Page 1

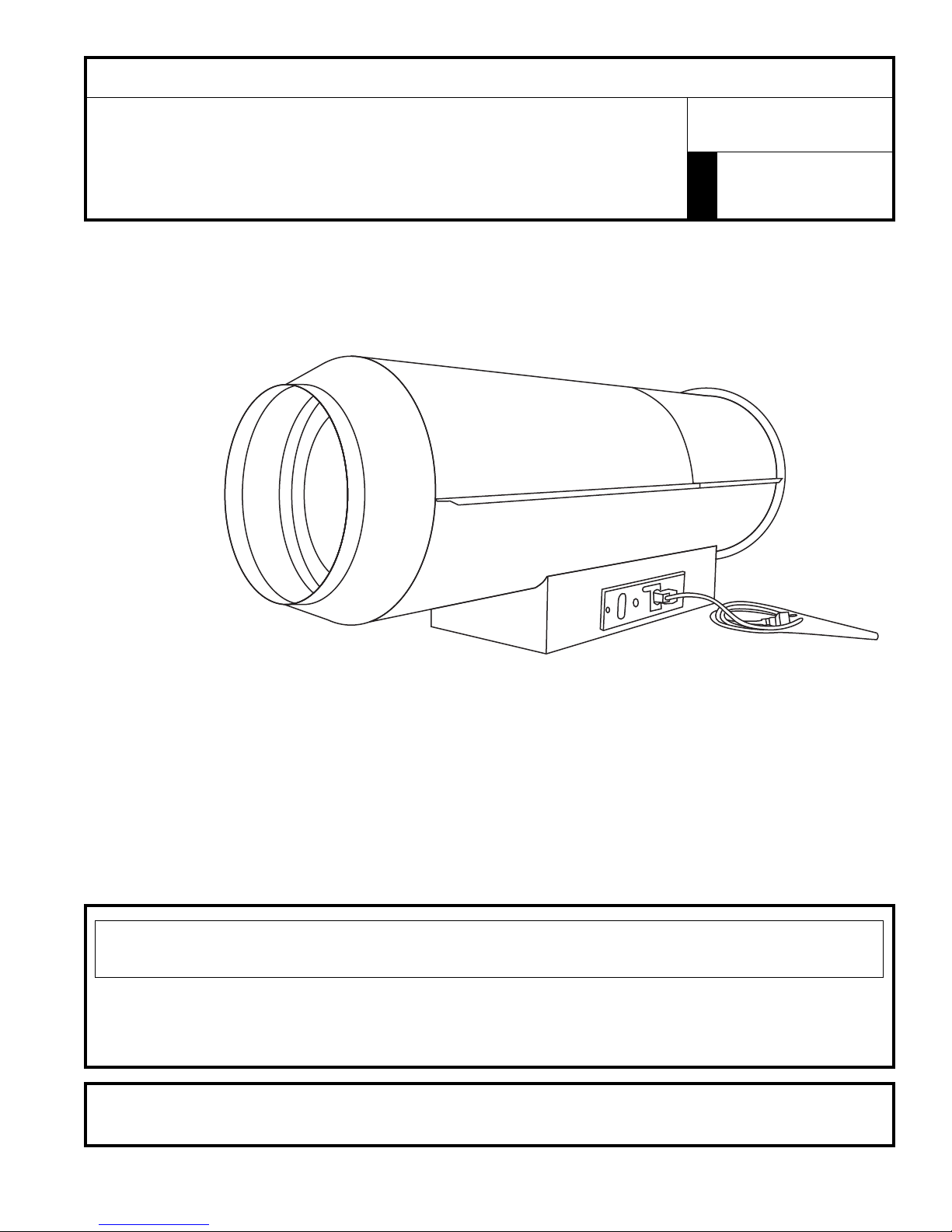

OPERATING INSTRUCTIO

NS AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY:

MODEL

and follow all instructions. Place instructions in

a safe place for future reference. Do not allow

anyone who has not read these instructions to

assemble, light, adjust or operate the heater.

Read

HEATSTAR

BY ENERCO

MODEL

HS4000 NG/LP

NATURAL GAS/

DIRECT FIRED

WARNING:

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

— Service must be performed by a qualified service agency.

This is a vented portable heater. It uses air (oxygen) from the area in which it is used. Adequate

combustion air and ventilation must be provided. Refer to page 5.

If the information in this manual is not followed exactly, afire or explosion

may result causing property damage, personal injury or loss of life.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 800-251-0001

LPG

FIRED

HEATER

08/11 50401

Page 2

WARNING :

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

GENERAL HAZARD WARNING :

FAILURE TO C OMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS H EATER, CAN

RESULT IN DEATH, S ERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAG E FROM HAZARDS OF FIRE,

EXPLOSION, BURN, ASPHYXIATI ON, CARBON M ONOXIDE POISONING, AND/ OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW

THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTIONS MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

WARNING :

NOT FOR HOME OR RECREATIONAL VEHICLE USE

WARNING :

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING MA TERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE

AWAY FROM THE HEATER AS RECOMMENDED BY TH E

INSTRUCTIONS NEVER USE THE HEATER IN SPACES

WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR UNKNOWN CH EMICALS.

WARNING :

The State of California requires the following warning:

COMBUSTION BY-PRODUCTS PRODUCED WHEN US ING THIS PRODUCT CONTAIN CARBON MONOXIDE,

A CHEMICAL KN OWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND BIRTH D EFECTS (OR OTHER

REPRODUCTIVE HARM).

WARNING :

READ THE INSTRUCTI

MANUAL B EFORE USING THE APPLIANCE .

• DO NOT USE GASOLINE, NAPHTHA OR VOLATILE

FUELS.

• THE ELECTRICAL SYSTEM TO WHICH THE APPLIANCE

IS CONNECTED MUST C OMPLY WITH A LL SAFETY

REGULATIONS IN FORCE. A R ESIDUAL CURRENT

CIRCUIT BREAKER MUST B E PROVIDED ON THE MAIN

DISTRIBUTION BOARD.

• UNPLUG THE HEATER BEFORE ATTEMPTING ANY

SERVICE OR MAINTENANCE.

• ALWAYS CHECK THE POWER SUPPLY CABLE BEFORE

USE. IT MUST N OT BE BENT, CRUSHED, OR ANYWAY

DAMAG ED.

• THE POWER SUPPLY CABLE MUST BE REPLACED ONLY

BY QUALIFIED PERSONNEL.

• ONLY USE AN ORIGINAL H07RN-F POWER CABLE

WITH WAT ERPROOF PLUG.

• DO NOT TOUCH THE EXHAUST GAS OUTLET. DANGER

OF BURNS!

ONS

GIVEN IN THIS

IMPORTANT

Before using the heater, read and understand all instructions and

follow them carefully. The manufacturer is not responsible for

damages to goods or persons due to improper use of units.

CONTENTS

WARNINGS .................................................................................. 2-3

SPECIFICATIONS ........................................................................... 4

SAFETY DEVICES .......................................................................... 4

OPERATION ................................................................................. 5

MAINTENANCE ............................................................................ 5

VENTILATION ............................................................................... 5

TROUBLESHOOTING .................................................................... 6

WIRING DIAGRAMS ..................................................................... 7

PARTS LIST .............................................................................11-16

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

2

Page 3

WARNING :

The heater is designed and approved for use as a construction heater in accordance with Standard

ANSI Z83,7 CGA 2.14.

CHECK WITH YOUR LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE QUESTIONS ABOUT

APPLICATIONS.

Other standards govern the use of fuel gases and heat producing products in specific

applications.Your local authority can advise you about these.

WARNING :

This heater can be washed, provided that:

A. The heater is disconnected from the electrical supply.

B. All access panels are securely clos

C. Water spray nozzle shall not discharge within 6 feet of the heater.

D. The heater is not reconnected to electrical supply until thoroughly dried.

Improper cleaning of the heater can cause severe personal injury or property damage due to water

and/or cleaning solutions:

A. In electrical components, connections and wires causing electrical shocks or component

failure.

B. On gas control components causing corrosion which can result in gas leaks and fire or

explosion from the leak.The hose assembly must be protected from the traffic, building

materials and contact with hot surfaces both during use andwhile in storage.

ed.

WARNING :

Proper gas supply must be provided to the inlet of the appliance.

Refer to rating plate for proper gas supply pressure.

Gas pressure in excess of maximum inlet pressure specified at the appliance inlet can cause fire or

explosions, leading to serious injury, death, building damage or loss of lives

Likewise, gas pressure below the minimum inlet pressure specified at the appliance inlet may cause

improper combustion,leading to asphyxation, carbon monoxide poisoning and therefore serious

injury or death to humans and livestock.

Position heater properly before use.

For either indoor or outdoor use adequate ventilation must be provided.

Minimum clearance from combustible materials and propane containers: 10 ft.

Do not operate heater with panels removed.

Not for use

To avoid injury from moving parts, disconnect all electrical power to equipment before opening

doors or removing panels.

with ductwork.

tock.

WARNING :

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING :

RETAIN THIS INSTRUCTION FOR FUTURE REFERENCE. .

Operating Instructions and Owner’s ManualENERCO GROUP, INC. |Indirect Fired Portable Heater

3

Page 4

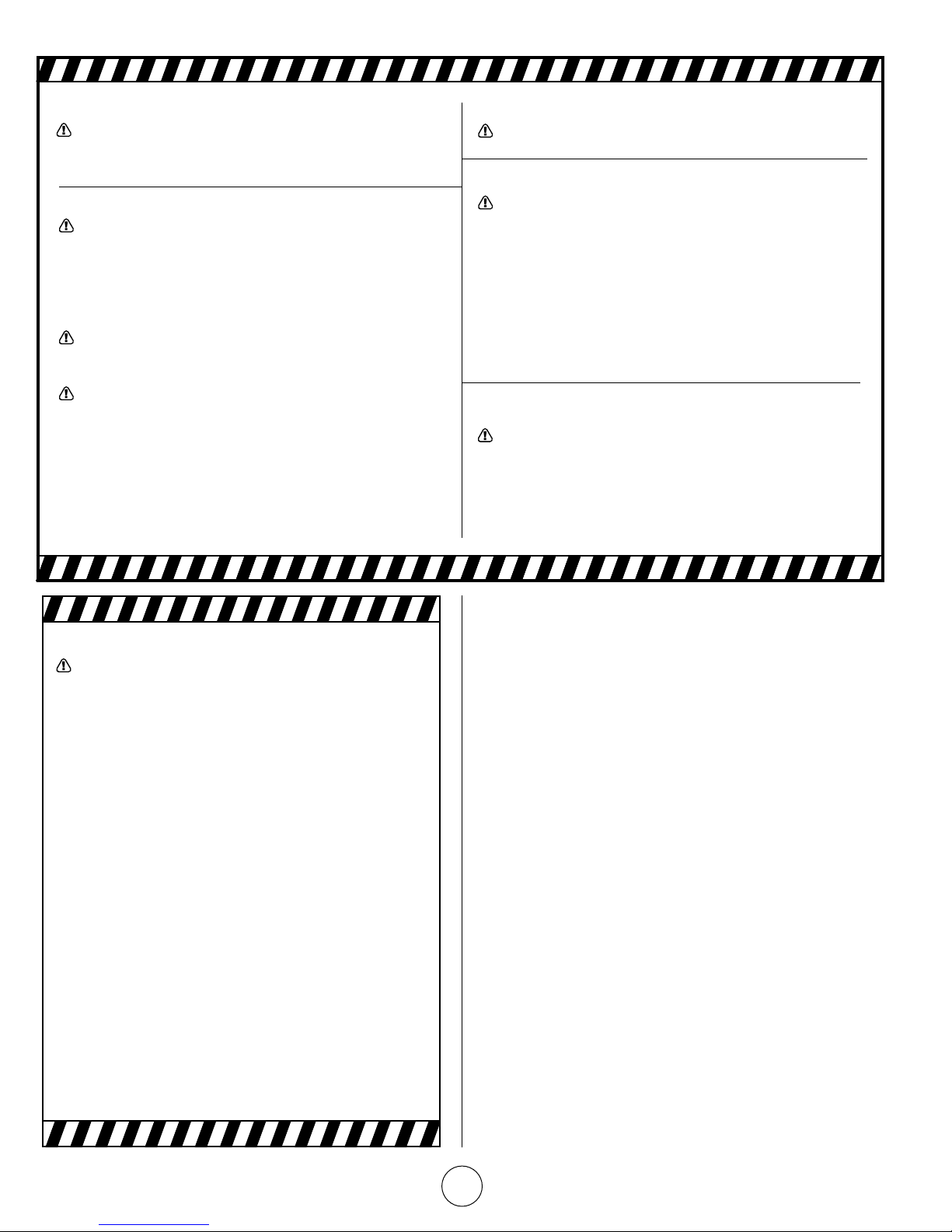

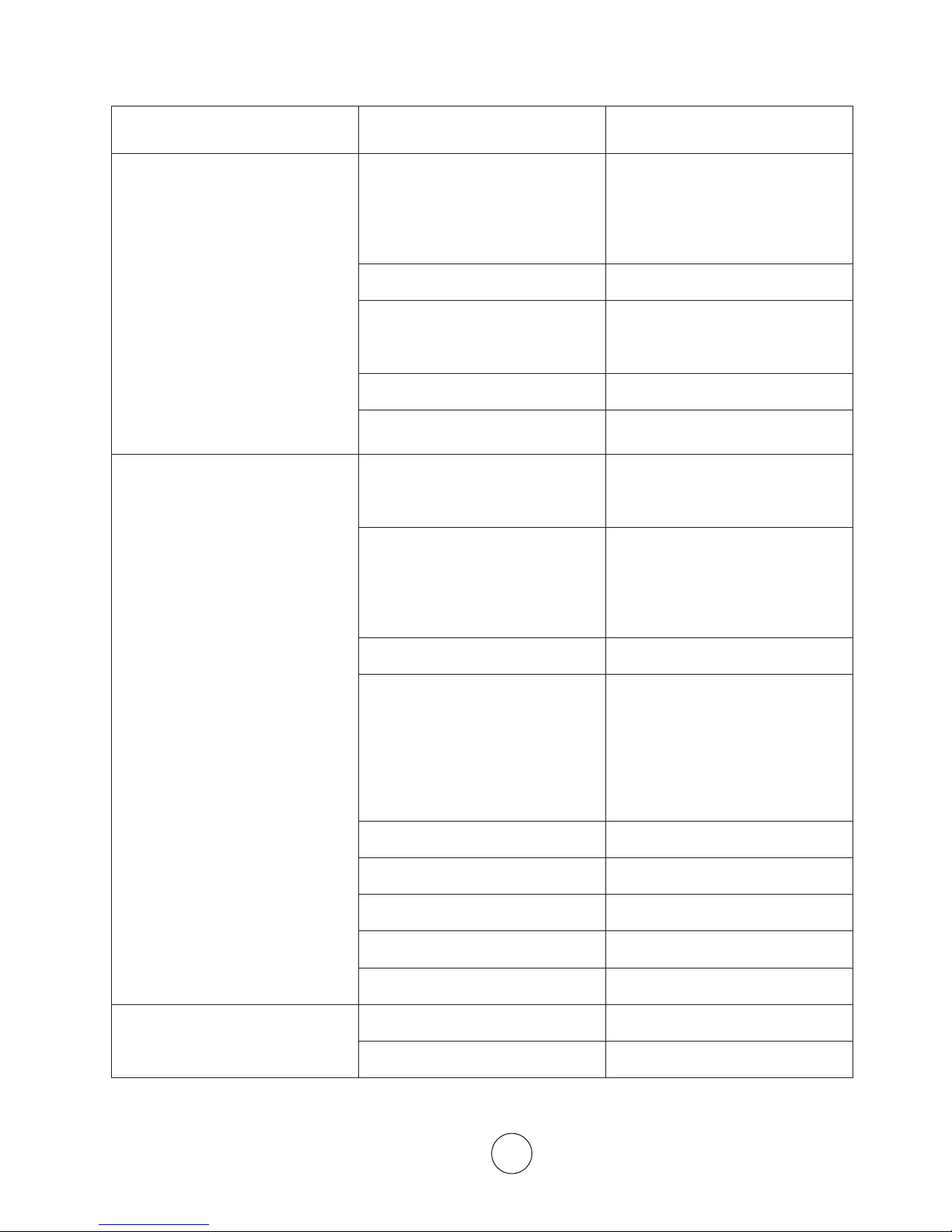

TECHNICAL SPECIFICATIONS GE/N 250C GE/N 400C

Normal

Canada)

Normal

Canada)

Natural gas

L.P.G.

altitude 0 -

2,000 ft above

sea level

(U.S.A. and

Altitude 2,000

- 4,500 ft

above sea

level (Canada

only)

altitude 0 -

2,000 ft above

sea level

(U.S.A. and

Supply pressure [in WC]

Selector valve position

Heat input [BTU/h] 254.684 403.753

Manifold pressure [in WC] 4,33 4,40

Fuel consumption [CFH] 241,52 381,35

Heat input [BTU/h] 229.216 363.378

Manifold pressure [in WC] 4,11 4,18

Fuel consumption [CFH] 217,37 343,21

Supply pressure [in WC]

Selector valve position

Heat input [BTU/h] 241.413 394.134

Manifold pressure [in WC] 4,28 4,50

Fuel consumption [CFH] 88,98 145,12

min 7" w.c.

max 10" w.c.

min 8" w.c.

max 13" w.c.

min 7" w.c.

max 10" w.c.

min 8" w.c.

max 13" w.c.

Altitude 2,000

- 4,500 ft

above sea

level (Canada

only)

Air flow [cfm] 2.766 4.120

Power supply

Electric consumption

Ring nozzle [in] N. 16 holes x 0,079" N. 16 holes x 0,102"

Gas inlet connection thread 3/4" NPT 3/4" NPT

Air distribution

duct

Noise level at 1 m [dBA] 77 74

Heater

Max Static pressure [in] 0,60 0,56

Max length [ft] 50 50

Heat input [BTU/h] 217.272 354.721

Manifold pressure [in WC] 4,06 4,27

Fuel consumption [CFH] 80,08 130,61

Phase 1 1

Voltage [V] 120 120

Frequency [Hz] 60 60

[W] 500 900

[A] 5,0 8,5

Dimensions, L x W x H [in] 40,6 x 24,6 x 21,7 56,,1 x 29,5 x 25,7

Weight [lb] 101 192

Packaging

Dimensions, L x W x H [in] 42,3 x 21,9 x 29,45 57,7 x 24,4 x 32,6

Weight [lb] 134 225

Operating Instructions and Owner’s ManualENERCO GROUP, INC. |Indirect Fired Portable Heater

4

Page 5

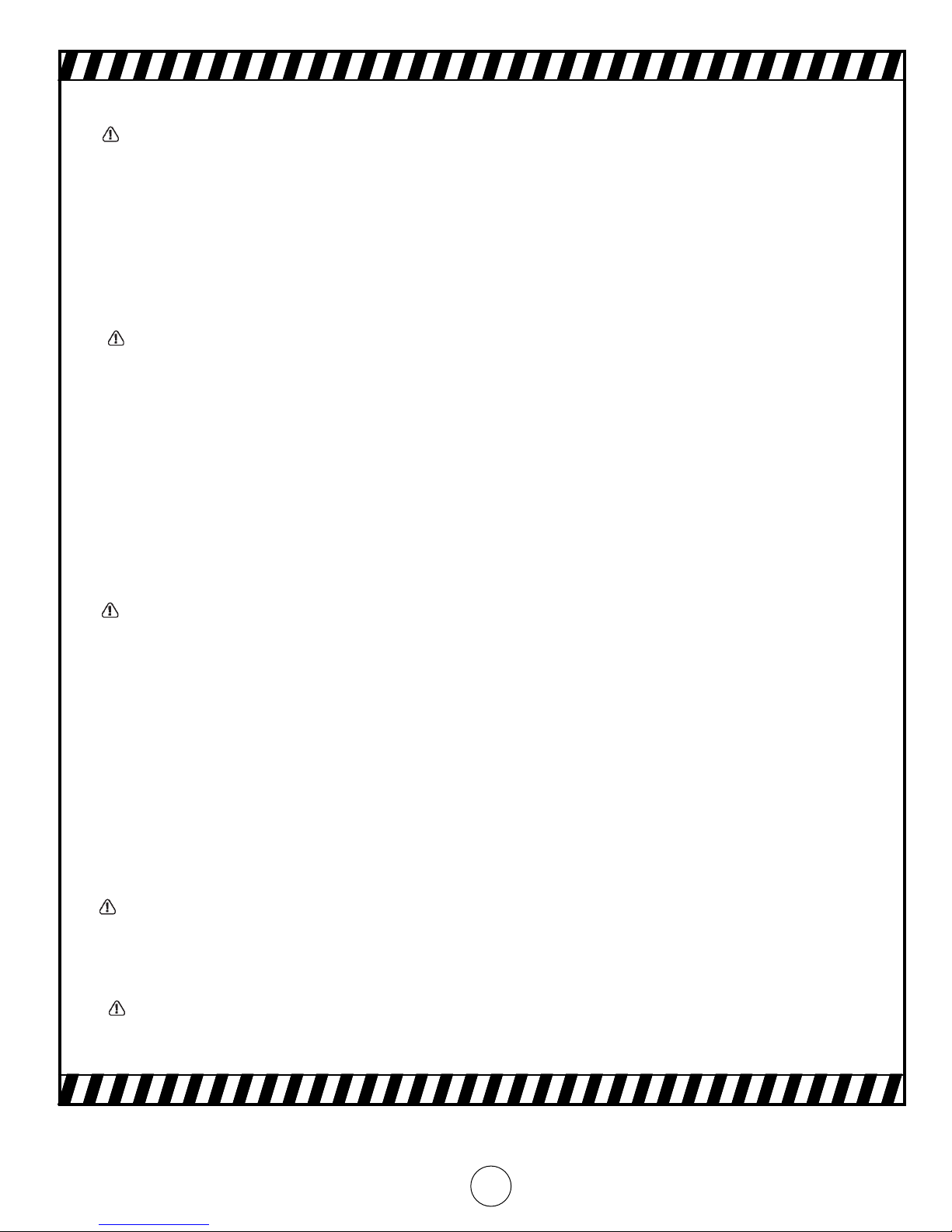

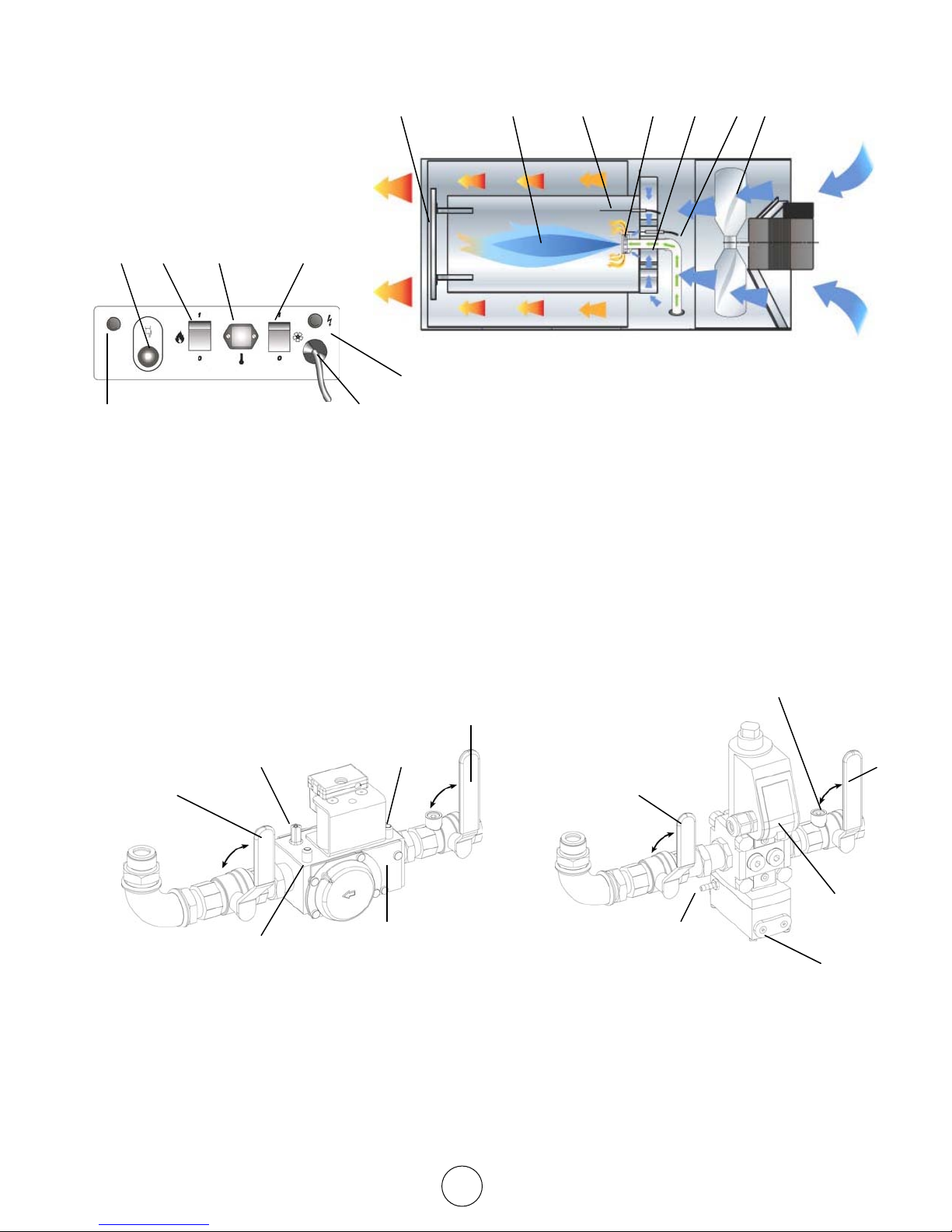

CONTROL PANEL - TABLEAU DE COMMANDE

89101312

11

14

abcdefabcde

f

4 1 6 3 2 7 5

Fig. 1

1 COMBUSTION CHAMBER

2 BURNER

3 DIFFUSION RING

4 FLAME GUARD SHIELD

5 COOLING FAN

6 IONIZATION ELECTRODE

7 IGNITION ELECTRODE

MANIFOLD ASSEMBLY

8 CONTROL FLAME ELECTRONIC RESET

9 HEATING SWITCH

10 ROOM THERMOSTAT PLUG

11 POWER CONTROL LAMP

12 POWER CORD

13 VENTILATION MODE SWITCH

14 PHASE / NEUTRAL LINE TEST PUSH BUTTON

GE/N 250 GE/N 400

a GAS SELECTOR VALVE

b MANIFOLD PRESSURE PORT (MANIFOLD)

c MANIFOLD PRESSURE REGULATOR

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

5

Fig. 2

d MAIN GAS VALVE

e INLET PRES

f SHUT OFF / FIRING VALVE

SURE PORT

Page 6

DESCRIPTION

The hot air generator is designed for heating medium and large

ventilated premises, for which a fixed or mobile heating system is

required.

Heater is to be run on heating with natural gas or L.P.G. according

to gas supply pressures that must be in conformity with the national

laws.

Gases to be used are indicated in Tab. I together with the supply

pressures, the regulation of the gas valves group (burner pressure)

and gas flow.

Hea

ter is supplied after a complete functional test and it’s therefore

prearranged for one of the working gas indicated in Tab. I: an

adhesive label applied on the gas selector valve (a) indicates the

selected gas.

To change the type of gas, follow the detailed instructions

indicated in section “CHANGING TYPE OF GAS”.

The heater is of the direct combustion type. The air is heated by

the energy developed during combustion and then conveyed to the

environment to be heated together with the combustion produ

thus making available 100% of the thermal power produced. The

environment must be suitably ventilated in order to ensure adequate

air circu-lation.

In the event of serious malfunction various safety devices

(electronic flame control unit, overheating thermostat, air pressure

switch) trigger turning off the heater.

The electronic flame control unit monitors if the flame is irregular or

goes out, the safety thermostat triggers when the temperature in the

combustion chambe

switch will cut in if the airflow is insufficient.

In each of the said cases the unit stops according to the procedure

described in “OPERATING INSTRUCTIONS”.

In each of the said cases the lamp (8) will light up and the heater

will stop working. The heater can be restarted only by pressing the

reset button (8). Nonetheless, the cause that triggered the safety

device should always be carefully analyzed and resolved before

restarting the

r exceeds the safety limit value, the air pressure

generator (cfr. “FAULTS, CAUSES AND REMEDIES”).

cts,

GENERAL ADVICES

Installation, setting and use of the heater must be effected in

accordance with the applicable regulations and laws relating to

machine use.

WARNING :

Check with your local fire safety authority if you have

questions about applications

• Make sure heater is inspected before each use, and at least

annually by a qualified service person.

• After use make sure the disconnecting switch is off.

When using any type of heater it is obligatory:

• not to exceed the maximum level of heat output of the furnace

(“TECHNICAL SPECIFICATION TABLE”);

• to make sure that there is adeguate air circulation and air supp

to the heater and that nothing is obstructing the aspiration and

expulsion of air; movement of air may be obstructed in various

ways including placing covers or other objects on the heater or

positioning the heater too near a wall or other large object. If the

airflow is not adequate, the combustion chamber will overheat

and the overheat thermostat will turn the burner off

(“OBSERVED FAULTS, CAUSES AND REMEDIES”).

INSTALLATION INSTRUCTION

WARNING :

All the operations described in this paragraph must

be performed by professional and skilled personnel

only

The installation shall be in accordance with National Fuel Gas

Code ANSI Z223.1/NFPA 54 and with CAN1-B149.1 Installation

code.

An approved manual gas valve shall be provided by the installer.

WARNING :

In case of installation in greenhouses, mechanical

ventilation shall be interlocked to the heater operation

or permanent openings shall be fixed for ventilation

air.

ELECTRICAL CONNECTIONS

WARNING :

The power line of the generator must fea

earthlead and a residual current circuit breaker.

The supply cable must be connected to a switchboard

with sectioning switch.

Every heater is supplied along with the safety and control devices

which are indispensable to the correct functioning of the unit being

already electrically connected.

ture an

ly

Here are a few guidelines which shall be followed:

• The instructions in this manual are carefully followed;

• Minimum clearances from combustible material must be:

1 m (3 feet) from side and rea

0.7 m(2 feet) from ceiling

3 m (10 feet) on air outlet of heater.

• Heater shall not be directed toward any propane-gas container

within 6 m (20 feet) and minimum clearances from gas cylinder

must be 3 m (10 feet)

• Don’t install the heater in places where there may be a risk of fire

or explosion

• All fire prevention regulations must be adhered to.

• For air distribution use only original ductworks type M1 Spiraflex

from distributor and respect max leng

• The room or building which is being heated must be sufficiently

ventilated so that the heater has enough air to function properly;

• The air suction and/or supply pipes are not blocked in any way,

there are not sheets or covers resting on the machine or walls

and bulky objects near the heater;

• The generator is placed near a power switchboard having

specifications in conformity with those declared;

• The unit is placed in a fixed position;

• The generator is regu

checked before being started up;

• Don’t let animals or children near the heater.

r (air inlet) of heater

th as declared in Tab. I

larly monitored during operation and

WARNING :

When installed, the appliance must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Elec

Code, ANSI/NFPA 70, and/or the CSA C22.1, Canadian

Electrical Code, if an external electrical source is

utilized.

The following operations must now be carried out:

• Plug in the power cord having read the rating plate that specify

electric supply characteristics.

• Connect accessories such as the room thermostat or clock to the

unit’s control panel with the thermostat receptacle.

Having completed all these operations check carefully that all

electrical connection

heater is first turned on you must check that the fan does not use

more current than the maximum permitted limit.

GAS LINE CONNECTIONS

The connection to the gas feed pipe, whose sizes must correspond

to the kind of system to be made, must be carried out by placing the

“gas ramp” as indicated in Fig. 3: the gas pipe, the interception tap

and the anti-vibration joint are not supplied with the heater and they

must be arranged by the person

Operating Instructions and Owner’s ManualENERCO GROUP, INC. |Indirect Fired Portable Heater

6

s correspond to the wiring diagram. When the

in charge of installation.

trical

Page 7

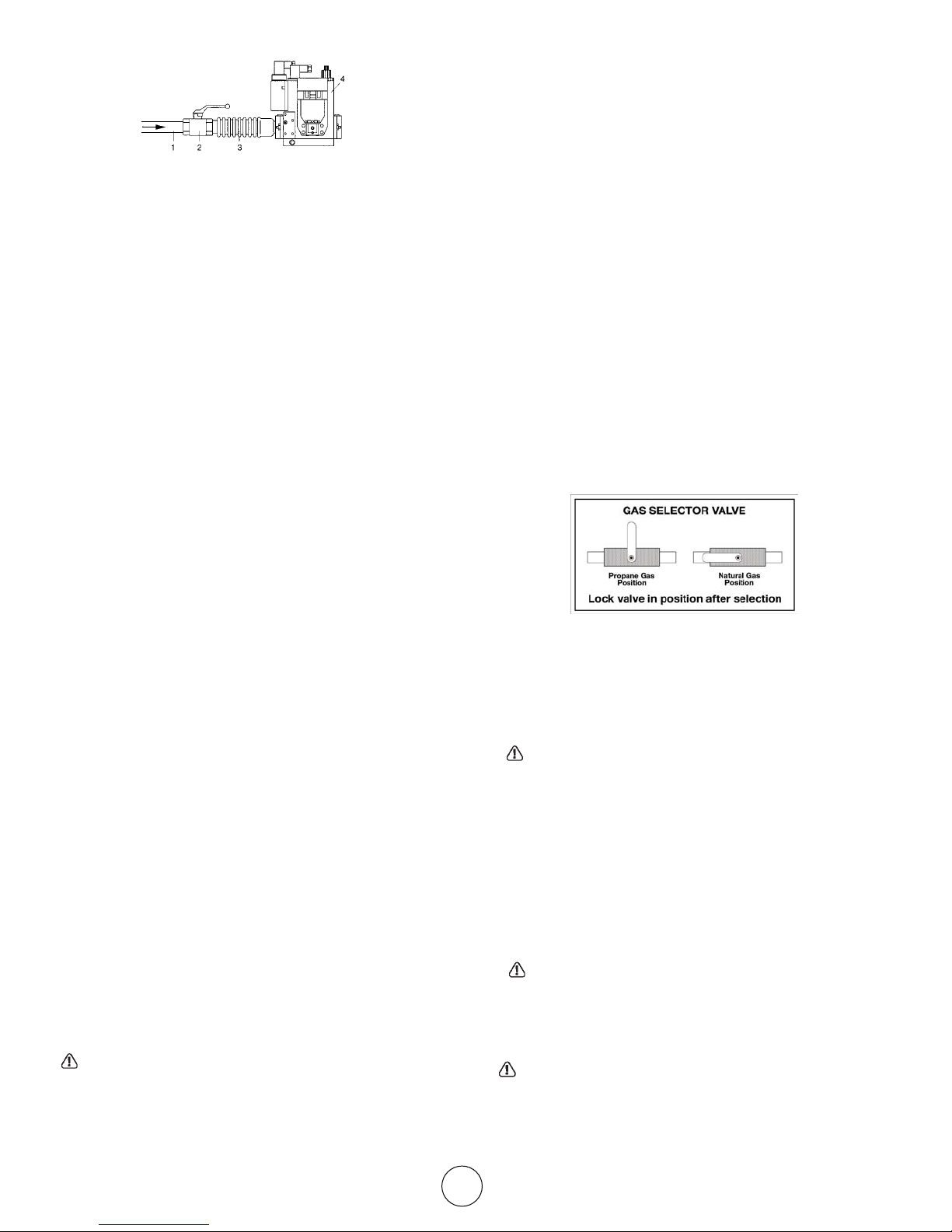

1 Main gas pipe 3 Antivibrating coupling

2 Manual shut-off valve 4 Gas valves group

Fig. 3

In case of connection of heater to natural gas, the installation shall

conform with local codes or, in the absence of local codes, with the

National Fuel Gas Code ANSI Z223.1/NFPA 54 and the Natural Gas

and Propane Installation Code, CSAB149.1.

In case of connection to a propane supply cylinder:

(a) the installation must conform with local codes or, in the

absence of local codes, with the Standard for the

Handling of Liquified Petroleum Gases, ANSI/NFPA 58 and the

Natural Gas and Propane Installation Code, CSA B149.1.

(b) to determine size and capacity of the cylinder(s) and for any

specific requirements consult your LP gas supplier. In any case

propane tank should not be lower than 100 lb (90 liters)

(c) the cylinder supply system shall be arranged to provide for

vapour withdrawal from the operating cylinder;

(d) the gas shall be turned off at the propane supply cylinder when

the heater is no

(e) when the heater is to be stored indoors, the connection

between the propane supply cylinder and the heater must be

disconnected and the cylinders removed from the heater and

stored in accordance with Standard for the Storage and

Handling of Liquified Petroleum Gases, ANSI/NFPA 58 and

CSA B149.1, Natural Gas and Propane Installation Code.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

appliance must be isolated from the gas supply piping system

The

by closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal or

less than 1/2 psi (3.5 kPa).

A minimum 1/8” NPT plugged tapping, accessible for test gauge

connection, must be installed immediately upstream of the gas

supply connection to the appliance.

STARTUP

The heater is supplied after a complete funct

therefore prearranged for one of the gas (natural or L.P.G.) indicated

in Tab. I: an adhesive label applied on the manual gas selector valve

(Fig. 4) indicates the working gas (usually it’s natural gas). Should it

necessary to change the kind of gas (from natural gas to L.P.G or

viceversa) follow the detailed instructions indicated in section

“CHANGING TYPE OF GAS”.

Only when the heater has been prearranged according to the

proper working gas it will be possible to carry ou

operations:

• Leak away some gas from the feed pipe;

• Check that the pipe is gas proof;

• Open the gas stopcock and start the hot air generator;

For installation in the U.S.A. at elevation above 2,000 feet (610 m),

the appliance shall be derated 4 per cent for each 1,000 feet (305 m)

of elevation above sea level.

For installation in Canada at elevation above 2,000 feet to 4,500

feet above sea level, the heater is deratedy reducing the input for the

appropriate fuel in accordance with the rating plate man

pressure.

t in use;

Storage and

ional test and it’s

t the following

ifold

WARNING :

THE CONVERSION SHALL BE CARRIED OUT BY A

MANUFACTURER’S AUTHORIZED REPRESENTATIVE,

IN ACCORDANCE WITH THE REQUIREMENTS OF THE

MANUGFACTURER, PROVINCIAL OR TERRITORIAL

AUTHORITIES HAVING JURISDICTION AND IN

ACCORDANCE WITH THE REQUIREMENTS OF THE

CAN/CGA-B149.1 OR CAN/CGAB149.2 INSTALLATION

CODES.

A conversion label shall be applied adiacent to the Rating Label:

THIS APPLIANCE HAS BEEN CONVERTED FOR USE

AT AN ALTITUDE OF _______

Orifice size: ______________________________________

Manifold pressure: ______________________________________

Input rate: ______________________________________

Date of conversion: ______________________________________

Type of fuel: ______________________________________

Converted by: ______________________________________

For installation in Canada at elevation above 4,500 feet above sea

level, consult Provincial or Territorial Authorities having jurisdiction.

CHANGING TYPE OF GAS

This operation may be carried out several times during the working

life of the

check the adhesive label attached to the manual gas selector valve

(a) in Fig. (2) to establish the original category of the gas and then

consult Tab. I to identify the supply pressure, the working pressure,

the use conditions of manual valve.

machine and not only at initial start-up. Therefore, first of all

To change kind of gas it is necessary (Fig. 2):

• to remove the sticker on the manual gas selector valve stating

the gas used at that time,

• to remove the screw under the sticker and

handle on the correct side according to the condition described in

Tab.I and by following instruction:

• After having moved the handle into the opposite position, put

again the fixing screw and a new sticker on it, stating the gas

which has to be used (a number of different stickers are supplied

with the machine)

____ FEET (ABOVE 2000 FEET)

turn the manual

Fig. 4

WARNING :

Burner pressure shall not be adjusted: the heater is

ready to run on the new gas

Should it necessary to check the burner pressure:

• connect a manometer to the pressure port (b) ,

• carry out the pressure reading on the manometer and turn the

pressure regulator (c) if necessary to ob

pressure value indicated in Tab. I

tain the correct burner

OPERATING INSTRUCTIONS

WARNING :

Any time the power cord of the heaters is connected to

a receptacle check the polarity of power supply:

• check switch (9) and (13) are on “0”

• connect plug to receptacle

• push button (14): if it lights up, then reverse polatiry

WARNING :

If the correspondance of phase / neutral polarity is not

correct, the unit may stop in the reset mode.

HEATING MODE

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

7

Page 8

Turning ON

• Make sure switch (9) is on “0”;

• Power the heater by means of the sectioning switch on the

switchboard;

• If the unit is operated manually (without any thermostat or any

other control device) turn the switch (9) to position “1”. The

burner starts up, the combustion chamber heats up and then the

fan starts;

• If the unit operates automatically (being connected to any

thermostat or any other control device) turn the switch (9) to

position “1” and set the room thermostat at the

heater will now start and stop automatically.

• If after these operations, the generator does not work, refer to the

“FAULTS, CAUSES AND REMEDIES” paragraph and find the

cause.

Setting Post Ventilation Mode

By the switch (13) on control panel, select the post-ventilation

mode, that is the time the fan goes on blowing air when unit is

switched off:

• when switch (134) is on pos. “0” then postventilation lasts for 30

sec.

• when switch (13) is on pos. “1” then

Turning OFF

In manual operation turn switch (9) to “0” or turn thermostat control

knob off.

After switching off the machine, a post ventilation function works

according to the previous setting.

postventilation is continuous.

desired level: the

WARNING :

Finally, close the gas supply stopcock, close the shutoff valve (f) and turn off the sectioning switch (Fig. 1-

2).

TRANSPORT AND HANDLING

WARNING :

Before moving the unit:

• Stop the machine as indicated in the “STOP”

paragraph;

• Disengage the power supply by removing the plug

from the power socket;

• Fully unscrew the fitting connecting the gas hose

pipe to the heater;

• Wait for the heater to cool down.

The hot air generators with wheels must be wheeled.

MAINTENANCE

To regulate operation of the unit, the fans, combustion chamber

and the burner must be at least annually inspected and periodically

cleaned by a qualified service pe

rson.

WARNING :

Before performing any maintenance operation:

• Stop the machine as indicated in the “STOP”

paragraph;

• Disengage the power supply by removing the plug

from the power socket;

• Close the gas supply stopcock and shut-off valve (f);

• Wait for the heater to cool down.

During cleaning any foreign bodies must be removed from the fan

suction grille.

To access the burner, remove the flame guard panel (4) by

removing the four screws and clean carefully inside

chamber and the whole burner head: any debris shall be taken away.

the combustion

VENTILATION MODE

To obtain the ventilation function only, make sure switch (9) is on

position “0” and then simply turn the switch (14

stop it, turn the switch “4” to position “O”.

) to position “1”. To

WARNING :

Whichever be the reason, the unit try to restart once.

If the cause of malfunction remain, the unit definitevely

stop and lamp (8) will light up

The heater can be restarted only by pressing the reset button (8).

Nonetheless, the cause that triggered the safety device should

always be carefully analyzed and resolved before restarting the

generator (cfr.“FAULTS, CAUSES AND REMEDIES”).

WARNING :

Do not direct jets of compressed air towards the air

pressure points near the main fan: the air pressure

switch could be permanently damaged.

Cleaning of the burner shall be regularly performed by qualified

service person. To access the burner, remove the flame guard panel

of combustuion chamber (front side) and clean carefully inside the

combustion chamber and the whole burner head and electrode

WARNING

Operating the heater without the flame guard panel of combustuion

chamber (4) can cause the flame to work with risk to the health of

exposed persons (because of formation of carbon monoxide, CO)

and constituting a danger for the environment.

:

After cleaning, the flame guard panel of combustion

chamber (4) must be put back in place and secured

with the relative screws before operate the heater.

s.

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

8

Page 9

TROUBLESHOOTING GUIDE

heater

FAULTS CAUSES REMEDIES

• Check power specifications

• The generator fails to start

• The generator stops and the indicator

light (1) comes on

• No power supply

• Main switch in wrong position • Select correct position

• Faulty operation of room thermostat

• Safety device (control unit, safety

thermostat, etc.) not reset after a repair

• The duct gives too much back pressure

and airpressure switch PA1 blocks the

• Gas pressure switch trips due to

interruption of gas flow (gas pressure

switch electric contact does not close

during operation)

• Micro-switch PAM intervention for fan

malfuction

• The flame sensor is not operating

correctly

• The safety thermostat trips due to

overheating of the combustion chamber

(the thermostat electrical contact does not

close during operation)

• Control unit trips due to irregular

operation of burner

• Faulty gas pressure switch

• Faulty micro-switch PAM

• Check power connections

• Check fuse integrity

• Check thermostat position

• Check thermostat operation

• Press button (1) on the control panel

• Reduce back pressure by straightening

the duct or by reducing duct length

• Make sure the gas supply hose has been

bled

• Check gas supply pressure

• Make sure the suction and feed grilles

are not blocked

• Make sure the fan is turning properly

• Check the electric motor and capacitor

and, if these are faulty, replace

• Remove the flame sensor and clean

• Makes sure the suction and feed grilles

are not blocked

• Make sure the environment is well

ventilated

• Make sure the warm air can exit freely

• Make sure the flow and pressure of the

gas are not too high

• Contact After-Sales Service

• Check the pressure switch and, if

necessary, replace

• Check the micro-switch and, if

necessary, replace

• Fan noise or vibrations

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

• Faulty electronic control unit • Check the unit and, if necessary, replace

• Faulty thermostat

• Foreign bodies on fan blades • Remove foreign bodies

• Little air circulation • Eliminate and obstacles to proper air flow

• Check the thermostat and, if necessary,

replace

9

Page 10

WIRING DIAGRAM

AP CONTROL BOX

FU FUSE

EL IONIZATION ELECTRODE

FUA FUSE

LI POVERHEAT THEMOSTAT

PA PRESSURE SWITCH 20 Pa

TA ROOM THERMOSTAT PLUG

IT TRANSFORMER H.T.

CO CAPACITOR

RV HEATING SWITCH

RE MOTOR RELAY

ST CONTROL LAMP

EV GAS TRAIN

MV COOLING MOTOR

RV1 VENTILATION MODE SWITCH

RE1 POST-VENTILATION RELAY

Operating Instructions and Owner’s ManualENERCO GROUP, INC. |Indirect Fired Portable Heater

10

Page 11

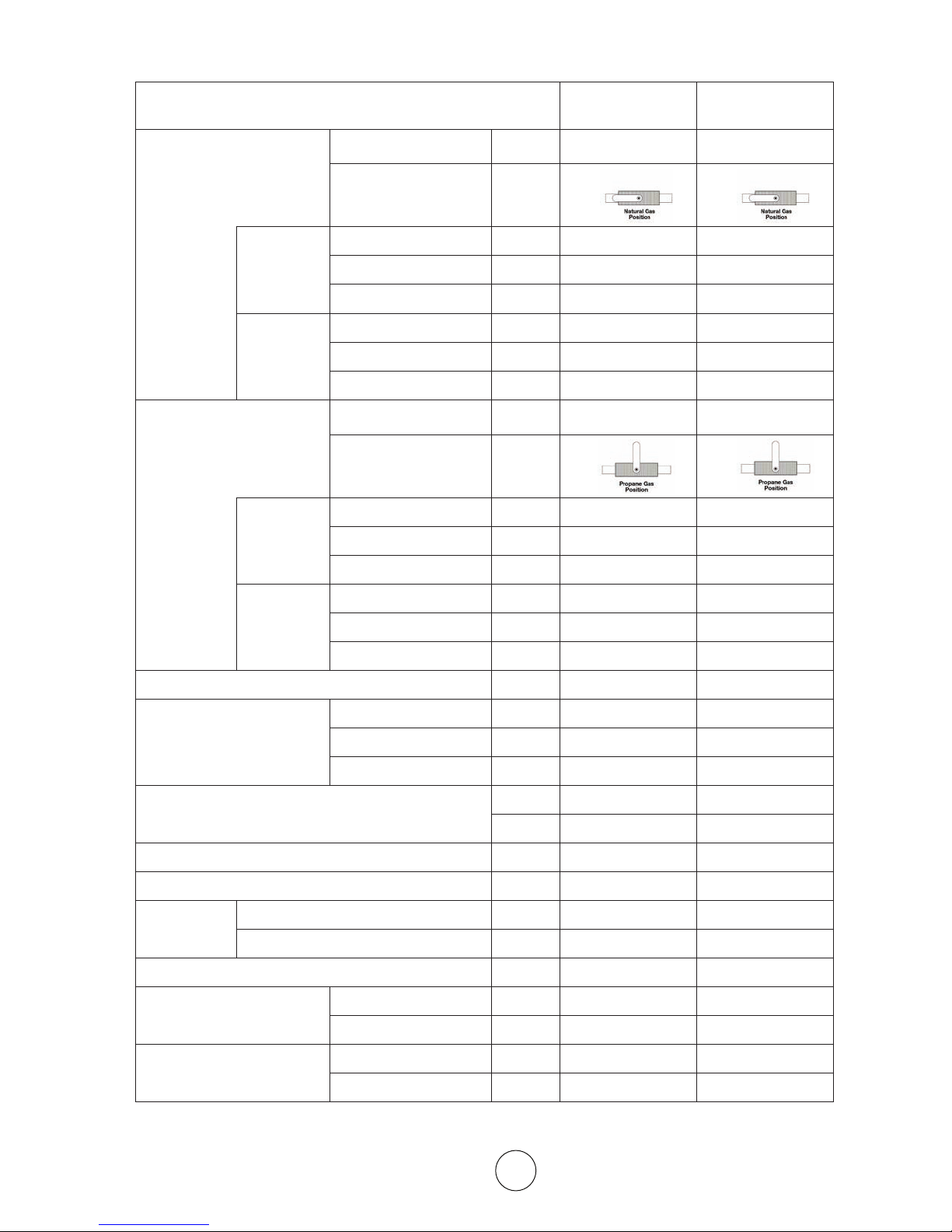

20

A

21

78

77

HS4000NG/LP

31

26

34

33

B

23

32

24

08

25

26

26

27

35

18

19

17

16

13

12

11

10

15

A

22

14

C

B

36

76

75

74

73

72

PL 10/07

07

01

04

02

03

05

06

09

48

05

49

47

46

38

39

40

37

45

43

44

50

41

42

55

50

54

56

57

53

52

66

51

60

C

58

70

65

71

42

62

64

63

62

61

59

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

11

Page 12

88

HS4000NG/LP

80

90

89

87

86

81

PL 10/07

82

81

79

83

84

85

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

12

Page 13

Terminal board

47 50260 E50750 Safety thermostat plastic profile

48 50370 G03159-9010 Base

49 50077 P50127 Control box cover

Electrical components drawer complete

52 50093 E20508 Fuse holder

54 50373 E11153 Relay finder 65.31.8.110AC

Transformer H.T. BRAHMA

Control box BRAHMA TGRD 81 120V

62 50337 E10110-1-P Switch 0-1

Electrical wire w/plug and cable fastener

Diffusion ring G20/G25-16 holes ø2.6

M20505 Wheel locking pin

8 G03173-9005 Rignt frame

50387 G03172-9005 Support

50389 G03174-9005 Left frame

5038

50390 G03175-9005 Handle

73 50378 GA.0010208 Burner plate

50383 G03169-9005 Lifting frame

50382 G03168-9005 Lifting frame

78 50417 G02078 H.T. cable connect 90°

80

50384 G03170-9005 Body support

50385 G03171-9005 Wheel axle ø25

40533 M20111 Washer ø26 x ø44 x 4mm

50386 C10556 Wheel ø 260-ø 26mm

40534

"FF

HS4000DF NG/LP HD Heater Parts List BM2

Lower body

Upper body

Screw TE M6x10

Flame guard shield

Combustion chamber

50346 M10203/1/B

50347 G03114

01 50345 G06139-9005 Outlet cone 46 50470 C30376 Cable protection ø36mm

02

NO. HS# BM2 # DESCRIPTION NO. HS# BM2 # DESCRIPTION

03

50515 M20413 Clip holder sensing bulb 51 50372 P50132 Electrical components drawer

50348 G03147

50349 E50745 Safety thermostat TY95H 50 50371 G00286

06

04

05

50351 G03150-9010

50352 G03152-9010 Cover inspection 53 50092 E10313 Fuse (6x30) 20A

50353 G03154-9010

50411 C30372 Protection cable ø35 55 50374 E20319

50354 G03126 Combustion chamber deflectors 56 50375 E20305 Terminal board

50356 E10245 Electrode ionisation probe 57 50329 E10931

07

08

09

10

11

12

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

50507 I39106 Anti vibration joint 59 50097 E11125 Relay finder 65.31AC

50545 I40332 Silicone pipe ø5x9 58 50330 E40229

14

13

Drain plug

50500 I20326 Connection 3/4"FF 60 50376 G06073 Plate for electrical components

50463 G06239-9010 Motor flange 61 50325 E20418 Stop button protection1750469 C30374

15

16

50454 E10704-110 Motor 450 W w/ capacitor 80µF 63 50570 E20640 Thermostat plug 3P+T

18

50455 E11249 Capacitor 80µF 64 50011 E20665 Drain plug

50166 T10261 Fan ø500 23° 65 50009 E30443

19

20

50050 P30129 Inlet grill 66 50008 E11030 Lamp 120VAC

50357 G06330-9005 Valve support plate 70 50081 I20325 Connection 1/8"

50506 I39102 Seal 3/4" 71 50079 I31130 Connection straight ø6 1/8"

21

22

23

13

50505 I31205-1 Connection 3/4"MM 72 50511 M10323/1 Screw TCEI M4x20

24

Connection 3/4

50504 I31204 Connection 3/4"MM 74 50379 GA.0100204

50500 I20326

26

25

50358 T30330-2 Gas selector valve 75 50380 E20679 Terminal board

27

50359 T30333 Manual gas test firing valve 76 50381 G03129 Burner support

31

50360 E20943 Cable fastener PG9 77 50134 E10215 Ignition electrode

32

Nut for PG9

Valve support

50361 E20932

50362 G06332-9005

50334 T30111 Valve solenoid main 79

33

35

34

50516 M20907 Valve support 81

36

50363 G03157-9010 Support for pressure plate 82

37

50364 E50443 Pressure switch 330Pa 83

38

50365 I30414 Oil filter 84

39

50337 E50441 Pressure switch 200Pa 85

40

50366 I40336 Silicone pipe ø4x1.5 86

41

40501 I40501 Silicone pipe ø4x8 87

42

50367 I20669 Connector straight T ø4 88

43

50368 E20952 Cable fasterner PG11 89

44

50369 E20955 Nut for PG11 90 40505 C10203 Handle

45

Page 14

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

READ INSTRUCTI ONS CAREFULLY: Read

and follow all instructions. Place instructions in

MODEL

a safe place for future reference. Do not allow

anyone who has not read these instructions to

assemble, light, adjust or operate the heater.

HEATSTAR

BY ENERCO

MODEL

4000IDG

HS

WARNING :

USE ONLY MANUFACTUR ER’S REPLACEMENT PARTS. US E OF ANY OTHER PARTS

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS AR E ONLY AVAI LABLE

DIRECT FROM TH E FACTORY AND MUST B E INSTALLED BY A QUA LIFIED SERVICE

AGENCY.

PARTS O RDERING IN FORMATI ON:

PURCHASING : Accessories may be purchased at any Mr. Heater/HeatStar local dealer

or direct from the factory

FOR IN FORMATI ON REGARDING SERVICE

Please call Toll-Free 800-251-0001 • www.enerco-mrheater.com

Our ofce hours are 8:30 AM – 5:00 PM, EST, Monday through Friday.

Email to: techservice@enerco-mrheater.com

Please include the model number, date of purchase, and description of problem in all

communication.

LIMITED WARRANT Y

The company warrants this product to be free from imperfections in material or workmanship,

under normal and proper use in accordance with instructions of The Company, for a period

of one year from the date of delivery to the buyer. The Company, at its option, will repair or

replace products returned by the buyer to the factory, transportation prepaid within said one

year period and found by the Company to have imperfections in material or workmanship.

If a part is damaged or missing, call our Technical Support Department at 800-251-0001.

Address any Warranty Claims to the Service Department, Enerco Group, Inc., 4560 W. 160TH

ST., Cleveland, Ohio 44135. Include your name, address and telephone number and include

details concerning the claim. Also, supply us with the purchase date and the name and address

of the dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no other

warranties, express or implied. Specically there is no warranty of tness for a particular

purpose and there is no warranty of merchantability. In no event shall the Company be liable for

delay caused by imperfections, for consequential damages, or for any charges of the expense

of any nature incurred without its written consent. The cost of repair or replacement shall be

the exclusive remedy for any breach of warranty. There is no warranty against infringement of

the like and no implied warranty arising from course of dealing or usage of trade. This warranty

will not apply to any product which has been repaired or altered outside of the factory in any

respect which in our judgment aects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This Warranty gives you specic legal

rights, and you may have other rights which

Enerco Group, Inc. reserves the right to make changes at any time, without notice or obligation,

in colors, specications, accessories, materials and models.

vary from state to state.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 800-251-0001

Mr. Heater is a registered trademark of Enerco Group, Inc.

© 2004, ENERCO GROUP, INC. All rights reserved

ANSI Z83,7 CGA 2.14.

ENERCO GROUP, INC. |Indirect Fired Portable Heater Operating Instructions and Owner’s Manual

14

Page 15

08/08 #50120ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 800-251-0001

© 2003, Enerco Group Inc. Tous droits réservés.

Mr. Heater et HeatStar sont des marques de commerce déposées de Enerco Group, Inc.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 É.-U. • 800-251-0001

Enerco Group Inc. se réserve le droit d’eectuer des modications en tout temps, sans préavis ni

avoir d’autres droits qui varient selon la province ou l’État.

peut-être pas. La présente garantie vous accorde des droits juridiques précis, mais vous pourriez

subséquents. Par conséquent, les limitations ou exclusions ci-dessus mentionnées ne vous concernent

Certains États ou provinces ne permettent pas d’exclure ou de limiter les dommages indirects ou

façon que ce soit sur l’état de l’appareil ou son fonctionnement, selon notre jugement.

La présente garantie ne s’applique à

ci-dessus constitue la responsabilité totale de l’entreprise. Il n’existe aucune autre

aucun produit qui a été réparé ou modié par d’autres que le fabricant si cela inue de quelque

usages du commerce ou de la façon habituelle d’échanger.

a aucune garantie contre une transgression de ce genre ni aucune garantie tacite découlant des

réparation ou du remplacement sera le seul recours possible en cas de violation de garantie. Il n’y

ni des dépenses encourues sans son consentement écrit, quelle que soit leur nature. Le coût de la

ne sera tenue responsable des retards causés par des défectuosités, ni des dommages indirects,

utilisation particulière ni aucune garantie concernant la qualité marchande. En aucun cas l’entreprise

garantie, expresse ou tacite. Plus précisément, il n’y a aucune garantie concernant l’adéquation à une

Ce qui est énoncé

du détaillant de qui vous avez acheté le produit.

ainsi que les détails de la réclamation. Indiquez-nous également la date d’achat et le nom et l’adresse

W. 160TH ST., Cleveland, Ohio 44135 États-Unis. Indiquez vos nom, adresse et numéro de téléphone

Adressez toute réclamation relative à la garantie à Service Department, Enerco Group, Inc., 4560

au 800-251-0001.

Si une pièce est endommagée ou manquante, téléphonez à notre service de soutien technique

d’œuvre.

période d’un an et jugés par l’entreprise comme présentant des défauts de matériel ou de mainremplacera, à sa discrétion, les produits retournés port payé par l’acheteur au fabricant dans la

e période d’un an à compter de la date de livraison à l’acheteur. L’entreprise réparera ou

pour un

conditions d’utilisation normale et adéquate, conformément aux instructions de l’entreprise,

L’entreprise garantit ce produit contre tout défaut de matériel ou de main-d’œuvre, dans des

GARANTIE LIMITÉE

dans toutes vos communications avec nous.

Veuillez indiquer le numéro du modèle, la date d’achat et la description du problème

Adressez vos courriels à : techservice@mrheater.com

Nos heures d’ouverture sont de 8 h 30 à 17 h HNE, du lundi au vendredi.

Appelez sans frais au 800-251-0001 • www.enerco-mrheater.com

POUR OBTENIR DES INFORMATIONS SUR LE SERVICE

locaux Mr. Heater/HeatStar ou directement du fabricant

ACHAT : On peut se procurer les accessoires par l’entremise de tous les détaillants

INFORMATIONS SUR LA COMMANDE DE PIÈCES :

HS4000DG

BY ENERCO

MODÈLE

HEATSTAR

DÉTAILLANTS LOCAUX MR. H EATER/HEATSTAR.

DE SE PROCURER CES PIÈCES DIRECTEMENT DE L’USINE OU PAR L’ ENTREMISE DES

N’UTILISEZ QUE LES PIÈCES DE REMPLACEMENT DU FABRICANT. IL EST POSSIBLE

AVERTISSEMENT:

faire fonctionner cet appareil de chauage.

instructions d’assembler, d’allumer, de régler ou de

Interdisez à quiconque n’ayant pas lu les présentes

les instructions pour vous y référer ultérieurement.

Lisez et observez toutes les instructions. Conservez

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS :

LE

GUIDE D’UTILISATION ET INSTRUCTIONS DE FONCTIONNEMENT

Page 16

13

Le fait de Faire marcher des Instructions et le Manuel de Propriétaire

44

45

50368 E20952 Cable fasterner PG11 89

50369 E20955 Nut for PG11 90 40505 C10203 Handle

50367 I20669 Connector straight T ø4 88

43

42

40501 I40501 Silicone pipe ø4x8 87

41

50366 I40336 Silicone pipe ø4x1.5 86

40

50337 E50441 Pressure switch 200Pa 85

39

50365 I30414 Oil filter 84

38

50364 E50443 Pressure switch 330Pa 83

37

50363 G03157-9010 Support for pressure plate 82

36

50516 M20907 Valve support 81

33

35

34

32

50361 E20932

50362 G06332-9005

50334 T30111 Valve solenoid main 79

50360 E20943 Cable fastener PG9 77 50134 E10215 Ignition electrode

Valve support

Nut for PG9

31

50359 T30333 Manual gas test firing valve 76 50381 G03129 Burner support

27

50358 T30330-2 Gas selector valve 75 50380 E20679 Terminal board

26

50504 I31204 Connection 3/4"MM 74 50379 GA.0100204

25

50500 I20326

Connection 3/4"FF

24

50505 I31205-1 Connection 3/4"MM 72 50511 M10323/1 Screw TCEI M4x20

23

50506 I39102 Seal 3/4" 71 50079 I

22

21

50357 G06330-9005 Valve support plate 70 50081 I20325 Connection 1/8"

50050 P30129 Inlet grill 66 50008 E11030 Lamp 120VAC

20

19

50166 T10261 Fan ø500 23° 65 50009 E30443

50455 E11249 Capacitor 80µF 64 50011 E20665 Drain plug

18

50454 E10704-110 Motor 450 W w/ capacitor 80µF 63 50570 E20640 Thermostat plug 3P+T

17

16

50469 C30374

50463 G06239-9010 Motor flange 61 50325 E20418 Stop button protection

Drain plug

12

13

15

14

50356

50545 I40332 Silicone pipe ø5x9 58 50330 E40229

50500 I20326 Connection 3/4"FF 60 50376 G06073 Plate for electrical components

50507 I39106 Anti vibration joint 59 50097 E11125 Relay finder 65.31AC

E10245 Electrode ionisation probe 57 50329 E10931

11

50354 G03126 Combustion chamber deflectors 56 50375 E20305 Terminal board

10

50411 C30372 Protection cable ø35 55 50374 E20319

09

08

07

06

50353 G03154-9010

50352 G03152-9010 Cover inspection 53 50092 E10313 Fuse (6x30) 20A

50351 G03150-9010

50515 M20413 Clip holder sensing bulb 51 50372 P50132 Electrical components drawer

Lower body

Upper body

05

04

50349 E50745 Safety thermostat TY95H 50 50371 G00286

50348 G03147

Combustion chamber

03

50347 G03114

Flame guard shield

02

01 50345 G06139-9005 Outlet cone 46 50470 C30376 Cable protection ø36mm

50346 M10203/1/B

Screw TE M6x10

NO. HS# BM2 # DESCRIPTION NO. HS# BM2 # DESCRIPTION

HS4000DF NG/LP HD Heater Parts List BM2

50390 G03175-9005 Handle

50389 G03174-9005 Left frame

50388 G03173-9005 Rignt frame

40534

50387 G03172-9005 Support

M20505 Wheel locking pin

40533 M20111 Washer ø26 x

50385 G03171-9005 Wheel axle ø25

50386 C10556 Wheel ø 260-ø 26mm

ø44 x 4mm

78 50417 G02078 H.T. cable connect 90°

80

50384 G03170-9005 Body support

50383 G03169-9005 Lifting frame

50382 G03168-9005 Lifting frame

73 50378 GA.0010208 Burner plate

62 50337 E10110-1-P Switch 0-1

54 50373 E11153 Relay finder 65.31.8.110AC

52 50093 E20508 Fuse holder

49 50077 P50127 Control box cover

48 50370 G03159-9010 Base

47 50260 E50750 Safety thermostat plastic profile

31130 Connection straight ø6 1/8"

Diffusion ring G20/G25-16 holes ø2.6

Electrical wire w/plug and cable fastener

Control box BRAHMA TGRD 81 120V

Electrical components drawer complete

Transformer H.T. BRAHMA

Terminal board

Page 17

85

12

PL 10/07

84

83

79

81

86

82

80

81

87

89

88

90

HS4000NG/LP

Page 18

11

61

62

64

63

42

59

62

71

65

70

58

C

60

51

66

52

53

57

56

54

55

50

42

41

50

44

43

45

37

40

39

38

46

47

49

05

48

09

06

05

PL 10/07

01

02

03

04

07

74

73

76

72

75

36

22

B

C

14

10

08

B

12

16

11

35

31

26

27

26

26

25

32

33

24

23

34

HS4000NG/LP

17

15

A

13

19

18

77

78

A

20

21

Page 19

10

Le fait de Faire marcher des Instructions et le Manuel de PropriétaireENERCO GROUP, INC. |Chauage portatif indirect-tiré

R RÉSISTANCE ANTI-HUMIDITÉ (opt)

RE1 RELAIS POST-VENTILATION

RV1 INTERRUPTEUR MODE VENTILATION

MV REFROIDISSEMENT MOTEUR

EV CONDUIT GAZ

ST VOYANT DE CONTRÔLE

RE RELAIS MOTEUR

RV INTERRUPTEUR DE CHAUFFAGE

CO CONDENSATEUR

IT TRANSFORMATEUR H.T.

TA PRISE THERMOSTAT D'AMBIANCE

RE2 RELAIS RETARD DÉMARRAGE (opt.)

PA PRESSOSTAT 20 Pa

LI THERMOSTAT PUISSANCE CHAUFFAGE

FUA FUSIBLE

EL ÉLECTRODE D'IONISATION

FU FUSIBLE

AP COFFRET DE SECURITE

SCHÉMA ÉLECTRIQUE

Page 20

9

ANOMALIES

Dispositif de sécurité (unité de contrôle,

PA1 bloque le générateur

longueur

défectueux

brûleur

Le fait de Faire marcher des Instructions et le Manuel de PropriétaireENERCO GROUP, INC. |Chauage portatif indirect-tiré

gêner le passage de l'air

• Supprimer tous les obstacles pouvant

• Retirer les corps étrangers

nécessaire

• Contrôler le thermostat et le remplacer si

nécessaire

• Contrôler le système et le remplacer si

nécessaire, le remplacer.

• Contrôler le microinterrupteur et, si

le remplacer.

• Contrôler le pressostat et, si nécessaire,

• Contacter l'Assistance technique

gaz n'est pas excessif

• Contrôler que le débit ou la pression des

librement

• Contrôler que l'air chaud peut sortir

aéré

• Vérifier que le local est correctement

de l'évacuation ne sont pas obstruées

• Vérifier que les grilles de l'aspiration et

nettoyer

• Retirer le capteur de flamme et le

• La circulation d'air est insuffisante

pales du ventilateur

• Des corps étrangers se trouvent sur les

• Thermostat défectueux

défectueux

• Système électronique de surveillance

• Défaillance du microinterrupteur PAM

• Défaillance pressostat gaz

suite au fonctionnement irrégulier du

• Intervention du système de surveillance

ferme pas pendant le fonctionnement)

(le contact électrique du thermostat ne se

correctement

• Le capteur de flamme ne fonctionne pas

vibrations

• Le ventilateur fait du bruit ou émet des

s'allume

• Le générateur s'arrête et le témoin (1)

condensateur et les remplacer s'ils sont

• Vérifier le moteur électrique et le

librement

• Vérifier que le ventilateur tourne

de l’évacuation ne sont pas obstruées

• Vérifier que les grilles de l’aspiration et

gaz

• Contrôler la pression d'alimentation du

gaz a été purgé

• Vérifier que le tuyau d'alimentation en

redressant le conduit ou en en réduisant la

• Réduire la pression de retour en

commande

• Enfoncer le poussoir (1) sur le tableau de

• Vérifier le fonctionnement du thermostat

• Vérifier la position du thermostat

correcte

• Placer l'interrupteur sur la position

• Vérifier que le fusible est intact

• Vérifier les branchements élec

l'alimentation électrique

• Vérifier les caractéristiques de

dysfonctionnement du ventilateur

• Intervention du pressostat d'air suite au

le fonctionnement)

pression du gaz ne se ferme pas pendant

(le contact électrique de l'interrupteur de

retour et l'interrupteur de pression d'air

• Le conduit fournit trop de pression de

réinitialisés après une réparation

thermostat de sécurité etc.) non

d'ambiance

• Fonctionnement irrégulier du thermostat

• Le générateur ne démarre pas

général

• Mauvaise position de l'interrupteur

• Manque d'alimentation électrique

DE FONCTIONNEMENT CAUSES SOLUTIONS

GUIDE DE DÉPANNAGE

Page 21

8

carbone CO) et constituer un danger pour l'environnement.

des personnes exposées (suite à la formation de monoxyde de

chambre de combustion (4) peut comporter des risques pour la santé

L'utilisation du générateur sans le panneau pare-flamme de la

ses vis avant d'utiliser le générateur.

combustion (4) doit être remis en place et fixé avec

Après le nettoyage, le pare-flamme de la chambre de

d'endommager irrémédiablement le pressostat de l'air.

pression d'air proches du ventilateur principal : cela risque

Ne pas diriger de jet d'air comprimé vers les prises de

r

• Attendre que le générateur soit froid.

coupure combustion (f.)

• Fermer le robinet d'alimentation de gaz et la valve

fiche de la prise ;

• Débrancher l'alimentation électrique en retirant la

fournies au paragraphe "ARRÊT” ;

• Arrêter le générateur en suivant les consignes

Avant toute opération d'entretien il est impératif de :

moins

Attendre que le générateur soit froid.

gaz au générateur ;

• Dévisser complètement le raccord qui relie le tuyau du

la prise ;

• Débrancher l'alimentation électrique en retirant la fiche de

au paragraphe "ARRÊT”;

lacement :

• Arrêter le générateur en suivant les consignes fournies

Avant tout dép

Attention

électrodes.

l'intérieur de la chambre de combustion, la tête du brûleur et les

de la chambre de combustion (par l'avant) et nettoyer soigneusement

personne qualifiée. Pour accéder au brûleur, déposer le pare-flamme

Le

nettoyage du brûleur doit être effectué régulièrement par une

Attention

les résidus de combustion.

chambre de combustion et la tête du brûleur : retirer les saletés et

dévissant les 4 vis et nettoyer soigneusement l'intérieur de la

Pour accéder au brûleur, déposer le panneau pare-flamme (4) en

éventuel des grilles d'aspiration des ventilateurs.

Le nettoyage devra être fait en enlevant tout corps étrange

Attention

qualifiée.

une fois par an et nettoyés périodiquement par une personne

chambre de combustion et le brûleur doivent être inspectés au

Pour optimiser le fonctionnement de l'unité, des ventilateurs, la

on se

électionner

(connexion à un

rateur d'air chaud, la post-ventilati

MAINTENANCE

l'aide des roues.

Le générateur d'air chaud équipé de roues doit être déplacé à

Attention

TRANSPORT ET MANUTENTION

ENERCO GROUP, INC. |Chauage portatif indirect-tiré Le fait de Faire marcher des Instructions et le Manuel de Propriétaire

"1". Pour l'arrêter, placer l'interrupteur "14" sur la position "0".

l'interrupteur (9) est sur "0" et placer l'interrupteur (14) sur la position

Pour obtenir la fonction ventilation uniquement, contrôler que

VENTILATION

(Fig. 1-2)

d'arrêt (f) et éteindre l'interrupteur de sectionnement

Fermer le robinet d'alimentation du gaz, le robinet

utateur (13) sur le tableau de contrôle, s

sation.

réinitiali

erronée, l'appareil peut s'arrêter en mode

Si la correspondance de polarité phase / neutre est

polarité.

• Enfoncer le bouton (14) : S'il s'allume, inverser la

• Brancher la fiche dans la prise

"0".

• Contrôler que les interrupteurs (9) et (13) sont sur

l'alimentation.

du générateur à une prise, contrôler la polarité de

Avant chaque branchement du cordon d'alimentation

Attention

poursuit pendant le temps programmé.

Après avoir éteint le géné

tourner le bouton de commande du thermostat sur "off".

En fonctionnement manuel, placer l'interrupteur (9) sur "0" ou

Arrêt

ventilation est continue.

• lorsque l'interrupteur (13) est sur la position "1", la post-

ventilation dure 30 secondes.

• lorsque l'interrupteur (13) est sur la position "0", la postcontinue de fonctionner après l'arrêt du générateur.

le mode post-ventilation ; c'est le temps pendant lequel le ventilateur

Avec le comm

Réglage du mode post-ventilation

dysfonctionnement.

CAUSES ET SOLUTIONS" et rechercher la raison du

consulter le paragraphe "ANOMALIES DE FONCTIONNEMENT,

• Si au terme de ces opérations le générateur ne fonctionne pas,

et s'éteindra automatiquement.

d'ambiance sur la température désirée : le chauffage s'allumera

l'interrupteur (9) sur la position "1" et régler le thermostat

thermostat ou tout autre dispositif de contrôle), placer

• Si l'appareil fonctionne en mode automatique

ventilateur se met en marche.

Le brûleur démarre, la chambre de combustion chauffe et le

dispositif de contrôle) placer l'interrupteur (9) sur la position "1".

• Si l'appareil est actionné manuellement (sans thermostat ni autre

coffret électrique d'alimentation;

• Alimenter l'appareil en agissant sur l'interrupteur général du

• Vérifier que l'interrupteur (9) est bien sur la position "0” ;

MISE EN MARCHE

MODE DE CHAUFFAGE

Attention

Attention

INSTRUCTIONS D'UTILISATION

, l'u

nité essaiera de redémarrer

CAUSES – SOLUTIONS.)

résolue avant de redémarrer le générateur (cf. ANOMALIES –

du dispositif de sécurité doit toujours être soigneusement analysée et

bouton de réinitialisation (8.) Néanmoins, la cause du déclenchement

Le générateur ne pourra être redémarré qu'en appuyant sur le

s'allumera.

générateur s'arrêtera définitivement et la voyant (8)

Si la cause du dysfonctionnement continue, le

une fois.

Quel que soit la raison

Attention

tention de la valeur indiquée dans le Tab. I

ob

manomètre et agir sur le régulateur de pression (c) jusqu'à

• Allumer le générateur d'air chaud, lire la valeur de pression sur le

• Brancher un manomètre à la prise de pression (b) ,

En cas de besoin, pour régler la pression du brûleur :

le nouveau type de gaz

Le générateur d'air chaud est prêt à fonctionner avec

soupape de gaz pour modifier la pression du brûleur.

Ne pas agir sur le régulateur de pression de la

Attention

Page 22

7

Le fait de Faire marcher des Instructions et le Manuel de PropriétaireENERCO GROUP, INC. |Chauage portatif indirect-tiré

l'alimentation se fait avec un autre type de gaz (de gaz naturel à GPL

fonctionnement de l'appareil (généralement gaz naturel). Si

livrées avec la machine).

en indiquant le gaz qui doit être utilisé (plusieurs étiquettes sont

la vis de fixation et la couvrir d'une nouvelle étiquette achésive

• Après avoir placé la poignée dans la position opposée, remettre

Fig. 4

sur la soupape de sélection du gaz (13) indique la catégorie de

(naturel ou GPL) indiqué dans le Tab. I : L'étiquette adhésive collée

fonctionnement complet et il est donc prédisposé pour l'un des gaz

Le générateur PHOEN N est fourni après un test de

I° MISE EN MARCHE

la connexion d'alimentation en gaz de l'appareil.

du manomètre de test, doit être installé immédiatement en amont de

Un bouchon taraudé de 1/8 NPT minimum, destiné à la connexion

inférieures à ½ psi (3,5 kPa.)

du système d'alimentation en gaz à des pression égales ou

fermant son robinet d'arrêt manuel pendant tout le test de pression

L'appareil doit être isolé du système d'alimentation en gaz en

système à des pressions supérieures à ½ psi (3,5 kPa.)

système d'alimentation de gaz en cas de test de pression du

t être débranchés du

Tab. I et suivre les instructions :

s correct conformément aux conditions du

poignée dans le sen

• Retirer la vis sous l'étiquette adhésive et tourner manuellement la

• Retirer l'étiquette adhésive sur la soupape de sélection du gaz,

2):

Pour passer d'un type de gaz à un autre, opérer comme suit (Fig.

fonctionnement, les conditions d'utilisation de la soupape manuelle.

Tab.I pour déterminer la pression d'alimentation, la pression de

pour déterminer la catégorie d'origine du gaz et consulter ensuite le

;

e utilisée.

eill

appliquée sur la soupape de sélection manuelle du gaz (a) Fig. 2

tou

t d'abord l'étiquette adhésive

marche. De ce fait, contrôler

la vie de la machine et pas uniquement à la première mise en

Cette commutation peut être effectuée plusieurs fois au cours de

GAZ

PASSAGE À UN AUTRE TYPE DE

compétentes.

(4.500 pieds), consulter les autorités provinciales ou territoriales

and Handling of

Pour l'installation au Canada, à une altitude supérieure à 1.372 m

Conversion exécutée par : _______________________________________

Type de combustible : _______________________________________

Date de

conversion : _______________________________________

Débit entrée : _______________________________________

Pression collecteur : _______________________________________

Dimensions de l'orifice : _______________________________________

A UNE ALTITUDE DE__________ m (SUPÉRIEUR À 2000 PIEDS)

CET APPAREIL A ÉTÉ CONVERTI POUR UNE UTILISATION

Fig. 3

des caractéristiques :

L'appareil et son robinet d'arrêt doiven

Code" CSA B 149.1.

ANSI/NFPA 58 et au "Natural Gas and Propane Installation

the Storage and Handling of Liquified Petroleum Gases"

le gaz doit être conforme aux prescriptions des "Standard for

doit être débranché de la cuve de gaz ; le récipient contenant

(e) Si le générateur d'air chaud est stocké à l'intérieur d'un local, il

générateur d'air chaud n'est pas utilisé

(d) La vanne d'arrêt de gaz de la cuve doit être fermée lorsque le

pour assurer le retrait de vapeur de la bout

(c) Le système d'approvisionnement par bouteille doit être conçu

propane ne doit pas être inférieure à 90 litres (100 lb).

de GPL. Dans tous les cas, la contenance de la bouteille de

pour toutes les exigences spécifiques, consulter le fournisseur

(b) Pour déterminer la taille et la capacité de la/des bouteille (s) et

and Propane Installation Code, CSA B149.1

Liquified Petroleum Gases, ANSI/NFPA 58 et au Natural Gas

ou, à défaut, au Standard for the Storage

(a) L'installation doit être conforme aux réglementations locales

En cas de raccordement à une bouteille de gaz propane :

Natural Gas and Propane installation Code CSAB149.1

défaut, au National Fuel Gas Code ANSI Z223.1/NFPA 54 et au

l'installation doit être conforme aux réglementations locales ou, à

En cas de raccordement du générateur au gaz naturel,

2 Robinet d'arrêt manuel 4 Groupe vannes gaz

1 Conduit de gaz principal 3 Manchon de couplage anti vibrations

Une plaquette de conversion doit être apposée près de l'étiquette

ICANT,

:

s du

les instruction

B149.1 OU CAN/CGAB149.2

RÉGLEMENTATION D'INSTALLATION CAN/CGACOMPÉTENTES ET AUX EXIGENCES DE LA

DES AUTORITÉS PROVINCIALES OU TERRITORIALES

CONFORMÉMENT AUX EXIGENCES DU FABR

REPRÉSENTANT AGRÉÉ DU FABRICANT,

LA CONVERSION DOIT ÊTRE EXÉCUTÉE PAR UN

Attention

conformité à la pression du collecteur indiquée sur la plaquette.

générateur doit être diminuée en réduisant l'arrivée de carburant en

(2.000 pieds) et jusqu'à 1.372 m (4.500 pieds), la puissance du

Pour l'installation au Canada, à une altitude supérieure à 610 m

pour chaque palier supplémentaire de 305 m (1.000 pieds).

m (2.000 pieds) la puissance de l'appareil devra être réduite de 4%

Pour l'installation aux Etats-Unis, à une altitude supérieure à 610

.

chaud

• Ouvrir la vanne d'arrêt du gaz et démarrer le générateur d'air

• Contrôler l'étanchéité du tuyau de gaz ;

• Purger le tuyau d'alimentation de gaz ;

continuer et d'exécuter les opérations suivantes

indications de la catégorie de service effective qu'il sera possible de

Ce n'est qu'après avoir réglé le générateur conformément aux

paragraphe "PASSAGE À UN AUTRE TYPE DE GAZ".

et inversement) suivre scrupuleusement

doivent être posés par l'installateur.

couplage antivibrations ne sont pas fournis avec le générateur et

illustré sur la Fig. 3 : tuyau de gaz, robinet d'arrêt et manchon de

effectuer et il doit être exécuté en réalisant la "rampe de gaz" comme

dimensions adéquates et correspondantes au type d'installation à

Le branchement au conduit d'alimentation du gaz doit avoir des

COMBUSTIBLE

BRANCHEMENT À LA LIGNE D'ALIMENTATION DU

ise pas plus de courant que la limite maximale autorisée.

n'util

câblage. Lors du premier allumage, contrôler que le ventilateur

toutes les connexions électriques correspondent au schéma de

Au terme de toutes ces opérations, contrôler soigneusement que

le thermostat.

une horloge au tableau de contrôle de l'unité avec logement pour

• Connecter des accessoires tels qu'un thermostat d'ambiance ou

conformité des caractéristiques sur la plaquette.

• Brancher le cordon d'alimentation après avoir contrôlé la

Page 23

6

ENERCO GROUP, INC. |Chauage portatif indirect-tiré Le fait de Faire marcher des Instructions et le Manuel de Propriétaire

Les opérations suivantes doivent être effectuées :

extérieure.

Code, en cas d'utilisation d'une source électrique

NFPA 70 et/ou de la CSA C22.1, Canadian Electrical

défaut, de la réglementation électrique nationale ANSI /

é à la terre

dans le respect des réglementations locales ou, à

Lors de l'installation, l'appareil doit être reli

électrique muni d'un sectionneur.

Le câble d'alimentation doit être branché à un coffret

magnétothermique avec différentiel.

d'une mise à la terre et d'un disjoncteur

La ligne d'alimentation électrique doit être équipée

fixées pour la ventilation.

chauff

age ou des ouvertures permanentes doivent être

mécanique doit être asservie à l'opération de

En cas d'installation dans une serre, la ventilation

doivent être exécutées que par un personnel qualifié

Toutes les instructions fournies dans ce paragraphe ne

Attention

électriquement connectés.

Tous les dispositifs de surveillance et de sécurité sont déjà

Attention

BRANCHEMENTS ÉLECTRIQUES

Attention

homologuée.

L'installateur doit fournir une soupape de gaz manuelle

Propane Installation Code" CSA B 149.1.

Fuel Gas Code" ANSI Z223/1NFPA 54 et au "Natural Gas and

L'installation pour le gaz naturel doit être conforme au "National

Attention

ies devront être

tout matériau combustible doivent

:

.

INSTRUCTIONS D'INSTALLATION

SOLUTIONS")

("ANOMALIES DE FONCTIONNEMENT – CAUSES –

de surchauffer et le thermostat de surchauffe éteindra le brûleur

le flux d'air n'est pas suffisant, la chambre de combustion risque

près d'un mur ou de tout autre objet de grandes dimensions. Si

d'autres objets sur l'appareil ou en positionnant l'appareil trop

diverses façons par exemple en plaçant des couvertures ou

l'expulsion d'air ; la circulation de l'air peut être entravée de

n'obstrue l'aspiration et

lifié et toujours avant la

;

;

générateur sont suffisantes et que rien

• S'assurer que la circulation d'air et que l'alimentation en air du

TECHNIQUES.)

par le générateur (TABLE CARACTÉRISTIQUES

• Ne pas dépasser le niveau maxi de chaleur pouvant être produit

il est obligatoire de

Lors de l'utilisation de n'importe quel type d'appareil de chauffage,

la position éteint "off".

• Au terme de l'utilisation, s'assurer que l'interrupteur est bien sur

mise en service pour la nouvelle saison de chauffage.

une fois par an par un technicien qua

• S'assurer que le générateur d'air chaud soit contrôlé au moins

l'appareil.

• Ne pas laisser les enfants et/ou les animaux s'approcher de

fonctionnement et contrôlé avant sa mise en marche

• Le générateur est régulièrement surveillé pendant son

• Une position fixe a été prévue pour l'appareil ;

déclarées

d'alimentation possédant des caractéristiques conformes à celles

• Le générateur est installé à proximité d'un coffret électrique

près du générateur ;

trop

posées sur l'appareil ou parois ou objets encombrants placés

et/ou d'évacuation de l'air, tels que bâches ou couvertures

• Il n'existe aucun obstacle ni obstruction aux conduits d'admission

garantie et suffit aux besoins du brûleur ;

• L'aération du local dans lequel est installé le générateur est

température excessive, pressostat de

rateurs d'air chaud de la série PHOEN N sont à

s d'alimentation, le réglage du groupe

respecter la longueur maxi indiquée dans le Tab. I.

uniquement des conduits d'origine, de type M1 Spiraflex et

• Pour la distribution d'air à partir du distributeur, utiliser

adoptées.

• Toutes les mesures aptes à prévenir les incend

risque d'incendie ou d'explosion

• Le générateur ne doit pas être installé dans des zones à fort

d'une bouteille de gaz.

d'une cuve de gaz propane et à moins de 3 mètres (10 pieds)

• Le générateur ne doit pas être dirigé à moins de 6 m (20 pieds)

3 m (10 pieds) de la sortie d'air du générateur.

0,7 m (2 pieds) du plafond

1 m (3 pieds) du côté et de l'arrière (entrée air) du générateur

être :

• Les distances minimales de

respectées ;

• Les instructions du présent livret sont scrupuleusement

Il convient de toujours s'assurer que

sur l’installation des générateurs.

Contacter les autorités locales pour tout renseignement

Attention

machine.

nationales et locales en vigueur concernant l'utilisation de la

doivent être accomplis dans le respect de toutes les normes, lois

L'installation, le réglage et l'utilisation du générateur d'air chaud

CONSEILS D'ORDRE GÉNÉRAL

SOLUTIONS”)

(voir "ANOMALIES DE FONCTIONNEMENT, CAUSES ET

sécurité et la supprimer avant de remettre le générateur en marche

rechercher la cause ayant provoqué l'intervention du dispositif de

réarmement correspondant (8). Néanmoins, le faut toujours

peut reprendre uniquement en pressant le bouton-poussoir de

générateur d'air chaud s'arrête. Le fonctionnement du générateur

Dans chacun des cas décrits, le témoin (8) s'allume et le

re décrite dans les "INSTRUCTIONS D'UTILISATION".

la procédu

Dans chacun des cas susmentionnés, l'appareil s'arrête en suivant

d'air est insuffisant.

franchit le seuil de sécurité, le pressostat de l'air intervient si le débit

excessive intervient si la température de la chambre de combustion

flamme est irrégulière ou si elle s'éteint, le thermostat de température

Le système électronique de surveillance du brûleur intervient si la

l'air) interviennent en cas de dysfonctionnement important.

surveillance, thermostat de

Plusieurs dispositifs de sécurité (système électronique de

correctement aéré afin d'assurer un recyclage d'air suffisant.

de la puissance thermique produite. le local devra toujours être

avec les produits de la combustion, rendant ainsi disponible la totalité

développée pendant la combustion puis envoyé au local à réchauffer

combustion indirecte. L'air est chauffé en utilisant l'énergie thermique

Les géné

paragraphe "PASSAGE À UN AUTRE TYPE DE GAZ”.

est nécessaire d'exécuter les opérations expressément prévues au

Pour passer à une autre catégorie, donc à un autre type de gaz, il

(a) indique le gaz pour lequel l'appareil a été préréglé.

Tab. I. Une étiquette adhésive appliquée sur le groupe soupapes gaz

fonctionnement et il est préréglé pour un des gaz indiqués dans le

Le générateur PHOEN N a fait l'objet d'un contrôle de

soupape gaz et le débit de gaz.

les gaz utilisables, les pression

pays de la Communauté européenne. Dans le Tab. I sont indiqués

d'alimentation en gaz, conformément aux lois en vigueur dans les

fonctionner au gaz naturel ou G.P.L à différentes pressions

Les générateurs d'air chaud de la série PHOEN N peuvent

nécessaire.

pour lesquels un système de chauffage fixe ou mobile est

pour chauffer des locaux aérés de moyenne ou grande dimension

Les générateurs d'air chaud de la série PHOEN N sont conçus

DESCRIPTION

Page 24

5

4163275

Le fait de Faire marcher des Instructions et le Manuel de PropriétaireENERCO GROUP, INC. |Chauage portatif indirect-tiré

f VALVE COUPURE COMBUSTION

e PORT PRESSION EN ENTRÉE

d SOUPAPE PRINCIPALE GAZ

Fig. 2

c

b

d

a

f

f

e

14 POUSSOIR TEST LIGNE PHASE / NEUTRE

ECTEUR)

GE/N 250 GE/N 400

d

e

b

a

c

c RÉGULATEUR PRESSION COLLECTEUR

b PORT PRESSION COLLECTEUR (COLL

a VALVE SÉLECTEUR GAZ

ENSEMBLE COLLECTEUR

7 IGNITION ELECTRODE

13 INTERRUPTEUR MODE VENTILATION

12 CORDON D'ALIMENTATION

11 VOYANT DE MISE SOUS TENSION

10 PRISE THERMOSTAT D'AMBIANCE

9 INTERRUPTEUR DE CHAUFFAGE

8 RAZ ÉLECTRONIQUE CONTRÔLE FLAMME

Fig. 1

12

11

6 IONISATION ELECTRODE

5 VENTILATEUR REFROIDISSEMENT

4 PARE-FLAMME

3 BAGUE DIFFUSEUR

2 BRÛLEUR

1 CHAMBRE DE COMBUSTION

14

8 9 10 13

CONTROL PANEL - TABLEAU DE COMMANDE

Page 25

4

Puissance thermique à

Puissance thermique à

Normal

Canada)

Puissance thermique à

l'entrée

Puissance thermique à

l'entrée

ENERCO GROUP, INC. |Chauage portatif indirect-tiré Le fait de Faire marcher des Instructions et le Manuel de Propriétaire

Poids [lb] 134 225

Dimensions, L x W x H [in] 42,3 x 21,9 x 29,45 57,7 x 24,4 x 32,6

Poids [lb] 101 192

Dimensions, L x W x H [in] 40,6 x 24,6 x 21,7 56,,1 x 29,5 x 25,7

Longueur maxi [ft] 50 50

Pression statique maxi [in] 0,60 0,56

[A] 5,0 8,5

[W] 500 900

Fréquence [Hz] 60 60

Tension [V] 120 120

Phase 1 1

Consommation [CFH] 80,08 130,61

Manifold pressure [in WC] 4,06 4,27

[BTU/h] 217.272 354.721

only)

level (Canada

above sea

- 4,500 ft

Altitude 2,000

Emballage

Générateur d'air chaud

Niveau de bruit à 1 m [dBA] 77 74

distribution air

Conduit

Connection entrée du gaz 3/4" NPT 3/4" NPT

Gicleur [in] N. 16 holes x 0,079" N. 16 holes x 0,102"

Consommation d'électricité

électrique

Alimentatione

Débit d'air [cfm] 2.766 4.120

Fuel consumption [CFH] 88,98 145,12

Manifold pressure [in WC] 4,28 4,50

[BTU/h] 241.413 394.134

Selector valve position

max 13" w.c.

min 8" w.c.

max 10" w.c.

min 7" w.c.

max 13" w.c.

min 8" w.c.

[BTU/h] 229.216 363.378

[BTU/h] 254.684 403.753

max 10" w.c.

min 7" w.c.

Supply pressure [in WC]

Consommation [CFH] 217,37 343,21

Manifold pressure [in WC] 4,11 4,18

l'entrée

Consommation carburant [CFH] 241,52 381,35

Pression collecteur : [in WC] 4,33 4,40

l'entrée

Position valve sélectrice

Pression d'alimentation [in WC]

(U.S.A. and

sea level

2,000 ft above

altitude 0 -

uniquement)

pieds (Canada

2.000 à 4.500

Altitude de

Canada)

(U.S.A. et

2.000 pieds

normale 0 –

Altitude

L.P.G.

Gaz naturel

CARACTÉRISTIQUES TECHNIQUES GE/N 250C GE/N 400C

Page 26

3

Le fait de Faire marcher des Instructions et le Manuel de PropriétaireENERCO GROUP, INC. |Chauage portatif indirect-tiré

ATTENTION

nnes ou d'animaux.

ATTENTION

CONSERVER CES INSTRUCTIONS POUR POUVOIR LES CONSULTER À TOUT MOMENT.

électrique avant de déposer un quelconque des carters recouvrant le générateur.

Pour éviter tout dommage causé par les organes en mouvement, débrancher l'alimentation

Ne pa

s démarrer le générateur d'air chaud lorsque les carters sont ouverts et/ou mal fermés.

Prévoir une ventilation adaptée aussi bien pour les applications à l'intérieur qu'à l'extérieur.

marche.

Placer le générateur d'air chaud de façon parfaitement stable et définitive avant de le mettre en

mort de personnes ou d'animaux.