Repair Parts Sheets for this product are available from the Enerpac web

site at www.enerpac.com, or from your nearest Authorized Enerpac

Service Center or Enerpac Sales office.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping damage is

not covered by warranty. If shipping damage is found, notify carrier at once.

The carrier is responsible for all repair and replacement costs resulting from

damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions, warnings and cautions carefully.

Follow all safety precautions to avoid personal injury or

property damage during system operation. Enerpac

cannot be responsible for damage or injury resulting from unsafe product use,

lack of maintenance or incorrect product and/or system operation. Contact

Enerpac when in doubt as to the safety precautions and operations. If you

have never been trained on high-pressure hydraulic safety, consult your

distribution or service center for a free Enerpac Hydraulic safety course.

Failure to comply with the following cautions and warnings could cause

equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

equipment or other property.

A WARNING indicates a potential danger that requires correct procedures

or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may cause

serious injury or even death.

• Check all Coupler Connections: Make sure all coupler

connections are complete. Loose or incomplete coupler

connections will cause complete or partial blockage of oil flow.

• Check all Hose Connections: Make sure all hose connections are

properly mated and secured.

• Do Not use excessive closing torque on valve handle or use any handle

extension. This will cause unnecessary wear on valve stem and seat and

may damage the spring.

• Check for Safe System Setups: Make sure that your valve, connecting

hoses, etc. are protected from any external source of damage, such as:

excessive heat, flame, moving machine parts, sharp edges, falling

objects, corrosive chemicals, dripping, etc.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

WARNING: Stay clear of loads supported by hydraulics. A

cylinder, when used as a load lifting device, should never be

used as a load holding device. After the load has been raised or

lowered, it must always be blocked mechanically.

WARNING: USE ONLY RIGID PIECES TO HOLD LOADS.

Carefully select steel or wood blocks that are capable of

supporting the load. Never use a hydraulic cylinder as a shim or

spacer in any lifting or pressing application.

DANGER: To avoid personal injury keep hands and feet away

from cylinder and workpiece during operation.

WARNING: Do not exceed equipment ratings. Never attempt to

lift a load weighing more than the capacity of the cylinder.

Overloading causes equipment failure and possible personal

injury. The cylinders are designed for a max. pressure of 700 bar

[10,000 psi]. Do not connect a jack or cylinder to a pump with a higher

pressure rating.

Never set the relief valve to a higher pressure than the maximum

rated pressure of the pump. Higher settings may result in

equipment damage and/or personal injury.

WARNING: The system operating pressure must not exceed the

pressure rating of the lowest rated component in the system.

Install pressure gauges in the system to monitor operating

pressure. It is your window to what is happening in the system.

CAUTION: Avoid damaging hydraulic hose. Avoid sharp bends

and kinks when routing hydraulic hoses. Using a bent or kinked

hose will cause severe back-pressure. Sharp bends and kinks

will internally damage the hose leading to premature hose failure.

Do not drop heavy objects on hose. A sharp impact may cause

internal damage to hose wire strands. Applying pressure to a

damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic equipment by the hoses or

swivel couplers. Use the carrying handle or other means of safe

transport.

CAUTION: Keep hydraulic equipment away from flames

and heat. Excessive heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose materials and

packings. For optimum performance do not expose

equipment to temperatures of 65°C [150°F] or higher. Protect hoses and

cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping oil under

pressure can penetrate the skin, causing serious injury. If oil is

injected under the skin, see a doctor immediately.

WARNING: Only use hydraulic cylinders in a coupled system. Never

use a cylinder with unconnected couplers. If the cylinder becomes

extremely overloaded, components can fail catastrophically causing

severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE LIFTING

LOAD. Cylinders should be placed on a flat surface that can

support the load. Where applicable, use a cylinder base for added

stability. Do not weld or otherwise modify the cylinder to attach a

base or other support.

Avoid situations where loads are not directly centered on the

cylinder plunger. Off-center loads produce considerable strain on

cylinders and plungers. In addition, the load may slip or fall,

causing potentially dangerous results.

Instruction Sheet

Sequence Valve

V-161

L916 Rev. O 02/04

®

®

®

®

®

Distribute the load evenly across the entire saddle surface.

Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be serviced by a

qualified hydraulic technician. For repair service, contact the

Authorized ENERPAC Service Center in your area. To protect

your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts by

genuine ENERPAC parts. Standard grade parts will break

causing personal injury and property damage. ENERPAC parts

are designed to fit properly and withstand high loads.

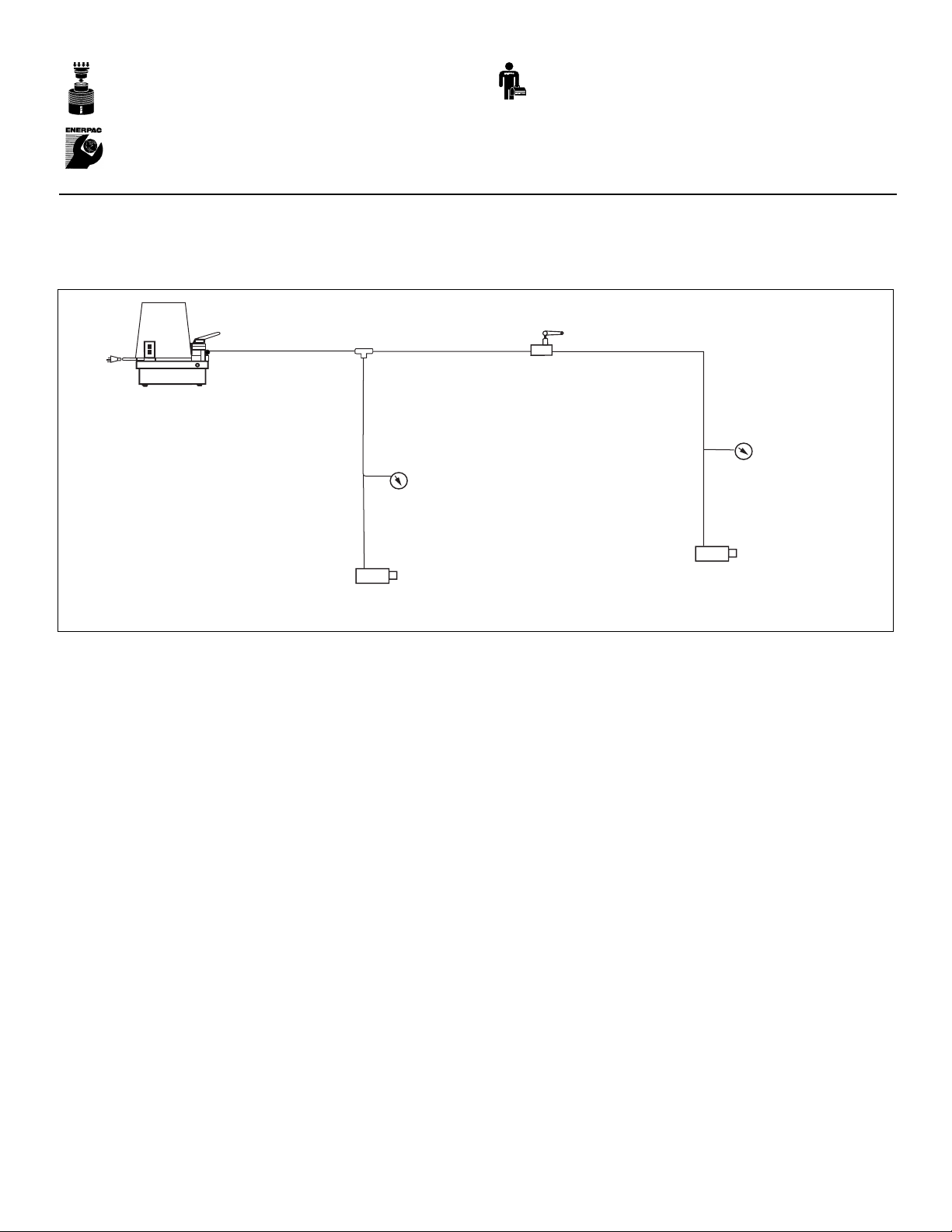

SEQUENCING VALVE, V-161

a. Connect valve as shown, plumbing "cyl." port to sequenced

cylinder.

b. Adjust Sequence Valve to desired sequencing pressure. Turn

sequence valve handle clockwise to increase pressure, or

counterclockwise to decrease pressure.

VALVE OPERATION (Example)

With sequence valve set at desired pressure (500 psi), close valve

on pump.The main cylinder will extend and the pressure will raise to

the desired sequence pressure (500 psi). The sequence valve will

then open at which point the pressure to both cylinders will increase

until the valve on the pump is returned to neutral, or until system

relief pressure is reached. (Note: the secondary cylinder pressure

will be 500 psi less than main cylinder.) Open valve on pump and

return system pressure to zero. Both cylinders will now retract.

DO NOT use excessive closing torque on valve handle or use any

handle extension. This will cause unnecessary wear on valve stem

and seat and may damage the spring.

Valve handle can be removed (loosen cap screw at end of handle)

to reduce tampering with valve settings. When handles are

reassembled on valve stem, make sure the cap screw is contacting

flat on the stem and the cap screw is tightened securely.

PROTECT YOUR WARRANTY, USE ONLY ENERPAC

HYDRAULIC OIL.

Enerpac Worldwide Locations

✦

e-mail: info@enerpac.com

✦

internet: www.enerpac.com

All Enerpac products are guaranteed against defects in workmanship and materials for as long as you own them.For your nearest authorized Enerpac Service Center, visit us at www.enerpac.com

Africa

ENERPAC Middle East FZE

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Australia

ENERPAC, Applied Power Australia

Ltd.

Block V Unit 3, Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

Tel: +61 297 438 988

Fax: +61 297 438 648

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

Tel: +55 11 5687 2211

Fax: +55 11 5686 5583

Toll Free in Brazil:

Tel: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

Tel: +1 905 564 5749

Fax: +1 905 564 0305

Toll Free:

Tel: +1 800 268 4987

Fax: +1 800 461 2456

Technical Inquiries:

techservices@enerpac.com

China

Actuant China Ltd.

1F, 269 Fute N. Road

Waigaoqiao Free Trade Zone

Pudong New District

Shanghai, 200 131 China

Tel: +86 21 5866 9099

Fax: +86 21 5866 7156

Actuant China Ltd. (Beijing)

709A Xin No. 2

Diyang Building

Dong San Huan North Rd.

Beijing City, 100028 China

Tel: +86 10 845 36166

Fax: +86 10 845 36220

Central and Eastern Europe

ENERPAC B.V.

Storkstraat 25

P.O. Box 269, 3900 AG Veenendaal

The Netherlands

Tel: +31 318 535 936

Fax: +31 318 535 951

France

ENERPAC Une division de

ACTUANT s.a.

B.P. 200

Parc d’Activités

du Moulin de Massy

F-91882 Massy CEDEX France

Tel: +33 1 601 368 68

Fax: +33 1 692 037 50

Germany, Austria, Switzerland,

Russia and CIS (excl. Caspian Sea

Countries) ENERPAC

Applied Power GmbH

P.O. Box 300113

D-40401 Düsseldorf

Germany

Tel: +49 211 471 490

Fax: +49 211 471 49 28

India

ENERPAC Hydraulics (India) Pvt. Ltd.

Plot No. A/571

MIDC, TTC Industrial Area

Mahape-400 701

Navi Mumbai, India

Tel: +91 22 2778 1472

Fax: +91 22 2778 1473

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

Tel: +39 02 4861 111

Fax: +39 02 4860 1288

Japan

Applied Power Japan Ltd.

1-1-11, Shimomae

Toda-shi

Saitama Pref.

Japan 335-0016

Tel: +81 484 30 1055

Fax: +81 484 30 1066

The Netherlands, Belgium,

Luxembourg, Sweden, Denmark,

Norway, Finland

ENERPAC B.V.

Storkstraat 25

P.O. Box 269, 3900 AG Veenendaal

The Netherlands

Tel: +31 318 535 911

Fax: +31 318 525 613

+31 318 535 848

Technical Inquiries Europe:

techsupport.europe@enerpac.com

Singapore

Enerpac Asia Pte. Ltd.

25 Serangoon North Ave. 5

#03-01 Keppel Digihub

Singapore 554914

Thomson Road

P. O. Box 114

Singapore 915704

Tel: +65 64 84 5108

+65 64 84 3737

Fax: +65 64 84 5669

Technical Inquiries:

chee@actuant.com.sg

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial

Complex, Jungwang-Dong,

Shihung-Shi, Kyunggi-Do

Republic of Korea 429-450

Tel: +82 31 434 4506

Fax: +82 31 434 4507

Spain, Portugal

ENERPAC

C/San José Artesano 8

Pol. Ind.

28108 Alcobendas

(Madrid) Spain

Tel: +34 91 661 11 25

Fax: +34 91 661 47 89

Middle East, Turkey ,

Caspian Sea, Greece

ENERPAC Middle East FZE

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

United Kingdom, Ireland

ENERPAC Ltd., P.O. Box 33

New Romney, TN28 8QF

United Kingdom

Tel: +44 01797 363 639

Fax: +44 01527 585 500

USA, Latin America

and Caribbean

ENERPAC

P. O. Box 3241

6100 N. Baker Road

Milwaukee, WI 53209 USA

Tel: +1 262 781 6600

Fax: +1 262 783 9562

User inquiries:

+1 800 433 2766

Distributor inquiries/orders:

+1 800 558 0530

Technical Inquiries:

techservices@enerpac.com

PUMP

GAUGE

V-161

SEQUENCE VALVE

"CYL." PORT

GAUGE

SECONDARY CYLINDER

MAIN CYLINDER

(Circuit 2)

(Circuit 1)

Loading...

Loading...