Page 1

Instruction Sheet

S-Series

Hydraulic Torque Wrenches

EIS 59.113-1

08/2005

Page 2

Choose the required product series

from the left side of the screen, then

click on the required language.

The following languages are listed:

CD with Instruction Manuals in PDF-format

Please find the CD enclosed in the back of this manual

English

Français

Deutsch

Italiano

Español

Nederlands

Portuguese

Svenska

Norsk

Suomi

Pycc

КИЙ

The install program of the Acrobat

Reader 6.0 is included on the CD.

Page 3

ENGLISH

3

Index

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Assembly and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Maintenance and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Recommended spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Instruction manual Torque wrench

S-series

Page 4

4

ENGLISH

Enerpac declares that these models meet

the applicable standards and directives

issued by the European Community.

For a detailed list refer to the separate

certification sheet.

2 Safety

Be aware that the operator is fully

responsible during the operation of this

tool. Enerpac is not responsible for

damage or injury caused by misuse of this

tool. Under some circumstances additional

safety requirements may be required.

Contact Enerpac immediately if a

potentially hazardous situation arises.

Read this manual carefully and observe all

safety precautions.

- Make sure you have completed a

safety induction training, specific to

the work surroundings. The operator

should be thoroughly familiar with the

controls and the proper use of the

tool.

- The operator must be at least 18

years of age.

- Always wear protective headwear, ear

protectors, footwear and gloves (at a

minimum rigger type gloves) suitable

for safe operation of the tool. The

protective clothing must not interfere

with safe operation of the tool or

restrict the ability to communicate

with co-workers.

- Make sure your workplace is safe.

- Do not place any part of the body

between the reaction arm and the

reaction point.

- Do not place any objects between the

reaction arm and the reaction point.

Keep the hoses away from the

reaction points.

1 Introduction

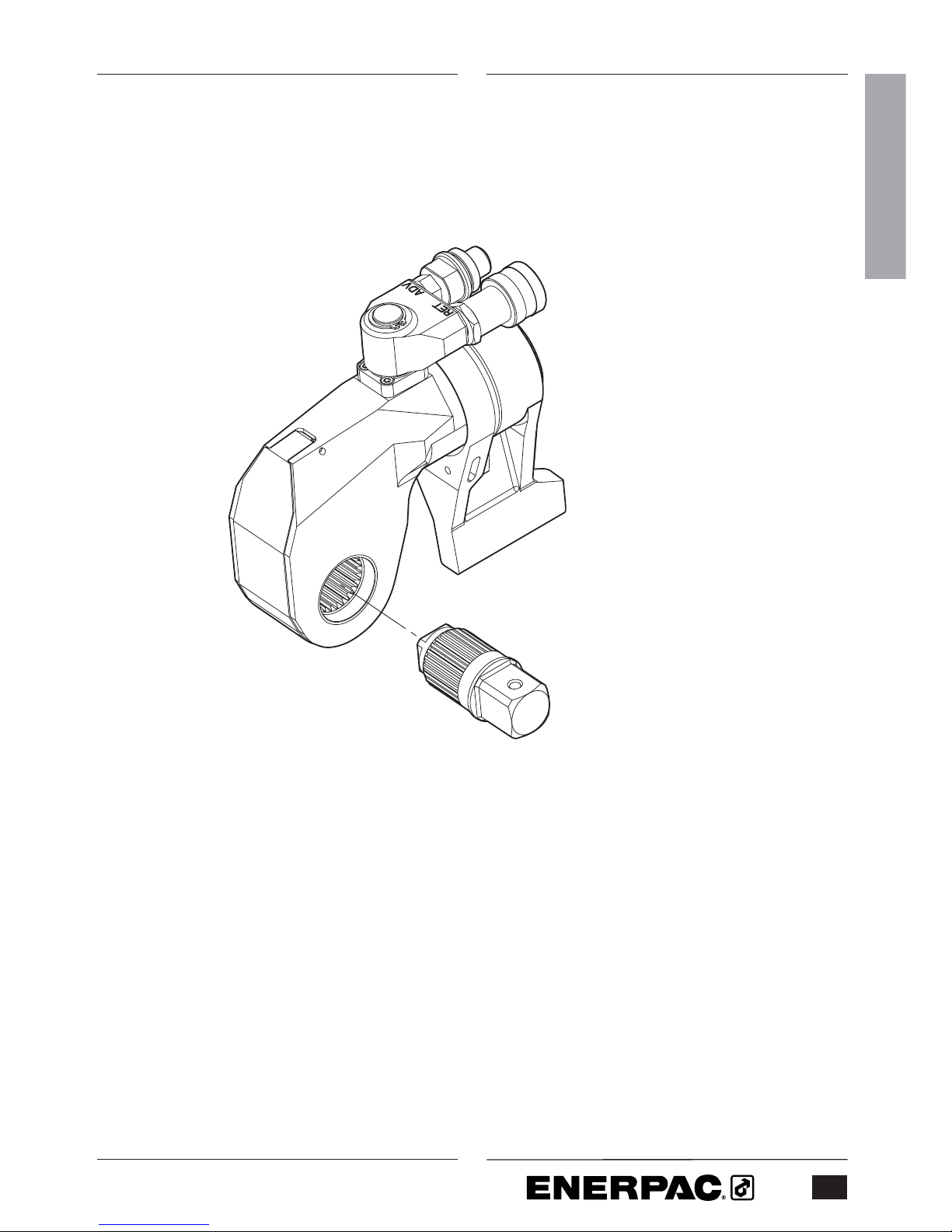

Enerpac S-Series

The Enerpac S-series of lightweight

hydraulic wrenches have been designed to

tighten and loosen nuts and bolts for

professional applications. The tool has an

interchangeable drive shaft for which a

wide range of socket sizes are available.

The adjustable reaction arm further

enhances the flexibility of the tool.

The tool easily connects to the range of

available Enerpac pumps. Enerpac can

supply air, electric or hand operated

pumps.

Delivery instructions

Upon delivery all components must be

inspected for damage incurred during

shipping. If damage is found the carrier

should be notified at once. Shipping

damage is not covered by the Enerpac

warranty.

Warranty

• Enerpac guarantees the product only

for the purpose for which is intended.

• All Enerpac products are guaranteed

against defects in workmanship and

materials for as long as you own

them.

Any misuse or alteration invalidates the

warranty.

• Observe all instructions as laid down

in this manual.

• Replace any parts with Enerpac spare

parts only.

CE Declaration of conformity

S1500/S3000/S6000/S11000/S25000

Page 5

ENGLISH

5

- Do not stand in the line of movement

of the tool when it is in operation. If

the tool separates from the nut or bolt

during operation it will detach in that

direction.

- Tightening and loosening nuts and

bolts involves little visible movement.

The pressure and loads, however are

extreme. Keep your hands away from

the fastener being loosened or

tightened.

- Make sure that the spanner used to

keep the nut or bolt on the opposite

end is secured.

- Always use Enerpac pumps and

hoses.

- Make sure appropriate guards are

always securely in position and free

from damage.

- Maximum pressure is 690 bar (10,000

psi). Never apply more pressure to

any tool or accessory than the

maximum allowable pressure. Refer to

the technical data tables for maximum

pressure setting.

- Make sure that the socket size

corresponds to the size of the

fastener being loosened or tightened.

Always make sure that the socket

receptacle corresponds to the drive

shaft. Failure to do so can result in the

tool becoming unstable and can lead

to catastrophic failure.

- Do not abuse or overstress the hoses

in any way. Do not bend the hoses

excessively.

- Never carry the tool by its hoses.

- Always use Enerpac spare parts.

- Always position the tool for maximum

stability.

- Make sure reaction points are

adequate for the forces at work

during operation of the tool.

- Be aware that a nut or bolt that

breaks off during operation of the tool

will become a high velocity projectile.

- Make sure the reaction point is of a

suitable shape. For example use an

adjacent nut or bolt as a reaction

point.

- When the hex socket is placed on the

nut or bolt a gap may exist between

the reaction arm and the reaction

plate. When the tool is operated the

reaction arm and point will make

forceful contact. Always make sure

the tool is stable.

- Provide adequate support in vertical

and inverted applications.

- The maximum torque output of the

tool must always exceed the torque

required to loosen or tighten the nut

or bolt.

- The torque required to loosen a nut is

variable and may exceed the torque

capacity of the tool. Therefore never

operate the tool at maximum or close

to maximum capacity when loosening

a nut or bolt.

- Never operate the tool with a

hydraulic supply connection to the

advance side only as this may

damage the internal parts.

- If the wrench is dropped from a

height, have the tool inspected before

you operate it again.

- In severe conditions the tool must be

cleaned and lubricated more frequently.

- Make sure to minimize torsional and

bending stresses in the tool, the

ratchet and any accessories.

- Do not strike the tool with a hammer

while under a full load. This will

invalidate the guarantee.

- Use of extension pieces or long-reach

sockets is not recommended. They

increase torsional and bending stresses,

and reduce stability of the tool.

- Always observe the maintenance

instructions.

Page 6

6

ENGLISH

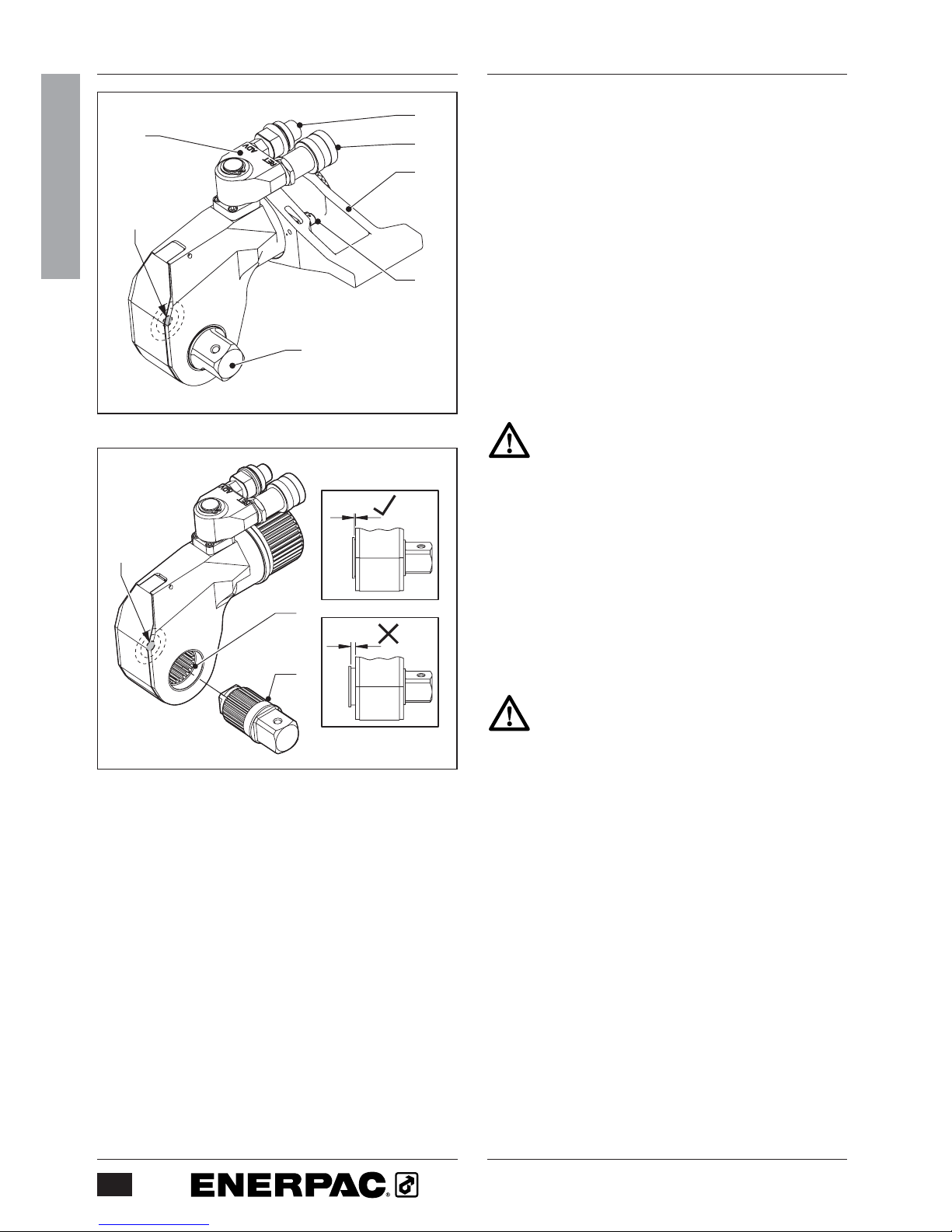

Fig. A

3 Assembly and adjustments

3.1 Overview and features (fig. A)

1 Drive shaft

2 Drive shaft release button

3 Swivel coupling

4 Advance hose connection

5 Return hose connection

6 Reaction arm

7 Reaction arm latch

3.2 To attach and remove the drive

shaft (fig. B)

Make sure to depressurize and

disconnect the tool from the hydraulic

supply first.

3.2.1 To attach the drive shaft

• Insert the drive shaft (1) into the

ratchet (8).

• Press the release button (2) and keep

it depressed.

• Push and turn the drive shaft until it

locks into place.

Make sure the drive shaft fits tightly

into the ratchet.

3.2.2 To remove the drive shaft

• Press the release button (2) and keep

it depressed.

• Pull the drive shaft (1) until it is

released.

• Remove the drive shaft from the

ratchet (8).

3.3 To select the drive direction (fig. B)

• For tightening operations, fit the drive

shaft (1) to the tool as shown.

• For loosening operations, fit the drive

shaft to the opposite side of the tool.

8

1

2

4

3

5

6

1

7

2

Fig. B

Page 7

ENGLISH

7

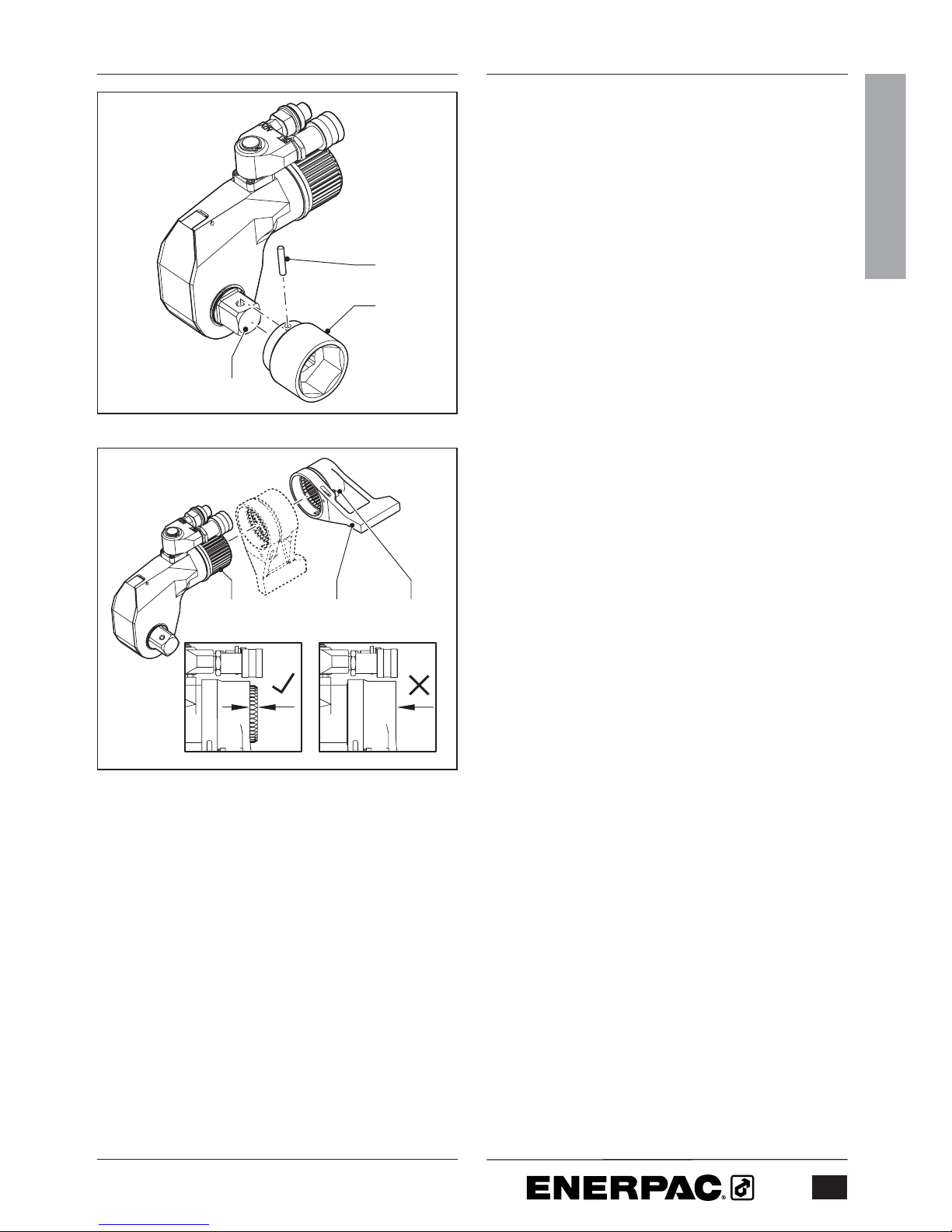

Fig. C

3.4 To fit and remove a hex socket

(fig. C)

3.4.1 To fit a hex socket

• Position the socket (9) onto the drive

shaft (1).

• Fit the retaining pin (10).

3.4.2 To remove a hex socket

• Remove the retaining pin (10).

• Take the socket (9) off the drive shaft

(1).

3.5 To mount the reaction arm (fig. D)

The reaction arm can be rotated through

360

o

for maximum stability against a

reaction point.

• Position the reaction arm (6) onto the

ratchet end (11) of the tool.

• Press the latch (7) and slide the arm

all the way onto the tool. Release the

latch to secure the arm.

• To adjust the angle of the reaction

arm (6), press the latch (7) and slide

the arm off the tool. Position the arm

as necessary.

Fig. D

1

10

9

11

76

Page 8

8

ENGLISH

3.6 To connect the hoses (fig. E)

Make sure all accessories meet the

pressure requirements.

Make sure the quick connect

couplings are securely attached

before operating the tool.

The tool is fitted with male and female

quick-connect couplings. Use Enerpac

twin safety hoses only. Refer to the table

below.

Hose model number Description

THQ-706T Two hoses, length

6 m (19.5 feet)

THQ-712T Two hoses, length

12 m (39 feet)

• Remove the hose dust caps.

• Connect the hose with the female

coupling (12) to the advance coupling

(4).

• Pull the sleeve on the female coupling

of the hose over the advance

coupling.

• Tighten the sleeve.

• Connect the hose with the male

coupling (13) into the return coupling

(5).

• Pull the sleeve on the return coupling

over the male coupling of the hose.

• Tighten the sleeve.

• Fit the hoses to the pump. Refer to

the pump instruction manual.

5

4

12

13

Fig. E

Page 9

ENGLISH

9

4 Operation

4.1 Prior to operation

- Make sure the nut or bolt to be

fastened are clean and free of dust.

- Make sure the nut or bolt runs

correctly on the thread.

- Make sure that the threads and the

bearing surface are liberally coated

with the correct lubricant or antiseizure compound.

- Make sure that the spanner used to

keep the nut or bolt on the opposite

end in place, is of the correct size and

that there is an adequate abutment

surface.

- Contact Enerpac if a suitable reaction

point is not available. Enerpac has

extensive experience with providing

special reaction devices.

4.2 To set the torque

Adjust the pressure on the pump as

necessary to set the torque. For a

complete list of torque settings, refer to

the table in the back of the manual.

4.3 To operate the tool (fig. F)

• Position the reaction foot (6) against

a suitable reaction point (14).

The reaction point will counteract the

force caused by operating the tool.

• Start the pump.

• Operate the tool to tighten or loosen

the nut or bolt.

• Stop the pump immediately after

work has finished.

Do not strike the tool, socket or nut

with a hammer while under a full load.

14 6

Fig. F

Page 10

10

ENGLISH

4.3.1 To tighten a nut or bolt (fig. G)

• Position the tool on the nut or bolt in

the orientation as shown.

• Operate the pump until the nut or bolt

has been tightened to the required

torque.

4.3.2 To loosen a nut or bolt (fig. H)

• Apply releasing oil to the threads.

Allow the oil to soak.

• Position the tool on the nut or bolt in

the orientation as shown.

• Operate the pump until the nut or bolt

is loose.

If the nut or bolt will be re-used avoid

excess load when loosening.

Use the tool to take the load off the

nut or bolt only.

For fully threaded UNC nuts or bolts

do not exceed one and a half times

nominal torque for a coefficient of

friction of 0.1.

- Be aware that when loosening a nut

or bolt more torque is usually required

than when tightening.

- Humidity corrosion (rust) requires up

to twice the torque required for

tightening.

- Sea water and chemical corrosion

requires up to two and a half times

the torque required for tightening.

- Heat corrosion requires up to three

times the torque required for

tightening.

Be aware that when loosening a nut

or bolt shock loading can occur.

Do not apply more than 75% of the

maximum torque when loosening nuts

or bolts.

Fig. H

Fig. G

Page 11

ENGLISH

11

5 Maintenance and troubleshooting

Preventative maintenance can be

carried out by the user. Full

maintenance must be carried out by

an approved and authorized

technician appointed by Enerpac.

- Non destructive testing must be

carried out if the tool has been used

under severe conditions.

5.1 Preventative Maintenance (fig. I & J)

• Remove the drive shaft

• Remove the housing guard screws

and remove the housing guard.

• Release the crank pin (16) from the

piston rod hook.

• Remove the crank assembly (17).

• Remove the ratchet (18), spring

loaded drive shoe (19), and

compression springs (20).

• Clean all exposed components with a

mild solvent.

• Inspect all parts for damage.

• Dry all components. Apply a thin coat

of molybdenum disulphide as

indicated (15).

Molybdenum disulphide is available

from Enerpac.

• Reassemble the components in

reverse order except the housing

guard. Make sure that the crank, drive

shoe, ratchet, and crank pin are

correctly installed. Failure to install

these parts correctly will result in

component damage.

• Connect the tool to the pump.

• Check the tool at a nominal pressure

to make sure the piston advances and

retracts freely.

• Release the pressure and make sure

the piston fully retracts.

• Attach the housing guard.

Fig. I

15

15

15

20

19

18

17 16 22 23 21

Fig. J

Page 12

5.2 Full maintenance

5.2.1 Piston removal (fig. J)

• Remove all components as described

for preventative maintenance.

• Remove the circlip from the swivel

coupling.

• Remove the swivel-coupling block

from the tool.

• Remove the pin by removing the pin

retaining screws.

• Remove all ‘O’ rings from the pin and

block.

• Carefully hold the cylinder body to

unscrew the cylinder gland.

• Loosen and remove the piston

locknut (21) using a socket spanner.

To prevent the piston from rotating,

you may temporarily replace the crank

(17).

• Remove the piston rod (22) from the

front of the tool.

• Remove the piston (23) by pushing a

suitable drift through the front of the

tool onto the piston.

• Remove the seals from the piston,

piston locknut and gland.

5.2.2 Cylinder bush removal (fig. K)

(S1500/S3000/S6000/S11000 only)

Only remove the cylinder bush if there

is hydraulic fluid leakage in the head

area.

• Press the retaining ring (24) radially

inward using a flat-head screwdriver.

• Lift the ring away from the groove and

out of the bore using a seal pick.

• The ring end must be positioned at

the slot in the bush for the seal pick

to locate under the bush. If the ring

end is not at the slot, use the

screwdriver to rotate the ring.

12

ENGLISH

242524

Fig. K

Page 13

• Remove the cylinder bush (25) by

pushing a suitable drift through the

front of the tool onto the bush.

• Remove both bush seals.

5.2.3 Reaction arm removal

Only remove the reaction arm if the

retainer is visibly damaged.

• Loosen the set screw.

• Remove the lever/pin and the retainer.

5.2.4 Drive shaft release button removal

Only remove the drive shaft release

button if it is damaged.

• Remove the retaining ring.

• Remove the button circlip.

• Remove the retaining bush.

• Clean all exposed components with a

mild solvent.

• Inspect all parts for damage.

5.2.5 Non Destructive Testing

• Carry out non destructive testing by

magnetic particle inspection on the

following components:

- Body

- Reaction arm

- Crank

- Drive shaft

- Ratchet

- Drive shoe

ENGLISH

13

5.2.6 Reassembly

• Dry all components. Apply a thin coat

of molybdenum disulphide as

indicated (15).

• Lubricate all seals with silicon grease

and reassemble in the reverse order.

• Insert the piston squarely in the bore.

• Apply Loctite 222 to the following

components:

- Swivel coupling pin retaining bolts

- Reaction arm retaining set screw

- Piston locknut threads

• Restrain the hook end of the piston

rod using the crank (17). Tighten the

locknut to the following torque.

Torque

(Nm) (Ft.lbs)

S1500 41 30

S3000 54 40

S6000/S11000 81 60

S25000 81 60

Page 14

5.3 Trouble shooting

Symptom Cause Remedy

Cylinder does not advance or retract Quick-connect coupling Replace the coupling

is damaged

Quick connect- coupling is Reconnect the hoses

not connected and couplings securely

Dirt in the direction control valve Disassemble the unit and

on the pumping unit clean the valve

Cylinder does not build up pressure Piston seal leaks Replace the seals

Pump does not build up pressure Adjust the pressure

Pump is defective Refer to the pump manual

Cylinder leaks Seal failure Replace the cylinder seals

Cylinder operates backwards Connections are reversed Reconnect the hoses

Ratchet returns on retract stroke Broken drive shoe Replace the drive shoe

Ratchet does not take Defective drive shoe Replace the drive shoe

successive strokes Lubricant on the ratchet Disassemble the head and

and/or drive shoe splines remove the lubricant

from splines

14

ENGLISH

Page 15

6 Technical specifications

6.1 Capacities and dimensions (fig. L)

S1500 S3000 S6000 S11000 S25000

Drive shaft inch 3/4 1 1 1/2 1 1/2 2 1/2

Socket capacity mm 15 - 50 20 - 100 41 - 155 41 - 155 60 - 255

inch 5/8 - 1 7/8 7/8 - 3 7/8 1 5/8 - 6 1/4 1 5/8 - 6 1/4 2 3/8 - 10

Maximum operating pressure bar 690 690 690 690 690

psi 10,000 10,000 10,000 10,000 10,000

Max. torque at 690 bar Nm 1.898 4.339 8.144 14.914 34.098

at 10,000 psi Ft.lbs 1,400 3,200 6,010 11,000 25,150

Min. torque at 69 bar Nm 190 434 814 1.491 3.410

at 1000 psi Ft.lbs 140 320 601 1,100 2,515

Dimensions A mm (inch) 39 (1.53) 48 (1.88) 57 (2.24) 71 (2.79) 87 (3.43)

B mm (inch) 63 (2.48) 77 (3.03) 90 (3.54) 111 (4.37) 143 (5.63)

C mm (inch) 110 (4.33) 134 (5.27) 179 (7.04) 196 (7.71) 244 (9.61)

D mm (inch) 95 (3.74) 126 (4.96) 162 (6.37) 185 (7.28) 240 (9.45)

E mm (inch) 136 (5.35) 172 (6.77) 201 (7.91) 226 8.89) 292 (11.50)

F mm (inch) 25,0 (.98) 33,0 (1.29) 42,0 (1.65) 49,5 (1.94) 63,5 (2.50)

G mm (inch) 69 (2.72) 90 (3.54) 112 (4.41) 132 (5.20) 182 (7.17)

H mm (inch) 119 (4.69) 159 (6.26) 187 (7.36) 227 (8.94) 292 (11.50)

Weight kg (lbs) 2,7 (5.94) 5,0 (11.0) 8,5 (18.7) 15,0 (33.0) 31,0 (68.4)

A

F

D

B

C H

G

E

Fig. L

ENGLISH

15

Page 16

16

ENGLISH

6.2 Torque settings

To set the torque, adjust the pump pressure according to the following calculation:

- Pump pressure = Torque / Torque factor

Torque factor

S1500 S3000 S6000 S11000 S25000

Metric system 2,753 6,293 11,818 21,631 49,417

Imperial system 0.14 0.32 0.601 1.1 2.515

Page 17

ENGLISH

17

6.2.1 Metric system table

S1500 S3000 S6000 S11000 S25000

Pump pressure (bar) Torque (Nm) Torque (Nm) Torque (Nm) Torque (Nm) Torque (Nm)

69 190 434 814 1.491 3.410

83 228 520 977 1.789 4.132

97 266 607 1.140 2.087 4.821

110 304 694 1.303 2.385 5.510

124 341 780 1.466 2.683 6.199

138 379 867 1.629 2.981 6.887

152 417 954 1.792 3.279 7.576

166 455 1.041 1.955 3.577 8.265

179 493 1.127 2.117 3.875 8.954

193 531 1.214 2.280 4.173 9.642

207 569 1.301 2.443 4.472 10.331

221 607 1.388 2.606 4.770 11.020

234 645 1.474 2.769 5.068 11.709

248 683 1.561 2.932 5.366 12.397

262 721 1.648 3.095 5.664 13.086

276 759 1.734 3.258 5.962 13.775

290 797 1.821 3.420 6.260 14.464

303 835 1.908 3.583 6.558 15.152

317 873 1.995 3.746 6.856 15.841

331 911 2.081 3.909 7.154 16.530

345 949 2.168 4.072 7.453 17.219

359 986 2.255 4.235 7.751 17.907

372 1.024 2.341 4.398 8.049 18.596

386 1.062 2.428 4.561 8.347 19.285

400 1.100 2.515 4.724 8.645 19.973

414 1.138 2.602 4.886 8.943 20.662

428 1.176 2.688 5.049 9.241 21.351

441 1.214 2.775 5.212 9.539 22.040

455 1.252 2.862 5.375 9.837 22.728

469 1.290 2.948 5.538 10.135 23.417

483 1.328 3.035 5.701 10.434 24.106

497 1.366 3.122 5.864 10.732 24.795

510 1.404 3.209 6.027 11.030 25.483

524 1.442 3.295 6.189 11.328 26.172

538 1.480 3.382 6.352 11.626 26.861

552 1.518 3.469 6.515 11.924 27.550

566 1.556 3.556 6.678 12.222 28.238

579 1.593 3.642 6.841 12.520 28.927

593 1.631 3.729 7.004 12.818 29.616

607 1.669 3.816 7.167 13.116 30.305

621 1.707 3.902 7.330 13.415 30.993

634 1.745 3.989 7.492 13.713 31.682

648 1.783 4.076 7.655 14.011 32.371

662 1.821 4.163 7.818 14.309 33.060

676 1.859 4.249 7.981 14.607 33.748

690 1.897 4.336 8.144 14.905 34.098

Page 18

18

ENGLISH

6.2.2 Imperial system table

S1500 S3000 S6000 S11000 S25000

Pump pressure (psi) Torque Torque Torque Torque Torque

(Ft.lbs) (Ft.lbs) (Ft.lbs) (Ft.lbs) (Ft.lbs)

1,000 140 320 601 1,100 2,515

1,200 168 384 721 1,320 3,048

1,400 196 448 841 1,540 3,556

1,600 224 512 962 1,760 4,064

1,800 252 576 1,082 1,980 4,572

2,000 280 640 1,202 2,200 5,080

2,200 308 704 1,322 2,420 5,588

2,400 336 768 1,442 2,640 6,096

2,600 364 832 1,563 2,860 6,604

2,800 392 896 1,683 3,080 7,112

3,000 420 960 1,803 3,300 7,620

3,200 448 1,024 1,923 3,520 8,128

3,400 476 1,088 2,043 3,740 8,636

3,600 504 1,152 2,164 3,960 9,144

3,800 532 1,216 2,284 4,180 9,652

4,000 560 1,280 2,404 4,400 10,160

4,200 588 1,344 2,524 4,620 10,668

4,400 616 1,408 2,644 4,840 11,176

4,600 644 1,472 2,765 5,060 11,684

4,800 672 1,536 2,885 5,280 12,192

5,000 700 1,600 3,005 5,500 12,700

5,200 728 1,664 3,125 5,720 13,208

5,400 756 1,728 3,245 5,940 13,716

5,600 784 1,792 3,366 6,160 14,224

5,800 812 1,856 3,486 6,380 14,732

6,000 840 1,920 3,606 6,600 15,240

6,200 868 1,984 3,726 6,820 15,748

6,400 896 2,048 3,846 7,040 16,256

6,600 924 2,112 3,967 7,260 16,764

6,800 952 2,176 4,087 7,480 17,272

7,000 980 2,240 4,207 7,700 17,780

7,200 1,008 2,304 4,327 7,920 18,288

7,400 1,036 2,368 4,447 8,140 18,796

7,600 1,064 2,432 4,568 8,360 19,304

7,800 1,092 2,496 4,688 8,580 19,812

8,000 1,120 2,560 4,808 8,800 20,320

8,200 1,148 2,624 4,928 9,020 20,828

8,400 1,176 2,688 5,048 9,240 21,336

8,600 1,204 2,752 5,169 9,460 21,844

8,800 1,232 2,816 5,289 9,680 22,352

9,000 1,260 2,880 5,409 9,900 22,860

9,200 1,288 2,944 5,529 10,120 23,368

9,400 1,316 3,008 5,649 10,340 23,876

9,600 1,344 3,072 5,770 10,560 24,384

9,800 1,372 3,136 5,890 10,780 24,892

10,000 1,400 3,200 6,010 11,000 25,150

Page 19

ENGLISH

19

7 Recommended spare parts

7.1 To order spare parts

Quote the information below when

ordering spare parts:

- The assembly name and serial

numbers.

- The component name and part

number.

- The contract number or

approximate date of purchase.

All item numbers quoted below refer to the

repair parts sheets. For specific

component part numbers refer to the

appropriate bill of materials.

7.2 Seal kit (item 3.0)

- 1 Gland ‘O’ ring

- 1 Piston ‘T’ Seal

- 1 Piston locknut ‘O’ ring - small

- 1 Piston locknut ‘ O’ ring - large

- 1 Rod ‘T’ seal

- 1 Body bush ‘O’ ring

- 2 Swivel manifold pin face ‘O’ rings

- 1 Swivel manifold pin ‘O’ ring

- 2 Swivel manifold block ‘O’ rings

- 1 Manifold retaining clip

7.3 Swivel manifold seal kit (item 2.0)

- 2 Swivel manifold pin face ‘O’ rings

- 1 Swivel manifold pin ‘O’ ring

- 2 Swivel manifold block ‘O’ rings

- 1 Manifold retaining clip

7.4 Spares kit (item 4.0)

- 1 Male coupling

- 1 Female coupling

- 1 Male adaptor

- 1 Body bush retaining ring

- 1 Guard screw (model S1500)

- 2 Guard screws (model S3000)

- 3 Guard screws

(model S6000/S11000/S25000)

- 1 Manifold retaining circlip

- 4 Swivel manifold pin retaining

screws

- 1 Crank pin

- 2 Drive shoe springs

- 1 Reaction arm retainer screw

- 1 Reaction arm retainer spring

- 1 Guard pin (S1500 only)

- 1 Drive shaft holder retaining ring

7.5 Drive shaft button kit (item 1.13)

7.6 Recommended tool kit

S1500

- 1 7/8” spanner

- 1 3/4” spanner

- 1 5/8” spanner

- 1 Circlip pliers

- 1 Seal extraction tool

- 1 14 mm socket

- 1 ø 4 x 20 mm PCD pin spanner

- 1 1,5 mm Allen key

- 1 2 mm Allen key

- 1 2,5 mm Allen key

- 1 3 mm Allen key

Page 20

20

ENGLISH

S3000

- 1 7/8” spanner

- 1 3/4” spanner

- 1 5/8” spanner

- 1 Circlip pliers

- 1 Seal extraction tool

- 1 20 mm socket

- 1 ø 4 x 25 mm PCD pin spanner

- 1 1,5 mm Allen key

- 1 2,5 mm Allen key

- 1 3 mm Allen key

S6000

- 1 7/8” spanner

- 1 3/4” spanner

- 1 5/8” spanner

- 1 Circlip pliers

- 1 Seal extraction tool

- 1 22 mm socket

- 1 ø 4 x 30 mm PCD pin spanner

- 1 1,5 mm Allen key

- 1 2,5 mm Allen key

- 1 4 mm Allen key

S11000

- 1 7/8” spanner

- 1 3/4” spanner

- 1 5/8” spanner

- 1 Circlip pliers

- 1 Seal extraction tool

- 1 26 mm socket

- 1 ø 4 x 40 mm PCD pin spanner

- 1 1,5 mm Allen key

- 1 3 mm Allen key

- 1 4 mm Allen key

S25000

- 1 7/8” spanner

- 1 3/4” spanner

- 1 5/8” spanner

- 1 Circlip pliers

- 1 Seal extraction tool

- 1 36 mm socket

- 1 ø 5 x 60 mm PCD pin spanner

- 1 1,5 mm Allen key

- 1 3 mm Allen key

- 1 4 mm Allen key

Page 21

Please contact Enerpac if the CD is not included,

or visit www.enerpac.com for a download of the manual.

Page 22

Africa

ENERPAC Middle East FZE

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Australia

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

Tel: +61 297 438 988

Fax: +61 297 438 648

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

Tel: +55 11 5687 2211

Fax: +55 11 5686 5583

Toll Free in Brazil:

Tel: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

Tel: +1 905 564 5749

Fax: +1 905 564 0305

Toll Free:

Tel: +1 800 268 4987

Fax: +1 800 461 2456

Technical Inquiries:

techservices@enerpac.com

China

Actuant China Ltd.

1F, 269 Fute N. Road

Waigaoqiao Free Trade Zone

Pudong New District

Shanghai, 200 131 China

Tel: +86 21 5866 9099

Fax: +86 21 5866 7156

Actuant China Ltd. (Beijing)

709A Xin No. 2

Diyang Building

Dong San Huan North Rd.

Beijing City

100028 China

Tel: +86 10 845 36166

Fax: +86 10 845 36220

Central and Eastern Europe

ENERPAC B.V.

Galvanistraat 115

P.O. Box 8097

6710 AB Ede

The Netherlands

Tel: +31 318 535 936

Fax: +31 318 535 951

France

ENERPAC

Une division de ACTUANT

France S.A.

B.P. 200, Parc d’Activités

du Moulin de Massy

F-91882 Massy CEDEX France

Tel: +33 1 601 368 68

Fax: +33 1 692 037 50

Germany, Austria, Greece

and Switzerland

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Germany

Tel: +49 211 471 490

Fax: +49 211 471 49 28

India

ENERPAC Hydraulics

(India) Pvt. Ltd.

Office No. 9,10 & 11,

Plot No. 56, Monarch Plaza,

Sector 11, C.B.D. Belapur

Navi Mumbai 400614, India

Tel: +91 22 2756 6090

Tel: +91 22 2756 6091

Fax: +91 22 2756 6095

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

Tel: +39 02 4861 111

Fax: +39 02 4860 1288

Japan

Applied Power Japan Ltd.

1-1-11, Shimomae

Toda-shi

Saitama Pref.

Japan 335-0016

Tel: +81 484 30 1055

Fax: +81 484 30 1066

Middle East, Turkey and

Caspian Sea

ENERPAC Middle East FZE

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Russia and CIS

(excl. Caspian Sea Countries)

Actuant LLC

Admiral Makarov Street 8

125212 Moscow, Russia

Tel: +7-095-9809091

Fax: +7-095-9809092

Singapore

Actuant Asia Pte. Ltd.

25 Serangoon North Ave. 5

#03-01 Keppel Digihub

Singapore 554914

Thomson Road

P.O. Box 114

Singapore 915704

Tel: +65 64 84 5108

+65 64 84 3737

Fax: +65 64 84 5669

Toll Free:

Tel: +1800 363 7722

Technical Inquiries:

techsupport@enerpac.com.sg

South Korea

Actuant Korea Ltd.

3Ba 717,

Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

Tel: +82 31 434 4506

Fax: +82 31 434 4507

Spain and Portugal

ENERPAC

C/San José Artesano 8

Pol. Ind.

28108 Alcobendas

(Madrid) Spain

Tel: +34 91 661 11 25

Fax: +34 91 661 47 89

The Netherlands, Belgium,

Luxembourg, Sweden,

Denmark, Norway, Finland

and Baltic States

ENERPAC B.V.

Galvanistraat 115

P.O. Box 8097, 6710 AB Ede

The Netherlands

Tel: +31 318 535 911

Fax: +31 318 525 613

+31 318 535 848

Technical Inquiries Europe:

techsupport.europe@enerpac.com

United Kingdom, Ireland

ENERPAC Ltd., P.O. Box 33

New Romney, TN28 8QF

United Kingdom

Tel: +44 1527 598 900

Fax: +44 1527 585 500

USA, Latin America

and Caribbean

ENERPAC

P.O. Box 3241

6100 N. Baker Road

Milwaukee, WI 53209 USA

Tel: +1 262 781 6600

Fax: +1 262 783 9562

User inquiries:

+1 800 433 2766

Distributor inquiries/orders:

+1 800 558 0530

Technical Inquiries:

techservices@enerpac.com

Hydraulic Technology Worldwide

e-mail: info@enerpac.com

Internet: www.enerpac.com

© 2005 Enerpac - Subjects to change without notice.

Loading...

Loading...