Page 1

Technical Information

RTD TH11 and TH12

General purpose RTD with terminal head or conductor extension

lead wires for process and laboratory applications

Areas of application

The TH11 and TH12 temperature sensors are RTD's

designed for use in the process industry or factory

automation type of environment. They are made up

of a measurement probe with a RTD, insulation and

sheath.

Among other applications the sensors can be used on:

• Heat exchangers

• Power & recovery area

• Carbon regeneration furnace

•Dryers

• Flue Gas

• Compressor stations

• Process reactors

Head Transmitters

Instead of directly wiring your temperature sensors to

your control system, use transmitters to reduce

wiring and maintenance costs while increasing

measurement accuracy.

TI00108R/24/en

71147552

Your benefits

• High flexibility due to modular assembly with standard

terminal heads and customized immersion length

• One Source shopping for temperature measurement

solutions. World class transmitter with integrated sensor

offering.

- Remove and Install straight out of the box!

• Improved Galvanic Isolation on most devices (2 kV)

• Simplified Model Structure: Competitively priced, offers

great value. Easy to order and reorder. A single model

number includes sensor and transmitter assembly for a

complete point solution

• All iTEMP

stability ≤ 0.05 % per year

• Fast response time with reduced/tapered tip form

®

transmitters provide long term

Page 2

TH11, TH12

Function and system design

Measuring principle These resistance thermometers use a Pt100 temperature sensor according to IEC 60751. This temperature

sensor is a temperature-sensitive platinum resistor with a resistance of 100 Ω at 0 °C (32 °F) and a temperature

coefficient is α = 0.003851 °C

There are generally two different kinds of platinum resistance thermometers:

• Wire wound (WW): Here, a double coil of fine, high-purity platinum wire is located in a ceramic support.

This is then sealed top and bottom with a ceramic protective layer. Such resistance thermometers not only

facilitate very reproducible measurements but also offer good long-term stability of the resistance/

temperature characteristic within temperature ranges up to 600 °C (1112 °F). This type of sensor is relatively

large in size and it is comparatively sensitive to vibrations.

• Thin film platinum resistance thermometers (TF): A very thin, ultrapure platinum layer, approx. 1 μm

thick, is vaporized in a vacuum on a ceramic substrate and then structured photolithographically. The

platinum conductor paths formed in this way create the measuring resistance. Additional covering and

passivation layers are applied and reliably protect the thin platinum layer from contamination and oxidation

even at high temperatures.

The primary advantages of thin-film temperature sensors over wire wound versions are their smaller sizes and

better vibration resistance. A relatively low principle-based deviation of the resistance/temperature

characteristic from the standard characteristic of IEC 60751 can frequently be observed among TF sensors at

high temperatures. As a result, the tight limit values of tolerance category A as per IEC 60751 can only be

observed with TF sensors at temperatures up to approx. 300 °C (572 °F). For this reason, thin-film sensors are

generally only used for temperature measurements in ranges below 400 °C (932 °F).

-1

.

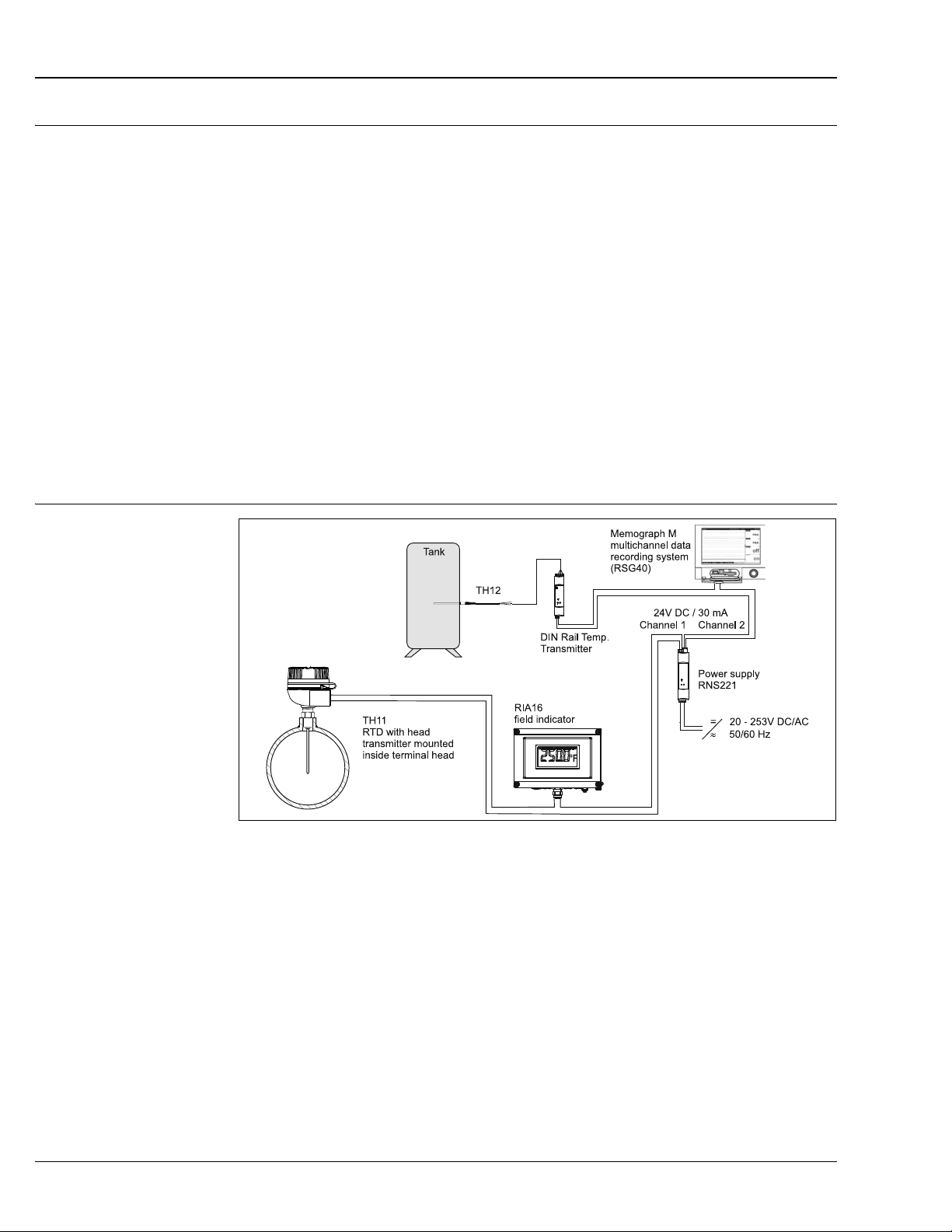

Measuring system

Example of an application of the temperature assemblies

A0016255-EN

RIA16 Field indicator

The field indicator records an analog measuring signal and shows this on the display. The LCD display shows

the currently measured value digitally and as a bargraph with limit value violation signalling. The indicator is

looped into the 4 to 20 mA circuit and obtains the required energy from there. Details see Technical

Information (see "Documentation").

RNS221

The RNS221S power supply (24 V DC, 30 mA) has two galvanically isolated outputs for supplying voltage to

loop powered transmitters. The two channel power supply has a wide-range input for mains power, 20 to

253 V DC/AC, 50/60 Hz to be used in any electrical circuit. Details see Technical Information (see

"Documentation"). RNS221 is an UL recognized component to UL-3III-1.

2 Endress+Hauser

Page 3

TH11, TH12

Memograph M, RSG40

Multichannel data recording system with multicolored TFT display (170 mm/7 in screen size), galvanically

isolated universal inputs (U, I, TC, RTD, pulse, frequency), digital input, transmitter power supply, limit relay,

communication interfaces (USB, Ethernet, RS232/485), internal SD memory, external SD card and USB stick.

100 ms scan rate for all channels. Details see Technical Information (see "Documentation").

Equipment architecture The single element RTDs are designed to measure temperature in a variety of process and laboratory

applications. These RTDs are specifically designed for use in two different process temperature ranges and they

will provide accurate and repeatable temperature measurement through a broad range of -200 to 600 °C

(-328 to 1112 °F). Low range thin film RTDs -50 to 200 °C (-58 to 392 °F) are constructed using silver plated

copper internal leads, PTFE wire insulations with potting compounds to resist moisture penetration. High range

RTDs -200 to 600 °C (-328 to 1112 °F) are constructed with nickel internal leads inside swaged MgO insulated

cable to allow higher temperature measurements at the RTD element and to provide higher temperature lead

protection along the sheath.

Measurement range

Family of temperature

transmitters

Construction Model code (class and type of sensor) max. range

Low temperature range

(thin film)

High temperature range

(wire wound)

TH11-_ _ _ (A/C/E/G/J/L) _ _ _ _ _ _

TH12-_ _ _ (A/C/E/G/J/L) _ _ _ _ _ _

TH11-_ _ _ (B/D/F/H/K/M) _ _ _ _ _ _

TH12-_ _ _ (B/D/F/H/K/M) _ _ _ _ _ _

-50 to 200 °C (-58 to 392 °F)

-200 to 600 °C (-328 to 1112 °F)

System components

Thermometers fitted with iTEMP® transmitters are an installation ready complete solution to improve

temperature measurement by increasing accuracy and reliability, when compared to direct wired sensors, as

well as reducing both wiring and maintenance costs.

PC programmable head transmitter TMT180 and TMT181

They offer a high degree of flexibility, thereby supporting universal application with low inventory storage. The

®

transmitters can be configured quickly and easily at a PC. Endress+Hauser offers the ReadWin® 2000

iTEMP

configuration software for this purpose. This software can be downloaded free of charge at

www.readwin2000.com. More information can be found in the Technical Information (see

"Documentation" section).

®

TMT182 head transmitter

HART

®

communication is all about easy, reliable data access and getting additional information about the

HART

measurement point more inexpensively. It can be installed as an intrinsically safe apparatus in zone 0 hazardous

areas and is used for instrumentation in the flat face terminal head to DIN EN 50446. iTEMP

integrate seamlessly into your existing control system and provide painless access to numerous diagnostic

information.

Configuration with a hand-held (Field Xpert SFX100 or DXR375) or a PC with configuration program

(FieldCare, ReadWin

®

2000) or configure with AMS or PDM. Details see Technical Information (see chapter

"Documentation").

®

transmitters

Endress+Hauser 3

Page 4

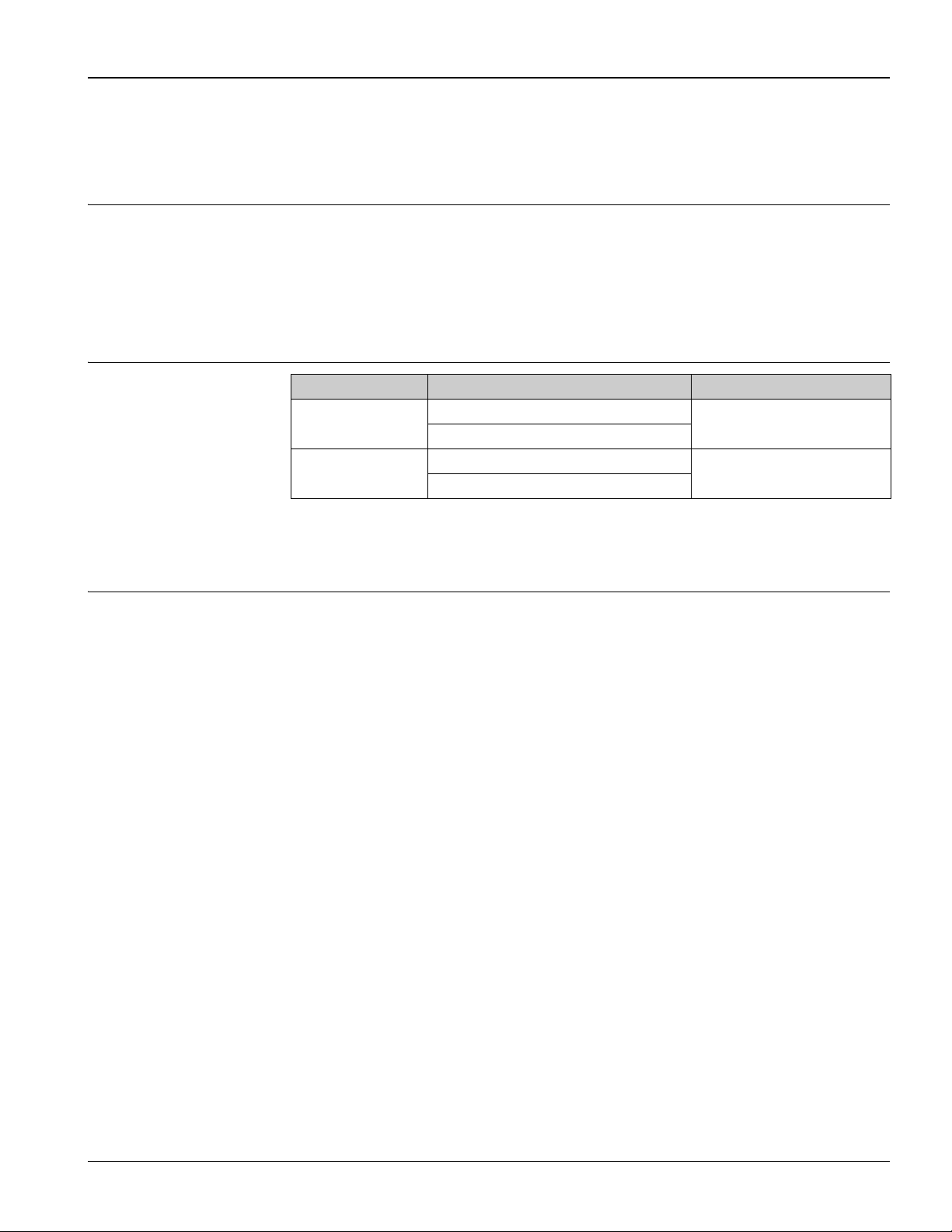

Type of transmitter Specification

®

iTEMP

TMT18x

• Material: Housing (PC), Potting (PUR)

• Terminals: Cable up to max. ≤ 2.5 mm

wire end ferrules

• Eyelets for easy connection of a HART

clips

• Degree of protection NEMA Type 4x Encl. (see also type of terminal head)

Details see Technical Information (see chapter "Documentation")

A0016380

HART® programmable head transmitter iTEMP® TMT82

The iTEMP® TMT82 is a 2-wire device with two measurement inputs and one analog output. The device

transmits both converted signals from resistance thermometers and thermocouples as well as resistance and

voltage signals via the HART

®

communication. It can be installed as an intrinsically safe apparatus in zone 0

hazardous areas and is used for instrumentation in the flat face terminal head to DIN EN 50446. Fast and easy

operation, visualization and maintenance via PC using configuration software such as FieldCare, Simatic PDM

or AMS.

Benefits are: Dual sensor input, maximum reliability, accuracy and long-term stability for critical processes,

mathematical functions, monitoring of thermometer drift, backup function of the sensor, diagnostic functions

of the sensor and sensor-transmitter matching based on the Callendar/Van Dusen coefficient. For more

information, refer to the Technical Information (see chapter "Documentation").

TH11, TH12

2

/ 16 AWG (secure screws) or with

®

-handheld terminal with alligator

®

PROFIBUS

Universally programmable head transmitter with PROFIBUS

PA TMT84 head transmitter

®

PA communication. Converting various input

signals into a digital output signal. High accuracy over the complete ambient temperature range. It can be

installed as an intrinsically safe apparatus in zone 0 hazardous areas and is used for instrumentation in the flat

face terminal head to DIN EN 50446. Swift and easy operation, visualization and maintenance using a PC

directly from the control panel, e. g. using operating software such as FieldCare, Simatic PDM or AMS.

Benefits are: dual sensor input, highest reliability in harsh industrial environments, mathematic functions,

thermometer drift monitoring, sensor back-up functionality, sensor diagnosis functions and sensor-transmitter

matching using Callendar-Van Dusen coefficients. Details see Technical Information (see chapter

"Documentation").

FOUNDATION Fieldbus™ TMT85 head transmitter

Universally programmable head transmitter with FOUNDATION Fieldbus™ communication. Converting

various input signals into a digital output signal. High accuracy over the complete ambient temperature range.

It can be installed as an intrinsically safe apparatus in zone 0 hazardous areas and is used for instrumentation

in the flat face terminal head to DIN EN 50446. Swift and easy operation, visualization and maintenance using

a PC directly from the control panel, e. g. using operating software such as FieldCare from Endress+Hauser or

the NI Configurator from National Instruments.

Benefits are: dual sensor input, highest reliability in harsh industrial environments, mathematic functions,

thermometer drift monitoring, sensor back-up functionality, sensor diagnosis functions and sensor-transmitter

matching using Callendar-Van Dusen coefficients. Details see Technical Information (see chapter

"Documentation").

4 Endress+Hauser

Page 5

TH11, TH12

24.1 (0.95)

33 (1.3)

Ø44 (1.73)

Ø7 (0.28)

Ø5 (0.2)

B

C

A

Type of transmitter Specification

®

TMT8x

iTEMP

Pluggable display TID10 as option

• Spring range L ≥ 5 mm (0.2 in), see Pos. A

• Fixing elements for pluggable measured value display, see Pos. B

• Interface for contacting measured value display, see Pos. C

• Material (RoHS-compliant)

Housing: PC

Potting: PU

•Terminals:

Screw terminals (cable up to max. ≤ 2.5 mm

or spring terminals (e. g. from 0.25 mm

for flexible wires with wire-end ferrules with plastic ferrule)

• Degree of protection NEMA Type 4x Encl. (see also type of terminal head)

A0007301

Details see Technical Information (see chapter "Documentation")

• Displays the actual measured value and the measurement point identification

• Displays fault events in inverse color with channel ident and diagnostics code

• DIP-switches on the rear for hardware set-up, e. g. PROFIBUS

address

Display is only available with suitable terminal head with display window, e.g.

TA30

2

/ 16 AWG)

2

to 0.75 mm2/ 24 AWG to 18 AWG

®

PA bus

A0009955

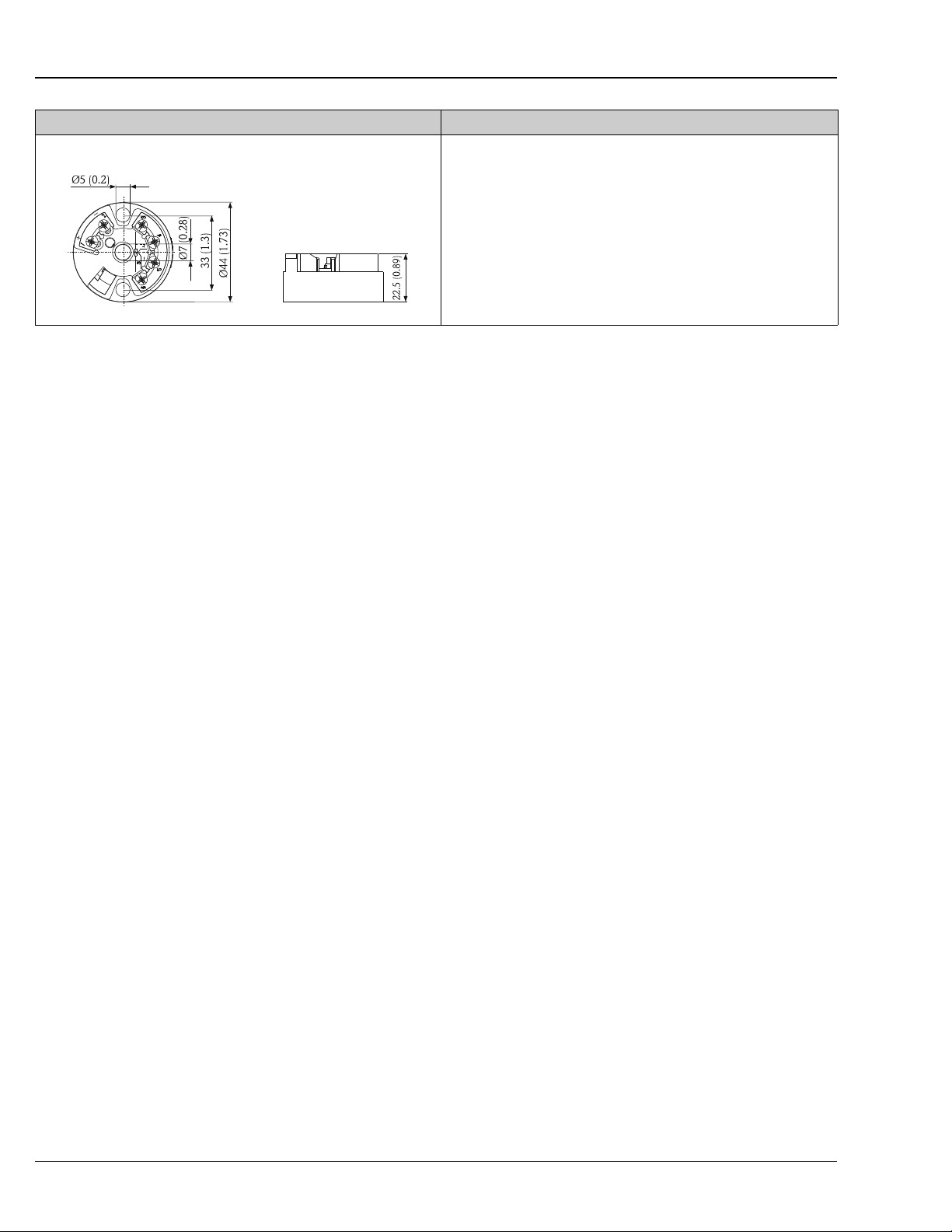

iTEMP® TMT162 field transmitter

Field transmitter with universal communication (HART®, PA, FF) and blue backlit display. Can be read easily

from a distance, in sunlight and at night. Large measurment value, bargraph and fault indication display.

Benefits are: dual sensor input, highest reliability in harsh industrial environments, mathematic functions,

thermometer drift monitoring and sensor back-up functionality, corrosion detection.

Type of transmitter (dimensions in mm [in]) Specification

®

Temperature field transmitter iTEMP

TMT162 for general purpose

• Material: Die-cast aluminium housing AlSi10Mg/AlSi12 with powder

coating on polyester base

• Separate electronics compartment and connection compartment

• Display rotatable in 90° increments

• Cable entry: 2 x ½" NPT

• Degree of protection: NEMA Type 4x Encl. (IP67)

• Brilliant blue backlit display with ease of visibilty in bright sunshine or pitch

darkness

• Gold plated terminals to avoid corrosion and additional measurement errors

Details see Technical Information (see "Documentation")

* Dimensions without display = 112 mm (4.41")

A0016656

Endress+Hauser 5

Page 6

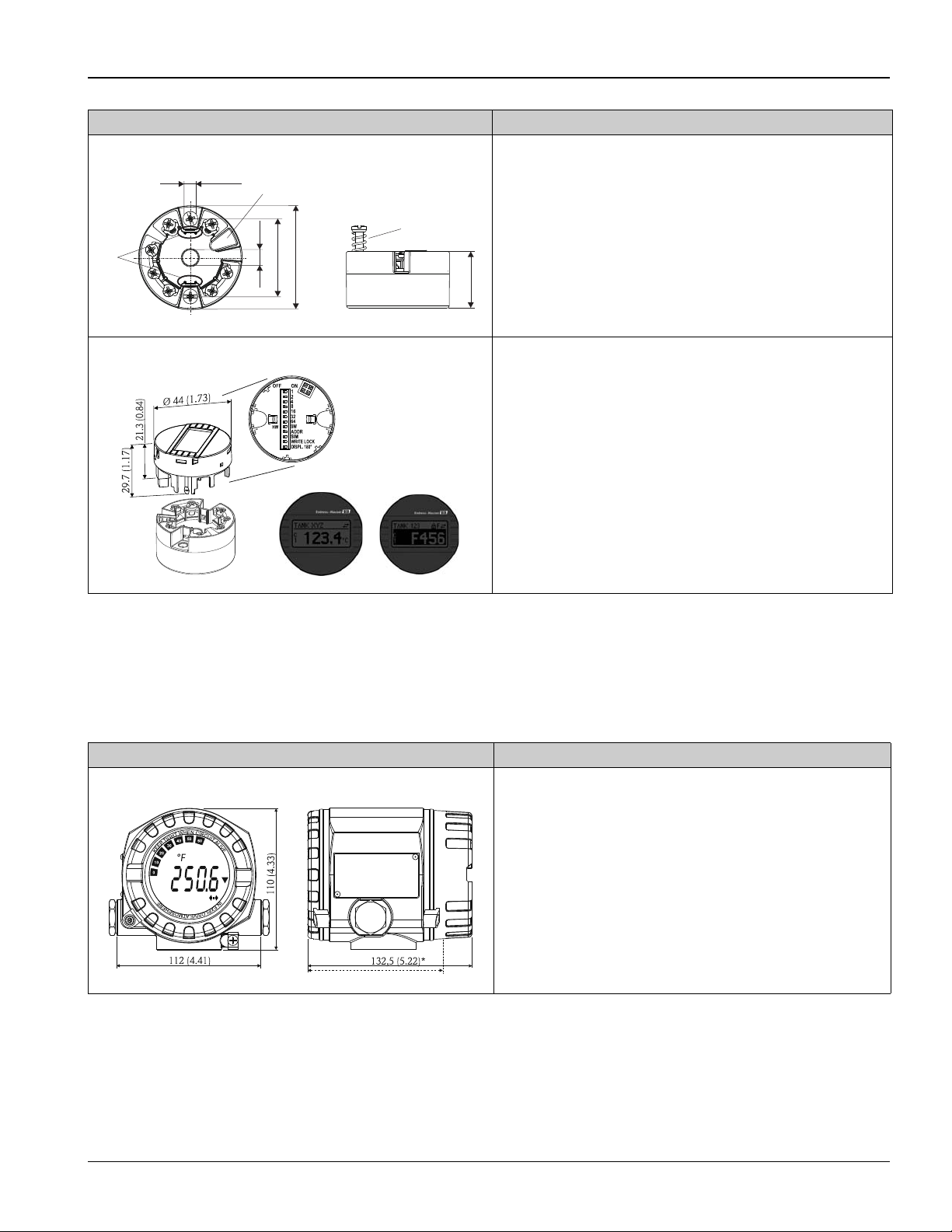

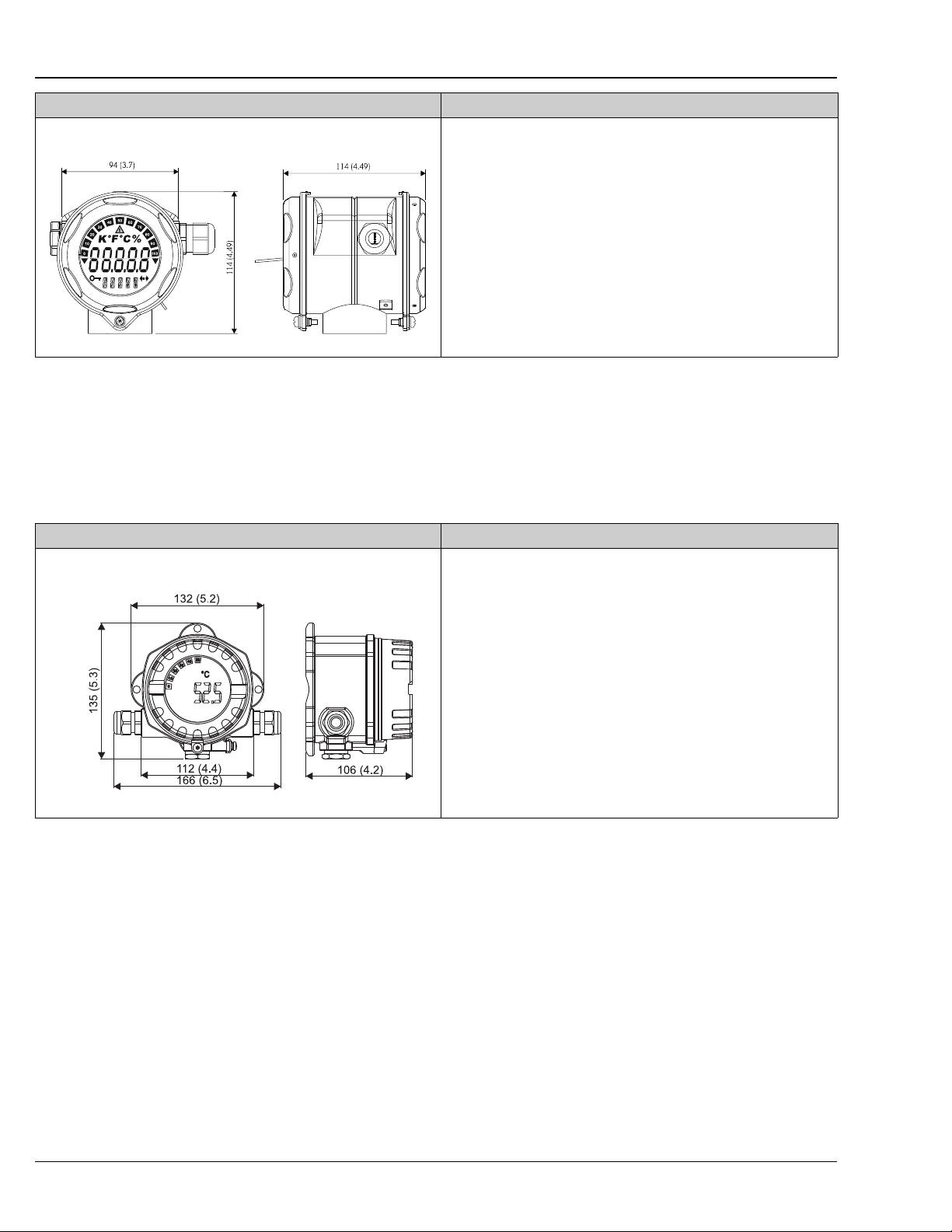

Type of transmitter (dimensions in mm [in]) Specification

Temperature field transmitter iTEMP® TMT162 for hygienic applications

• Material: Stainless steel 1.4435 (AISI 316L) for hygienic applications (T17

housing)

• Separate electronics compartment and connection compartment

• Display rotatable in 90° increments

• Cable entry: 2 x ½" NPT

• Degree of protection (IP69K)

• Brilliant blue backlit display with ease of visibility in bright sunshine or pitch

darkness

• Gold plated terminals to avoid corrosion and additional measurement errors

Details see Technical Information (see "Documentation")

A0016655

Field transmitter TMT142 - Single compartment housing

®

Field transmitter with HART

communication. The one channel TMT142 allows for cost effective replacement

of smaller transmitters with tiny display and old style analog transmitters. Large and brilliant blue backlit

display. Regardless of whether you install the transmitter in a dark location or in direct sunlight, you still get a

clear temperature reading. Reliable temperature measurment through advanced diagnostics. For details, see

Technical Information.

TH11, TH12

Type of transmitter (dimensions in mm [in]) Specification

Temperature field transmitter iTEMP

HART® TMT142

• Material: Die-cast aluminium housing AlSi10Mg/AlSi12 with powder

®

coating on polyester base

• Display rotatable in 90° increments

• Cable entry: 3 x ½" NPT

• Degree of protection NEMA Type 4x Encl. (IP67)

• Brilliant blue backlit display with ease of visibility in bright sunshine or pitch

darkness

• Gold plated terminals to avoid corrosion and additional measurement errors

Details see Technical Information (see "Documentation")

T09-TMT142ZZ-06-00-06-xx-000

6 Endress+Hauser

Page 7

TH11, TH12

Housing

Type of housing (dimensions in mm [in]) Specification

TA30A

TA30H

• Degree of protection: IP66/68

• Temperature: -50 °C to +150 °C (-58 °F to +302 °F) without cable gland

• Material: aluminium, polyester powder coated

Seals: silicone

• Cable entry incl. glands: ½" NPT and M20x1.5, only thread: G½",

plugs: M12x1 PA, 7/8" FF

• Protection armature connection: M24x1.5

• Head color: blue RAL 5012

• Cap color: gray RAL 7035

• Weight: 420 g (14.81 oz)

• Head transmitter optional with TID10 display

A0009821

• Flameproof (XP) version, explosion-protected, captive screw cap

• Degree of protection: IP66/68

• Temperature: -50 °C to +150 °C (-58 °F to +302 °F) for rubber seal without

cable gland (observe max. permitted temperature of the cable gland!)

• Material: aluminium; polyester powder coated

• Cable entry glands:

½" NPT, ¾" NPT, M20x1.5, only thread G½";

plug: M12x1 PA, 7/8" FF

• Neck tube/thermowell connection: ½" NPT

• Color of head: blue, RAL 5012

• Color of cap: gray, RAL 7035

• Weight: 860 g (30.33 oz)

• Head transmitter optionally available with TID10 display

Terminal head Al (dimensions in inch)

Terminal head plastic (dimensions in inch)

A0009831

• Material: Die-cast Aluminium head

• Sensor connection: ½" NPT Female

• Cable entry: ½" NPT or ¾" NPT Female ½" NPT has got Al reducer bushing

• Color of head: Spray SPU, RAL 5012

• Color of cap: Spray SPU, RAL 7035

• Coating thread (body-cover), lubricant acc. E+H standard, MgO coating;

benefits include ease of opening/closing cover and improved thread

engagement. Improves life time of the terminal head.

• Degree of protection NEMA Type 4x Encl. (IP 66/68)

T09-TH11xxxx-06-xx-xx-ae-001

• Polyprolylene, FDA compliant

• Sensor connection: ½" NPT Female

• Cable entry: ½" NPT or ¾" NPT Female ½" NPT with nylon reducer bushing

(FDA compliant)

• Degree of protection NEMA Type 4x Encl.

T09-TH11xxxx-06-xx-xx-ae-000

Endress+Hauser 7

Page 8

Type of housing (dimensions in mm [in]) Specification

Terminal head deep drawn stainless steel, TA20J style

• Material: Deep drawn stainless steel AISI 316L SS (hygienic design)

• Optional with display and/or head transmitter

• Sensor connection: ½" NPT female

• Cable entry: ½" NPT female

• Degree of protection NEMA Type 4x Encl. (IP66)

Display:

• 4 digits 7-segments LC display (loop powered)

• Maximum error: 0.1% of programmed range

• Loop drop: 2.5 V at 22 mA

• Max. ambient temperature: -20 to 70°C (-4 to 160 °F)

The programming is executed through 3 keys mounted on the bottom of the

display.

TH11, TH12

* dimensions with optional display

Compression fitting All dimensions in inches

Type of fitting Sheath Ø

Material

• One time adjustable fitting

316 Stainless Steel coldfinished bar stock in accordance with ASTM A-479. Shaped bodies are machined

from close-grained 316 stainless steel forgings in accordance with ASTM A-182.

• Re-adjustable fitting

316 Stainless Steel with TFE ferrule.

A0005938

T09-TH1112xx-03-xx-xx-ae-000

Process

(T)

1/16" 1/8"-27 NPT 1.03 5/16" 7/16"

1/8"

3/16"

¼" 1/8"-27 NPT 1.29 9/16" ½"

¼" ¼"-18 NPT 1.49 9/16" 9/16"

3/8" ¼"-18 NPT 1.57 11/16" 5/8"

connection

(PT)

1/8"-27 NPT 1.20 7/16" 7/16"

¼"-18 NPT 1.40 7/16" 9/16"

1/8"-27 NPT 1.23 ½" ½"

¼"-18 NPT 1.43 ½" 9/16"

Over all

length (L)

Nut Hex

(NH)

Body Hex

(BH)

Performance characteristics

Response time 63% response time per ASTM E644

Construction Ø 1/8" Ø 3/16" Ø ¼" Ø 3/8" red. 3/16"

High temp. range 2 s 2 s 3 s not available

Low temp. range 3 s 7 s 9 s 6 s

Response time for the sensor assembly without transmitter.

8 Endress+Hauser

Page 9

TH11, TH12

Maximum measured error RTD corresponding to IEC 60751

Sensor element Class max. Tolerances (°C) Temperature range

Thin film (TF) A ± (0.15 + 0.002 · |t|

B ± (0.3 + 0.005 · |t|

Wire wound (WW) A ± (0.15 + 0.002 · |t|

B ± (0.3 + 0.005 · |t|1) -200 °C to +600 °C (-328 °F to +1112 °F)

1) |t| = absolute value °C

For measured error in °F, calculate using equation above in °C, then multiply the outcome by 1.8.

Transmitter specifications

1

)

1

)

1

) -100 °C to +450 °C (-148 °F to +842 °F)

-50 °C to +200 °C (-58 °F to +392 °F)

TMT82 HART®/

TMT84 PA /

TMT85 FF

Measurment

accuracy ± typ. 0.25 °C (0.45 °F)

Sensor current I ≤ 0.3 mA I ≤ 0.6 mA I ≤ 0.2 mA I ≤ 0.3 mA

Galvanic isolation

(input/output)

1) % is related to the adjusted measurement range (the larger value applies)

U = 2 kV AC - U = 2 kV AC

Transmitter long-term

stabiltiy

TMT180 Pt100 PCP TMT181

multifunctional

PCP

0.2 °C (0.36 °F), optional

0.1 °C (0.18 °F) or 0.08%

1

0.5 °C (0.9 °F) or 0.08%

TMT182 HART® TMT162 HART®

Field transmitter

1

≤ 0.105 °C (0.19 °F) 0.2 °C (0.36 °F)

≤ 0.1 °C/year (≤ 0.18 °F / year) or ≤ 0.05% / year

Data under reference conditions; % relates to the set span. The larger value applies.

TMT142

Insulation resistance Insulation resistance between terminals and probe sheath, test voltage 250 V.

• ≥100 MΩ at 25 °C (77 °F)

• ≥10 MΩ at 300 °C (572 °F)

Self heating RTD elements are not self-powered and require a small current be passed through the device to provide a

voltage that can be measured. Self-heating is the rise of temperature within the element itself, caused by the

current flowing through the element. This self-heating appears as a measurement error and is affected by the

thermal conductivity and velocity of the process being measured; it is negligible when an Endress+Hauser

®

temperature transmitter is connected.

iTEMP

Endress+Hauser 9

Page 10

Wiring

Wiring diagrams Type of sensor connection TH11

Head transmitter mounted

Head mounted transmitter iTEMP® TMT8x (dual input)

TH11, TH12

A0016433-EN

A0008848-EN

10 Endress+Hauser

Page 11

TH11, TH12

Head mounted transmitter iTEMP® TMT162

Head mounted transmitter iTEMP® TMT142

T09-TMT162ZZ-04-00-XX-en-000

T09-TMT142ZZ-04-00-XX-en-003

Endress+Hauser 11

Page 12

Terminal block mounted

TH11, TH12

T09-TH1112xx-04-xx-XX-ae-001

Wire specifications TH11

24AWG, 19 strand silver plated copper with 0.010” PTFE extruded outer, 1/8” sensors have 28AWG seven

strand wires with the same extrusion.

TH12

24AWG, seven strand silver plated copper with 0.010” PTFE then 0.015” FEP outer jacket, 1/8” sensors are

28AWG, seven strand SPC, 0.010” PTFE, 0.015” FEP white outer jacket. Flex armor is 0.272” nominal OD,

304SS 0.010” thick , square lock style.

The maximum temperature for the extension cable is 200 °C (392 °F).

TH12 is available only with conductor external lead wires, DIN rail transmitters (TMT121 PCP /

TMT122 HART

®

) are available, see "Documentation".

The blocks and transmitters are shown as they sit inside the heads in reference to the conduit opening.

12 Endress+Hauser

Page 13

TH11, TH12

Installation conditions

Orientation No restrictions for installation orientation.

Installation instructions

Ambient temperature

Installation examples

A - B: In pipes with a small cross section the sensor tip should reach or extend slightly past the center line of the pipe (= L).

C - D: Tilted installation.

A0009538

The immersion length of the thermometer influences the accuracy. If the immersion length is too small then

errors in the measurement are caused by heat conduction via the process connection and the container wall.

If installing into a pipe then the immersion length must be half of the pipe diameter, ideally.

• Installation possibilities: Pipes, tanks or other plant components

• Minimum immersion length = 80 to 100 mm (3.15 to 3.94 in)

The immersion length should correspond to at least 8 times of the thermowell diameter. Example:

Thermowell diameter 12 mm (0.47 in) x 8 = 96 mm (3.8 in). A standard immersion length of 120 mm

(4.72 in) is recommended

• ATEX certification: Always take note of the installation regulations!

When operating in small nominal bore pipes it must be guaranteed that the thermowell tip is extending far

enough into the process to reach out past the pipe center line (see Pos. A and B). A further solution could be

an angled (tilted) installation (see Pos. C and D). When determining the immersion length all thermometer

parameters and the process to be measured must be taken into account (e.g. flow velocity, process pressure).

Environmental conditions

Terminal head Temperature in °C (°F)

Without mounted head transmitter Depends on the terminal head used and the cable gland or fieldbus connec-

tor, see 'Terminal heads' section, → ä 7

With mounted head transmitter -40 to 85 °C (-40 to 185 °F)

With mounted head transmitter and display -20 to 70 °C (-4 to 158 °F)

Shock and vibration resistance 4G / 2 to 150 Hz as per IEC 60068-2-6

Endress+Hauser 13

Page 14

Process conditions

Process pressure limits p/T load curve example for low temperature range - thin film construction according to Dittrich.

• L = insertion length

= flow velocity air

•v

a

•v

= flow velocity water or steam

w/s

Example calculation: Probe = 316 SS

sheath ∅ = ¼", 0.028" wall thickness

Avoid resonance frequency as this will

cause damage to the probe!

• L = 4 and 6 in:

Resonance frequency occurs when

permanent flow velocity is at 18.1,

22.6 or 27.1 ft/s (air) for 6 in and/or

40.5, 50.6 or 60.8 ft/s (air) for 4 in

probe (T = 482 °F, p = 2700/2600

psi).

• L = 9 and 12 in:

Resonance frequency occurs when

permanent flow velocity is at 8.1, 10.1

or 12.1 ft/s (air) for 9 in and/or 4.6,

5.7 or 6.8 ft/s (air) for 12 in probe (T

= 482 °F, p = 2600 psi).

TH11, TH12

T09-TH1112xx-05-xx-xx-ae-000

T09-TH1112xx-05-xx-xx-ae-001

Max. allowable process pressure (PSIG) for instrumentation with one time adjustable compression fittings.

Temperature 1/8" NPT & ¼" NPT compression fitting

°F °C sheath Ø = 1/8"

x 0.012" wall

thickness

-20 to 300 -28 to 149 2850 3150 3350 3900

400 204 2750 3050 3250 3800

500 260 2550 2850 3000 3500

600 316 2400 2700 2850 3300

700 371 2350 2600 2750 3200

800 427 2300 2550 2650 3100

900 482 2200 2450 2600 3050

1000 538 2100 2300 2450 2850

1) Not available with compression fittings 1/8" NPT

sheath Ø = 3/16"

x .0.020" wall

thickness

sheath Ø = ¼" x

0.028" wall

thickness

sheath Ø = 3/8"

x 0.12" wall

thickness

1

For high temperature range construction with compacted magnesium oxide (MgO) the values might

be higher. In any case for different length, other materials, variation in sheath diameter or wall

thicknesses stress analysis is recommended. Failures are caused by forces imposed by static pressure,

steady state flow and vibration.

Re-adjustable compression fittings are not intended to be used for pressure retaining applications and

should only be used tor the mechanical holding of sensors.

14 Endress+Hauser

Page 15

TH11, TH12

Design, dimensions

Mechanical construction

For values related to this graphic please refer to the table below.

Dimensions in inches:

Immersion length X Wire length B Sheath diameter A

TH11 TH12

4", 6", 9", 12" 6", 12", 18", 24"

specified length 2" to 96" in ½"

increments

1) High temperature version is not available with reduced tip.

Weight From 1 to 5.5 lbs

Material Wetted parts 316 SS

48", 72", 120"

specified length

12" to 300" in

12" increments

(A’)

1/8 in 316 SS 0.012" -

3/16 in 316 SS 0.020" -

¼ in 316 SS 0.028" -

3/8 in (A’) red.

3/16 in (A) 316 SS

Wall thickness s Reduced

0.120" (0.016" at tip) 1¼"

1

T09-TH1112xx-06-xx-xx-ae-000

length L

Endress+Hauser 15

Page 16

TH11, TH12

Certificates and approvals

CE Mark The iTEMP® Series of temperature transmitters complies with the legal requirements laid out within the EU

regulations.

Other standards and

guidelines

UL Temperature transmitter are recognized components to UL 3111-1 (iTEMP

• IEC 60529:

Degrees of protection by housing (IP-Code).

• IEC 61010:

Safety requirements for electrical measurement, control and laboratory instrumentation.

• ASTM E644:

American society for testing and materials, standard test methods for testing industrial

resistance thermometers.

• NEMA - ANSI / NEMA 250

Standardization association for the electrical industry.

• IEC 60571

Industrial platinum resistance thermometer

®

Series).

16 Endress+Hauser

Page 17

TH11, TH12

Ordering information

Detailed ordering information is available from the following sources:

•In the Product Configurator on the Endress+Hauser web page:

www.endress.com → Select country → Instruments → Select device → Product page function:

Configure this product

• From your Endress+Hauser Sales Center: www.endress.com/worldwide

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as measuring range or

operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Documentation

Short operation manual:

• TH11 RTD temperature sensor (KA178r/24/ae)

• TH12 RTD temperature sensor with cable (KA179r/24/ae)

Technical Information:

• Temperature head transmitter:

–iTEMP® HART® TMT82 (TI01010T/09/en)

–iTEMP® PROFIBUS PA TMT84 (TI138R/09/en)

–iTEMP® FF TMT85 (TI134R/09/en)

–iTEMP

–iTEMP® HART® TMT162 (TI086r/24/ae)

–iTEMP® PCP TMT181 (TI070r/24/ae)

–iTEMP

–iTEMP® HART® TMT182 (TI078r/24/ae)

®

HART® TMT142 (TI107R/09/en)

®

Pt TMT180 (TI088r/24/ae)

Application example:

• Technical information:

– Field indicator RIA16 (TI00144R/09/en)

– Power supply RNS221 (TI081R/24/ae)

– Data Manager Memograph M, RSG40 (TI133R/09/en)

Endress+Hauser 17

Page 18

CanadaUSA

Endress+Hauser Canada

1075 Sutton Drive

Burlington, ON L7L 5Z8

Canada

Tel.905-681-9292

800-668-3199

Fax905-681-9444

www.ca.endress.com

Endress+Hauser, Inc.

2350 Endress Place

Greenwood, IN 46143

USA

Tel.317-535-7138

Fax317-535-8498

Sales888-ENDRESS

Service800-642-8737

inquiry@us.endress.com

www.us.endress.com

México

Endress+Hauser, México, S.A. de C.V.F

Fernando Montes de Oca 21 Edificio A Piso 3

Fracc. Industrial San Nicolas

54030. Tlalnepantla de Baz

México

Tel.+52 55 5321 2080

Fax+52 55

eh.mexico@mx.endress.com

www.mx.endress.com

Estado de México

5321 2099

Instruments International

Endress+Hauser

Instruments International AG

Kaegenstrasse 2

4153 Reinach

Switzerland

Tel.+41 61 715 81 00

Fax+41 61 715 25 00

www.endress.com

info@ii.endress.com

TI00108R/24/en/01.11

71147552

FM9.0

Loading...

Loading...