Environmental Water Systems CWL CHLORAMINE 1865 User Manual

Since 1987

PRODUCT AND INSTALLATION MANUAL

Professional Series Spectrum Systems

Central Water Filtration

Model Numbers:

1

Spectrum Systems:

CS-EWS-1354-7000

CS-CWL-1354-7000

Chloramine Spectrum Systems:

EWS-CC-1465-7, EWS-CC-1865-7

CWL-CC-1465-7, CWL-CC-1865-7

ALL FILTRATION PRODUCT PROUDLY MADE & ASSEMBLED IN THE USA

EWS, Inc./Environmental Water Systems

ofce. 702.256.8182

Monday - Friday, 8:30 am - 4:30 pm Pacic Standard Time

fax. 702.256.3744

www.ewswater.com

e-mail. customerservice@ewswater.com

Retain this Product & Installation Manual for Maintenance and Information

Please Register this Product - It is a Requirement for Warranty

Revised 11/11

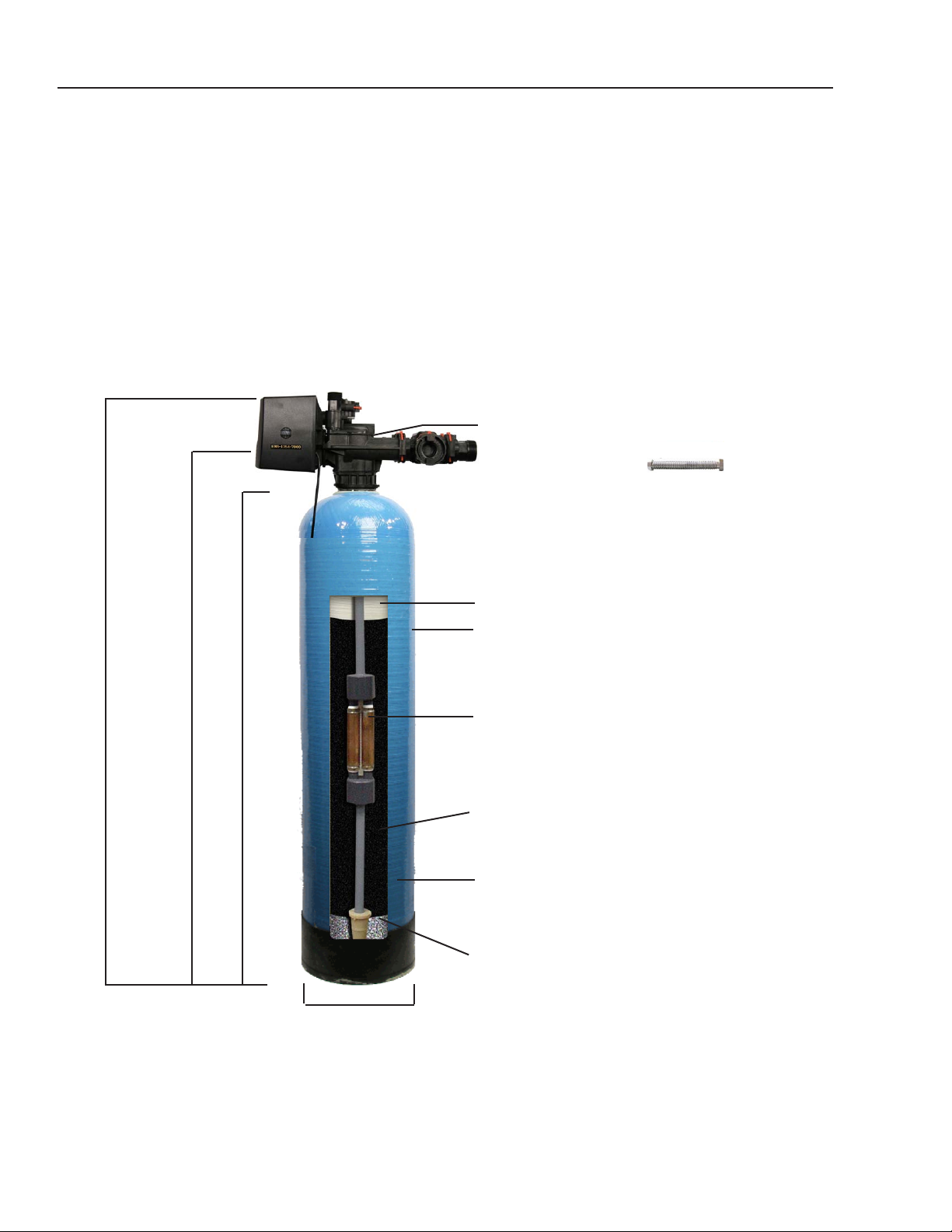

SCHEMATIC: SPECTRUM SYSTEMS

Model #’s: CS-EWS-1354-7000, CS-CWL-1354-7000

For Illustration Purposes Only:

Cut-away of CS-EWS-1354-7000

Tank, valve and all contents (as pictured below) delivered fully assembled.

Bypass and supplied adaptors some assembly required.

2

18” clearance needed from center of tank for proper installation

Valve (front view)

Not pictured: Bypass Valve to the rear of the Valve.

Highly Recommended:

Stainless steel corrugated water connectors, PEX or PVC Sch 40 have a

exible capability that may assist with issues where the rough and nish

measurements are slightly off or where pressure surges/spikes or back

pressure occur. This exible connection may prevent tank and valve issues

where rigid or hard pipe create problems over time. Perform all plumbing

according to state or local codes.

overall

height

62”

height

to center of

bypass

58”

tank

height

54”

self leveling

base

tank width 13”

Freeboard: Space allows media space to lift during backwash.

Tank: Non-corrosive, seamless, one-piece blow molded with tough epoxy

and berglass outer laminate. Note: actual color of tank may vary.

Outer Cover: White plastic cover and the coordinating plastic dome are

strictly aesthetic and are non-functional parts of the Spectrum System.

Conditioning (EWS Series Only): ICN Riser Manifold contains two ICN

conditioners that catalytically suspend hardness minerals so they inhibit

adhesion to surfaces: Note: CWL Series does not contain this part.

Riser: Specialty PVC tubing food & beverage compliant for distribution of

ltered water ow up through the riser and out to the home or water down

through the riser to lift and properly backwash in order to self clean ltra-

tion media

Filtration: 2.5 cubic feet or 65 pounds of EWS proprietary high-grade

granular activated carbon.

Lower Riser Screen and Underbed: Maintains a closed system where

media does not escape into home plumbing during normal operation. The

underbed provides greater water distribution during ltration and backwash.

All measurements are approximates and system heights may have variances up to 1”.

Review this Manual for Proper Setup, Installation and Start-up of this System.

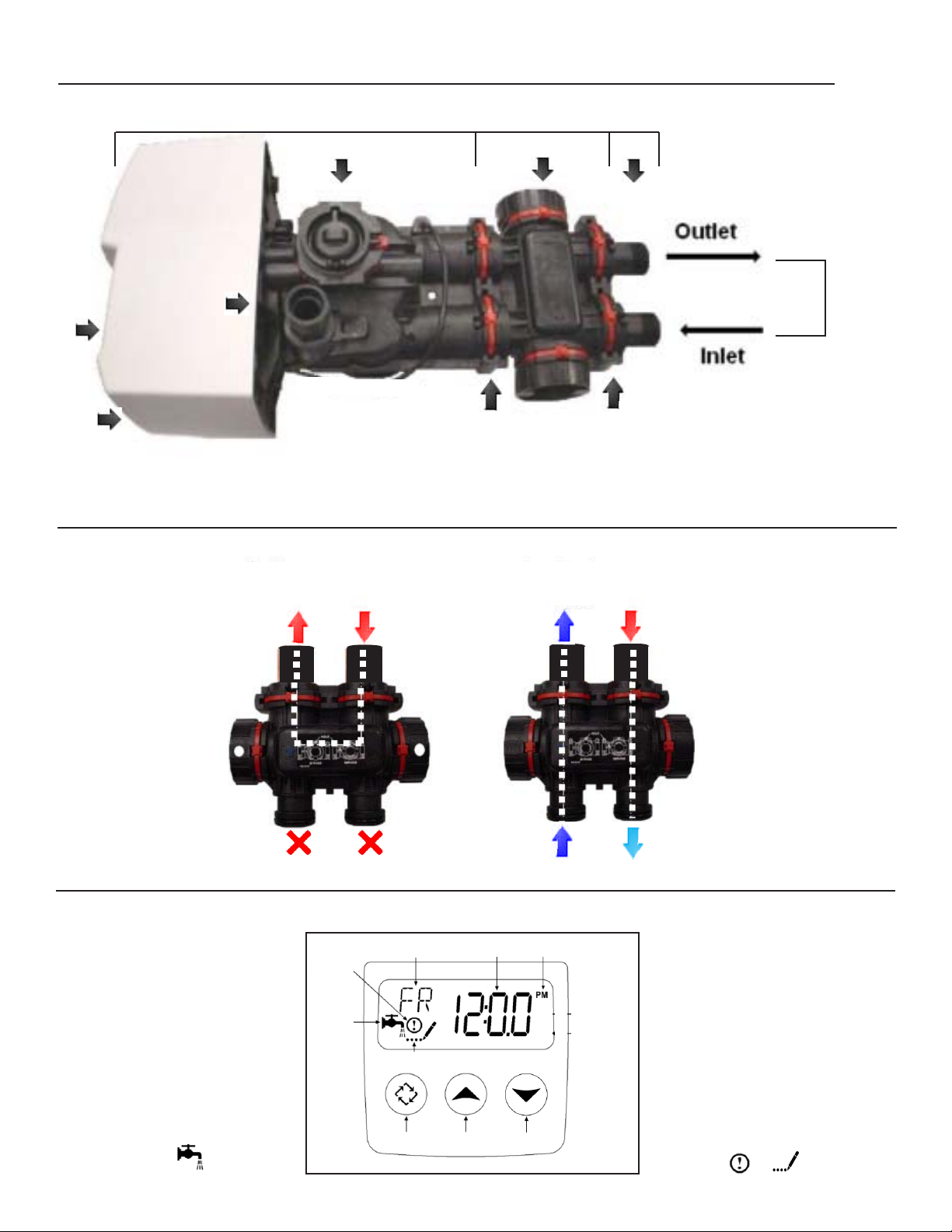

SCHEMATIC: ALL SYSTEMS - Valve, Bypass, Adaptors and Valve Controls

ALL SYSTEMS: Illustration of Complete Valve Assembly, Bypass and Provided Adaptors: 18” Overall Length Front to Back

3

valve body

built-in bypass

1”, 1 1/4” & 1 1/2”

removable

valve

cover

A

valve

controls

NOTE: a total of seven (7) red connection clips are used**

A (1) - clip, top cap assembly, B (2) - clips, valve to bypass, C (2) - clips, bypass to adaptors, D (2) - clips, bypass assembly

**WARNING:

Removal of any red clip while unit is under pressure will result in water damage and damage to valve. See other cautions within this manual.

1” MNPT

drain tting with

grey clip

model number

and labeling

7’ electric cord &

24v transformer

(not shown)

B

B

B

valve to bypass

clip connections

D

C

C

D

bypass to adaptors

clip connections

MNPT adaptors provided

3”

on center

C

Supplied Bypass Valve - All Systems

Top View

BYPASSED IN SERVICE

NOTE: Inlet and Outlet Valves are open and in the service posi-

tion when the holes appear at the sides (or do not appear on top)

as shown to the left

OUTLET

Outlet Valve

Closed

NOTE: Inlet and Outlet Valves are closed and in the bypass

position when the holes appear at the top and bottom as shown

to the right

What is normally seen on the display:

No Flow Into System

Current Time of Day in Data Display

PM Indicator (if applicable)

Data Display will alternate (every 10

seconds) between Time of Day to another

number and then back to the Time of Day

- this is normal and tells the user the next

time the system will backwash counting

down each day from 6 (factory pre-set) until

backwash

In Service Icon

INLET

Incoming

Water

Supply

Inlet Valve

Closed

OUTLET

Filtered

Water to

Outlet Valve

Open

Flow of Filtered

Water from System

Valve Controls - All Systems

Up

Button

Data

Display

Error

Information

Icon

In Service

Icon

Parameter

Display

Programming Icon

Extra Cycle

Button

Home

Indicator

Down

Button

PM

INLET

Incoming

Water

Supply

Inlet Valve

Open

Flow Into System

to be Filtered

During Installation when instructed:

Use the Up and/or Down Button to set

the Time of Day

Use the Extra Cycle Button to ush the

system. The Parameter Display will appear

and indicate the cycle engaged (“BW” or

“RR”) during backwashing and the Data

Display will indicate time remaining during

a cycle

Contact EWS Customer Service if you see

an Error Icon or have wandered into a Programming Mode that you do not understand.

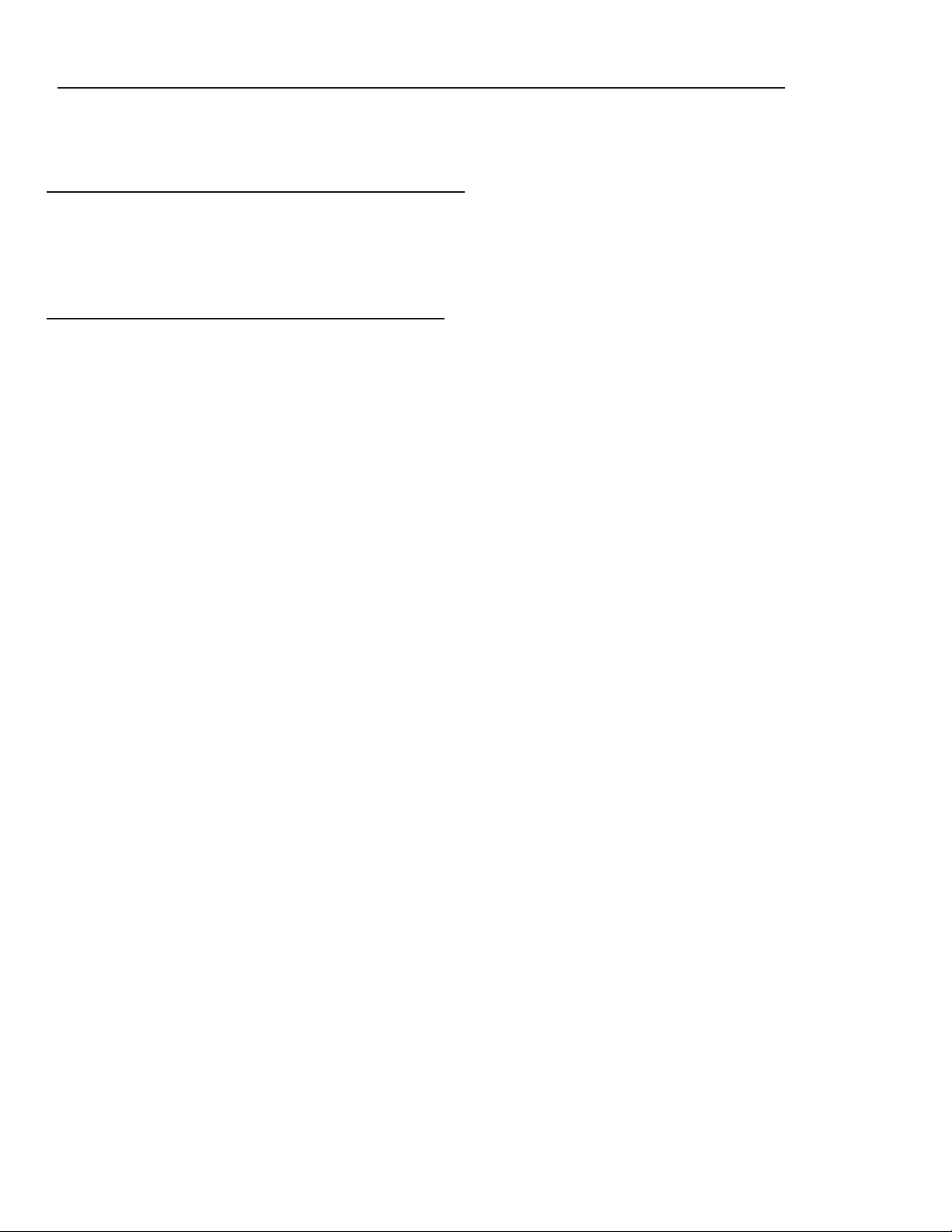

SCHEMATIC: CHLORAMINE SPECTRUM SYSTEMS

Model #’s: EWS-CC-1465-7, EWS-CC-1865-7, CWL-CC-1465-7, CWL-CC-1865-7

For Illustration Purposes Only:

Cut-away of EWS-CC-1865-7

On-Site Assembly Required

Due to shipping weight for all Spectrum Chloramine Systems,

tank, valve and all contents (as pictured below) must be assembled on site.

Bypass and supplied adaptors some assembly required.

18” clearance needed from center of tank for proper installation

Valve, Bypass Valve and threaded Adaptors (side view)

Highly Recommended:

Stainless steel corrugated water connectors, PEX or PVC Sch 40

have a exible capability that may assist with issues where the rough

and nish measurements are slightly off or where pressure surges/

spikes or back pressure occur. This exible connection may prevent

tank and valve issues where rigid or hard pipe create problems over

time. Perform all plumbing according to state or local codes.

4

overall

height

73”

height

to center of

bypass

69”

tank

height

65”

self leveling

base

tank width

14” 1465 models

18” 1865 models

Freeboard: Space allows media space to lift during backwash.

Tank: Non-corrosive, seamless, one-piece blow molded with tough epoxy

and berglass outer laminate. Note: actual color of tank may vary.

Cover Not Available with Spectrum Chloramine Systems

Conditioning (EWS Series Only): ICN Riser Manifold ICN conditioners that

catalytically suspend hardness minerals so they inhibit adhesion to surfaces.

• EWS-CC-1465-7 contains 2 ICN Conditioners

• EWS-CC-1865-7 contains 3 ICN Conditioners

• CWL Series does not contain this part.

Riser: Specialty PVC tubing food & beverage compliant for distribution of

ltered water ow up through the riser and out to the home or water down

through the riser to lift and properly backwash in order to self clean ltra-

tion media

Filtration: EWS proprietary high grade chloramine reduction media

• EWS-CC-1465-7 and CWL-CC-1465-7 contains 3 cubic feet or 90 lbs.

• EWS-CC-1865-7 and CWL-CC-1865-7 contains 5 cubic feet or 150 lbs.

Lower Riser Screen and Underbed: Maintains a closed system where

media does not escape into home plumbing during normal operation. The

underbed provides greater water distribution during ltration and backwash.

All measurements are approximates and system heights may have variances up to 1”.

Review this Manual for Proper Setup, Installation and Start-up of this System.

Assembly Instructions - Chloramine Spectrum Systems Only

CHECKING THE PARTS LIST PRIOR TO ASSEMBLY

Below is a box count for each system and its’ contents.

EWS-CC-1465-7 and CWL-CC-1465-7 should have 6 boxes.

5

One Box - Tall containing the 14” x 65” Tank with a 1.05” (26.67mm) Riser ( ICN Riser Manifold - EWS Series only)

One Box (master carton) contains Valve, Valve Screen, Bypass Valve, Adaptors, Riser Cap, Funnel, Service Information Packet

One Box contains 50 lbs. underbed (pea gravel material specic to this system, ltration media and ow rate)

Three Boxes containing 1 cubic foot each of EWS’ proprietary Chloramine Reduction Media (CRM)

EWS-CC-1865-7 and CWL-CC-1865-7 should have 8 boxes.

One Box - Tall containing the 18” x 65” Tank with a 1.26” (32mm) Riser (ICN Riser Manifold - EWS Series only)

One Box (master carton) contains Valve, Valve Screen, Bypass Valve, Adaptors, Riser Cap, Funnel, Service Information Packet

One Box contains 50 lbs. underbed (pea gravel material specic to this system, ltration media and ow rate)

Five Boxes containing 1 cubic foot each of EWS’ proprietary Chloramine Reduction Media (CRM)

ASSEMBLY PROCEDURE - ALL SPECTRUM CHLORAMINE SYSTEMS

1. From tall box remove Tank.

Caution: Riser (or ICN Riser Manifold - EWS Series only) is in the Tank. Do not remove and be careful not

to damage. Riser will be positioned upon the loading of the underbed and ltration media.

2. Move the Tank to (or near) the systems’ nal install location. The Tank will be getting heavy once lled.

3. From master carton remove Valve, Valve Screen, Bypass Valve, Adaptors, Riser Cap and Funnel.

4. Cap the top of the clean Riser to prevent lling with CRM ltration media. Use Riser Cap included or any heavy-duty tape.

5. Place or adjust capped Riser in the center of the tank.

Caution: Riser rests at the bottom and center of Tank. Do not press down and follow loading instructions.

6. Load the Tank, using supplied Funnel in the following order:

A: From one box with Underbed (a “pea gravel” for better water distribution) load all materials until box is empty.

Caution: Slowly ll and make small adjustments as needed to make sure Riser is straight up and down, and

centered in Tank.

B: Find 3 (1465 systems) or 5 (1865 systems) boxes with pre-measured CRM ltration media. This material is black and

granular. Empty all the contents of each box into the Tank.

Note: Top 1/3 of Tank should be empty. This is called freeboard for proper backwashing of the system.

Caution: Slowly ll and make small adjustments as needed to make sure Riser is straight up and down, and

centered in Tank.

Caution: Media is dusty. Do not inhale. Work in area with good ventilation and/or take preventative measures.

7. After Underbed and all CRM ltration media is loaded, remove the Riser Cap or tape from the top of the Riser.

8. Installation of the Valve onto the Tank:

A: Connect Valve Screen to the bottom of the Valve before connecting Valve to the Tank

B: Make sure the top of the Tank and Tank threads are clean of any debris or materials from Steps 1 through 6.

C: Center Riser where the Riser ts up into the center & bottom of the Valve. The Valve Screen at the bottom of the Valve

will help center and guide the Riser into the proper position. Back off the installation if resistence occurs and retry unitil

Riser ts into position without any issues.

Warning: DO NOT force Riser up into the center & bottom of the Valve. Riser should be straight and centered and

should t snugly into that position. A Riser that is forced to t, bent or off-center may fail under pressure.

D: Install the Valve onto the Tank by turning clockwise. Be careful not to cross-thread Valve onto Tank.

9. Thank you for properly lling and assembling the Tank, all its’ contents and connecting the Valve.

Please go to Page 7 and follow all instructions for the proper setup, installation and startup of all Spectrum Systems.

Table of Contents

SCHEMATIC: SPECTRUM SYSTEM ............................................................................................... 2

SCHEMATIC: VALVE, BYPASS, CONTROLS - ALL SYSTEMS.............................................................. 3

SCHEMATIC: SPECTRUM CHLORAMINE SYSTEM ....................................................................... 4

SPECTRUM CHLORAMINE SYSTEM: ON SITE ASSEMBLY PROCEDURE............................................. 5

IMPORTANT SAFETY INFORMATION – All Systems

Instructions Before Using ........................................................................................................ 7

SETUP - All Systems ....................................................................................................................... 8

Unpacking and Inspection

Where to Install the System

6

INSTALLATION INSTRUCTIONS - All Systems

Plumbing Connections ..................................................................................................................... 9

Drain Line .................................................................................................................................. 11

Electrical Connection ..................................................................................................................... 11

START-UP PROCEDURES - All Systems

Flush and Clear Home Lines with System Still in Bypass ................................................................. 12

Tank Fill Slowly .................................................................................................................................. 12

Setting the Time of Day while The Tank is Filling Slowly ................................................................. 13

Flushing the System Procedure ........................................................................................................ 13

Last Steps Before Leaving the System ........................................................................................... 15

Repeat Flushing (if needed)

Open Outlet Side of Bypass

System Ready for Use

Run Water throughout the Home

GENERAL TERMS AND STANDARD CONDITIONS OF SALE ..................................................... 17

LIMITED WARRANTY ....................................................................................................................... 18

www.ewswater.com o. 702.256.8182; (m-f; 8:30am-4:30pm; PST) f. 702.256.3744 e-mail. customerservice@ewswater.com

Loading...

Loading...