Page 1

®

EPSON

Twinax

Interface

C82315*

USER’S GUIDE

REDIENUNGSANI FITUNG

MODE D'EMPLOI

GUIA DEL USUARlO

I

Card

MANUALE PER

L'UTENTE

Page 2

Errata to C82315* EPSON User’s Guide

Revised 9/321/93

for Software Revision 4.1

For all emulations

Host download is now supported on the parallel port as well as the IBM twinax port.

3812 emulation

1.2.X Point Forms XRess is now supported.

Escape character substituted when “logic¬ E” ( E) is received. Example:

PCL command for underline = ESC & d0D (lB 26 64 30 44 ) can be sent as

E&d0D

3.4.10 CPI will print as 10.3 CPI when using A4 paper

Scalable font sod point sizes can he selected using a “logical-not F F) string.

The command format is as follows:

Fnnnnn,ppp where

Example :

F5687.25 will select the Times Roman font at 25 point

ppp=desiredpointsize(11099!&

nnnnn = number of scalable font selected from the

following list

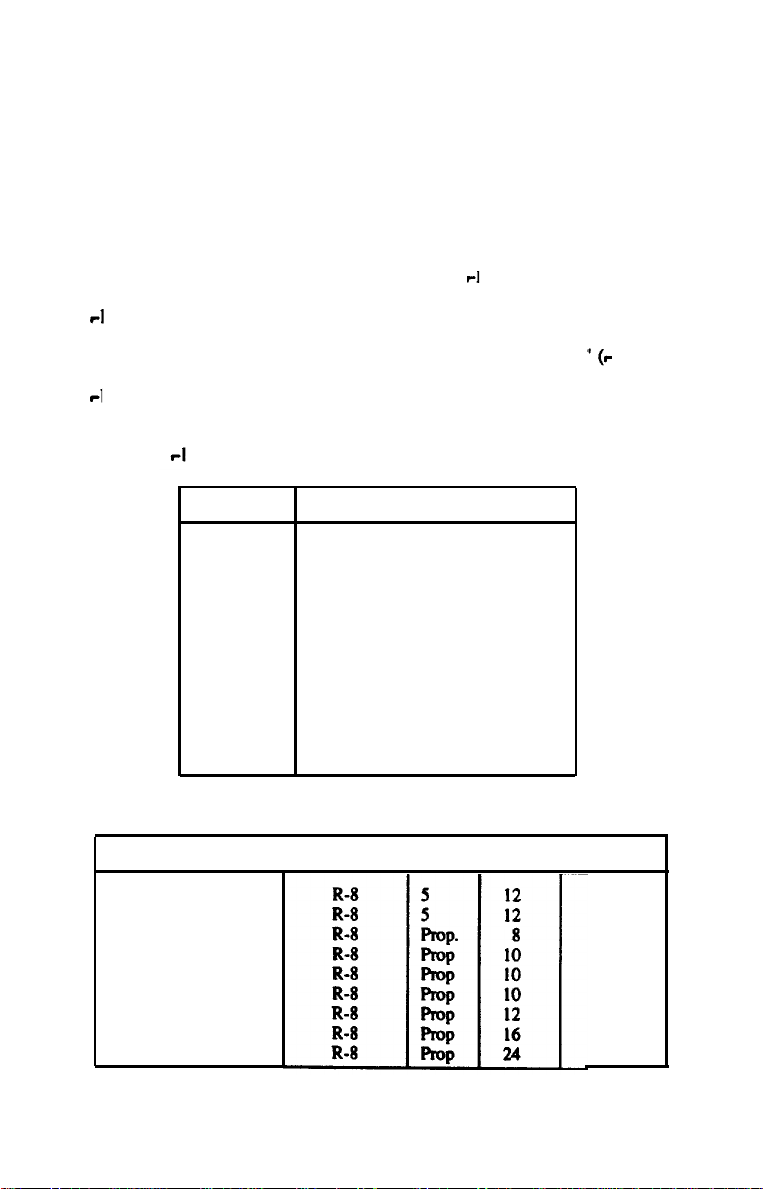

nnnnn

5687

5815

5707

5835

34103

34231

34123

34251

33335

33463

33355

33483

5.

New fonts added to support 3812 font numbers:

Typeface

Courier

Courier Bold

Sonoran-Serif*

Sonoran-Serif*

Sonoran-Serif Bold*

Sonoran-Serif Italic*

Sonoran-Serif*

Sonoran-Serif Bold*

Sonoran-Serif Bold*

Scalable Foot

Times Roman

Times Roman Italic

Ties Roman Bold

Times Roman Bold Italic

Sans Serif Medium

Sans Serif Medium Italic

Sans Serif Bold

Sans Serif Bold Italic

Sans Serif Condensed

Sans Serif Condensed Italic

Sans Serif Condensed Bold

Sans Serif Condensed Bold Italic

Symbol Set pitch point 3812#

244

245

751

1051

1053

1056

1351

1653

2103

* Uses Times Roman typeface

OMAN01

Page 3

COPYRIGHT NOTICE:

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, mechanical,

photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation. No patent liability is assumed with respect to the use

of the information contained herein. While every precaution has been taken in the

preparation of this book, Seiko Epson Corporation assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from

the use of the Information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser

of this product or third parties for damages, losses, costs, or expenses incurred

by the purchaser or third parties as a result of: accident, misuse, or abuse of this

product or unauthorized modifications, repairs, or alterations to this product, or

(excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s

operating and maintenance instructions.

Epson and Epson ESC/P are registered trademarks of Seiko Epson Corporation.

IBM is a registered trademark of International Business Machines Corporation.

HP LaserJet II is a trademark, and Hewlett-Packard and PCL are registered

trademarks of Hewlett-Packard Company.

PostScript is a trademark of Adobe Systems Incorporated.

Command-Pass-Thru is a registered trademark of I-O Corporation.

WordPerfect is a registered trademark of WordPerfect Corporation.

Microsoft Is a registered trademark of Microsoft Corporation.

Univers, Times, and Helvetica are registered trademarks of Linotype AG and its

subsidiaries.

CG Times, CG Century Schoolbook, and Microstyle are products and CG

Triumvirate Is a trademark of AGFA Compugraphic, a Division of Agfa Corporation.

Serifa is a trademark of Fundicion Tipografica Neufville, SA.

ITC Dingbats is a U.S. registered trademark of International Typeface Corporation.

General Notice: Other product names used herein are for identification purposes

only and may be trademarks of their respective companies.

Copyright © 1992 by Seiko Epson Corporation

Nagano, Japan

Page 4

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Pan 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment Is operated In a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used In accordance with the

instruction manual, may cause harmful interference in which case the

user will be required to correct the interference at his own expense.

This devise complies with Pan 15 of the FCC Rules. Operation Is

subject to the following two conditions:

harmful interference. and (2) this device must accept any interference

received, including interference that my cause undesired operation.

FOR CANADIAN USERS

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digitai apparatus as set out ln the radio Interference

regulations of the Canadian Department of Communications.

Le présent apparell numérique n’émet pas de bruits radioélectriques

dépassant Ies limits applicables aux appareils numériques de Class A

prescrites dans le règiment our le brouillage radioélectrique édicté par

le Ministére des Communications du Canada.

(1) This device may not cause

WARNING

The connection of a non-shielded equipment Interface cable to this

equipment will invalidate the FCC Certification of this device and may

cause lnterference levels which exceed the limits established by the

FCC for this equipment. It is the responsibility of the user to obtain and

use a shielded equipment interface cable with thfs device. When this

equipment is attached to some printers. you should not leave cables

connected to the printer’s built-in connectors. See your printer’s user’s

manual for details.

Changes or modifications not expressly approved by Seiko Epson

Corporation. could void the user’s authority to operate the equipment.

Page 5

TWINAX INTERFACE CARD C82315*

USER’S GUIDE

SCHNITTSTELLENDARTE TWINAX C82315*

BEDIENUNGSANLEITUNG.

CARTE D’INTERFACE TWINAX C82315*

MODE D’EMPLOI

TARJETA DE INTERFACE TWINAX C82315*

GUIA DEL USUARIO

SCHEDA DI INTERFACCIA TWINAX C82315*

MANUALE PER L’UTENTE

APPENDIX

ANHANG/APPENDlCE/APÉNDICE/APPENDICE

Page 6

EPSON

User’s Guide

Contents:

Twinax

Interface Card

Introduction

Setting up the interface card

Making additional settings

Printersharing

Emulation details

..............................................

Unpacking, the interface

Selecting the emulation

Preparing to install the interface card

Setting the jumpers

Installing the interface card

Setting the switches

Switch settings

Performing a self test

Connecting to the host computer system

Command-pass-thru

User-defined command-pass-thru strings

Interface setup commands

Display station setup mode

Memory setup mode

............................................

...........................................

4214/5224 emulation

Line-feed increment

Paper bins

Graphics printing

5219 emulation

3812 emulation

Paper tray or cassette

Computer output reduction

Font id.....................................

Paper size and envelopes

Justification

....................................

.....................................

.....................................

..................................

...............................

...............................

......................

............................

.............................

...................................

..............................

.................................

..................

..................................

............

.............................

.............................

.................................

.................................

............................

..................................

.............................

..........................

......................

.......................

.................................

1

2

2

2

3

4

5

7

7

8

8

9

9

10

11

14

15

16

17

17

17

17

17

18

18

18

18

20

20

20

Page 7

Interface test modes

Hex print.. ........................................

Communications test

Interface diagnostics

Interface diagnostics error messages

Interface diagnostic loopback

........................................

.................................

.................................

...............

...........................

20

21

21

21

22

24

Specifications

C82315* interface specifications

Parallel interface specifications

EBCDIC character tables

Appendix

................................................

Sample printouts - Self Test

Display Station Setup Mode

Font IDs

Sample printouts - Hex Print

Sample printouts - PC850 character set

Sample printouts - HP Roman 8 character set

.............................................

.........................

..........................

..............................

............................

............................

..........................................

............................

....................

...............

25

25

26

29

A-1

A-1

A-2

A-3

A-4

A-5

A-6

Page 8

INTRODUCTION

The Epson C82315* Twinax Interface Card allows you to connect your Epson

printer to an IBM 34/38/38 or IBM AS400 computer system or to a remote

controller connected to these systems.

This interface card provides your Epson printer with the following features:

Emulation of the IBM 5219 or 3812 letter-quality printers as well as the

IBM 4214 or 5224 matrix printers

Conformance to IBM 5250 product-attachment specifications

The ability to receive data through a multi-tap, twin-axial connected

system at a maximum burst rate of 2 million bits per second

The ability to receive data through either the twin-axial connector or

through a parallel connector, allowing you to print from both the twinaxial system and a PC system

Automatic switching between the twin-axial connector and parallel port

based on selectable time-out periods

The ability to bypass IBM emulation and send commands directly to the

printer, allowing you to take advantage of unique Epson printer capabili-

ties

A special setup mode for changing various interface settings that allows

you to make yes or no answers to printed questions

A Display Station setup mode that displays setup information on an IBM

system display station; you can then change the settings on the screen

as necessary.

You can use the Epson C82315* Twinax Interface Card in the following Epson

printers:

DLQ-2000

SQ-870/1 170

Action Printer 5000/5500

You may be able to use this interface on other Epson printers as well. For a list

of optional interfaces that can be used with your printer, see your printer’s user’s

manual.

LQ570/1070

EPL-4000/4100

ActionLaser II

1

LQ-870/1170

EPL-8000/8100

Page 9

SETTING UP THE INTERFACE CARD

Follow the instructions in this section to install this interface in your Epson printer.

UNPACKING THE INTERFACE

Check that in addition to this user’s guide, your interface kit includes all the items

listed below, and that none has been damaged during shipping.

Twinax interface card (in a plastic anti-static bag)

Twin-axial “V-cable’ connector

Parallel printer sharing cable

Caution: This interface can be harmed by static electricity. Leave the interface

card In the anti-static bag until you are ready to install it in your printer.

SELECTING THE EMULATION

Before you can use the printer, you must tell the host computer which IBM printer

the interface is emulating. Ask your system manager or operator to make the

settings for you.

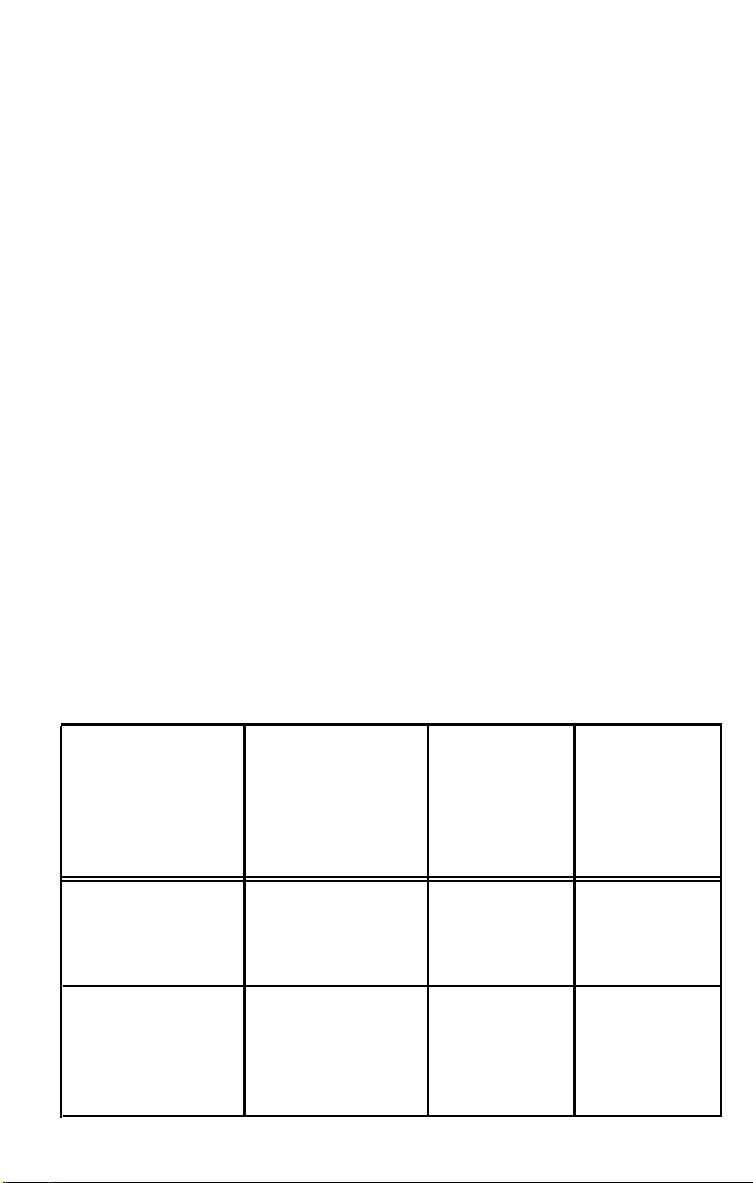

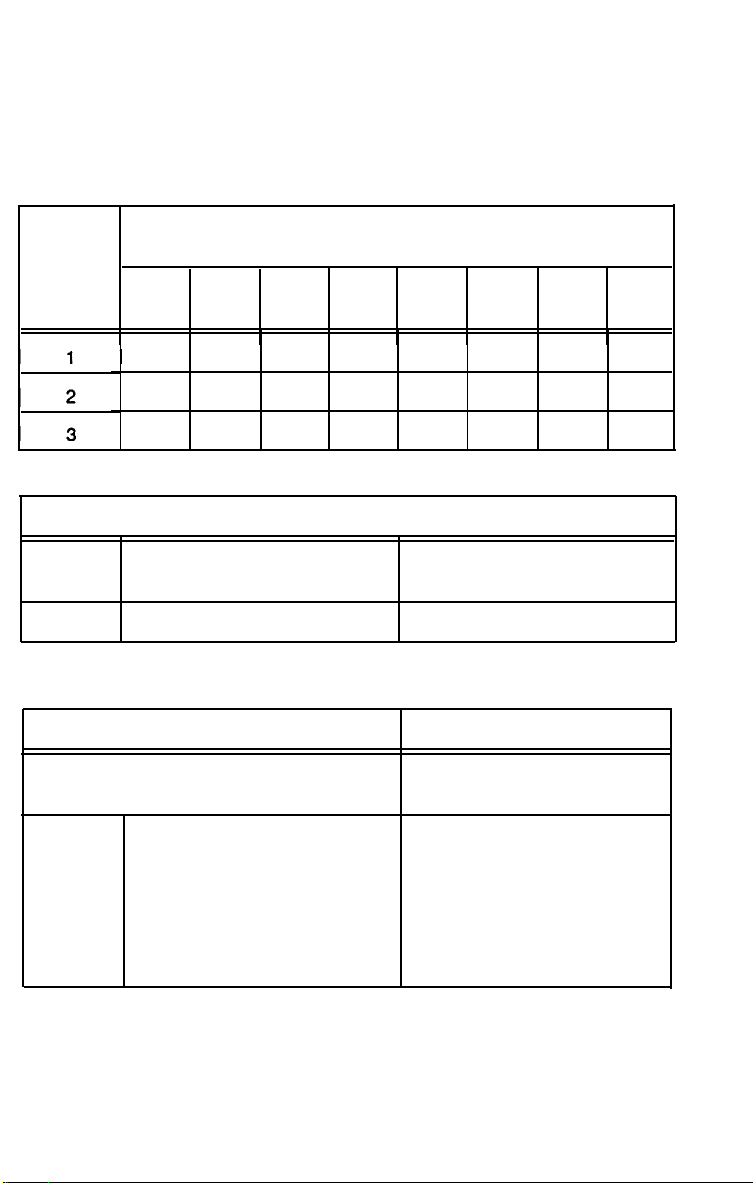

The following table shows you the recommended settings to make in your host

system:

Emulation and host system printer setting selection

If your system

is...

System 36,

System 38, AS400

and 5294 or 5394

remote controller

System 36,

System 38, AS400

and 5294 or 5394

remote controller

and the Epson

printer you are

using is...

laser printer (using

HP commands)

24148 element dot

matrix printer or

laser printer (using

ESC/P

commands)

the emulation and you

you should

select is...

3812

5219

2

should select

one of the

following

host system

settings

3812-1

5219 mdl D02

Page 10

If your system

Is...

and the Epson

printer you are

using is...

the emulation and you

you should

select is...

should select

one of the

following

host system

settings

System 36,

System 38, AS400

and 5294 or 5394

remote controller

System 34 or 5251

m12 remote

controller

You should keep the following in mind when selecting the emulation.

Only the 3812 emulation supports HP laser printer commands.

If you have a choice between the 5224 and 4214 emulations, you should select

4214. The 4214 emulation adds control of the following features: lines per inch,

pitch, graphics, print quality, and single-sheet handling.

If your printer supports Epson Job Language (EJL) commands, do not change the

printer mode using the EJL commands or the command-pass-thru feature while

the interface is installed. Also you may not be able to change the printer mode

using the control panel.

Never select the PostScript™ printer mode while this interface is installed.

9/24/48 element

dot matrix printer

or laser printer

(using ESC/P

commands)

9/24/48 element

dot matrix printer

or laser printer

(using ESC/P

commands)

4214

5224

4214 model 2

5224 (2P)

5225 (2P)

5258 (P)

PREPARING TO INSTALL THE INTERFACE CARD

Before installing this interface card you may need to set several jumpers,

depending

on

the following factors:

The type of Epson printer you are using

The type of IBM printer you want the interface to emulate

The type of twin-axial connector your host system uses

3

Page 11

Also, because this interface can be damaged by static electricity, you should

prepare the interface card for installation according to the procedure below:

1. While the interface is still in its anti-static bag, place it next to your printer.

2. Place the twin-axial cable from the host computer on top of the anti-static bag;

make sure the metal connector on the cable is in contact with the bag.

3. Remove the interface card

the twin-axial cable.

4. Set the jumpers on the interface card according to the instructions

from the

bag

and place it on top of the bag next to

in the

following section.

SETTING THE JUMPERS

A jumper is a small, square plastic object that fits over two terminals (prongs) on

To

the interface card.

disconnect a jumper, place it over one terminal only. All jumpers are connected

when shipped from the factory.

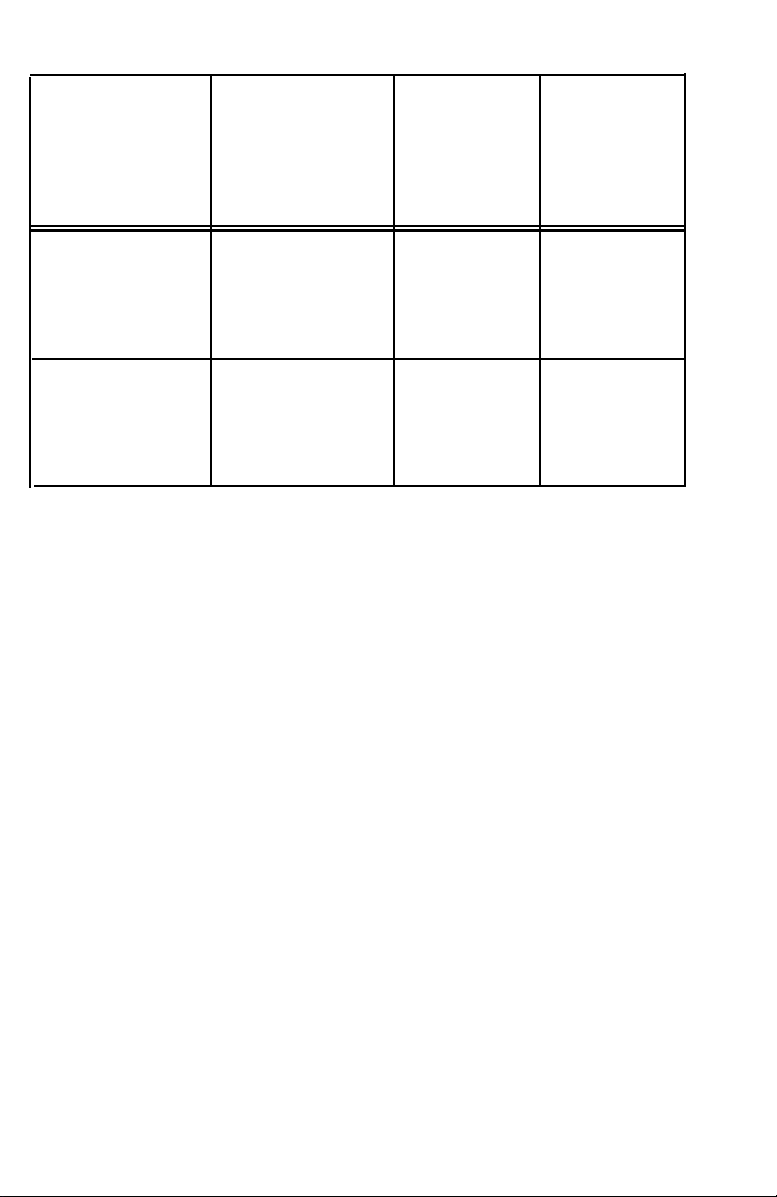

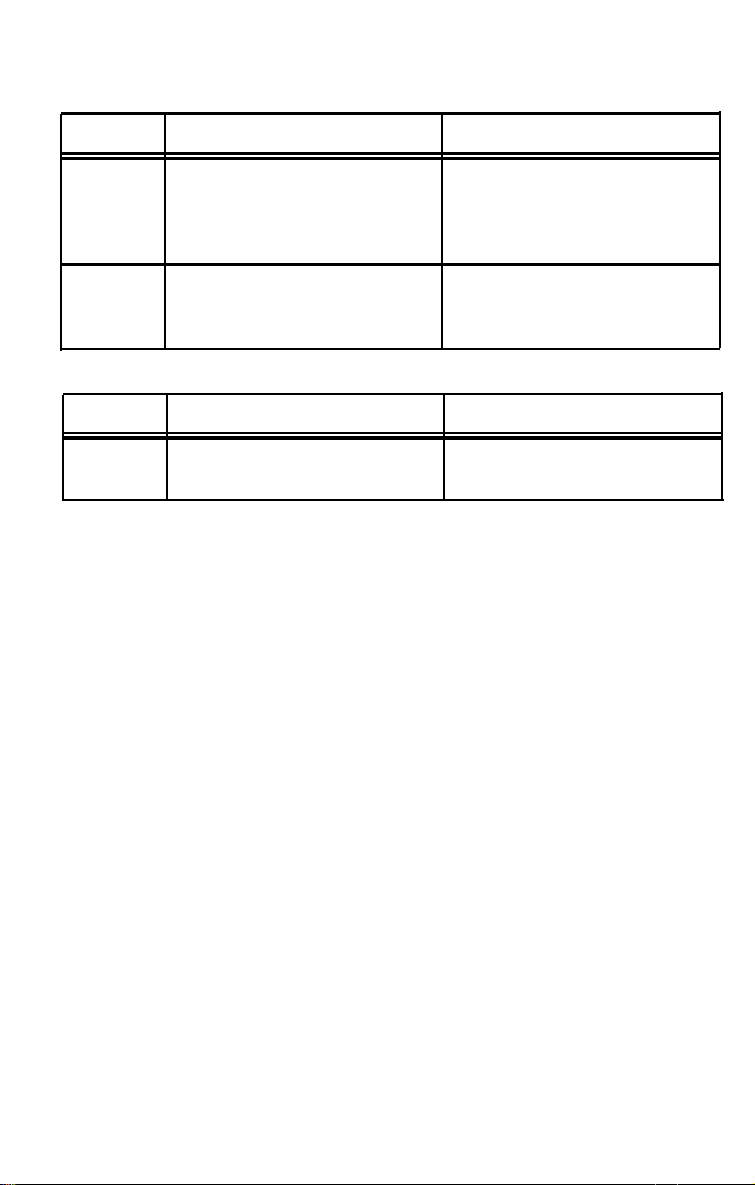

The C82315* interface card has three jumpers, labeled as J2, J5, and J6. The

settings for J5 and J6 are different for the different emulations. After deciding on

an emulation, set the jumpers according to the tables below.

Applies to all emulations

Jumper

J2

Dot-matrix 4214/5224 printer emulation

I

Jumper

Normal twin-axial cable

connect a jumper, place the jumper over both terminals. To

Connected

Twisted-pair ‘passive star panel’ cable

Use only if problems found on this type

of cable.

Connected

Disconnected

Disconnected

J5

J6**

Sends a printer ID code for

an IBM 4214 model 2 to the

host

Sends Epson ESC/P 9-pin

FX Commands to the printer

Sends a printer ID code for an IBM 5224

model 1 to the host

Sends Epson ESCIP 24145pin LQ commands to the printer

4

Page 12

Letter Quality 5219

5

emulation

Jumper

J5

J6**

** If the interface’s self test prints a name for your printer, you do not need to

set the J6 jumper.

Letter Quality 3812/HP Laser printer emulation

Jumper

J5

J6*

*

When you choose fixed page orientation, the orientation is selected by the settings of

switches 6 and 7.

Selects 5219 ESWP letter

quality emulation

Sends Epson EWP 9-pin

PX commands to the printer

Invalid selection

Sets the page orientation au- Sets a fixed page orientation when you

tomatically when you use the use the Computer Output Reduction feaComputer Output Reduction ture

feature

Connected

lnvalid selection

Sends Epson ESC/P 24/48 -pin LQ commands to the printer

Connected

Emulates an IBM 3612 printer using HP

LaserJet II commands

Disconnected

Disconnected

INSTALLING THE INTERFACE CARD

After making any necessary changes in the jumper settings, you should install the

C82315* Twinax Interface Card in your printer.

Instructions on installing this interface card are included in your printer’s user’s

guide. Follow these steps carefully.

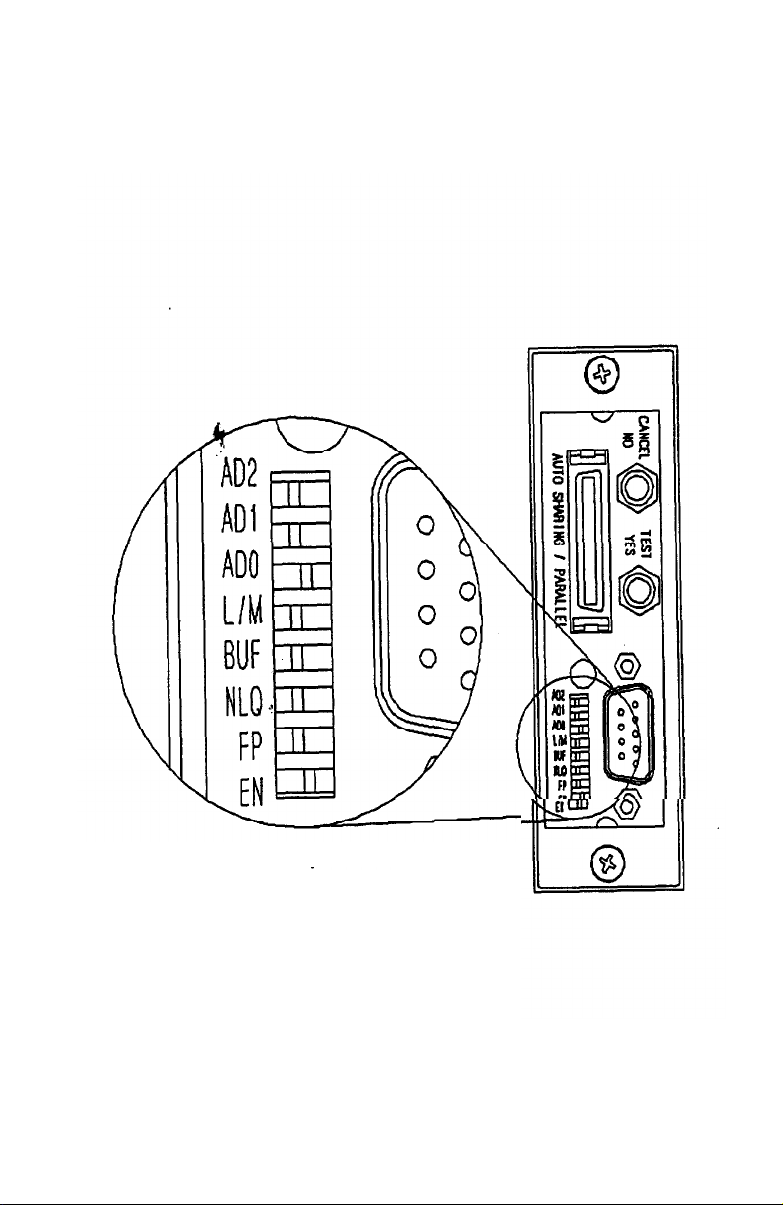

SETTING THE SWITCHES

The C82315* Twinax Interface Card comes with eight switches that are used to

determine many of the default settings of the interface card. Details on these

settings are listed in the following section.

You can set the switches located on the rear side of the card at any time.

However, the interface only checks these settings when the printer is first turned

on. Always turn the printer off and then back on again after changing a setting.

Page 13

Change the switch settings with a pointed object, such as a ball-point pen. A

switch is on when in the upper position (if the interface is Installed horizontally) or

in the right position (if the interface is installed vertically), as shown below.

Active ’

Page 14

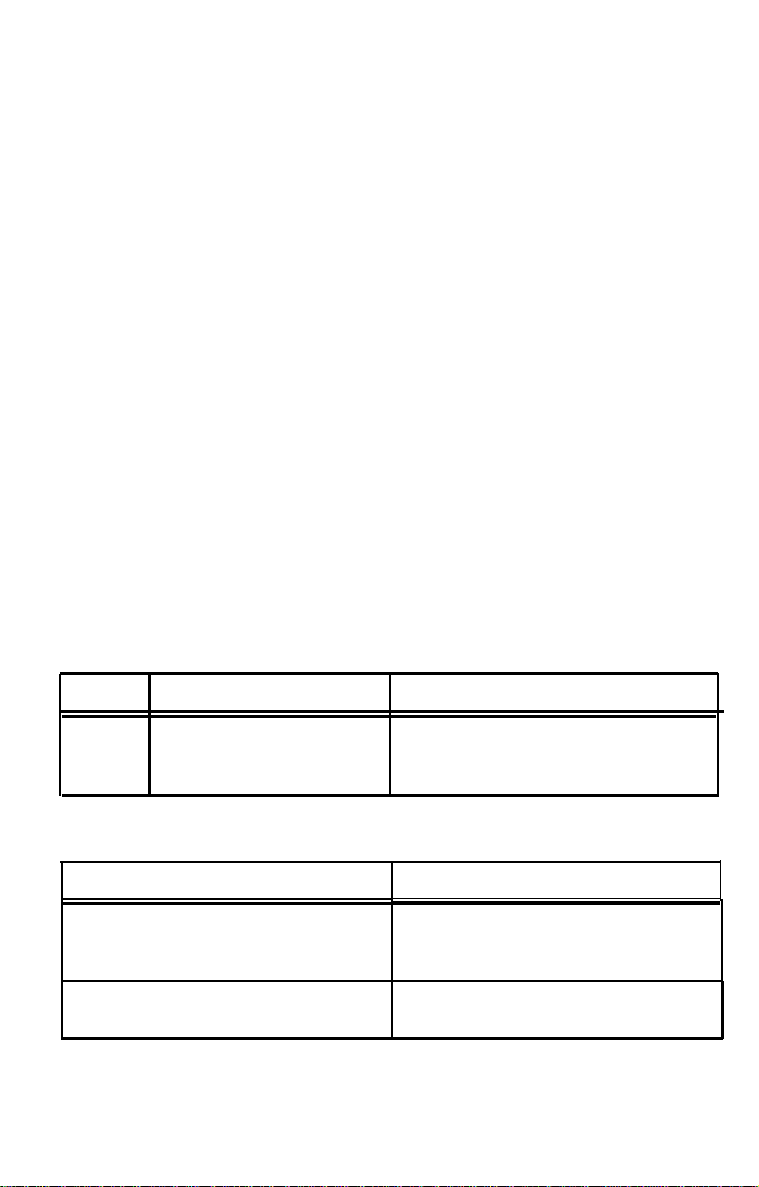

SWITCH

You can select the features listed below by changing the switches to the settings

indicated. Settings for switches 6 and 7 are different if HP LaserJet II (IBM 3812)

emulation is selected (switch 4 is on and jumper J5 is disconnected).

Switch

SETTlNGS

I

(ask the system manager for the correct address)

Cable

(Device) Address

0

Off Off

Off Off On On Off Off

Off On

Switch

4

5

Non-HP LaserJet II mode

Switch

6

7

Emulates an IBM 4214/5224 Emulates an IBM 5219/3812

printer printer

Prints normally

Selects draft printing as the

default

Passes all commands from

the host on to the printer.

Select this if you want to set

pitch and print quality from

your software.

1

2 3 4 5 6 7

Off Off On

Off On

Off

Off

Off On

Prints buffer diagnostic test

Selects LQ printing as the

default

Passes all commands from

the host on to the printer

except character pitch and

print quality commands.

Select this if you want to set

pitch and print quality from

vour orinter’s control panel.

On

On

On

Test

On On

On On

Off On

7

Page 15

HP Lase Jet II mode

8

Switch

6

7

Switch

8

Off

Sets orientation automatically

during Computer Output

Reduction

Sets orientation automatically

during Computer Output

Reduction

Off

Selects the C823W interface

card

Sets orientation to landscape

during Computer Output

Reduction

Sets orientation to Portrait

during Computer Output

Reduction

Selects the printer’s built-in

interface

On

On

PERFORMING A SELF TEST

To verify the interface is installed and the settings are correct, perform an interface

self test according to the following steps.

1. Turn on the printer and load paper. Make sure the cable address (set with

switches 1, 2, and 3) is not set to 7.

2. Press the TEST button on the interface. The printer then prints out a list of the

jumper, switch, and feature settings, similar to the self test sample printout shown

in Appendix A-l.

The name of the printer printed in the self test may differ from your

printer’s actual model name.

3. Turn the printer off to end the self test.

If the warning message is printed, it indicates the interface’s emulation mode

differs from the emulation mode selected by your printer.

CONNECTING TO THE HOST COMPUTER SYSTEM

After you confirm the interface is installed and settings are correct, you can

connect it to the host system according to the following steps.

Page 16

1.

Connect the twin-axial connectors of the twin-axial V connector to your host

computer system cable.

2. Insert the twin-axial V serial cable into the 9 pin twin-axial serial connector on

the interface.

3. Tighten the thumbscrews on both sides of the twin-axial serial cable connector

to secure it to the interface.

MAKING ADDITIONAL SETTINGS

In addition to setting the switches and jumpers described in Setting Up, you can

make interface or printer settings with the C82315* interface in four more ways:

command-pass-thru, interface setup commands, display station setup mode, and

memory setup mode.

COMMAND-PASS-THRU

This feature allows you to insert commands within your print files that are sent

directly to the printer, without being processed first by the interface. You can then

take advantage of the advanced features of Epson printers (such as color printing

and super/subscripts) that are not supported in IBM printers.

Follow the steps below to send command-pass-thru commands.

Convert the Epson printer commands you wish to send into two-digit

1.

hexadecimal codes. See your Epson printer’s user’s guide for a list of all

commands; the hexadecimal values of each command are shown there.

2. Inside the document you are sending to the printer, insert the following

characters:

&%

When the interface receives these two characters, it knows that the characters

following are commands in hexadecimal format. (These are the default characters:

you can define different characters with interface setup command 06 described

in Interface Setup Commands.)

3.

Immediately following the &% characters, insert your commands in

hexadecimal format; the interface recognizes characters from 00 to FF only

(alphabet characters must be upper case).

9

Page 17

You may insert one or several commands, as long as they are all in hexadecimal

format, and they are commands that are used by your printer in its current mode.

You may also insert spaces between hexadecimal pairs to increase visual clarity;

however, do not put any’spaces after the first &% characters or before the last

&% characters.

4. After you have inserted all your commands, insert the &% characters again.

This tells the interface that command-pass-thru Is finished and the data following

is normal print data.

Note:

Although these characters are displayed in your document on the display

screen, the interface treats them as commands and does not print them.

If part of the sequence is printed, you have made an error in entering the

codes; check your document and make sure you are using the correct

format and hexadecimal characters.

Avoid sending codes that would move the print position during

command-pass-thru. Since the interface does not process these

commands, it cannot keep track of the print position changes; this may

affect the position of following characters and page layout.

You can also send these commands by typing them on the screen and

pressing the screen print key.

Example:

To print the word ‘scalable” in the following sentence in bold using

Epson ESC/P commands, you could use command-pass-thru as follows

(the bold on/bold off commands are ESC E and ESC F):

Epson ESC/P 2 offers advanced &% 1B 45&%scalable&%1B46&% fonts

for laser-like printing at dot-matrix prices.

USER-DEFINED COMMAND-PASS-THRU STRINGS

You can define up to eight of your own custom command-pass-thru command

strings (0 to 7) to be stored in interface memory. The method of defining strings

is described in the following section.

Once you have defined these strings, you send them in the following format:

&%U1

The U1 tells the interface to send user-defined string number 1 to the printer.

10

Page 18

For example, you

turn on bold printing, as used in the example in the previous section. Then,

instead of inserting the &% 1B 45&% command in your text, you would insert only

&%U1.

could

define user-defined string 1 to be the command string to

INTERFACE SETUP COMMANDS

You send these commands in a similar manner to command-pass-thru, but the

commands are used to make interface settings instead of being sent on to the

printer. These interface settings control printing regardless of the printer model

connected.

The format of the interface setup commands is as follows:

&%Z##,P

The 8%Z indicates that an interface setup command follows. The ## is a two-digit

number, indicating the number of the command. The P is the parameter of the

command: the length of the parameter varies by command.

A table of commands and parameters, as well as a short description of each

follows.

11

Page 19

Command

12

Number

Parameters Name/Description

Command

Examples

01

02

03

Control the setup memory, Resets or saves

settings in the interface’s setup memory

1

2

Reset to factory settings

Store the current-setting in permanent

&%Z01 ,1

&%Z01,2

memory

Select the default international character set

Selects the international character set used.

See your printer’s user’s guide for a list of

characters affected by international character set

selection.

00 Multinational

01

03

04

05

06

07

08

09

10

11

12

13

14

15

UWCanadaCommand

Belgium

Brazil

Canada/French

Denmark/Norway

Finland/Sweden

France

Italy

Japan

Japan (English)

Portugal

Spain

Spanish speaking

United Kingdom

&%Z02,00

&%Z02,01

&%Z02,02

&%Z02,03

&%Z02,04

&%Z02,05

&%Z02,08

&%Z02,07

&%Z02,08

&%Z02,08

&%Z02,10

&%Z02,11

&%Z02,12

a%Z02,13

&%Z02,14

&%Z02,15

Selects the character table used

(PC 850 is the recommended setting)

04

02

03

Not used

PC850

HP Roman 8

&%Z03,02

&%Z03,03

Page 20

Command

Number

Parameters Name/Description

Command

Examples

05

06

07

Control paper size selection (laser printers only)

Makes paper size settings

01

Feeds paper size selected by the host

computer

02

03

Feeds any paper size

Feeds A4 size paper

Select alternate command-pass-thru delimeter

Selects the characters that both begin and end

the command-pass-thru feature. You can select

any two characters, as long as the first is not an

ampersand (a). The default value is the &%

characters.

xx

Selects the two characters represented

by the XX characters.

Select print-complete handling

Tells the interface when to send a print-complete signal.

(Check your self test results to see

lf your printer supports true print complete.)

1

Selects early print-complete handling

(all data has been sent to printer’s

buffer, but printer may still be printing)

2

Selects true print-complete handling

(all data has been sent to printer, and

printer has finished printing)

&%Z05,01

&%Z05,02

&%Z05,03

&%Z06,*!

&%Z07,1

&%Z07,2

08

09

Set printer sharing timeout period

Sets the amount of time (in seconds) the printer

waits for additional data before switching

between the twin-axial host system and the PC

system connected to the auto-sharing/parallel

connector (8 seconds is the default). If your

printer supports intelligent emulation switching

(IES) make sure your printer’s IES timeout

period is less than this setting.

xx

Selects a waiting period of XX seconds

Parallel port initialization string

Defines a string of characters that is sent to the

printer when the parallel port is activated (up to

25 characters can be included in the string)

13

&%Z08,05

Page 21

Command

Number

Command

Parameters Name/Description Examples

10

(HH..HH)

Defines the string of hexadecimal values that are

sent to the printer as HH..HH

Define User Custom command-pass-thru strings

for details.

Defines up to eight strings (0-7) of commands

(up to 25 characters can be included in the

string). See User-defined command-pass-thru

strings for details.

#(HH..HH)

Defines string number # to be the character

string defined by the hexadecimal values

HH..HH

&%Z09,0(1B40)

&%Z10,3(1B45)

DISPLAY STATION SETUP MODE

When the printer is connected to a twin-axial cable that is also connected to a

display station, you can display an interface setup screen showing various setup

parameters. You can then change these parameters and save them in the

interface memory.

See Appendix A-2 for an example of the setup screen.

Follow the steps below to change settings in display station setup mode.

1.

Turn off the printer and all devices connected to the same twin-axial cable.

2.

Disconnect the twin-axial cable from the IBM host computer, and make sure

that at least one display station is connected to the cable and is turned on.

Turn off switch 8 to deactivate the twinax interface. Then make sure you

3.

have set a valid address other than 7 (switches 1,2,3), and turn on the printer.

4.

Press the TEST button on the interface. The interface setup screen appears

on the display station.

5.

Use the cursor keys to move to settings you want to change. Use the

backspace to delete old settings, then type in the new settings.

14

Page 22

When you finish changing settings, press the Enter key to save the new

6.

settings in the interface memory.

Turn off the printer and return switch 8 to the on position to resume using

7.

the twinax interface.

MEMORY SETUP MODE

You can have the printer print out various interface settings one at a time and then

change them by responding to printed questions using the YES and NO buttons

on the interface.

Follow the steps below to change settings using memory setup mode.

1. Enter memory setup mode by holding down both the YES and NO buttons

while turning on the printer. The printer then prints out the first setting and asks

the following:

Do you want this changed? (Yes/No)

2. If you then press YES, the interface changes thesetting to the next available

parameter. It then prints out the new setting and asks again if you want to change

the setting. The printer repeats the question for all the parameters until you press

NO, indicating you do not want to change the current setting.

If you answer NO the first time, the printer goes on to the next setting.

3. Continue to answer the questions and make desired setting changes until the

following question is printed:

Do you wish to save current selections? (Yes/No)

4. Press YES to save the settings you have just made. Press NO to return to the

old settings and exit memory setup mode.

Note:

You may need to use the line feed button on the printer’s control panel

to advance the paper so you can see the printed messages.

This method of making settings is not recommended for laser printers;

to see the questions, you would have to eject one page every time a

question is printed.

15

Page 23

The settings you can make in memory setup mode are

details on the settings, see the descriptions for the command of the

same name in the section on interface setup commands.

Select the default international character set.

Select the character table

Control paper size selection

Select print-complete handling

listed below. For

PRINTER SHARING

If the C82315* is connected to a PC with the Parallel Sharing Cable,

the PC must be turned on.

The C62315* Interface is equipped with two interface connectors: a serial connector for connecting the twinax V-connector and a parallel connector. By connecting

a PC to the parallel connector, you can share the printer between the PC and

Twinax systems.

When you first turn the printer on, the twinax connector is selected. If the twinax

system sends no data for a certain period, and the PC system sends data, the

interface switches to the parallel connector. (The period the interface wafts before

switching can be set with Display station Setup or Command 06 described in

Interface Setup Commands--the default is 8 seconds.)

After a print job is completed from either connector, and no additional data is

received for a certain period, the interface monitors both connectors for the next

data.

Since printing alternates between the twinax and PC systems during printer

sharing, it is recommended that you reset the printer at the beginning of each

print job. Otherwise, page layout, character spacing, and other settings remain

from the previous print job.

You can use Command 09 described in Interface Setup Commands to define a

string of up to 25 characters that are sent to the printer each time the interface

switches to the parallel connector.

The interface automatically restores settings for character pitch, lines per inch, and

page length when lt returns to twinax printing.

16

Page 24

EMULATION DETAILS

The C82315* interface emulates several IBM printers. However, you should be

aware of slight differences in operation caused by mechanical and other differ-

ences between IBM and Epson printers.

The differences for each emulation are described in the following sections.

4214/5224 EMULATION

Epson printers and 4214/5224 printers have the following differences.

LINE-FEED INCREMENT

A 4214 printer advances paper in 1/120-inch increments for continuous paper, and

1/10-inch increments for single-sheet paper. 5224 printers use a 1/72-inch

increment. Epson O-pin printers advance paper in 1/216-inch increments, and

24/48 printers advance paper in 1/360-inch increments. The C82315* interface

calculates the difference in paper advancing increments and corrects for errors

as printing proceeds.

PAPER BINS

A 4214 printer can select from three paper bins; an Epson printer can select from

two. If you select bin 3, the Epson loads paper from bin 2.

GRAPHICS PRINTING

You can create graphics on the 4214 printer by sending the Load Alternate

Character (LAC) command. This is the command used by the IBM programs APF

and BGU. This command defines a pattern to be printed in place of a certain

character, similar to the Epson ESC/P user-defined character feature.

The C82315* interface accepts two variations of the LAC command: the LAC-1

and LAC-2 commands. The LAC-1 command defines a 9-dot wide by 8-dot high

pattern while the LAC-2 command defines a 10-dot wide by a 8-dot high pattern.

The C82315* interface prints graphics data using the quad-density, 240 dot per

inch graphics mode. In order to maintain the proper pitch, each character should

be defined with the following widths:

10 CPI Graphics - 24 Columns

12 CPI Graphics - 20 Columns

15 CPI Graphics - 16 Columns

17.1 CPI Graphics - 14 Columns

17

Page 25

Because the interface adjusts data to fit in the number of columns available on

Epson printers, printed characters may not be perfectly symmetrical.

NOTE: When printing high-density graphics, you may not be able to print adjacent

dots. This may cause gaps when printing bar codes, so bar code printing is not

recommended.

5219 EMULATION

The font ID numbers sent to a 5219 printer select the Epson character pitches and

typefaces shown below; the ID numbers marked with a + are the recommended

settings.

10 CPI: 12 CPI:

Roman

Sans Serif

Courier*

Script*

Prestige*

*Not available on 9-pin printers.

13+, 5+

14, 26+

11+

10,20+

12+ 86+

82, 87+

84+, 91+

85+

80+

15 CPI:

222+

224,225+ 159+

223+

220

221+

PROFIT

160+

158+

161

162

3812 EMULATION

Epson printers and 3812 printers have the following differences.

PAPER TRAY OR

If you have an optional paper tray or cassette installed in your Epson laser printer,

you should use SelecType on your printer’s control panel to select optional for the

input setting. See your printer’s user’s guide for details on using SelecType.

CASSETTE

COMPUTER OUTPUT REDUCTION

Epson laser printers cannot print on 13.2 x 11 inch paper, so you may need to

reduce or rotate the image to fit data processing reports onto the paper available.

The chart on the following page shows how to print data processing reports onto

smaller size paper.

18

Page 26

Computer Output Reduction (COR)

LANDSCAPE mode REDUCED

Verical spacing is 8LPI

0.5’ Margins top end lelt

10 pitch fonts lo 13 pitch

12 pitch fonts lo IS pitch

IS pitch fonts to 19 pinch

(I) Yield Paper size is less than or equal to 1 1/2' x 14'

(2) Portrait Orientation (lasted at COR ) can be

Selected by:

Size OCI: Text -YES or Notate-0

size CL :priority [•STD] or (•NLQ) or

AS/400 : PRIORITY (STD) and Pagrit (•COM)

19

Page 27

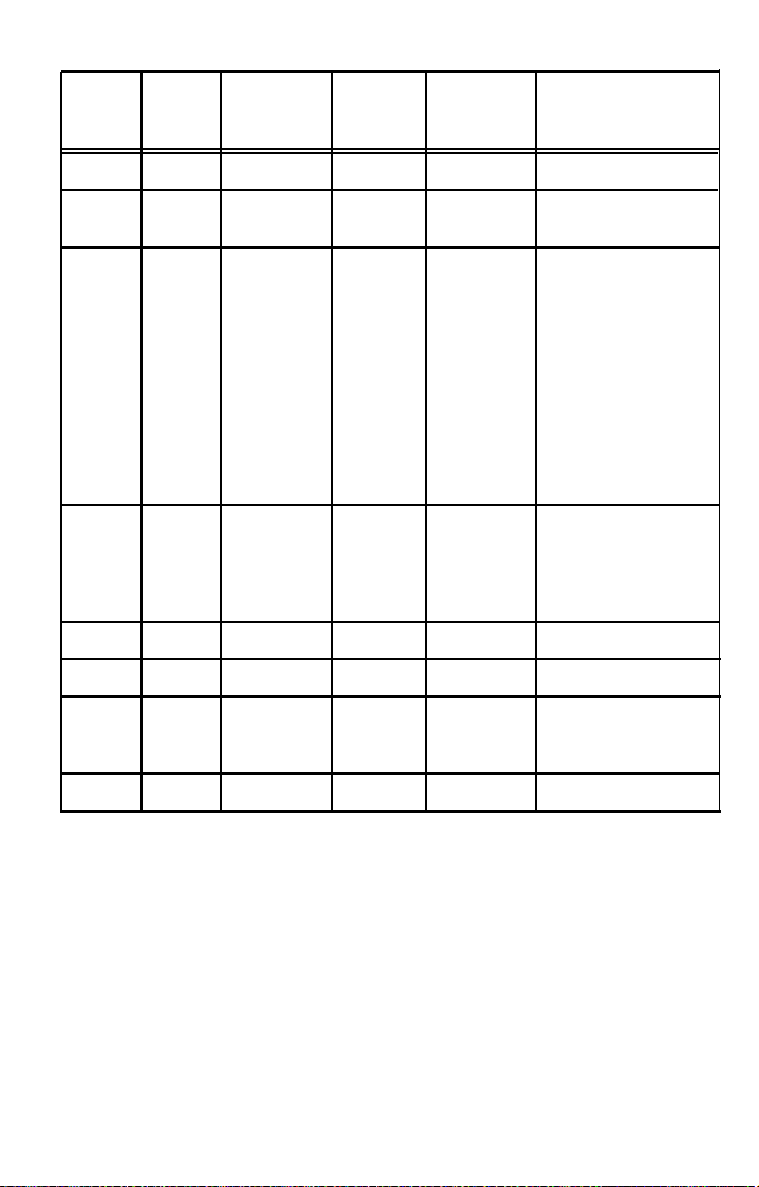

FONT ID

The 3812 emulation uses IBM font ID’s to switch from one HP font to another.

Only certain IBM font ID's can be used as the system default. These are noted by

an asterisk (*) in the Font ID table in Appendix A-3 of this manual.

You specify the default font ID for your printer when you configure the printer on

the IBM host. Have your system operator set your default to the font ID you use

most and then change as necessary with a printer override, OCL command, or

word processing font ID.(See Appendix A-3 for font ID table.)

PAPER SIZE AND ENVELOPES

The 3812 emulation supports the following paper sizes:

Letter

Legal

A4

Executive

Epson printers support the following envelope sizes:

Commercial

Monarch

DL

CS

You must send the paper and envelope dimensions from the IBM host to the

printer in order for the proper size to be selected. You can use interface setup

commands to select A4 size paper as the default or to feed paper regardless of

size.

JUSTIFICATION

The 3812 emulation supports right hand justification for all fixed pitch fonts as well

as proportional font ID

10

8.5 x 11 inches

8.5 x 14 inches

210 x 297 mm (8.27’x11

7.25 x 10.5 inches

9.5 x 4.125 inches

7.5 x 3.875 inches

220 x 110 mm (8.66’x4.333

229 x 162 mm (9.02’ x 6.38”)

S

158, 159, and 162 (found in the 5410 font cartridge).

.69’)

INTERFACE TEST MODES

In addition to the self-test described in the section on installing the interface, the

C82315* has four other tests you can perform: hex print, communications test,

interface diagnostics, and the interface diagnostic loopback.

20

Page 28

HEX PRINT

During hex print, the printer prints the data received in hexadecimal format. You

can then check if the data you are sending is reaching the printer.

The printer prints this hex data on a grid corresponding to the data’s position in

the buffer. If the hex data represents a printable character, that character is printed

to the right of the hex data.

Turn switch 5 on to enter hex print mode.

for

See Appendix A-4

hex print sample.

COMMUNICATIONS TEST

The C82315* can mimic a host computer and send commands to the twin-axial

cable. You can use this feature to test a second printer connected to the same

twin-axial cable.

Follow the steps below to perform the communications test.

1. Make sure that both printers are set to the same-cable address, and that the

Epson printer is turned off.

2. Make sure that the cable end attached to the second printer is set for

termination, or uses an auto-termination cable, and that the cable is not

connected to a host system.

3. Turn switch 5 on to print the buffer diagnostic test.

4. Turn on the Epson printer; then press the TEST button on the inter face.

The second printer should then print the buffer diagnostic test header, print out

any errors encountered in communications, and then print the EBCDIC character

set.

5. After completing the test,

off position.

turn

off the Epson printer and return switch 5 to the

INTERFACE DIAGNOSTICS

During interface diagnostics, the interface transmits data to itself and then

analyzes how that data is processed. If an error is detected, an error message is

printed on the printer. A list of error messages is listed at the end of this section.

Follow the steps below to perform interface diagnostics.

21

Page 29

1. Make sure the printer is turned off.

2. Disconnect the V-connector from any twin-axial cables

to the interface). Since the interface transmits data to itself during this test, leaving

it connected to the twin-axial cable could disrupt the twin-axial system.

3. Write down the positions of switches 1, 2, and 3 (you need to return them to

their initial positions after the test is completed). Then turn switches 1, 2, and 3

on. This selects cable address location 7. Address 7 is used only during interface

diagnostics and interface diagnostic loopback.

4. Turn on the printer; then press the TEST button on the interface. The printer

then performs the test and prints the following:

TEST SEQUENCE COMPLETE

The printer performs the test sequence over and over; error messages are printed

between the TEST SEQUENCE COMPLETE” messages.

5. After you are finished running the test, turn the printer off and reset switches

1, 2, and 3 to their original position.

(but leave it

connected

INTERFACE DIAGNOSTICS ERROR MESSAGES

The error messages and explanations are listed below.

If an error occurs, the following tests may not be performed.

OUTPUT TIMING ERROR

The

twin-axial output circuits are not responding

expected. This could be caused by a non-functioning circuit or by a termi-

to the microprocessor as

nated cable not being attached to the interface.

UNEXPECTED VECTOR or IMPROPER BYTE VECTOR

The interrupt handling process received an improper interrupt value.

Possible causes are initialization problems, non-functioning circuits, or

microprocessor problems.

22

Page 30

ERROR IN POLL ADDRESS X

A poll test was sent to the indicated address but was not received

properly. This could be caused by a terminated cable not being properly

installed, a circuit that is non-functioning, or intermittent connections.

INCORRECT DATA ON POLL TO ADDRESS X

A poll was sent to the indicated address and was detected as a poll;

however, the data received was not the expected data. This could be

caused by a problem with the twin-axial receiver circuitry.

NO INTERRUPT ON DATA

A byte of data (not a poll) was sent and the receiver circuitry did not

interrupt the microprocessor. This could be caused by problems in the

receiver circuitry, or problems with the microprocessor interrupts.

OUTPUT DATA AVAILABLE BIT BAD

The transmitter timing is not staying busy for the proper period. This

indicates an ASIC failure.

INPUT DATA AVAILABLE BIT BAD

The bit signaling that data was received was not set as expected. This

could be caused by not having a properly terminated cable attached, a

driver circuitry failure, a receiver circuit failure, or an ASIC failure.

NO INTERRUPT ON BAD PARITY or WRONG INTERRUPT ON BAD

PARITY

This test sends a transmission with the parity purposely invalid to test the

proper reaction. Either no interrupt or the wrong interrupt was received in

this test. This indicates an ASIC failure.

INTERRUPT W/O NMI ON POLL TO ADDRESS X

During a poll test, the transmission was received as data; not as a poll,

This indicates an ASIC failure.

23

Page 31

INPUT NOT INDICATING BUSY

This is an ASIC internal test during a transmission, and indicates an ASIC

failure.

TWO BYTE DATA CHECKS BAD

This test verifies multi-byte data transmissions for proper data. A failure

could be caused by a -5-volt supply problem, a transmitter circuit failure,

a receiver circuit failure, or an ASIC failure.

OVERFLOW COUNTER BAD

This tests the protection circuit-in the ASIC designed to prevent a host

failure from over-filling the interface buffer and causing an error in operation. This message indicates an ASIC failure.

BAD DATA, EXPECTING XX RECEIVED XX

A byte of data was sent, and the receiver circuitry interrupted the

microprocessor. However, when the data was checked, it was not the

same as when it was sent. This would indicate a problem with the

twin-axial circuitry data paths.

PARITY ERROR DETECTED or PARITY FAILURE

This error indicates that the twin-axial receiver detected a parity error on

receiving polls or data. This would indicate an error in the parity generation by the twin-axial output, malfunctioning of the parity checking circuit

of the twin-axial receiver, or a poor cable connection.

INTERFACE DIAGNOSTIC LOOPBACK

Interface

only difference is that no error messages are generated. A qualified technician can

diagnostic loopback is essentially the same as interface diagnostics; the

use this test to check the circuitry with an oscilloscope.

Interface diagnostic loopback is performed in basically the same way as interface

diagnostics; however, you must turn switch 8 off before starting. Always return

switch 8 to the on position when you are finished with interface diagnostic

loopback.

24

Page 32

SPECIFICATIONS

The C82315* interface specifications and the C82315*‘s parallel interface

specifications are listed below

C82315* INTERFACE SPECIFICATIONS

input Protocol:

Output Protocol:

Receive Data Rate:

Data Buffering:

Language Support:

Supported printer

character sets:

Connectors:

Indicators:

IBM 5250 twin-axial protocol, parallel

input data

EPSON TYPE B internal interface connection

5250 protocol =

bits/second

Effective rate: 1 million bits/second

Dual 256 byte buffers for received

twin-axial data

16-byte twin-axial command buffer

Single byte parallel data buffer

16 major language selections; same Ianguage

character sets as supported by IBM 4214

IBM Code Page 850

H.P. Roman 8

DB9 connector for twin-axial T-cable

connection.

36-pin (50 mil) parallel connector

36-pin internal printer connector

1 LED showing Line Sync.

This light indicates the following:

Maximum burst: 2 million

FLASHING - The interface card is in

a diagnostic mode.

ON - The C82315* is communicating with

the Epson printer and the host.

OFF - The C82315* and the printer are

communicating properly, but the

interface is not communicating with the

IBM host. In other words, there is no

25

Page 33

Line Sync between host and interface.

Switches:

8 SIP piano switches for device address,

emulation mode, buffer print, print quality,

and interface enable

Push Button for TEST/YES

Push Button for CANCEL/NO

Selection Jumpers: 3 hardware configuration shorting jumpers

Twin-axial Connection:

Power

Requirements:

Processor:

Memory:

Both cable-thru and automatic termination available

using provided V-connector cable

All power supplied by the printer

Z80A CMOS

8 Kbytes of static memory

PARALLEL INTERFACE SPECIFICATIONS

Signal

Pin

1

Return

Pin

19

Signal

STROBE

Parallel

Cable

Pin

1

Direction

IN

Description

Strobe pulse to read

data in. Pulse width

must be more than

.5 sec. at the interface.

2

3

4

5

6

7

8

9

20

21

22

23

24

25

26

27

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DATA6

2

3

4

5

6

7

8

9

IN

IN

IN

IN

IN

IN

IN

IN

These signals represent information in

bits 1 to 8 of parallel

data respectively.

Each signal is HIGH

when data is logical

1 and LOW when it

is logical 0.

26

Page 34

Signal

Pin

Return

Pin

Signal

Parallel

Cable

Pin

Direction

Description

10

11

12

13

28

29

30

ACKNLG

BUSY

PE

SLCT

10

11

12

13

OUT

OUT

OUT

OUT

A LOW pulse of

minimum width of 4

µ sec. A low indicates that data has

been received and

that the printer is

ready to accept

more data.

A

HIGH signal indi-

cates that the printer

cannot receive data.

The signal goes

HIGH in these

cases:

-Data entry, for

each character

--When off line or in

error state

-When serving the

IBM host and a byte

of parallel data is

received.

HIGH when the

printer is out of

paper.

Pulled up to +5v

through a 3.3K ohm

resistance.

16

17

AUTO

FEED

14

27

IN

THIS SIGNAL IS

NOT SUPPORTED

BY THE C82315*

INTERFACE. (Defined by many print-

a

ers to add

LF to

each CR. The IBM

Page 35

Signal Return

Pin Pin

Signal

Parallel Direction

Cable

Pin

Description

18 -

19-30 -

31

32 -

33 34 35 -

NC

GND

INIT

ERROR

GND

NC

HIGH

21-24

16 IN

15

25

OUT

Not used

Twisted

pair

ground

returns listed above

Defined to reset and

dear the printer

LOW: THE RE-

when

SET AND CLEAR

ARE NOT SUP-

PORTED BY THE

C82315*, As the IBM

host cannot be interrupted by this

signal. An ACKNLG

is generated for

handshaking.

This signal goes

LOW when the

printer is in an error

state such as out Of

paper.

Logic ground

Not

used

Pulled up to +5v

through a 3.3K ohm

resistance

36 -

NOTE:

SLCTIN

17

NOT SUPPORTED

The parallel connector is a DDK type DHA-36 or equivalent.

The column heading ‘DIRECTION’ refers to the direction of signal flow as viewed

from the C82315* interface.

‘RETURN’ denotes the twisted-pair return, to be connected at signal ground level.

For the interface wiring. be sure to use twisted-pair cable for each signal and to

complete the connection on the return side. The cable should be shielded and

connected to the chassis of the host computer and printer.

All interface conditions as based on TTL levels. Both the rise and the fall times

of each signal must be less than 0.2 u sec.

28

Page 36

TIMING

DATA IIN

STROBE-

Data transfer is carried out by observing the ACKNLG

transfer to the printer occurs only after receipt of the ACKNLG signal or when the

BUSY signal is LOW.

or BUSY signals. Data

BUSY

ACKNLG

Data must be present a minimum of 0.5 u sec before and after a minimun 0.5

µ sec STROBE Pulse. BUSY goes high before the end of the STROBE signal and

remains high until the end of an ACKNLG pulse of’ minimun 4 µ sec.

I

I-

I

t

EBCDIC CHARACTER TABLES

PC850 character table

See Appendix A-S for an example of the PC850 character table.

Note: PC850 is the recommended

HP Roman 8 character table

See Appendix A-6 for an example of the HP Roman 8 character table.

Note:

This character table is available only when HP emulation is selected

(3812 emulation).

character table for matrix emulations.

29

Page 37

APPENDIX A-1

Anhang A-1 / Appendice A-1 / Apendice A-1 / Appendice A-1

Sample printouts - Self Test

Druckmuster - Selbsttest

Exemples d’impression - Autotest

Ejemplos de impresión - Auto-test

Esempi di stampa - Test automatico

EPSON CS2315. TWIN-Ax INTERFACE

COPYRIGHT (C)1991 SHERWOOD DIGITAL ELECTRONICS

REV 3.4 SOFTWARE

INSTALLED IN EPL-4000

Switch and Jumper Selections:

Device Address . . . . . . . . . . . . . : 0

Twin-ax cable drive selected.....: Normal

Self Test (Buffer Print).........: Off

IBM-Printer Emulated...;.........: 4214

Default print quality............: DRAFT

Pitch and Print Quality.....

EPSON command set..........

Active Configuration Selections:

Language..............

02 03 -

Character Set Option..

- Printer Options.......

04

Laser Feed Options....

05 06

- Alternate Delimiters..

Print Complete method.......:Only Early Print Complete Supported

07 -

- Printer Sharing Timeout.....: 08

08

Parallel Port Initialization:

09 -

10 -

User Defined Strings......:

u0:

u1:

u2:

u3:

u4:

u5:

U6:

u7:

EBCDIC to ASCII Translate Table

405060708090

0:

2026209B9DF8

1:

20822F90616A

2:

638886D26260

3:

84898ED3636C

4:

858A07D4646D759F444D5534

5:

A0Al05Db656E

6:

C60CClD7666F

7:

66888BD86770

a:

878D80DE6871

9:

A4ElA56069727AF349525A39

A: 5B 5D 7C 3A AE A6 AD AA 2D FB FD FC

B:

2E242C23AFA7A8B39396E2EA

C: 3C2A2540DO91DlEE9481999A

D:

2629SF27EC87

E: 26 30 3E 3D ES 92 E7 EF A2 A3 EO E9

F:

21SE3F22FlCFA9F2E498ES20

RAN OK

ROM OK

WITH

CURRENT

EMULATION ESCP24-84

. . . . . . Host Control

. . . . . LQ

. . . . . . 00

. . . . . .

. . . . . . Normal

. ....

. . . . . &%

A0B0CODOLOFO

E6BD7B7DSC30

7E9C414A0031

73BE42485332

74FA434C5433

16F5454C5635

71F4464F5736

78AC47505637

79AB48515930

EDF99597E3EB

- Multinational

Code Page 850

Feed Host $election

Page 38

APPENDIX A-2

Anhang A-2 / Appendice A-2 / Appéndice A-2 / Appendice A-2

Display Station Setup Mode

Die Bildschirmanzeige sieht etwa so aus

Mode de configuration de poste d’affichage

Modo de configuración desde un terminal de pantalla

Modalità impostazione da videoterminaie

Printer Sharing Timeout (seconds) . . . . . . . . :08

Language..............................:00MULTI

Alternate Delimiters (EBCDIC).........:

Parallel port Initialization (ASCII):

User Defined String (ASSCII):

U0

U1

U2

u3

u4

u5

u6

u7

Character Set Option: Code Page 650 Print Complete: Early .

Laser Feed Options..: Normal

Address (SWI-3) ................: 4

Letter Quality Emulation (SW4).: No

Buffer Print (SW5) .............: No

Default - NLQ (SW6) ............: No

Front Panel override (SW7) .....: No

5224 Emulation (Zi) ............: No

FX Comnands (J6) ...............: Yes

Epson ESC/P2 Setup Screen Version 0.1

Up,Down Arrows = Change Selection

Field Exit, Field l = Down

Back Tab, Field - - Up

Backspace = Delete Character

Enter -

Save Parameters

Page 39

APPENDIX A-3

Anhang A-3 / Appendice A-3 / Apéndice A-3 / Appendice A-3

Font ID

S

Schrinhtypen-10

ID de police

ldentificaciòn de fonts

ldentificativi di font

Typaface

symbol Orient.

Bet

Resident

Courier R-8 P/L‘

Courier Bold R-8

Line Printer

Line Printer

Line Printer

Line Printer

5410

Time

Time R-8 P

Time Bold

Time Italic

Helvetica Bold

Epson Cartridges

R-8

R-8

R-8

R-8

R-8 P

R-8

R-8 P

R-B

5411

Courier Bold

Courier Italic

u-a

R-B

5412

Prestige

Prestige Bold

Prestige Italic

R-a

R-a

R-B

5413

Letter Gothic

Letter Gothic Bold R-B

Letter Gothic Italic R-a

R-B

P/L

P/L

P/L

P/L

P/L

P

P

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

Pitch Point

10

10 12

13.3

15

17.1

19

Prop.

prop.

Prop.

prop.

Prop.

1O

10

12

12

12

12

12

12 10

Size

12

8.5

8.5

8.5

8.5

8

10

10

10

14.4

12

12

10

10

10

12 87

12

Typestyle

Number

11

46

201

223

254

282

157

158

159

155

34126

46

18

86

111

112

110

112

Page 40

Typeface

Symbol

set

orient.

Pitch

Point

size Number

Typestyle

Helvetica

Helvetica

Helvetica Bold

Helvetica Bold

Helvetica Bold

Helvetica Bold

Tax Line Draw

Letter Gothic

Letter Gothic

OCR-A 10N

OCR-E 10N

Code 3-9 4.6N

Code 3-9 9.3N

EAN/UPC Bold Bar Code UPC

EAN/UPC

Procollection

Line Printer

Courier Bold

Courier Italic

Courier

Courier Bold

Courier Italic

Courier

Courier Bold

Courier Italic

Courier

Courier Bold

Courier Italic

Prestige Elite

Prestige Elite

Prestige Elite

Prestige Elite

Prestige Elite

Prestige Elite

Prestige Elite Bold

Prestige Elite Italic Legal

Letter Gothic

Letter Gothic

Letter Gothic

Letter Gothic

Letter Gothic Bold

Letter Gothic Italic ASCII

Times Roman

Tines Roman

Times Roman Bold

Times Roman Italic

Times Roman

Times Roman Bold

Times Roman Italic

Times Roman

Times Roman

Times Roman Bold

Bar Code

HP cartridges

LinDrw-7

Bold ASCII

Italic ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

R-8

R-8

OCR-A

OCR-B

3 of 9

3 of 9

UPC

ASCII

ASCII

ASCII

ASCII

ASCII.

ASCII

Legal

Legal

Legal

Legal

Legal

Legal

ASCII

ASCII

Legal

Legal

Legal

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

Legal

Legal

Legal

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P/L

P/L

P/L

P/L

P/L

P/L

P

P

P

P

P

P

P/L

P/L

P/L

P/L

P

P

P

P

P/L

P/L

P/L

P/L

P/L

P/L

P

P

P

P

P

P

P

P

P

P

Prop.

Prop.

Prop.

Prop. 10

Prop. 12

Prop.

10

10

17.1

10

10 12

4.6

9.3

Prop.

Prop.

17.1

10

10

12

12

12

10

10

10

12

12

12

15

12

12

12

15

12

12

12

27

19

17.1

12

12

12

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

6

0

8

14

12

14.4 40

9.4

12 19

12

12

12

12

8.5

12

12

10

10

10

12

12

12

10

10

10

7

10

10

10

7

10

10

10

3.6

6

9.5

8

12

12

12

10

10

10

17

12

12

10

1O

181

183

182

185

188

190

34

255

3

240

61

171

170

253

45

17

85

108

92

51

52

53

93

94

95

220

83

113

114

219

97

98

99

291

281

257

66

69

69

163

164

165

166

167

168

169

173

174

175

Page 41

Typeface

Times Roman Italic

Times Roman

Times Roman Bold

Times Roman Italic

Helvetica

Helvetica

Helvetica Bold

Helvetica Italic

Helvetica

Helvetica Bold

Helvetica Italic

Helvetica Bold

Helvetica Bold

WordPerfect

---------

CG Times

CG Times

CG Times Bold

CG Times Italic

CG Times

CG Times Bold

CG Times Italic

CG Times

CG Times Bold

CG Times Italic

CG Times

CG Times Bold

CG Times Italic

CG Times Bold

CG Times Bold

Univers

Univers

Univers

icrosoft

--------Helv

Helv

Helv Bold

Helv Italic

Helv

Helv Bold

Helv Italic

Helv Sold

TmsRmn

TmsRmn

TmsRmn Bold

TmsRmn Italic

TmsRmn

TmsRmn Bold

TmsRmn Italic

TmsRmn Bold

Line Printer

symbol

set

Legal

Logal

Logal

Legal

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

Legal

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

DskTop

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

Orient.

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P/L

Pitch

Prop. 10

Prop.

Prop.

Prop.

prop.

Prop. 10

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

15

Point

size

12

12

12

8

10

10

12

12 188

12 189

14

14

6

8

8

8

10

10

10

12

12

12

14

14

14

18

24

14

18

24

8

10

10

10

12

12

12

14

8

10

10

8.5

10

12

12

12

14

Typestyle

Number

176

177

170

179

183

184

185

186

187

190

191

4685

4686

4706

4814

4607

4707

4815

4688

4708

4816

4689

4709

4817

4711

4714

4709

4791

4794

34102

34103

34123

34231

34104

34124

34232

34125

5686

5607

5707

5815

5680

5708

5816

5709

223

Page 42

Typeface symbol

Polished Worksheets

------------------Prestige Elite R-8

Prestige Elite R-8

Prestige Elite Bold R-8

Prestige Elite Italic R-8

Prestige Elite Legal

Prestige Elite Legal

Prestige Elite Bold

Prestige Elite Italic Legal

Letter Gothic

Letter Gothic R-8

Letter Gothic Bold R-8

Letter Gothic Italic R-8

Letter Gothic

Letter Gothic

Letter Gothic Bold

Letter Gothic Italic Legal

Presentation Bold

Presentation Bold

Persuasive Presentations

------------------------

Letter Gothic

Letter Gothic

Presentation Bold

Presentation Bold

Presentation Bold

Presentation Bold

Presentation Bold

Presentation Bold

Presentation Bold

Presentation Bold

Helv Outline

Helv Outline

serifa

Serifa

Line Draw

PC Line Bold

Forms, Etc.

--------Univers

Univers

Univers Bold

Univers Bold

Univers Bold

Univers Bold

Helv Cond. Black Bold TaxNum

OCR-A

Tax Line Draw

Legal

R-8

Legal

Legal

Legal

ASCII

Legal

ASCII

Legal

ASCII

Legal

ASCII

Legal

ASCII

Legal

ASCII

Legal

ASCII

Legal

ASCII

Legal

LinDrw

PCLin

R-8

R-8

R-8

R-8

R-8

R-8

OCR-A

TaxLinDnd P/L

Set

Orient.

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P/L

P

Pitch

15

12

12

12

15

12

12

12

27

12

12

12

27

12

12

12

8.1

8.1

10

10

10

10

8.1

8.1

6.5

6.5

5.7

5.7

Prop.

Prop.

Prop.

Prop.

10

10

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

10 12

10

Point

Size

7

10 86

10

10 112

7

10 97

10 98

10 99

3.6 290

12 87

12

12

3.6

12

12

12

16

16

14

14 38

14

14

16

16

18

18

24

24 433

24

24

24

24

14

14

6

8

8

10

12

14

24

Typestyle

12

Number

221

111

219

110

109

292

90

107

106

434

431

39

6

7

434

431

435

432

436

34115

34116

34215

34216

31

32

33101

33102

33122

33123

33124

33125

34128

19

30

Page 43

Typeface

Dar Codes & More

_---------------

Letter Gothic

Letter Gothic

Letter Gothic

OCR-A

OCR-B

Code 3 of 9

Code 3 of 9

EAN/UPC 10 Mil

BAN/UPC 13 Mil Bold

USPS Zip

Line Draw

Text Equations

-------------Prestige Elite

Prestige Elite

Prestige Elite

Prestige Elite Bold

Prestige Elite Italic R-8

CG Times

CG Times Bold

CG Times Italic

Global Text

----------CG Century Schoolbook R-8

CG Century Schoolbook R-8

CG Century Schlbk Bld R-8

CG Century Schlbk It1 R-8

CG Triumvirate

CG Triumvirate Bold

Pretty Faces

----------Microstyle

Microstyle Bold

Hobo Medium

Hobo Medium

Thunderbird

Signet Roundhand

Signet Roundhand

ITC Dingbats

ITC Dingbats

Symbol

Set

R-8

R-8

R-8

OCR-A

OCR-B

3 of 9

3 of 9

UPC

UPC

ZIP

LinDrw

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

R-8

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ASCII

ITC

ITC

Orient.

P/L

P/L

P/L

P

P

P

P

P

P/L

P/L

P

P

P

P

P

P

P

P

P

P/L

P/L

P/L

P/L

P/L

P/L

P

P

P

P

P

P

P

P

P

Pitch

15

12

10

10

10

8.1

4.6

Prop.

Prop.

Prop.

10

15

17.1

12 10

12

12

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Prop.

Point Typestyle

Size Number

9.5

12 87

14

12 19

12

12

12

12

12

12

12 33

7

7

10 111

10

8

10

10 159

10

8

10

10

10

10

14

18

36

30

14

54

18

14

36

18

230

40

3

60

240

170

171'

172

221

256

86

112

157

158

155

16950

16951

16971

17079

33335

33357

5910

5920

5930

5940

5950

5960

5970

5980

5990

Page 44

APPENDIX A-4

Anhang A-4 / Appendice A-4 / Apéndice A-4 / Appendice A-4

Sample printouts - Hex Print

Oruckmuster - Sedezimaldruck

Exemples d’impression - Impression Hexodécimale

Ejemplos de impresión - Impresión hexadecimal

Esampl di stampa - Stampa esadacimale

01 0 1 2 3 4 5 6 7 8 9 A B C D E F

0

oc

00 0 1 2 3 4 5 6 7 8 9 A B C D E F

2B C6 02 OC 2B D2 04 29 00 OA 2B D1 03 81 00 2B

0

C1 02, 04 2B C2 D2 42 2B CB 03 40 01

1

01 0

1 2 3 4 5 6 7

C1 C2 C3 C4 C5 C6 C7 C8 C9 Dl D2 D3 D4 D5 D6 D7

0

1 D8

D9 E2E3E4E5

2 40

00

00

0

c2

1

D9

2

40

40

3

4

93

5

40

6

5A

7

7B

8

40

01 0

0

C3c4C5

1

E2

2

40

3

40

4

94

5

40

6

5B

7

7c

6

40

40 40

C2

E2

40

40

94

40

51

7C

40

1 2 3

E3

FO

40

95

40

5c

7D

40

1

c4

E4

FI

40

95

40

5D

7D

Cl

FlF2F3F4F5F6F7

F0

4

2 3

C4 C5 C6

EJ E4 E5

40

40

95

40

5B

7C

40

E4

F1

40

9697

40

5D

7D

C1

2

Cb

E5

F2

40

91

40

5E

7F

c2

F1 F2

40

40

96

97

40

40

5D

SD

7E

40

Cb

ES

F3

F2

40

40

98

40

40

5F

5E

7E

9F

C2

3 4

c7 c8

E6 E7

F3 F4

81 82

99

90

40

40

60

5E

Al

7F

C3

7F

c1

4

c7

Eb

5

C7

E5

F3

40

98

40

5E

A1

5

C8

E7

F-4

81

99

40

60

Al

5

c9

E8

F5

83

A2

40

61

co

8 9

E667E8E9

6 7

8

40

4A

D3

F8

A5

4B

6C

40

9

D1

D2

E9

40

F6

F7

84

85

A3

A4

4A

40

6B

6A

DO

EO

9

6

D2

D3D4

4040

F7FB

8687

85

A4

AS

4A4B4c

6B6C