Enerpac Ultima P-18, Ultima P-39, Ultima P-77, Ultima P-80, Ultima P-801 Instruction Sheet

...Page 1

Instruction Sheet

ULTIMA Series Hand Pumps

P-18, P-39, P-77, P-80, P-801 and P-84

POWERFUL SOLUTIONS. GLOBAL FORCE.

L3070 Rev. E 05/12

Repair Parts Sheets for this product are available

from the Enerpac web site at www.enerpac.com, or

from your nearest Enerpac Authorized Service Center

or Enerpac Sales office.

1.0 IMPORTANT RECEIVING

INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If

shipping damage is found, notify carrier at once. The

carrier is responsible for all repair and replacement

costs resulting from damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instruc tions ,

warn ings and cautions

carefully. Follow all safety

precautions to avoid personal injury or property

damage during system operation. Enerpac cannot be

responsible for damage or injury resulting from unsafe

product use, lack of maintenance or incorrect product

and/or system operation. Contact Enerpac when in

doubt as to the safety precautions and operations. If

you have never been trained on high-pressure

hydraulic safety, consult your distribution or service

center for a free Enerpac Hydraulic safety course.

Failure to comply with the following cautions and

warnings could cause equipment damage and

personal injury.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

damage to, or destruction of equipment or other

property.

A WARNING indicates a potential danger that

requires correct procedures or practices to avoid

personal injury.

A DANGER is only used when your action or lack of

action may cause serious injury or even death.

WARNING: Wear prope r persona l

protective gear when operating hydraulic

equipment.

WARNING: Stay clear of loads supported

by hydraulics. A cylinder, when used as a

load lifting device, should never be used

as a load holding device. After the load

has been raised or lowered, it must always be

blocked mechanically.

WARNING: USE ONLY RIGID PIECES

TO HOLD LOADS. Carefully select steel

or wood blocks that are capable of

supporting the load. Never use a hydraulic cylinder

as a shim or spacer in any lifting or pressing

application.

DANGER: To avoid personal injury

keep hands and feet away from cylinder

and workpiece during operation.

WARNING: Do not exceed equipment

ratings. Never attempt to lift a load

weighing more than the capacity of the

cylinder. Overloading causes equipment

failure and possible personal injury. The cylinders are

designed for a max. pressure of 700 bar [10,000 psi].

Do not connect a jack or cylinder to a pump with a

higher pressure rating.

WARNING: Never set the relief valve

pressure above 10,500 psi [725 bar].

Serious personal injury could result if this

maximum limit is exceeded. Damage to pump and

components may also occur.

WARNING: The syste m ope rating

pressure must not exceed the pressure

rating of the lowest rated component in

the system. Install pressure gauges in the

system to monitor operating pressure. It is your

window to what is happening in the system.

Index:

English ............................................................... 1-9

Français ......................................................... 10-18

Deutsch ........................................................ 19-27

Italiano .......................................................... 28-36

Español ......................................................... 37-45

Nederlands ................................................... 46-54

Portuguese ................................................... 55-63

...........................................................

64-71

..........................................................

72-79

Finnish ........................................................... 80-88

Norwegian ..................................................... 89-97

Svenska ....................................................... 98-106

Russian ...................................................... 107-115

Greek ......................................................... 116-125

Page 2

2

CAUTION: Avoid damaging hydraulic

hose. Avoid sharp bends and kinks when

routing hydraulic hoses. Using a bent or

kinked hose will cause severe backpressure. Sharp bends and kinks will internally

damage the hose leading to premature hose failure.

Do not drop heavy objects on hose. A

sharp impact may cause internal damage

to hose wire strands. Applying pressure to

a damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel

couplers. Use the pump lifting/transport

handle or other means of safe transport.

CAUTION: Keep hydraulic equipment

away from flames and heat. Excessive

heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose

materials and packings. For optimum performance

do not expose equipment to temperatures of 150° F

[65° C] or higher. Protect hoses and cylinders from

weld spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin, causing serious injury.

If oil is injected under the skin, see a doctor

immediately.

WARNING: Only use hydraulic cylinders in

a coupled system. Never use a cylinder

with unconnected couplers. If the cylinder

becomes extrem ely over loade d,

components can fail catastrophically causing severe

personal injury.

WARNING: BE SURE SETUP IS STABLE

BEFORE LIFTING LOAD. Cylinders

should be placed on a flat surface that can

support the load. Where applicable, use a

cylinder base for added stability. Do not weld or

otherwise modify the cylinder to attach a base or

other support.

Avoid situations where loads are not

directly centered on the cylinder plunger.

Off-center loads produce considerable

strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially

dangerous results.

Distribute the load evenly across the

entire saddle surface. Always use a saddle

to protect the plunger.

IMPORTANT: Hydraulic equipment must

only be serviced by a qualified hydraulic

technician. For repair service, contact the

Authorized ENERPAC Service Center in

your area. To protect your warranty, use only

ENERPAC oil.

WARNING: Immediately replace worn or

damaged parts with genuine ENERPAC

parts. Standard grade parts will break

causing personal injury and property

damage. ENERPAC parts are designed to fit properly

and withstand high loads.

CAUTION: Always use the pump lifting/

transport handle to carry the pump.

Carrying the pump by the hose may

damage the hose and/or the pump.

3.0 PRODUCT INFORMATION

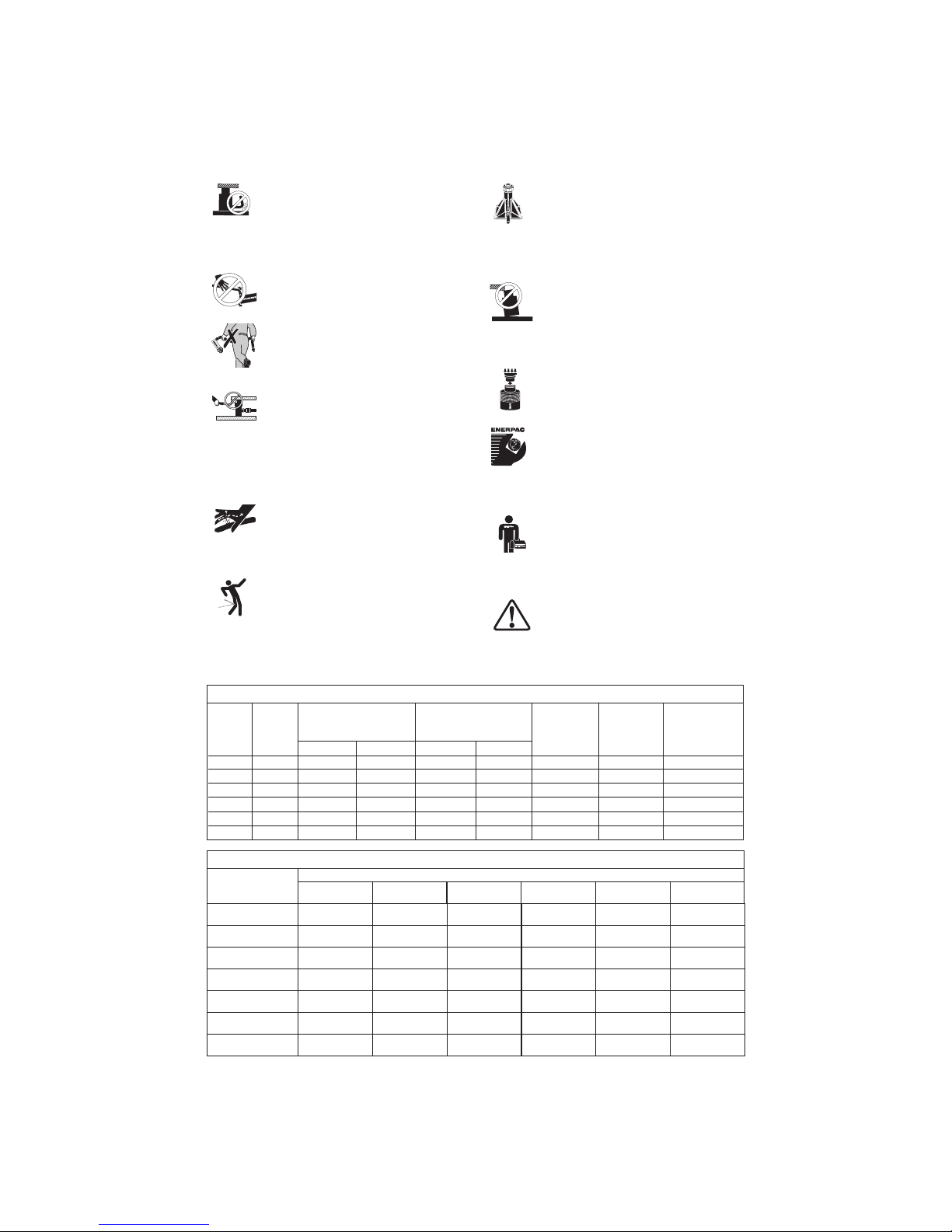

Table 1, Specifications - ULTIMA Series Hand Pumps

Pump

Model

Pump

Type

(Speed)

Stage 1 Stage 1Stage 2 Stage 2

Usable Oil

Capacity

in3 [cm3]

Weight

With Oil

lbs [kg]

Max. Handle

Effort

lbs [kg]

Max. Pressure Rating

psi [bar]

Oil Volume Per Stroke

in3 [cm3]

P-18

P-39

P-77

P-80

P-801

P-84

1

1

2

2

2

2

—

—

500 [34]

500 [34]

500 [34]

500 [34]

—

—

1.00 [16.38]

1.00 [16.38]

1.00 [16.38]

1.00 [16.38]

2850 [200]

10,000 [700]

10,000 [700]

10,000 [700]

10,000 [700]

10,000 [700]

0.15 [2,46]

0.15 [2,46]

0.15 [2,46]

0.15 [2,46]

0.15 [2,46]

0.15 [2,46]

22 [360]

47 [769]

47 [769]

134 [2195]

250 [4095]

134 [2195]

11.0 [5,2]

13.6 [6,2]

15.6 [7,1]

23.6 [10,7]

31.0 [14,0]

26.0 [11,7]

34 [16]

85 [38]

88 [40]

77 [35]

77 [35]

77 [35]

P-18

Release ValveARelease Valve Release Valve Release Valve Release Valve

4-Way, 3-Position

Control Valve

One 3/8" NPTF

Outlet Port

B

One 3/8" NPTF

Outlet Port

One 3/8" NPTF

Outlet Port

One 3/8" NPTF

Outlet Port

One 3/8" NPTF

Outlet Port

Two 3/8" NPTF

Outlet Ports

Oil Fill Plug

C

Oil Fill Plug Oil Fill Plug Oil Fill Plug Oil Fill Plug Oil Fill Plug

Mounting

Slots

D

Mounting

Slots

Mounting

Slots

Mounting

Slots

Mounting

Slots

Mounting

Slots

User-Adjustable

Relief Valve

E

User-Adjustable

Relief Valve

User-Adjustable

Relief Valve

User-Adjustable

Relief Valve

User-Adjustable

Relief Valve

User-Adjustable

Relief Valve

—

F

— —

3/8" NPTF Return

to Tank Port

3/8" NPTF Return

to Tank Port

—

—

G

— Bypass Valve Bypass Valve Bypass Valve Bypass Valve

Pump Model

Table 2,

Features and Major Components -

ULTIMA Series Hand Pumps

P-39 P-77 P-80 P-801 P-84

Item

(See figures 1 thru 4

for item locations)

Page 3

3

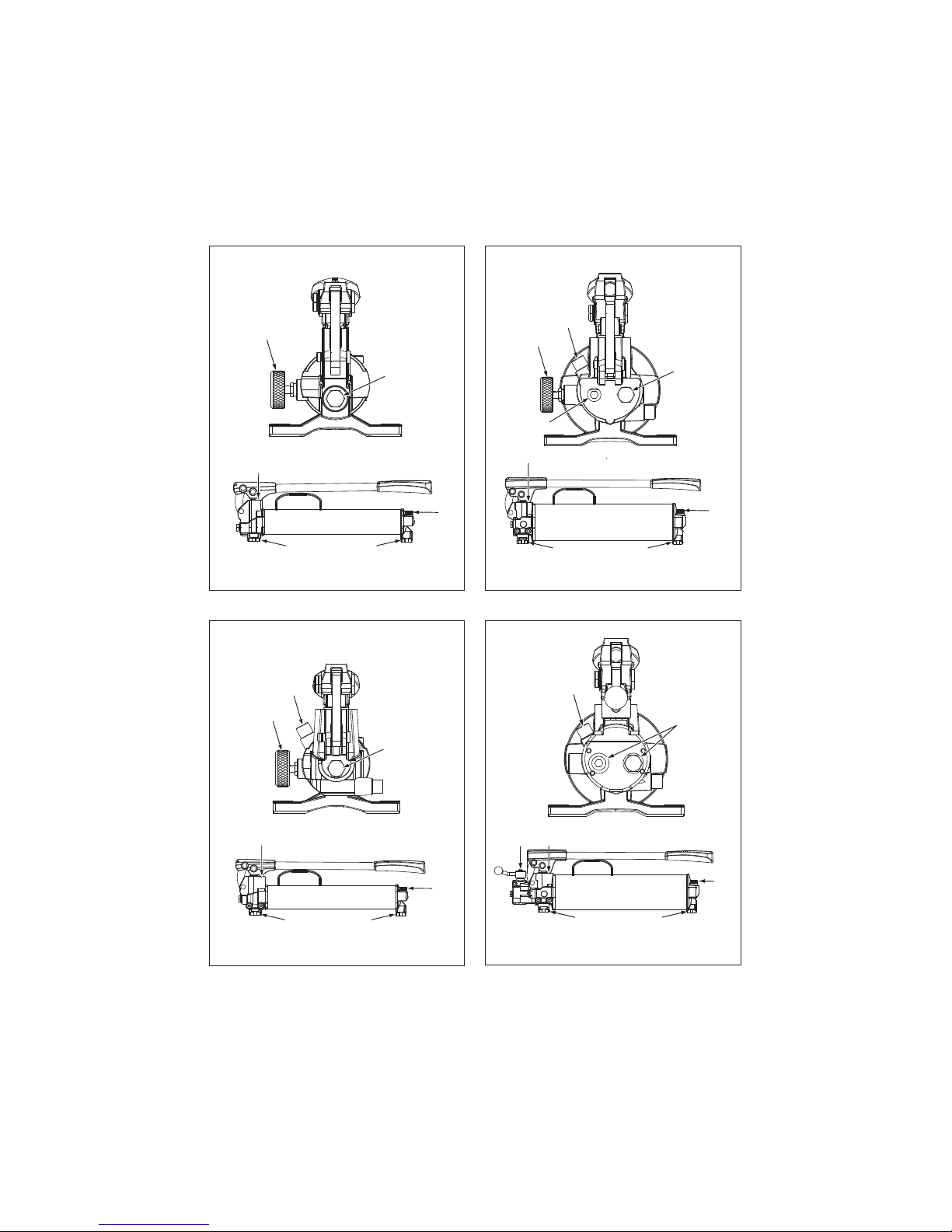

3.1 Pump Features and Major Components

See figures 1 through 4 for the locations of pump

features and major components. Refer to Table 2 for

descriptions of items A through G.

A

B

C

D D

E

Figure 1, Models P-18 and P-39

A

B

C

DD

E

G

Figure 2, Model P-77

A

B

C

DD

E

F

G

Figure 3, Models, P-80 and P-801

B

C

DD

E

A G

Figure 4, Model P-84

Page 4

4

4.0 INSTALLATION

4.1 Connecting the Pump

Figure 6

1. Remove shipping plug(s)

from pump outlet port(s).

2. Ad just the r elief

valve to the desired

hydraulic pressure limit.

See Section 7.0 for

instructions.

3. Connect hos e(s ) to

pump. To seal threads,

use anaerobic thread sealer,

Teflon® paste or Teflon®

tape.

IMPORTANT: When using Teflon® tape, apply the

tape one thread back from the end of the fitting to

prevent pieces of tape from entering the hydraulic

system. See Figure 6.

4. Install a pressure gauge in-line from the pump for

added safety and better control.

5. Connect the hose(s) to your cylinder or tool.

• For single-acting cylinders, connect one hose

from the pump to the cylinder.

• For double-acting cylinders, connect two hoses.

Connect one hose from port (A) of the pump to

the advance port of the cylinder. Connect another

hose from port (B) of the pump to the retract port

of the cylinder.

Models P-80 and P-801 only: If an external

pressure reducing valve is being used in the

circuit, connect the tank port of the valve to the

return-to-tank port on the pump.

Note: Cylinders, hoses and accessories shown

in Figure 5 are sold separately and not included

with pump. Refer to the Enerpac catalog for a

complete description of available components and

accessories. The exact components required for

your system will vary, depending on application and

other factors.

4.2 Pump Venting

The ULTIMA series hand pumps are designed

for non-vented operation. The oil fill plug can be

loosened if needed to vent air from the system but

should be fully installed before using the pump.

IMPORTANT: To prevent contaminants from entering

the hydraulic system, do not operate pump with oil fill

plug loosened or removed.

3 9

8 10 7

5 6 1

10 5 6

7

8

4 9 5 6

11

2

Key:

1. Cylinder (single-acting)

2. Cylinder (double-acting)

3. Hand Pump w/Release Valve

4. Hand Pump w/4-Way Valve

5. Hose

6. Male Coupler

Figure 5, Hydraulic Connections (typical)

7. Female Coupler

8. Pressure Gauge

9. Gauge Adapter

10. Swivel Connector

11. Safety Holding Valve

P-84

P-18, P-39, P-77, P-80, P-801

Page 5

5

4.3 Pump Position

The pump may be operated in either the horizontal or

vertical position. See Figure 7.

When operated in the vertical position, hose end of

pump must be pointed down, or the pump will pick

up air and will not properly build pressure.

Note: The pump is not designed for use in the

inverted (upside-down) position.

OK

OK

Figure 7, Pump Orientation

5.0 OPERATION

5.1 Before Using the Pump

1. Check all system fittings and connections to be

sure they are tight and leak free.

2. Check oil level in reservoir and add oil if required.

Refer to instructions in Section 9.1.

3. Read and understand the following precautions

before operating pump:

WARNING: In certain situations the pump

handle can “kick back”. Always keep your

body to the side of the pump, away from

the line of force of the handle.

WARNING: When operating the pump

handle, keep hands and fingers away from

pinch point area between pump handle

and lifting/transport handle.

CAUTION: Always remove shipping

plug(s) from pump outlet port(s) and

replace with proper hydraulic fitting(s)

before operating pump handle. If pump handle is

operated with shipping plug(s) installed, plug(s) could

eject from port(s) with great force, resulting in

possible personal injury.

CAUTION: Never add extensions to pump

handle. Extensions cause unstable pump

operation.

CAUTION: To prevent mechanical

damage, do not pull on pump handle after

it has reached the end of its travel. Do not

apply side force to pump handle.

IMPORTANT: To reduce handle effort at high

pressure, take short strokes. Maximum leverage is

obtained in the last 5 degrees of stroke.

5.2 Two Stage Flow

Models P-77, P-80, P-801 and P-84

Two-speed pumps provide two stage flow. Under

no-load, the pump operates in the high flow first

stage for rapid advance. When the load is contacted,

the pump automatically shifts to the second stage

for building pressure. After the pump shifts, pumping

takes less effort.

Note: For best performance, operate pump handle

at moderate speed during the high flow first stage.

Rapid handle speed in the first stage will prevent the

pump from delivering full volume of oil.

5.3 Pump Operation

Models P-18, P-39, P-77, P-80 and P-801

All pump models except the P-84 are designed for

use with single-acting cylinders and are equipped

with an integral release valve.

1. Close the release valve by turning knob clockwise

until it stops. See Figure 8.

CAUTION: Close release valve finger tight

ONLY. Using tools on release valve can

damage it and cause the pump to

malfunction.

2. Operate pump handle to deliver hydraulic power

to system. Pressure will be maintained until

release valve is opened.

3. Open the release valve by turning knob counterclockwise. Pressure will be released, allowing oil

to flow back to the reservoir.

CLOSE

OPEN

Figure 8, Release Valve (all except P-84)

CAUTION: If release valve knob is difficult

to turn or becomes stuck, immediately

discontinue using pump. Have pump

inspected and repaired by an Enerpac Authorized

Service Center.

Page 6

6

5.4 Pump Operation - Model P-84

The model P-84 is equipped with a 4-way, 3-position

control valve. It is designed for use with doubleacting cylinders. See figures 9 and 10.

1. Position lever on 4-way valve to select function as

follows:

(A) Flow directed to port “A”; port “B” returns flow

to the reservoir.

(N) Neutral -

ports “A” and “B” open to the reservoir.

(B) Flow directed to port “B”; port “A” returns flow

to the reservoir.

WARNING:

Valve contains no load holding

device. Be sure load is supported by

blocking, mechanical stands or other

appropriate supports before moving valve lever to the

neutral (N) position.

A B A B A B

(A) (N) (B)

Figure 9, 4-Way Valve Diagram (P-84)

(B) (A)

(N)

Port

“A”

Port

“B”

Figure 10, Control Valve Lever Positions

and Hose Connections (P-84)

2. Operate pump to perform work.

3. Change valve positions as needed.

WARNING: Opera te double-acting

cylinder only when both hoses are

connected to the pump. If one coupler is

left unconnected, high pressure will build behind the

coupler which could cause personal injury and/or

equipment damage.

6.0 AIR REMOVAL

Removing air from the hydraulic system will help the

cylinder to advance and retract smoothly.

6.1 Pump With Single-Acting Cylinder

1. Loosen and remove oil fill plug to provide reservoir

venting during the following steps.

2. Fully close release valve.

3. Position pump in the horizontal position at higher

elevation than cylinder. See Figure 11.

4. Position cylinder with the plunger end down (up if

using pull cylinder).

5. Operate pump to fully extend the cylinder (retract

if using pull cylinder).

6. Open release valve to retract cylinder (extend if

using pull cylinder). This will force the trapped air

to move up to the pump reservoir.

7. Repeat steps 2 through 6 as needed, until cylinder

operation is smooth.

8. Add oil if necessary. See Section 9.1.

9. Reinstall oil fill plug.

6.2 Pump With Double-Acting Cylinder

1. Loosen oil fill plug several turns to allow reservoir

venting during the following steps.

2. Position pump in the horizontal position at higher

elevation than cylinder. See Figure 11.

3. Put cylinder in horizontal position with ports up.

4. Fully advance and retract the cylinder 2 to 3 times.

5. Repeat steps 2 through 4 as needed, until cylinder

operation is smooth.

6. Add oil if necessary. See Section 9.1.

7. Reinstall oil fill plug.

7.0 RELIEF VALVE ADJUSTMENT

1. All models except P-84: Install a 0-15,000 psi

[0-1000 bar] pressure gauge in the pump oil

outlet port. Close the release valve (turn knob fully

clockwise until it stops).

Figure 11, Air Removal

air

air

Single-acting

Cylinder

Double-acting

Cylinder

Page 7

7

2. Model P-84 only: install a 0-15,000 psi [0-1000

bar] pressure gauge in the pump “A” port. Install

a pipe plug in the pump “B” port. Move the control

valve lever to the (A) position.

3. Using a 1/4" Allen wrench, remove the dust plug

over the relief valve adjustment screw.

• On models P-18 and P-39, the relief valve is

located on the top surface of the pump head. See

Figure 12.

• On models, P-77, P-80, P-801 and P-84, the

relief valve is located on the side of the pump

head. See Figure 13.

Note: To obtain an accurate setting during the

following steps, always decrease the pressure to a

point below the desired final setting and then slowly

increase the pressure until the final setting is reached.

4. Using a 7/32" Allen wrench, loosen the relief valve

adjustment screw about 2 turns. See Figure 14.

5. While operating the pump handle, slowly turn

the relief valve adjustment screw clockwise until

pressure increases to the desired setting. The

pressure setting is indicated when additional

pumping does not result in a higher pressure

reading on the gauge.

WARNING: Never set the relief valve

pressure above 10,500 psi [725 bar].

Serious personal injury could result if this

maximum limit is exceeded. Damage to pump and

components may also occur.

6. All models except P-84: After the desired

setting is obtained, turn the release valve counter

clockwise to relieve system pressure. Check that

pressure gauge indicates zero (0) psi/bar.

7. Model P-84 only: After the desired setting is

obtained, move the valve handle to the (N) neutral

position to relieve system pressure. Check that

pressure gauge indicates zero (0) psi/bar.

8. All models except P-84: Remove pressure gauge

from pump oil outlet port. Reinstall dust plug over

relief valve adjustment screw.

9. Model P-84 only: Remove pressure gauge from

pump “A” port. Remove pipe plug from pump

“B” port. Reinstall dust plug over relief valve

adjustment screw.

Dust

Plug

Figure 12, Relief Valve (P-18 and P-39)

Dust

Plug

Figure 13, Relief Valve (P-77, P-80, P-801 and P-84)

Decrease Increase

Figure 14, Relief Valve Adjustment Screw

8.0 BYPASS VALVE ADJUSTMENT

MODELS P-77, P-80, P-801 and P-84

The bypass valve controls the pressure at which a

two-speed pump shifts from the first to the second

stage. See Figure 15.

The bypass valve is factory set and should not

require readjustment unless the pump is overhauled

or repaired. If needed, readjustment should be

performed only by an Enerpac Authorized Service

Center.

Bypass

Valve

Figure 15, Bypass Valve

(P-77, P-80, P-801 and P-84)

Page 8

8

9.0 MAINTENANCE

Use only Enerpac hydraulic oil with the pump to

promote long pump life and to protect your warranty.

Viton and EPR seal kits are available for some hand

pump models. Contact your Enerpac representative

for more information on these products and their

applications.

9.1 Adding Oil to the Pump

WARNING: Always add oil with cylinders

fully retracted (extended if pull cylinders)

or the system will contain more oil than the

reservoir can hold.

Check oil level regularly and add oil if needed. Refer

to the following steps:

1. Place pump in the horizontal position on a level

surface.

2. Remove oil fill plug from reservoir.

3. Check oil level. See Figure 16. If oil level is low,

add additional oil until oil level is up to the bottom

thread of the oil fill plug opening.

IMPORTANT: Do not overfill! Some air space must

be present in reservoir to allow proper operation. If

the reservoir contains too much oil, a vacuum will

form, preventing oil flow when pump is operated.

4. Reinstall oil fill plug after adding oil. Be sure that

plug is fully installed (not loose).

5. Remove air from system if necessary. See Section

6.0. Recheck oil level after removing air.

Oil Fill Plug

Fill Line

FILL TO

BOTTOM

OF THREADS

Figure 16, Reservoir Oil Level

WARNING: The oil fill plug contains an

integral pressure relief passage, a safety

feature that prevents over-pressurization

of the reservoir. Use only the oil fill plug supplied with

the pump or a genuine Enerpac replacement plug of

identical specifications.

CAUTION:. Never attempt to return more

oil to the reservoir than it is capable of

holding.

9.2 Changing the Oil

Drain all oil from reservoir and refill with clean

Enerpac oil every 12 months. If pump is used in dirty

environments, change the oil more frequently.

1. Remove oil fill plug from reservoir.

2. Tilt pump to drain out old oil.

IMPORTANT: Dispose of used oil in accordance with

all applicable laws and regulations.

3. Fill reservoir with new Enerpac oil. Refer to

Section 9.1 for additional information.

4. Reinstall oil fill plug.

9.3 Lubrication

To extend pump life and improve performance,

lubricate the three pump handle pins regularly, using

roller bearing grease. See Figure 17.

Pin 1

Pin 3

Pin 2

Figure 17, Lubrication Points

9.4 Keeping Oil Lines Clean

Always install dust caps when coupler halves are

disconnected. To help prevent failure of pump and

other components, use every precaution to guard

the system against entrance of dirt and other foreign

matter.

10.0 TROUBLESHOOTING GUIDE

The information in the troubleshooting guide (see

Table 3) is intended only as an aid to help diagnose

and correct selected problems that may occur.

A system failure may or may not be the result of a

pump malfunction. To determine the cause of the

problem, the complete system must be included in

any diagnostic procedure.

For repair service, contact your local Enerpac

Authorized Service Center. Only an Enerpac

Authorized Service Center should service the pump

or system components.

Page 9

9

Cylinder does

not advance,

advances slowly,

or advances

erratically.

Cylinder

advances, but

does not hold

pressure.

Cylinder does

not retract,

retracts part

way, or retracts

more slowly than

normal.

1. Low oil level in pump reservoir.

2. Release valve open or not fully

closed.

3. Relief valve setting too low.

4. Hydraulic coupler not properly

connected.

5. Load is too heavy.

6. Air trapped in system.

7. Reservoir overfilled.

8. Cylinder plunger binding.

1. Leaking connection.

2. Leaking seals.

3. Internal leakage in pump.

4. Bypass valve setting too low.

(Models P-77, P-80, P-801 and

P-84)

1. Release valve closed.

2. Reservoir overfilled.

3. Hydraulic coupler not properly

connected.

4. Air trapped in system.

5. Hose inside diameter too

narrow.

6. Cylinder retraction spring

broken or other cylinder

damage.

7. In-line valve closed.

1. Add oil according to the instructions in Section 9.1.

2. Close the release valve.

3. Set the relief valve pressure according to

instructions in Section 7.0.

4. Check that all couplers are fully tightened.

5. Do not attempt to lift more than rated tonnage.

6. Remove air according to the instructions in

Section 6.0.

7. Remove excess oil from reservoir.

Note: If cylinder operates normally when pump oil fill

plug is loosened, reservoir may be overfilled with oil.

8. Check for damage to cylinder. Have cylinder

serviced by an Enerpac Authorized Service Center.

1. Check that all connections are tight and leak free.

2. Locate leak(s) and have equipment serviced by an

Enerpac Authorized Service Center.

3. Have pump serviced by an Enerpac Authorized

Service Center.

4. Have an Enerpac Authorized Service Center adjust

the bypass valve setting.

1. Open the release valve.

2. Remove excess oil from reservoir.

Note: If cylinder operates normally when pump oil fill

plug is loosened, reservoir may be overfilled with oil.

3. Check that all couplers are fully tightened.

4. Remove air according to the instructions in

Section 6.0.

5. Use larger diameter hydraulic hose.

6. Have cylinder serviced by an Enerpac Authorized

Service Center.

7. Ensure that in-line valves (if used) are correctly

set.

Table 3,

Troubleshooting Guide - ULTIMA Series Hand Pumps

Problem Possible Cause Solution

Note: For the location of your nearest Enerpac Authorized Service Center go to www.enerpac.com

Page 10

Australia and New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

T +61 (0)2 9743 8988

F +61 (0)2 9743 8648

sales-au@enerpac.com

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

T +55 11 5687 2211

F +55 11 5686 5583

Toll Free: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

customer.service@actuant.com

China

Actuant (China) Industries Co. Ltd.

No. 6 Nanjing East Road,

Taicang Economic Dep Zone

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

Toll Free: +86 400 885 0369

sales-cn@enerpac.com

France, Switzerland, North Africa and

French speaking African countries

ENERPAC

Une division d’ACTUANT France S.A.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

sales-fr@enerpac.com

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf, Germany

T +49 211 471 490

F +49 211 471 49 28

sales-de@enerpac.com

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore, 560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

sales-in@enerpac.com

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

sales-it@enerpac.com

Japan

Applied Power Japan LTD KK

Besshocho 85-7

Kita-ku, Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

sales-jp@enerpac.com

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Oce 423, LOB 15

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

sales-ua@enerpac.com

Russia

Rep. oce Enerpac

Russian Federation

Admirala Makarova Street 8

125212

Moscow, Russia

T +7 495 98090 91

F +7 495 98090 92

sales-ru@enerpac.com

Singapore

Actuant Asia Pte Ltd.

83 Joo Koon Circle

Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free: +1800 363 7722

sales-sg@enerpac.com

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

sales-kr@enerpac.com

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

sales-es@enerpac.com

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg,

Central and Eastern Europe,

Baltic States, Greece, Turkey

and CIS countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 535 848

sales-nl@enerpac.com

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P.O. Box 421

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

integratedsolutions@enerpac.com

South Africa and other English

speaking African countries

Enerpac Africa Pty Ltd.

No. 5 Bauhinia Avenue

Cambridge Oce Park

Block E

Highveld Techno Park

Centurion 0157

South Africa

T: +27 12 940 0656

United Kingdom and Ireland

ENERPAC Ltd.,

Bentley Road South

Darlaston, West Midlands

WS10 8LQ

England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

sales-uk@enerpac.com

USA, Latin America and Caribbean

ENERPAC

P.O. Box 3241

Milwaukee WI 53201 USA

T +1 262 293 1600

F +1 262 293 7036

User inquiries:

T +1 800 433 2766

Distributor inquiries/orders:

T +1 800 558 0530

F +1 800 628 0490

Technical inquiries:

techservices@enerpac.com

sales-us@enerpac.com

All Enerpac products are guaranteed against

defects in workmanship and materials for as

long as you own them.

For the location of your nearest authorized

Enerpac Service Center, visit us at

www.enerpac.com

Enerpac Worldwide Locations

e-mail: info@enerpac.com internet: www.enerpac.com

101711

Loading...

Loading...