Page 1

®

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

SERVICE MANUAL Rosko

Color Inkjet Printer

EPSON Stylus C82

SEIJ02003

Page 2

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR

OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 3

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4. DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5. ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for

servicing the product.

APPENDIX Provides the following additional information for

reference:

• Connector pin assignments

• Exploded diagram

• Electrical circuit boards schematics

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It

may also provide additional information that is related to a

specific subject, or comment on the results achieved through a

previous action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or

loss of life.

Indicates that a particular task must be carried out according to a

certain standard after disassembly and before re-assembly,

otherwise the quality of the components in question may be

adversely affected.

Page 4

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

CONTENTS

Chapter 1 PRODUCT DESCRIPTION

1.1 Features ............................................................................................................... 9

1.2 Specifications ....................................................................................................... 9

1.2.1 Physical Specification ..................................................................................

1.2.2 Printing Specification .................................................................................. 9

1.2.3 Paper Feeding ............................................................................................ 10

1.2.4 Input Data Buffer ....................................................................................... 10

1.2.5 Electric Specification ................................................................................. 10

1.2.6 Environmental Condition ........................................................................... 11

1.2.7 Reliability .................................................................................................. 11

1.2.8 Safety Approvals ....................................................................................... 11

1.2.9 Acoustic Noise ........................................................................................... 11

1.2.10 CE Marking ............................................................................................. 11

1.3 Operator Controls ............................................................................................ 12

1.3.1 Operate Switch ........................................................................................... 12

1.3.2 Control Panel ............................................................................................. 12

1.3.2.1 Switches ............................................................................................. 12

1.3.2.2 Indicators ........................................................................................... 12

1.3.3 Panel Functions .......................................................................................... 12

1.3.4 Printer Condition and Panel Status ............................................................ 13

1.3.5 Errors ......................................................................................................... 13

1.4 Paper .................................................................................................................. 13

1.4.1 Paper Handling .......................................................................................... 13

1.4.2 Paper Specification .................................................................................... 13

1.4.3 Printing Area .............................................................................................. 14

1.4.3.1 Cut Sheet ........................................................................................... 14

1.4.3.2 Envelopes .......................................................................................... 15

1.5 Ink Cartridge .................................................................................................... 15

1.5.1 Black Ink Cartridge .................................................................................... 15

1.5.2 Color Ink Cartridge .................................................................................... 15

Chapter 2 OPERATING PRINCIPLES

2.1 Overview ............................................................................................................ 17

2.1.1 Printer Mechanism ..................................................................................... 17

9

2.1.2 Carriage Motor Specification .................................................................... 17

2.1.3 Paper Feeding Motor Specification ........................................................... 17

2.1.4 Paper Loading Mechanism (New ASF unit) ............................................. 17

2.1.4.1 Drive Process ..................................................................................... 17

2.1.5 Ink System Mechanism ............................................................................. 18

2.1.5.1 Pump Unit & Wiper mechanism ....................................................... 18

2.2 Electrical Circuit Operating Principles .......................................................... 18

2.2.1 C486 PSB/PSE Board ................................................................................ 18

2.2.2 C486 MAIN Board .................................................................................... 19

Chapter 3 TROUBLESHOOTING

3.1 Overview ............................................................................................................ 22

3.1.1 Troubleshooting With LED Error Indications ........................................... 22

3.1.1.1 Paper Out/Double Feed Error ............................................................ 22

3.1.1.2 Ink Out ............................................................................................... 22

3.1.1.3 Fatal Error ......................................................................................... 22

3.1.1.4 Paper Supply Faults ........................................................................... 23

3.1.1.5 Dot missing 1 .................................................................................... 23

3.1.1.6 Dot missing 2 .................................................................................... 23

Chapter 4 DISASSEMBLY AND ASSEMBLY

4.1 Overview ............................................................................................................ 25

4.1.1 Precautions ................................................................................................. 25

4.1.2 Tools .......................................................................................................... 25

4.1.3 Screws ........................................................................................................ 25

4.2 Disassembly ....................................................................................................... 26

4.2.1 Housing Removal ...................................................................................... 27

Page 5

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

4.2.1.1 Upper Housing Removal ................................................................... 27

4.2.1.2 Panel Housing/C486 PNL Board Removal ....................................... 27

4.2.1.3 Printhead Removal ............................................................................ 28

4.2.1.4 Lower Housing/Printer Mechanism Removal ................................... 29

4.2.2 Board Removal .......................................................................................... 30

4.2.2.1 C486 Main Board Removal ............................................................... 30

4.2.2.2 C486 PSB/PSE Board Removal ........................................................ 32

4.2.3 Printer Mechanism Disassembly ............................................................... 32

4.2.3.1 ASF Unit Removal ............................................................................ 32

4.2.3.2 ASF Unit Disassembly ...................................................................... 33

4.2.3.3 PE Sensor/PE Sensor Holder/PE Lever Removal ............................. 35

4.2.3.4 PF Encoder & PF Encoder Base Removal ........................................ 36

4.2.3.5 Linear Scale Removal ....................................................................... 37

4.2.3.6 CR Guide Shaft/Carriage Unit Removal ........................................... 37

4.2.3.7 Ink System Unit Removal ................................................................. 39

4.2.3.8 CR Motor Removal ........................................................................... 39

4.2.3.9 PF Motor Removal ............................................................................ 40

4.2.3.10 Paper Eject Frame Unit Removal .................................................... 40

4.2.3.11 EJ Roller Unit Removal .................................................................. 41

4.2.3.12 Front Paper Guide Removal ............................................................ 41

4.2.3.13 Upper Paper Guide Removal ........................................................... 42

4.2.3.14 Rear Paper Guide Removal ............................................................. 42

4.2.3.15 PF Roller Unit Removal .................................................................. 42

7.1.2 EEPROM Address Map ............................................................................. 54

7.2 Exploded Diagram ............................................................................................ 57

7.3 Electrical Circuits ............................................................................................. 58

Chapter 5 ADJUSTMENT

5.1 Overview ............................................................................................................ 44

5.1.1 Conditions for Each Adjustment ............................................................... 44

Chapter 6 MAINTENANCE

6.1 Overview ............................................................................................................ 47

6.1.1 Cleaning ..................................................................................................... 47

6.1.2 Service Maintenance .................................................................................. 47

6.1.3 Lubrication ................................................................................................. 48

Chapter 7 APPENDIX

7.1 Connector Summary ........................................................................................ 52

7.1.1 Major Component Unit .............................................................................. 52

Page 6

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

CHAPTER

PRODUCT DESCRIPTION

1

Page 7

EPSON Stylus C82 Revision A

1.1 Features

The major features of EPSON Stylus C82 are:

High color print quality

2880 (H) x 1440 (V) dpi printing (Max resolution)

4 color printing (YMCK)

Separate ink cartridge for each color

Built-in auto sheet feeder

Holds 150 cut-sheets (90g/m2)

Holds 15 envelopes

Built-in 2 I/F

Bi-directional parallel I/F (IEEE-1284 level 1 device)

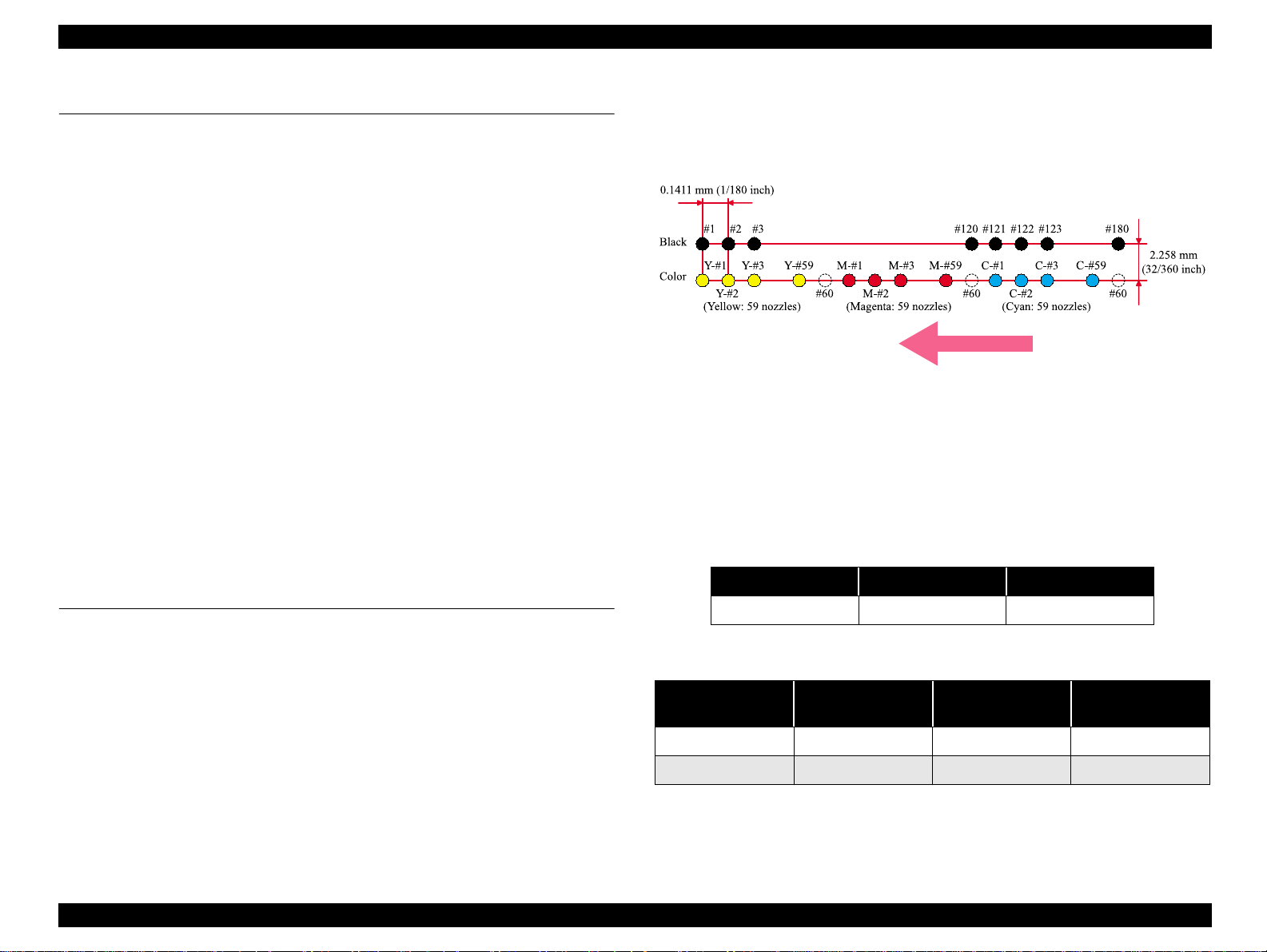

Nozzle configuration

Monochrome 180 nozzles

Color 59 nozzles x 3 (Cyan, Magenta, Yellow)

Paper ejecting direction

NOTE: The #60 for each nozzle is only a space.

Figure 1-1. Nozzle rear view

USB

Windows/Macintosh exclusive

Options

Print direction

Bi-direction with logic seeking

10/100 Base-TX External Print Server : C82378

EpsonNet 802.11b Wireless Ext. Print Server : C12C82396

Print speed & Printable columns

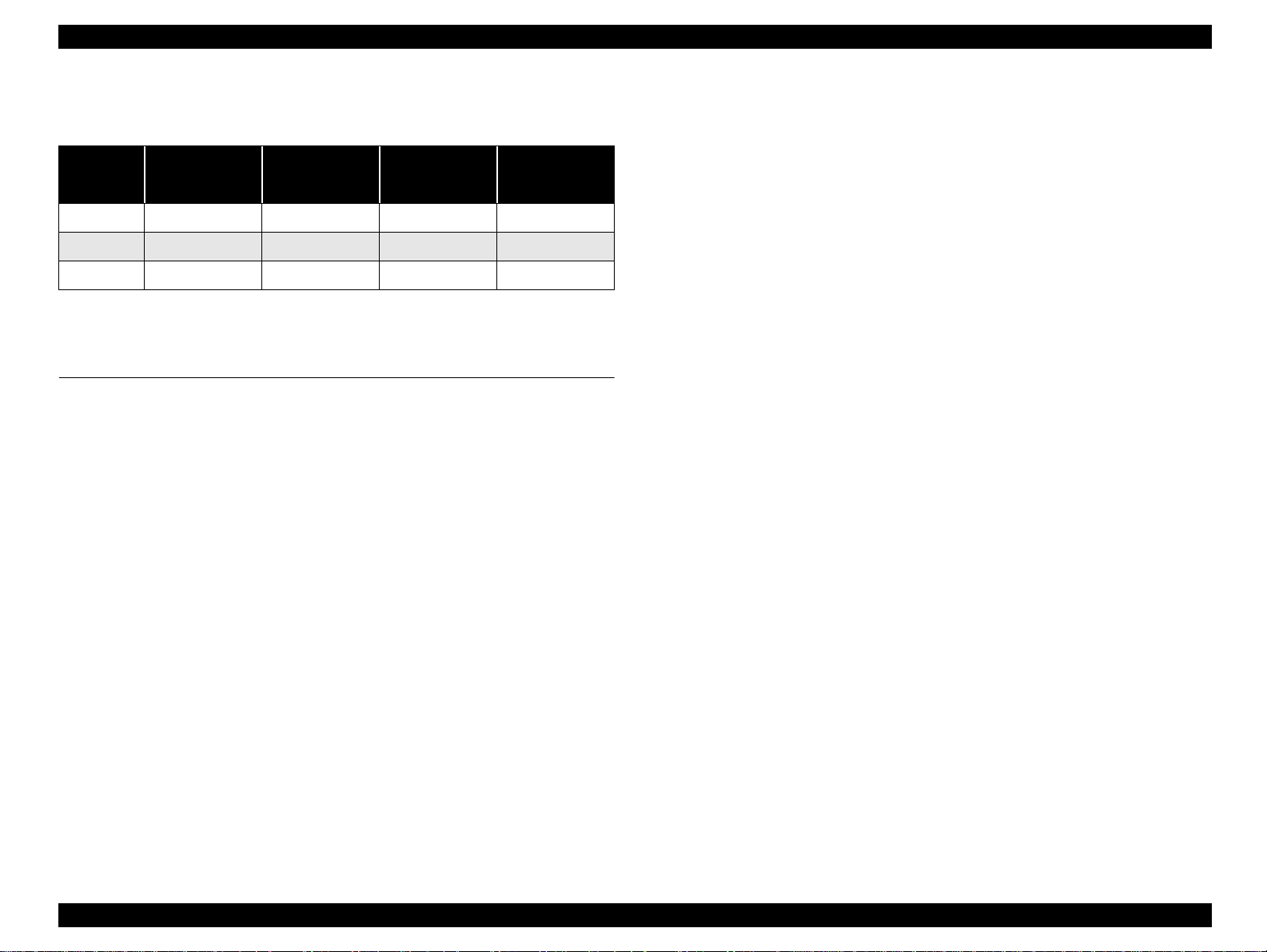

Table 1-1. Character mode

Character pitch Printable columns LQ speed

1.2 Specifications

10CPI (Pica) 80 245CPS

This section covers specifications of the printers.

1.2.1 Physical Specification

Weight : 5.2kg (without the ink cartridges)

Dimension : 470mm (W) x 593mm (D) x 316mm (H)

Horizontal

resolution

180dpi 209.8mm (8.26inch) 1488 291CPS

360dpi (Black) 209.8mm (8.26inch) 2976 245CPS

1.2.2 Printing Specification

Print method

On demand ink jet

PRODUCT DESCRIPTION Features 9

Table 1-2. Raster graphics mode

Printable area Available dot CR speed

Page 8

EPSON Stylus C82 Revision A

Table 1-2. Raster graphics mode

Horizontal

resolution

360dpi (Color) 209.8mm (8.26inch) 2976 225CPS

720dpi 209.8mm (8.26inch) 5952 245CPS

1440dpi 209.8mm (8.26inch) 11904 190CPS

Control code

ESC/P2 expanded raster graphics code

EPSON Remote command

Typeface

Bit map LQ font: EPSON Courier 10 CPI

Printable area Available dot CR speed

1.2.3 Paper Feeding

Feeding method

Friction feed with ASF

Paper path

Cut-sheet ASF (Top entry Front out)

Feed speed

220.86mm/sec (8.70inch/sec) (Normal, 25.4mm feed)

294.0mm/sec (11.5inch/sec) (Fast, continuous feed)

1.2.4 Input Data Buffer

Input buffer size : 32KB

1.2.5 Electric Specification

[120V version]

Rated voltage : AC 120V

Input voltage range : AC 99 to 132V

Rated frequency range : 50 to 60Hz

Input frequency range : 49.5 to 60.5Hz

Rated current : 0.4A (Max. 1.3A)

Power consumption : Approx. 16W (ISO 10561 Letter Pattern)

Approx. 3.5W in sleep mode

Approx. 0.35W in powered off mode

Energy Star compliant

Insulation resistance : 10M ohms min.

(between AC line and chassis, DC 500V)

Dielectric strength : AC 1000V rms. 1 minute or

AC 1200V rms. 1 second

(between AC line and chassis)

[220 to 240V version]

Rated voltage : AC 220 to 240V

Input voltage range : AC 198 to 264V

Rated frequency range : 50 to 60Hz

Input frequency range : 49.5 to 60.5Hz

Rated current : 0.2A (Max. 0.7A)

Power consumption : Approx. 15W (ISO10561 Letter Pattern)

Approx. 3.5W in sleep mode

Approx. 0.5W in powered off mode

Energy Star compliant

Insulation resistance : 10M ohms min.

(between AC line and chassis, DC 500V)

Dielectric strength : AC 1500V rms. 1 minute

(between AC line and chassis)

PRODUCT DESCRIPTION Specifications 10

Page 9

EPSON Stylus C82 Revision A

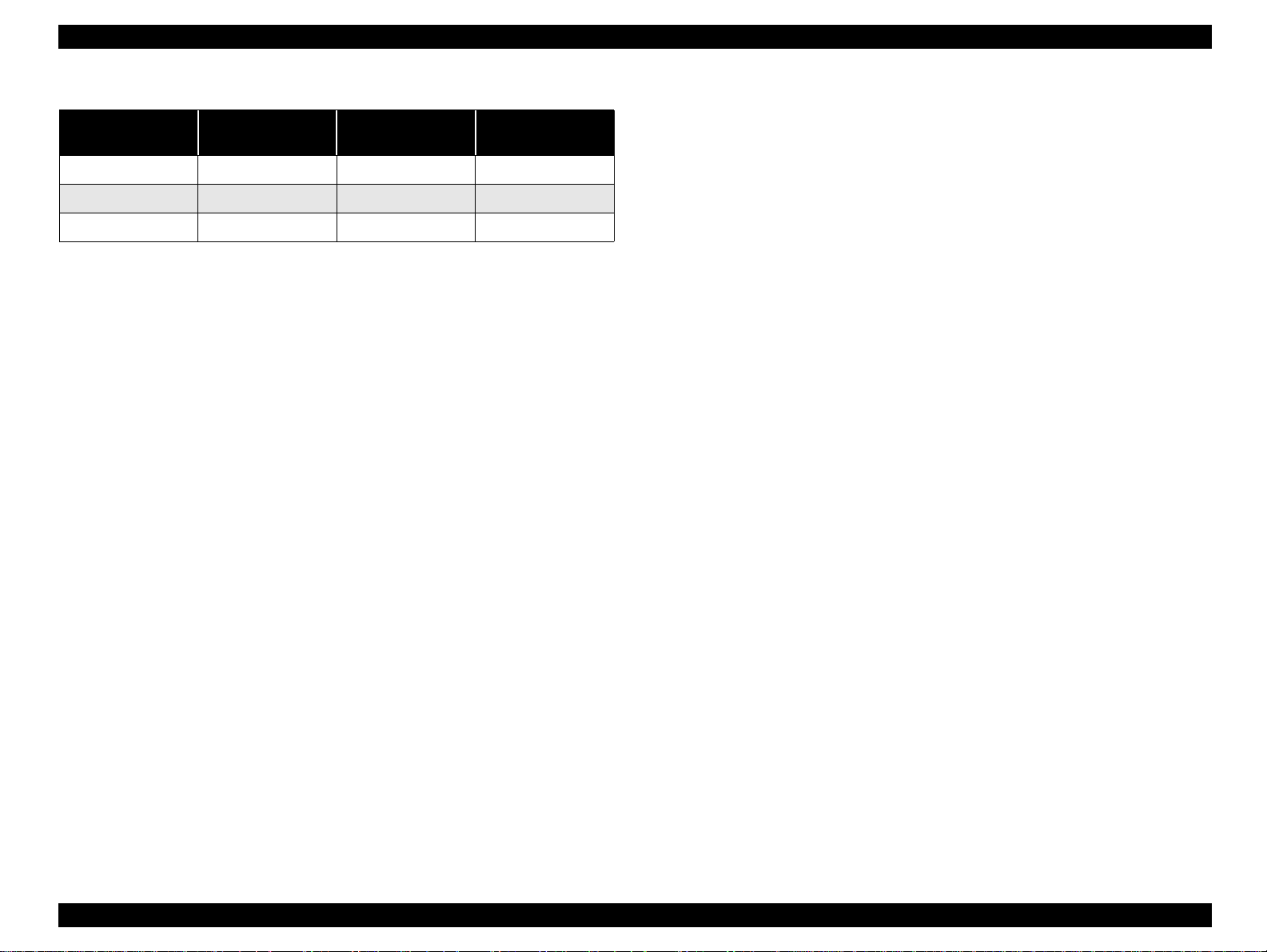

1.2.6 Environmental Condition

Table 1-3. Environmental Condition

Operating Non-operating

Temperature 10 to 35°C

Humidity

(Without condensation)

Resistance to shock 1G, within 1ms 2G, within 2ms

Resistance to vibration 0.15G 0.50G

20 to 80% RH

(*2)

(*2)

NOTE: (*1) With shipment container

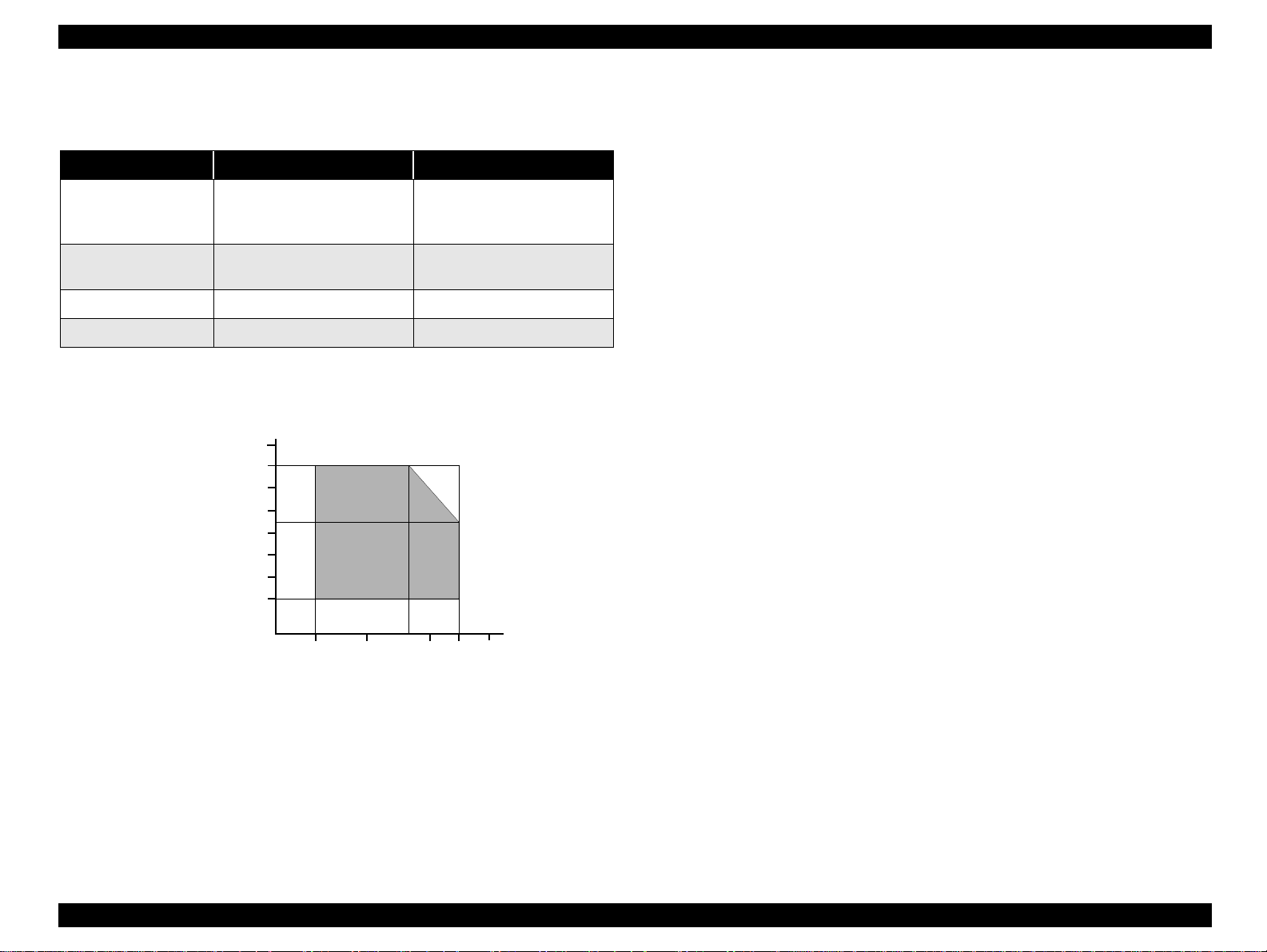

NOTE: (*2) Condition is as following figure

90

80

70

60

Humidity (%)

50

40

30

20

27

10

20

30

Temperature (°C)

Figure 1-2. Temperature/Humidity range

-20 to 40°C

(1 month at 40°C and

120 hours at 60°C)

5 to 85% RH

35

40

(*1)

1.2.7 Reliability

Total print volume : 50,000 pages (A4, Letter) (Black)

20,000 pages (A4, Letter) (Color)

Printhead Life : 3000 million dots/nozzle

1.2.8 Safety Approvals

[120V version]

Safety standards : UL1950

CSA 22.2 No.950

EMI : FCC part 15 subpart B class B

CSA C108.8 class B

[220 to 240V version]

Safety standards :EN60950 (VDE)

EMI : EN55022 (CISPR Pub.22) class B

AS/NZS 3548 class B

1.2.9 Acoustic Noise

Level : Approx. 42dB (A) (According to ISO 7779)

1.2.10 CE Marking

[220 to 240V version]

Low voltage directive 73/23/EEC :EN60950

EMC directive 89/336/EEC : EN55022 class B

EN55024

EN61000-3-2

EN61000-3-3

PRODUCT DESCRIPTION Specifications 11

Page 10

EPSON Stylus C82 Revision A

1.3 Operator Controls

1.3.1 Operate Switch

Operate switch is located on the control panel.

1.3.2 Control Panel

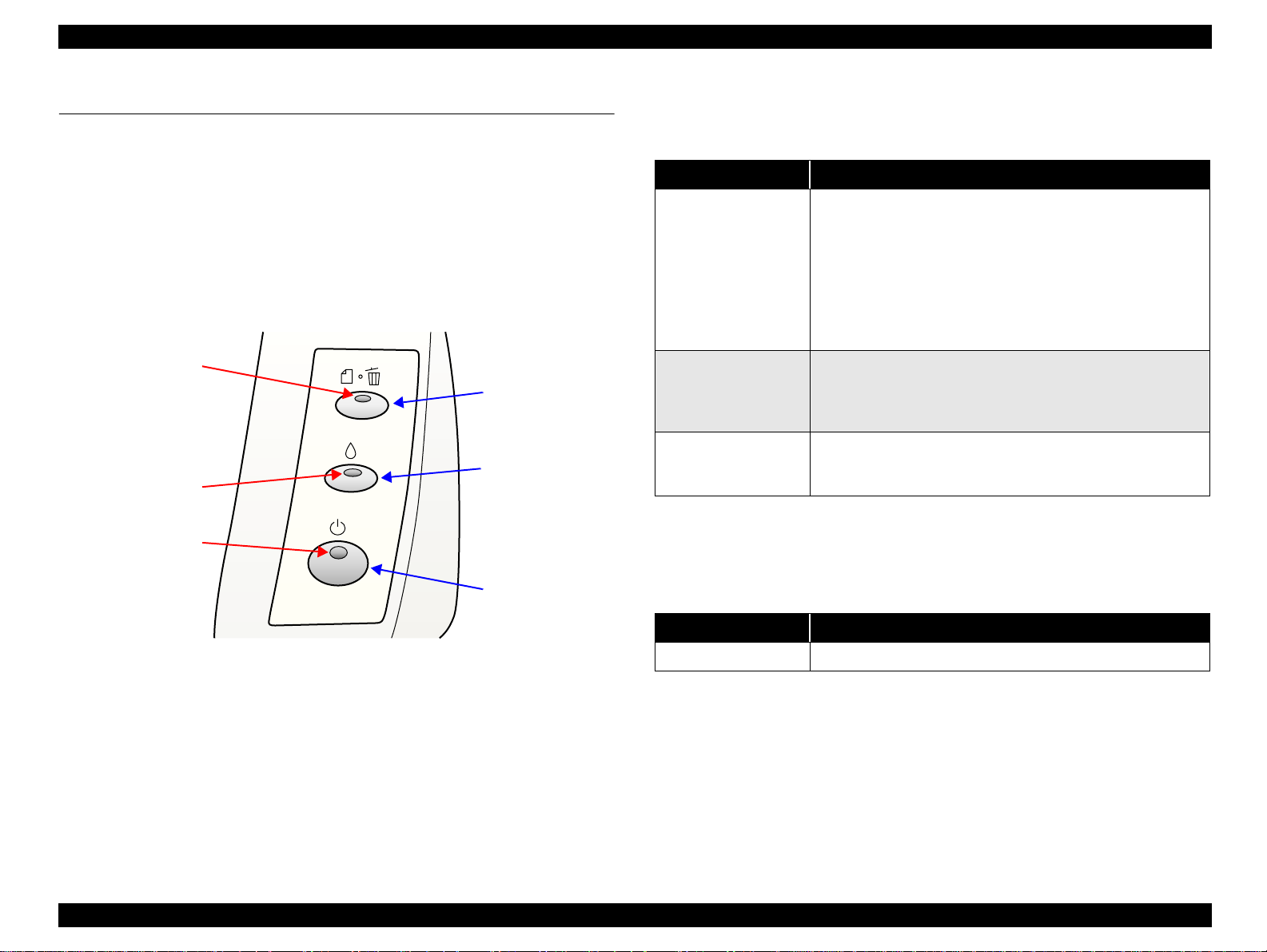

1.3.2.1 Switches

There are 3 non-lock type push switches, and 3 LEDs.

Paper Out LED

Ink Out LED

Power LED

Paper SW

Ink SW

1.3.3 Panel Functions

Table 1-4. Panel functions

Switch Function

• Loads or ejects the paper.

• When carriage is on the ink check position, move carriage to

next ink check position or cartridge change position.

Paper

print cancel

Ink

Ink

(Pushing for 2 seconds

NOTE: (*1) 3 seconds is required at the user’s manual.

NOTE: (*2) This function is not available in printing status.

• When carriage is on the ink cartridge change position, return

carriage from ink cartridge change position.

• In the condition of “Double feed error”, recovering from error

condition, printing is restarted.

• In the condition of printing, cancel the print job.

• Starts the ink cartridge change sequence.

Move the carriage to cartridge change position.

• When carriage is on the ink change position, return carriage

from ink cartridge change position.

• Starts the cleaning of head.

• In the condition of “Ink low” or “Ink out” or “No ink cartridge”,

*1)

starts the ink cartridge change sequence.

(*2)

1.3.2.2 Indicators

Figure 1-3. Control panel

Power SW

Switch Pressing with power on function

Paper Start status printings.

NOTE: (*) Status printings prints firmware version, ink counter and nozzle

Table 1-5. Panel functions with power on

(*1)

check patterns.

Power

Lights when the operate switch is “ON”, and AC power is supplied.

Paper Out

Lights during the paper-out condition, and blinks during the paper-jam condition.

NOTE: The Stylus C82 cannot cancel a maintenance error from the control

panel. When a maintenance error is generated, use the Adjustment

Program to clear the counter value.

Ink Out

Lights during no ink condition, and blinks during the ink low condition.

PRODUCT DESCRIPTION Operator Controls 12

Page 11

EPSON Stylus C82 Revision A

Paper jam

1.3.4 Printer Condition and Panel Status

When printer fails to eject a sheet, it goes paper jam error.

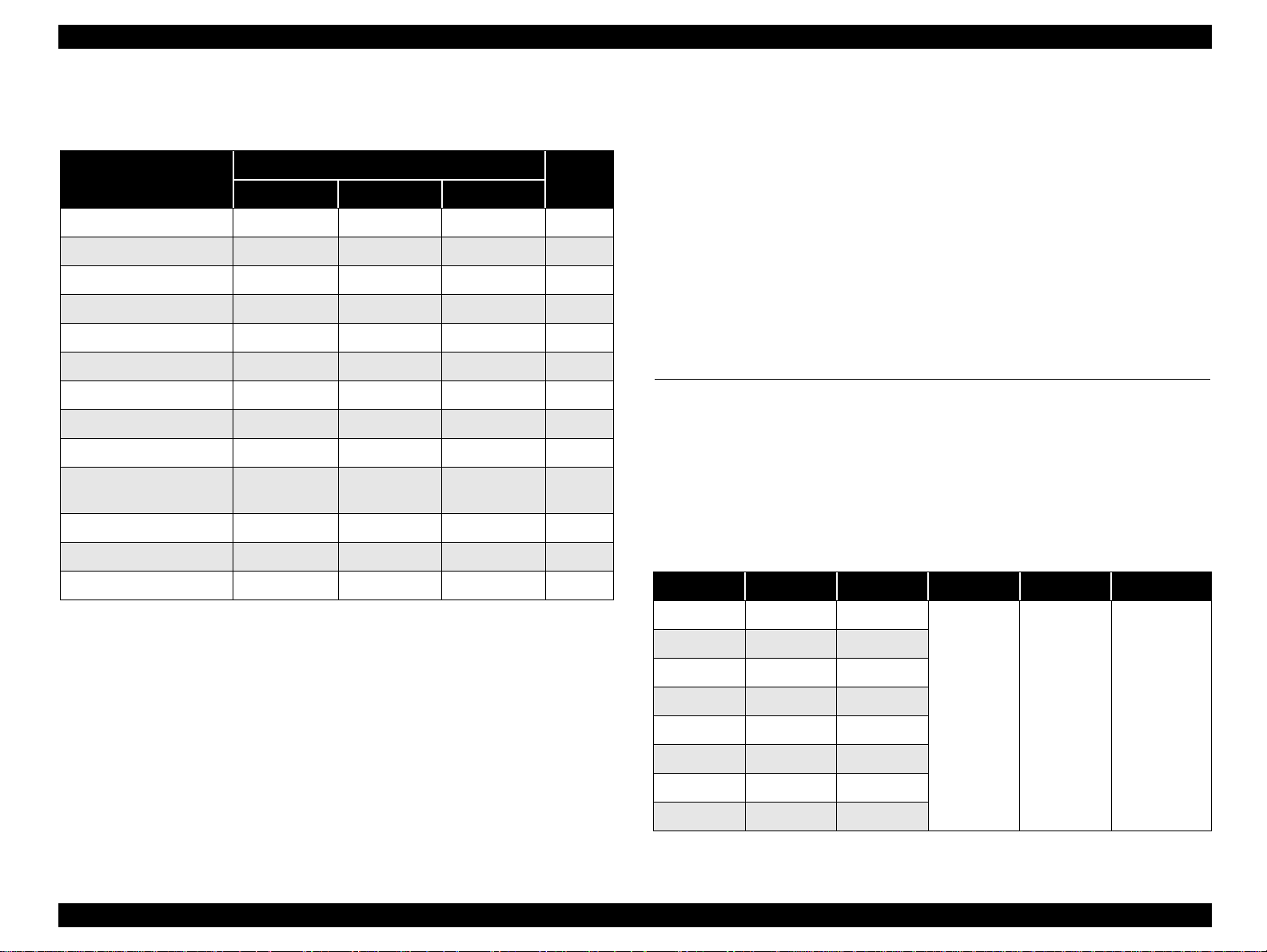

Table 1-6. Printer condition and LED status

Printer status

Indicators

Priority

Power Ink out Paper out

Maintenance request

When the total quantity of ink wasted through the cleanings and flushing is

reaches to the limit, printer indicates this error and stops.

Fatal errors

Power on condition On - - 11

Ink sequence Blink - - 7

Ink cartridge change mode Blink - - 6

At occurrence of a Carriage Control Error, CG Access Error or Head Hot Error, a

Fatal Error is generated in order to allow recovery of dot-missing the next time

power is turned on.

Double feed error

Data processing Blink - - 9

Paper out - - On 5

When printer fails to load a sheet, it goes double feed error.

Double feed error - - On 5

Paper jam condition - - Blink 4

No ink cartridge/Ink out - On - 8

Ink level low - Blink - 10

Enter EEPROM and Timer

IC reset

Maintenance request Fast blink Fast blink Fast blink 3

Fatal error Blink On Blink 2

Power off Blink Blink Blink 1

- On On -

NOTE: (-) Don’t care.

NOTE: Error messages for the printer driver are classified as "Paper out error"

and "Double feed error."

1.3.5 Errors

No ink cartridge/Ink out

Ink low : Blink

Ink out : On

Paper out

When printer fails to load a sheet, it goes paper out error.

1.4 Paper

1.4.1 Paper Handling

Reverse feed of more than 9.5mm (0.38") is not allowed.

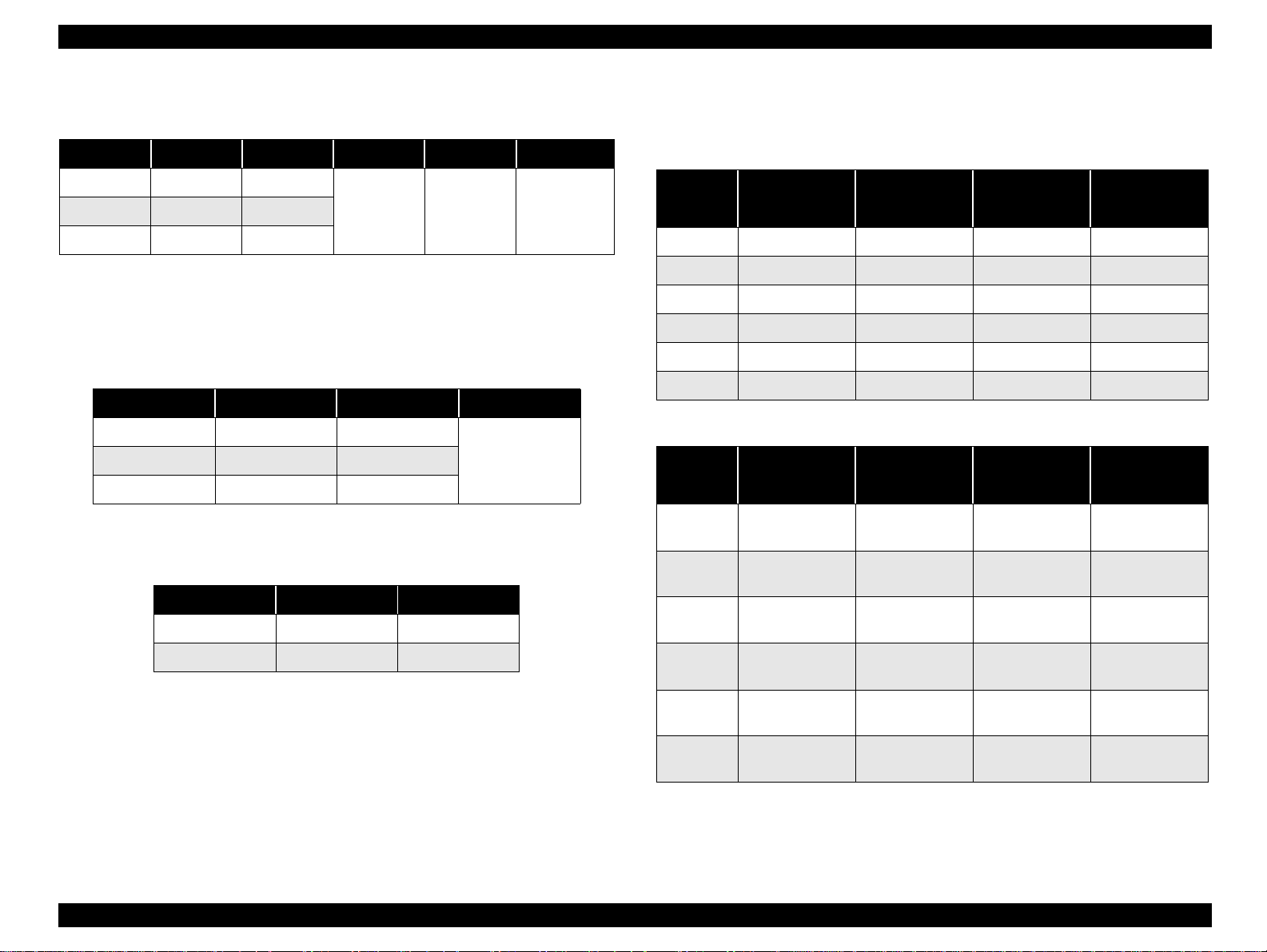

1.4.2 Paper Specification

Cut sheet

Table 1-7. Paper specification (Cut sheet)

Paper size Paper width Paper length Thickness Weight (lb) Quality

A4 210mm 297mm

Letter 215.9mm 279.4mm

B5 182mm 257mm

Legal 215.9mm 355.6mm

Executive 184.2mm 266.7mm

Half-letter 139.7mm 215.9mm

A5 148mm 210mm

Photo paper 101.6mm 152.4mm

0.08 to

0.11mm

64 to 90g/m

(17 to 24)

• Exclusive

2

paper

• Bond paper

•PPC

PRODUCT DESCRIPTION Paper 13

Page 12

EPSON Stylus C82 Revision A

Envelope

Table 1-8. Paper specification (Envelope)

Paper size Paper width Paper length Thickness Weight (lb) Quality

No.10 241mm 104.8mm

DL 220mm 110mm

C6 162mm 114mm

0.16 to

0.52mm

45 to 75g/m

(12 to 20)

• Bond paper

2

• Plain paper

• Air mail

1.4.3 Printing Area

1.4.3.1 Cut Sheet

Table 1-11. Character mode

LM

Paper size

A4 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14mm (0.54”)

(Left margin)

(min.)

RM

(Right margin)

(min.)

TM

(Top margin)

(min.)

(Bottom margin)

BM

(min.)

NOTE: Envelope printing is only available at normal temperature.

NOTE: Keep the longer side of the envelope horizontally at setting.

Index card

Table 1-9. Paper Specification (Index card)

Paper size Paper width Paper length Thickness

A6 Index card 105mm 148mm

5 x 8" Index card 127mm 203mm

10 x 8" Index card 254mm 203mm

Post cards (Card)

Less than 0.23mm

Table 1-10. Paper Specification (Post cards)

Paper size Paper width Paper length

Post card 100mm 148mm

Return post card 200mm 148mm

Letter 3mm (0.12”) 9mm (0.35”) 3mm (0.12”) 14mm (0.54”)

B5 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14mm (0.54”)

Legal 3mm (0.12”) 9mm (0.35”) 3mm (0.12”) 14mm (0.54”)

Statement 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14mm (0.54”)

Exclusive 3mm (0.12”) 3mm (0.12”) 3mm (0.12”) 14mm (0.54”)

Table 1-12. Raster graphics mode

LM

Paper size

A4 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Letter 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

B5 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Legal 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Statement 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

(Left margin)

(min.)

RM

(Right margin)

(min.)

TM

(Top margin)

(min.)

BM

(Bottom margin)

(min.)

14mm (0.54”) /

3mm (0.12”)

14mm (0.54”) /

3mm (0.12”)

14mm (0.54”) /

3mm (0.12”)

14mm (0.54”) /

3mm (0.12”)

14mm (0.54”) /

3mm (0.12”)

(*)

(*)

(*)

(*)

(*)

Executive 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

14mm (0.54”) /

3mm (0.12”)

(*)

NOTE: (*) Bottom margin is expanded to 3mm when paper dimension is

defined by using command, otherwise it is not expanded (14mm).

NOTE: From a form lower end 3mm as for 14mm area a printing may scramble.

PRODUCT DESCRIPTION Paper 14

Page 13

EPSON Stylus C82 Revision A

1.4.3.2 Envelopes

Table 1-13. Envelope margin

LM

Paper size

No.10 3mm (0.12”) 20mm (0.78”) 3mm (0.12”) 3mm (0.12”)

DL 3mm (0.12”) 20mm (0.78”) 3mm (0.12”) 3mm (0.12”)

C6 3mm (0.12”) 20mm (0.78”) 3mm (0.12”) 3mm (0.12”)

(Left margin)

(min.)

NOTE: Keep the shorter side of the envelope horizontally at setting.

RM

(Right margin)

(min.)

TM

(Top margin)

(min.)

BM

(Bottom margin)

(min.)

1.5 Ink Cartridge

1.5.1 Black Ink Cartridge

Bk : Completely compatible between Stylus C80/C70.

Type : Exclusive cartridge

Color : Black

Print capacity : 1240 pages/A4 (ISO/IEC 10561 Letter Pattern at 360dpi)

Ink life :2 years from production data.

Storage temperature :-20

Dimension : 22.0mm (W) x 71.2mm (D) x 66.5mm (H)

o

C to 40oC (Storage, within a month at 40oC)

o

-30

C to 40oC (Packing storage, within a month at 40oC)

o

-30

C to 60oC (Transit, within 120 hours at 60oC

and within a month at 40

o

C)

Storage temperature :-20

o

C to 40oC (Storage, within a month at 40oC)

o

-30

C to 40oC (Packing storage, within a month at 40oC)

o

-30

C to 60oC (Transit, within 120 hours at 60oC

and within a month at 40

o

C)

Dimension : 12.7mm (W) x 71.2mm (D) x 66.5mm (H)

NOTE: Ink cartridges cannot be refilled. Only new cartridges are prepared for

use. To prevent ink leakage, be sure not to peel off blue label attached to

side of cartridge.

NOTE: Do not use the ink cartridge which was passed away the ink life.

NOTE: Ink will be frozen under -4

o

C environment, however it will be usable after

placing it more than 3 hours at room temperature.

1.5.2 Color Ink Cartridge

CMY : Not compatible between Stylus C80/C70.

Type : Exclusive cartridge

Color : Magenta, Cyan, Yellow

Print capacity :420 pages / A4 (360 dpi, 5% duty each color)

Ink life :2 years from production date

PRODUCT DESCRIPTION Ink Cartridge 15

Page 14

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

CHAPTER

OPERATING PRINCIPLES

2

Page 15

EPSON Stylus C82 Revision A

2.1 Overview

This section describes the operating principles of the printer mechanism and electrical

circuit boards

2.1.1 Printer Mechanism

The basic component of the printer mechanism is same the Stylus C80/C70.

Only the ASF is newly designed.

For throughput improvement, the special use Flashing Box utilizes 0/80 digit bidirection.

Paper can be supplied by 0/80 digit bi-direction. (Economy printing only.)

2.1.2 Carriage Motor Specification

Table 2-1. CR motor Specification

Items Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Coil resistance 27.1Ω ± 10% (per phase at 25 degree)

Inductance

Drive method PWM, constant-current chopping

Driver IC LB11947

19.8mH ± 25% (1KH 1VmA)

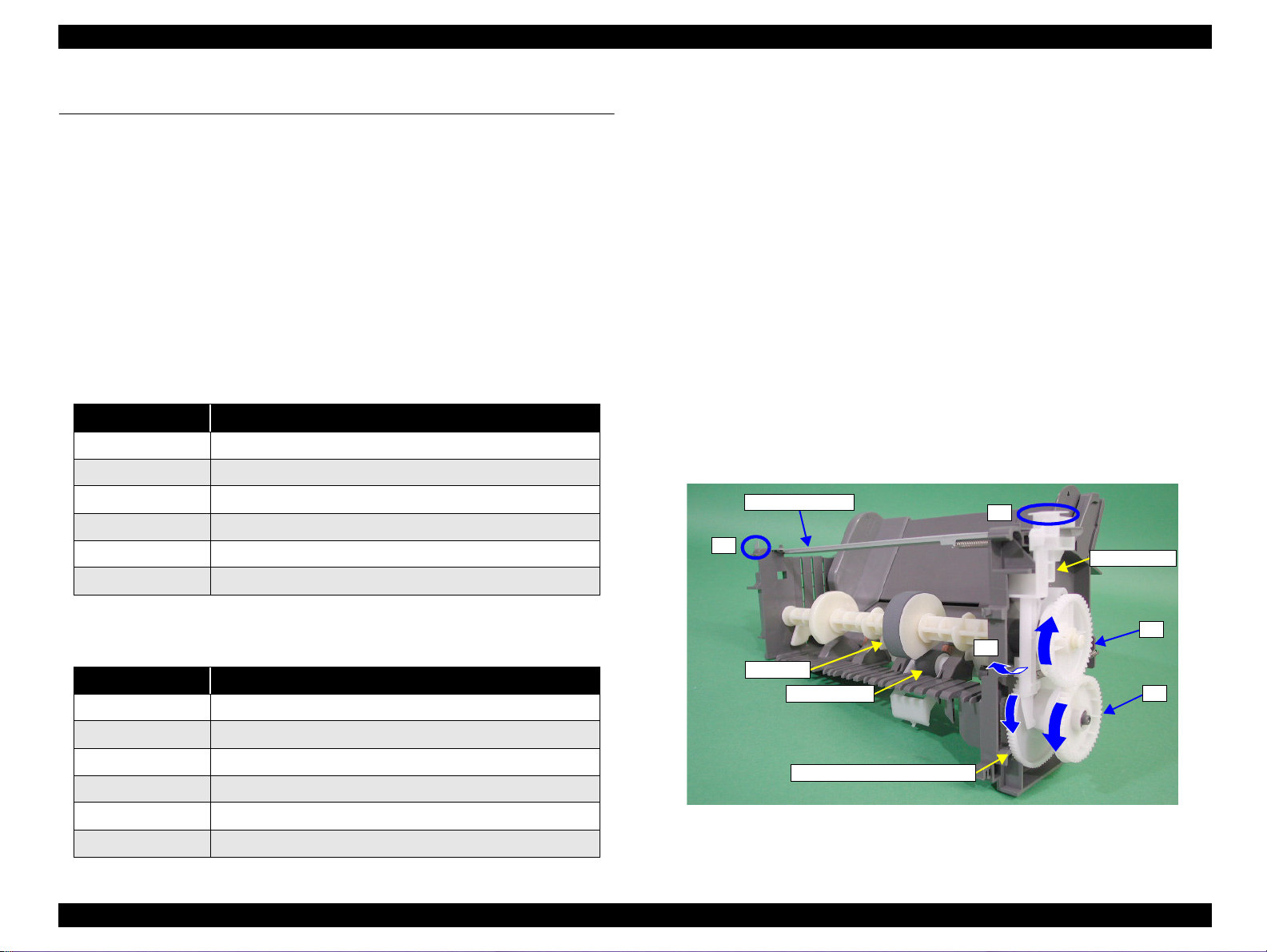

2.1.4 Paper Loading Mechanism (New ASF unit)

The ASF of this printer is newly designed. It has the following characteristics.

Uses a Retard Roller. (Laser printers also use this roller.)

New design of PF/ASF change mechanism. (Operating principle same as

previous.)

2.1.4.1 Drive Process

1. The motion of the PF Motor is always transmitted to the Combination Gear

Ratchet 65.6 but not transmitted to the LD Roller.

2. After receiving the paper feed command, the Carriage Unit contacts the A or B

ASF Trigger Lever.

3. At this point, the Change Lever extends in the direction of arrow C, locking the

Clutch mechanism.

4. The motion of Combination Gear Ratchet 65.6 is transferred to Clutch Gear 1.

5. LD Roller Gear 2 rotates one time (LD Roller rotates once), and then the LD

Roller is stopped by the Clutch Gear again contacting the Change Lever.

ASF trigger lever

B

A

Change lever

2.1.3 Paper Feeding Motor Specification

Table 2-2. PF motor Specification

Items Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Coil resistance 22.3Ω ± 25% (per phase at 25 degree)

Inductance 17.3mH ± 25% (1KH 1VmA)

Drive method PWM

Driver IC LB11947

C

LD roller

Retard roller

Combination gear ratchet 65.6

Figure 2-1. Drive Process

2

1

OPERATING PRINCIPLES Overview 17

Page 16

EPSON Stylus C82 Revision A

2.1.5 Ink System Mechanism

With this printer, when the PF Motor turns, power is always transmitted to the ink

system.

2.1.5.1 Pump Unit & Wiper mechanism

Table 2-3. PF motor rotational direction & Ink system mechanism

Directions Functions

Counterclockwise

Clockwise

(*1)

(*1)

(*1): The PF Motor rotational direction = seen from the left side of the printer.

•Set wiper.

•Draw ink.

• Set CR lock lever.

• Reset wiper.

•Release pump.

• Reset CR lock lever.

2.2 Electrical Circuit Operating Principles

The electric circuit of the Stylus C82 consists of the following boards.

Main board : C486 MAIN Board

Power supply board : C486 PSB/PSE Board

Panel board : C486 PNL Board

This section provides Block diagram of both C486 MAIN Board and C486 PSB/PSE

Board.

2.2.1 C486 PSB/PSE Board

+42VDC

F51

Over Current

Protection

D51

+5VDC

ZD52, 87

Q91, ZD51

+42VDC Line

Constant Control

C51

Smoothing

Circuit

TRANS(T1)

Smoothing

Circuit

ZD53

+5VDC Line

Over Voltage

Limitation

+42VDC Line

Over Voltage

Limitation

Q1C11

Main Switching

Circuit

ZD90

C84, Q84

Power Drop

Delay Circuit

PSC Signal from

Main board

+42VDC Line

Drop Limitation

PC1,

PC2

Q2, Q31

Abnormal Feed

Photo

Coupler

back circuit

AC Input

Over Curren t

Protection

Filter Circuit

Full Wave

Rectifier circuit

DB1L1, C1F1, TH1

Figure 2-2. C486 PSB/PSE Board Block Diagram

OPERATING PRINCIPLES Electrical Circuit Operating Principles 18

Page 17

EPSON Stylus C82 Revision A

2.2.2 C486 MAIN Board

Table 2-4. C486 MAIN Board Major Components and Primary Functions

IC Location Function

ROM IC1

Transceiver IC3

Reset regulator IC4

D-RAM IC5

EEPROM IC6 1 kbit capacity for default setting or adjusted value.

Motor Driver IC8

Head Driver 1 IC9 For creating trapezoidal waveform, 5V drive

ASIC IC10

Head Driver 2 Q2, Q3 Based on IC9 control, trapezoidal waveform creates, 42V drive

8 Mbit ROM program for CPU provided with CG table, 3.3V

drive (not DOS compliant)

Transceiver IC for the Centronics I/F response to IEEE1284 and

ECP more, Data transfer by DMA, 3.3V drive

Formed reset signals shown below.

1. Dropping 42V line to 36.3V, 2. Dropping 5V line to 4.2V

4 Mbit RAM 2-CAS type, 16 bit bus, 5V and 3.3V drive provide

page access functions.

For driving both CR and PF motors, PWM control by program

timer, 5V regulation, 42V drive

CPU (equivalent of H8S/2323), Internal 8Kbit RAM, Internal

MASK ROM, 24MHz, 3.3Vdrive

OPERATING PRINCIPLES Electrical Circuit Operating Principles 19

Page 18

EPSON Stylus C82 Revision A

E01A38CA

ASIC (IC10)

+42V

Parallel

I/F

ROM

(IC1)

DATA

D-RAM

(IC5)

CN1

D0 (#164), D1 (#169)

D2 (#174), D3 (#4)

D4 (#5), D5 (#176)

D6 (#171), D7 (#166)

D8 (#167), D9 (#172)

D10 (#1), D11 (#6)

DATA

ADDRESS

ADDRESS

DATA

Transceiver

(IC3)

D12 (#2), D13 (#173)

D14 (#168), D15 (#163)

A1 (#154), A2 (#152)

A3 (#149), A4 (#147)

A5 (#144), A6 (#141)

A7 (#139), A8 (#136)

A9 (#133), A10 (#135)

A11 (#138), A12 (#140)

A13 (#143), A14 (#146)

A15 (#148), A16 (#151)

A17 (#153), A18 (#134)

A19 (#61)

DATA0 (#115)

to

DATA4 (#111)

DATA5 (#109)

to

DATA7 (#107)

/ACK (#122), BUSY (#121)

PE (#119), SLCT (#118)

/ERR (#117)

/STB (#104), /INIT (#103)

/AFXT (#102), /SLIN (#101)

LH (#106)

DIR (#124)

HD (#123)

/HWFLR (#36)

HWSDATA (#39)

HWSCLK (#30)

/HWSLAT (#31)

HWCLK1 (#33)

HWCLK2 (#34)

HWA0 (#40)

to

HWA4 (#44)

RST_DCMCU (#89)

PWM1_MCU (#82)

PWM2_MCU (#87)

DATA1_MCU (#81)

CLK1_MCU (#83)

DATA2_MCU (#86)

CLK2_MCU (#88)

ECS (#128)

ECK (#127)

EDO (#126)

EDI (#125)

ENCA_PFDCU (#54)

ENCB_PFDCU (#55)

SWA1 (#72)

DATA

Motor driver

CN12

Head

driver 1

(IC9)

(IC8)

EEPROM

(IC6)

CN4

F1

F2

Q2

Q3

CN14

CN13

CN8

Printhead

CN9

CR motor

PF motor

PF Encoder

PE sensor

USB

CN3

Reset regulator

(IC4)

DP (#98)

DM (#99)

USBLH (#95)

MRES (#129)

/NMI (#131)

/RESET (#130)

PSC0 (#69)

LED2 (#66) to LED0 (#68)

SW0 (#57) to SW2 (#59)

CN19

CN20

PS Board

Panel Board

Table 2-5. Block diagram for the C486 MAIN Board

OPERATING PRINCIPLES Electrical Circuit Operating Principles 20

Page 19

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

CHAPTER

TROUBLESHOOTING

3

Page 20

EPSON Stylus C82 Revision A

3.1 Overview

This chapter describes how to troubleshoot problems.

W A R N I N G

C H E C K

P O I N T

3.1.1 Troubleshooting With LED Error Indications

3.1.1.1 Paper Out/Double Feed Error

Is the PE Sensor disconnected from the Main Board?

Be careful to avoid electric shocks when checking the electrical

circuit boards (C486 MAIN, PSE and B circuit boards) while the

power is turned on.

Touching an FET, transistor or heat sink with one hand while

touching a metal part of the mechanism with the other hand

could result in an electric shock, so carefully avoid this.

After initial filling of ink has been repeated several times,

immediate moving or tilting of the printer could result in leaking

of ink that has not been completely absorbed by the Waste Ink

Pad. When initial filling of ink has been repeated several times,

check the ink remaining in the tip of the Waste Ink Tube and the

waste ink not absorbed by the Waste Ink Pad before moving the

printer.

Disassembly and reassembly of parts is often required when

identifying the causes of problems. The parts should be

disassembled and re-assembled correctly while referring to

"Chapter 4 Disassembly and Assembly" so that the operation

and status of each check item can be correctly verified.

Some individual part and units may require adjustment once

they are removed or replaced. If removing or replacing parts

which have specific instructions for adjustment included in

"Chapter 4 Disassembly and Assembly", be sure to make these

adjustments after repairing the problem location.

3.1.1.2 Ink Out

The Ink Out indicator did not recover immediately after installation of the Ink

Cartridge. Press the Ink Switch and the Ink Out indicator will go out after the

Carriage Unit returns to the HP. (Use same procedure for Ink Low after installing

other Ink Cartridge.)

3.1.1.3 Fatal Error

There are 3 types of Fatal Errors: Carriage Error, PF Error and Head Hot Error.

1. Press the Power Switch, then turn on power again. (If it does not recover, see

Table 3-1.)

Table 3-1. Carriage Error and PF Error Check Points

<Situation> <Check point>

• Does the CR Motor turn? • CR motor

• CR motor connector

• Linear scale position

• CR encoder connector

• Does the PF Motor turn? •PF motor

• PF motor connector

• Rotary scale position

• PF encoder connector

2. Possible Head Hot Error Verification

Before eliminating the cause of the Error, use Adjustment Program to check

EEPROM 2Dh error history.

2Dh → 0Dh : Indicates that Head Hot Error was generated for black

nozzle line.

2Dh → 0Eh : Indicates that Head Hot Error was generated for color

nozzle line.

Is the PE Lever properly operating?

C A U T I O N

1. Ink Out is not activated by Head Hot Error.

2. Automatic cleaning starts next time power is turned on.

3. Head Hot Error (Fatal Error) is generated only when a large

quantity of Dot Missing is generated.

TROUBLESHOOTING Overview 22

Page 21

EPSON Stylus C82 Revision A

3. Fatal Error Reference Information (Aside from Head Hot Error)

Fatal Error cause can be analyzed by referring to EEPROM Address and Error

Code shown below.

Table 3-2. [2Dh address: Sequence error]

Address Error Condition Address Error Condition

00h No error 05h Mechanism edge detection error

01h Memory free error 06h CR home seeking 1 error

02h Board hot/cold error 07h CR home seeking 2 error

03h DRAM error 08h CR lock retry error

04h Timer IC initialize error 09h to 0Ch Motor sequence error

Table 3-3. [2Eh address: DC motor error]

Address Error Condition Address Error Condition

00h No error FBh to FFh PF motor control error

01h to 0Ch CR motor control error

C A U T I O N

When printer cannot detect Ink Out, a Head Hot Error is handled

as a Fatal Error and displayed. Because of this, the printer makes

every effort to automatically recover from Ink Out Error without

expecting that the existing Ink Cartridge had to have been

replaced.

3.1.1.5 Dot missing 1

1. Use operation from Panel or Driver Utility to execute cleaning 4~5 times.

2. Use Adjustment Program to execute strongest cleaning 2~3 times.

3. Use Adjustment Program to execute Ink Charge.

4. Allow printer to sit for one day and check printing again the next day. If problem

continues, replace the Printhead.

3.1.1.6 Dot missing 2

When a specific single dot is missing only with color printing and cannot be recovered,

check whether or not the Stylus C80 Printer Driver is being used. With the Stylus C82,

59 nozzles are used for each color nozzle, so 1 dot will be missing if the Stylus C80

Printer Driver is used.

3.1.1.4 Paper Supply Faults

1. Use a cleaning sheet to clean the Retard Roller and LD Roller inside the ASF Unit.

(See "Chapter 6 Maintenance" for details.)

2. Clean the Retard Roller or LD Roller with a cloth moistened with a cleaning

solution like alcohol.

3. Replace the Retard Roller or LD Roller. (It is recommended that both be replaced

at the same time.)

TROUBLESHOOTING Overview 23

Page 22

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

CHAPTER

DISASSEMBLY AND ASSEMBLY

4

Page 23

EPSON Stylus C82 Revision A

4.1 Overview

This section describes procedures for disassembling the main components of the

product. Unless otherwise specified, disassembly units or components can be

reassembled by reversing the disassembly procedure. Things, if not strictly observed,

that could result in injury or loss of life are described under the heading “WARNING”.

Precautions for any disassembly or assembly procedures are described under the

heading “CAUTION”. Chips for disassembling procedures are described under the

heading “CHECK POINT”.

If the assembling procedure is different from the reversed procedure of the

disassembling, the procedure is described under the heading “REASSEMBLY”.

Any adjustments required after disassembling the units are described under the heading

“ADJUSTMENT REQUIRED”. When you have to remove any units or parts that are

not described in this chapter, refer to the exploded diagrams in the appendix.

Read precautions described in the next section before starting.

4.1.1 Precautions

See the precautions given under the handling “WARNING” and “CAUTION” in the

following column when disassembling or assembling the product.

W A R N I N G

Disconnect the power cable before disassembling or assembling

the printer.

If you need to work on the printer with power applied, strictly

follow the instructions in this manual.

Wear protective goggles to protect your eyes from ink. If ink gets

in your eye, flush the eye with fresh water and see a doctor

immediately.

Always wear gloves for disassembly and reassembly to avoid

iujury from sharp metal edges.

To protect sensitive microprocessors and circuitry, use static

discharge equipment, such as anti-static wrist straps, when

accessing internal components.

Never touch the ink or wasted ink with bare hands. If ink comes

into contact with your skin, wash it off with soap and water

immediately. If irritation occurs, contact a physician.

Make sure the tip of the waste ink tube is located at correct

position when reassembling the waste ink tube. Otherwise it will

cause ink leakage.

Avant de commencer, assurez vous que l’imprimante soit eteinte

W A R N I N G

et que le cordon d’alimentation soit debranche.

Veillez a jeter les piles usagees selon le reglement local.

C A U T I O N

When transporting the printer after installing the ink cartridge,

be sure to pack the printer for transportation without removing

the ink cartridge.

Use only recommended tools for disassembling, assembling or

adjusting the printer. (Refer to Table 4-1 "Special Tool List".)

Observe the specified torque when tightening screws.

Apply lubricants and adhesives as specified. (Refer to Chapter 6

for details.)

Make the specified adjustments when you disassemble the

printer. (Refer to Chapter 5 for details.)

4.1.2 Tools

Use only specified tools to avoid damaging the printer.

Table 4-1. Special Tool List

Name Supplier Parts No.

Phillips Screw Driver (No.1) EPSON 1080530

Phillips Screw Driver (No.2) EPSON 1080532

Tweezers EPSON 1080561

Acetate Tape EPSON 1003963

4.1.3 Screws

The screws used in the printer are as shown in Table 4-2. Make sure you always use the

correct type and number of screws for the assembling part.

Table 4-2. Screw Specifications

Abbreviation Description

C.B.P Cross-recessed Binding Head P-tight screw

C.B.S Cross-recessed Binding Head S-tight screw

C.C Cross-recessed Cup Head screw

DISASSEMBLY AND ASSEMBLY Overview 25

Page 24

EPSON Stylus C82 Revision A

4.2 Disassembly

The flowchart below shows step-by-step disassembly procedures. When disassembling each unit, refer to the page number shown in the figure.

Upper Housing

Removal

4.2.1.1 P.27

Lower Housing/

Printer Mechanism

Removal

4.2.1.4 P.29

Paper Eject Frame

Unit Removal

4.2.3.10 P.40

EJ Roller Unit

Removal

4.2.3.11 P.41

Front Paper Guide

Removal

4.2.3.12 P.41

ASF Unit Removal

4.2.3.1 P.32

Printhead Removal

4.2.1.3 P.28

Linear Scale

Removal

4.2.3.5 P.37

CR Guide Shaft/

Carriage Unit

Removal

4.2.3.6 P.37

PE Sensor/

PE Sensor Holder/

PE Lever Removal

4.2.3.3 P.35

Panel Housing/

C486 PNL Board

Removal

4.2.1.2 P.27

Ink System Unit

Removal

4.2.3.7 P.39

Upper Paper Guide

Removal

4.2.3.13 P.42

C486 Main Board

Removal

4.2.2.1 P.30

C486 Main Board

Removal

4.2.2.1 P.30

C486 PSB/PSE

Board Removal

4.2.2.2 P.32

C486 PSB/PSE

Board Removal

4.2.2.2 P.32

CR Motor

Removal

4.2.3.8 P.39

Rear Paper Guide

Removal

4.2.3.14 P.42

PF Encoder &

PF Encoder Base

Removal

4.2.3.4 P.36

PF Motor

Removal

4.2.3.9 P.40

PF Roller Unit

Removal

4.2.3.15 P.42

PF Encoder &

PF Encoder Base

Removal

4.2.3.4 P.36

PE Sensor/

PE Sensor Holder/

PE Lever Removal

4.2.3.3 P.35

* Use the flowchart to determine the shortest

procedure for the unit to be replaced, then

disassemble the printer by following that

procedure.

* The step for the unit or discrete part within the

broken line is not the shortest removal step but is

the step necessary for removing the next unit or

discrete part.

ASF Unit Removal

4.2.3.1 P.32

ASF Unit

Disassembly

4.2.3.2 P.33

Figure 4-1. Disassembling Flowchart

DISASSEMBLY AND ASSEMBLY Disassembly 26

Page 25

EPSON Stylus C82 Revision A

4.2.1 Housing Removal

4.2.1.1 Upper Housing Removal

1. Remove 4 screws (C.B.P 3x10) holding the Upper Housing.

2. Open Stacker.

C.B.P 3x10 (6±1kgf.cm) x2

Lower Housing

Figure 4-2. Upper Housing Removal 1

3. Follow the order shown in Figure 4-3 to release 5 hooks from the Lower Housing.

(Use a pair of tweezers to press hooks 1 and 2 into slots and release while pressing

in the direction of the arrow. Hooks 4 and 5 can be released by pressing them

through the slots with a pair of tweezers.)

<Left Rear Side>

C.B.P 3x10 (6±1kgf.cm) x2

Upper Housing

Stacker

<Right Rear Side>

4. While slightly lifting Upper Housing, follow the order shown below to remove (1)

1 screw (C.B.S 3x6) and (2) FFC (from C486 PNL Board). Then remove the

Upper Housing.

C486 PNL board

C.B.S 3x6 (6±1kgf.cm)

1

Disconnect

<Right Front Side>

FFC

2

Figure 4-4. Upper Housing Removal 3

4.2.1.2 Panel Housing/C486 PNL Board Removal

1. Remove Upper Housing. (See Section 4.2.1.1)

2. While pressing inward the 2 hooks holding the Panel Housing, remove the Panel

Housing by pushing it in the direction of arrow A.

Hook

4

3

Hook

<Left Side (Inner Side)>

Hook

2

<Left Front Bottom Surface>

Hook

5

1

<Right Front

Bottom Surface>

Upper Housing

A

Hook

Panel Housing

Figure 4-5. Panel Housing/C486 PNL Board Removal 1

Hooks

Figure 4-3. Upper Housing Removal 2

DISASSEMBLY AND ASSEMBLY Disassembly 27

Page 26

EPSON Stylus C82 Revision A

3. Remove 3 screws (C.B.P 3x8) holding the C486 PNL Board, then remove the

C486 PNL Board from the Panel Housing.

C.B.P 3x8 (6±1kgf.cm) x3

C486 PNL Board

Panel Housing

Figure 4-6. Panel Housing/C486 PNL Board Removal 2

4.2.1.3 Printhead Removal

1. Remove Upper Housing. (See Section 4.2.1.1)

2. Use a pair of tweezers to push and lift one side of the Spring Cartridge at a time

from the 2 slots of the Carriage Unit, then remove the Spring Cartridge from the

Carriage Unit.

3. Remove 2 screws (C.B.P (P4) 3x8) holding the Fastener Head, then remove the

Fastener Head in the direction of arrow A.

Fastener Head

A

C.B.P (P4) 3x8 (5±1kgf.cm)

<Right Front Side>

Figure 4-8. Printhead Removal 2

4. Push Carriage Lock Lever forward, then shift Carriage Unit to the left side.

5. Use the order shown below to release 4 hooks, then remove Cable Head Holder

from Carriage Unit in upward direction.

4

Cable Head Holder

Spring Cartridge

Carriage Unit

2

1

3

Carriage Lock Lever

Figure 4-9. Printhead Removal 3

Slots

<Right Front Side>

Figure 4-7. Printhead Removal 1

DISASSEMBLY AND ASSEMBLY Disassembly 28

Page 27

EPSON Stylus C82 Revision A

6. While avoiding 2 hooks, follow order shown below to remove Printhead from

Carriage Unit.

Hook Hook

2

C A U T I O N

When the FFC has been replaced, be sure to attach sponge as

shown in lower left diagram. Because double-sided tape is attached

to FFC service parts, simply installing sponge is sufficient.

Printhead

Figure 4-10. Printhead Removal 4

7. Remove 2 FFCs from the Printhead.

Printhead

A D J U S T M E N T

R E Q U I R E D

When removing or replacing the Printhead, the adjustments are

necessary. Refer to "Chapter 5 Adjustment" for the adjustment

procedure.

1

4.2.1.4 Lower Housing/Printer Mechanism Removal

1. Remove Upper Housing. (See Section 4.2.1.1)

2. Remove 4 screws (C.B.P 4x12: 3, C.B.S 3x8: 1) holding Printer Mechanism.

Sponge

FFCs

Lower Housing

C.B.P 4x12 (6±1kgf.cm) x3

Printer Mechanism

C.B.S 3x8 (6±1kgf.cm)

Figure 4-11. Printhead Removal 5

Figure 4-12. Lower Housing/Printer Mechanism Removal 1

DISASSEMBLY AND ASSEMBLY Disassembly 29

Page 28

EPSON Stylus C82 Revision A

3. As shown below, remove AC Cable Cover and Ink Tube from Lower Housing and

C486 Main Board.

AC Cable Cover : Release while pushing 2 hooks in direction of arrow

A, then remove cover by pushing out in direction of

W A R N I N G

Make sure the tip of the waste ink tube is located at correct

position when reassembling the waste ink tube. Otherwise it will

cause ink leakage.

arrow B.

Ink tube : While pressing inward both edges of retainer, remove

Ink Tube in direction of arrow C.

<Left Rear Side>

A D J U S T M E N T

R E Q U I R E D

When replacing the Printer Mechanism, the adjustments are

necessary. Refer to "Chapter 5 Adjustment" for the adjustment

procedures.

FFC

Disconnect

4.2.2 Board Removal

4.2.2.1 C486 Main Board Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

AC Cable Cover

Hook

A

B

<Center Rear Side (Inner Side)>

Hook

A

Hook

D

Retainer

Ink tube

C

<Right Front Side>

Cables

C486 Main Board

Acetate Tapes

Figure 4-13. Lower Housing/Printer Mechanism Removal 2

2. Remove all cables from C486 Main Board and peel off acetate tape in 2 places.

4. As shown above (lower left photo), while releasing hook in direction of arrow D,

lift Printer Mechanism and remove from Lower Housing.

Figure 4-14. Main Board Removal 1

<Left Rear Side>

DISASSEMBLY AND ASSEMBLY Disassembly 30

Page 29

EPSON Stylus C82 Revision A

3. Remove 4 screws (C.B.S 3x6: 1, C.B.S 3x8: 2, C.B.S 3x16: 1) holding C486 Main

When C486 Main Board has been replaced by a service part, the

Board, then remove Printer Mechanism from C486 Main Board in upward

direction.

C.B.S 3x8

(8±1kgf.cm)

C.B.S 3x6 (5±1kgf.cm)

C.B.S 3x16

(5±1kgf.cm)

C.B.S 3x8

(5±1kgf.cm)

Figure 4-15. Main Board Removal 2

W A R N I N G

The CN19 cable on the C486 Main Board has a specified

installation direction. The pin connected to the blue line of the

cable should be inserted into the Pin 1 side of the connector.

<Printer Rear Side>

W A R N I N G

C H E C K

P O I N T

installation screw holes do not have threads, as shown below.

When installing C486 Main Board to the Printer Mechanism,

metal chips that are formed in the process can become a source

for shorting the printer. For this reason, use a brush to clean 2

places in the order shown below and remove the metal chips.

Screw Installation Holes

1

2

C486 Main Board

Figure 4-17. Metal Chips Removal

C486 Main Board has no ROM and is established as a service part

by the Socket attachment.

CN19

A D J U S T M E N T

R E Q U I R E D

When replacing the C486 Main Board, the adjustments are

necessary. Refer to "Chapter 5 Adjustment" for the adjustment

procedures.

Blue Line

Pin 1

<Printer Front Side>

Figure 4-16. CN19 Connection Direction

DISASSEMBLY AND ASSEMBLY Disassembly 31

Page 30

EPSON Stylus C82 Revision A

4.2.2.2 C486 PSB/PSE Board Removal

1. Remove C486 Main Board. (See Section 4.2.2.1)

2. Remove 2 screws (C.B.S 3x6) holding C486 PSB/PSE Board.

3. After shifting C486 PSB/PSE Board temporarily in the direction of arrow A,

release the hook, then pull the board in the direction of arrow B and remove it from

the Printer Mechanism.

C.B.S 3x6 (8±1kgf.cm)

Hook

AB

C486 PSB/PSE Board

Figure 4-18. C486 PSB/PSE Board Removal

A D J U S T M E N T

R E Q U I R E D

When replacing the C486 PSB/PSE Board, the adjustments are

necessary. Refer to "Chapter 5 Adjustment" for the adjustment

procedures.

C.B.S (P4) 3x8 (8±1kgf.cm) x2

CN4

ASF Unit

Wrapped Location

Slot

Figure 4-19. ASF Unit Removal 1

4. Remove 1 screw (C.B.S 3x6) holding the LD Roller Cover and then shift LD

Roller Cover in direction of arrow A.

C.B.S 3x6

(8±1kgf.cm)

LD Roller Cover

A

<Center Rear Side>

4.2.3 Printer Mechanism Disassembly

Figure 4-20. ASF Unit Removal 2

4.2.3.1 ASF Unit Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

2. Disconnect connector CN4 from C486 Main Board, unfasten it from the wrapped

location, then remove the CN4 cable by pulling it through the slot in the ASF Unit.

3. Remove 2 screws (C.B.S (P4) 3x8) holding the ASF Unit.

DISASSEMBLY AND ASSEMBLY Disassembly 32

Page 31

EPSON Stylus C82 Revision A

5. Release the union location between Pump Frame and ASF Unit.

C A U T I O N

Be careful because pulling strongly on Pump Frame can cause it to

break.

6. Push Head Cable Cover with pair of tweezers, shift it to the right and temporarily

release its hold.

7. Allow ASF Unit to rotate in direction of arrow A, the remove ASF Unit together

with LD Roller Cover from Printer Mechanism.

A

Head Cable Cover

Pump Frame

4.2.3.2 ASF Unit Disassembly

1. Remove ASF Unit. (See Section 4.2.3.1)

2. After releasing the hook holding the Paper Back Cam, let the control of Torsion

Spring move in the direction of arrow A, then remove the Paper Back Cam from

the ASF Unit.

3. Follow order shown below to remove these items from ASF Unit: (1) Clutch Gear

and Clutch. (2) Extension Spring 1.47. (3) Change Lever. (4) Combination Gear

Ratchet 65.6.

C A U T I O N

If Clutch Gear and Clutch are not removed with a pair of

tweezers as described in Step 3, it is possible that the Extension

Spring 0.143 inside could be lost.

When removing Extension Spring 1.47, be careful not to lose it.

Change lever

3

Paper back cam

Hook

2

Extension spring 1.47

Hooks

A

Torsion

Spring

Union Location

Figure 4-21. ASF Unit Removal 3

Clutch Gear + Clutch

1

Combination gear ratchet 65.6

4

Figure 4-22. ASF Unit Disassembly 1

When installing ASF Unit, be sure to install it while Main Board

and PSB/PSE Board are not installed. If this procedure is ignored,

the Pump Frame may interfere with the ASF Unit and result in

4. Release Extension Spring 1.67 from hooks on ASF Frame and ASF Trigger Lever,

then remove spring.

damage.

C A U T I O N

When removing Extension Spring 1.67, be careful not to lose it.

DISASSEMBLY AND ASSEMBLY Disassembly 33

Page 32

EPSON Stylus C82 Revision A

5. Follow the order below to remove ASF Trigger Lever from ASF Frame.

ASF Frame

3

1

2

ASF Trigger Lever

Extension spring 1.67

1'

2'

Hooks

Figure 4-23. ASF Unit Disassembly 2

6. Follow the order below using a common screwdriver to release the Hopper (left

side) attachment from the ASF Frame, then remove the Hopper from the ASF

Frame.

Hook

1

Hopper

4

8. While spreading the left side surface of the ASF Frame toward the outside, follow

the order shown below to remove LD Roller Shaft.

ASF Frame

Compression spring 2.9

LD Roller Shaft

1

2

3

Figure 4-25. ASF Unit Disassembly 4

9. Release Extension Spring 2.25 from hooks on ASF Frame and Retard Roller

Holder, then remove spring.

10. Pull the protrusion of the Retard Roller Holder fastened to the ASF Frame away

from the ASF Frame in the direction of the arrow for one side and then the other.

Then remove Retard Roller along with Retard Roller Holder.

3

2

Figure 4-24. ASF Unit Disassembly 3

7. Allow the Compression Spring 2.9 to rotate to the left from the ASF Frame, then

remove it.

Extension spring 2.25

Hook

Hook

Retard Roller Holder

<ASF Frame Bottom Surface>

Figure 4-26. ASF Unit Disassembly 5

DISASSEMBLY AND ASSEMBLY Disassembly 34

Page 33

EPSON Stylus C82 Revision A

4.2.3.3 PE Sensor/PE Sensor Holder/PE Lever Removal

ASF Unit Assembly Points

1. Set Clutch Spring (when assembling Clutch and Clutch Gear)

2. Position Paper Back Support Lever (when setting the Paper

Back Cam to LD Roller Shaft at first step)

3. Align phase (when inserting Paper Back Cam into LD Roller

Shaft at last step)

1

Clutch Gear Clutch

3

Paper Back

Cam

Clutch Gear

22'Correct State

Paper Back Support Lever

Wrong State

1. Remove ASF Unit. (See Section 4.2.3.1)

2. Disconnect connector from PE Sensor.

3. While lifting PE Sensor Holder upwards, use a pair of tweezers to release 4 hooks

holding the PE Sensor Holder starting from the upper direction of the printer by

following the order shown below. Then remove the PE Sensor and PE Lever along

with the PE Sensor Holder.

3 4

Hooks

1

<Front Side>

2

PE Sensor

Hook

PE Sensor Holder

PE Lever

Hooks

Connector

Hook

<Rear Side>

Figure 4-28. PE Sensor/PE Sensor Holder/PE Lever Removal 1

4. Release 3 hooks fastening the PE Sensor to the PE Sensor Holder, then remove PE

Sensor from the PE Sensor Holder.

5. Follow the order shown below to remove the PE Lever along with Torsion Spring

0.28 from the PE Sensor Holder.

Hooks

Figure 4-27. Assembly Points

PE Sensor

Torsion Spring 0.28

1

2

PE Lever

Figure 4-29. PE Sensor/PE Sensor Holder/PE Lever Removal 2

DISASSEMBLY AND ASSEMBLY Disassembly 35

Page 34

EPSON Stylus C82 Revision A

There are 2 types of the Rotary Scale, the Film type that has been

Condition of PE Lever and Torsion Spring 0.28 after installation.

Torsion Spring 0.28

PE Lever

Figure 4-30. Condition of PE Lever after installation.

4.2.3.4 PF Encoder & PF Encoder Base Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

2. Release 4 hooks holding PF Encoder Base, then remove PF Encoder Base along

with PF Encoder from Printer Mechanism.

Hooks

PF Encoder Base

Rotary Scale

PF Encoder

<Left Side>

C A U T I O N

available since first mass production and a new Plastic type.

Needed information about details and repair are given below.

1. In the America, the Film type Rotary Scale available since first mass

production has been introduced for patent considerations. In another

development, an all new Plastic type Rotary Scales have been

introduced.

2. Concerning functioning, because the Film type and Plastic type are

completely interchangeable, PF Roller Unit and Printer Mechanism

service parts are continuing with the Film type regardless of the

developments.

3. After patent concerns are settled in America, both new products and

service parts (PF Roller Unit and Printer Mechanism) will use the

new Plastic type.

4. Points that should be considered for repair are shown below with

relationships between Rotary Scale type and PF Encoder Base type.

Table 4-3. Rotary Scale and PF Encoder Base Relationships

Type of PF Encoder Base

Type of Rotary Scale

Film type Yes No (*1)

Plastic type Yes (*2) Yes

"Yes" means exchangeability between PF Encoder Base and Rotary

Scale. "No" means not exchangeability between these parts.

(*1): In this case, use the Long Horn Type for the PF Encoder Base.

(*2): In this case, because the horn becomes an obstacle, it is

necessary to cut off the horn. After consulting the diagram

below to confirm the correct location for cutting the horn of the

PF Encoder Base, use nippers to cut off the horn.

Long horn type No horn type

Long horn type

(1108620)

No horn type

(1214696)

Figure 4-31. PF Encoder & PF Encoder Base Removal

Cut Location

Figure 4-32. PF Encoder Base Cut Location

DISASSEMBLY AND ASSEMBLY Disassembly 36

Page 35

EPSON Stylus C82 Revision A

4.2.3.5 Linear Scale Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

2. Release Extension Spring 2.94 from Printer Mechanism hook 1.

3. Release right edge of Linear Scale from Printer Mechanism hook 2.

4. Remove Linear Scale by pulling it to the left side from back of Carriage Unit.

5. Allow Linear Scale to rotate 90°, release it from Printer Mechanism hook 3, then

remove the Linear Scale along with Extension Spring 2.94 from the Printer

Mechanism.

Assembly Point

Hook 1

Extension spring 2.94

<Left Side> <Right Side>

Linear Scale

Hook 3

Figure 4-33. Linear Scale Removal

Linear Scale Assembly Point

Pass the Linear Scale through the CR Encoder on the rear side

of the Carriage Unit.

Hook 2

4.2.3.6 CR Guide Shaft/Carriage Unit Removal

1. Remove Linear Scale. (See Section 4.2.3.5)

2. Use a common screwdriver to release Extension Spring 26.46 from hooks on

Pulley Driven Holder and Printer Mechanism, then remove spring.

3. Shift Pulley Driven Holder in direction of arrow A, the remove it in direction of

arrow B.

Pulley Driven Holder

Extension Spring 26.46

Hook

Figure 4-35. CR Guide Shaft/Carriage Unit Removal 1

4. Follow order shown in Figure 4-36 (lower right photo) to remove these items from

the Printer Mechanism: (1) Spacer. (2) PG Lever. (2') Torsion Spring 67.78. (3)

Leaf Spring. (4) 1 Screw (C.B.S (P4) 3x6). (5) Bushing.

5. Follow order shown in Figure 4-36 (lower left photo) to remove these items from

the Printer Mechanism: (6) Spacer. (7) 1 Screw (C.B.S (P4) 3x6). (8) Bushing.

B

A

Hook

<Right Rear Side>

CR Encoder

Linear Scale

<Carriage Unit Rear Side>

C H E C K

P O I N T

The Bushings at both sides of the Printer Mechanism can be

released from their attachment by allowing the printer to rotate

rearward.

Figure 4-34. Linear Scale Position

DISASSEMBLY AND ASSEMBLY Disassembly 37

Page 36

EPSON Stylus C82 Revision A

6. Remove CR Guide Shaft from Printer Mechanism in direction of arrow C while

taking care not to damage slots in Printer Mechanism.

7. Allow Carriage Unit to rotate in direction of arrow D and remove Carriage Unit

from Printer Mechanism.

Carriage Unit

10

Connector

CR Guide Shaft

9

D

FFC

Relay Board

Slot

C

<Right Side><Left Side>

PG lever

3

2

Leaf

spring

Spacer

1

Removal

Direction

2'

Torsion spring

67.78

7

C.B.S (P4) 3x6

Bush

8

Spacer

6

(6±1kgf.cm)

Hooks

Bush

5

C.B.S (P4) 3x6

4

(6±1kgf.cm)

Figure 4-36. CR Guide Shaft/Carriage Unit Removal 2

8. Disconnect FFC from connector on Relay Board of Carriage Unit, then remove

Carriage Unit.

C A U T I O N

A D J U S T M E N T

R E Q U I R E D

Figure 4-37. CR Guide Shaft/Carriage Unit Removal 3

Be careful when installing the Bushings at each side of the Printer

Mechanism because the Left Bushing and Right Bushing have

different shapes. (See Figure 4-36)

Leaf Spring Installation

Leaf spring

Bush

PG lever

Figure 4-38. Leaf Spring Installation

When removing or replacing the CR Guide Shaft/Carriage unit,

the adjustments are necessary. Refer to "Chapter 5 Adjustment"

for the adjustment procedure.

DISASSEMBLY AND ASSEMBLY Disassembly 38

Page 37

EPSON Stylus C82 Revision A

4.2.3.7 Ink System Unit Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

2. Remove 2 screws ((1)C.B.S 3x8, (2) C.B.S 3x6) holding the Ink System Frame,

then remove the Ink System Frame from the Printer Mechanism.

3. Remove 2 screws ((3)C.B.S 3x8, (4) C.B.S 3x6) holding the Ink System Frame

from the Printer Mechanism.

C A U T I O N

Use a pair of tweezers to replace the Cleaner Blade. While doing

this, do not touch the Printhead with the tweezers. In addition, do

not touch the Printhead with bare hands.

Contact Location

0 Digit Flashing Box

1

Push & lift

2. C.B.S 3x6 (8±1kgf.cm)

Ink System Frame

4. C.B.S 3x6 (8±1kgf.cm)

2

Ink System Unit

3. C.B.S 3x8 (8±1kgf.cm)

1. C.B.S 3x8 (8±1kgf.cm)

Figure 4-39. Ink System Unit Removal

4. When ASF Unit is installed, release union location of Pump Frame and ASF Unit.

(See Section 4.2.3.1 Step 4)

5. Remove Ink System Unit from the Printer Mechanism.

6. Follow the order shown above to remove the 0 Digit Flashing Box from the Printer

Mechanism.

Cleaner Blade

Figure 4-40. Cleaner Blade Handling

4.2.3.8 CR Motor Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

2. Disconnect CN14 connector from C486 Main Board.

3. Remove 1 screw (C.C 3x4) holding CR Motor, then remove CR Motor.

Label side

C.C 3x4 (3±1kgf.cm)

CR Motor

<Left Side>

Figure 4-41. CR Motor Removal

DISASSEMBLY AND ASSEMBLY Disassembly 39

Page 38

EPSON Stylus C82 Revision A

Installation of screws holding PF Motor

1. Follow order shown in lower left diagram to set screws

temporarily.

2. Pull PF Motor in direction shown by arrow in lower left

diagram, then while maintaining tension on the Timing Belt

completely fasten the PF Motor. (Completely tighten.)

When installing the PF Motor, the label of the PF Motor should

not be visible from the rear side of the Printer Mechanism. If the

label is visible, rotate it 180°°°° and reinstall it.

A D J U S T M E N T

R E Q U I R E D

When installing CR Motor, install it with the label of the motor

facing upwards.

When replacing the CR Motor, the adjustments are necessary.

Refer to "Chapter 5 Adjustment" for the adjustment procedure.

4.2.3.9 PF Motor Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

2. Disconnect CN13 connector from C486 Main Board.

3. Remove 2 screws (C.C 3x4) holding PF Motor, then remove PF Motor.

No label side

1

C.C 3x4 (3±1kgf.cm)

2

PF Motor

<Left Side>

Figure 4-42. PF Motor Removal

A D J U S T M E N T

R E Q U I R E D

When removing or replacing the PF motor, the adjustments are

necessary. Refer to "Chapter 5 Adjustment" for the adjustment

procedure.

4.2.3.10 Paper Eject Frame Unit Removal

1. Remove Printer Mechanism. (See Section 4.2.1.4)

2. While releasing the hooks at each side (2 hooks) holding the Paper Eject Frame

Unit, let it rotate in the direction of arrow A, then remove it upwards.

Hook

A

Paper Eject Frame Unit

Hook

Figure 4-43. Paper Eject Frame Unit Removal

DISASSEMBLY AND ASSEMBLY Disassembly 40

Page 39

EPSON Stylus C82 Revision A

4.2.3.11 EJ Roller Unit Removal

1. Remove Paper Eject Frame Unit. (See Section 4.2.3.10)

2. Remove Grounding Wire from Printer Mechanism.

3. Release hook for Bushing 5 located at each side of EJ Roller Unit, then let Bushing

5 rotate 90° upwards.

4. Remove EJ Roller Unit along with 3 Holders in upwards direction.

Bush 5

Hook

Grounding Wire

EJ Roller Unit

Holders

Figure 4-44. EJ Roller Shaft unit Removal

Bush 5

Hook

4.2.3.12 Front Paper Guide Removal

1. Remove EJ Roller Unit. (See Section 4.2.3.11)

2. Remove 2 screws (C.B.S 3x6) holding Front Paper Guide.

3. Remove Front Paper Guide upwards while being careful that the Front Paper

Guide hook at the left side does not touch Spur Gear 28.8.

Front Paper Guide

Hook

Spur Gear 28.8

Figure 4-46. Front Paper Guide Removal

When installing Front Paper Guide, be careful not to damage Spur

Gear 28.8.

C.B.S 3x6 (8±1kgf.cm)

When installing EJ Roller Unit, be careful about the direction of

the CR Lock.

Upper

CR Lock

Lower

Figure 4-45. CR Lock Direction

DISASSEMBLY AND ASSEMBLY Disassembly 41

Page 40

EPSON Stylus C82 Revision A

4.2.3.13 Upper Paper Guide Removal

1. Remove Front Paper Guide and PE Sensor Holder. (See Section 4.2.3.12 and

4.2.3.3)

2. Release 2 hooks holding each Extension Spring 4.07, then remove Extension

Spring 4.07 (4 springs).

3. Follow order shown below to remove Upper Paper Guide from Printer

Mechanism.

Rear Paper Guide

B

A

Hook

Extension Spring 4.07

Upper Paper Guide

Hooks Hooks

1

2

<Rear Side>

Figure 4-47. Upper Paper Guide Removal

4.2.3.14 Rear Paper Guide Removal

1. Remove Upper Paper Guide and C486 PSB/PSE Board. (See Section 4.2.3.13 and

4.2.2.2)

2. Release Rear Paper Guide from right side hook, then shift Rear Paper Guide in

direction of arrow A.

3. Release 2 hooks fastening Rear Paper Guide to PF Roller Unit, then remove Rear

Paper Guide by pushing it in direction of arrow B.

HookHook PF Roller Unit

Figure 4-48. Rear Paper Guide Removal

When installing Rear Paper Guide, if hooks are not completely

fastened, the ASF Unit cannot be properly set.

4.2.3.15 PF Roller Unit Removal

1. Remove Rear Paper Guide. (See Section 4.2.3.14)

2. Use tweezers to remove leg of Compression Spring 4.89 from Printer Mechanism.

3. Use tweezers to release left and right Bushing 8 fastening PF Roller Unit to Printer

Mechanism, then allow the PF Roller Unit to rotate in directions shown by arrows

A and B.

4. Follow the order shown below to remove PF Roller Unit from Printer Mechanism.

Bush 8

A

3

2

1

Compression Spring 4.89

4

PF Roller Unit

B

Bush 8

Figure 4-49. PF Roller Unit Removal

DISASSEMBLY AND ASSEMBLY Disassembly 42

Page 41

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

CHAPTER

ADJUSTMENT

5

Page 42

EPSON Stylus C82 Revision A

5.1 Overview

This section describes all adjustment procedures for Stylus C82.

5.1.1 Conditions for Each Adjustment

The Stylus C82 adjustment program is Epson's first use of a sequential program for performing mechanical/electrical adjustments in an established order. The program will use an

interactive method to guide you through suitable adjustments that correspond to repairs that have actually been made. This chapter only lists the adjustment conditions.

C A U T I O N

The adjustment program only operates with PCs running Win95/Win98.

When performing ink charge for a cartridge currently in use (same as initial ink charge), an ink out error may be generated during the operation. If this

occurs, replace the ink cartridge and try the operation again.

There are mainly two functions on the Stylus C82 adjustment program. One is the sequential adjustment mode depending on your repaired/removed