Endress+Hauser Tankvision NXA820 Operating Instructions Manual

Products Solutions Services

BA01137G/00/EN/03.17

71387780

Valid as of software version:

V 02.01.00

Operating Instructions

Tankvision

NXA820 OPC Server

User Manual

Tankvision

2 Endress+Hauser

A0023555

Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to

these Instructions.

Order code:

Ext. ord. cd.:

Ser. no.:

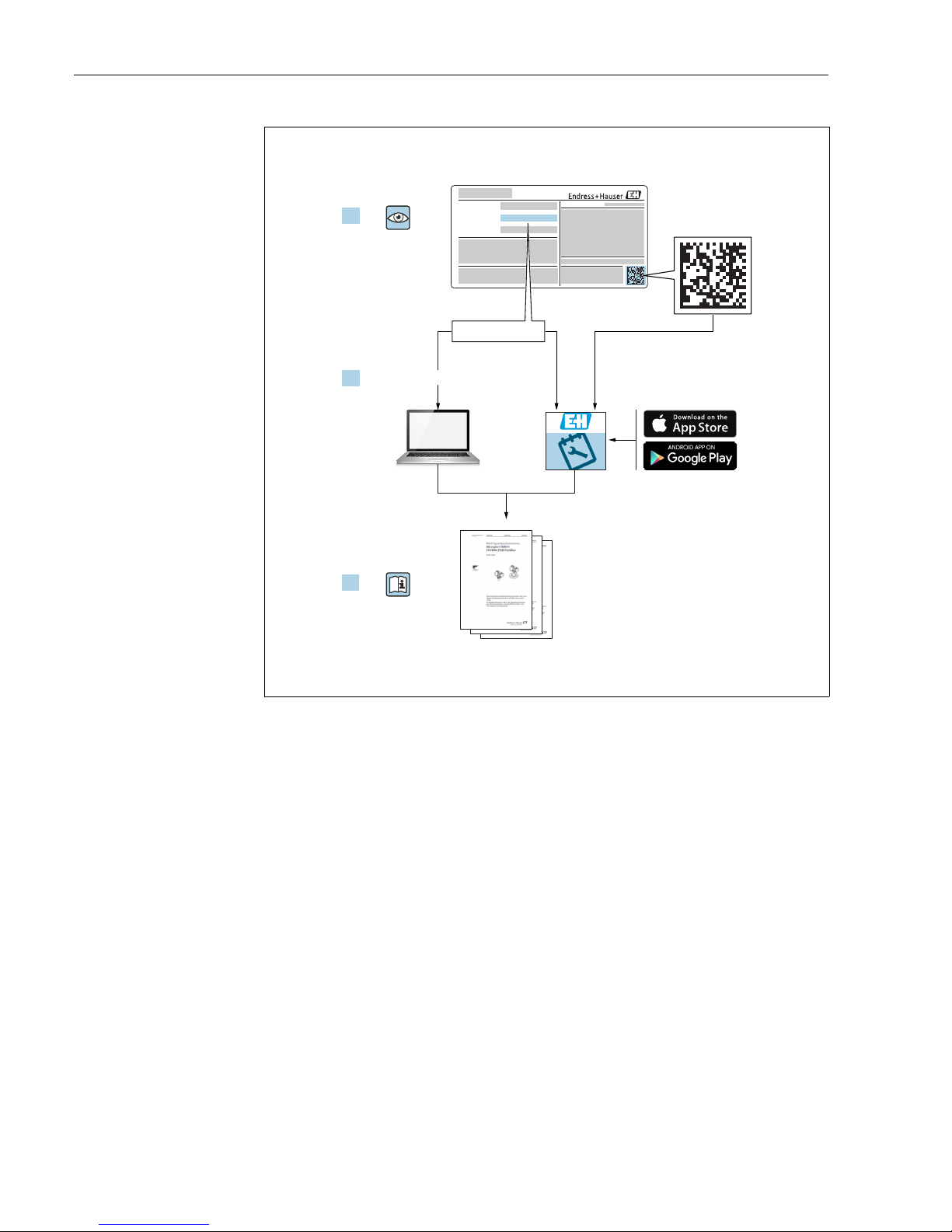

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

Tankvision

Endress+Hauser 3

Table of Contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Target audience for this manual . . . . . . . . . . . . . . . 4

1.2 Version history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Acronyms, Abbreviation and Definition . . . . . . . . 4

1.4 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Basic safety instructions . . . . . . . . . . . . . 7

2.1 Requirements for the personnel . . . . . . . . . . . . . . . 7

2.2 IT security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Required files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Supported Windows version . . . . . . . . . . . . . . . . . . 9

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Configuration . . . . . . . . . . . . . . . . . . . . . 12

4.1 Basic OPC Server Configuration . . . . . . . . . . . . . 13

4.2 Start OPC Server . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Stop OPC Server . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 OPC Data Structure . . . . . . . . . . . . . . . .14

6 Tankvision OPC Parameter. . . . . . . . . . 15

6.1 Tank Parameter Reference . . . . . . . . . . . . . . . . . 19

7 Advanced OPC Server Configuration. . 23

7.1 TankvisionOPC.config . . . . . . . . . . . . . . . . . . . . . . 23

Document information Tankvision

4 Endress+Hauser

1 Document information

1.1 Target audience for this manual

This documents describes installation and user guide for configuration and usage of

Tankvision OPC DA 3.0 Server.

This guide is for users of Tankvision system and OPC Servers/Clients. The intended audience

includes Project Engineers and System Administrators.

Beside basic PC operating knowledge no special training is needed to perform the Tank

Gauging System operations. Nevertheless it is recommended receiving a training on the

system by Endress+Hauser.

1.2 Version history

1.3 Acronyms, Abbreviation and Definition

1.4 Document function

1.4.1 Used symbols

Safety symbols

Document version Valid for SW version Changes to the previous version

BA01137G/00/EN/01.13 01.05.00 Initial version

BA01137G/00/EN/02.17 02.00.00 Added Temperature and Density Profile

parameters

BA01137G/00/EN/03.17 02.01.00 Introduced Floating Roof Weight

Correction, Redundancy functionality

with NXA820 Interface Only, CH alarm

for Volume or Mass

Abbreviation Meaning

OPC

OLE for Process Control

Open Interoperability standards developed by OPC Foundation

OPC DA 3.0 OPC Data Access specification version 3.0 specification

COM Component Object Model

DCOM Distributed Component Object Model

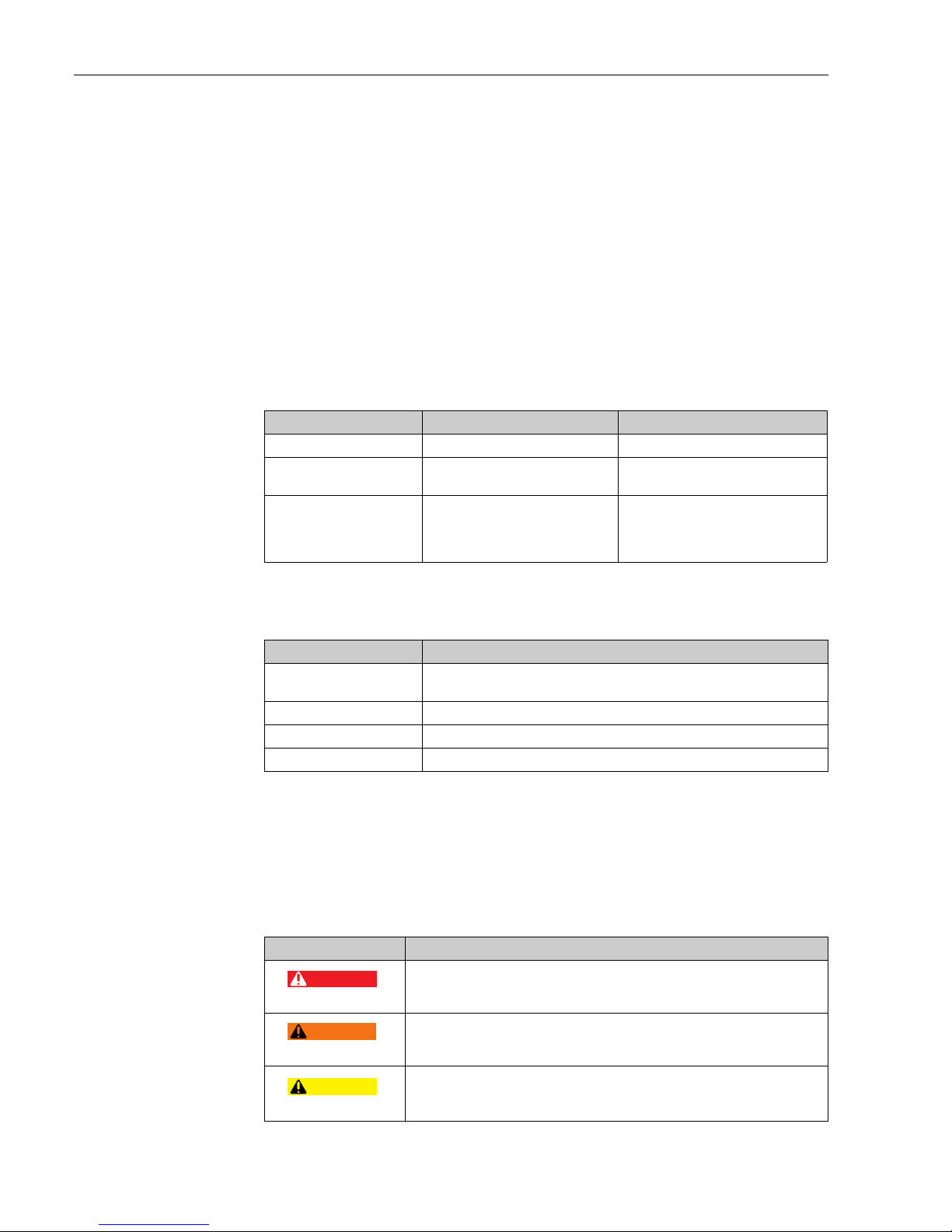

Symbol Meaning

A0011189-EN

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

A0011190-EN

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

A0011191-EN

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

DANGER

WARNING

CAUTION

Tankvision Document information

Endress+Hauser 5

Electrical symbols

Symbols for certain types of information

Symbols in graphics

A0011192-EN

NOTICE!

This symbol contains information on procedures and other facts which do not result

in personal injury.

Symbol Meaning

A0011197

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

A0011198

Alternating current

A terminal to which alternating voltage is applied or through which alternating current flows.

A0011200

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

system.

A0011199

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Symbol Meaning

A0011193

Tip

Indicates additional information.

A0011195

Reference to page

Refers to the corresponding page number.

, , ... Series of steps

A0018373

Result of a sequence of actions

Symbol Meaning

1, 2, 3 ... Item numbers

, , ... Series of steps

A, B, C ... Views

A0011187

Hazardous area

Indicates a hazardous area.

A0011188

Indicates a non-hazardous location

Safe area (non-hazardous area)

Symbol Meaning

NOTICE

)

*

1.2.1.

2.

-

.

Document information Tankvision

6 Endress+Hauser

1.5 Documentation

1.5.1 Operating instructions

Document number Instrument Type of Document

BA01137G/00 Tankvision NXA820 OPC Server User Manual

Tankvision Basic safety instructions

Endress+Hauser 7

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner operator

• Following the instructions in these Operating Instructions

2.2 IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser can be contacted to provide support in performing this task.

2.3 Designated use

2.3.1 Application

Tankvision is a dedicated tank inventory management system.

Components:

• Tankvision Tank Scanner NXA820

scans parameters from tank gauges and performs tank calculations

• Tankvision Data Concentrator NXA821

summarizes data from various Tank Scanners NXA820

• Tankvision Host Link NXA822

provides data to host systems (such as PLC or DCS) via Modbus

The above mentioned components are operated via a standard web browser. It does not

require any proprietary software. Tankvision is based on a distributed architecture on a Local

Area Network (LAN). Due to its modular structure it can be adjusted to any application. It is

ideally suited for small tank farms with only a couple of tanks, but also for large refineries

with hundreds of tanks.

Basic safety instructions Tankvision

8 Endress+Hauser

2.4 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national

regulations.

• Switch off the supply voltage before connecting the device.

2.5 Operational safety

Risk of injury!

• Operate the device in proper technical condition and fail-safe condition only.

• The operator is responsible for interference-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers

• If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

• Carry out repairs on the device only if they are expressly permitted.

• Observe federal/national regulations pertaining to repair of an electrical device.

• Use original spare parts and accessories from Endress+Hauser only.

2.6 Product safety

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device complies with the

applicable standards and regulations as listed in the EC declaration of conformity and thus

complies with the statutory requirements of the EG directives. Endress+Hauser confirms the

successful testing of the device by affixing to it the CE mark.

Tankvision Installation

Endress+Hauser 9

3Installation

3.1 Required files

TankvisionOPCServer_Installer.msi: This file contains complete installable for Tankvision

OPC Server application.

3.2 Supported Windows version

• Windows XP (Service Pack 3)

• Windows 7 (32 bit / 64 bit)

• Windows 10 (32 bit / 64 bit)

On 64-bit machines OPC Server will be installed and run in 32-bit compatibility mode.

I.e. OPC Server will be installed in C:\Program Files(x86) or equivalent location.

3.3 Installation

You need to have administrator access right to install the software.

Install Microsoft .NET Framework 4 or higher before installation.

3.3.1 Install Microsoft .NET Framework 4

• Web Installer

http://www.microsoft.com/en-us/download/details.aspx?id=17851

• Standalone Installer

http://www.microsoft.com/en-in/download/details.aspx?id=17718

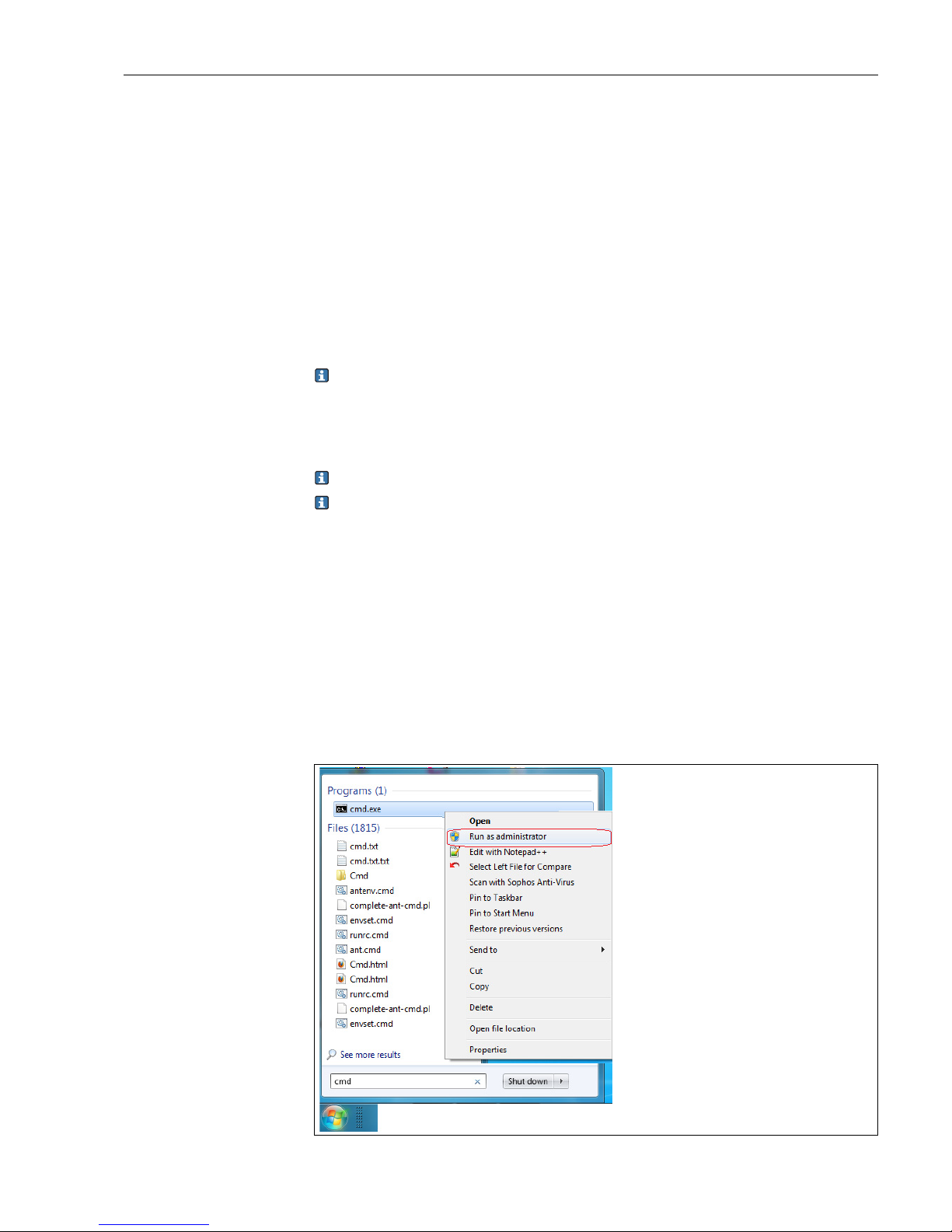

3.3.2 Install Tankvision OPC Server

Windows 7

Open Command prompt in Administrator mode as shown in below figure:

Loading...

Loading...