Page 1

32KB

Parallel Interface

Page 2

EPSON OVERSEAS MARKETING LOCATIONS

1

EPSON AMERICA. INC.

2780 Lomita Blvd..

Torrance, Calif. 90505. U.S.A

Phone: (213) 539-9140

Fax: (213) 534-5654

EPSON UK LTD.

Campus 100. Maylands Avenue.

Hemel Hempstead.

HP2 7EZ. U.K.

Phone:

Telex. 5 162467

EPSON AUSTRALIA PTY. LTD.

““at

3. 17 Rodborough Road.

Frenchr Forest. NSW 2066, Austreha

Phone:

Fax:

(2)

EPSON ELECTRONICS TRADING LTD.

25/F.

Harbour

25 Harbour Road.

Hong Kong

Phone: 5-6314600

Telex: 65542

EPSON

V. le F.

SESTO S. GIOVANNI

Phone: 2.26233,

Fax: 2.2440750

SEIKO EPSON CORPORATION

(Hirooka

80

Harashmden, Hiraoka

Sh,o,m-sh,. Nagano-ken

399.07

Phone: (0263) 52.2552

Her,s.

442-61144

12) 452-0666

975-1409

Centre.

Wanchai.

ITALIA S.D.A.

111 Carwaghi.

Office)

Japan

427 20099

MI.

Italy

EPSON DEUTSCHLAND GmbH

ZUlpicher

Stra6e

F.R. Germany

Phone: 10211) 56030

Telex: 6584766

EPSON FRANCE S. A.

68 bis. rue

LevallowPerref.

Phone: (1) 47-373333

Telex. 610657

EPSON SINGAPORE PTE. LTD.

No. 1 Raffles Place #26-00

OUB Centrs. Singapore 0104

Phone: 533-0477

Fax: 533-6119

6. 4000 OUsseldarf

Marjohn

92300.

France

11

EPSON ELECTRONICS TRADING LTD.

(TAIWAN BRANCH)

1OF.

No. 287

Nankmg

Taipei. Taiwan. R.O.C.

Phone: (02) 717-7360

Fax: (02) 712-9164

EPSON-ST1

Pans.

152.

Phone: 4

1034.00

Fax: 239-95-17

E. Road Sec. 3.

S.A.

08036 Barcelona.

Span

1989 July

Printed in Japan 89.12-.4

Page 3

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class B digital device.

Pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful Interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However there is no guarantee that

interference Will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

-

Reorient or relocate the receiving antenna

-

Increase the separation between the equipment and receiver.

-

Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

-

Consult the dealer or an experienced radio/TV technician for help

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1)

this device may not cause harmful interference. and

(2)

this device must accept any interference received,

including interference that may cause undesired operation.

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital

apparatus as set out in the radio interterence regulations of the Canadian Department of

Communications.

Le pr6sent apparelI numerique

applicables aux appareils numdnques de Class B prescrites dam lr rGglrment

radi&lectrique

The connection of a non-shielded printer interface cable to this printer will invalidate the FCC

Certification of this device and may cause interference levels which exceed the limits established

by the FCC for this equipment. If this equipment has more than one intertace connector. do not

leave cables connected to unused interfaces.

Seiko Epson Corporation shall not be liable against any damages or problems arising from the use

of any options or any consumable products other than those designated as Original Epson

Products or Epson Approved Products by Seiko Epson Corporation.

All rights reserved. Reproduction of any part of this manual, in any form whatsoever without Seiko

Epsons express written permission is forbidden.

The contents of this manual are subject to change without notice.

All efforts have been made to ensure the accuracy of this manual. However. should any errors be

detected, Seiko Epson would greatly appreciate being informed of them

The above notwithstanding, Seiko Epson can assume no responsibility for any errors in this

manual or their consequences.

Copyright © 1989 by Seiko Epson Corporation. Nagano. Japan

edict6

FOR CANADIAN USERS

“‘Pm&

pas de bruits radioClectriques depassant les limites

par

le

Minis&w des Commumcatmns du Canada.

WARNING

NOTICE

SW le

brouillage

Page 4

32KB Parallel Interface

32-KB-Schnittstellenkarte

Interface parallsle 32Ko

Interface en paralelo de 32KB

Interfaccia parallela da 32 KB

Page 5

TABLE OF CONTENTS

INTRODUCTION

About this guide

SETTING THE CONDITIONS

Board layout

DIP switch settings

Jumpers

Jumper settings

DATA ENTRY

About data entry

SELF TEST

SPECIFICATIONS

HARDWARE DESCRIPTION

INSTALLATION

FX, FX+

LX-80/86

LQ-800/1000

2

3

4

4

5

6

7

9

9

10

11

12

Page 6

About this guide

This guide is designed to give you detailed information on

how to install your C82303* interface board in a variety of

Epson printers. Installation procedures vary slightly depending upon the printer model that you have.

Also included, are instructions on how to adjust the settings of

the C82303* interface board, as well as a general description of

parallel data communication.

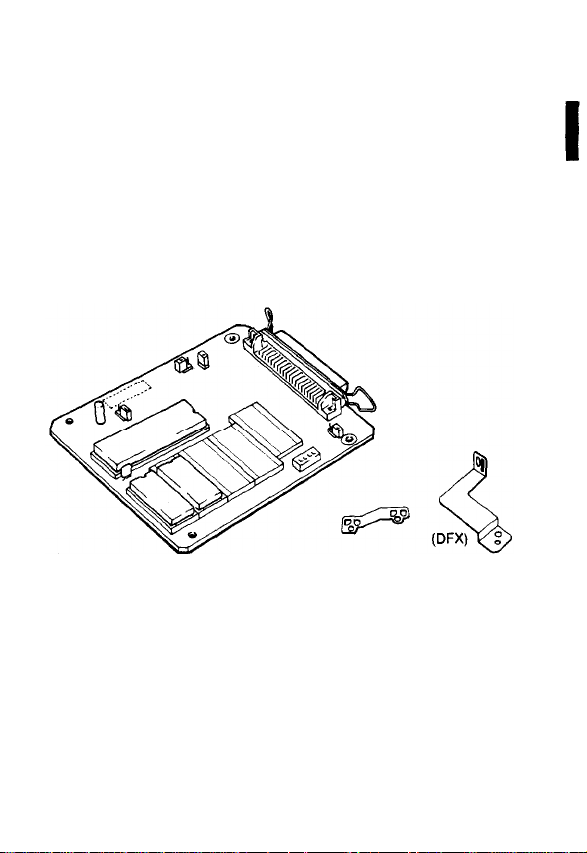

The C82303* option package contains the following items:

C82303* parallel I/F board (1)

FG plate

3

Page 7

SETTING THE CONDITIONS

The C82303* interface board has a set of DIP (Dual In-line

Package) switches, and 6 jumpers. This switch and jumpers

are used for selecting various interface operations.

Board layout

The diagram below shows the layout of the C82303* board,

and the locations of the DIP switch and jumpers.

Figure 1. Board layout

Page 8

DIP switch settings

Before you install the C82303* interface, you may need to

adjust some of the settings. When making DIP switch setting

changes, it is best to use a pointed device, such as a ball-point

pen

or small screwdriver.

Caution

All changes of DIP switch and jumper settings should be made

with the printer power turned off. The printer checks and

recognizes new settings only at the time the power is turned

About DIP switches

A set of DIP switches on the C82303* is labelled SW1. SW1

contains a number of individual toggle type switches that can

be set either on or off. The individual switches are referred to

by set (SW1) and number. Therefore, the switch in set SW1

marked by the small number 3 is called DIP switch 1-3.

5

Page 9

DIP

switch

1

The table below contains information on switch functions, and

the factory setting of each switch. The switches on DIP switch

1 allow you to change interface functions.

Table 1. DIP

1

SW pin No.1

I

1-1 I/F board enable/disable Enable Disable

1-2

1-3

1-4

switch 1

(

Function

Buffer enable/disable Enable Disable

Self test enable/disable

I

Not used.

ON 1 Off ( Factory setting

Enable Disable

I I

-

)

ON

ON

OFF

-

OFF

J

Jumpers

The jumper is a small terminal used for connecting or discon-

necting a circuit. The jumper is on when the jumper plug

covers both wires of the terminal. Jumper settings can be

changed by either attaching or removing the rectangular

jumper plug. If the jumper is to be turned off, connect it to just

one of the two terminal pins as shown in the figure below. By

doing this, you can avoid losing the unused jumper plug.

Figure 2.

lumpers

OFF (open)

ON (close)

6

Page 10

Jumper settings

The tables below give you information about the interface

conditions that can be selected using jumpers. In all cases, ON

denotes the connection of the jumper (covering both terminals), while OFF denotes the disconnection of the jumper.

Table 2. Jumper settings

Jumper

ON: SLCT IN signal is enable. (See Note 1.)

J1

Fixed (See Note 2.)

12

Fixed (See Note 2.)

J3

A

Data latch liming selection. See Table 3.

J4

B

I

ON: Connect Chassis Ground to Signal Ground.

JG

Note

1.

SLCT IN signal can be fixed LOW by setting the printer

DIP switch , jumper or SelecType function. If this signal is

fixed Low, you should not connect J1. When J1 is ON,

SLCT IN signal (pin No. 36 of I/F connector on the I/F

board) is connected to the printer through the I/F board to

enable it to be controlled by a Host computer. Sampling

this signal is always carried out by the printer, therefore

this function depends on the printer specification.

2.

J2 and J3 jumpers are connected at the factory, and you

should not change these setting.

Function

Factory Setting

OFF

-

-

OFF

I

Page 11

Table 3. Data latch timing selection

Jumper

* ON

J4

Falling edge of

B OFF STROBE ON STROBE

Function

OFF

Rising edge of

Note

Either J4A or J4B jumper must be connected.

Factory Setting

ON

OFF

1

8

Page 12

DATA ENTRY

About data entry

To accommodate data entry, the C82303* interface board is

equipped with a buffer that temporarily stores data before

I

transferring it to the printer. When this buffer becomes full,

any additional transmitted data cannot be accepted

and

is

discarded.

The buffered data is transferred transparently to the printer

main board every time the printer enters the READY state. A

maximum of 512K bytes of data can be buffered with this

board depending on its setting.

9

Page 13

SELF TEST

The self test mode can be set by the DIP switch 1-3. To set, first

turn off the power to the printer and then change the DIP

switch setting. When the power is turned back on, the new

setting automatically comes into effect. To exit from the self

test, turn off the power and reset the DIP switch.

The interface board first checks the RAM condition. After

checking the RAM, data in the range between

<3&H

to

<3!bH

is sent to the printer and printed. The print out is only 80

columns wide.

Table 4. Self test mode

Note

It takes some time to check the RAM before

test printing.

Page 14

SPECIFICATIONS

1.

Data transmission:

2. Synchronization:

3. Handshaking:

4.

Logic level:

5. RAM capacity:

6. Connector:

S-bit parallel

External supplied STROBE pulse

Via ACKNLG or BUSY

signals

TTL level

32K bytes

57-30360 (Amphenol), 36 pin or its

equivalents .

Interface timing

The figure below shows the timing for the parallel interface.

Figure 3. Interface timing

I

STROBE

I

I

11

Page 15

HARDWARE DESCRIPTION

For signal description and pin assignment, refer to the table

below:

Table 5. Signal description and pin assignment

I

Signal

izn

Pin

12

13

Pin

19

20

21

22

23

24

25

26

27

30

-

-

I

I

Signal

YimiE

DATA 1

DATA 2

DATA 3 IN

DATA 4

DATA 5

DATA 6 IN

DATA 7

DATA 8

vXNLG

BUSY

SLCT

Ike&on

IN

IN

IN

IN

IN

IN

IN

OUT

OUT

OUT

OUT

L

Description

STROBE pulse to read data. Pulse

width must be more than 0.5 microseconds at the receiving

These signals represent information

of the 1st to 8th bits of parallel data,

respectively. Each signal is at

HIGH level when data is logical 1

and LOW when it is logical 0.

About a IO-microsecond pulse.

LOW indicates that data has been

received and that the interface

board is ready to accept more data.

This signal is output as a pair

together with BUSY.

A HIGH signal indicates that the

interface board cannot receive data.

The signal goes HIGH in the

following cases:

1) During data entry (ea. car. time)

2) When off line

3) During printer-error state

A HIGH signal indicates that the

printer is out of paper.

Pulled up to +5 V through 3.3k ohm

resistance.

terminal.

12

Page 16

13

Page 17

Note

1.

The column heading “Direction” refers to the direction of

signal flow as viewed from the printer.

2.

All interface conditions are based on TTL level. Both the

rise and fall of each signal must be less than 0.2

KS.

14

Page 18

-

3

:

‘Xii

NOILV-IWLSNI

xda

+xiI

L

Page 19

98/08-X1

000T/008-iTI

we

C

Loading...

Loading...