Page 1

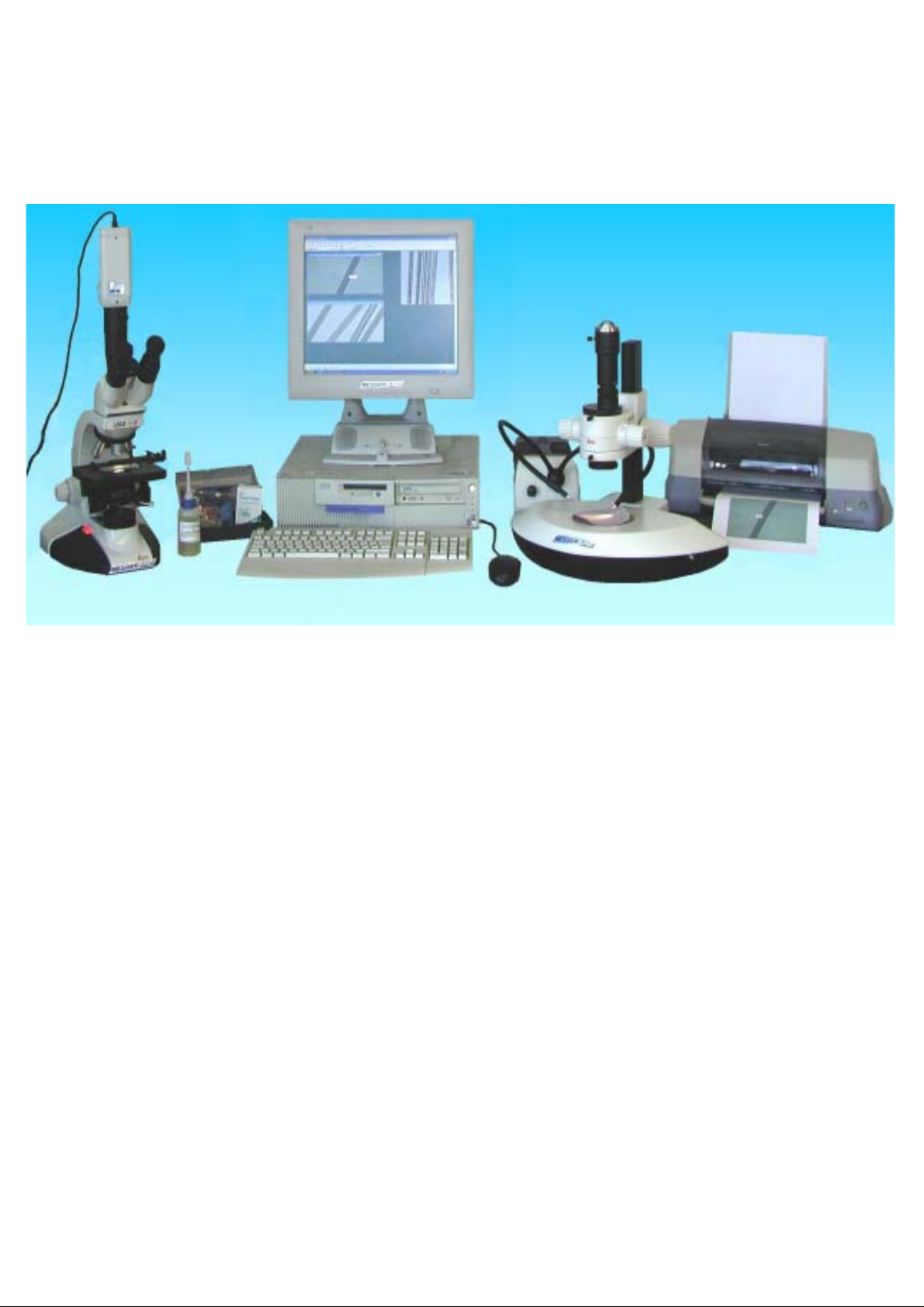

Video Analyser-2000

Code 250D

The most advanced computerised high definition system for the

microscopic analysis of fibers, yarns and fabrics.

The system is composed by:

- Leica Biological Microscope.

- Leica S tereo-Microscope.

- Professional colour Video camera with 1/2’’ CCD.

- Optical fibre illumination device (150W) with two 50 cm arms .

- «Mesdan Video Analyser» graphic card for images acquisition .

- S pecial «Mesdan Video Analyser» software.

- IBM Personal Computer.

- PHILIPS 17’’ LCD Monitor (or equivalent).

- EPSON STYLUS COLOR high quality printer.

- Sample preparation kit for longitudinal and sectional analysis (microtome, slides and

covers, immersion oil and other accessories)

- Fabric support kit for the analysis of irregularities in woven and knitted fabrics and for the

measurement of the weft and warp density per cm.

- Equipment functioning instructions and sample preparation literature.

- Calibration slide (for the system calibration control).

- Microsoft Office software package for the statistics processing and report production.

Page 2

EQUIPMENT SUITABLE TO:

- Perform in a fast and easy way the fineness analysis of single fibres, by

operating with the live image and by means of the mouse only.

- Identify the different fibres contained in a blend and analyse the composition

percentage, by operating with the live image, in accordance with the IWTO 8, IWSTM

24, ISO 137, ASTM D2130 international standards.

Longitudinal image of a cotton and a wool

fibre, to highlight how different fibres can

be easily detected.

- Check the purchased material (searching for possible foreign fibres) and identify

the type of fibre, comparing it with the fibre pictures stored in the DataBank, with both

the longitudinal and the sectional views.

Viscose fibre in longitudinal and sectional view.

Longitudinal and sectional view of a glass fibre.

Page 3

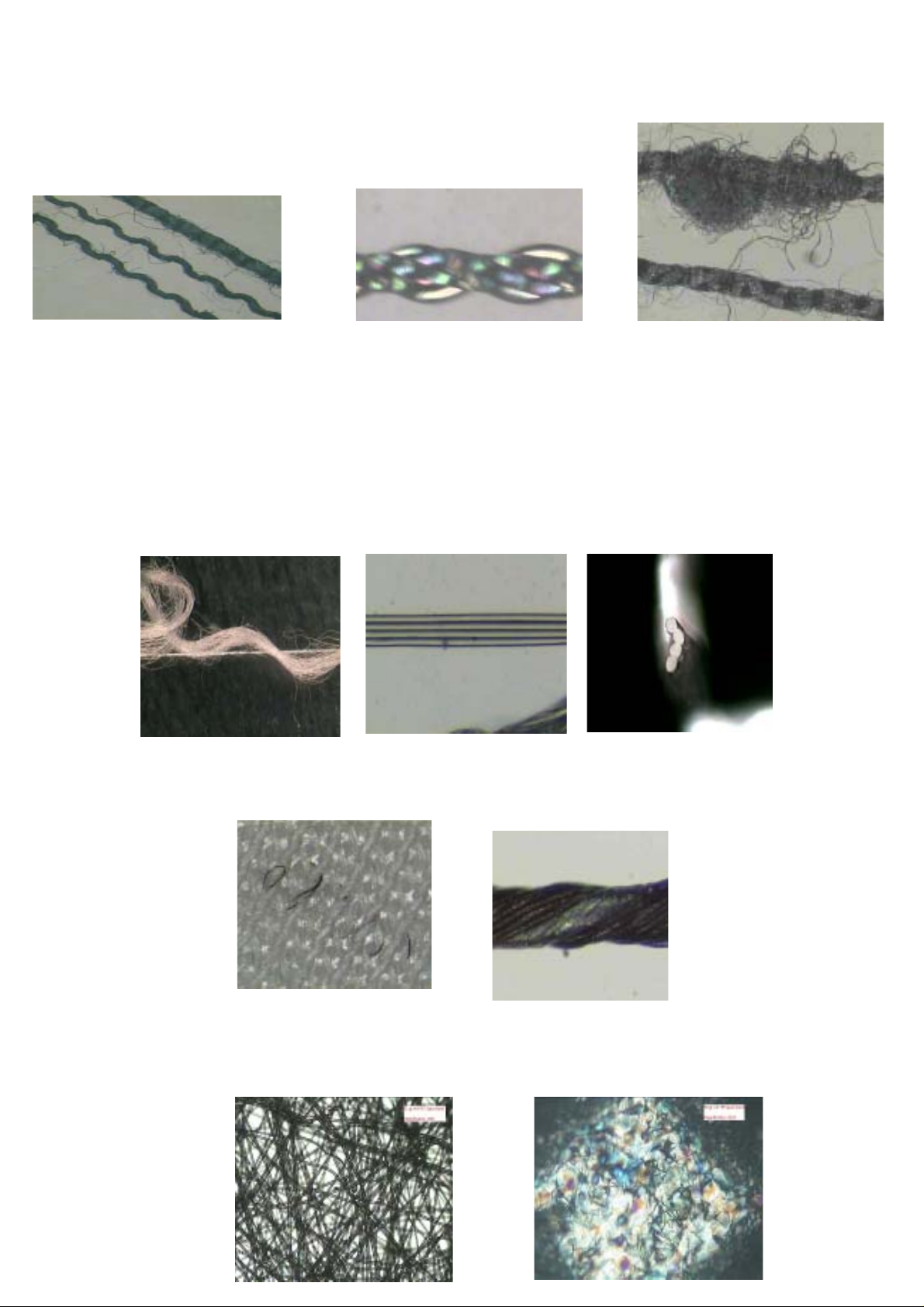

- Analyse the yarn structure and detect possible defects. Check the single threads

of a twisted yarn; check the single yarn fibres.

- Measure the count of circular section yarns and filaments in Dtex or den .

- Check and measure the quality and shape of Lycra or synthetic multifilament single

threads.

- Detect, identify and measure possible impurities contained in textile materials

(neps, pollution due to foreign fibre content in a fabric, oil or grease content in a yarn).

- Analyse the compactness of non-woven fabrics.

Page 4

- Perform a micro analysis of yarns and fibre sections.

- Measure section surfaces and perimeters.

- Analyse mechanical parts (i.e. needle points, spinnerets, etc).

Example of spinnerets

Example of a nozzle of a splicer

mingling chamber .

Example of spinning rings

Page 5

- Perform a macro analysis of a yarn section.

Example of an indigo dyed yarn section,

extracted from a denim fabric

- Reduce the fabric warp and weft density to a cm or a inch.

The operator simply traces a reference line

of desired length on the warp and weft and

identifies the number of threads.

The «Mesdan Video Analyser» software

automatically determines the number of

threads per cm (and inch).

The collected data are automatically

exported onto an excel sheet that produces

a report with the thread reduction each cm

(and inch).

Page 6

- Process, store and print the produced measurements and the minimum, medium and

maximum values, CV% and distribution graphs.

I.e. count analysis of a circular section fibre, in tex and den: data are automatically processed; the report can be either printed or

stored.

MESDAN VIDEO ANALYSER

DATA:

15/02/2005

Note: Use it ONLY if you are sure that the section of the fiber is circular.

Importante:Da utilizzare SOLO se si è certi che la sezione delle fibre sia circolare.

Test parameters/ Parametri di test

Material/ Materiale Test 630Optics X/ Ingrandimenti X

Customer/Cliente

Sample description/

Descrizione campione

Observations/ Osservazioni

101010

Test

Davide

Total measures/Misure totaliLot/Lotto 20

Standard test/ Normativa

Unit of measurement Unità di

misuraExaminer/Esaminatore

Statistical results/ Risultati statistici

Material

Materiale

Measure

number Numero

di misure

POLIESTER Nylon 0 0 0

10 10 0 0 0 11

//

microns (µm)

Mean/ Media

Max

Min

CV[%]

Dev. St

Range [%]

Specific weight

Peso specifico

(g/cm³)

Count (Dtex)

Count (Denari)

20,380 25,080

22,200 25,900

19,700 24,000

3,604 2,074 3,604 2,074 #VALORE!

0,735 0,520

12,267 7,576

1

2

1,38 1,14 1,0 1,0

2,210 2,000

1,989 1,800

Single measures/ misure singole

N° measure N°

misura POLIESTER Nylon

1 20,00 25,00

2 21,00 25,30

3 20,00 25,40

4 22,20 25,00

5 20,10 25,60

6 19,90 24,80

7 19,70 24,00

8 20,30 25,90

9 20,50 25,00

10 20,10 24,80

3

4

000

5

In accordance with the following International Standards: UNI 5423, AATCC 20,

ASTM 276-00, ASTM 2130-90, IWS TM 24, ASTM 276-00A, IWTO 8-97, ASTM D62999, UNI 1130, UNI EN 12751 ISO 137

Page 7

SYSTEM COMPOSITION

LEICA biological Microscope with professional lenses, recommended for the

longitudinal and sectional analysis of fibres and yarns.

- High quality and accuracy Microscope

- Phototube trinocular viewing body with Siedentopf

design, to adjust the interpupillary distance without

changing the focussing.

- Koehler illumination device for the phase contrast

and micro photographs (20W).

- Objective image viewing.

- Polarising filter (for a better sample viewing), blue

and green coloured filters.

- High precision focussing system.

- Slide movement device with micrometric

regulation.

- On screen magnifications: from 128X to 2000X.

- Highly accurate revolving lenses system.

LENSES IN USE OCULAR

MAGNIFICATION

4X 40X 128X 1.6

10X 100X 320X 0.65

20X 200X 640X 0.35

40X 400X 1280X 0.15

63X (optional) 630X 2016X 0.1

Note: by using the 0.50X additional lens between the microscope and the video-camera

(available as optional) the on screen magnification rate decreases by 50% and the field of

vision increases by 50%.

ON SCREEN

MAGNIFICATION

ON SCREEN FIELD

OF VISION (mm)

- The mentioned dimensions and final magnifications also depend on the hardware in use.

- The above mentioned magnifications and fields of vision have been calculated by using a 17” monitor with 1280X1024 resolution.

PROFESSIONAL VIDEO-CAMERA with 1/2’’ CCD;

compared to the 1/3’’ CCD, it has a much wider field of vision –

hence a wider surface of the sample is visualised – and a

quicker reaction to light variations. Complete with achromatic

C step connector with 1:1 lens, for the insertion on the

microscope, to give the maximum contrast, colour and planarity

quality.

Page 8

SYSTEM COMPOSITION

LEICA Stereo-Microscope for the analysis of fabrics, yarns

and mechanical parts like traveller, needles and spinnerets.

- High quality and precision Microscope

- Illuminated base. Adjustable light intensity and direction,

particularly suitable for the analysis of fabrics

- High precision focussing device

- Video-camera connector (oculars supplied as optional)

- 5 fixed focus lenses

LENS IN USE ON SCREEN

MAGNIFICATION

ON SCREEN FIELD

OF VISION (mm)

0.63X 20X 11.6

1X 32X 6.8

1.6X 51X 4.1

2.5X 80X 1.9

4X 128X 1.6

Note: by using the 0.50X additional lens between the microscope and the video-camera

(available as optional) the on screen magnification rate decreases by 50% and the field of

vision increases by 50%.

- The mentioned dimensions and final magnifications also depend on the hardware in use.

- The above mentioned magnifications and fields of vision have been calculated by using a 17” monitor with 1280X1024 resolution.

150W OPTICAL FIBRE ILLUMINATION DEVICE (cold light)

with two 50 cm semi-rigid fibre optic goosenecks. Necessary for

a perfect illumination of a sample from different adjustable angles.

Page 9

MESDAN VIDEO ANAL YSER SOFTWARE

High flexibility to perform

measurements on stored

images as well as on live images

(in accordance with International

Standards).

Measurements of lengths,

surfaces, perimeters, angles,

distances between two points

or lines or objects.

The software allows to save a

picture (complete with

measurements and comments)

into the Data Bank and to

compare the live picture with a

stored one (or more

simultaneously).

It is possible to attach to the image an informative chart, containing the material composition,

the type of lens in use and other information; this chart can be opened with a simple mouse

click and can be printed together with the picture.

All the measurements can be exported into an Excel template for the data processing (and to

produce statistics and comparative graphs). The operator can also create self-made Excel

templates, according to his requirements.

Languages in use: Italian, English, Spanish, Portuguese and Polish.

The software is provided with a readyto-use Excel template to perform on 5

different materials: fibre % content in a

blended yarn; perimeter and surface

calculation; count measurements on

perfectly circular section yarns; fabric

warp and weft density reduction to cm

or inch; general counting on lengths.

The obtained data allow to produce

reports with statistics (CV%, mean

values, percentages, etc) and

comparative graphs, that can be either

printed or stored.

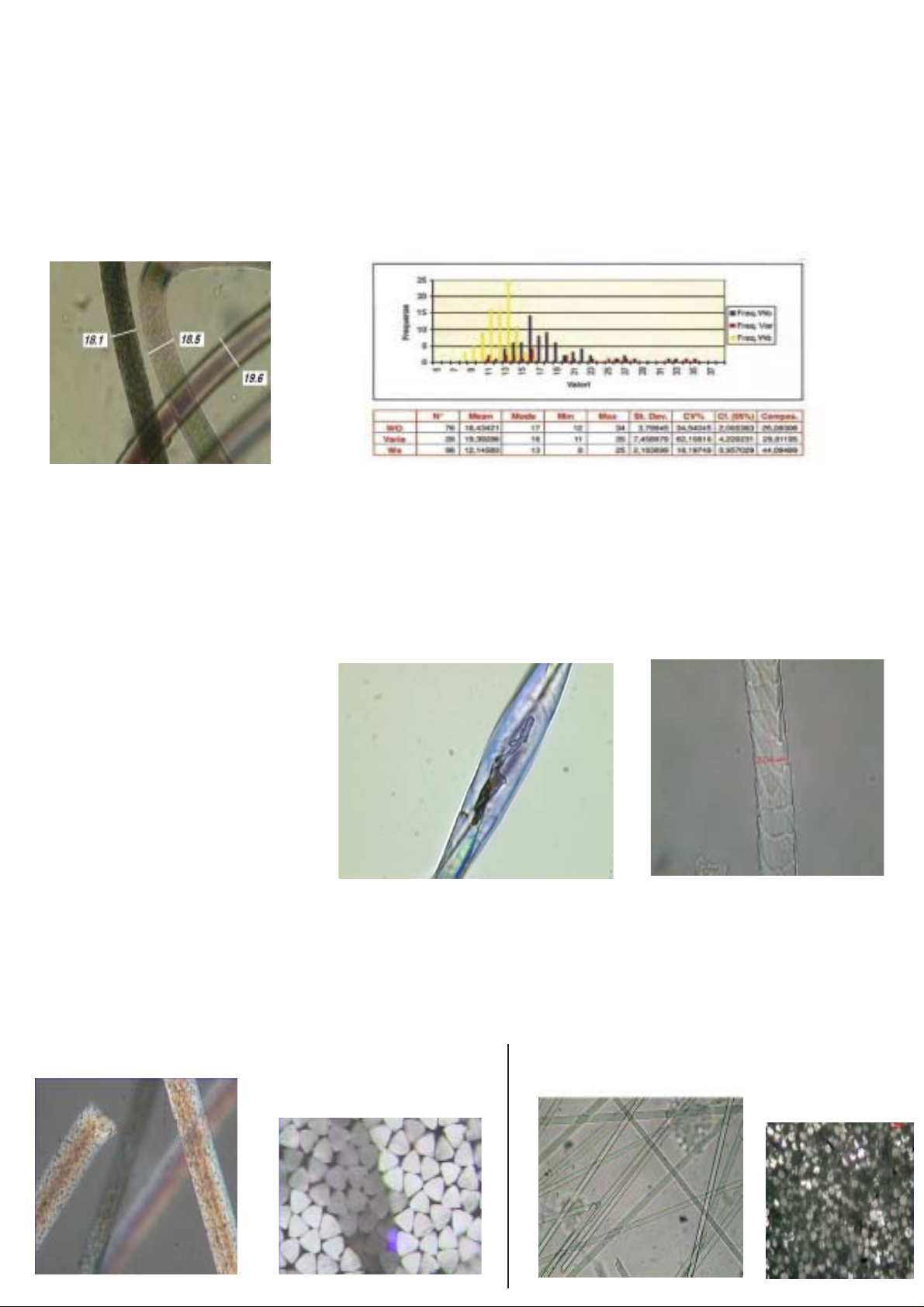

Fineness analysis of a blend with 3 components

Page 10

1) Window to display the live picture: it is possible to store and/or print a picture complete

with comments and measurements. It is then possible to perform measurements and

send them to an Excel template in order to obtain statistics.

2) View finder window on the area where measurements are being taken, in order to

guarantee the maximum measure accuracy.

3) Material chart: the name of the material to be tested is inserted here (the measurements

on the picture will be expressed in different colours); if necessary, the measurements

of every material will be inserted automatically in different Excel columns.

The simple and intuitive application bar makes the software easier to use also for less expert operators.

The software includes a Data Bank with reference pictures that can be

personalised according to the user’s needs.

In order to help the operator and guarantee the maximum accuracy, different special

features are available: i.e. light and colour adjusting can be made digitally through the

software (as well as mechanically, by operating on the microscope filters).

Page 11

Personal Computer

IBM PC complete with «Mesdan

Video Analyser» acquisition card,

Philips LCD 17’’ monitor and

photographic quality Epson printer. A

set of ink cartridges and high

definition photographic paper is

supplied as spare.

Sample preparation and analysis kit

1) Complete set for sample preparation:

scissors, tweezers, and other

accessories; blades, needles, yarn,

slides and slide holders.

2) Immersion oil.

3) Fabric analysis support.

4) Fibre section analysis plate.

Calibration slide

Necessary for the system routines calibration.

Page 12

Optional accessories (to be ordered separately)

63X LENS (for the Biological Microscope) as replacement of one of the

4 lenses supplied as standard with the microscope, it enables a 2000X on

screen magnification. Code 250 336

C-STEP CONNECTOR WITH 0.5X LENS (for the Biological

Microscope) The installation of this connector allows to halve the magnification on

screen and double the sample field of vision. Code 250 338

TRINOCULAR KIT (for the Stereo-Microscopio) to display the sample

image either on the PC monitor or in the oculars.

Code 250 340

C-STEP CONNECTOR WITH 0.5X LENS (for the Stereo-Microsco-

pio) The installation of this connector allows to halve the magnification on screen

and double the sample field of vision. Code 250 334

Additional consumables

- Set of 50 slides ** code 191 50 **

- Set of 100 slide covers ** code 191 52 **

- Immersion oil bottle ** code 191 54 **

- Pack of paper for printer ** code 250 18 **

- Set of cartridges for printer ** code 250 322 **

Loading...

Loading...