Page 1

EPSON

Serial Interface

Card

C82305*

C8230*

English

Deutsch

Français

ESpañol

Italiano

4000152

C01-00

Page 2

All rights reserved. Reproduction of any part of this manual in any form whatsoever

NOTICE

without Seiko Epson’s express written permission is forbidden.

The contents of this manual are subject to change without notice.

All efforts have been made to ensure the accuracy of this manual. However, should any

error

S be detected. Seiko Epson would greatly appreciate being informed of them

The above notwithstanding. Seiko Epson can assume no responsibility for any errors

in this manual or their consequences.

Copyright © 1990 by- Seiko Epson Corporation. Nagano, Japan

Page 3

Serial Interface

C82305 * /C82306 *

English

Schnittstellenkarte

C82305 * /C82306 *

Interface série

C82305 * /C82306*

Interface en serie

C82305 * /C82306*

Interfaccia seriale

C82305* /C82306*

Deutsch

Français

Español

Italiano

Page 4

TABLE OF CONTENTS

INTRODUCTION

About this guide

SETTING THE CONDITIONS

Card layout

DIP switch and jumper settings

DIP switches

Jumpers

DATA ENTRY

Serial communication

About data entry

Handshaking protocol

SPECIFICATIONS

HARDWARE DESCRIPTION

RECOMMENDED CIRCUIT CONNECTIONS

INSTALLATION

2

3

4

4

5

5

10

13

13

13

14

17

19

21

22

Page 5

INTRODUCTION

The Serial Interface Card 032305 * /C82306 * is an interface

that allows asynchronous serial data communication

between a host computer and an EPSON printer.

This interface card offers the following features:

• Data transmission that can be set at either RS-232D

or 20 mA Current Loop levels (RS-232D has been

revised from the former RS-232C. Set the signal

levels for RS-232D the same as for RS-232C.)

• Handshaking protocol using X-on/X-off or DTR flag

control

• Selectable data word structure that allows you to

choose parity (Odd, Even, or None) and word bit

settings (either 7 or 8 bit)

• Selection of baud rate settings from 75 to 19,200 BPS

(Data transmission speed is limited to 1,200 BPS

when the signal level is set to 20 mA Current Loop)

l DIP switch 1 settings that you can change even after

installation

Page 6

About this guide

This guide is designed to give you detailed information

on how to install your C82305 * /C82306 * serial interface

card in a variety of EPSON printers. Installation

procedures vary slightly depending upon the printer

model that you have.

Also included are instructions on how to adjust the

settings of the C82305 * /C82306 * interface card, as well as

a general description of serial data communication.

The C82305 * /C82306 * option package contains the

following items:

C82305*

C82306* serial I/F card (1)

Optional connector lock nuts (2)

Note

When attaching the interface cable to the interface, you

may find that the screws of your interface cable do not

fit into the connector lock nuts. If this happens you will need

to replace the connector lock nuts with the optional ones

provided in this package.

3

Page 7

SETTING THE CONDITIONS

The C82305 * /C82306 * interface card has two sets of

DIP (Dual In-line Package) switches, and seven jumpers.

These switches and jumpers are used for selecting

various interface operations.

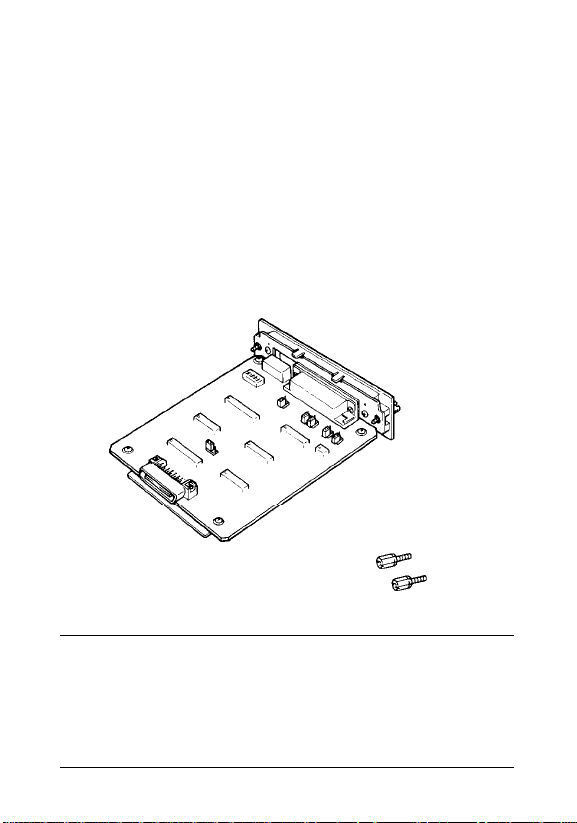

Card layout

The figure below shows the layout of the C82305 * /C82306 *

card, and the locations of the DIP switches and jumpers.

Figure 1. Card layout

4

Page 8

DIP switch and jumper settings

Before you install the C82305 * /C82306 * interface, you may

need to adjust the DIP switch 2 and jumper settings.

You can change the DIP switch 1 settings after you

install the interface. When making DIP switch setting

changes, it is best to use a pointed device, such as a

ball-point pen or small screwdriver.

Caution

All changes of DIP switch and jumper settings should be

made with the printer power turned off. New settings

become valid only when the printer is turned on.

DIP switches

The settings on DIP switches allow you to change

interface functions. The two sets of DIP switches on the

C82305 * /C82306* are labelled SW1 and SW2. Each set

contains a number of individual toggle-type switches

that can be set either on or off. The individual switches are

referred to by set (SW1 or SW2) and number. Therefore,

the switch in set SW1 marked by the small number 3 is

called DIP switchl-3.

5

Page 9

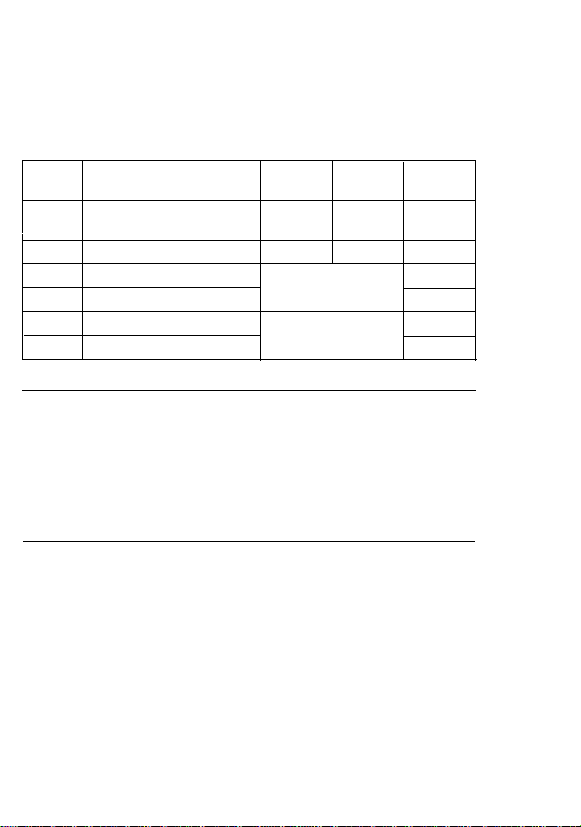

DIP switch 1 (interface operations)

The table below contains information on switch

functions, and the factory setting of each.

Table 1. DIP switch 1

Switch

number

1-1

(Note)

l-2

l-3 Parity check 1

1-4

l-5

l-6

Function

I/F card enable/disable

Word length

check

Parity

Baud rate 1

Baud rate 2

2

ON

Enable

8 bit 7 bit ON

See

See Table 5.

OFF

Disable ON

I

Table

Factory

setting

4.

OFF

OFF

ON

OFF

Note

Some printers have a selecting switch (or function) that

allows you to select between the optional and original

interfaces. If you install the interface card in this type of

printer, you should set DIP switch l-l on the interface

card to ON and also change the setting in the printer to

select the optional interface.

6

Page 10

DIP switch 2 (interface operations)

The table below contains information on switch

functions, and the factory setting of each.

Table 2.

Data word structure

The data word structure is also operator selectable

through DIP switch settings (See Table 1). The word

structure for serial data is:

1 start bit +7 or 8 data bits (selectable) + 1 parity

bit (selectable) +1 or more stop bits.

Page 11

The table below shows the possible word structure

combinations.

Table 3. Word structure

You can select the parity check method by DIP switch

settings. (See Table 4.)

Table 4. Parity check

Note

Since the selection of parity check depends on your type of

printer, refer to your printer’s manual for details.

Page 12

Baud rate selection

In serial data communication, data is transmitted in the

form of bits. These data bits go out one at a time along

a single path, and in a specified order. The BPS (Bits

Per Second) rate, or speed at which these bits are

transmitted, can be selected using a combination of DIP

switch settings.

Note

In the current loop mode, accurate data transfer cannot be

guaranteed at a baud rate setting exceeding 1,200 BPS.

Table 5. Baud rate selection

Page 13

Note

• The printer will assume a setting of 1,200 BPS for

switch combinations other than those shown above.

• Since the maximum transmission speed (baud rate)

depends on your type of printer, refer to your

printer’s manual for details.

Jumpers

The jumper is a small terminal used for connecting or

disconnecting a circuit. The jumper is on when the

jumper plug covers both wires of the terminal. Jumper

settings can be changed by either attaching or removing

the rectangular jumper plug. If the jumper is to be

turned off, connect it to just one of the two terminal

pins as shown in the figure below. By doing this, you

can avoid losing the unused jumper plug.

Figure 2. Jumpers

10

Page 14

Jumper settings

Table 6. shows information about the interface

conditions that can be selected using jumpers. In all

cases, ON denotes the connection of the jumper

(covering both terminals), while OFF denotes the

disconnection of the jumper.

Table 6. Jumper settings

Note

If the host computer is not equipped with a power

supply for the Current Loop interface, these jumpers

must be connected to perform communication via the

Current Loop interface.

11

Page 15

Table 7. Flag polarity selection

Jumper Function

MARK (do not accept data) =

ON:

JNOR

J5

JREV

Current ON

ON: MARK (do not accept data)=

Negative EIA level

MARK (do not accept data) =

ON:

Current OFF

MARK (do not accept data)=

ON:

Positive EIA level

Factory

setting

Note

Either the JNOR or JREV jumper must be connected.

ON

OFF

12

Page 16

DATA ENTRY

This section gives a brief description of serial data

communication conditions and handshaking protocols

supported by the C82305 * /C82306 * interface card.

Serial data communications

The CL32305 * /C82306 * interface allows you to select

either RS-232D or 20 mA Current Loop signal levels;

but never both at the same time.

This interface card also provides for either DTR (Data

Terminal Ready) or X-on/X-off handshaking protocol.

About data entry

Transmitted data from a host computer is stored in your

printer’s internal buffer. (This interface card has no

buffer memory.) When this buffer becomes full, any

additional transmitted data cannot be accepted and

would be discarded. To prevent such data loss, special

handshaking protocols are provided to regulate the flow

of data transmission. The two protocols available on the

C82305 * /C82306 * interface card are DTR and X-on/X-off.

Note

When a parity error (if parity check is enabled), framing

error, or overrun error is detected in the data received,

data is ignored or an asterisk (*) is printed instead.

(Since the handling of communication errors depend on

your type of printer, refer to your printer’s

specifications for details.)

13

Page 17

Handshaking protocol

DTR and X-on/X-off handshaking protocols can be

performed under either RS-232D or 20mA Current Loop

transmission.

X-on/X-off Protocol

X-on/X-off protocol is a system in which the printer

transmits a code to the computer to indicate that it

cannot accept more data, and a second code when it is

once again ready.

The C82305* /C82306* interface card sends an

X-on < 11

an X-off < 13 >

may be transmitted from the TXD terminal at RS-232D

signal levels, or through the TTY-TXD terminal at 20

mA Current Loop levels.

After the X-on flag has been set, data can be accepted

up to the maximum capacity of the buffer.

• Transmit timing of X-off signal

The X-off signal is transmitted when the vacant area

in the buffer drops below the specified value

(typically 256 bytes; refer to your printer manual).

• Data transfer after X-off signal

Data can be sent to the printer even after the X-off

signal is transmitted as long as sufficient room for

data remains in the buffer. However, if the

transmitted data exceeds the vacant area in the

buffer, it will be discarded.

> H code when it is ready to receive data, and

H when it is busy. The X-on/X-off signals

14

Page 18

• Transmit timing of X-on signal

The X-on signal is transmitted when the power is first

turned on, or when the vacant area in the buffer is

greater than the specified value (typically 512 bytes;

refer to your printer manual).

Figure 3. X-on/X-off thing

X-ON

POWER ON Buffer capacity less

X-OFF

than specified value

X-ON

Buffer capacity greater

than specified value

DTR protocol

Under this system, when the printer is turned on the

DTR enters the SPACE state, meaning that data entry is

enabled. When the rate of data reception is greater than

that of printing, the buffer gradually fills up. Once the

vacant area in the buffer drops below the specified value

(typically 256 bytes; refer to your printer manual), the

DTR sets the status flag to prohibit further data entry.

This flag is output through the DTR pin (No. 20) at

RS-232D signal levels, and through the TTY-TXD pin

(No. 17) at Current Loop Levels.

15

Page 19

With the status flag set, and data reception prohibited,

the vacant area of the buffer gradually increases as the

printer continues to print. When the vacant area in the

buffer reaches the specified value (typically 512 bytes;

refer to your printer manual), the flag is reset and data

entry is again enabled.

Note

Reverse Channel pin (No. 11) and DTR pin (No. 20) are

internally connected on the interface board and must

have identical signal levels.

Printer status error

The flag will be set immediately regardless of the

remaining buffer capacity if the printer detects an error.

16

Page 20

SPECIFICATIONS

1.

Synchronization: Asynchronous

2.

Baud Rate: 75, 110, 134.5, 150, 200, 300, 600,

3.

Word length:

Start bit: 1 bit

Data bit: 7 or 8 bits (selectable)

Parity bit: Odd, even, none, or ignore (selectable)

Stop bit: 1 bit or more

4. Input signal polarity:

1) With RS-232D:

MARK = logic "1' ( - 3 to -25V)

SPACE = logic "0" ( +3 to +25V)

2) Current loop:

MARK = logic "1" (Current ON)

SPACE = logic "0" (Current OFF)

Note

The above voltage, between pin No. 17 and No. 24,

must not exceed 25V.

1,200, 1,800, 2,400, 4,800, 9,600, or

19,200 BPS (selectable)

17

Page 21

5. Handshaking

Table 8. Handshaking

Control Loop

between pin No. 17

High(SPACE)-data

Data transmitted by

the change of the

impedance between

pin No. 17 and pin

No. 24 is controlled a

follows;

X-ON<ll>H-data

entry is enabled

X-OFF<13>H-data

entry is disabled

Using DTR protocol

Using X-ON/X-OFF

protocol

US-232D

The two signal The impedance

conditions at pm No.

11 and pin No. 20 are and pin No. 24 is as

as follows; follows;

MARK-data entry is LOW(MARK)-data

disabled entry is disabled

SPACE-data entry is

enabled entry is enabled

Data transmitted from

pin No. 2 is controller

as follows;

X-ON<ll>H-data

entry is enabled

X-0FF<13>H-data

entry is disabled

The DTR signal is always set to SPACE while X-on/

X-off handshaking is selected.

X-on/X-off characters will not be transmitted from TXD

while DTR handshaking is selected (TXD signal is

always set to MARK).

Note

Operation is not guaranteed when using the current loop

mode at rates over 1,200 BPS.

s

18

Page 22

HARDWARE DESCRIPTION

19

1. I/F board connector: EIA standard 25-pin D-SUB

female connector.

2. For signal description and pin assignment, refer to

the table below:

Table 9. Signal Description and Pin Assignment

Pin No. Signal name

protective

1

Ground

Transmitted

2

Data (TXD)

Received Data

3

(RXD)

Request to

4

Send (RTS) positive EIA level.

I

7

Signal Ground

Reverse

11 Channel

(=2nd RTS)

Data Terminalk t

20

Ready (DIR)

Direction

I

—

Text

Ill

out

In

Out

Out

Description

Chasis ground

Transmitted serial data

Received serial data

This signal is always at the

Return path for data and

control signals.

This

EIA Level when the printer is

ready to accept data entry

and at the negative EIA

level when the printer is not

ready to accept data entry

Operator can invert the

polarity of the signal with

jumper 15.

signal is at he positive

Page 23

Pin No.

17

24

25

23

Signal Name

TTY-TXD

TTFTXD

Return

TTY_RXD In

Text

Return

Direction*

out

—

—

Description

High impedance (‘SPACE’)

between pin No. 17 and No

24 or an X-on signal sent

across pin No. 17 and No.

24 indicates that the printer

is ready to accept data. Low

impedance (‘MARK’) or an

X-off signal being sent

indicates that the printer is

busy. Operator can invert

the polarity of this signal

with jumper J5.

Input data of serial Current

Loop.

Note

• The column heading “Direction” refers to the direction

of signal flow as viewed from the printer.

• All signals except TTY-TXD and TTY-RXD comply

with the EIA RS-232D standard.

20

Page 24

RECOMMENDED CIRCUIT CONNECTIONS

Recommended line driver and line receiver for RS-232D

signal level settings. (As viewed from the host computer.)

Figure 4. RS-232D

Serial Interface Card

Line Receiver

Recommended line interface circuit for 20mA Current

Loop signal level settings. (As viewed from the host

computer.)

Figure 5. Current Loop

Note

The value of "R" should be selected so that the loop

current is set between 10 and 20 mA. The "+v" should

be 3V to 24V.

21

Page 25

INSTALLATION

The C82305* /C82306* interface card is designed to be

installed inside the printer. Installation or removal of the

interface board is easy, and requires only a screwdriver.

The following section gives you detailed information on

how to install your interface card in a variety of

EPSON printers.

Caution

• Turn off the power to the printer and the computer

before installing the serial interface. Make sure that all

power and interface cables are removed.

• Avoid touching the printer’s circuit board contacts, as

many of these components are sensitive to static

electric charges that may build up on your body.

1. First, you may need to adjust the DIP switches and

jumper settings.

If the screws don’t fit your interface cable, you will

need to replace the connector lock nuts with the

optional ones provided in this package.

Note

The original CS2305* lock nuts are imperial standard

(inch), and the C82306* lock nuts are metric.

22

Page 26

2. Fit both sides of this interface card into the guides

inside the compartment.

3. Insert this interface card until the interface pins mate

with the connector inside your printer.

4. Secure the interface with the two screws.

23

Page 27

Current-Loop Transmitter/Receiver

Circuit Diagrams

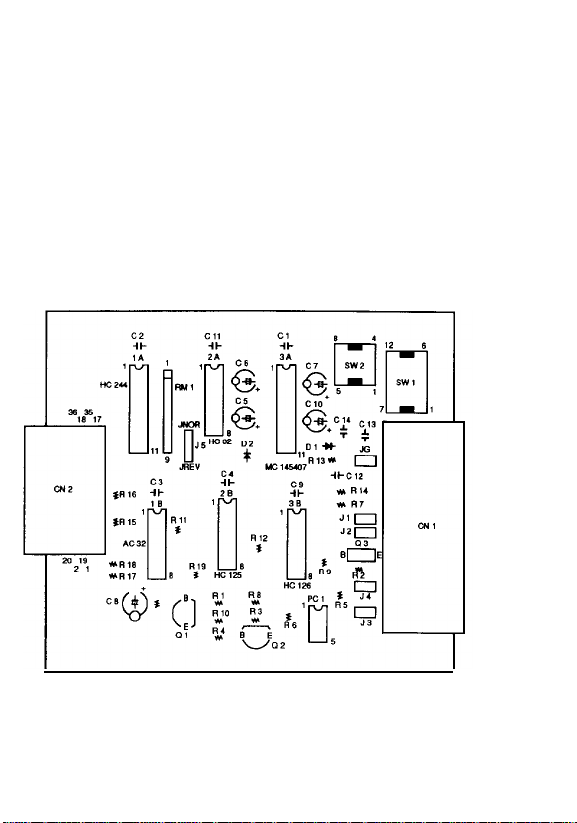

Set the Jumper Jl, J2, J3, and J4 referring to the

following diagrams.

Transmitter Circuit Diagram

121

Page 28

Receiver Circuit Diagram

122

Page 29

EPSON OVERSEAS MARKETING LOCATIONS

l

EPSON AMERICA. INC.

2780 Lomita Blvd.

Torrance. Cailif. 90505. U S A

Phone (213) 539-9140

Fax (213) 534-5854

EPSON UK LTD.

campus 100. Maylands Avenue.

Hemel, Hempstead. Herts.

HP2 7EZ, UK

Phone: 442-61144

Telex: 5182467

EPSON AUSTRALIA PTY. LTD.

Unit 3, 17 Rodborough Road.

Frenchs Forest NSW 2086 Australia

Phone: (2) 452-0666

Fax (2) 975-1409

EPSON HONG KONG LTD.

25/F, Harbour Centre.

25 Harbour, Road Wanchal

Hong Kong

Phone: 8314600

Telex: 65542

EPSON ITALIA S.p.A.

V, le F. IIi Casiraghi. 427 20099

SESTO S, GIOVANNI MI. Italy

Phone: 2-262331

Fax: 2-2440750

SEIKO EPSON CORPORATION

(Hirooka Office)

80 Harashinden. Hirooka

Shiojiri-Shi, Nagano-Ken

399-07 Japan

Phone: (0263) 52-2552

EPSON DEUTSCHLAND GmbH

Zülpicher StraBe 6,4000 Düsseldorf 11

F.R. Germany

Phone: (0211) 56030

Telex: 6584786

EPSON FRANCE S. A.

68 bis. rue Marjolin 92300

Levallois-Perret, France

Phone: (1) 47-373333

Telex: 610657

EPSON SINGAPORE PTE. LTD.

No. 1 Raffles Place #26-00

OUB Centre. singapore 0104

Phone: 5330477

Fax: 5338119

EPSON ELECTRONICS TRADING LTD.

(TAIWAN BRANCH)

1OF, No, 287 Nanking E. Road Sec. 3,

Taipei. Taiwan R. O. C.

Phone: (02) 717-1360

Fax: (02) 712-9164

EPSON IBERICA. S.A.

paris. 152, 08036 Barcelona. Spain

Phone: 410-34-00

Fax: 439-95-17

1990 May

Printed in Japan 90.07-.2

Loading...

Loading...