Page 1

OPERATING INSTRUCTIONS

Model #

HS170NG

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place instructions in a safe

place for future reference. Do not allow anyone who has not read these instructions to assemble,

light, adjust or operate the heater.

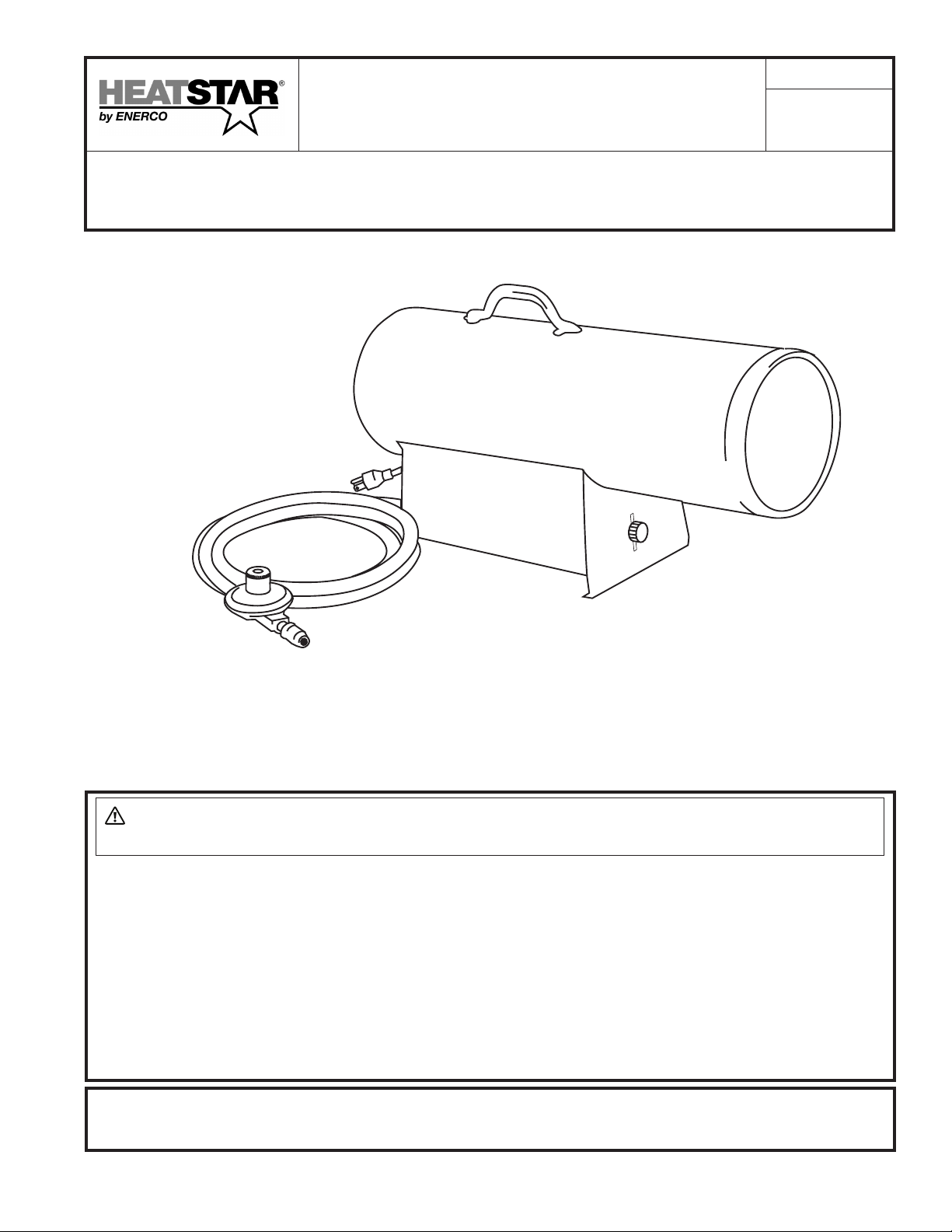

Model # 170FAVT and 170FAV

FORCED-AIR NATURAL GASCONSTRUCTION HEATER

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light appliance.

• Extinguish any open flame.

• Shut off gas to appliance.

— Service must be performed by a qualified service agency.

This is an unvented gas-fired portable heater. It uses air (oxygen) from the area in which it is used.

Adequate combustion and ventilation air must be provided. Refer to page 3.

70101 2015 JMHeatstar by Enerco, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 2

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

WARNING:

NOT FOR HOME OR RECREATIONAL VEHICLE USE

WARNING:

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF FIRE,

EXPLOSION, BURN, ASPHYXIATION, CARBON MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW

THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTIONS MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

THE STATE OF CALIFORNIA REQUIRES THE FOLLOWING WARNINGS:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING

MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE

AWAY FROM THE HEATER AS RECOMMENDED BY THE

INSTRUCTIONS. NEVER USE THE HEATER IN SPACES

WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR UN-

KNOWN CHEMICALS.

WARNING: Combustion by-products produced when using this product contain carbon monoxide, a chemical

known to the State of California to cause cancer and birth defects (or other reproductive harm).

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.

CONTENTS

Specifications .................................................................... 2

Operating Precautions ....................................................... 3

Safety Precations ...............................................................3

Odor Fade Warning ..........................................................4

Operating Instructions ...................................................... 4

Storage & Service ............................................................. 5

Lighting Instructions .........................................................5

Wiring Diagram 170 FAVT ................................................. 6

Parts List 170 FAVT ............................................................ 7

Exploded View Drawing 170 FAVT ..................................... 7

SPECIFICATIONS

MODEL NO. ................................................. HS170NG

GAS TYPE ............................................. NATURAL GAS

BTU RATING. .......................................150,000 BTU/hr

(43.9 kW)

GAS SUPPLY PRESSURE TO REGULATOR

Maximum: 1/2 psig (4.5kPa), Minimum: 9”WC (2.3

kPa)

REGULATOR OUT.............................. 4” WC (0.98 kPa)

ELECTRICAL INPUT ........................115V, 60 Hz, 1Ø, 3a

IGNITION....................... Direct Spark, interrupted type

PRIMARY FLAME CONTROL ... SolidState,10-15 sec. timing

HIGH TEMPERATURE CONTROL

Minimum Ambient Temp. Rating: 0°F (-17.8°C)

.......................240°F (116°C)

FUEL CONSUMPTION ............................. 138 cu-m/hr

FHEATED AIR OUTPUT: ....... 450 CFM (12.74 CU M/M)

2

Force-Air Propane Construction HeaterOperating Instructions and Owner’s Manual

(3.9 cu-m/hr)

Page 3

OPERATING PRECAUTIONS

This is a natural gas, direct-fired, forced air heater. It’s

intended use is primarily temporary heating of buildings

under construction, alteration or repair.

If natural gas leaks from a connection or fitting, it can mix

with the surrounding air, forming a potentially explosive

mixture. Obviously, natural gas leaks should be avoided,

so set up the natural gas supply with utmost care. Read

“Odor Fade” section for additional information about

detectingnatural gas leaks. Leak check new connections or

reconnections with a soap and water solution and follow all

connection instructions herein. Also ask your natural gas

dealer for advice on the natural gas application and supply

installation and ask him to check it if there are any questions

This heater was designed and certified for use as a

construction heater in accordance with ANSI Standard Z83.7/

CGA 2.14. Check with your local fire safety authority if you

have any questions about your applications. Other standards

govern the use of fuel gases and heat producing products

in specific applications. Your local authority can advise you

about these.

Direct-Fired means that all of the combustion products enter

the heated space. Even though this heater operates very close

to 100 percent combustion efficiency, it still produces small

amounts of carbon monoxide. Carbon monoxide (called CO)

is toxic. We can tolerate small amounts but not a lot. CO can

build up in a heated space and failure to provide adequate

ventilation could result in death.

The symptoms of inadequate ventilation are:

• headache

• dizziness

• burning eyes and nose

• nausea

• dry mouth or sore throat

So, be sure to follow advice about ventilation in these

operating instructions.

Forced Air means that a blower or fan pushes the air through

the heater. Proper combustion depends upon this air flow;

therefore, the heater must not be revised, modified or

operated with parts removed or missing. Likewise, safety

systems must not be circumvented or modified in order to

operate the heater.

SAFETY PRECAUTIONS

1. Check the heater thoroughly for damage. DO NOT operate a

damaged heater.

2. DO NOT modify the heater or operate a heater which has been

modified from its original condition.

3. Use only natural gas.

4. Protect all natural gas connections from traffic or damage.

5. IMPORTANT Use only the regulator assembly provided with

the heater. Match the color stripe on the hangtag attached

to the hose assembly with the color on the label located near

the natural gas inlet fitting on the heater. Inspect the flexible

natural gas connections before each use of the heater. If there

is excessive abrasion or wear, or connection is damaged in any

way, replace with a connection meets all local, state, etc. codes

and requirements

6. For indoor use only. Area must be well ventilated. Figure 1.

(also see “Operating Precautions”).

7. If at any time gas odor is detected, IMMEDIATELY

DISCONTINUE operation until the source of gas has been

located and corrected. Read enclosed Odor fade and Propane

Sheet for additional information about detecting propane leaks.

8. Install the heater such that it is not directly exposed to water

spray, rain and/or dripping water.

9. Maintain minimum clearance from normal combustible material

(like paper). Figure 2.

10. Due to the high surface and exhaust temperatures, adults and

children must observe clearances to avoid burns or clothing

ignition.

11. Operate only on a stable, level surface.

12. Do not use with duct work. Do not restrict inlet or exit.

13. Use only the electrical power specified. The electrical

connection and grounding must comply with National Electrical

Code - ANSI/NFPA 70 (USA) and CSA C22.1 Canadian Electrical

Code, Part 1 (Canada).

14. Use only a properly grounded 3-prong receptacle or extension

cord.

15. Do not move, handle or service while hot or burning.

16. Do not adjust the heater combustion tube elevation while

heater is running or hot. Adjustments to elevation should only

be made after the heater has cooled to touch.

17. Use only in accordance with local codes or, in the absence of

local codes, with the Standard for the Storage and Handling

of Liquefied Petroleum Gases ANSI/NFPA 58 and CSA B149.1,

Natural Gas and Propane Installation Code.

When the heater is to be operated in the presence

of other people the user is responsible for properly

acquainting those present with the safety precautions

and instructions, and of the hazards involved.

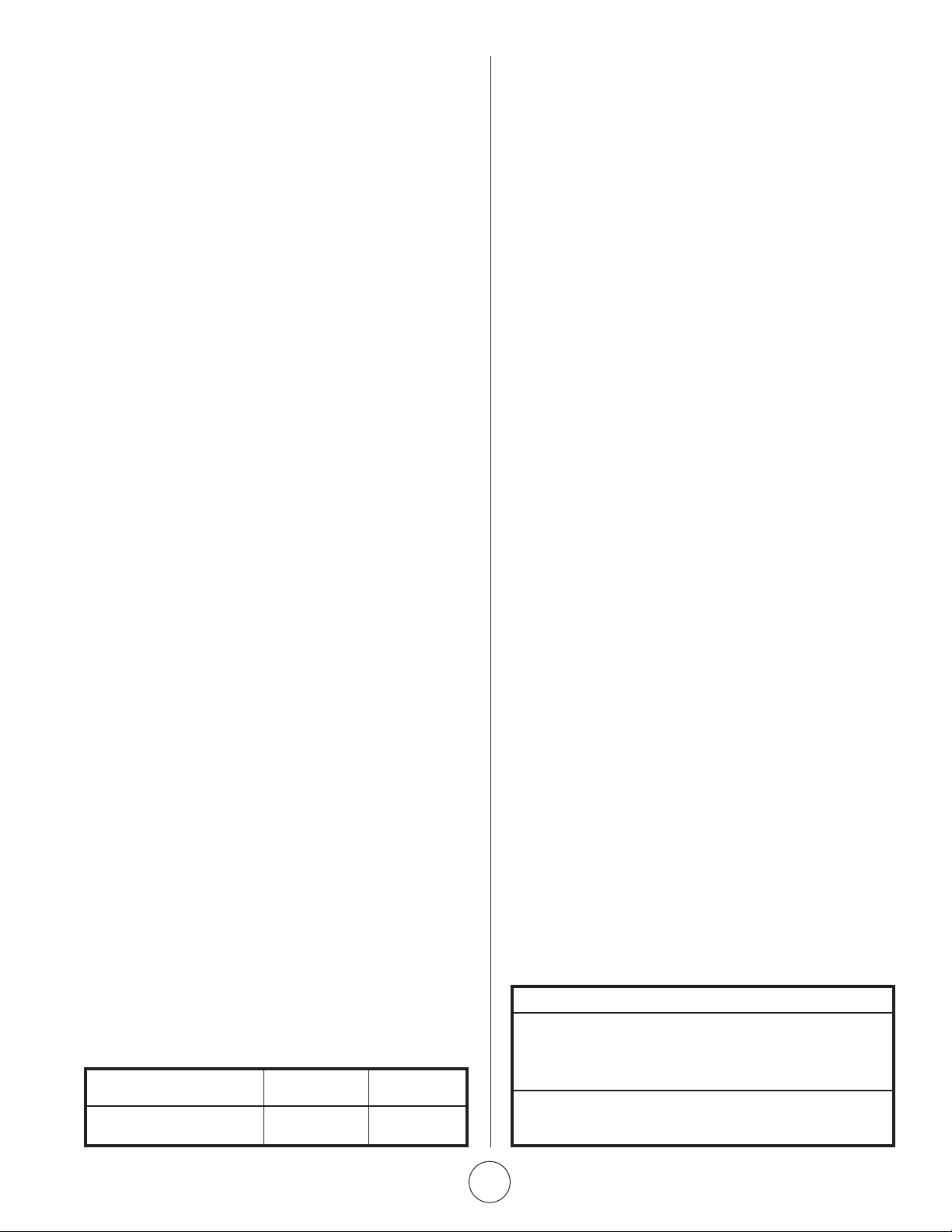

Figure 1

VENTILATION: Minimum openings required

Opening Opening

Heater near floor near ceiling

Forced air (HS170NG) 3 ft2 3 ft

Force-Air Propane Construction Heater Operating Instructions and Owner’s Manual

2

Figure 2: MINIMUM CLEARANCE: From normal combustible materials

Clearance Forced Air HS170NG

From floor .......................................................0 ft

From outlet .....................................................6 ft

From sides ......................................................2 ft

From top .........................................................3 ft

Locate 10 ft. from canvas or plastic tarpaulins or similar

coverings and secure them to prevent flapping or movement

due to wind action.

3

Page 4

ODOR FADE WARNING

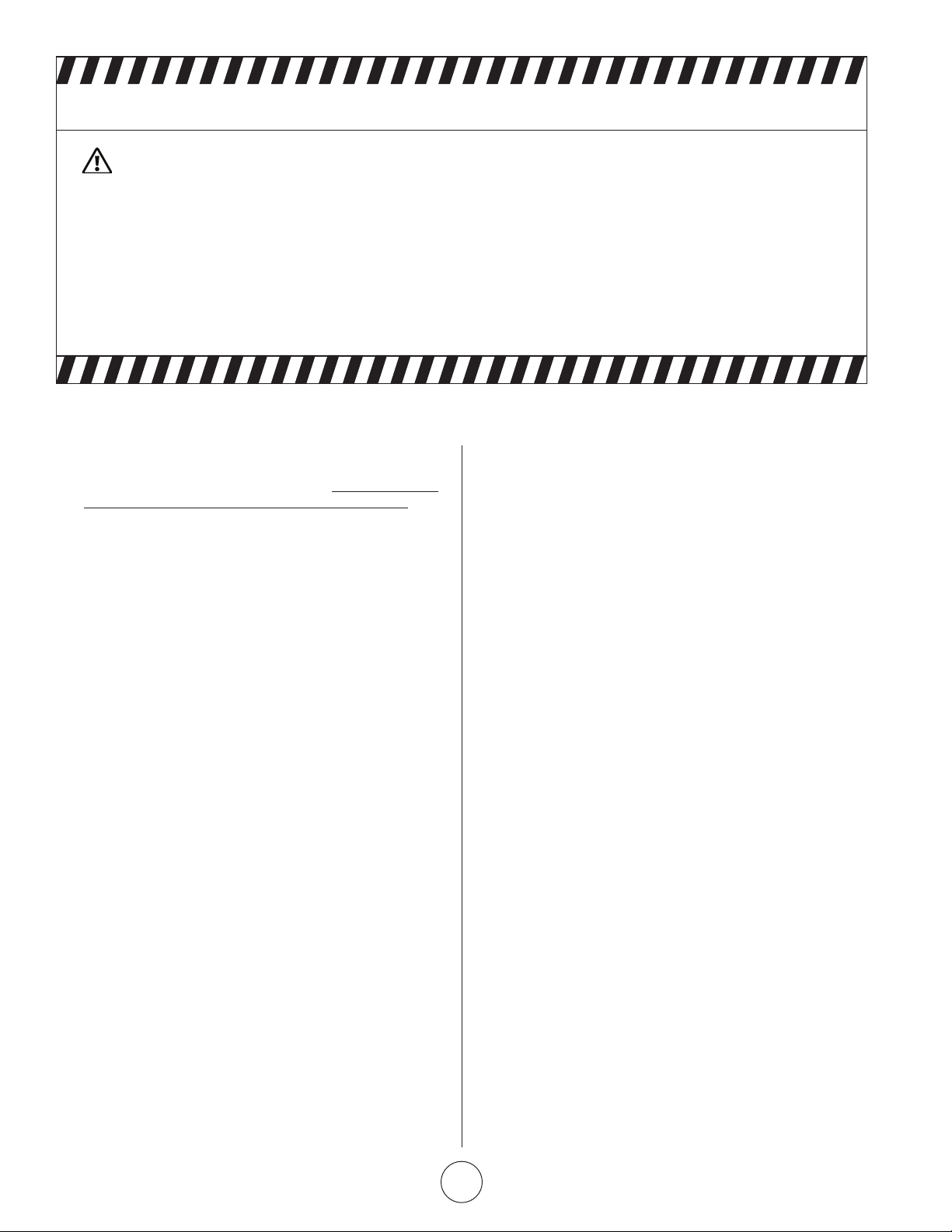

WARNING

Asphyxiation Hazard

• Do not use this heater for heating human living quarters.

• Do not use in unventilated areas.

• The flow of combustion and ventilation air must not be obstructed.

• Proper ventilation air must be provided to support the combustion air requirements of the heater being used.

• Refer to the specification section of the heater’s manual, heater dataplate, or contact the Factory to determine combustion air

ventilation requirements of the heater.

• Lack of proper ventilation air will lead to improper combustion.

• Improper combustion can lead to carbon monoxide poisoning leading to serious injury or death. Symptom of carbon monoxide

poisoning can include headaches dizziness and difficulty in breathing.

FUEL GAS ODOR

LP gas and natural gas have man-made odorants added

specifically for detection of fuel gas leaks.

If a gas leak occurs you should be able to smell the fuel

gas. Since Propane (LP) is heavier than air you should

smell for the gas odor low to the floor. ANY GAS ODOR

IS YOUR SIGNAL TO GO INTO IMMEDIATE ACTION!

• Do not take any action that could ignite the fuel gas. Do

not operate any electrical switches. Do not pull any power

supply or extension cords. Do not light matches or any other

source of flame. Do not use your telephone.

• Get everyone out of the building and away from the area

immediately.

• Close all fuel supply valves, or the main fuel supply valve

located at the meter if you use natural gas.

• Use your neighbor’s phone and call your fuel gas supplier and

your fire department. Do not re-enter the building or area.

• Stay out of the building and away from the area until declared

safe by the firefighters and your fuel gas supplier.

• FINALLY, let the fuel gas service person and the firefighters

check for escaped gas. Have them air out the building and

area before you return. Properly trained service people must

repair any leaks, check for further leakages, and then relight

the appliance for you.

ODOR FADING - NO ODOR DETECTED

• Some people cannot smell well. Some people cannot smell

the odor of the man-made chemical added to propane (LP) or

natural gas. You must determine if you can smell the odorant

in these fuel gases.

• Learn to recognize the odor of propane (LP) gas and natural

gas. Local propane (LP) gas dealers will be more than happy

to give you a scratch and sniff pamphlet. Use it to become

familiar with the fuel gas odor.

• Smoking can decrease your ability to smell. Being around

an odor for a period of time can affect your sensitivity to

that particular odor. Odors present in animal confinement

buildings can mask fuel gas odor.

• The odorant in propane (LP) gas and natural gas is

colorless and the intensity of its odor can fade under

some circumstances.

• If there is an underground leak, the movement of gas

through the soil can filter the odorant.

• Propane (LP) gas odor may differ in intensity at different

levels. Since Propane (LP) gas is heavier than air, there may

be more odor at lower levels.

• Always be sensitive to the slightest gas odor. If you

continue to detect any gas odor, no matter how small, treat

it as a serious leak. Immediately go into action as discussed

previously.

ATTENTION - CRITICAL POINTS TO

REMEMBER!

• Propane (LP) and natural gas have a distinctive odor.

Learn to recognize these odors. (Reference Fuel Gas

Odor and Odor Fading sections above.

• Even If you are not properly trained in the service and repair

of the heater, ALWAYS be consciously aware of the odors of

propane (LP) gas and natural gas.

• If you have not been properly trained in repair and service

of propane (LP) or natural gas then do not attempt to light

heater, perform service or repairs, or make any adjustments

to the heater on the propane (LP) or natural gas fuel system.

• A periodic sniff test around the heater or at the heater’s

joints; i.e. hose, connections, etc., is a good safety practice

under any conditions. If you smell even a small amount of

gas, CONTACT YOUR FUEL GAS SUPPLIER IMMEDIATELY. DO

NOT WAIT!

Heater Elevation Adjustment

This heater is equiped with an elevation adjustment panel

located at the exhaust end of the control box.

1. Do not adjust the heater combustion tube elevation while

heater is running or hot. Adjustments to elevation should

only be made after the heater has cooled to touch.

2. To adjust the heater combustion tube elevation, turn the

adjustment screw knob counterclockwise and lift the

combustion tube to desired position.

4

Force-Air Propane Construction HeaterOperating Instructions and Owner’s Manual

Page 5

OPERATING INSTRUCTIONS

PREPARING FOR OPERATION

1. Check the heater for possible shipping damage. If any is

found, immediately notify the factory.

2. Follow all of the “Precautions”.

3. Assemble the regulator to the heater fuel inlet with the gas

flow arrow pointed toward the heater. You should use a pipe

sealant onto the male pipr thread, since this will insure that

no sealant gets into the fuel system. Then screw the male

thread into the inlet and tighten by rotating clockwise.

4. Connect the hose to the heater by rotating the hose fitting

clockwise.

5. Securely tighten all gas connections.

6. Open the natural gas valve and check all gas connections

with a soap and water solution. DO NOT USE A FLAME.

7. Connect power cord to well-grounded 115V, 60 Hz, 1Ø source

of power.

8. When using an extension cord, make certain that it is a

3-wire (grounded) cord of proper wire size.

START

1. Slowly open the main valve at propane cylinder to prevent

excess flow check valve from closing.

2. Set thermostat to full on. Heater will ignite automatically.

3. Adjust ball valve on control panel to desired burn rate.

4. Set thermostat to desired temperature. Heater will turn off

and on automatically as the temperature varies in the heater

area.

STOP

1. Securely close valve on the propane cylinder.

2. Continue to operate heater until all fuel in the hose has

burned.

3. Turn the heater thermostat to “off”. For extended shut down

or in areas where the temperature is below 0°F, unplug the

heater.

SERVICING

A hazardous condition may result if a heater is used that has

been modified or is not functioning properly.

When the heater is working properly:

• The flame is contained within the heater.

• The flame is essentially blue with perhaps some

yellow tipping.

• There is no strong disagreeable odor, eye burning or

other physical discomfort.

• There is no smoke or soot internal or external to the

heater.

• There are no unplanned or unexplained shut downs

of the heater.

The parts lists and wiring diagram show the heater as it was

constructed. Do not use a heater which is different from

that shown. In this regard, use only the regulator supplied

with the heater. IMPORTANT Match the color stripe on the

hangtag attached to the hose assembly with the color on the

label located near the propane inlet fitting on the heater. Do

not use alternates. For this heater, the regulator must be set

as shown in “specifications”. If there is any uncertainty about

the regulator setting, have it checked.

A heater which is not working right must be repaired, but

only by a trained, experienced service person.

In-warranty products will be repaired with no charge for

either parts or labor. Please include a brief statement

indicating date, place of purchase, the nature of the problem

and proof of purchase.

Out-of-warrranty products will be repaired with a charge for

parts and labor.

RESTART AFTER SAFETY SHUTDOWN

1. Securely close valve at propane cylinder. Unplug heater.

2. Wait 5 minutes.

3. Restart following “Start” procedure.

MAINTENANCE AND STORAGE

1. The heater should be inspected before each use, and at least

annually by a qualified person.

2. Turn off the natural gas supply valve when the heater is not

in use.

Force-Air Propane Construction Heater Operating Instructions and Owner’s Manual

5

Page 6

HOW MUCH HEAT DO I REQUIRE?

For economy, it is important to match input to that required. But

heat requirements often vary. For example, it usually takes a lot

more heat to get things warm than it does to keep them that way.

Likewise, outside air temperature usually changes during the day

so you may need more heat at night than you do in the daytime.

An approximation of the heat required can be found by using the

chart below.

BTU’S PER HOUR REQUIRED

Cubic feet Temperature Rise Required (oF)*

of space to

be heated 20

5,000 14,000 20,000 27,999 34,000

o

30

o

40

o

50

o

CHASSIS

GROUND

CHASSIS

GROUND

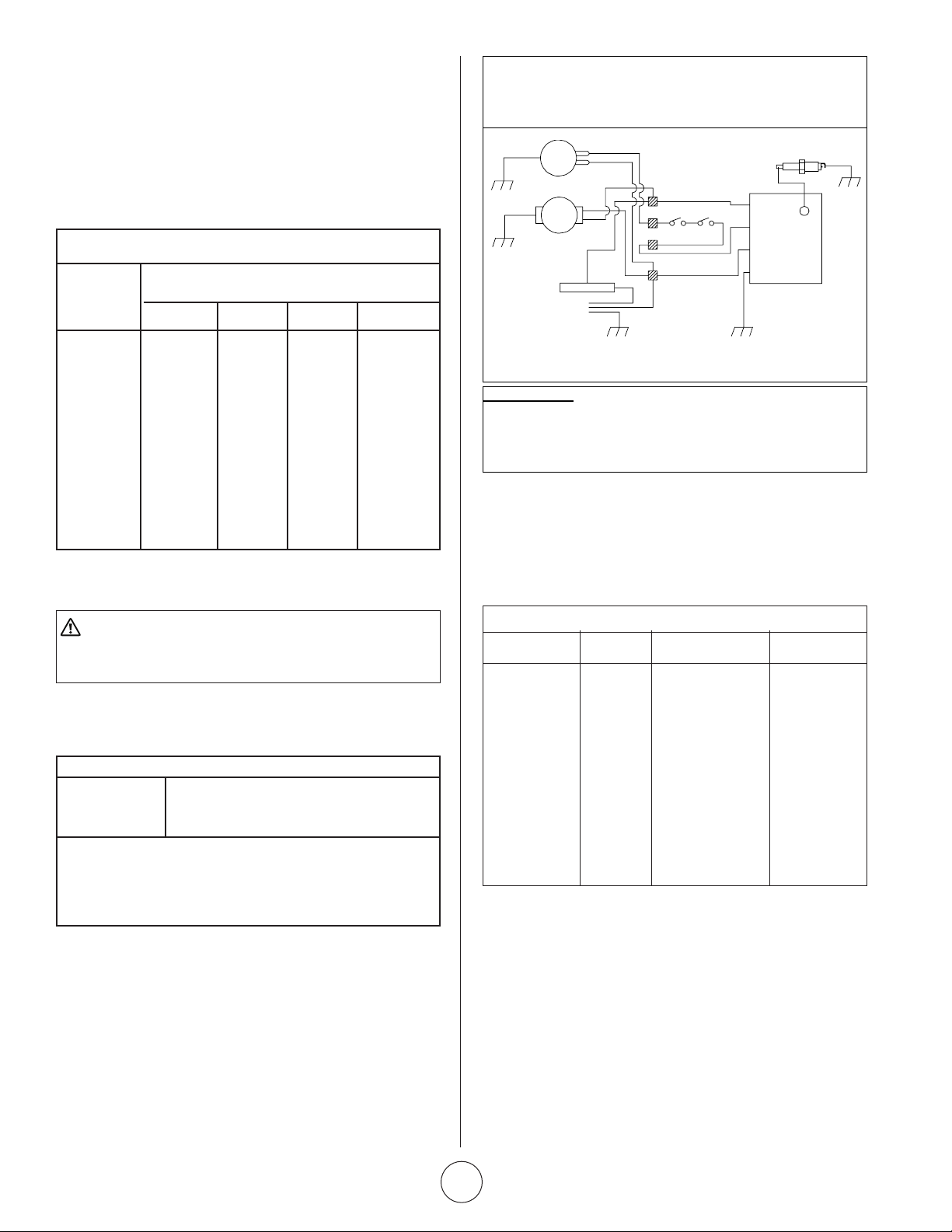

MODEL HS170NG

WIRING DIAGRAM

B

B

R

THERMOSTAT

B

G

B

W

CHASSIS

GROUND

W

HIGH-LIMIT

Y

GAS

G

VALVE

G

MOTOR

LINE CORD

B

SWITCH X2

Y

R

W

CHASSIS

GROUND

LINE

VALVE

NEUT

GRD

FLAME CONTROL

G

SPARK PLUG

G

CHASSIS

GROUND

7,000 19,000 28,000 38,000 47,000

10,000 27,000 40,000 54,000 67,000

15,000 40,000 60,000 80,000

100,000

20,000 54,000 80,000 107,000 133,000

30.000 80,000 120,000 160,000 200,000

50,000 133,000 200,000 266,000 333,000

WARNING: When using a thermostat controlled heater,

its exit area should be protected from personnel and

warnings posted of sudden startup.

Recommended Minimum Gauge

for Cord Extensions

Wire Gauge Chart A.W.G.

Name

Plate 120V Cord Length in Feet

Amps. 25 50 100 150

5-6 18 16 14 12

6-8 18 16 12 10

8-12 18 14 12 10

10-12 16 14 10 8

12-14 16 12 10 8

COLOR CODE

B - BLACKR - RED

L - BLUE W - WHITE

G - GREEN

O - ORANGE

If any original wiring as supplied by the heater must be replaced,

it must be replaced with type AWG 105° C wire or its equivalent

except as indicated (*type SF2-200, **SGI 250° C).

170FAVT - WIRING CHART

COLOR LENGTH FROM TO

White 7” Valve Terminal Block

Black 6” On/Off Switch Terminal Block

Red-(Hi-Temp) 16 1/2” High Limit Switch Valve

Red-(Hi-Temp) 16 1/2” High Limit Switch Terminal Block

Orange 11” Flame Control Spark Plug

(Ignition)

Green 7” Flame Control Ground

(Harness)

Red 7” Flame Control Terminal Block

(Harness)

White 6” Flame Control Terminal Block

(Harness)

Black 6” Flame Control Terminal Block

(Harness)

6

Force-Air Propane Construction HeaterOperating Instructions and Owner’s Manual

Page 7

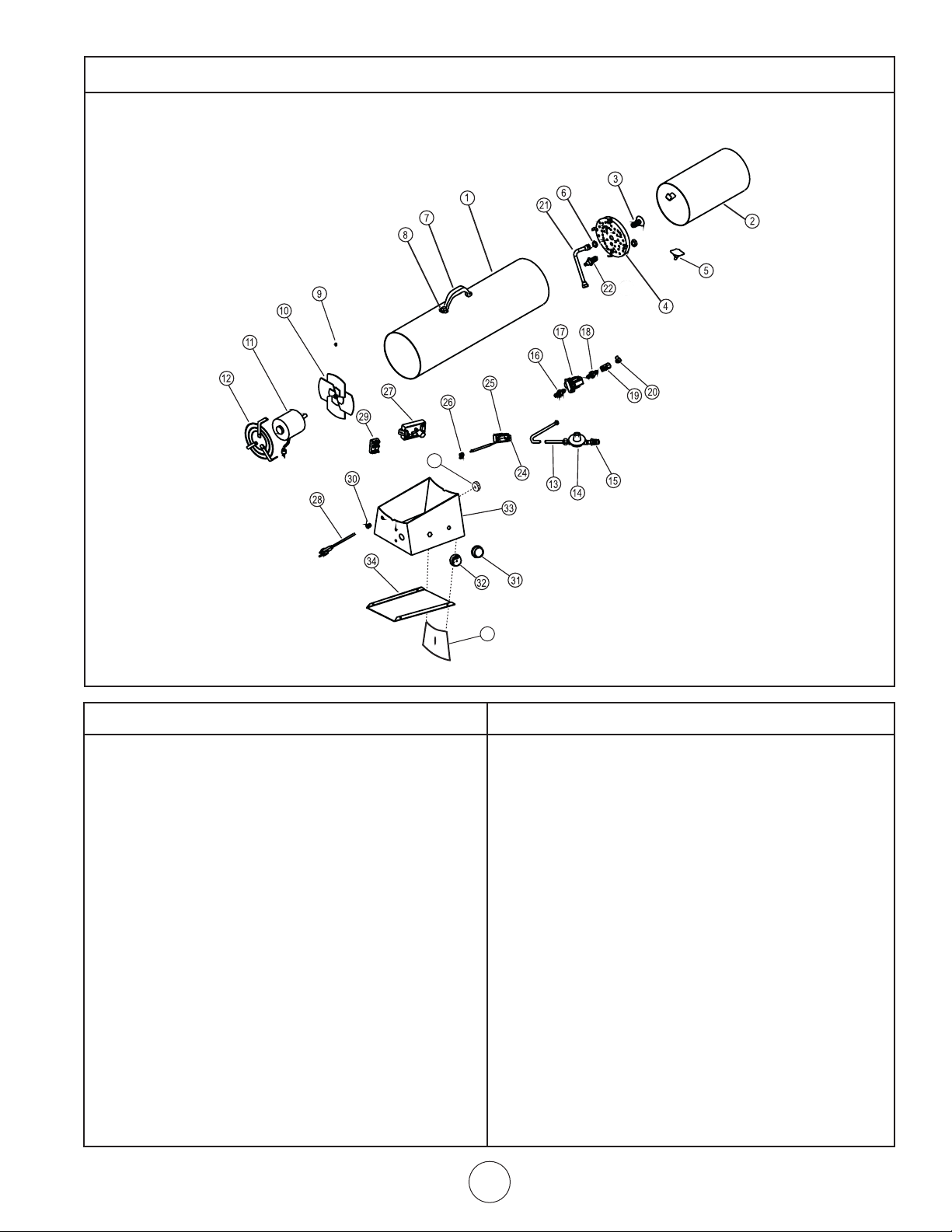

Model #170FAVT (WITH THERMOSTAT) PARTS LIST

36

35

Item Part No. Description Qty.

1 21735 Outer Shell - Model MH, HS 1

2 22249 Middle Cylinder 1

3 22287 Orifice Assembly 1

4 21146 Flame Holder Assembly 1

5 26168 High Limit Switch 1

6 23038 Orifice Nut 1

7 27095 Handle 1

8 27094 Handle Mounting Clips 2

9 26010 Set Screw, Nyloc 1

10 26074 Fan 1

11 22251 Motor Assembly 1

12 22252 Grille, Inlet/Motor Mounting 1

14 26257 Regulator, 4” WC 1

16 22263 Male Fitting Conn. 1

3/8MPT x 3/8SAE FLR

17 22264 Solenoid Valve, Goyen 1

18 22265 Fitting Close Nipple 1

21 22266 Fuel Tube Assembly 1

22 22287 Electrode, Spark 1

24 24340 Thermostat Mounting Bracket 1

25 22254 Thermostat Assembly 1

26 26070 Loop Clamp, 5/16 1

Item Part No. Description Qty.

27 27808 Flame Control, Potted 1

28 21036 Power Cord Assembly 1

29 28771 Terminal Board 1

30 26223 Bushing Strain Relief 1

31 28772 Knob, Thermostat 1

32 28773 Knob, Burn Rate Adjustment 1

33 22255 Control Box 1

34 22273 Base, Control Box 1

35 22274 Elevation Plate 1

36 22275 Elevation knob 1

Force-Air Propane Construction Heater Operating Instructions and Owner’s Manual

7

Page 8

OPERATING INSTRUCTIONS

Model #

HS170NG

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place instructions in a safe

place for future reference. Do not allow anyone who has not read these instructions to assemble,

light, adjust or operate the heater.

WARNING:

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE ONLY AVAILABLE DIRECT

FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE AGENCY.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any HeatStar local dealer or direct

from the factory.

FOR INFORMATION REGARDING SERVICE

Please call Toll-Free 866-447-2194 • www.HeatStar.com

Our office hours are 8:00 AM – 5:00 PM, EST, Monday through Friday.

Email to: techservice@enerco-HeatStar.com

Please include the model number, date of purchase, and description of problem in all

communication.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or workmanship,

under normal and proper use in accordance with instructions of The Company, for a period of

one year from the date of delivery to the buyer. The Company, at its option, will repair or replace

products returned by the buyer to the factory, transportation prepaid within said one year period

and found by the Company to have imperfections in material or workmanship.

If a part is damaged or missing, call our Technical Support Department at 866-447-2194.

Address any Warranty Claims to the Service Department, HeatStar, Inc., 4560 W. 160th St.,

Cleveland, Ohio 44135. Include your name, address and telephone number and include details

concerning the claim. Also, supply us with the purchase date and the name and address of the

dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no other

warranties, express or implied. Specifically there is no warranty of fitness for a particular purpose

and there is no warranty of merchantability. In no event shall the Company be liable for delay

caused by imperfections, for consequential damages, or for any charges of the expense of

any nature incurred without its written consent. The cost of repair or replacement shall be the

exclusive remedy for any breach of warranty. There is no warranty against infringement of the

like and no implied warranty arising from course of dealing or usage of trade. This warranty will

not apply to any product which has been repaired or altered outside of the factory in any respect

which in our judgment affects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This Warranty gives you specific legal

rights, and you may have other rights which vary from state to state.

HeatStar, Inc., reserves the right to make changes at any time, without notice or

obligation, in colors, specifications, accessories, materials and models.

ANSI Z83.7b/CGA 2.14b-2009

PRODUCT REGISTRATION: Thank you for your purchase.

Please log in to http://www.egiregistration.com to register your product.

HeatStar, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

HeatStar is a registered trademarks of Enerco Group, Inc.

© 2015, Enerco Group, Inc. All rights reserved

Page 9

GUIDE D’UTILISATION ET

Modèle nº

MANUEL DU PROPRIÉTAIRE

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS : Lisez et observez toutes les instructions. Conservez ces

instructions dans un endroit sécuritaire pour vous y référer ultérieurement. Ne permettez pas à quiconque

n’ayant pas lu les présentes instructions d’assembler, d’allumer, de régler ou de faire fonctionner l’appareil.

HS170NG

Modèle n° 170FAVT et 170FAV

APPAREIL DE CHAUFFAGE AU GAZ NATUREL À AIRPULSÉ POUR CHANTIER DE CONSTRUCTION

AVERTISSEMENT : Le non-respect des instructions, telles qu’indiquées dans le présent

guide, risque de causer une explosion ou un incendie entraînant des dommages matériels

ou des blessures graves, voire mortelles.

— N’entreposez ni n’utilisez d’essence ou autres liquides ou vapeurs inflammables à proximité de

ce type d’appareil.

— EN PRÉSENCE D’UNE ODEUR DE GAZ

• Ne tentez pas d’allumer l’appareil de chauffage.

• Éteignez toute flamme nue.

• Fermez l’alimentation en gaz à l’appareil.

— L’entretien doit être effectué par un fournisseur de services d’entretien qualifié.

Cet appareil de chauffage portatif alimenté au gaz n’est pas ventilé. Il utilise l’oxygène de l’air ambiant.

Une circulation d’air adéquate doit être assurée pour la combustion et la ventilation. Voir page 3.

70101 2015 JMHeatstar by Enerco, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 800-251-0001

Page 10

AVERTISSEMENT :

VOTRE SÉCURITÉ EST IMPORTANTE POUR VOUS ET POUR LES

AUTRES, PAR CONSÉQUENT VEUILLEZ LIRE CES DIRECTIVES

AVANT DE FAIRE FONCTIONNER CET APPAREIL DE CHAUFFAGE.

AVERTISSEMENT :

NON CONÇU POUR UNE UTILISATION À L’INTÉRIEUR DE LA

MAISON OU DANS UN VÉHICULE RÉCRÉATIF.

AVERTISSEMENT :

AVERTISSEMENT GÉNÉRAL

DE DANGER :

LE NON-RESPECT DES MESURES DE PRÉVENTION ET DES

INSTRUCTIONS FOURNIES AVEC CET APPAREIL DE CHAUFFAGE

RISQUE DE CAUSER LA MORT, DES BLESSURES GRAVES ET

DES DOMMAGES OU DES PERTES MATÉRIELLES RÉSULTANT

D’INCENDIE, D’EXPLOSION, DE BRÛLURE, D’ASPHYXIE,

D’INTOXICATION AU MONOXYDE DE CARBONE ET/OU

D’ÉLECTROCUTION. SEULES LES PERSONNES APTES

À COMPRENDRE ET À RESPECTER LES INSTRUCTIONS

DEVRAIENT UTILISER OU EFFECTUER LE SERVICE DE CET

APPAREIL DE CHAUFFAGE.

SI VOUS AVEZ BESOIN D’AIDE OU D’INFORMATION

CONCERNANT L’APPAREIL DE CHAUFFAGE TELS QUE

MANUEL D’INSTRUCTIONS, ÉTIQUETTES, ETC., VEUILLEZ

COMMUNIQUER AVEC LE FABRICANT.

L’ÉTAT DE CALIFORNIE EXIGE QUE L’AVERTISSEMENT SUIVANT SOIT FOURNI :

DANGER D’INCENDIE, D’INHALATION ET D’EXPLOSION.

GARDEZ LES COMBUSTIBLES SOLIDES TELS QUE LES

MATÉRIAUX DE CONSTRUCTION LE PAPIER ET LE CARTON À

UNE DISTANCE SÉCURITAIRE DE L’APPAREIL DE CHAUFFAGE

TEL QUE RECOMMANDÉ DANS LES INSTRUCTIONS.

N’UTILISEZ JAMAIS L’APPAREIL DE CHAUFFAGE DANS UN

ENDROIT QUI CONTIENT OU RISQUE DE CONTENIR DES

COMBUSTIBLES VOLATILES OU EN SUSPENSION DANS L’AIR,

OU DES PRODUITS TELS QUE DE L’ESSENCE, DES SOLVANTS,

DU DILUANT À PEINTURE, DES PARTICULES DE POUSSIÈRE

OU DES PRODUITS CHIMIQUES INCONNUS.

AVERTISSEMENT : Les sous-produits de combustion émis lors de l’utilisation de cet appareil contiennent du monoxyde de

carbone, un produit chimique reconnu par l’état de Californie comme pouvant causer le cancer et des malformations congénitales (ou autres

dommages au système reproducteur).

AVERTISSEMENT : Cet appareil contient des produits chimiques reconnus par l’état de Californie comme pouvant causer

le cancer et des malformations congénitales ou autres dommages au système reproducteur.

TABLE DES MATIÈRES

Spécifications .............................................................................. 2

Précautions liées au fonctionnement

Précautions liées à la sécurité

Avertissement relatif aux substances odorantes

Instructions de fonctionnement

Entreposage et entretien

Instructions d’allumage

Schéma de câblage (Modèle n° HS170NG)

Liste des pièces (Modèle n° HS170NG)

Plan détaillé (Modèle n° HS170NG)

............................................................ 5

.............................................................. 5

.......................................... 3

..................................................... 3

.......................... 4

................................................. 5

.................................. 6

........................................ 7

............................................. 7

SPÉCIFICATIONS

MODÈLE N°.................................................................HS170NG

TYPE DE GAZ...........................................................Gaz Naturel-

COTE BTUDe...............................................

..................43.9 kW

0,000 BTU/hr)

(15

2

Force-Air Propane Construction HeaterOperating Instructions and Owner’s Manual

Page 11

PRÉCAUTIONS LIÉES AU FONCTIONNEMENT

Cet appareil de chauffage à air pulsé et à feu direct fonctionne

au gaz propane. Il est destiné principalement à chauffer

temporairement des édifices en construction, en rénovation ou en

réparation.

Le gaz propane est plus lourd que l’air. Si du gaz propane fuit

d’une connexion ou d’un raccord, il se dirige vers le plancher, se

mélange avec l’air ambiant et forme un mélange potentiellement

explosif. Évidemment, les fuites de gaz propane devraient être

évitées ; il est donc important de raccorder l’alimentation en

propane avec le plus grand soin. Veuillez lire le feuillet « Substance

odorante et gaz propane » ci-joint pour obtenir plus de précisions

relatives à la détection des fuites de gaz propane. Vérifiez la

présence de fuite aux nouvelles connexions et raccords en

utilisant un mélange d’eau et de savon et suivez les instructions

mentionnées. Obtenez également les conseils de votre détaillant

quant à votre installation au propane et posez-lui toute question

que vous auriez à cet égard.

Cet appareil a été conçu et homologué pour être utilisé

comme appareil de chauffage pour chantier de construction,

conformément à la norme ANSI Z83.7/CGA 2.14. Soumettez

à l’organisme local responsable de la sécurité et des incendies

toute question relative à votre type d’installation. Selon le type

d’application, d’autres normes peuvent s’appliquer et régir

l’utilisation des produits de combustion, de gaz combustible et des

appareils de chauffage. L’organisme local qui en est responsable

saura vous conseiller à cet égard.

Le fonctionnement à feu direct de cet appareil signifie que tous

les produits de combustion se retrouvent dans l’air ambiant.

Même si l’efficacité de combustion de l’appareil de chauffage est

presque complète, il produit quand même de petites quantités

de monoxyde de carbone. Le monoxyde de carbone (appelé CO)

est toxique. Notre organisme ne peut en supporter que de faibles

quantités. Il est possible que le CO s’accumule dans le local à

chauffer. Une ventilation inadéquate pourrait ainsi causer la mort.

Les symptômes ressentis en cas de ventilation inadéquate sont les

suivants :

• mal de tête

• étourdissement

• sensation de brûlure au nez et aux yeux

• nausée

• mal de gorge ou bouche sèche

Assurez-vous donc de respecter les conseils au sujet de la

ventilation mentionnés dans ces instructions.

Un appareil à air pulsé signifie que l’air est soufflé dans l’appareil

de chauffage par un ventilateur. La qualité de la combustion

dépend du débit d’air. Par conséquent, l’appareil de chauffage ne

doit pas être modifié ni fonctionner si des pièces sont manquantes.

Dans le même ordre d’idée, les systèmes de sécurité ne doivent pas

être contournés ni modifiés pour faire fonctionner l’appareil.

Lorsque l’appareil de chauffage doit fonctionner en présence

d’autres personnes, l’utilisateur est responsable d’informer

ces dernières des instructions et précautions liées à la

sécurité et de les avertir des dangers inhérents.

Figure 1

VENTILATION : Ouvertures minimales requises

Ouverture Ouverture

Appareil de chauffage près du plancher près du plafond

Air pulsé (170 FAV T ) 3 pi2 (3 ft2) 3 pi2 (3 ft2)

PRÉCAUTIONS LIÉES À LA SÉCURITÉ

1. Vérifiez attentivement si l’appareil de chauffage a subi des

dommages. NE FAITES PAS fonctionner un appareil endommagé.

2. NE MODIFIEZ PAS l’appareil de chauffage et ne le faites pas

fonctionner s’il n’est plus dans son état original.

3. Utilisez uniquement du gaz propane.

4. Utilisez uniquement une alimentation au propane à ÉLIMINATION DES

ÉMANATIONS. Si vous avez des questions à propos de l’élimination

des émanations, consultez votre détaillant de gaz propane.

5. Installez les bonbonnes de propane verticalement (robinet de

fermeture vers le haut). Fixez-les comme il convient de sorte qu’ils

ne puissent se décrocher accidentellement et protégez-les contre

les dommages.

6. Placez les réservoirs de gaz propane à une distance minimale

(aux États-Unis) de 2,13 m (7 pi) ou (au Canada) de 3 m (10 pi)

de l’appareil de chauffage et n’orientez pas l’échappement

directement vers les réservoirs.

7. IMPORTANT : Utilisez uniquement le tuyau et le régulateur fourni

avec l’appareil. Faites correspondre la bande de couleur de l’étiquette

fixée au tuyau à la couleur de l’étiquette située près du raccord

d’entrée de gaz propane sur l’appareil. Inspectez le tuyau avant

chaque utilisation de l’appareil de chauffage. En cas d’abrasion,

d’usure excessive ou de coupure, remplacez le tuyau par l’ensemble

de tuyaux recommandé avant d’utiliser l’appareil de chauffage.

8. Pour utilisation intérieure seulement. La ventilation doit être

adéquate. Figure 1. (voir également « Précautions liées au

fonctionnement »).

9. Si une odeur de gaz est détectée, ARRÊTEZ IMMÉDIATEMENT

l’appareil de chauffage jusqu’à ce que la source d’émission du gaz

ait été localisée et colmatée. Veuillez lire le feuillet « Substance

odorante et gaz propane » ci-joint pour obtenir plus de précisions

relatives à la détection des fuites de gaz propane.

10. Installez l’appareil de chauffage de façon à ce qu’il ne soit pas

exposé à l’eau.

11. Conservez un écart minimal entre l’appareil et tout matériel

combustible (tel que du papier). Figure 2.

12. En raison des températures élevées de la surface et de

l’échappement, les adultes et les enfants doivent respecter les

distances de sécurité pour éviter des brûlures et l’inflammation

des vêtements.

13. Utilisez uniquement sur des surfaces stables et de niveau.

14. N’utilisez pas l’appareil avec des conduits d’air. N’obstruez pas

l’entrée et la sortie d’air.

15. N’utilisez qu’avec l’alimentation électrique spécifiée. Le

raccordement électrique et la mise à la terre doivent être

conformes au Code national de l’électricité - ANSI/NFPA 70 (aux

États-Unis) - et à la norme CSA C22.1, partie 1 du Code canadien

de l’électricité (au Canada).

16. N’utilisez qu’avec une prise ou une rallonge mise à la terre munie

de trois broches.

17. Ne déplacez pas l’appareil, ne le touchez pas et n’essayez pas

d’en faire l’entretien alors qu’il est chaud.

18. Vous ne devez jamais ajuster la hauteur du tube de combustion

de l’appareil de chauffage lorsque l’appareil est chaud

ou fonctionne. Les réglages de hauteur doivent être faits

uniquement lorsque l’appareil n’est pas chaud au toucher.

19. Utilisez l’appareil en observant les codes de sécurité en vigueur

localement ou référez-vous aux normes relatives à l’entreposage et

à la manutention des produits de pétrole liquéfiés ANSI/NFPA 58 et

CSA B149.1 du Code d’installation du gaz naturel et du gaz propane.

Figure 2

ÉCART MINIMUM : entre l’appareil et tout matériel combustible.

Écart Air pulsé 170 FAVT

Du plancher ............................................ 0 pi (0 ft)

De la sortie ............................................. 6 pi (6 ft)

Des côtés ................................................ 2 pi (2 ft)

Du dessus ............................................... 3 pi (3 ft)

Placez l’appareil à 3 m (10 pi) des toiles en tissu ou en plastique

ou des revêtements similaires et fixez-les afin d’empêcher tout

battement ou mouvement causé par le vent.

Force-Air Propane Construction Heater Operating Instructions and Owner’s Manual

3

Page 12

AVERTISSEMENT RELATIF AUX SUBSTANCES ODORANTES

AVERTISSEMENT

Risque d’asphyxie

• Cet appareil ne doit pas être utilisé pour le chauffage de locaux où demeurent des gens.

• Ne l’utilisez pas dans des endroits non aérés.

• Le débit de chaleur et d’air de ventilation ne doit pas être obstrué.

• Le processus de combustion de cet appareil exige un apport adéquat en air de ventilation.

• Consultez la rubrique portant sur les spécifications techniques dans le manuel de l’appareil ou sur la plaque de données de

l’appareil, ou communiquez avec le fabricant pour obtenir les renseignements relatifs aux exigences en apport d’air de ventilation

pour la combustion.

• Le processus de combustion ne peut s’effectuer correctement si l’apport en air de ventilation est insuffisant.

• Une combustion inadéquate produit des émanations nocives de monoxyde de carbone pouvant entraîner des troubles de santé

graves, voire mortels. Les symptômes d’empoisonnement au monoxyde de carbone sont les maux de tête, les étourdissements et

la difficulté respiratoire.

ODEUR DU GAZ COMBUSTIBLE

Des additifs odorants ont été ajoutés au gaz propane liquéfié

et au gaz naturel dans le but de faciliter la détection de fuites.

Vous devriez remarquer une odeur de gaz combustible s’il y

a une fuite. Comme le gaz propane (liquéfié) est plus lourd

que l’air, l’odeur de gaz se détecte plus facilement près

du sol. TOUTE ODEUR DE GAZ EST UN SIGNAL QU’IL FAUT

INTERVENIR IMMÉDIATEMENT !

• Ne prenez aucune mesure qui provoquerait l’allumage des

vapeurs de gaz. N’utilisez aucun interrupteur électrique. Ne

tirez sur aucune source d’alimentation électrique ou rallonge

électrique. N’allumez pas d’allumettes ni aucune source de

flamme. N’utilisez pas votre téléphone.

• Faites évacuer immédiatement toute personne se trouvant

dans l’immeuble.

• Fermez tous les robinets d’alimentation du réservoir de gaz

propane (liquéfié) ou de la bonbonne, ainsi que le robinet

d’alimentation principale situé sur le compteur, si vous utilisez

du gaz naturel.

• Le gaz propane (liquéfié) est plus lourd que l’air et peut

s’accumuler dans les endroits près du sol. Si vous croyez qu’il y a

une fuite de gaz propane, éloignez-vous des endroits plus bas.

• Utilisez le téléphone d’un voisin et communiquez avec votre

fournisseur en gaz combustible et votre service d’incendies.

Ne retournez pas dans l’immeuble ou dans le secteur.

• N’entrez pas dans l’immeuble et restez-en à l’écart jusqu’à ce

que le personnel du service des incendies ou le fournisseur

en gaz combustible ait confirmé que l’endroit ne comporte

aucun risque.

• EN DERNIER LIEU, laissez le personnel du service des

incendies ou d’approvisionnement en gaz combustible vérifier

si du gaz s’échappe. Assurez-vous qu’ils aient aéré l’immeuble

avant d’y retourner. Le personnel d’entretien expérimenté doit

colmater toute fuite, vérifier la présence d’autres fuites, puis

se charger d’allumer l’appareil pour vous.

SUBSTANCE ODORANTE AUCUNE ODEUR

DÉCELÉE

• Certaines personnes ne détectent pas bien les odeurs. Il est

donc possible que certaines personnes ne puissent sentir la

substance odorante ajoutée au gaz propane (liquéfié) ou au

gaz naturel. Vous devez savoir si vous arrivez à déceler l’odeur

de cette substance dans le gaz combustible.

• Apprenez à reconnaître l’odeur du gaz propane et celle du gaz

naturel. Pour ce faire, les détaillants de gaz propane (liquéfié)

locaux seront heureux de vous fournir un feuillet comprenant

une pastille à humer. Servez-vous de cette pastille pour vous

aider à reconnaître l’odeur de gaz combustible.

• Le tabagisme peut nuire à votre faculté olfactive. Votre facilité

à déceler une odeur quelconque peut s’estomper si vous

demeurez un certain temps dans un endroit où cette odeur

est présente. La présence d’animaux dans des endroits clos

peut aussi masquer l’odeur du gaz combustible.

• La substance odorante contenue dans le gaz propane

(liquéfié) et le gaz naturel est incolore et, selon

certaines circonstances, son odeur pourrait s’estomper.

•

En cas de fuite souterraine, le déplacement du gaz dans le

sol peut filtrer l’odeur.

•

L’intensité de l’odeur du gaz propane (liquéfié) peut varier à

différents niveaux. Étant donné que le gaz propane (liquéfié)

est plus lourd que l’air, l’odeur peut être plus prononcée à

des niveaux inférieurs.

• Portez toujours attention à la moindre odeur de gaz. Si

une odeur de gaz persiste, même si elle est minime, agissez

comme s’il s’agissait d’une fuite importante. Intervenez

immédiatement tel que décrit précédemment.

ATTENTION - POINTS ESSENTIELS À RETENIR !

• Le gaz propane (liquéfié) dégage une odeur particulière.

Apprenez à reconnaître cette odeur. Consultez les rubriques

Odeur du gaz combustible et Substance odorante, ci-dessus.

• Même si vous n’avez pas été formé pour effectuer l’entretien et

la réparation de l’appareil, soyez TOUJOURS attentif aux odeurs

que dégagent le gaz propane (liquéfié) et le gaz naturel.

• Si vous n’êtes pas formé pour procéder à l’entretien et à la

réparation des appareils au gaz propane (liquéfié), ne tentez

pas d’allumer l’appareil, de le réparer ou de l’entretenir, ni

d’apporter des réglages au système d’alimentation en gaz

propane de l’appareil.

• Peu importe les conditions, une bonne pratique de sécurité

consiste à sentir de temps à autre autour de l’appareil, des

raccords, du tuyau et autres éléments. Si vous décelez la

moindre odeur de gaz, COMMUNIQUEZ IMMÉDIATEMENT

AVEC VOTRE FOURNISSEUR EN GAZ COMBUSTIBLE.

N’ATTENDEZ PAS !

Réglage en hauteur de l‘appareil de chauffage

Cet appareil est équipé d’un panneau de réglage en hauteur situé

à l’extrémité de l’échappement du boîtier de contrôle.

1. Ne pas régler la hauteur du tube de combustion de l’appareil

de chauffage quand l’appareil est en marche ou est encore

chaud. Les réglages de hauteur ne doit être faits qu’après

que le chauffage soit froid au toucher.

2. Pour régler la hauteur du tube de combustion de l’appareil

de chauffage, tournez le bouton de la vis de réglage dans

le sens anti-horaire et soulevez le tube de combustion à la

position désirée.

4

Force-Air Propane Construction HeaterOperating Instructions and Owner’s Manual

Page 13

INSTRUCTIONS DE FONCTIONNEMENT

AVANT LE FONCTIONNEMENT

1. Vérifiez soigneusement tout dommage qu’aurait pu subir

l’appareil de chauffage pendant l’expédition. Si vous en

découvrez, avertissez immédiatement le fabricant.

2. Respectez toutes les « Précautions ».

3. Branchez le raccord POL (filet à gauche) du tuyau et du

régulateur en tournant l’écrou POL en sens anti-horaire dans

la sortie du robinet de la bonbonne de gaz propane, puis

serrez-le avec une clé.

4. Raccordez le tuyau à l’appareil de chauffage en tournant le

raccord dans le sens des aiguilles d’une montre.

5. Serrez fermement toutes les connexions de gaz.

6. Ouvrez le robinet de gaz de la bonbonne et vérifiez toutes

les connexions au moyen d’un mélange d’eau et de savon.

N’UTILISEZ PAS DE FLAMME.

7. Raccordez le cordon d’alimentation à une source

d’alimentation électrique de 115 V, 60 Hz, 1 Ø, mise à la terre

comme il se doit.

8. Lorsque vous utilisez une rallonge électrique, assurez-vous

que celle-ci comporte trois fils (mis à la terre) de dimension

appropriée.

REDÉMARRAGE APRÈS UN ARRÊT D’URGENCE

1. Fermez complètement le robinet sur la bonbonne de gaz

propane. Débranchez l’appareil de chauffage.

2. Attendez cinq minutes.

3. Recommencez la procédure « Démarrage ».

ENTRETIEN ET ENTREPOSAGE

1. L’appareil de chauffage doit être vérifié avant chaque utilisation

et au moins une fois par année, par un technicien qualifié.

2. Avant chaque utilisation, vérifiez l’assise du joint torique

souple à la partie arrondie du raccord POL (filet à gauche).

Si le joint torique est coupé, usé ou endommagé de quelque

façon, remplacez-le par la pièce n° 6681.

3. Coupez l’alimentation en gaz propane liquéfié quand

l’appareil n’est pas utilisé.

4. Quand l’appareil de chauffage est rangé à l’intérieur, la

connexion entre la bonbonne d’alimentation en gaz propane

liquéfié et l’appareil doit être débranchée et la bonbonne

doit être retirée de l’appareil et rangée à l’extérieur, tel que

précisé au chapitre 5 de la norme relative au rangement et à

la manutention des produits de pétrole liquéfiés ANSI/NFPA

58 et CSA B149.1 du Code d’installation du gaz naturel et du

gaz propane.

170FAVT

(AVEC LE THERMOSTAT)

DÉMARRAGE

1. Ouvrez lentement le robinet principal de la bonbonne de

propane afin de prévenir la fermeture du clapet limiteur

de débit.

2. Réglez le thermostat en position maximale. L’appareil de

chauffage s’allumera automatiquement.

3. Réglez le clapet à bille sur le panneau de commande au

taux de combustion désiré.

4. Réglez le thermostat à la température désirée. L’appareil

de chauffage se mettra en fonction et s’arrêtera

automatiquement selon les variations de température

dans la zone chauffée.

ARRÊT

1. Fermez le robinet sur la bonbonne de gaz propane.

2. Laissez l’appareil fonctionner jusqu’à ce que tout le gaz

dans le tuyau ait brûlé.

3. Tournez le thermostat de l’appareil de chauffage en

position « off » (arrêt). Pour les arrêts prolongés ou

dans les régions où la température est inférieure à

-17,8 ºC (0 ºF), débranchez le cordon d’alimentation de

l’appareil de chauffage.

ARRÊT

1. Fermez le robinet sur la bonbonne de gaz propane.

2. Laissez l’appareil fonctionner jusqu’à ce que tout le gaz

dans le tuyau ait brûlé.

3. Débranchez le cordon d’alimentation.

ENTREPOSAGE

Un appareil de chauffage qui a été modifié ou qui ne

fonctionne pas correctement risque d’être une cause de

dangers.

• La flamme reste dans l’appareil de chauffage.

• La flamme a une teinte bleue avec des pointes de

couleur jaune.

• Il n’y a pas de forte odeur désagréable, ni de sensation

de brûlure aux yeux, ni de malaise physique en général.

• Il n’y a pas de production de fumée ou de suie à

l’intérieur ou à l’extérieur de l’appareil de chauffage.

• Il ne se produit pas d’arrêts imprévus ou inexpliqués de

l’appareil.

La liste des pièces et le schéma de câblage présentent

l’appareil de chauffage tel qu’il a été construit. N’utilisez pas

un appareil de chauffage qui diffère de ce qui est illustré.

N’utilisez à cet effet que le tuyau flexible, le régulateur et

le raccord de bonbonne (appelé raccord POL) fournie avec

l’appareil de chauffage. IMPORTANT : Faire correspondre la

bande de couleur de l’étiquette fixée au tuyau à la couleur de

l’étiquette située près du raccord d’entrée de gaz propane.

N’utilisez aucun élément de substitution. Sur cet appareil de

chauffage, le régulateur doit être réglé tel qu’indiqué à la

rubrique « Spécifications ». Si vous avez un doute au sujet du

réglage du régulateur, faites-le vérifier.

Les produits couverts par la garantie seront réparés sans frais,

pièces et main-d’œuvre comprises. Veuillez joindre une courte

description de la nature du problème avec la date, le lieu et la

preuve d’achat.

Si un appareil de chauffage

il doit être réparé, mais

expérimenté.

Les produits couverts par la garantie seront réparés sans frais,

pièces et main-d’œuvre comprises. Veuillez joindre une courte

description de la nature du problème avec la date, le lieu et la

preuve d’achat.

Les produits non couverts par la garantie seront réparés aux

frais (pièces et main-d’œuvre) du client.

ne fonctionne pas

seulement

par un technicien formé et

correctement,

Force-Air Propane Construction Heater Operating Instructions and Owner’s Manual

5

Page 14

DIMENSIONS ET CONTENANCES DES

BONBONNES DE GAZ PROPANE

Les tableaux ci-dessous présentent la dimension approximative

de la bonbonne requise pour ces appareils de chauffage.

Pour utiliser le tableau :

1. Sélectionnez la température de l’air la plus basse prévue (au

bas du tableau).

2. Déplacez-vous en ligne droite vers le haut jusqu’au temps de

fonctionnement souhaité (côté gauche du tableau).

3. Notez la dimension de la bonbonne requise.

Tous les appareils de chauffage

doivent disposer de :

bonbonnes pleines,

d’une circulation d’air adéquate et

ne pas présenter de givre.

AVERTISSEMENT : Lors de l’utilisation d’un appareil de

chauffage contrôlé par thermostat, sa zone d’échappement

doit être protégée et des avertissements de démarrage

soudain doivent être affichés à l’intention du personnel.

Calibre minimum recommandé pour rallonges

Tableau de calibre de câble AWG

Plaque

d’identification

120 V A

5-6 18 16 14 12

6-8 18 16 12 10

8-12 18 14 12 10

10-12 16 14 10 8

12-14 16 12 10 8

Longueur de la rallonge en pieds

25 50 100 150

DE QUELLE QUANTITÉ DE CHALEUR AIS-JE

BESOIN ?

Pour des raisons d’économie, il est important que le rendement

corresponde aux besoins. Mais les besoins en matière de

chaleur varient souvent. Par exemple, beaucoup de chaleur est

habituellement requise pour réchauffer des objets que pour les

conserver au chaud. Dans le même ordre d’idées, la température

de l’air extérieur augmente habituellement durant la journée ;

la demande en chaleur est donc plus grande durant la nuit que

durant la journée. Une approximation de la chaleur requise peut

être établie à l’aide du tableau ci-dessous.

BTU PAR HEURE REQUIS

Pieds cubes

d’espace

à chauffer

5 000 14 000 20 000 27 999 34 000

7 000 19 000 28 000 38 000 47 000

10 000 27 000 40 000 54 000 67 000

15 000 40 000 60 000 80 000 100 000

20 000 54 000 80 000 107 000 133 000

30 000 80 000 120 000 160 000 200 000

50 000 133 000 200 000 266 000 333 000

Élévation de température requise (ºC/ºF)*

-6,6 ºC

(20 ºF)

1,0 ºC

(30 ºF)

4,4 ºC

(40 ºF)

10 ºC

(50 ºF)

Si du câblage d’origine fourni avec l’appareil de chauffage doit

être remplacé, il faut utiliser du câblage de type AWG 105 °C ou

un équivalent, à moins d’indication contraire. (*type SF2-200,

**SGI 250 °C).

170FAVT - SCHÉMA DE CÂBLAGE

COULEUR LONGUEUR DE À

Blanc 18 cm (7 po) Robinet Bloc de raccordement

Noir 15 cm (6 po) Interrupteur Bloc de raccordement

Rouge (Haute

température)

Rouge (Haute

température)

Orange 28 cm (11 po) Commande de

Ver t 18 cm (7 po) Commande de la

Rouge 18 cm (7 po) Commande de la

Blanc 15 cm (6 po) Commande de la

Noir 15 cm (6 po) Commande de la

42 cm

(16,5 po)

42 cm

(16,5 po)

Interrupteur

commande max.

Interrupteur

commande max.

la flamme

(Allumage)

flamme (Faisceau)

flamme (Faisceau)

flamme (Faisceau)

flamme (Faisceau)

Robinet

Bloc de raccordement

Bougie d’allumage

Masse

Bloc de raccordement

Bloc de raccordement

Bloc de raccordement

6

Force-Air Propane Construction HeaterOperating Instructions and Owner’s Manual

Page 15

Modèle nº 170FAVT (avec un thermostat) LISTE DES PIÈCES

36

35

Article

N° art.

Description Qté

1 21732 Coque extérieure - Modèle MH 1

2 22249 Cylindre central 1

3 22287 Ensemble de l’orifice 1

4 21146 Ensemble porte-flamme 1

5 26168 Interrupteur de limite haute de la course 1

6

7

8

9

10

11

12

14

16

17

18

21

22

24

23038 Écrou de l’orifice

27095 Poignée

27094 Clips de montage de la poignée

26010 Vis de réglage, Nyloc

26074 Ventilateur

22251 Moteur

22252 Grille, montage d’admission/du moteur

26257 Régulateur, 28" de colonne d’eau

26122 Connexion à raccord mâle 3/8MPT x

3/8 SAE FLR

22264 Électrovanne, Goyen

22265 Raccord étroit

22266

Ensemble de tube à carburant 1

22287 Electrode, Spark

24340 Support de montage du thermostat

Article

25

26

27

28

1

1

2

1

1

1

1

1

1

1

1

1

1

29

30

31

32

33

34

35

36

N° art.

Description Qté

22254 Thermostat

26070 Support de collier, 5/16

27808 Commande de la flamme, encapsulée

21036 Cordon d’alimentation

28771 Panneau de raccordement

26223 Réducteur de tension de la bague

28772 Bouton, thermostat

28773 Bouton, réglage du taux de combustion

22255 Boîtier de commande

22273 Base, boîtier de commande

22274 Plaque de soulèvement

22275 Bouton de soulèvement

1

1

1

1

1

1

1

1

1

1

1

1

Force-Air Propane Construction Heater Operating Instructions and Owner’s Manual

7

Page 16

GUIDE D’UTILISATION ET

Modèle nº

MANUEL DU PROPRIÉTAIRE

HS170FAVT

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS : Lisez et observez toutes les instructions. Conservez ces

instructions dans un endroit sécuritaire pour vous y référer ultérieurement. Ne permettez pas à quiconque

n’ayant pas lu les présentes instructions d’assembler, d’allumer, de régler ou de faire fonctionner l’appareil.

AVERTISSEMENT :

N’UTILISEZ QUE LES PIÈCES DE REMPLACEMENT DU FABRICANT. L’UTILISATION

D’AUTRES PIÈCES RISQUE DE CAUSER DES BLESSURES ET LA MORT. LES PIÈCES DE

REMPLACEMENT NE SONT OFFERTES QUE PAR LE FABRICANT ET DOIVENT ÊTRE

INSTALLÉES PAR UNE ENTREPRISE SPÉCIALISÉE.

INFORMATIONS SUR LA COMMANDE DE PIÈCES :

ACHATS : Les accessoires peuvent être achetés chez n’importe quel revendeur local

Mr. Heater ou directement à l’usine.

POUR OBTENIR DES INFORMATIONS SUR LE SERVICE

Veuillez appeler sans frais le 866-447-2194 • www.HeatStar.com

Nos heures d’ouverture sont de 8 h 00 à 17 h HE, du lundi au vendredi.

Adressez vos courriels à : techservice@enerco-HeatStar.com

Veuillez indiquer le numéro du modèle, la date d’achat et la description du problème

dans toutes vos communications avec nous.

GARANTIE LIMITÉE

L’entreprise garantit ce produit contre tout défaut de matériel ou de main-d’œuvre, dans des

conditions d’utilisation normale et adéquate, conformément aux instructions de l’entreprise, pour une

période de un an à compter de la date de livraison à l’acheteur. L’entreprise réparera ou remplacera,

à sa discrétion, les produits retournés port payé par l’acheteur au fabricant dans la période de un an

et jugés par l’entreprise comme présentant des défauts de matériel ou de main-d’œuvre.

Si une pièce est endommagée ou manquante, téléphonez à notre service de soutien technique

au 866-447-2194.

Envoyez toutes les demandes de garantie au service à la clientèle, HeatStar, Inc., 4560 W. 160th

St., Cleveland, Ohio 44135. Incluez votre nom, l’adresse et le numéro de téléphone et aussi les

détails concernant la demande. Nous fournir également la date d’achat et le nom et l’adresse du

concessionnaire auprès duquel vous avez acheté notre produit.

Ce qui est énoncé ci-dessus constitue la responsabilité totale de l’entreprise. Il n’existe aucune autre

garantie, expresse ou tacite. Plus précisément, il n’y a aucune garantie concernant l’adéquation à une

utilisation particulière ni aucune garantie concernant la qualité marchande. En aucun cas l’entreprise

ne sera tenue responsable des retards causés par des défectuosités, ni des dommages indirects, ni des

dépenses encourues sans son consentement écrit, quelle que soit leur nature. Le coût de la réparation

ou du remplacement sera le seul recours possible en cas de violation de garantie. Il n’y a aucune

garantie contre une transgression de ce genre ni aucune garantie tacite découlant des usages du

commerce ou de la façon habituelle d’échanger. La présente garantie ne s’applique à aucun produit

qui a été réparé ou modifié par d’autres que le fabricant si cela influe de quelque façon que ce soit

sur la condition de l’appareil ou son fonctionnement, selon notre jugement.

Certains États ou provinces ne permettent pas d’exclure ou de limiter les dommages indirects

ou subséquents. Par conséquent, les limitations ou exclusions ci-dessus mentionnées ne vous

concernent peut-être pas. La présente garantie vous accorde des droits juridiques précis, mais

vous pourriez avoir d’autres droits qui varient selon la province ou l’État.

ANSI Z83.7b-2015/CSA 2.14b-2009

Mr. Heater, Inc., se réserve le droit de modifier en tout temps, sans préavis ni obligation, les

couleurs, spécifications, accessoires, matériaux et modèles.

ENREGISTREMENT DU PRODUIT : Nous vous remercions pour votre achat.

Veuillez vous connecter à http://www.egiregistration.com pour enregistrer votre produit.

HeatStar, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

HeatStar est une marque déposée de Enerco Group, Inc

© 2015, Enerco Group, Inc. Tous droits réservés

Page 17

INSTRUCCIONES DE USO

Modelo N.°

Y MANUAL DEL USUARIO

LEA CUIDADOSAMENTE LAS INSTRUCCIONES: lea y siga todas las instrucciones. Consérvelas en

un lugar seguro para futura referencia. No permita que nadie que no haya leído estas instrucciones

arme, encienda, ajuste o use el calentador.

HS170FAVT

Modelos N.° 170FAVT y 170FAV

CALENTADOR DE PROPANO A AIRE

FORZADO PARA CONSTRUCCIÓN

ADVERTENCIA: Si no se siguen al pie de la letra las instrucciones de este manual, podría

producirse un incendio o una explosión que provocaría daños materiales, lesiones o muertes.

— No almacene ni utilice gasolina ni ningún otro vapor ni líquido inflamable cerca de este ni de

ningún otro artefacto.

— Los cilindros LP que no estén conectados al calentador no deben almacenarse cerca de este ni

de ningún otro artefacto.

— QUÉ HACER SI DETECTA OLOR A GAS

• No intente encender el artefacto.

• Apague todas las llamas expuestas.

• Corte el suministro de gas al artefacto.

— El mantenimiento debe ser realizado por una agencia de reparación calificada.

Este calentador portátil a gas no tiene una fuente propia de ventilación. Utiliza el aire (oxígeno) del área en la

cual se emplea. Debe suministrarse el aire necesario para la ventilación y la combustión. Consulte la página 3.

70251 2015Heatstar by Enerco, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 18

ADVERTENCIA:

SU SEGURIDAD ES IMPORTANTE PARA USTED Y PARA LOS

DEMÁS. POR ELLO, LEA ESTAS INSTRUCCIONES ANTES DE

UTILIZAR EL CALENTADOR.

ADVERTENCIA:

NO APTO PARA USAR EN EL HOGAR NI EN CASAS

RODANTES.

ADVERTENCIA GENERAL DE

PELIGRO:

EL NO CUMPLIR CON LAS PRECAUCIONES E

INSTRUCCIONES QUE VIENEN CON ESTE CALENTADOR

PUEDE CAUSAR LA MUERTE, LESIONES GRAVES Y

PÉRDIDAS Y DAÑOS MATERIALES DERIVADOS DEL

PELIGRO DE INCENDIO, EXPLOSIÓN, QUEMADURAS,

ASFIXIA, ENVENENAMIENTO CON MONÓXIDO DE

CARBONO Y/O DESCARGAS ELÉCTRICAS.

SOLO LAS PERSONAS QUE ENTIENDAN Y PUEDAN SEGUIR

LAS INSTRUCCIONES DEBEN USAR O MANTENER ESTE

CALENTADOR.

SI NECESITA AYUDA O INFORMACIÓN ACERCA DEL

CALENTADOR, COMO MANUALES DE INSTRUCCIONES,

ETIQUETAS, ETC., PÓNGASE EN CONTACTO CON EL

FABRICANTE.

ADVERTENCIA:

PELIGRO DE INCENDIO, QUEMADURAS, INHALACIÓN Y

EXPLOSIÓN. MANTENGA LOS COMBUSTIBLES SÓLIDOS

COMO MATERIALES DE CONSTRUCCIÓN, PAPEL O

CARTÓN A UNA DISTANCIA SEGURA DEL CALENTADOR

TAL COMO LO RECOMIENDAN LAS INSTRUCCIONES.

NUNCA USE EL CALENTADOR EN ESPACIOS QUE

CONTIENEN O PODRÍAN CONTENER COMBUSTIBLES

VOLÁTILES O PRODUCTOS COMO GASOLINA,

SOLVENTES, DILUYENTE DE PINTURA O PRODUCTOS

QUÍMICOS DESCONOCIDOS.

EL ESTADO DE CALIFORNIA EXIGE LAS SIGUIENTES ADVERTENCIAS:

ADVERTENCIA: Uno de los elementos generados por la combustión al usar este equipo es monóxido de

carbono, un producto químico que de acuerdo con el estado de California produce cáncer y defectos de nacimiento

(u otros daños reproductivos).

ADVERTENCIA: Este producto contiene sustancias químicas que de acuerdo con el estado de California

producen cáncer y defectos de nacimiento u otros daños reproductivos.

CONTENIDOS

Especificaciones ................................................................2

Precauciones de utilización ................................................ 3

Precauciones de seguridad ................................................ 3

Advertencia de disipación del olor ..................................... 4

Instrucciones de uso ......................................................... 4

Almacenamiento y reparación ........................................... 5

Instrucciones de encendido ............................................... 5

Diagrama de cableado 170 FAVT ....................................... 6

Lista de piezas 170 FAVT ...................................................7

Diagrama extendido 170 FAVT ........................................... 7

Diagrama de cableado 170 FAV (sin termostato) ................ 8

Lista de piezas 170 FAV (sin termostato) ............................ 9

Diagrama extendido 170 FAV (sin termostato) ...................9

ESPECIFICACIONES

MODELO N.°: .........................................................170FAV´T

TIPO DE GAS

ESPECIFICACIONES BTU.

PRESIÓN DEL SUMINISTRO DE

GAS AL REGULADOR

Máxima: Presión del cilindro.

Mínima: 5 psig (34,5 kPa)

SALIDA DEL REGULADOR

ENTRADA DE CORRIENTE

ENCENDIDO

CONTROL PRIMARIO

DE LA LLAMA ........................ del estado sólido 10-15 segundos

CONTROL DE ALTA

TEMPERATURA ....................... 240 °F (116 °C)

Temperatura ambiente mínima Especificaciones: 0 °F (-17,8 °C)

CONSUMO DE COMBUSTIBLE

N.° DEL PUERTO DEL

ORIFICIO DE COMBUSTIBLE:

TAMAÑO DEL PUERTO DEL

ORIFICIO DE COMBUSTIBLE:

SALIDA DE AIRE CALIENTE:

............................................................Propano

.................. 125.000-170.000 BTU/hr

(36,6-49,8 kW)

....... 28” WC (6,97 kPa)

....... 115 V, 60 Hz, 1Ø, 3a

........................... Chispa directa, no constante

... 5,8 - 7,9 libras/hr

(2,6-3,6 kg/hr)

..18

......0,80 mm favt

0,82 MM FAV

.... 450 PCM (12,74 M/M CÚBICOS)

2

Force-Air Propane Construction HeaterOperating Instructions and Owner’s Manual

Page 19

PRECAUCIONES DE UTILIZACIÓN

Este artefacto es un calentador de propano de caldeo directo

a aire forzado. Está diseñado para usarse principalmente en la

calefacción temporaria de edificios en construcción, remodelación

o reparación.

El propano es más pesado que el aire. Cuando el propano escapa

de una conexión o acople, desciende hacia el piso y se acumula

allí con el aire circundante, y forma una mezcla potencialmente

explosiva. Obviamente, las fugas de propano deben evitarse, así

que debe establecer la conexión del suministro de propano con

extremo cuidado. Lea el documento adjunto “Propano y disipación

del olor” para obtener más información sobre la detección de

fugas de propano. Realice una comprobación de fugas utilizando

una solución de agua jabonosa siempre que establezca una nueva

conexión o realice una reconexión, y siga todas las instrucciones

de conexión incluidas en este documento. Además, solicite

asesoramiento del proveedor de propano acerca de la aplicación

e instalación del suministro de propano, y pídale que realice una

revisión si tuviera alguna duda.

Este calentador fue diseñado y certificado para ser utilizado

como un calentador para sitios de construcción de acuerdo con

el estándar ANSI Z83.7/CGA 2.14. Consulte con la autoridad

de seguridad antiincendios si tiene alguna pregunta sobre sus

aplicaciones. Hay otros estándares que rigen el uso de gases

combustibles y productos que producen calor en aplicaciones

específicas. La autoridad local podrá asesorarlo al respecto.

De caldeo directo quiere decir que todos los productos de la

combustión ingresan al espacio que se calefacciona. Aunque este

calentador funciona casi a un 100 % de eficiencia de combustión,

produce pequeñas cantidades de monóxido de carbono. El

monóxido de carbono (CO) es tóxico. Podemos tolerar pequeñas

cantidades, pero no grandes cantidades. El CO puede acumularse

en el lugar que se calienta y si no se establecen las condiciones de

ventilación adecuadas puede resultar mortal.

Los síntomas de ventilación inadecuada son:

• dolores de cabeza

• mareos

• ardor en los ojos y en la nariz

• náuseas

• boca reseca o dolor de garganta

Por tanto, asegúrese de seguir las recomendaciones sobre las

condiciones de ventilación que se incluyen en estas instrucciones

de uso.

Aire forzado significa que un soplador o ventilador impulsa el aire

a través del calentador. La combustión depende de este flujo de

aire para realizarse correctamente, por tanto, el calentador no

debe modificarse, alterarse ni utilizarse si se le han sustraído o

le faltan piezas. Asimismo, no se deben alterar ni modificar los

sistemas de seguridad para utilizar el calentador.

Cuando deba utilizarse el calentador en presencia de

otras personas, el usuario será responsable de poner

a los presentes al corriente de las precauciones e

instrucciones de seguridad, y de los posibles peligros.

Figura 1

VENTILACIÓN: aperturas mínimas necesarias

Apertura Apertura

Calentador cerca del piso cerca del cielorraso

Aire forzado

(170 FAV T ) 0,3 m2 (3 pies2) 0,3 m2 (3 pies2)

PRECAUCIONES DE SEGURIDAD

1. Revise cuidadosamente si el calentador presenta daños. NO

use un calentador dañado.

2. NO modifique el calentador ni lo use si su configuración

original ha sido modificada.

3. Utilice únicamente gas propano.

4. Utilice únicamente suministro de propano con

RECUPERACIÓN DE VAPOR. Si tiene alguna pregunta sobre la

recuperación de vapor, consulte al proveedor de propano.

5. Monte los cilindros de propano verticalmente (válvula hacia

arriba). Asegúrelos para que no caigan ni sean arrojados al

piso y protéjalos de daños.

6. Ubique los envases de propano por lo menos a 2,13 m

(7 pies) (EE. UU.) o a 3 m (10 pies) (Canadá) del calentador y

no apunte el escape hacia ellos.

7. IMPORTANTE: Use únicamente la manguera y el regulador que

vienen con el calentador. Haga coincidir la franja de color de la

etiqueta colgante que se encuentra en el acople de la manguera

con el color de la etiqueta situada cerca del acople de entrada

del propano en el calentador. Inspeccione siempre el conjunto

de la manguera antes de utilizar el calentador. Si el conjunto de

la manguera estuviera excesivamente estropeado o desgastado,

o si presentara cortaduras, reemplácelo por uno de los que se

especifica en la lista de piezas antes de utilizar el calentador.

8. Solo para uso en interiores. El área debe estar bien ventilada.

Figura 1. (consulte también la sección “Precauciones de

utilización“).

9. Si detectara olor a gas en algún momento, INTERRUMPA

INMEDIATAMENTE la utilización del equipo hasta que haya

sido detectada y corregida la fuente de gas. Lea el documento

adjunto “Propano y disipación del olor“ para obtener más

información sobre la detección de fugas de propano.

10. Instale el calentador de forma tal que no esté directamente

expuesto a salpicaduras de agua, lluvia ni goteo de agua.

11. Mantenga las distancias mínimas de materiales combustibles

normales (como el papel). Figura 2.

12. Dadas las elevadas temperaturas de la superficie y del escape,

tanto los adultos como los niños deben mantener la distancia

adecuada para evitar quemaduras o la ignición de su ropa.

13. Úselo únicamente sobre una superficie nivelada y estable.

14. No lo utilice en redes de conductos. No restrinja las entradas

ni las salidas.

15. Utilice únicamente la alimentación de corriente especificada. La

conexión eléctrica y a tierra debe cumplir con los requisitos del

Código Eléctrico Nacional - ANSI/NFPA 70 (EE.UU.) y del Código

Eléctrico Canadiense CSA C22. 1, Primera parte (Canadá).

16. Utilice únicamente un cable de extensión o un receptáculo de

3 patas correctamente conectado a tierra.

17. No mueva, manipule ni ajuste el artefacto mientras esté

caliente o encendido.

18. No ajuste la elevación del tubo de combustión del calentador

mientras esté en funcionamiento o caliente. Se deben realizar

los ajustes en la elevación solo después de que el calentador

se haya enfriado al tacto.

19. Utilice únicamente de acuerdo con los códigos locales o, en la

ausencia estos, de acuerdo con los Estándares ANSI/NFPA 58

y CSA B149.1 para almacenamiento y manipulación de gases

licuados del petróleo del Código de instalación de propano y

gas natural.

Figura 2: DISTANCIAS MÍNIMAS de materiales combustibles normales

Distancia Aire forzado 170FAVT

Desde el piso .................................................. 0 m (0 pies)

Del tomacorriente ...........................................1,83 m (6 pies)

Desde los laterales ..........................................0,60 m (2 pies)

Desde la parte superior ................................... 0,91 m (3 pies)

Colóquelo a 3 m (10 pies) de lonas o cubiertas de protección

plásticas o cubiertas similares y asegúrelas para evitar que ondeen

o se muevan por la acción del viento.

Force-Air Propane Construction Heater Operating Instructions and Owner’s Manual

3

Page 20

ADVERTENCIA DE DISIPACIÓN DEL OLOR

ADVERTENCIA

Peligro de asfixia

• No utilice este calentador para calefaccionar locales habitados por personas.

• No lo utilice en áreas sin ventilación.

• No obstruya el flujo de aire necesario para la combustión y la ventilación.

• Deberá suministrar la ventilación adecuada para garantizar que el calentador disponga del aire que necesita para la combustión.

• Consulte la sección de especificaciones del manual del calentador, la placa del calentador o póngase en contacto con el

fabricante para conocer los requerimientos de ventilación del calentador.

• Si la ventilación no es la adecuada, la combustión no se llevará a cabo correctamente.

• Una combustión inadecuada puede producir envenenamiento con monóxido de carbono con graves daños para la salud, o causar la

muerte. Los síntomas de envenenamiento con monóxido de carbono incluyen dolores de cabeza, mareos y dificultad para respirar.

OLOR A GAS COMBUSTIBLE

Los gases LP y el gas natural contienen sustancias

aromáticas artificiales -añadidas específicamente para

facilitar la detección de fugas de gas.

Si se produjera una fuga de gas, usted debe poder oler

el gas combustible. Dado que el propano (LP) es más

pesado que el aire, debe tratar de detectar el olor lo más

cerca del piso posible. ¡CUALQUIER OLOR A GAS SERÁ

LA SEÑAL PARA TOMAR MEDIDAS INMEDIATAMENTE!

• No haga nada que pudiera inflamar el gas combustible. No

active ningún interruptor eléctrico. No desconecte ninguna

toma de corriente ni cables de extensión. No encienda fósforos

ni ninguna otra fuente de llamas. No utilice el teléfono.

• Saque a todas las personas del edificio y aléjelas del área

inmediatamente.

• Cierre todas las válvulas de suministro de combustible de

los cilindros o del tanque de gas propano (LP), o la válvula

principal de suministro de combustible que se encuentra en el

medidor si emplea gas natural.

• El gas propano (LP) es más pesado que el aire y puede

asentarse en áreas bajas. Cuando sospeche que puede haber

una fuga de propano, manténgase alejado de las áreas bajas.

• Utilice el teléfono de su vecino y llame al proveedor de gas y

al departamento de bomberos. No vuelva -a entrar al edificio

ni se acerque al área.

• Manténgase alejado del edificio y del área hasta que los

bomberos y el proveedor de gas hayan declarado que no hay

peligro.

• POR ÚLTIMO, permita que la persona del servicio de gas y los

bomberos revisen si hay fugas de gas. Haga que ventilen el

edificio y el área antes de su regreso. Un agente de servicios

calificado debe reparar cualquier fuga, revisar si hay otras

fugas y volver a encender el artefacto por usted.