Page 1

Starting Serial Numbers - Page 2

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and

MR. HEATER

MODEL

MHU 45

MHU 75

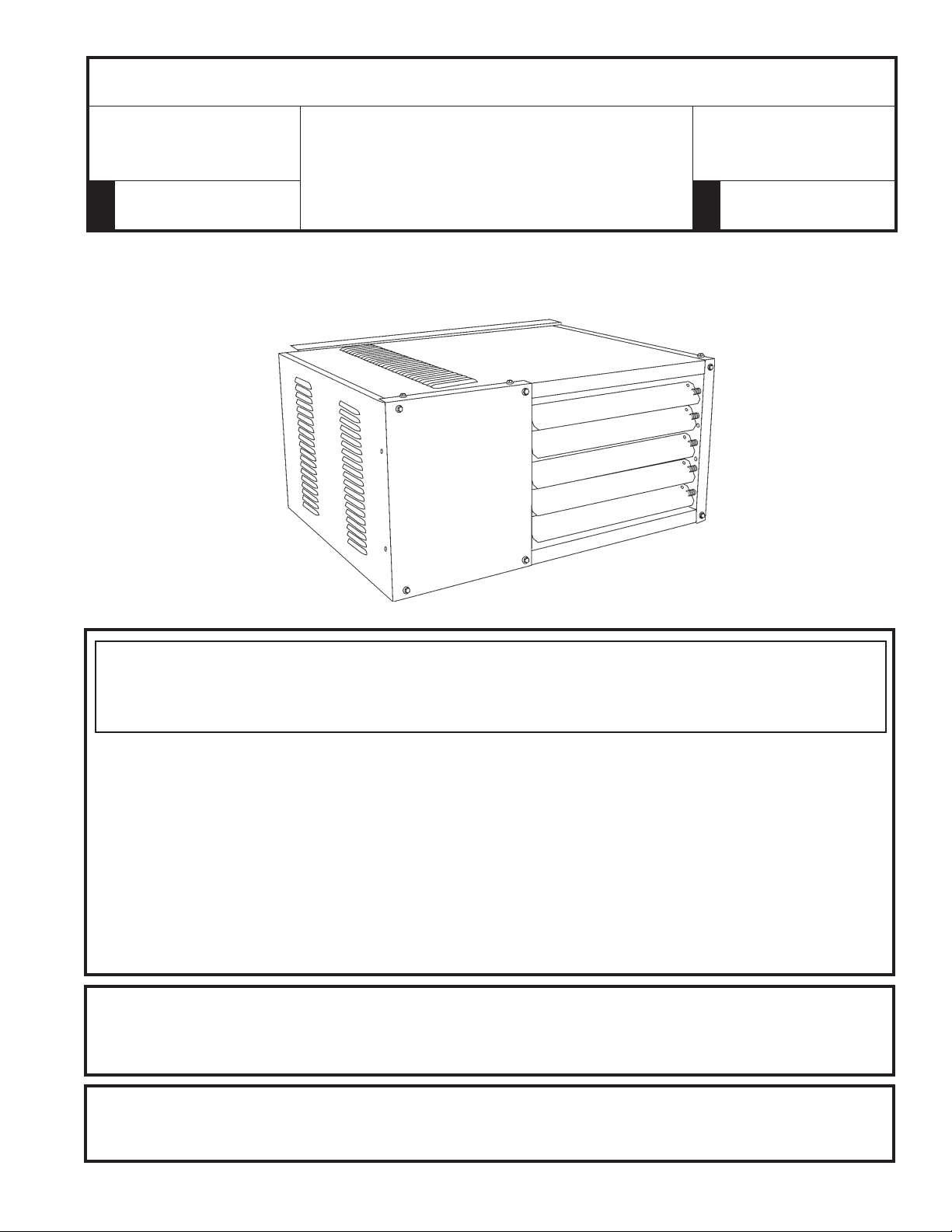

COMPACT UNIT HEATER

follow all instructions. Place instructions in a

safe place for future reference. Do not allow

anyone who has not read these instructions to

assemble, light, adjust or operate the heater.

HEATSTAR

MODEL

HSU 45

HSU 75

WARNING: Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage. Refer to this manual. For assistance or

additional information consult a qualified installer, service agency or the gas supplier.

—

WHAT TO DO IF YOU SMELL GAS

• Open Windows

• DO NOT try to light any appliance.

• DO NOT use electrical switches.

• DO NOT use any telephone in your house. Immediately call your local gas supplier from a

neighbor’s telephone. Follow the gas supplier’s instructions.

• Do not touch any electrical switch; do not use any phone in your building.

• Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

• If you cannot reach your gas supplier, call the Fire Department.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING: If the information in these instructions are not followed exactly, a fire or

explosion may result causing property damage, personal injury or loss of life.

10/09 #60016ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

Page 2

Starting Serial Numbers

MHU45NG -- 260045-09001001

MHU45LP -- 260145-09001001

MHU75NG -- 260775-09001001

MHU75LP -- 260875-09001001

HSU45NG -- 160245-09001001

HSU45LP -- 160345-09001001

HSU75NG -- 160775-09001001

HSU75LP -- 160975-09001001

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

2

Page 3

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF

FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON

MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW

THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTION MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

CONTENTS

UNIT DIMENSIONS .................................................................. 4

SHIPPING ................................................................................. 5

REQUIREMENTS ....................................................................... 5

UNIT HEATER INSTALLATION.................................................... 6

COMBUSTION & VENTILATION AIR .......................................... 6

VENTING .............................................................................6-10

ELECTRICAL CONNECTIONS ....................................................10

GAS CONNECTION ................................................................. 11

LEAK CHECK ........................................................................... 11

START-UP OPERATION ............................................................. 11

HEATING SEQUENCE OF OPERATION ......................................12

IGNITION CONTROL LED ......................................................... 12

ADJUSTMENTS........................................................................ 12

SERVICE ..................................................................................13

WIRING DIAGRAM ..................................................................14

PARTS LIST ..............................................................................16

WARRANTY ............................................................................18

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING

MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE

AWAY FROM THE HEATER AS RECOMMENDED BY THE

INSTRUCTIONS NEVER USE THE HEATER IN SPACES

WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR

UNKNOWN CHEMICALS.

WARNING:

The State of California requires the following warning:

COMBUSTION BY-PRODUCTS PRODUCED WHEN USING

THIS PRODUCT CONTAIN CARBON MONOXIDE, A

CHEMICAL KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND BIRTH DEFECTS (OR OTHER

REPRODUCTIVE HARM).

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

3

Page 4

AIR

FLOW

HEAT EXCHANGER

(ALUMINIZED STEEL)

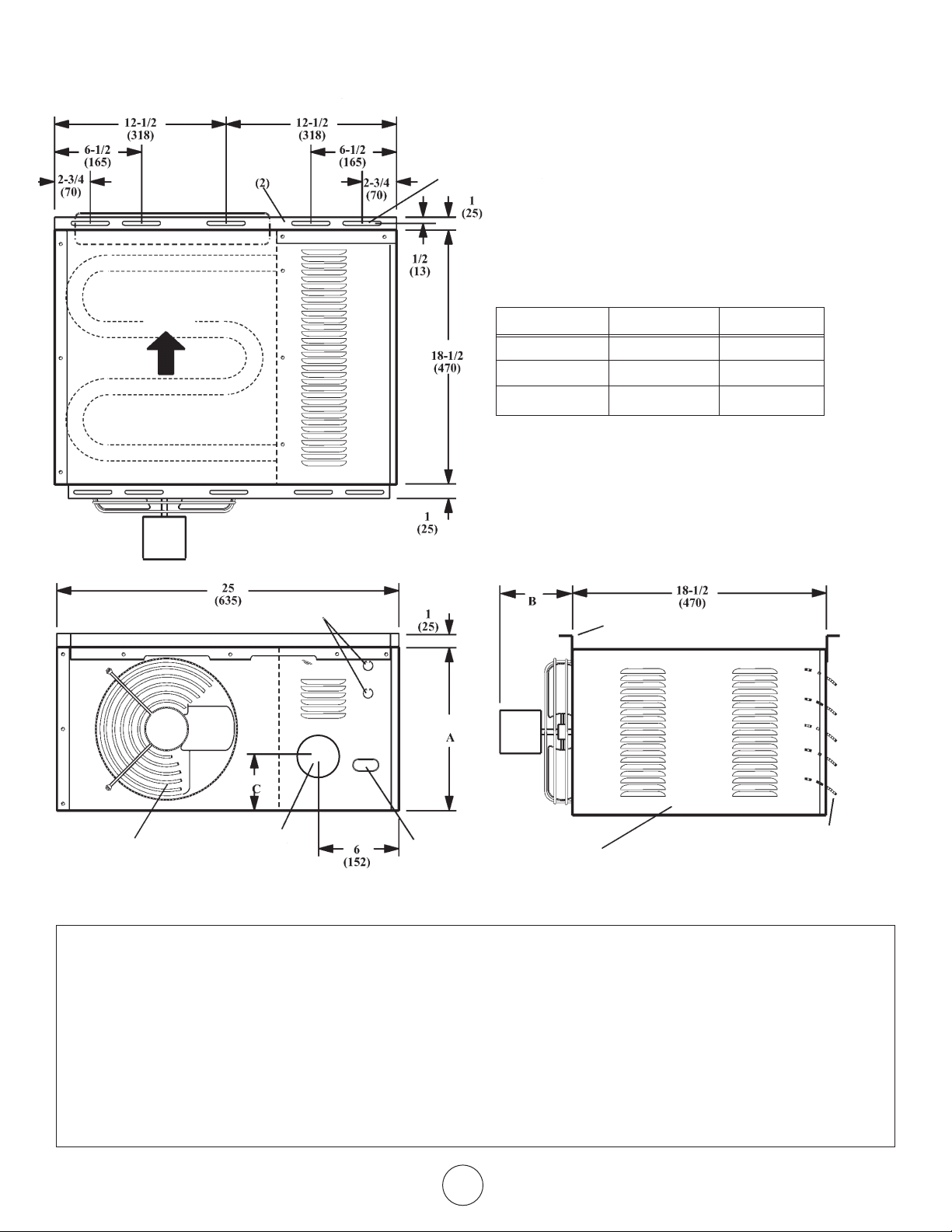

MHU45/MHU75 AND HSU45/HSU75 UNIT DIMENSIONS

(N-NATURAL GAS, P-PROPANE)

HANGING

BRACKETS

MOUNTING SLOTS (Typical)

5/16 x 3 Inches (8 x 76 mm)

DIMENSION 45 75

A 12 (305) 17 (432)

B 5-1/2 (140) 6-1/2 (165)

C 4-1/4 (108) 6-3/4 (171)

TOP VIEW

ELECTRICAL

INLETS

DIRECT

DRIVE FAN

FLUE

OUTLET

GAS

INLET

BACK VIEW

START–UP AND PERFORMANCE CHECK LIST

Job Name: __________________________________________

Job Location: ________________________________________

Installer: ____________________________________________

Unit Model No.: ______________________________________

Electrical Connections Tight? _______________________________________________

Supply Voltage ___________________________________________________________

Gas Piping Connections Tight & Leak-Tested? __________________________________

Motor Amps _____________________________________________________________

Furnace Btu Input ________________________________________________________

Line Pressure ____________________________________________________________

Manifold Pressure w.c. ____________________________________________________

Job No.: ______________________________________

City: _________________________________________

City: _________________________________________

Serial No.:_____________________________________

HANGING

BRACKETS (2)

ADJUSTABLE

SERVICE

ACCESS PANEL

LOUVERS

SIDE VIEW

Date: _______________________________________

State/Province: _______________________________

State/Province: _______________________________

Service Technician: ____________________________

Flue Connections Tight? __________________________________________________

Fan Timer Operation Checked? _____________________________________________

THERMOSTAT

Calibrated? _____________________________________________________________

Heat Anticipator Properly Set?

Level? _________________________________________________________________

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

4

Page 5

SHIPPING

The heater is completely assembled. Installation instructions,

two mounting brackets (shipped loose), and a flue transition are

included. Check the unit for shipping damage. The receiving party

should contact the last carrier immediately if any shipping damage

is found.

REQUIREMENTS – CSA IN THE USA

Installation of gas unit heaters must conform with local building

codes or, in the absence of local codes, with the current National

Fuel Gas Code ANSI Z223.1.

Installation in aircraft hangers must be in accordance with the

current Standard for Aircraft Hangers ANSI/NFPA No. 409.

Installation in parking structures must be in accordance with the

current Standard for Parking Structures ANSI/NFPA No. 88A.

Installation in repair garages must be in accordance with the

current Standard for Repair Garages ANSI/NFPA No. 88B.

These units are approved for residential applications. For

installation in a residential garage these units must be installed

so that burners and ignition source are located no less than 18”

(457mm) above floor. Heater must be located or protected to

avoid physical damage by vehicles. Refer to the National Fuel Gas

Code, ANSI Z223.1, current edition.

Authorities having jurisdiction should be consulted before NFPA

installation. Air for combustion and ventilation must conform

to the methods outlined in ANSI Z223.1, section 5.3, Air for

Combustion and Ventilation, or applicable provisions of local

building codes. The National Fuel Gas Code is available from:

American National Standard Institute Inc.

11 West 42nd Street

New York, NY 10036

These units are CSA International design certified. These unit

heaters are certified for installation to combustible material

as listed in table 1 and on unit rating plate. Accessibility and

service clearances must be observed in addition to fire protection

clearances.

All electrical wiring and ground for unit must be in accordance

with the regulations of the current National Electric Code ANSI/

No. 70.

The National Electric Code is available from:

National Fire Protection Association

1 Batterymarch Park

PO Box 9101

Quincy, MA 02269-9101

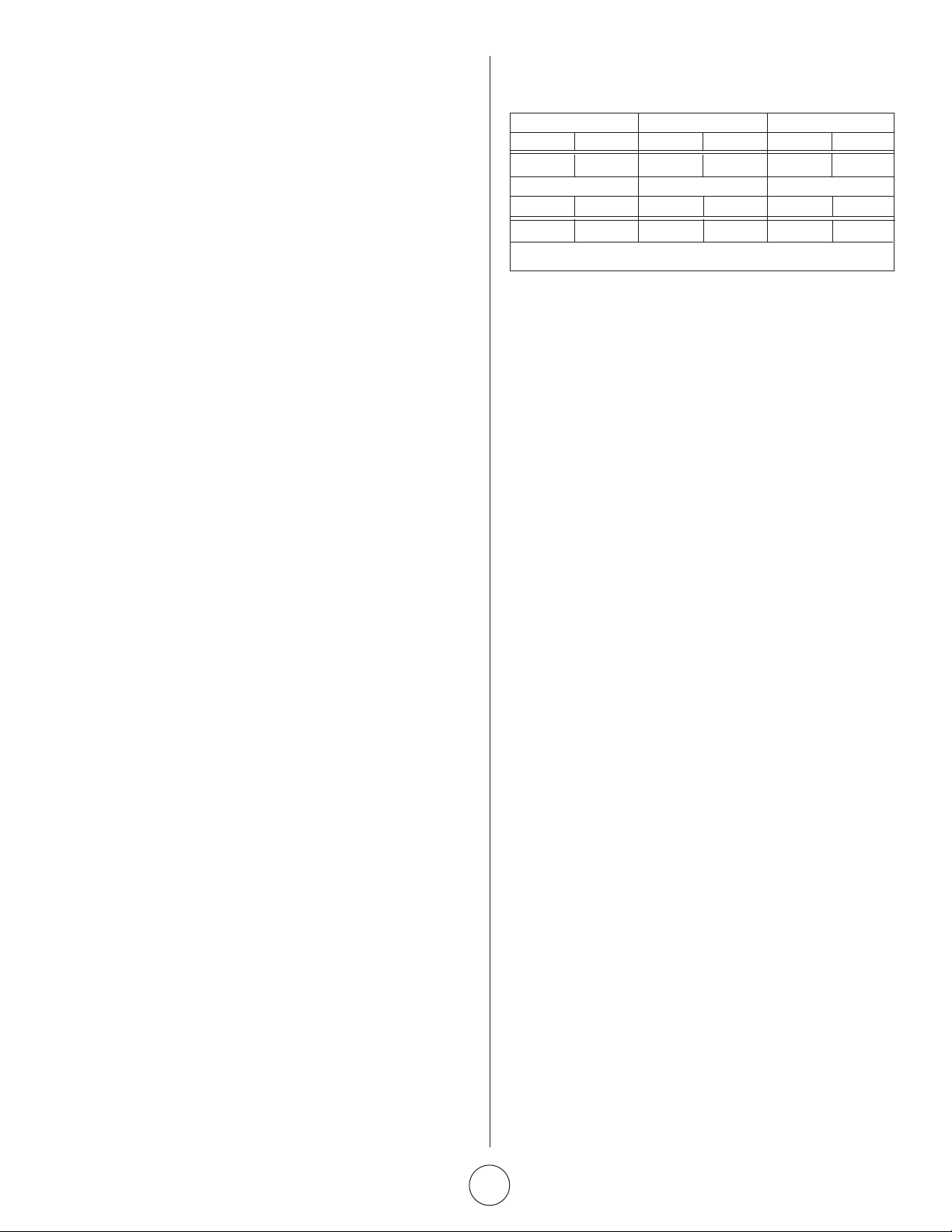

TABLE 1

UNIT CLEARANCES

Top Sides Access Panel

in mm in mm in mm

1 25 1 25 18 457

Bottom Rear Single Wall Vent*

in mm in mm in mm

0 0 18 456 6 152

*Except for listed clearance thimbles.

REQUIREMENTS – CSA IN CANADA

The instructions are intended only as a general guide and do not

supersede local codes in any way. Authorities having jurisdiction

should be consulted before installation. The installation must

conform with local building codes or in the absence of local

codes, with the current CSA B149.1, Natural Gas and Propane

Installation Code. All electrical wiring and grounding for the unit

must also comply with the Canadian Electrical Code CSA C22.1,

current edition.

These unit heaters are CSA International certified for the

clearances to combustible material listed on the rating plate

and table 1. Adequate clearance around air openings into the

combustion chamber, clearances from combustible material, and

provisions for accessibility and for combustion and ventilation

air supply. Provision shall be made for service accessibility to the

heater. Note that fire protection clearances may be exceeded to

provide additional space for service and accessibility.

GARAGE INSTALLATIONS:

Installation in parking structures must be in accordance with the

current Standard for Parking Structures ANSI/NFPA No. 88A.

Installation in repair garages must be in accordance with the

current Standard for Repair Garages ANSI/NFPA No. 88B.

1. In a storage area, clearance from heaters to combustible

materials must be such that the material shall not attain a

temperature above 160°F by continuous operation of the unit.

2. Eight foot minimum clearance from the oor to the bottom

of the heater must be maintained. Refer to the CSA B149.1,

Natural Gas and Propane Installation Code

AIRCRAFT HANGER:

Installation of gas unit heaters must conform with local building

codes or, in the absence of local codes, with the current National

Fuel Gas Code ANSI Z223.1.

1. In an area where aircraft are housed or serviced, 10’

minimum clearance from highest surface of aircraft to bottom

of the heater must be maintained.

2. In other areas, 8’ minimum clearance from the oor to

bottom of heater must be maintained.

3. Heaters should be located so as to be protected from

damage from aircraft or other appliances needed for

servicing of aircraft. Refer to requirements of the enforcing

authorities.

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

5

Page 6

These units are approved for residential applications. For

installation in a residential garage, these units must be installed

so that burners and ignition source are located no less than 18”

(457mm) above floor. Heater must be located or protected to

avoid physical damage by vehicles. Refer to CSA B149.1, Natural

Gas and Propane Installation Code current edition.

In a confined area, the heater must be installed in accordance

with the CSA B149.1, Natural Gas and Propane Installation Code.

Be sure to check with local codes and ordinances for additional

requirements.

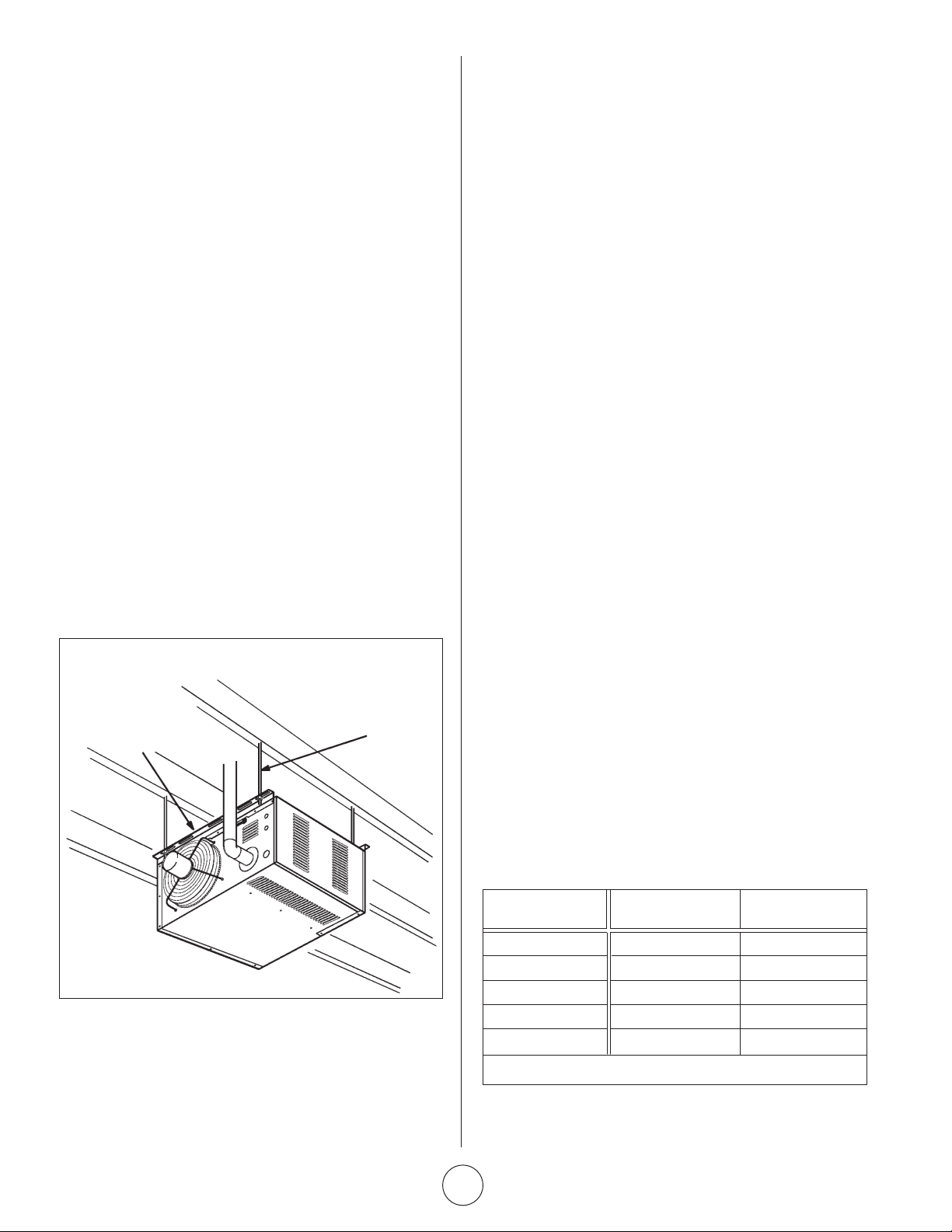

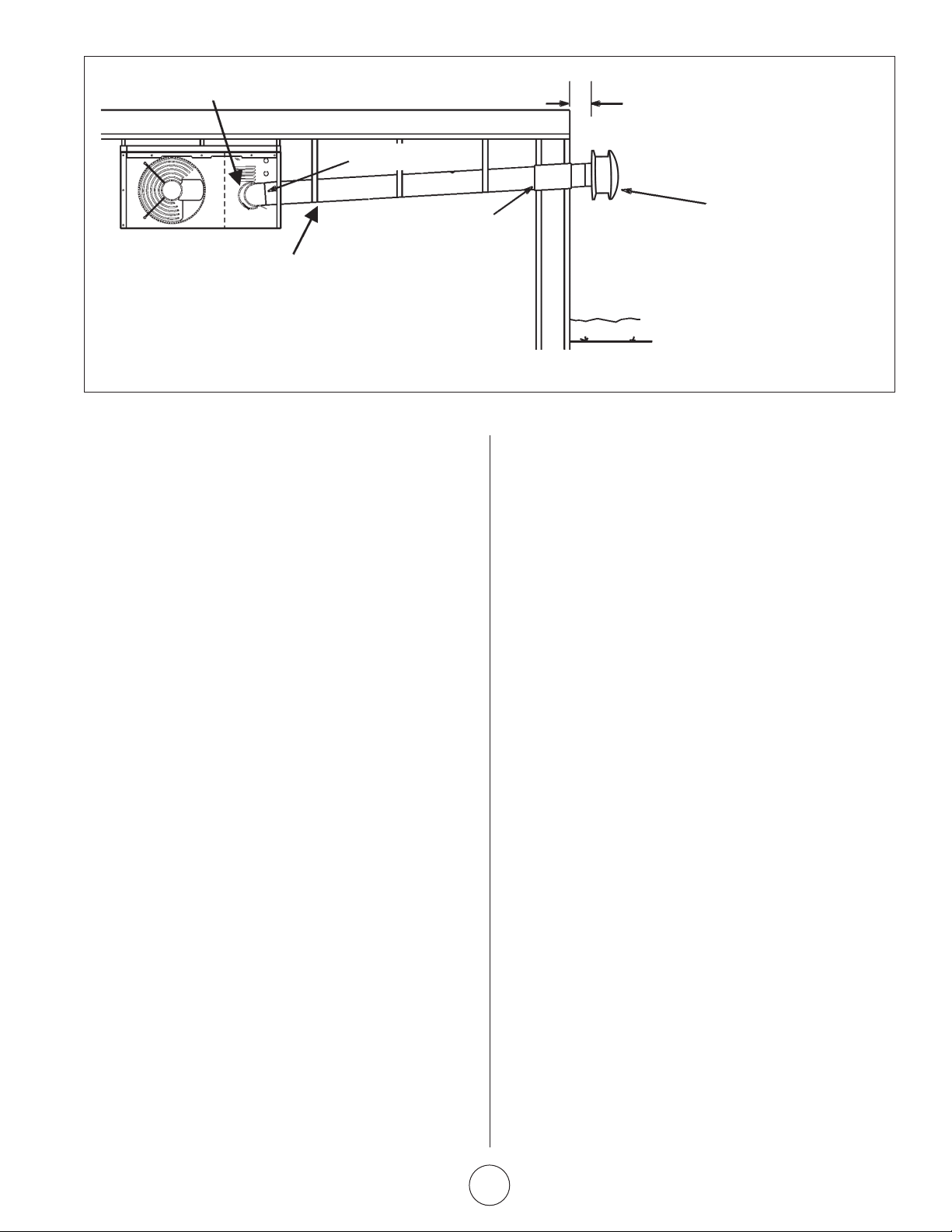

UNIT HEATER INSTALLATION

Unit is shipped ready for installation. Unit may be installed as

shown in figure 1 or inverted 180o depending on desired location

as governed by clearances, vent connection, air direction, gas

supply, electrical supply and service accessibility.

1. If installing unit in an inverted position: Remove and retain

screws securing door and rotate door 180o. Secure with

retained screws. Rotate louvers directing airflow as desired.

2. Choose location for mounting brackets.

3. Remove and retain three screws along top edge (bottom

edge when inverted) of front of unit.

4. Align screw holes on mounting bracket with holes along

top edge (either upright or inverted) of unit. Secure one

mounting bracket to front of unit with retained screws.

Secure other mounting bracket to back of unit with screws

provided in bag assembly containing flue transition.

5. To support unit, secure mounting bracket to ceiling joist or

truss. Unit may also hang on rods as shown in figure 1.

INSTALL UNIT HEATER

MOUNTING

BRACKETS (2)

SUPPORT

RODS

Gas Code, ANSI Z223.1, in the U.S.A., CSA B149.1 Natural Gas

and Propane Installation Code, or applicable provisions of local

building codes.

All gas fired appliances require air to be used for the combustion

process. In many buildings today, there is a negative indoor

air pressure caused by exhaust fans, etc. If sufficient quantities

of combustion air are not available, the heater or another or

another appliance will operate in an inefficient manner, resulting

in incomplete combustion which can result in the production of

excessive carbon monoxide.

CAUTION Insufficient combustion air can cause headaches,

nausea, dizziness, asphyxiation or death.

If indoor air is to be used for combustion, it must be free of the

following substances or the life of the heat exchanger will be

adversely affected: chlorine, carbon tetrachloride, cleaning solvent,

halogen refrigerants, acids, cements and glues, printing inks,

fluorides, paint removers, varnishes, or any other corrosives.

VENTING

A – GENERAL RECOMMENDATIONS AND

REQUIREMENTS

NOTE: The vent is a passageway, vertical or nearly so, used to

convey flue gases from an appliance, or its vent connector, to the

outside atmosphere. The vent connector is the pipe or duct that

connects a fuel-gas burning appliance to a vent or chimney.

Unit heaters must be vented in compliance with all local codes

or requirements of the local utility, the current standards of the

(American) National Fuel Gas Code, ANSI Z223.1 or (Canada)

CSA B149.1 Natural Gas and Propane Installation Code, and the

following instructions.

A metal stamped/extruded transition is supplied with this certified

unit. It must not be modified or altered and must be installed

on the outlet of the induced draft blower assembly prior to the

installation of the vent or vent connector. Failure to comply with

this requirement will void the certification of the unit by the

approval agencies. All joints shall be secured with at least two

corrosion resistant screws. All joints must be checked for gas

tightness after installation.

FIGURE 1

COMBUSTION AND VENTILATION AIR

Adequate facilities for supplying air for combustion and ventilation

must be provided in accordance with the latest edition of section

5.3, Air for Combustion and Ventilation, of the National Fuel

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

TABLE 2

MAXIMUM VENT LENGTHS

HORIZONTAL VENTS

No. of ft m

Elbows

1 25 7.6

2 20 6.1

3 15 4.6

4 10 3.0

5 5 1.5

Maximum length of vent connector not to exceed 30 ft. (9.1m).

6

Page 7

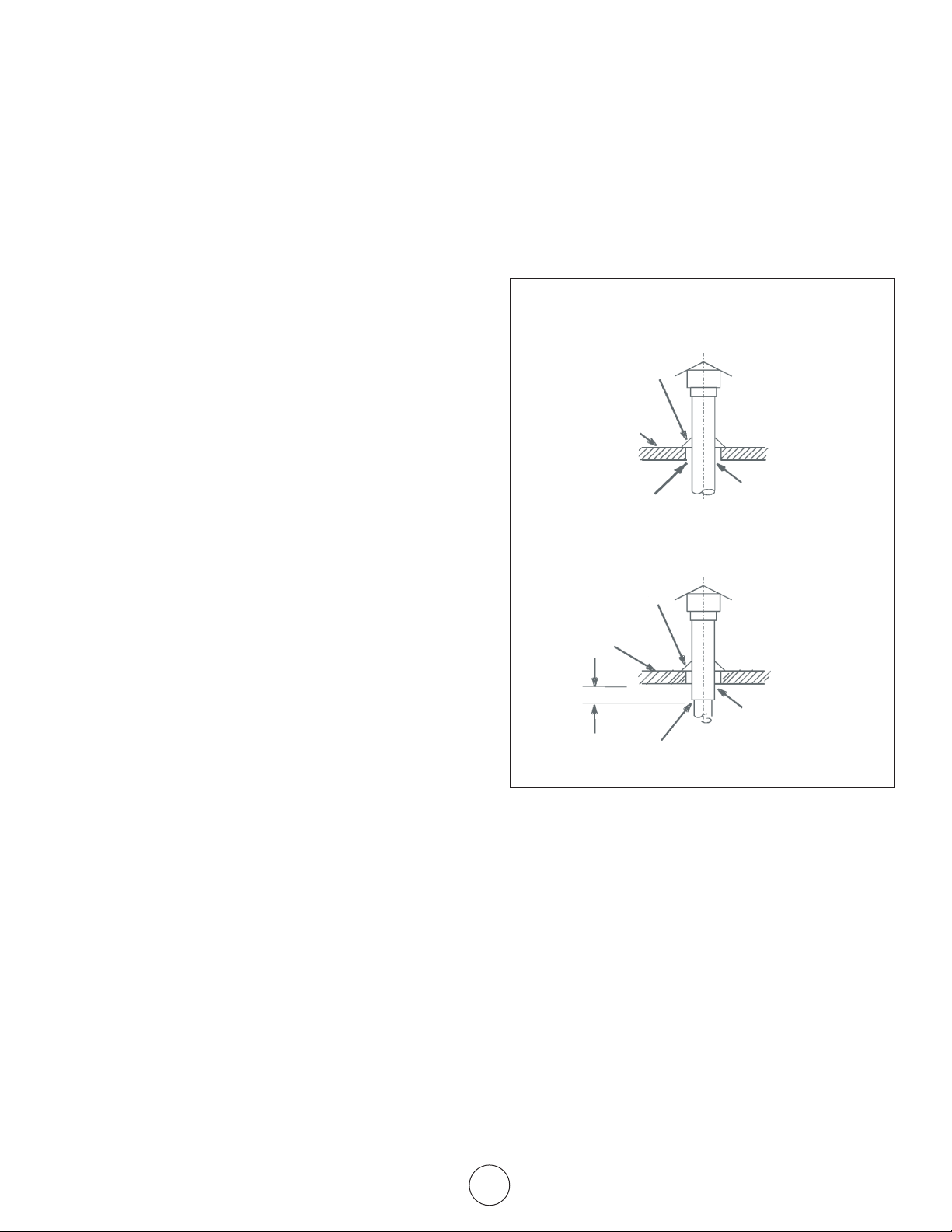

B – VERTICAL VENTS USING METAL VENT

VENT TERMINATION ON SINGLE WALL VENT

SINGLE WALL TERMINATION

DOUBLE WALL (TYPE B-1) TERMINATION

ROOF FLASHING

ROOF PITCHED

FROM 0” TO 45”

SHALL NOT BE A

CONCEALED SPACE

2” CLEARANCE

THIMBLE

ROOF FLASHING

ROOF PITCHED

FROM 0” TO 45”

12” MAX

CLEARANCE TO BE AS

SPECIFIED ON TYPE “B”

VENT PIPE

SEAL JOINT BETWEEN SINGLE WA LL VENT

AND “B”VENT AND THE ANNULAR SPACE OF THE “B” VENT

PIPE – COMMERCIAL AND RESIDENTIAL

INSTALLATIONS

MHU/HSU compact unit heaters are listed as Category I

appliances for vertical vent installations.

1. MHU/HSU unit heaters are to be used with NFPA- or ANSI-

approved chimneys, U.L. listed type B-1 gas vents, single

wall metal pipe, or listed chimney lining system for gas

venting where applicable, as well as the modifications and

limitations listed in figure 2. Seal single wall vent material

according to the section A - General Recommendations

and Requirements.

2. The vent connector shall be 3” (76mm) diameter on 45 units.

In all cases, a flue transition piece (supplied) is required to

fit over the outlet of the induced draft assembly on the

appliance.

3. Keep the vent connector runs as short as possible with

a minimum number of elbows. Refer to the (American)

National Fuel Gas Code ANSI Z223.1 or (Canada) CSA B149.1

Natural Gas and Propane Installation Code for maximum

vent and vent connector lengths. Horizontal run of the vent

connector from the induced draft blower to the chimney/vent

cannot exceed the values in table 2.

4. When the length of a single wall vent, including elbows,

exceeds 5 feet (1.5m), the vent shall be insulated along

its entire length with a minimum of 1/2” thick foil faced

berglass 1-1/2# density insulation. If a single wall vent is

used in an unheated area it shall be insulated. Failure to do

so will result in condensation of flue gases.

5. The unit may be vented vertically as a single appliance or as

a common vent with other gas-red appliances. In common

venting situations, vent connectors for other appliances

must maintain a 4” (100mm) vertical separation between

the vent connectors. Refer to common venting tables in the

(American) National Fuel Gas Code ANSI Z223.1 or (Canada)

CSA B149.1 Natural Gas and Propane Installation Code for

proper vent size.

6. Clearance to combustible material is 6” (152mm) for single

wall vent material except where a listed clearance thimble is

used. Clearance to combustible material for type B-1 vent or

factory-built chimney is per manufacturer’s instructions.

7. The vent connector shall be supported without any dips or

sags. Vertical vents shall be supported in accordance with

their listing and manufacturers’ instructions. All horizontal

vent connector runs shall have a slope up to the vertical vent

of at least 1/4” per foot (1mm per 50mm).

8. All vertical type B-1 vents, single wall vents, or listed chimney

lining system must be terminated with a listed vent cap or

listed roof assembly.

9. The vent must extend at least 3’ (1m) above the highest point

where it passes through a roof of a building and at least 2’

(0.6m) higher than any part of a building within a horizontal

distance of 10’ (3.05m) unless otherwise specified by the

(American) National Fuel Gas Code, ANSI Z223.1 or (Canada)

CAN/CGA-B149 Installation Code. The vent must extend at

least 5’ (1.6m) above the highest connected equipment flue

collar.

C – HORIZONTAL VENTING – GENERAL

Common venting is not allowed when horizontally venting the unit

heater.

The minimum horizontal vent length is three feet (914mm).

1. If possible, do not terminate the horizontal vent through a

wall that is exposed to prevailing wind. Exposure to excessive

winds can affect unit performance.

2. Vent termination must be free from obstructions and at least

12” (306mm) above grade level and maximum snow height.

FIGURE 2

3. Do not terminate vent directly below roof eaves or above

a walkway, or any other area where condensate dripping

may be troublesome and may cause some staining. Avoid

windows where steam may cause fogging or ice buildup.

4. When horizontally vented, minimum clearance for termination

from any door, window, gravity air inlet, gas or electric

meter, regulators, and relief equipment is 4 ft. (1.2m) for U.S.

installations. Refer to NFPA 54/ANSI Z223.1 in the U.S.A. and

CSA B149.1 Natural Gas and Propane Installation Code and

.2 in Canada or with authorities having local jurisdiction. In

Canada, vent termination must have a minimum 6 ft. (1.8

m) horizontal clearance from gas and electric meters and

relief devices as specified in the Canadian B149.1, Natural Gas

Installation Code.

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

7

Page 8

5. Vent termination must be a minimum of 4’ (1.2m) below or

4’ (1.2m) horizontally from any soft vent or under-eave vent.

6. Vent must be a minimum of 6’ from an inside corner formed

by two exterior walls. If possible, leave a 10’ clearance.

7. Vent termination must be a minimum of 10’ (3m) from any

forced air inlet (includes fresh air inlet for other appliances,

such as a dryer).

8. When termination is routed through an exterior combustible

wall the vent must be supported using a listed clearance

thimble. Where local authorities permit, a single section

of type B-1 vent pipe may be used as an alternative to the

thimble. When using a type B-1 vent termination use the

clearances specified by the vent manufacturer. Seal the

connection between the single wall and double wall pipes

and the annular space of the double wall pipe as shown in

gure 2. Inside edge of vent termination tee must be at least

12 inches from outside wall as shown in figure 3.

9. For horizontal venting, the vent pipe shall be supported with

hangers no more than 3ft. (1m) apart to prevent movement

after installation.

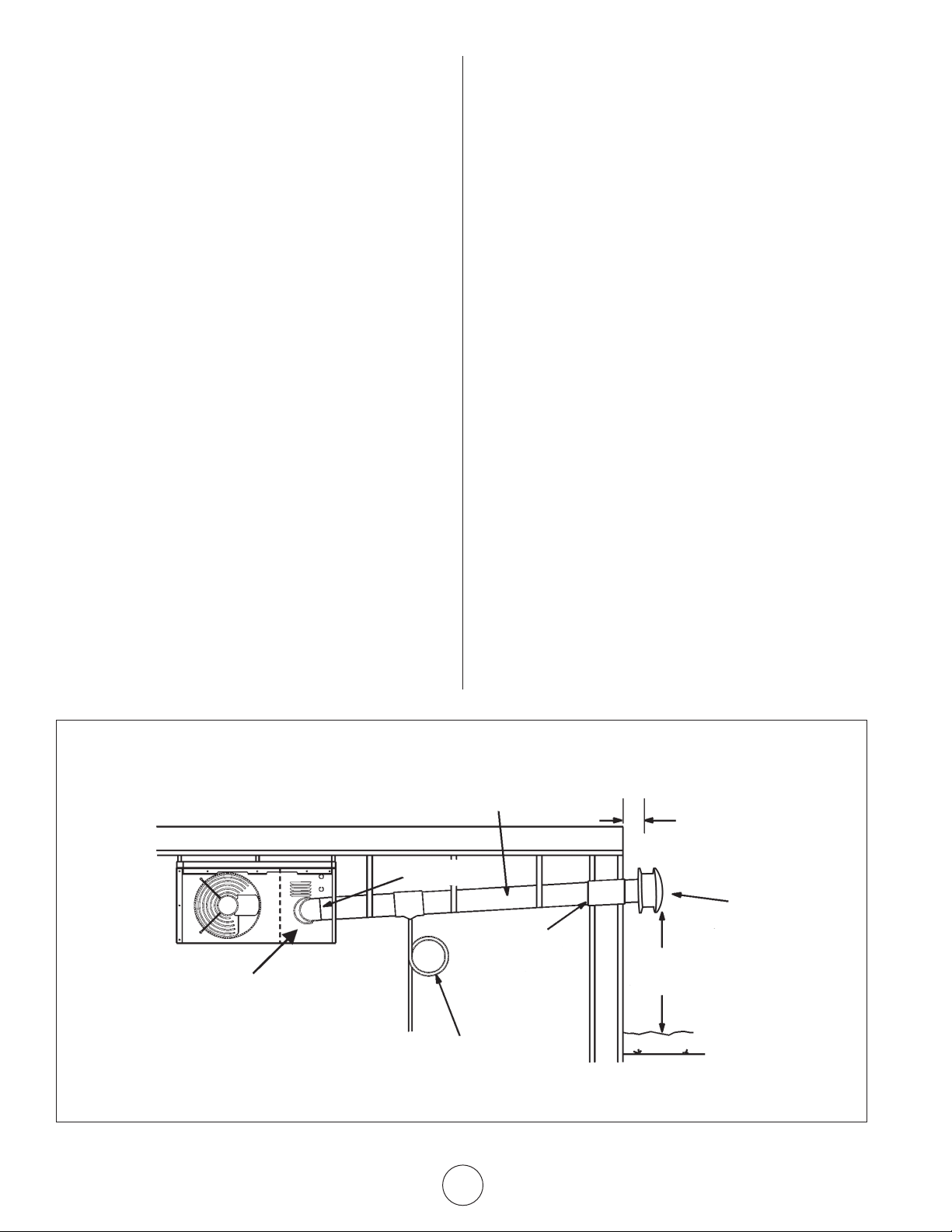

D – HORIZONTAL VENTING – COMMERCIAL

1. Horizontal commercial installations are for buildings which

are not attached to living spaces. The vent may be single wall

vent material installed according to the sections

Venting A - General Recommendations and

Requirements and C - Horizontal Venting General and D Horizontal Venting - Commercial. Refer to figure 3.

2. The vent pipe diameter for horizontal commercial installations

shall be 4V” (76mm) on 45 units. In all cases, a ue transition

piece (supplied) is required to fit over the outlet of the

induced draft assembly on the appliance.

3. Refer to table 2 for maximum vent connector lengths.

4. Select a wall termination point that will maintain ¼” rise

per foot slope of horizontal run of vent pipe. The vent

may be single wall material minimum 26 GSG (0.46mm)

galvanized steel or equivalent grade stainless steel. Seal

single wall vent material according to the section A - General

Recommendations and Requirements.

5. For upward sloped vent a condensate tee and drain must

be installed within the first 5’ (1.5m) from the unit heater

to protect the appliance. If a flexible condensate drain line

is used, the drain line must include a loop entering the

structure. If the unit is shut down for an extended period of

time and will be exposed to sub-freezing temperatures, the

condensate may freeze.

E – HORIZONTAL VENTING – RESIDENTIAL

1. For horizontal residential installations these units are

certified as Category I appliances. The vent may be single

wall material minimum 25 GSG (0.46mm) galvanized steel

or equivalent grade stainless steel. Venting A - General

Recommendations and Requirements and C - Horizontal

Venting General and E - Horizontal Venting - Residential.

Refer to figure 6.

2. The vent pipe diameter for horizontal residential installations

shall be 4” (100mm) on 45 units. A standard vent transition is

required at unit in addition to the transition supplied with the

unit.

3. The maximum vent length is 5’ (1.5m) plus one 90-degree

elbow. The minimum length is 3’(.91m).

4. The vent must maintain a ¼” rise per foot of slope upwards

toward the termination.

CONDENSATE DRAIN THROUGH TEE PIPE AND DRAIN LOOP

UPWARD SLOPE ON HORIZONTAL VENT-COMMERCIAL INSTALLATION

MAY BE SINGLE WALL (26 GSG) GALV. OR EQUIV. STAINLESS STEEL SEALED ACCORDING TO

THESE INSTALLATION INSTRUCTIONS. SLOPE: + 1/4 INCH FOR 1 FOOT RUN MINIMUM.

INDUCED DRAFT BLOWER

NOTE - MINIMUM HORIZONTAL LENGTH 3 FT. (914MM),

NOT INCLUDING CAP FOR TERMINATION. REFER TO TABLE

2 FOR MAXIMUM LENGTH AND NUMBER OF ELBOWS.

COMMON VENTING NOT ALLOWED WHEN HORIZONTALLY VENTING THE UNIT HEATER

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

FLUE TRANSITION

(PROVIDED)

LISTED THIMBLE

THROUGH COMBUSTIBLE

WALL

DRAIN LOOP WITH WATER

TRAP (TO CONDENSATE DRAIN)

FIGURE 3

8

12 INCHES MIN.

(30.5 CM)

VENT TERMINATION

CAP

12” (30.5 CM)

MINIMUM ABOVE ALL

HIGHEST SNOWFALL

Page 9

INDUCED DRAFT BLOWER

MAY BE SINGLE WALL (26 GSG) GALV. OR EQUIV. STAINLESS

STEEL SEALED ACCORDING TO THESE INSTALLATION

INSTRUCTIONS OR A SINGLE SECTION OF TYPE B-1 VENT.

SLOPED: + 1/4 INCH FOR 1 FOOT RUN MINIMUM.

NOTE - MINIMUM HORIZONTAL LENGTH 3FT. (914MM), NOT

INCLUDING CAP FOR TERMINATION.

MAXIMUM HORIZONTAL LENGTH 5FT. (1.5M) PLUS ONE

90-DEGREE ELBOW.

HORIZONTAL VENTING - RESIDENTIAL INSTALLATION

FLUE TRANSITION

(PROVIDED)

LISTED THIMBLE THROUGH

COMMON VENTING NOT ALLOWED WHEN HORIZONTALLY VENTING THE UNIT HEATER.

UPWARD SLOPE

12 INCHES

MIN. (30.5CM)

VENT TERMINATION CAP

COMBUSTION WALL

FIGURE 6

F – VENTING USING A MASONRY CHIMNEY

The following additional requirements apply when a lined masonry

chimney is being used to vent the compact unit heater.

1. Masonry chimneys used to vent Category I units heaters

must be either tile-lined or lined with a listed metal lining

system or dedicated gas vent. Unlined masonry chimneys are

prohibited. A category I appliance must never be connected

to a chimney that is servicing a solid fuel appliance. If a

fireplace chimney flue is used to vent this appliance, the

fireplace opening must be permanently sealed.

2. A fan assisted unit heater may be commonly vented into an

existing lined masonry chimney provided:

• The chimney is currently serving at least one draft-hood

equipped appliance.

• The vent connector and chimney are sized in accordance

with venting tables in the (American) National Fuel Gas

Code ANSI Z223.1 or (Canada) CSA B149.1 Natural Gas

and Propane Installation Code.

IMPORTANT Single appliance venting of a fan assisted unit

heater into a tile lined masonry chimney (interior or outside wall)

is prohibited. The chimney must rst be lined with either type B-1

vent or an insulated single wall flexible vent lining system, sized

in accordance with venting tables in the (American) National Fuel

Gas Code ANSI Z223.1 or (Canada) CSA B149.1 Natural Gas and

Propane Installation Code.

3. A type B-1 vent or masonry chimney liner shall terminate

above the roof surface with a listed cap or a listed roof

assembly in accordance with the terms of their respective

listings and the vent manufacturer’s instructions.

4. Do not install a manual damper, barometric draft regulator, or

flue restrictor between the unit heater and the chimney.

5. If type B-1 double-wall vent is used inside a chimney, no other

appliance can be vented into the chimney. Outer wall of type

B-1 vent pipe must not be exposed to ue products.

6. Insulation for the flexible vent pipe must be an encapsulated

fiberglass sleeve recommended by the flexible vent pipe

manufacturer.

7. The space between liner and chimney wall should NOT

be insulated with puffed mica or any other loose granular

insulating material.

8. If type B-1 vent or an insulated exible vent pipe cannot be

used as liners, the chimney must be rebuilt to accommodate

one of these methods or some alternate approved method

must be found to vent the appliance. When inspection

reveals that an existing chimney is not safe for the intended

purpose, it shall be rebuilt to conform to nationally

recognized standards, lined or relined with suitable materials

or replaced with a gas vent or chimney suitable for venting

unit heaters. The chimney passageway must be checked

periodically to ensure that it is clear and free of obstructions.

G – REMOVAL OF UNIT FROM COMMON VENT

In the event that an existing unit heater is removed from a venting

system commonly run with separate gas appliances, the venting

system is likely to be too large to properly vent the remaining

attached appliances. The following test should be conducted while

each appliance is in operation and the other appliances are not in

operation, yet remain connected to the common venting system.

If the venting system has been installed improperly, the system

must be corrected.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and

horizontal pitch. Determine there is no blockage or

restriction, leakage, corrosion, or other deficiencies which

could cause an unsafe condition.

3. If practical close all building doors and windows and all

doors between the space in which the appliances remaining

connected to the common venting system are located and

other spaces of the building. Turn on clothes dryers and any

appliances not connected to the common venting system.

Turn on any exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the appliance being

inspected in operation. Adjust thermostat so appliance will

operate continuously.

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

9

Page 10

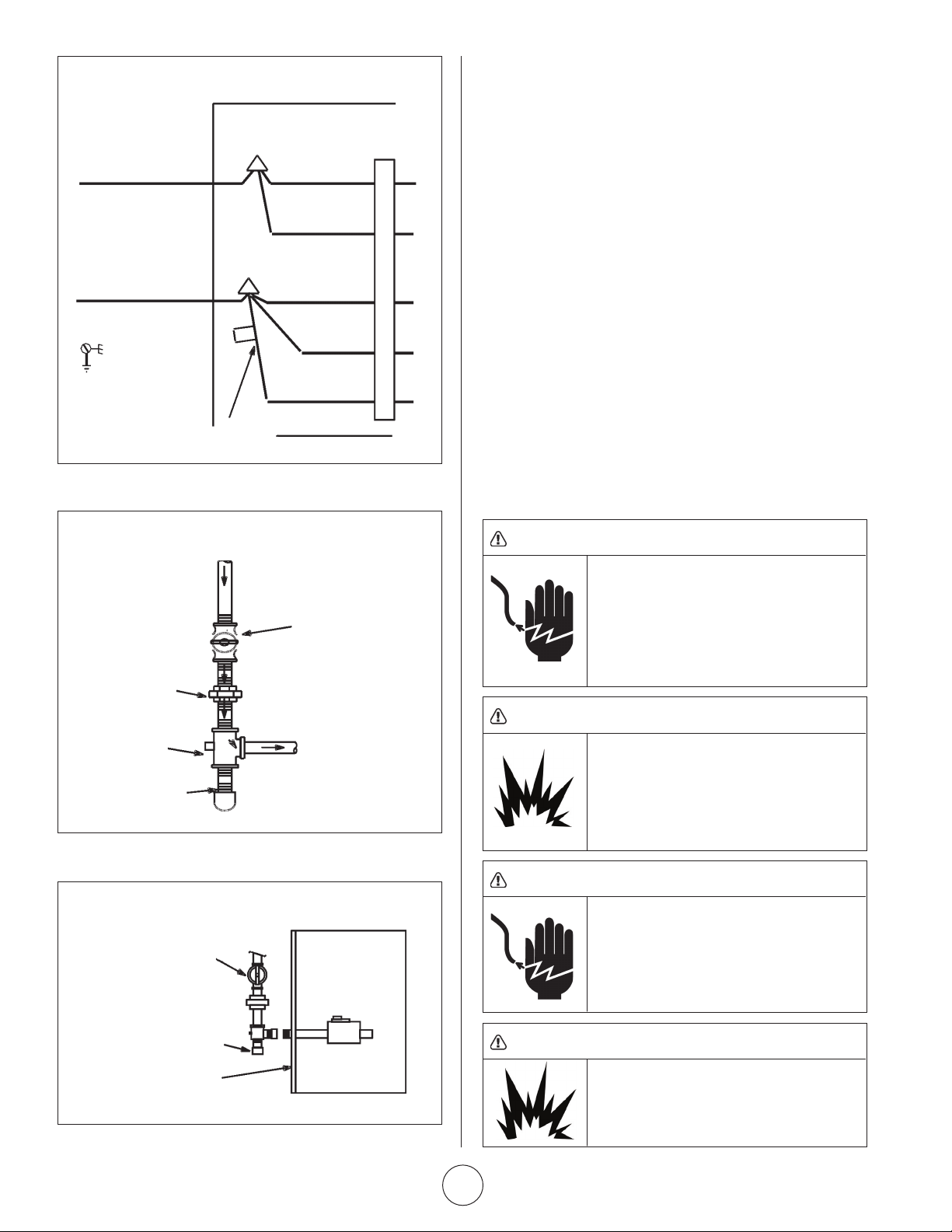

L1

N

EQUIPMENT

GROUND

LINE VOLTAGE FIELD WIRING

UNIT

BLACK

BLACK

WHITE

WHITE

5. Test for spillage at the draft hood relief opening after five

minutes of main burner operation. Use the flame of a match

or candle, or smoke from a cigarette, cigar, or pipe.

6. After it has been determined that each appliance remaining

connected to the common venting system properly vents

when tested as outlined above, return doors, windows,

exhaust fans, replace dampers and any other gas-burning

appliance to their previous condition of use.

7. If improper venting is observed during any of the above

tests, the common venting system must be corrected. The

common venting system should be resized to approach the

minimum size as determined by using the appropriate tables

in Appendix G in the current standards of the National Fuel

Gas Code, ANSI Z223-1 in the U.S.A. and the appropriate

Category I Natural Gas and Propane appliances venting sizing

tables in the current standards of the CSA B149.1 Natural Gas

and Propane Installation Code in Canada.

NOTE Local codes may supersede any of the above provisions.

BLACK WIRE WITH WHITE TAPE OR

WHITE WIRE WITHOUT TAPE

FIGURE 7

GAS SUPPLY CONNECTION

GROUNDED

JOINT UNION

1/8 NPT

PLUGGED TAP

DRIP LEG

FIGURE 8

MANUAL

MAIN SHUT-OFF VALVE

(FURNISHED BY INSTALLER)

GAS FLOW

ELECTRICAL CONNECTIONS

NOTE The MHU/HSU series unit heaters use a direct spark

ignition system. There is no pilot necessary as the spark lights

the main burner as the gas valve is turned on. The direct spark

WARNING

Electric shock hazard. Can cause injury or

death. Do not use this heater if any part

has been under water. Immediately call

a qualified service technician to inspect

the furnace and to replace any part of

the control system and any gas control

which has been under water.

WARNING

Danger of explosion. Can cause injury or

product or property damage. If overheating occurs or if gas supply fails to

shut off, shut off the manual gas valve

to the appliance before shutting off

electrical supply.

GAS SUPPLY TO UNIT HEATER

MANUAL MAIN SHUT-OFF VALVE

WILL NOT HOLD NORMAL TEST

PRESSURE

CAP

UNIT HEATER

FIGURE 9

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect

ISOLATE

GAS VALVE

switch(es). Unit may have multiple power

supplies.

WARNING

Danger of explosion and fire. Can

cause injury or product or property

damage. You must follow these

instructions exactly.

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

10

Page 11

ignition control board emits radio noise as the sparking process

is underway. The level of energy may be sufficient to disturb

a logic circuit in a microprocessor controlled thermostat. It is

recommended that an isolation relay be used when connecting

the unit heaters to a microprocessor controlled thermostat.

Install the thermostat according to instructions provided. Select

circuit protection and wire size according to the unit rating plate.

Install a separate disconnect switch (protected by either fuse or

circuit breaker) near the unit so that power can be turned off

for servicing. Connect wiring through knockout on the junction

box located on the side of the unit heater. Refer to heater wiring

diagram for connection information. Use 18 gauge wire or larger

for thermostat connections.

Electrically ground unit in accordance with local codes or, in the

absence of local codes, in accordance with the current National

Electrical Code (ANSI/NFPA No. 70) in the U.S.A., and in Canada

with the current Canadian Electrical Code, Part 1 CSA C22.1.

NOTE Un-insulated ground wires must be wrapped in electrical

tape to avoid damage to the electrical system.

Make line voltage connections as shown in figure 7. Connect field

wiring as shown on wiring diagram on unit. Also refer to typical

diagram in this manual. An additional thermostat wire must be

run to terminal “G” on heater when continuous blower is desired.

GAS CONNECTION

When connecting gas supply, the length of the run from the

meter must be considered in determining the pipe size to avoid

excessive pressure drop. A line pressure of 7” w.c. (178mm w.c.)

for natural gas should be maintained when sizing piping. A line

pressure of 13” w.c. (330mm w.c.) should be maintained for

liquefied petroleum (LP) gas. For correct sizing of piping, refer to

the (American) National Fuel Gas Code ANSI Z223.1 or (Canada)

CSA B149.1, Natural Gas and Propane Installation Code or consult

the utility having jurisdiction.

A drip leg should be installed in the vertical pipe run to the unit.

In some localities, codes may require that a manual main shutoff

valve and union (furnished by installer) be installed external to the

unit. Union must be of the ground joint type. A drip leg should be

readily accessible to permit cleaning and emptying. See figure 8.

NOTE If a switch box is mounted over electrical knockouts on

back of unit, leave a minimum of 4” (102mm) clearance between

switch box and drip leg.

A 1/8” NPT plugged tap shall be installed immediately upstream

of the gas supply connection to the heater.

NOTE Compounds used on threaded joints of gas piping must be

resistant to the actions of liquefied petroleum gases.

LEAK CHECK

After gas piping is completed, carefully check all piping

connections, (field and factory), for gas leaks. Use a soap solution

or other preferred means.

Due to the natural heating cycles and vibration of this unit it is

recommended, as part of its annual maintenance, to check these

connections for proper tightness and leak-check with a soap

solution or other preferred means prior to putting into service.

CAUTION DO NOT use matches, candles, flame or other sources

of ignition to check for gas leaks.

IMPORTANT The heater and its individual shut off valve must

be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2

psig (3.45kPa).

The appliance must be isolated from the gas supply piping system

by closing its individual manual gas shutoff valve during any

pressure testing of the gas supply system at test pressures equal

to or less than 1/2 psig (3.45kPa). See figure 9.

NOTE In case emergency shutdown is required, shut down main

gas valve and disconnect main power to unit. These devices

should be properly labeled by the installer.

START – UP AND OPERATION

UNIT START–UP

FOR YOUR SAFETY READ BEFORE LIGHTING

BEFORE LIGHTING smell all around the appliance area for gas.

Be sure to smell next to the floor because some gas is heavier

than air and will settle on the floor.

Use only your hand to push in or turn the gas control knob. Never

use tools. If the knob will not push in or turn by hand, do not try

to repair it, call a qualified service technician. Force or attempted

repair may result in a fire or explosion.

MHU45/75 and HSU45/75 unit heaters are equipped with an

automatic spark ignition system. There is no pilot. In case of a

safety shutdown, move thermostat switch to OFF, then return the

thermostat switch to HEAT position.

Should overheating occur, or the gas supply fail to shut off, shut

off the manual gas valve to the appliance before shutting off the

electrical supply.

GAS VALVE OPERATION FOR ROBERTSHAW

2000DER SERIES VALVE (FIGURE 10)

1. STOP! Read the safety information at the beginning of this

section.

2. Set the thermostat to lowest setting.

3. Turn off all electrical power to appliance.

4. This appliance is equipped with an ignition device which

automatically lights burner. DO NOT attempt to light the

burners manually.

5. Depress knob on gas valve; knob will snap to OFF.

(See Figure 10)

6. Wait five minutes to clear out any gas. If you then smell gas,

STOP! Immediately call your gas supplier form a neighbor’s

phone. Follow the gas supplier’s instructions. If you do not

smell gas go to next step.

7. Turn knob on gas valve 90o counterclockwise to ON.

8. Turn on electrical power to unit.

9. Set the thermostat to desired setting.

10. The combustion air blower will start. The burners will light

within 40 seconds.

11. If unit does not light first time (gas line not fully purged) it

will attempt up to two more ignitions before locking out.

11

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

Page 12

ROBERTSHAW 2000DER GAS VALVE

GAS VALVE KNOB SHOWN

IN OFF POSITION

PRESSURE TAP

MANIFOLD

7. The ignition control will energize the fan approximately 45

seconds after ignition is established.

8. After the thermostat demand is satised the gas valve

is closed; 5 seconds after the demand is satisfied the

combustion air blower is shut off.

9. The control center shall shut off the system fan approximately

150 seconds after the gas valve is de-energized.

IGNITION CONTROL LED

The ignition control board contains a green LED which indicates

the following:

TABLE 3

IGNITION CONTROL LED

INLET PRESSURE TAP

MANIFOLD PRESSURE ADJUSTMENT

SCREW UNDER CAP

FIGURE 10

12. If lockout occurs, repeat steps 1 through 9.

13. If appliance still will not operate, follow the instructions “TO

TURN OFF GAS TO UNIT” and call your service technician or

gas supplier.

TO TURN OFF GAS TO UNIT

1. Set thermostat to lowest level.

2. Turn off all electrical power to unit if service is to be

performed.

3. Depress knob on gas valve; knob will snap to OFF.

HEATING SEQUENCE OF OPERATION

1. When the thermostat calls for heat, the combustion air

blower starts immediately.

2. Combustion air pressure switch proves blower operation

before allowing power to the ignition controller. This switch is

factory set and no adjustment is necessary.

3. After pre-purge of approximately 30 seconds, the spark

ignition is energized and the solenoid valves open in the gas

valve.

4. The spark then ignites the gas, the ignition sensor proves the

flame and the combustion process continues.

5. In the event that the flame is not detected after the first

10-second trial for ignition, the controller will repeat steps

3 and 4 an additional two times before locking out the gas

valve. Ignition control will then automatically repeat steps 3,

4, and 5 after 60 minutes.

To interrupt the 60-minute lockout period, move thermostat

from “Heat” to “OFF” then back to “HEAT.” Heating sequence

then restarts at step 1.

6. The burners shall light without noticeable crossover delay.

There shall be no flame lifting from the burner heads,

flashback or burning within the burner. The flames shall

be predominantly blue in color and shall be approximately

centered in the tubes with no apparent impingement taking

place.

OPTIONAL GAS CONVERSION KIT

LED UNIT OPERATION

Slow Flash* Normal Operation - No call for heat

Fast Flash Normal Operation - Call for heat

Current signal at FLAME terminal 0.6 to 1.0 microamps

2 Flashes System lockout - failed to detect or sustain ame

Current signal at FLAME terminal <0.6 microamps

3 Flashes Pressure switch failed closed before CAB is energized

or failed open after CAB is energized

4 Flashes High limit or rollout switch open

5 Flashes Flame sensed and gas valve not energized

Steady Off Loss of power

Steady On Ignition control failure

*When thermostat is placed in continuous fan mode LED will slowly flash.

Unit not available for conversion at this time.

ADJUSTMENTS

HIGH ALTITUDE

Units may be red at full input up to 2000 ft. (610m) above sea

level. Above 2000 ft. (610m), manifold pressure must be adjusted

on some units. Adjust pressure regulator to pressure shown in

table 4 for natural gas and table 5 for LP/propane gas.

GAS FLOW

To check for proper gas flow to the combustion chamber,

determine the Btu input from the appliance rating plate. Divide

this input rating by the Btu per cubic feet of available gas. Result is

the required number of cubic feet per hour. Determine the flow of

gas through the gas meter for two minutes and multiply by 30 to

get the hourly flow of gas.

GAS PRESSURE

1. Check gas line pressure with unit firing at maximum rate. A

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

12

Page 13

minimum of 5.0” w.c. for natural gas or 10.4” w.c. for LP/

propane gas should be maintained for proper unit operation.

2. After line pressure has been checked and adjusted, check

manifold pressure. Correct manifold pressure is shown on the

unit rating plate. See figure 10 for gas pressure adjustment

screw location. A natural gas to LP/propane gas changeover

kit is required to convert unit. Refer to installation instructions

provided with changeover kit for conversion procedure.

LIMIT CONTROL

The limit control switch is factory set and not field adjustable.

LOUVER VANE ADJUSTMENTS

TABLE 4

NATURAL GAS MANIFOLD PRESSURES - IN.WG. (KPA)

ALTITUDE FT. (M)

MHU45/75 HSU45/75 0-2000 2000-4500

(0-610) (610-1370)

45/75 4.0 (0.99)* 3.6 (0.89)

*No adjustment required.

TABLE 5

LP/PROPANE GAS MANIFOLD PRESSURES - IN.WG. (KPA)

ALTITUDE FT. (M)

MHU45/75 HSU45/75 0-2000 2000-4500

(0-610) (610-1370)

45/75 10 (2.49)* 8.0 (1.99)

*No adjustment required.

Rotate louver vanes to direct airflow upward, downward, straight,

or any combination of these directions. When unit is installed

in an inverted position, louvers may be positioned in the same

manner.

COMBUSTION AIR PRESSURE SWITCH

This pressure switch checks for proper combustion air blower

operation before allowing an ignition trial. The switch is factory set

and no field adjustment is necessary.

FLAME ROLLOUT SWITCH

The flame rollout switch(es) are located on the burner box top,

behind the ignition control board. This normally closed switch

opens on a temperature rise. Check for adequate combustion air

before manually resetting switch.

SERVICE

CAUTION Turn off gas and electrical power to unit before

performing any maintenance or service operations on this unit.

Remember to follow lighting instructions when putting unit back

into operation after service or maintenance.

If any of the original wire as supplied with the appliance must

be replaced, it must be replaced with wiring material having a

temperature rating of at least 105°C.

Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and replace any gas control which has been under

water.

BURNERS

1. Periodically examine burner flames for proper appearance

during the heating season.

2. Before each heating season examine the burners for any

deposits or blockage that may have occurred.

3. Clean burners as follows:

• Turn off both electrical and gas supplies to unit.

• Disconnect gas supply piping, high tension and sensor

leads. Remove gas manifold. Remove burner tray.

• Clean burners as necessary. Make sure that burner

heads line up properly to ensure flame crossover. Check

spark gap on electrode and adjust if required. The gap

should be between 0.110 inch and 0.140 inch (2.79mm

to 3.56mm). The gap may be checked with appropriately

sized twist drills or feeler gauges.

• Reinstall burner tray, gas manifold, high tension and

sensor leads. Reconnect gas supply piping.

• Restore electrical power and gas supply. Follow lighting

instructions to light unit. Check burner flame.

FLUE PASSAGEWAY AND FLUE BOX

The flue passages and flue box should be inspected and cleaned

prior to each heating season. The sequence of operation should

be as follows:

1. Turn off both electrical and gas supply to unit.

2. Disconnect combustion air blower wiring.

3. Remove screws securing flue box to unit. Remove flue box. If

necessary, remove blower assembly from flue box. Clean flue

box with wire brush.

4. Remove turbulator retention bracket and turbulators. Clean

turbulators with wire brush.

5. Remove burners as described in section “BURNERS” section.

6. Clean tubes with a wire brush.

7. Reassemble unit. The combustion air and flue box gaskets

should also be replaced during reassembly.

8. Restore electrical power and gas supply. Follow lighting

instructions to light unit. Check operation of unit.

COMBUSTION AIR BLOWER

Under normal operating conditions, the combustion air blower

should be checked and cleaned prior to the heating season with

the power supply disconnected. Use a small brush to clean blower

wheel.

13

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

Page 14

BLUE

BLUE

BLACK

BLACK

BLACK

BLACK

EQUIPMENT

GROUND

WHITE WHITE

WHITE (COM)

WHITE

YELLOW

VLV

RTN

VLV

OUT

YELLOW

GREEN/YELLOW

1(S47)

T1 24V

120V

L1

A3

LINE VOLTAGE FIELD INSTALLED

MAXIMUM LOAD NOT TO EXCEED

20VA AT 24V, CLASS 2.

DISCONNECT ALL POWER

BEFORE SERVICING.

FOR PROPER GROUNDING,

REFER TO LOCAL CODES.

DESCRIPTION

COMPONENT

CONTROL, BURNER, IGNITION

MOTOR, FAN

MOTOR, COMBUSTION AIR BLOWER

VALV E, GAS

LIMIT, PRIMARY, GAS

SWITCH, COMB, AIR BLWR PRONE

SWITCH-FLAME ROLLOUT 1

SWITCH-FLAME ROLLOUT 2

TRANSFORMER CONTROL

KEY

A3

B3

B6

6VI

510

518

(1) S47

(2) S47

T1

SET THERMOSTAT HEAT ANTICIPA T ION

ROBERTSHAW VALVE............ .4

WARNINGELECTRIC SHOCK HAZARD, CAN CAUSE INJURY

OR DEATH, UNIT MUST BE GROUNDED IN ACCORDANCE

WITH NATIONAL AND LOCAL CODES.

CLASS II 24 VAC FIELD INSTALLED

DENOTES OPTIONAL COMPONENTS

B6

B3

L1

CWB

BLWR

HTG

ACC

ACC

ACC

ACB

LOW

ACB

COOL

ACB

HEAT

N

2(S47)

BROWN

RED

ORANGE

COM

S18

S10

GV1

GND

3

4

1

5

F5

A3

R

G

W

C

P20

2

6

HIL

OUT

HEAT 1 (W1)

24V POWER (R)

ONLY WITH

MANUAL FAN

BLOWER (G)

HIL

RTN

PSW

RTN

24VAC

HOT

PSW

OUT

FLAME

SENSOR

SPARK

ELECTRODE

GND PROGRAMMABLE

THERMO.

24V COMMON (C)

WIRING SCHEMATIC FOR UNITS WITH

6-PIN CONNECTOR GCI-3A (23L53) CONTROL BOARD

OPTIONAL THERMOSTAT INSTALLATION

IT IS RECOMMENDED TO USE 18AWG WIRE

WHEN INSTALLING THE THERMOSTAT.

CONNECT THERMOSTAT WIRING TO

TERMINALS ‘R’ AND ‘W’ AS ILLUSTRATED ON

THE SCHEMATIC DIAGRAM.

NOTE: IF ANY OF THE ORIGINAL WIRE AS

SUPPLIED WITH THE APPLIANCE MUST BE

REPLACED, IT MUST BE REPLACED WITH

WIRING MATERIAL HAVING A TEMPERATURE

RATING OF AT LEAST 105°C.

WIRE DIAGRAM

GAS FIRED UNIT HEATER DSI-IGNITION

MHU45LP MHU45NG

HSU45LP HSU45NG

MHU75LP MHU75NG

HSU75LP HSU75NG

60006 REV.

LADDER DIAGRAM

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

14

Page 15

ELECTRICAL

1. Check all wiring for loose connections.

2. Check for correct voltage at unit (unit operating).

3. Check amperage draw.

FLUE AND CHIMNEY

Check all vent and vent connector joints for tightness. Ensure that

connections are sealed and that there are no blockages.

FAILURE TO OPERATE

If unit fails to operate check the following:

1. Is thermostat calling for heat?

2. Is main disconnect closed?

3. Is there a breaker tripped or a fuse blown?

4. Is gas turned on at meter?

5. Is manual shutoff valve open?

6. Is unit ignition system in lock out? If unit locks out again, call

service technician to inspect unit.

7. Is pressure switch closed? Obstructed flue will cause unit to

shut off at pressure switch. Check flue passage and outlet.

REPAIR PARTS

When ordering repair parts include the complete unit model

number listed on the unit rating plate. For example: MHU45/75

and HSU45/75.

THIS COLUMN INTENTIONALLY LEFT BLANK

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

15

Page 16

PARTS LIST:

SEE BACK PAGE FOR PARTS ORDERING INFORMATION

REF #. DESCRIPTION 45 ITEM # QUANTITY 75 ITEM # QUANTITY

1.................CIRCUIT BOARD .................................................... 60105 .......................1 ....................................S/A ....................... 1

2.................LIMIT SENSOR ....................................................... 60022 ......................1 ....................................60021 ................... 2

3.................ELECTRODE IGNITER .............................................. 60035 ......................1 ....................................S/A ....................... 1

4.................ELECTRODE SENSOR .............................................. 60040 ......................1 ....................................S/A .......................1

5.................BURNER ................................................................60050 ......................3 ....................................S/A ....................... 5

6.................IGNITION LEAD ..................................................... 60045 ......................1 ....................................S/A ....................... 1

7.................SENSOR LEAD .......................................................60046 ......................1 ....................................S/A .......................1

8.................ORIFICE (NAT) ....................................................... 60049 ......................3 ....................................S/A .......................5

9.................ORIFICE (LP) .......................................................... 60056 ......................3 ....................................S/A ....................... 5

10 ............... GAS VALVE (NAT) .................................................. 02 812 .......................1 ....................................S/A .......................1

11 ...............GAS VALVE (LP) .....................................................0 2 8 11 ........................1 ....................................S/A ....................... 1

12 ............... TRANSFORMER .....................................................60025 ......................1 ....................................S/A ....................... 1

13 ............... PRESSURE SWITCH ................................................ 60030 ......................1 ....................................S/A ....................... 1

14 ............... HI LIMIT SENSOR HEAT EXCH. ............................... 60015 .......................1 ....................................S/A .......................1

15 ............... PRESSURE SWITCH TUBE ....................................... 60031 .......................1 ....................................S/A ....................... 1

16 ............... INDUCED DRAFT MOTOR ...................................... 60020 ......................1 ....................................S/A .......................1

17 ...............VENT ADAPTER ..................................................... 60130 .......................1 ....................................60140 ................... 1

18 ...............INDUCED DRAFT MOTOR GASKET ......................... 60135 .......................1 ....................................S/A ....................... 1

19 ............... BACK BRACKET .................................................... 60075 ......................1 ....................................S/A ....................... 1

20 ...............FRONT BRACKET .................................................. 60080 ......................1 ....................................S/A ....................... 1

21 ............... LOUVERS .............................................................. 60100 .......................5 ....................................S/A .......................7

22 ............... LOUVER SPRING ................................................... 60103 .......................5 ....................................S/A ....................... 7

23 ............... FLUE BOX .............................................................. 60085 ......................1 ....................................60087 ...................1

24 ............... FLUE BOX GASKET ................................................. 60090 ......................1 ....................................60092 ...................1

25 ............... HEAT EXCHANGER ................................................ 60065 ......................1 ....................................60068 ...................1

26 ............... ACCESS DOOR .....................................................60070.......................1 ....................................60072 ................... 1

27 ...............FRONT .................................................................. 60095 ......................1 ....................................60097 ...................1

28 ............... SIDE DOOR .......................................................... 60110 .......................1 ....................................60112 ....................1

29 ............... WRAPPER ............................................................. 60115 ........................3 ....................................60117 ....................3

30 ............... FAN MOTOR .......................................................... 60055 ......................1 ....................................60054 ................... 1

31 ............... FAN GUARD ......................................................... 60120 .......................1 ....................................60122 ....................1

32 ............... FAN ASSEMBLY ..................................................... 60125 .......................1 ....................................60127 ....................1

33* ............. CAPACITOR STARTER .....................................................................................................................28788 ...................1

34* ............. MANIFOLD ............................................................ 60062 ......................1 ....................................60064 ................... 1

*Not Shown

Optional Installation Components

24V THERMOSTAT ................................................. 103 71

4” VERTICAL VENT KIT (75) ...................................F102848

3” VERTICAL VENT KIT (45) ...................................F102840

4” HORIZONTAL VENT KIT (45,75) .........................F102845

Gas Conversion Kits

Natural Gas to Liquid Propane

MHU/HSU45 45,000 BTU ......................60067

MHU/HSU75 75,000 BTU ......................60069

Liquid Propane to Natural Gas

MHU/HSU45 45,000 BTU ......................60066

MHU/HSU75 75,000 BTU ......................60071

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

16

Page 17

Mr. Heater / HeatStar • Compact Unit Heater • Model # MHU45/75 HSU45/75

17

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

Page 18

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

MR. HEATER

MODEL

MHU 45

MHU 75

READ INSTRUCTIONS CAREFULLY: Read and

follow all instructions. Place instructions in a

safe place for future reference. Do not allow

anyone who has not read these instructions to

assemble, light, adjust or operate the heater.

HEATSTAR

MODEL

HSU 45

HSU 75

WARNING:

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE ONLY AVAILABLE

DIRECT FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE

AGENCY.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any Mr. Heater local dealer or direct

from the factory

FOR INFORMATION REGARDING SERVICE

Please call Toll-Free 800-251-0001 • www.mrheater.com • www.enerco.com

Our ofce hours are 8:30 AM – 5:00 PM, EST, Monday through Friday.

Please include the model number, date of purchase, and description of problem in all

communication.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or workmanship,

under normal and proper use in accordance with instructions of The Company, for a period of

three years on parts (limited) and 10 years on the heat exchanger, from the date of delivery to

the buyer. The Company, at its option, will repair or replace products returned by the buyer to

the factory, transportation prepaid within said one year period and found by the Company to

have imperfections in material or workmanship.

If a part is damaged or missing, call our Technical Support Department at 800-251-0001.

Address any Warranty Claims to the Service Department, Enerco Group, Inc., 4560 W. 160TH

ST., CLEVELAND, OHIO 44135. Include your name, address and telephone number and include

details concerning the claim. Also, supply us with the purchase date and the name and address

of the dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no other

warranties, express or implied. Specifically there is no warranty of fitness for a particular purpose

and there is no warranty of merchantability. In no event shall the Company be liable for delay

caused by imperfections, for consequential damages, or for any charges of the expense of

any nature incurred without its written consent. The cost of repair or replacement shall be the

exclusive remedy for any breach of warranty. There is no warranty against infringement of the

like and no implied warranty arising from course of dealing or usage of trade. This warranty

will not apply to any product which has been repaired or altered outside of the factory in any

respect which in our judgment affects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This Warranty gives you specific legal

rights, and you may have other rights which vary from state to state.

®

ANS Z83.8-(2006) CSA 2.6-(2006)

UNIT HEATER

CSA .10.96 U.S. (2ND ED.)

UNIT HEATER FOR RESIDENTIAL INSTALLATION

CATEGORY/CATEORIE I

Enerco Group, Inc. reserves the right to make changes at any time, without notice or

®

obligation, in colors, specifications, accessories, materials and models.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

Mr. Heater is a registered trademarks of Enerco Group, Inc.

© 2003, Enerco/Mr. Heater. All rights reserved

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

18

Page 19

18

Enerco | Appareils de chauffage compacts Guide d’utilisation et instructions de fonctionnement

© 2003, Enerco/Mr. Heater. Tous droits réservés.

Mr. Heater est une marque de commerce déposée d'Enerco Group Inc.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 USA • (216) 916-3000

ni obligation, aux couleurs, aux spécications, aux accessoires, aux matériaux et aux modèles.

®

éd.)

e

CATÉGORIE 1

INSTALLATION RÉSIDENTIELLE

APPAREIL DE CHAUFFAGE POUR

CSA .10.96 É.-U. (2

APPAREIL DE CHAUFFAGE

ANS Z83.8-(2006) CSA 2.6-(2006)

®

Enerco Group Inc. se réserve le droit d'effectuer des modications en tout temps, sans préavis

droits qui varient selon la province ou l'État.

être pas. La présente garantie vous accorde des droits juridiques précis, mais vous pourriez avoir d'autres

subséquents. Par conséquent, les limitations ou exclusions ci-dessus mentionnées ne vous concernent peutCertains États ou provinces ne permettent pas d'exclure ou de limiter les dommages indirects ou

cela influe de quelque façon que ce soit sur l'état de l'appareil ou son fonctionnement, selon notre jugement.

La présente garantie ne s'applique à aucun produit qui a été réparé ou modié par d'autres que le fabricant si

ce genre ni aucune garantie tacite découlant des usages du commerce ou de la façon habituelle d'échanger.

le seul recours possible en cas de violation de garantie. Il n'y a aucune garantie contre une transgression de

sans son consentement écrit, quelle que soit leur nature. Le coût de la réparation ou du remplacement sera

responsable des retards causés par des défectuosités, ni des dommages indirects, ni des dépenses encourues

particulière ni aucune garantie concernant la qualité marchande. En aucun cas l'entreprise ne sera tenue

expresse ou tacite. Plus précisément, il n'y a aucune garantie concernant l'adéquation à une utilisation

Ce qui est énoncé ci-dessus constitue la responsabilité totale de l'entreprise. Il n'existe aucune autre garantie,

vous avez acheté le produit.

détails de la réclamation. Indiquez-nous également la date d'achat et le nom et l'adresse du détaillant de qui

ST., CLEVELAND, OHIO 44135 États-Unis. Indiquez vos nom, adresse et numéro de téléphone ainsi que les

Adressez toute réclamation relative à la garantie à Service Department, Enerco Group, Inc., 4560 W. 160TH

Si une pièce est endommagée ou manquante, composez le 1 800 251-0001.

main-d'œuvre.

fabricant dans la période de un an et jugés par l'entreprise comme présentant des défauts de matériel ou de

L'entreprise réparera ou remplacera, à sa discrétion, les produits retournés port payé par l'acheteur au

sur les pièces (limitée) et de 10 ans sur l'échangeur de chaleur, à compter de la date de livraison à l'acheteur.

d'utilisation normale et adéquate, conformément aux instructions de l'entreprise, pour une période de 3 ans

L'entreprise garantit ce produit contre tout défaut de matériel ou de main-d'œuvre, dans des conditions

GARANTIE LIMITÉE

vos communications avec nous.

Veuillez indiquer le numéro du modèle, la date d'achat et la description du problème dans toutes

Nos heures d'ouverture sont de 8 h 30 à 17 h HNE, du lundi au vendredi.

Appelez sans frais au 1 800 251-0001 • www.mrheater.com • www.enerco.com

POUR OBTENIR DES INFORMATIONS SUR LE SERVICE

directement du fabricant.

ACHAT : on peut se procurer des accessoires auprès de tous les détaillants locaux Mr. Heater ou

INFORMATIONS SUR LA COMMANDE DE PIÈCES :

INSTALLÉES PAR UN FOURNISSEUR DE SERVICES D'ENTRETIEN QUALIFIÉ.

RECHANGE NE SONT DISPONIBLES QUE DIRECTEMENT DE L'USINE ET DOIVENT ÊTRE

D'AUTRES PIÈCES RISQUE DE CAUSER DES BLESSURES OU LA MORT. LES PIÈCES DE

N'UTILISEZ QUE LES PIÈCES DE REMPLACEMENT DU FABRICANT. L'UTILISATION

AVERTISSEMENT :

HSU 75

HSU 45

MODÈLE

faire fonctionner cet appareil de chauffage.

instructions d'assembler, d'allumer, de régler ou de

Interdisez à quiconque n'ayant pas lu les présentes

les instructions pour vous y référer ultérieurement.

HEATSTAR

Lisez et observez toutes les instructions. Conservez

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS.

MHU 75

MHU 45

MODÈLE

MR. HEATER

GUIDE D'UTILISATION ET INSTRUCTIONS DE FONCTIONNEMENT

Page 20

17

Guide d’utilisation et instructions de fonctionnementEnerco | Appareils de chauffage compacts

Mr. Heater / HeatStar • Appareil de chauf fage compact • Modèle MHU45/75 HSU45/75

Page 21

16

Enerco | Appareils de chauffage compacts Guide d’utilisation et instructions de fonctionnement

MHU/HSU75 75 000 BTU ...................... 60071

MHU/HSU45 45 000 BTU ...................... 60066

Du propane liquide au gaz naturel

MHU/HSU75 75 000 BTU ...................... 60069

MHU/HSU45 45 000 BTU ...................... 60067

Du gaz naturel au propane liquide

Ensembles de conversion au gaz

ENSEMBLE DE VENTILATION VERTICALE 4 PO (45, 75) .......F102845

ENSEMBLE DE VENTILATION VERTICALE 3 PO (45) .............F102840

ENSEMBLE DE VENTILATION VERTICALE 4 PO (75) .............F102848

THERMOSTAT 24 V ............................................................10 371

Pièces d'installation facultatives

* Non illustré

34* ...................RAMPE À GAZ ..............................................................................60062 ............................... 1 ................................................60064 ............................1

33* ...................DÉMARREUR PAR CONDENSATEUR ..........................................................................................................................................2878 8 ............................1

32 .....................ENSEMBLE VENTILATEUR .............................................................6 012 5 ................................ 1 ................................................ 6 012 7 .............................1

31 ......................GRILLE DE PROTECTION ...............................................................6 0 12 0 ................................ 1 ................................................ 6 012 2 .............................1

30 .....................MOTEUR DE VENTILATEUR .......................................................... 60055 ................................ 1 ................................................ 60054 ............................1

29 .....................ENVELOPPEUR .............................................................................. 6011 5 ................................. 3 ................................................ 6 0 117 ..............................3

28 .....................PORTE LATÉRALE .........................................................................6 0 11 0 ................................. 1 ................................................6 011 2 ..............................1

27 ......................AVANT ...........................................................................................60095 ............................... 1 ................................................ 60097 ............................1

26 .....................PORTE D'ACCÈS ............................................................................60070 ................................ 1 ................................................60072 ............................1

25 .....................ÉCHANGEUR DE CHALEUR..........................................................60065 ............................... 1 ................................................ 60068 ............................1

24......................JOINT DE BOÎTE DE CONDUIT DE CHEMINÉE ............................ 60090 ............................... 1 ................................................60092 ............................1

23 .....................BOÎTE DE CONDUIT DE CHEMINÉE ............................................. 60085 ............................... 1 ................................................ 60087 ............................1

22 .....................RESSORT DE GRILLE D'AÉRATION................................................ 6010 3 ................................ 5 ................................................ S/A ................................7

21 ......................GRILLES D'AÉRATION ...................................................................60100 ................................5 ................................................S/A ................................7

20 .....................SUPPORT FRONTAL ......................................................................60080 ............................... 1 ................................................S/A ................................1

19 ......................SUPPORT ARRIÈRE .......................................................................60075 ................................ 1 ................................................ S/A ................................1

18 ......................JOINT DU MOTEUR À TIRAGE INDUIT ........................................ 60 13 5 ................................. 1 ................................................S/A ................................1

17 ......................RACCORD D'ÉVENT ...................................................................... 6 013 0 ................................ 1 ................................................60140 .............................1

16 ......................MOTEUR DU VENTILATEUR À TIRAGE INDUIT...........................60020 ................................ 1 ................................................ S/A ................................1

15 ......................TUBE DU PRESSOSTAT ................................................................. 60031 ................................ 1 ................................................ S/A ................................1

14 ......................ÉCHANG. DE CHALEUR À DISP. DE COMMANDE À MAX. ...... 60015 ................................ 1 ................................................S/A ................................1

13 ......................PRESSOSTAT ..................................................................................60030 ............................... 1 ................................................S/A ................................1

12 ......................TRANSFORMATEUR ......................................................................60025 ................................ 1 ................................................S/A ................................1

11 ......................SOUPAPE À GAZ (PROPANE) ........................................................0 2 8 11 ................................. 1 ................................................S/A ................................1

10 ......................SOUPAPE À GAZ (GAZ NAT) ........................................................ 0 2 812 ................................. 1 ................................................S/A ................................1

9 .......................ORIFICE (PROPANE) ....................................................................... 60056 ............................... 3 ................................................ S/A ................................5

8 .......................ORIFICE (GAZ NAT) .......................................................................60049 ............................... 3 ................................................S/A ................................5

7 .......................FIL CONDUCTEUR DE LA SONDE ................................................ 60046 ............................... 1 ................................................S/A ................................1

6 .......................FIL CONDUCTEUR D'ALLUMAGE ................................................. 60045 ............................... 1 ................................................ S/A ................................1

5 .......................BRÛLEUR........................................................................................ 60050 ............................... 3 ................................................S/A ................................5

4 .......................SONDE À ÉLECTRODE...................................................................60040 ............................... 1 ................................................S/A ................................1

3 .......................ALLUMEUR PAR ÉLECTRODE ........................................................60035 ................................ 1 ................................................S/A ................................1