Page 1

SERVICE MANUAL

Large Format Color Inkjet Printer

EPSON Stylus Pro 11880/11880C

SEIJ07008

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2007 SEIKO EPSON CORPORATION.

Imaging Products CS, PL & Environmental Management

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) Damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURY FROM METAL PARTS WITH

SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO

THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN AIR DUSTER IS USED ON THE REPAIR AND THE MAINTENANCE WORK, THE USE OF THE AIR DUSTER PRODUCTS CONTAINING

THE INFLAMMABLE GAS IS PROHIBITED.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

CHAPTER 7.APPENDIX

Provides the following additional information for reference:

• Connectors

• ASP List

• Exploded Diagrams

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Indicates that a particular task must be carried out according to a certain

standard after disassembly and before re-assembly, otherwise the quality

of the components in question may be adversely affected.

Page 5

Revision Status

Revision Date of Issue Description

A September 25, 2007 First release

B December 26, 2007 Rivise

<Chapter 1>

• "1.2.4 Reliability/Durability" (P. 14): Ink tube’s life was revised.

• "1-6 Designated Roll Paper List"

<Chapter 2>

• "2.7 Other Mechanisms" (P. 55): Auto nozzle check was deleted.

<Chapter 3>

• "3.2 List of Error Messages" (P. 59): Some items were revised.

• "3.4 Remedies for Maintenance Requests"

• "3.5 Remedies for Service Call Error" (P. 68): Some items were revised.

<Chapter 4>

• "4.3.1.2 Unlocking the Carriage Unit" (P. 84): The procedure was revised.

• "4.3.3.1 Control Panel" (P. 92): The procedure was revised.

• "4.3.3.4 Right Side Cover"

• "4.3.3.5 Left Side Cover"

• "4.3.3.7 Rear Cover" (P. 98): The procedure was revised.

• "4.3.7.1 Printhead"

• "4.3.7.2 Ink System Unit"

(P. 147): The procedure was revised.

(P. 16): Some items were revised.

(P. 67): Some items were revised.

(P. 95): The procedure was revised.

(P. 96): The procedure was revised.

(P. 150): The procedure was revised.

Page 6

Revision Date of Issue Description

B December 26, 2007 <Chapter 5>

• "5.1.3 Parts and Units that Require Adjustments" (P. 166):

Some items were added.

• "5.1.4 Required Adjustments by Part or Unit"

• "5.1.5 Description of Adjustments"

• "5.2.7 Air Leak Check for Ink Supply System" (P. 180):

• "5.3.2 Head Rank ID"

• "5.3.5 Print Head Slant Adjustment (PF)"

• "5.3.6 Print Head Slant Adjustment (CR)"

• "5.3.18 Colorimetric Calibration (Color ID)" (P. 204): Caution was added.

• "5.3.20 Installing Firmware"

• "5.3.22 Auto Bi-D Adjustment"

• "5.3.23 Auto Uni-D Adjustment" (P. 224) Paper size was modified.

• "5.3.26 AID Inspection PG Adjustment"

• "5.3.27 AID Function Check"

• "5.5 Clear Counters" (P. 236): Some items were added.

(P. 185): Caution was added.

(P. 169): Some items were added.

(P. 221): A step was revised.

(P. 223): Paper size was modified.

(P. 228): A step was revised.

(P. 167):

Some items were modified.

Some steps were revised.

(P. 188): A step was revised.

(P. 190):A step was revised.

(P. 226): A step was revised.

Page 7

Stylus Pro 11880/11880C Revision B

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Product Description ............................................................................................ 10

1.2 Basic Specifications ............................................................................................ 12

1.2.1 Basic Specifications ................................................................................... 12

1.2.2 Electric Specifications ............................................................................... 12

1.2.3 Environmental Conditions ......................................................................... 13

1.2.4 Reliability/Durability ................................................................................. 14

1.3 Printing Specifications ........................................................................................ 15

1.3.1 Paper Feed Specifications .......................................................................... 15

1.3.2 Paper Specification .................................................................................... 15

1.3.3 Printable Area ............................................................................................ 20

1.3.4 Borderless Printing Specification .............................................................. 21

1.3.5 Cutting of Roll Paper ................................................................................. 22

1.4 Dimensions and Main Components .................................................................... 23

1.4.1 Dimensions and Weight ............................................................................. 23

1.4.2 Part Names ................................................................................................. 23

1.5 Control Panel ...................................................................................................... 24

1.5.1 Menu Mode Settings .................................................................................. 30

1.5.2 Maintenance Mode .................................................................................... 37

1.5.3 Serviceman Mode ...................................................................................... 38

Chapter 2 OPERATING PRINCIPLES

2.1 Overview ............................................................................................................ 43

2.2 Print Mechanism ................................................................................................. 46

2.3 Ink Supply Mechanism ....................................................................................... 47

2.4 Cleaning Mechanism .......................................................................................... 48

2.5 Carriage Mechanism ........................................................................................... 50

2.5.1 Carriage Movement Mechanism ................................................................ 50

2.5.2 Platen Gap Adjustment Mechanism .......................................................... 51

2.6 Paper Feed Mechanism ....................................................................................... 52

2.7 Other Mechanisms .............................................................................................. 55

2.8 Colorimetric Calibration (Color ID) Overview .................................................. 56

Chapter 3 TROUBLE SHOOTING

3.1 Overview ............................................................................................................ 58

3.1.1 Preliminary Check ..................................................................................... 58

3.1.2 Troubleshooting Procedure ........................................................................ 58

3.2 List of Error Messages ....................................................................................... 59

3.3 Remedies for Error Messages ............................................................................. 61

3.4 Remedies for Maintenance Requests ................................................................. 67

3.5 Remedies for Service Call Error ........................................................................ 68

3.6 Remedies for Print Quality Troubles .................................................................. 73

Chapter 4 DISASSEMBLY & ASSEMBLY

4.1 Overview ............................................................................................................ 76

4.1.1 Precautions ................................................................................................. 76

4.1.2 Orientation Definition ................................................................................ 78

4.1.3 Recommended Tools ................................................................................. 78

4.2 Disassembly Flowchart ...................................................................................... 79

4.3 Disassembly and Assembly Procedure ............................................................... 84

4.3.1 Basic Operations ........................................................................................ 84

4.3.2 Consumables/Accessories ......................................................................... 85

4.3.3 Housing ...................................................................................................... 92

4.3.4 Electric Circuit Components ................................................................... 105

4.3.5 Carriage Mechanism ................................................................................ 120

4.3.6 Paper Feed Mechanism ............................................................................ 137

4.3.7 Ink System Mechanism ........................................................................... 147

7

Page 8

Stylus Pro 11880/11880C Revision B

Chapter 5 ADJUSTMENT

5.1 Overview .......................................................................................................... 166

5.1.1 Precautions ............................................................................................... 166

5.1.2 Adjustment Workflow ............................................................................. 166

5.1.3 Parts and Units that Require Adjustments ............................................... 166

5.1.4 Required Adjustments by Part or Unit ..................................................... 167

5.1.5 Description of Adjustments ..................................................................... 169

5.1.6 Tools for Adjustments ............................................................................. 172

5.1.7 Adjustment Program Basic Operations ................................................... 173

5.2 Mechanical Adjustment .................................................................................... 174

5.2.1 CR Timing Belt Tension Adjustment ...................................................... 174

5.2.2 PF Timing Belt Tension Adjustment ....................................................... 175

5.2.3 CR Encoder Sensor Adjustment .............................................................. 176

5.2.4 Ink Mark Sensor Height Adjustment ....................................................... 177

5.2.5 Cutter Height/Position Adjustment .......................................................... 178

5.2.6 PF Encoder Sensor Adjustment ............................................................... 179

5.2.7 Air Leak Check for Ink Supply System ................................................... 180

5.2.8 Paper Cutting Position Check .................................................................. 183

5.3 Basic Adjustment .............................................................................................. 184

5.3.1 RTC&USB ID ......................................................................................... 184

5.3.2 Head Rank ID .......................................................................................... 185

5.3.3 T&B&S (Roll Paper) + Band Feed .......................................................... 186

5.3.4 Cutter Pressure Adjustment ..................................................................... 187

5.3.5 Print Head Slant Adjustment (PF) ........................................................... 188

5.3.6 Print Head Slant Adjustment (CR) .......................................................... 190

5.3.7 Skew Check ............................................................................................. 192

5.3.8 Platen Position Adjustment ...................................................................... 193

5.3.9 Initial Ink Charge Flag ON/OFF .............................................................. 194

5.3.10 NVRAM Backup and Write .................................................................. 195

5.3.11 Ink Discharge ......................................................................................... 196

5.3.12 Initial Ink Charge ................................................................................... 196

5.3.13 Cleaning ................................................................................................. 197

5.3.14 Paper Thickness Sensor Position Adjustment ....................................... 198

5.3.15 PG Adjustment ....................................................................................... 200

5.3.16 Rear Sensor Adjustment ........................................................................ 202

5.3.17 Input Serial Number .............................................................................. 203

5.3.18 Colorimetric Calibration (Color ID) ...................................................... 204

5.3.19 Head Cleaning ....................................................................................... 220

5.3.20 Installing Firmware ................................................................................ 221

5.3.21 Ink Mark Sensor Adjustment ................................................................. 222

5.3.22 Auto Bi-D Adjustment ........................................................................... 223

5.3.23 Auto Uni-D Adjustment ........................................................................ 224

5.3.24 Super Sonic Cleaning ............................................................................ 225

5.3.25 Network Communication Check ........................................................... 225

5.3.26 AID Inspection PG Adjustment ............................................................. 226

5.3.27 AID Function Check .............................................................................. 228

5.3.28 Rear Sensor Position Adjustment .......................................................... 230

5.3.29 Ink Cover Solenoid Adjustment ............................................................ 231

5.4 Check Results ................................................................................................... 232

5.4.1 Check Nozzle ........................................................................................... 232

5.4.2 Print Image .............................................................................................. 233

5.4.3 Print Adjustment Check Pattern .............................................................. 234

5.4.4 Check Alignment ..................................................................................... 235

5.5 Clear Counters .................................................................................................. 236

Chapter 6 MAINTENANCE

6.1 Overview .......................................................................................................... 238

6.2 Cleaning ............................................................................................................ 240

6.3 Lubrication ....................................................................................................... 241

Chapter 7 APPENDIX

7.1 Block Wiring Diagram ..................................................................................... 244

7.2 Parts List ........................................................................................................... 245

7.3 Exploded Diagram ............................................................................................ 249

8

Page 9

PRODUCT DESCRIPTION

CHAPTER

1

Page 10

Stylus Pro 11880/11880C Revision B

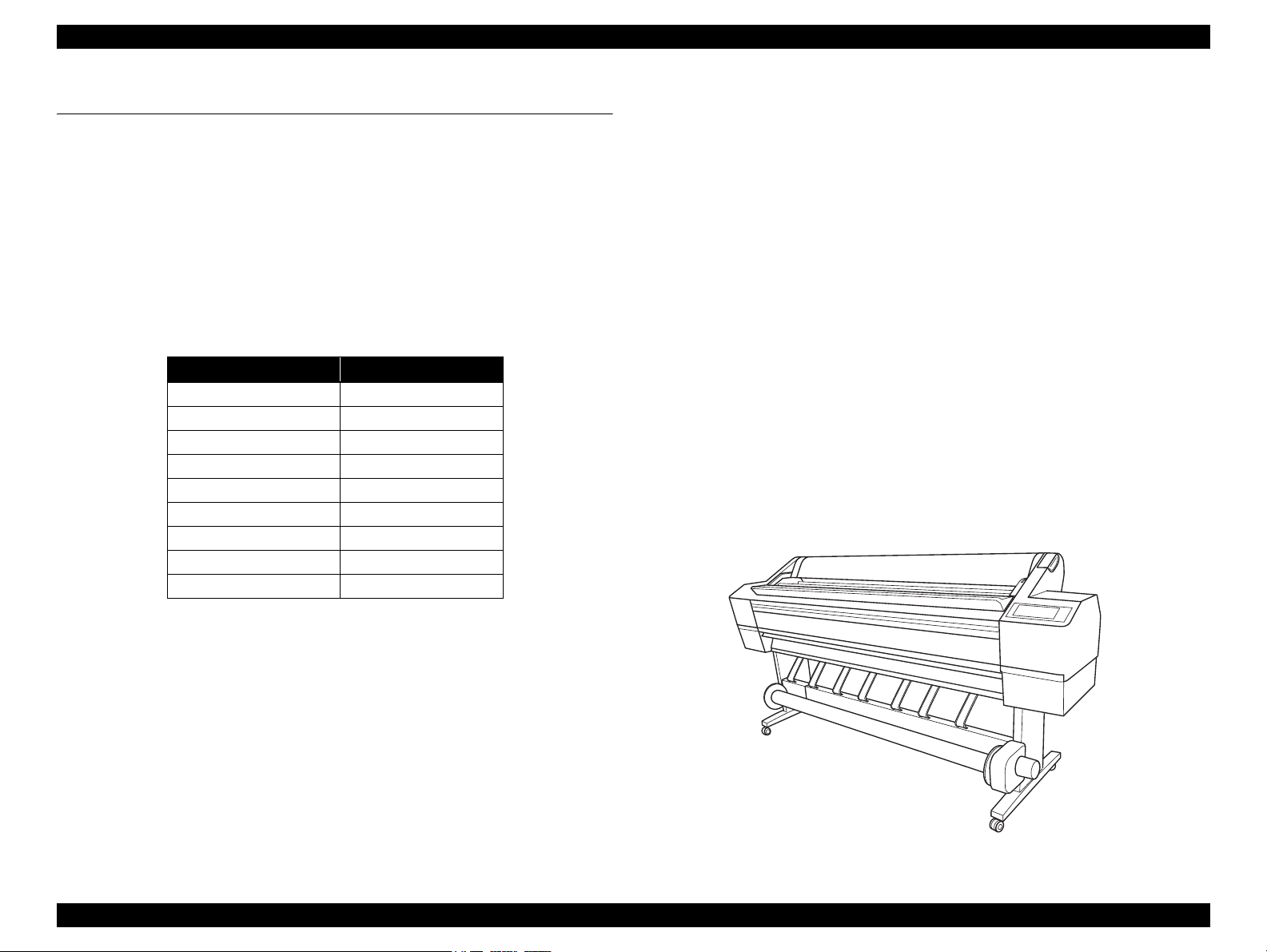

1.1 Product Description

Stylus Pro 11880/11880C is a wide-format color inkjet printer that supports up to 64

inch-wide paper. The main features are;

Supports super large-sized paper

Maximum available paper width: 1625.6 mm (64 inch), up to 64 x 80 inch size

Ink configuration

Installs the following nine ink cartridges and equips with a physical ink channel

for each of the nine colors. The black ink is automatically switched between Photo

and Matte black depending on paper type (printing is made in eight colors).

Table 1-1. Ink Colors

Color Abbreviation

Photo Black PK

Matte Black MK

Cyan C

Vivid Magenta VM

Yellow Y

Light Cyan Lc

Vivid Light Magenta VLm

Light Black LK

Light Light Black LLk

Media handling

Supports a variety of media

Auto take-up reel unit comes as standard

Stores roll paper usage history and updates it automatically by reading a

barcode. This enables automatic detection of remaining amount of the paper.

Equips with auto cutter for roll paper

Borderless print is supported

The latest-type RIP

Supports software RIP made by other companies

Options

The following items are optionally available.

Maintenance Tank

Auto cutter spare blade

Roll paper belt

Paper basket

Dual tension roll feed spindle

Super high print quality

Achieves amazing print quality with eight colors of ink, resolutions up to 2880 x

1440 dpi, and variable dot sizes (minimal 3.7 picoliter)

Lower running cost

Employs super high-capacity (700 ml) independent ink cartridges

Equips with the AID function

Ink suction mechanism for automatic nozzle cleaning is provided for each two

head columns independently. It achieves efficient cleaning with low ink

consumed.

Figure 1-1. External View

PRODUCT DESCRIPTION Product Description 10

Page 11

Stylus Pro 11880/11880C Revision B

High speed printing

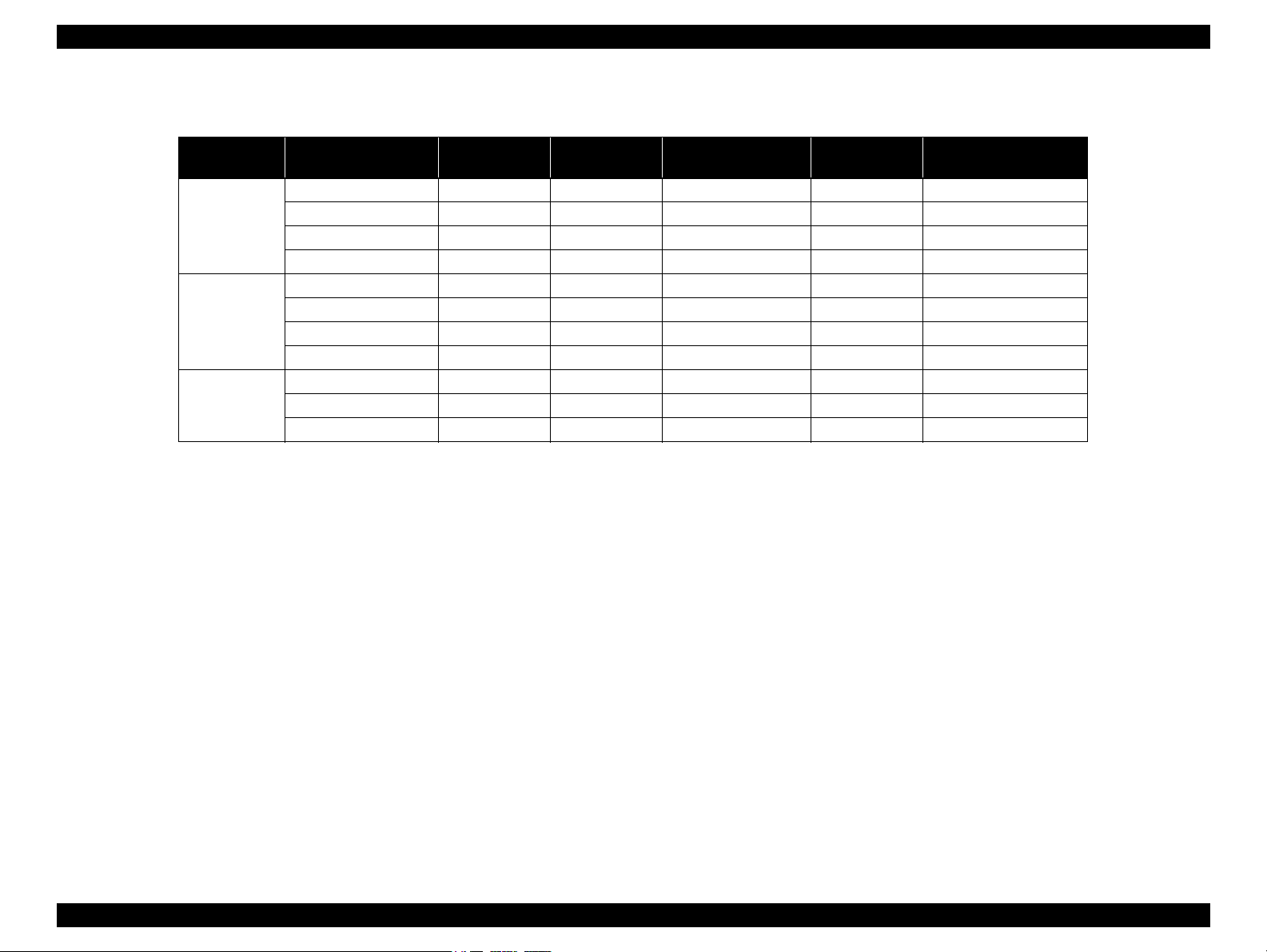

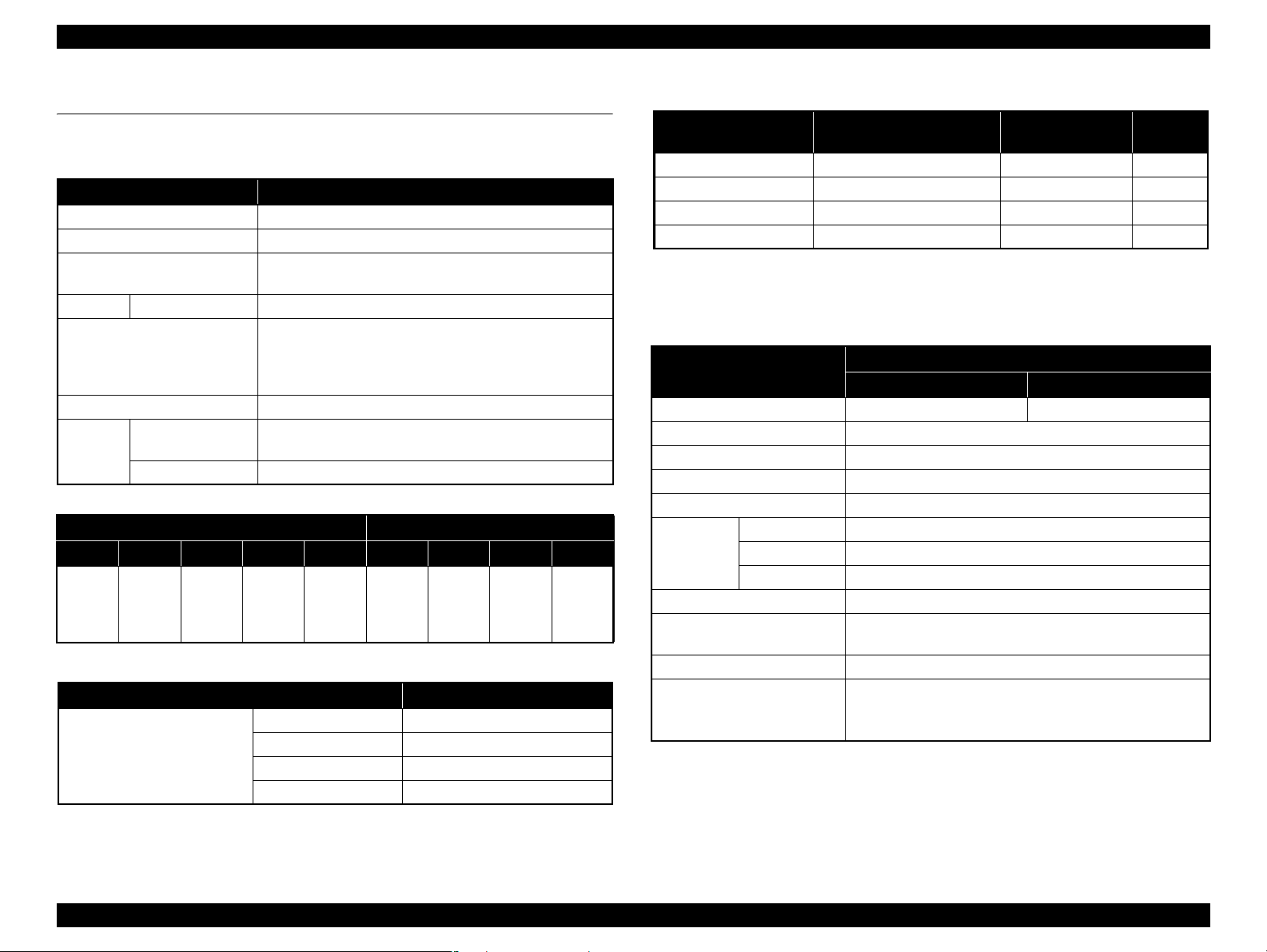

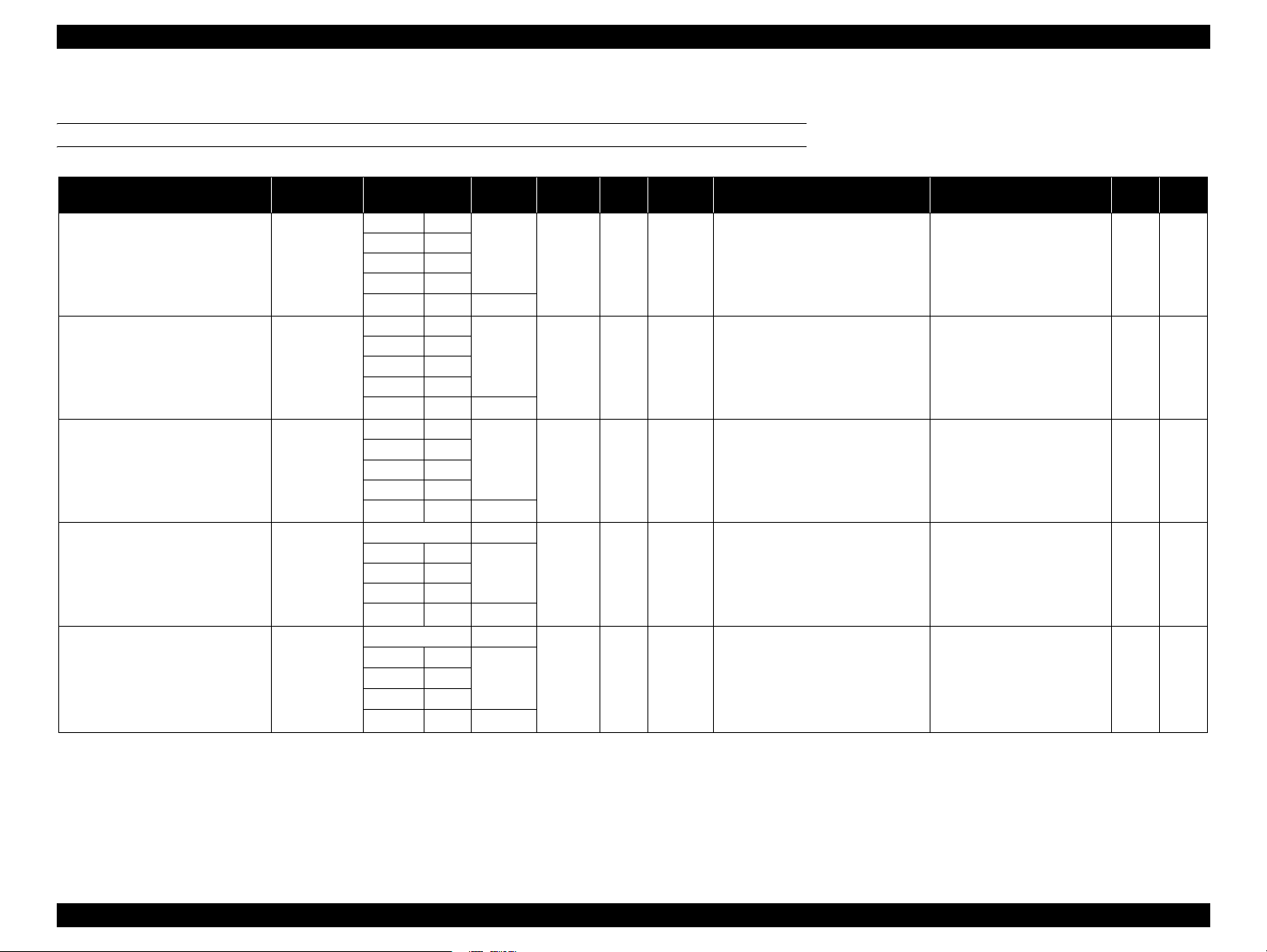

Table 1-2. Print Speed (throughput) List

Paper Type Print Quality Dot Size Resolution (dpi) Mode

Draft VSD1 360 x 360 Bi-D MF 300CPS 1 2.0 minutes

Plain paper

Matte paper

FA paper

Coated paper

Speed VSD1 360 x 720 Bi-D MF 300CPS 2 3.3 minutes

Quality VSD2 720 x 720 Bi-D FOL 240CPS 5 6.8 minutes

Fine-720 F. detail on VSD2 720 x 720 Bi-D FOL 240CPS 7 9.0 minutes

Speed VSD1 720 x 360 Bi-D FOL 300CPS 4 2.3 minutes

Quality VSD2 720 x 720 Bi-D FOL 240CPS 8 10.1 minutes

S.Fine-1440 VSD3 1,440 x 720 Bi-D 4-path 240CPS 11 15.3 minutes

S.Photo-2880 VSD4 2,880 x 1,440 Bi-D 4-path 240CPS 18 24.4 minutes

Speed VSD2 720 x 720 Bi-D FOL 240CPS 7 9.0 minutes

Quality VSD3 1,440 x 720 Bi-D 4-path 240CPS 11 15.3 minutes

S.Photo-2880 VSD4 2,880 x 1,440 Bi-D 4-path 240CPS 18 24.4 minutes

Number of

Print Path

Throughput

(A0-size cut sheet print time)

PRODUCT DESCRIPTION Product Description 11

Page 12

EPSON Stylus Pro 11880/11880C Revision A

1.2 Basic Specifications

1.2.1 Basic Specifications

Item Specification

Maximum paper width 1625.6 mm (64 inch)

Print method On-demand inkjet

Printing direction

Printhead Number of nozzles 360 nozzles for each of nine colors

Ink colors

Maximum resolution 2,880dpi x 1,440dpi

Print

speed &

Print area

Alphanumeric

characters

Graphic mode See Table 1-5

Table 1-3. Cartridge Alignment Sequence

Left Ink Holder Right Ink Holder

Row 1 Row 2 Row 3 Row 4 Row 5 Row 6 Row 7 Row 8 Row 9

Vivid

Light

Magenta

(VLm)

Light

Light

Black

(LLK)

Matte

Black

(MK)

Table 1-4. Print speed & Area (alphanumeric characters)

Item Specification

Print speed & Print area

Bi-directional shortest-direction printing (high-speed return,

high-speed skip)

Photo black, Matte black, Cyan, Vivid magenta, Yellow,

Light Cyan, Vivid light magenta, Light black, Light light

black

(See Table 1-3 for the alignment sequence of the cartridges)

See Table 1-4

Light

Black

(LK)

Light

Cyan

(Lc)

Character quality Fine

Character pitch 10 CPI

Print area 643 digits

Print speed Max. 300 cps

Cyan

(C)

Vivid

Magenta

(VM)

Photo

Black

(PK)

Yellow

(Y)

Table 1-5. Print speed & Area (graphic mode)

Horizontal Resolution

(dpi)

360 1633.5 mm (64.31 inch) 23,151 300 cps

720 1633.5 mm (64.31 inch) 46,303 240 cps

1440 1633.5 mm (64.31 inch) 92,606 240 cps

2880 1633.5 mm (64.31 inch) 185,212 240 cps

Note : Includes margins that bleed off the edges of paper. (max. 3 mm for home side, max. 5 mm for the

opposite side)

Max. Print Area Printable Dots

Print

speed

1.2.2 Electric Specifications

Item

Rated voltage 100 to 240 VAC 220 to 240 VAC

Input voltage range 90 to 264 VAC

Rated frequency 50 to 60Hz

Input frequency range 49 to 61Hz

Rated current 1.2A to 0. 6A

Power

consumption

Insulation resistance 10MΩ or more (between AC line and chassis at 500 VDC)

Dielectric strength

Leek current 0.5 mA or less

Compliance with regulations

Note "*1" : The printer goes into the sleep mode when no operation is made for 10 minutes.

Operating 100 W

Sleep mode*

Standby Less than 1W

1

100/120V Model 220/240V Model

1.0 kVrms AC for 1 min. or 1.2 kVrms AC for 1 sec.

(between AC line and chassis)

Conforms to International Energy Star Program

(Category: the harmonic restraint measure guideline)

Conforms to VCCI Class B (with full options installed)

Specification

20 W or lower

PRODUCT DESCRIPTION Basic Specifications 12

Page 13

EPSON Stylus Pro 11880/11880C Revision A

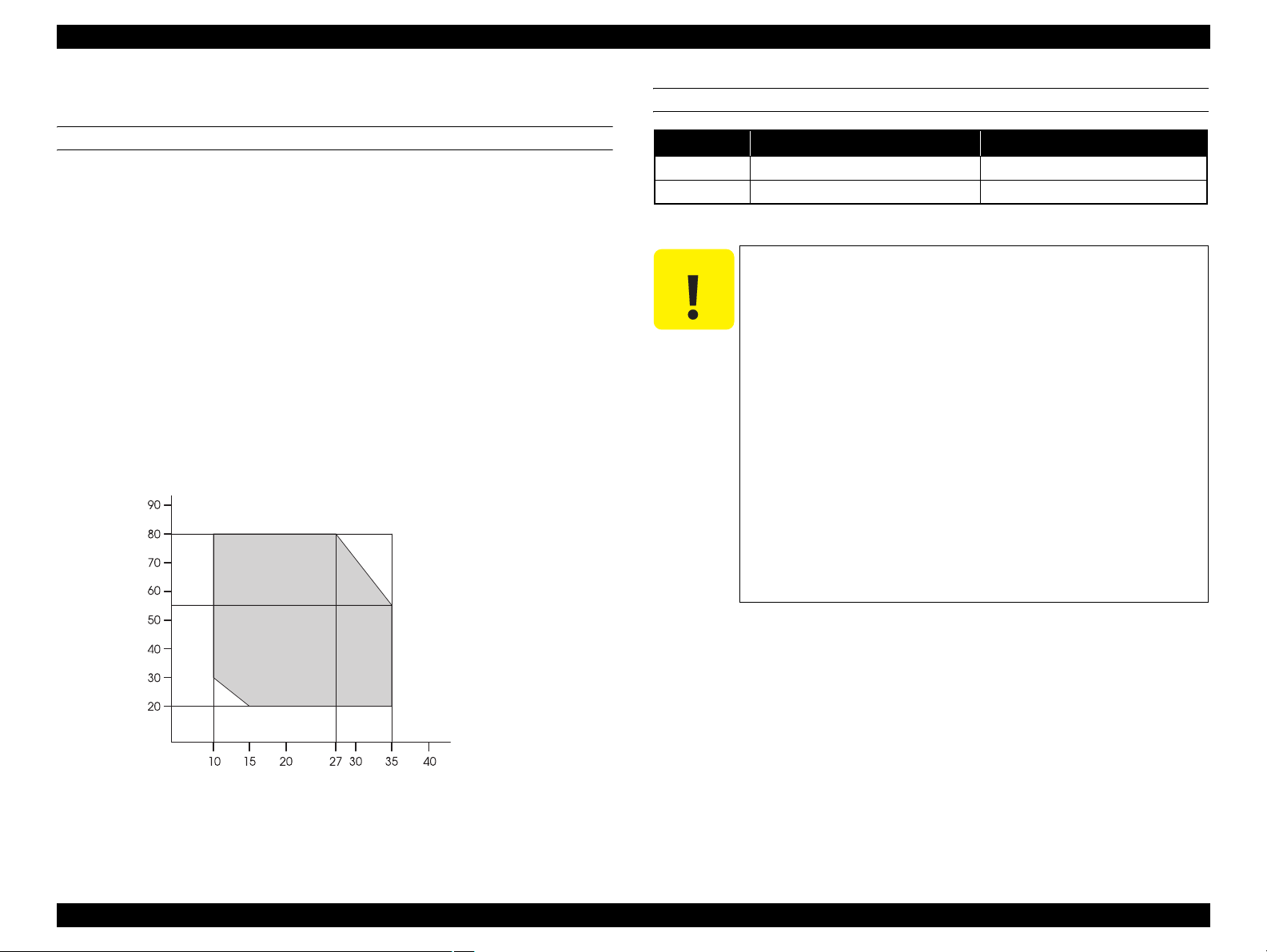

1.2.3 Environmental Conditions

TEMPERATURE/HUMIDITY

Temperature

Operating; 10 to 35

Storage (before unpacking): -20 to 60°C

(within 120 hours under 60 °C, and within 1 month under 40 °C)

Storage (after unpacking): -20 to 40

(within 1 month under 40°C)

Humidity

Operating; 20 to 80% (no condensation)

Storage (before unpacking): -20 to 85% (no condensation)

Storage (after unpacking): 5 to 85% (no condensation)

Humidity (%)

°C

°C

RESISTANCE TO VIBRATION/SHOCK

Status Vibration Shock

Operating 0.15G, 10 to 55Hz 1G, within 1 ms

Storage 0.50G, 10 to 55Hz 2G, within 2 ms

C A U T I O N

Whenever storing the printer, press the Power button to turn

off the power, and make sure that the carriage stops at the right

end to put the cap on the printhead. And even if the printer will

not be used for an extended period, do not remove the ink

cartridges.

Whenever transporting the printer, leave the ink cartridges

installed, and make sure that the printhead is capped. Then

secure the printhead with the metal plate that comes with the

printer being attached to the head.

If you find the carriage is not at the right end position (the

printhead is not capped) while the printer power is off, turn on

the printer and turn it off with the Power button to move the

carriage to the right end. At this time, the ink cartridges must

have been installed.

The print quality is guaranteed under normal room

temperature conditions. If the printer is used under conditions

out of the normal range, color reproduction accuracy may

drop, and bands or smudges may appear on the printout.

Temperature (°C)

Figure 1-2. Temperature/Humidity Range

PRODUCT DESCRIPTION Basic Specifications 13

Page 14

EPSON Stylus Pro 11880/11880C Revision A

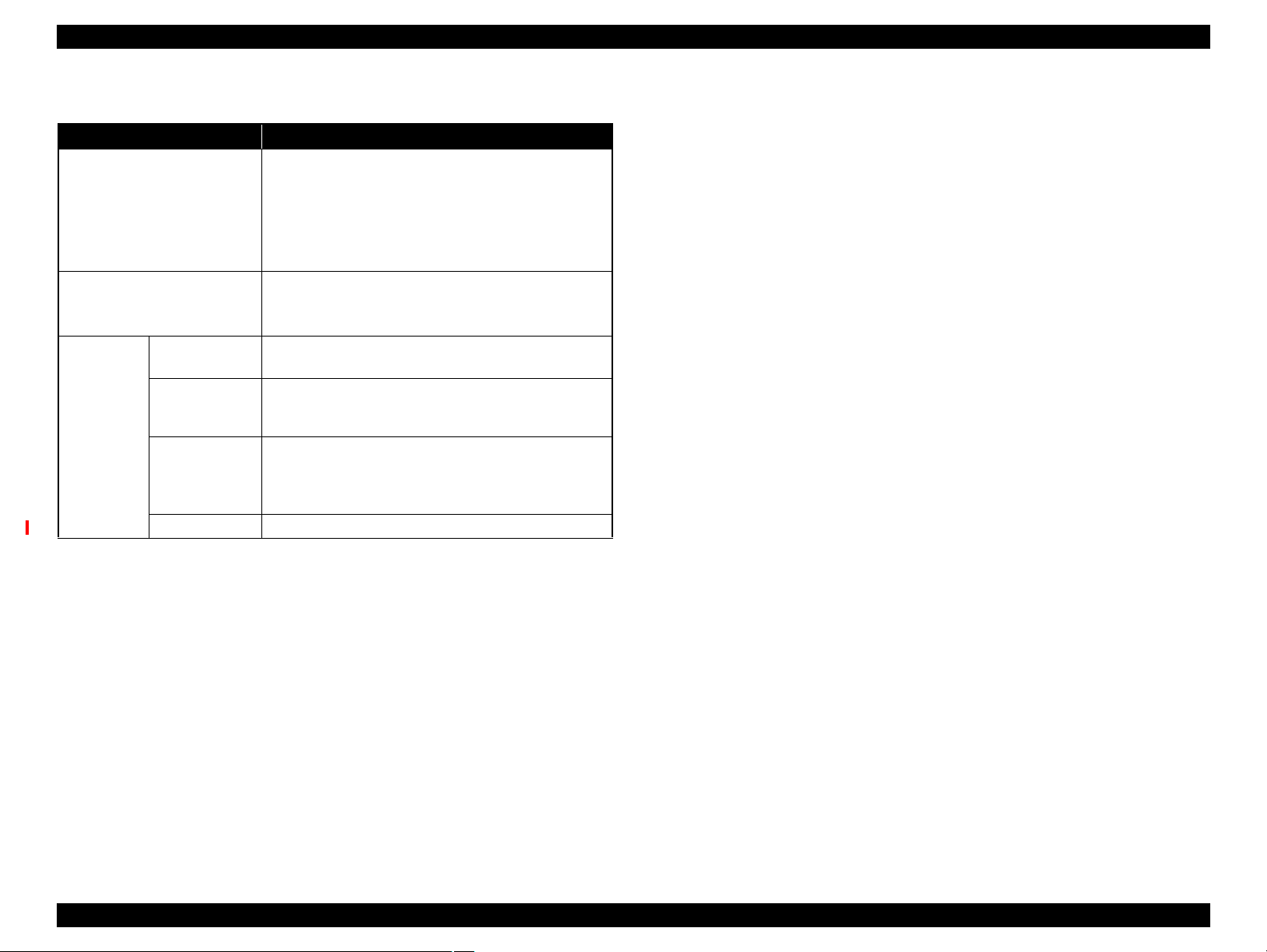

1.2.4 Reliability/Durability

Item Specification

Until any one of the following conditions is met.

• Approx. 20,000 pages

Operating life of the printer

Cutter life (reference)

RTC backup

battery

Maintenance unit

Consumables

life

CR motor,

Drive pulley,

Carriage unit,

FFC

Tube 6,300,000 paths

(Super B0 size plain paper, Quality mode, 720x360

FOL Bi-D)

• Carriage life: 6,300,000 paths

• 5 years

64"-wide roll paper, 4 cuts for one page

• Coated paper: approx. 2,000 pages (sheets)

• Film: approx. 1,000 pages (sheets)

5 years or longer

Approx. 20,000 pages (reference value)

(Super B0 size EPSON paper, Draft mode, 720x720,

continuous printing)

Approx. 12,600,000 paths

PRODUCT DESCRIPTION Basic Specifications 14

Page 15

EPSON Stylus Pro 11880/11880C Revision A

1.3 Printing Specifications

1.3.1 Paper Feed Specifications

Item Specification

Paper feed method Friction feed

Line pitch Programmable in units of 1/6 inch or 1,440 inch

Paper feeder

Feed speed 245

1.3.2 Paper Specification

1.3.2.1 Supported Paper

The following explains the supported paper sizes and thickness.

C A U T I O N

Do not use wrinkled, scuffed, torn, or soiled paper.

Load paper just before printing. Do not leave paper loaded on

the printer when not printing. Store paper properly following

the instruction that comes with the paper.

When large quantities of paper need to be prepared in advance,

make a test print using the paper before purchase.

Roll paper manual feed

Cut sheet manual feed

± 10 mm/sec (6.35 mm feed)

PAPER SIZE

Item Specification

Cut sheet

Roll paper

1580

1118

PAPER THICKNESS

Paper width: 210 to 1,118 mm

Paper length: 279 to 1,580 mm

Paper width: 406 to 1,626 mm

Paper length: 127 to 15,000 mm

210

279

15000

406

127

1626

Unit: mm

Item Specification

0.08 to 1.5 mm

Cut sheet

Roll paper 0.08 to 0.5 mm

(Paper length: 279 to 728 mm)

0.08 to 0.5 mm

(Paper length: 728 to 2,032 mm)

PRODUCT DESCRIPTION Printing Specifications 15

Page 16

EPSON Stylus Pro 11880/11880C Revision A

1.3.2.2 Designated Paper

ROLL PAPER

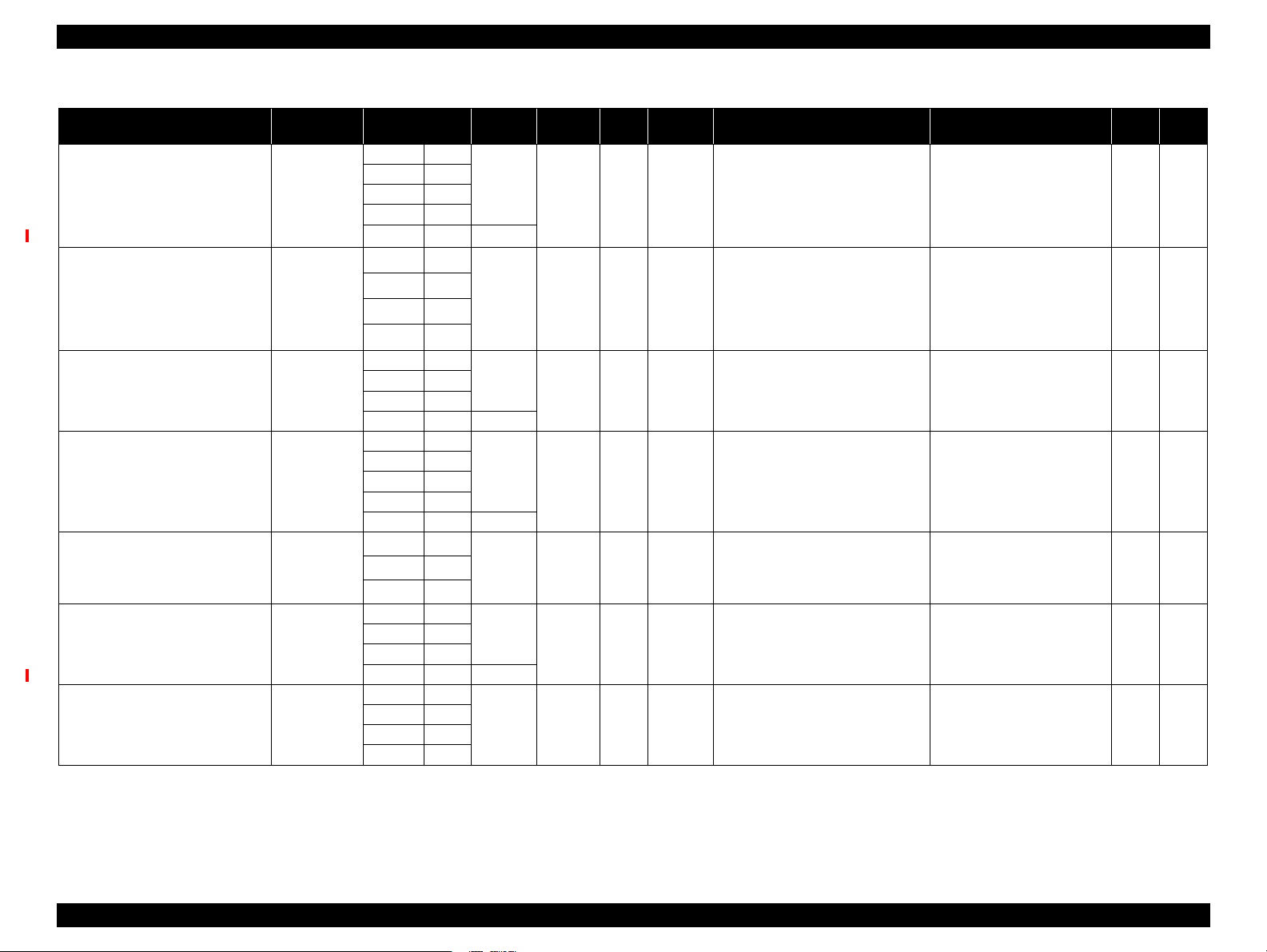

Table 1-6. Designated Roll Paper List

Name

Premium Glossy Photo Paper (250) Photograph,

Premium Semigloss Photo Paper (250) Photograph,

Premium Luster Photo Paper (260) Photograph, 406mm 16" OK! 0.27mm 3" Normal

Premium Glossy Photo Paper (170) Photograph,

Premium Semigloss Photo Paper (170) Photograph,

Note "*1" : OK!: Recommended for borderless printing

OK: Borderless printing is available

NA: Borderless printing is Not available

Borderless printing on the borderless printing available paper (OK) may result in drop in print quality or fail to

produce complete borderless (white margins may appear) due to expanding of the paper. Borderless printing can

be made on commercially available paper, however, note that the availability is restricted by the paper size.

Main

Application

Contact Proof

Contact Proof

Contact Proof

Contact Proof

Size

406mm 16" OK! 0.27mm 3" Normal

610mm 24"

914mm 36"

1118mm 44"

1524mm 60" NA

406mm 16" OK! 0.27mm 3" Normal

610mm 24"

914mm 36"

1118mm 44"

1524mm 60" NA

610mm 24"

914mm 36"

1118mm 44"

1524mm 60" NA

420mm (A2) NA 0.18mm 2" Normal

610mm 24" OK!

914mm 36"

1118mm 44"

1524mm 60" NA

420mm (A2) NA 0.18mm 2" Normal

610mm 24" OK!

914mm 36"

1118mm 44"

1524mm 60" NA

Borderless

*1

Print

Thickness

Core

Diameter

Spindle

Tension

ICC Profile

• Photo Black:

When Bi-D is ON

Pro11880 PGPP250 Bi-D.icc

When Bi-D is OFF

Pro11880 PGPP250 Uni-D.icc

• Matte Black: ---

• Photo Black:

When Bi-D is ON

Pro11880 PSPP250 Bi-D.icc

When Bi-D is OFF

Pro11880 PSPP250 Uni-D.icc

• Matte Black: ---

• Photo Black:

When Bi-D is ON

Pro11880 PLPP260 Bi-D.icc

When Bi-D is OFF

Pro11880 PLPP260 Uni-D.icc

• Matte Black: ---

• Photo Black:

When Bi-D is ON

Pro11880 PGPP170 Bi-D.icc

When Bi-D is OFF

Pro11880 PSPP170 Uni-D.icc

• Matte Black: ---

• Photo Black:

When Bi-D is ON

• Pro11880 PSPP170 Bi-D.icc

• When Bi-D is OFF

Pro11880 PSPP170 Uni-D.icc

• Matte Black: ---

"*2": OK: Auto cut is available

NA: Auto cut is Not available

(manually cut the paper with a commercially available cutter)

Paper Type&Name

indicated by Driver

Photo Paper

Premium Glossy Photo Paper

(250)

Photo Paper

Premium Semigloss Photo Paper

(250)

Photo Paper

Premium Luster Photo Paper

(260)

Photo Paper

Premium Glossy Photo Paper

(170)

Photo Paper

Premium Semigloss Photo Paper

(170)

<Continued to the next page>

Auto

*2

Cut

OK PK

OK PK

OK PK

OK PK

OK PK

Black

Ink

PRODUCT DESCRIPTION Printing Specifications 16

Page 17

Stylus Pro 11880/11880C Revision B

Table 1-6. Designated Roll Paper List

Name

Epson Proofing Paper White

Semimatte

Main

Application

Size

Contact Proof 432mm 17" OK 0.25mm 3" Normal

610mm 24"

914mm 36"

1118mm 44"

1524mm 64" NA

Epson Proofing Paper Publication Contact Proof 432mm 17" OK 0.20mm 3" Normal

610mm 24"

914mm 36"

1118mm 44"

Doubleweight Matte Paper Photograph,

Indoor Signage,

Proof

610mm 24" OK 0.21mm 2" Normal

914mm 36"

1118mm 44"

1626mm 64" NA

Enhanced Matte Paper Photograph,

Indoor Signage,

Proof, Fine Art

Reproduction

432mm 17" OK 0.25mm 3" Normal

610mm 24"

914mm 36"

1118mm 44"

1626mm 64" NA

Watercolor Paper - Radiant White Photograph,

Fine Art

Reproduction

610mm 24" OK 0.29mm 3" High

914mm 36"

1118mm 44"

UltraSmooth Fine Art Paper Photograph,

Fine Art

Reproduction

432mm 17" OK 0.32mm 3" High

610mm 24"

1118mm 44"

1524mm 60" NA

Textured Fine Art Paper Photograph,

Fine Art

Reproduction

432mm 17" OK 0.37mm 3" High

610mm 24"

914mm 36"

1118mm 44"

Note "*1" : OK!: Recommended for borderless printing

OK: Borderless printing is available

NA: Borderless printing is Not available

Borderless printing on the borderless printing available paper (OK) may result in drop in print quality or fail to

produce complete borderless (white margins may appear) due to expanding of the paper. Borderless printing can

be made on commercially available paper, however, note that the availability is restricted by the paper size.

Borderless

*1

Print

Thickness

Core

Diameter

Spindle

Tension

ICC Profile

• Photo Black:

When Bi-D is ON

Pro11880 Proof_WS_Bi-D.icc

When Bi-D is OFF

Pro11880 Proof_WS_Uni-D.icc

• Matte Black: ---

• Photo Black:

When Bi-D is ON

Pro11880 Proof_Pub_Bi-D.icc

When Bi-D is OFF

Pro11880 Proof_Pub_Uni-D.icc

• Matte Black: ---

• Photo Black: ---

• Matte Black:

Pro118800 DWMP.icc

• Photo Black:

Pro11880 EMP_PK.icc

• Matte Black:

Pro118800 EMP_MK.icc

• Photo Black:

Pro11880 WCRW_PK.icc

• Matte Black:

Pro118800 WCRW_MK.icc

• Photo Black:

Pro11880 USFAP_PK.icc

• Matte Black:

Pro118800 USFAP_MK.icc

• Photo Black:

Pro11880 TFAP_PK.icc

• Matte Black:

Pro118800 TFAP_MK.icc

"*2": OK: Auto cut is available

NA: Auto cut is Not available

(manually cut the paper with a commercially available cutter)

Paper Type&Name

indicated by Driver

Proofing Paper

Epson Proofing Paper White

Semimatte

Proofing Paper

Epson Proofing Paper

Publication

Matte Paper

Doubleweight Matte Paper

Matte Paper

Enhanced Matte Paper

Fine Art Paper

Watercolor Paper - Radiant

White

Fine Art Paper

UltraSmooth Fine Art Paper

Fine Art Paper

Textured Fine Art Paper

<Continued to the next page>

Auto

Black

*2

Cut

OK PK

OK MK

OK MK

OK MK

OK PK/

OK PK/

OK PK/

Ink

MK

MK

MK

PRODUCT DESCRIPTION Printing Specifications 17

Page 18

EPSON Stylus Pro 11880/11880C Revision A

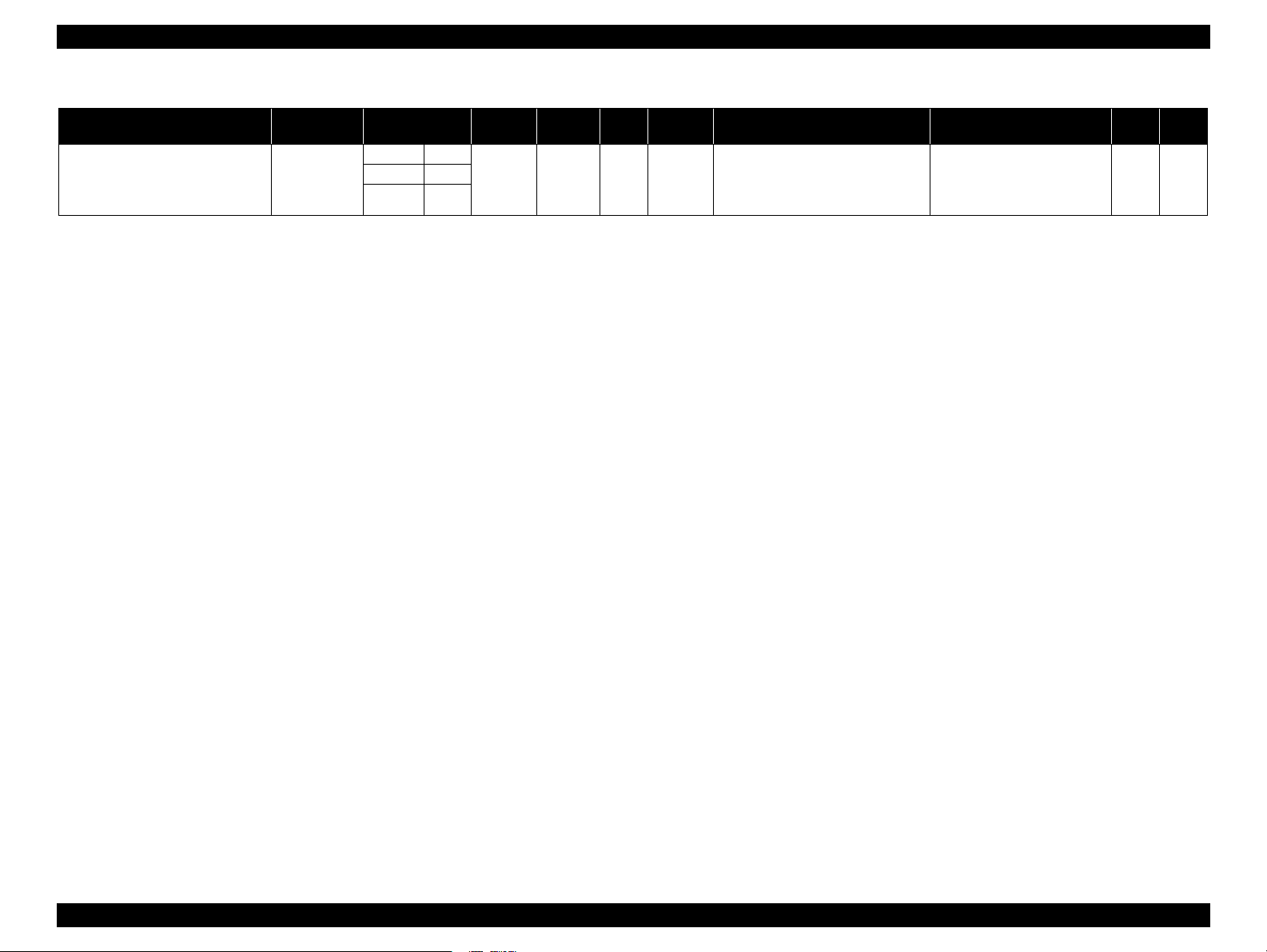

Table 1-6. Designated Roll Paper List

Name

Main

Application

Canvas Photograph,

Fine Art

Reproduction

Size

610mm 24" OK 0.46mm 2" Normal

914mm 36"

1118mm 44"

Borderless

*1

Print

Thickness

Core

Diameter

Spindle

Tension

ICC Profile

• Photo Black:

Pro11880 Canvas_PK.icc

• Matte Black:

Pro118800 Canvas_MK.icc

Paper Type&Name

indicated by Driver

Fine Art Paper

Canvas

Auto

Black

*2

Cut

NA PK/

Ink

MK

Note "*1" : OK!: Recommended for borderless printing

OK: Borderless printing is available

NA: Borderless printing is Not available

Borderless printing on the borderless printing available paper (OK) may result in drop in print quality or fail to

produce complete borderless (white margins may appear) due to expanding of the paper. Borderless printing can

be made on commercially available paper, however, note that the availability is restricted by the paper size.

"*2": OK: Auto cut is available

NA: Auto cut is Not available

(manually cut the paper with a commercially available cutter)

PRODUCT DESCRIPTION Printing Specifications 18

Page 19

EPSON Stylus Pro 11880/11880C Revision A

CUT SHEET

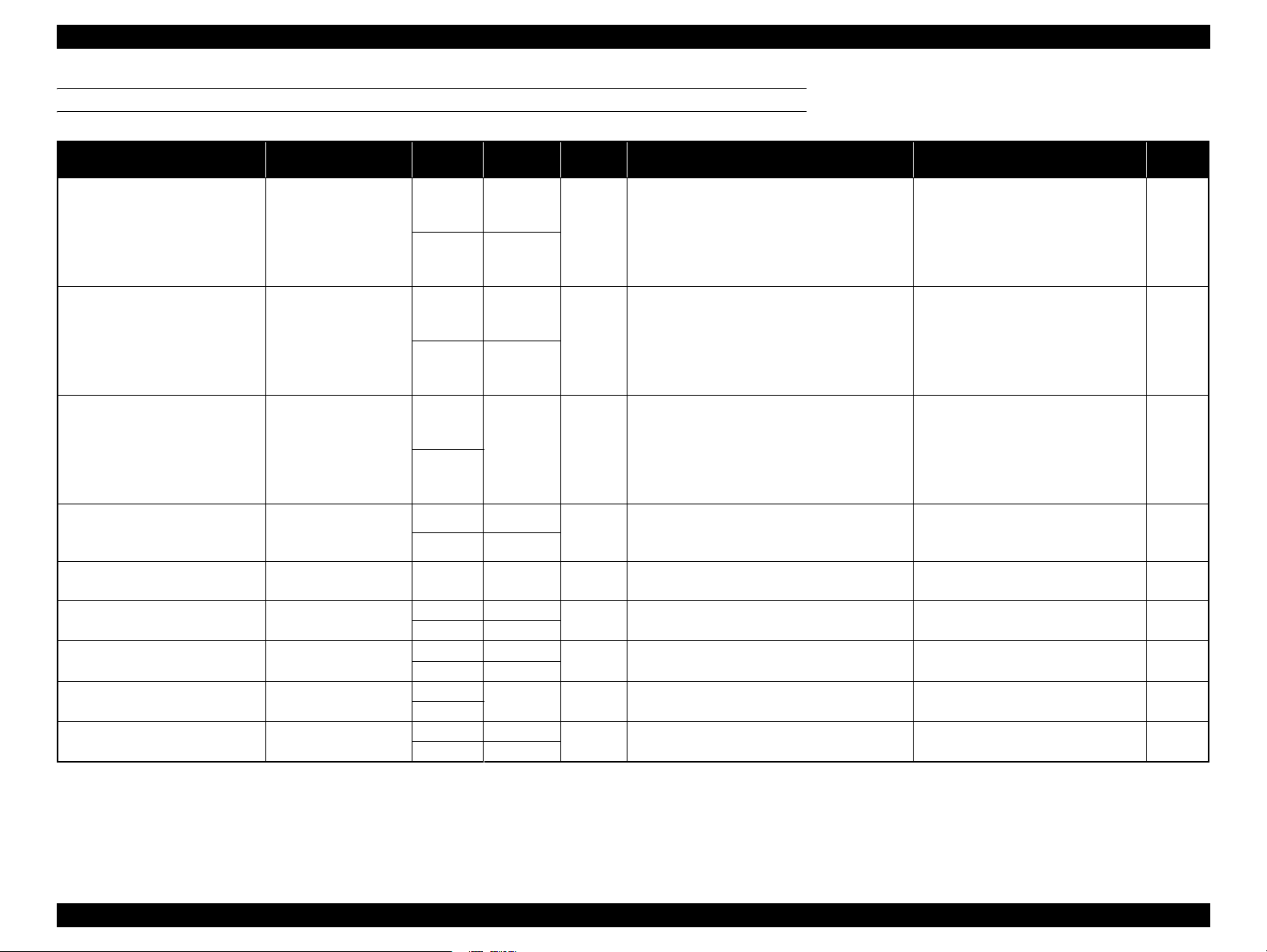

Table 1-7. Designated Cut Sheet List

Name Main Application Size

Premium Glossy Photo Paper Photograph, Contact Proof Super A3 OK! 0.27mm

A2 NA

Premium Semigloss Photo Paper Photograph, Contact Proof Super A3 OK! 0.27mm

A2 NA

Premium Luster Photo Paper Photograph Super A3 OK! 0.27mm

A2

Archival Matte Paper Indoor Signage,

Photograph, Proof, Fine

Art Reproduction

Watercolor Paper - Radiant White Photograph, Fine Art

Reproduction

UltraSmooth Fine Art Paper Photograph, Fine Art

Reproduction

Velvet Fine Art Paper Photograph, Fine Art

Reproduction

Textured Fine Art Paper Photograph, Fine Art

Reproduction

Enhanced Matte Posterboard Indoor Signage, Proof,

Fine Art Reproduction

Super A3 OK 0.26mm

A2 NA

Super A3 OK 0.29mm

Super A3 OK 0.46mm

A2 NA

Super A3 OK 0.48mm

A2 NA

24" x 30" OK 0.69mm

36" x 44"

24" x 30" OK 1.3mm

30" x 40" NA

Borderless

*1

Print

Thickness ICC Profile Paper Name indicated by Driver Black Ink

• Photo Black:

When Bi-D is ON

Pro11880 PGPP Bi-D.icc

When Bi-D is OFF

• Pro11880 PGPP_Uni-D.icc

• Matte Black: ---

• Photo Black:

When Bi-D is ON

Pro11880 PSPP Bi-D.icc

When Bi-D is OFF

Pro11880 PSPP Uni-D.icc

• Matte Black: ---

• Photo Black:

When Bi-D is ON

Pro11880 PLPP Bi-D.icc

When Bi-D is OFF

Pro11880 PLPP Uni-D.icc

• Matte Black: ---

• Photo Black: Pro11880 ARMP_PK.icc

• Matte Black: Pro118800 ARMP_MK.icc

• Photo Black: Pro11880 WCRW_PK.icc

• Matte Black: Pro118800 WCRW_MK.icc

• Photo Black: Pro11880 USFAP_PK.icc

• Matte Black: Pro118800 USFAP_MK.icc

• Photo Black: Pro11880 VFAP_PK.icc

• Matte Black: Pro118800 VFAP_MK.icc

• Photo Black: Pro11880 TFAP_PK.icc

• Matte Black: Pro118800 TFAP_MK.icc

• Photo Black: Pro11880 EMPB_PK.icc

• Matte Black: Pro118800 EMPB_MK.icc

Photo Paper

Premium Glossy Photo Paper

Photo Paper

Premium Semigloss Photo Paper

Photo Paper

Premium Luster Photo Paper

Matte Paper

Archival Matte Paper

Fine Art Paper

Watercolor Paper - Radiant White

Fine Art Paper

UltraSmooth Fine Art Paper

Fine Art Paper

Velvet Fine Art Paper

Fine Art Paper

Textured Fine Art Paper

Others

Enhanced Matte Posterboard

PK

PK

PK

PK/MK

PK/MK

PK/MK

PK/MK

PK/MK

PK/MK

Note "*": OK!: Recommended for borderless printing

OK: Borderless printing is available

NA: Borderless printing is Not available

Borderless printing on the borderless printing available paper (OK) may result in drop in print quality or fail to produce complete borderless (white margins may appear) due to expanding of the paper.

Borderless printing can be made on commercially available paper, however, note that the availability is restricted by the paper

size.

PRODUCT DESCRIPTION Printing Specifications 19

Page 20

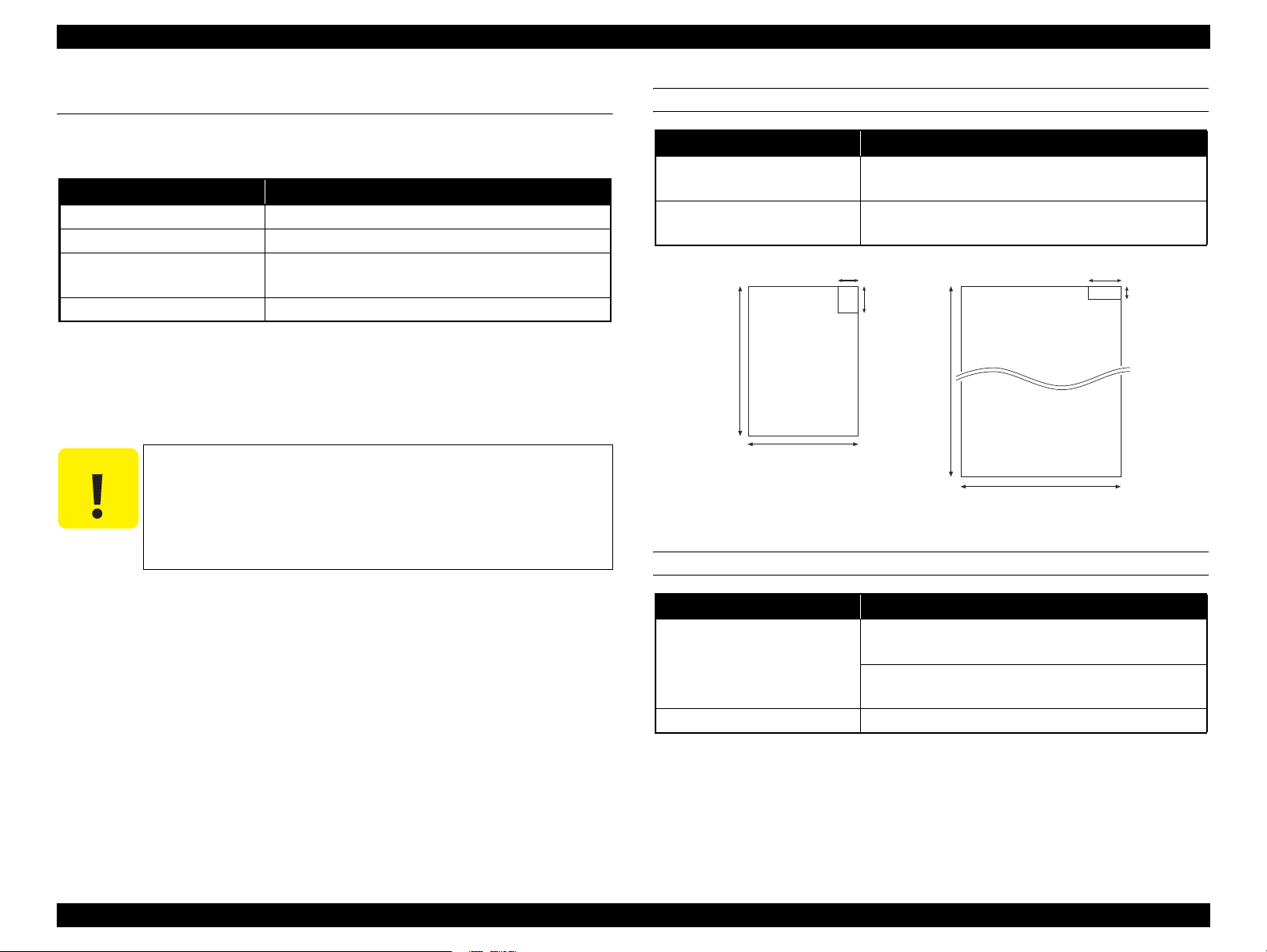

EPSON Stylus Pro 11880/11880C Revision A

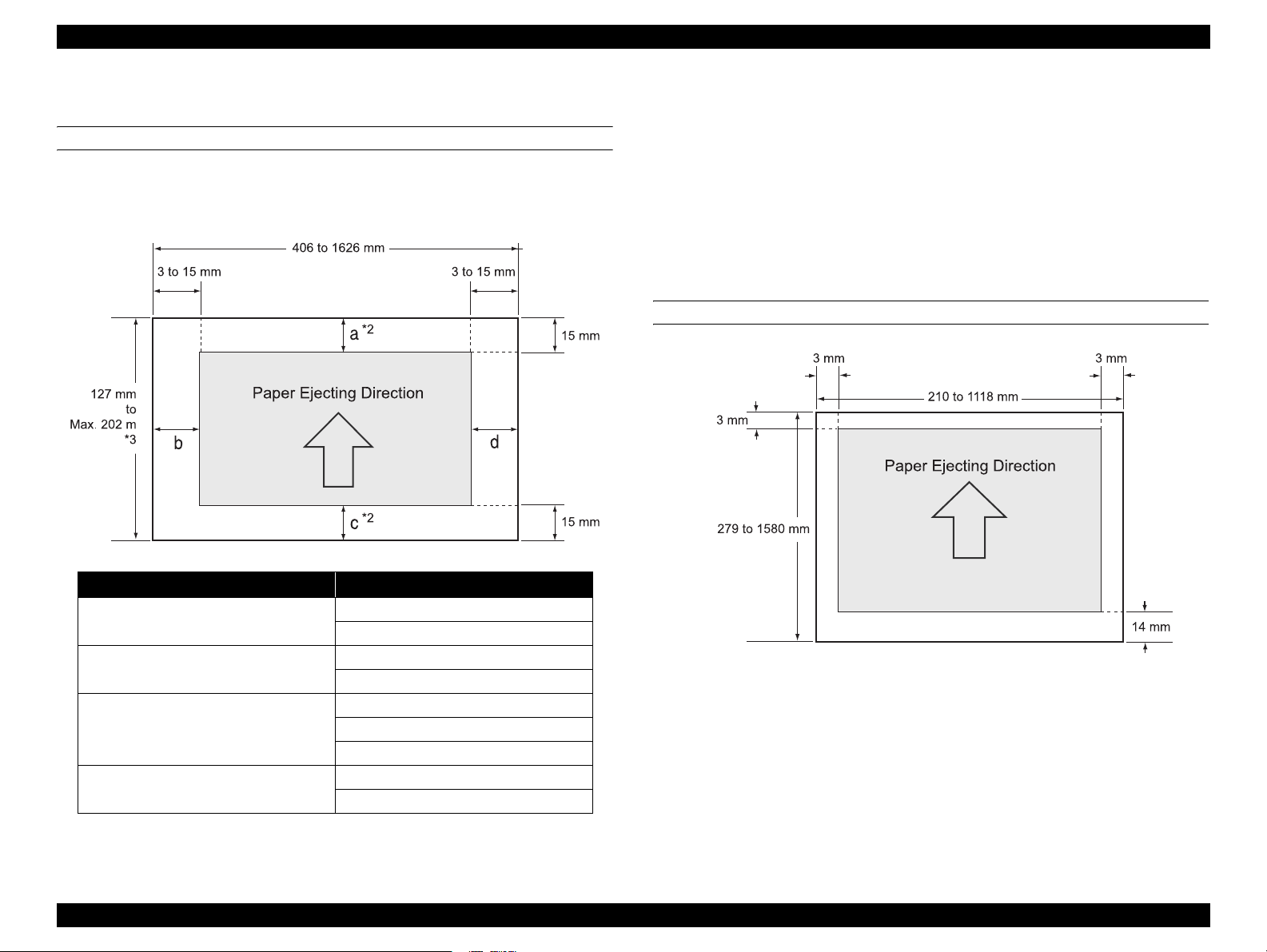

1.3.3 Printable Area

ROLL PAPER

Margins for roll paper depends on the ROLL PAPER MARGIN settings in the

PRINTER SETUP menu.

Note "*1" : When the Default is selected, "a" becomes 20mm and “c” becomes 15mm for the following

paper types; Premium Glossy Photo Paper(250), Premium Semigloss Photo Paper(250), and

Premium Luster Photo Paper(260).

"*2": When the"Roll Paper (Banner)" is selected for the "Source" in the "Paper Settings" of the

printer driver, the top and bottom margins become 0 mm.

"*3": The maximum paper length settable with the printer driver is as follows.

Windows: 15,000 mm (590.6 inch)

Mac OS X: 15,240 mm (600 inch)

When paper length longer than the above is required, select the "Roll Paper (Banner)". The

printer driver allows the setting if the application used for the data supports the length.

CUT SHEET

ROLL PAPER MARGIN settings Explanation

Default

TOP/BOTTOM 15mm

TOP 35/BOTTOM 15MM

3mm

a = c = 15 mm *1

b = d = 3 mm

a = c = 15 mm

b = d = 3 mm

a = 35 mm

c = 15 mm

b = d = 3 mm

a, b, c, d = 3 mm

a, b, c, d = 15 mm

PRODUCT DESCRIPTION Printing Specifications 20

Page 21

EPSON Stylus Pro 11880/11880C Revision A

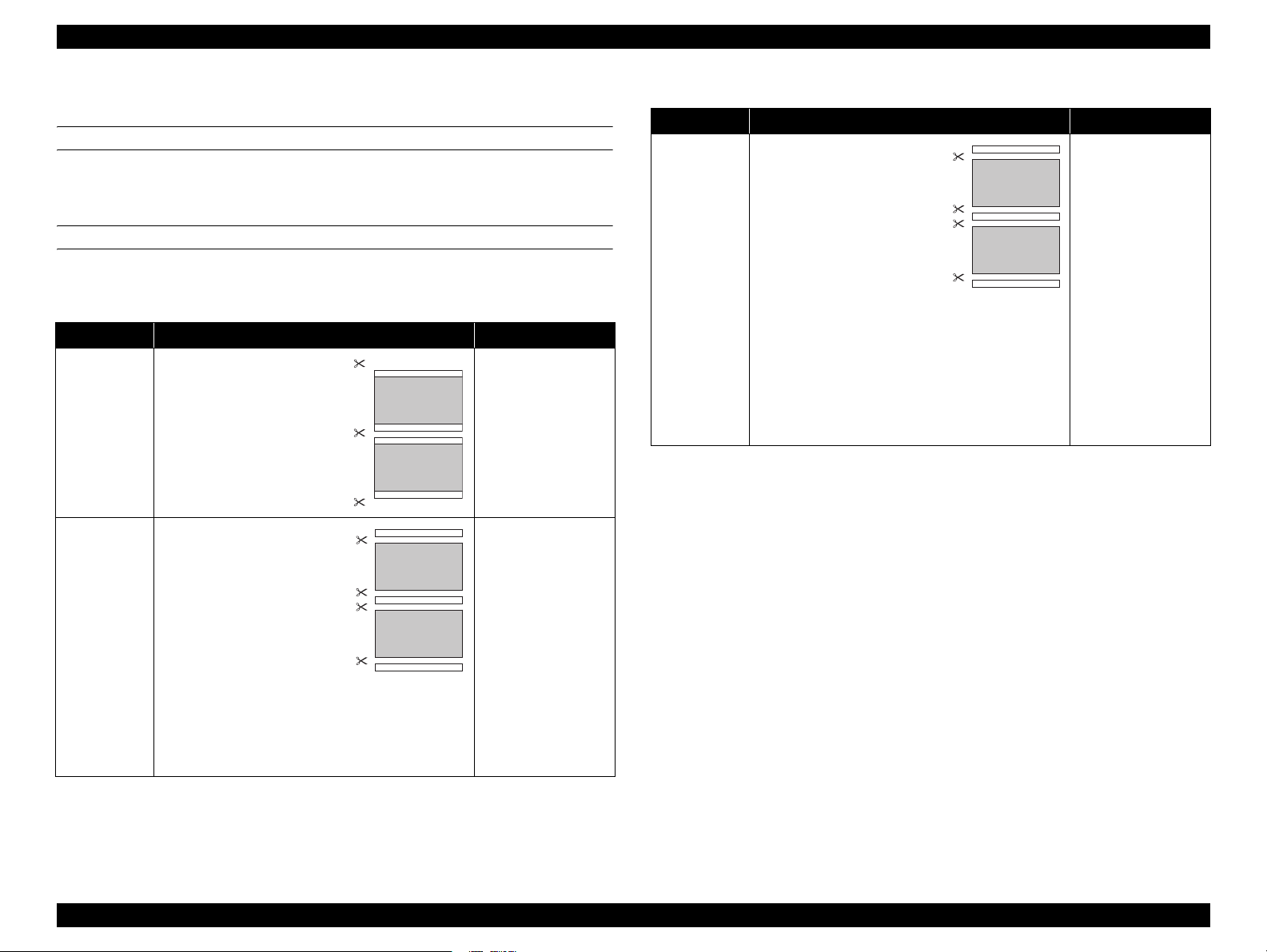

1.3.4 Borderless Printing Specification

AVAILABLE PAPER TYPE

For the paper types and sizes that support the borderless printing, see “1.3.2.2

Designated Paper” on page 16.

BORDERLESS PRINTING MODE

The following types of borderless printing are available with the printer driver.

Table 1-8. Borderless Printing Mode

Driver Setting Printer Operation Remarks

Default

• Printing is interrupted

for cutting off the top

margin of the first

page. This may cause

color inconsistencies

depending on the print

data.

• The cut line between

pages may be slightly

off the border.

Normal Cut*

Single Cut

3

*1*2*

Prints an image bleeding it off

the left and right edges of

paper. The top and bottom

margins are determined by

2

ROLL PAPER MARGIN

setting.

Prints an image bleeding it off

the all edges of paper.

The cutting methods is as

follows.

The minimum width

required for cutting is

applied as the top margin

of the first page, then the

top margin is cut off during

printing.

No margin is provided between pages, and the

cutting is made on the border between the pages.

When the job is finished, the bottom side of the last

page is cut off without margin.

Table 1-8. Borderless Printing Mode

Driver Setting Printer Operation Remarks

Prints an image bleeding it off

the all edges of paper.

The cutting methods is as

follows.

The auto refresh margin is

applied as the top margin

of the first page, then the

Double Cut

3

*1*2*

top margin is cut off during

printing.

The bottom side of each

page is cut off without margin.

The minimum width required for cutting is applied

as margins between pages.

Note "*1" : The cut pages vertical length become about 2mm shorter than the specified size.

"*2": When the Auto Cut is OFF and the Page Line print function is ON, page lines for manual

cutting are printed.

"*3": Color inconsistencies or ink smudges due to the interruption of printing for cutting off top

margins are likely to occur on the following papers.

• Doubleweight Matte Paper

• Singleweight Matte Paper

• Enhanced Matte Paper

• Textured Fine Art Paper

• UltraSmooth Fine Art Paper

• Printing is interrupted

for cutting off the top

margin of the first

page. This may cause

color inconsistencies

depending on the print

data.

• The top and bottom

sides of each page are

cut off at the position

slightly inward the

image edges so that no

white margin appears

on the edges of the cut

pages. This causes the

vertical length of the

cut page about 2mm

shorter than the

specified length.

PRODUCT DESCRIPTION Printing Specifications 21

Page 22

EPSON Stylus Pro 11880/11880C Revision A

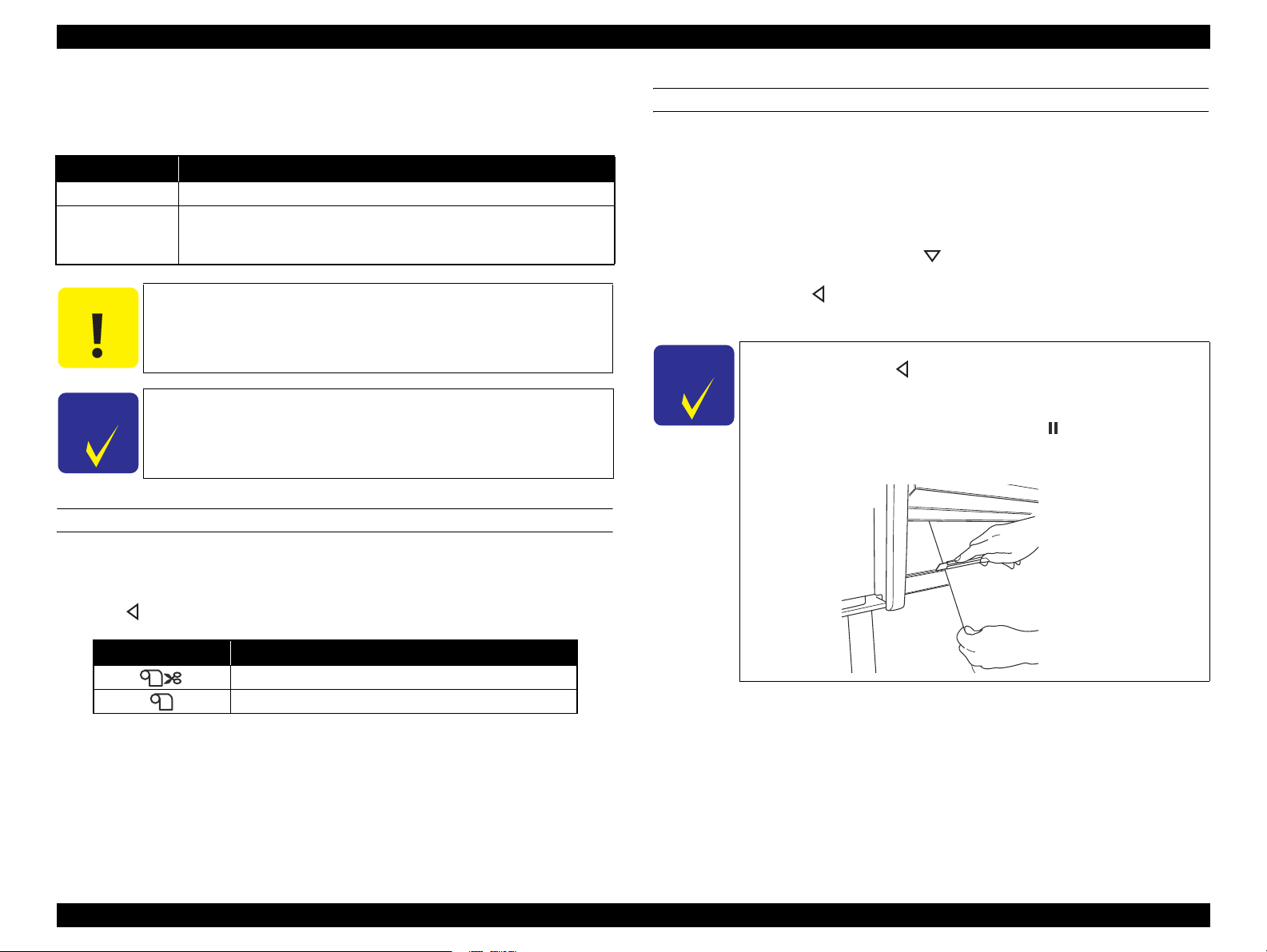

1.3.5 Cutting of Roll Paper

The printer offers both manual and auto cutting for roll paper.

Cut Method Description

Auto cut The printer automatically cuts paper with the built-in cutter.

The user can manually move the built-in cutter to cut paper, or use a

Manual cut

C A U T I O N

C H E C K

P O I N T

SETTING BEFORE PRINTING

The cut method setting can be made by the control panel or the printer driver.

commercially available cutter. Select this setting when using the Auto

Take-up Reel Unit.

Some types of roll paper cannot be cut with the built-in cutter.

Use a commercially available cutter for such types.

It may takes time for the cutting operation. The approx. waiting

time will be indicated on the display of the control panel.

The “Auto Cut” setting of the printer driver takes priority over

the “Roll Auto Cut Off” setting made by the control panel.

HOW TO CUT

Auto cut

The printer automatically cuts paper with the built-in cutter each time a page is

printed.

Manual cut

Follow the procedure below to cut paper at the desired position.

1. After a page is printed, press the button to advance the paper to the cut

position.

2. Hold down the button for 3 seconds or longer.

The built-in cutter moves and cuts the paper.

C H E C K

P O I N T

When the paper type is the one that the built-in cutter does not

support, pressing the button advances the paper to the position

for manual cutting using a commercially available cutter. Cut the

paper manually with your cutter along the lower frame of the front

cover. When cutting is completed, press the button to return the

panel display to the normal standby status.

When setting with the control panel (for printing a status sheet or etc.)

Press button to select the cut method.

Icon Description

Roll Auto Cut On

Roll Auto Cut Off

When setting from a computer

Select “Auto Cut” in the “Paper Setting” window of the printer driver.

PRODUCT DESCRIPTION Printing Specifications 22

Page 23

EPSON Stylus Pro 11880/11880C Revision A

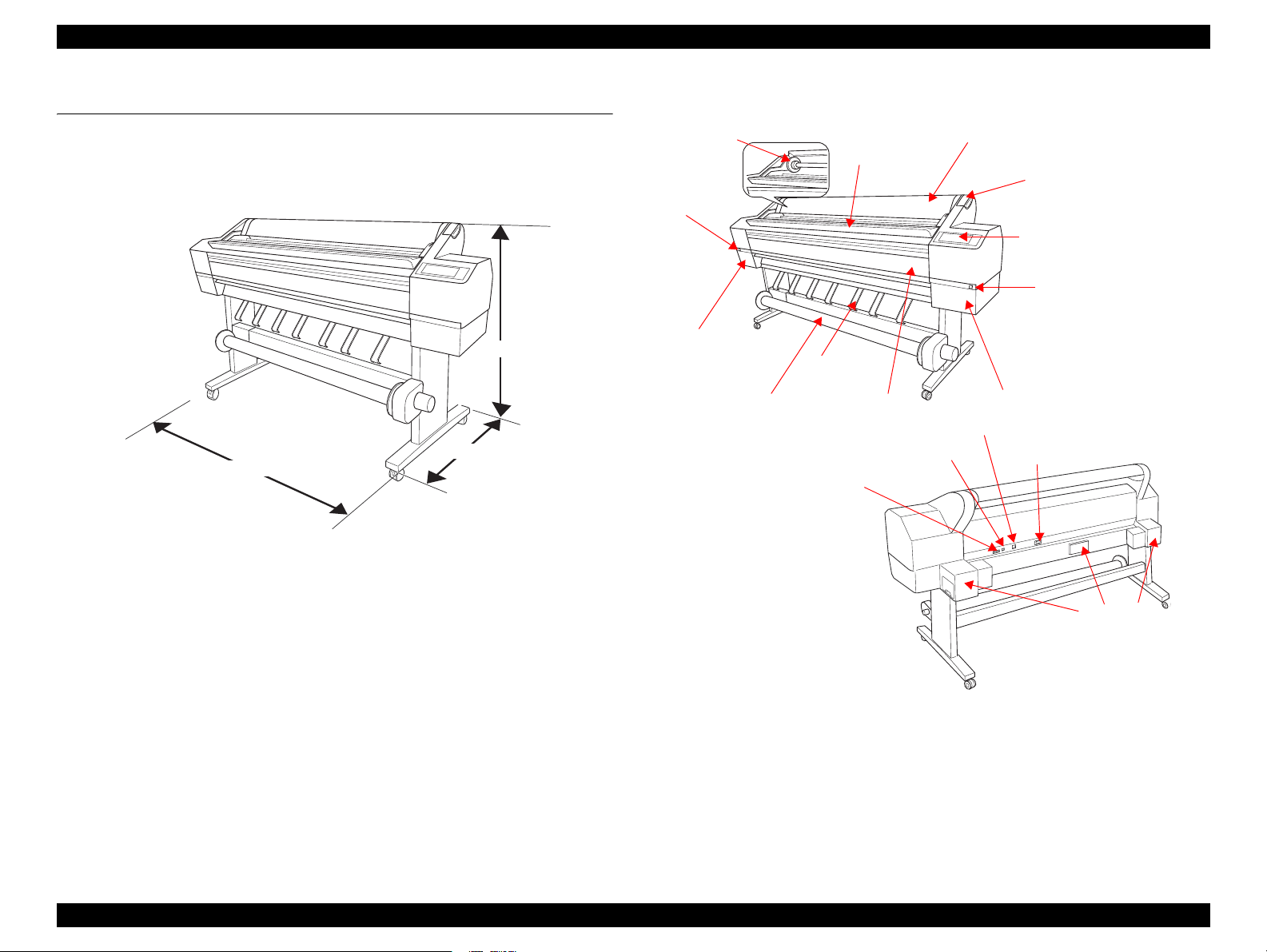

1.4 Dimensions and Main Components

This section provides the printer dimensions and shows the main components.

1.4.1 Dimensions and Weight

1,190 mm

685 mm

2,348 mm

Figure 1-3. Printer Dimensions (standard)

1.4.2 Part Names

Spindle

Ink Cover

Open Button

Ink Cartridge

Compartment

Auto Take-up Reel Unit

Auto Take-up Reel Unit Connector

Paper Eject

Paper Roll

Front Cover

USB Interface Connector

Roll Paper

Paper Lever

Control Panel

Ink Cover Open Button

Ink Cartridge Compartment

Network Interface Connector

AC Inlet

Dimensions

Standard (with the Auto Take-up Reel Unit):

2,348 (W) x 685 (D) x 1,190 (H) mm

Maintenance

Tank

Without the Auto Take-up Reel Unit:

2,348 (W) x 667 (D) x 1,190 (H) mm

When using the Paper Basket:

2,348 (W) x 740 (D) x 1,190 (H) mm

Figure 1-4. Part Names

Weight

Printer main body and the Base Unit (excludes the ink cartridges and paper):

Approx. 150.5 kg

Printer main body only (excludes the ink cartridges and paper):

Approx. 127.3 kg

The Base Unit and the Auto Take-up Reel unit: Approx. 23.2 kg

PRODUCT DESCRIPTION Dimensions and Main Components 23

Page 24

EPSON Stylus Pro 11880/11880C Revision A

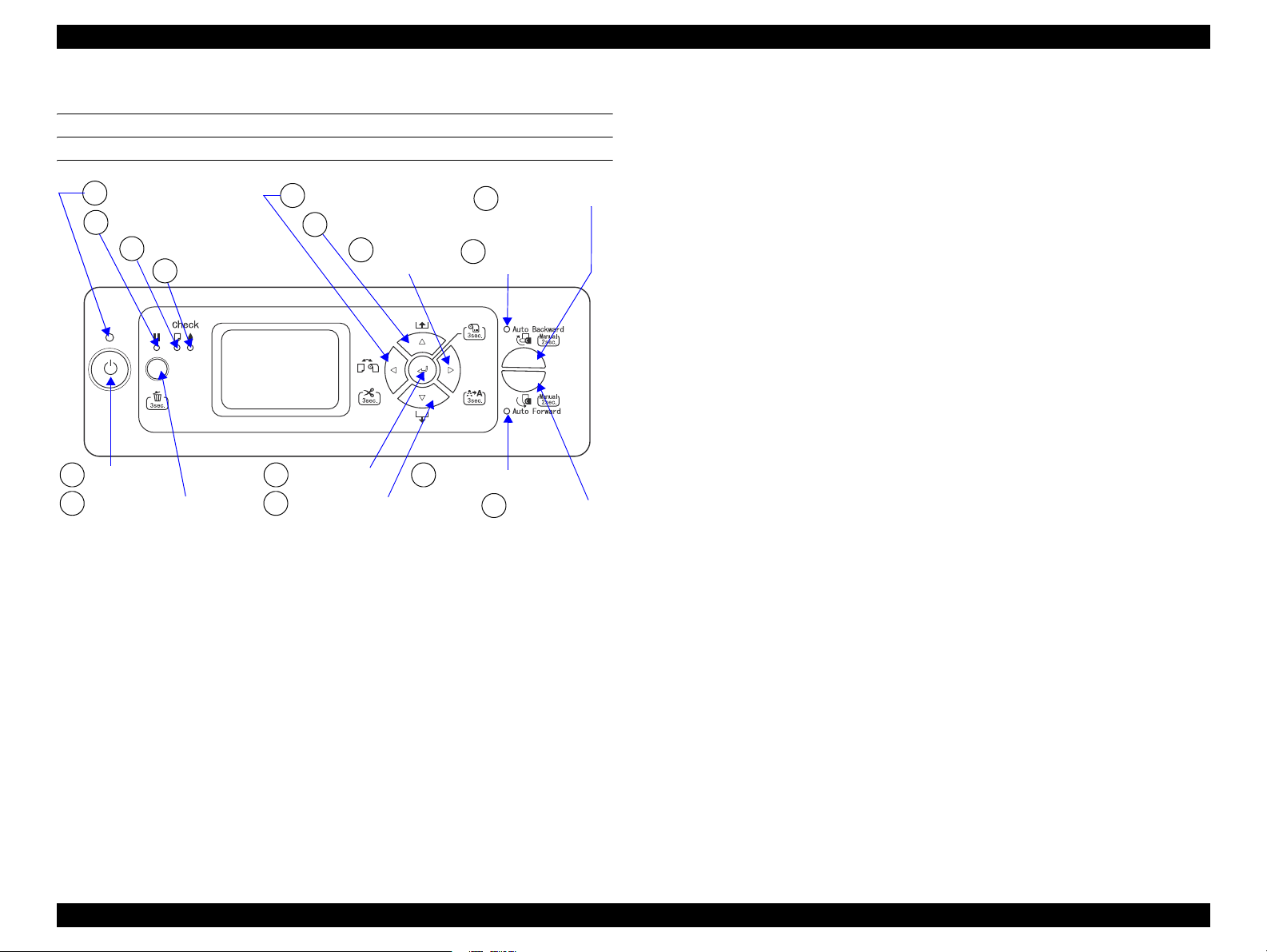

1.5 Control Panel

BUTTONS AND LIGHTS

Power Light

A

Pause Light

B

Paper Check Light

C

Ink Check Light

D

[Paper Source (left)] button

4

[Paper Feed (reverse)] button

5

[Menu (right)]

3

button

[Auto Backward]

9

button

Auto Backward

E

Light

[Power] button

1

[Pause/Reset] button

2 6

[Enter] button

7

[Paper Feed (forward)] button

Auto Forward Light

F

8

[Auto Forward]

button

PRODUCT DESCRIPTION Control Panel 24

Page 25

EPSON Stylus Pro 11880/11880C Revision A

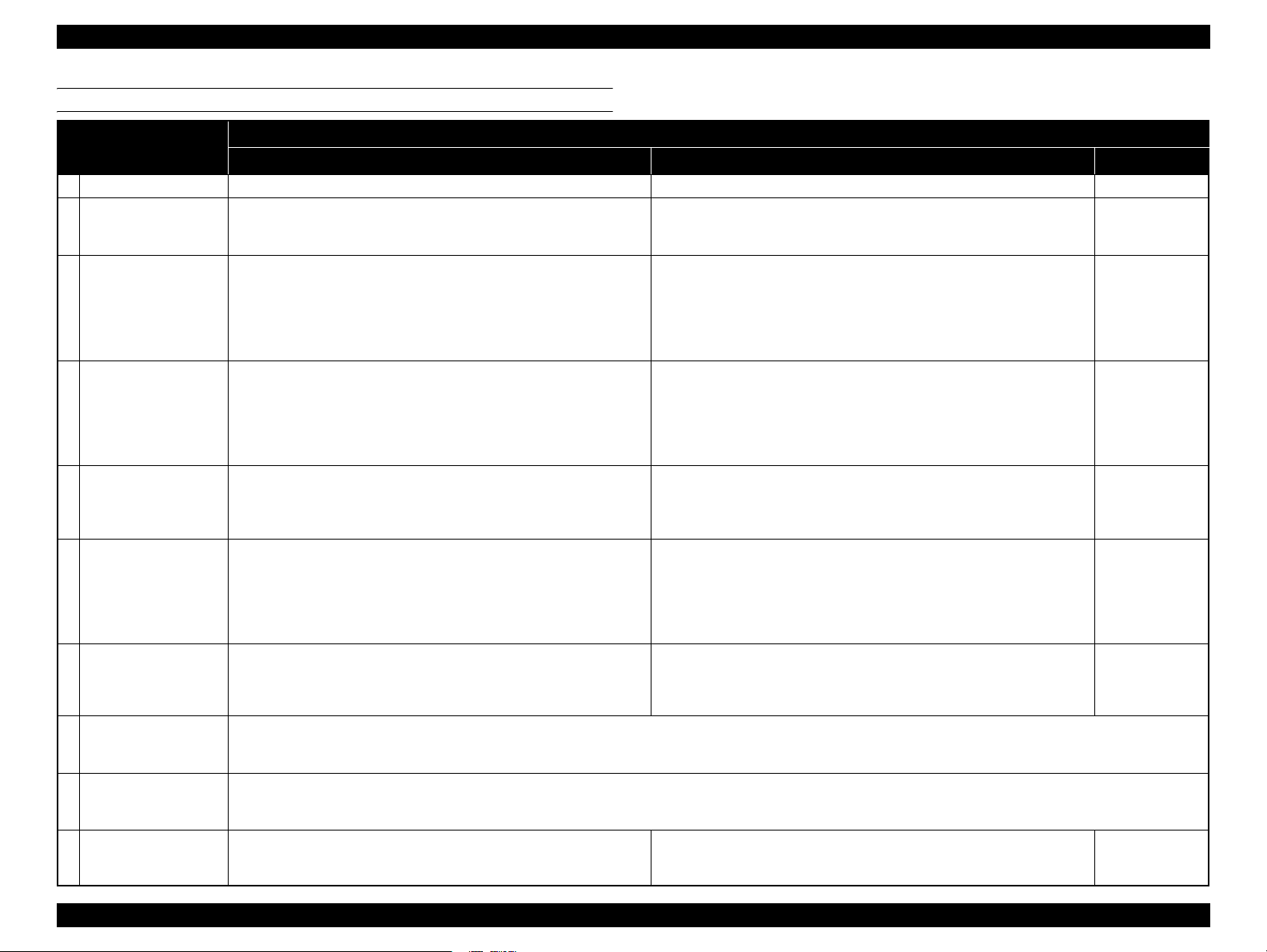

BUTTONS

Button Name

Function

When pressed normally When pressed down for 3 sec. For panel setting

1[Power] Turns the printer On or Off. --- Power-off

2[Pause/Reset]

3 [Menu (right)]

4 [Paper Source (left)]

5 [Paper Feed (reverse)]

6 [Paper Feed (forward)]

7[Enter]

8[Auto Forward]

9 [Auto Backward]

2

+ 4[Pause] + [Paper Source]

• Pauses or resumes the operation.

• Resets the paper settings to the default.

• Makes the printer recover from an error.

• During printing: Goes to the PRINTER STATUS menu.

• When not printing: Goes to Menu mode.

• During printing: Does not function.

• When not printing:

Changes the paper type.

When the ROLL PAPER REMAINING function is set to ON, switching

between roll paper and cut sheet cannot be made.

• When roll paper is loaded: Feeds the paper backward.

• When roll paper is not loaded: Does not function.

• While the Paper Lever is released: Increases the power of the paper suction

fan.

• When roll paper is loaded: Feeds the paper forward.

• When roll paper is not loaded: Does not function.

• While the Paper Lever is released: Decreases the paper suction fan power.

• When cut sheet is selected and a cut sheet is loaded on the printer: Feeds the

cut sheet to the print start position.

• When a cut sheet has been set in the printer: Ejects the cut sheet.

• When printing on a cut sheet is finished and the next paper has not been set:

Ejects the cut sheet.

• Other than the above: Does not function.

• Automatically reels roll paper with the printed surface facing outward when the roll paper is detected by the sensor.

• When pressed for two seconds during the Auto Forward light is on, reeling operation by the Auto Take-up Reel Unit and paper feeding operation by the printer are made

simultaneously.When pressed for two seconds during the light is off, only the Auto Take-up Reel Unit operates to reel the paper.

• Automatically reels roll paper with the printed surface facing inward when the roll paper is detected by the sensor.

• When pressed for two seconds during the Auto Backward light is on, reeling operation by the Auto Take-up Reel Unit and paper f

simultaneously.When pressed for two seconds during the light is off, only the Auto Take-up Reel Unit operates to reel the paper.

Cancels or activates the ROLL PAPER REMAINING function while the printer

is in standby mode.

Cancels the print job.

(when D4 is not set: reset)

• When less than 0.8 mm paper thickness is detected by the sensor: Runs a head

cleaning.

• When more than 0.8 mm paper thickness is detected by the sensor: Makes the

printer recover from a cleaning error, and runs a head cleaning.

• When printing on paper whose thickness is detected as more than 0.8 mm: Does

not function.

• When paper exists (not during printing and not error status):

When Auto Roll Paper Cut is ON: Cuts and ejects the paper.

When Auto Roll Paper Cut is OFF: Advances the paper to the manual cut position.

Cut sheet: Ejects the sheet.

• When drying ink: Cancels the operation and ejects the paper.

• Other than the above: Does not function.

• When roll paper is loaded: Feeds the paper backward at high speed.

• When roll paper is not loaded: Does not function.

• When roll paper is loaded: Feeds the roll paper forward at high speed.

• When roll paper is not loaded: Does not function.

• When the ROLL PAPER REMAINING - REMAINING PPR SETUP is set to

ON: PRINT EVERY PAGE, and paper type setting is roll paper:

Prints a barcode on the top edge of the roll paper and releases the Paper Lever.

eeding operation by the printer are made

--- ---

Cancels the panel

settings.

Goes to the next

item.

Goes to the

previous item.

Increases the set

value.

Decreases the set

value.

Accepts the change,

Executes the

operation, Stores

the settings

PRODUCT DESCRIPTION Control Panel 25

Page 26

EPSON Stylus Pro 11880/11880C Revision A

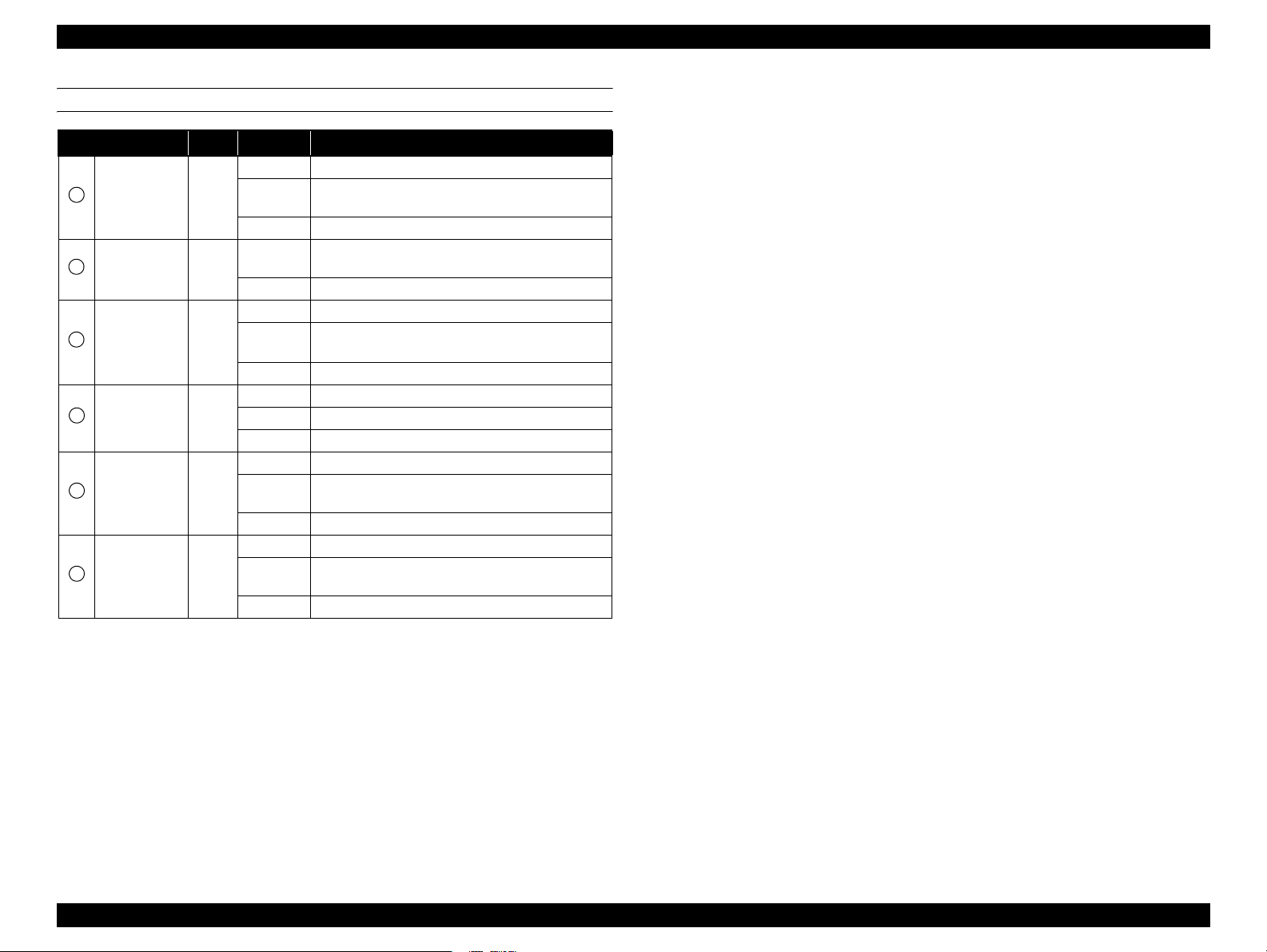

LIGHTS (LED)

Name Color Status Description

ON The printer power is on.

A

Power Green

B

Pause Yellow

C

Paper Check Red

D

Ink Check Red

E

AutoForward Green

F

AutoBackward Green

Flashing*1

OFF The printer power is off.

ON

OFF The printer is in the standby mode.

ON Paper is not ready for printing.

Flashing

OFF No error or warning is occurring.

ON An error related to ink is occurring.

Flashing*1 A warning related to ink is occurring.

OFF No error or warning is occurring.

ON The AutoForward function is enabled.

Flashing

OFF The AutoForward function is disabled.

ON The AutoBackward function is enabled.

Flashing

OFF The AutoBackward function is disabled.

The printer is receiving a data or performing the poweroff sequence.

The printer is in the Menu mode or pausing a operation,

or an error is occurring.

• An error related to feeding/ejecting paper is occurring.

*1

• A maintenance call error is occurring.

An error related to reeling of paper by the AutoForward

function is occurring.

An error related to reeling of paper by the

AutoBackward function is occurring.

Note "*1" : Repeats turning On and Off every 500 ms.When a maintenance error is occurring, the LED

repeats ON for 100 ms and OFF for 5 seconds.

"*2": The all LEDs flash when a service call error is occurring.

PRODUCT DESCRIPTION Control Panel 26

Page 27

EPSON Stylus Pro 11880/11880C Revision A

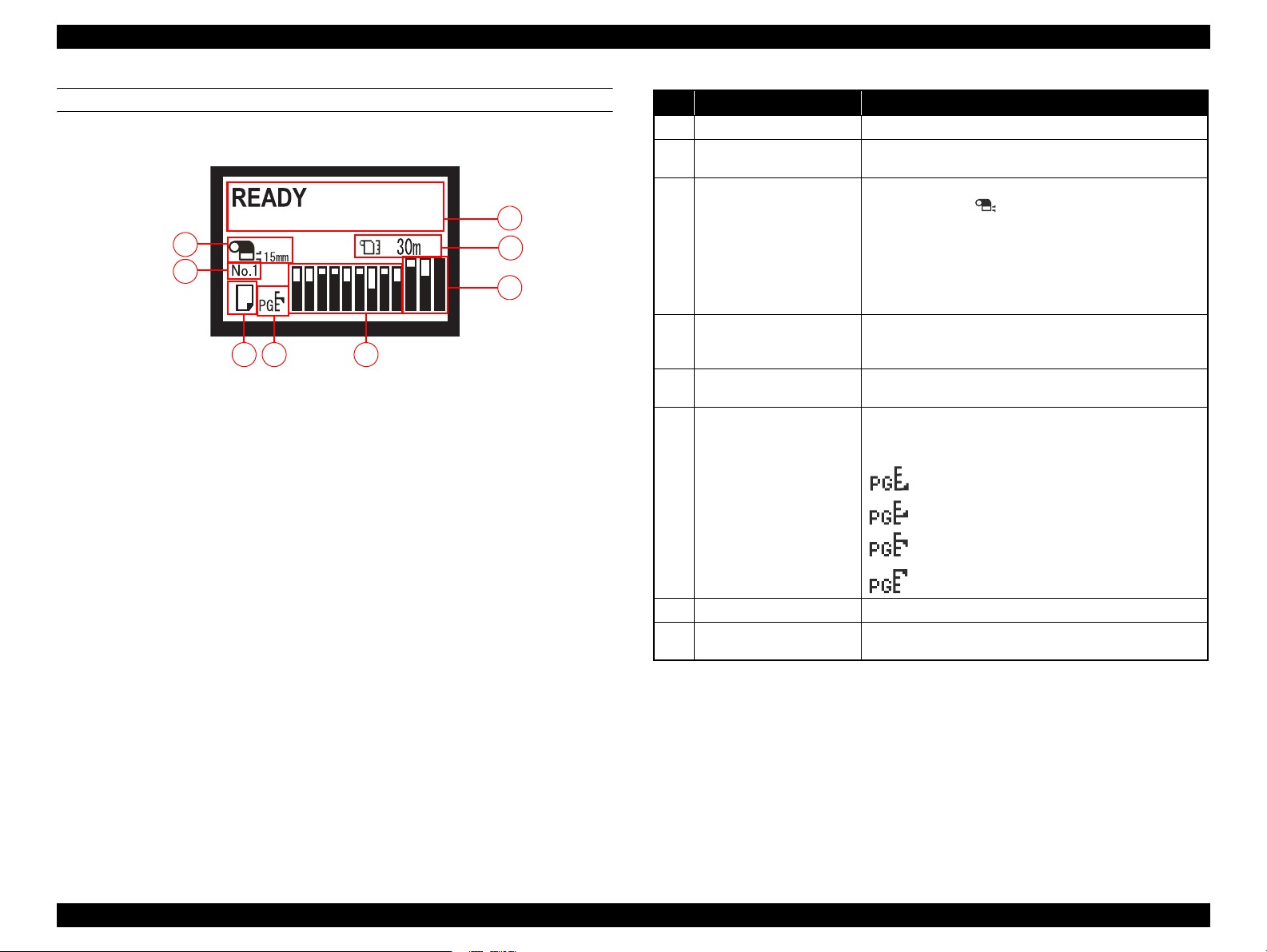

LCD

Normal indication

3

4

6

5

7

Figure 1-5. LCD (Normal indication)

No. Item Description

Message Printer status, operating status, or an error message is displayed.

1

Remaining amount of roll

2

paper

1

ROLL PAPER MARGIN

2

3

settings

8

Registered “CUSTOM

4

PAPER” No.

Paper type and roll paper cut

5

setting

“PLATEN GAP” setting

6

The remaining length of the roll paper is displayed.

The setting made by the ROLL PAPER MARGIN menu is

indicated beside the .

• 15mm: “TOP/BOTTOM 15 mm” is selected.

• 35/15mm: “TOP 35/BOTTOM 15 mm” is selected.

• 3mm: “3mm” is selected.

• 15mm: “15mm” is selected.

Nothing appears when the “DEFAULT” is selected for the ROLL

PAER MARGIN.

When the paper type registered using “PAPER NO.1 ñ 10” in the

“CUSTOM PAPER” is selected, the registered number is

displayed.

Selected paper type (cut sheet or roll) and roll paper cut settings is

displayed.

“PLATEN GAP” setting is displayed as shown below.

While the registered number of the “CUSTOM PAPER” is

displayed, the “PLATEN GAP” setting is not displayed.

: “NARROW” is selected.

: “WIDE” is selected.

: “WIDER” is selected.

: “WIDEST” is selected.

Ink level The current ink level in each of the nine cartridges is indicated.

7

Waste ink level in the

8

maintenance tanks

The current waste ink level in each of the three maintenance tanks

is indicated.

PRODUCT DESCRIPTION Control Panel 27

Page 28

EPSON Stylus Pro 11880/11880C Revision A

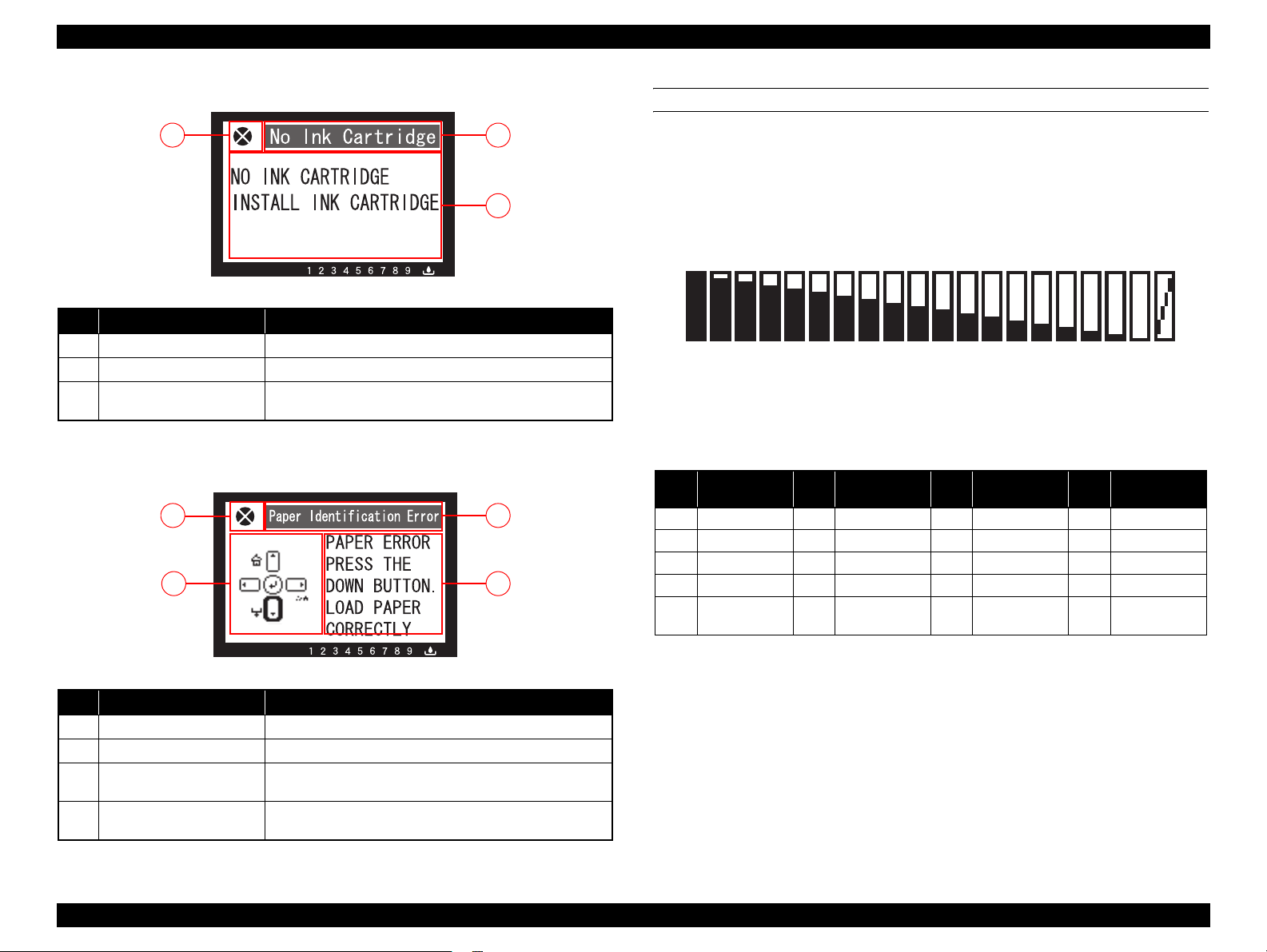

Error indication

12

3

Figure 1-6. LCD (Error indication)

No. Item Description

Error name An error name is displayed inverted.

1

Error icon An error icon is displayed.

2

Remedy

3

Note : When multiple errors are occurring simultaneously, the errors are indicated in the order of preset

priority. After recovering one of the error, the next error is displayed.

An explanation about the error or an instruction to recover from

the error is displayed.

LCD (Error indication with an image)

2

1

3 4

ICONS ON THE LCD

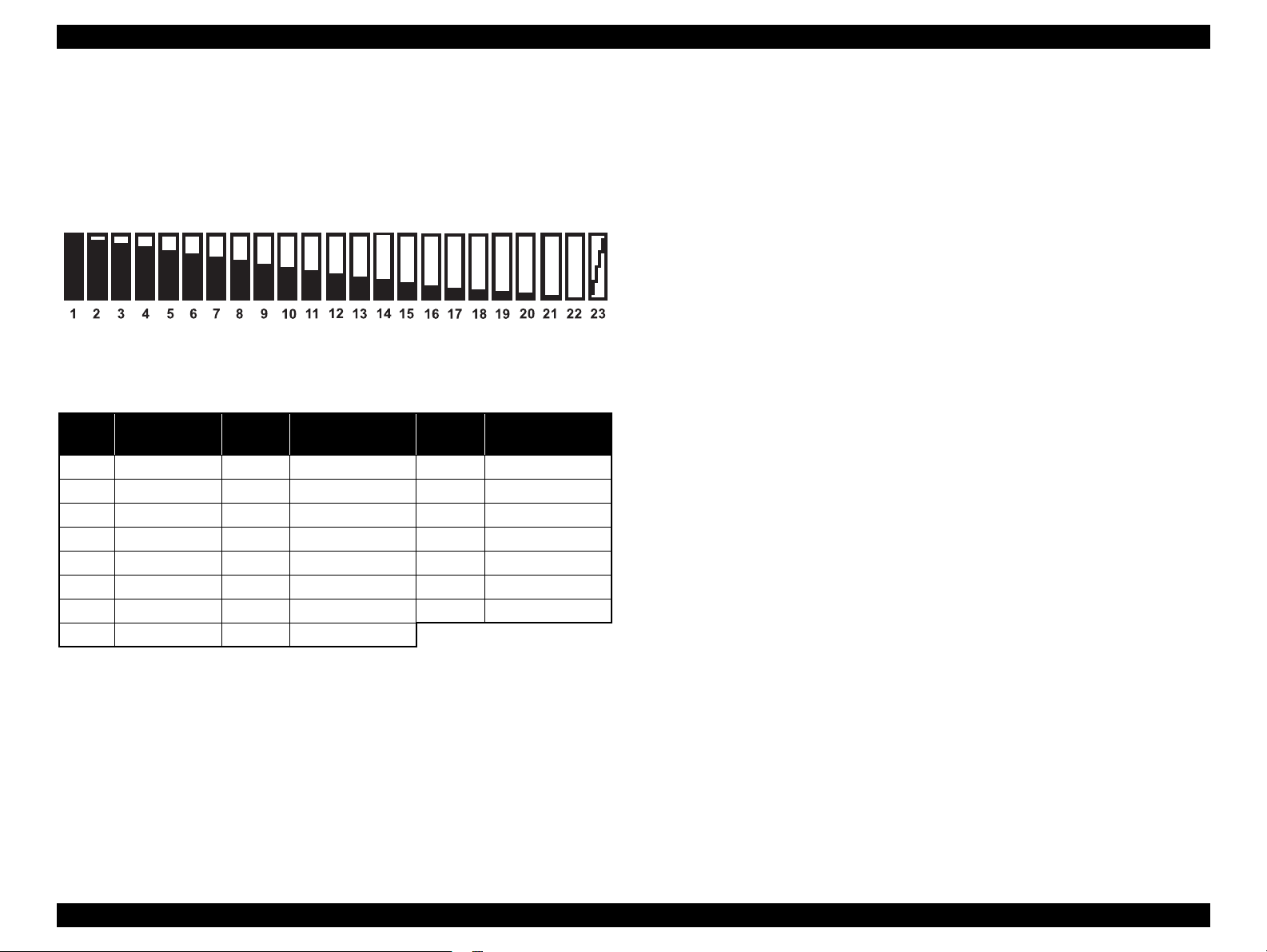

Ink level Indicator

Indicator

The current ink level in each of the nine cartridges is indicated. The

following figure and table explain the relation between the indicated

level and the actual level.

12 4 5678 91011

3

12

Figure 1-8. Ink level Indicator

Table 1-9. Ink Level Indicator and Actual Ink Level

Actual Level

No.

1 95-100 6 67-72 11 39-44 16 12-16

2 89-94 7 62-66 12 34-38 17 6-11

3 84-88 8 56-61 13 28-33 18 1-5

4 78-83 9 51-55 14 23-27 19 Empty

5 73-77 10 45-50 15 17-22 20

(%)

No.

Actual Level

(%)

No.

14

13

15

Actual Level

(%)

16 17 18 19 20

No.

Actual Level

(%)

Ink cartridge

error

Figure 1-7. LCD (Error indication with an image)

No. Item Description

Error name An error name is displayed inverted.

1

Error icon An error icon is displayed.

2

Image

3

Remedy

4

Note : When multiple errors are occurring simultaneously, the errors are indicated in the order of preset

priority. After recovering one of the error, the next error is displayed.

An illustration that demonstrates the explanation or instruction

for the error is displayed.

An explanation about the error or an instruction to recover from

the error is displayed.

PRODUCT DESCRIPTION Control Panel 28

Page 29

EPSON Stylus Pro 11880/11880C Revision A

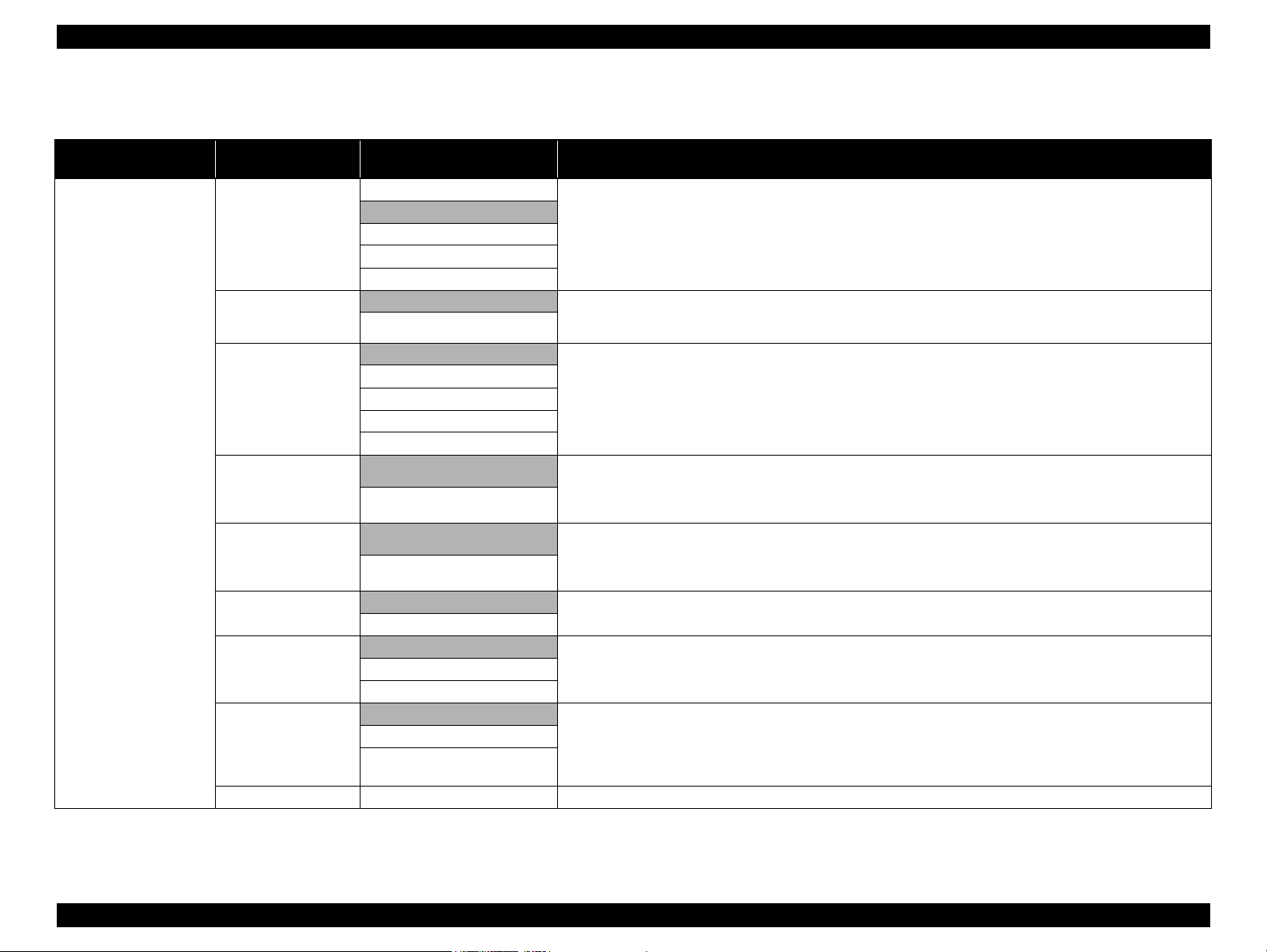

Waste ink level in the maintenance tanks

Indicator

The waste ink level in each of the three maintenance tanks are

indicated. The following figure and table explain the relation between

the indicated level and the actual level.

Figure 1-9. Maintenance Tank Waste Ink Level Indicator

Table 1-10. Waste Ink Level and Actual Level

No.

1

2

3

4

5

6

7

8

Actual Level

(%)

96-100

91-95

86-90

81-85

77-80

72-76

67-71

62-66

No. Actual Level (%) No. Actual Level (%)

10

11

12

13

14

15

16

9

58-61

53-57

48-52

43-47

39-42

34-38

29-33

24-28

17

18

19

20

21

22

23

20-23

15-19

10-14

5-9

1-4

0

Full

PRODUCT DESCRIPTION Control Panel 29

Page 30

EPSON Stylus Pro 11880/11880C Revision A

1.5.1 Menu Mode Settings

Table 1-11. Menu Mode Settings List

Top Menu Menu Item

PRINTER SETUP

PLATEN GAP

PAGE LINE

ROLL PAPER MARGIN

PAPER SIZE CHECK

PAPER SKEW CHECK

REFRESH MARGIN

AUTO NOZZLE

CHECK

PRINT NOZZLE

PATTERN

INITIALIZE SETTING

(shaded one is the default)

TOP 35/BOTTOM 15mm

Settings

NARROW

STANDARD

WIDE

WIDER

WIDEST

ON Sets whether to print a page line (line for manual cutting) on roll paper or not.The page line is printed when ON is selected.

OFF

DEFAULT

TOP/BOTTOM 15mm

15 mm

3 mm

ON

OFF

ON

OFF

ON

OFF

ON: PERIODICALLY

OFF

OFF The printer prints a nozzle check pattern automatically at the specified timing.This setting is available only when roll paper is

ON: EVERY PAGE

ON: EVERY 10 PAGES

EXECUTE All the settings made using the control panel are returned to their default.

Sets the platen gap (gap between the printhead and the platen).

When the “Others” is selected in the PAPER TYPE of the CUSTOM PAPER menu, the platen gap designated at the

CUSTOM PAPER menu has a priority over the setting made here. Refer to "PG Settings List" on page 35.

When the roll paper width specified by the printer driver is narrower than that loaded on the printer, vertical page lines are

printed.

Sets the margins for roll paper.

When the Default is selected, the top margin becomes 20mm and the bottom margin becomes 15mm for the following paper

types; Premium Glossy Photo Paper(250), Premium Semigloss Photo Paper(250), and Premium Luster Photo Paper(260).

When borderless printing is specified, this setting is ignored and the all margins become 0mm.

Sets whether to detect the paper width or not.

Setting to OFF deactivates the sensor that detects the paper width when paper is loaded on the printer. This allows the user to

use paper whose width is out of the sensor’s detectable range. It means that the user can print an image larger than the paper

size. The user should know that doing so soils the platen and may cause a print quality or any other trouble.

Sets whether to detect the paper skew or not.

Setting to OFF does not carry out the detection and printing is continued even if the paper is skewed. When this setting is set

to OFF, the user should have known the risk.

This setting is not available for cut sheet because the skew detection function after printing is not provided for cut sheet.

When this is set to ON, the top edge area of paper soiled by the previous borderless printing is automatically cut off.

The printer runs a nozzle check automatically at the specified timing.ON: EVERY JOB

used.

When the set number of pages is reached, the nozzle check pattern is printed on the top of the page. The counter for counting

the pages is not reset even by power-off.When this setting is changed, the counter is cleared. Printing patterns preset in the

printer is not counted except the network status sheet.

Explanation

PRODUCT DESCRIPTION Control Panel 30

Page 31

EPSON Stylus Pro 11880/11880C Revision A

Table 1-11. Menu Mode Settings List

Top Menu Menu Item

TEST PRINT

MAINTENANCE

PRINTER STATUS

PRINTER STATUS

(shaded one is the default)

NOZZLE CHECK PRINT

STATUS SHEET PRINT Prints an information on the printer status.

NETWORK STATUS

SHEET

JOB INFORMATION PRINT Prints a print job history report (up to 10 jobs) that is stored in the printer.

CUSTOM PAPER PRINT Prints the settings made in the CUSTOM PAPER menu.

CUTTER

ADJUSTMENT

CUTTER

REPLACEMENT

POWER CLEANING EXECUTE Runs a power cleaning that is stronger than the normal cleaning.

CLEAN EACH COLOR

CLOCK SETTING MM/DD/YY HH:MM Sets the date and time for the internal clock.

CONTRAST

ADJUSTMENT

VERSION F0xxxx-xx.xx.IBCC Displays the firmware version. Refer to "Firmware version information" on page 36.

PRINTABLE PAGES (ink color) nnnnnnn PAGES Displays the number of pages printable with the installed ink cartridges.

INK LEVEL (ink color) nn% Displays the ink level in the installed ink cartridges.

MAINTENANCE TANK

USAGE COUNT

CLEAR USAGE

COUNT

Settings

Prints a nozzle check pattern, the firmware version, paper/ink consumption, and waste ink level in the maintenance

tanks.Visually check the printout patterns for any missing lines or segments. If missing lines or segments are observed, run a

manual cleaning as necessary.

PRINT Prints an information on the network status.

EXECUTE

EXECUTE Runs a cutter replacement sequence.

C/VM

PK

MK/Y

LLK/LK

VLM/LC

0

-20 - 0 - +20 (dec)

LEFT nn%

RIGHT nn%

INK xxxxx.xml Displays the total amount of consumed ink in ml unit.

PAPER xxxxx.xcm Displays the total roll paper length consumed in cm unit.

INK EXECUTE Resets the USAGE COUNT counter for ink to its default.

PAPER EXECUTE Resets the USAGE COUNT counter for paper to its default.

Adjusts the built-in cutter position.

A cutter position adjustment pattern is printed. Examine the printout patterns and select the number for the best pattern.

Runs a cleaning for the specified nozzle columns.

Adjusts the contrast of the LCD on the control panel.

Displays the waste ink level in the installed maintenance tanks.CENTER REAR nn%

Explanation

PRODUCT DESCRIPTION Control Panel 31

Page 32

EPSON Stylus Pro 11880/11880C Revision A

Table 1-11. Menu Mode Settings List

Top Menu Menu Item

PRINTER STATUS

PAPER SETUP

(shaded one is the default)

JOB HISTORY

TOTAL PRINTS nnnnnn PAGES Displays the total printed pages using 6-digit decimal number.

NOT STARTED, ENABLED,

EDM STATUS

MM/DD/YY HH:MM GMT

PAPER TYPE

REMAINING PPR SETUP

ROLL PAPER

REMAINING

CUSTOM PAPER PAPER NO.1 - 10

PAPER TYPE

Settings

No.0 to No.9

Ink xxxxx.xml

Paper xxx.x cm2

DISABLED

LAST UPLOADED

(NOT UPLOADED)

Photo Paper

Fine Art Paper

Matte Paper

Plain paper

Others

CUSTOM PAPER

NO PAPER SELECTED

ROLL PAPER LENGTH

ROLL LENGTH ALERT

Photo Paper

Fine Art Paper

Matte Paper

Plain paper

Others

Explanation

Job No.

Displays the job number that is stored in the printer.The latest job number is 0 (zero).

The amount of ink consumed

Displays the amount of ink consumed for each job.

The amount of paper consumed

Displays the total area of paper used for each job.

Displays the EDM status.

Sets the paper type loaded on the printer.

Sets whether and when to count the remaining amount of paper.

OFF: Disables the roll paper remaining amount count function.

ON: PRINT EVERY PAGE: Displays the roll paper remaining amount on the LCD. Each time a print job is finished,

a barcode that includes information on PAPER TYPE, PAPER LENGH, and ROLL_LENGTH_ALERT settings.

ON: AT ROLL EXCHANGE: Displays the roll paper remaining amount on the LCD. When roll paper is replaced with a new

one and the [Enter] button is pressed for more than 3 seconds, the Paper Lever is locked and a barcode includes

information on PAPER TYPE, PAPER LENGH, and ROLL_LENGTH_ALERT settings is printed on the top of the

paper. The printer reads the barcode and automatically applies the read settings for the new roll paper.

Sets roll paper length, and the remaining length of roll paper to be alerted when the set amount is reached. The printer displays

the roll paper remaining amount and the alert on the control panel according to the settings made here.

The user can register custom paper settings up to 10. The custom paper settings include PAPER TYPE, PLATEN GAP,

THICKNESS PATTERN, CUT METHOD, PAPER FEED ADJUST,DRYING TIME, PAPER SUCTION settings.

Selects the paper type.

PRODUCT DESCRIPTION Control Panel 32

Page 33

EPSON Stylus Pro 11880/11880C Revision A

Table 1-11. Menu Mode Settings List

Top Menu Menu Item

PAPER SETUP

PAPER SETUP

HEAD ALIGNMENT

(shaded one is the default)

PLATEN GAP

THICKNESS PATTERN PRINT Prints a pattern for checking the thickness of the loaded paper.

CUT METHOD

PAPER FEED ADJUST

DRYING TIME

PAPER SUCTION

PAPER THICKNESS

ALIGNMENT

Settings

NARROW

STANDARD

WIDE

WIDER

WIDEST

STANDARD

THIN PAPER

THICK PAPER, FAST

THICK PAPER, SLOW

0.00% Adjusts the paper feed line pitch.

-0.70% to +0.70%

0.0 SEC

0.0 SEC to 10.0 SEC

STANDARD

-1 to -4

SELECT PAPER TYPE Sets thickness of paper to be used.

SELECT THICKNESS

AUTO Sets whether to carry out the head alignment adjustment automatically or manually.

MANUAL

Adjusts the platen gap (gap between the printhead and paper surface) according to the paper thickness.

STANDARD: use this setting under normal conditions

NARROW: select this when using thin paper.

WIDE, WIDER: select this when smudges or blurring appear due to an excess pressure on the paper.

WIDEST: select this when using heavy paper.

Selects the auto cut setting.

The larger the value is, the more the possibility to cause white bands on printout image.

The smaller the value is, the more the possibility to cause black bands on printout image.

Sets a time period to pause the carriage movement for drying the printed surface. Depending on paper type and density, drying

ink may take longer. Check the result and set longer time period in such case.

Sets the power level of the suction fan.

• When Epson paper is used, select the paper type.

• When not Epson paper is selected, enter the thickness of the selected paper.

AUTO:

The adjustment is carried out automatically after the adjustment pattern is printed.

MANUAL:

Select this to carry out the adjustment manually (visually check the patterns and enter selected values) after printing the

adjustment pattern.

Explanation

PRODUCT DESCRIPTION Control Panel 33

Page 34

EPSON Stylus Pro 11880/11880C Revision A

Table 1-11. Menu Mode Settings List

Top Menu Menu Item

NETWORK SETUP

NETWORK SETUP

IP ADDRESS SETTING

IP, SM, DG SETTING

BONJOUR

INIT NETWORK

SETTING

(shaded one is the default)

ADDRESS

SUBNET

MASK

DEFAULT

GATEWAY

Settings

DISABLE

ENABLE

AUTO

PANEL

000.000.000.000

IP

ON

OFF

EXECUTE Returns the network settings to their default.

-

255.255.255.255

192.168.192.168

000.000.000.000

-

255.255.255.255

255.255.255.000

000.000.000.000

-

255.255.255.255

255.255.255.255

Enables or disables the network settings.

The NETWORK SETUP menu items appear on the LCD only when this is set to ENABLE.

Sets whether to set the IP address automatically or manually.

When the PANEL is selected, the IP, SM, DG SETTING menu is enabled to enter the address manually.

Sets the IP address, subnet mask, and default gateway manually.

Enables or disables the BONJOUR.

Explanation

PRODUCT DESCRIPTION Control Panel 34

Page 35

Stylus Pro 11880/11880C Revision B

PG Settings List

The table below shows the actual platen gap amount specified by the printer driver

or the control panel.

Table 1-12. PG Settings List

Paper

Thickness

Sensor

0.3 mm or

lower

Paper Thickness

Setting by Driver

No setting

0.0 to 0.8mm

0.9mm to 1.5mm -- -- 2.6

Menu Setting

NARROW

STANDARD

WIDE

WIDER

Widest

Media Table or Printer

Driver PG Setting

Narrow 0.8

Standard 0.8

Wide 1.2

Wider 1.6

Widest 2.1

Narrow 0.8

Standard 1.2

Wide 1.6

Wider 2.1

Widest 2.6

Narrow 1.2

Standard 1.6

Wide 2.1

Wider 2.6

Widest 2.6

Narrow 1.6

Standard 2.1

Wide 2.6

Wider 2.6

Widest 2.6

Narrow 2.1

Standard 2.6

Wide 2.6

Wider 2.6

Widest 2.6

PG Values

(mm)

Paper

Thickness

Sensor

0.4mm to

0.6mm

0.7mm to

2.0mm

Table 1-12. PG Settings List

Paper Thickness

Setting by Driver

No setting

0.0 to 0.8mm

0.9mm to 1.5mm -- -- 2.6

-- -- -- 2.6

Menu Setting

NARROW

STANDARD

WIDE

WIDER

WIDEST

Media Table or Printer

Driver PG Setting

Narrow 0.8

Standard 0.8

Wide 1.2

Wider 1.6

Widest 2.1

Narrow 0.8

Standard 1.2

Wide 1.6

Wider 2.1

Widest 2.6

Narrow 1.2

Standard 1.6

Wide 2.1

Wider 2.6

Widest 2.6

Narrow 1.6

Standard 2.1

Wide 2.6

Wider 2.6

Widest 2.6

Narrow 2.1

Standard 2.6

Wide 2.6

Wider 2.6

Widest 2.6

PG Values

(mm)

PRODUCT DESCRIPTION Control Panel 35

Page 36

Stylus Pro 11880/11880C Revision B

Firmware version information

The table below explains the firmware version information (F0XXXXxx.xx.IBCC) printed by selecting the VERSION in the PRINTER STATUS menu.

Table 1-13. Firmware Version Information

Item Explanation

F0

XXXX Indicates the firmware version installed on the printer.

xx.xx Indicates the network firmware version.

I "8" is indicated for Stylus Pro 11880/11880C.

B

C

A code assigned to each printer.

"0" (zero) is assigned to a special version of printer.

Indicates the available functions for business system. “1 to F” hexadecimal

number appears according to the combination of available functions. When

"0" is assigned to each of the three bits, "0" is indicated. "3" is indicated for

Stylus Pro 11880/11880C because the printer does not support the business

system functions.

bit0: Graphic printing control function

0: Disabled

1: Enabled

bit1: Credit function

0: Disabled

1: Enabled

bit2: Credit counter

0: Disabled or the counter is

1: Enabled and the counter is “1” or above.

bit3: Reserved

A hexadecimal number (00H-FFH) appears to indicate the specified custom

number that registers special operation setting. When no custom operation is

"00"

specified,

appears.

"0"

.

PRODUCT DESCRIPTION Control Panel 36

Page 37

Stylus Pro 11880/11880C Revision B

1.5.2 Maintenance Mode