Page 1

Technical Information

TI155T/02/en

No. 71108023

Industrial protecting tube

omnigrad TA556

Heavy duty - General purpose

From round bar stock - Ø 35 mm

1" NPT threaded or flanged weld type

Also ENI BAR 3 & BAR 4

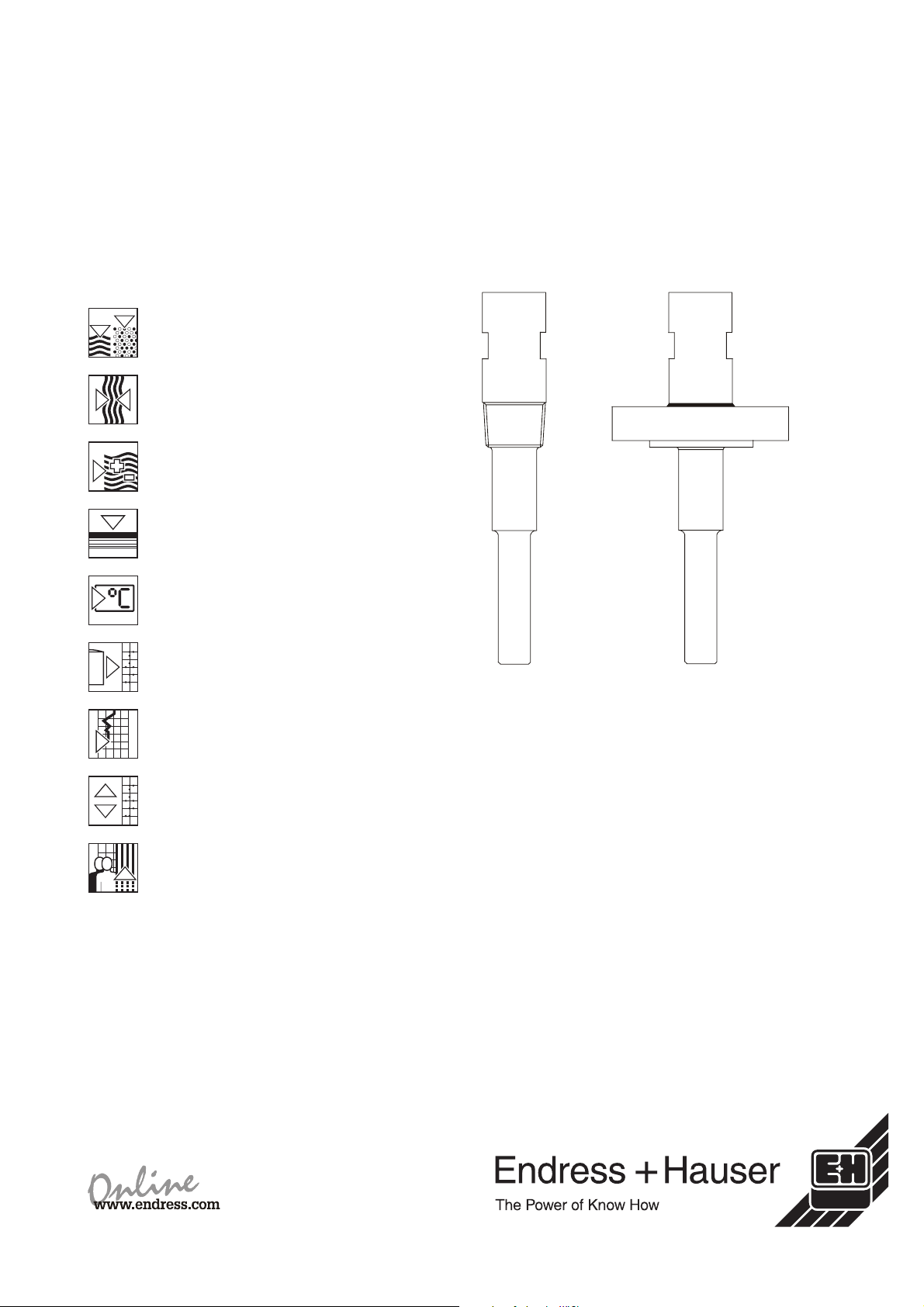

Threaded

process connection

Description

TA556 is an industry standard

thermowell, manufactured from round bar

stock (drilled).

The process connection can be threaded

or flanged weld.

The thermowell stem shape can be

straight or conical.

The extension and the immersion lengths

as well as the bar dimensions can be

chosen according to process

requirements.

A wide choice of standard materials and

process connections is available; other

versions can be ordered according to

specification.

Different grades of surface finishing are

also available.

Flanged

process connection

Application

TA556 is designed for use with resistance

and thermocouple thermometers mainly

in heavy duty applications.

Page 2

Technical data

Round bar Standard reference: ENI BAR 3 & BAR 4

Extension O.D.: 35 mm

Immersion O.D.: <

Standard ext. length: 100 mm

Standard bore diameter: 10 or 14 mm

Standard material: AISI316/W.1.4401, AISI316L/W.1.4404

Process connection Type: threaded or flanged weld

Thread: 1" NPT

Flange type: ANSI slip-on

Flange material: AISI 316 or A 105

Flange mounting: threaded and back welded - 3x3 mm wide

Tip Bottom shape: straight or tapered

Std. bottom thickness: 5 mm

28 mm

omnigrad TA556

Surface Finishing: refer to the order key

2 Endress+ Hauser

Page 3

omnigrad TA556

Notes:

(1) Wall thickness 3 mm minimum

(Q2 - F) / 2 ≥ 3 mm and

(2) Nominal length A: 160 ÷ 1000 mm

Ø 35

¾ NPT

”

T

1 NPT

”

A

U

T

A

U

R

Ø 35

Ø Q1

Ø F

Ø Q2

¾ NPT

”

Ø Q1

Order key

TA556- HEAVY DUTY THERMOWELL - General purpose - From round bar stock

Ø 35 mm - 1" NPT threaded or flanged weld type - Also ENI BAR 3 & BAR 4

Extension, thermowell shape and type (2)

A 100 mm=T,Q1/Q2=25/20 R=110mm,ENI

B 100 mm=T,Q1/Q2=25/16 R=110mm,ENI

Y mm=T, Q1=mm Q2=mm R=mm special tap (1)

Immersion Length U (60-900mm) (2)

TF 150 mm immersion length U

XX mm immersion length to specific.

YY mm special immersion length

Thermowell type, price per mm A (U+T)

C Thermowell material: SS316 / 1.4401

D Thermowell material: SS316L / 1.4404

Y Special version

Finishing of immersion length

4 1,6 micron finishing immersion length

1 0,8 micron finishing immersion length

Process connection type

AA Process connection: none (1" NPT)

CD Slip-on 1" ANSI 300 RF SS316

CH Slip-on 1 1/2" ANSI 150 RF SS316

CK Slip-on 1 1/2" ANSI 300 RF SS316

CP Slip-on 1 1/2" ANSI 600 RTJ SS316

CV Slip-on 2" ANSI 300 RF SS316

CX Slip-on 2" ANSI 300 RTJ SS316

YY Special version

Flange finishing

1 Finishing: not required (no flange)

2 Finishing: standard for ASME/ANSI

9 Flange finishing as specified

Thermowell bore diameter F

5 ENI BAR 4; 10mm thermowell bore

6 ENI BAR 3; 14mm thermowell bore

9 Special version (1)

Plug and chain

A Safety plug not selected

B Safety plug: SS 304 with chain

Markings

0 Markings not selected

1 Markings punched on

R

Ø F

Ø Q2

TA556- Complete Order Code

Endress+Hauser 3

Page 4

Supplementary

Documentation

• Technical Information Industrial Protecting Tubes (TI138T/02/en)

TI155T/02/en/05.01

FM+SGML 6.0

No: 71108023

Endress+Hauser

Gmbh+Co.

Instruments International

P.O. Box 2222

D-79574 Weil am Rhein

Germany

Tel. (07621) 975-02

Tx 773926

Fax (07621) 975 345

http://www.endress.com

info@ii.endress.com

Loading...

Loading...