Enerco HS1000ID User Manual

DIESEL SPACE HEATER-SERVICE MANUAL

INDEX

1.CONTROLS AND COMPONENTS

2.FLAME CONTROL CYCLES

3.MAINTENANCE SCHEDULE

4.REPAIR PROCEDURES

1.FAN MOTOR ASSEMBLY

2.FUEL FILTER ASSEMBLY

3.FUEL PUMP ASSEMBLY

4.ELECTRIC PANEL ASSEMBLY

5.AIR PRESSURE SWITCH

6.COMBUSTION HEAD ASSEMBLY

7.COMBUSTION CHAMBER

5.TROUBLESHOOTING GUIDE

6.WIRING DIAGRAMS

7.TECHNICAL SHEETS

HS1000ID

L-S 101.00-BM

WARNING

The operations described in this booklet must be carried out by qualified and instructed personnel only.

Incorrect maintenance may result in improper operation and serious injury.

1

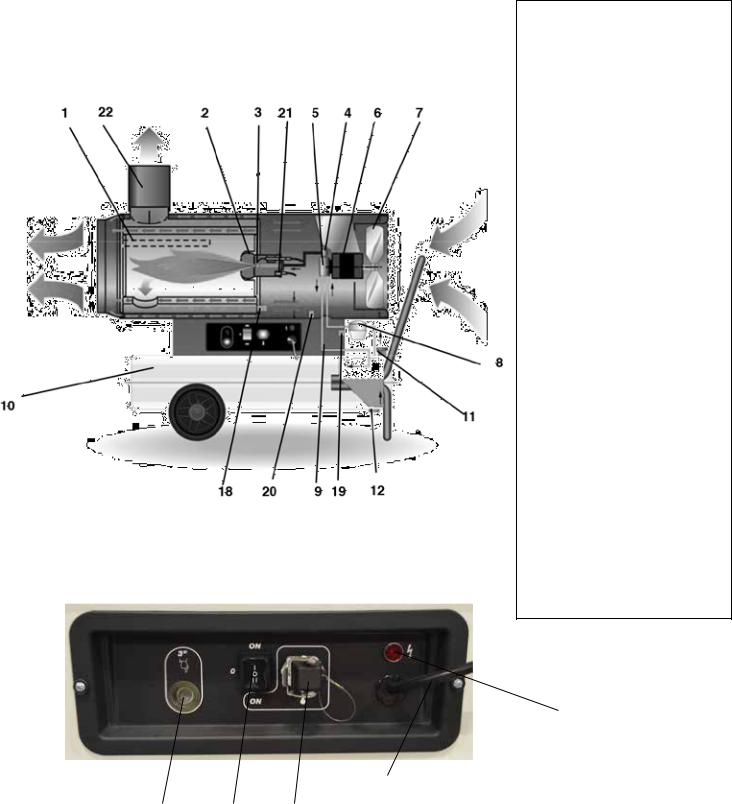

1. CONTROLS AND COMPONENTS

INDIRECT HEATER WITH STACK AND METAL FUEL TANK:HS1000ID

CONTROL PANEL

17

1 COMBUSTION CHAMBER

2 BURNER ASSEMBLY

3NOZZLE

4FUEL VALVE

5DIESEL PUMP

6MOTOR

7FAN

8FUEL FILTER

9FUEL CIRCUIT

10FUEL TANK

11FUEL TANK PLUG

12DRAIN PLUG

13RESET BUTTON/LAMP OF CONTROL FLAME

14MAIN SWITCH

15ROOM THERMOSTAT PLUG

16CONTROL LAMP

17POWER CORD

18OVERHEAT THERMOSTAT

19AIR PRESSURE SWITCH GAUGE

(LOW PRESSURE SIDE)

20AIR PRESSURE SWITCH GAUGE (HIGH PRESSURE SIDE)

21FLAME DETECTOR (PHOTOCELL)

22STACK

16

13 |

14 |

15 |

2 |

|

CONTROL SYSTEM

The heater has all operational controls located in a watertight control panel mounted on a lateral side of the unit (EC 100) or rear side of the unit (EC 100PT).

The control panel consists of:

•a 3-position switch for heating function: normal operation, stop or thermostat operation

•plug to connect a remote room thermostat

•power cord

•control flame box to handle starting / running cycle (see paragraph 2.).

The control flame box is equipped with a reset button and a high voltage transformer that geneates a spark to ignite the flame.

The control system utilizes:

•a safety shut off switch that is an overheat thermostat shutting down the unit if the temperature of combustion chamber and outlet air exceed the maximum allowed level

•an air pressure switch, that stops the unit if the air flow is not sufficient for combustion.

•a flame detector, that is a photocell monitoring constantly the flame presence and its integrity.

•a pair of ignition rods to create the ignition spark

FUEL SYSTEM

The fuel system consists of:

•fuel tank, that can be made of:

•steel, corrosion proof (EC 100) or

•plastic, shock absorption and fuel resistant (EC 100PT)

Both types of fuel tanks have a drain plug located underneath the fuel tank to allow discharge of residual fuel before cleaning.

•fuel filter

•fuel pump. A screw fitted on the fuel pump allows the adjustment of fuel pressure setting

•fuel ON/OFF solenoid valve

•during normal operation the valve is open and the pressurized fuel flows to the nozzle where it is atomized, mixed with primary combustion air and ignited by the electrode spark

•during abnormal operation (see paragraph 2.) the flame control unit closes the fuel solenoid valve and the unit stops.

•fuel circuit, including suction and return hoses from fuel tank to fuel pump and high pressure microhose from fuel pump to nozzle

•burner head

•nozzle

COMBUSTION CHAMBER

It consists of:

•the internal combustion chamber (stainless steel) that containing the flames and

•the external high efficient heat exchaner (aluminated steel), that leads smoke to chimney / stack.

BURNER HEAD

The burner head is the assembly that determines the correct mixing of combustion air and fuel inside the combustion chamber and it consists of:

•Fuel nozzle

•Nozzle support

•Flame diffuser

•Air opening baffle: a screw fitted on the burner head allows the adjustment of combustion air setting

•Ignition electrodes

•Flame detector

FAN - MOTOR ASSEMBLY

The electric motor drives the fuel pump assembly and a fan which blows air inside and around combustion chamber.

3

2. FLAME CONTROL RUNNING / FAILURE CYCLE

2.1 STARTING CYCLE Room thermostat

Burner Fan

Ignition Transformer

Fuel Valve

Photocell

Reset Lamp

TP 20 s |

TS 5 s |

The flame control unit starts the sequence of operation after a heating request (normal operation or thermostat operation) and it consists of the following steps:

•Self-test (less than 3 s): self-check of electronics efficiency;

•Purging time TP (20 seconds): fan motor and ignition transformer are simultaneously switched on while the fuel valve remains closed to eliminate any fuel or unburnt residual.

During the purging stage, the flame signal is constantly monitored for any kind of failure leading to combustion prevents the burner ignition.

In case of heating request off (room thermostat off), the control unit goes to stand-by position. The device remains in this status till closing of the room thermostat;

•Safety time (5 seconds): at the end of the purging time TP, the fuel valve is switched on and opens the fuel to the nozzle.

In case of flame detection failure by the end of the TS safety time, the control unit goes to lockout, and the fan motor, the ignition transformer and the fuel valve are de-energized, while the lockout signal is enabled.

Otherwise, at the end of the TS safety time the control unit disables the ignition transformer and goes to running position.

2.2 SHUT OFF CYCLE |

Room thermostat |

|

Burner Fan |

|

Ignition Transformer |

|

Fuel Valve |

|

Photocell |

|

Reset Lamp |

|

90 s |

When the heating request (normal operation or thermostat off or low) opens:

•fuel valve and ignition transformer are switched off and the flame lights off;

•burner fan operates a 90 s post-purge ventilation

Restoring the heating request causes the post-purge to be interrupted and the starting cycle to be performed.

4

2.3 FLAME FAILURE DURING STARTING CYCLE

Room thermostat

Burner Fan

Ignition Transformer

Fuel Valve

Photocell

Reset Lamp

TP 20 s |

TS 5 s |

If during the safety time TS, the photocell monitors a flame failure (signal to photocell becomes lower than minimum), at the end of safety time the unit goes in lock out condition:

•burner fan, ignition transformer and fuel valve are de-energized;

•alarm lamp on rest button becomes red

Unit can re-start only if pressing the reset button (3 seconds)

2.4 EXTRANEOUS LIGHT OR FLAME DURING PRE-PURGE TIME TP

Room thermostat

Burner Fan

Ignition Transformer

Fuel Valve

Photocell

Reset Lamp

TP 20 s

If during the pre-purge time the photocell monitors any residual flame then the unit goes in stand-by condition:

•burner fan goes on to purging combustion chamber

•fuel valve and ignition transformer are de-energized

•reset lamp is off;

5

2.5 FLAME FAILURE DURING RUNNING STATUS (ONE TRIAL RECYCLING)

Room thermostat |

|

Burner Fan |

|

Ignition Transformer |

|

Fuel Valve |

|

Photocell |

|

Reset Lamp |

|

TP 20 s |

TS 5 s |

|

90 s |

In case of flame failure in running status, the flame control unit make one trial restarting the unit.

If the reason of flame failure is confirmed, then the unit stops in lock-out mode, and the reset lamp becomes red.

2.6 RESET LAMP COLOR

! WARNING

The reset button may have different colours:

•

light off: unit is in stand-by status, waiting for heating request.

light off: unit is in stand-by status, waiting for heating request.

•  steady orange light : the heater stops temporarily to allow H/T/ transformer cooling down and automatically restarts when the time has passed

steady orange light : the heater stops temporarily to allow H/T/ transformer cooling down and automatically restarts when the time has passed

•  steady green light: unit is working normally (starting cycle or working cycle)

steady green light: unit is working normally (starting cycle or working cycle)

•  steady red light: the heater stops permanently in lock-out status and can restart only if reset button is pressed.

steady red light: the heater stops permanently in lock-out status and can restart only if reset button is pressed.

6

3. MAINTENANCE SCHEDULE

Periodic maintenance of the heater is necessary to ensure proper performance and to prevent failures and it shall be performed at the following periodic intervals:

•Daily maintenace

i.Inspect air inlet / air outlet and exhaust stack, remove debris if any

ii.If any air hose is installed, secure it. Minimize bends and keeps ducts straight

iii.Verify fuel tank is full

iv.Verify that exhaust stack is properly installed

•Weekly maintenance

i.Disassemble, inspect and clean fuel filter with clean fuel

ii.Remove top cover and clean the motor, fan blade and the interior shell

iii.Inspect the fuel hose assembly and check for any leaks

•6 months maintenance

i.Disassemble burner head

1.Inspect and clean burner diffuser

2.Inspect and replace nozzle as necessary

3.Clean ignition electrodes and adjust settings

4.Check air combustion setting

ii.Check overheat thermostat

iii.Inspect and clean the combustion chamber

iv.Open electric board, inspect electrical components and check connections

v.Check fuel pressure setting of fuel pump

vi.Inspect and test the burner

7

Loading...

Loading...