ENVIROMAC 103 User Manual

Table of Contents

GENERAL INFORMATION. ................................................................................................................ 4

PURPOSE. ........................................................................................................................................ 4

OPTIONS .......................................................................................................................................... 4

RESERVATIONS OF THE MANUFACTURER. ..................................................................................... 5

TECHNICAL DATA. ........................................................................................................................... 6

Working ranges and reaches of arms. .................................................................................................................................... 6

Dimensions of mounting flanges ............................................................................................................................................. 7

CONSTRUCTION .............................................................................................................................. 8

Basic components .................................................................................................................................................................. 8

Wall or ceiling mounted version: ............................................................................................................................................. 9

Portable (Bench Mount) version: ............................................................................................................................................ 9

Optional hood accessories (special order): ............................................................................................................................ 9

MOUNTING AND ASSEMBLY INSTRUCTION ..................................................................................... 9

Light kit: ................................................................................................................................................................................. 11

USE AND MAINTENANCE INSTRUCTION AND ARM ADJUSTMENT ................................................ 12

Adjustment. ........................................................................................................................................................................... 13

TROUBLESHOOTING. .................................................................................................................... 14

The arm will not stay where it is placed ................................................................................................................................ 14

Stronger resistance during rotation of the arm ..................................................................................................................... 14

Decrease in air volume ......................................................................................................................................................... 14

SAFETY GUIDELINES. ................................................................................................................... 14

ACCESSORIES ............................................................................................................................... 14

Light kit .................................................................................................................................................................................. 14

Hoods .................................................................................................................................................................................... 14

Mounting brackets ................................................................................................................................................................ 14

Fans ...................................................................................................................................................................................... 14

Pivoting booms ..................................................................................................................................................................... 14

Complete Fume Arm ............................................................................................................................................................. 15

EXPLODED VIEWS ........................................................................................................................ 15

Base Assembly ..................................................................................................................................................................... 16

Middle Joint ........................................................................................................................................................................... 17

Hood Assembly ..................................................................................................................................................................... 18

Damper Assembly ................................................................................................................................................................ 19

Spring Assembly ................................................................................................................................................................... 20

PARTS LIST .................................................................................................................................... 21

6” Wall or Ceiling Mount ....................................................................................................................................................... 21

4” Wall or Ceiling Mounted Arm ............................................................................................................................................ 37

3” Bench, Wall or Ceiling Mounted Arm ............................................................................................................................... 43

IN USA

Email: info@enviroflex.com

IN CANADA

Email: info@enviroflex.com

USER AND MAINTENANCE MANUAL

ENVIROFLEX SNORKVAC™ SELF-SUPPORTING FUME ARMS

Enviroflex International Inc.

1051 Clinton Street

Unit 217

Buffalo, NY

14206-2823

Phone: (716) 883-2319

Toll Free (877) ENV-FLEX(368-3539)

Fax: (716) 892-2139

Web Site:

www.enviroflex.com

Enviroflex International Inc.

17 Brownridge Rd

Unit 8

Halton Hills, Ontario

L7G 0C6

Phone: (905) 636-1177

Toll Free (877) ENV-FLEX(368-3539)

Fax: (905)636-1178

Web Site:

www.enviroflex.com

Date: October 24, 2013

This manual is designed to inform the user about the proper

assembly and use of the device. The user is advised to get fully

manual before installation of

acquainted with the contents of the

the device and to handle the device according to the manual.

General information.

This manual contains basic technical data of the self-supporting suction arms type ENVIROFLEX®

SNORKVAC™ and necessary information about installation, start and use of the devices. Before

assembly and use of the device the owner and operator should read this manual carefully in order to

fully understand the construction of the device, the principles of it s operation, as well as its service and

safety features. This will permit safe, efficient operation and assembly of the device. The manufacturer

reserves the right to make design and technological changes, which may improve the device. The

manufacturer doesn’t take any responsibility if the device isn’t used according to m anual.

Purpose.

ENVIROFLEX® SNORKVAC™ self-supporting Fume Arms are designed to easily position near the

source of fume generation and to easily provide for the extraction of dust and gas emissions in the

workplace.

The arms ensure the most efficient means of protecting the worker from the impurities by removing

them before they enter the operators breathing zone. Proper Use of the self-locking joints and the

flexible hoses ensures very easy extension of the hood close to the source of the contaminant.

Closing of the manual damper allows the operator to divert the air to other units on the same system,

which increases efficiency of the complete ventilation ducting.

Options

The ENVIROFLEX® SNORKVAC™ Self-supporting Fume Arms can be connected with:

- pivoting extension booms 3ft(.9M), 7ft.(2M), 10ft.(3M), 14ft.(4M), 161/2ft.(5M) and 19 1/2ft.(6M) in

length giving you a maximum reach of 33 1/2ft.(10M)

- different filtering devices or with fans

- energy efficient automatic equipment

Limitation of use :

corrosive, caustic and explosive gases

Some of the possible areas for use of the Enviroflex® Snorkvac™ Fume Arms are:

- chemicals

- gluing

- grinding applications

- light dusts

- painting

- polishing

- soldering

- welding processes

• For all non stainless steel versions - corrosive and caustic gases and dust

• For version with light installed in the hood –

and dust

Reservations of the manufacturer.

The manufacturer reserves the right to make design and technological changes, which may improve

the device. Before mounting and use of the arm the owner and operator should read this manual

carefully in order to understand fully the construction of t he device, the principles of its operation, as

well as its service and safety features. This will permit safe, efficient operation and assembly of the

device.

The manufacturer doesn’t take any responsibility if the device isn’t used accor ding t o the manual.

Technical data.

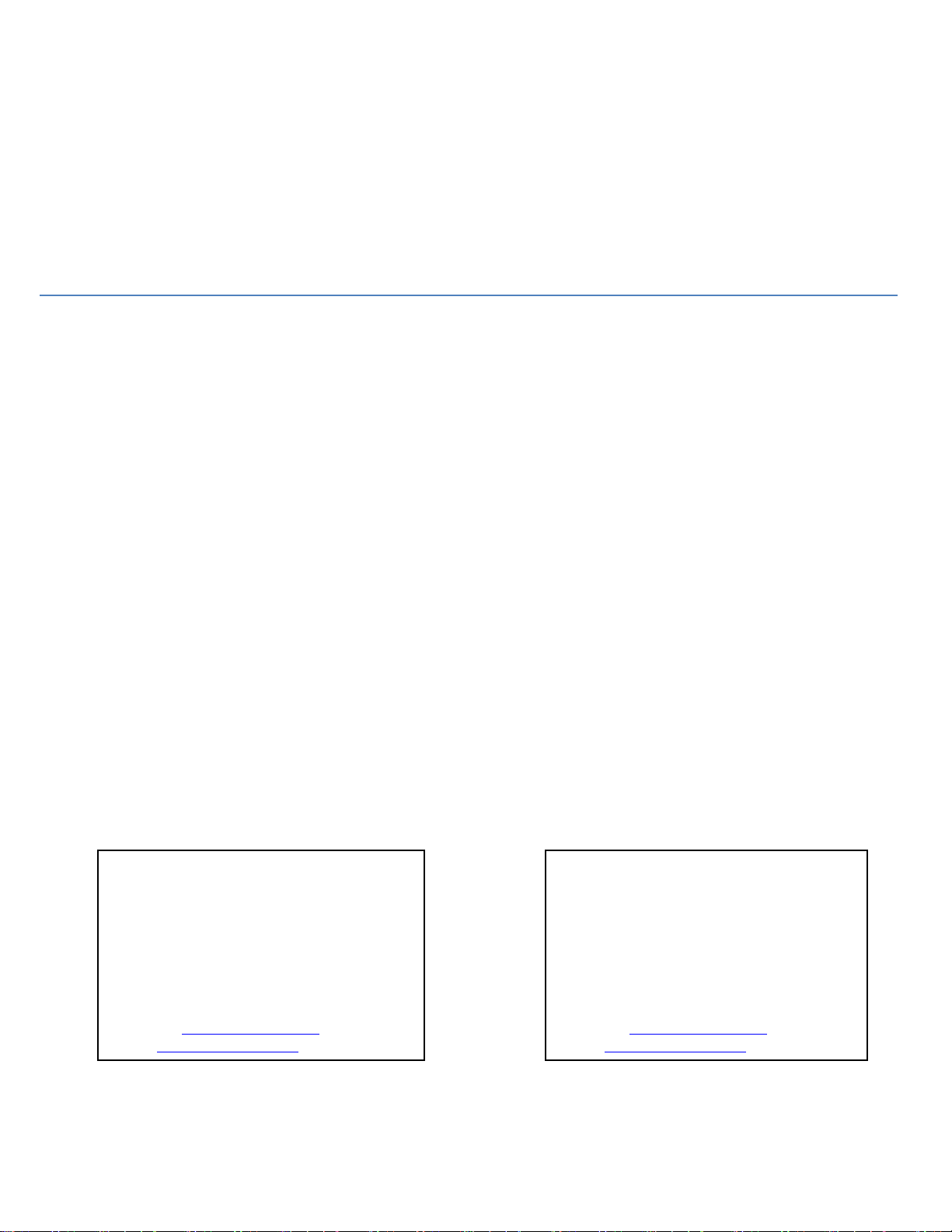

4”, 6”, 8” Enviroflex® Snorkvac™

self-supporting arm can be turned

through 350

o

;

Arm reach

[feet] / [m]

Arm diameter

[mm]

9

103.1007

14 / 4.0

6 / 160

12 (14) / 315 (350)

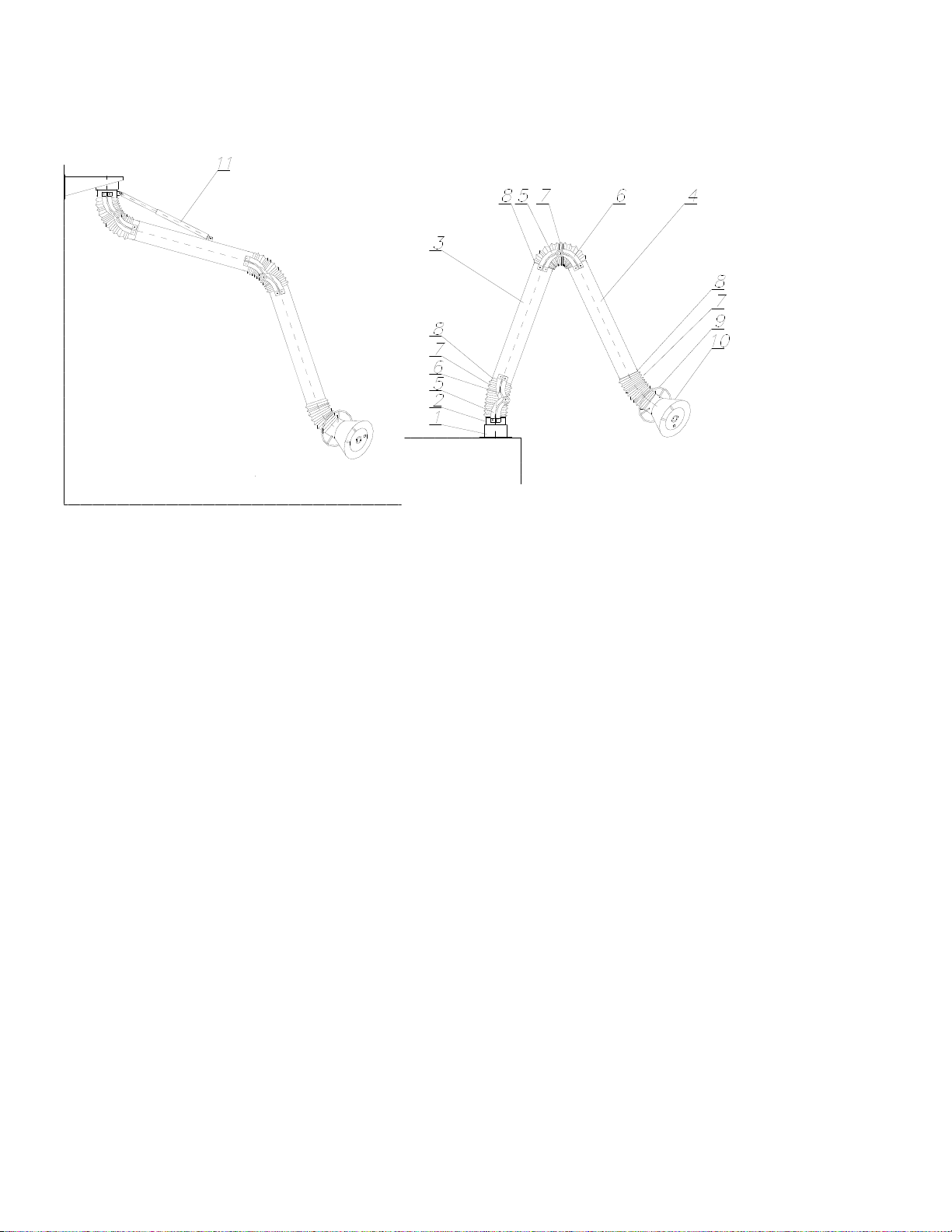

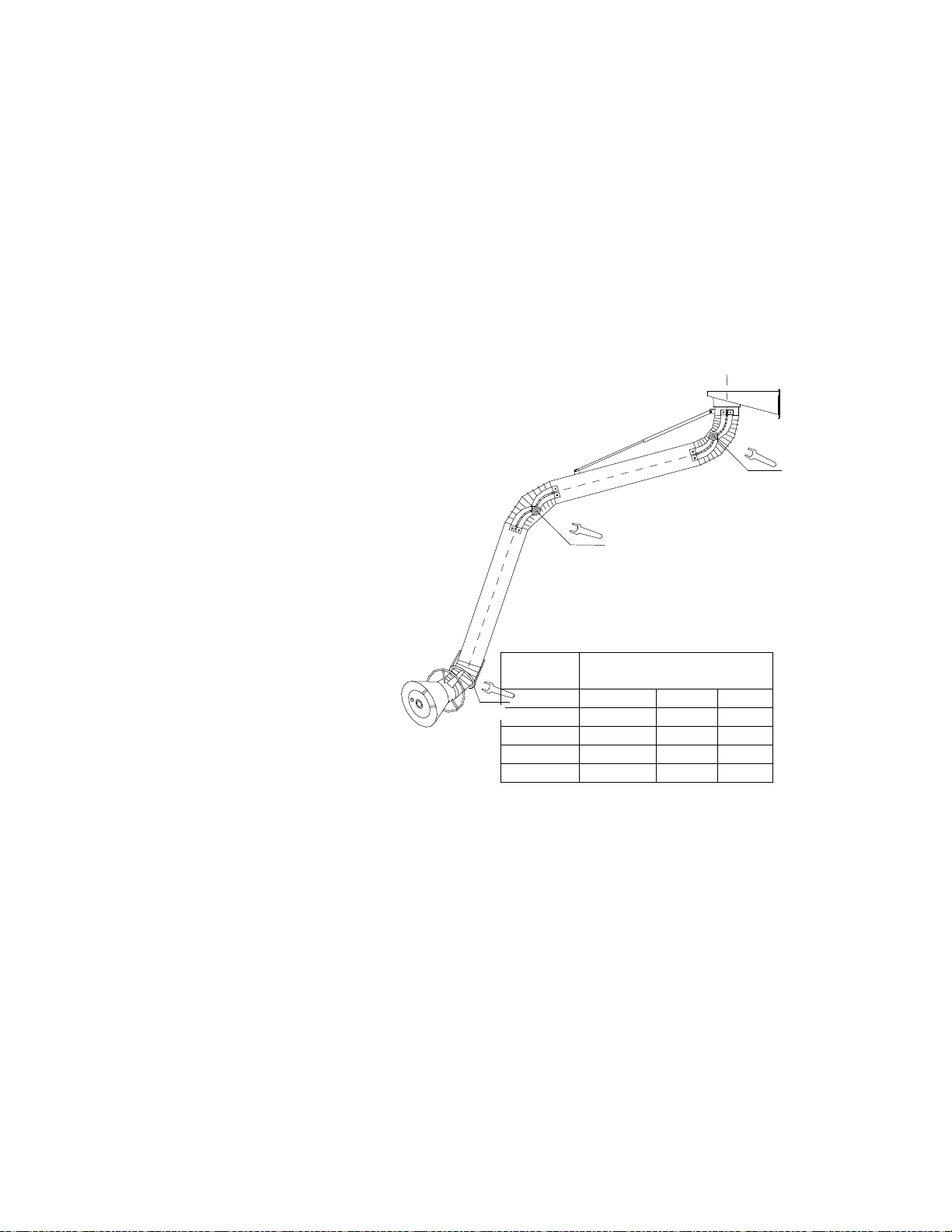

Drawing 1.

Working ranges and reaches of arms.

Table 1. Product range.

Model

R

max

[inches] /

Available hood diameter

[inches] / [mm]

A large variety of hoods can be manufactured to suit a particular requirement. Different diameters,

constructions, material are available.

All hoods are equipped for installation of an optional light kit.

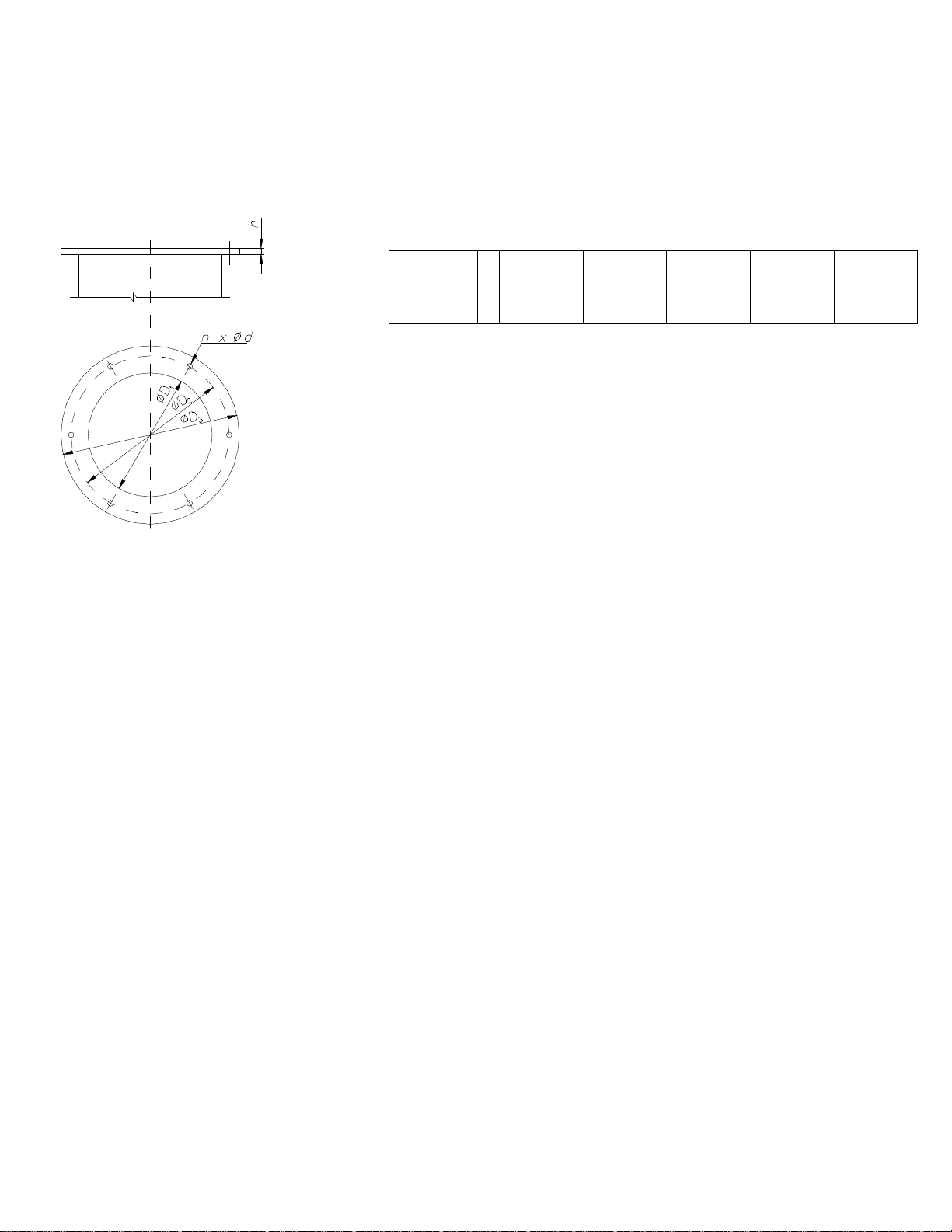

Diameter

[inches]

6”

6

.28/7

6.02/153

7.68/195

8.66/220

.26/7

Dimensions of mounting flanges

of arms

n

- D [in.]/[mm]

D1

[in.]/[mm]

D2

[in.]/[mm]

D3

[in.]/[mm] h [in.]/[mm]

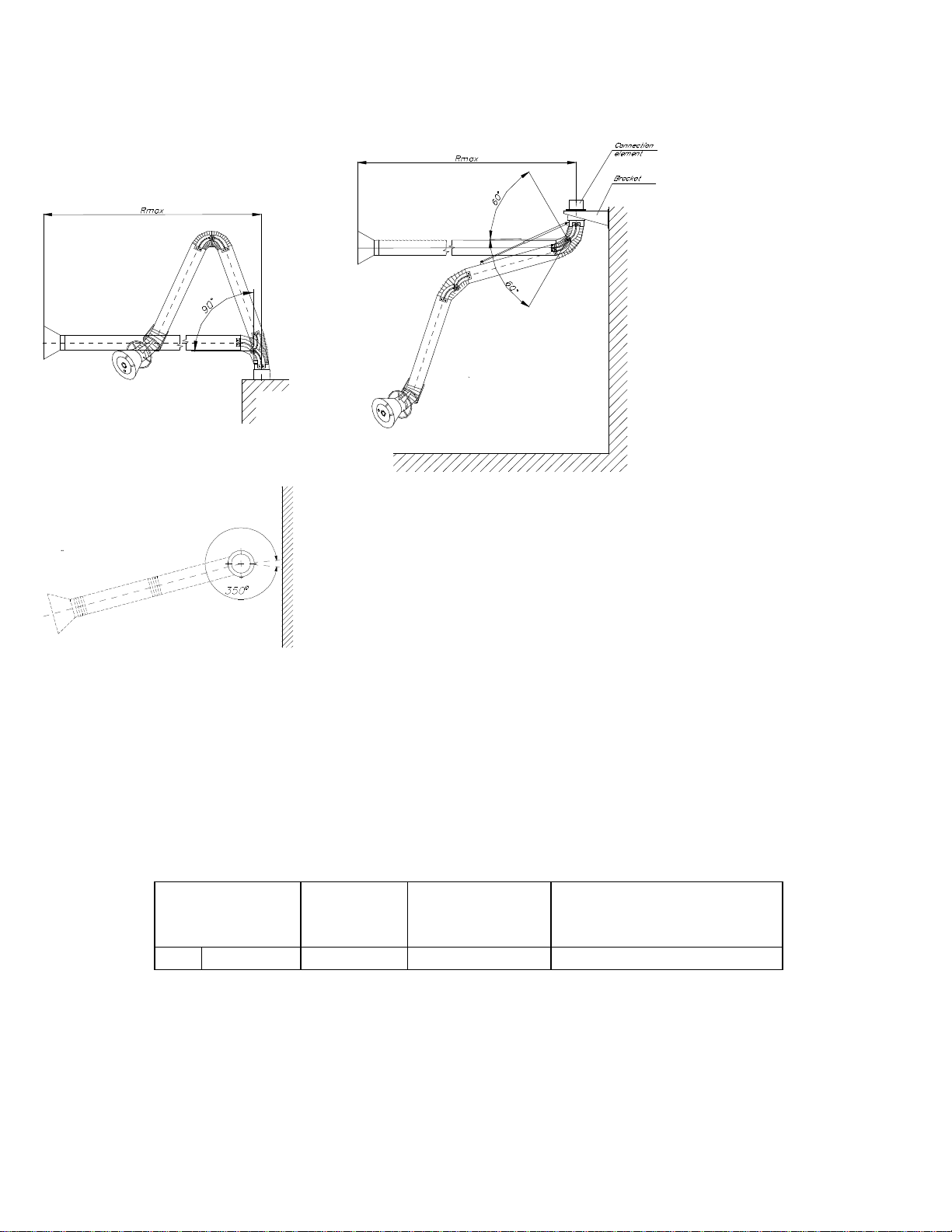

Construction

Construction of self-supporting suction arm.

ENVIROFLEX® SNORKVAC™ – Wall or ceiling mounted arm ENVIROFLEX® SNORKVAC™ – Bench mounted arm

Drawing 2.

Basic components

• The rotating socket which consists of the outer sleeve (1) (cast aluminum) with the connecting

flange and the other inner sleeve (2) (steel). The sleeves for 4”, 6”, and 8” arms are connected

together by means of a thread. The rotation of the sleeves in the range of 35 0° is limited by a stop.

The 3” arm does not use the thread so it can be rotated 360°. The complete unit is electrostaticall y

powder coated, with "thermo-hardened" paint.

• The arms I (3) and II (4) - pipes (rolled sheet steel), covered and painted as above.

• The flat joints inner (5) and outer (6) – For 6” and 8 “versions - Cast Aluminum painted by the

electrostatic method (as above), and bolted to the inner sleeve of the rotating socket and to the arm

I and II. For 3”, 4” version - steel elements also painted and bolted as above.

• The friction joints are separated with the frictional insert and washer. These elements are bolted

together.

• The flexible hose (7) connecting the elements of the self-supporting arm (“bending” of device) are

attached by means of gear clamps (8).

• The hood (10) is fabricated of aluminum sheet with the handle (9), which facilitat es easy placement

of the unit in the required position. The hood is added according to the version and powder coated

with polyestro-epoxide "thermo-hardened" paint.

• The manual damper installed on the arm tube II (4) near the hood.

Wall or ceiling mounted version:

• Mounted via the flange of the outer sleeve ( of rotating socket) to the support structur e (bracket) by

means of six screws M6 (3/8”).

• To aid the up and down movement of the arm, each 4”, 6” and 8” unit is provided with an

encapsulated spring (11) and fixed to the inner sleeve of the rotating socket and the tube of arm I.

Portable (Bench Mount) version:

• Mounted via the flange of the outer sleeve (of rotating socket) to the support struct ure by means of

bolts M6 (3/8”).

• To aid the up and down movement of the arm, each 4”, 6” and 8” unit is provided with a cylinder

springs fixed to the inner sleeve of the rotating socket and the tube of arm I. These springs are

placed inside the tube.

• To protect the arm from falling below a certain level, a steel cable is attached parallel t o the spring

as above (6” and 8” versions).

Optional hood accessories (special order):

• Inlet Hood Grill to prevent rags and large objects from entering the arm.

• Light Kit with Control Switch for light and/or fan.

Mounting and assembly instruction

Mounting instructions:

• The self-supporting suction arm is fixed to the bracket installed on the wall or to the pivoting

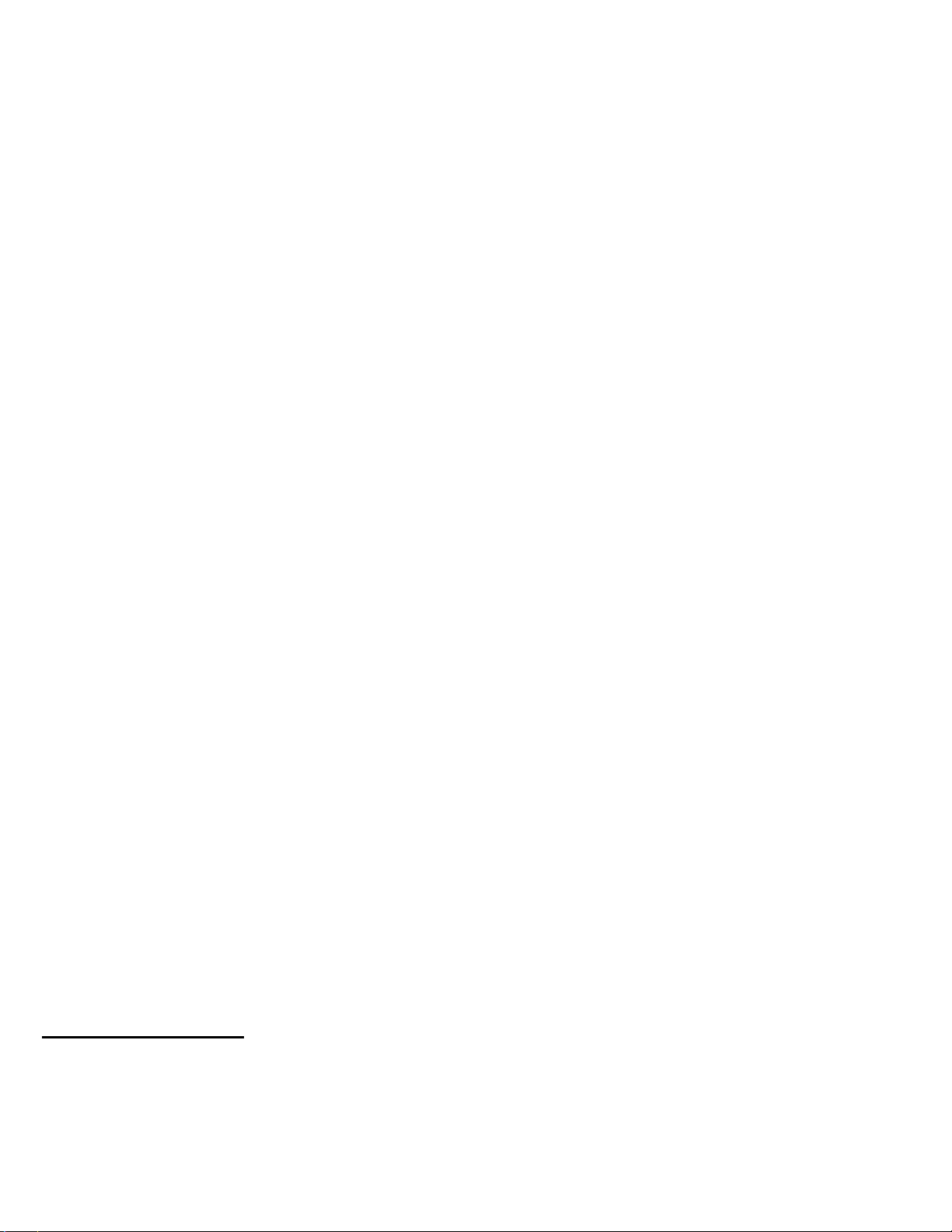

Example of the assembly of the self-supporting arm in the ducting.

1. ENVIROFLEX SNORKVAC™ self-

extension boom that enlarges the working range of the device, or to other element having a

connecting flange with dimensions the same as the inner sleeves of the rotating socket.

• NOTE: THE SOCKET'S AXIS (OF FUME ARM) MUST BE VERTICAL!

• The rotating socket should be fixed so as the protrusion on the outer sleeve that limits t he rot ating is

opposite the wall, bracket or the pivoting axis of the pivoting extension boom – see Drawing 3.

Note: In case of the installing the bracket at a height less than 8ft. (2,5m) above the floor, t he bracket

should be turned up-side-down and replace the standard connector to the welded-high one.

supporting fume arm

2. Bracket

3. Fan

4. Gear clamp

5. Flexible hose

Drawing 3.

6 5 4 3 2 1 10 8 7

wall mounting

rotary socket of

protrusion –

mount at wall side!

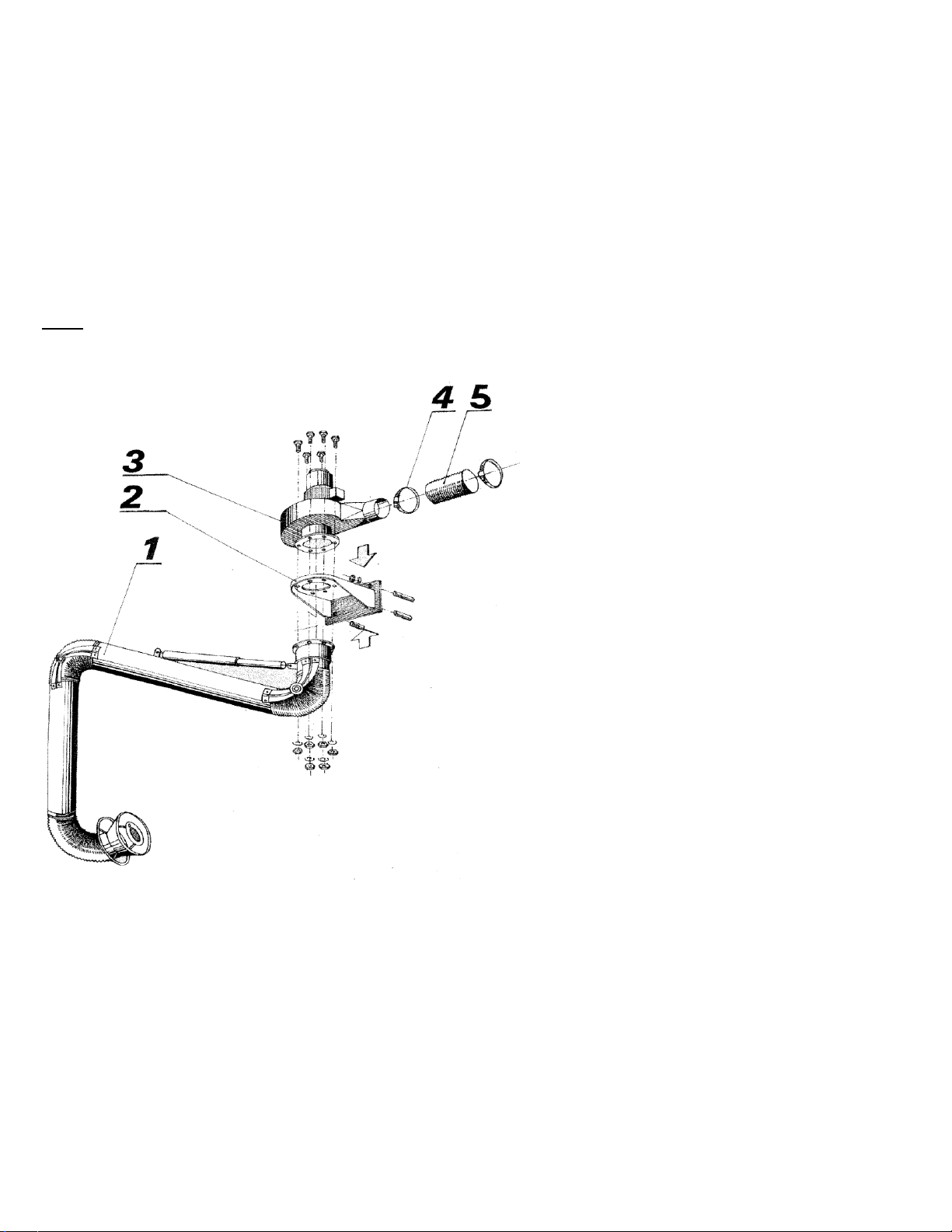

Light kit:

bracket

fume arm

Drawing 4.

Mounting the socket of Fume Arm.

1 wire set

2

3

4

5

6

7

8

9

10

11

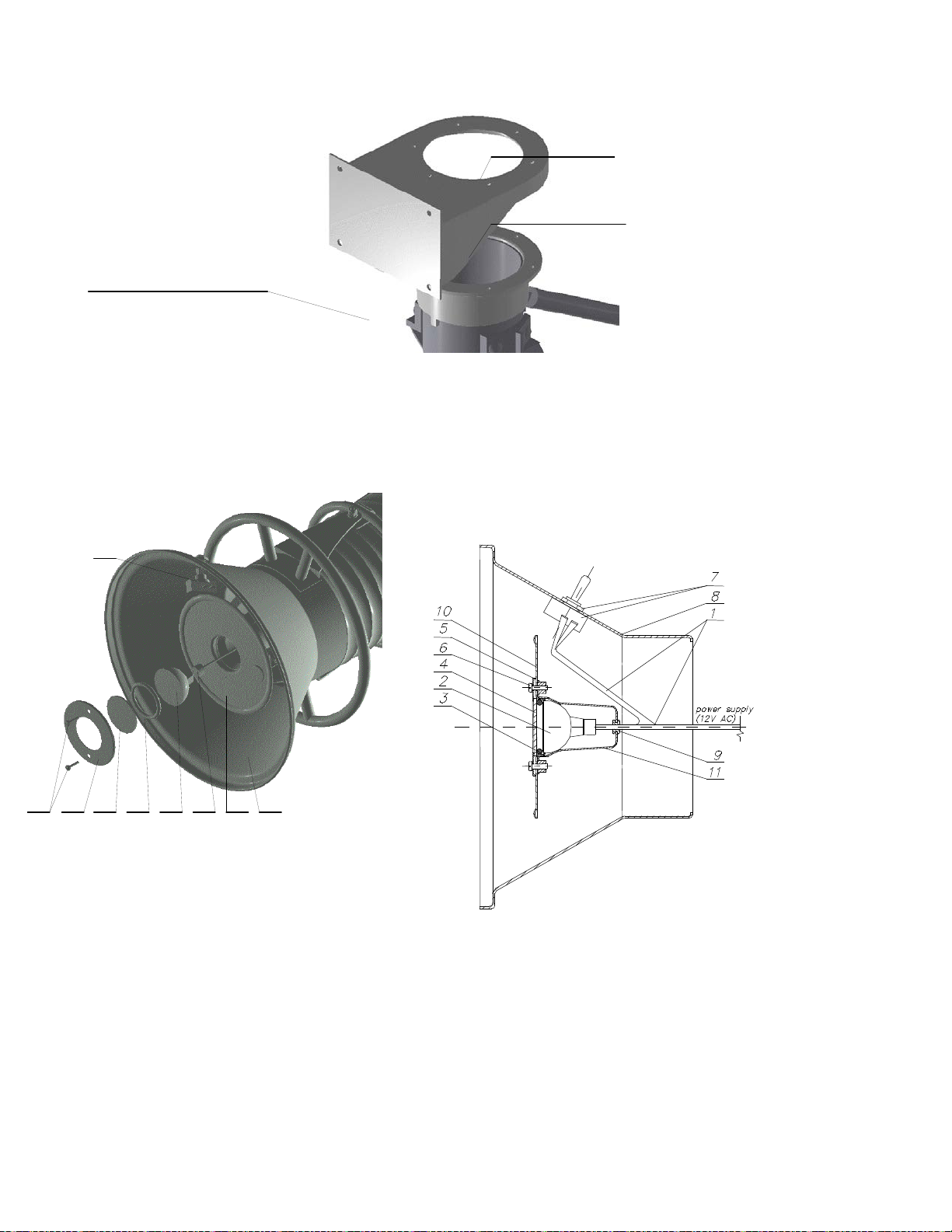

Drawing 5.

Light kit mounting.

Before mounting the light kit, remove the plug from the side of the hood (f or mounting a control switc h)

and unscrew the plate at the centre of the hood (for mounting halogen lamp) . You need also to remove

the hose from the hood joint (4”, 6” and 8” versions) or take the hood off (3” version).

Do the following after you have completed the above:

− place the wire set (1) moving it through the wire seal (9) inside the light kit dome (11)

− connect the control switch (7) to the wire set (1) and mount the switch on the side of hood (8)

− plug in (connect) the halogen lamp (2) into the wire set socket

halogen lamp („cold type”) 12VAC/35W

o-ring seal

protecting glass

mounting plate

bolts

control switch

hood

wire seal

shield

light kit dome

− put halogen lam p ( 2), o-ring seal (3), protecting glass (4) together and place them inside the hood

Install the mounting plate (5) with using the bolts (6).

−

Use and maintenance instruction and arm adjustment

The installed self-supporting arm should be checked for freedom of movement and rotation of the

socket. If excessive resistance exists at the joints, adj ustment must be carried out. It is recommended

to spray the hood (before work, each day) with antispatter preparation. It will make easier cleani ng of

the device every day.

The maintenance of the device is carried out periodically as follows:

a) every day

• Clean inner surface of the hood and outer surface of the arm.

• Check self-locking of the arms and the hood, and adjust it if it is necessary.

b) once per month

• Grease the rotating socket with bearing grease which does not react with aluminum.

• Check self-locking and adjust if necessary.

Arm

diameter

1st joint

2

nd

joint

3

rd

joint

3”

13

13

10

4”

17

17

10

6”

21

21

13

8”

21

21

13

1

st

2

nd

3

rd

c) once every 3 months

• Disassemble the flexible hoses; clean up the inside of the self-supporting arm (warm water with

detergent).

• Replace the glass panel in the spotlight.

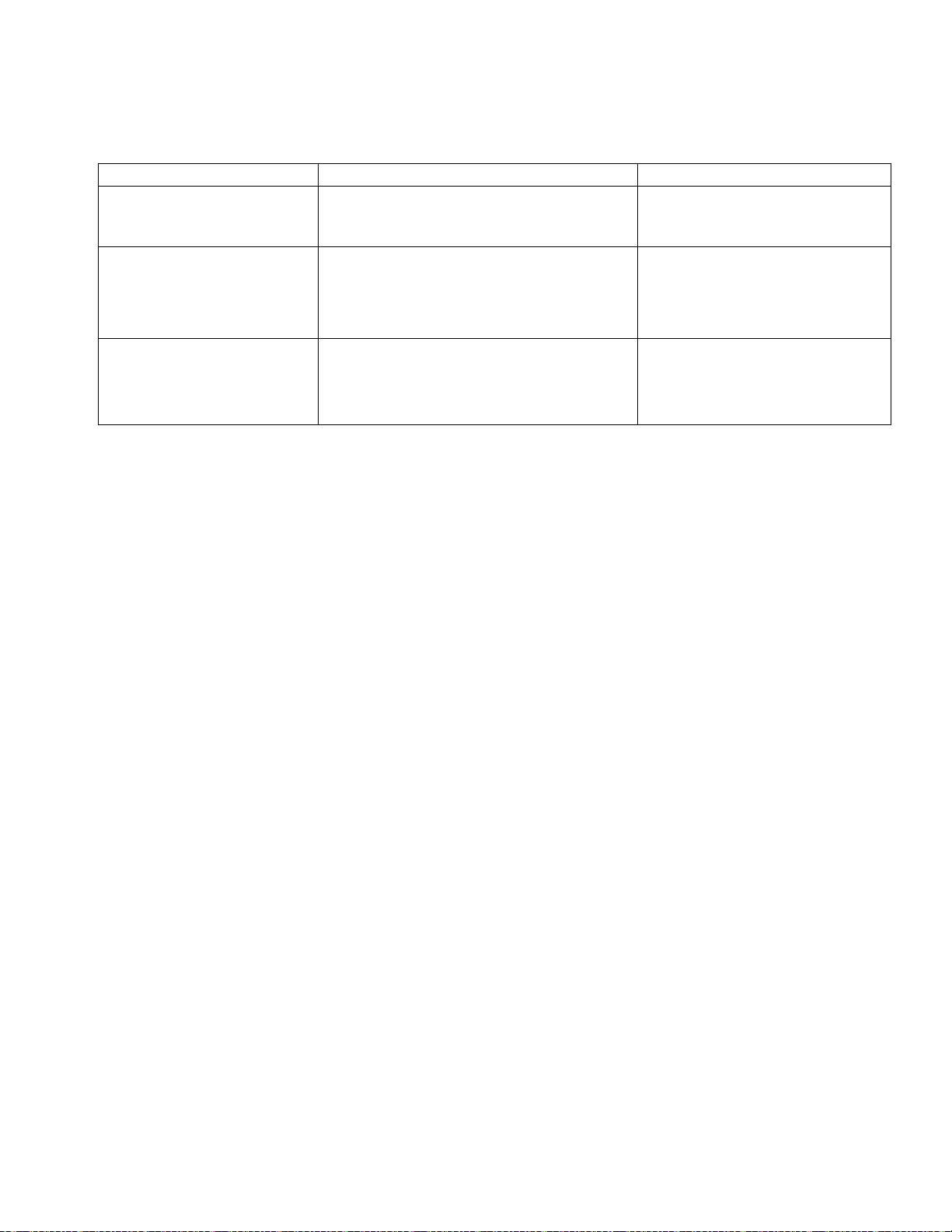

Adjustment.

For adjustment of any joint, you need to use two wrenches.

Adjustment is made with arm horizontally levelled.

• Adjust the 1st set of the flat joints

between the arms by holding the Bolt

and tightening the self-locking nuts on

the joint pairs. With 3” version of arms

you need one wrench; knob nuts

placed in this version are used for

locking the nuts.

• Adjust the 2nd set as above.

The horizontally positioned arm

shouldn't fall down when letting go.

• Adjust the hood joint (3rd) with the

same way as described above.

Wrench size

Symptoms

Possible reasons

Solution

The arm will not stay

where it is placed

The joints require adjustment

Adjust the joints (item VIII)

Stronger resistance

Lack of grease in the rotating socket

Grease the rotating socket

Decrease in air volume

A/ Hose not properly connected to

C/ The Damper is closed

A/Reconnect Hose.

C/ Open Arm Damper

during rotation of the

arm

Troubleshooting.

Arm tubes.

B/ The flexible hose is damaged.

Safety guidelines.

B/ Replace Damaged Hoses.

For the safe operation of the ENVIROFLEX® SNORKVAC™ self-supporting Fume Arms:

• DO NOT rotate the arm beyond the noticeable "resistance" (4”, 6” and 8” versions).

• DO NOT bend it beyond vertical axis of the rotating socket.

ACCESSORIES

Light kit

The light kit includes an LED lamp with hood switch, wires and mounting brackets for the hood.

Hoods

• You can get optional extension hoods.

• φ14” for 6” arm

• φ20” for 8” arm

Mounting brackets

Wall brackets see Drawing 2.

Ceiling Brackets

Fans

A variety of fans are available with various voltages, HP and CFM requirements

Pivoting booms

Numerous lengths and styles of boom are also available.

Loading...

Loading...