Instruction Manual

M

ANU

AL

Super Boom Lift

SBL1

SBL1100

- 1100 Sh. Te Hydraulic Gantry -

100

Document number ED.02518.001.R03.ENG

Issued

Revision No. 3

Revision Date 27-06-2011

23-12-2010

Dear customer,

This is the manual for the Enerpac product you have purchased.

This manual contains important information for the correct use and safe

operation of the machine.

If this manual should become wholly or partly unusable, you can order a new

replacement copy of it, making reference to the number shown on the cover.

Enerpac reserves the right to modify this manual at any time, at its discretion

or according to its advancing insight.

ED.02518.00.001.R03.ENG

Page 2

Contents

Contents ______________________________________________________________________ 3

Introduction ___________________________________________________________________ 5

1. General Information _________________________________________________________ 7

1.1. General _______________________________________________________________________ 7

1.2. Manufacturer’s address __________________________________________________________ 7

1.3. Declaration ____________________________________________________________________ 7

1.4. Identification __________________________________________________________________ 7

1.5. Liability _______________________________________________________________________ 8

1.6. Appropriate use ________________________________________________________________ 8

1.7. Application limits _______________________________________________________________ 8

1.8. The basic principle ______________________________________________________________ 9

1.9. General Specifications ___________________________________________________________ 9

1.10. Machine overview ___________________________________________________________ 10

2. Safety ____________________________________________________________________ 11

2.1. Mandatory protective gear while working with or on the system _______________________ 12

2.2. Explanation of symbols in this manual _____________________________________________ 12

2.3. Explanation of symbols on the machine ____________________________________________ 13

3. Preparation for a lifting operation _____________________________________________ 14

3.1. Lifting capacity of the units ______________________________________________________ 15

3.2. Capacity of the Side shift or Lug __________________________________________________ 18

3.3. Capacity of the Header beam ____________________________________________________ 19

3.4. Surface loading for full support of the skid tracks ____________________________________ 19

3.5. Surface load with filler material under the skid tracks ________________________________ 21

3.6. Maximum permissible wind loading _______________________________________________ 23

4. Explanations of Methods ____________________________________________________ 24

4.1. Storage ______________________________________________________________________ 24

4.2. Handling _____________________________________________________________________ 25

4.3. Placement of the skid tracks _____________________________________________________ 29

4.4. Placement of the unit __________________________________________________________ 36

4.5. Connection of power cable ______________________________________________________ 36

4.6. Erect the mast ________________________________________________________________ 37

4.7. Mounting the header beams _____________________________________________________ 40

4.8. Mounting the side shift _________________________________________________________ 41

ED.02518.00.001.R03.ENG

Page 3

5. Before raising the load ______________________________________________________ 42

6. Checklists _________________________________________________________________ 44

6.1. Preparation for a lifting operation ________________________________________________ 44

6.2. Setting up the portal system _____________________________________________________ 45

6.3. Before raising the load __________________________________________________________ 45

7. The operation of the machine _________________________________________________ 46

7.1. The control panel on the unit ____________________________________________________ 47

7.2. The Intellilift control panel ______________________________________________________ 49

7.3. Manual control ________________________________________________________________ 50

7.4. Intellilift control _______________________________________________________________ 50

7.5. Mechanical locking ____________________________________________________________ 62

8. Special applications _________________________________________________________ 64

8.1. Tilting a load __________________________________________________________________ 64

9. Maintenance ______________________________________________________________ 67

9.1. Lubrication Points _____________________________________________________________ 68

9.2. Maintenance of the hydraulic system _____________________________________________ 69

9.3. Adjust guides _________________________________________________________________ 72

9.4. Lubricating the rams ___________________________________________________________ 76

9.5. Roller Chain __________________________________________________________________ 78

Appendices ___________________________________________________________________ 80

Appendix A Checklist for work preparation ______________________________________________ 80

Appendix B Checklist for setting up the machine __________________________________________ 82

Appendix C Checklist for lifting the load _________________________________________________ 83

Appendix D Hydraulic fluid safety information sheet ______________________________________ 85

Appendix E Skid track requirements ____________________________________________________ 90

ED.02518.00.001.R03.ENG

Page 4

Introduction

Introduction

Dear customer,

In purchasing the SBL portal lift system, you have bought a quality product from the

Enerpac company.

We thank you for the confidence you place in us by your purchase of this portal lift

system.

Operating an SBL system is only permitted if you are certified by Enerpac as an

authorised operator.

In order to be able to use the portal lift safely, we urgently request you to read this

manual thoroughly before you start working with the machine.

The manual is made up in such a way that you are comprehensively provided with

information during the course of the working situation. The whole consists of

comprehensive directions and instructions about maintenance, safe use, safe

practices and specific safety instructions. It is necessary, important and

advantageous to the proper function and reliability of your SBL portal lift system, and

to maintain its value, to take these directions and instructions into account.

Note:

In the rest of this manual, the portal lift is also referred to by the term

“Machine”.

NOTE:

This manual is part of the machine.

Only operate the machine after you have been trained, and taking this manual into

account.

Follow the safety instructions exactly!

Also observe the applicable directions to prevent accidents and the generally

recognised safety regulations, as well as the health and safety inspectorate’s

regulations.

All information, illustrations and technical data in this manual are applicable to the

situation existing at the time of publication.

We strive continuously to improve our products and therefore reserve the right to

implement improvements and changes whenever it is necessary and possible to do

so, without any obligation to apply improvements or changes to models purchased

previously.

If this manual should become wholly or partly unusable,

you can order a new replacement copy of it, making reference to the number shown

on the cover.

This manual is continually updated. We welcome suggestions which make the reading

of this manual or the use of the SBL system easier or safer.

ED.02518.00.001.R03.ENG

Page 5

even death.

Introduction

Despite the fact that this manual has been drafted with great care, we cannot

guarantee that it does not contain any errors. The interpretation and use of that

described in this document and possible consequences through improper use of the

system are wholly the responsibility of the user. Enerpac shall under no

circumstances accept responsibility for such improper use.

Improper use of the machine or failure to take the changes

indicated in this manual into consideration may result in

accidents causing damage not only to the machine itself, but also

to objects and goods in its vicinity or mounted to the machine, as

well as injuries to people in the immediate area, and possibly

All rights reserved. Nothing in this publication may be duplicated, stored in an

automated database or made public in any form or in any manner, whether

electronic, mechanical, by photocopying, recording or any other means, without prior

written approval by Enerpac.

We hope you find your Enerpac machine very useful.

Enerpac.

ED.02518.00.001.R03.ENG

Page 6

General Information

Enerpac Integrated Solutions B.V.

1. General Information

The manual contains fundamental instructions that must be taken into consideration

in preparing for a lifting operation, and for assembly, use and maintenance. For this

reason it is essential that the user read this manual before working with or on the

machine, and it must always be available for reference.

Points that must be followed are mentioned, not only in the safety chapter; in other

chapters too there are specific directions that must be read and followed.

1.1. General

This manual applies to a complete SBL1100 system.

1.2. Manufacturer’s address

Enerpac Integrated Solutions B.V.

Opaalstraat 44 7554 TS

Hengelo The Netherlands

Tel. +31 - 74 - 242 20 45

Fax. +31 - 74- 243 03 38

E-mail: info.hengelo@Enerpac.com

1.3. Declaration

EC Conformity declaration according to Directive.

1.4. Identification

Each unit; header beam, side shift and skid track is provided with a type plate as

illustrated below.

The type plates are official documents and must not be altered or made

ED.02518.00.001.R03.ENG

illegible!

Page 7

General Information

1.5. Liability

In the risk analysis conducted by Enerpac, intended usage and reasonably

foreseeable incorrect usage of the SBL portal lift system were assessed. The

instructions in this manual came into being based upon this analysis.

It is expected of the user of the SBL portal lift system that he or she has read and

understood this manual.

In cases of doubt about the use or application of this machine, always make contact

with Enerpac for advice and recommendations.

Unauthorised alterations to the machine may have a deleterious effect on the

characteristics of the machine and may disrupt the control functions. Unauthorised

alterations therefore annul any resultant damage claims against the manufacturer.

1.5.1. Limitations of liability:

We accept no liability whatsoever:

- for damage as a result of this equipment;

- to objects and third party equipment;

- to vehicles;

- for personal injury.

1.6. Appropriate use

The SBL1100 hydraulic portal lift is a four point lifting system. All four units must

always be used when lifting or transferring various objects. The centre of gravity

(C.O.G.) of the load must always remain within the four feet and under the header

beam.

The machine has been designed to be controlled using the associated Intellilift

remote control. Using this, the user can and must remain outside the range of the

machine while working with it.

Additional possible applications for the machine with the associated warnings are to

be found in Chapter 8, “special applications”.

The machine must not be used in potentially explosive environments.

1.7. Application limits

The application limits for the capacity, lifting height, skew, wind and environmental

influences are the maxima either calculated or tested by the manufacturer. During

practical applications, you must bear in mind that, through influences these

characteristics may exercise on each other, they may reinforce each other, and must

then be appropriately altered. Enerpac can advise you on this point.

ED.02518.00.001.R03.ENG

Page 8

General Information

(1)

(2)

(2)

used because they may lock up.

1.8. The basic principle

Each lifting unit consists of a basic frame with its own drive and octagonal telescopic

masts. In each telescopic mast there is an extending hydraulic ram.

The internal propulsive force is provided by a hydraulically driven roller track system.

This reduces the basic loading in comparison with conventional wheels. Moreover, the

resistance when bridging rail systems is reduced. It is impossible for wheels to slip

through!

One of the unique characteristics of the SBL1100 portal lift is the integration of the

power source into the basic frame. In contrast to conventional systems, this means

no separate power source and no hoses or data cables between power source and

units.

The beams across the top of the units create a portal.

The load is affixed to the beam by means of a side shift module or lifting anchor.

1.9. General Specifications

Each separate unit has a load carrying capacity of 2,670 kN.

The exact permissible loading is described in detail in Chapter 3.

The hydraulic pumps have a fixed stroke capacity. The machine's speed is variable

thanks to the built-in frequency controller.

Specification of the power source:

Voltage.......................................................................... :360 to 480 V AC/ 3-phase

Current.......................................................................... :16 A per unit

Frequency...................................................................... :50-60 Hz

Power............................................................................ :7.5 kW per unit (10 hp)

The units feature automatic phase selection according to the rotation direction of the electric motors.

Noise pressure................................................................ :77 dB(A)

.

Temperatures

Minimum operating temperature of the machine.................. :-25°C

Maximum operating temperature of the machine................. :50°C

Minimum storage temperature of the machine.................... :-25°C

Maximum storage temperature of the machine................... :60°C

Minimum storage temperature of the Intellilift control panel.. :20°C/0°C

Maximum storage temperature of the Intellilift control panel. :60°C/45°C

(1)

measured at ear height at nominal loading one metre away from any unit’s

electric motor

(2)

While charging the battery.

NOTE:

ED.02518.00.001.R03.ENG

There is a risk of ice accretion at temperatures below 0ºC.

If ice has accreted on machine components, they cannot be

Page 9

2

2

3

4

3

4

1

1

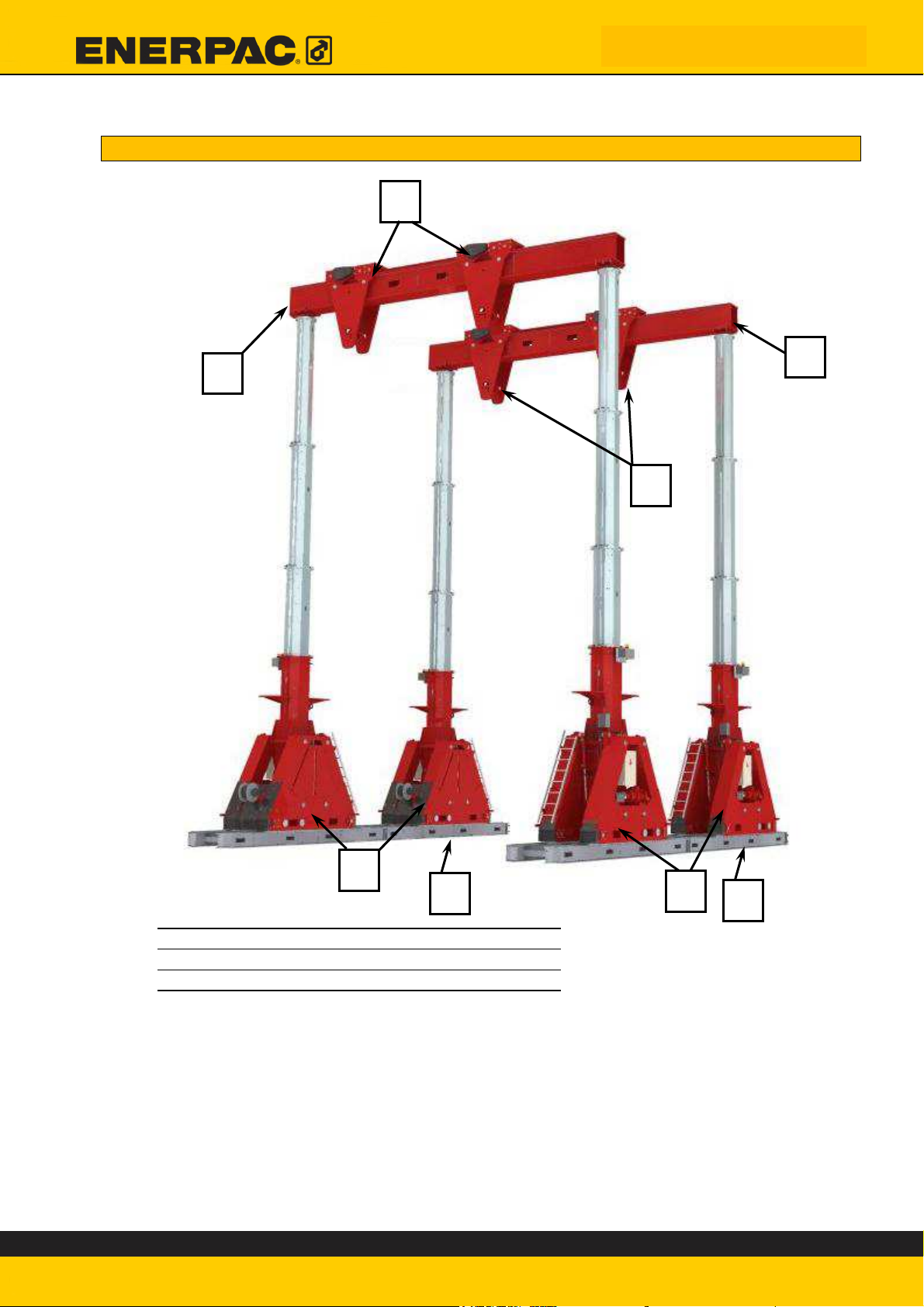

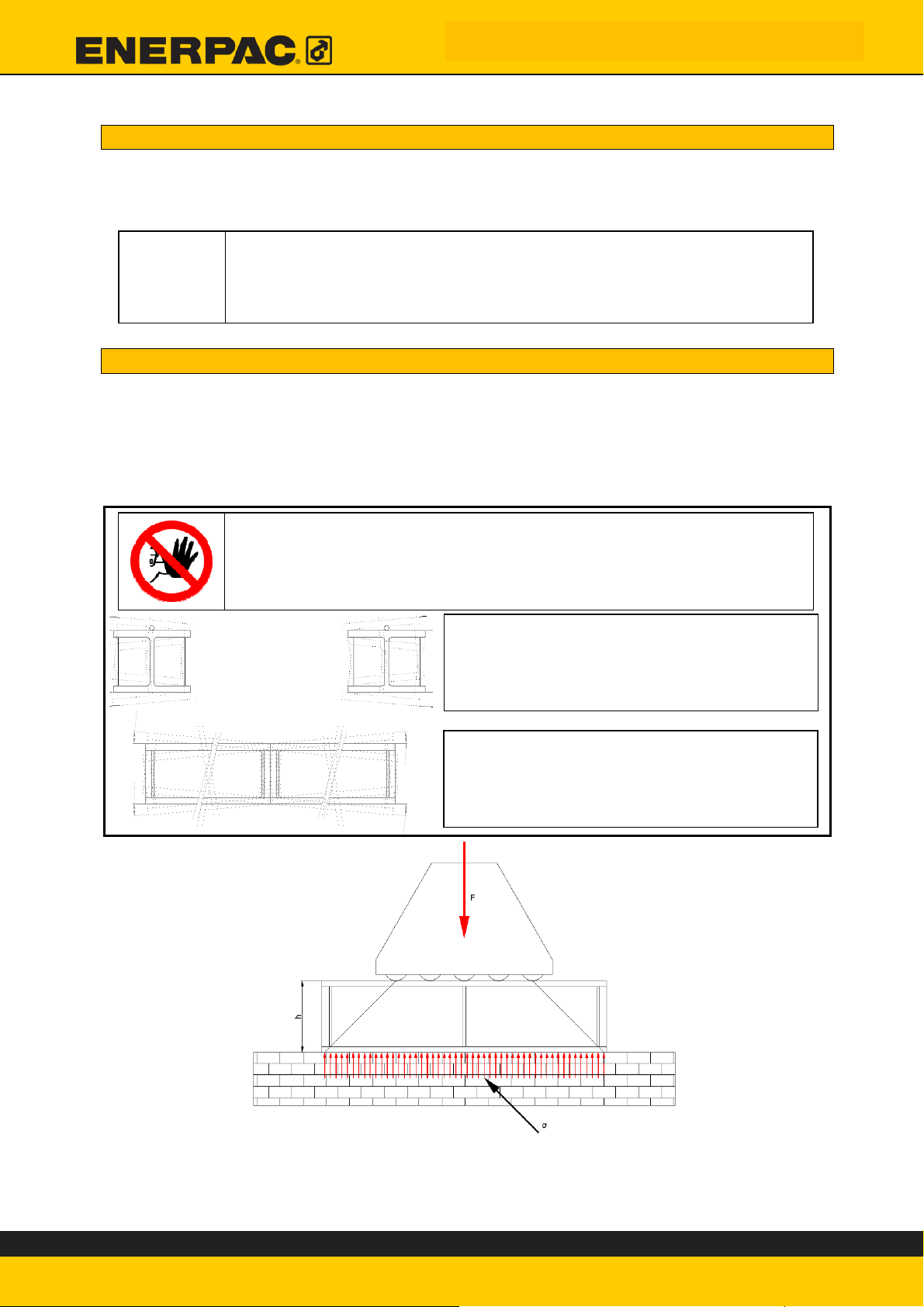

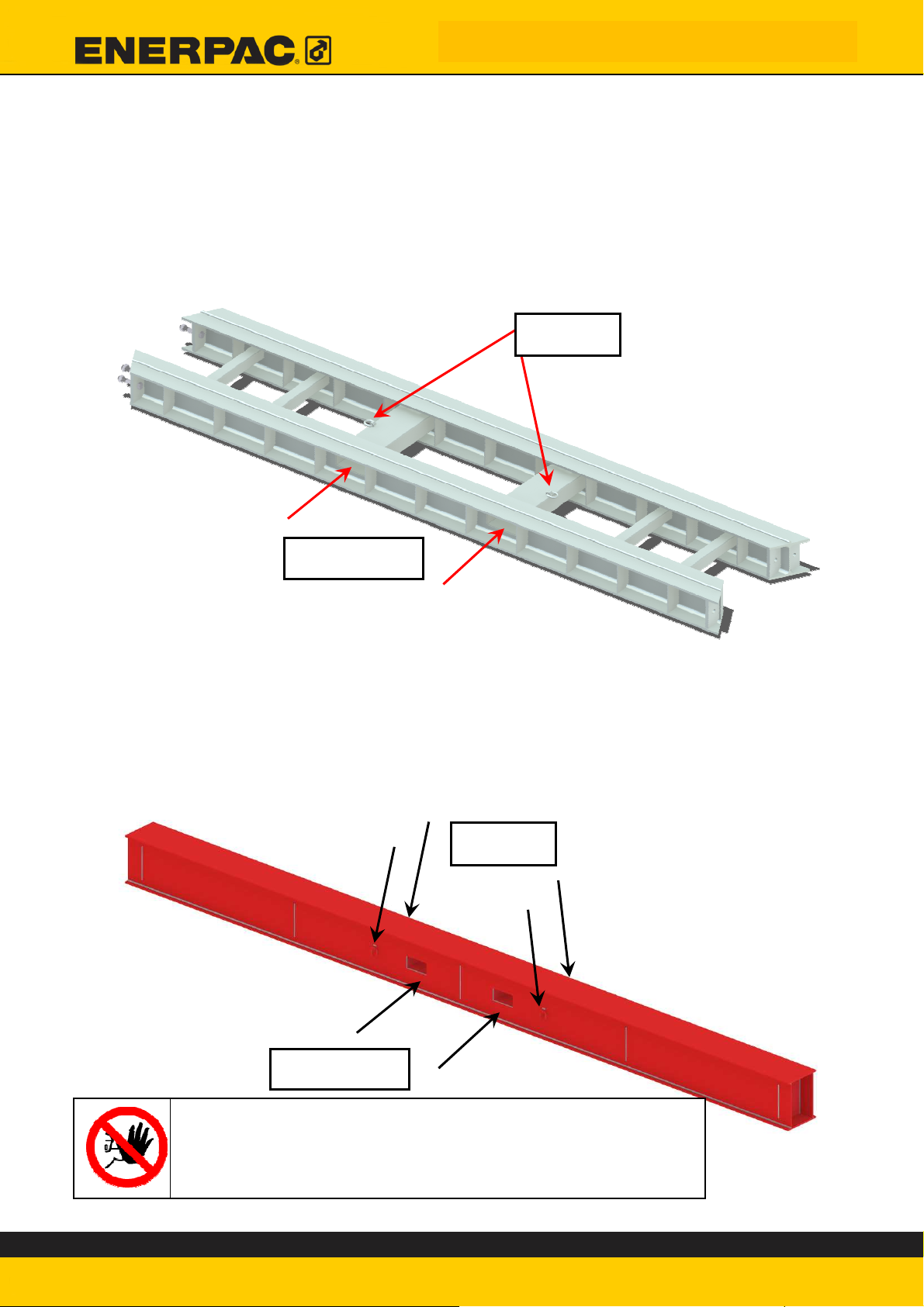

1.10. Machine overview

General Information

1) Skid track Required

2) Lift unit Required

3) Header beam* Required

4) Side shift unit** Required

*The figure shows a 10-metre beam. Beam dimensions and material may vary from

customer to customer.

** The figure shows an HBS6000 Side Shift unit. It is also possible to opt for a

different type of side shift, or fixed anchors.

ED.02518.00.001.R03.ENG

Page 10

Safety

2. Safety

Points that must be followed are covered not only in this chapter; in other chapters

too there are specific safety directions that must be read and followed.

It is very important to inspect the condition of the SBL system before every individual

start-up, given the fact that the slightest defect may have disastrous, and in some

cases fatal, consequences.

Keep your equipment clean. Badly maintained equipment can cause time wastage

and lead to permanent damage to the equipment and/or it surroundings.

Do not use equipment, whether loaded or not, while people are in the vicinity of the

equipment or object. The SBL series has been designed for used without manpower

inside the range of the portal lift, and must be operated according to the instructions.

Only operate the SBL system if you have been certified by Enerpac as an authorised

operator.

Only use original Enerpac spares to repair machine faults.

Maintain concentration during the work. Carelessness may result in serious injuries to

others, and possibly even death.

Additional lifting gear and accessories such as hawsers, shackles etc. must comply

with the legal requirements imposed in the country of use.

Enerpac is not liable for improper use of such accessories in combination with the SBL

system.

Adhere to the checklists during all work activities: during

preparation for the lifting operation, system construction, and for

lifting the load.

Failure to adhere to the checklists may result in serious injury to

the user, possibly even death.

ED.02518.00.001.R03.ENG

Page 11

Safety

2.1. Mandatory protective gear while working with or on the system

Ensure that you and other people in the vicinity and during the operation of the portal

lift wear a safety helmet and that the applicable safety regulations are observed.

Wear safety footwear, safety goggles, and, when not using the remote control, safety

gloves*.

*We strongly advise against wearing safety gloves while using the Intellilift remote

control.

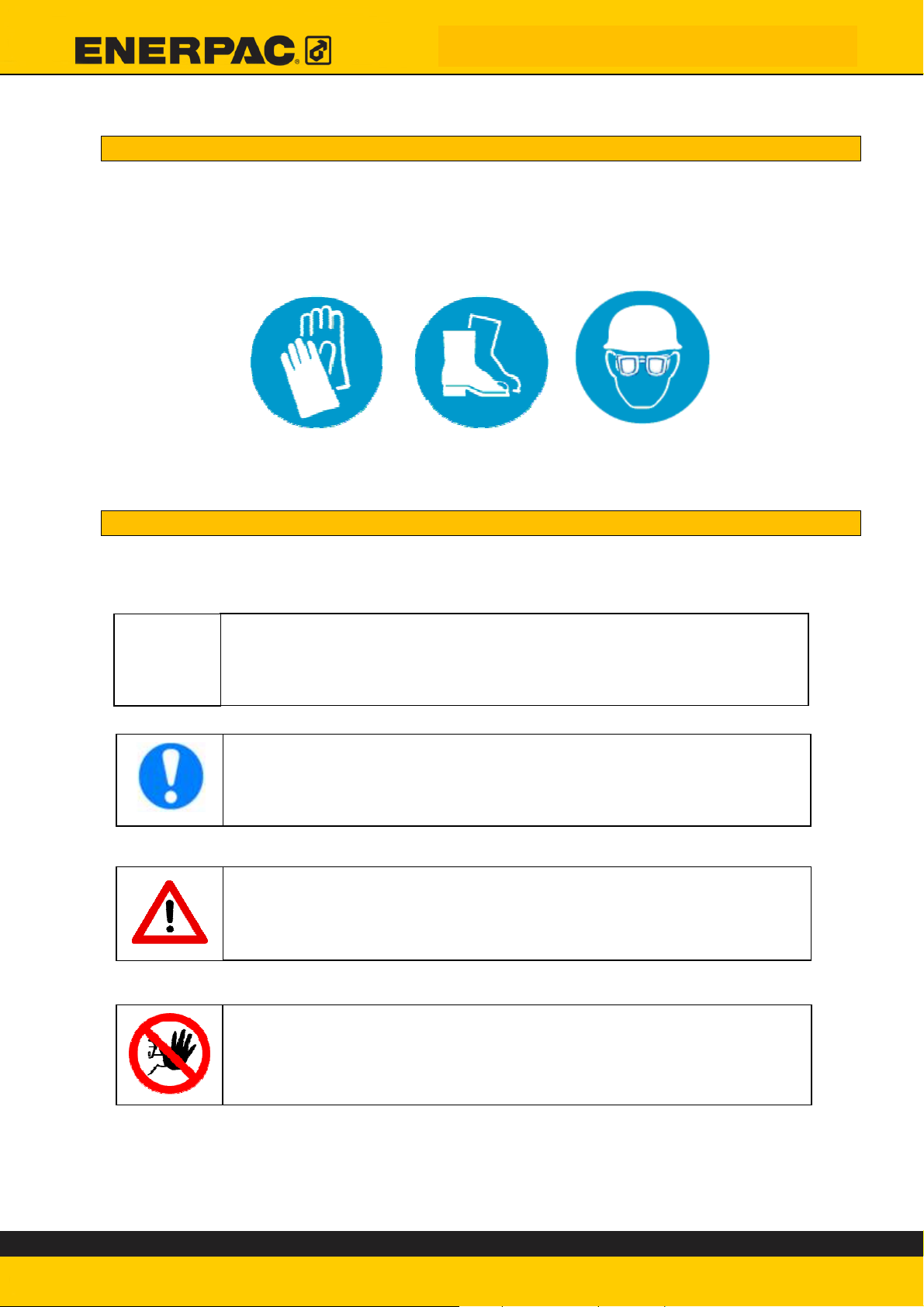

2.2. Explanation of symbols in this manual

The following symbols are used in this design manual to elucidate the various specific

instructions.

Indicates to the user that something needs to be filled in on the

checklist.

Gives the user hints and tips on simple control procedures and

work activities

General warning to the operator for possible damage to

equipment and to the environment in general.

Draws the user's attention to risks to personnel if work

instructions are not followed precisely

ED.02518.00.001.R03.ENG

Page 12

Safety

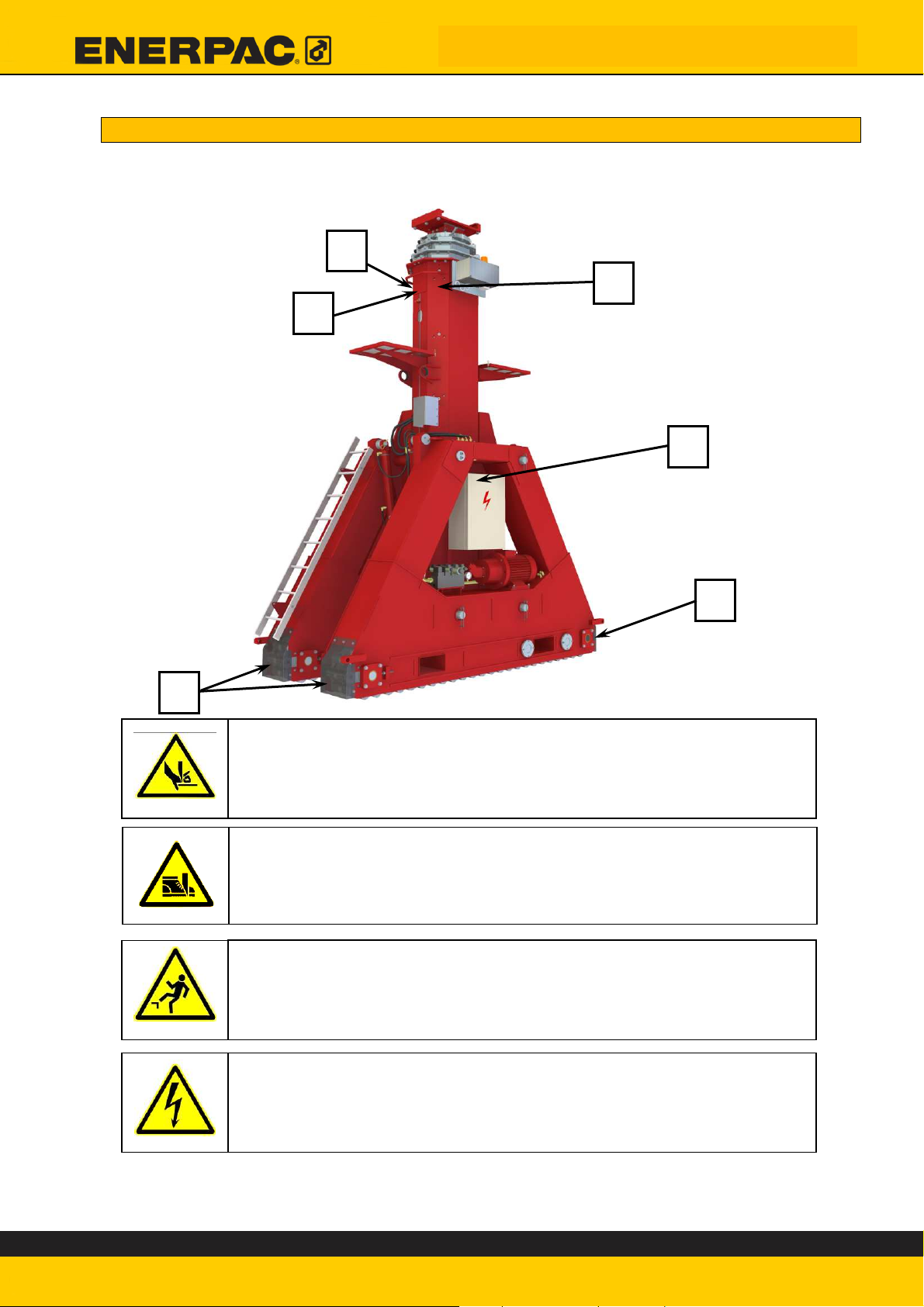

4 stickers (On protective caps)

2

2

1

4

3

1

2.3. Explanation of symbols on the machine

Instructions on labels applied directly to the machine must be followed without

question, and always be kept in a fully and properly legible condition.

1. Risk of trapping parts of the hand

2. Risk of trapping parts of the foot

3. Risk of falling

4. Risk from electricity

4 stickers (Around the bottom ram)

2 stickers (visible from stage)

2 stickers (On motor and Switchbox)

ED.02518.00.001.R03.ENG

Page 13

Preparation for a lifting operation

3. Preparation for a lifting operation

In this chapter, the essential preparations for a lifting preparation are

comprehensively described.

Before this preparation can be started, certain information must be known:

• Mass of the load.

• Centre of gravity of the load.

• Dimensions of the load.

• Maximum lifting height.

• Allowable pressure on the subsoil before subsidence happens.

First, the position of the load’s centre of gravity within the units should be

determined. Then the maximum lifting height is determined.

Thereafter, it is checked whether the following details are adequate:

• Lifting capacity of the most heavily loaded unit.

• Capacity of the side shift.

• Capacity of the header beams.

• Load capacity of the subsoil.

Finally, the maximum acceptable wind speed should be calculated.

This preparation results in:

A checklist for use while setting up the machine.

A checklist the operator must follow during use of the machine.

It is of the utmost importance to read this whole chapter

carefully before setting up the machine.

Failure to prepare correctly for a lifting operation may

result in total loss of machine stability during use.

ED.02518.00.001.R03.ENG

Page 14

Preparation for a lifting operation

=

⋅

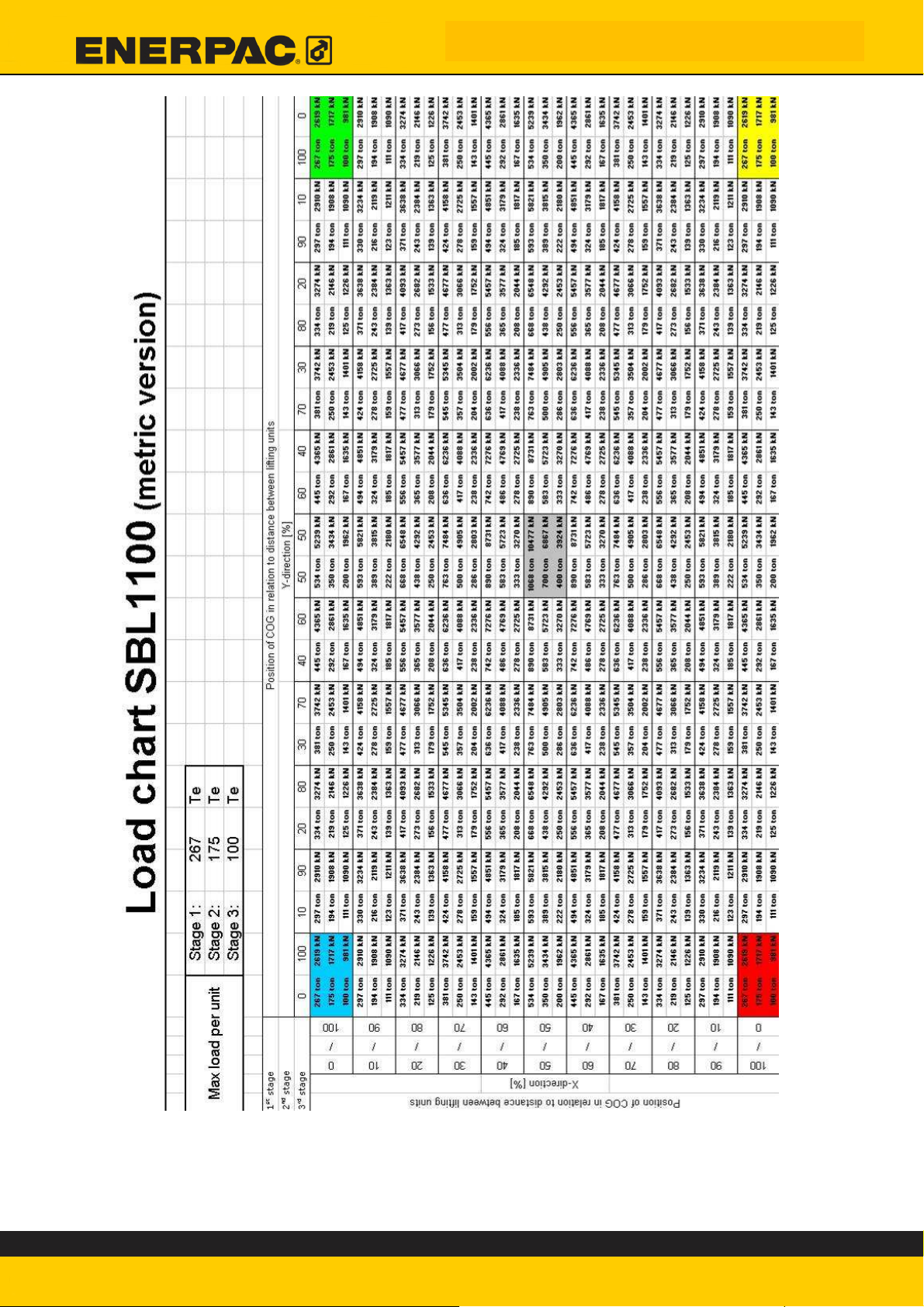

3.1. Lifting capacity of the units

Determine the maximum for the lifting height needed for your lifting operation.

3.1.1. Maximum load

The portal lift system comprises four units. Given the fact that each unit is

provided with a telescopic hydraulic ram, the capacity varies according to the

phase. The working pressure for each step is around 350 bar. This results in the

following lifting capacities:

st

1

stage: 2670 kN, → lifting height: 0 mm to 2934 mm

nd

2

stage: 1750 kN, → lifting height 2934 mm to 5698 mm

nd

3

stage: 1000 kN, → lifting height: 5698 mm to 7632 mm

Theoretically, this means that the maximum loading is

this is only applicable if the load is evenly distributed over the portal lift. In other

words, if the centre of gravity is positioned in such a way that each lifting units

carries exactly the same load. This is naturally a situation that never arises in

practice. In order to prevent overloading of the portal lift, the loading table must

be used.

Dimensions of the units, beams, side shift, and skid tracks.

may be found in Appendix D to G.

This information can be used to determine the required lifting

height.

Fill the maximum lifting height into the checklist in appendix A

1068026704

kN

kN. But

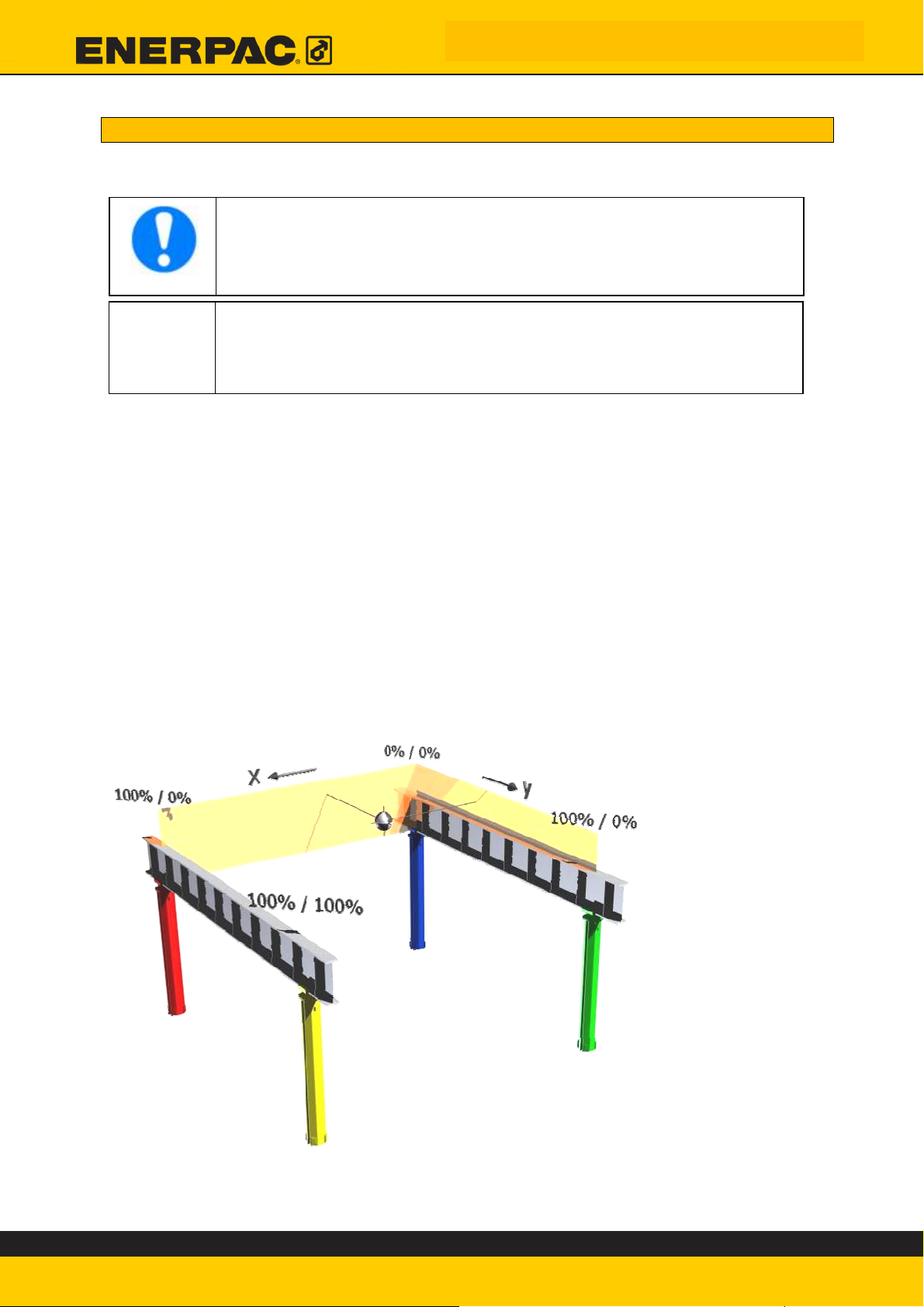

The figure shows the orientation of the table with respect

to the portal lift.

The coloured cells in the load chart correspond to the

lifting units in the figure

ED.02518.00.001.R03.ENG

Page 15

The stability of the system is such that if the COG is positioned in

the centre of the machine, then any movement of the COG out of

the ideal centre will result in reduced stability of the overall

system.

The table on the next page should always be used before and

during side-shift operations.

During this kind of work, the load's centre of gravity (COG) shifts

from one point to another. After this kind of shift, one or two

units will bear more of the load, and the other two will bear less

of it. In order to ensure that the maximum permissible load is

not exceeded for any of the units, it is necessary to consult the

table before each operation.

Use the load chart to fill the maximum force per unit occurring

during the lifting operation into checklist A

(Only for the unit under the heaviest load)

Preparation for a lifting operation

ED.02518.00.001.R03.ENG

Page 16

Preparation for a lifting operation

This table must always be used for side shift operations. During this kind of work,

the load's centre of gravity (COG) shifts from one point to another. After this kind

of shift, one or two units will bear more of the load, and the other two will bear

less of it. In order to ensure that the maximum permissible load is not exceeded

for any of the units, it is necessary to consult the table before each operation.

ED.02518.00.001.R03.ENG

Page 17

Preparation for a lifting operation

3.1.2. Minimum load

Due to friction in the hydraulic cylinders, it is possible that the extension order of

the first and second step may not be followed properly, due to insufficient loading

of the units. In other words, the units also have a minimum lifting capacity. The

total minimum loading is 50 kN. In most cases, the header beams’ own weight is

sufficient.

3.2. Capacity of the Side shift or Lug

The force on each anchor point cannot under any circumstances be greater than

the capacity of the side shift unit or lug. The capacity of the side shift or lug is

indicated on the documentation provided on delivery.

Use the load chart to fill the minimum force per unit occurring

during the lifting operation into checklist A

(Only for the unit under the lightest load)

Always determine the force on each anchor point. Even for

relatively light loads. This can be done using a centre of gravity

calculation.

The preparer is expected to possess this skill. In case of doubt,

Fill the maximum anchor load into the checklist in

appendix A

ED.02518.00.001.R03.ENG

Page 18

Preparation for a lifting operation

0

,

2

°

3.3. Capacity of the Header beam

The force on each anchor point may not in any case be greater than the capacity

of the header beam. The capacity of the header beams is shown in the beam load

chart.

3.4. Surface loading for full support of the skid tracks

If it is not possible to have the underside of the skid tracks 100% supported,

Azobé wood and steel plates must be installed under the skid track – see section

3.5.

The surface load is defined as follows: the load due to the weight exerted on the

subsoil by the guide rails.

Fill the maximum permissible beam load into the checklist

in appendix A

If the following requirements cannot be met: then the skid tracks

must be set up using filler materials.

In this case, the force on the subsoil is determined in chapter

3.5.

The rails may not be skewed in side

view. The angle from the horizontal

plane must be less than 0.2° in both

axes.

0

,

2

°

0

,

2

°

°

2

,

0

The incline angle of the running surface

must not be more than 0.2°.

The surface loading is dependent on the type of guide rails used.

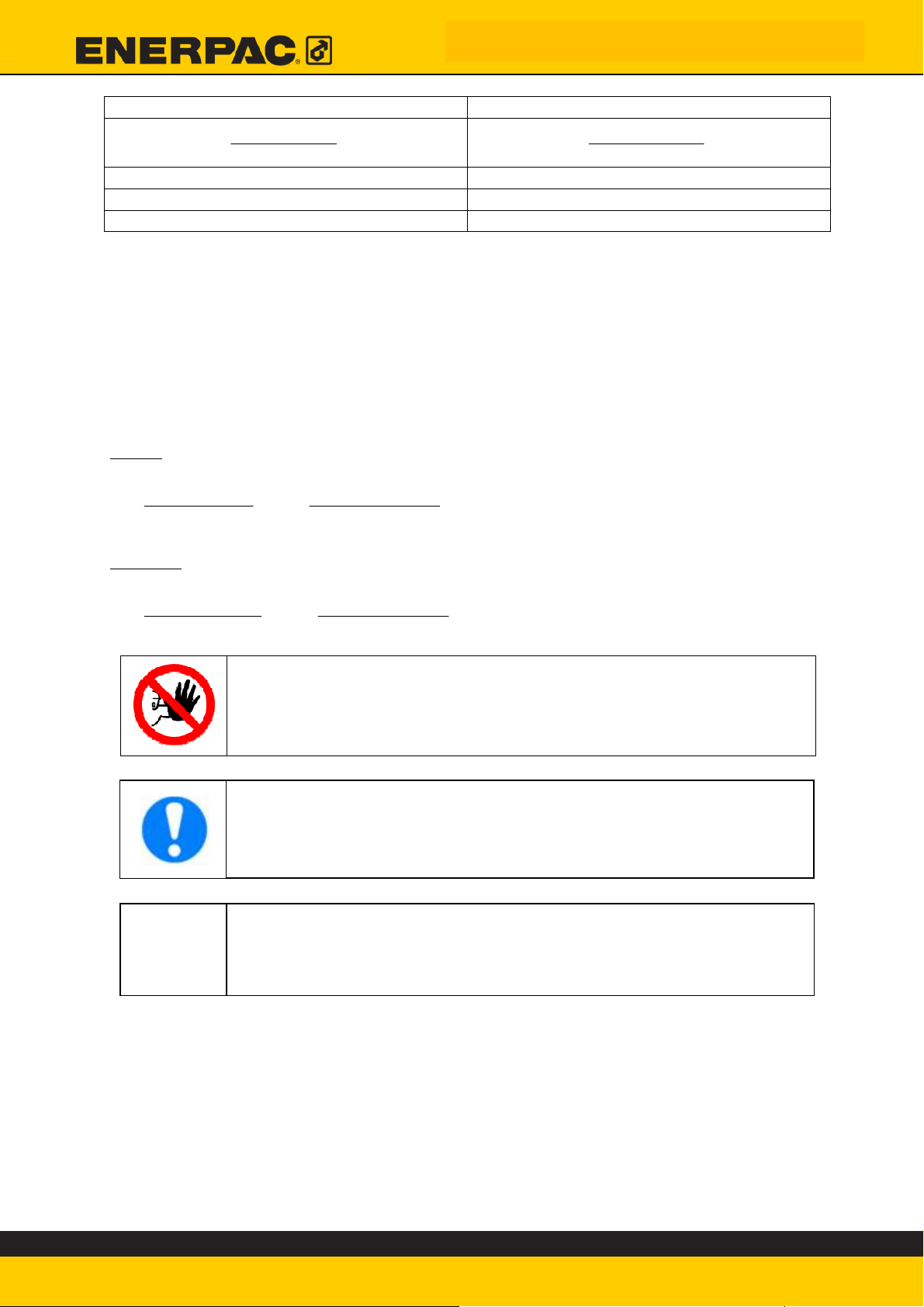

The height h is indicated on the drawing provided with the skid tracks.

The surface loading may be calculated by means of the formulae below; a small

extra safety factor is already included in these formulae.

ED.02518.00.001.R03.ENG

Page 19

Preparation for a lifting operation

1380

+

+

⋅

h

33.54

+

+

⋅

h

1380

400

1380

+

+

⋅

+

+

⋅

h

33.54

15

33.54

+

+

⋅

+

+

⋅

h

Metric system Imperial system

5000100

=

σ

σ = surface load, [metric tonnes/m2] σ = surface load, [short tonnes/ft2]

F = load on a particular foot, [kN] F = load on a particular foot, [kips]

h = rail height, [mm] h = rail height, [inches]

The load F is the maximum load on one particular lifting foot. This is the force

determined in section 3.2 and indicated as the maximum force per unit occurring

during the lifting operation.

Replace parameter F in the formula with this maximum load to determine the

maximum surface load during the lifting work.

Examples:

Metric: The expected maximum load on one of the feet is 1200 kN. The height of

the rail is 400 mm. The resulting maximum surface loading is then:

5000100

=

σ

F

F

7.1*

=

7.1*

50001200100

1197.1*

=

metric Te/m2, or

=

σ

F

11.2079.1

1.19

N/mm2.

7.1*

Imperial: The expected maximum load on one of the feet is 350 kips. The height

of the rail is 15”. The resulting maximum surface loading is then:

=

σ

F

11.2079.1

7.1*

=

The surface load occurring with complete underfilling of the skid

tracks must always be less than the permissible surface load.

The height of the skid tracks is indicated on the drawing provided

with the skid tracks

Fill the maximum surface load into the checklist in

appendix A

11.2035079.1

9,157.1*

=

sh. tonnes/ft2.

ED.02518.00.001.R03.ENG

Page 20

Preparation for a lifting operation

+

=

*.*6.

33

+

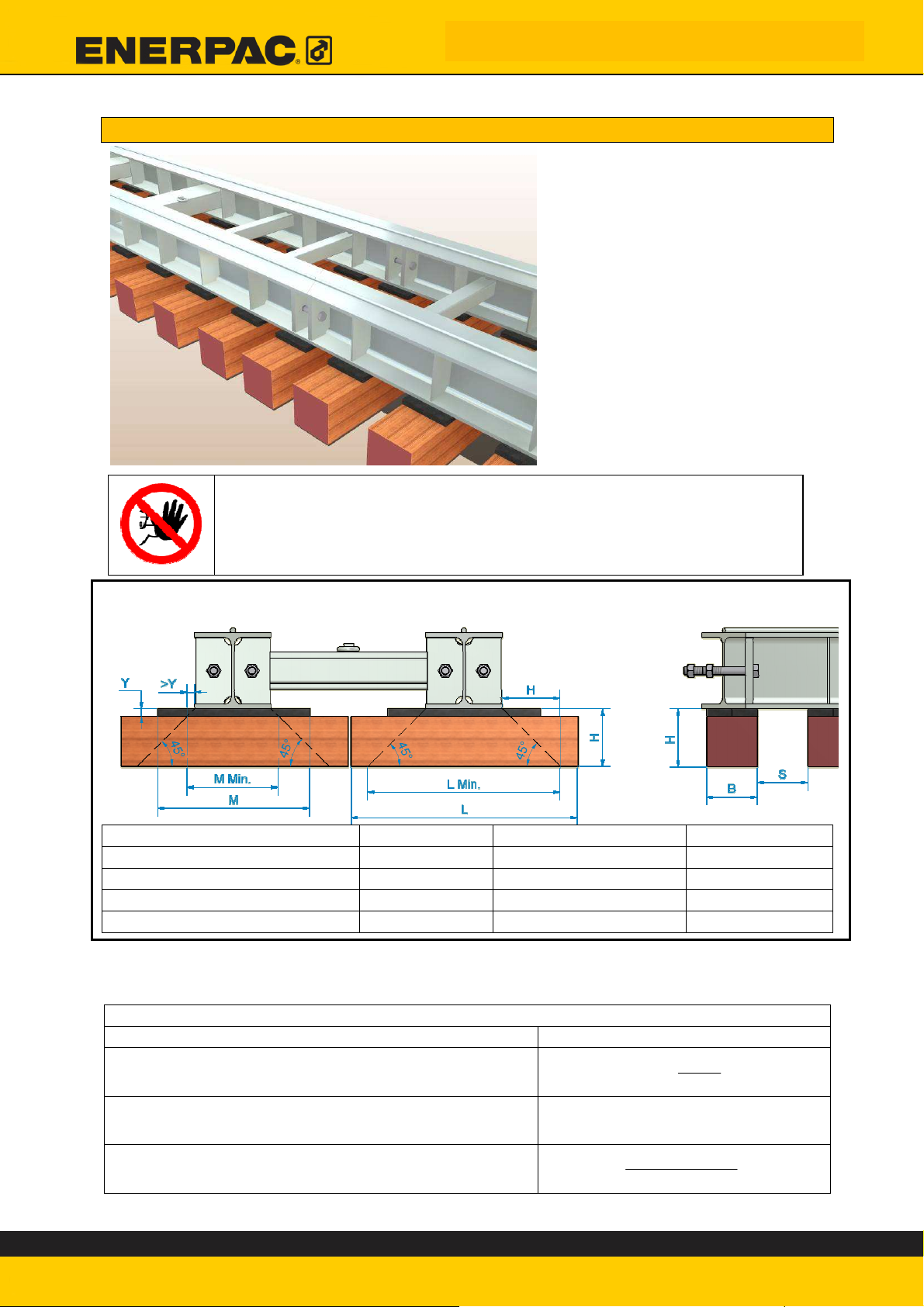

3.5. Surface load with filler material under the skid tracks

If it is necessary to use Azobé

wood under the rails to

compensate for unevenness in

the subsoil, or to create a lower

surface loading, then a number

of matters must be borne in

mind!

The points of attention are

dealt with in this chapter and in

the chapter “Explanations of

Methods”. The preparer must

also go through and

understand section 4.3.

Geometrical requirements for the Filler material:

Only use filler materials in accordance with section 4.3.2

Read section 4.3.2 before proceeding any further in this section.

In case of doubt, consult Enerpac

Description Parameter Requirements Comment

Length of the filler material L > L Min. Max. 914mm

Length between plates M > M Min.

Width of the filler material B > H and > 250 mm

Space in between S < 250 mm

The surface loading may be calculated by means of the formulae below; a small

extra safety factor is already included in these formulae.

Length measurements in metres

Description Formulas

O = filler material ratio

O+=

B

SB

L net. = Effective Length

Please Note: L net can never be greater than 0.914 m

σ = surface load, [metric tonnes/m2]

F = load on a particular foot, [kN]

=

σ

ED.02518.00.001.R03.ENG

Page 21

HLnet *23.0.

100

F

7.1*

OLnet

Preparation for a lifting operation

25.04.

0

+

=

+

=

*.*6.

33

+

61.0*9.0*6.33

+

The load F is the maximum load on one specific lifting foot; this is the force

specified in section 3.2, defined as the maximum force arising during the lifting

operation.

Example:

The expected maximum load on one of the feet is 1200 kN.

B= 400mm 0.40m

H= 300mm 0.30m

S= 250mm 0.25m

The resulting maximum surface loading is then:

O+=

σ

B

61.0+=

SB

HLnet *23.0.

100

F

=

7.1*

m

OLnet

The actual surface load must always be less than the permissible

surface load.

The formulas in this section are based on the

Enerpac Rollertrack

4.0

3.0*23.0.9.0

2

/120

=mton

1001200

7.1*

Fill the maximum surface load, the L, W, H and the S from

the checklist in appendix A

ED.02518.00.001.R03.ENG

Page 22

Preparation for a lifting operation

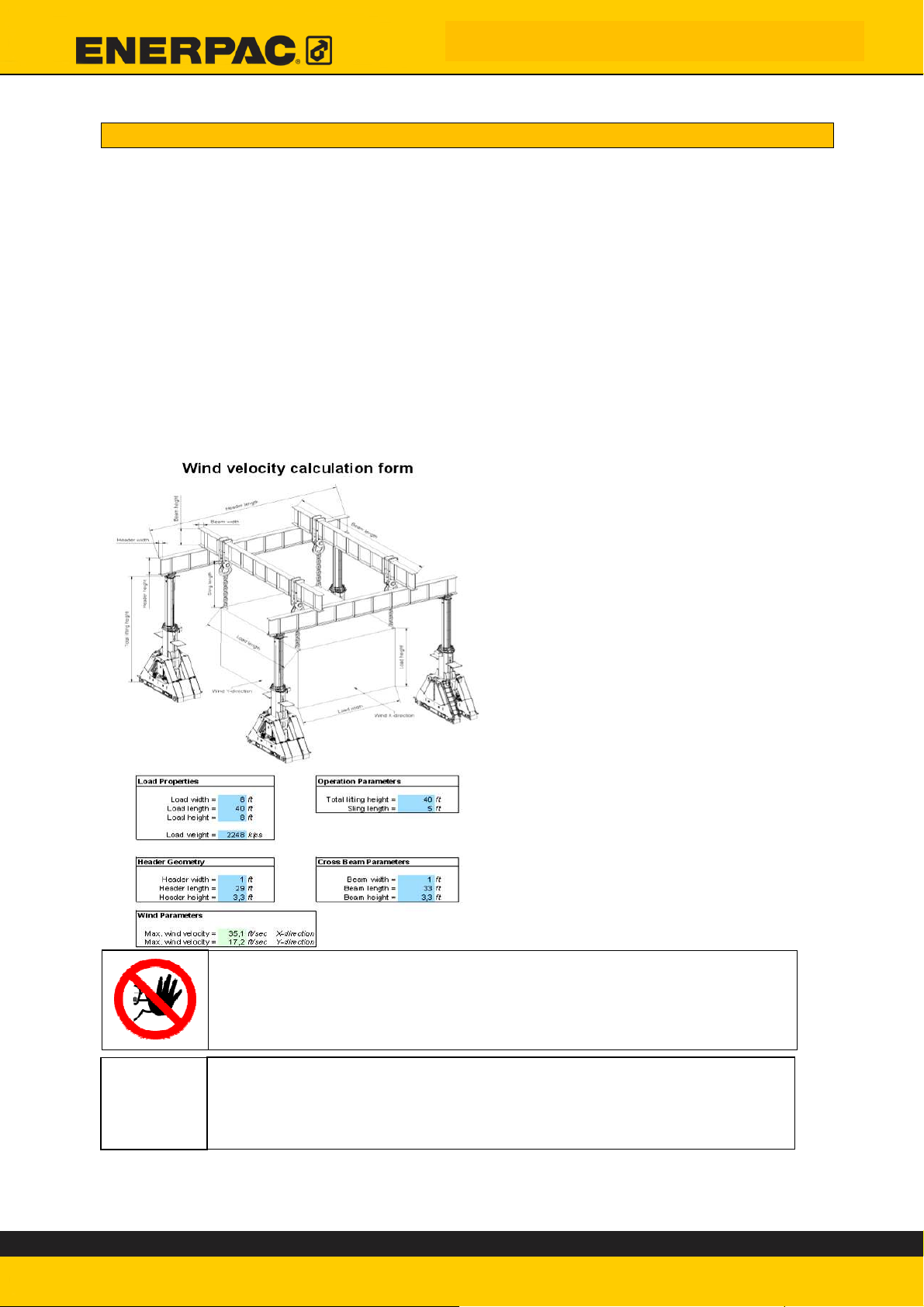

3.6. Maximum permissible wind loading

Another factor that must be taken into account when lifting is the sidewards

loading. During activities in the open air, the wind exerts a certain force on the

object lifted by the portal, which directly results in a sidewards loading. The

permissible sidewards loading is dependent upon a number of factors, namely the

size of the object, the wind speed and the height of the top beams (lifting height).

This means that, before every lifting operation, it must be checked that the wind

does not present danger.

The maximum wind speed is calculated in accordance with a calculation form for

loads; this form can be found on the CD-ROM supplied. The form shows the

maximum permissible wind speed in both directions under different

circumstances.

Under no circumstances whatsoever may lifting operations be carried out when

the wind speed is greater than the values given on the form.

On the left, you will find an example

of a fully completed form:

Only certain parameters have to be

entered. Enter the dimensions

referred to as the outline dimensions

of the object. These are the x-y-z

dimensions of the outline of the

beams and load. The foot

dimensions of the portal lift are

already entered and cannot be

changed. Always start from the most

adverse situation.

Do not forget that the wind speed

and direction may change during

lifting.

When lifting, always assume a worst-case scenario. The wind can

be unpredictable, quickly changing speed and direction. Do not

take any chances: if the wind is strong, that means it's a 'no go'!

Fill the maximum permissible windspeed into the checklist in

appendix A

ED.02518.00.001.R03.ENG

Page 23

Explanations of Methods

4. Explanations of Methods

This chapter provides detailed information about putting the SBL1100 system into

use. The preparations to be made for the working location, the portal lift etc. are

described here.

4.1. Storage

In storing the SBL system, you should distinguish between temporary storage and

storage for a long period. If you intend to store the system for a longer period, a

dry and preferably closed space is recommended.

During short-term storage, especially in

the open air, cover the units with a

tarpaulin in order keep electrical and

other moisture-sensitive components dry.

During storage in the open air, cover the units with a tarpaulin in

order keep electrical and other moisture-sensitive components

dry.

If the stroke meter gets wet, its functioning may be impaired. So

pay special attention to the encoder box.

The tarpaulin is not included in the delivery, but can be added as

an option.

ED.02518.00.001.R03.ENG

Page 24

Explanations of Methods

4.2. Handling

Each unit is fitted with four lifting eyes, as shown in the figure below:

Always use all four of the lifting eyes

The lower section of the base is provided with two lifting openings for a forklift

truck:

Lifting eyes can only be used when the mast is in retracted position (horizontal

position). Use of the forklift trucks is permitted in both positions. Please note that

when using the forklift truck with the mast in extended position, the centre of

gravity (COG) of the unit is considerably higher, and therefore less stable.

ED.02518.00.001.R03.ENG

Page 25

Explanations of Methods

In extended position, only use the fork openings

In this setup, it is possible to use both the lifting

eyes and the fork openings.

In order to prevent damage to the wheels, all movements, in any direction, must

be executed at a height of 300 mm off the ground.

In order to prevent damage to the wheels, all movements, in any

direction, must be executed at a minimum height of 300 mm off

the ground.

• The unit can only be moved if the telescopic cylinder is

fully retracted.

• Movement of the unit is not permitted with the top beams

mounted on the top plates.

for lifting trucks to move the units.

Hold the mast of the lifting truck upright.

Leaning it too far back may cause damage to the roller tracks.

ED.02518.00.001.R03.ENG

Page 26

Explanations of Methods

4.2.1. Skid tracks

The skid tracks may be moved in two ways:

1. With a forklift truck. For this, the skid tracks are fitted with fork holes

2. Using a crane. For this, the skid tracks are fitted with 2 lifting eyes.

See illustration below:

Lifting

Fork holes

4.2.2. Header beam

The header beams may be moved in two ways:

1. With a forklift truck; the header beam is provided with fork openings for

this

2. Using a crane; for this, the header beam is provided with four lifting eyes.

See illustration below:

Lifting

Fork holes

Always use all four lifting eyes

ED.02518.00.001.R03.ENG

Page 27

Explanations of Methods

4.2.3. Side shift

The side shift may only be moved using the lifting eyes. Once the side shift is off

the beam, it must be laid down flat as shown in the illustration below:

In order to place the side shift on the beam, it is

provided with lifting eyes.

During assembly, always work with two or three

lifting chains; in this way the side shift always

remains horizontal during lifting. See

illustration:

In this case, set a filling

block for lifting.

Always set a filling block between the roller bearings first before

raising the side shift.

This is to prevent damage to the shift shift motor.

ED.02518.00.001.R03.ENG

Page 28

Explanations of Methods

4.3. Placement of the skid tracks

In order to ensure proper functioning, the system should be set up level on the

ground. In many cases, the subsoil is not flat and must be graded to create a

good solid foundation on which the system can work safely.

The definition of a good supporting surface is:

a properly graded base that cannot be deformed by transverse forces under load

or overloading.

Guide rails have two functions:

• The use of guide rails reduces the basic loading

• They guide the portal lift over their length, so that the possible danger of

misalignment is avoided.

Creating a proper foundation must be handled with the utmost of

care, as it is the system's primary safety issue.

Failure to use the guide rails

may result in improper

alignment.

Unstable surfaces cause instability.

Concrete is not a suitable

foundation for wheels.

4.3.1. Requirements for the skid tracks

Permissible skid tracks are:

1. The skid tracks manufactured by Enerpac, supplied with the machine.

2. Additional skid tracks supplied by Enerpac.

3. Skid tracks that comply with the following requirements:

a. Prescribed material and the dimensional tolerances specified on the

drawing in Appendix F and in Chapter 4.3.2.

b. The materials used must be accompanied by materials certificates

type 3.1.B.

c. The skid track must be tested statically before use to an overloading

of 125% of the maximum capacity; during this a notified body must

have been present. The said notified body must issue a certificate

for this.

d. At an overloading of 125%, the stresses in the material must remain

below 60% of the yield point.

e. All welding work must be executed according to EN-ISO 15614-1.

f. The quality of the welding processes must comply with EN729.

g. The welding must be approved and in this comply with EN-ISO 5817

class B.

Check of the skid tracks before use

ED.02518.00.001.R03.ENG

Page 29

Explanations of Methods

4.3.2. Check the skid tracks for damage before installation.

Several minimum requirements are listed below.

Pay special attention to the welds:

Pay special attention to the welds. There should be no fissures in them.

Enerpac can provide you with skid tracks: the wide range of

available lengths is listed in appendix G.

These skid tracks are hot-dip galvanized and meet all of

Enerpac's requirements for skid tracks.

The flatness tolerance of the running

surface is 5 mm over 3 m (1/5” over

10’).

The rails may not be skewed in side

view. The angle from the horizontal

plane must be less than 0.2° in both

axes.

°

2

,

0

0

,

2

°

0

,

2

°

°

2

,

0

The incline angle of the running surface

must not be more than 0.2°.

Never use rails which do not meet the above requirements.

4.3.3. Requirements for the filler material

The filler material must be stacked contiguously so that there is no

risk of spring action!

Minor deformations in filler material or subsoil may result in strong

internal transverse forces or diagonal or longitudinal movements of

the load or masts.

ED.02518.00.001.R03.ENG

Page 30

r

Permitted filler materials:

1. Hard wood with a mechanical compressive strength of at least

25 N/mm² without occurrence of deflection

However, Enerpac strongly recommends adhering to

30N/mm². Preferably Azobe.

The minimum hard wood thickness is 50 mm and the

maximum thickness is 150 mm.

NOTE:

Use of other wood types such as plywood, multiply, pine

and compressed wood is expressly prohibited.

Wood is a natural product, which means its quality is not standardly

assured. In order to guarantee quality an appropriate test must

be conducted before use to verify that the material meets the set

requirements.

2. Steel filler plates, provided they are properly secured with a

mechanical compressive strength of at least 30 N/mm²

without occurrence of deflection.

Use of other materials is not permitted!

In case of doubt, consult Enerpac

For your planning, please bear in mind that the ideal wood is not

only hard to the touch; it is also hard to acquire.

Explanations of Methods

4.3.4. Placement of the filler material

If it has become apparent from Chapters 3.4 and 3.5 that it is necessary to install

filler material under the skid tracks, this must be implemented as prescribed in

Chapter 3.5.

The parameters L, H, B and S are listed in the checklist in Appendix A.

When laying the filler material, always consult with the person

who performed the calculation in section 3.5.

This is necessary to prevent excessive surface loading.

ED.02518.00.001.R03.ENG

Page 31

Explanations of Methods

Standard geometrical requirements for the filler material:

Parameter Requirements

L > L Min. (to 914mm)

M > M Min.

B > H and > 250mm

S < 250 mm

1. Install the filler material as determined by the preparer.

Pay attention in this to the following points:

Filler material must be laid with the largest surface on the horizontal

zone.

Track couplings must always be fully supported.

ED.02518.00.001.R03.ENG

Page 32

Always put filler material under the ribs in the skid track!!

Explanations of Methods

Always place a steel plate with

a minimum thickness of 15 mm

between the skid track and the

filler material at the joint.

At least 150 mm of each skid

track must be on the steel

plate.

Steel plate width at least 300

mm + 2x the thickness of the

plate

2. Next, place the skid tracks on the filler material.

3. Align the guide rails

4. Ensure that the rails run parallel to each other:

A maximum deviation of ½’’ (~12 mm) in the alignment is permissible:

ED.02518.00.001.R03.ENG

Page 33

Explanations of Methods

5. Ensure that no clearance is left between the filler material and skid

tracks.

Before the units are placed on the skid tracks, these must comply with

the following requirements!

Ensure that no clearance is left between the filler material and

skid tracks.

For filler material requirements, see section 4.3.2.

Enerpac can provide you with additional skid tracks or advise you

on an appropriate design for your application during the planning

phase.

The flatness tolerance of the running

surface is 5 mm over 3 m (1/5” over

10’).

The rails may not be skewed in side

view. The angle from the horizontal

plane must be less than 0.2° in both

axes.

°

2

,

0

0

,

2

°

0

,

2

°

°

2

,

0

The incline angle of the running surface

must not be more than 0.2°.

Ensure that the running surfaces of the

rails are aligned. Otherwise, use shims

to align the surfaces. Ensure that the

angle of incline created is less than

0.2°.

ED.02518.00.001.R03.ENG

Page 34

Check that the skid tracks meet all requirements and

fill this in on the checklist in appendix B.

Explanations of Methods

Connect the rails or plates together

under tension. Gaps between the

surfaces may cause dislocation of the

lifting foot and thus of the load.

ED.02518.00.001.R03.ENG

Page 35

Explanations of Methods

4.4. Placement of the unit

After the rails have been correctly aligned and connected, the lifting feet may be

placed on to the rails. The groove in the wheels must engage with the guide ridge

on the rails.

Check that the units are on the rails properly and

fill this in on the checklist in appendix B.

4.5. Connection of power cable

Once the units are in position, the power cable can be connected. Each unit must

be connected separately to the electricity supply. Connect the power cables to

each of the units’ power connections:

Specification of the power source:

Voltage :360 to 480 V AC/ 3-phase

Current :16 A per unit

Frequency :50-60 Hz

Power :7.5 kW per unit (10 hp)

The units feature automatic phase selection according to the rotation direction of

the electric motors.

Once the power supply has been connected, the masts can be set upright.

ED.02518.00.001.R03.ENG

Page 36

Explanations of Methods

4.6. Erect the mast

Once the rails have been installed, the lifting feet brought into position and the

cables connected, the SBL1100 is ready for use. The masts can now be extended.

Mast extension is a manual operation and is performed on the electrical control

panel of the SBL1100.

Never attempt to extend or retract masts to which something is

attached or which are fitted with a buffer beam. The extension

cylinders are not designed to bear additional weight.

Do not attempt to erect or retract an extended mast. The upright

structure has a very different centre of gravity (COG). This will

damage critical structural components.

Do not extend masts when a person is too close to the masts.

ED.02518.00.001.R03.ENG

Page 37

Explanations of Methods

Remove the three lifting shafts from the frame. To do so, first remove the spring

clips. Pull the shafts out until there is no connection between the mast and the

frame (approximately 80%). The fourth shaft is locked and serves as a point of

rotation. This shaft cannot be removed, except during maintenance.

Check that there is no one within the range of the lifting foot. Check that no

cables are pinched and that there is no load on the masts. Use the switch on the

front panel to extend the masts.

ED.02518.00.001.R03.ENG

Page 38

Explanations of Methods

When the masts are in vertical position, put the shafts into position and lock them

with the spring clips:

After setting and locking all pins, decompress the extension cylinders by retracting

them slightly. Keep an eye on the pressure gauge: there should not be any

pressure buildups.

Always put all three shafts into position. The portal lift is

designed to distribute weight across the shafts. A missing shaft

may result in an unstable foot and thus also an unstable system.

ED.02518.00.001.R03.ENG

Page 39

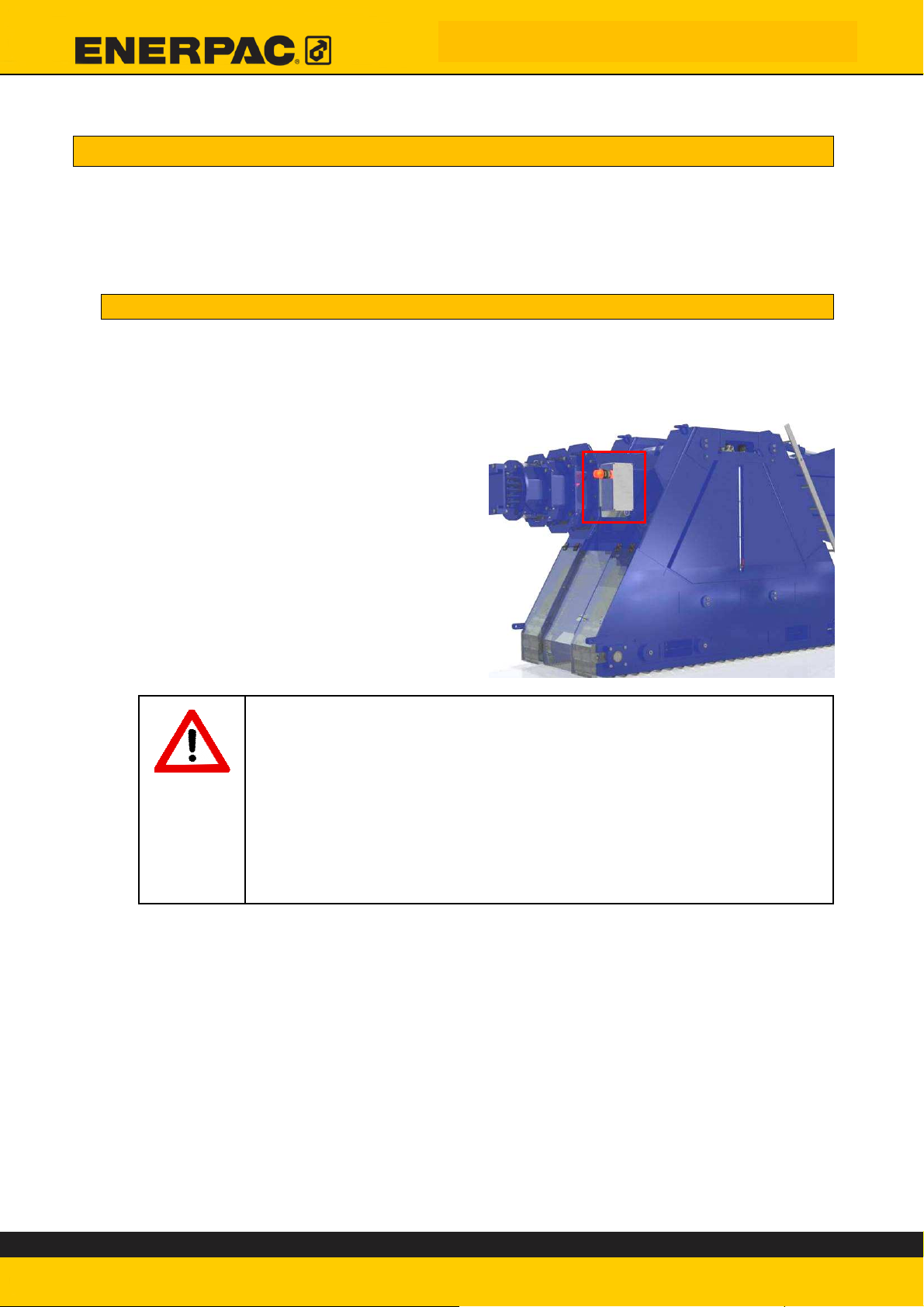

4.7. Mounting the header beams

In order to mount the header

beams on the units, the six bolts

on the top of the swivel plate

must first be removed. Remove

the locking strips.

Place the header beam on top of

the swivel.

Replace the strips and the six

bolts (M20 St8.8 Elvz.). Adjust

the beams to be level before the

beam is fixed to the lift.

In this way, a fixed connection

between the unit and the beam

is achieved. (For the operation of

the machine, see Chapter 7.)

Tighten the bolts to 370Nm

Always install all six bolts. The header beam may shift slightly,

which will exert a considerable amount of force on the bolts. If all

bolts are not used, the structure may get damaged.

Check that the beam is level and that all bolts are tightened

properly. Fill this in on the checklist in appendix B.

Explanations of Methods

ED.02518.00.001.R03.ENG

Page 40

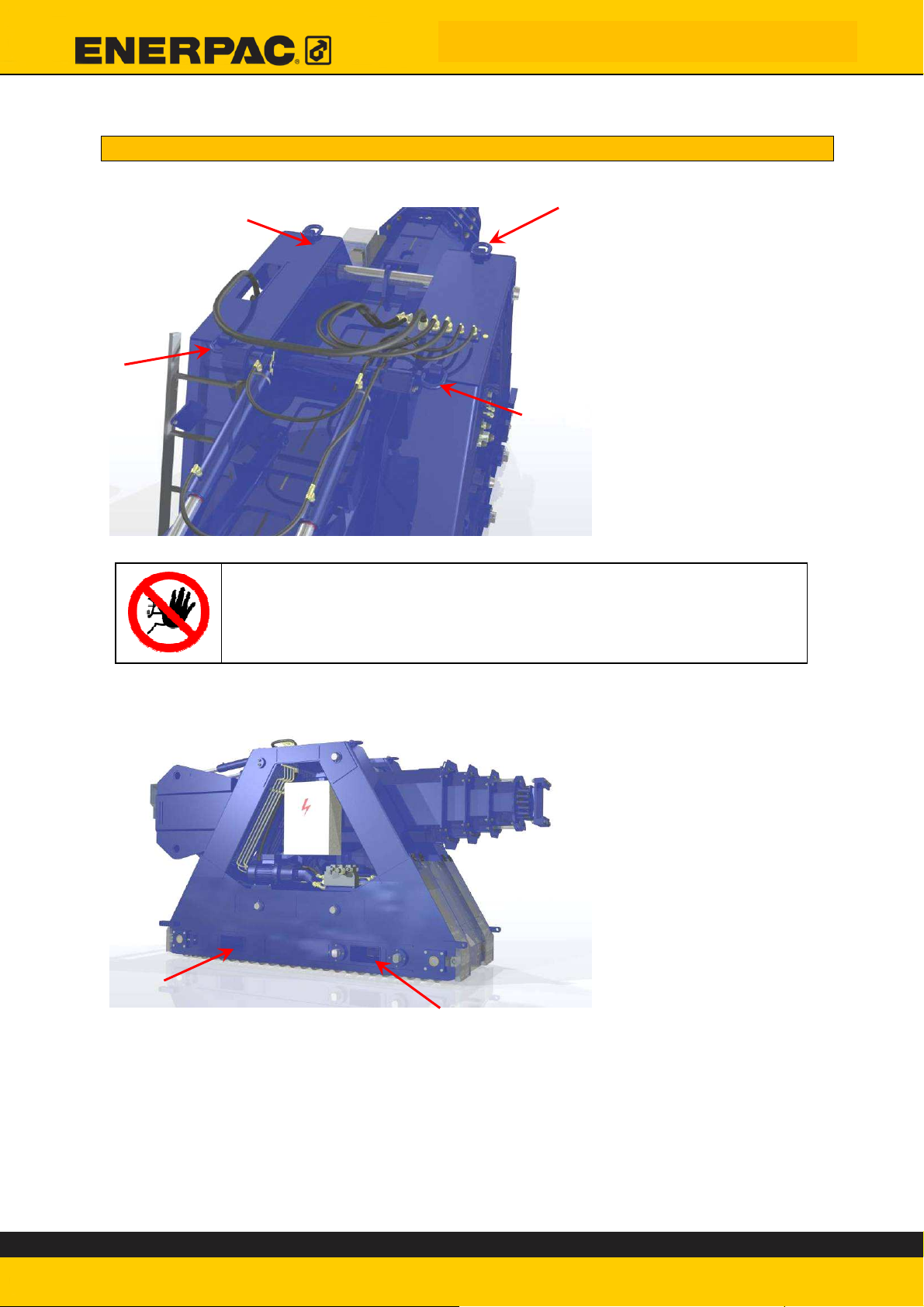

4.8. Mounting the side shift

Place the side shift on the beam as shown in the

illustration alongside. See section 4.2.4 for how to lift

the side shift.

Place the lifting beam as illustrated

alongside:

Explanations of Methods

Feed the cable through the guide

roller.

Fix the cable into the connector and

attach the strain relief to the eye

provided.

Ensure that the cable is mounted in such a way that it cannot get

pinched.

Fit the locking strip as shown in the

illustration next to this text. Tighten the bolts

(M12) to

60 Nm.

Check that the side shift is on the beam properly and that the lifting

beam is set and locked. Fill this in on the checklist in appendix B.

ED.02518.00.001.R03.ENG

Page 41

Before raising the load

5. Before raising the load

Before using the portal lift, certain matters must be checked.

1) Check whether the checklist in Appendix B has been fully completed and

signed.

2) Carry out a visual inspection of all lifting feet. Assure yourself that there are

no signs of excessive rust and that no parts of the portal lift are damaged.

Rust means a weaker structure.

3) Carry out a visual inspection of all hydraulic components.

Assure yourself that there are no signs of wear or damage.

Oil leakage may indicate wear or damage to the system.

4) Define what is known as a defined drop zone. This is the area outside of

which you and all bystanders and goods on the site are safe, if anything

should go wrong. Cordon off this area using barriers, tape etc., in such a

way that no one can enter the area.

5) Ensure that the running surfaces of the skid tracks are clean and that the

unit cannot slip or be obstructed.

6) Check whether all wedges have been removed from the rams.

See Chapter 7.4.

7) Slide all masts in and out a little to check that all communication functions

are working properly.

8) Drive the units forwards and backwards a short distance.

9) If applicable, do the same for the Side Shift units.

10) Check whether the correct load is indicated. This is of course the

weight of the beams and the internal resistance of the feet themselves. The

load must only be raised after all preparatory measures have been

implemented and the system is fully ready for use.

Always check the points given in this section before beginning to

move with a load.

ED.02518.00.001.R03.ENG

Page 42

Before raising the load

11) Check before raising loads that the load anchorages are in line with

the fixing points on the load:

Use a plumb line, a laser, or a theodolite.

If the anchors are not in line with the fixing point, the load will start to sway as

soon as it comes off the ground. This causes a huge transverse load on the

portal lift, and might even lead to the portal lift tipping over. Such accidents

have happened in the past, and were attributable to carelessness on the part

of the operators.

12) Always keep lifting straps as short as possible. With long lifting

strops, the load will always have the tendency to start swinging during

travelling or sidewards movement. This can also cause unexpected

sidewards loading of the portal lift:

13) The beam must remain level at all times, with a tolerance of ± 0.2°.

This section is associated with the checklist in appendix C

The load cannot be moved until the checklist in appendix C has been

completed in full and signed.

ED.02518.00.001.R03.ENG

Page 43

Checklists

6. Checklists

The checklists have been drafted to ensure safety before and during the lifting

operation.

The checklists have been prepared in chronological order in order to keep their

completion as simple as possible.

Only once all checklists have been fully completed, and all the requirements in the

checklists have been fulfilled, may the load be raised.

Always have the checklist verified and signed in approval by a second person

authorised by the machine’s owner.

The objective of this is to create extra certainty that the checks have been

correctly executed.

Work exclusively according to the checklists: during preparation

for the lifting operation, system construction, and for lifting the

load.

Failure to adhere to the checklists may result in serious injury to

users and bystanders, and possibly even death.

6.1. Preparation for a lifting operation

The checklist for preparation may be found in Appendix A.

Make a copy of the list, or print one out from the CD-ROM supplied.

The checklist during preparation is to check:

• The machine is able to carry the load.

• The foundation can carry the load.

• To establish how high the wind speed may be during the operation.

Various pieces of information that are important during setting up the machine are

entered in this list during the work preparation.

It is therefore important that this list is continuously available during setting up

the machine.

It is only permitted to start setting up the machine once the checklist is fully

completed and if all the requirements stated in this manual are fulfilled.

ED.02518.00.001.R03.ENG

Page 44

Checklists

6.2. Setting up the portal system

The checklist for erection is to be found in Appendix B.

Make a copy of the list, or print one out from the CD-ROM supplied.

The checklist during erecting the machine is to check:

• The machine is erected according to the directions in the manual.

• The machine is erected according to the data upon which the calculations

during preparation were based (Appendix A).

This checklist has been drafted in chronological order. Therefore, it is

necessary to go through this list point-by-point from top to bottom. During

checking, as well as during construction.

If it is necessary to use lifting strops, chains or other accessories, this should

also be noted on the checklist.

6.3. Before raising the load

The checklist for during lifting is to be found in Appendix C.

Make a copy of the list, or print one out from the CD-ROM supplied.

The checklist for raising the load serves to check that:

• The machine is not damaged and shows no signs of wear

• The machine’s functions are correct and all work in the right direction

• That the machine is correctly situated above the load.

This list must be completed by the operator of the machine during the lift

operation.

ED.02518.00.001.R03.ENG

Page 45

Working with the machine

7. The operation of the machine

The portal lift may be used in two ways:

• Manual operation, known as “local control”.

• Using the Intellilift, known as “Remote control”.

Once the header beams have been installed on the units, the machine may only

be operated using the Intellilift control panel.

Manual control should only be used during installation.

Before the machine can be operated, the user must read and

understand the manual in its entirety.

In case of doubt, consult Enerpac.

Local control us only permitted if there is a beam attached to the

unit.

A unit is only part of the central emergency stop system if the

control selector switch is in the remote position.

ED.02518.00.001.R03.ENG

Page 46

controller is

controller is not

active

the lifting cylinder

remote control

7.1. The control panel on the unit

Local control of the

travel motors and

Switches to tilt the

mast

Move side shift to

the left and right

Switch to equalize

the travel direction

Working with the machine

Switching voltage

present

Motor for hydraulic

pump running

Frequency

Switch to equalize

the side shift

direction

Speed selection for

local control

Toggle switch

between local and

Button to switch

unit on/off

Frequency

Side shift overload

protection signal

Emergency switch

NOTE: this only

works on other

units if they also

work on remote

control

Emergency stop

signal active.

An emergency stop

switch is active or

there is no

connection with the

Intellilift panel.

ED.02518.00.001.R03.ENG

Main power switch

Page 47

The direction of the side shift and travel depends on the “travel

direction” and “side shift direction” selector switches

Before the shaft between the side shift units is coupled, the direction

of the side shifts must be checked.

Working with the machine

ED.02518.00.001.R03.ENG

Page 48

The RS845 connection. Connection

Display. Displays basic

Emergency stop switch. When activated,

Fast/slow

rse

7.2. The Intellilift control panel

Working with the machine

information, such as load per

lifting foot, lifting height per

foot, and messages

Cylinder

selection.

Activates and

deactivates

individual lifting

feet. Useful

for fixed wiring. This connection is

also used to charge the batteries.

power is cut to all power cables.

They must be reactivated manually for each

lift component.

Power

Lift

Lift/lower

Travel

Forward/reve

Side shift

Left/right

Zero lift switch. Resets the

lift counters of the

activated lifting feet to 0.

Always select "tortoise mode" on the speed selector switch when

working with a load on the machine.

Only one function can be active at a time!

ED.02518.00.001.R03.ENG

Page 49

Working with the machine

7.3. Manual control

Local control is useful during assembly of the machine. It may be used to put the

separate units into the correct position.

During local control, no detection of the load or hysteresis takes place. In other

words: manual control is unsafe control, and must only be used during installation

of the units and as long as no beams have been mounted on the units.

This is how you work with a unit manually:

1. Ensure that the main switch on the control panel of the unit in question is

set to 'on'.

2. In order to raise a lifting foot manually, the control switch on the unit

should be set to ‘local’.

3. Switch the unit on using the operation switch on the unit’s control panel.

4. The desired speed can be selected using the speed selection switch on the

control panel.

5. The following functions may be controlled via the control panel on the unit:

a. The ram can be extended and retracted.

b. The unit can be made to travel.

c. The mast can be tilted.

d. The side shift can be controlled.

Important: only for maintenance purposes.

7.4. Intellilift control

7.4.1. About Intellilift

The Intellilift control system has been developed to allow loads to be raised and

lowered under control.

The control system ensures that the units remain within a hysteresis of 24mm.

For this, it is necessary that the Intellilift is set up correctly.

See section 7.4.3.2

The emergency stop system will not work if the control valves are

not calibrated by Intellilift.

7.4.2. Communication

7.4.2.1. Cordless

Intellilift uses cordless communication. This means that

communication with the lifting units takes place via radio

waves.

The frequency of the cordless communication is 2.4 gigahertz.

ED.02518.00.001.R03.ENG

Page 50

Working with the machine

Dongle

7.4.2.2. Data cables

In places where the use of radio waves is not allowed, data cable communication

may be used.

See section 7.4.4.3 for how to switch between cordless and data cable

control.

For a wired connection of the lifting feet, the data cables are connected together

using RS-485 connection, in such a way that the following network arises:

Intellilift control

panel

The use of a network requires a closed circuit. Connect a dongle (terminator) to

the last unit in the circuit.

It is not important which cable is in which connector as long as the circuit is

terminated. The same applies to the dongle. The right- and left-hand connectors

are identical.

Switchbox, nothing

connected.

Switchbox, with connections

from one unit to the next

Connected switchbox, end of

the ring network.

Dongle

7.4.3. Normal operation

1. Switch the Intellilift control panel on by setting the “power” switch to “on”.

2. The Intellilift control panel will now start up; during start-up, the software

version number is displayed.

3. Before using, check that the control panel battery is fully charged.

This is to prevent problems due to a flat battery during the lifting operation.

A full battery has a capacity of around 8 hours.

ED.02518.00.001.R03.ENG

Page 51

Working with the machine

See section 7.4.7 for charging the battery.

(full battery on the display)

4. Ensure that the “Emergency stop” button on the Intellilift control panel is in

the non-activated position.

5. Switch the main power switches on the control panels on the units to “on”.

If the power supply is in order, the “power on” indicator on the control

panel of the unit in question will light up green.

6. Ensure that the “Emergency stop” buttons on the units’ control panels are in

the non-activated position.

7. Switch the local/remote selector switches on the units’ control panels to the

‘rem.’ position.

The “emergency active” indicator on the control panel of the unit in question

will light up blue.

8. Switch the “RAM SELECT” switches of the units you wish to operate to the

“on” position.

The units required can now be detected by the Intellilift control panel. If the

connection is in order, the “emergency active” indicator on the control panel

of the unit in question will go out.

9. As soon as the “emergency active” indicator has gone out, the unit can be

activated.

10.It is now possible to use the following functions: Lift, Travel, and Side shift.

A unit may be deactivated temporarily using the ram selection switches.

Only one function can be operated at a time.

Level indicator

7.4.3.1. Lift

If you want to start lifting or lowering, first check the values indicated on the lift

counter on the display.

Remember that the control unit keeps the lifting height of all units selected using

“ram select” within a hysteresis of 24 mm.

You can reset the values on the lift counter using the ZERO LIFT button.

By pressing this button, the current, absolute position is set as start point, so that

all lift counters indicate zero.

When you start the lifting or lowering action, the unit stops a ram as soon as the

lifting position exceeds the range by too much (more than the hysteresis of

20 mm).

ED.02518.00.001.R03.ENG

Page 52

Working with the machine

Once the position is back to within half of the hysteresis, the movement is

restarted.

Besides this, you may during lifting put the ‘speed’ switch into the “hare” position

to increase the speed while working without load.

Whenever one single ram is extended too far in comparison with the others (more

than half of the hysteresis), the movement is slowed until all the other rams are

within a quarter of the hysteresis range.

After repositioning the skid tracks, the beams must be levelled.

After this, give the zero lift command.

Always select "tortoise" mode on the "speed" selector switch

when working with a load on the machine.

7.4.3.2. Travel

The SBL system is a self-driven system. Each unit is provided with two

hydraulically-driven travel motors. These motors are connected via chains to the

roller tracks under the frames.

If the direction of one or more units does not match, this can be changed using

the “direction travel” selector switch on the control panel of the relevant unit.

Only use the "travel direction" selector switch after the machine

has come to a complete standstill.

Travel motor

Roller track

Travel motor

The synchronous travel of the four SBL units is realised using what are known as

pulse counters that are fitted on the output shaft of the travel motors:

ED.02518.00.001.R03.ENG

Page 53

Working with the machine

Pulse

Pulse gear

The pulses from each SBL unit are counted by the Intellilift remote control unit.

Whenever, on one unit, four pulses more than on the other three units are

counted, the drive to the unit concerned is briefly interrupted, until four more

pulses are added for the other three units. Then, the stopped SBL unit continues

travelling.

This four-pulse discrepancy is equivalent to a 15.4 mm difference in distance for

the SBL units. In other words, the maximum discrepancy between the four units is

15.4 mm. This is a standard setting that cannot be changed.

You may during travelling put the ‘speed’ switch into the “hare” position to

increase the speed while working without load.

Always select "tortoise" mode on the speed selector switch when

working with a load on the machine.

Every time the travel function is used, the synchronization is

reset.

Therefore, use this function until the lift is in the desired position.

If the machine comes to a complete standstill during travel:

check that there is nothing blocking the unit.

Position the individual units correctly before travelling further

with multiple units.

ED.02518.00.001.R03.ENG

Page 54

Working with the machine

7.4.3.3. Side shift

Each side shift is provided with an electrical drive. This drive has a single speed.

There is no equal-travel regulation, although the drive roller is provided with

knurling for sufficient traction on the beam. The side shifts on the same beam can

be coupled together mechanically with a coupling rod.

If the direction of one or more side shifts does not match, this can be changed

using the “side shift direction” selector switch on the control panel of the relevant

unit(s).

7.4.4. LCD screen

The LCD screen is provided with background lighting.

In order to extend the battery life, the background lighting is switched off if no

changes are detected for a period of 15 seconds.

Only use the "side shift direction" selector switch after the

machine has come to a complete standstill.

7.4.4.1. Level indicator

The following values are displayed on the screen:

• The total load on the selected units: “Tot”

• The absolute “position” for each unit

• The “lift” position with respect to the zero lift position

• The “load” on each unit

You can read the load on each selected cylinder separately from the control panel.

The values indicated for the non-selected cylinders are invalid! The load indicated

is calculated using the value from the pressure sensor and the ram range. Given

that the cylinder has multiple stages, the conversion factor changes from stage to

stage. Enerpac has configured the position where the factor change ought to take

place. Small errors in the position indication may cause a ‘jump’ in the load

indication at a switch point.

If an incorrect factor is used on the second or third stage, then an overload

message may be displayed. There is however no actual physical overload! This

can be resolved by recalibrating the position measurement, or by slightly reducing

the switchover point (please contact Enerpac for this).

Due to the nature of the hydraulic system, the load value is only

valid in static situations!

ED.02518.00.001.R03.ENG

Page 55

Working with the machine

7.4.4.2. Overload warning

If the calculated load is above the maximum value, an asterisk appears before and

after the load value (*900*).

Once this indication appears, it is not possible to extend the unit in question any

further.

7.4.4.3. Communication timeout

When it becomes difficult to communicate with a certain unit, a message like this

appears: Communication-time-out.

Try moving to a different position – this usually helps. (The fault may be caused

by reflections in areas known as reception dead areas.) Also check that the unit in

question is still receiving power.

Switching to data cable control (RS485 mode)

If you experience many problems in cordless mode, as a result of external

influences or a fault, you may use wired mode.

• Switch off the Intellilift control panel and the main power switches on the

units.

• Connect the communications cable between the Intellilift panel and the

units.

o First switch all units on according to steps 5 to 8

in section 7.4.3.

• Switch on the Intellilift panel with all selection switches in the OFF position;

if communication is working properly, a star will be displayed after the lift

value – see illustration

• The LCD display indicates that the control has been switched to wired and

the cordless control is deactivated until you switch the control panel off and

back on again (without cables connected).

ED.02518.00.001.R03.ENG

Page 56

Working with the machine

7.4.5. Emergency stop system

If the emergency stop button on the control panel is pressed, the message

“***Emergency pressed***” appears on the display.

This message also appears when the emergency stop button on one of the units is

pressed, but only if that unit's cylinder was selected!

The display also shows which unit caused the emergency switch-off.

In such cases, the main motors for all cylinders are stopped.

The system may be started up again by going through steps 6 to 8 in section

7.4.3.

7.4.6. Switching off the control panel

When the control panel is switched off, you can no longer control the units.

If the units receive no signals for 2 seconds, all outputs switch to a stand-by

condition.

If the ram receives no messages for 10 seconds, the main motor is also switched

off.

After the connection is restored, the system may be started up again by going

through steps 6 to 8 in section 7.4.3.

If the control panel is switched off during an emergency situation, the main power

supply to all units must be switched off for at least 20 seconds before the system

can be restarted.

7.4.7. Charging the battery

There is a lithium ion battery in the control unit. The battery has a capacity of

around 8 hours in normal operating mode. In order to extend the battery life, the

background lighting is switched off if no changes are detected for a period of

15 seconds.

After completing a lifting operation, connect the charger to the control panel (set

the power switch to the OFF position). The display shows the current battery level

and charging status. A fully charged battery should read 8.4 V. The charger feeds

the circuit a controlled 12.0V power supply.

Do not use any other voltage levels, as this may damage the

circuit!

Do not charge the battery at temperatures below 0ºC (32º

Fahrenheit) or above 45ºC.

Only use the adapter provided with the equipment to charge the

batteries.

ED.02518.00.001.R03.ENG

Page 57

Working with the machine

7.4.8. Settings

7.4.8.1. Learning a replacement Intellilift control panel

Each control panel has a unique code. In order to make control possible, you must

match the separate receivers with the control panel. This has usually already been

done by the programmers at Enerpac. But in the case of a serious fault, it may be

necessary to reprogram the panel. This is also true when the old panel is replaced

with a new one. The matching remains valid, even after switching off the power.

Steps to reprogram the panel:

1. Check that the battery is fully charged

2. Switch off all ram selection switches on the control panel

3. Switch on the control panel

4. Switch on the unit to be ‘matched’

5. Put the RAM SELECT SWITCH 1 (on the control panel) to ON

6. On cylinder 1, press and hold the ‘LEARN’ button for about half a second

(and then release it)

7. As soon as the NO ANSWER message disappears, set the RAM SELECT

SWITCH back to OFF

8. Repeat steps 5 to 7 for cylinders 2, 3 and 4

If the control panel is switched on first, then the system will start

up faster during power up.

Always ensure that you match RAM 1 with selection switch 1, given that the

settings are individually calibrated!

ED.02518.00.001.R03.ENG

Page 58

Working with the machine

7.4.8.2. Recalibration procedure

This subsection describes how to reset the masts to zero position:

Step 1: Set all cylinders to the minimum position

Step 2: Deselect all cylinders

Step 3: Switch off the power supply to the remote control unit

Step 4: Switch the “Speed switch” to the ‘hare’ symbol (high speed)

and press the “Zero lift” button.

Step 5: Keep the “Zero lift” button pressed and switch on the power

supply to the remote control.

Step 6: Keep the “Zero lift” button pressed until the message “System

not ready” appears on the remote control unit display

ED.02518.00.001.R03.ENG

Page 59

Working with the machine

Step 7: Release the “Zero lift” button and the “Calibration mode”

message will appear on the display

Step 8: Now select the cylinder you wish to calibrate, wait for about 5

seconds and then deselect the cylinder.

Step 9: Thereafter the power supply to the remote control unit should

be switched off. The cylinder position is now calibrated and the position on

the display is around 0 mm

If the calibration proceeded successfully, this message appears:

“Calibration succeeded”.

If there was poor communication during the calibration, causing it to fail,

the following message appears:

”Calibration failure”.

ED.02518.00.001.R03.ENG

Page 60

Working with the machine

communication timeout to

7.4.9. Correction of faults

Here you find a short list of possible faults, their causes and solutions:

Symptom

Load value –300 (large

negative value)

Large negative position

value

All units selected, but

none move up

All units selected, but

only one moves up

After switching on the

control panel, it will take

a moment for the

disappear.

No display indication after

switching on the control

unit

Communication problems

when you place your

hand on the top right

corner of the control

panel

Possible cause

Faulty wiring or loose

connector on the LED

indicator

Faulty wiring, loose

sensor wire

Possible solution

Check the wiring,

measure the current

(should be 4 - 20mA)

Check the position

reading for the physical

cable, check the position

sensor

One of the main motors

has stopped, is outside of

Press the START button

to restart the motor

the lifting hysteresis

Lifting value was not

reset, only the unit with

the lowest lifting value

moved up

This is normal – the

receivers continuously