Page 1

L3096 Rev. B Date: 12/11

Index:

English ................................................................ 1-11

Français ............................................................... N/A

Deutsch ............................................................... N/A

Italiano ................................................................. N/A

Español ................................................................ N/A

Nederlands .......................................................... N/A

Portuguese .......................................................... N/A

..................................................................

Repair Parts Sheets for this product are available

from the Enerpac web site at www.enerpac.com, or

from your nearest Authorized Enerpac Service Center

or Enerpac Sales office.

N/A

1.0 IMPORTANT RECEIVING

INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If

shipping damage is found, notify carrier at once. The

carrier is responsible for all repair and replacement

costs resulting from damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions, warnings

and cautions carefully. Follow

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage

or injury resulting from unsafe product use, lack of

maintenance or incorrect product and/or system

operation. Contact Enerpac when in doubt as to the

safety precautions and operations. If you have never

been trained on high-pressure hydraulic safety,

consult your distribution or service center for a free

Enerpac Hydraulic safety course.

Failure to comply with the following safety

precautions could cause equipment damage and

personal injury.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

damage to, or destruction of equipment or other

property.

A WARNING indicates a potential danger that

requires correct procedures or practices to avoid

personal injury.

A DANGER is only used when your action or lack of

action may cause serious injury or even death.

all safety precautions to avoid

Instruction Sheet

70 Bar Swing Cylinders

2,0 kN, 3,5 kN, 5,0 kN, 7,0 kN, 9.0 kN and 20 kN

WARNING: Wear proper personal

protective gear when operating hydraulic

equipment.

WARNING: Stay clear of loads supported

by hydraulics. A cylinder, when used as a

load lifting device, should never be used as

a load holding device. After the load has been raised

or lowered, it must always be blocked mechanically.

DANGER: To avoid personal injury

keep hands and feet away from cylinder

and workpiece during operation.

WARNING: Do not exceed the product

operating specifications. The cylinders

are designed for a maximum pressure of

70 bar [1000 psi]. Never adjust the circuit pressure

beyond the maximum operating pressure

recommendation for the clamp arm length.

Exceeding these specifications can cause equipment

failure and possible personal injury.

DANGER: Never set the relief valve to a

higher pressure than the maximum rated

pressure of the pump. Higher settings

may result in equipment damage and/or personal

injury. Do not remove relief valve.

WARNING: The system operating

pressure must not exceed the pressure

rating of the lowest rated component in

the system. Install pressure gauges in the

system to monitor operating pressure. It is your

window to what is happening in the system.

CAUTION: Avoid damaging hydraulic

hose. Avoid sharp bends and kinks when

routing hydraulic hoses. Using a bent or

kinked hose will cause severe back-pressure. Sharp

bends and kinks will internally damage the hose

leading to premature hose failure.

Page 2

Do not drop heavy objects on hose. A

sharp impact may cause internal damage

®

to hose wire strands. Applying pressure to

a damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel couplers.

Use the carrying handle or other means of

safe transport.

CAUTION: Keep hydraulic equipment

away from flames and heat. Excessive

heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose

materials and packings. For optimum performance do

not expose equipment to temperatures of 65 °C [150

°F] or higher. Protect hoses and cylinders from weld

spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin, causing serious injury.

If oil is injected under the skin, see a doctor

immediately.

3.0 PRODUCT DATA

Table 1 - Model Number Code

1

S =

Swing

Clamp

2

U =

Upper

Flange

3

R =

Right Hand

L =

Left Hand

4

S =

Single Acting

D =

Double Acting

WARNING: Only use hydraulic cylinders in

a coupled system. Never use a cylinder with

unconnected couplers. If the cylinder

becomes extremely overloaded, components can fail

catastrophically causing severe personal injury.

IMPORTANT: Hydraulic equipment must

only be serviced by a qualified hydraulic

technician. For repair service, contact the

Authorized ENERPAC Service Center in your area. To

protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or

damaged parts with genuine ENERPAC

parts. Standard grade parts will break

causing personal injury and property damage.

ENERPAC parts are designed to fit properly and

withstand high loads.

5678

7=

70 bar

pressure

rating

2 = 2 kN [441 lbs]

3 = 3,5 kN [769 lbs]

5 = 5,0 kN [1111 lbs]

7 = 7,0 kN [1570 lbs]

2 =

Metric

S =

Position

Indicator

Staff

9 = 9,0 kN [2019 lbs]

20 = 20,0 kN [4490 lbs]

Table 2 - Cylinder Specifications

Capacity kN [lbs]

Body Style

Cylinder Type

Hydraulic

Stroke

mm [in]

Effective

Area

2

[in2]

mm

Oil

Capacity

3

cm

[in3]

clamp

total

clamp

unclamp

clamp

unclamp

2 kN

[441 lbs]

Upper

Flange

Single or

Double

Acting

12,0

[0.47]

22,1

[0.87]

3,02

[0.47]

6,16

[0.95]

6,7

[0.41]

13,61

[0.83]

3,5 kN

[769 lbs]

Upper

Flange

Single or

Double

Acting

12,0

[0.47]

22,1

[0.87]

5,28

[0.82]

9,08

[1.41]

11,7

[0.71]

20,07

[1.22]

5 kN

[1111 lbs]

Upper

Flange

Single or

Double

Acting

12,0

[0.47]

22,1

[0.87]

7,54

[1.17]

11,34

[1.76]

16,7

[1.02]

25,06

[1.53]

2

7 kN

[1570 lbs]

Upper

Flange

Single or

Double

Acting

12,0

[0.47]

22,1

[0.87]

10,30

[1.60]

15,21

[2.36]

22,8

[1.39]

33,60

[2.05]

9 kN

[2019 lbs]

Upper

Flange

Single or

Double

Acting

12,0

[0.47]

22,1

[0.87]

13,19

[2.04]

18,10

[2.80]

29,1

[1.78]

39,99

[2.44]

20 kN

[4490 lbs]

Upper

Flange

Single or

Double

Acting

12,0

[0.47]

22,1

[0.87]

30,44

[4.72]

38,48

[5.97]

67,3

[4.10]

85,05

[5.19]

Page 3

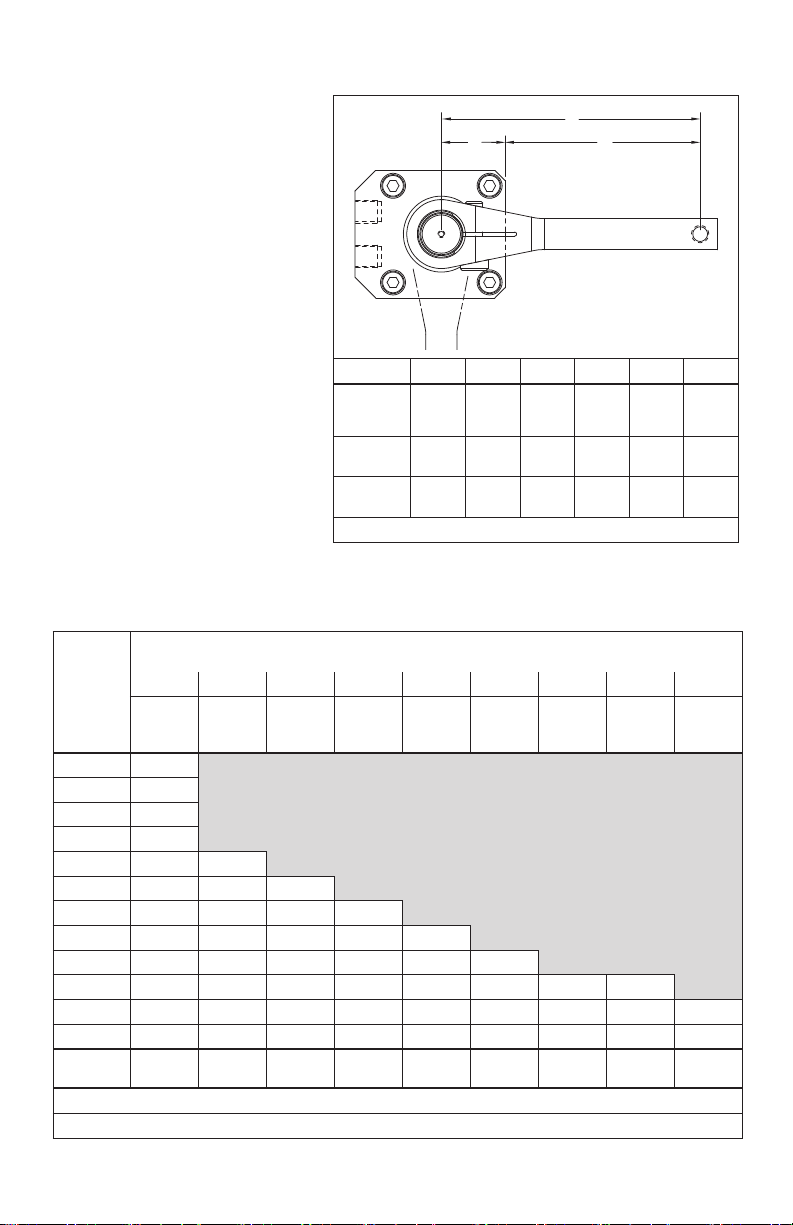

3.1 Clamping Force vs.

Arm Length

Refer to the tables in this section when

selecting the swing cylinder model and

arm length for your application.

IMPORTANT: As the arm length

increases, the maximum allowable

pressure and flow rate decreases.

Exceeding these limits may cause

damage to the product. If the pressure

required for a desired clamping force

and arm length exceeds the specified

limits, select a higher capacity swing

cylinder model.

Table 3 - Clamp Arm Dimensions “M”, “N” and “P”

P

N

(REF)

M

Size

Dimension

“M”

Dimension

“N”

Dimension

“P”

Conversion Information: 1 mm = 0.039 in.

2 kN 3,5 kN 5 kN 7 kN 9 kN 20 kN

See

See

See

Table

Table

25 mm 27 mm 30 mm 37 mm 38 mm 49 mm

M + N M + N M + N M + N M + N M + N

5

4

Table

6

See

Table

7

Table

Table 4 - Clamping Force vs. Arm Length - 2 kN Models

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

10* 20 30 40 50 60 70 80 95**

(kN)

Clamp

Force

Pressure

(bar)

70 1,96

65 1,82

60 1,69

55 1,56

45 1,25 1,33

40 1,11 1,20 1,18

35 0,98 1,07 1,02 1,02

30 0,85 0,89 0,85 0,85 0,85

25 0,71 0,76 0,71 0,71 0,71 0,71

20 0,56 0,62 0,58 0,58 0,58 0,58 0,58 0,56

15 0,42 0,44 0,40 0,40 0,40 0,40 0,40 0,40 0,38

10 0,29 0,31 0,27 0,27 0,27 0,27 0,27 0,27 0,27

Maximum

Flow (lpm)

Notes: * CAS-722 standard arm ** CAL-722 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

Clamp

Force

(kN)

0,41 0,31 0,25 0,21 0,18 0,15 0,14 0,12 0,11

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

Clamp

Force

(kN)

(kN)

NOT RECOMMENDED

Clamp

Force

(kN)

Clamp

Force

(kN)

See

See

Table

8

9

Clamp

Force

(kN)

3

Page 4

Table 5 - Clamping Force vs. Arm Length - 3,5 kN Models

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

Pressure

(bar)

Maximum

Flow (lpm)

Notes: * CAS-7352 standard arm ** CAL-7352 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

23* 30 40 50 60 70 80 90 100 110 120 125**

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Force

Force

Force

Force

Force

Force

Force

(kN)

(kN)

(kN)

(kN)

(kN)

(kN)

70 3,42

65 3,20

60 2,94 3,16

55 2,71 2,89

2,22 2,36 2,36 2,36

45

1,96 2,09 2,09 2,09 2,09

40

1,73 1,85 1,78 1,78 1,78 1,78

35

1,47 1,60 1,51 1,51 1,51 1,51 1,51 1,51

30

1,25 1,33 1,25 1,25 1,25 1,25 1,25 1,25 1,25 1,22

25

0,98 1,07 0,98 0,98 0,98 0,98 0,98 0,98 0,98 0,98 0,98 0,96

20

0,73 0,80 0,76 0,76 0,76 0,76 0,76 0,76 0,76 0,71 0,71 0,69

15

0,49 0,53 0,49 0,49 0,49 0,49 0,49 0,49 0,49 0,49 0,49 0,49

10

0,82 0,79 0,73 0,67 0,63 0,59 0,55 0,52 0,50 0,47 0,45 0,44

NOT RECOMMENDED

(kN)

Force

(kN)

Force

(kN)

Clamp

Force

(kN)

Table 6 - Clamping Force vs. Arm Length - 5 kN Models

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

Pressure

(bar)

Maximum

Flow (lpm)

Notes: * CAS-7352 standard arm ** CAL-7352 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

23* 30 40 50 60 70 80 90 100 110 120 125**

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Force

Force

Force

Force

Force

Force

Force

(kN)

(kN)

(kN)

(kN)

(kN)

(kN)

70 4,94

65 4,58

60

4,27 4,51

55

3,91 4,14

45 3,20 3,38 3,38

40 2,85 3,02 2,94 2,94

35 2,49 2,67 2,54 2,54

30 2,14 2,27 2,14 2,14

25 1,78 1,87 1,78 1,78

20 1,42 1,51 1,42 1,42

15 1,07 1,11 1,02 1,02

10 0,71 0,76 0,71 0,71

1,31 1,26 1,16 1,08 1,01 0,94 0,89 0,84 0,79 0,75 0,72 0,70

2,94

2,54 2,54

2,14 2,14 2,11

1,78 1,78 1,78 1,73 1,73 1,71

1,42 1,42 1,42 1,42 1,42 1,40 1,38 1,38

1,02 1,02 1,02 1,02 1,00 1,00 0,98 0,98

0,71 0,71 0,71 0,71 0,71 0,71 0,67 0,67

NOT RECOMMENDED

(kN)

Force

(kN)

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

4

Page 5

Table 7 - Clamping Force vs. Arm Length - 7 kN Models

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

Pressure

(bar)

Maximum

Flow (lpm)

Notes: * CAS-7792 standard arm ** CAL-7792 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

18,5* 20 30 40 50 60 70 80 90 100 115**

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Force

Force

(kN)

Force

(kN)

(kN)

70 6,98

65 6,54 6,98

60 6,00 6,18

55 5,52 5,65 5,52

45

40

35

30

25

20

15

10

4,49 4,63 4,45 4,45

4,00 4,14 3,91 3,91 3,91

3,51 3,60 3,38 3,38 3,38 3,34 3,34

3,02 3,11 2,89 2,89 2,89 2,89 2,89 2,85

2,49 2,58 2,36 2,36 2,36 2,34 2,34 2,31 2,31 2,31

2,00 2,05 1,87 1,87 1,87 1,87 1,87 1,87 1,82 1,82 1,78

1,51 1,56 1,42 1,42 1,42 1,42 1,42 1,42 1,42 1,42 1,38

1,00 1,02 0,93 0,93 0,93 0,93 0,93 0,93 0,89 0,89 0,89

1,64 1,62 1,51 1,42 1,35 1,28 1,21 1,16 1,11 1,06 1,04

Force

(kN)

Force

(kN)

Force

Force

(kN)

(kN)

NOT RECOMMENDED

Force

(kN)

Clamp

Force

(kN)

Table 8 - Clamping Force vs. Arm Length - 9 kN Models

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

Pressure

(bar)

Maximum

Flow (lpm)

Notes: * CAS-7792 standard arm ** CAL-7792 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

17,5*

Clamp

Force

(kN)

70 8,98

65 8,38 8,72

60 7,74 8,05

55 7,12 7,38 7,25

45 5,78 6,05 5,87 5,87

40 5,16 5,34 5,12 5,12

35 4,49 4,67 4,49 4,49

30 3,87 4,00 3,83 3,83

25 3,20 3,34 3,16 3,16

20 2,58 2,67 2,49 2,49

15 1,91 2,00 1,87 1,87

10 1,29 1,33 1,25 1,25

2,05 2,02 1,89 1,78 1,68 1,60 1,52 1,45 1,38 1,32 1,27

20 30 40 50 60 70 80 90 100 120**

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Force

(kN)

Force

(kN)

Force

(kN)

Force

(kN)

Force

(kN)

Force

(kN)

Force

(kN)

Clamp

Force

(kN)

NOT RECOMMENDED

5,12

4,45 4,45 4,45

3,83 3,78 3,78 3,74

3,16 3,11 3,11 3,09 3,07 3,07

2,49 2,49 2,49 2,45 2,45 2,45 2,40

1,87 1,87 1,87 1,82 1,78 1,78 1,73

1,25 1,25 1,25 0,71 1,20 1,20 1,16

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

5

Page 6

Table 9 - Clamping Force vs. Arm Length - 20 kN Models

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

Pressure

(bar)

Maximum

Flow (lpm)

Notes: * CAS-7202 standard arm ** CAL-7202 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

4.0 DESCRIPTION

Enerpac 70 Bar swing cylinders are designed to

swing 90° in a clockwise or counter-clockwise

direction. Single-acting and double-acting models are

available. Clamp arms are not supplied with cylinders.

Clamp arms can be purchased separately or may be

fabricated according to the specifications in Section

10.0 of this manual.

4.1 Preliminary Information

IMPORTANT: Failure to read and follow these

instructions may lead to system malfunction or

product failure, and could invalidate your warranty.

1. High flow rates can lead to excessive cylinder

speed which can damage the index mechanism.

Hydraulic pressure and cylinder speed must be

adjusted to match the length of clamp arm. The

clamping force also varies with the length of the

clamp arm. Refer to sections 3.0 and 3.1 of this

manual for operating specifications and clamp arm

length information.

2. Flow controls with return checks should be used to

reduce swing cylinder speed to the recommended

rate. The return checks help minimize back pressure

that could lead to an unclamp malfunction on singleacting systems.

3. When using single-acting swing cylinders, limit

the return flow back pressure to 3,5 bar [50 psi]

maximum. Large diameter tubing (10 mm [3/8 in.]

O.D. or larger) and flow controls with free flow

19* 20 20 20 20 60 70 80 90 100 120 125**

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Force

Force

Force

Force

Force

Force

Force

(kN)

(kN)

(kN)

(kN)

(kN)

(kN)

70 19,97

65 18,64 19,79

60 17,21 18,24

55 15,79 16,72 16,41

45 12,90 13,70 13,30 13,30 13,26

40 11,48 12,19 11,70 11,70 11,70 11,65

35 10,05 10,63 10,10 10,10 10,05 10,05 10,01 10,01

30 8,58 9,12 8,67 8,67 8,67 8,67 8,63 8,63 8,63

25 7,16 7,61 7,16 7,16 7,12 7,12 7,12 7,07 7,03 6,98 6,98

20 5,74 6,09 5,74 5,74 5,74 5,74 5,74 5,69 5,65 5,60 5,60 5,56

15 4,31 4,58 4,27 4,27 4,27 4,23 4,23 4,23 4,23 4,18 4,18 4,14

10 2,85 3,02 2,8 2,80 2,80 2,78 2,76 2,76 2,76 2,76 2,76 2,71

4,10 4,05 3,71 3,42 3,17 2,96 2,77 2,61 2,47 2,33 2,22 2,16

NOT RECOMMENDED

(kN)

Force

(kN)

Force

(kN)

Clamp

Force

(kN)

return checks help minimize back pressure. Consult

Enerpac for proper system design.

4. An excessive retract flow rate can cause damage

to the index mechanism. Double acting systems

should be set up with a metered-in flow control, with

a reverse check used in the clamp port.

5. Clamping of the part should occur at the midpoint

of the vertical travel. No clamping of part shall occur

while the swing cylinder clamp is turning. Clamp arm

should freely travel during the 90° rotation (avoid

contact with cutter heads, tools, etc.).

6. Attaching clamp arm to cylinder plunger must be

done according to the instructions in Section 6.4.

5.0 MOUNTING SPECIFICATIONS

5.1 Mounting Upper Flange Cylinders

The Enerpac 70 bar swing cylinders feature an upper

flange design. The cylinder can be mounted to the fixture

using the supplied mounting bolts. Oil can be supplied

to the cylinder using either the BSPP hydraulic ports on

the flange or the O-Ring manifold ports on the underside

of the flange. The sections that follow provide detailed

mounting instructions and should be reviewed before

attempting to install the cylinders on the fixture.

WARNING: The fixture must be capable of

withstanding 70 bar [1000 psi] hydraulic

manifold mounted.

working pressure when the cylinders are

Clamp

Force

(kN)

Clamp

Force

(kN)

6

Page 7

Table 10 - Mounting Dimensions (Refer to Figure 1)

Cylinder

Capacity

2,0 kN [441 lbs] 44,5 M5 x 0,8 x 30 mm long 10

3,5 kN [769 lbs] 50,5 M5 x 0,8 x 30 mm long 11

5,0 kN [1111 lbs] 55,5 M6 x 1,0 x 30 mm long 12 0.47 568-011 13,5-15,0 10.0-11.0

7,0 kN [1570 lbs] 65,5 M6 x 1,0 x 30 mm long 15

9,0 kN [2019 lbs] 88,5 M8 x 1,25 x 30 mm long 15

20,0 kN [4490 lbs] 90,5 M10 x 1,5 x 35 mm long 20 0.79 568-011 47,9-53,1 65.0-72.0

Note: O-rings and mounting bolts included with cylinder.

Fixture

Thread

Ø D3

mm

Mounting Bolt

Thread (J)

Minimum

Mounting

Depth (J2)

Manifold

O-ring

ARP No.

Lubricated Bolt

Torque

mm inch Nm ft-lbs

0.39

0.43

0.59

0.59

568-010 8,0-9,0 5.9-6.6

568-010 8,0-9,0 5.9-6.6

568-011 13,5-15,0 10.0-28.0

568-011 32,0-38,0 23.6-28.0

Mounting Bolts

Manifold

O-Rings

(included)

0,5mm x 45º

ø 4,8mm

63

ø D3

Mtg. Hole

(included)

0.004

J2

J

Figure 1, Cylinder Mounting Details

Before a swing cylinder can be manifold mounted,

the port screw plugs must be removed. The O-Rings

provided should be lubricated and installed in the

counter-bore around the port prior to mounting and

bolting down the swing cylinder.

Be sure that the O-Ring does not get pinched or

damaged during mounting as leakage could result. To

prevent leakage from the manifold mounting, provide

a fixture mounting surface with latness within 0,08 mm

[0.003 inch] and a surface roughness not to exceed

Ra 1,6.

6.0 INSTALLATION

6.1 Port Identification

“Unclamp”

Position

Manifold

Ports

SIDE VIEW

BOTTOM VIEW

“Clamp”

Position

Upper Flange

Port Screw Plug

(remove)

O-Ring

Figure 2, Port Screw Plug Removal

KEY:

A Port: Plunger rotates 90 ° and clamps

B Port: Double-acting -- Plunger unclamps and

rotates -90 °

Single-acting -- Vent Port

Do not remove vent plug except to attach tubing.

(see Section 6.3 for additional information)

Figure 3, Cylinder Port Locations

7

Page 8

6.2 Hydraulic Connections

To make port connections, install fittings rated for 70

bar [1000 psi].

DO NOT use thread sealant. Sealing is accomplished

by using an O-Ring on the fitting boss. Lubricate the

O-Ring prior to assembly.

When designing your hydraulic circuit, consider

the factors listed in Section 4.1 of this manual.

For additional information about plumbing hydraulic

circuits, refer to the Enerpac Workholding product

catalog.

Table 11 - Cylinder Ports

Cylinder Capacity BSPP Port Size

G ¹

⁄

G ¹

G ¹

G ¼

G ¼

G ¼

8

⁄

8

⁄

8

2,0 kN [441 lbs]

3,5 kN [769 lbs]

5,0 kN [1111 lbs]

7,0 kN [1570 lbs]

9,0 kN [2019 lbs]

20,0 kN [4490 lbs]

6.3 Vent Plug

Single-acting cylinders have a vented plug on the left

side of the cylinder when you are facing the hydraulic

ports. To prevent entry of chips and coolant, the vent

plug must not be removed. If the vent plug is subjected

to a continuous coolant flood condition, attach tubing

to the port using a BSPP fitting, and run the tubing to a

non-contaminated area of the fixture.

6.4 Attaching Clamp Arm

1. Remove the retaining ring from the top of the

plunger.

2. Slide the clamp arm down over the plunger and

use a pliers to push the retaining ring back onto

the plunger groove. Orient the retaining ring so the

retaining ring gap will face the back of the clamp

arm. See Figure 4.

3. Move the clamp arm up until it is firmly against the

retaining ring and in the desired position. While

maintaining this position, torque the clamp arm bolt

to specification shown in Table 12.

Retaining

Clamp Arm

Ring

Plunger

Clamp Arm

Bolt

Figure 4, Attaching Clamp Arm

CAUTION: Inadequate torquing of the

clamp arm bolt could cause the arm to slip

during operation. BE SURE TO USE

QUALITY 12.9 DIN 912 (GRADE 8) SOCKET HEAD CAP

SCREWS (supplied with standard clamp arms).

6.5 Contact Bolt Clearance

When using a contact bolt with upper flange body style

cylinders, you must be certain that the bolt head will

clear the cylinder upper flange during operation. The

clamp arm must be long enough for the bolt head to

clear the upper flange as the arm swings down. Refer to

Figure 5 and Table 13.

“P” Dimension - CAS Series Arm

(see Table 13)

P

Max. Bolt Length

(see Table 13)

Note: Bolt head diameter

must not be larger than

16 mm [0.63 in.]

Figure 5, Contact Bolt Clearance

Table 12 - Clamp Arm Bolt Torque

Cylinder Capacity Bolt Type Torque

2,0 kN [441 lbs] M8 x 1,0 x 20 mm long 32,5-39,0 Nm [24-29 ft-lbs]

3,5 kN [769 lbs] M8 x 1,0 x 25 mm long 32,5-39,0 Nm [24-29 ft-lbs]

5,0 kN [1111 lbs] M8 x 1,0 x 25 mm long 32,5-39,0 Nm [24-29 ft-lbs]

7,0 kN [1570 lbs] M10 x 1,25 x 25 mm long 60,0-72,0 Nm [44-53 ft-lbs]

9,0 kN [2019 lbs] M10 x 1,25 x 25 mm long 60,0-72,0 Nm [44-53 ft-lbs]

20,0 kN [4490 lbs] M12 x 1.25 x 35 mm long 95,5-108,0 Nm [70-80 ft-lbs]

8

Page 9

Table 13 - Maximum Contact Bolt Length

Cylinder Capacity CAS Series Arm (See Fig. 5)

“P” Dimension

2,0 kN [441 lbs] CAS-722 35,05 mm [1.38 inch] 14,48 mm [0.57 inch]

3,5 kN [769 lbs] CAS-7352 53,09 mm [2.09 inch] (unlimited)

5,0 kN [1111 lbs] CAS-7352 53,09 mm [2.09 inch] (unlimited)

7,0 kN [1570 lbs] CAS-7792 55,63 mm [2.19 inch] 14,48 mm [0.57 inch]

9,0 kN [2019 lbs] CAS-7792 55,63 mm [2.19 inch] 14,48 mm [0.57 inch]

20,0 kN [4490 lbs] CAS-7202 68,07 mm [2.68 inch] 14,48 mm [0.57 inch]

Maximum Contact Bolt Length

(See Fig. 5)

Clearance problems are most common when using the

CAS series standard length arm, with the final clamping

position located at the side of the cylinder. You may

need to use the longer CAL Series clamp arm for these

applications. You can cut CAL series arms to meet your

own requirements, or make your own custom arms, in

accordance with the dimensions shown in Section 10.0

of this manual.

7.0 OPERATION

Swing cylinders rotate 90° during the first portion of

the stroke, continuing without rotation for the final

clamping stroke. The straight downward stroke is the

clamping stroke of the cylinder. Clamping force must

be applied only during the vertical travel, not during

the swing motion.

• To ensure maximum cylinder performance and

• Be sure all items are rated to withstand system

CAUTION: If clamping force is applied

during the rotation portion of the stroke,

internal plunger damage may result.

safety, be sure all hydraulic connections, hoses,

and fittings are properly sealed and fully tightened.

pressures. Under-rated components will not

withstand higher pressure. Using under-rated

components will lead to equipment damage and

possible personal injury.

7.1 Pressure and Flow Rate

The clamp arm length determines the swing cylinder’s

required operating pressure and flow rate.

Set operating pressure and flow rate according to the

recommendations contained in Section 3.1 for your

swing cylinder model.

IMPORTANT: Do not exceed the load-to-length

pressure ratios described in Section 3.1, tables 4

through 9. As the arm length increases, the clamping

force and maximum operating pressure are reduced.

7.2 Position Indicating Staff

Enerpac 70 Bar Swing Cylinders are available with

a positioning indicating staff (optional equipment)

that anchors into the plunger and follows the plunger

movement. The indicating staff is designed for use with

either limit or proximity switches.

A suitable target or flag can be attached using the male

M4 x .07 mm threads on the staff end. See Figure 6.

Clearance below the clamp must be sufficient for the

extended portion of the staff to avoid damage.

CAUTION: It is very important that you use

the correct pressure and flow settings.

damage to the swing cylinder. Damage caused by

exceeding rated pressure and maximum flow is NOT

COVERED BY WARRANTY.

Operating outside these limits will cause

For

“Unclamp”

Detection

For

“Clamp”

Detection

Figure 6, Position Indicating Staff

8.0 MAINTENANCE

Maintenance is required when wear or leakage is

noticed. Periodically inspect all components to detect

any problem requiring service and maintenance.

Enerpac offers ready-to-use repair parts kits. Repair

parts sheets are available with assembly diagrams and

parts lists. Contact Enerpac.

IMPORTANT: Consult the swing cylinder repair parts

sheet for service information about correct assembly

and disassembly. Incorrect maintenance and service

such as wrong torque values may cause product

malfunctions and/or personal injury.

9

Page 10

9.0 TROUBLESHOOTING

Allow only qualified hydraulic technicians to service the swing cylinder or system components. A system failure

may or may not be the result of a swing cylinder malfunction. To determine the cause of the problem, the

complete system must be included in any diagnostic procedure.

The information in the following chart is intended to be used only as an aid in determining if a problem exists.

For repair service, contact your local Enerpac Authorized Service Center.

Table 13 - Troubleshooting Guide

Problem Possible Cause Solution

a. Pump release valve open. Close pump release valve.

b. No oil in pump reservoir. Fill pump reservoir.

1. Cylinder will not

clamp/unclamp.

2. Cylinder advances part way.

3. Cylinder clamps/unclamps

slower than normal.

4. Cylinder clamps/unclamps

but will not hold pressure.

5. Cylinder leaks oil.

c. Air in system. Remove air from hydraulic system.

d. Couplers not fully tightened. Retighten couplers.

e. Blocked hydraulic line. Check valves, fittings, and tubing.

f. Spring broken in cylinder.

(single-acting models only)

a. Oil level in pump too low. Fill pump reservoir.

b. Plunger binding.

a. Leaking connection or loose fitting. Retighten fittings, couplers and tubing.

b. Restricted hydraulic line. Check valves, fittings and tubing.

c. Pump malfunction. Refer to pump instruction sheet.

a. Seals damaged.

b. Leaking connection. Retighten fittings, couplings and tubing.

c. Pump malfunction. Refer to pump instruction sheet.

a. Seals damaged.

b. Plunger worn or damaged.

Replace spring.

Replace damaged parts - refer to cylinder

repair parts sheet.

Replace seals - refer to cylinder repair parts

sheet.

Replace seals - refer to cylinder repair parts

sheet.

Replace worn or damaged parts - refer to

cylinder repair parts sheet.

6. Clamp arm does not make

swing movement.

a. Clamp arm loose.

b. Plunger worn or damaged.

10

Reposition and tighten clamp arm - refer to

Section 6.4 for instructions.

Replace worn or damaged parts - refer to

cylinder repair parts sheet.

Page 11

10.0 CLAMP ARM MACHINING SPECIFICATIONS

C

A

H

J

L

V

2.3

U

K

E

B

D

G

3 PLACES

M

F

P

Q

N

125

S

115

R

2 PLACES

T

IMPORTANT: Refer to Section 3.1 to

determine the maximum clamp arm

length and pressure for the desired

clamping force.

Item

A 25 [0.99] 27 [1.06] 30 [1.18] 38 [1.49]

B (Max.) 150 [5.90] 190 [7.48] 190 [7.48] 210 [8.26]

C 30 [1.18] 34 [1.34] 40 [1.57] 48 [1.89]

D 16 [0.63] 16 [0.63] 18 [0.70] 21 [0.82]

E 19,5 [0.77] 20 [0.79] 22 [0.87] 26 [1.02]

F (3 places) 67 [0.26] 84 [3.30] 86 [3.39] 100 [3.94]

G 29 [1.14] 31 [1.22] 34 [1.34] 40 [1.58]

H 12,5 [0.49] 13,5 [0.53] 15 [0.59] 19 [0.74]

J 15 [0.59] 17 [0.67] 20 [0.79] 24 [0.94]

K (Dia.) ø 13,5 [0.53] ø 13,5 [0.53] ø 16,5 [0.65] ø 18,5 [0.73]

L 9 [0.35] 11 [0.43] 11 [0.43] 13 [0.51]

M (Dia.) ø 8,5 [0.33] ø 8,5 [0.33] ø 10,5 [0.41] ø 12,5 [0.49]

N (thread) M8 x 1,25 M8 x 1,25 M10 x 1,5 M12 x 1,25

P 6 [0.23] 8 [0.31] 9 [0.35] 12,75 [0.50]

Q 12 [0.47] 16 [0.63] 18 [0.71] 25,5 [1.00]

R (2 places) 21º - 23º 21º - 23º 21º - 23º 21º - 23º

S (Dia.) ø 22,75 - 23,00

T (Dia.) ø 20 H8 ø 22 H8 ø 25 H8 ø 32 H8

U 3,8 - 4,3 [0.15 - 0.17] 3,8 - 4,3 [0.15 - 0.17] 3,8 - 4,3 [0.15 - 0.17] 4,7 - 5,3 [0.19 - 0.21]

V 1,0 - 2,0 [0.04 - 0.09] 1,0 - 2,0 [0.04 - 0.09] 1,0 - 2,0 [0.04 - 0.09] 1,0 - 2,0 [0.04 - 0.09]

Dimensions in millimeters [inches] unless otherwise noted

2,0 kN 3,5 kN and 5,0 kN 7,0 kN and 9,0 kN 20,0 kN

[0.895 - 0.905]

ø 24,75 - 25,00

[0.974 - 0.984]

ø 27,75 - 28,00

[1.092 - 1.102]

ø 35,50 - 36,00

[1.397 - 1.417]

50

40

11

Page 12

Enerpac Worldwide Locations e-mail: info@enerpac.com internet: www.enerpac.com

Australia and New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

T +61 (0)2 9743 8988

F +61 (0)2 9743 8648

sales-au@enerpac.com

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

T +55 11 5687 2211

F +55 11 5686 5583

Toll Free: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

customer.service@actuant.com

China

Actuant (China) Industries Co. Ltd.

No. 6 Nanjing East Road,

Taicang Economic Dep Zone

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

Toll Free: +86 400 885 0369

sales-cn@enerpac.com

France, Switzerland, North Africa and

French speaking African countries

ENERPAC

Une division d’ACTUANT France S.A.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

sales-fr@enerpac.com

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf, Germany

T +49 211 471 490

F +49 211 471 49 28

sales-de@enerpac.com

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore, 560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

sales-in@enerpac.com

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

sales-it@enerpac.com

Japan

Applied Power Japan LTD KK

Besshocho 85-7

Kita-ku, Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

sales-jp@enerpac.com

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Oce 423, LOB 15

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

sales-ua@enerpac.com

Russia

Rep. oce Enerpac

Russian Federation

Admirala Makarova Street 8

Moscow, Russia

125212

T +7 495 98090 91

F +7 495 98090 92

sales-ru@enerpac.com

Singapore

Actuant Asia Pte Ltd.

83 Joo Koon Circle

Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free: +1800 363 7722

sales-sg@enerpac.com

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

sales-kr@enerpac.com

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

sales-es@enerpac.com

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg,

Central and Eastern Europe,

Baltic States, Greece, Turkey

and CIS countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 535 848

sales-nl@enerpac.com

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P.O. Box 421

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

integratedsolutions@enerpac.com

South Africa and other English

speaking African countries

Enerpac Africa Pty Ltd.

No. 5 Bauhinia Avenue

Cambridge Oce Park

Block E

Highveld Techno Park

Centurion 0157

South Africa

T: +27 12 940 0656

United Kingdom and Ireland

ENERPAC Ltd.,

Bentley Road South

Darlaston, West Midlands

WS10 8LQ

England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

sales-uk@enerpac.com

USA, Latin America and Caribbean

ENERPAC

P.O. Box 3241

Milwaukee WI 53201 USA

T +1 262 293 1600

F +1 262 293 7036

User inquiries:

T +1 800 433 2766

Distributor inquiries/orders:

T +1 800 558 0530

F +1 800 628 0490

Technical inquiries:

techservices@enerpac.com

sales-us@enerpac.com

All Enerpac products are guaranteed against

defects in workmanship and materials for as

long as you own them.

For the location of your nearest authorized

Enerpac Service Center, visit us at

www.enerpac.com

101711

Loading...

Loading...