Page 1

Instruction Sheet

Swing Cylinders — Metric 2,2 and 5,6 kN

POWERFUL SOLUTIONS. GLOBAL FORCE.

L2058 Rev. C 03/12

Repair Parts Sheets for this product are available

from the Enerpac web site at www.enerpac.com, or

from your nearest Authorized Enerpac Service Center

or Enerpac Sales office.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If

shipping damage is found, notify carrier at once. The

carrier is responsible for all repair and replacement

costs resulting from damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions,

warnings and cautions

carefully. Follow all safety

precautions to avoid personal injury or property

damage during system operation. Enerpac cannot be

responsible for damage or injury resulting from unsafe

product use, lack of maintenance or incorrect product

and/or system operation. Contact Enerpac when in

doubt as to the safety precautions and operations. If

you have never been trained on high-pressure

hydraulic safety, consult your distribution or service

center for a free Enerpac Hydraulic safety course.

Failure to comply with the following cautions and

warnings could cause equipment damage and

personal injury.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

damage to, or destruction of equipment or other

property.

A WARNING indicates a potential danger that

requires correct procedures or practices to avoid

personal injury.

A DANGER is only used when your action or lack of

action may cause serious injury or even death.

WARNING: Wear proper personal

protective gear when operating hydraulic

equipment.

WARNING: Stay clear of loads

supported by hydraulics. A cylinder,

when used as a load lifting device, should

never be used as a load holding device. After the

load has been raised or lowered, it must always be

blocked mechanically.

DANGER: To avoid personal injury keep

hands and feet away from cylinder and

workpiece during operation.

WARNING: Do not exceed equipment

ratings. Never attempt to lift a load

weighing more than the capacity of the

cylinder. Overloading causes equipment failure and

possible personal injury. The cylinders are designed

for a max. pressure of 350 bar [5,000 psi]. Do not

connect a jack or cylinder to a pump with a higher

pressure rating.

DANGER: Never set the relief valve to a

higher pressure than the maximum rated

pressure of the pump. Higher settings may

result in equipment damage and/or personal injury.

Do not remove relief valve.

WARNING: The system operating

pressure must not exceed the pressure

rating of the lowest rated component in

the system. Install pressure gauges in the

system to monitor operating pressure. It is your

window to what is happening in the system.

CAUTION: Avoid damaging hydraulic

hose. Avoid sharp bends and kinks when

routing hydraulic hoses. Using a bent or

kinked hose will cause severe back-pressure. Sharp

bends and kinks will internally damage the hose

leading to premature hose failure.

Do not drop heavy objects on hose. A

sharp impact may cause internal damage

to hose wire strands. Applying pressure to

a damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel

couplers. Use the carrying handle or other

means of safe transport.

CAUTION: Keep hydraulic equipment

away from flames and heat. Excessive

heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose

materials and packings. For optimum performance

do not expose equipment to temperatures of 65 °C

[150 °F] or higher. Protect hoses and cylinders from

weld spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin, causing serious injury.

If oil is injected under the skin, see a doctor

immediately.

®

Index:

English...............................................................1-9

Deutsch.........................................................14-20

Français.........................................................21-27

Español .........................................................28-34

Italiano...........................................................35-41

Nederlands....................................................42-48

Page 2

2

WARNING: Only use hydraulic cylinders in a coupled system. Never use a cylinder with unconnected

couplers. If the cylinder becomes extremely overloaded, components can fail catastrophically causing

severe personal injury.

IMPORTANT: Hydraulic equipment must only be serviced by a qualified hydraulic technician. For

repair service, contact the Authorized ENERPAC Service Center in your area. To protect your warranty,

use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts by genuine ENERPAC parts. Standard grade

parts will break causing personal injury and property damage. ENERPAC parts are designed to fit

properly and withstand high loads.

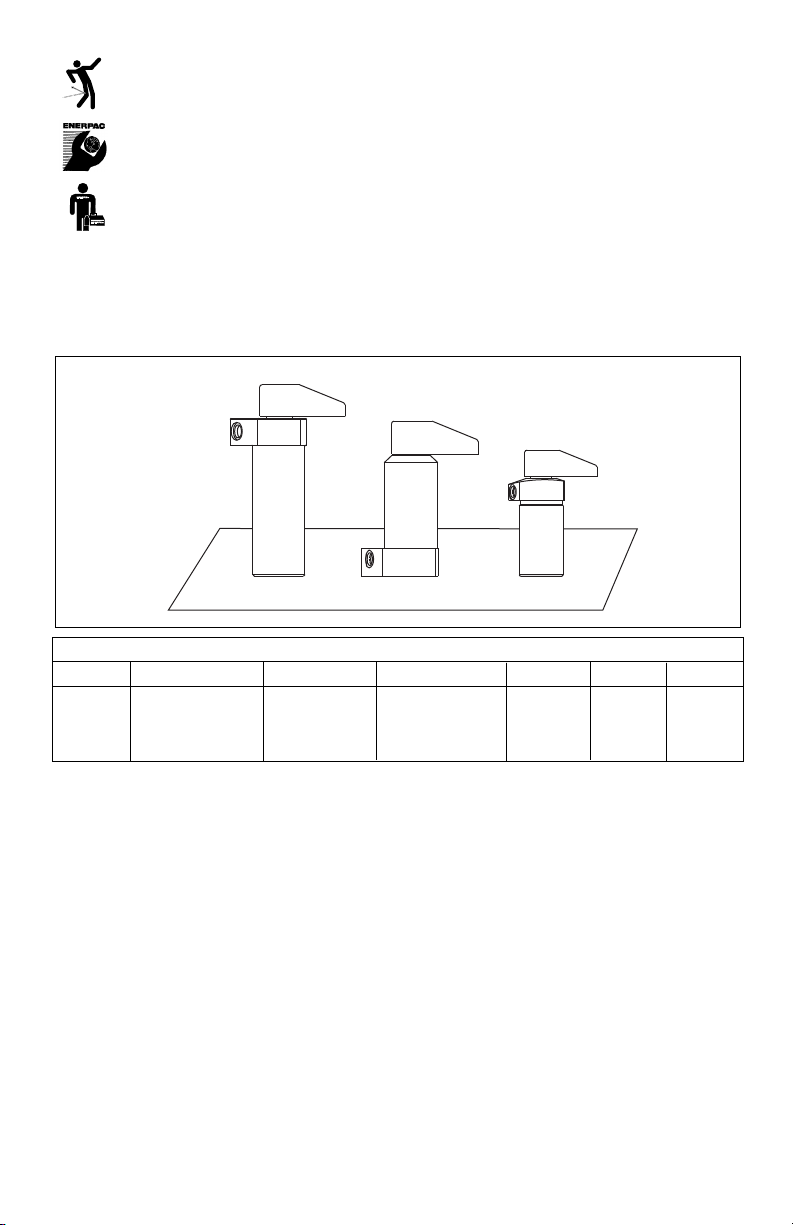

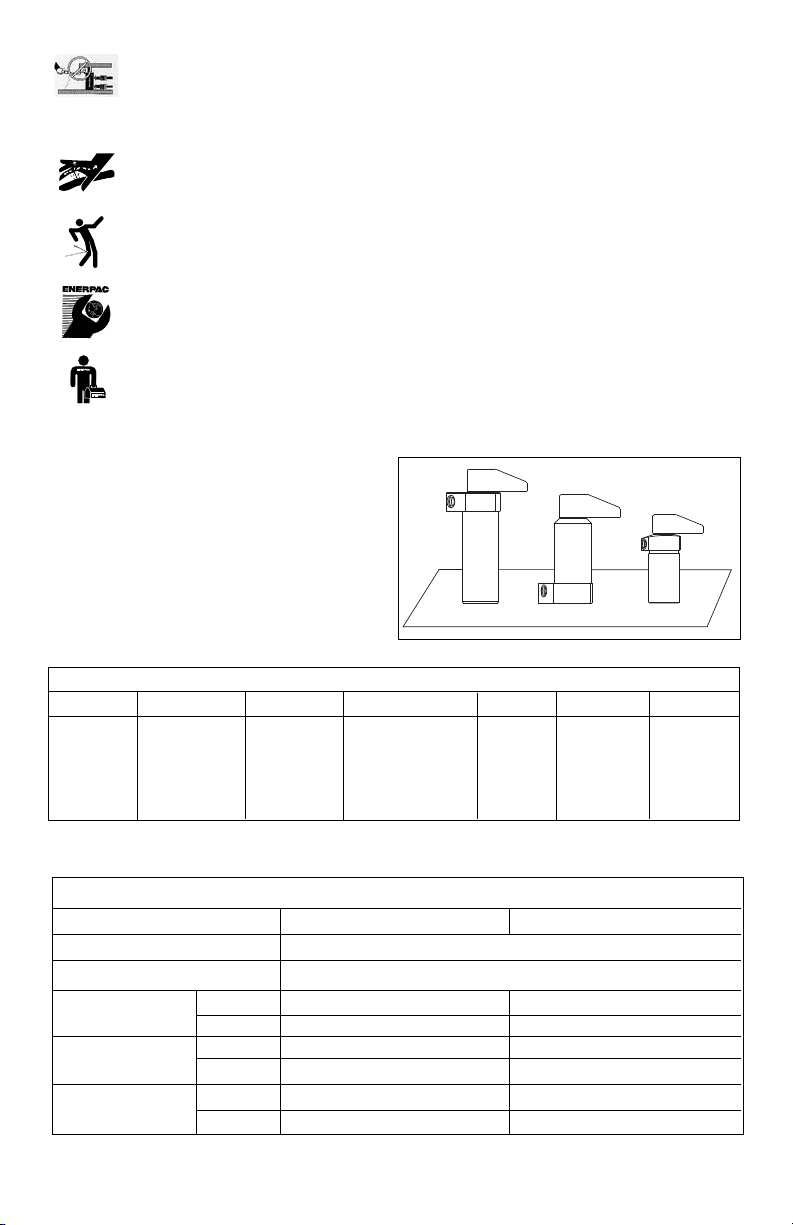

3.0 DESCRIPTION

These swing cylinders are designed to swing 90° in a clockwise or counter-clockwise direction. They can also

be used in straight clamping applications. Single-acting and double-acting swing cylinders are available.

Clamp arms are not supplied with cylinders. Clamp arms can be purchased separately or made according to

the specifications on page 13.

4.0 PRELIMINARY INFORMATION

IMPORTANT: Failure to read and follow these instructions may lead to system malfunction or product

failure, and could invalidate your warranty.

(1) High flow rates can lead to excessive cylinder speed which can cause cylinder damage. Hydraulic

pressure and cylinder speed must be adjusted to match the length of clamp arm. The clamping force

also varies with the length of the clamp arm. Refer to page 2 for operating specifications.

(2) Flow controls with return checks should be used to reduce swing cylinder speed to the

recommended rate. The return checks help minimize back pressure that could lead to an unclamp

malfunction on single-acting systems.

(3) When using single-acting swing cylinders, limit the return flow back pressure to 3,5 bar (50 psi)

maximum. Large diameter tubing (10 mm O.D. or larger) and flow controls with free flow return

checks help minimize back pressure. Consult Enerpac for proper system design.

(4) Excessive return flow back pressure can also damage double-acting swing cylinders. Limit the

return flow back pressure to 42 bar (600 psi) maximum. Double-acting systems should be set up for

a metered-in with reverse free flow in the clamp port.

(5) Clamping of the part should occur at the midpoint of the vertical travel. No clamping of part shall occur

while the swing clamp is turning. Clamp arm should freely travel during the 90° rotation (avoid contact

with cutter heads, tools, etc.).

(6) Attaching clamp arm to cylinder plunger must be done according to the instructions on page 6.

Model Number Code

1 2 3 4 5 6 Optional

S = swing T = threaded body R = right swing S = single-acting 2 = 2,2 kN 2 = metric V = Viton

cylinder U = upper flange L = left swing D = double-acting 5 = 5,6 kN

L = lower flange S = straight

(no swing)

Page 3

3

Cylinder Specifications

Capacity [kN (lbs.)] 2,2 (500) 5,6 (1250)

Body Style threaded body, lower flange, or upper flange mounting

Cylinder Type single-acting and double-acting

Hydraulic clamp 8,1 (0.32) 9,9 (0.39)

Stroke [mm (in)] total 16,5 (0.65) 22,6 (0.89)

Effective Area clamp 1,22 (0.19) 1,81 (0.28)

[cm2(in2)]

unclamp 1,55 (0.24) 3,81 (0.59)

Oil Capacity clamp 4,59 (0.28) 10,3 (0.63)

[cm

3

(in3)] unclamp 9,67 (0.59) 20,2 (1.23)

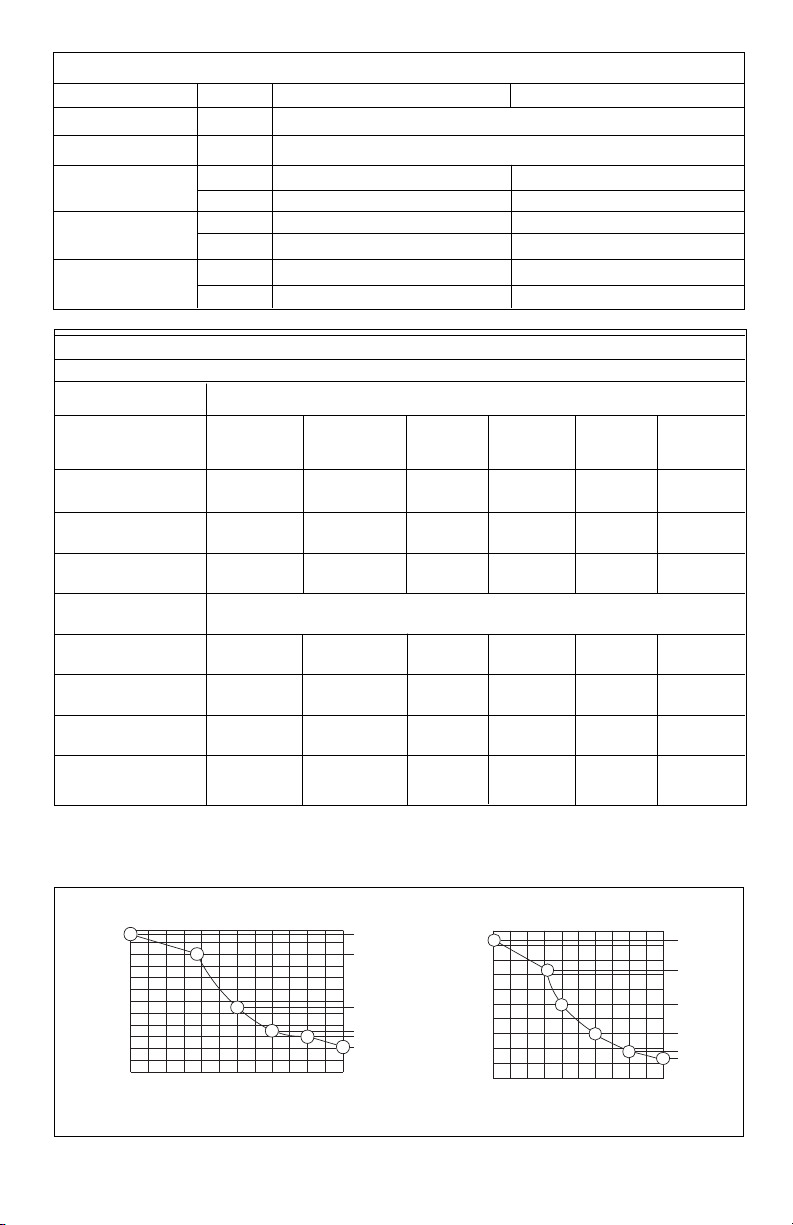

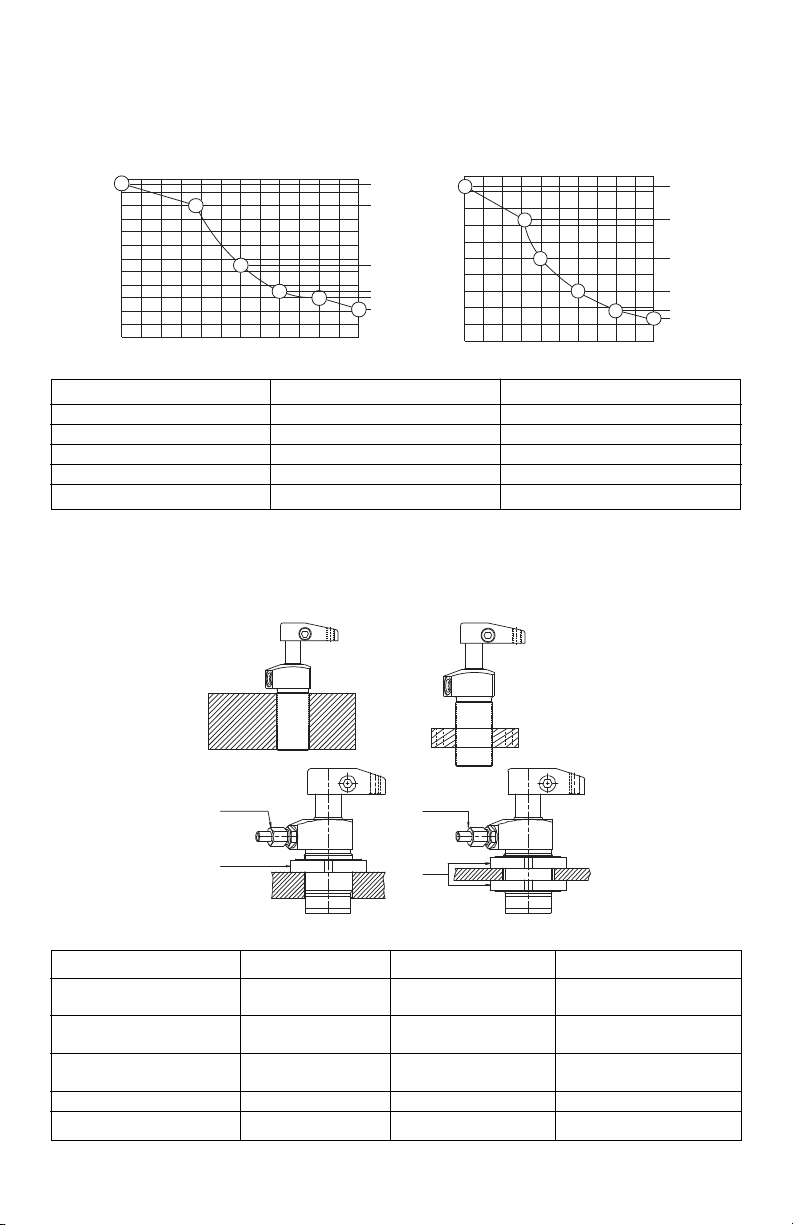

Operating Specifications — Maximum Flow Rate Chart

Also see graphs below.

2,2 kN (500 lb) — Maximum Clamp Arm Length is 76 mm (3")

Arm Length 25 (0.97) 38 (1.5 ) 51 (2.0) 64 (2.5) 76 (3.0)

[mm (in)] straight pull standard arm extended extended extended extended

Max. Flow

[cc/min (in3/min)] 197 (12) 197 (12) 98 (6) 98 (6) 98 (6) 98 (6)

Max. Pressure

[bar (psi)] 350 (5000) 350 (5000) 207 (3000) 145 (2100) 128 (1850) 107 (1550)

Clamping Force

[kN (lbs)] 2,6 (585) 2,2 (500) 1,2 (275) 0,8 (175 ) 0,7 (150) 0,5 (110)

5,6 kN (1250 lb) — Maximum Clamp Arm Length is 127 mm (5")

Arm Length 40 (1.58) 51 (2.0) 76 (3.0) 102 (4.0) 127 (5.0)

[mm (inches)] straight pull standard arm extended extended extended extended

Max. Flow

[cc/min (in3/min)] 410(25) 410 (25) 197 (12) 197 (12) 197 (12) 197 (12)

Max. Pressure

[bar (psi)] 350 (5000) 350 (5000) 262 (3800) 172 (2500) 131 (1900) 103 (1500)

Clamping Force

[kN (lbs)] 6,2 (1390) 5,0 (1100) 3,3 (750) 2,0 (450) 1,2 (275) 0,9 (200)

0

Clamping Force vs Arm Length Graphs

2,67 [600]

2,00 [450]

1,34 [300]

0,67 [150]

Clamping Force (kN [lbs.])

2,2 kN (500 lb) Models

0

0

1

2

13

[.50]25[1.00]38[1.50]51[2.00]64[2.50]

Arm Length (mm [in.])

3

4

[3.00]

5

76

Max. Clamp Pressure (bar [psi])

350 [5000]

350 [5000]

207 [3000]

145 [2100]

128 [1850]

107 [1550]

6,67 [1500]

5,34 [1200]

2,67 [600]

Clamping Force (kN [lbs.])

1,33 [300]

5,6 kN (1250 lb) Models

0

4,00[900]

[1.00]51[2.00]76[3.00]

1

2

25

Arm Length (mm [in.])

Max. Clamp Pressure (bar [psi])

350 [5000]

350 [5000]

262 [3800]

3

102

[4.00]

172 [2500]

131 [1900]

4

5

103 [1500]

127

[5.00]

Page 4

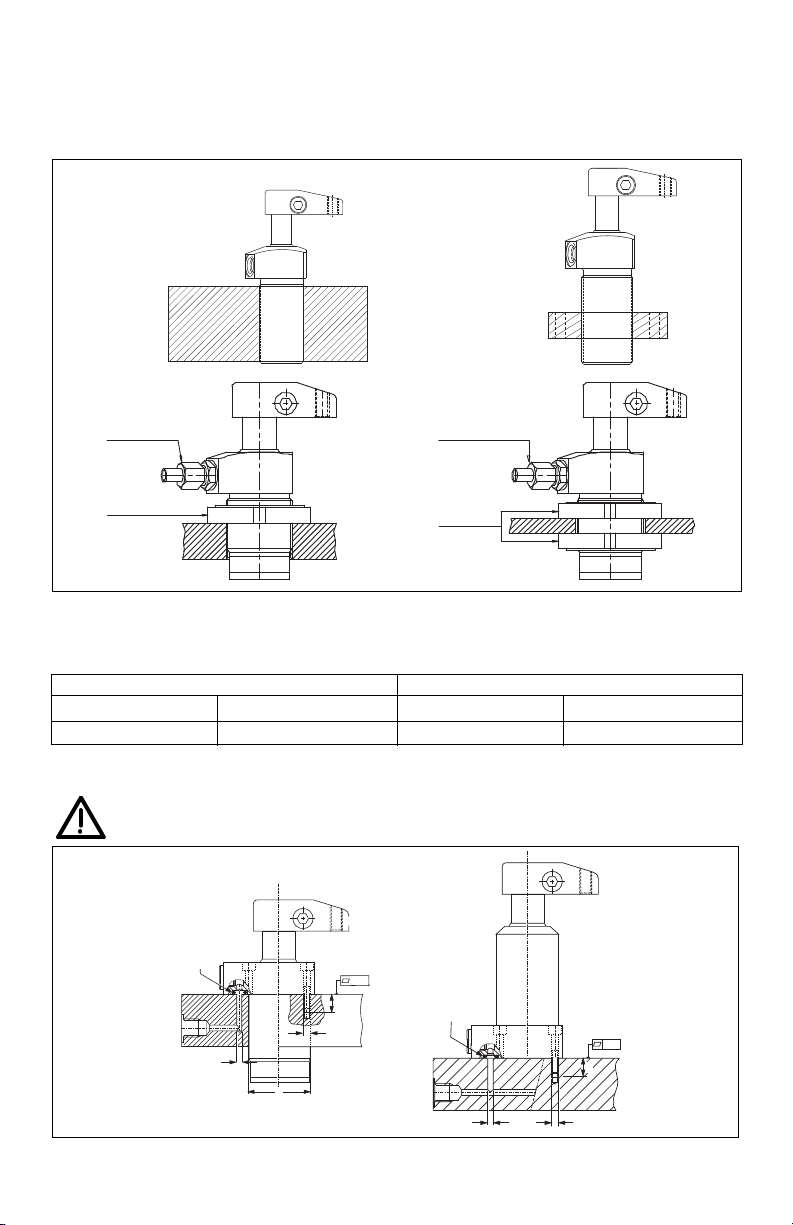

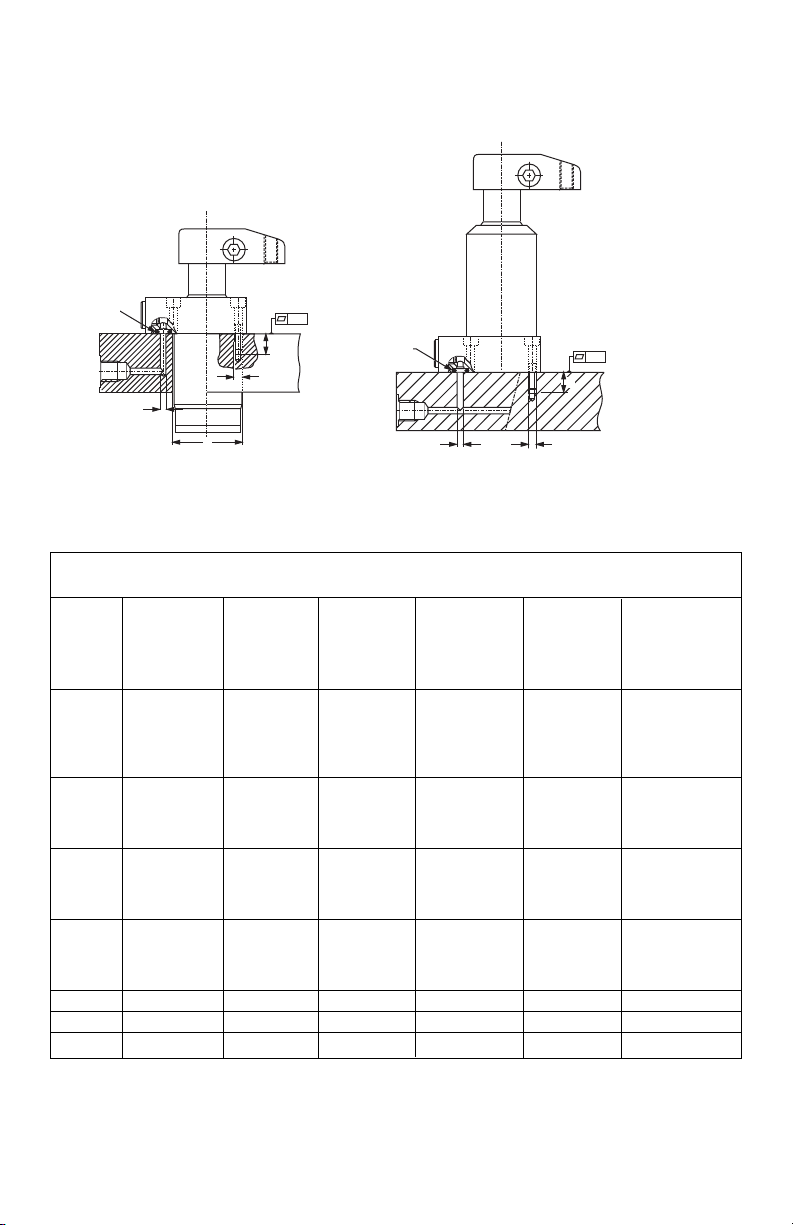

5.0 MOUNTING SPECIFICATIONS

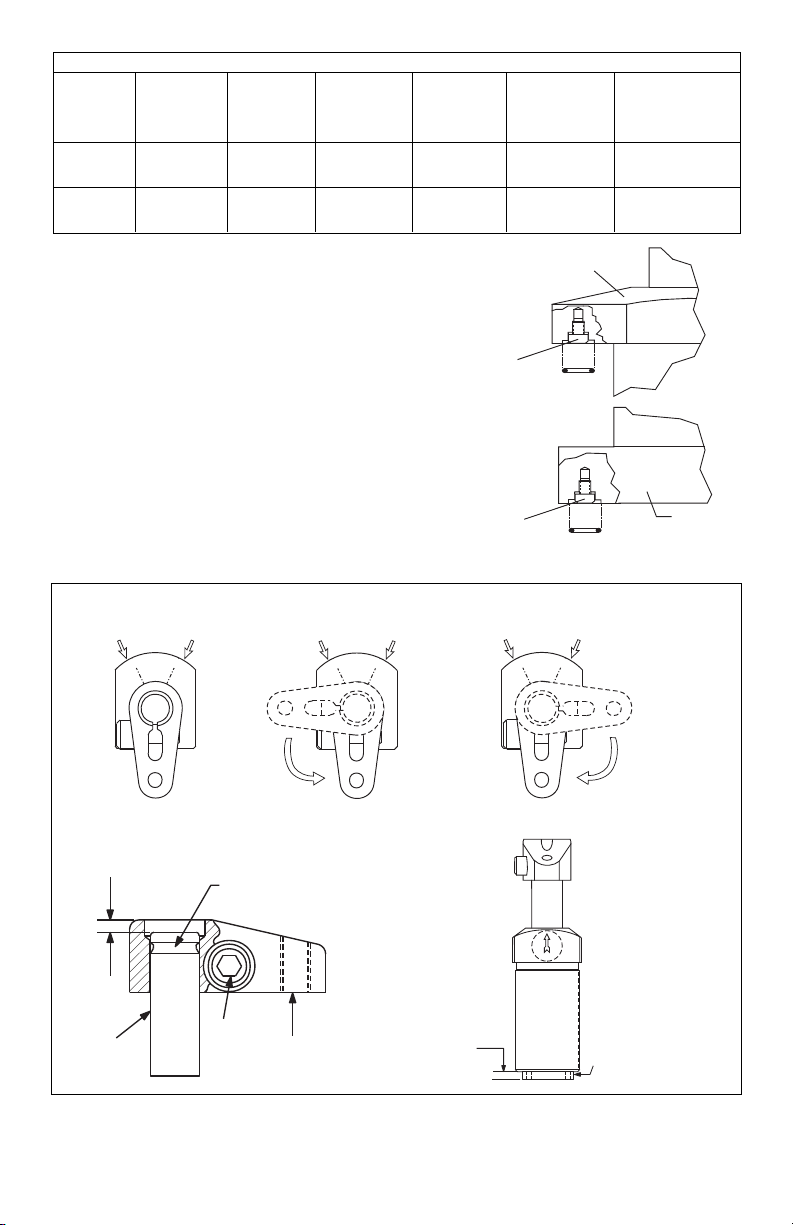

5.1 Mounting Threaded Body Cylinders

Threaded body cylinders can be threaded into a tapped hole, secured to the fixture using a mounting flange,

threaded into the fixture and secured with a jam nut, or mounted through a clearance hole and secured with

jam nuts. See illustrations below.

When a threaded body style swing cylinder is being installed in a fixture, the thread engagement should be no

less than the thread engagement for the standard Enerpac mounting flange. If a cylinder is being mounted

using just the lower portion of the threads, the engagement should be increased for additional support. See

table below for minimum thread engagement.

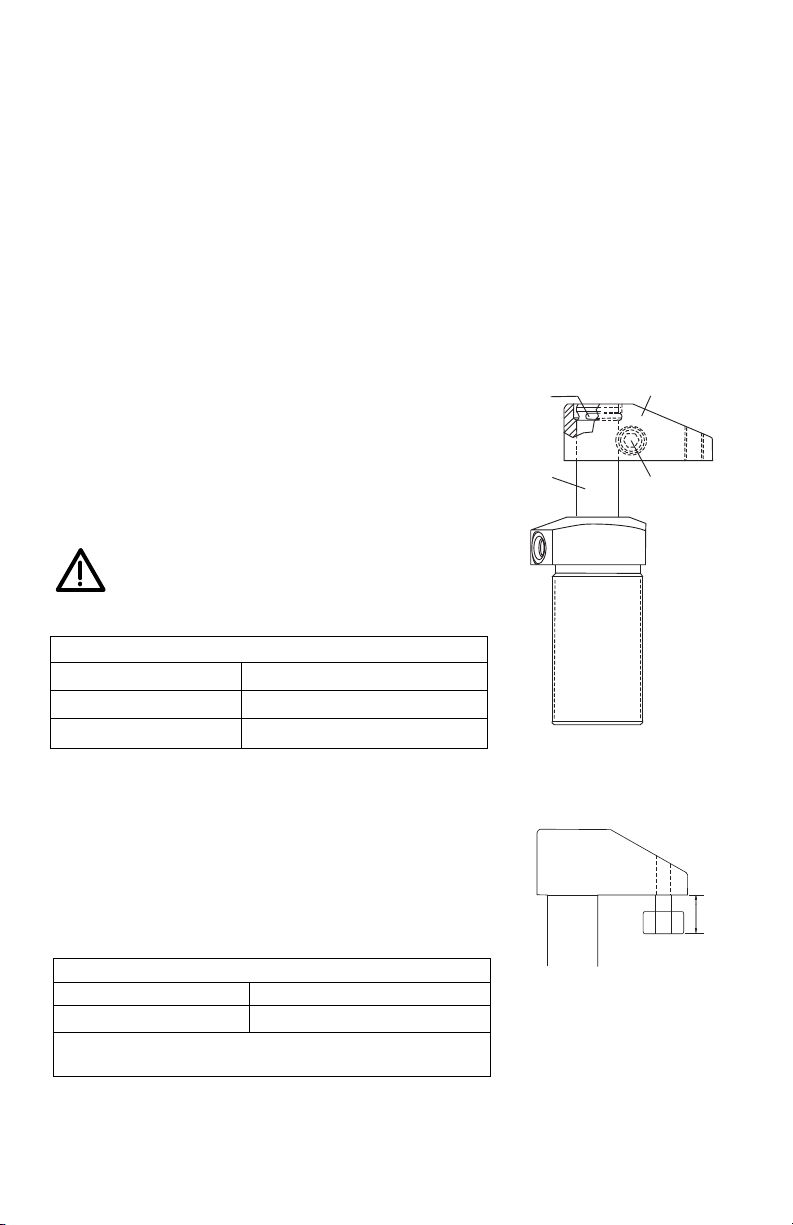

5.2 Mounting Upper and Lower Flange Cylinders

WARNING: The fixture must be capable of withstanding 350 bar (5000 psi) hydraulic working

pressure when the cylinders are manifold mounted.

4

Oil connection

Oil connection

Threaded into fixture

Mounting flange

Jam nut

Jam nut

Cylinder Capacity Minimum Thread Engagement

2,2 kN 500 lb 13 mm .50"

5,6 kN 1250 lb 13 mm .50"

Manifold

O-ring

Manifold

O-ring

0,01

D

C

A

B

0,01

D

A

C

Page 5

Before a swing cylinder can be manifold mounted, the port screw plugs and

copper gaskets must be removed.

The o-rings provided should be lubricated and installed in the counterbore around the port prior to mounting and bolting down the swing

cylinder.

Be sure that the o-ring does not get pinched or damaged during

mounting as leakage could result. To prevent leakage from the

manifold mounting, provide a fixture mounting surface with

flatness within 0,08 mm (0.003 in.) and a surface roughness not

to exceed Ra 1,6.

6.0 INSTALLATION

These Swing Cylinders are designed so that you can set the

position of the clamp arm after mounting the cylinder. If you need

to change the rotation direction, do it before mounting the

cylinder.

6.1 Changing Plunger Rotation (if needed)

5

Manifold Specifications

Cylinder Max. Oil Fixture Mounting Minimum Lubricated Manifold

Capacity Channel Hole Threads Thread Mounting O-Ring

Diameter Diameter Depth Bolt Torque Dimensions

Ø A Ø B C D I.D. x w

2,2 kN 4 mm 1.15 ± .03 M5 12 mm 4,5-5,4 Nm 6,07 x 1,78 mm

500 lb 0.156" 0.473" 40-48 in-lbs 0.239 x 0.070"

5,6 kN 4 mm 1.42 ± .03 M6 15 mm 12,2-14,9 Nm 7,65 x 1,78 mm

1250 lb 0.156" 0.591" 9-11 ft-lbs 0.301 x 0.070"

Clamp position

Unclamp port

Unclamp position

Clamp port

Clamp position

Clamp and

unclamp position

Unclamp

position

Unclamp portClamp port

Unclamp portClamp port

Retaining ring removed

from groove.

Plunger

Clamp

arm

bolt

Clamping

arm

Approximately

4 turns out.

Bottom plug

STRAIGHT LEFT SWING RIGHT SWING

Upper Flange

Remove port

screw plug.

O-ring

O-ring

Lower

Flange

Remove port

screw plug.

A

B

A

B

A

B

L

.25 "

6,4 mm

(6,4mm)

(0.25")

R

S

R

S

L

S

L

R

Page 6

Change plunger rotation by lining up the letter on top of the plunger with the arrow on the side of the cylinder

opposite the ports. To change rotation, refer to illustrations and follow procedure below. You will need a

spanner wrench.

1. Position the arm on the plunger to provide a handle to grasp for moving the plunger.

(a) Release the clamp arm bolt.

(b) Remove the retaining ring and slide the clamp arm down the plunger until the top of the arm is 6 mm

(0.25") from the top surface of the plunger.

(c) Tighten the clamp arm bolt. DO NOT discard the retaining ring.

2. Place spanner wrench on bottom cylinder plug and turn the plug (facing you) counter-clockwise 4 turns.

NOTE: Single-acting cylinders may need the bottom plug to be rotated more than 4 turns to help relieve

return spring tension.

3. Push down on the plunger and rotate it to line up the desired letter (L, R, S) with the arrow on the side of

the cylinder.

4. Once the letter and arrow are lined up, pull the plunger up, turn the bottom plug backin (clockwise) 4 turns,

and tighten firmly.

6.2 Attaching Clamp Arm

1. Remove the retaining ring from the top of the plunger.

2. Slide the clamp arm down over the plunger and use a

pliers to push the retaining ring back onto the plunger

groove. Orient the retaining ring so the retaining ring

gap will face the back of the clamp arm. See

illustration.

3. Move the clamp arm up until it is firmly against the retaining ring

and in the desired position. While maintaining this position,

torque the clamp arm bolt to specification listed below.

CAUTION: Inadequate torquing of the clamp arm bolt

could cause the arm to slip during operation. BE SURE

TO USE QUALITY GRADE 8 (12.9 DIN 912) SOCKET

HEAD CAP SCREWS (supplied with standard clamp arms).

6.3 Arms for Upper Flange Body Style

To use the upper flange body style cylinders, you have to be sure that the

contact bolt will clear the upper flange during operation. The clamp arm

must be long enough for the contact bolt to clear the upper flange as the

arm swings down. Clearance problems are most common when the final

clamping position is at the side of the cylinder and the contact bolt must

pass by the front or back of the upper flange as it swings down. You may

need to use the longer, CAL Series clamp arm for these applications.

6

Clamping arm

Clamping arm

bolt

Retaining ring

(Opening toward

back of clamp.)

Plunger

Clamp Arm Bolt Torque

Cylinder Capacity Lubricated Torque

2,2 kN (500 lbs) 16,3 to 20,3 Nm (12 to 15 ft-lbs)

5,6 kN (1250 lbs) 32,5 to 39,3 Nm (24 to 29 ft-lbs)

Maximum Contact Bolt Length

Cylinder Capacity Maximum Length

2,2 kN (500 lbs) 19,1 mm (0.75")

NOTE: Maximum length provided here is for 2,2 kN upper flange

models only.

Max.

Length

Contact

Bolt

Page 7

Side View

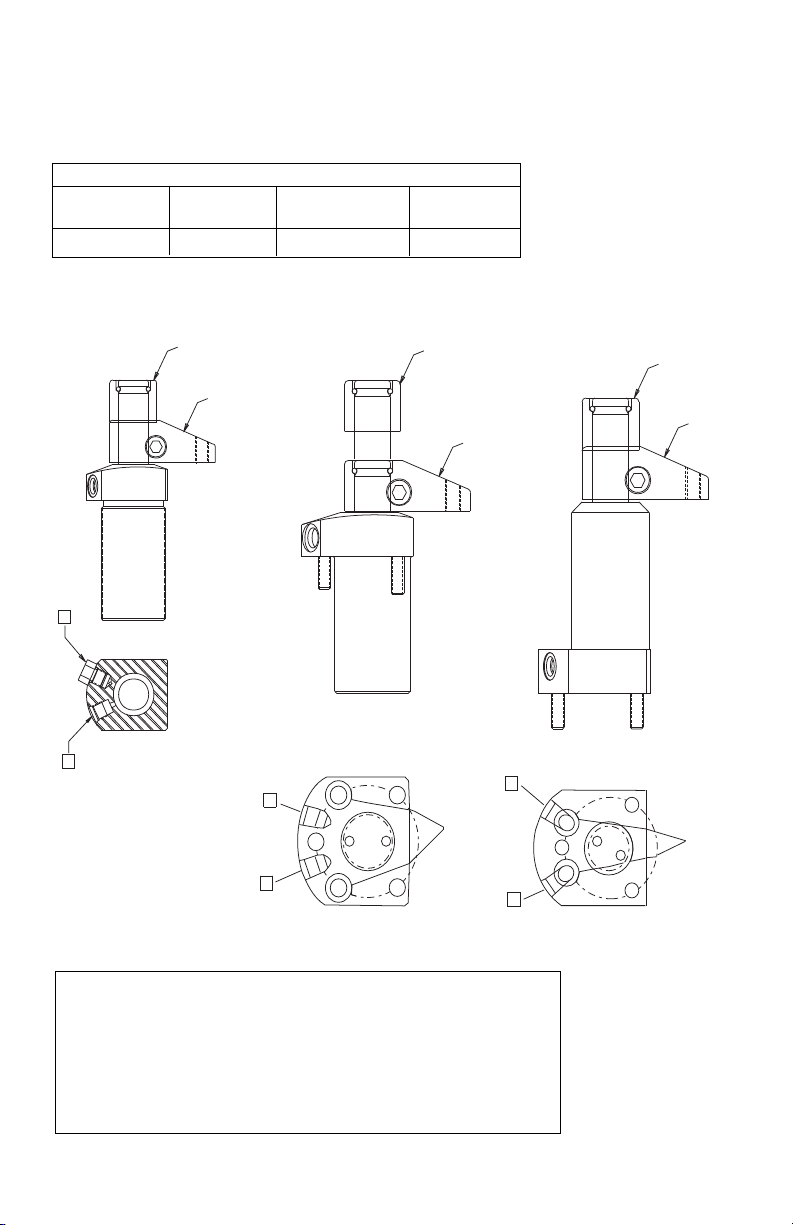

6.4 Hydraulic Connections

To make port connections, install fittings rated for 350 bar (5000 psi). DO NOT use thread sealant. Sealing is

accomplished by using an o-ring on the fitting boss. Lubricate the o-ring prior to assembly. When designing

your hydraulic circuit, consider the factors listed in PRELIMINARY INFORMATION on page 2. For more

information about plumbing hydraulic circuits, see your Enerpac Catalog.

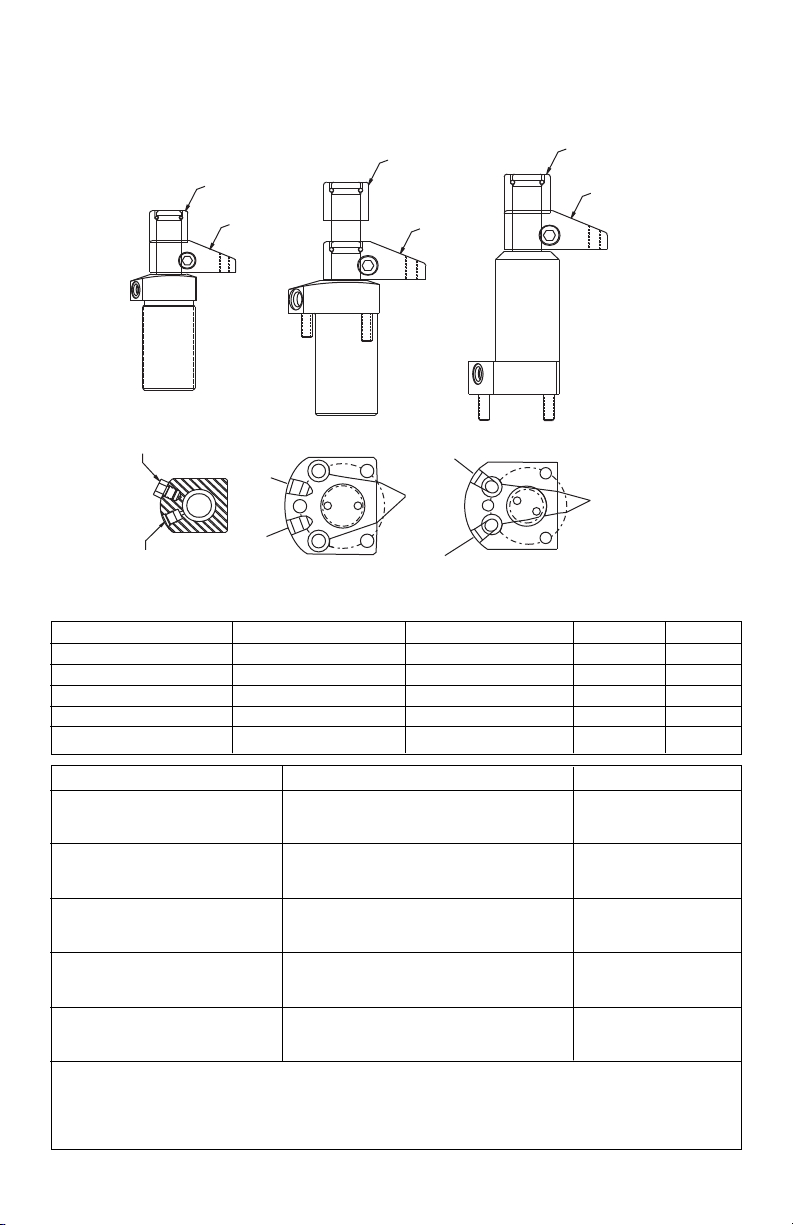

6.5 Port Identification

7

Cylinder Ports

Cylinder 350 bar Cylinder 350 bar

Capacity BSPP Fitting Capacity BSPP Fitting

2,2 kN (500 lbs) G 1/8 5,6 kN (1250 lbs) G 1/8

KEY

A Port:

Plunger rotates 90° and clamps

B Port:

double-acting, plunger unclamps and rotates -90°

single-acting, vent port

Do not remove vent plug except to attach tubing. (See vent plug section.)

Unclamp

Clamp

Clamp

Clamp

Unclamp

Unclamp

Threaded

Body

Style

Upper

Flange

Body

Style

Lower

Flange

Body

Style

Side View

Side View

Bottom

View

Bottom

View

Bottom

View

Manifold

Ports

Manifold

Ports

B

A

A

A

B

B

Page 8

7.0 OPERATION

Swing cylinders rotate 90° during the first portion of the stroke, continuing without rotation for the final

clamping stroke. The straight downward stroke is the clamping stroke of the cylinder. Clamping force must be

applied only during the vertical travel, not during the swing motion.

CAUTION:

— If clamping force is applied during the rotation portion of the stroke, internal plunger damage will result.

— To ensure maximum cylinder performance and safety; be sure all hydraulic connections, hoses, and

fittings are properly sealed and fully tightened.

— Be sure all items are rated to withstand system pressures. Under-rated components will not withstand

higher pressure. Using under-rated components will lead to equipment damage and possible personal

injury.

7.1 Vent Plug

Single-acting cylinders have a vented plug on the left side of the cylinder when you are facing the hydraulic

ports. To prevent entry of chips and coolant, the vent plug must not be removed. If the vent plug is subjected

to a continuous coolant flood condition, attach tubing to the port using a BSPP fitting, and run the tubing to a

non-contaminated area of the fixture.

7.2 Pressure and Flow Rate

Clamp arm length (L) determines operating pressure setting and flow rate.

See Operating Specifications — Maximum Flow Rate Chart on page 2 for clamp arm length, pressure setting

and flow rate. Set operating pressure and flow rate according to the limits established by the length of the

clamp arm. Do not exceed the load-to-length pressure ratios. As the arm length increases, the clamping force

and maximum operating pressure are reduced.

CAUTION: It is very important that you use the correct pressure and flow settings. Operating

outside these limits will cause damage to the swing cylinder. Damage caused by exceeding

rated pressure and maximum flow is NOT COVERED BY WARRANTY.

8.0 MAINTENANCE

Maintenance is required when wear or leakage is noticed. Occasionally inspect all components to detect any

problem requiring service and maintenance. Enerpac offers ready-to-use Repair Parts Kits. Repair Parts Sheets

are available with assembly drawing and parts list. Contact Enerpac.

IMPORTANT: Consult the Repair Parts Sheet for service information about correct assembly and disassembly.

Incorrect maintenance and service such as wrong torque values may cause product malfunctions and/or

personal injury.

9.0 TROUBLESHOOTING

The following information is intended to be used only as an aid in determining if a problem exists. For repair

service, contact your Distributor or Authorized Enerpac Service Center.

8

L

Page 9

9

1. Cylinder will not

clamp/unclamp.

2. Cylinder advances

part way.

3. Cylinder

clamps/unclamps

slower than normal

4. Cylinder

clamps/unclamps

but will not hold

pressure.

5. Cylinder leaks oil.

6. Clamp arm does

not make swing

movement.

A. Pump release valve open

B. No oil in pump reservoir

C. Air in system

D. Couplers not fully tightened

E. Blocked hydraulic line

F. Spring broken in cylinder

A. Oil level in pump too low

B. Plunger binding normal.

A. Leaking connection

B. Restricted hydraulic line

C. Pump malfunction

A. Seals damaged

B. Leaking connection

C. Pump malfunction

A. Seals damaged

B. Plunger worn or damaged

A. Clamp arm loose

B. Plunger damaged

A. Close pump release valve

B. Fill pump reservoir

C. Remove air from hydraulic system

D. Retighten couplers

E. Check valves, fittings, and tubing

F Replace spring

A. Fill pump reservoir

B. Replace damaged parts — refer to Repair

Parts Sheet

A. Retighten fittings, couplers, and tubing

B. Check valves, fittings, and tubing

C. Refer to pump Instruction Sheet

A. Replace seals — refer to Repair Parts Sheet

B. Retighten fittings, couplers, and tubing

C. Refer to pump Instruction Sheet

A. Replace seals — refer to Repair Parts Sheet

B. Replace damaged parts — refer to Repair

Parts Sheet

A. Reposition and tighten clamp arm — see

Attaching Clamp Arm

B. Replace damaged parts — refer to Repair

Parts Sheet

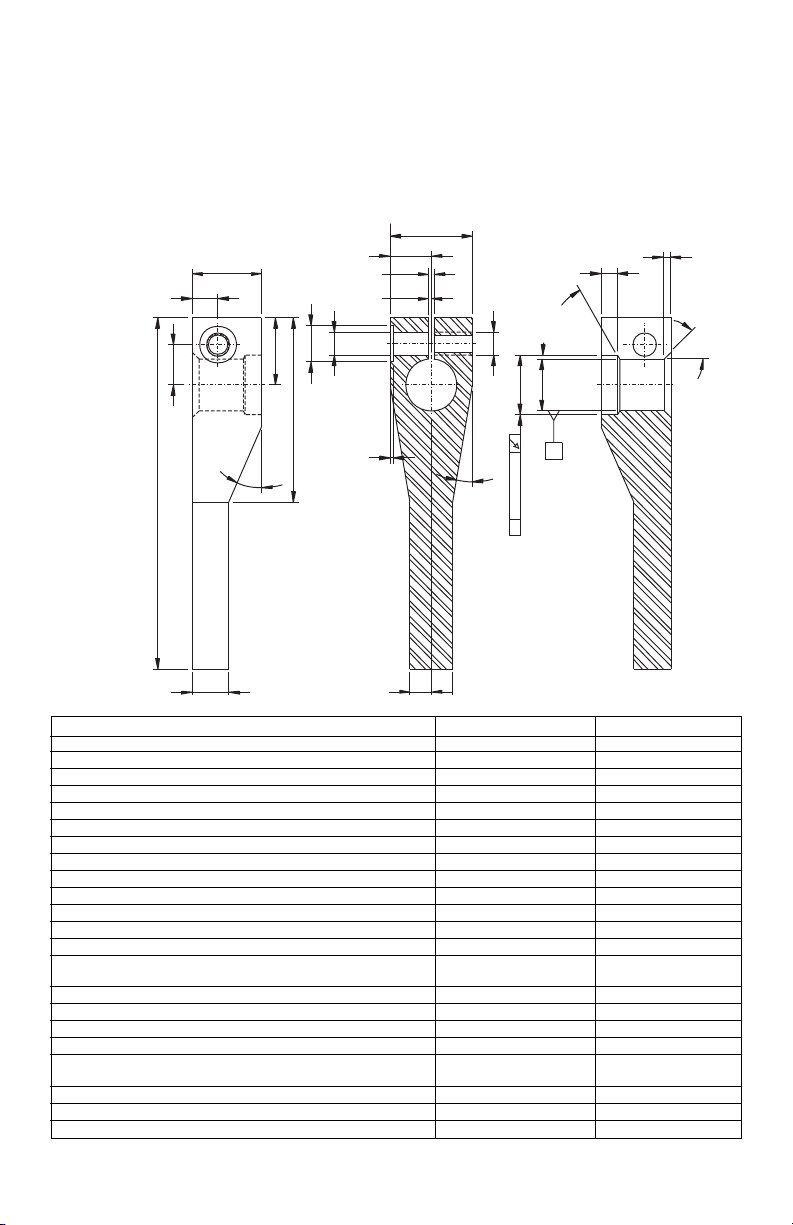

Clamp Arm Machining Specifications (page 13)

See Pressure and Flow Rate on page 8 to correctly measure the arm length. To determine the maximum

clamping force for the arm, refer to Operating Specifications — Maximum Flow Rate Chart on page 3.

Problem Possible Cause Solution

Page 10

Grafiken — Spannkraft im Verhältnis zur Spannarmlänge

Diagrammes de force de bridage/longueur de bras

Gráficas de fuerza de fijación vs. longitud del brazo

Diagrammi della forza di serraggio in funzione della lunghezza del braccio

Grafieken klemkracht -v- lengte arm

A B C

Spannkraft Max. Spanndruck Spannarmlänge

Force de bridage Pression maxi. de bridage Longueur du bras

Fuerza de fijación Presión máx. de fijación Longitud del brazo

Forza di serraggio Pressione di serraggio max. Lunghezza del braccio

Klemkracht Max. klemdruk Lengte arm

Montage von Zylindern mit Außengewinde

Montage des Vérins à Corps Fileté

Montaje de Cilindros de Cuerpo Roscado

Montaggio dei Cilindri a Corpo Filettato,

Monteren van cilinders met Schroefdraadlichaam

A B C D

In die Vorrichtung Montageflansch Ölanschluß Gegenmutter

geschraubt (Gegenmuttern)

vérin vissé sur la machine bride de fixation raccord d’huile écrou de écrou de blocage

blocage (écrous de blocage)

atorinillado en el aparejo brida de montaje conexión de aceite contratuerca

(contratuercas)

avvitato nel supporto fisso flangia di montaggio raccordo del olio controdado (controdadi)

in appendage geschroefd montageflens oileaansluiting tegenmoer (tegenmoeren)

10

A

B

C

D

C

D

A (kN)

2,67

2,00

1,34

0,67

0

2,2 kN

1

2

3

0

C (mm)

350

350

207

145

4

128

5

107

7613 25 38 51 64

B (bar)

6,67

5,34

4,00

A (kN)

2,67

1,33

0

25 51 76 102 127

0

5,6 kN

350

1

2

3

C (mm)

350

B (bar)

262

172

131

4

5

103

Page 11

Montage von Kopf- und Fußflanschzylindern

Montage des Vérins Par Bride Supérieure ou Inférieure

Montaje de Cilindros Con Brida Superior y Brida Inferior

Montaggio dei Cilindri a Flangia Superiore ed Inferiore

Monteren van Onder- en Bovenflens van Cilinders

Anschlußspezifikationen, Caractéristiques du bloc foré,

Especificaciones del colector, Specifiche del collettore, Specificaties verdeelstuk

Zylinder Max. Ölkanal- Durchmesser Befestigungs- Mindest- Anzug-Dreh- O-Ring-Anschluß

kapazität durchmesser der Öffnung gewinde Einschraubtiefe moment der Innendurch

Befestigungs- messer x B

schrauben

(geschmiert)

Capacité Diamètre maxi. Diamètre Filets de Profondeur Couple de Dimensions du

du du passage du trou de montage minimum serrage du joint torique

vérin d’huile la machine boulon de D.I. x I.

montage

lubrifié

Capacidad Diámetro máx. Diámetro de Roscas de Profundidad Apriete de Dimensiones de

del de conducto agujero en montaje mín. de rocas pernos de anillo "O"

cilindro de aceite aparejo montaje de colector

lubricatos D. I. x ancho

Forza Diametro max. Diametro foro Filetti di Profunditá Coppia di Dimensioni

sviluppata condotto olio supporto fisso montaggio min. dei filetti montaggio O-Ring

dal bullone collettore

cilindro lubrificato D.I. x s

Cilinder Max. diameter Diameter gat Montage- Minimale Aandraai- Afmeting

capaciteit oliekanaal appendage schroefdraad scroefdraad- moment O-Ring

diepte gesmeerde verdeelstuk

montagebaut binnendiam. x b

Ø A Ø B C D E

2,2 kN 4 mm 1,15 ± 0,03 M5 12 mm 4,5-5,4 Nm 6,07 x 1,78 mm

5,6 kN 4mm 1,42 ± 0,03 M6 12 mm 12,2-14,9 Nm 7,65 x 1,78 mm

11

Manifold

O-ring

E

A

B

0.003

0,01

D

C

Manifold

O-ring

E

A

0.003

0,0 1

D

C

Page 12

Anschlußbeschreibung

Identification d’oriface

Identficación de Lumbreras

Identificazione degli Attacchi

Identificatie Poorten

T U L D E

Zylinder mit Außengewinde Zylinder mit Kopfflansch Zylinder mit Fußflansch Entspannen Spannen

Corps fileté Corps à bride supérieure Corps à bride inférieure Débridage Bridage

Cuerpo roscado Cuerpo con brida superior Cuerpo con brida inferior Soltado Fijación

Corpo filettato Corpo a flangia superiore Corpo a flangia inferiore Rilascio Serraggio

Schroefdraadlichaam Lichaam met bovenflens Lichaam met onderflens Afspannen Klemmen

A B C

Anschluß A: Kolben schwenkt Anschluß B: doppelt wirkend — Verteilerkopfanschlüsse

90° und spannt Kolben entspannt und schwenkt -90°

einfach wirkend — Entlüftungsanschluß

Orifice A: le piston pivote à 90° Orifice B: double effet — Orifices du bloc foré

le piston débride et pivote à -90°

simple effet — Orifice d’aération

Lumbrera A: El émbolo gira Lumbrera B: acción doble — Lumbreras del colector

90° y se fija El émbolo se suelta y gira -90°

acción única — Lumbrera de ventilación

Attacco A: lo stantuffo ruota Attacco B: a doppio effetto -- Attacchi del collettore

di 90° e serra. lo stantuffo rilascia e ruota di -90°

ad effetto semplice -- attacco di sfiato

A Poort: plunjer draait B Poort: dubbelwerkend — Poorten verdeelstuk

90° en klemt plunjer spant af en draait -90°

enkelwerkend — ontluchtingspoort

Den Entlüftungsstopfen nicht entfernen, es sei denn zum Anschließen von Rohren. (Siehe den Abschnitt Entlüftungsstopfen.

Ne pas retirer le bouchon à évent, sauf pour brancher la conduite. (Voir la section bouchon à évent.)

No saque el tapón ventilado salvo para conectar tubería en su lugar. (Vea la sección del tapón ventilado.)

Non rimuovere il tappo di sfiato, fuorché per il collegamento di tubi (vedere la sezione sul tappo di sfiato).

Verwijder de ontluchtingsstop alleen voor het bevestigen van slangen. (Zie het gedeelte Ontluchtingsstop.)

12

Seitenansicht, Vue de côté, Vista lateral, Zijaanzicht

Ansicht von unten, Vue de dessous, Vista inferior, Vista dal basso, Onderaanzicht

D

D

E

E

D

E

T

B

A

U

A

C

B

L

A

C

B

Page 13

Clamp Arm Machining Specifications

Fertigungsmasse für Spannarme

Spécifications pour l’usinage des bras de bridage

Especificaciones de fabricacion del brazo de fijacion

Specifiche della lavorazione a macchina del braccio di serraggio

Bewerkingsspecificaties voor klemarm

2,2 kN (500 lb) 5,6 kN (1250 lb)

"A" 16,5-15,8 (.65-.62) 19,5-18,8(.77-.74 )

"B" Max. 101,0-100,6 (3.98-3.96) 157,7-156,8 (6.21-6.17)

"C" 19,5-18,9 (.77-.74) 25,9-25,2 (1.02-.99)

"D" 10,6-10,0 (.42-.39) 11,9-11,3 (.47-.44)

"E" 9,2-9,6 (.36-.38) 12,8-13,2(.50-.52 )

"F"

(3 Places, 3 Stellen, 3 emplacements, 3 puntos, 3 punti, 3 Plaatsen) 49,7-48,8 (1.96-1.92) 70,8-69,9 (2.79-2.75)

"G" 18,1-18,7 (.71-.74) 22,1-22,8 (.87-.90)

"H" 8,7-9,1 (.34-.36) 11,2-11,6 (.44-.46)

"J" 9,4-10,1 (.37-.40) 12,5-12,9 (.49-.51)

"K" (Dia.,Durchm., diám., Diam.) Ø10,2-10,6 (.40-.42) Ø13,0-13,4 (.51-.53)

"L" 1,3-1,7 (.05-.07) 1,3-1,7 (.05-.07)

"M" (Dia.,Durchm., diám., Diam.) Ø7,12-7,34 (.280-.289) Ø8,69-8,91 (.342-.351)

"N" Thru (Durch, Traversant, Agujero N, passante, Doorloop) M6 x 1 M8 x 1,25 or M10 x 1,5

or .250-28 UNF-2b .3125-24 UNF-2B

"P" 5,4-5,8 (.21-.23) 6,9-7,3 (.27-.29)

"Q" 11,6-11,0 (.46-.43) 14,4-13,8 (.57-.54)

"R" (2 Places, 2 Stellen, 2 emplacements, 2 puntos, 2 punti, 2 Plaatsen)

7°-8° 6°-8°

"S" (Dia., Durchm., diám., Diam.) 11,82-11,91 (Ø.456-.469) Ø18,47-18,56 (.727-.731)

"T" (Dia., Durchm., diám., Diam.) 9,998-10,012 (Ø.3932-.3942) Ø15,990-16,014

(.6295-.6305)

"U" 3,0-3,5 (.12-.14) 4,1-4,5 (.16-.18)

"V" 0,5-1,0 (.02-.04) 0,5-1,0 (.02-.04)

"V" 13°-15° 11°-13°

13

55∞-60∞

"U"

"T"

"S"

0,08 [.003]

A

A

63√ [1,6]

1,1-1,5 [.04-.06]

2,1-3,0 [.08-.12]

"J"

"L"

"R"

2-PLACES

"P"

"M"

"K"

"N"

"D"

"H"

"A"

"F" 3-PLACES

"G"

"E"

"B"

"W"

40∞-50∞

"V"

"C"

Dimensions are in mm [in].

Abmessungen in mm [in].

Les dimensions sont en mm [po].

Las dimensiones se dan en mm [pulg].

Le dimensioni sono in mm [in].

Afmetingen zijn in mm [in].

Page 14

14

Das Ersatzteilblatt für dieses Produkt finden Sie auf der

Enerpac Website www.enerpac.com, oder bei Ihrem

nächstgelegenen authorisierten Enerpac Service Center

oder einem Enerpac Vertriebsbüro.

1.0 WICHTIGE VERFAHRENSHINWEISE FÜR

DEN EMPFANG:

Alle Komponenten auf sichtbare Transport-schäden

inspizieren. Transportschäden sind nicht von der

Garantie gedeckt. Werden solche Schäden festgestellt,

ist unverzüglich das Transportunternehmen zu

verständigen. Das Transportunternehmen ist für alle

Reparatur- und Ersatzkosten, die auf Transportschäden

zurückzuführen sind, verantwortlich.

SICHERHEIT GEHT VOR

2.0 SICHERHEITSFRAGEN

Alle Anleitungen, Warnungen und

Vorsichtshinweise sorgfältig

durchlesen. Beachten Sie alle

Sicherheitsvorkehrungen, um Verletzungen oder

Sachschäden während des Systembetriebs zu

vermeiden. Enerpac ist weder für Schäden noch

Verletzungen haftbar, die durch einen fahrlässigen

Gebrauch des Produkts, mangelhafte Instand-haltung

oder eine unvorschriftsmäßige Anwendung des

Produkts und/oder des Systems verursacht werden. Bei

evtl. Fragen in bezug auf Sicherheitsvorkehrungen und

Betriebsabläufe wenden Sie sich bitte an ENERPAC.

Wenn Sie an keinerlei Sicherheitsschulungen im

Zusammenhang mit Hochdruckhydraulikanlagen

teilgenommen haben, fordern Sie von Ihrer Vertriebsund Kundendienstzentrale einen kostenlosen EnerpacHydraulik-Sicherheitskurs an.

Ein Mißachten der folgenden Vorsichtshinweise und

Warnungen kann zu Geräteschäden und Verletzungen

führen.

Mit einem VORSICHTSHINWEIS wird auf

ordnungsgemäße Betriebs- oder Wartungsverfahren

und –praktiken hingewiesen, um Schäden an den

Geräten oder anderen Sachwerten bzw. deren

Zerstörung zu vermeiden.

Eine WARNUNG verweist auf eine potentielle

Verletzungsgefahr, die durch ordnungsgemäße

Verfahren oder Praktiken vermieden werden kann.

Ein GEFAHRENSHINWEIS wird nur dann gegeben,

wenn eine bestimmte Handlung oder die Unterlassung

einer bestimmten Handlung schwere oder tödliche

Verletzungen zur Folge haben kann.

WARNUNG: Beim Betrieb hydraulischer

Anlagen geeignete Schutzkleidung und

–ausrüstung tragen.

WARNUNG: Von Lasten fernhalten, die

durch ein Hydrauliksystem abgestützt

werden. Ein als Lastenhebegerät

eingesetzter Zylinder darf niemals als ein

Lastenhaltegerät verwendet werden. Nach Heben oder

Senken der Last muß diese stets auf mechanische Weise

gesichert werden.

GEFAHR: Zur Vermeidung von

Verletzungen während des Betriebs

Hände und Füße von Zylinder und

Werkstück fernhalten.

WARNUNG: Die zugelassene Nennleistung

der Geräte nicht überschreiten. Keine Last zu

heben versuchen, deren Gewicht das

Hebevermögen des Zylinders übersteigt. Überlastungen

verursachen Maschinenausfälle und können zu

Verletzungen führen. Die Zylinder wurden für einen max.

Druck von 350 bar konstruiert. Keinen Heber oder

Zylinder an eine Pumpe mit einer höheren nominalen

Druckleistung anschließen.

GEFAHRENSHINWEIS: Das Überdruckventil

keinesfalls auf einen höheren Druck als den

maximal zulässigen Druck der Pumpe

einstellen. Höhere Einstellungen können zu

Geräteschäden und/oder Verletzungen führen. Nicht

das Druckbegrenzungs-Ventil entfernen!

WARNUNG: Der Systembetriebsdruck darf

den zulässigen Nominaldruck der Systemkomponente mit der niedrigsten Nennleistung

nicht überschreiten. Zur Überwachung des

Betriebsdrucks sind Manometer im System zu installieren. Dies ist das Fenster zu den Abläufen im System.

VORSICHT: Beschädigungen am

Hydraulikschlauch vermeiden. Beim

Verlegen der Hydraulikschläuche enge Bögen

und Abknicken vermeiden. Der Einsatz eines

gebogenen oder geknickten Schlauchs führt zu einem

hohen Rückstau. Starke Biegungen und Knickstellen

schädigen den Schlauch auf der Innenseite und führen zu

dessen vorzeitigem Ausfall.

Keine schweren Gegenstände auf den

Schlauch fallen lassen. Starke Erschütterungen können Schäden an den im

Schlauchinnern verlaufenden Drahtlitzen verursachen. Ein

Schlauch, auf den Druck ausgeübt wird, kann bersten.

WICHTIG: Hydraulische Geräte weder an

den Schläuchen noch den

Gelenkanschlüssen anheben. Dazu den

Tragegriff oder eine andere sichere

Transportmethode verwenden.

®

Bedienungsanleitung

Schwenkspannzylinder

Metrisch 2,2 N und 5,6 N

L2058 Rev. C 03/12

®

Page 15

VORSICHT: Hydraulische Geräte von Flammen und Hitzequellen fernhalten. Zu hohe Temperaturen

weichen Füllungen und Dichtungen auf und bewirken Flüssigkeitslecks. Große Hitze schwächt außerdem die

Schlauchmaterialien und –dichtungen. Zur Gewährleistung einer optimalen Leistung darf die Anlage keinen

Temperaturen über 65°C ausgesetzt werden. Außerdem müssen Schläuche und Zylinder beim Schweißen vor

Funkenschlag geschützt werden.

GEFAHR: Nicht mit unter Druck stehenden Schläuchen hantieren. Unter Druck austretendes Öl kann in

die Haut eindringen und schwere Verletzungen verursachen. Falls Öl unter die Haut gelangt, ist sofort ein

Arzt aufzusuchen.

WARNUNG: Hydraulikzylinder nur in einem gekopelten System verwenden. Niemals einen Zylinder

mit unverbundenen Kupplungen verwenden. Bei einer extremen Überlastung des Zylinders können

dessen Komponenten schlagartig bersten, was schwere Verletzungen hervorrufen kann.

IWICHTIG: Hydraulische Geräte müssen von einem qualifizierten Hydrauliktechniker gewartet werden.

Bei Reparaturarbeiten an die autorisierte ENERPAC-Kundendienstzentrale der jeweiligen Region wenden.

Zur Aufrechterhaltung der Garantie nur ENERPAC-Öl verwenden.

WARNUNG: Abgenutzte oder beschädigte Teile unverzüglich durch ENERPAC-Originalteile ersetzen.

Standardteile anderer Hersteller versagen und verursachen Verletzungen und Sachschäden. ENERPAC-

Teile werden so konstruiert, daß sie richtig passen und hohen Lasten standhalten.

3.0 BESCHREIBUNG

Diese Schwenkspannzylinder schwenken um 90° im

Uhrzeigersinn oder gegen den Uhrzeigersinn. Sie

können auch linear geführt werden. Es sind einfach

wirkende und doppelt wirkende Schwenkspannzylinder erhältlich. Die Spannarme sind nicht im

Lieferumfang der Zylinder enthalten. Die Spannarme

können einzeln gekauft oder gemäß den

Spezifikationen auf Seite 13 gefertigt werden.

15

Modellnummercode

1 2 3 4 5 6

Sonderzubehör

S =

Schwenk-

T =

Zylinder mit

R =

rechts

S =

einfach wirkend

2 = 2,2 kN 2 = metrisch V = Viton

spannzylinder Außengewinde schwenkend D = doppelt wirkend 5 = 5,6 kN

U = Kopfflansch L = links

L = Fußflansch schwenkend

S=gerade (nicht

schwenkbar)

TECHNISCHE DATEN

Zylinderspezifikationen

Kapazität [kN] 2,2 5,6

Zylinderausführung Zylinder mit Außengewinde, Montage am Fußflansch oder Kopfflansch

Zylindertyp einfach wirkend und doppelt wirkend

Hydraulikhub spannen 8,1 9,9

[mm] gesamt 16,5 22,6

Arbeitsbereich spannen 1,22 1,81

[cm2]

entspannen 1,55 3,81

Ölfassungsvermögen spannen 4,59 10,3

[cm

3

] entspannen

9,67 20,2

Page 16

Betriebsspezifikationen — Max. Durchflußratentabelle

Siehe auch die Grafiken: Spannkraft im Verhältnis zur Spannarmlänge auf Seite 10.

2,2 kN — Die maximale Spannarmlänge beträgt 76 mm

Spannarmlänge

25 38 51 64 76

[mm]

gerader Standard- ausgefahren ausgefahren ausgefahren ausgefahren

Anzug Spannarm

Max. Durchfluß [cc/min] 197 197 98 98 98 98

Max. Druck [bar] 350 350 207 145 128 107

Spannkraft [kN] 2,6 2,2 1,2 0,8 0,7 0,5

5,6 kN — Die maximale Spannarmlänge beträgt 127 mm

Spannarmlänge 40 51 76 102 127

[mm ]

gerader Standard- ausgefahren ausgefahren ausgefahren ausgefahren

Anzug Spannarm

Max. Durchfluß [cc/min] 410 410 197 197 197 197

Max. Druck [bar] 350 350 262 172 131 103

Spannkraft [kN] 6,2 5,0 3,3 2,0 1,2 0,9

4.0 EINLEITENDE INFORMATIONEN

WICHTIG: Falls diese Anweisungen nicht gelesen und beachtet werden, können Systemstörungen oder

Produktversagen die Folge sein, und die Garantie kann verfallen.

(1) Zu hohe Durchflußraten können zu übermäßiger Zylindergeschwindigkeit führen, die den Zylinder

beschädigen kann. Hydraulikdruck und Zylindergeschwindigkeit sind entsprechend der Spannarmlänge zu

bestimmen. Die Spannkraft ist außerdem je nach Spannarmlänge unterschiedlich. Siehe hierzu die obigen

Betriebsspezifikationen

(2) Flußsteuerungen mit Rücklaufventilen sollten zur Verringerung der Schwenkzylindergeschwindigkeit auf die

empfohlene Geschwindigkeit benutzt werden. Die Rücklaufventile dienen zur Minimierung des Staudrucks,

der zu einem Versagen bei der Entspannung auf einfach wirkenden Systemen führen kann.

(3) Bei der Verwendung von einfach wirkenden Zylindern ist der Rücklauf-Staudruck auf maximal 3,5 bar zu

begrenzen. Rohre mit großem Durchmesser (10 mm Außendurchmesser oder größer) und

Durchflußsteuerungen mit Freifluß-Rücklaufventilen helfen den Staudruck zu verringern. Wenden Sie sich an

Enerpac, um Informationen über entsprechende Systementwürfe zu enthalten.

(4) Übermäßiger Rücklauf-Staudruck kann außerdem doppelt wirkende Schwenkarmzylinder beschädigen. Bei

der Verwendung von doppelt wirkenden Zylindern ist der Rücklauf-Staudruck auf maximal 42 bar zu

begrenzen. Doppelt wirkende Systeme sollten einen begrenzbaren Ölfluß mit umgekehrtem Freifluß im

Spannausgang aufweisen.

(5) Das Einspannen des Objekts sollte am Mittelpunkt des vertikalen Arbeitshubs beginnen. Keine Objekte

dürfen eingespannt werden, während sich die Schwenkklemme dreht. Der Spannarm muß sich während der

90° Drehung frei drehen (Kontakt mit Schneidspitzen, Werkzeugen usw. vermeiden).

(6) Die Montage des Spannarms am Zylinderkolben muß entsprechend den Anweisungen auf Seite 18 erfolgen.

5.0 MONTAGESPEZIFIKATIONEN

5.1 Montage von Zylindern mit Außengewinde

Die Zylinder mit Außengewinde können in eine Gewindebohrung eingeschraubt, mit einem Flansch in der

Vorrichtung eingebaut, in die Vorrichtung eingeschraubt und mit einer Gegenmutter befestigt oder durch eine

Zugangsöffnung montiert und mit Gegenmuttern befestigt werden. Siehe die Abbildungen auf Seite 10.

Wenn ein Schwenkspannzylinder mit Außengewinde in einer Vorrichtung eingebaut wird, muß er genau so weit

eingeschraubt werden wie im Enerpac Standardflansch. Wenn ein Zylinder nur an den untersten

Gewindegängen eingeschraubt wird, sollte er tiefer eingeschraubt werden, um zusätzliche Haltekraft zu

erzielen. Siehe die nachstehende Tabelle für die Mindest-Einschraubtiefe.

5.2 Montage von Kopf- und Fußflanschzylindern (Siehe Seite 11.)

ACHTUNG: Die Vorrichtung muß dem angewandten hydraulischen Arbeitsdruck von 350 bar

standhalten, wenn die Zylinder an einem Verteilerkopf montiert sind.

16

Page 17

Bevor Schwenkspannzylinder mit O-Ring an einem Verteilerkopf

montiert werden können, müssen die Verschlußstopfen (A) und die

Kupferdichtungen entfernt werden.

Die zur Verfügung gestellten O-Ringe (B) sollten gefettet und vor dem

Montieren und Verschrauben des Schwenkspannzylinders in die

Ansenkung um die Versorgungsbohrung eingelegt werden.

Stellen Sie sicher, daß der O-Ring während der Montage nicht

zusammengedrückt oder beschädigt wird, da dies zu Leckagen

führen kann. Um Leckagen durch die Anschlußmontage zu

vermeiden, muß die Oberfläche im Auflagebereich des Zylinders

eine Ebenheit von 0,08 mm sowie eine Oberflächenrauhigkeit bis

höchstens Ra 1,6 aufweisen.

6.0 INSTALLATION

Diese Schwenkspannzylinder sind so konstruiert, daß die Stellung

des Spannarms nach der Montage des Zylinders eingestellt

werden kann. Wenn die Drehungsrichtung geändert werden muß,

muß dies vor der Montage des Zylinders geschehen.

6.1 Ändern der Kolbendrehung (falls erforderlich)

Die Kolbendrehrichtung wird geändert, indem der Buchstabe auf der Kolbenoberseite mit dem Pfeil auf dem

Zylinder auf der den Anschlüssen gegenüberliegenden Seite ausgerichtet wird. Die Abbildungen beachten und

das angeführte Verfahren ausführen, um die Drehrichtung zu ändern. Es wird ein Schraubenschlüssel benötigt.

S L R

Gerade Linke Drehung Rechte Drehung

A B C D E

Spannung- Entspannungs- Spannungs- und Spannposition Entspannungs

sanschluß anschluß Entspannungs- position

position

.25 "

(6,4mm)

6,4 mm

(0.25")

I

G

H

F

J

A

B

S

L

R

A

B

R

S

L

A

B

L

R

S

A

CEE

A

ABBB

DD

S

L

R

17

A

A

B

B

Kopfflansch

Fußflansch

Zylinderkapazität Mindest-Einschraubtiefe

2,2 kN 13 mm

5,6 kN 13 mm

Page 18

1. Bringen Sie den Arm (F) so auf dem Kolben (G) an, daß er als Griff zum Bewegen des Kolbens benutzt

werden kann.

(a) Lösen Sie die Spannarmschraube (H).

(b) Entfernen Sie den Sicherungsring (I) und schieben Sie den Spannarm über den Kolben nach unten, bis

die obere Kante des Spannarms 6 mm von der Kolbenoberseite entfernt ist.

(c) Ziehen Sie die Spannarmschraube (J) an. Werfen Sie den Sicherungsring NICHT weg.

2. Legen Sie einen Schraubenschlüssel an die Bodenschraube des Zylinders an und drehen Sie den Stopfen

(zu Ihnen gerichtet) 4 Umdrehungen gegen den Uhrzeigersinn.

HINWEIS: Bei einfach wirkenden Zylindern muß die Bodenschraube unter Umständen mehr als 4

Umdrehungen gedreht werden, um den Federdruck der Rückpreßfeder zu entlasten.

3. Den Kolben nach unten drücken und ihn so drehen, bis der gewünschte Buchstaben (L, R, S; Links, Rechts,

Gerade) mit dem Pfeil seitlich am Zylinder ausgerichtet ist.

4. Wenn der Buchstabe und der Pfeil ausgerichtet sind, ziehen Sie den Kolben nach oben, drehen Sie die

Bodenschraube wieder (4 Umdrehungen) hinein und ziehen Sie sie fest an.

6.2 Befestigung des Spannarms

1. Entfernen Sie den Sicherungsring (A) vom oberen Teil des Kolbens (B).

2. Schieben Sie den Spannarm (C) über den Kolben nach unten und verwenden Sie

eine Zange, um den Sicherungsring zurück in die Kolbennut zu drücken. Bringen

Sie den Spannarm in Stellung und richten Sie den Sicherungsring so aus, daß

dessen Öffnung am hinteren Teil des Spannarms liegt. Siehe die Abbildung.

3. Bewegen Sie den Spannarm so lange nach oben, bis er fest am Sicherungsring in

der gewünschten Stellung anliegt. In dieser Stellung befestigen Sie den Spannarm

mit dem erforderlichen Anzugsdrehmoment laut nachstehender Spezifikation.

VORSICHT: Durch falsches Anzugsdrehmoment der Span narm

schraube könnte der Spannarm während des Betriebs verrutschen. VERWENDEN SIE BITTE

NUR SECHSKANT INBUS-SCHRAUBEN DER QUALITÄTSKLASSE 8 (12.9 DIN 912) (werden

mit Standard-Spannarmen geliefert).

6.3 Spannarme für Zylinder mit Kopfflansch

Für die Verwendung von Kopfflanschzylindern muß sichergestellt sein, daß

die Druckschraube während der Verwendung nicht mit dem Kopfflansch

kollidiert. Der Spannarm muß lang genug sein, daß die Druckschraube den

Kopfflansch nicht berührt, wenn der Arm abwärts geschwenkt wird.

Abstandsprobleme sind sehr häufig, wenn die endgültige Spannposition an

der Seite des Zylinders ist, und das Druckstück an der Vorderseite oder

Rückseite des Kopfflansches vorbei abwärts geschwenkt werden muß.

Unter Umständen muß der längere Spannarm der Serie CAL für solche

Anwendungen verwendet werden.

18

C

A

B

D

Anzugsdrehmoment der Spannarmschraube (D)

Zylinderkapazität Anzugsdrehmoment (geschmiert)

2,2 kN 16,3 to 20,3 Nm

5,6 kN 32,5 to 39,3 Nm

A

Maximale Länge der Druckschraube

Zylinderkapazität Maximale Länge

2,2 kN 19,1

HINWEIS: Die hier angegebene maximale Länge gilt nur für

Kopfflanschmodelle mit 2,2 kN Kapazität.

Page 19

6.4 Hydraulikanschlüsse

Als Anschlußverschraubungen werden Verschraubungen mit 350 bar Nennleistung benutzt.

KEINE Gewindedichtmittel benutzen. Die Dichtung erfolgt durch einen O-Ring in der Verschraubung.

Schmieren Sie den O-Ring vor dem Zusammenbau. Bei der Zusammenstellung des Hydraulikkreises sind die

Faktoren zu beachten, die unter EINLEITENDE INFORMATIONEN auf Seite 16 angegeben sind. Weitere

Hinweise zur Installation von Hydraulikkreisen finden Sie im Katalog Enerpac.

Zylinderanschlüsse

Zylinderkapazität 350 bar Zylinderkapazität 350 bar

BSPP-Verschraubung BSPP-Verschraubung

2,2 kN G 1/8 5,6 kN G 1/8

Anschlußbeschreibung (Siehe Abbildung 4 auf Seite 12.)

7.0 BETRIEB

Schwenkspannzylinder drehen sich im ersten Teil des Hubs um 90° und setzen dann ohne Drehung mit einem

Spannhub fort. Der Spannungshub des Zylinders ist ein gerader Abwärtshub. Die Spannung darf nur im

vertikalen Hubbereich erfolgen, nicht während der Schwenkbewegung.

VORSICHT

— Wenn die Spannkraft im Schwenkbereich aufgebracht wird, führt dies zu einer internen

Beschädigung des Kolbens.

— Um höchstmögliche Leistung und Sicherheit des Zylinders zu gewährleisten, stellen Sie bitte sicher,

daß alle hydraulischen Verbindungen, Schläuche und Anschlußstücke vollständig angezogen und

abgedichtet sind. Stellen Sie sicher, daß alle Teile dem Systemdruck standhalten.

— Auf niedrigen Druck ausgerichtete Komponenten können einem höheren Druck nicht standhalten.

Die Verwendung von Teilen, die auf niedrigen Druck ausgerichtet sind, führt zu Beschädigung des

Materials und möglicherweise zu Arbeitsunfällen.

7.1 Entlüftungsstopfen

Einfach wirkende Zylinder haben einen Entlüftungsstopfen auf der linken Seite des Zylinders (wenn Sie auf die

Hydraulikanschlüsse blicken). Um das Eindringen von Splittern und Kühlmittel zu verhindern, darf der

Entlüftungsstopfen nicht entfernt werden. Wenn ständig Kühlmittel über den Entlüftungsstopfen fließt, kann ein

Kunststoffschlauch mit einer BSPP-Verschraubung auf dem Anschluß befestigt werden und der Schlauch an

einen externen, sauberen Bereich der Vorrichtung verlegt werden.

7.2 Druck und Durchflußrate

Die Spannarmlänge (L) bestimmt die Betriebsdruckeinstellung und die Durchflußrate.

Siehe die Tabelle für maximale Durchflußrate in den Betriebsspezifikationen auf Seite 16 für Spannarmlänge,

Druckeinstellung und Durchflußrate. Stellen Sie den Betriebsdruck und die Durchflußrate gemäß den

Grenzwerten ein, die durch die Spannarmlänge festgelegt werden. Überschreiten Sie nicht die Last-zu-LängeDruckverhältnisse. Je länger der Arm, desto geringer die Spannkraft und der maximale Betriebsdruck.

VORSICHT: Es ist sehr wichtig, daß die korrekten Einstellungen für Druck und Durchfluß

benutzt werden. Ein Betrieb außerhalb dieser Grenzwerte führt zur Beschädigung des

Schwenkspannzylinders. Beschädigungen aufgrund der Überschreitung von

Nenndruckwerten und Höchstdurchflußwerten SIND NICHT DURCH DIE GARANTIE GEDECKT.

19

L

Page 20

8.0 WARTUNG

Die Wartung ist erforderlich, wenn Abnutzung oder Leckage festgestellt werden. Sie gelegentlich alle

Komponenten, um eventuelle Probleme festzustellen, die Wartung und Service benötigen. Enerpac bietet

verwendungsfertige Reparaturteilsätze an. Reparaturteilbögen mit schematischen Einbauzeichnungen und

Ersatzteillisten sind erhältlich. Wenden Sie sich hierzu an Enerpac.

WICHTIG: Entnehmen Sie bitte alle Informationen zur korrekten Montage und Demontage den Ersatzteilbögen.

Falsche Wartung und falscher Service wie z.B. falsche Anzugsdrehmomente können Funktionsfehler und/oder

Arbeitsunfälle verursachen.

9.0 FEHLERBESEITIGUNG

Die folgende Information soll nur als Hilfe zur Fehlerfeststellung dienen. Wenden Sie sich wegen Reparaturen

an Ihr Vertriebsunternehmen oder das zuständige autorisierte Enerpac Service-Center.

FERTIGUNGSMASSE FÜR SPANNARME

Siehe Seite 13. Zur korrekten Messung der Armlänge siehe Druck und Durchflußrate auf Seite 19. Zur

Bestimmung der maximalen Spannkraft für den Arm siehe die Tabelle für maximale Durchflußrate in den

Betriebsspezifikationen auf Seite 16.

20

Problem Mögliche Ursache Lösung

1. Zylinder spannt/

entspannt nicht.

2. Zylinder fährt nur

teilweise aus.

3. Zylinder spannt/

entspannt

langsamer als

üblich.

4.Zylinder spannt/

entspannt, hält aber

keinen Druck.

5. Zylinder verliert Öl.

6. Spannarm macht

keine

Schwenkbewegung.

A. Pumpenentlastungsventil

offen

B. Kein Öl im Pumpentank

C. Luft im System

D. Kupplungen nicht ganz

festgezogen

E. Verstopfte Hydraulikleitung

F. Feder im Zylinder gebrochen

A. Ölstand in der Pumpe zu

niedrig

B. Kolben klemmt

A. Leckage in der Verbindung

B. Verstopfte Hydraulikleitung

C. Funktionsstörung der Pumpe

A. Dichtungen defekt

B. Leckage in der Verbindung

C. Funktionsstörung der Pumpe

A. Dichtungen defekt

B. Kolben abgenutzt oder

beschädigt

A. Spannarm lose.

B. Kolben beschädigt.

A. Das Pumpenentlastungsventil schließen

B. Tank der Pumpe auffüllen

C. Luft aus dem Hydrauliksystem entfernen

D. Die Verschraubungen erneut festziehen

E. Ventile, Anschlüsse und Rohrverlegungen

prüfen

F. Feder ersetzen

A. Tank der Pumpe auffüllen

B. Schadhafte Teile ersetzen siehe Ersatzteilbogen

A. Anschlüsse, Verschraubungen und

Rohrverlegungen festziehen

B. Ventile, Anschlüsse und Rohrverlegungen

prüfen

C. Siehe Pumpenanleitungsblatt

A. Dichtungen ersetzen — siehe Ersatzteilbogen

B. Anschlüsse, Verschraubungen und

Rohrverlegungen festziehen

C. Siehe Pumpenanleitungsblatt

A. Dichtungen ersetzen — siehe Ersatzteilbogen

B. Schadhafte Teile ersetzen — siehe

Ersatzteilbogen

A. Spannarm neu positionieren und festziehen —

siehe Befestigung des Spannarms, Seite 18

B. Schadhafte Teile ersetzen — siehe

Ersatzteilbogen.

Page 21

21

Les vues éclatées de ce produit sont disponibles sur

le site Enerpac www.enerpac.fr. Vous pouvez

également les obtenir auprès de votre réparateur

agréé Enerpac ou auprès d'Enerpac même.

1.0 INSTRUCTIONS IMPORTANTES

RELATIVES À LA RÉCEPTION

Inspecter tous les composants pour vous assurer qu’ils

n’ont subi aucun dommage en cours d’expédition. Les

dommages subis en cours de transports ne sont pas

couverts par la garantie. S’ils sont abîmés, aviser

immédiatement le transporteur, qui est responsable

des frais de réparation et de remplacement résultant de

dommages en cours de transport.

LA SÉCURITÉ AVANT TOUT !

2.0 SÉCURITÉ

Lire attentivement toutes les

instructions et mises en garde et

tous les avertissements. Suivre

toutes les précautions pour éviter d’encourir des

blessures personnelles ou de provoquer des dégâts

matériels durant le fonctionnement du système.

Enerpac ne peut pas être tenue responsable de

dommages ou blessures résultant de l’utilisation

risquée du produit, d’un mauvais entretien ou d’une

application incorrecte du produit et du système. En

cas de doute sur les précautions ou les applications,

contacter Enerpac.

Respecter les mises en garde et avertissements

suivants sous peine de provoquer des dégâts

matériels et des blessures corporelles.

Une mise en garde ATTENTION sert à indiquer des

procédures d’utilisation et de maintenance correctes

qui visent à empêcher l’endommagement voire la

destruction du matériel ou d’autres dégâts.

Un AVERTISSEMENT indique un danger potentiel

qui exige la prise de mesures particulières visant à

écarter tout risque de blessure.

La mention DANGER n’est utilisée que lorsqu’une

action ou un acte de négligence risque de causer des

blessures graves, voire mortelles.

AVERTISSEMENT : Porter un équipement

de protection personnelle adéquat pour

utiliser un appareil hydraulique.

AVERTISSEMENT : Rester à l’écart de

charges soutenues par un mécanisme

hydraulique. Un vérin, lorsqu’il est utilisé

comme monte-charge, ne doit jamais

servir de support de charge. Après avoir monté ou

abaissé la charge, elle doit être bloquée par un

moyen mécanique.

DANGER : Pour écarter tout risque

de blessures corporelles, maintenir

les mains et les pieds à l’écart du

vérin et de la pièce à usiner durant l’utilisation.

AVERTISSEMENT: Ne pas dépasser les

valeurs nominales du matériel. Ne jamais

essayer de soulever une charge d’un

poids supérieur à la capacité du vérin. Une

surcharge entraînera la panne du matériel et risque

de provoquer des blessures corporelles. Les vérins

sont conçus pour une pression maximale de 350 bar.

Ne pas connecter de cric ou de vérin à une pompe

affichant une pression nominale supérieure.

DANGER : Ne jamais régler la soupape

de sûreté à une pression supérieure à la

pression nominale maximale de la pompe

sous peine de provoquer des dégâts

matériels et/ou des blessures corporelles. Ne pas

retirer le limiteur de pression.

AVERTISSEMENT : La pression de

fonctionnement du système ne doit pas

dépasser la pression nominale du

composant du système affichant la plus

petite valeur. Installer des manomètres dans le

système pour surveiller la pression de

fonctionnement. Ils permettent de vérifier ce qui se

passe dans le système.

ATTENTION : Éviter d’endommager les

tuyaux hydrauliques. Éviter de les plier et

de les tordre en les mettant en place. Un

tuyau plié ou tordu entraînera un fort retour de

pression. Les plis et coudes prononcés

endommageront par ailleurs l’intérieur du tuyau,

provoquant son usure précoce.

Ne pas faire tomber d’objets lourds sur le

tuyau. Un fort impact risque de causer des

dégâts intérieurs (torons métalliques).

L’application d’ une pression sur un tuyau

endommagé risque d’entraîner sa rupture.

IMPORTANT : Ne pas soulever le matériel

hydraulique en saisissant ses tuyaux ou

ses raccords articulés. Utiliser la poignée

de transport ou procéder d’une autre manière sûre.

ATTENTION : Garder le matériel

hydraulique à l’écart de flammes et

d’une source de chaleur. Une forte

température amollira les garnitures et les joints et

provoquera par conséquent des fuites. La chaleur

affaiblit également les matériaux et les garnitures du

tuyau. Pour une performance maximale, ne pas

exposer le matériel à une température supérieure ou

égale à 65 °C [150 °F]. Protéger tuyaux et vérins de

projections de soudure.

®

Fiche d’instructions

Vérins de bridage pivotants

métriques 2,2 et 5,6 kN

L2058 Rev. C 03/12

®

Page 22

DANGER : Ne pas manipuler les tuyaux sous pression. L’huile sous pression qui risque de s’en

échapper peut pénétrer dans la peau et provoquer des blessures graves. En cas d’injection d’huile

sous la peau, contacter immédiatement un médecin.

AVERTISSEMENT : Utiliser des vérins hydrauliques uniquement dans un système couplé. Ne

jamais utiliser un vérin en présence de raccords déconnectés. La surcharge du vérin peut avoir des

effets désastreux sur ses composants, qui peuvent causer des blessures graves.

IIMPORTANT : Le matériel hydraulique doit uniquement être réparé par un technicien hydraulique

qualifié. Pour toute réparation, contacter le centre de réparation ENERPAC agréé le plus proche. Pour

assurer la validité de la garantie, n’utiliser que de l’huile ENERPAC.

AVERTISSEMENT: Remplacer immédiatement les pièces usées ou endommagées par des pièces

ENERPAC authentiques. Les pièces de qualité standard se casseront et provoqueront des blessures

et des dégâts matériels. Les pièces ENERPAC sont conçues pour s’ajuster parfaitement et résister

à de fortes charges.

3.0 DESCRIPTION

Ces vérins de bridage sont conçus pour pivoter à

90° vers la droite ou la gauche. Ils peuvent

également être utilisés pour des applications de

bridage en ligne droite. Des vérins à simple et

double effet sont disponibles. Les bras de bridage

ne sont pas fournis avec les vérins. Ils peuvent être

commandés séparément ou fabriqués selon les

spécifications de la page 13.

CARACTÉRISTIQUES

Caractéristiques du vérin

Capacité [kN] 2,2 5,6

Type de corps fileté, montage à bride inférieure ou supérieure

Type de vérin simple et double effet

Course bridage 8,1 9,9

hydraulique

total 16,5 22,6

[mm]

Surface utile

bridage 1,22 1,81

[cm2]

débridage 1,55 3,81

Contenance en

bridage 4,59 10,3

huile [cm

3

] débridage 9,67 20,2

22

Modellnummercode

1 2 3 4 5 6

Sonderzubehör

S = Vérin-T = corps fileté R = Pivotement S = Simple effet 2 = 2,2 kN 2 = Métrique V = Viton

de bridage

U =

Bride à droite

D =

Double effet

5 = 5,6 kN

pivotant supérieure

L =

Pivotement

L = Fußflansch

à gauche

inférieure

S =

Droit (sans

pivotement)

Page 23

Caractéristiques de fonctionnement -- Tableau de débits maximum

Voir également les diagrammes de force de bridage/longueur de bras page 10.

2,2 kN -- La longueur maximum de bras de bridage est 76 mm

Longueur

25 38 51 64 76

du bras [mm] tirage droit étendu étendu étendu étendu

Débit maxi. [c3/mn] 197 197 98 98 98 98

Pression maxi. [bar] 350 350 207 145 128 107

Force de bridage [kN] 2,6 2,2 1,2 0,8 0,7 0,5

5,6 kN -- La longueur maximum de bras de bridage est 127 mm

Longueur du bras 40 51 76 102 127

[mm] tirage droit bras standard étendu étendu étendu étendu

Débit maxi. [c3/mn] 410 410 197 197 197 197

Pression maxi. [bar] 350 350 262 172 131 103

Force de bridage [kN] 6,2 5,0 3,3 2,0 1,2 0,9

4.0 INFORMATIONS PRÉLIMINAIRES

IMPORTANT : Toute négligence de la lecture ou du respect de ces instructions peut résulter en une

panne du système ou une défaillance du produit et annuler la garantie.

(1) Des débits élevés peuvent causer une vitesse excessive du vérin et, éventuellement, l’endommager.

La pression hydraulique et la vitesse du vérin doivent être ajustées en fonction de la longueur du bras

de bridage.

(2) La force de bridage dépend également de la longueur du bras. Voir les caractéristiques de

fonctionnement.

(3) Des régulateurs de débit avec clapet de retenue peuvent être utilisés pour limiter la vitesse du vérin

pivotant à la valeur recommandée. Ce clapet de retenue minimise la pression en retour risquant de

causer des problèmes de fonctionnement sur les systèmes à simple effet.

(4) Si des vérins pivotants à simple effet sont utilisés, limiter la pression en retour à 3,5 bar maximum.

Des tuyaux de gros diamètre (diamètre extérieur de 10 mm ou plus) et des commandes de débit avec

clapets de retenue à écoulement libre aident à minimaliser la pression en retour.

(5) Consulter Enerpac pour la configuration de système correcte. Une pression en retour excessive peut

également endommager les vérins pivotants à double effet. Limiter la pression en retour à 42 bar

maximum. Les systèmes à double effet doivent être configurés pour une entrée régulée avec

écoulement libre inversé sur l’orifice de bridage. Le bridage de la pièce doit se faire à mi-chemin de

la course verticale et non pas lorsque la bride pivotante tourne. Le bras de bridage doit effectuer

librement sa rotation à 90° (ne pas toucher les têtes de coupe, outils, etc.).

(6) Le bras de bridage doit être fixé au piston du vérin conformément aux instructions de la page 25.

5.0 SPÉCIFICATIONS DE MONTAGE

5.1 Montage des vérins à corps fileté

Les vérins à corps fileté peuvent être vissés dans un trou taraudé, assujettis à la machine au moyen d’une

bride, vissés et maintenus par un écrou de blocage ou installés au travers d’un trou de dégagement et

assujettis par des écrous de blocage. Voir les illustrations page 10.

Si un vérin pivotant à corps fileté est installé, l’engagement du filet doit être au moins égal à celui requis pour

la bride de fixation Enerpac standard. Si un vérin est monté en n’utilisant que la partie inférieure du filetage,

l’engagement doit être accru pour obtenir davantage de support. Voir le tableau ci-dessous pour l’engagement

minimum de filet.

23

Capacité du vérin Engagement minimum du filet

2,2 kN 13 mm

5,6 kN 13 mm

Page 24

5.2 Montage des vérins par bride supérieure ou inférieure (Voir page 11.)

AVERTISSEMENT : La machine doit pouvoir supporter une pression de service de 350 bar

lorsque les vérins sont montés sur un bloc foré.

Pour pouvoir installer un vérin pivotant sur un bloc foré, les bouchons

filetés d’orifices (A) et les joints en cuivre doivent être retirés.

Les joints toriques (B) fournis doivent être lubrifiés et installés dans la

noyure du pourtour de l’orifice avant de monter et de boulonner le

vérin pivotant.

Veiller à ce que le joint torique ne soit ni pincé ni endommagé

durant le montage, ce qui pourrait causer des fuites. Pour éviter

des fuites au bloc foré, la tolérance de planéité de la surface de

montage ne doit pas excéder 0,08 mm et la rugosité Ra 1,6.

6.0 INSTALLATION

Ces vérins de bridage pivotants sont conçus de manière à pouvoir

régler la position du bras de bridage après avoir monté le vérin. S’il

est nécessaire de changer le sens de rotation, le faire avant de

monter le vérin.

6.1 Changement du sens de rotation du piston du

vérin (si nécessaire)

S L R

Droit Pivotement à gauche Pivotement à droite

A B C D E

Orifice de Orifice de Position de Position de Position de

bridage débridage bridage/ débridage bridage

débridage

Pour changer le sens de rotation du piston du vérin, aligner la lettre du haut du piston avec la flèche du flanc

du vérin, à l’opposé des orifices. Pour changer le sens de rotation, voir les illustrations et procéder comme suit.

Une clé réglable est nécessaire.

1. Placer le bras (F) sur le piston (G) afin de disposer d’une poignée pour le déplacer.

(a) Desserrer le boulon du bras de bridage (H).

24

A

A

B

B

Bride supérieure

Bride inférieure

A

B

S

L

R

A

B

R

S

L

A

B

L

R

S

A

CEE

A

ABBB

DD

S

L

R

.25 "

(6,4mm)

6,4 mm

(0.25")

I

G

H

F

J

Page 25

(b) Retirer la bague de retenue (I) et glisser le bras de bridage vers le bas du piston, jusqu’à ce que le haut

du bras se trouve à 6 mm de la surface supérieure du piston.

(c) Serrer le boulon du bras de bridage. NE PAS jeter la bague de retenue.

2. Placer la clé réglable sur le bouchon inférieur (J) du vérin et le tourner (le bouchon face à soi) de 4 tours

vers la gauche.

NOTE: Sur les vérins à simple effet, il peut être nécessaire de donner plus de 4 tours au bouchon pour soulager

la tension du ressort de rappel.

3. Appuyer sur le piston du vérin et le tourner pour aligner la lettre désirée (S, L, R) avec la flèche du flanc du

vérin.

4. Une fois la lettre et la flèche alignées, tirer le piston du vérin vers le haut, revisser le bouchon inférieur de 4

tours et serrer fermement.

6.2 Montage du bras de bridage

1. Retirer la bague de retenue (A) du haut du piston (B) du vérin.

2. Glisser le bras de bridage (C) vers le bas, par-dessus le piston et utiliser des pinces

pour pousser la bague de retenue sur la rainure du piston. Orienter la bague de

retenue de façon à ce que son ouverture soit dirigée vers l’arrière du bras de

bridage. Voir l’illustration.

3. Remonter le bras de bridage jusqu’à ce qu’il s’appuie fermement sur la bague de

retenue, dans la position désirée. En le maintenant dans cette position, serrer le

boulon du bras de bridage (D) au couple spécifié ci-dessous.

ATTENTION : Un serrage insuffisant du boulon du bras de bridage peut causer le glissement

du bras pendant le fonctionnement. VEILLER À UTILISER DES BOULONS À TÊTE CREUSE,

CLASSE 8 (12.9 DIN 912) (fournis avec les bras de bridage standard).

6.3 Bras de bridage pour vérin à bride supérieure

Pour utiliser les vérins à bride supérieure, s’assurer que le boulon de contact

ne touche pas la bride pendant le fonctionnement. Le bras de bridage doit

être assez long pour que le boulon de contact ne touche pas la bride

supérieure lorsque le bras pivote vers le bas. Les problèmes de dégagement

sont les plus fréquents lorsque la position finale du bridage se trouve sur le

côté du vérin et lorsque le boulon de contact doit passer devant ou derrière

la bride supérieure lorsqu’il pivote vers le bas. Pour ces applications, il peut

être nécessaire d’utiliser le bras de la série CAL, plus long.

6.4 Branchements hydrauliques

Pour faire les branchements sur les orifices, poser des raccords prévus pour une pression de service de 350 bar.

NE PAS utiliser de produit d’étanchéité pour filetages. L’étanchéité est assurée par un joint torique posé sur le

bossage du raccord. Lubrifier le joint torique avant le montage.

Lors de la conception du circuit hydraulique, tenir compte des facteurs mentionnés dans la section

INFORMATIONS PRÉLIMINAIRES, page 23. Pour plus de détails sur les circuits hydrauliques, consulter le

catalogue d’automatisation de production Enerpac.

25

C

A

B

D

A

Longueur maximum du boulon de contact

Capacité du vérin Longueur maximum

2,2 kN 19,1

NOTE: La longueur maximum indiquée ici ne s'applique qu'aux

modèles à bride supérieure 2,2 kN.

Couples de serrage du boulon de bras de bridage

Capacité du vérin Couple du boulon lubrifié

2,2 kN 16,3 to 20,3 Nm

5,6 kN 32,5 to 39,3 Nm

Page 26

Orifices de vérin

Capacité du vérin Raccord BSPP 350 bar Capacité du vérin Raccord BSPP 350 bar

2,2 kN G 1/8 5,6 kN G 1/8

Identification d’orifice (Voir page 11.)

7.0 FONCTIONNEMENT

Les vérins pivotants tournent de 90° pendant la première partie de la course et continuent sans rotation pour

le bridage final. La course verticale descendante est la course de bridage du vérin. La force de bridage doit

être appliquée uniquement pendant ce déplacement vertical et non pas durant le mouvement de rotation.

ATTENTION

— Si la force de bridage est appliquée pendant la rotation, le piston risque subir des

dommages internes.

— Pour assurer une performance et sécurité d’utilisation maximum des vérins, veiller à ce que tous les

branchements, flexibles et raccords soient étanches et bien serrés.

— S’assurer que toutes les pièces sont prévues pour supporter les pressions de service. Des

composants de moindre résistance ne peuvent pas supporter les pressions élevées. Leur utilisation

entraînera des dommages matériels et corporels.

7.1 Bouchon à évent

Les vérins simple effet sont munis un bouchon à évent situé sur leur flanc gauche lorsque l’on fait face aux

orifices hydrauliques. Pour éviter l’entrée de limailles et de liquide de refroidissement, le bouchon à évent ne doit

pas être retiré. Si le bouchon à évent est continuellement noyé par le liquide de refroidissement, brancher un

tuyau sur l’orifice au moyen d’un raccord BSPP et l’acheminer jusqu’à un endroit non contaminé de la machine.

7.2 Pression et débit

La longueur (L) du bras de bridage détermine la

pression et le débit de fonctionnement.

Pour la longueur du bras de bridage, le réglage de

pression et le débit, voir Caractéristiques de

fonctionnement - Tableau de débits maximum,

page 23. Régler la pression de fonctionnement et

le débit suivant les limites établies par la longueur

du bras de bridage. Ne pas dépasser les limites

prescrites. Plus le bras est long, plus la force de

bridage et la pression de fonctionnement

maximale diminuent.

ATTENTION: Il est très important d’utiliser les réglages corrects de pression et de débit. Le

fonctionnement en dehors de ces limites endommagera le vérin pivotant. Les dégâts causés

par le dépassement des pressions et débits maximum permis NE SONT PAS COUVERTS PAR

LA GARANTIE.

8.0 ENTRETIEN

L’entretien est nécessaire en cas d’usure ou de fuites. De temps à autre, inspecter tous les composants en vue

d’éventuels problèmes exigeant l’entretien ou la réparation. Enerpac offre des kits de réparation prêts à

l’emploi. Des planches illustrées des pièces détachées sont disponibles avec schémas d’assemblage et

nomenclature. Contacter Enerpac.

IMPORTANT : Consulter la planche de pièces détachées pour les instructions d’assemblage et

désassemblage. La négligence du respect des instructions d’entretien et de réparation, par exemple l’usage

de couples de serrage incorrects, peut entraîner des problèmes de fonctionnement et/ou causer des blessures.

26

L

Page 27

9.0 DÉPANNAGE

Les informations suivantes ne sont fournies qu’à titre indicatif afin de déterminer l’existence d’un problème.

Pour les réparations, contacter le distributeur ou centre local Enerpac agréé.

27

Problème Cause possible Remède

1. Le vérin ne

bride/débride pas.

2. Le vérin ne sort

que partiellement.

3. Le vérin

bride/débride plus

lentement que la

normale.

4. Le vérin bride/

débride, mais ne

maintient pas la

pression.

5. Fuite d’huile au

vérin.

6. Le bras de bridage

n’effectue pas le

mouvement

pivotant.

A. Soupape de décharge de la

pompe ouverte

B. Pas d’huile dans le réservoir

C. Air emprisonné dans le

circuit.

D. Raccords mal serrés

E. Conduite hydraulique

obstruée

F. Ressort cassé dans le vérin

A. Niveau d’huile de la pompe

insuffisant

B. Piston grippé

A. Fuite de branchement

B. Conduite hydraulique

obstruée

C. Défaillance de la pompe

A. Joints endommagés

B. Fuite de branchement

C. Défaillance de la pompe

A. Joints endommagés

B. Piston usé ou endommagé

A. Bras de bridage desserré

B. Piston endommagé

A. Fermer la soupape de décharge de la pompe

B. Remplir le réservoir de la pompe

C. Purger l’air du circuit hydraulique

D. Resserrer les raccords

E. Vérifier les soupapes, raccords et tuyaux

F. Remplacer le ressort

A. Remplir le réservoir de la pompe

B. Remplacer les pièces endommagées — Voir la

planche des pièces détachées

A. Resserrer les raccords et branchements

B. Vérifier les soupapes, raccords et tuyaux

C. Voir la feuille d’instructions de la pompe

A. Remplacer les joints — Voir la planche des

pièces détachées

B. Resserrer les raccords et branchements

C. Voir la feuille d’instructions de la pompe

A. Remplacer les joints — Voir la planche des

pièces détachées

B. Remplacer les pièces endommagées —

Voir la planche des pièces détachées

A. Repositionner et serrer le bras de bridage —

Voir Fixation du bras de bridage

B. Remplacer les pièces endommagées —

Voir la planche des pièces détachées

SPÉCIFICATIONS POUR L’USINAGE DES BRAS DE BRIDAGE

Voir page 13. Voir Pression et débit, page 26, pour la mesure correcte de la longueur du bras. Pour déterminer

la force de bridage maximum du bras, voir Caractéristiques de fonctionnement - Tableau de débits maximum,

page 23.

Page 28

28

Las hojas de despiece para este producto estan

disponibles en la página web de Enerpac en la dirección

www.enerpac.com,o en su centro de Asistencia Técnica

ó punto de venta Enerpac mas cercano.

1.0 IMPORTANTES INSTRUCCIONES DE

RECEPCIÓN

Inspeccione visualmente todos los componentes

para verificar si hay daños de envío. Debido a que la

garantía no ampara daños por envío, si los hubiese,

infórmeselo inmediatamente a la empresa de

transportes, puesto que ésta es responsable de

todos los gastos de reparaciones o reemplazo que

resulten por daños de envío.

SEGURIDAD PRIMERO

2.0 ASPECTOS DE SEGURIDAD

Lea todas las instrucciones,

advertencias y precauciones.

Acate todas las precauciones de

seguridad para evitar lesiones personales o daños a la

propiedad durante la operación del sistema.

ENERPAC no puede ser responsable de daños o

lesiones que resulten de no usar el producto de forma

segura, falta de mantenimiento o aplicación incorrecta

del producto y/u operación del sistema. Comuníquese

con ENERPAC si tuviese dudas sobre las