Instruction Sheet

WCR4000 Roller Cassette

L4021

English (GB) Rev. B 09/2013

2

Instruction Sheet Roller Cassette

WCR4000

ENGLISH

Index

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Assembly and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Maintenance and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Technical specifications and torque settings . . . . . . . . . . . . . . . . . . . . 13

7 Replacement parts and recommended tools . . . . . . . . . . . . . . . . . . . . 16

3

1 Introduction

2 Safety

Overview

The Enerpac WCR4000 roller cassette

provides controlled tightening and loosening

ENGLISH

of fasteners on pipe flanges. It is designed

for use in confined spaces where an ordinary

hydraulic torque wrench might not fit.

The roller cassette is powered by the

Enerpac W4000 Series drive unit and a

compatible 690 bar (10,000 psi) torque

wrench pump.

Spanners are available from Enerpac in a

wide range of bolt sizes typically used on

API flanges. The spanners can be changed

quickly using standard hand tools.

Note: Drive unit, pump and spanners are

sold separately and are not included with

the roller cassette.

Delivery instructions

Upon delivery all components must be

inspected for damage incurred during

shipping. If damage is found the carrier

should be notified at once. Shipping damage

is not covered by the Enerpac warranty.

Warranty

• Enerpac guarantees the product only

for the purpose for which is intended.

• All Enerpac products are guaranteed

against defects in workmanship and

materials for as long as you own them.

Any misuse or alteration invalidates the

warranty.

• Observe all instructions as

communicated in this manual.

• Replace any parts with Enerpac spare

parts only.

Be aware that the operator is fully

responsible during the operation of this

tool. Enerpac is not responsible for

damage or injury caused by misuse of

this tool. Under some circumstances

additional safety requirements beyond

those described in this manual may be

required. Contact Enerpac immediately if

a potentially hazardous situation arises.

Read this manual carefully and

observe all safety precautions.

- Make sure you have completed a

safety induction training, specific to

the work surroundings. The operator

should be thoroughly familiar with the

controls and the proper use of the tool.

- The operator must be at least

18 years of age.

- Always wear protective headwear, ear

protectors,

minimum rigger type gloves) suitable

for safe operation of the tool.

The protective clothing must not

interfere with safe operation of

the tool or restrict the ability to

communicate with co-workers.

- Make sure your workplace is safe.

- Do not place any part of the body

between the reaction roller and the

pipe flange.

- Do not place any objects between

the reaction roller and the pipe flange.

Keep the hoses away from this area

to prevent them from becoming

pinched or crushed.

footwear and gloves (at a

4

- Do not stand in the line of movement

of the tool when it is in operation. If

the tool separates from the nut or bolt

during operation it will detach in that

direction.

- Tightening and loosening nuts and

bolts involves little visible movement.

The pressure and loads, however

are extreme. Keep your hands away

from the fastener being loosened or

tightened.

- Make sure that the spanner used to

retain the nut or bolt on the opposite

end is secured.

- Always use Enerpac pumps and

hoses.

- Make sure appropriate guards are

always securely in position and free

from damage.

- Maximum pressure is 690 bar (10,000

psi). Never apply more pressure

to any tool or accessory than the

maximum allowable pressure. Refer to

pressure/torque tables for pressure/

torque settings. (see sections 6.3.1

and 6.3.2)

- Make sure that the spanner size

corresponds to the hex size of the

fastener being loosened or tightened.

Failure to do so can result in the tool

becoming unstable and can lead to

catastrophic failure of the tool.

- Do not abuse or overstress the hoses

in any way. Do not bend the hoses

excessively.

- Never carry the tool by its hoses.

- Always use Enerpac spare parts.

- Always position the tool for maximum

stability.

- Make sure the pipe flange is adequate

for the forces at work during

operation of the tool.

- Be aware that a nut or bolt that

breaks off during operation of the tool

may become a high velocity projectile.

- When the spanner is placed on the

nut or bolt a gap may exist between

the reaction roller and the pipe flange.

When the tool is operated the reaction

roller will make forceful contact with

the pipe flange. Always make sure the

tool is stable.

- Provide adequate support in vertical

and inverted applications.

- The maximum torque output of the

tool must always exceed the torque

required to loosen or tighten the nut

or bolt.

- The torque required to loosen a nut is

variable and may exceed the torque

capacity of the tool. Therefore never

operate the tool at maximum or close

to maximum capacity when loosening

a nut or bolt.

- Never operate the tool with a

hydraulic supply connection to

the advance side only as this may

damage the internal parts.

- If the wrench is dropped from a

height, have the tool inspected before

you operate it again.

- In severe conditions the tool must

be cleaned and lubricated more

frequently (see section 5).

- Check that the swivel

manifold post

screws (see section 5.3.2) and gland

are tight prior to use.

- If oil leakage is evident, replace seals

accordingly (see section 5.3.2).

- Stop operation immediately if a gap

appears between the cylinder locating

plate and the drive unit. Have the tool

inspected and serviced before you

operate it again.

- Make sure to minimize torsional and

bending stresses in the tool, the

spanner and any accessories.

- Do not strike the tool with a hammer.

This will invalidate the product

warranty.

- Always observe the maintenance

instructions.

ENGLISH

5

ENGLISH

Fig. A

Fig. B

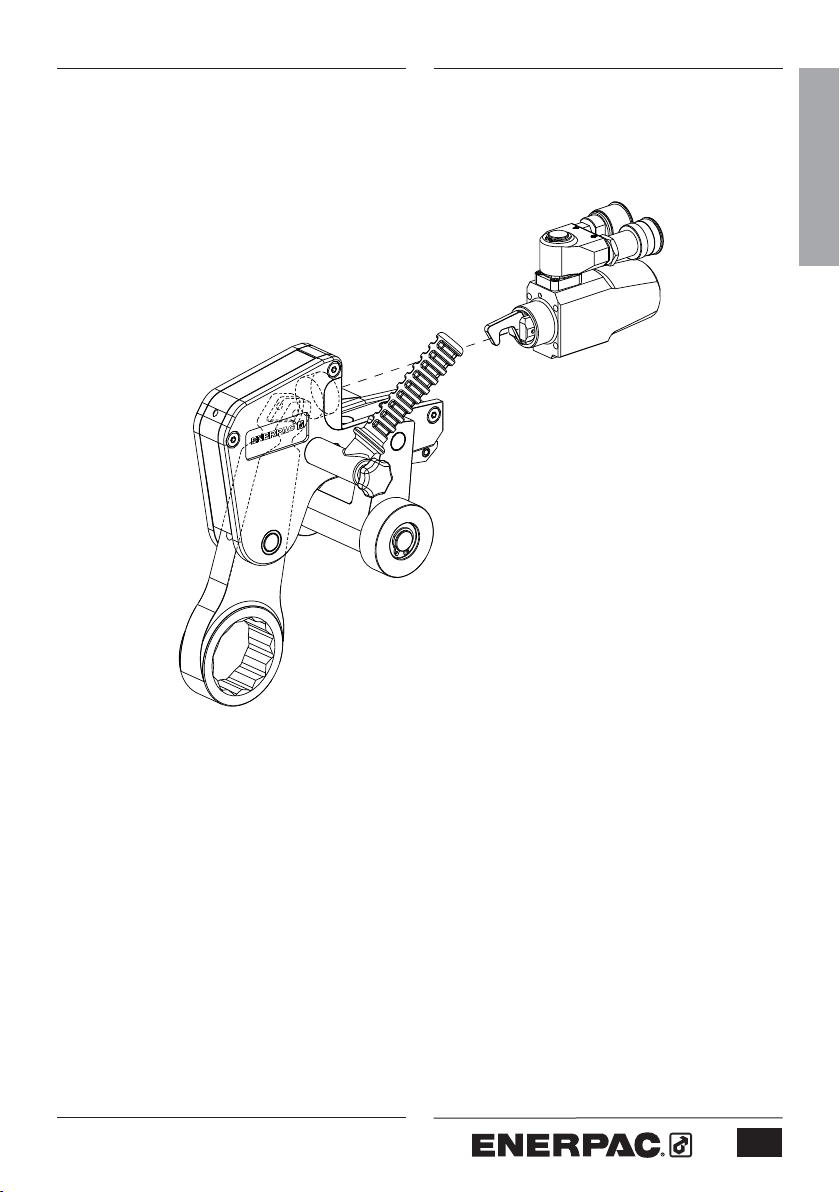

3 Assembly and adjustments

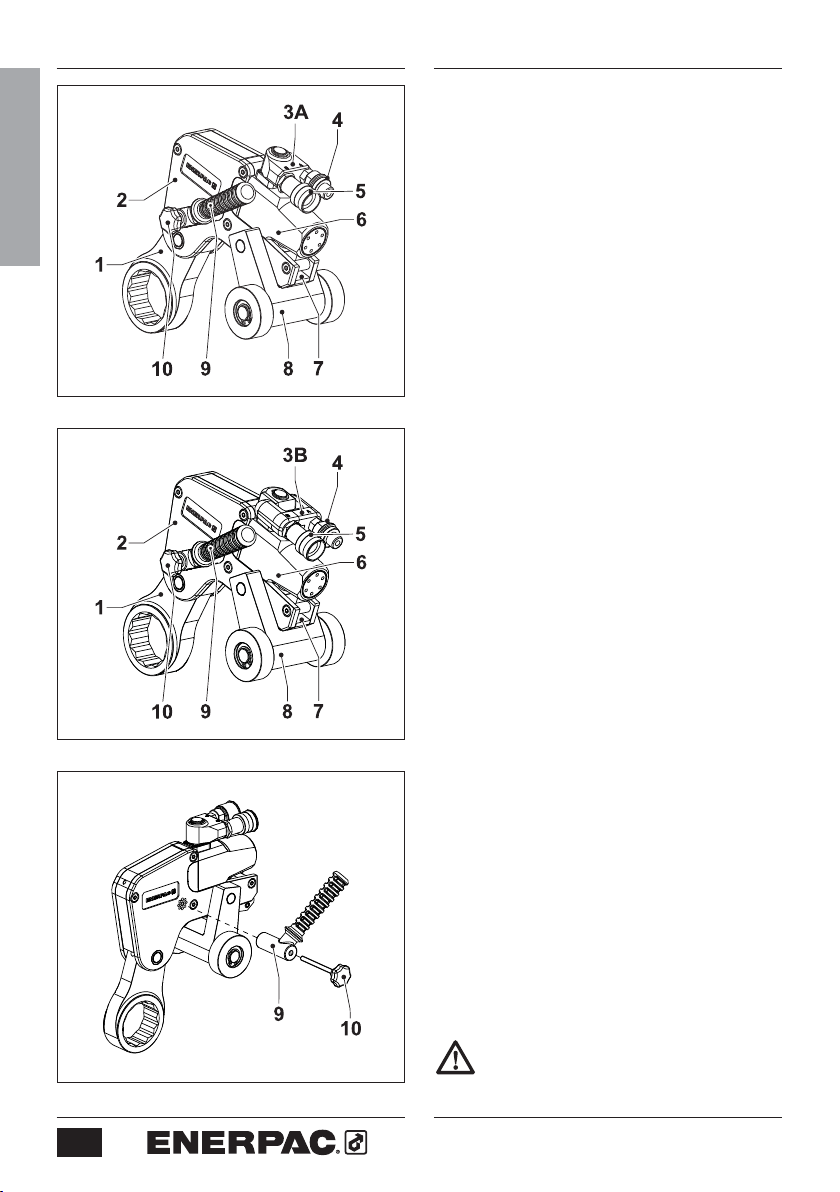

3.1 Overview and features (fig. A or B)

1 Spanner

2 Roller Cassette

3A Swivel

3B TSP-Pro Swivel

4 Advance hose connection

5 Return hose connection

6 Hydraulic drive unit

7 Cassette release lever

8 Reaction roller bracket and rollers

9 Positioning handle

10 Thumb screw

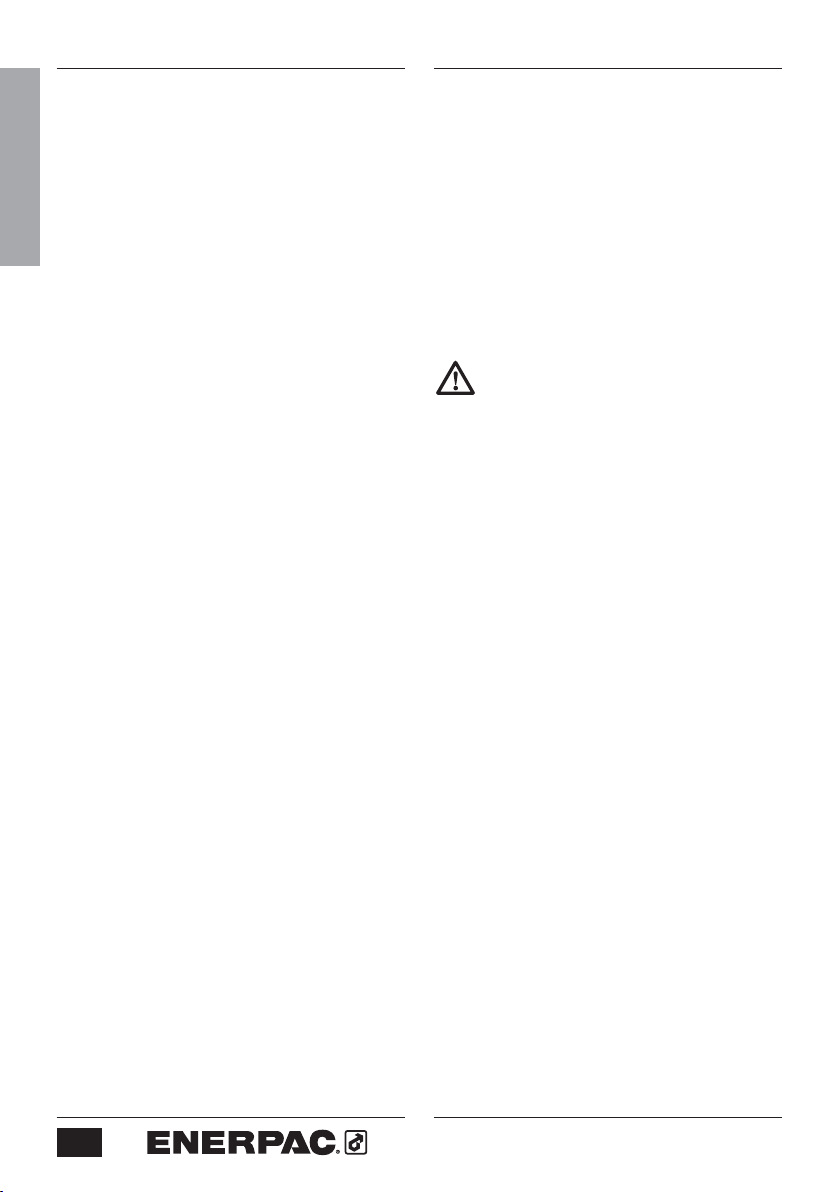

3.2.1 To attach the positioning handle

• Secure the positioning handle (9) with

Note: handle can be installed on

3.2.2 To remove the cassette (fig. D)

• Make sure the piston is fully retracted.

• Hold the tool with the drive unit

• Swing the

• Pull the release lever (7) outwards.

• Remove the cassette (2) from the

manifold (standard)

manifold (optional)

(fig. C)

thumb screw (10). Tighten hand tight.

either side of wrench (as needed).

pointing upwards.

reaction roller bracket (8)

inward, toward center of tool.

hydraulic drive unit (6).

Fig. C

6

3.2.3 To attach the cassette (fig. D and E)

• Make sure the retract link (11) aligns

with the slot (12) in the spanner (1).

Rotate the piston rod if necessary.

• Pull the release lever (7) outwards.

• Push the spigot (13) through the hole

in the cylinder locating plate (14).

• Push the release lever (7) back into

the cassette (2). Make sure the ball

detent clicks into place.

Do not operate the tool if the cassette

release lever is not fully closed.

Fig. D

Fig. E

• Swing the reaction roller bracket (8)

outward, away from center of tool.

3.3 To connect the hoses (fig. F)

Make sure all accessories meet the

pressure requirements.

Make sure the quick connect

couplings are securely attached

before operating the tool.

The tool is fitted with male and female

quick-connect couplings. Use Enerpac

twin safety hoses only. Refer to the table

below:

Hose model number Description

THQ-706T

THQ-712T

Two hoses, length

6 m (19.5 feet)

Two hoses, length

12 m (39 feet)

• Remove the hose dust caps.

• Connect the hose with the female

coupling (15) to the advance

coupling (4).

• Pull the sleeve on the female coupling

of the hose over the advance

coupling.

• Tighten the sleeve.

• Connect the hose with the male

coupling (16) into the return

coupling (5).

• Pull the sleeve on the return coupling

over the male coupling of the hose.

• Tighten the sleeve.

• Connect the hoses to the pump.

Refer to the pump instruction manual.

ENGLISH

Fig. F

7

ENGLISH

Fig. G

Fig. H

Fig. I

4 Operation

4.1 Prior to operation

- Make sure the nut or bolt to be

fastened is clean and free of dust.

- Make sure the nut or bolt runs

correctly on the thread.

- Make sure that the threads and the

bearing surface are liberally coated

with the correct lubricant or antiseizure compound.

- Make sure that the spanner used to

keep the nut or bolt on the opposite

end in place, is of the correct size

and that there is an adequate

abutment surface.

4.2 To set the torque

Adjust the pressure on the pump as

necessary to set the torque. Refer to sections

6.3.1 and 6.3.2 for torque setting tables.

4.3.1 To tighten a nut or bolt (fig. G, H, I)

• Place the wrench on the ground or on

a solid surface, such as a workbench.

• Operate the pump in the Retract

direction until drive unit is fully

retracted and the spanner socket

moves fully outward. Stop the pump.

• Swing the reaction roller bracket fully

outward, away from center of tool.

• Position the tool on the nut (bolt) with

the clockwise (+) side facing upwards.

• Position reaction roller against pipe

flange. Note: If a gap between

roller and flange is present, position

the roller as close to the flange as

possible, so that gap is minimal.

• Operate the pump in the Advance

direction to activate the wrench and

begin tightening the nut (bolt).

Stop operation immediately if a gap

appears between the cylinder

locating plate and the drive unit.

Never strike the tool with a hammer.

8

PINCH POINT

HAZARD

Keep hands and fingers clear of pinch

point area between spanner and

reaction roller. See Fig J.

Keep hands and fingers clear of pinch

point area between pipe flange and

reaction roller. See Fig J.

• Repeat previous steps as required

until nut (bolt) is tightened to the

proper torque.

Notes:

Spanner must be repositioned

after each wrench cycle by operating

the pump in the Retract direction. The

tool contains no spring return.

ENGLISH

Fig. J

Fig. K

4.3.2 To loosen a nut or bolt (fig. K, L)

• Apply penetrating oil to the threads.

Allow the oil to soak.

•

Reinstall the positioning handle on

counter-clockwise (-) side of wrench.

• To loosen the nut (bolt), follow steps

in section 4.3.1, but with the counterclockwise (-) side of wrench facing

upward.

• Repeat steps until nut (bolt) is loose.

If the nut or bolt will be re-used avoid

excess load when loosening.

- Be aware that when loosening a nut

or bolt more torque is usually required

than when tightening.

- Humidity corrosion (rust) requires

up to twice the torque required for

tightening.

- Sea water and chemical corrosion

requires up to two and a half times

the torque required for tightening.

- Heat corrosion requires up to

three times the torque required for

tightening.

Fig. L

Be aware that when loosening a nut

or bolt shock loading can occur. Do

not apply more than 75% of the

wrench’s maximum torque when

loosening nuts or bolts.

9

ENGLISH

Fig. M

Fig. N

5 Maintenance and troubleshooting

5.1 Spanner replacement (Fig M)

• Remove drive unit from cassette.

• Loosen and remove

• Tap

spanner pin (18) on one end and

remove it from the cassette.

• Slide spanner (1) out of cassette

housing.

• Apply a thin coat of molybdenum

disulphide lubricant

of the new spanner and to the

pin

at top of spanner.

• Slide new spanner (1) into cassette

housing. Align hole in spanner with

mating holes in sideplates.

• Install

spanner pin (18) through holes.

Before installation, be sure that flat

area of pin is aligned with

hole in spanner.

• Apply a small amount of Loctite 243

to threads of

• Reinstall

set screw (17).

5.2 Preventative maintenance (Fig N & O)

Preventative maintenance can be

carried out by the user. Full

maintenance must be carried out by

an approved and authorized

technician appointed by Enerpac.

Recommended service intervals are:

a) 3 months – Heavy Duty use

b) 6 months – Normal use

c) 12 months – Infrequent use

set screw (17).

to the sides

spring

set screw

set screw (17).

Fig. O

10

- Non destructive testing must be

carried out if the tool has been used

under severe conditions.

5.2.1 The roller cassette

• Remove drive unit from cassette.

• Remove

the shoulder screws (20). Lift

and remove the sideplate (21).

• Remove spanner (1),

and

set screw (17) as an assembly.

• Remove

reaction roller bracket pin

spanner pin (18)

(22) and reaction roller bracket (23).

• Remove circlips (24) reaction rollers

(25) and

roller pin (26).

• Clean all exposed components with a

mild solvent.

• Inspect all parts for damage.

• Dry all components. Apply a thin coat

of molybdenum disulphide lubricant

as indicated.

ENGLISH

5.2.2 The hydraulic drive unit

• Check tightness of swivel

manifold

post retaining screws (see 5.3.2) and

gland.

• Pressurize the drive unit to maximum

pressure (Advance and Retract), and

check for any signs of leakage.

• Any damaged components or seals

must be replaced.

• Dry all components and apply a

thin coat of molybdenum disulphide

lubricant

as indicated.

5.3 Full maintenance

Note: Refer to the WCR4000 repair

parts sheet for detailed views of

components and subassemblies

referenced in sections 5.3.1 and 5.3.2.

5.3.1 The roller cassette

• Strip down and clean all exposed

components with a mild solvent.

• Drift out the

cylinder retaining pin, and remove

retaining pin

spring pin holding the

the

.

• Inspect all parts for damage.

•

Perform non destructive testing by

magnetic particle inspection on the

following components:

-

Sideplates

- Cylinder locating plate

- Cylinder retaining pin

- Reaction roller bracket and pin

- Reaction rollers and roller pin

• Dry all components. Apply a thin coat

of molybdenum disulphide lubricant

as indicated.

Retaining Pin Height - Dimension “X”

Metric Imperial

5,00 mm 0.197 inch

Fail Safe Pin Height - Dimension “Y”

Metric Imperial

3,00 mm 0.118 inch

Fig. P

• Check retaining pin height (X) and fail

safe pin height (Y). Refer to Fig.P.

• Reverse the procedure to reassemble

the tool.

5.3.2 The hydraulic drive unit

• Remove the circlip from the

swivel

manifold block.

• Remove the hydraulic couplings.

• Remove the

swivel manifold block

from the drive unit.

• Remove

swivel manifold post

the retaining screws and the

.

• Remove all ‘O’ rings from swivel

manifold post.

• Carefully hold the cylinder body to

unscrew the cylinder gland.

• Hold the two flat sides of the piston

rod with a spanner. The rod is located

at the spigot.

• Remove the button head cap screw

from the piston.

• Remove the piston rod from the

cylinder spigot end.

• Remove the piston from the cylinder

gland end, using a suitable drift.

11

• Clean all exposed components with a

• Reverse the procedure to reassemble.

mild solvent.

• Inspect all parts for damage.

•

Perform non destructive testing by

magnetic particle inspection on the

ENGLISH

following components:

- Cylinder

body

- Piston rod

• Apply a small amount of Loctite 243

to the threads of the

capscrew

before reassembly.

button head

When reassembling the drive unit make

sure that the piston rod is inserted

through the cylinder spigot end.

When reassembling the drive unit

make sure that the piston is inserted

through the gland end. Tap the piston

gently into place against the piston

rod.

• Apply a small amount of Loctite

243 to the threads in the drive unit,

assemble the swivel

manifold post

and tighten the degreased retaining

screws to 5,1 Nm

(3.76 Ft.lbs).

• Pressurize the assembled drive unit to

max pressure (Advance and Retract),

and check for any signs of leakage.

5.4 Troubleshooting

5.4.1 Drive Unit

Symptom Cause Remedy

Cylinder does not advance or retract. Quick-connect coupling Replace the coupling.

is damaged.

Quick connect coupling is Reconnect the hoses

not connected. and couplings securely.

Dirt in the direction control Disassemble the unit and

valve on the pumping unit. clean the valve.

Cylinder does not build pressure. Piston seal leaks. Replace the seals.

Pump does not build pressure. Adjust the pressure.

Pump is defective. Refer to the pump manual.

Cylinder leaks. Seal failure. Replace the cylinder seals.

Cylinder operates backwards. Connections are reversed.

Reconnect hoses correctly.

5.4.2 Cassette

Symptom Cause Remedy

Drive unit operates Spanner broken Replace the spanner.

but spanner does not move. or damaged. Note: Top of spanner

contains fail-safe area

that is designed to

break in event of overload.

Spanner operation Fasteners loose. Check tightness of all

rough or erratic. screws and other fasteners.

Parts bent, worn Disassemble and inspect

or damaged. roller cassette. Clean,

lubricate and replace

parts as needed.

12

A

ENGLISH

Fig. Q

C

B

D

E

6 Technical specifications and torque settings

6.1 Capacities and dimensions - Model WCR4000

(fig. Q)

Spanner size range mm 36 - 80

inch 1

Maximum operating pressure bar 690

psi 10,000

Max. torque at 690 bar Nm 5.762

at 10,000 psi Ft.lbs 4,250

Min. torque Nm 576

Ft.lbs 425

Dimensions A mm (inch) 226 (8.9)

B mm (inch) 161 (6.3)

C mm (inch) 159 (6.25)

D mm (inch) 241 (9.5)

E mm (inch) 131 (5.2)

Weight (cassette only) kg (lbs) 6,2 (13.6)

(drive unit only) kg (lbs) 4,0 (8.8)

(drive unit and cassette) kg (lbs) 10,2 (22.5)

Note: Refer to section 6.2 for spanner weights and dimensions.

7

/16 - 3 1/8

13

6.2 Technical Data - Closed End Spanners

(fig. R)

6.2.1 Metric system table

ENGLISH

Spanner (F) (G) (H) Weight

Model

mm mm mm kg

W4107CS 36 31,0 30,0 1,9

W4108CS

W4110CS

W4113CS

W4114CS

W4200CS

W4203CS

W4206CS

W4209CS

W4212CS

W4215CS

W4302CS

38 32,8 30,0 2,1

41 32,8 30,0 2,2

46 35,6 30,0 2,1

48 38,4 30,0 2,1

50 38,4 30,0 2,2

55 41,2 30,0 2,1

60 45,0 30,0 2,2

65 46,8 30,0 2,1

70 49,6 30,0 2,2

75 52,1 30,0 2,1

80 55,4 30,0 2,2

6.2.2 Imperial system table

Spanner (F) (G) (H) Weight

Model

inch inch inch lbs

W4107CS 1 7/16 1.22 1.18 4.0

W4108CS 1 1/2 1.26 1.18 4.7

W4110CS 1 5/8 1.26 1.18 4.7

W4113CS 1 13/16 1.38 1.18 4.6

W4114CS 1 7/8 1.50 1.18 4.6

W4200CS 2 1.50 1.18 4.8

W4203CS 2 3/16 1.61 1.18 4.5

W4206CS 2 3/8 1.81 1.18 4.9

W4209CS 2 9/16 1.81 1.18 4.5

W4212CS 2 3/4 1.93 1.18 4.9

W4215CS 2 15/16 2.05 1.18 4.5

W4302CS 3 1/8 2.17 1.18 4.9

G

Fig. R

F

H

14

6.3 Torque settings

To set the torque, adjust the pump pressure

according to the following calculation:

Pump pressure = Torque / Torque factor

Measurement system Torque factor

Metric 8,351

Imperial 0.425

ENGLISH

6.3.1 Metric system pressure/torque

table - Model

WCR4000

Pump pressure (bar) Torque (Nm)

69 576

124 1.036

179 1.495

207 1.729

234 1.954

262 2.188

290 2.422

317 2.647

345 2.881

372 3.107

400 3.340

428 3.574

455 3.800

483 4.034

510 4.259

538 4.493

566 4.727

593 4.952

621 5.186

648 5.411

690 5.762

6.3.2 Imperial system pressure/torque

table - Model WCR4000

Pump pressure (psi) Torque (Ft.lbs)

1,000 425

1,800 765

2,600 1,105

3,000 1,275

3,400 1,445

3,800 1,615

4,200 1,785

4,600 1,955

5,000 2,125

5,400 2,295

5,800 2,465

6,200 2,635

6,600 2,805

7,000 2,975

7,400 3,145

7,800 3,315

8,200 3,485

8,600 3,655

9,000 3,825

9,400 3,995

10,000 4,250

15

7 Replacement parts and

recommended tools

7.2 Recommended

maintenance and repairs

tools for performing

7.1 To order replacement parts

ENGLISH

For replacement parts information,

refer to the Enerpac repair parts

sheet for your wrench model. Repair

parts sheets are available on the

internet at www.enerpac.com.

Have the following information ready

when ordering replacement parts:

- Wrench model and serial numbers

(for both drive unit and cassette).

- Approximate date of purchase.

- Part number and description of each

part being ordered.

– 1 7/8" A/F spanner

– 1 3/4" A/F spanner

– 1 5/8" A/F spanner

– 1 Circlip pliers

– 1 Seal extraction tool

– 1 ø 4 mm x 5 mm LG x 25 mm PCD

pin spanner

– 1 6 mm A/F Allen key

– 1 4 mm A/F Allen key

– 1 3 mm A/F Allen key

– 1 2,5 mm A/F Allen key

– 1 Copper hammer

– 1 3 mm terminal screwdriver

Notes:

A/F = Across Flats

PCD = Pitch Circle Diameter

16

NOTES:

17

NOTES:

18

NOTES:

19

Australia and New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

T +61 (0)2 9743 8988

F +61 (0)2 9743 8648

sales-au@enerpac.com

Brazil

Power Packer do Brasil Ltda.

Rua

Luiz Lawrie Reid, 548

09930-760

- Diadema (SP)

T +55 11 5687 2211

F +55 11 5686 5583

Toll Free: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

customer.service@actuant.com

China

Actuant (China) Industries Co. Ltd.

No. 6 Nanjing East Road,

Taicang Economic Dep Zone

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

Toll Free: +86 400 885 0369

sales-cn@enerpac.com

France, Switzerland, North Africa and

French speaking African countries

ENERPAC

Une division d’ACTUANT France S.A.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

sales-fr@enerpac.com

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf, Germany

T +49 211 471 490

F +49 211 471 49 28

sales-de@enerpac.com

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore, 560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

sales-in@enerpac.com

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

sales-it@enerpac.com

Japan

Applied Power Japan LTD KK

Besshocho 85-7

Kita-ku, Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

sales-jp@enerpac.com

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Oce 423, LOB 15

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

sales-ua@enerpac.com

Russia

Rep. oce Enerpac

Russian Federation

Admirala Makarova Street 8

125212 Moscow, Russia

T +7 495

98090 91

F +7 495 98090 92

sales-ru@enerpac.com

and Taiwan

Actuant Asia Pte Ltd.

83 Joo Koon Circle

Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free: +1800 363 7722

sales-sg@enerpac.com

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

sales-kr@enerpac.com

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

sales-es@enerpac.com

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg,

Central and Eastern Europe,

Baltic States, Greece, Turkey

and CIS countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 535 848

sales-nl@enerpac.com

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P.O. Box 421

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

integratedsolutions@enerpac.com

South Africa and other English

speaking African countries

Enerpac Africa Pty Ltd.

No. 5 Bauhinia Avenue

Cambridge Oce Park

Block E

Highveld Techno Park

Centurion 0157

South Africa

T: +27 12 940 0656

United Kingdom and Ireland

ENERPAC Ltd.,

Bentley Road South

Darlaston, West Midlands

WS10 8LQ

England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

sales-uk@enerpac.com

USA, Latin America and Caribbean

ENERPAC

P.O. Box 3241

Milwaukee WI 53201 USA

T +1 262 293 1600

F +1 262 293 7036

User inquiries:

T +1 800 433 2766

Distributor inquiries/orders:

T +1 800 558 0530

F +1 800 628 0490

Technical inquiries:

techservices@enerpac.com

sales-us@enerpac.com

All Enerpac products are guaranteed against

defects in workmanship and materials for as

long as you own them.

For the location of your nearest authorized

Enerpac Service Center, visit us at

www.enerpac.com

Enerpac Worldwide Locations e-mail: info@enerpac.com internet: www.enerpac.com

012313

Southeast Asia, Hong Kong

© Enerpac 09-2013 - All contents subject to change without notice.

Loading...

Loading...