Page 1

SAFETY FIRST

L1680

Rev. C

02/98

®

A UNIT OF APPLIED POWER INC.

Instruction Sheet

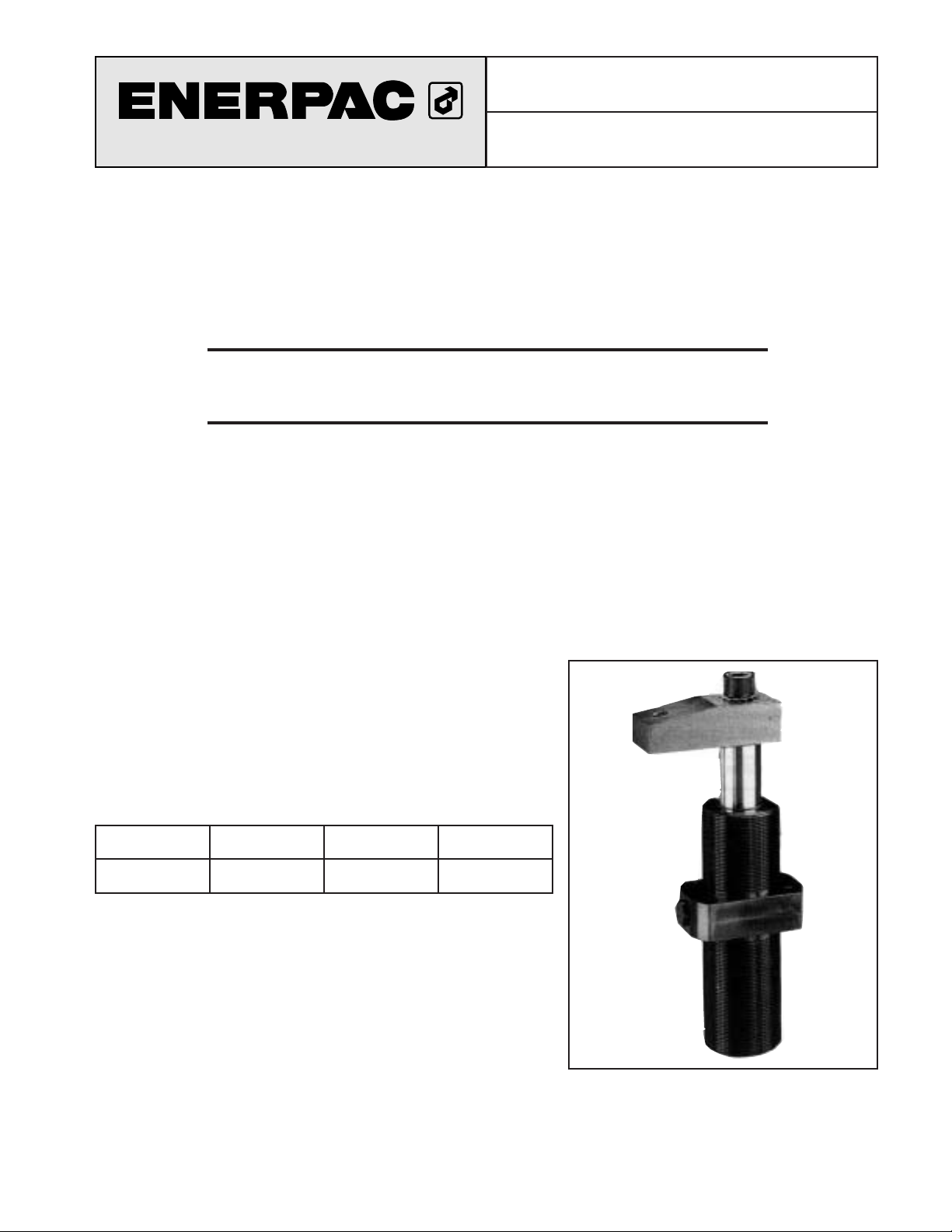

SC-1 Swing Clamps

IMPORTANT RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage. If any shipping damage is found, notify carrier at once. Shipping damage is NOT covered

by warranty. The carrier is responsible for all repair or replacement cost resulting from damage in shipment.

Carefully plan your system by selecting components designed to perform the intended operation and which will adequately perform with existing equipment. Always check the product limitations regarding pressure ranges, load capacities and set-up requirements. The system operating pressure must not exceed the pressure rating of the lowest rated component in the system. Read all CAUTIONS, WARNINGS and INSTRUCTIONS included with, or attached to,

each product. Follow all safety precautions to avoid personal injury or property damage during

the system operation. ENERPAC CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY

RESULTING FROM UNSAFE USE OF PRODUCT, LACK OF MAINTENANCE, OR INCORRECT PRODUCT AND SYSTEM APPLICATION. Contact ENERPAC when in doubt as to

safety precautions, or applications.

Description

Enerpac SC-1 swing clamps can be set for left swing,

right swing, or straight pull operations. Swing cylinders

rotate 90° during the first portion of the stroke, continuing without rotation for the final clamping stroke.

Swing cylinders can be operated as either single acting or double acting. SC-1 cylinders come with a

retract spring for single acting operation. A standard

clamp arm is supplied with cylinder.

Specifications

■ Operating Pressure: 3000 PSI maximum

■ Maximum Frequency: 40 Cycles/Minute

■ Swing Arc: 90°

■ Seal Material: Buna-N/Polyurethane/Molythane

STROKE Initial Clamping Total

1.00” 0.50 1.50”

Figure 1: SC-1 Swing Clamps

Page 2

2

Accessories

■ Cylinder brackets

■ Buttons and toggle parts

■ SC1CN locknut

■ DCA-2 double clamp arm

Installation

Clamp Arms

Clamp arms supplied with cylinders can be

used to full operating pressure of cylinders,

and will produce maximum clamping force.

Longer or modified clamp arms require lowering the maximum operation pressure so

that less clamping force is produced.

Tightening Clamp Arm to Cylinder

1. Back out the ball bearing plug located on

the side of the cylinder opposite of the

advance port. This will help to prevent possible internal damage to the cylinder while

tightening the clamp arm to the plunger.

2. Place clamp arm in vise. DO NOT place

the body of the cylinder in the holding

device.

3. Tighten the bolt holding the arm to the

cylinder.

4. Retighten the ball bearing plug.

Setting Plunger Rotation

Swing cylinders are supplied with rotation

set to clockwise. Follow steps below to

change rotation.

1. Remove plug located opposite advance

port to access plunger guide ball. Remove

ball.

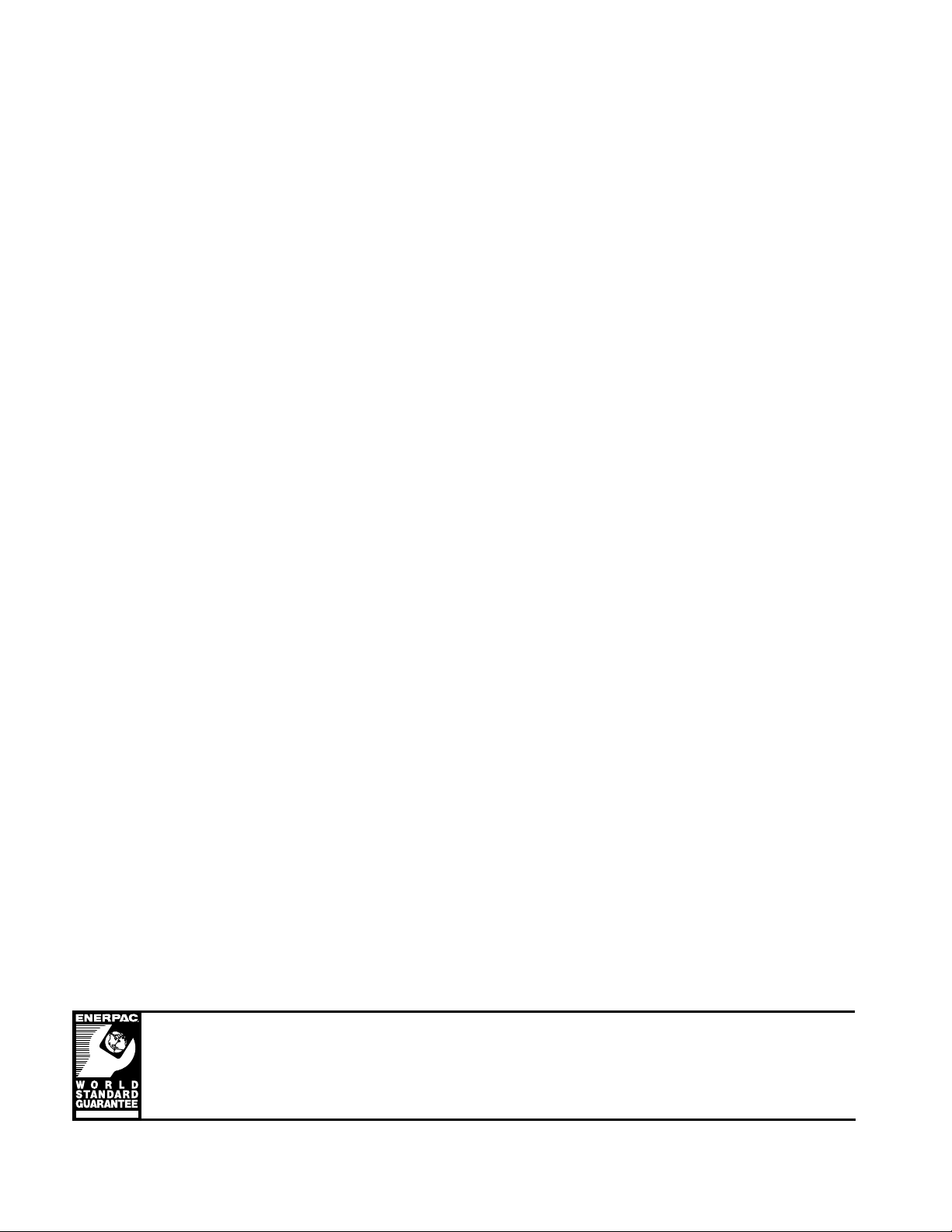

2. Turn plunger until selected groove is visible. See Figure 4.

3. Replace ball, making sure it is seated in

the groove and reinstall plug.

WARNING

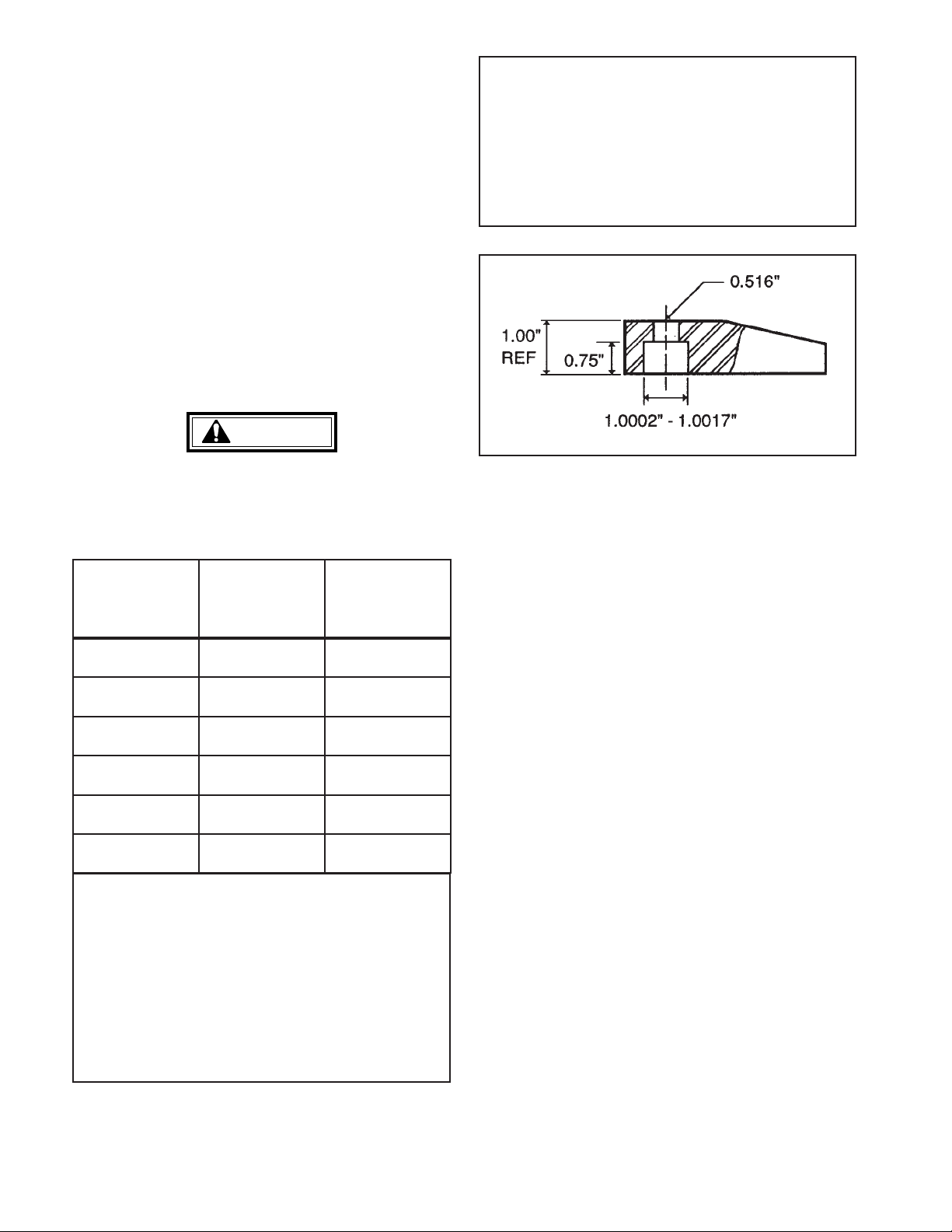

DO NOT exceed the values shown in Figure 2

or equipment damage and/or personal injury

could result.

Clamp Arm

Length

(Inches)

Maximum

Rated Pressure

(PSI)

Cylinder

Capacity (lbs)

@max. PSI

No clamp ★ 3000 2640

2 ★★ 3000 2164

3 3000 1960

4 3000 1740

5 2400 1200

6 2000 840

Figure 2: Clamp Arm Specifications

NOTE: Maximum recommended flow

rate with standard arm is 200 cubic inches per minute. When using longer clamp

arms, the flow rate should be reduced

and a V66-F flow control valve should be

used.

Figure 3: Clamp Arm Dimensions

★ For double arm clamping (DCA-2),

use half of straight pull capacity for each

side.

★★ Standard clamping arms supplied.

Longer arms indicated in chart can be

fabricated by the user. See Figure 3 for

dimensions.

Page 3

3

Mounting Swing Clamp

Secure swing clamp to fixture using one of

the following methods:

■ Screw threaded housing into tapped hole

(1 7/8”-16 UN).

■ Bolt cylinder down using the 4 mounting

holes in the flange. Mounting holes are 0.40”

diameter.

■ Mount in a through-hole and secure with a

locknut (P/N SC1CN).

Operation

Connection for Single Acting

Connect pressure line to 1/4”-18 NPT port in

flange.

Connections for Double Acting

1. Remove plunger return spring.

2. Connect advance line to 1/4”-18NPT lower

side port or the 1/8-27NPT bottom port. If

using the bottom port, plug the lower side

port with a 1/4”-18NPT pipe plug.

Air Removal

1. Apply low hydraulic pressure (approximately 10-20 PSI) to the system.

2. Loosen plug opposite advance port slightly to allow air to escape until hydraulic fluid

appears.

3. Tighten the plug to prevent further leakage.

WARNING

WARNING

Figure 4: Plunger Rotation (Top View)

NEVER exceed maximum pressure rating of lowest rated component in your system. Maximum

pressure for SC-1 swing cylinder with standard clamp arm is 3000 PSI. When using custom

clamp arms over 4 inches long, the maximum pressure rating is LOWER. See Figure 2 for clamp

arm specifications. Exceeding rated pressure will result in component failure and may cause

equipment damage and/or personal injury.

If your swing cylinder requires repair work, contact a local ENERPAC authorized

service center.

NEVER operate a double-acting swing clamp unless BOTH ports are connected to the hydraulic

circuit. If one of the ports is left uncoupled, pressure will build up behind it when the swing

clamp is operated. This may lead to equipment damage and/or personal injury.

Page 4

4

Australia

ENERPAC

Applied Power Australia, Ltd.

P.O. Box 261 Regents Park

Sydney, N.S.W. 2143

Tel: (61) (2) 9743 8988

Fax: (61) (2) 9743 8648

CIS

Applied Power Moscow

Leninsky Prospekt 95A

117313 Moscow, Russia

Tel: (7)(95) 956 5090

Fax: (7)(95) 936 2006

France, Switzerland,

Turkey, Greece, Africa,

Middle East

ENERPAC S.A.

B.P.200, Parc d'Activitiés

du Moulin de Massy

1 rue du Saule Trapu,

F-91882 Massy CEDEX

(Paris) France

Tel: (33) 1 60 13 68 68

Fax: (33) 1 69 20 37 50

Germany, Scandinavia,

Eastern Europe, Austria,

Switzerland

ENERPAC

Applied Power GmbH

P.O. Box 30 01 13

Mündelheimer Weg 51

40472 Düsseldorf 30

Germany

Tel: (49) (211) 47 14 90

Fax: (49) (211) 4714 940

Holland, Belgium,

and Luxemburg

ENERPAC B.V.

P.O. Box 269, Storkstraat 25

3900AG Veenendaal

Holland

Tel: (31) (318) 535911

Fax: (31) (318) 525613

Hong Kong

ENERPAC

Applied Power Asia PTE LTD.

Room No. 907, Workingberg

Commercial Building

41-47 Marble Road,

North Point

Tel: (852) 2561-6285

Fax: (852) 2561-6772

India

ENERPAC

Hydraulics (India) Pvt Ltd.

203 Vardhaman Chambers

Plot #84, Sector 17

Vashi, New Bombay 400 705

Maharashtra, India

Tel: 91-22-7632061

Fax: 91-22-7670309

Italy

ENERPAC

Applied Power Italiana S.p.A.

Via Canova, 4

20094 Corsico (Milano)

Italy

Tel: 39 2 45 82 741

Fax: 39 2 48 60 12 88

Japan

Applied Power Japan LTD

10-17 Sasame Kita-cho

Toda-City

Saitama 335,

Japan

Tel: 81 048 422 2251

Telex: J26275

Fax: 81 048 422 0596

Mexico

ENERPAC

Applied Power Mexico

Av. Principal La Paz #100

Fracc. Industrial La Paz

42092 Pachuca, Hidalgo, Mexico

Tel: (52) 771 33700

Fax: (52) 771 83800

Singapore

Applied Power Asia PTE LTD.

47 Jalan Pemimpin #01-02 &

#01-03 Sin Cheong Building

Singapore 577200

Tel: (65) 258 1677

Fax: (65) 258 2847

United Kingdom, Ireland

ENERPAC Ltd. Unit 3

Colemeadow Road

North Moons Moat

Redditch, Worcester B98 9BP

England

Tel: 44 01527 598 900

Fax: 44 01527 585 500

United States, Canada,

Latin America and

Caribbean

ENERPAC

13000 West Silver Spring Drive

Butler, Wisconsin 53007, USA

Tel: (414) 781-6600

1-800-433-2766 (End User)

1-800-558-0530 (Distributor)

Fax: (414) 781-1049

Canada

Tel: 1-800-426-4129 (End User)

Tel: 1-800-426-2284 (Distributor)

Latin America and Caribbean

Tel: (414) 781-6600 ext. 263

Fax: (414) 781-5561

All Enerpac products are guaranteed against defects in workmanship and materials for as long as you

own them. Under this guarantee, free repair or replacement will be made to your satisfaction.

For prompt service, contact your Authorized Enerpac Service Center or call toll free:

In U.S.A. 1-800-558-0530

In Canada 1-800-426-2284

PRINTED IN U.S.A.

R

South Korea

ENERPAC

Applied Power Korea Ltd.

163-12, Dodang-Dong

Wonmi-ku, Buchun-Shi,

Kyunggi-Do

Republic of Korea

Tel: (82) (32) 675 0836

Fax: (82) (32) 675 3002

Spain, Portugal

ENERPAC

Applied Power International, S.A.

Calle de la Imprenta, 7

Polígono Industrial

28100 Acobendas (Madrid)

Spain

Tel: (34) 1 661 11 25

Fax: ( 34) 1 661 47 89

Loading...

Loading...