Page 1

Repair Parts Sheets for this product are available from the Enerpac

web site at www.enerpac.com, or from your nearest Authorized

Enerpac Service Center or Enerpac Sales office.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage or injury

resulting from unsafe product use, lack of maintenance or incorrect

product and/or system operation. Contact Enerpac when in doubt

as to the safety precautions and operations. If you have never

been trained on high-pressure hydraulic safety, consult your

distribution or service center for a free Enerpac Hydraulic safety

course.

Failure to comply with the following cautions and warnings could

cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

WARNING: Wear proper personal protective gear

when operating hydraulic equipment.

WARNING: Stay clear of loads supported by

hydraulics. A cylinder, when used as a load lifting

device, should never be used as a load holding device.

After the load has been raised or lowered, it must always be

blocked mechanically.

WARNING: USE ONLY RIGID PIECES TO HOLD LOADS.

Carefully select steel or wood blocks that are capable

of supporting the load. Never use a hydraulic cylinder

as a shim or spacer in any lifting or pressing application.

DANGER: To avoid personal injury keep hands

and feet away from cylinder and workpiece

during operation.

WARNING: Do not exceed equipment ratings. Never

attempt to lift a load weighing more than the capacity

of the cylinder. Overloading causes equipment failure

and possible personal injury. The cylinders are designed for a

max. pressure of 700 bar [10,000 psi]. Do not connect a jack or

cylinder to a pump with a higher pressure rating.

Never set the relief valve to a higher pressure than the

maximum rated pressure of the pump. Higher settings

may result in equipment damage and/or personal injury.

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated

component in the system. Install pressure gauges in

the system to monitor operating pressure. It is your

window to what is happening in the system.

CAUTION: Avoid damaging hydraulic hose. Avoid

sharp bends and kinks when routing hydraulic hoses.

Using a bent or kinked hose will cause severe backpressure. Sharp bends and kinks will internally damage the

hose leading to premature hose failure.

Do not drop heavy objects on hose. A sharp impact

may cause internal damage to hose wire strands.

Applying pressure to a damaged hose may cause it

to rupture.

IMPORTANT: Do not lift hydraulic equipment by the

hoses or swivel couplers. Use the carrying handle or

other means of safe transport.

CAUTION: Keep hydraulic equipment away from

flames and heat. Excessive heat will soften packings

and seals, resulting in fluid leaks. Heat also weakens

hose materials and packings. For optimum performance do

not expose equipment to temperatures of 65°C [150°F] or

higher. Protect hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

®

®

®

Instruction Sheet

PT and DA Series

Mono-strand Stressing Jacks

L2944 Rev. B 10/10

Index:

English: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Español: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Portuguese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

POWERFUL SOLUTIONS. GLOBAL FORCE.

Page 2

2

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected

couplers. If the cylinder becomes extremely

overloaded, components can fail catastrophically causing

severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a flat

surface that can support the load. Where applicable,

use a cylinder base for added stability. Do not weld or

otherwise modify the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered

on the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially

dangerous results.

Distribute the load evenly across the entire saddle

surface. Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualified hydraulic technician. For repair

service, contact the Authorized ENERPAC Service

Center in your area. To protect your warranty, use only

ENERPAC oil.

WARNING: Immediately replace worn or damaged

parts by genuine ENERPAC parts. Standard grade

parts will break causing personal injury and property

damage. ENERPAC parts are designed to fit properly and

withstand high loads.

3.0 SAFETY INSTRUCTIONS SPECIFIC TO MONO-

STRAND STRESSING JACKS

1. DON'T stress any tendons which contain concrete slurry

inside the anchor cavity. Concrete in the anchor cavity will

prevent proper seating of the wedges. It is safer and less

expensive to clean out concrete slurry than to have to

detension, repair or replace tendons, or repair the jack.

2. DON'T use the jack when you can see that it does not seat

properly on the face of the anchor.

3. DON'T overstress tendons in order to achieve proper

elongation.

4. DON'T allow obstructions in the path of the jack extension.

5. DON'T continue stressing if you suspect that something is not

working properly.

6. DON'T detension with loose plates, spacing shims or piggy

backing.

7. DON'T stand immediate vicinity of the jack, or between the

jack and the pump during stressing or detensioning.

8. DON'T permit other workmen in the immediate area of the

jack or pump during stressing operations.

9. DON'T hammer or beat the jack or jack cylinders.

10. DON'T do anything if you are not sure - ask someone who

knows.

ALL OF THE INFORMATION LISTED IS MEANT TO BE A

GENERAL GUIDELINE FOR OPERATION OF POST TENSION

STRESSING EQUIPMENT. THE POST TENSIONING INSTITUTE

PUBLISHES A “FIELD PROCEDURES MANUAL FOR UNBONDED

SINGLE STRAND TENDONS” WHICH CAN BE OBTAINED BY

CALLING (602) 840-7540.

4.0 PRODUCT DESCRIPTION

4.1 PT Series

For slab-on-grade applications where high volume is required, the

PT Series are the jacks of choice, and are available in a wide

range of configurations to meet any customer requirements.

Spring-Loaded Wedge Seater

PTJ5S - 20 ton jack with spring-loaded wedge seater, 0.5" strand

PTJ6S - 30 ton jack with spring-loaded wedge seater, 0.6" strand

Spring pressure keeps the wedge setter against the wedges in the

anchor as the strand is being stressed. With simple, cost-effective

performance, this is the most popular jack configuration.

Power-Seating Wedge Seater

PTJ5P - 20 ton jack with power-seating wedge seater, 0.5” strand

PTJ6P - 30 ton jack with power-seating wedge seater, 0.6” strand

In this configuration, spring pressure is still used to keep the

wedges in place while stressing. After the desired stressing

®

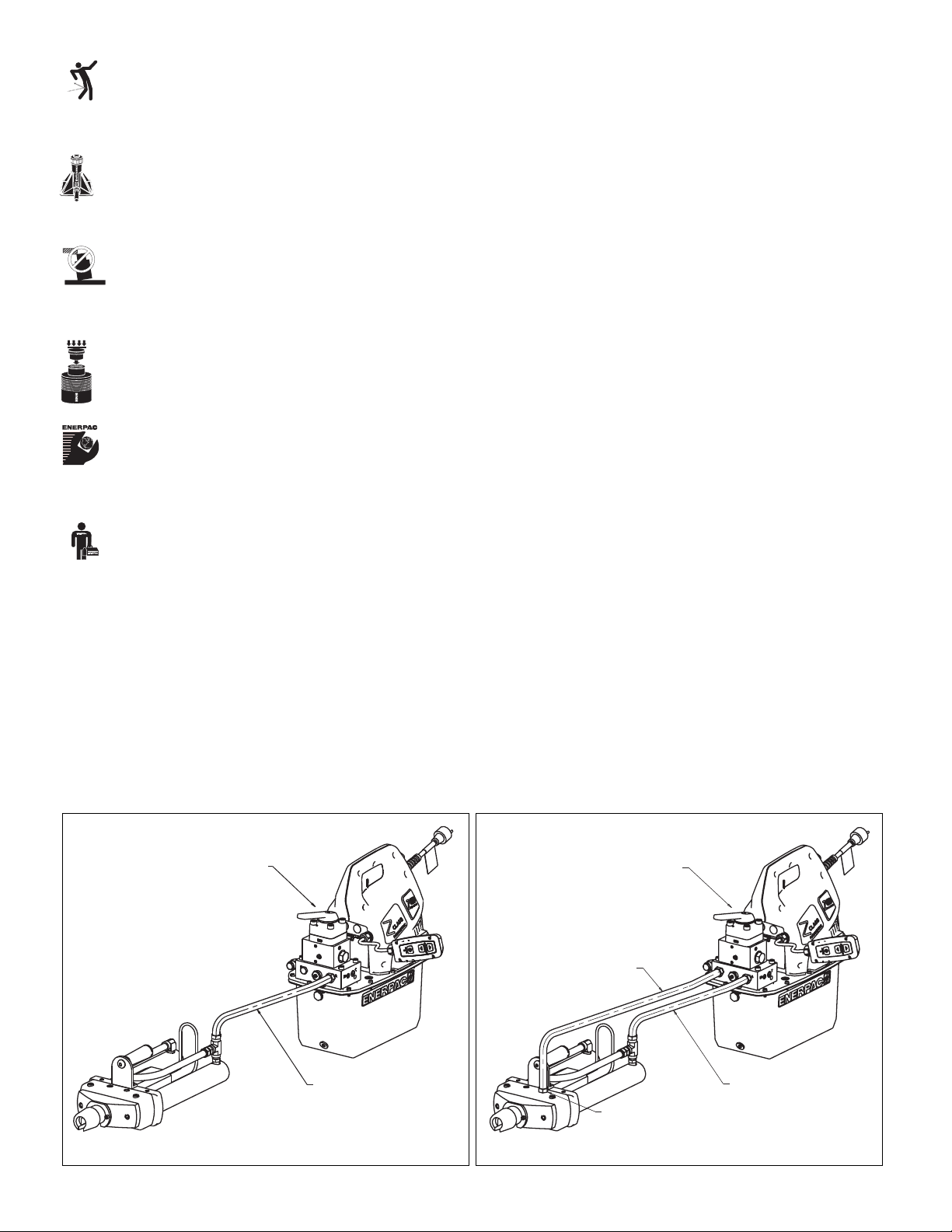

ZU4 electric pump with

VM43LPS post-tensioning valve.

ZU4 electric pump with VM43 control valve

or VM43LPS post-tensioning valve.

Pressure hose connects to "A"

port on control valve.

Power seating hose connects to

"B" port on control valve.

Pressure hose connects to

"A" port on control valve.

FZ-1055 adapter

PTJ5S / PTJ6S

PTJ5P / PTJ6P

Page 3

3

pressure is achieved, the valve on the pump is switched to the

retract position. The valve maintains pressure on the strand.

Engaging the pump causes the wedge setter to push forward and

seat the wedges; when a preset pressure is achieved, the jack will

then begin its return stroke.

Capacities

20 ton jacks -- stress strand up to .5" in diameter. For use with

smaller strand, jack grippers of different sizes are available.

30 ton jacks -- stress strand up to .6" in diameter. For use with

smaller strand, jack grippers of different sizes are available.

4.2 DA Series

The DA series of jacks are manufactured from a single piece of

hardened steel. The durable, lightweight, and compact design

make the DA jacks the tool of choice for elevated construction

projects.

Double-Acting System

5DA1 / 5DA1AL - 20 ton, double-acting jack with power-seating

wedge seater, 0.5" strand

6DA1 - 30 ton, double-acting jack with power-seating wedge seater,

0.6" strand

The DA series jacks are double-acting, meaning that the jacks

extend and retract using hydraulic power. Both jacks use power

wedge seaters to seat the wedges into the anchor. After the

desired stressing pressure is achieved, the valve on the pump is

switched to the retract position. The valve then maintains pressure

on the strand. Engaging the pump causes the wedge seater to

push forward and seat the wedges; when a preset pressure is

achieved, the jack will then begin its return stroke.

Capacities

5DA1 / 5DA1AL, 20 ton jack -- stresses strand up to .5" in

diameter. For use with smaller strand, jack grippers of different

sizes are available.

6DA1, 30 ton jack -- stresses strand up to .6" in diameter. For use

with smaller strand, jack grippers of different sizes are available.

5.0 OPERATION

1. Improper care and use of stressing equipment may result in

property damage, and/or personal injury.

Only trained, qualified personnel should be allowed in the

immediate vicinity of equipment during use.

Personnel doing the stressing and inspectors should remain

clear of the strand being stressed at all times. Never permit

anyone to stand in the immediate vicinity of the jack and the

pump while stressing.

2. Open the jack gripper by pulling back on the gripper handle or

cable.

3. Position the jack on the strand to be stressed and push

forward until the jack nose bears on the anchor. Never attempt

to adjust the position of the jack, either by striking or pushing

after any load has been applied. Remove the jack and

reposition if necessary.

4. Push the jack grippers forward to engage the strand making

sure that:

a. Jack grippers are parallel to avoid damage to themselves or

the strand.

b. Strand is in proper position within jack grippers.

5. Place the pump 4-way valve in stressing position.

6. Operate the pump by use of the pendant switch. (Use of the

pendant switch allows the operator to stand to the side of the

pump, out of harm's way, should the tendon or jack grippers

fail.)

7. On pumps equipped with a sequence valve or automatic

seating valve:

a. Start pump motor and run until proper pressure is indicated

on pressure gauge.

b. Switch 4way valve to retract position.

c. Pressure will remain on the pressure side of the jack, but

gauge pressure will drop to zero and start to rebuild

pressure.

d. When preset pressure is achieved (depending on the

equipment used), the seating plunger will be fully

pressurized, a popping noise will be heard, and the jack will

start to retract.

e. When the jack is fully retracted, stop the pump and switch

the 4-way valve to stressing position. The seating plunger

should fully retract. It is important to stop the pump and

switch the valve quickly to avoid excessive pressure build-

up in the jack after it has completely returned. This

excessive pressure build-up can cause premature failure

of the jack seals, hoses and fittings.

f. Slide the jack forward to release the jack grippers and

remove the jack from the strand.

Note: For jacks without power seating wedge seaters, after proper

gauge pressure is achieved, by switching the valve to the retract

position, the jack will begin to retract.

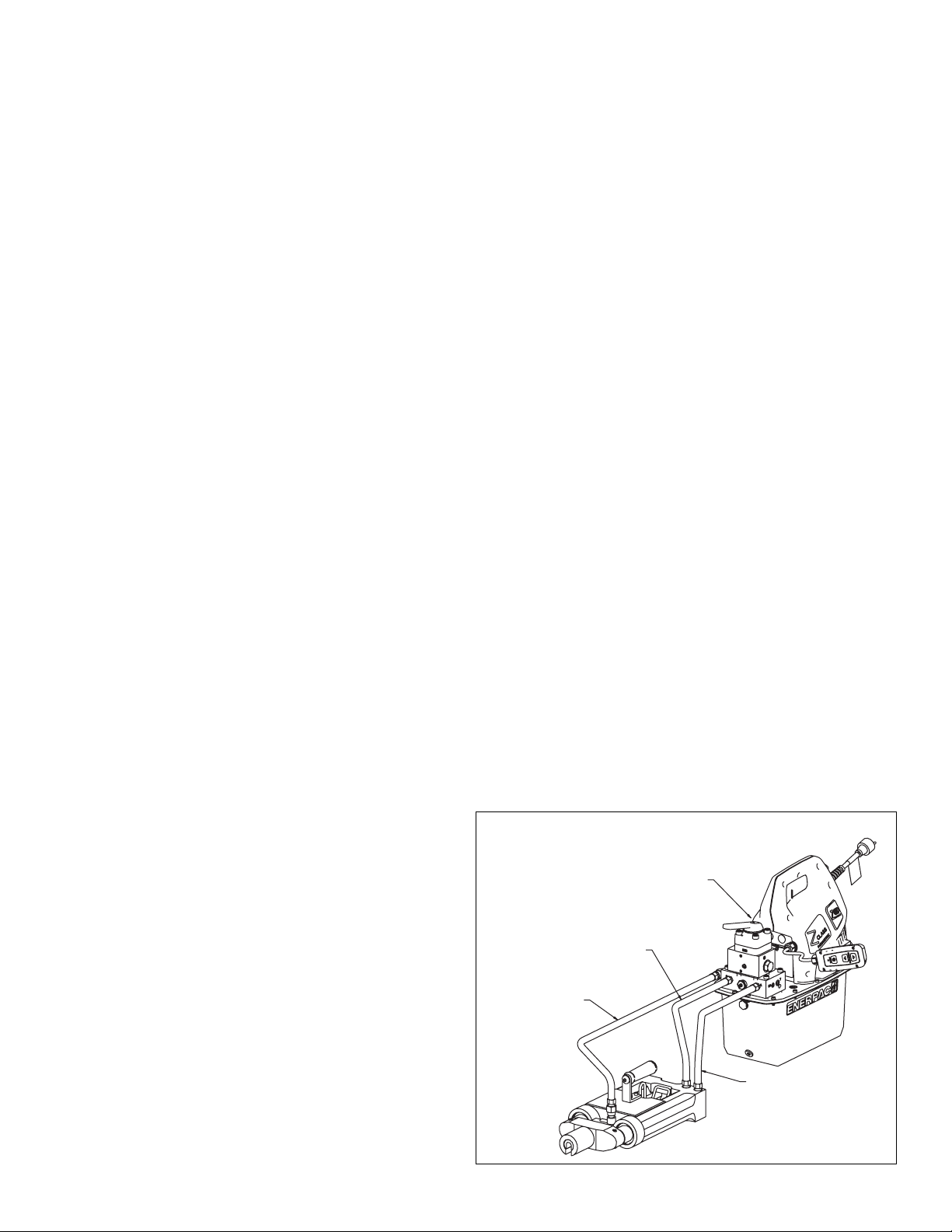

5DA1 / 5DA1AL / 6DA1

ZU4 electric pump with

VM43LPS post-tensioning valve

Pressure hose connects to "A"

port on control valve.

Retract hose connects to "B"

port on control valve

Pressure seat hose

connects to "GB" port

on control valve

Page 4

4

Las hojas de despiece para este producto estan disponibles en la

página web de Enerpac en la dirección www.enerpac.com,o en su

centro de Asistencia Técnica ó punto de venta Enerpac mas cercano.

1.0 IMPORTANTES INSTRUCCIONES DE RECEPCIÓN

Inspeccione visualmente todos los componentes para verificar si

hay daños de envío. Debido a que la garantía no ampara daños

por envío, si los hubiese, infórmeselo inmediatamente a la

empresa de transportes, puesto que ésta es responsable de todos

los gastos de reparaciones o reemplazo que resulten por daños de

envío.

SEGURIDAD PRIMERO

2.0 ASPECTOS DE SEGURIDAD

Lea todas las instrucciones, advertencias y

precauciones. Acate todas las precauciones de

seguridad para evitar lesiones personales o daños a

la propiedad durante la operación del sistema. ENERPAC no

puede ser responsable de daños o lesiones que resulten de no

usar el producto de forma segura, falta de mantenimiento o

aplicación incorrecta del producto y/u operación del sistema.

Comuníquese con ENERPAC si tuviese dudas sobre las

precauciones de seguridad o sobre las aplicaciones. Si nunca ha

sido capacitado en seguridad hidráulica de alta presión, consulte a

su distribuidor o centro de servicio para obtener un curso de

seguridad gratis denominado ENERPAC Hydraulic.

El no cumplir con las siguientes precauciones y advertencias

podría causar daños al equipo y lesiones personales.

Una PRECAUCIÓN se utiliza para indicar procedimientos y

prácticas de operación o mantenimiento correctos para evitar

daños o la destrucción de equipo u otra propiedad.

Una ADVERTENCIA indica un potencial peligro que requiere de

procedimientos o prácticas correctos para evitar lesiones

personales.

Un PELIGRO se utiliza sólo cuando su acción o falta de acción

podría causar lesiones graves o incluso la muerte.

ADVERTENCIA: Use el equipo de protección personal

adecuado cuando opere equipo hidráulico.

ADVERTENCIA: Manténgase alejado de las cargas

soportadas por sistemas hidráulicos. Cuando un

cilindro se utiliza como dispositivo para levantar

carga, nunca debería usarse como dispositivo para sostener

carga. Después de que la carga haya sido levantada o

descendida, debe bloquearse siempre en forma mecánica.

ADVERTENCIA: USE SÓLO PIEZAS RÍGIDAS PARA

SOSTENER CARGAS. Seleccione cuidadosamente

bloques de acero o de madera capaces de soportar la

carga. Nunca use un cilindro hidráulico como calza o

separador en aplicaciones de levantamiento o presión.

PELIGRO: Para evitar lesiones personales,

mantenga las manos y los pies alejados del

cilindro y pieza de trabajo durante la operación.

ADVERTENCIA: No sobrepase el valor nominal del

equipo. Nunca intente levantar una carga que pese

más de la capacidad del cilindro. Las sobrecargas

ocasionan fallas del equipo y posibles lesiones personales. Los

cilindros están diseñados para resistir una presión máxima de

700 bar. No conecte un gato o cilindro a una bomba cuyo valor

nominal de presión es mayor que el indicado.

Nunca fije la válvula de seguridad a una presión más

alta que el máximo valor nominal de presión de la

bomba. Los ajustes más altos pueden resultar en

daños al equipo y/o lesiones personales.

ADVERTENCIA: La presión de operación del sistema

no debe sobrepasar el valor nominal de presión del

componente con el valor nominal más bajo en el

sistema. Instale manómetros de presión en el sistema para

vigilar la presión de operación. Es su ventana a lo que está

sucediendo en el sistema.

PRECAUCIÓN: Evite dañar la manguera hidráulica.

Evite pliegues y curvas agudos al guiar las mangueras

hidráulicas. Usar una manguera con pliegues o curvas

puede causar severa contrapresión. Los pliegues y curvas

agudos causarán daños internos la manguera, lo que

ocasionará que ésta falle prematuramente.

No deje caer objetos pesados sobre la manguera. Un

impacto directo puede causar daños internos a las

hebras de alambre de la manguera. Aplicar presión a

una manguera dañada puede ocasionar que se quiebre.

IMPORTANTE: No levante el equipo hidráulico por

las mangueras o acopladores giratorios. Use el mango

de transporte u otros medios para transportarla con

seguridad.

PRECAUCIÓN: Mantenga el equipo hidráulico

alejado de las llamas y el calor. El calor en exceso

ablandará las juntas y sellos, lo que resultará en

fugas de líquidos. Asimismo, el calor debilita los materiales de

la manguera y juntas. Para lograr un rendimiento óptimo, no

exponga el equipo a temperaturas de 65°C [150°F]

o mayores. Proteja las mangueras y cilindros de salpicaduras

de soldadura.

®

®

®

Hoja de Instrucciones

GATOS DE TENSIÓN DE CABLE ÚNICO DE LA

SERIE PT Y DA

L2944 Rev. B 10/10

POWERFUL SOLUTIONS. GLOBAL FORCE.

Page 5

PELIGRO: No manipule mangueras bajo presión. El

aceite que escape bajo presión puede penetrar la piel

y causar lesiones graves. Si se inyecta aceite bajo la

piel, consulte a un médico inmediatamente.

ADVERTENCIA: Use cilindros hidráulicos únicamente

en sistemas acoplados. Nunca use un cilindro si los

acopladores no están conectados. Si el cilindro se

sobrecarga, los componentes pueden fallar calamitosamente,

lo que causaría lesiones personales graves.

ADVERTENCIA: Asegurese que el equipo sea antes de

levantar la carga. El cilindro debe colocarse sobre una

superficie plana capaz de soportar la carga. De ser

necesario, utilice una base de cilindro para mayor

estabilidad. No suelde ni modifique el cilindro en modo

alguno para fijarle una base u otro medio de soporte.

Evite las situaciones en las cuales las cargas no estén

directamente centradas sobre el émbolo del cilindro.

Las cargas descentradas producen un esfuerzo

considerable sobre los cilindros y los émbolos. Adeás, la

carga podria resbalar o caerse, creando situaciones

potencialmente peligrosas.

Distribuya la carga uniformemente sobre la superficie

total del asiento del cilindro. Siempre utilice un

asiento para proteger el émbolo cuando no se usen

accesorios roscados.

IMPORTANTE: Únicamente técnicos calificados en

sistemas hidráulicos habrán de prestarle servicio al

equipo hidráulico. Comuníquese con el Centro de

Servicio ENERPAC autorizado en su zona para prestarle

servicio de reparaciones. Use únicamente aceite ENERPAC a

fin de proteger su garantía.

ADVERTENCIA: Reemplace inmediatamente las

piezas gastadas o dañadas por piezas ENERPAC

genuinas. Las piezas de clasificación estándar se

romperán, lo que causará lesiones personales y daños a la

propiedad. Las piezas ENERPAC están diseñadas para encajar

debidamente y resistir altas cargas.

3.0 INSTRUCCIONES DE SEGURIDAD ESPECÍFICAS

DE LOS GATOS TENSADOS DE CABLE ÚNICO

1. NO tense ninguna palanca que contenga lechada de cemento

dentro de la cavidad de anclaje. El hormigón dentro de la

cavidad de anclaje impide el asentamiento adecuado de las

cuñas. Es más seguro y económico para limpiar la lechada de

cemento antes que tener que destensar, reparar o reemplazar

las palancas o reparar el gato.

2. NO utilice el gato cuando note que no se asienta

correctamente en el frente del anclaje.

3. NO sobrecargue las palancas para obtener la elongación

adecuada.

4. NO obstruya el trayecto de la extensión del gato.

5. NO continúe tensando si sospecha que algo no está

funcionando adecuadamente.

6. NO destense con placas sueltas, cuñas de separación o

lingotes de apoyo.

7. NO se pare cerca del gato ni entre el gato y la bomba durante

el proceso de tensado o destensado.

8. NO permita que otros trabajadores estén cerca del gato o de

la bomba durante las operaciones de tensado.

9. NO martillee ni golpee el gato o los cilindros del gato.

10. NO haga nada si no está seguro; pregúntele a alguien que

sepa.

TODA LA INFORMACIÓN INCLUIDA TIENE EL PROPÓSITO DE

SERVIR COMO GUÍA GENERAL PARA OPERAR EL EQUIPO DE

TENSIÓN Y POST TENSIÓN. EL POST-TENSIONING

INSTITUTE PUBLICA UN “MANUAL DE PROCEDIMIENTOS DE

ÁREA PARA PALANCAS SUELTAS DE CABLE ÚNICO” QUE SE

PUEDE OBTENER LLAMANDO AL (602) 840-7540.

4.0 DESCRIPCIÓN DEL PRODUCTO

4.1 Serie PT

Para aplicaciones de losa a nivel de tierra donde se requiere un

alto volumen, los gatos de la Serie PT son los elegidos. Están

disponibles en una amplia gama de configuraciones para

satisfacer cualquier necesidad de los clientes.

Asiento de cuña accionado por resortes

PTJ5S - gato de 20 toneladas con asiento de cuña accionado por

resortes, cable de 0.5 pulgadas

®

5

Bomba eléctrica ZU4 con válvula de

post tensión VM43LPS.

Bomba eléctrica ZU4 con válvula de control

VM43 o válvula de post tensión VM43LPS.

La manguera de presión se

conecta al puerto "A" en la

válvula de control.

La manguera de asiento de potencia

se conecta al puerto "B" en la

válvula de control.

La manguera de presión se

conecta al puerto "A" en la válvula

de control.

Adaptador FZ-1055

PTJ5S / PTJ6S

PTJ5P / PTJ6P

Page 6

PTJ6S - gato de 30 toneladas con asiento de cuña accionado por

resortes, cable de 0.6 pulgadas

La presión del resorte mantiene el regulador de la cuña contra las

cuñas en el anclaje mientras se tensa el cable. Por su funcionamiento

simple y económico, ésta es la configuración de gato más popular.

Asiento de cuña de potencia

PTJ5P - gato de 20 toneladas con asiento de cuña de potencia, cable

de 0.5 pulgadas

PTJ6P - gato de 30 toneladas con asiento de cuña de potencia, cable

de 0.6 pulgadas

En esta configuración, la presión del resorte todavía se utiliza para

mantener las cuñas en su lugar mientras se tensa. Una vez

alcanzada la presión de tensión deseada, la válvula en la bomba se

cambia a posición de retorno. La válvula mantiene la presión en el

cable. Al engranar la bomba, el regulador de la cuña empuja hacia

delante y asienta las cuñas. Cuando se alcanza la presión

preseleccionada, el gato comenzará entonces con su golpe de

retorno.

Capacidades

Gatos de 20 toneladas; tensan el cable hasta 0.5 pulgadas de

diámetro. Para utilizarlo con un cable más pequeño, están

disponibles agarraderas de distintos tamaños para gatos.

Gatos de 30 toneladas; tensan el cable hasta 0.6 pulgadas de

diámetro. Para utilizarlo con un cable más pequeño, están

disponibles agarraderas de distintos tamaños para gatos.

4.2 Serie DA

La serie DA de gatos se fabrica a partir de una sola pieza de acero

endurecido. El diseño durable, liviano y compacto hace que los

gatos DA sean la herramienta elegida para proyectos de

construcción elevada.

Sistema de doble acción

5DA1 / 5DA1AL - gato de 20 toneladas con asiento de cuña de

potencia, cable de 0.5 pulgadas

6DA1 - gato de 20 toneladas con asiento de cuña de potencia,

cable de 0.6 pulgadas

Los gatos de la serie DA tienen doble acción, lo que significa que

se extienden y se retraen utilizando energía hidráulica. Ambos

gatos utilizan asientos de cuña de potencia para asentar las cuñas

en el anclaje. Una vez alcanzada la presión de tensión deseada, la

válvula en la bomba se cambia a posición de retorno. Entonces, la

válvula mantiene la presión en el cable. Al engranar la bomba, el

asiento de la cuña empuja hacia adelante y asienta las cuñas.

Cuando se alcanza la presión preseleccionada, el gato comenzará

entonces con su golpe de retorno.

Capacidades

5DA1 / 5DA1AL, gatos de 20 toneladas; tensan el cable hasta 0.5

pulgadas de diámetro. Para utilizarlo con un cable más pequeño,

están disponibles agarraderas de distintos tamaños para gatos.

6DA1, gatos de 30 toneladas; tensan el cable hasta 0.6 pulgadas

de diámetro. Para utilizarlo con un cable más pequeño, están

disponibles agarraderas de distintos tamaños para gatos.

5.0 OPERACIÓN

1. El cuidado o uso indebido de los equipos de tensión pueden

resultar en daños a la propiedad y/o daños personales.

Sólo al personal capacitado y calificado se le puede permitir

estar cerca del equipo mientras éste se utiliza.

El personal que realiza la tensión y los inspectores deben

permanecer lejos del cable que se tense en todo momento.

Nunca permita que alguien esté parado cerca del gato y de la

bomba durante las operaciones de tensado.

2. Abra la agarradera del gato retirando el mango de la

agarradera o el cable.

3. Ubique el gato sobre el cable para que se tense y empuje

hacia adelante hasta que la nariz del gato se apoye sobre el

anclaje. Nunca intente ajustar la posición del gato, ya sea

golpeando o empujando, después de haber colocado alguna

carga. Saque el gato y vuelva a ubicarlo si es necesario.

4. Empuje las agarraderas del gato hacia adelante para

enganchar el cable asegurándose que:

a. Las agarraderas del gato estén paralelas para evitar

daños a las mismas o al cable,

b. El cable esté en la posición correcta dentro de las

agarraderas del gato.

5. Ubique la válvula de 4 vías de la bomba en posición de

tensado.

6. Opere la bomba utilizando el interruptor colgante. (El uso del

interruptor colgante permite que el operador se pare al lado

de la bomba, lejos del peligro, si la palanca o las agarraderas

del gato fallan.)

7. En bombas equipadas con una válvula de secuencia o una

válvula con asiento automática:

a. Encienda el motor de la bomba y déjelo encendido hasta

que se indique la presión adecuada en el medidor de

presión.

b. Cambie la válvula de 4 vías a posición de retorno.

c. La presión se mantendrá en el lado de la presión del

gato, pero la presión del medidor caerá a cero y

comenzará a restablecer la presión.

d. Cuando se alcanza la presión preseleccionada (según el

equipo que se utilice), el pistón de apoyo estará

completamente presurizado, se escuchará un ruido y el

gato comenzará a retraerse.

6

5DA1 / 5DA1AL / 6DA1

Bomba eléctrica ZU4 con válvula de

post tensión VM43LPS

La manguera de presión se

conecta al puerto "A" en la válvula

de control.

La manguera de retorno se conecta al

puerto "B" en la válvula de control

La manguera de

asiento de presión se

conecta al puerto "GB"

en la válvula de control

Page 7

7

e. Cuando el gato esté completamente retraído, pare la

bomba y cambie la válvula de 4 vías a posición de

tensado. El pistón de apoyo debe estar completamente

retraído. Es importante detener la bomba y cambiar la

válvula rápidamente para evitar el aumento excesivo de

presión en el gato después de que éste haya regresado

completamente. Este aumento excesivo de presión

puede provocar fallas prematuras en juntas, mangueras

y accesorios del gato,

f. Deslice el gato hacia adelante para liberar las

agarraderas y separar el gato del cable.

Nota: Para los gatos sin asientos de cuña de potencia, una vez

que se alcanza la presión adecuada del medidor, el gato

comenzará a retraerse el cambiar la válvula a posición de retorno.

Page 8

8

Folha de Instruções

MACACOS DE PROTENSÃO PARA MONO

CABOS – SÉRIES PT E DA

L2944 Rev. B 10/10

Folhas de Instrução para este produto estão disponíveis no Site de

Enerpac - www.enerpac.com, ou no Centro de Serviço Autorizado

mais próximo, ou com o Escritório de Vendas Enerpac.

1.0 INSTRUÇÕES IMPORTANTES NO RECEBIMENTO

Inspecione visualmente todos os componentes verificando se

houve avarias durante o transporte. Avarias no transporte não são

cobertas pela garantia. Caso haja avarias no transporte, avise o

transportador imediatamente. O transportador é responsável por

todos os custos de consertos e substituições decorrentes de

avarias ocorridas no transporte.

SEGURANÇA EM PRIMEIRO LUGAR

2.0 ASSUNTOS DE SEGURANÇA

Leia cuidadosamente todas as instruções,

advertências e avisos sobre precaução. Siga

todas as recomendações de segurança para

evitar lesões pessoais ou danos à propriedade durante a

operação do sistema. Enerpac não pode ser responsável por

danos ou lesões pessoais resultantes do uso indevido do produto,

falta de manutenção ou operação inadequada do produto e/ou

sistema. Entre em contato com Enerpac quando houver dúvidas

sobre as recomendações de segurança e operações. Se você

nunca recebeu treinamento em segurança na hidráulica de alta

pressão, consulte o seu distribuidor ou centro de serviço sobre um

curso de segurança hidráulica Enerpac.

Falhas no cumprimento das advertências e avisos de precaução

podem causar lesões pessoais e avarias ao equipamento.

PRECAUÇÃO é usada para indicar a operação correta ou os

procedimentos e métodos de manutenção para prevenir o dano,

a destruição do equipamento ou outras propriedades.

ADVERTÊNCIA indica um perigo potencial que exige

procedimentos ou métodos corretivos para evitar lesões pessoais.

PERIGO é usado somente quando a ação ou a falta da mesma

podem causar lesões sérias ou mesmo a morte.

ADVERTÊNCIA: Use equipamentos individuais de

proteção quando acionar equipamentos hidráulicos .

ADVERTÊNCIA: Mantenha distância de cargas

apoiadas por cilindros hidráulicos. Um cilindro,

quando utilizado como dispositivo de levantamento,

jamais deve ser usado como dispositivo de sustentação de

carga. Depois de haver sido levantada ou baixada, a carga

deve sempre ser bloqueada mecanicamente

ADVERTÊNCIA: USE SOMENTE PEÇAS RÍGIDAS PARA

APOIAR AS CARGAS. Selecione cuidadosamente

blocos de madeira ou ferro que sejam capazes de

sustentar a carga. Nunca use um cilindro hidráulico como um

calço ou espaçador em qualquer aplicação de levantamento ou

prensagem.

PERIGO: Para evitar lesões pessoais mantenha

mãos e pés longe do cilindro e da área de

trabalho durante a operação.

ADVERTÊNCIA: Não exceda a capacidade do

equipamento. Nunca tente levantar uma carga mais

pesada que a capacidade do cilindro. Excesso de carga

pode causar falhas no equipamento e possíveis lesões pessoais.

Os cilindros são projetados para uma pressão máxima de 700

bar [10.000 psi]. Não faça a ligação entre um macaco ou um

cilindro com uma bomba com capacidade maior de pressão.

Nunca ajuste uma válvula de alívio com pressão

maior que a capacidade de pressão máxima da

bomba. Ajustes maiores podem resultar em danos ao

equipamento e/ou lesões pessoais.

ADVERTÊNCIA: A pressão de operação do sistema não

deve exceder a capacidade de pressão do componente

de menor capacidade no sistema. Instale manômetros

de pressão no sistema para monitorar a pressão de operação.

É a sua janela para o que está acontecendo no sistema.

PRECAUÇÃO: Evite danificar mangueiras hidráulicas.

Evite curvas ou dobras pronunciadas quando

direcionar as mangueiras hidráulicas. O uso de uma

mangueira curvada ou dobrada causará aumento na pressão

de retorno. Curvas ou dobras pronunciadas danificarão a

mangueira internamente, levando a um desgaste prematuro.

Não derrube objetos pesados na mangueira. Um

forte impacto pode causar danos à trama interna de

aço da mangueira. A aplicação de pressão em uma

mangueira danificada pode causar a sua ruptura.

IMPORTANTE: Não levante o equipamento hidráulico

pela mangueira ou pelos engates. Use manoplas ou

outros meios mais seguros para o transporte.

PRECAUÇÃO: Mantenha o equipamento hidráulico

longe do calor e das chamas. O calor excessivo

amolece vedações e selos, resultando em vazamento

de fluídos. O calor também enfraquece o material das

mangueiras e das juntas. Para um desempenho otimizado não

exponha o equipamento a temperatura maiores que 65 °C

[150 °F]. Proteja mangueiras e cilindros dos respingos de solda.

®

®

®

POWERFUL SOLUTIONS. GLOBAL FORCE.

Page 9

9

PERIGO: Não manuseie mangueiras pressurizadas. O

escape do óleo sob pressão pode penetrar na pele,

causando lesões sérias. Se o óleo penetrar na pele,

procure um médico imediatamente.

ADVERTÊNCIA: Use somente cilindros hidráulicos

num sistema acoplado. Nunca use um cilindro com

engates não conectados. Caso o cilindro se torne

extremamente sobrecarregado, os componentes podem

falhar catastroficamente, causando severas lesões pessoais.

ADVERTÊNCIA: ESTEJA CERTO QUE A MONTAGEM

É ESTÁVEL ANTES DE LEVANTAR A CARGA. Os

cilindros devem ser colocados em superfícies planas

que podem apoiar a carga. Quando aplicável, use uma base

de cilindro Enerpac para aumentar a estabilidade. Não faça

soldas ou, de qualquer forma, modifique o cilindro para

acrescentar uma base ou outro apoio.

Evite situações em que as cargas não estão centradas

na haste do cilindro. Cargas fora de centro podem

causar deformações consideráveis nas hastes e nos

cilindros. Além disto, a carga pode escorregar ou cair,

causando resultados potencialmente perigosos.

Distribua a carga uniformemente em toda a superfície

do assento. Use sempre um assento para proteger a

haste.

IMPORTANTE: Somente técnicos em hidráulica,

devidamente qualificados, devem fazer a manutenção

de equipamentos hidráulicos. Para serviços de

manutenção, entre em contato com o Centro de Serviço

Autorizado Enerpac em sua área. Para proteger sua garantia,

use somente óleo Enerpac.

ADVERTÊNCIA: Substitua imediatamente peças

gastas ou danificadas por peças genuínas Enerpac.

Peças não genuínas podem quebrar, causando lesões

pessoais ou danos à propriedade. As peças Enerpac são

projetadas para se encaixar adequadamente e sustentar

cargas pesadas.

3.0 INSTRUÇÕES ESPECÍFICAS DE SEGURANÇA

PARA OS MACACOS DE PROTENSÃO PARA

MONO CABOS

1. NÃO tensione qualquer cordoalha quando houver massa de

concreto dentro da cavidade da âncora. Concreto na

cavidade da âncora não permitirá o assentamento correto das

cunhas. É mais seguro e mais barato limpar a massa de

concreto do que aliviar a tensão, reparar ou substituir os

tendões, ou consertar o macaco.

2. NÃO utilize o macaco quando você pode ver que ele não está

assentado adequadamente na superfície da âncora.

3. NÃO coloque tensão anormal na cordoalha, para conseguir

alongamentos peculiares.

4. NÃO permita obstruções entre o macaco e a cordoalha.

5. NÃO continue o tensionamento, caso suspeite que alguma

coisa não está funcionando corretamente.

6. NÃO tire a tensão com placas soltas, calços espaçadores ou

outros suportes.

7. NÃO fique nas imediações do macaco, ou entre o macaco e

a bomba durante o tensionamento ou alívio da tensão.

8. NÃO permita outros trabalhadores ao redor do macaco ou da

bomba durante as operações de protensão.

9. NÃO martele ou bata no macaco ou nos cilindros.

10. NÃO faça qualquer coisa, caso você não tenha certeza –

pergunte a quem sabe.

TODAS AS INFORMAÇÕES AQUÍ RELACIONADAS DEVEM

SER CONSIDERADAS COMO UMA ORIENTAÇÃO GERAL

PARA AS OPERAÇÕES COM O EQUIPAMENTO DE PÓS

TENSIONAMENTO. O “INSTITUTO DE PÓS TENSIONAMENTO”

(POST TENSIONING INSTITUTE) PUBLICA UM “MANUAL DE

PROCEDIMENTOS NO CAMPO PARA TENDÕES DE MONO

CABOS” (FIELD PROCEDURES MANUAL FOR UNBONDED

SINGLE STRAND TENDONS) QUE PODE SER OBTIDO

ATRAVÉS DO TELEFONE (602) 840-7540.

®

Bomba elétrica ZU4 com válvula de pós-

tensionamento VM43LPS.

Bomba elétrica ZU4 com válvula de

controle VM43 ou válvula de

pós-tensionamento VM43LPS.

Mangueira de pressão é conectada

na saída “A” da válvula de controle.

Mangueira para cravação

hidráulica é conectada na saída

“B” da válvula de controle.

Mangueira de pressão é conectada

na saída "A" da válvula de controle.

Adaptador FZ-1055

PTJ5S / PTJ6S

PTJ5P / PTJ6P

Page 10

4.0 DESCRIÇÃO DO PRODUTO

4.1 Série PT

Para aplicações de corte em placas de cimento, quando um

volume alto é necessário, a Série PT é a escolha de macacos e

está disponível em grande variedade de configurações para

atender as necessidades de qualquer cliente.

Cunha com molas para cravação

PTJ5S - Macaco de 20 ton. contendo cunha com molas para

cravação, para cabos de 12,7 mm.

PTJ6S - Macaco de 30 ton. contendo cunha com molas para

cravação, para cabos de 15,2 mm.

A pressão da mola mantém a cunha assentada contra os calços na

âncora, enquanto os cabos estão sendo tensionados. Com um

desempenho barato e simples, esta é a configuração mais popular de

macaco.

Cunha hidráulica para cravação

PTJ5P - Macaco de 20 ton. contendo cunha hidráulica para

cravação, para cabos de 12,7 mm.

PTJ6P - Macaco de 30 ton. contendo cunha hidráulica para

cravação, para cabos de 15,2 mm.

Nesta configuração, a pressão da mola ainda é usada para manter

as cunhas em posição, durante o tensionamento. Depois que a

pressão de tensionamento é atingida, a válvula da bomba deve ser

girada para a posição de retorno. A válvula mantém a pressão na

cordoalha. O acionamento da bomba faz com que a cunha para

cravação empurre mais e assente as cunhas; quando a pressão préestabelecida é atingida, o retorno do curso do macaco terá início.

Capacidades

Macacos de 20 ton. – para tensionamento de cordoalha de até

12,7 mm. de diâmetro. Para utilização com cordoalhas de menor

diâmetro, grampos de diferentes tamanhos estão disponíveis.

Macacos de 30 ton. – para tensionamento de cordoalha de até

15,2 mm. de diâmetro. Para utilização com cordoalhas de menor

diâmetro, grampos de diferentes tamanhos estão disponíveis.

4.2 Série DA

Os macacos da série DA são fabricados a partir de uma única

peça de aço de alta resistência. O projeto compacto, durável e

leve torna os macacos DA a ferramenta escolhida para numerosos

projetos de construção.

Sistema de Dupla Ação

5DA1 / 5DA1AL - Macaco de dupla ação de 20 ton., contendo

cunha hidráulica para cravação, para cabos de 12,7 mm.

6DA1 - Macaco de dupla ação de 30 ton., contendo cunha

hidráulica para cravação, para cabos de 15,2 mm.

Os macacos da série DA são de dupla ação, isto é, avançam e

retornam com o uso da força hidráulica. Ambos os macacos

utilizam cunha hidráulica para cravação para assentar os calços na

âncora. Depois que a pressão de tensionamento é atingida, a

válvula da bomba deve ser girada para a posição de retorno. A

válvula mantém a pressão na cordoalha. O acionamento da bomba

faz com que a cunha de cravação fique mais encaixada e assente

as cunhas; quando a pressão pré-estabelecida é atingida, o retorno

do curso do macaco terá início.

Capacidades

5DA1 / 5DA1AL, Macaco de 20 ton. -- tensionamento para

cordoalha de até 12,7 mm. de diâmetro. Para utilização com

cordoalhas de menor diâmetro, grampos de diferentes tamanhos

estão disponíveis.

6DA1, Macaco de 30 ton. -- tensionamento para cordoalha de até

15,2 mm. de diâmetro. Para utilização com cordoalhas de menor

diâmetro, grampos de diferentes tamanhos estão disponíveis.

5.0 OPERAÇÃO

O uso inadequado ou descuido com o equipamento de protensão

podem resultar em danos à propriedade e/ou lesões pessoais.

1. Somente pessoas treinadas e qualificadas têm permissão

para permanecer nas imediações do equipamento, durante

sua utilização.

Durante todo o tempo, o pessoal que trabalha com o

equipamento e os inspetores devem permanecer longe da

cordoalha que está sendo tensionada. Nunca permita que

alguém fique nas imediações do macaco e da bomba durante

a protensão.

2. Abra o grampo do macaco, puxando para fora o grampo de

aperto ou o cabo.

3. Posicione o macaco na cordoalha a ser tensionada e empurre

para fora até que o bico do macaco assente na âncora.

Jamais tente ajustar a posição do macaco, tanto por

pancadas, como empurrando, depois que qualquer tipo de

carga tenha sido aplicada. Remova o macaco e re-posicione,

caso necessário.

4. Empurre para frente os grampos do macaco para travar a

cordoalha, certificando-se de que:

a. Os grampos do macaco estão paralelos, evitando danos

aos mesmos ou à cordoalha.

b. A cordoalha está em posição apropriada dentro dos

grampos do macaco.

5. Coloque a válvula de 4 vias da bomba na posição de

protensão.

6. Acione a bomba através do interruptor do controle remoto. (O

uso do interruptor do controle permite que o operador

permaneça ao lado da bomba, fora do alcance de possíveis

danos, caso a cordoalha ou os grampos do macaco venham

a falhar.)

7. Em bombas equipadas com válvula seqüencial ou válvula

automática de retorno:

a. Acione o motor da bomba e deixe-o funcionar até que a

pressão adequada seja indicada no manômetro de

pressão.

b. A válvula de 4 vias deve ser girada para a posição de

retorno.

c. A pressão será mantida no macaco, mas no manômetro,

esta cairá para zero, iniciando-se um novo processo de

pressurização.

d. Quando a pressão pré-estabelecida é alcançada

(dependendo do equipamento utilizado), a haste de

cravação estará totalmente pressurizada, um “estalo”

será ouvido e o retorno do macaco terá início.

e. Quando o retorno completo do macaco estiver completo,

interrompa a bomba e gire a válvula de 4 vias para a

posição de tensionamento. A haste de cravação deve

estar totalmente retraída. É importante que, rapidamente,

a bomba seja interrompida e a posição da válvula seja

10

Page 11

modificada, para evitar a criação de excesso de pressão

dentro do macaco, depois de seu completo retorno. Este

excesso de pressão pode causar uma falha prematura

nas vedações do macaco, nas conexões e nas

mangueiras.

f. Faça com que o macaco deslize para frente, a fim de

liberar os grampos e soltar a cordoalha.

Nota: Para os macacos sem a cunha hidráulica para cravação,

depois que a pressão apropriada for atingida, com a modificação

da posição da válvula para retorno, o retorno do curso do macaco

terá início.

11

5DA1 / 5DA1AL / 6DA1

Bomba elétrica ZU4 com válvula para

pós-tensionamento VM43LPS.

Mangueira de pressão é

conectada na saída "A" da

válvula de controle.

Mangueira de retorno é conectada na

saída "B" da válvula de controle.

Mangueira de pressão para

cravação é conectada na

saída "GB" da válvula de

controle.

Page 12

Africa

ENERPAC Middle East FZE

Office 423, JAFZA 15

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Australia, New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

Tel: +61 297 438 988

Fax: +61 297 438 648

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

Tel: +55 11 5687 2211

Fax: +55 11 5686 5583

Toll Free in Brazil:

Tel: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

Tel: +1 905 564 5749

Fax: +1 905 564 0305

Toll Free:

Tel: +1 800 268 4987

Fax: +1 800 461 2456

Technical Inquiries:

techservices@enerpac.com

China

Actuant Industries Co. Ltd.

No. 6 Nanjing Road

Taicang Economic Dep Zone

Jiangsu, China

Tel: +86 0512 5328 7529

+86 0512 5328 7500 7529

Fax: +86 0512 5335 9690

Actuant China Ltd. (Peking)

709B Diyang Building

Xin No. 2

Dong San Huan North Rd.

Beijing City

100028 China

Tel: +86 10 845 36166

Fax: +86 10 845 36220

France, Switzerland

francophone

ACTUANT - ENERPAC

France S.A., ZA de Courtaboeuf

32, avenue de la Baltique

91140 Villebon / Yvettte

France

Tel: +33 1 60 13 68 68

Fax: +33 1 69 20 37 50

Germany, Austria, Switzerland,

Greece, Baltic States, Central

and Eastern Europe

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse13

D-40549 Düsseldorf

Germany

Tel: +49 211 471 490

Fax: +49 211 471 49 28

India

ENERPAC Hydraulics

(India) Pvt. Ltd.

No. 1A,

Peenya Industrial Area,

llnd Phase

Bangalore, 560 058 India

Tel: +91 80 40 792 777

Fax: +91 80 40 792 792

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

Tel: +39 02 4861 111

Fax: +39 02 4860 1288

Japan

Applied Power Japan LTD KK

Besshochou 85-7

Kita-ku,

Saitama-shi 331-0821

Japan

Tel: +81 48 662 4911

Fax: +81 48 662 4955

Middle East, Turkey and

Caspian Sea

ENERPAC Middle East FZE

Office 423, JAFZA 15

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Russia and CIS

(excl. Caspian Sea Countries)

Actuant LLC

Admiral Makarov Street 8

125212 Moscow, Russia

Tel: +7-495-9809091

Fax: +7-495-9809092

Sweden, Denmark, Norway,

Finland and Iceland

ENERPAC Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

Tel: +46 31 7990281

Fax: +46 31 7990010

scandinavianinquiries@enerpac.com

Singapore

Actuant Asia Pte. Ltd.

37C, Benoi Road Pioneer Lot,

Singapore 627796

Tel: +65 68 63 0611

Fax: +65 64 84 5669

Toll Free: +1800 363 7722

Technical Inquiries:

tech.service-sg@enerpac.com

South Korea

Actuant Korea Ltd.

3Ba 717,

Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

Tel: +82 31 434 4506

Fax: +82 31 434 4507

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C

& D

Pol. Ind. Los Frailes

28814 DAGANZO DE ARRIBA

(Madrid)

Spain

Tel: +34 91 884 86 06

Fax: +34 91 884 86 11

Sweden, Denmark, Norway,

Finland and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

Tel: +46 (0) 31 7990281

Fax: +46 (0) 31 7990010

Inquiries:

Scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg

ENERPAC B.V.

Galvanistraat 115, 6716 AE Ede

P.O. Box 8097, 6710 AB Ede

The Netherlands

Tel: +31 318 535 800

Fax: +31 318 525 613

+31 318 535 848

beneluxinquiries@enerpac.com

Technical Inquiries Europe:

techsupport.europe@enerpac.com

United Kingdom, Ireland

Enerpac Ltd

Bentley Road South

Darlaston, West Midlands

WS10 8LQ, United Kingdom

Tel: +44 (0)121 50 50 787

Fax: +44 (0)121 50 50 799

USA, Latin America

and Caribbean

ENERPAC

P.O. Box 3241

6100 N. Baker Road

Milwaukee, WI 53209 USA

Tel: +1 262 781 6600

Fax: +1 262 783 9562

User inquiries:

+1 800 433 2766

Inquiries/orders:

+1 800 558 0530

Technical Inquiries:

techservices@enerpac.com

ENERPAC

704 W. Simonds

Dallas, TX 75159 USA

Tel: +1 972 287 2390

Fax: +1 972 287 4469

09/30/09

Enerpac Worldwide Locations

✦ e-mail: info@enerpac.com ✦ internet: www.enerpac.com

All Enerpac products are guaranteed

against defects in workmanship and

materials for as long as you own them.

For your nearest authorized Enerpac

Service Center, visit us at

www.enerpac.com

Loading...

Loading...