Page 1

Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

WHC, WMC, and WHR

Hydraulic Cutters

L1106 Rev. B 08/12

IMPORTANT RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage. Shipping damage is not covered

by warranty. If shipping damage is found, notify carrier at once. The carrier is responsible for all repair and replacement costs resulting

from damage in shipment.

SAFETY FIRST

Carefully plan your system by selecting components designed to perform the intended operation and which will

adequately perform with existing equipment. Always check the product limitations regarding pressure ranges, load

capacities and set-up requirements. The system operating pressure must not exceed the pressure rating of the lowest

rated component in the system. Read all CAUTIONS, WARNINGS, and INSTRUCTIONS included with, or attached to, each product.

Follow all safety precautions to avoid personal injury or property damage during the system operation. ENERPAC CANNOT BE

RESPONSIBLE FOR DAMAGE OR INJURY RESULTING FROM UNSAFE USE OF PRODUCT, LACK OF MAINTENANCE, OR

INCORRECT PRODUCT AND SYSTEM APPLICATION. Contact Enerpac when in doubt as to safety precautions or applications.

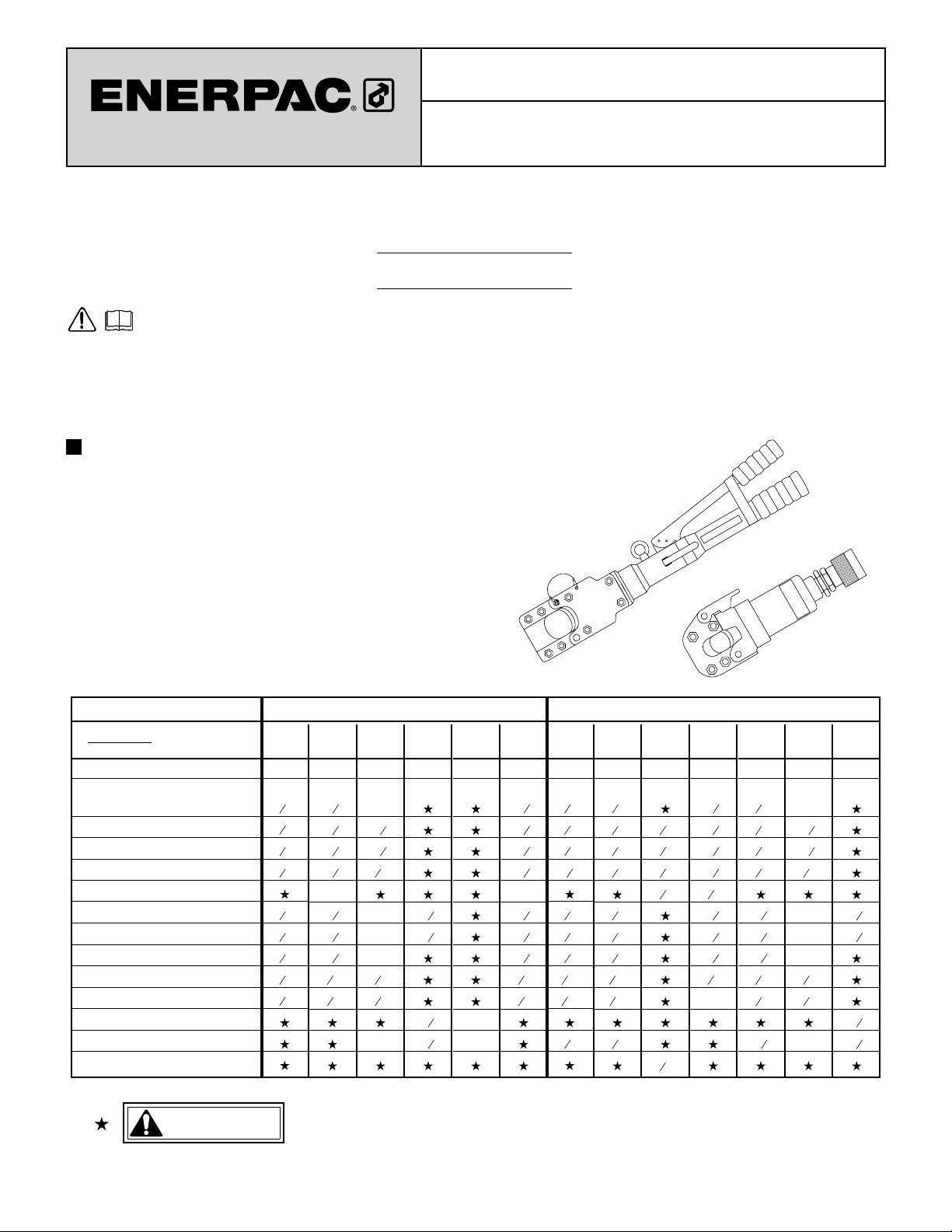

DESCRIPTION

Enerpac cutters can be used for a variety of cutting operations.

The table below lists the size and type of material your tool is

capable of cutting.

Self-contained hydraulic cutters (WMC models) are extremely

portable. Hydraulic cutterheads (WHC & WHR models)

require 10,000 psi hydraulic pumps and are recommended for

applications where many cuts must be made in a short amount

of time.

WMC-2000

Cutting Capacity Chart

MAXIMUM

MATERIAL (inches)

Capacity (tons)

Steel Wire Rope 6x7, 6x12,

6x19 Hempcore or IWRC

Copper Wire or Bar

Aluminum Wire or Bar

Soft Steel Bolts

Reinforcing Bar

Bare Copper Wire Strand

Bare Aluminum Wire Strand

ACSR Wire Strand

Guy Steel Wire Strands 1x7

Guy Steel Wire Strand 1x19

Telephone Cable

Underground Cable (Power)

Grade 70 or 80 Alloy Chain

DIAM

ETER OF

WARNING

WHC

-750

4

11

16

11

16

11

16

11

16

3

4

3

4

3

4

5

8

5

8

Hydraulic Cutterheads

WHC

-1250

"

"

"

"

"

"

"

"

"

WHC

-2000

20

1

1

"

4

1

1

"

8

1

1

"

4

1

1

"

8

WHC

-3380

13

1"

1

1

"

4

1

1

"

4

7

"

8

1"

1

1

"

2"

4

1

1

"

4

1

1

"

4

7

"

8

7

"

8

1

2"

1

2"

3

"

4

3

"

4

3

2"

3

WHC

-4000

3

WHR

WMC

-1250

8

-580

20

1

1

1

1

4

1

5

"

"

4

8

5

1

1

1

"

"

8

8

5

"

"

8

4

5

"

8

8

1"

5

"

8

11

"

16

3

"

4"

8

3

"

4"

8

1

1

1

1

5

"

"

4

8

1

5

"

"

4

8

1

5

"

"

8

4

7

9

"

8

7

"

8

"

16

9

"

16

5

"

8

Self-Contained Cutters

WMC

-750

4

3

11

11

11

3

3

3

9

16

9

16

11

WMC

-1000

20

"

4

3

"

16

16

16

"

4

"

4

"

4

"

4

3

"

"

4

3

"

"

4

3

"

4

"

"

"

16

1

"

2

Unit is not designed to cut this size or type of material.

Any attempt to do so will result in personal injury and/or

damage to the unit and will void the warranty.

WMC

-1250

20

1

1

1

1

1

1

1

1

7

8

1

1

1

1

1

1

7

8

1"

WHC-750

WMC

-1580

"

4

"

8

"

4

"

4

WMC

-2000

6

3

"

4

3

"

4

3

"

4

3

"

4

WMC

-3380

13

3

1"

1

1

"

4

1

1

"

4

7

"

8

"

1

"

1

"

4

"

1

4

"

1

4

5

"

5

1

2"

2

5

"

2"

8

5

"

2"

8

3

"

8

3

"

8

5

"

2"

8

5

1

"

8

11

1

"

16

"

4

"

4

3

3

"

8

3

3

"

8

Page 2

OPERATION

PRELIMINARY INFORMATION: Be sure to observe safe operating procedures. Follow the warnings listed below and all

other safety information contained in this document or decals attached to cutter. Failure to do so will result in personal injury

and/or equipment damage.

WARNING

CUTTING HAZARD: Keep

hands away from cutter

blades. Only one person

should operate cutter. Do

not have one person working

WARNING

Never use the cutter on

electrically active or "hot" wire

or cable. Be sure power has

been turned o before working

on electrical wire or cable.

near the blades while another

person controls the pump.

1. WHC and WHR models: Couple pump hose to cutter. Turn

collar on coupler fi nger tight only. No tools are needed to make

this connection.

2. Select material to be cut. When cutting short pieces of wire

rope, clamp or tape it fi rst to help prevent wires from jamming

between the blade and head.

3. Inspect blade and cutting head. Cutting case hardened steel

will dent blades and cutting heads. The blades will eventually

fatigue and crack. Replace cracked blades immediately. DO

NOT operate tool with cracked or chipped blades.

4. Unlatch cutter head.

5. Place material between blade and head shear.

6. IMPORTANT: Securely latch the cutter head.

WARNING

When working with wire rope or

cable, wrap section being cut to

prevent pieces from fl ying loose

as they are cut.

Cutter Head

Latch Pin

Head

Shear

Release

Blade

9. If the material being cut (usually wire rope or soft cables)

seems to be cut but does not break free of the tool, the blade

is hung up on something and needs to be removed. See

"Troubleshooting" on page 3.

10. Lift release lever or shift pump to release position to retract

blade. If blade does not retract, see "Troubleshooting" on

page 3.

Lever

CAUTION

Most broken blades are the result of not latching the cutter

head. When the blade is advanced, it pushes on the cutter

head. As the cutter head is pushed open, a diagonal force

causes the blade to break, and, in some cases, the cutter

head may crack.

7. On self-contained units, push release lever in toward cutter

body. For hydraulic cutterheads, close or shift valve on pump to

advance position.

8. Operate handle or pump until blade is fully advanced. DO

NOT exceed maximum cutting limits printed on tool decal.

11. Return tool to carrying case to protect from dirt and

corrosion. Always keep a spare blade on hand.

NOTE: Do not operate an empty cutter. The new blade

and cutter head shear edges will "roll" slightly with the

fi rst material cut, creating a burr. This burr falls o as

the cut takes place. Extending the blade prior to the

fi rst material cut will also raise a burr on the blade. With

no material present to knock the burr o , the blade and

head shear edges may lock together and the cutter will

not retract. To correct this situation, the blade must be

removed. Remove blade screw and blade. Unlatch cutter

head.

Use a sharpening stone to remove burr from blade. Run

the stone across the blade on the fl at side (not the knife

edge side). Keep the stone fl at and parallel to the blade.

Take care not to create a gap between the blade and

head shear.

2

Page 3

TROUBLESHOOTING

Problem

Blade will not advance.

Blade will not retract.

Unit leaks oil.

Cause

Low oil level.

Loose coupler

connection.

(WHC & WHR models)

Debris caught between

cutter head shear and

blade.

Fluid release lever not

working.

Seal damage caused by

overloading cutter or by

normal use of cutter

over a period of time.

Solution

Be sure reservoir is filled with Enerpac oil.

Be sure all coupler connections are complete. Loose

or incomplete coupler connections will cause complete

or partial blockage of oil flow.

Remove blade screw from piston to release pressure.

Remove cutter head latch pin or spring latch to free

blade.

Clean the blade and blade track. Hone the blade. See

Maintenance step 6 on page 4. Lubricate the blade

and track with silicone spray.

See illustration below. Place wooden wedge against

the release pin and lightly strike wedge with a

hammer. The lever should release forward to by-pass

and relieve pressure.

The blade should retract. If debris is caught between

the blade and cutter head, disassemble and clean as

described above.

Replace seals. Seals are available as part of the

Repair Kit for your cutter. An Authorized Enerpac

Service Center can perform the repairs for you.

Place wooden wedge

behind release lever.

Use wood or other

soft material to avoid

damaging cutter body.

Open cutter

Blade

head to

remove blade.

Blade Screw

Lighty strike wedge

with a hammer.

3

Page 4

MAINTENANCE

Perform maintenance regularly to keep your hydraulic cutter in good operating condition.

1. Clean dirt from cutter using grease solvent.

2. Lubricate the head and blade with silicone spray rather than

oil. Oil attracts dirt, silicone does not.

3. Keep reservoir full of clean oil. Drain all oil and refi ll with

clean Enerpac oil every 12 months. Change oil more often

under dirty environmental conditions.

Dispose of used oil properly.

4. If cutter has been used under water or in severe conditions,

wash the cutter and lubricate immediately. Remove and clean

the handle cylinder.

5. Repaint unit as necessary. If cutter is used in water regularly,

repaint it with light colored corrosive resistant paint.

6. Keep blade and cutter head shear sharp. Hone blade by

rubbing a sharpening stone across the blade on the fl at side

(not the knife edge side).

Keep the stone fl at and parallel to the blade. Keep back bevel

to a minimum, or blades will separate and break.

Discard cracked or chipped blades. New blades can be

purchased separately.

7. Fluid leakage is usually the result of overloading the cutter

and damaging the seals. Repair kits are available. Repair kits

include piston seals, latch spring or pin, and blade screws.

Contact your local Authorized Enerpac Service Center if your

cutter needs to be repaired.

TO PROTECT YOUR WARRANTY, USE ONLY ENERPAC HYDRAULIC OIL.

Enerpac Worldwide Locations e-mail: info@enerpac.com internet: www.enerpac.com

Australia and New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

T +61 (0)2 9743 8988

F +61 (0)2 9743 8648

sales-au@enerpac.com

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

T +55 11 5687 2211

F +55 11 5686 5583

Toll Free: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

customer.service@actuant.com

China

Actuant (China) Industries Co. Ltd.

No. 6 Nanjing East Road,

Taicang Economic Dep Zone

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

Toll Free: +86 400 885 0369

sales-cn@enerpac.com

France, Switzerland, North Africa

and French speaking African

countries

ENERPAC

Une division d’ACTUANT France S.A.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

sales-fr@enerpac.com

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf, Germany

T +49 211 471 490

F +49 211 471 49 28

sales-de@enerpac.com

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore, 560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

sales-in@enerpac.com

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

sales-it@enerpac.com

Japan

Applied Power Japan LTD KK

Besshocho 85-7

Kita-ku, Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

sales-jp@enerpac.com

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Oce 423, LOB 15

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

sales-ua@enerpac.com

Russia

Rep. oce Enerpac

Russian Federation

Admirala Makarova

125212 Moscow, Russia

T +7 495 98090 91

F +7 495 98090 92

sales-ru@enerpac.com

Singapore

Actuant Asia Pte Ltd.

83 Joo Koon Circle

Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free: +1800 363 7722

sales-sg@enerpac.com

Street 8

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

sales-kr@enerpac.com

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

sales-es@enerpac.com

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg,

Central and Eastern Europe,

Baltic States, Greece, Turkey

and CIS countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 535 848

sales-nl@enerpac.com

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P. O. Bo x 42 1

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

integratedsolutions@enerpac.com

4

4

South Africa and other English

speaking African countries

Enerpac Africa Pty Ltd.

No. 5 Bauhinia Avenue

Cambridge Oce Park

Block E

Highveld Techno Park

Centurion 0157

South Africa

T: +27 12 940 0656

United Kingdom and Ireland

ENERPAC Ltd.,

Bentley Road South

Darlaston, West Midlands

WS10 8LQ

England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

sales-uk@enerpac.com

USA, Latin America and Caribbean

ENERPAC

P.O. Box 3241

Milwaukee WI 53201 USA

T +1 262 293 1600

F +1 262 293 7036

User inquiries:

T +1 800 433 2766

Distributor inquiries/orders:

T +1 800 558 0530

F +1 800 628 0490

Technical inquiries:

techservices@enerpac.com

sales-us@enerpac.com

All Enerpac products are guaranteed

against defects in workmanship and

materials for as long as you own them.

For the location of your nearest authorized

Enerpac Service Center, visit us at

www.enerpac.com

101711

Loading...

Loading...