Page 1

Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

L3080 Rev. D 06/14

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to

avoid personal injury or property damage

during system operation. Enerpac cannot be responsible for

damage or injury resulting from unsafe product use, lack of

maintenance or incorrect product and/or system operation.

Contact Enerpac when in doubt as to the safety precautions and

operations.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

Failure to comply with the following hazard alert statements could

cause equipment damage and/or personal injury:

WARNING: Make no modifi cations to any SafeLink

component. Any modifi cations to the product not

expressly approved by Enerpac could void the user’s

authority to operate the product. Contact Enerpac factory for more

information.

WARNING: SafeLink products must only be serviced by a

qualifi ed electronic technician. For factory authorized

repair service, contact the ENERPAC Authorized Service

Center in your area.

WARNING: Never use any component of the SafeLink

system as a sensing device for personal protection. Doing

so could lead to serious injury or death. The SafeLink

system does NOT include the self-checking redundant circuitry

necessary to allow its use in personal safety applications. A sensor

failure or malfunction can cause either an energized or deenergized sensor output condition.

SafeLink Pallet Monitoring System

WARNING: Some SafeLink components are powered by

a 3.6 volt lithium battery. As with all batteries, there is a

fi re, explosion, and severe burn hazard risk. Do not burn

or expose the battery to high temperatures. Do not recharge,

crush, disassemble, or expose the contents to water.

WARNING: All live supply circuits must be disconnected

before wiring the machine control.

WARNING: To avoid personal injury, keep hands and feet

away from fi xture cylinder(s) and workpiece during

operation.

Note: All specifi cations published in this document are subject to

change. Enerpac reserves the right to modify the specifi cations of

products without notice. Enerpac reserves the right to update or

change documentation at any time.

1

Page 2

3.0 SPECIFICATIONS

Table 1 - General Specifi cations

IP Rating Meets IEC IP67 Standards. Dust tight, immersion up to one meter.

Radio Frequency 2.4 GHz, Global Standard

Transmit Power 21 dBm conducted

Input Power for Receive Unit (SLR-1, SLR-2) + 10 VDC to + 30 VDC Supplied by machine control.

Battery for Send Unit (SLS-1, SLS-2, SLS-3) 3.6 Volt Lithium Battery, Size D (Xeno XL-205F or equivalent).

Outputs + 24 VDC, NMOS Sinking

FCC Rating FCC part 15, Subpart C, 15.247

Receive Unit Communication Protocols

(SLR-1, SLR-2)

Receive Unit Outputs (SLR-1, SLR-2) 24 VDC, Maximum of 6 per unit, NPN Sinking

Modbus RTU RS485. Modbus TCP/IP or Ethernet IP when

system is equipped with SLEB-1 Ethernet Bridge.

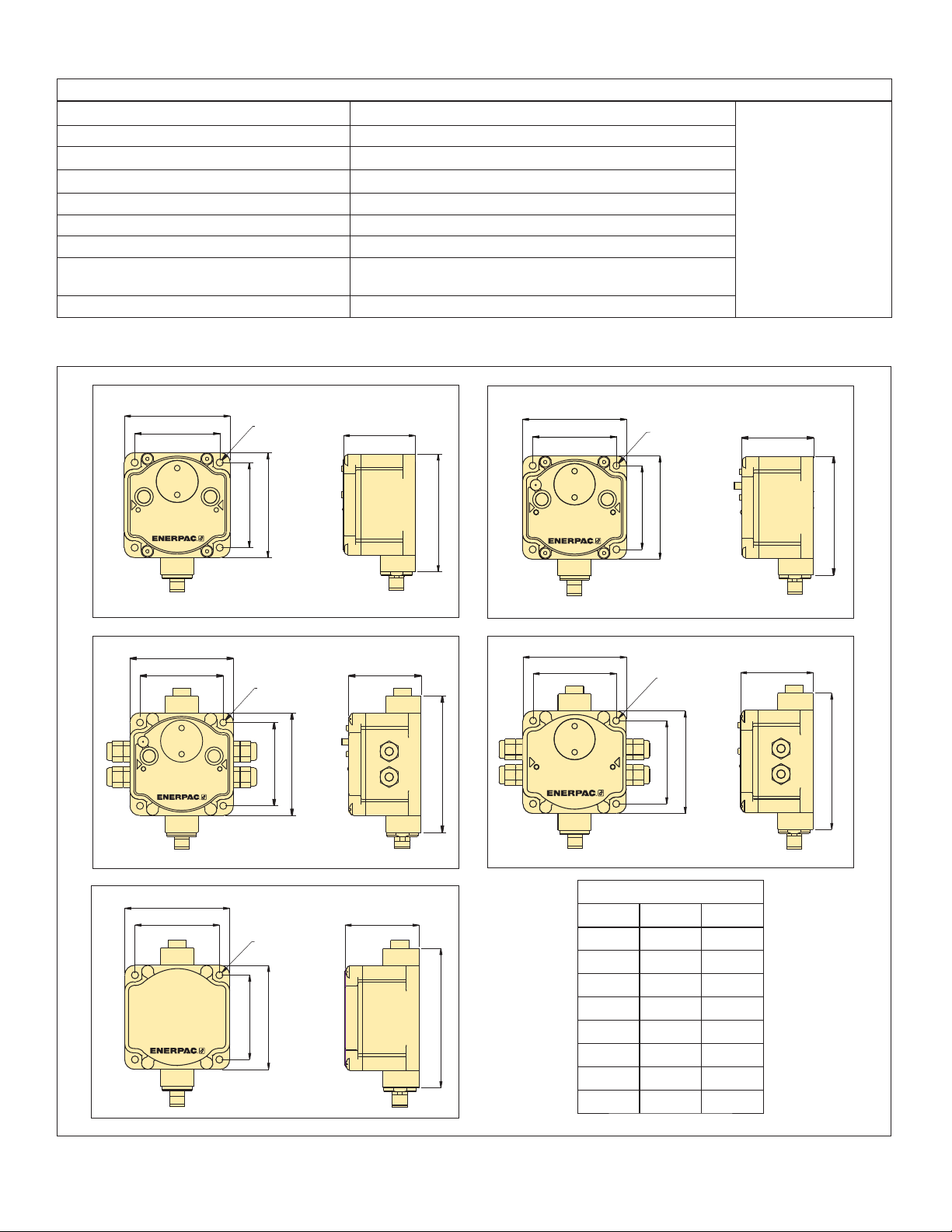

4.0 MOUNTING DIMENSIONS

SEND UNIT

INPUT CAPABILITIES:

SLS-1 & SLS-2: Monitors

two inputs and contains

a communications check

channel (For use only

with receive unit Model

SLR-1).

SLS-3: Monitors three

inputs (For use only

with receive unit Model

SLR-2).

D1

D2

D1

D2

D3

(4X)

D5

D4

D6

SLR-1, SLR-2 Receive Unit

D3

(4X)

D4

D5

D8

D6

D7

D1

D2

D3

(4X)

D5

D4

D6

D8

Note: Antenna not shown.

D1

D2

SLEM-1 Expansion Module

D3

(4X)

D5

D4

D6

D7

SLS-1 Send Unit SLS-2, SLS-3 Send Unit

Note: Antenna not shown.

D1

D2

D4

SLEB-1 Ethernet Bridge

D3

(4X)

D5

D6

D7

Dimensions

Item inch mm

D1

D2

D3

D4

D5

D6

D7

D8

3.18 80,8

2.56 65,0

Ø 0.22 Ø 5,5

2.56 65,0

3.16 80,1

2.23 56,6

4.20 106,7

3.67 93,2

Figure 1, Mounting Dimensions

2

Page 3

5.0 MAJOR FEATURES AND COMPONENTS

SLS-1, SLS-2 and SLS-3 Send Unit SLR-1 and SLR-2 Receive Unit

H

HHH

B C, D

E

A

F

G

I

Key:

A. LED indicator, #1

B. Push Button, #1

C. Rotary Switch, “Left”

D. Rotary Switch, “Right”

E. Push Button, #2

F. LED indicator, #2

G. LCD Display

H. Antenna (SLS-2, SLS-3,

SLR-1 and SLR-2 only)

I

B

C, D

A

G

K

I. 1/2" NPT Port (equipped with plug if not used)

J. Access Holes (equipped with caps if not used)

K. Quick Disconnect Serial Port, 5-Pin M12

E

J

F

SLEM-1 Expansion Module SLEB-1 Ethernet Bridge

I I

C, D

J

K K

Figure 2, Major Features and Components

Note: The Enerpac SLCS-1 Power and Communication Splitter

Cable (sold seperately - see Figure 17) is required for use with the

SLEM-1 Expansion model or the SLEB-1 Ethernet Bridge.

Note: Housing color on current production models is black. Yellow

housing shown in this manual is for illustrative purposes only, to

help ensure that product features and details are clearly visible.

3

Page 4

6.0 INSTALLATION

6.1 Overview

The SafeLink wireless pressure monitoring system continuously

monitors the clamping pressure in a fi xture during the machining

process. It is designed to be interfaced to the machine control so

the machine can be stopped immediately if clamping pressure is

lost. If desired, the SafeLink system can also be used to monitor

limit switch based position sensing on clamping cylinders.

The basic SafeLink system consists of a battery powered send

unit (SLS-1, SLS-2 or SLS-3) mounted in or on the fi xture, and

a matching receive unit (SLR-1 or SLR-2) that is connected and

interfaced to the machine control. Radio communication between

the two units is 2.4 GHz.

Pressure switches (sold separately) are installed in each fi xture

circuit to be monitored. Loss of pressure in one or more of the

switches is communicated from the send unit to the receive unit,

resulting in a fault condition being triggered. The machine control

will then initiate appropriate shut down of the machinery.

A special communication verifying feature in the receive unit

periodically queries the send unit every few seconds, to ensure

that it is responding. If there is no response, a fault condition

will be triggered, and the machine control will initiate appropriate

shut down of the machinery.

Up to 47 send units can be linked to one receive unit if

TCP/IP or Ethernet IP communication protocol is used. These

Modbus

protocols require the use of the SafeLink SLEB-1 Ethernet Bridge.

IMPORTANT: Installation and setup instructions are contained

in the following sections of this manual. These instructions are

intended only for use by experienced installation technicians with

appropriate skills and training. If custom installation services are

required, contact Enerpac for additional information.

6.2 Installing the SLR-1 or SLR-2 Receive Unit

The SLR-1 or SLR-2 receive unit should be mounted on an

external surface on the machine control enclosure, or inside of

the control enclosure on a DIN Rail using the Enerpac SLDB-1

DIN rail mounting bracket (optional accessory). See Figure 3.

6.3 Installing the SLS-1 Send Unit on a Fixture

The SLS-1 send unit must be mounted externally on the fi xture

in a location that does not expose the unit to excessive coolant

fl ow or fl ying chips.

It must be positioned so that the internal antenna can transmit

freely without interference. Use the four 5 mm mounting holes on

the base to securely mount the unit.

The SLS-1 is IEC rated at IP67, protected from dust and

immersion to 1 meter.

6.4 Installing the SLS-2 or SLS-3 Send Unit

on a Fixture

The SLS-2 and SLS-3 send units are intended to be mounted

inside of a fi xture (such as a four-sided tombstone) in a location

that does not expose the unit to excessive coolant fl ow or fl ying

chips. The SLS-2 and SLS-3 are IEC rated at IP67, protected

from dust and immersion to 1 meter. Use the four 5 mm mounting

holes on the base to securely mount the unit.

Both models contain an external antenna jack and separate

antenna. The antenna can be cabled if the fi xture has a cover.

Use the Enerpac SLS-2AC cable (optional accessory) to connect

either SLS send unit to an externally mounted antenna.

7.0 WIRING AND CONNECTIONS

7.1 Pressure Switch Installation and Wiring

All pressure switches should be located in a protected area,

where they are not exposed to excessive coolant fl ow or fl ying

chips. Wire each switch normally open, so that the circuit in the

pressure switch will close when the pressure setting is reached,

but will go open if the system pressure has decreased below

acceptable limits.

The use of an Enerpac PSCK-8 or PSCK-9 pressure switch

(optional accessory) is recommended. Connect wires to

terminals 1 and 3, so that the switch is wired normally open. See

Figure 4 for switch wiring details. Refer to Enerpac instruction

sheet L2391 for additional information regarding PSCK pressure

switch installation.

Figure 3, SLDB-1 DIN Rail Mounting Bracket (optional)

The SLR-1 and SLR-2 receive units require a connection to a 24

VDC power supply. A connection of the output from the SLR-1

or SLR-2 into the machine control is also required.

Note: The SLR receive units communicate to the machine

control via either a 24 VDC output or via Modbus RTU RS485

protocol. If Modbus TCP/IP or Ethernet IP protocols are used,

the optional SLEB-1 Ethernet Bridge is required. See sections 9

and 10 of this manual for additional information.

Both models contain an external antenna jack and separate

antenna. The antenna can be cabled if the control enclosure has

a cover. Use the Enerpac SLS-2AC cable (optional accessory)

to connect either SLR receive unit to an externally mounted

antenna.

1

3

2

PSCK-8, PSCK-9

Wiring Diagram

Function Terminal

Common 1

Normally Closed 2

Normally Open 3

Ground (not used) 4

1

3

DIN Style connector plug

(with protective cover removed)

1

3

2

2

4

Figure 4, Pressure Switch Connections (typical)

7.2 Wiring Pressure Switch to the Send Unit

(SLS-1, SLS-2 or SLS-3)

Connect the pressure switch to the SLS send unit as described

in the following procedure:

4

Page 5

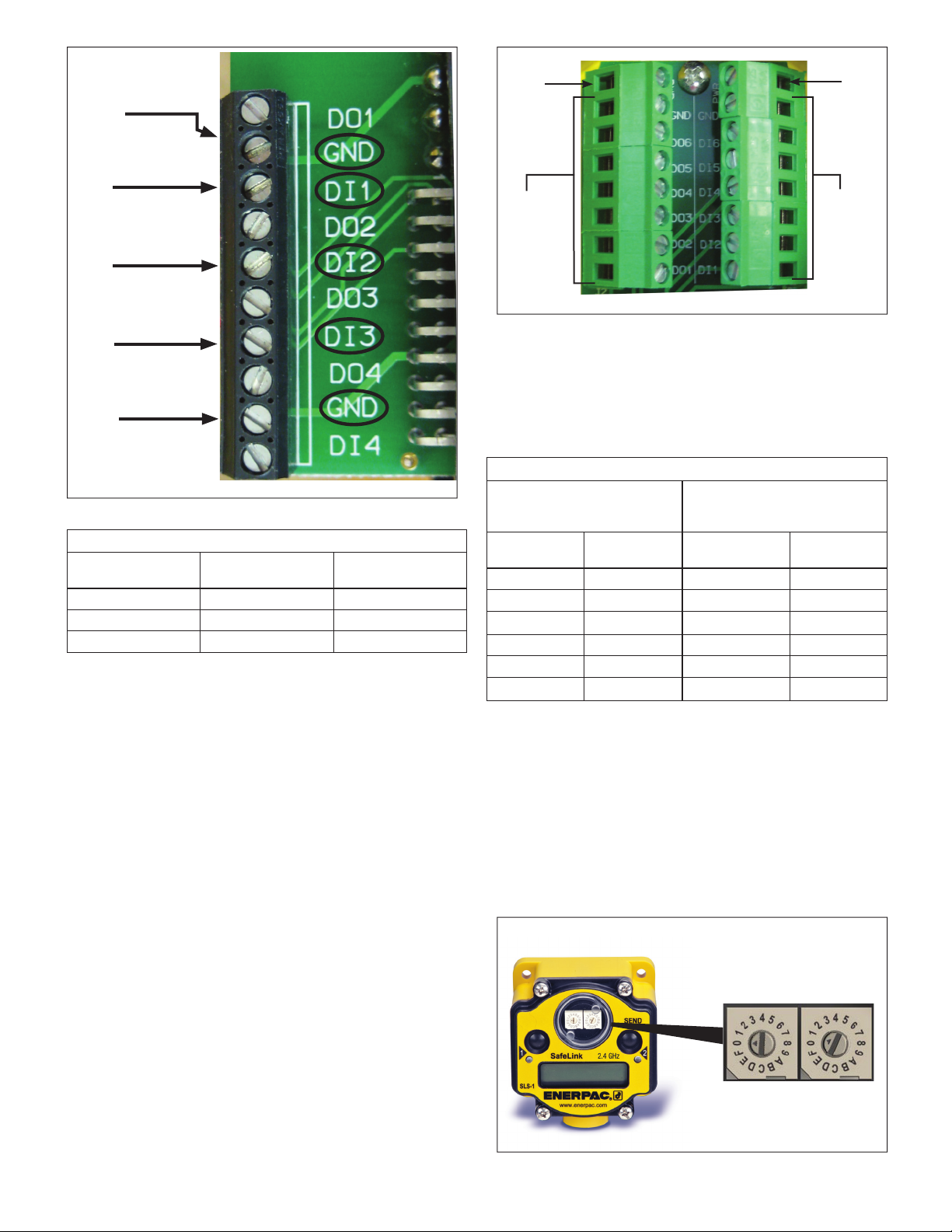

Ground Terminal

(GND)

Input 1 Terminal

(DI1)

Input 2 Terminal

DI2)

(

SLS-3 Only:

Input 3 Terminal

(

DI3)

Ground Terminal

(GND)

Figure 5, Send Unit Terminal Block (SLS-1, SLS-2, SLS-3)

Table 2 - SLS-1, SLS-2 and SLS-3 Wiring information

Input

Function

Input #1

Input #2

Input #3 (SLS-3 only)

SEND UNIT Input

Connection Terminal

DI1 GND

DI2 GND

DI3 GND

SEND UNIT Ground

Terminal

Remove the four screws that secure the face plate of the SLS

send unit. Locate the terminal strip inside the housing. See Figure

5.

Wire the leads from the pressure switch to the DI1 and ground

terminals per Table 2. Note that the strip contains two ground

(GND) connections. Use whichever one is most convenient. If

more than one pressure switch is used, be sure to connect them

in series.

A position sensing limit switch (if used) can be connected to

terminal DI2. Or, if desired, this terminal can instead be used to

connect one or more additional pressure switches.

IMPORTANT: Use only limit type position switches. Proximity

type switches are not compatible with the SafeLink system.

Note: For SLS-1 and SLS-2, communication input terminal

DI3 is assigned to a circuit that periodically checks for proper

operation of the sending unit during SafeLink operation. For SLS1 and SLS-2, DO NOT make any connections to terminal DI3.

Terminals DO1, DO2, DO3, DO4 and DI4 are NOT USED.

7.3 Connecting the 24 VDC Outputs of Receive Unit

SLR-1 or SLR-2 to the Machine Control

Note: This section covers typical connections using the standard

24 VDC I/O machine interface. If using Modbus RTU, Modbus

TCP/IP or Ethernet IP, please refer to sections 9 and 10 of this

manual.

Remove the four screws that secure the face plate of the SLR-1

or SLR-2 receive unit. Locate the receive unit terminal block. See

Figure 6.

PWR

Terminal

Output

Terminals

DO1 - DO6

PWR

Terminal

Input

Terminals

(not used)

Figure 6, Receive Unit Terminal Block (SLR-1, SLR-2)

Wire the output terminals of the SLR-1 or SLR-2 to the machine

control input terminals. Refer to Table 3 for SLR terminal block

connection information.

Note: Two + 24 VDC power terminals (PWR) are available at the

top of the terminal block. The DO-x outputs of the SLR receive

unit are pre-paired to the DI-x inputs of the SLS send unit.

Table 3 - SLR-1 and SLR-2 Wiring information

Send Unit ID and Input

(SLS-1, SLS-2, SLS-3)

ID # Input #

01

01

01 DI3* DO3* *

02

02

02

DI1 DO1 PWR

DI2 DO2 PWR

DI1 DO4 PWR

DI2 DO5 PWR

DI3

* DO6* *

8.0 SETUP

Receive Unit Terminals

(SLR-1, SLR-2)

See Figure 6

Output

(-24 VDC)

Power

(+24 VDC)

PWR

PWR

* SLS-3 only. * * SLR-2 only.

8.1 Selecting the Send Unit ID

Open clear round cover on SLS-1, SLS-2 or SLS-3.

Using the rotary switches, set the send unit ID. Start with “01” for

the fi rst send unit in your network. The second send unit would

be “02”. See Figure 7.

Note: The maximum number of send units that can be paired

with a receive unit will vary, depending on the communication

protocol being used. Refer to Section 9 of this manual for

additional information.

Set ID for each

SEND UNIT using

rotary switches.

5

Figure 7, Setting ID Number of SLS Send Unit

Page 6

Note: The rotary switches on the SLR receive unit are used only

to select the desired SLS send unit to be viewed on the receive

unit LCD display. They DO NOT determine the send unit ID.

Refer to Section 8.4 for additional information.

8.2 Turning Send Unit Power ON

Press and hold Button #1 on SLS send unit for 3-4 seconds

The display window will scroll though the status of each

possible I/O. LED #2 will fl ash red. See Figure 8.

Press and hold

Button #1 for

about 3 seconds

to turn ON.

LED #2 will

fl ash RED.

Figure 8, Turning Power ON - SLS Send Unit

8.3 Binding Send Unit to Receive Unit

Press Button #2 on the SLS send unit three times. The display

will show “NETWORK BINDING”. See Figure 9.

After binding occurs, the SLS send unit will fl ash BOUND

several times and will then begin scrolling. However, it will

remain in a standby mode until the SLR receive unit is returned

to the RUN mode.

Until the SLR receive unit is returned to the RUN mode, LED #2

on the SLS send unit will continue to fl ash red. Both LED #1 and

#2 on the receive unit will continue to fl ash alternately.

Note: At this time, repeat the binding procedure for any other

SLS send units in the network (if present).

After all SLS send units in the network have been bound,

press button #2 on the SLR receive unit once. The SLR

receive unit will exit BINDING mode and return to RUN mode.

Communication between the SLR receive unit and the SLS

send unit(s) is now enabled.

Note: After the SLR receive unit is placed in the RUN mode,

approximately 10-15 seconds will be required for the SLR

receive unit to begin communicating with the SLS send unit(s).

When the units begin communicating, LED #2 on the SLS send

unit will shut o and LED #1 will begin fl ashing green, indicating

that communication is in progress. See Figure 11.

On the SLR receive unit, LED #1 will change from fl ashing red to

a steady green. LED #2 will turn o . The display will then scroll

through an I/O status check. It will show “RUN”, the Network ID

(NID) of the system network and the status of each input (ON or

OFF). See Figure 13.

Note: Press Button #2 twice on either unit to stop the scrolling

display.

Press Button #2

on SEND UNIT three

times.

Display will show

“NETWORK BINDING”.

LED’s #1 and #2

will both fl ash RED.

Figure 9, Network Binding - SLS Send Unit

Press Button #2 on the SLR receive unit three times. Check that

display shows “BINDING”. This indicates that the radios in the

SLS and the SLR units are seeking each other. See Figure 10.

Press Button #2

on RECEIVE UNIT

three times.

Display will show

“BINDING”.

LED’s #1 and #2

will both fl ash RED.

Figure 10, Network Binding - SLR Receive Unit

Press button #2 once

on SLR RECEIVE

UNIT to return to

RUN mode and start

communication.

Figure 11, Starting Communication - SLR Receive Unit

LED #2 will be OFF.

LED #1 will fl ash GREEN

when SEND UNIT begins

communicating with

RECEIVE UNIT.

Figure 12, Communication In Progress - SLS Send Unit

6

Page 7

Display will begin scrolling

when RECEIVE UNIT is

placed in RUN mode.

LED #1 will turn GREEN

when SEND UNIT begins

communicating with

RECEIVE UNIT.

Figure 13, RUN Mode - SLR Receive Unit

7. Press button #1 to scroll to “RUN”.

8. The display will scroll through the status of the SLS send

unit selected by the rotary switches on the SLR receive

unit.

Press Button #1 on RECEIVE

UNIT to scroll to site.

Press button #2 to

begin viewing the

selected SEND UNIT.

Press button #2 again

to start the survey of

the signal strength.

8.4 Checking Signal Strength

The SLR-1 or SLR-2 can be used to measure the strength

of the wireless signal between each SLS send unit and the

SLR receive unit. Measure signal strength as described in the

following steps:

1. On the SLR receive unit, Set the rotary switches to the ID

number of the desired send unit to be viewed. See Figure

14.

Set RECEIVE UNIT rotary

switches to desired SEND

UNIT ID to be viewed.

Figure 14, Selecting Send Unit to be Viewed

by SLR Receive Unit

2. Press button #1 to scroll to “#SITE”.

3. Press button #2 to start SLR viewing mode. “NOD x” will

appear on the display (x = ID number of the SLS send unit

to be viewed by the SLR-1 receive unit). See Figure 15.

Press button #2 again to start the survey of the signal

4.

strength between the SLS send unit and the SLR receive

unit.

G = Good Signal Strength

Y = Medium Signal Strength

R = Low Signal Strength

M = Missed Signals

Note: The number (1-100) following the G, Y, R or M

indicates how many signal checks out of 100 are G, Y, R or

M.

5. Press button #2 twice to return to “NOD x”.

6. Press button #2 twice to set to “#SITE”.

Figure 15, Checking Signal Strength - SLR Receive Unit

8.5 LED Status Indicator Lights

During operation of the system, the LED lights provide a quick

visual indication of the status of the send units and the receive

unit.

See Tables 4 and 5.

Table 4 - SLR-1 and SLR-2 Receive Unit Status Indicators

STATUS LED 1 LED 2

Power ON

Modbus

Communication

Active

Modbus

Communication

Error

System Error

Green

OFF

OFF

Red Flash

Table 5 - SLS-1, SLS-2 & SLS-3 Send Unit Status Indicators

STATUS LED 1 LED 2

Green Flash

RF Link OK

(1 per second)

RF Link Error

System Error

OFF

Red Flash

OFF

Yellow Flash

Red Flash

(1 every 3 seconds)

Red Flash

OFF

Red Flash

(1 per second)

Red Flash

(1 per second)

7

Page 8

8.6 Removing an SLS Send Unit from the Network

Before taking a fixture out of service or moving it to another

system, the fixture’s SLS send unit must be removed from the

network.

Use the following procedure to unbind an SLS-1, SLS-2 or

SLS-3 send unit from an SLR-1 or SLR-2 receive unit:

Note: Refer to Section 5.0 for button locations.

1. On the SLS send unit, press and hold button #1 for 3 to 4

seconds. This will turn-off the send unit.

2. On the SLR receive unit:

• Check that the display shows “ERROR”.

• Press button #2 once.

Check that the display shows “NOD x”

Note: “x” is the ID number (node) of the SLS send unit that

was turned-o in step 1.

• Press button #2 again.

Check that the display shows “EC 53”.

• Press button #1.

Check that the display shows “CLEAR”.

• Press button #2 to accept the changes.

Check that the display shows “ERASED”.

The SLS send unit should now be unbound from the SLR

receive unit. It will no longer be included in the network.

9.0 SETTING UP EXPANDED SYSTEMS

Refer to Table 6 for an overview of SafeLink expansion

possibilities.

If only one or two additional SLS send units are required, the

SLEM-1 Expansion Unit can be used. For systems requiring

greater numbers of additional SLS send units (such as a pallet

pool system) the interface to the machine control can be

achieved using either the standard 5-Pin serial port connection

located on the SLR receive unit or by using the SLEB-1

Ethernet Bridge. The SLEB-1 allows the SafeLink system to be

connected to an Ethernet network.

9.1 Using the SLEM-1 Expansion Module

For systems with up to 4 fi xtures, where 24 VDC output is the

desired interface to the machine control, the SLEM-1 Expansion

Module (optional accessory) provides additional expansion

capabilities. The SLEM-1 allows up to two additional SLS send

units to be added to the SafeLink system.

The output terminal block of the SLEM-1 is the same as

that used on the SLR receive unit. See Figure 6 for wiring

instructions.

9.2 Setting up a Modbus Based System

For machine controls that use Modbus RTU or TCP protocols,

the SLR-1 and SLR-2 receive units provide a built in Modbus

system.

The Modbus Serial Line RTU protocol is a master-slave protocol

typically used for industrial applications. It is an open standard

implementation of Modbus based on Internet protocols.

Modbus TCP/IP is similar to Modbus RTU but transmits

information within TCP/IP data packets.

Table 6 - Expanded System Data and Recommendations

Number of

fi xtures:

1 SLS-1, SLS-2 or SLS-3 3 SLR-1 or SLR-2 24 VDC 6

2 SLS-1, SLS-2 or SLS-3 3 SLR-1 or SLR-2 24 VDC 6

3 to 4 SLS-1, SLS-2 or SLS-3 3 SLR-1 or SLR-2 with SLEM-1 24 VDC 12

5 or more

SafeLink send unit

model number:

SLS-1, SLS-2 or SLS-3 3 Modbus from SLR-1 or SLR-2 Modbus 47

SLS-1, SLS-2 or SLS-3 3 SLR-1 or SLR-2 with SLEB-1 Ethernet 47

Number of outputs

available from each

send unit:

Recommended connection to

machine control:

Output protocol:

Number of

outputs to

machine control:

Table 7 - Modbus Holding Registers

I/O Port Receive #1 Send #1 Send #2 Send #3 Send #4 Send #5 Send #6 Send #7 Send #8

1 173349658197113129

2 183450668298114130

3 193551678399115131

8 24 40 56 72 88 104 120 136

99

10 10

11 11

12 12

13 13

14 14

8

Page 9

Modbus RTU is the native protocol for the SafeLink system.

All wireless devices are organized with a two-byte register

for each I/O point. Sixteen registers are allocated for each

device, typically eight registers for inputs and eight registers

for outputs. For Modbus, these registers are addressed

consecutively beginning with the Receive (SLR-1 or SLR-2)

then Send 1 (SLS-1, SLS-2 or SLS-3) through Send (N) (SLS-1,

SLS-2 or SLS-3).

Go to www.modbus.org for additional information regarding

Modbus.

9.3 Holding Registers

Refer to Table 7 for additional information.

There are 16 Modbus holding registers for each SafeLink

device. A holding register is the location in the internal memory

of a PLC for a particular input. For example, in Table 7, I/O port

1 for Send#1 is register 17. This may correspond to a pressure

switch used on I/O port 1 in Send #1. Calculate the holding

register number for each device using the following equation:

Register number = 40,000 + (I/O # + (Send # x 16))

9.4 Modbus Connection to Controller

The Modbus output from the SLR-1 or SLR-2 receive unit is

through the 5pin European style serial connector located at the

bottom of the housing. See Figure 16 for wiring information.

A power and communication cable is supplied with the SLR-1

or SLR-2 receive unit. Additional components not included with

the SafeLink system may be required to interface with various

controllers. See your machine supplier for information on

required adaptors and other items that may be needed for your

installation.

9.5 Setting up Ethernet IP Communication

Ethernet setup is the same as for a Modbus based system.

Refer to Table 7 to determine the register assignments.

The default IP address for the SLEB-1 Ethernet Bridge is

IP 192.168.0.1.

Contact Enerpac for additional information if you wish to

reassign the SLEB-1 to a di erent IP address.

9.6 SLCS-1 Power and Communication Splitter Cable

The Enerpac SLCS-1 (optional

accessory) is used to connect the

SLEB-1 Ethernet Bridge and the SLR-1

or SLR-2 receive unit to the machine

controller and Ethernet network. See

Figure 17.

The SLCS-1 is also required when

using an SLEM-1 Expansion Module

with a standard 24 VDC I/O machine

interface.

Refer to Figures 19 through 25 in

Section 10.0 for typical hookups using

the SLCS-1.

Figure 17, SLCS-1

Wire No Wire Color Description

1 Brown 10 to 30 VDC

2 White RS485 / D1 / B / +

3 Blue DC Common (Ground)

4 Black RS485 / D0 / A /-

5 Gray Communications Ground

CAUTION: DO NOT connect DC Power to pins #2

(white wire) #4 (black wire) or #5 (gray wire). Doing

so will cause permanent damage to the SLR receive

unit. Such damage is not covered under warranty.

Figure 16, 5-Pin Serial Port Connector (SLR-1 or SLR-2)

9

Page 10

10.0 TYPICAL SYSTEM LAYOUTS

PALLET #1

Input #1

Input #2

SLS-1 or SLS-2

PALLET #1

Input #1

Input #2

SEND/RECEIVE connected

“SEND” unit

SLR-1

“RECEIVE”

unit

PALLET #2

Input #1

Input #2

SLS-1 or SLS-2

PALLET #2

Input #1

Input #2

SEND/RECEIVE connected

“SEND” unit

Figure 18, Basic System with I/O Machine Interface

(SLS-1 or SLS-2 with SLR-1)

machine controller

Output to machine controller: 24 VDC from RECEIVE unit.

PALLET #1

Input #1

Input #2

SLS-1 or SLS-2

PALLET #1

Input #1

Input #2

SEND/RECEIVE connected

“SEND” unit

PALLET #2

Input #1

Input #2

SLS-1 or SLS-2

SLCS-1

“SPLITTER

CABLE”

PALLET #2

Input #1

Input #2

SEND/RECEIVE connected

“SEND” unit

PALLET #3

Input #1

Input #2

SLS-1 or SLS-2

“SEND” unit

PALLET #4

Input #1

Input #2

SLR-1

“RECEIVE”

unit

SLEM-1

“EXPANSION

MODULE”

PALLET #3

Input #1

Input #2

SEND/RECEIVE connected

PALLET #4

Input #1

Input #2

SEND/RECEIVE connected

machine controller

SLS-1 or SLS-2

“SEND” unit

Figure 19, Larger System with I/O Machine Interface (SLS-1 or SLS-2 with SLR-1)

Output to machine controller: 24 VDC from RECEIVE unit and EXPANSION

MODULE.

10

Page 11

PALLET #1

Input #1

Input #2

SLS-1 or SLS-2 “SEND” unit

PALLET #2

Input #1

Input #2

SLS-1 or SLS-2 “SEND” unit

SLR-1

PALLET #3

Input #1

Input #2

“RECEIVE”

unit

SLS-1 or SLS-2 “SEND” unit

PALLET #4

Input #1

Input #2

SLS-1 or SLS-2 “SEND” unit

Figure 20, Larger System with Modbus RTU Machine Interface

(SLS-1 or SLS-2 with SLR-1)

PALLET #1

Input #1

Input #2

SLS-1 or SLS-2 “SEND” unit

machine controller

Output to machine controller: Modbus RTU RS-485.

PALLET #2

Input #1

Input #2

SLCS-1

“SPLITTER

CABLE”

SLS-1 or SLS-2 “SEND” unit

PALLET #3

Input #1

Input #2

SLS-1 or SLS-2 “SEND” unit

SLR-1

“RECEIVE”

unit

SLEB-1

“ETHERNET

BRIDGE”

PALLET #4

Input #1

Input #2

SLS-1 or SLS-2 “SEND” unit

machine controller

Output to machine controller: Ehternet IP or Modbus TCP/IP.

Figure 21, Larger System with Ethernet IP Machine Interface (SLS-1 or SLS-2 with SLR-1)

11

Page 12

PALLET #1

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

PALLET #1

Input #1

Input #2

Input #3

PALLET #2

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

Figure 22, Basic System with I/O Machine Interface

PALLET #1

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

SLR-2

“RECEIVE”

unit

PALLET #2

Input #1

Input #2

Input #3

(SLS-3 with SLR-2)

PALLET #1

Input #1

Input #2

Input #3

machine controller

Output to machine controller: 24 VDC from RECEIVE unit.

PALLET #2

Input #1

Input #2

Input #3

SLCS-1

“SPLITTER

CABLE”

PALLET #2

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

PALLET #3

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

PALLET #4

Input #1

Input #2

Input #3

SLR-2

“RECEIVE”

unit

SLEM-1

“EXPANSION

MODULE”

PALLET #3

Input #1

Input #2

Input #3

PALLET #4

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

Figure 23, Larger System with I/O Machine Interface (SLS-3 with SLR-2)

12

machine controller

Output to machine controller: 24 VDC from RECEIVE unit and EXPANSION

MODULE.

Page 13

PALLET #3

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

PALLET #3

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

SLR-2

“RECEIVE”

unit

PALLET #3

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

PALLET #3

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

Figure 24, Larger System with Modbus RTU Machine Interface

(SLS-3 with SLR-2)

machine controller

Output to machine controller: Modbus RTU RS-485.

13

Page 14

PALLET #1

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

PALLET #1

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

PALLET #1

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

SLCS-1

“SPLITTER

CABLE”

SLR-2

“RECEIVE”

unit

SLEB-1

“ETHERNET

BRIDGE”

machine controller

PALLET #1

Input #1

Input #2

Input #3

SLS-3 “SEND” unit

Figure 25, Larger System with Ethernet IP Machine Interface

Output to machine controller: Ehternet IP or Modbus TCP/IP.

(SLS-3 with SLR-2)

14

Page 15

11.0 MAINTENANCE

Follow these instructions to perform basic maintenance tasks.

11.1 Replacing The Main Body Gasket

Check the main body

gasket every time the

device is opened.

Replace the gasket

when it is damaged,

discolored, or showing

signs of wear.

The gasket must be:

• Fully seated within its

channel along the full

length of the perimeter,

and. . .

• Positioned straight

within the channel with

no twisting, stress, or

stretching.

Figure 26, Main Body Gasket

11.2 Replacing The Rotary Dial Cover

Check the o-ring on the rotary switch access cover whenever the

access cover is removed. Replace the o-ring when it is damaged,

discolored, or showing signs of wear.

The o-ring should be:

• Seated fi rmly against the

threads without stretching

to fi t or without bulging

loosely, and. . .

• Pushed against the

fl anged cover.

When removing or closing

the rotary switch access

cover, manually twist the

cover into position.

Do not allow crossthreading between the

cover and the device’s

face.

Once the cover is in place and manually tightened, use a small

screwdriver (no longer than 5 inches [127 mm] total length) as a

lever to apply enough torque to bring the rotary switch access

cover even with the cover surface.

Figure 27, Rotary Switch Cover

11.3 Battery Replacement

To replace the lithium “D” cell battery in the SLS-1, SLS-2 or

SLS-3 send unit, follow these steps:

1. Remove the four screws mounting the device face plate to

the housing and remove the face plate.

2. Remove the discharged battery and replace with a new

battery. Use only a 3.6V lithium battery from Xeno, model

number XL-205F.

3. Verify the battery’s positive and negative terminals align to

the positive and negative terminals of the battery holder

mounted within the case. The negative end is toward the

spring. Caution: There is a risk of explosion if the battery is

replaced incorrectly.

4. After replacing the battery, allow up to 60 seconds for the

device to power up.

Figure 28, Battery

(SLS-1, SLS-2 and SLS-3 Only)

When removing the battery, press the battery towards the

negative terminal to compress the spring. Pry up on the battery’s

positive end to remove from the battery holder. Properly dispose

of your used battery according to local regulations by taking it to

a hazardous waste collection site, an e-waste disposal center, or

other facility qualifi ed to accept lithium batteries.

WARNING: As with all batteries, these is a fi re,

explosion, and severe burn hazard risk. Do not burn or

expose the battery to high temperatures. Do not

recharge, crush, disassemble, or expose the contents to water.

12.0 PRODUCT WARRANTY

SafeLink products are warranted by Enerpac to be free from

defects in material and workmanship for 2 years following the

date of shipment. Enerpac will repair or replace, free of charge,

any SafeLink product which, at the time it is returned to the

factory, is found to have been defective during the warranty

period. This warranty does not cover damage or liability for

misuse, abuse, or the improper application or installation of the

SafeLink product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED

(INCLUDING, WITHOUT LIMITATION, ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE), AND WHETHER ARISING UNDER COURSE OF

PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the

discretion of Enerpac, replacement. IN NO EVENT SHALL

ENERPAC BE LIABLE TO BUYER OR ANY OTHER PERSON

OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES,

LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL

OR SPECIAL DAMAGES RESULTING FROM ANY PRODUCT

DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY,

STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR

OTHERWISE.

Enerpac reserves the right to change, modify or improve the

design of the product without assuming any obligations or

liabilities relating to any product previously manufactured by

Enerpac.

15

Page 16

Enerpac Worldwide Locations e-mail: info@enerpac.com internet: www.enerpac.com

Australia and New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

T +61 (0)2 9743 8988

F +61 (0)2 9743 8648

sales-au@enerpac.com

Brazil

Power Packer do Brasil Ltda.

Rua

Luiz Lawrie Reid, 548

09930-760

T +55 11 5525 2311

Toll Free: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

customer.service@actuant.com

China

Actuant (China) Industries Co. Ltd.

No. 6 Nanjing East Road,

Taicang Economic Dep Zone

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

Toll Free: +86 400 885 0369

sales-cn@enerpac.com

France, Switzerland, North Africa

and French speaking African

countries

ENERPAC

Une division d’ACTUANT France S.A.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

sales-fr@enerpac.com

-

Diadema (SP) - Brazil

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf, Germany

T +49 211 471 490

F +49 211 471 49 28

sales-de@enerpac.com

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore, 560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

sales-in@enerpac.com

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

sales-it@enerpac.com

Japan

Applied Power Japan LTD KK

Besshocho 85-7

Kita-ku, Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

sales-jp@enerpac.com

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Oce 423, LOB 15

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

sales-ua@enerpac.com

Russia

Rep. oce Enerpac

Russian Federation

Admirala Makarova Street 8

125212 Moscow, Russia

T +7 495 98090

F +7 495 98090 92

sales-ru@enerpac.com

Southeast Asia, Hong Kong

and Taiwan

Actuant Asia Pte Ltd.

83 Joo Koon Circle

Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free: +1800 363

sales-sg@enerpac.com

91

7722

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

sales-kr@enerpac.com

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

sales-es@enerpac.com

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg,

Central and Eastern Europe,

Baltic States, Greece, Turkey

and CIS countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 535 848

sales-nl@enerpac.com

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P.O. Box 421

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

integratedsolutions@enerpac.com

South Africa and other English

speaking African countries

Enerpac Africa Pty Ltd.

No. 5 Bauhinia Avenue

Cambridge Oce Park

Block E

Highveld Techno Park

Centurion 0157

South Africa

T: +27 12 940 0656

United Kingdom and Ireland

ENERPAC UK Ltd.

5 Coopies Field

Morpeth, Northumberland

NE61 6JR, England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

sales-uk@enerpac.com

USA, Latin America and Caribbean

ENERPAC

P.O. Box 3241

Milwaukee WI 53201 USA

T +1 262 293 1600

F +1 262 293 7036

User inquiries:

T +1 800 433 2766

Distributor inquiries/orders:

T +1 800 558 0530

F +1 800 628 0490

Technical inquiries:

techservices@enerpac.com

sales-us@enerpac.com

All Enerpac products are guaranteed

against defects in workmanship and

materials for as long as you own them.

For the location of your nearest authorized

Enerpac Service Center, visit us at

www.enerpac.com

121313

Loading...

Loading...