INSTALLATION & OPERATION MANUAL

MODEL NUMBERS: 12-FPP 50-SFP12P 50-TFP12P

12-FPL 50-SFP12L 50-TFP12L

12-FPG 50-SFP12G 50-TFP12G

Thank you for purchasing this product from a fine line of heating equipment.

We wish you many years of safe heating pleasure with your new heating appliance.

Save These Instructions.

IMPORTANT: IF YOU HAVE A PROBLEM WITH THIS UNIT DO NOT RETURN IT TO THE

DEALER. CONTACT TECHNICAL SUPPORT @ 1-800-245-6489.

Questions? Need Parts or Options ? www.englanderstoves.com

Please Note the Following Precautionary Statements:

England’s Stove Works highly recommends the use of smoke detectors and Carbon

Monoxide detectors with any hearth product, including this unit. Follow all manufacturer’s

instructions when using smoke or Carbon Monoxide detectors.

CAUTION: This unit must be installed in accordance with these instructions

and must comply with local building and fire codes. Failure to do so

could result in a chimney or house fire.

Keep children, furniture, fixtures, and all combustible materials

away from any heating appliance. Refer to this owner’s manual for

all clearances to combustible materials.

DO NOT INSTALL THIS UNIT IN A MOBILE HOME!!!

DO NOT MODIFY THIS UNIT IN ANY WAY!!!

SAVE THIS MANUAL FOR FUTURE REFERENCE.

Non-Effected Facility 35 to 1 Air to Fuel Ratio

Read this entire manual before you install and use your new room heater. If this room

heater is not properly installed, a house fire may result. To reduce the risk of fire,

follow the installation instructions. Failure to follow instructions may result in

property damage, bodily injury, or even death.

IMPORTANT NOTICE: This unit must be properly installed to prevent the possibility of a house fire

or “smoke-back.” The instructions must be strictly adhered to.

Do not use makeshift methods or material which may compromise the installation.

Your unit requires periodic maintenance and cleaning (refer to manual). Failure to maintain your unit

may lead to a variety of problems, including but not limited to smoke spillage into the home.

England’s will not be liable for consequential or indirect damages to property or persons resulting

from the use of this product.

Rev. 1/10

A letter from our Technical Support department

:

Thank you

for purchasing this fine product from England’s Stove Works!

England's Stove Works was started, and is still owned by, a family that

believes strongly in a "Do It Yourself" spirit – that’s one reason you found this

product at your favorite “Do It Yourself” store.

We intentionally design and build our stoves so that any homeowner can

maintain his or her unit with basic tools, and we're always more than happy to

show you how to do the job as easily and as inexpensively as possible.

From our free,

downloadable service sheets, to our new "wizard-style," clickthrough Troubleshooting guide on our web site, we have always tried to help

our customers stay "heat-ready," especially when oil and electricity prices

continue to skyrocket.

Please look at our vast Help section on our web site and call our Technical

Support department at (800) 245-6489 if you need any help with your unit.

We are nearly always

able to help “walk you through” any repairs, problems or

questions you may have.

PLEASE NOTE

: While information obtained on our web site and through our

800 number is always free of charge, there will be a service charge incurred

with any “on-site” repairs or maintenance that we may arrange.

Wishing you years of efficient, quality and “comfy” heating,

England’s Stove Works

Technical Support Department

www.englanderstoves.com

(800) 245-6489

IF YOU HAVE A PROBLEM WITH THIS UNIT DO NOT RETURN IT TO THE DEALER.

CONTACT TECHNICAL SUPPORT at 1 (800) 245-6489.

2

CAUTION

If you have any doubt concerning your ability to complete your installation in a professionallike manner after reading these instructions, you should obtain the services of an installer

who is versed in all aspects as to the correct and safe installation. Do not use temporary,

makeshift compromises during installation.

BEFORE INSTALLATION OF YOUR APPLIANCE

1. HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS.

2. DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS.

3. Check with the building inspector’s office for compliance with local codes; a permit may be

required.

4. This room heater must be connected to (1) a listed Type HT (2100°F) chimney per UL 103 or

ULC S629, or (2) a code-approved masonry chimney with a flue liner. The chimney size

should not be less than the area of the flue collar, or more than three times greater than the

cross-sectional area of the flue collar.

5. A 6” diameter flue is required for proper performance.

6. Always connect this unit to a chimney and NEVER vent to another room or inside a building.

7. DO NOT connect to any duct work to which another appliance is connected, such as a

furnace.

8. DO NOT connect this unit to a chimney flue serving another appliance.

9. DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE.

10. The connector pipe and chimney should be inspected periodically and cleaned if necessary.

11. Remember the clearance distances when you place furniture or other objects within the area.

DO NOT store wood, flammable liquids or other combustible materials too close to the unit.

12. Contact your local fire authority for information on how to handle a chimney fire. Have a

clearly understood plan to handle a chimney fire. In the event of a chimney fire, turn air control

to a closed position and CALL THE FIRE DEPARTMENT.

13. DO NOT ta mper with the combustion air control beyond normal adjustment.

14. Once the required draw is obtained, operate only with doors closed; open doors slowly when

re-fueling (this will reduce or eliminate smoke from entering the room).

15. DO NOT install these units in a mobile home or trailer. These units are NOT mobile home

approved.

16. Visit our web site at www.englanderstoves.com for helpful information, frequently asked

questions, parts/accessory orders and more. Technical Support: (800) 245-6489.

3

OPERATION

WHY THE CORRECT FLUE SIZE IS IMPORTANT: 6”

“Draft” is the force that moves air from the appliance up through the chimney. The amount of draft in

your chimney depends on the length of the chimney, local geography, nearby obstructions, and other

factors. Too much draft may cause excessive temperatures in the appliance. An uncontrolled burn or

a glowing red part or chimney connector can indicate excessive draft. Inadequate draft may cause

back puffing into the room and “plugging” of the chimney and/or cause the appliance to leak smoke

into the room through appliance and chimney connector joints.

Today’s solid fuel appliances are much more efficient than in the past. The units are designed to give

you controlled combustion, as well as maximum heat transfer, using less fuel to do so.

The design of your new appliance is such that the exhaust “smoke” is now at lower temperatures than

in the past, therefore requiring proper chimney size to give adequate draft. If your chimney is too

large, the heating appliance will have a difficult time to raise the “chimney flue” temperature to give

adequate draft, therefore causing a smoke back up, poor burn, or both.

Should you experience such problems, call in a local chimney expert.

With the door closed, the rate of burning is regulated by the amount of air allowed to enter the unit

through the air control. With experience, you will be able to set the control for heat and burning time

desired.

Attempts to achieve higher output rates that exceed heater design specifications can result in

permanent damage to the heater. The recommended wood load is level with the top of the firebricks.

Overloading may prevent sufficient air entering the heater to properly fuel the fire.

Do not tamper with the combustion air control beyond the normal adjustment capacity.

Operate this heater only with the door closed, and installed damper in the fully open position.

ALWAYS PROVIDE A SOURCE OF FRESH AIR INTO THE ROOM WHERE THE UNIT IS

INSTALLED. FAILURE TO DO SO MAY RESULT IN AIR STARVATION OF OTHER FUEL

BURNING APPLIANCES AND THE POSSIBLE DEVELOPMENT OF HAZARDOUS

CONDITIONS.

THIS HEATER IS EXTREMELY HOT WHILE IN OPERATION. SERIOUS BURNS CAN RE SUL T

FROM CONTACT. CAUTION SHOULD BE OBSERVED, ESPECIALLY WHEN CHILDREN ARE

PRESENT.

DANGER: RISK OF ELECTRIC SHOCK. DISCONNECT POWER BEFORE SERVICING UNIT.

This unit is set up for installation of an optional 2-speed blower motor. The fan speed

OPTIONAL BLOWER MOTOR OPERATING INSTRUCTIONS:

should be run on “Low” when the unit is operating at lower burn settings, and set to “High”

See Illustration 3 (later in this manual) for installation location of your optional blower.

Fasten blower motor to rear heat shield with the four screws that are already provided on

your stove. When routing the power cord, be sure that the cord does not come into contact

OPTIONAL BLOWER: MODEL AC-16

120 VOLTS, 60Hz, 0.75 AMPS, 2900 RPM

for high burns.

with any hot surface.

The optional heat circulation blower on this stove requires periodic lubrication; this lubrication should be performed no

less than every three months of normal operation. To properly lubricate the blower, use an eye dropper or similar

dispensing device to drip 5-7 droplets of SAE 20 oil into the oil port on the side of the blower motor.

4

FLUE SYSTEM

1. Existing Flue System

If you have chosen a freestanding unit, this stove is designed to connect to an existing flue system,

such as masonry or a pre-manufactured Class A flue system. If you have a masonry flue system, the

inner liner should be inspected carefully for cracks; if there is no liner in your chimney, we recommend

you install a steel liner or have one installed. If you have an existing pre-manufactured system the

inner liner should be inspected for warping or buckling. Either type chimney system should be

thoroughly cleaned before installing your new stove. We strongly recommend you have a qualified

chimney sweep clean and inspect your entire system, as the sweep can spot problems you might

overlook. The sweep in most cases can make any necessary repairs or recommend a qualified

person to do so. It is not permissible to connect this unit to a chimney that is servicing another

unit.

2. Flue Size

The proper flue size is determined by measuring the inside diameter of the flue collar on the unit.

This stove is equipped with a six inch (6”) TOP EXHAUST FLUE COLLAR.

Therefore, the connector pipe should be six inches (6”) and never less in diameter than the collar on

the stove. The area of the chimney liner must also be equal to or greater than the area of the flue

collar on the stove. If the area of the flue is greater than the collar, it should never be more than three

(3) times greater.

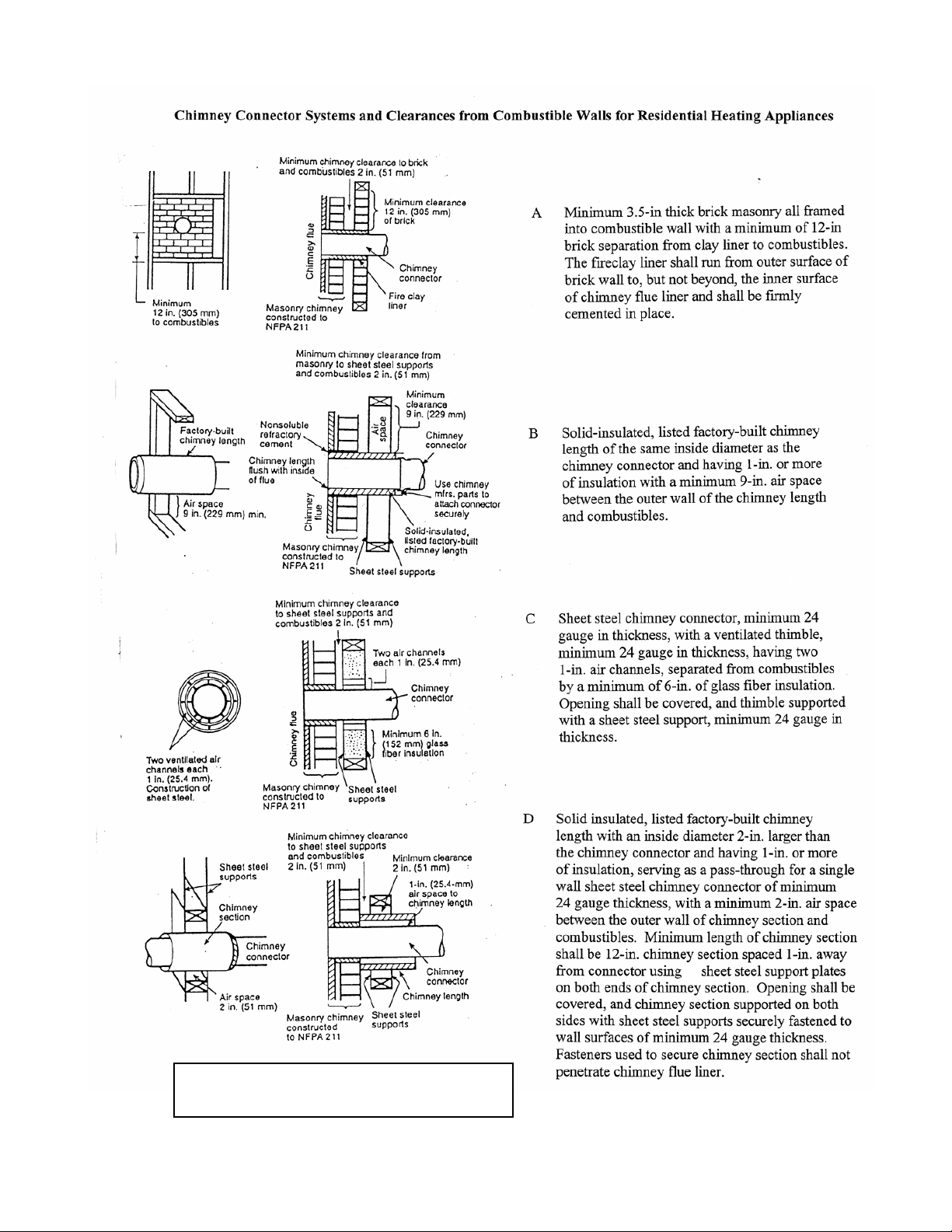

The black connector pipe should be 24 gauge steel and 10.5” from a combustible wall or ceiling.

This clearance can be reduced to 10.0” if you are using a double wall or shielded pipe. (See “C” in

the clearances diagrams on the following page)

3. Installation of a New Flue System

Note: Flue systems and flue pipe are not furnished with the unit.

Masonry Flue: In the event that you plan to install or have a system installed, there are several

approaches that you can take. In the middle and late seventies masonry flue systems became very

popular, and today this type system is satisfactory. If you are considering a masonry system, you

should consult with your local building officials for the proper procedures on this type chimney. We

recommend you consult with and have your flue built by a licensed, bonded contractor. Most masonry

chimney systems are placed against an outside wall and extend upward beside the house. The flue

thimble is then inserted through the wall, making the connection with the stovepipe and the vertical

flue. Exercise extreme caution when drilling through the wall -- you must maintain proper clearance

between the connecting liner and any combustible material in the wall.

We also recommend you have a flue clean-out door located at least two feet (2’) below your

thimble for easy cleaning of the system. This door should be made as airtight as possible. It is the

consumer’s responsibility to ensure the chimney system is safe and in good operating condition.

The manufacturer will not be held responsible for an accident attributed to a unit connected to a faulty

chimney system.

Appliance Clearances Unprotected Surfaces

Single wall connector,

with and without side heat

Double wall connector,

with side heat shields

CLEARANCE TO COMBUSTIBLES (See Illustration 1)

Side

(A)

6 in 6 ½ in 5 in 10 ½ in 14 in

shields

6 in 6 ½ in 5 in 10 in 13 ½ in

NOTE: Minimum alcove or ceiling height = 77 in

Rear

(B)

Corner

(D)

Flue to

backwall (C)

Flue to wall

(corner) (E)

5

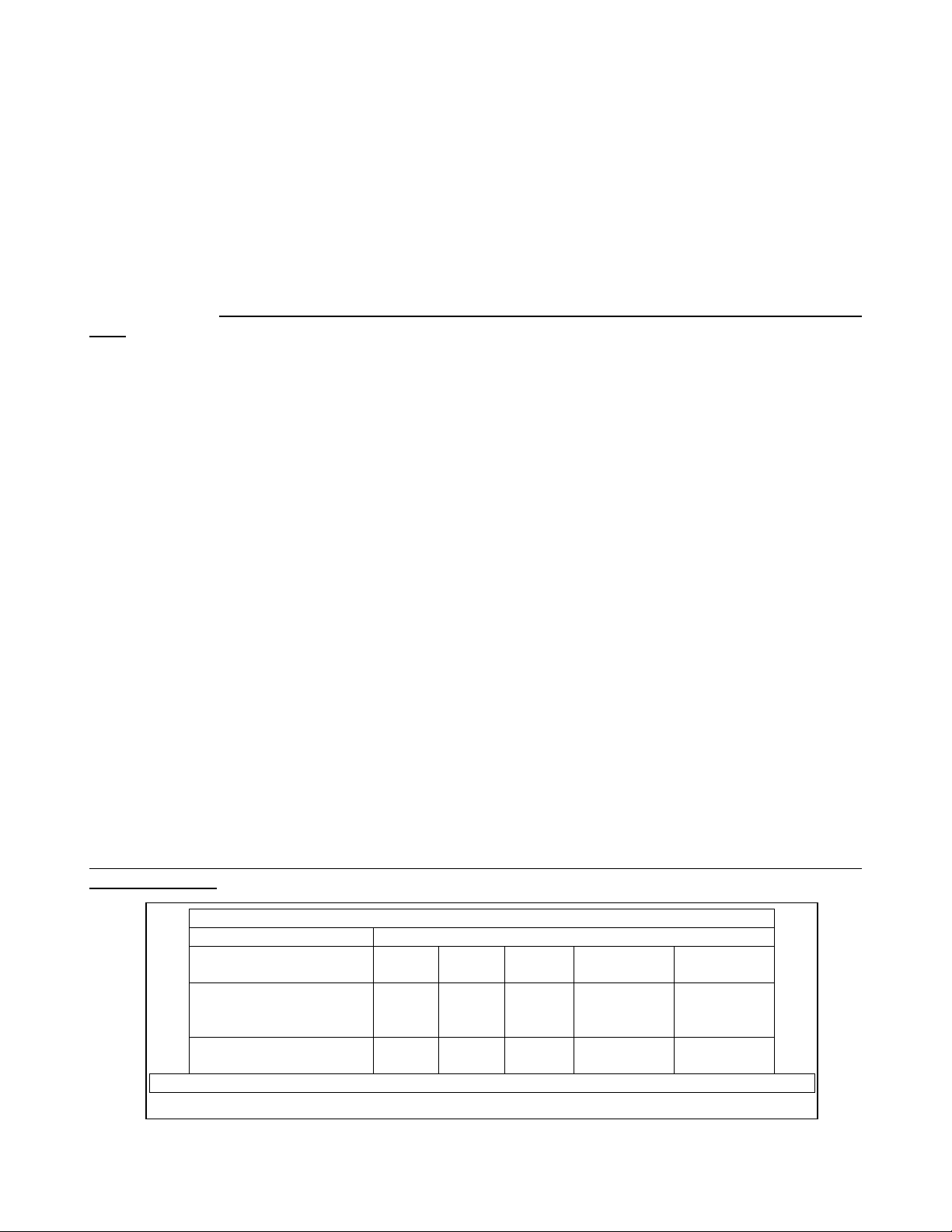

INSTALLATION APPLICATIONS

)

)

A

Illustration 1

NOTE:

1

. Horizontal run not to exceed 6’.

2. Total flue length should not

exceed 25’.

3. Floor protection required:

Min. size 48” x 48”.

4. Always check local codes for

clearances, installation, etc.

18” Min.

Masonry Chimney

10.5” Min. 10.5” Min.

See Note (3) See Note (3

Lined with

clay tile or

other liner

Single Wall

Chimney

Connector

(Exterior) Wall

Supported

18” Min.

Class “A”

Chimney System

C

B

(Interior) Ceiling

See Note (3)

Supported

And Floor Protection section

Single Wall

Chimney

Connector

10.5” Min.

E

D

See Note (3

*IMPROPER INSTALLATION: The manufacturer will not be held responsible for damage caused by

the malfunction of a stove due to improper installation. Do not use makeshift methods or material

which may compromise the installation. The manufacturer will not be responsible for an accident

caused by a unit connected to a faulty flue system. England’s will not be liable for consequential or

indirect damages to property or persons resulting from the use of this product.

-

-

6

INSTALLATION APPLICATIONS, Cont’d.

Illustration 1b

7

Pre-Manufactured Flue System: In the past few years pre-manufactured flue systems have

become very popular, because this type system is easily installed and, when done correctly, is very

safe. There are many pre-manufactured flue systems on the market, and when making your choice it

should be U.L., B.O.C.A. or I.C.B.O. approved. Any of these systems are constructed of the proper

materials and meet the proper safety standards. Your local dealer normally handles an approved

brand of flue pipe. There are two very popular methods for installation of this type system.

The first, most popular and least expensive is through the ceiling and out the roof. This is the

most direct route and creates a good draw because it requires less pipe. It is less expensive because

insulated pipe is needed only from the ceiling to the roof and above -- single wall chimney connect, 24

gauge or thicker is used from the unit to the ceiling; maintain 10.5” clearance between single wall

chimney connector and any combustibles.

The second method for installing a pre-manufactured system is to exit through the wall and run the

system vertically up the outside of the structure. This method is more expensive because more

insulated pipe is required -- you must use insulated pipe through the wall and up the outside of the

structure. In either installation, proper clearances to combustibles should be maintained. Your flue

pipe manufacturer furnishes a wall thimble or ceiling support box and, when installed properly, the

correct clearances are achieved. If you are unable to install this type system your local dealer may be

able to recommend a qualified contractor for this installation. It is the customer’s responsibility to

ensure that his system is installed properly and is in good operating condition.

FLOOR AND WALL PROTECTION

1. Floor Protection

You will not need any floor protection if your

floor is constructed of a non-combustible material

such as brick or concrete. If your floor is

constructed with a combustible material such as

hardwood, carpet or linoleum, you must place

protection between the stove and the combustible

material.

There are many floor and wall board

manufacturers, and you should be very cautious in

choosing the proper protection. The type board you

choose should be U.L. rated and listed. After

examining the area you plan to place your stove and determining it requires a board, the next step

is to select the proper size. The stove you choose will determine the size board that is required.

The approved protector board should be large enough to provide a minimum of eight inches (8”)

behind the unit, eight inches (8”) on either side and sixteen inches (16”) in the front where the door

is located. Floor protection should also exist under the chimney connector, and should extend two

inches (50 mm) beyond each side of the chimney connector. This stove requires a minimum

standard floor protector size of 48” x 48”.

Installation on a Concrete Floor

An appliance mounted on a concrete floor does not require floor protection.

Carpeting and any other combustible material must not cover the Floor Protector.

If a combustible surface is applied to the concrete floor, a clearance must be maintained

equivalent to the area reserved for the floor protector.

8”

8

Installation on a Combustible Floor

If the appliance is to be installed on a combustible floor or a combustible floor covering, it must

be installed on a 1” thick non-combustible millboard floor protector or a durable equivalent, with a

“R” factor of no less than “2.” The pad must be installed beneath the unit, extending 16” (U.S.) on

the side equipped with a door, and 8” on all other sides. The pad must cover any horizontal

chimney connector runs and extend 2” beyond each side.

Alternate Floor Protection:

An easy means of determining if a proposed alternate floor protector meets requirements is to

follow this procedure:

1) Convert specification to R-value:

i R-value is given – no conversion is needed

ii k-factor is given with a required thickness (T) in inches: R = 1/k x T

iii C-factor is given: R = 1/C

2) Determine the R-value of the proposed alternate floor protector:

i Use the correct formula given in step 1 (above) to convert values not expressed as

“R.”

ii For multiple layers, add R-values of each layer to determine overall R-value.

3) If the overall R-value of the system is greater than the R-value of the specified floor

protector, the alternate is acceptable.

EXAMPLE:

The specified floor protector should be ¾” thick material with a k-factor of 0.84. The proposed

alternate is 4” brick with a C-factor of 1.25 over 1/8” mineral board with a k-factor of 0.29.

Step (a): Use formula above to convert specification to R-value. R = 1/k x T = 1/0.84 x .75 =

0.893

Step (b): Calculate R of proposed system.

4” brick of C = 1.25, therefore R brick = 1/C =1/1.25 = 0.80

1/8” mineral board of k = 0.29, therefore Rmin.bd. = 1/0.29 x 0.125 = 0.431

Total R = Rbrick + Rmineral board = 0.8 + 0.431 = 1.231

Step (c): Compare proposed system of R of 1.231 to specified R of 0.893. Since proposed

system R is greater than required, the system is acceptable.

Definitions:

Thermal conductance = C = Btu = W

(hr)(ft

2

)(deg F) (m2)(deg K)

Thermal conductivity = k = (Btu)(inch) = W = Btu

(hr)(ft

Thermal resistance = R = (ft

2

)(deg F) (m)(deg K) (hr)(ft)(deg F)

2

)(hr)(deg F) = (m2)(deg K)

Btu W

2. Wall Protection

Please see Illustration 1 for clearances to walls. In some areas local codes may require thirtysix inches (36”) from a combustible, therefore it is very important that you check with local officials.

If you need to place your unit closer to a combustible wall, some protection will be necessary. If an

approved wall board is used this will reduce your clearance by two thirds (2/3); however, a one

inch (1”) air space has to be between the board and the wall. If you have a ceiling flue hook-up,

you will need protection from the floor to the ceiling if you do not meet the normal clearances. If

you have a wall flue hook up, you will need wall protection at least twelve inches (12”) above the

wall thimble.

9

3. Side Heat Shields

This accessory item

comes with the hardware

(six (6) mounting screws)

necessary to install it on

the rear of the stove. This

is a two-piece heat shield,

but is installed one piece at

a time. There are prepunched holes on each

side of the Rear Heat

Shield; while holding each

piece of the Side Heat

Shield in place, align the

pre-punched holes in the

Side Heat Shield with the

existing holes in the Rear

Heat Shield, and fasten

with the screws provided.

See Illustration 1 for

clearances with and

without side heat shields.

1 – 9” x 4” x 1.25” brick (Qty. 14)

2 – 4” x 4.5” x 1.25” brick (Qty. 2)

3 – 4.5” x 4” metal plate

BRICK LAYOUT

(Ash Drawer Plate, Qty. 1)

Rear Heat Shield

Side

Heat

Shield

Side

Heat

Shield

Install AC-16 Optional

Blower on these (4) mounting

holes. See “Optional Blower

Instructions” on page 3 for

instructions.

Illustration 3 – Side Heat Shield and Blower Installation

Illustration 4

10

FREESTANDING PLACEMENT AND INSTALLATION

The first problem you may encounter is getting your stove into your home -- all of our stove

products are well constructed, which makes them rather heavy. Three to four adults can normally

handle a unit, but we still recommend using a handcart. Never attempt to handle a heating product

alone!!! The door and brick can be temporarily removed to lighten the unit (refer to Brick Layout).

After the unit is placed into position, install the spring handles and attach any optional equipment.

Chimney Connector Pipe

The black pipe must be six inches (6”) in diameter and at least 24 gauge steel pipe. Do not us e

aluminum or galvanized steel pipe, as it will not withstand the extreme temperatures generated by

the stove. Also, do not use single wall connector pipe as a chimney -- you must connect your stove

to a chimney comparable to those listed earlier in this manual. The crimped end of your pipe

should be inserted into the flue collar and, by doing this, all the pipe will be reversed. If you use this

method the creosote will run back down the inside of your pipe and not out of the joints onto your

stove. As a safety precaution, all joints should be sealed with high temperature silicone (AC-RTV3)

and secured with sheet metal screws.

For proper operation the chimney connector should be as short as possible and never exceed a

six foot (6’) horizontal run. Horizontal runs of chimney connector pipe should have an upward slope

of one quarter of an inch (1/4”) per foot. You will need to maintain 10.5” of clearance from the wall

and 18.0” from the ceiling unless you are using double wall or shielded pipe.

Attach and secure the chimney connector to the stove with a minimum of three (3) sheet metal

screws, and also use a minimum of three (3) sheet metal screws to secure each adjoining section

of pipe.

11

INSTALLATION

1. Remove all parts from inside the stove body. (If you purchased a leg unit, and it has the

factory packaging, remove the body of the stove from the shroud that it is attached to, referring

to Illustration 7 later in this manual. Those instructions detail how to exchange legs and

pedestal, but removal of the shroud is accomplished in the same manner).

2. Select the proper location for the stove. These appliances must not be installed any closer

than the minimum clearance to combustible materials shown in Illustration 1. The stove must

be installed on a non-combustible surface as shown in Illustration 1 and Illustration 2.

FAILURE TO FOLLOW THE MINIMUM CLEARANCE REQUIREMENTS MAY RESULT IN

AN UNSAFE INSTALLATION.

3. If non-combustible materials have been installed on the walls, obtain the minimum clearances

from either the manufacturer of these materials or the local building inspector’s office.

4. Install the stovepipe INSIDE the flue collar on the top of the stove, between the stove and the

chimney.

5. DO NOT use a grate to elevate the fire.

6. A clearance of 10.5” between single wall chimney connector and combustible materials is

required. Check with authorities having jurisdiction in your area with any questions.

7. All pipe sections must be connected with the male (crimped) end toward the stove.

8. Fasten the stove pipe to the flue collar by the use of three sheet metal screws. Do the same

at each additional joint to make the entire installation rigid.

9. Maintain the required diameter flue for the entire installation.

10. If you are connecting the stove to an old masonry flue, be sure to have it inspected for cracks

and general condition. Relining with a stainless steel liner may be required.

11. It is recommended that no more than two 90-degree bends be used in the stovepipe

installation. More than two 90-degree bends may decrease the amount of draw, and possibly

cause smoke spillage.

12. This unit has a factory-installed damper. Do not install or use additional dampers with this

unit.

13. Single wall flue pipe assemblies must not exceed 10 feet in overall length.

12

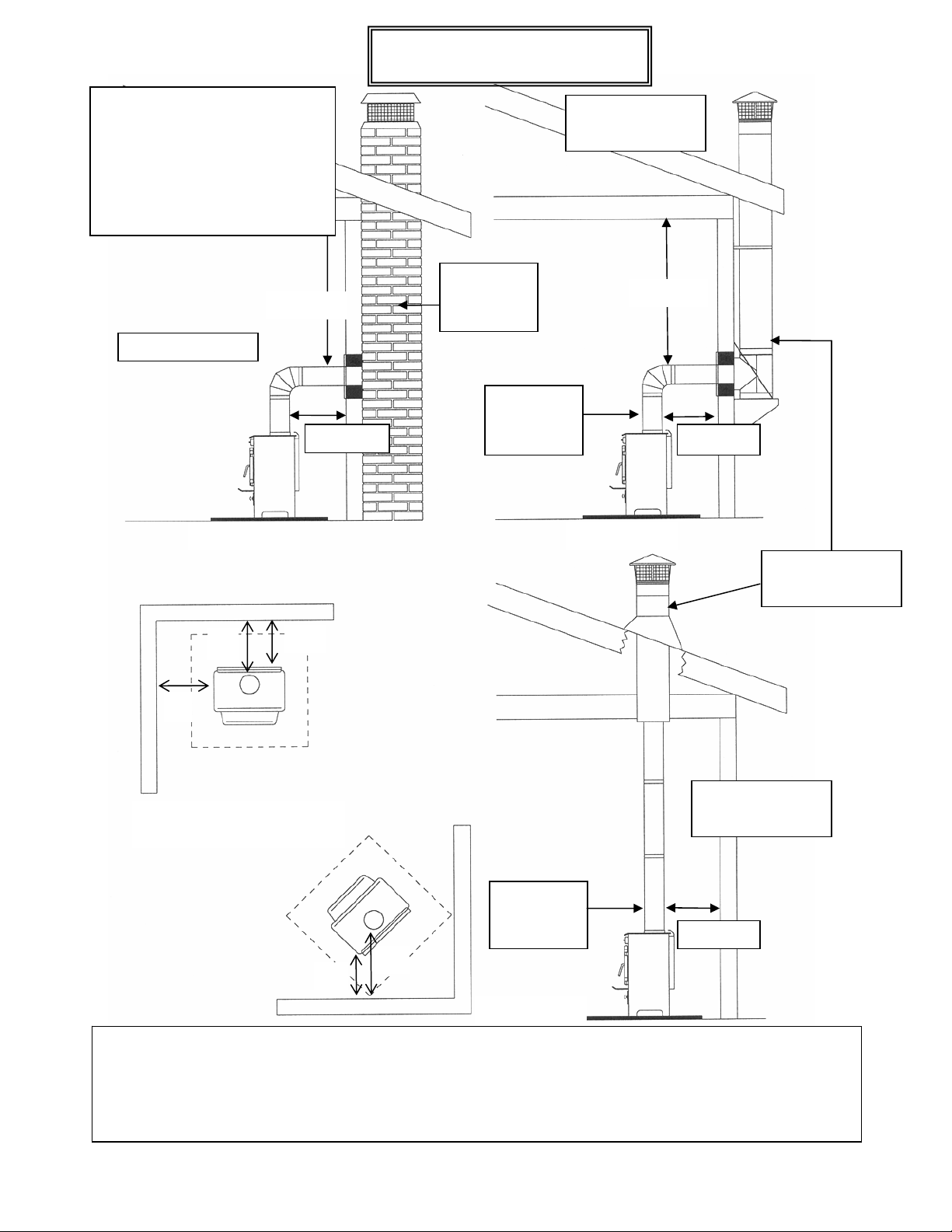

CHIMNEY

REFER TO CHIMNEY AND CHIMNEY CONNECTOR MANUFACTURER’S INSTRUCTIONS

2 Ft. higher than

nearest point of roof

within 10 ft.

3 Ft. min. from

Roof Penetration

Min. overall

height from floor

15 Ft.

CONTACT YOUR LOCAL BUILDING AUTHORITY

FOR APPROVED METHODS OF INSTALLATION

1. This appliance requires a masonry or premanufactured chimney listed to UL103HT

sized correctly.

2. If a masonry chimney is used, it is

advisable to have your chimney inspected

for cracks, and check the general condition

before installing your unit. Relining may

be required to reduce the flue diameter

to the appropriate functional size.

3. To help ensure a good draft, the top of the

chimney should be at least 3 feet above

the point of penetration through the roof,

and be at least 2 feet higher than any point

of the roof within 10 feet.

4. The chimney connector shall not pass

through an attic, roof space, closet,

concealed space, floor, ceiling, wall, or any

partition of combustible construction.

5. The minimum overall height of your

chimney should be 15 feet from the floor.

6. Do not use makeshift compromises during

installation.

OPERATION

Do not use a grate or elevate the fire. Build the wood fire directly on the bricks. When the stove

is used for the first time, solvents in the paint will smoke off as the stove “cures.”

WOOD –

This heater is designed to burn natural wood only. Higher efficiency and lower emissions

generally result when burning air-dried seasoned hardwood, as compared to softwood or to green

or freshly-cut hardwood.

Use only dry, seasoned wood. Green wood, besides burning at only 60 percent of the fuel value

of dry wood, deposits creosote on the inside of the stove and along the chimney. This can cause

extreme danger of chimney fire. To be called “seasoned,” wood must be dried for a year.

Regardless of whether the wood is green or seasoned, it should be stored in a ventilated,

sheltered area to allow proper drying during the year. Wood should be stored beyond

recommended clearances from combustibles.

DO NOT BURN:

Treated Wood, Garbage, Solvents, Trash, Cardboard, Colored Paper or Coal.

13

FIRST FIRE –

Remember to ventilate well.

Allow the stove to cure before burning for long periods of time at high temperatures.

Flat spots on the painted surface are normal.

Shiny spots on the painted surface (before burning) are normal.

Call Technical Support at (800) 245-6489 if you have any questions.

BUILDING A FIRE

1. Open the air inlet control and installed damper fully.

2. Place a small amount of crumpled paper in the stove.

3. Cover the paper with a generous amount of kindling in a “teepee” shape, and a few small

pieces of wood.

4. Ignite this fuel and close the door most of the way (leave it open slightly).

5. Add larger pieces of wood as the fire progresses, being careful not to overload. Do not fill the

firebox beyond the firebrick area, as this may result in over-firing. A coal bed of (ideally)

1” to 2” should be established to achieve optimum performance.

6. This unit is designed to function most effectively when air is allowed to circulate to all areas of

the firebox. A good way of achieving this is to rake a small (1” to 2” wide) “trough” in the

center of the coal bed, from front to back, prior to loading the fuel.

7. Once fuel has been loaded, close the door and fully open the air inlet control, until the fire is

well established (approximately 20 minutes), being careful not to over-fire.

8. Readjust the air inlet control to the desired burn rate. If excessive smoke fills the firebox, open

the air inlet control slightly, until flames resume and the wood is sufficiently ignited. Basically,

Closed = “Low;” ½ Way Open = “Medium;” and Fully Open = “High.”

9. When refueling, adjust the air control to the fully open position. When the fire brightens,

open the door VERY slowly and carefully. This will prevent gases from igniting and causing

smoke and flame spillage.

10. At this point you may add fuel, being careful not to overload.

11. Only close the installed damper when the fire is completely out.

The use of flammable liquids, too much wood or burning trash in the stove may result in an “overfired” unit. If the chimney connector pipe or stove turns red or white, the stove has been over-fired. In

the event this happens, close the air control immediately! This condition can ignite creosote in the

chimney and cause a house or chimney fire. This type fire can cause structural damage to the

chimney system; do not use the stove again until the entire system has been checked thoroughly and

any damaged parts repaired or replaced. A chimney sweep can normally perform this inspection.

NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, KEROSENE, CHARCOAL

LIGHTER FLUID, OR SIMILAR LIQUIDS TO START OR ‘FRESHEN UP’ A FIRE IN THIS

HEATER. KEEP ALL SUCH LIQUIDS WELL AWAY FROM THE HEATER WHILE IT IS

IN USE.

14

GLASS CARE

REPLACE GLASS ONLY WITH HIGH-TEMPERATURE ROBAX PYROCERAM OF THE

PROPER SIZE AND THICKNESS.

The following use and safety tips should be observed:

1. Inspect the glass regularly for cracks or breaks. Surface scratches are acceptable and

normal, but if you detect a crack or a break, extinguish the fire immediately, and contact your

dealer or Technical Support at (800) 245-6489 for replacement (or log on to

www.englanderstoves.com ).

2. Do not slam the door or otherwise impact the glass. When closing doors, make sure that logs

or other objects do not protrude and impact the glass.

3. Do not clean the glass with materials which may scratch (or otherwise damage) the glass.

Scratches on the glass can develop into cracks or breaks.

4. Never attempt to clean the glass while the unit is hot. If the deposit is not very heavy, normal

glass cleaners are adequate with a plain, non-abrasive scouring pad. Heavier deposits may

be removed with the use of an oven cleaner.

5. NEVER put substances that can ignite explosively inside the unit, since even small explosions

in confined areas can blow out the glass.

6. This unit has an airwash system, designed to reduce deposits on the glass.

GASKET REPLACEMENT

After extensive use, the sealing material which provides glass and door seal may need to be replaced

if it does not sustain its resilience. Inspect the glass and door seal periodically to ensure proper seal.

If the gaskets become frayed or worn, replace immediately. Contact your dealer or Technical Support

at (800) 245-6489 for approved replacement parts.

The following steps should be followed for replacement of the glass gasket:

1. Ensure that the appliance is not in operation, and is thoroughly cooled.

2. Remove the screws and glass clips.

3. Lift glass out from glass clips.

4. Remove the old gasket, and clean the glass.

5. Replace the new gasket, starting at the bottom of the glass and working along the edges. Be

sure to center the gasket channel on the glass.

6. Trim the gasket to length and butt the ends together.

7. Replace the glass in the door, being sure not to over-tighten the screw and clip.

or by calling (800) 516-3636 (parts orders only, call 800-245-6489 for technical questions).

You may order parts and options on our web site: www.englanderstoves.com,

15

The following steps should be followed for replacement of the door gasket:

1. Ensure the appliance is not in operation and is thoroughly cooled.

2. Remove the old door gasket and clean the gasket channel.

3. Using an approved high-temperature gasket cement, apply a thin coat in the bottom of the

channel.

4. Starting at the hinge side of the door, work into the channel around the door unit, trim to length

and butt the ends together.

5. Close the door and allow three to four hours for the cement to set before restarting any fire.

CREOSOTE

When wood is burned slowly, it produces tar and other organic vapors. These combine with moisture

to form creosote. Creosote vapors condense in the relatively cool chimney flue of a slow-burning fire

– as a result, creosote residue accumulates on the lining of the flue. If ignited, this creosote makes an

extremely hot fire. The chimney should be inspected on a regular basis during the heating season, to

determine if a creosote build-up has accumulated. If it has, the creosote should be removed to

reduce the risk of chimney fire.

WARNING: THINGS TO REMEMBER IN CASE OF A CHIMNEY FIRE:

1. CLOSE DRAFT CONTROL 2. CALL THE FIRE DEPARTMENT

WAYS TO PREVENT AND KEEP UNIT FREE OF CREOSOTE

1. Burn with the air control fully open for several minutes at numerous intervals throughout each

day during the heating season, being careful not to over-fire the unit. This should remove the

slight film of creosote that accumulates during low burn periods.

2. Burn the stove with the draft control fully open for approximately 20-30 minutes every time you

apply fresh wood. This allows wood to achieve the charcoal stage faster, and burns wood

vapors which might otherwise be deposited within the system.

3. BURN ONLY SEASONED WOOD. Avoid burning wet or green wood. Seasoned wood is

wood that has been dried for at least one year.

4. A small, hot fire is preferable to a large, smoldering one that can deposit creosote within the

system.

5. Establish a routine for fuel, wood burner and firing technique. Check daily for creosote build-

up until experience shows you how often you need to clean to be safe. Keep in mind that the

hotter the fire, the less creosote is deposited, and weekly cleanings may be necessary in

milder weather, although monthly cleanings may be enough in the coldest months. Contact

your local authority for information on how to handle a chimney fire, and have a clearlyunderstood plan to handle a chimney fire.

16

ASH DISPOSAL

A

A

Regularly inspect the ash build-up in your unit and remove as necessary. Ashes can be removed

from the unit by shoveling them off the firebrick. This unit has an ash drawer plate (see Illustration 4)

that can be removed from the stove; once removed, the ashes can be raked through the opening and

into the ash pan.

Caution: The ash drawer plate can be extremely hot!! Never remove red-hot ashes from the

appliance; allow ashes to cool before dropping into the ash pan. Ashes should be placed in a metal

container with an airtight lid. The ashes should be placed on a noncombustible surface and

completely away from any combustible materials. The ashes should remain in the airtight container

until they have completely cooled.

Illustration 6 – Air Inlet Control

CONTROL SETTINGS

Burn Rate Inlet Air Setting

Low Fully Closed

Med. Low ¼ Open

Med. High ¾ Open

High Fully Open

DIRECTIONS FOR INSTALLATION OF

(Stove must be cooled and all ashes cleaned out)

*

Remove bricks, disconnect flue, and turn stove on its

back.

* If you are replacing existing legs or pedestal,

disconnect the existing legs or pedestal.

To install legs:

1. Each leg will fit into a pre-made slot on each corner

of the bottom of the unit.

2. A 3/8” x 1-1/2” Carriage Bolt and matching nut is

supplied with each leg. Fit a leg into a slot, and

match the hole on the leg with the hole in the slot.

ttach the legs one at a time, using the supplied

bolts and nuts. Tighten securely.

To install pedestal:

1. Place spacers (provided) between the slots on the

unit and the pedestal base (one spacer will fit on

each side of the pedestal). Match the four holes in

the pedestal (2 on each side) with the holes in the

spacers and slots on the unit.

2. Use the four 3/8” x 1-1/2” Carriage Bolts and nuts

(provided) to attach the pedestal to the base of the

stove. Tighten securely.

*

fter attaching the legs or pedestal, turn unit upright,

reconnect flue and replace bricks according to

manual.

LEGS OR PEDESTAL:

17

IMPORTANT: HELPFUL HINTS AND TIPS WORTH REVIEWING

1. What is the correct way to start a fire?

You will need small pieces of dry wood (kindling) and paper. Use only newspaper or paper

that has not been coated or that has had materials glued or applied to it. Never use coated

or colored paper (such as advertising flyers).

Open the door of the wood stove.

Crumple several pieces of paper, and place them in the center of the firebox, directly on

the firebricks of the stove. Never use a grate to elevate the fire.

Place small pieces of dry wood (kindling) over the paper in the form of a “teepee.” This

allows for good air circulation, which is important for good combustion.

Light the crumpled paper in two or three different locations. NOTE: It is important to heat

the air in the stovepipe for draft to begin.

Fully open the air control of the wood stove, and close the door until it is just slightly open,

allowing for air to be introduced into the firebox. Never leave the door fully open, as sparks

from the kindling may occur, causing injury. As the fire begins to burn the kindling, some

additional kindling may be needed to sustain the fire. DO NOT add more paper after the

fire has started.

Once the kindling has begun to burn, start adding some small pieces of seasoned, dry

firewood. NOTE: Adding large pieces at the early stages will only serve to smother the

fire. Continue adding small pieces of seasoned, dry firewood, keeping the door slightly

open until each piece starts to ignite. Remember to always open the door slowly when

placing wood into the fire.

Once the wood has started to ignite and the smoke has reduced, close the stove door fully.

(Reduction of smoke is a good indication that the draft in the chimney has begun, and

good combustion is now possible.) Larger pieces of seasoned, dry firewood can now be

added when there is sufficient space in the firebox. Adjust the air control setting to your

desired setting.

NOTE: The lower the air control setting, the longer the burn time of the firewood.

2. What type of wood is best to use as firewood?

Dry, seasoned hardwood should be used. Avoid green, un seasoned wood. Green wood,

besides burning at only 60% of the fuel value of dry seasoned wood, will deposit creosote

on the inside of the stove and along to inside of the chimney.

3. What does dry, seasoned wood mean, and what is considered to be hardwood?

Wood that has been dried for a period of one year in a well-ventilated and sheltered area is

considered dry, seasoned wood. Hardwoods generally come from slow-growth trees, such

as Oak or Fir. Softwoods generally come from fast-growth trees, such as Pine or Spruce.

4. Will following the steps listed above result in a perfect fire every time?

A good answer would be “most of the time.” There are many variables that can affect your

rate of success when starting a fire, and experience will teach you how to deal with the

variables. This section of the manual will cover some of the variables that can affect a fire,

and time and patience will contribute to your ability to start a good fire consistently.

5. Why can’t I get the fire lit?

Damp or wet wood and poor draft are the main reasons for poor results when starting a

fire. Remember to always use dry, seasoned wood for your fire. Even wood that has been

dried (seasoned) for a long period of time will be difficult to light if it has gotten wet.

6. Why is there always a large quantity of thick black smoke in the firebox?

A large quantity of thick black smoke in the firebox is a possible indication that you have

poor draft.

18

7.

Is it normal for soot to cover the glass at the beginning of a fire?

This stove has been built with an air wash system that will h elp keep the glass clear when

the firebox has reached a good operating temperature, and also has a good draft. Cold

firebox temperature and poor draft cause soot to form on the glass. Once the firebox

temperature and the draft increase, the soot should burn off.

8. What is “draft?”

Draft is the ability of the chimney to exhaust draw by-products produced during the normal

process of combustion.

9. What can cause a poor draft?

There are several common factors that can contribute to poor draft:

A. Atmospheric Pressure and Air Supply

Atmospheric pressure affecting the draft from a chimney can be outside the home,

inside the home, or both. Outside the home, a high-pressure (clear and cool) day

generally creates a better draft in the chimney than a low-pressure (overcast and damp)

day. Inside the home, household appliances, such as forced-air furnaces or clothes

dryers, compete for air, often resulting in inadequate amounts of air available to fuel a fire

and creating a condition known as negative pressure. Extreme conditions of negative

pressure can cause the combustion by-products to be drawn from the chimney and into the

house. This condition is commonly known as “down drafting.”

There are several factors that can affect the amount of air available in the home.

Increased amounts of insulation, vinyl windows, extra caulking in various places and door

seals can all keep heat in, but may also make a home too airtight. If you are in doubt as to

whether or not there is sufficient air in your home for your stove, refrain from using those

appliances known to consume air when possible, or open a door or a window to allow

some air to enter the home.

B. Environmental Conditions

High trees, a low-lying house location (such as in a valley), tall buildings or structures

surrounding your house and even windy conditions can cause pool draft or down drafting.

C. Cold Chimney Temperature

Avoid cold chimney temperatures by burning a hot fire for the first fifteen to forty minutes

after building a fire, being careful not to over-fire. If any part of the chimney or parts of the

stove start to glow, you are over-firing the stove. Where possible, install a temperature

gauge on the chimney so temperature drops can be seen.

D. Chimney Installation and Maintenance

Avoid using too many elbows or long horizontal runs. If in doubt, contact a chimney

expert and/or chimney manufacturer for help. Clean your chimney, rain cap(s) and

especially the spark arrester regularly, in order to prevent creosote build-up – which can

significantly reduce chimney draw and possibly create a chimney fire.

10. Should I close or open the air control fully when shutting down the stove?

When shutting down the stove, fully open the air control. This will allow chimney

temperatures to remain as high as possible for as long as possible. Remember, cold

chimney temperatures create creosote.

NOTE: This section is intended as an aid and does not supersede any local, state or

like requirements. Check with officials or authorities having jurisdiction in your area.

19

PARTS, ACCESSORIES AND OPTIONS LIST

(Options and trim (i.e. brass and nickel) interchange for variety. Gold door and legs may also be ordered to

replace existing door and pedestal or regular cast legs.)

REPLACEMENT PARTS

AC-G17 DOOR GLASS KIT WITH GASKET (16 ½ “ x 9 ¼ “ x .197”)

AC-GGK DOOR GLASS GASKET KIT (gasket only, no glass)

AC-DGKNC DOOR GASKET KIT (5/8” High-Density fiberglass rope gasket)

AC-SB 9” X 4” X 1 ¼” FIREBRICK (see Brick Layout diagram)

AC-SB4.5 4” X 4 ½” X 1 ¼” FIREBRICK (see Brick Layout diagram)

AC-SH BRASS DOOR SPRING HANDLE

AC-SHN NICKEL DOOR SPRING HANDLE

AC-SH4 BRASS AIR CONTROL SPRING HANDLE

AC-SH4N NICKEL AIR CONTROL SPRING HANDLE

AC-03 BRASS ASH PAN KNOB

AC-03BN NICKEL ASH PAN KNOB

AC-MBSP HI-TEMPERATURE BLACK PAINT

OPTIONS

AC-16 ROOM AIR BLOWER

AC-NCSHSB SIDE HEAT SHIELD SYSTEM (BLACK)

AC-108 BRASS ACCENT TRIM RING FOR DOOR (“C,” “P” AND “L” MODELS ONLY)

AC-108BN NICKEL ACCENT TRIM RING FOR DOOR (“C,” “P” AND “L” MODELS ONLY)

AC-107 BRASS LIP TRIM

AC-107BN NICKEL LIP TRIM

CA-12G GOLD PLATED LEG

CA-13G GOLD PLATED DOOR

All parts can be ordered from your local dealer or from the factory at 1-800-516-3636.

NOTE: Parts and accessories are also available on our web site: www.englanderstoves.com

If you have any questions or problems contact the Technical Support Department.

TECHNICAL SUPPORT DEPARTMENT

P.O. BOX 206

MONROE, VA. 24574

Technical Questions/Technical Support: (800-245-6489) (Fax: 434-929-4810)

Parts orders only: (800-516-3636)

service@englanderstoves.com

.

20

You may write your unit’s Manufacture Date and Serial Number in the

blank spaces on this sample tag, for future reference. This sample tag

also shows the safety info. such as UL testing standard, etc. for your

local officials, or anyone else who may need reference information.

21

Have this information on hand if you phone the factory or your dealer regarding this product.

Retain for your files:

Model Number __________________________

Date of Purchase ________________________

Date of Manufacture _________________ Serial #_____________________

LIMITED 5 YEAR WARRANTY

FROM THE DATE OF PURCHASE TO THE ORIGINAL OWNER

The manufacturer extends the following warranties:

Five Year Period:

1. Carbon steel and welded seams in the firebox are covered for 5 years against splitting.

2. The cast iron door, hasp and hinges are covered for 5 years against cracking.

One Year Period:

3. Component parts such as damper and brick retainers are covered for 1 year against cracking,

breakage and welded seams from separating.

4. Electrical components, accessory items, glass and the painted surface are covered for 1 year from

the date of purchase.

Conditions and Exclusions:

Damage from over-firing will void your warranty.

This warranty does not apply if damage occurs because of an accident, improper handling, improper

installation, improper operation, abuse, or unauthorized repair made or attempted to be made.

The manufacturer is not liable for indirect, incidental, or consequential damages in connection with the

product including any cost or expense providing substitute equipment or service during periods of

malfunction or nonuse.

All liability for any consequential damage for breach of any written or implied warranty is disclaimed

and excluded. Some states do not allow the exclusion or limitations of incidental or consequential

damages, so the above may not apply to you.

Procedure:

Purchaser must give notice of claim of defect within the warranty period and pay transportation to and

from a service center designated by the factory. The dealer from which the unit was purchased or the

factory, at our option, will perform the warranty service.

Other Rights:

This warranty gives you specific legal rights, and you may also have other rights, which may vary from

state to state.

NOTE: THIS WARRANTY IS NULL AND VOID IF YOU DO NOT RETURN THE

ATTACHED WARRANTY REGISTRATION WITH A COPY OF THE SALES

RECEIPT WITHIN 30 DAYS FROM THE DATE OF PURCHASE.

WARRANTY IS NOT TRANSFERABLE.

22

WARRANTY REGISTRATION for England’s Stove Works

Purchased by (Name) ______________________________________________

Address _________________________________________________________

City ________________________ State __________ Zip _________________

Telephone _______________________________________________________

Email Address ___________________________________________________

DEALER INFORMATION

Purchased From (Dealer) ___________________________________________

Address _________________________________________________________

City ________________________ State __________ Zip _________________

UNIT INFORMATION

(Please be sure to refer to sticker on back of manual or box to complete this section)

Model Number _________________________ Purchase Date ____________________

Purchase Price ________________________

Serial Number _________________________ Mfg. Date ______________________

How did you first hear about our product? (please check one)

___ Word of Mouth ___ Burn Trailer Demonstration ___ Internet

Other: ____________________________________________________

Where did you receive information about our product? (please check one)

___ Rec’d. info. via phone ___ Dealer (Name of dealer): ______________________

___ Internet Other: _________________________________________________

IMPORTANT NOTICE

THIS REGISTRATION INFORMATION MUST BE ON FILE FOR THIS WARRANTY TO BE VALID.

PLEASE MAIL THIS INFORMATION WITHIN THIRTY (30) DAYS FROM THE DATE OF PURCHASE.

Mail To

England’s Stove Works, Inc.

Technical Support Department

P.O. Box 206

Monroe, VA 24574

Or, Fax To:

(434) 929-4810 – 24 hours a day

Or, now available – Go online to complete your Warranty Registration

Visit www.englanderstoves.com if you prefer to register online.

:

!

23

Loading...

Loading...