Page 1

EPSON AMERICA, INC.

Product Support Bulletin

Subject: DFX-5000 paper loading problems.

EPSON

Date: 01/04/94

Page(s): 1 of 2

The purpose of this bulletin is to resolve a problem with the DFX-5000 printers that

constantly or intermittently perform a load and eject cycle or fail to load paper

completely.

1. Problem:

The initial and final platen gap values cannot be determined as read from the platen

gap sensor.

2. Explanation:

There are two possible solutions to this problem. The fix that has been used in the past

with moderate success is to gap the platen gap motor with a thin strip of regular copy

paper. The platen gap motor (PGM) was set for zero backlash from the factory, and as

the unit ages, it is increasingly difficult for the carriage guide shaft (CGS) to rotate and

find the initial and final platen gap (PG) values. The printer would load and eject paper

constantly and on rare occasion, the paper would stay loaded.

PSB No: P-0102

Originator: SEK

If the PGM backlash adjustment does not cure the problem, there are two friction

clutches that keep the CGS from rotating while printing. On older units, or units used in

harsher environments, the lubricant on the friction plates will dry out or get

contaminated causing sluggish response of the CGS. The CGS will seem like it is

harder to turn than other printers, although the amount is very slight and is difficult to

measure.

3. Resolution:

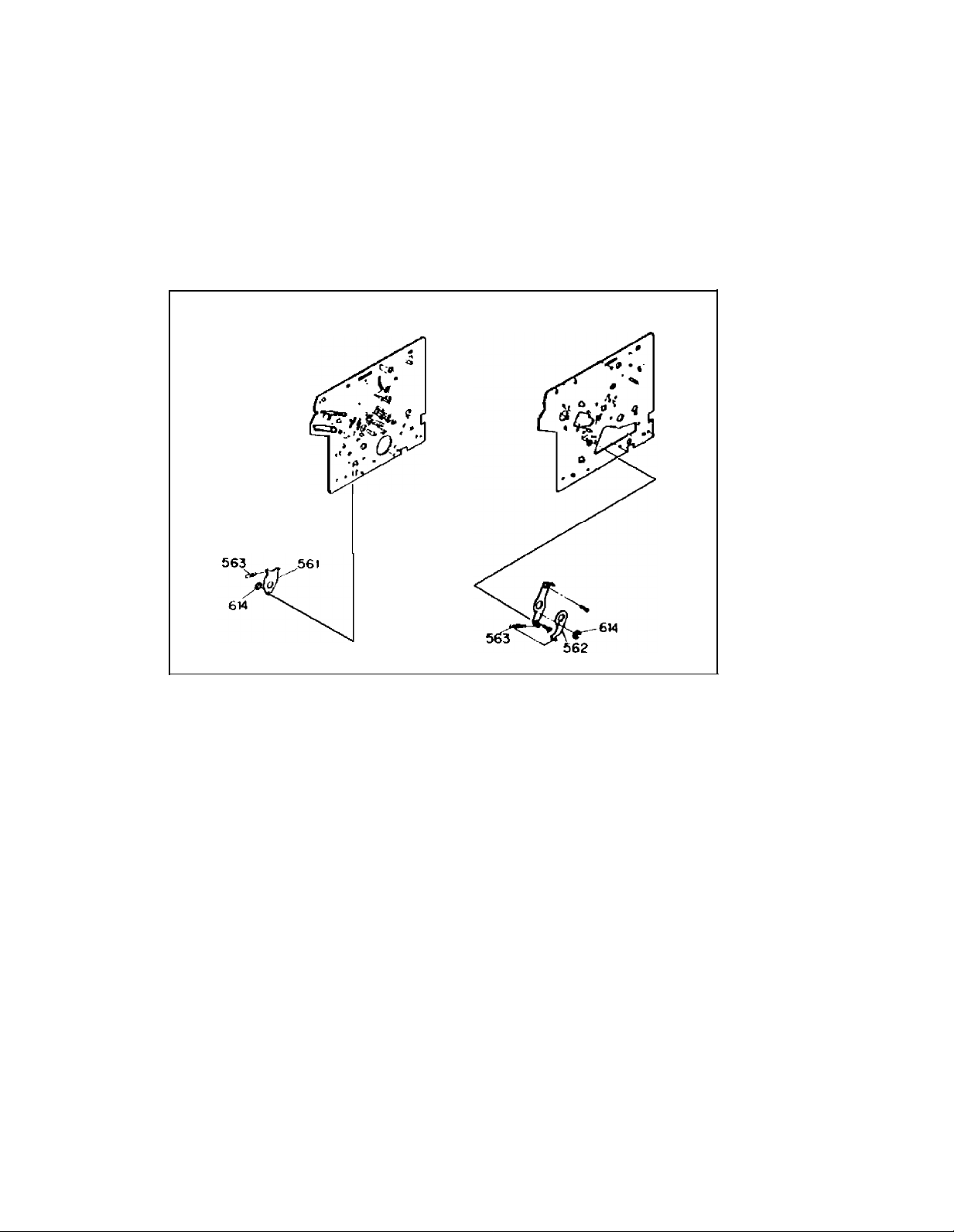

On each side of the CGS there is a friction clutch (Figure 1, Reference 561, 562, 563

and 614). These clutch plates must be removed, cleaned, lubricated and reinstalled.

This is the procedure:

1.

Remove the interlock switch before lifting the mechanism out.

2.

Remove the four screws that hold the mechanism in the printer, all cables and

ground straps.

3.

Remove the junction board, the PG sensor and the PG motor.

4.

Remove the E ring that holds the CGS gear and the other small gear.

5.

Remove the E ring (563) and spring (614) that attaches the “Guide shaft holding

lever” or clutch plate.

Page 2

PSB No: P-0102

Page: 2 of 2

6.

Clean the plate and the end of the CGS. Lube the assembly with light

machine oil (Epson 02 oil).

7.

Do the same for the right side by first removing the carrage motor.

Figure 1

8.

Remove the E ring and spring that attaches the “Guide shaft holding lever” or

clutch plate.

9.

Mark the parallelism adjustment plate and remove the two screws that attach it.

10. Clean the plates and the end of the CGS. Lube the assembly with light machine oil

11. Assemble in reverse order, do the PGM backlash adjustment, check and perform

the parallelism adjustment if necessary and test.

Page 3

EPSON AMERICA, INC.

Product Support Bulletin

Subject: DFX-5000, DFX-8000 and Avatar EP-Connect

EPSON

Date: 10/9/92

Page(s): 1 of 1

Avatar Corporation distributes the EP-Connect coax interface for the Epson DFXseries and other Epson dot-matrix printers that use A-type interfaces. This EPConnect coax interface allows a connection to an IBM 3174/3274/3276 control unit

or 4300 series Display Printer Adaptor using standard type A coaxial cable.

When using EP-Connect and the DFX-series printers, there have been some

intermittent operational problems reported. It has been determined that this is

caused by the type of connector used on the EP-Connect interface that plugs into

the printer’s main controller board. There are two types of connectors that have

been used on the EP-Connect coax interface. One type is a “FUJITSU” connector.

The other is a “HONDA” connector. The “FUJITSU” connector has slightly shorter

pins than the “HONDA’ connector. Epson America, Inc. does

use of the EP-Connect interface that has the ‘FUJITSU’ connector unless it is used

on a unit that has the countermeasure described below.

To identify which connector type the EP-Connect interface has, simply look directly

at the interface connector. The “HONDA” connector will have the name “HONDA

printed directly on the black part of the connector.

“FUJITSU” connector. Epson America, Inc. recommends the “HONDA” connector.

PSB No: P-0091

Originator: REW

not

recommend the

If there is no label, it is the

There are approximately 1,600 of the EP-Connect interfaces on the market that

contain the non-approved “FUJITSU” connector. To accommodate these interfaces

Epson has taken a countermeasure on the DFX series printers. This involves

adjusting the position of the ORII/F circuit board and changing the securing points.

As a result, Epson only recommends the use of the Avatar board with the

“FUJITSU” connector on DFX series printers that have the countermeasure

installed. The starting serial

installed is outlined below.

PRINTERS

DFX-5000

DFX-8000

If further information is needed on this subject, please contact Epson’s Technical

Support Department. For additional information on the EP-Connect interface,

please contact Avatar Corporation at (508) 435-6872.

number for the printers that have the countermeasure

STARTING SN#

0G20A11434

0VZ0007714

Loading...

Loading...