend on the external signal.

ON

12 inch 11 inch

On

On

On

fiw

;:;-

SLCT-:?-!

SLCT-IN

OFF

off

off

off

signal to “LOW” level.

I

I

,.-,

1.

1-18

Page 28

1.5 SELF TEST OPERATION

The

FX-850/l

● Control Circuit Functions

● Printer Mechanism Functions

● Print Quality

● DIP Switch Settings

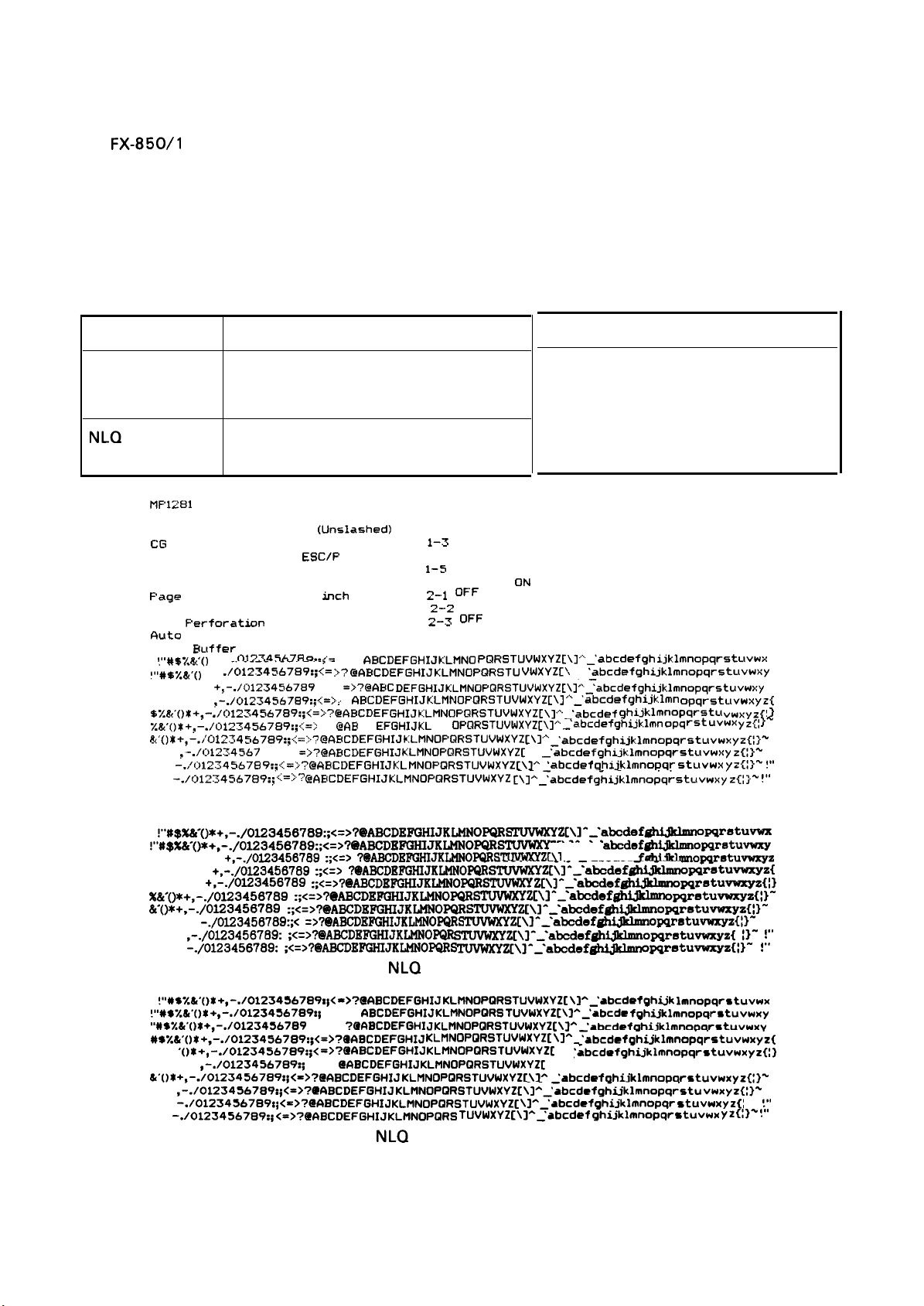

Table 1-23 lists the self test operating instructions and Figure 1-8 shows the self test printing.

050 printer has the following self test (self printing) function which checks the following:

Table 1-23. Self Test Operation

REV.-A

Type-face

Draft

NLQ

Start

stop

Turn the power ON while pressing the

LINE FEED switch.

● Paper out condition.

● Press the ON-LINE switch, and turn

Turn the power ON while pressing the

the power OFF.

FORM FEED switch.

MF’12S1

Default character

Shape of zero

CG

Table

Protocol mode

Automatic tear-off

Country

F’age Length

CSF Mode

F“erforation

Skip

fiuto

LF

Input

Buffer

110#57-&.0X +,_

ill’#*~&-OX

“#S%& ’OX+,

#% Z&’ OX+,

5Z&’OX+,-./O1234567 i39:;<=>?@ABCDE FGHIJKLMNOP~RSTUVWXYZ[ \l’’’abcdefdef ghljklmnOpqrstL~ vw~yz{l }

%&’()*+,–./cU234567 s,.,...–.,

&’OX+,-./O134567 E19:;~:=???? @A.SCDEFGHIJKLMNOFRRSTUVWXYZ[\l”” –’abcdefghijklmnOpqrStuvwxy~{i}’”

‘OX+, -./O1234567S9:; <=>?@

-./O134S67E19:;< :=::?

()*+,

)x+,

-./O134567S9:;:; =:}?}? d

O

,

Jl~34567S 9:;<=

/

+,_.

/O12X4S67s9:;<= ;>?

-./0123456789::

-./Ol2S4567S9:;<=> :

ROM

(Unslashed)

o

Italics

ESC/P

Valid

U.S.A. 1-6 ON

11

tich

Invalid

None

Depend on

Valid

=>?@

. . ..-..-,@

:

fN3CDEFGHIJ

@?4r3CDEFGHIJKLKL MNOPQRSTUVWXYZ[\lA

CAEICDEFGHIJKLMNOPQRSTUVWXYZ

I/F

>?@

AECDEFGHIJKLMN0 PQRs

GABCDEFGHIJ

AEICIC DEFGHIJliLMNOPflRSTUVWXYZ[\l”’”-Yabcde fghi.jk.lmnOpqrstuvw~:y

‘@

AECDEFGHIJKLMNOFQRSTUVWXYZ[\l ““-’abcdefgh~JklmnO pqrstLLvw~Y~{

~Bc

DE

FGHIJKL

1–1 OFF

1-2 OFF

1-3

OFF

1-4 OFF

1-5

OFF

1-7

~-~

OFF

2-2

OFF

~-~

OFF

2-4

OFF

KLMNOPQRSTU VWXYZ[’.

MN

OpQRSTUVWXYZ[\],. -’abcdefghijklmn

KLMNOP12RSTUVWXYZ[ \]-’

ON

TuvwxYZ[\]’”’-’

[\l-–Tabcdefghijklmnopqrstuvwxy

1-S ON

abcdefgh IJklmnOPqrstuvw~

]’”

‘abcdefghijklmnopqrstuvwxy

opq

rSt UVWx Y2’[~ }-

‘abcdefghijk.lmnopqrstuvwxy

abcdefghijklmnopqr stuvwx Yz{i}- !“

:

zC}*

Z{ll+ !“

Draft Mode

z

!

!''#$%&-()*+,-./ol23456789:;<=>?@ABcDEFGHIJKLMNoPQRs

!''#$X&-()*+,-./Ol23456789:;c=>?@ABCDEFGHZJKLMNOPQRBTWWKY

-

''#$%&

#$X&-()*

$%&-()*

X&’()*+,-./O123456789 :;C=>?MBCDEFGHIJKLMNOPQRS

&"()*+,-./O123456789 :;C=>?@ABCDEFGHZJKLMNOPQRSTWWKY

‘()*+,

ox+,

)*+,

()&+,

()*

+,-./O123456789 :;<=> ?WBCDEl?GHIJKLMNOFQRSTUVWKYZ[\l

+,-./0123456789 :;<=> ?WBCDEFGHIJKLMNOPQR

+,-./Ofi3456789 :;C=>?@~CDE~~JK~O=~

-./O123458789:;< =>?@ABCDEFGH1JKLMNOPQRS

-./O123456769:; <=>?@ABCDEFGHIJKLMNOFQR

-./012345678g:; <=>?@ABCDE~JKLMN()~S

NLQ

!“#s%&’()*+

!“#s%&’()*+

“tlS%&’OX+, -./O1234567B9:;

#sz&’()*+,-./O1234567

s%& J()*+,

%&’ OX+,

&’(); +,-./O1234567S9:; <=>?@ABCDEFGHIJ

‘08+,

-./O1234S67E9:;< =>?@ABCDEFGHIJ

-./O1234567S9:; <=>?@ABCDEFGHIJ

)*+,

-./01234S67S9:;

,-./O123456789SI< =>?@ABCDEFGHIJ

,-./O123456789:;

-./01234567e9:;<

-./O123456789:;<

<=>7@ABCDEFGHIJKLIINOpQRS

<=>?@

<=>?@

S9:;<=>?@ASCDEFGHIJ

=>?@

fiBCDEFGHIJKLllNOPQRS TUVWXYZ[\ln–’abcde fghijklmnopqrstu VWXY

RBCDEFGHI

=>?@ABCDEFGHIJ KLMNOPQRSTUVWXYZ[ \]”-

IlBCDEFGHIJ

KLMNOPQRSTUVWXYZ[

NLQ

TUVWXYZ[\l’-’abcdef@jkhnn

BTUVWKYZ[\l--’abcdefsMjkhnopqrstuvwxyz{

TWWXYZC\l---abcdef~

(Roman) Mode

KLMNOPQRSTUVWXYZ[

JKLMNOPQRSTUVWXYZ[

KLMNOPQRSTUVWXYZ[

KLMNOP12RSTUVWXYZ[ \] A-’

KLMNOPQRSTUVWXYZ[

KLMNOPQRSTUVWXYZ[

TUVWXYZ[\]A-’abcdef ghijklmnopqrstuvwx Yz{l}+ !“

(Saris-Serif) Mode

TWWXYZ[\:-T’abcdefgMjkhn

Z[\l -

BTWWXYZ[\]”-TabcdefghiJkhn

abcdefghLlklmomrstuvwxy

‘abode

“

Z[\]--’abodefghijklm

TUVWXYZ[\l--’abcdefghijkbn

Z[\l--’abcdefghi@nnomretuvwxyz{l}-

\]A–’abcdefghijk lmnopqrstuvwx

\ln

‘abcdefghti”klmnopqrstuvwxy

\lA-

‘abcdefghijklmnopqrstuvwxyz(

‘abcdefghti”klmnopqrstuvwxyz{;}

● bcdefghti”klmnopqrstuvwxyz{:}-

\]A ‘abcdefghijklmnopqrstuvwxyz{:}+

\l*-%bcdefghti”klmnopqrstu

\]a–’abcdefghijklmnopqr

Figure 1-8. Self Test Printing

1-19

omratuvwx

fghkikhunomrstuwvxyz

opgretuvwxyz{

omrstuvwxyz{!}

opgrstuvwxyz{i}-

omretuwxyz{l}-

!}- !“

!

opgretuvwxyz{j}- !“’

z

VWXYZC}-

stuvwxyz{;

}%

!

!“’

Page 29

REV.-A

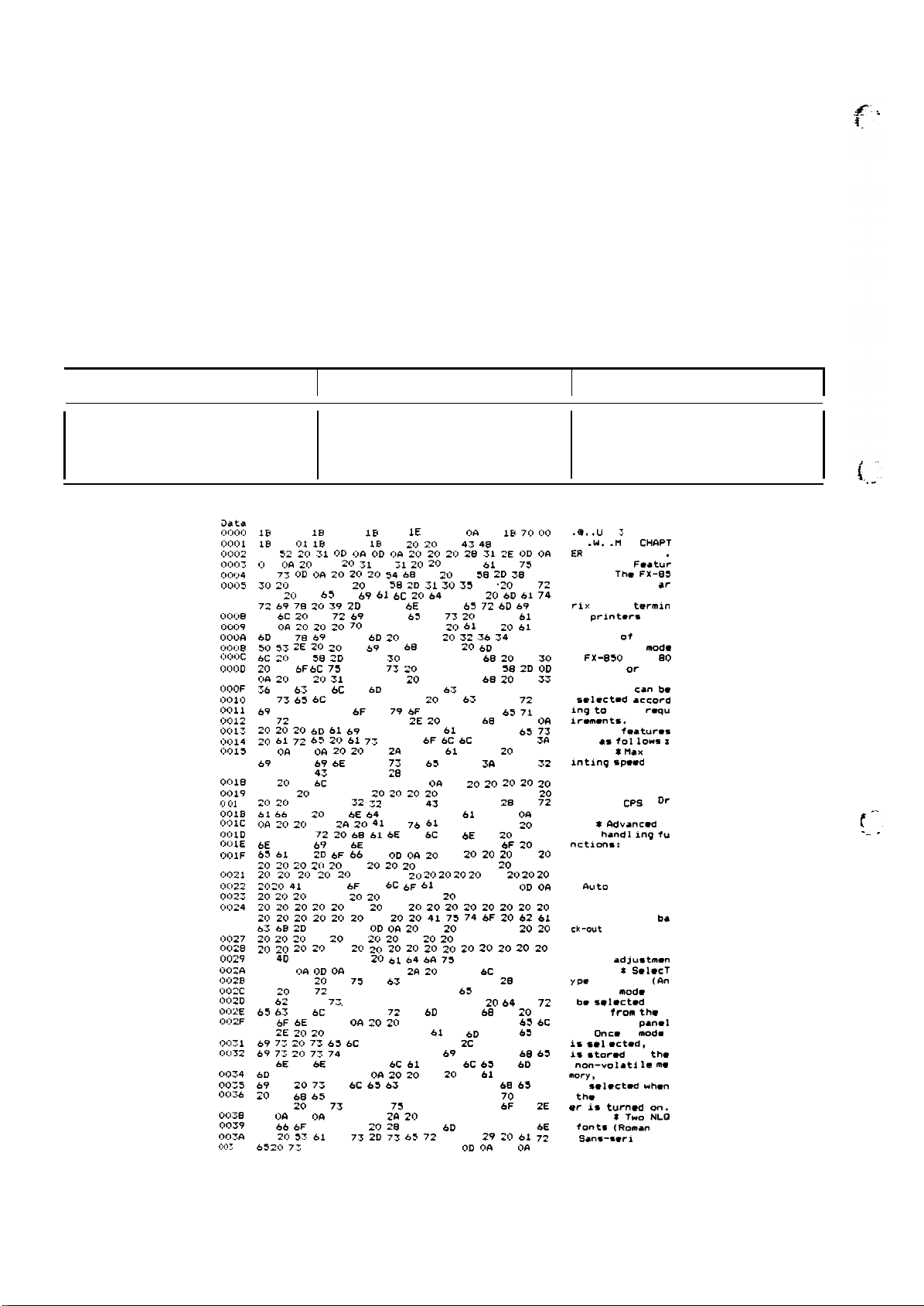

1.6 HEXADECIMAL DUMP FUNCTION

The hexadecimal dump function causes the printer to print the received data in hexadecimal. The printer

prints 16 values in hexadecimal, followed by the corresponding ASCII characters, on one line. If there

is no corresponding printable character for a value (i.e. a control code), a period (.) is printed. Any

remaining data (less than 16 values) can be printed by operating the ON LINE switch. No panel settings

can be made in the hexadecimal dump mode. This function makes it easy for technician to identify

source of communications problems between the printer and computer.

Table 1-24 lists the self test operating instructions and Figure 1-9 shows the hexadecimal dump printing.

Table 1-24. Hexadecimal Dump Operation

the

I

Function Operation

Hexadecimal dump mode

CIata

0,:,0,:,

(:>0(>1

(:)002

0003

00<.,4

,)0(:)5

0006

0007

0008

0009

OOOA

C,ooe

,:,,:,OC

,j(j,jl)

OWE

OOOF

0010

0011

0012

0<113

0014

,:,015

0016

0017

0010

ljo19

,:, C,l

iIOIB

O(>1C

CJOID

Oc:DIE

,>,:,1,=

0020

0021

,:,022

0023

0(>24

0025

0026

,:,027

,5028

0029

OCUA

O(jzn

O02C

OC13J

O(;12E

O02F

0030

0(:,31

0032

0033

CIOT4

0035

0036

0037

CMHB

0039

OO?.la

,>,]y

Turn the power ON while

pressing both the LINE FEED

and FORM FEED switches

Dump Mode

IB 40 00 IB 55 00 IB .33

18 7e 01 IB 57 00

45

S2 20 31 OD

#:,

D

(:,&

20 2,)

6S

7T OD

30

2,>

61 6E 64 20 46 58 2D

&,5

2,:,

73 63 72 b9 61 6C

72 6? 78 20 39 2D 70 69

61

6C 20 70 72 69 6E 74 65 72 73 20 74 68 61 74

OD

OA 20 20 20 70 72 69 6E 74

6D 61 78 69 6D 75 6D 20 6F 66 20 32 36 34 20 4.3

50 53 2E 20 20 45 b? 74 6S 65 72 20 6D 6F 64 65

6C W 46 5S 2D 3S 35

20 63 bF bC 75 6D 6E 77 20 6F 72 20 46 58 2D

OA 20 20 20 31 30 35 30 20 77 69 74 60 20 31 33

36 20 6S 6F 6C 75 6D 6E 73 20 63 61 6E 20 62 65

20

73 65 6C 65 63 74 65 64 20 61 63 63 6F 72 64

b~ 6E 67 20 74 6F 20 79 6F 75 72 20 72 65 71 75

69

72 65 6D 6S 6E 74 73 2E 20 20 S4 68 65 OD OA

20 20 20 6D 61 b9 6E 20 66 65 61 74 73 72 65 73

20 61 72

OD

06 OD OA 20

b9 6E 74 69 6E 67 20 73 70 63 65 64 36 20 20 32

36 34 20

64

20 45 6C 69 74 65 29 OD

20 20

A

El

20

20 20 20 20 20 3Z Z~ 30 20 43 50 53 20 28 44 7Z

61 .% 74 20 61 6E 64 20 50 6? 63 61 29 OD 06 OD

of+

20 20 2,> 2A 20 41 64 76 61 &E 63 65 64 ~o 70

61 70 65

6E 63 74 69 6F 6E 7S 3& 20 20 41 75 74 6F 20 74

6S 61 72 2D 6F 66 66 OD OA 20 20 20 20 20 20 20

20 20 20

20 20 20 20 20 20 20

2<)

20

41 75 74 6F 20 6C 6F 61 64 69 6E 67 oD oA

20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20

20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20

~,> ZIJ

20 20 20 ~. 20 20 20 q~ 75 ,4 # 20 62

.53

6B 2D 6F 75 74 OD OR 20 20 20 20 20 20 20 20

20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20

2(]

20 20

20

4D 69 63 72 6F

74 OD

0~

79 70 65

7?

20 70 72 69 6E 74 20 6D 6F 64 65 20 63 61 6E

20

62 65 20 73 65 6C 6.5 6.3 74 65 64 20 64 69 72

63 63 74 6C 79 20 66 72 6F bD 20 74 60 65 20 66

72

6F 6E 74 OD OA 20 20 20 20 20 70 61 6E 65 6C

29

2E 20 20 4F 6E 6.3 65 20 61 20 6D 6F 64 63 20

b9

7Z 20 7Z 63 6C 65 63 74 69 64 2C 20 &9 74 20

69

77 20 73 74 6F 72 6S 64 20 69 6E 20 74 68 63

20

6E 6F 6E 2D 76 6F 6C 61 74 69 6C 63 20 6D 65

bD 6F 72 79 2C OD 06 20 20 20 20 20 61 6E 64 20

b9

73 20 73 65 6C 65 63 74 65 64 20 77 6B 65 6E

20 74 68 63 20 70 72 69 6E 74 65 72 20 70 6F 77

65 72

20

OD

20

64

b5 20

69 73 20’ 74 75 72 6E 6S 64 20 6F 6E 2E

OA OD

.56

bF 6E 74 73 20 2S 52 6F 6D 61 6E 20 61 6E

20 57 61 6E 73 2D 71 65 72 69 66 29 ~o 61 7Z

7Z 74 61 6E 64 61 72 64 2E OD 06 OD OA 20

oia OD

2,>

31 2E 31

OFI 20 20 20

6!5 2[>

61 77 20 66

2,)

43

50 53 20 2S 44 72 61 66 74 20 61 6E

20 20 20 20 20 20 20 20 20 20 20 20 20

72 20 68 61 6E 64 AC 69 6E 67 20 66 75

21-1 20

20 20 20 20 20 20 20 20 20 20 20

Zf)

20 20 ~o

I>D OA

20 20 20 2A 20 53 65 6C 65 63 54

20 66

7!3

6E 63 74 69 6F 6E 20 20 41 6E

OFI

20 20 20 2A 20 S4 77 6F 20 4E 4C 51

IE 00 OD oA 12

IEI

4D 20 20 20 43 48 41 50 54

OR W 20

54 68 65 20 46 5S 2D 3S .35

?.0

20 77 69 74 68 20 3S

20 20 20 4D 61 78 2E 20 70 72

2!3

20 20

2,>

~1 64 6A 75 73 74 60 65 6E

2!>

2,>

.20 b4

.5E

Z(j 3) 20 20 20

2e 31 2E OD OA

20 4& 65 61 74 75 72

,31

30 35 30

6F 74 20 6D 61 74

20 74 65 72 6D 67 6E

2,>

61 74 20 61 20

.5F 6C

6C 6F 77 73 30

0(4

20 20 20 20 20 20

213 20

Zrj 20 20 20 Zcl

IEI

.20

70 00

61 72

21J 20

20

stop

● Press the ON LINE switch to

set the printer off line. Next,

turn off the printer.

.@.

.U

. .

z

. . . . . .

.x.

.W.

ER

1 . . . . ( 1 . .

. .

1.1

es. .

O ● nd FX-105O ar

e serial dot mat

rix 9-pin termin

● l

printwe

print at ●

. .

maximum of 264 C

Ps .

Either

1

?.0

OD

6.1

FX-850

columns or FX-.

1050 with 13

6 columns

selectmd accord

ing to your

irmmmnts.

main

● ra as fol lows

. . . .

inting speed

64 CPS (

d Elite) . .

220

●

ft and Pica) . . .

* Advancwd

● per handl inq tu

nctions:

ear-off . .

Auto

ck-out

. .

Micro

t

. . . .

YPR function (An

y print

be

swlected

● ctly from th~ f

rent. .

Dnc=

).

is 8Ql Qcted, it

is

stored

no”-volati

mory,

. .

is

soloctmd

thm printer POW

er is

. . . .

fonts (Roman ● n

d

Sans-seri

e standard. . . . .

.M

loading. .

turn-d

CHAPT

Featur

Thm FX-8S

that

mod-

with

can b.

rmqu

Thin. .

features

$

Max . pr

: 2

Draft ● n

CPS

( Dr

auto t

Auto ba

adjustmmn

i SO1OCT

mod-

can

dir

panel

●

mod=

in the

le

● nd

wh.”

o“.

* Two NLQ

f ) ● r

P.

.

80

z

p

ma

f ---

.— -

Figure 1-9. Hexadecimal Dump Printing

1-20

Page 30

REV.-A

1.7 PRINTER INITIALIZATION

There are two initialization methods: hardware initialization and software initialization.

1.7.1 Hardware Initialization

This type of initialization occurs when printer power is turned on or when the printer receives the INIT

signal from the host computer via the 8-bit parallel interface.

When printer is initialized in this way, it performs the following actions:

● Initializes printer mechanism.

● Sets the on-line mode.

● Sets the page length to 11 or 12 inches according to the DIP switch.

● Clears the input data buffer and print buffer.

● Read DIP switch and jumper settings.

● Sets the print mode according to the DIP switch and the non-volatile memory set by control panel.

● Sets printer selections to their default values

1.7.2 Software Initialization

This type of initialization occurs when the printer receives command

(ESC @)

via software.

When the printer is initialized in this way, it performs the following actions:

● Clears the print buffer.

● Sets printer selections to their default values.

NOTE: The printer’s default values are as follows:

Page Position Preset paper position becomes top of form position

Left and Right Margin

Released

Line Spacing 1/6 inches

Vertical Tab Position

Cleared

Horizontal Tab Position Every 8 characters (relative)

VFU Channel Channel O

Family Number of Type Style Roman (Family Number O)

Downloaded Characters Deselected: Software initialize

Cleared:

Hardware initialize

Justification Left justification

Character Per Inch

Bit Image Mode Assignment

Printing Effects

10

ESC

ESC

Z =

Cleared

K =

ESC

ESC

X 3

X O,

ESC

L =

ESC

X 1,

ESC

=

ESC

X 2,

●

1-21

Page 31

REV.-A

1.8 BUZZER OPERATION AND ERROR CONDITIONS

This section describes the buzzer operation and error conditions of the printer.

1.8.1 Buzzer Operation

The buzzer beeps as follows:

●

When a BEL code is sent to the printer, the buzzer sounds for 0.1 second.

When the following error has occured:

●

Carriage Trouble . . . . . . . . . . . . . . . . . . . . .

Paper End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abnormal Voltage . . . . . . . . . . . . . . . . . . .

RAM Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short circuited printhead

drive transistor . . . . . . . . . . . . . . . . . . . . . . . .

●

Recognition of the control panel operation

Beeps once in the following cases:

Self print mode

Hexadecimal dump mode

Print mode setting

●

Proportional space alternation

Beeps once when old proportional space is selected and twice new one is selected.

Beeps 6 times, pausing briefly after 3rd beep.

Beeps 20 times, pausing briefly after every 4 beeps.

Beeps 5 times, pausing every beep.

Beeps 6 to 10 times, pausing briefly after every 2 beeps. The beeps

warn which RAM is incorrect as follows:

6 times . . . . . . . .

8 times . . . . . . . .

10 times . . . . .

Beeps 10 times, pausing after every beep.

Internal RAM (CPU)

Lower Address RAM

Upper Address RAM

(IC)

(IC)

1.8.2

Error Conditions

The printer enters an error state and sets the ERROR signal LOW and BUSY signal HIGH to prohibit

reception of data when any of the following states occurs.

●

The carriage home signal is not detected after the printer mechanism has been initialized (carriage

error).

●

The carriage home position is detected during printing (carriage error).

The printer is set OFF LINE using the ON LINE switch.

●

An internal DC voltage drop is detected (abnormal voltage is detected).

●

●

During initialization, an error is detected by a READ/WRITE check of the RAM in the control circuit.

●

printhead drive transistor is shorted.

A

Interface signal PE is also set HIGH in addition to the above error sequence when any of the following

states occurs.

● The printhead is moved outside of the printable area by a forms override function (paper end state).

● The paper end state continues after the cut sheet feeder mode has been set and paper loading has

been completed (paper end state).

1-22

Page 32

REV.-A

1.9 PAPER HANDLING FUNCTIONS

The push tractor unit can be easily mounted or removed using the paper release lever. Either continuous

paper or cut sheets can be easily selected by operating the LOAD/EJECT switch and paper release lever.

Various paper handling functions are described below.

1.9.1 Autoloading and Backout Function

Loading and ejecting a cut sheet:

When no sheet is loaded, push the paper release lever backward, load the sheet along the sheet guide,

TOF

and press the LOAD/EJECT switch so that the sheet is automatically fed up to the

When the LOAD/EJECT switch is pressed with a sheet loaded, the sheet will be ejected.

Loading and ejecting continuous paper (auto back-out):

Pull the paper release lever forward, load continuous paper onto the push tractor unit, and press the

TOF

LOAD/EJECT switch so that the paper is automatically fed up to the

When the LOAD/EJECT switch is pressed with the paper loaded, the paper is fed in the reverse direction

(ejected) up to the tractor waiting position (auto back-out). If the paper cannot be fed in the reverse

direction at 1/6 inch line spacing, the paper ejection process will be terminated.

position.

position.

1.9.2 Short Tear-Off Function

For continuous paper (when the paper release lever is moved to the tractor feeder side), the paper will

be automatically fed to the perforations (tear-off position) when printing is completed, no data is being

received from the host computer, and the print buffer is empty. At this time, the micro-adjustment

set function becomes valid so that the tear-off position can be adjusted accurately using the LF and

FF switches. The adjusted tear-off position is stored in the memory and remains valid even after the

printer power is turned off, so that the paper will be automatically fed to that position when the tear-off

function is executed later.

After the paper is cut off, the paper is automatically returned to the previous position by sending new

print data or setting the printer OFF LINE.

1.9.3 Micro-Adjustment Top-of-Form Set Function

After paper loading is completed, set the printer ON LINE by pressing the ON LINE switch. In this state,

the paper loading position can be finely adjusted by operating the LF and FF switches. When the printer

is in the micro adjustment mode, the ON LINE LED on the panel blinks. The paper loading position can

be adjusted individually for the friction feed, tractor feed, and cut sheet feeder modes, and the adjusted

values are stored in the memory. The value for the tractor feed remains valid even after the printer power

is turned off.

NOTE: If paper is already loaded when the printer power is turned on, the position of the paper will

TOF

be recognized as the

position.

TOF

1-23

Page 33

REV.-A

1.10 PAPER END DETECTION

The paper end is detected by the PE sensor. When the paper end is detected, the printer indicates it

by lighting the lamp on the control panel and ringing the buzzer. The printer sets the parallel interface

signals

After the paper end is detected, load a new sheet and press the ON LINE switch so that the printer enters

the ON LINE mode. Figure 1-10 shows the paper end detection position.

as shown below, and enters the OFF LINE mode.

● BUSY signal: HIGH

● PE signal:

. ERROR signal: LOW

HIGH

T

Approx.

59. 9mm

I

.-.

ABC

Printable

.------

Paper End Detection

ABC

— —

------------

Area

Posltlon

XYZ

XYZ

1...

---

Fig. 1-10. Paper End Detection Position

1-24

Page 34

1.11 MAIN COMPONENTS

The

FX-850/l

Model-3B 10\3B60 printer mechanism

●

PEGX

●

● PGPNL board (control panel)

PEBFIL-11

●

● Housing

Figure 1-11 shows the

050 printer includes the following major subassemblies:

board (main board)

board (filter board) and power transformer

FX-850/l

050 component locations.

— Power Transformer

FIEV.-A

Pape

Unit

PEBFIL-ll–

Board

r

Tension

Plunger–

Printhead

PEGX

Board

=

Paper Feed Motor

-

Carriage Motor

FX-850

NOTE: In

FX-1 050

FX-850, the paper tension unit and push tractor unit are excluded.

Figure 1-11. Component Locations

1-25

Page 35

REV.-A

1.11.1

The

range of usable paper,

mechanisms are based on printer mechanisms Model-53 10/5360 for the

pull tractor unit or cut sheet feeder can be mounted to the mechanism. Since the construction of these

printer mechanisms are simplified, maintenance is very easy.

Printer Mechanism

Model-3B

10

(FX-850)/3B60 (FX-1

050) are 9-pin dot matrix printer mechanisms, and feature a wide

light weight, compact size, and advanced paper handling function. These

LQ-850/l

050. The optional

F’”

.-,

,.

Figure 1-12.

Figure 1-13.

Model-3B10

Model-3B60

(FX-850)

(FX-105O)

..

.

●

1-26

Page 36

REV.-A

1.11.2 PEGX Board (Main Board)

PEGX

The

board is the main board, and interfaces the printer to the host computer, controls the printer

mechanism and control panel, and supplies DC voltage. Since the complicated logic circuit section is

PEGX

implemented using gate arrays, the

Driver circuits for the motors, sensors, and

on the

Universal

Gate

Memory

PEGX

board are:

IC

STK6722HZ (IC2A)......... . . . . . . . . . . . . . . . . . . . .

●

NJM2355 (lCIA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Array

E05A15HA (IC3A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

E05A16GA (IC7A)......... . . . . . . . . . . . . . . . . . . . . . . .

●

IC

●

EP-ROM (IC4A)

●

S-RAM (IC5A and 6A).. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

board features very compact construction.

printhead are also included on this board. Other main

Carriage Motor Driver

.

Switching Regulator

Paper Feed and Carriage

and

Printhead

driver

IC

Motors controller,

Host computer interface

Program ROM, 256 K-bit

Buffer and Back up memory

ICS

GA (E05A15HA)

CPU (PPD7810HG)

Figure 1-14.

PEGX

S-RAM (8 KBX2)

%&h

Board

~~

Lithium Battery

GA(E05A16GA)

DIP

DIP

SW2

SW1

1-27

Page 37

REV.-A

1.11.3 PEBFIL-11 Board (Filter Board) and Power Transformer

.K !%

?

The DC power supply circuit is on the main board. The

PEBFIL-11

board and power transformer remove

noise from the AC power supply section and drop the AC input voltage.

Figure 1-15 shows the

PEBFIL-11

board and power transformer.

220/240V

t--

120V

\

220V

(240V)

120V

Figure 1-15.

PEBFIL-11

Board and Power Transformer

1-28

Page 38

REV.-A

1.11.4 PGPNL Board (Control Panel)

LEDs,

There are 11

seven switches, and a buzzer on the control panel. Among these, seven

three switches are for the panel setting function

(SelecType).

Font, character pitch, and condensed mode

LEDs

and

can be selected directly using these switches. Settings set using the SelecType mode are stored in the

memory and are set on the panel when the printer hardware is initialized.

Normally, the SelecType

function is valid when not printing. The printers have various other functions that can be selected from

the control panel.

Figure 1-16 shows the control panel.

Switches

ON LINE

FORM FEED

LINE FEED

Figure 1-16. Control Panel

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This button controls the printer’s on line/off line status.

When the printer is on

line, ON LINE light is on and the

printer can receive and print data from the computer.

When this lamp is flickering, the micro adjustment

function can be used.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When the printer is off line, press this button to eject a

single sheet of paper or to advance continuous paper to

the top of the next page.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When the printer is off line, press this button to advance

the paper one line, or hold it down to advance the paper

continuously.

1-29

Page 39

REV.-A

LOAD/EJECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This button is used to feed the paper to the loading position,

or to eject paper when paper is already loaded. Paper is

ejected forward if the paper release lever is set to the single

sheet position, and is ejected backward (removed from the

paper path) if the release lever is set to the continuous paper

position.

FONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This button is used to select

SERIF, or DRAFT mode. The yellow indicator light shows the

selected font.

PITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This button is used to select 10 CPI, 12 CPI, or PS

(proportional) spacing. The yellow indicator light shows the

selected pitch.

This button is used to select or deselect the condensed

mode. The yellow indicator light is on when the printer is

in the condensed mode. In this mode all characters are

printed at approximately 60% of their normal width.

LEDs

POWER (Green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

READY (Green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On when the POWER switch is on, and power is supplied.

On when the printer is ready to accept input data. This LED

flickers while data is printed.

PAPER OUT (Red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On when the paper end sensor detects that the printer is

out of paper.

NLQ

ROMAN,

NLQ

SANS-

f

““

;.-

L

. ._.’

!.

I

1-30

!

Page 40

REV.-A

1.11.5 Housing

The housing consists mainly of the upper and lower cases. The components described in the former

sections (1. 11.1 through 1.11 .3) are accommodated in the lower case. Other components are the paper

feed knob, paper separator, and printer cover. The DIP switch position is changed from the rear side

of the printer (conventional) to the right side. A removable cover is located on the upper case so that

the DIP switches on the optional board can be set without removing the upper case.

Figure 1-17 shows the upper and lower cases.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FX-850

FX-1 050

Figure 1-17. Housing

1-31

Page 41

CHAPTER 2

OPERATING PRINCIPLES

REV.-A

2.1 GENERAL

2.1.1 Cable Connections

2.2 PRINTER MECHANISM OPERATION

2.2.1 Printhead

2.2.2 Carriage Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Home Position Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Ribbon Feed Mechanism

2.2.5 Paper Feed Mechanism

2.3 CIRCUIT OPERATION

2.3.1 General

2.3.2 Power Supply Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5.1 Push Tractor Feeding Method . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.5.2 Friciton Feeding Method

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Information

2.3.1.1

2.3.1.2

2.3.1.3

2.3.2.1 Filter Circuit

Power Supply Section

Control Circuit Section

Memory Mapping

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-1

2-3

2-4

.

2-5

.

2-5

2-6

2-7

2-9

2-10

2-1o

2-1o

2-12

2-14

2-15

2-1 e

2.3.2.2 Transformer

2.3.2.3 Rectifier and Smoothing Circuit . . . . . . . . . . . . . . . . . . . . 2-17

2.3.2.4 Chopper-Type Switching

Regulator Circuit

2.3.2.5 Pulse-Width Modulation

+5V

2.3.2.6

2.3.2.7

2.3.2.8 + 12V DC Supply Circuit

2.3.2.9 Vx Voltage Supply Circuit

2.3.3 Main

2.3.4 Main Circuit Operation

IC Function

2.3.3.1 CPU Functions

2.3.3.2 E05A15HA Gate Array Functions ................ 2-29

2.3.3.3 E05A16GA Gate Array Functions ................ 2-31

2.3.4.1 Reset Circuit

2.3.4.2 Interface Control Circuit

2.3.4.3 DIP Switch Circuit and Jumpers .................. 2-37

Regulator Circuit

+24V

Regulator Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(PWM)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .