Page 1

OPERATING MANUAL

Index:

L14004710 rev: preliminary F 03/07/14

1.0 SAFETY & GENERAL INFORMATION ............ 1

2.0 SAFETY PRECA UTIONS ................................. 1

3.0 SPECIFICATIONS ............................................ 2

4.0 INSTALLATION ................................................ 3

5.0 OPERATION ..................................................... 4

6.0 MAINTENANCE ................................................ 5

7.0 TROUBLESHOOTING GUIDE ......................... 5

8.0 ATTACHED DOCUMENTATION TABLE ......... 6

1.0 SAFETY & GENERAL INFORMATION

Read all instructions, warnings and

cautions carefully. Follow all safety

precautions to avoid personal injury or

property damage during s ystem operation.

Enerpac cannot be responsible for damage or injury

resulting from uns afe product us e, lack of m aintenance

or incorrect product and/or system operation. Contact

Enerpac when in doubt as to the safety precautions

and operations. If you have never been trained on

high-pressure h ydraulic safet y, consult your dist ributio n

or service center for a free Enerpac Hydraulic safety

course.

Failure to comply with the following cautions and

warnings could cause equi pment damage and personal

injury.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

damage to, or destruction of equipment or other

property.

A WARNING ind icates a potential danger that requires

correct procedures or practices to avoid personal

injury.

SFP SERIES

2.0 SAFETY PRECAUTIONS

WARNING: Stay clear of loads suppor ted by

hydraulics. A cylinder, wh en used as a load

lifting device, should ne ver be us e d as a loa d

holding device. After the load has been

raised or lowered, it must always be blocked

mechanically.

WARNING: use only rigid pieces to hold

loads. Carefully select steel or wood blocks

that are capable of supporting the load.

Never use a hydraul ic cylinder as a shim or spac er in

any lifting or pressing application.

WARNING: Wear proper personal protective

gear when operating hydraulic equ ipm ent .

DANGER: To avoid personal injury keep

hands and feet away from cylinder and

workpiece during operation.

WARNING: Do not exceed equipment

ratings. Never att empt to lift a lo ad weighing

more than the capacity of the cylinder.

Overloading causes equipment failure and possible

personal injury.

A DANGER is only used when your action or lack of

action may cause serious injury or even death.

1

CAUTION: Do not connect a jack or cylinder

to a pump with a higher pressure rating.

Never set the relief valve to a higher

pressure than the maximum rated pressure

of the pump. Higher settings may result in

equipment damage and/or personal injury.

WARNING: The system operatin g pressure

must not exceed the pressure rating of the

lowest rated component in the system.

Install pressure gauges in the system to monitor

operating pressure. It is your window to what is

happening in the system.

Page 2

CAUTION: Avoid damaging hydraulic hose.

Avoid sharp bends and kinks when routing

hydraulic hoses. Us ing a bent or kinked hose

will cause severe backpressure. Sharp

bends and kinks will internally damage the

hose leading to premature hose failure.

CAUTION: Do not drop heavy objects on

hose. A sharp impact may cause internal

damage to hose wire strands. Applying

pressure to a damaged hos e may cause it to

rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel couplers.

Use the carrying handle or other means of

safe transport.

CAUTION: Keep hydraulic equipment away

from flames and heat. Excessive heat will

soften packings and seals, resulting in fluid

leaks. Heat also weakens hose materials

and packings. For optim um performance do

not expose equipment to temperatures of

65°C [150°F] or higher. Protect hoses and

cylinders from weld spatter.

DANGER: Do not hand le pres surized h oses.

Escaping oil under pressure can penetrate

the skin, causing serious injury. If oil is

injected under the skin, see a doctor

immediately

WARNING: Only use hydra ulic cylinders in a

coupled system. Never use a cylinder with

unconnected couplers. If the cylinder

becomes extrem ely overloaded, com ponents

can fail catastrophically causing severe

personal injury.

WARNING: be sure setup is stable before

lifting load. Cylin ders should be placed on a

flat surface that can support the load. Where

applicable, use a cylinder base for added

stability. Do not weld or otherw ise modif y the

cylinder to attach a base or other support.

CAUTION: Avo id situations where loads ar e

not directly center ed on the c ylinder plunger.

Off-center loads produce considerab le strain

on cylinders and plungers. In addition, the

load may slip or fall, causing potentially

dangerous results.

CAUTION: D istribute the load evenly across

the entire saddle surface. Always use a

saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must

only be serviced by a qualified hydraulic

technician. For repair service, contact the

Authorized ENERPAC Service Center in

your area.

WARNING: In case of leakage contact

ENERPAC parts. Standard grade parts will

break causing personal injury and property

damage. ENERPAC parts are designed to fit

properly and withstand high loads.

WARNING: Do not use electric pum ps in an

explosive atmosphere. Adhere to all local

and national electrical codes. A qualified

electrician must do installation and

modification

WARNING: Start the pump with the valve in

the neutral position to prevent accidental

cylinder operation. Keep hands clear of

moving parts and pressurized hoses.

WARNING: These pumps have internal

factory adjusted rel ief valv es , which m ust not

be repaired or adjusted except by an

Authorized Enerpac Service Center.

CAUTION: To prevent damage to pump

electric motor, check specifications. Use of

incorrect power source will damage the

motor.

CAUTION: Check motor rotation dir ection to

prevent damage to hydraulic pump (See 4.0

installation)

PUMP MODEL

RESERVOIR CAPACITY (L) 40 150

OUTLETS (points) 2 4 6 2 4

FLOW (l/min) at 700 BAR 1,3 0,45 0,45 2,8 4,2 0,9 1,4 2,1

2

MOTOR POWER KW 5,5 7,5 11 5,5 7,5 11

WEIGHT (Kg) 240 488 526 475 488 526

3.0 SPECIFICATIONS

SFP213SW

SFP213MW

The system is composed by a powerpack which

commands 4 double acting cylinders.

There are different m odels of powerpack depe nding on

the number of outlets and flow. Check in the next table

the features of the powerpack concerning to the

equipment acquired

SFP404SW

SFP404MW

SFP604SW

SFP604MW

SFP228SW

SFP228MW

SFP242SW

SFP242MW

SFP409SW

SFP409MW

SFP414SW

SFP414MW

SFP421SW

SFP421MW

Page 3

4.0 INSTALLATION

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If

shipping damage is found, notify carrier at once. The

carrier is responsible for all repair and replacement

costs resulting from damage in shipment.

Install or position the pump to ensure that air flow

around the motor and pump is unobstruc ted. Keep the

motor clean to ensure maximum cooling during

operation.

1. The disconnection and line circuit protection to be

provided by customer. Line circuit protection to be

115% of motor full load c urrent at maxim um pressure

of application.

IMPORTANT: T he pumps with reservoir of 40 L. have

the motor rotation direction sense. When connect the

male plug to the e lectr ic main power, be s ur e tha t th ere

is in the cor rect phase. If not, change th e phase of th e

motor.

4.3 Hydraulic connections

IMPORTANT: Eliminate the presence of side load

forces when using hydraulic cylinders. Side load can

occur through:

1. An eccentric load on the plunger.

2. A horizontal load on a structure.

3. A structure and/or cylinder misalignment.

4. Non synchronized lifting actions.

5. Non stable cylinder base support.

Always use a flat, hard surface as a cylinder support

plate. Use a low friction mat erial on top of the saddle.

To reduce cylinder offset loading, optional CATGswivel saddles are available. Always use grease

underneath swivel saddles.

IMPORTANT: It is mandatory that the operator has a

full understanding of all ins tructions, saf ety regulations ,

cautions and warnings, be fore starting to operate any

of this high force tool equipment. In case of doubt,

contact Enerpac.

4.1 Transportation

WARNING: On double-acti ng cylinders be certain that

hoses are connected to BOTH couplers. Ne ver attempt

to pressurize a do uble-acting cylinder if only one hose

is connected.

IMPORTANT: T o dec om press ports prior t o con nectin g

hoses, move the manua l va lve s ev eral t imes in position

advance and retract with the motor switched off

(manual valves). For solenoid valves turn clockwise

completely the valve handl er in every valve as showed

in the picture (previous unlock the locknut) and leave

finally valves deactivated.

For transportation the frame has two forklift truck

pockets that make available for forklift lift, and four

hoisting certified eyes for lifting with cranes.

dwg 1

4.2 Electric connections

The pump is factory equipped with a 3

phase electrical plug for the given voltage,

altering the plug t ype shoul d only be done by

a qualified electrician, adhering to all applicable local

and national codes.

The plug supplied is set as follow: 3+N+PE 380V 16 A

Connect the hydraulic hoses using the following

diagram.

Port A to the advance side of the cylinder

Port B to the retract s i de of the cylinder (on l y for double

acting cylinders, for single acting cylinder leave it

disconnected).

Follow the next steps to correctly connect the hos es :

1. Keep cylinder con nected to a hydraulic system with

a fluid cleanliness level minimum of NAS 1638 Class 6.

2. Remove dust covers/rubber plugs from oil ports

3. Inspect all threads and fittings for signs of wear or

damage and replace as needed.

4. Clean all threads and fittings.

5. Make hydraulic connections for double-acting

cylinders using t wo hoses.

6. Fully hand-tighten all couplers. Loose coupler

connections will block the flow of oil between the pump

and the cylinder.

7. Check for leaks in system and have repaired by

qualified personnel.

3

Page 4

4.4 Flow level

Check the oil level of the pump prior to start-up, if

necessary add oil by rem oving the plug f rom the top of

the reservoir. The reservoir is full when the oil level

reaches the top of the sight glass.

IMPORTANT: Add oil only when all system

components are fully retracted, otherwise the system

will contain more oil than the reservoir can hold.

5.0 OPERATION

5.1 Manual valve Control

Some models have been design ed to be operated 2, 4

or 6 manual valves, one per output (depend on the

model type:

To move the cylinder moves the handler of the valve

according to the desired movement. The movement

advance or retract is described in a label on the valve.

1. Cylinder 4 selector: This selector actives the

movement of cylinder 4

2. Cylinder 3 selector: This selector actives the

movement of cylinder 3

3. Cylinder 2 selector: This selector actives the

movement of cylinder 2

4. Cylinder 1 selector: This selector actives the

movement of cylinder 1

5. Retracting plunger: Pushing this button the flow of

the port A goes to tank, therefor e in a general purpose

cylinder the plunger goes in.

6. Advancing plunger: Pushing this button the flow of

the port A goes to the c ylinder, therefore in a general

purpose cylinder the plunger goes out.

7. Emergency button: Push ing this button the machine

stops all the movements.

5.3 Electric panel description

On the electric panel (models with solenoid valves)

there are the necessary controls to switch on the

machine.

dwg 2

5.2 Pendant Control

Some machines (models with solenoid valves) have

been designed to be operated by a remote control

connected to the electric cabinet with a 10 m cable in

the connector Nr 6 (see dwg 3).

Through this device the operator can operate every

cylinder (2, 4 or 6 cylinders depending on model).

Therefore it is important to familiarize yourself with

every button. See the next explanation for it:

dwg 3

dwg 4

1. Main electrical switch

2. Power on led

3. System Alarm Light

4. Reset Pushbutton

5. Start/Stop Motor Pushbutton

6. Decompress Pushbutton

7. Pendant Control Connector

8. Power supply connector

5.4 Turning the powerpack on

5.4.1 Pumps with manual valves

To turn the motor on following the next steps:

1. Turn the main switch to the right on the electrical

cabinet

2. Press the motor starter button for 3 seconds.

4

Page 5

Now the machine is able to work. Use the manual

valves to move the cylinders as explained in the

paragraph 5.1.

5.4.2 Pumps with solenoid valves

2. Push decompress button in the electric cabinet

3. Push at the same time the button up in the pendant

The solenoid valve will move to leave free way to the

pressurized line.

To turn the motor on following the next steps:

1. Turn the main switch (Nr 1) to the right on the

electrical cabinet

2. Deactivate the emergency stop button (on the

pendant).

3. Press the reset button to reset the security system

after the emergency button have been activated (Nr 4)

4. Press the motor starter button for 3 seconds (Nr 3)

Now the machine is able to work with the pen dant. U se

the pendant to move the cylind ers as explained in the

paragraph 5.2.

5.5 Setting up the relief valve

The powerpack has been designed to set the

relief valves u p by the operator. T he maximum

pressure of the relief valve is between 10 and

700 bar. For this propose the op erator needs

the next tools:

1. Plain slot screwdriver (1 unit)

2. Spanner of 13 mm (1 unit)

3. Manometer 0-1000 bar (f or press ures up to 700 bar )

(4 units).

Manometers must be connected to the MP port (1/4”

NPT), in order to know the pressure in each line.

To set the relief valve up, follow the next steps:

1. Connect the output to one cylinder

2. Unblock the hexagonal nut of the relief valve.

3. Turn the bolt with the screwdriver totally (counter

clockwise)

4. Turn the bolt a q uart er t ur n in or der to op en the relief

valve (clockwise)

5. Press the motor starter button for 3 seconds (Nr 3)

6.0 MAINTENANCE

6.1 Check Oil Level

Check the oil level of the pump prior to start-up, and

add oil, if necessary, by removing the fill port cap.

Always be sure cylinders are fully retracted before

adding fluid to the reservoir.

6.2 Change Oil and Clean Reservoir

Enerpac HF oil is a crisp blu e color. Frequently check

oil condition for contam ination by comparing pump oil

to new Enerpac oil. As a genera l rule, completel y drain

and clean the reservoir every 250 hours, or more

frequently if used in dirty environments.

NOTE: This procedure requires that you remove the

pump from the res ervoir. Work on a clean bench and

dispose of used oil according to local codes.

1. Unscrew the bolts holding the cover plate to the

reservoir and lift the pum p unit out of the reser voir. Be

careful not to damage the filter screen.

2. Pour all oil out of the reservoir.

3. Thoroughly clean t he reser voir and reser voir m agnet

with a suitable cleaning agent.

4. Reassemble the pump and reservoir

5. Fill the reservoir with clean Enerpac hydraulic oil.

The reservoir is full when oil level is in middle of the

sight gauge

6.3 Changing the Filter Element

The f ilter element shou ld be replaced e very 250 hours,

or more frequently in dirty environments. The filter

manifold is equipped with a 25 psi (1,7 bar) b ypass to

prevent over pressure rupture if filter plugging occurs

and with a small gauge that shows the pressure when

the filter is dirty (see in the hydraulic diagrams num 8).

6. Extract the cylinder plunger up to final. (When the

plunger reaches the final of the stroke the pressure

gets up. See in the manometer the m aximum pressure

reached).

7. Turn the bolt (counter clockwise to decrease the

pressure, or clockwise to increase the pressure) with

the screw driver to reach the desired pressure.

8. Block the nut with the spanner to block the relief

valve.

5.6 Decompressing system

With the motor switched off:

1. Select cylinders to decompress in the pendant

5

7.0 TROUBLESHOOTING GUIDE

Only qualified hydrau lic technicians should ser vice the

pump or system components. A system failure may or

may not be the result of a pump malfunction. To

determine the cause of the problem, the complete

system must be included in any diagnostic procedure.

Refer to the troubleshooting chart for a list of typical

cylinder problems and possible causes. The

troubleshooting chart is not all-inclus ive, and should be

considered only as an aid to help diagnose the most

common problems. For repair service, contact your

local Authorized Enerpac Service Center.

Page 6

7.1 Troubleshooting chart

PROBLEM

POSSIBLE CAUS E

SOLUTION

Cylinder does not advance,

A. Oil level in pump reservoir is low.

A. Add oil to pump.

authorized Enerpac service center

Cylinder advances, but does not

A. Leaking oil connection.

A. Check that all connections are

authorized Enerpac service center.

Cylinder does not retract

A. Pump reservoir overfilled.

A. Drain oil level to full mark.

retract the cylinder

Wrong motor rotation direction

A. The phase of the motor is wrong

A change the phase of the motor

Alarm light switched on

A. Thermic protection is down.

A. Open the electric cabinet and

Have pump serviced by an

authorized Enerpac service center.

advances slowly or in spurts

hold pressure.

B. Release valve open.

C. Loose hydraulic coupler.

D. Air trapped in system.

E. Cylinder plunger binding

B. Leaking seals.

C. Internal leakage in pump.

B. Loose hydraulic coupler.

C. Air trapped in system.

D. Oil flow to cylinder blocked.

E. Hose internal diameter too narrow.

F. No load on a load return cylinder

B. Close pump release valve.

C. Check that all couplers are fully

tightened.

D. Remove air.

E. Check for damage to cylinder.

Have cylinder serviced by an

tightened.

B. Locate leak(s) and have

equipment serviced by an Enerpac

service center.

C. Have pump serviced by an

B. Check that coupler(s) are fully

tightened.

C. Remove air.

D. Check that coupler(s) are correctly

connected fully tighten ed a nd valving

is functioning properly.

E. Use a larger diameter hose.

F. CLL and CLS cylinders are load

return. Apply load force to completely

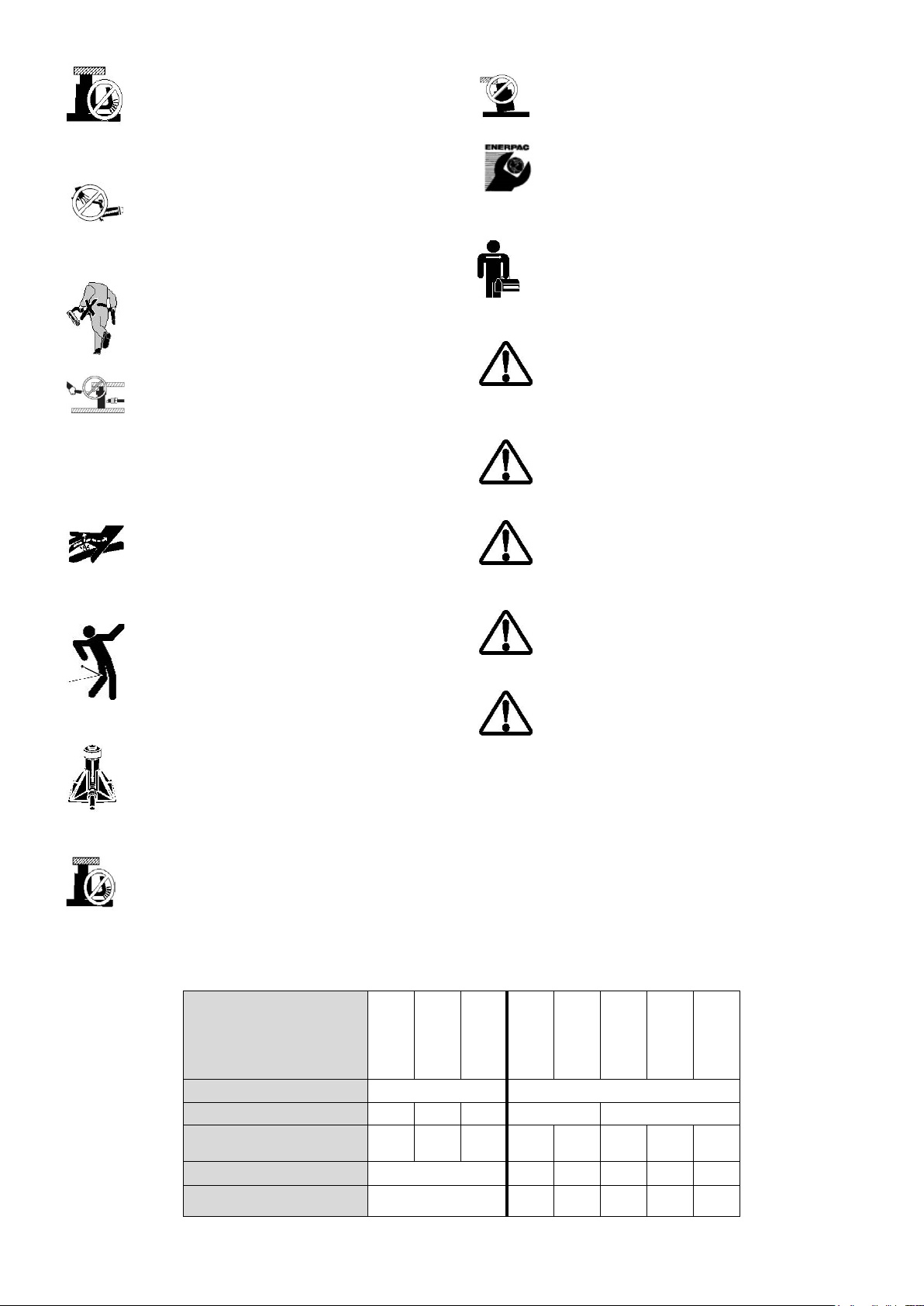

8.0 ATTACHED DO CUMENTATION TABLE

In this manual other documents hav e been attac hed which are necessary t o interpret this manual. I n th e nex t tab le

there is an index to facilitate finding these documents. Push on the paper icon

150 L RESERVOIR 40 L RESERVOIR

MANUAL VALVES SOLENOID VALVES MAN. VALVES SOLEN. VALVES

PUMP MODEL

ASSEMBLY DRAWING

HYDRAULIC SCHEME

SPARE PARTS

B. DC protection is down.

SFP228MW

SFP242MW

SFP409MW

SFP414MW

SFP421MW

switch up the thermic protection

B.

to show them.

SFP228SW

SFP242SW

SFP409SW

SFP414SW

SFP421SW

SFP213MW

SFP404MW

SFP213SW

SFP404SW

SFP604MW

SFP604SW

CE DECLARATION

6

Loading...

Loading...