Page 1

Technical Information

71098772

Omnigrad S -TR61

RTD thermometer EEx-d or EEx-ia certified, replaceable insert,

thermowell from pipe, process connection: threaded or flanged or sliding.

PCP (4...20 mA), HART® or PROFIBUS-PA® electronics

Range of uses

The Omnigrad S TR61 is an RTD industrial thermometer with

a inset (Pt100) and thermowell from pipe.

It is developed for the use in the chemical, petrochemical and

energy industries, but suitable also for other generic applications.

In compliance to EN 50014/18/20 (ATEX certification) it is

therefore particularly suitable also for hazardous areas.

When required, it’s also available with a transmitter(PCP,

HART® or PROFIBUS-PA®) into the housing.

The process connection of the thermowell can be threaded,

flanged or with a compression fitting in compliance to the standard rule DIN 43772 (form 2/3, 2G/3G and 2F/3F).

Application areas

• Chemicals industry

• Energy industry

• Gas Processing industry

• Petrochemical industry

• General industrial services

Features and benefits

• SS 316L/1.4404, SS 316Ti/1.4571 and Hast. C276/2.4819

for the “wetted” parts

• The most common process connections: threaded, flanged

and compression fitting are standard; others are on request

• Customized immersion length

• Surface finishing down to Ra < 0.8 μm

• Aluminium housing, with protection grade from IP66 to IP68

• Mineral oxide replaceable insulated insert (MgO) diameter:

3 or 6 mm

• PCP, HART® and PROFIBUS-PA®, (4...20 mA 2-wire transmitters)

• The accuracy of the sensing element (Pt100) is: class A or 1/3

DIN B (IEC 60751) with electrical connection to 2, 3 or 4

wires

• The sensing elements (Pt100) are available in wire-wound

WW (range:-200...600°C) or thin-film TF (range:-

50...400°C) with single or double Pt100 execution

• ATEX 1/2 GD EEx-ia certification

• ATEX 1/2 GD EEx-d certification

• ATEX 2 GD EEx-d certification

4 0

TI280T/02/en

Page 2

Omnigrad S -TR61

Function and system design

Measuring principle The RTD (Resistance Temperature Detector), is a sensor where the electrical resistance varies with the tem-

perature. The material of the RTD is Platinum (Pt) with a value of the resistance (R), referred to a nominal value

at the temperature of 0°C = 100,00 Ω (in compliance to rule EN 60751; it is called Pt100). The very important

is to define the RTD; it is defined with a standard "α" value measured between 0°C and 100°C.

This value is: α = 3.85 x 10

The temperature is measured indirectly by reading the voltage drop across the sensing resistor in the presence

of a constant current flowing through it using Ohm’s. The measuring current should be as small as possible to

minimise possible sensor selfheating; normally this current is around 1mA, no higher.

The resistance value measured for each degree is about = 0,391 Ohm/K; over 0°C it is opposite proportional

at the temperature. The standard RTD connection at the plant instrument can be to 2,3 or 4 wires for simple

or double RTD element.

Equipment architecture The construction of the Omnigrad S TR61 temperature sensor is based on the following standards:

• EN 50014/18 (housing)

• DIN 43772 (thermowell)

• EN 600751 (inset).

-3

°C-1.

The housing is in painted aluminium alloy; it is suitable to contain a transmitter and/or the ceramic

block of the inset; the “Ingress Protection” is from

IP66 to IP68.

The thermowell can be made from tube with diameter 9, 11 or 12 mm.

The final part of the thermowell can be straight,

tapered or reduced.

The process connection of the thermowell can be

threaded (GAS or NPT), flanged (DIN or ANSI) or

with a compression fitting (see the section "System

components").

The replaceable inset is a probe’s tip with a Pt100

positioned into; it is placed inside the thermowell.

Material & Weight

Operating conditions

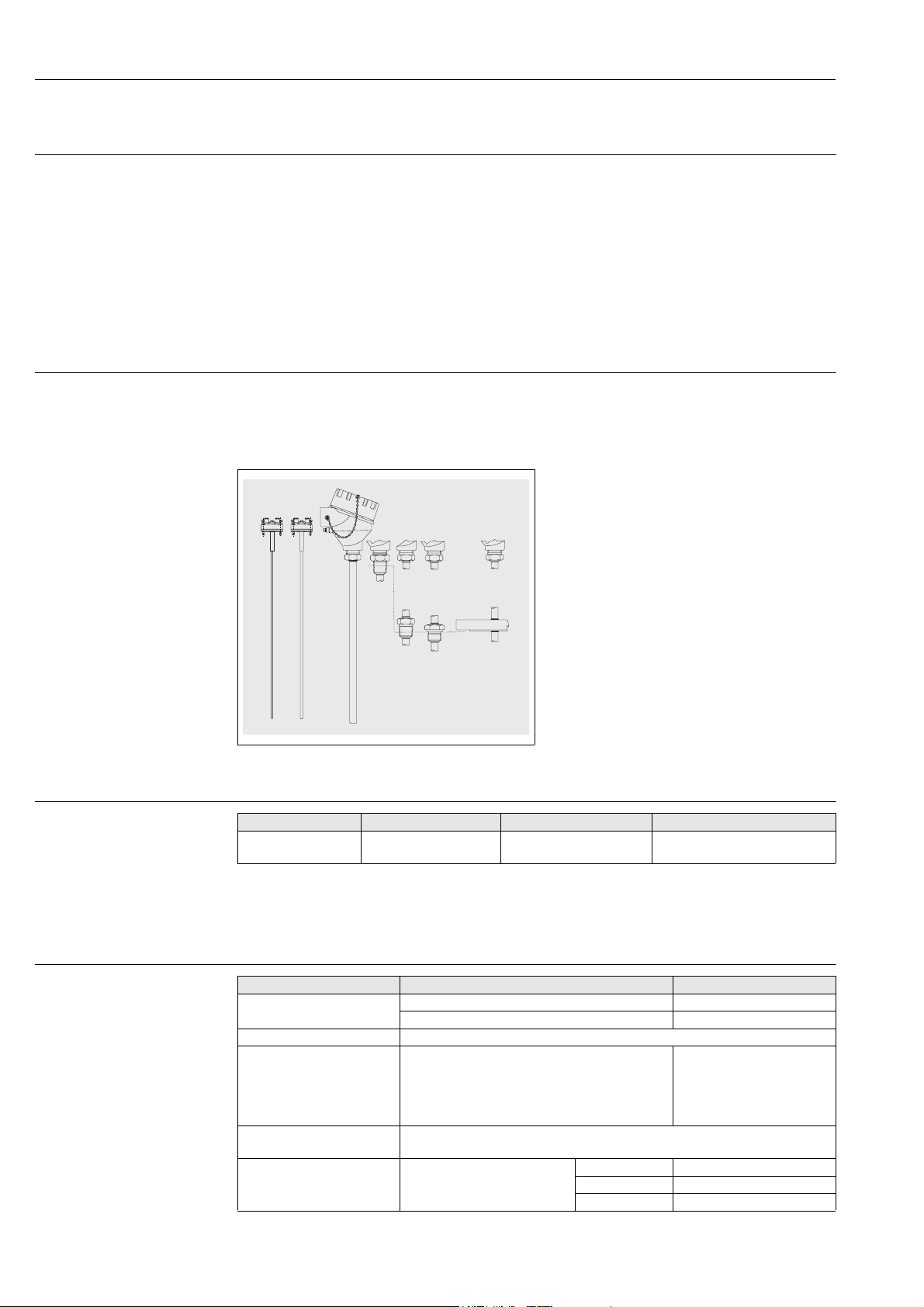

Fig. 1: TR61 with the various types of process connections and end parts of the probe

Housing Insert Process connection Weight

aluminium epoxy

coated

sheath in SS 316L/1.4404 fixed or sliding SS

316/1.4401

From 0.5 to 1.0 kg for standard

options

Performance

Operating condition or test Product type or rules Value or data of test

Ambient temperature housing (without head-mounted transmitter -40÷130°C

housing (with head-mounted transmitter) -40÷85°C

Process temperature Same of measurement range (see below).

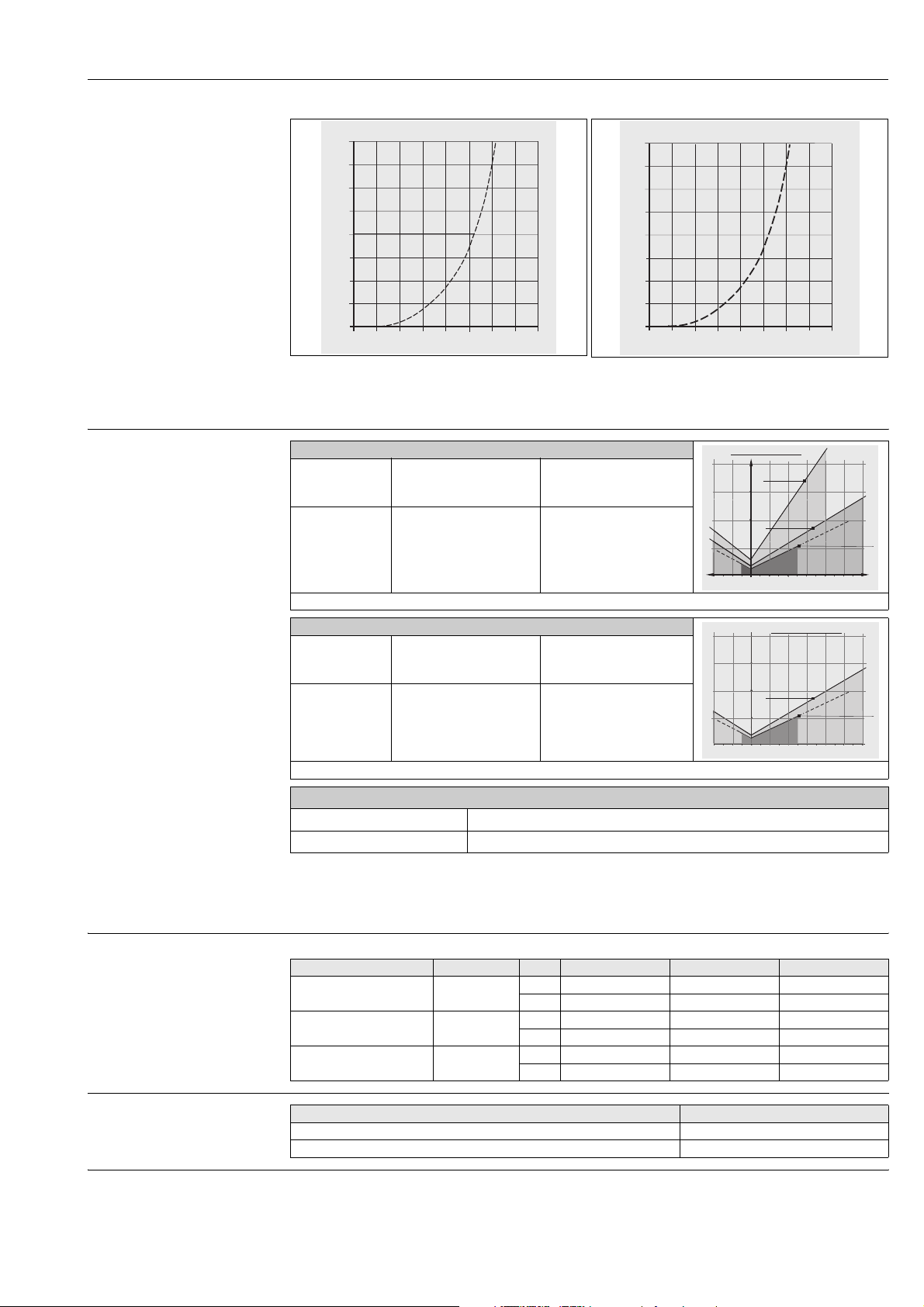

Process pressure (Maximum) The pressure values to which the thermowell can be

Maximum flow velocity The highest flow velocity, (of the stream or of the fluid), tolerated by the thermowell,

Shock and vibration resistance

test

subjected at the various temperatures are illustrated

by the drawings in fig. 2 . For 9 mm diameter pipes,

with a limited flow velocity, the maximum tolerated

pressures are the following:

diminishes with increasing lengths, of the thermowell/probe exposed (fig. 2 ).

RTD Inset in according to the rule

IEC 60751:

Acceleration 3 g of peak

Frequency from 10Hz to 500Hz and back

Time of the test 10 hours

50 bar to 20°C

33 bar to 250°C

24 bar to 400°C

2 Endress+ Hauser

Page 3

Omnigrad S -TR61

L=250 mm; Vsteam = 40 m/s

25

50

75

100

0

100 150

200 250 300

50

°C

Temperature

Maximum

pressure

allowed

125

150

350

400

Bar

450

Steam pressure

L=220 -> 280 mm; Vwater = 3 m/s

L=220 mm; Vair = 40 m/s

L=280 mm; Vair = 40 m/s

175

200

L=220 mm; Vsteam = 40 m/s

L=280 mm; Vsteam = 40 m/s

form 3

Accuracy

200

Bar

175

150

125

L = -> mm; Vwater=3m/s250 400

100

75

50

L = 250 mm; Vair = 40 m/s

Maximum pressure allowed

25

L = 400 mm; Vair = 40 m/s

0

50

form 2

Steam pressure

L = 250 mm; Vsteam= 40 m/s

L = 400 mm; Vsteam= 40 m/s

100 150 200 250 300

Temperature

form 3

Steam pressure

L = 220 -> 280 mm; Vwater = 3 m/s

L = 220 mm; Vair = 40 m/s

L=280mm; Vair=40m/s

Maximum pressure allowed

350

400

450

°C

200

L = 220 mm; Vsteam = 40 m/s

L = 280 mm; Vsteam = 40 m/s

Fig. 2: Pressure/temperature drawing for thermowell with straight tube ø 11 mm in SS 316Ti/1.4571(left), with tapered tube ø 12 mm in

SS 316Ti/1.4571 (right)

RTD maximum error type TF - Range: -50 to 400°C

Cl. A 3σ = 0.15+0.0020It|

3σ = 0.30+0.0050ItI

Cl. 1/3 DIN B 3σ = 0.10+0.0017It|

3σ = 0.15+0.0020ItI

3σ = 0.15+0.0020ItI

3σ = 0.30+0.0050ItI

= -50…250°C

= +250…400°C

= 0…100°C

= -50...0

= 100...250°C

= 250…400°C

DIN-IEC-EN 60751

2,0

Class B (°C)

1,5

1,0

Class A (°C)

Tolerance

0,5

-200 -100 0 100 200 300 400 500 600°C

Class 1/3 DIN B (°C)

±3σ = range including 99.7% of the readings. (|t|= absolute value of the temperature in °C).

RTD maximum error type WW - Range: -200 to 600°C

Cl. A 3σ = 0.15+0.0020It| = -200…600°C

2,0

1,5

DIN-IEC-EN 60751

Cl. 1/3 DIN B 3σ = 0.10+0.0017It|

3σ = 0.15+0.0020ItI

3σ = 0.15+0.0020ItI

= -50...250°C

= -200...-50

= 250…600°C

1,0

Class A (°C)

Tolerance

0,5

-200 -100 0 100 200 300 400 500 600°C

Class 1/3 DIN B (°C)

±3σ = range including 99.7% of the readings. (|t|= absolute value of the temperature in °C).

Others errors

Transmitter maximum error See the corresponding documentation (codes at the end of the document)

Display maximum error 0.1% FSR + 1 digit (FSR = Full Scale Range)

The “4 wires” configuration, is provided as a standard connection for the single Pt 100’s excludes additional

errors in every condition.

Generally in the “4 wires” configuration there is a higher guarantee of accurancy.

Response time Tests in water at 0.4 m/s (according to IEC 60751; from 23 to 33°C step changes)

Insulation

Diameter of the stem Pt100 type t

9TF / WWt

11 TF / WW t

12 TF / WW t

Measurement Insulation type Result

Insulation resistance between terminals and probe sheath above 100 MΩ at 25°C

according to IEC 60751, test voltage 250 V above 10 MΩ at 300°C

Reduced tip Tapered tip Straight tip

(x)

7,5 s 11 s 18 s

50

t

21 s 37 s 55 s

90

7,5 s -- 18 s

50

t

21 s -- 55 s

90

-- 10 s 38 s

50

t

-- 24 s 125 s

90

Self heating Negligible when the E+H iTEMP® transmitters are employed.

Endress+Hauser 3

Page 4

Omnigrad S -TR61

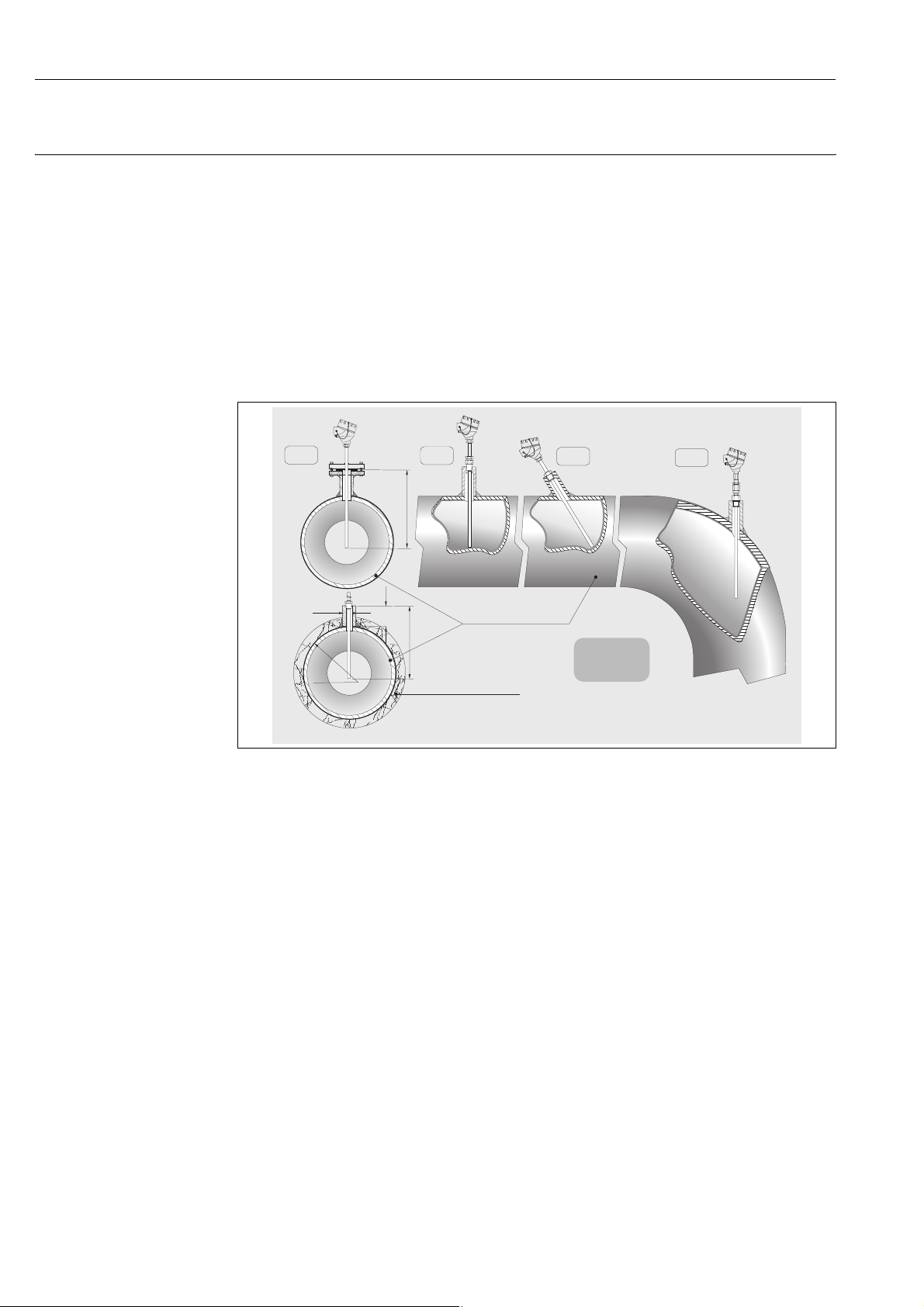

Installation

The Omnigrad S TR61 thermometers can be installed on pipes or tanks by means of threaded or flanged connections. The immersion length must take into account all the parameters of the thermometer and the process

to measure. If the immersion is too low, an error may be generated in the temperature recorded due to the

lower temperature of the process fluid near to the walls and heat transfer, which takes place through the sensor

stem. The incidence of such an error can be not negligible if there is a big difference between the process temperature and the ambient temperature. To prevent measuring errors of this kind, it is advisable to use thermometer with a small diameter on well and an immersion length (L) of at least 80÷100 mm.

In small section ducts the tubing’s axis must be reached and preferibly slightly exceeded by the tip of the probe

(see fig. 3A-3C).

Insulation of the outer part of the sensor reduces the effect produced by a low immersion. Alternatively, it is

also possible to adopt a tilted installation (see fig. 3B-3D).

With regard to corrosion, the base material of the wetted parts (SS 316L, SS 316Ti, Hastelloy C) can tolerate

the common corrosive media right up to even the highest temperatures.

A

d

D

Fig. 3: Installation examples

h

L

L

C

METALLIC SHEATH

THERMAL

INSULATING

D

h d/2

»

L > D/2+h

B

For further information on specific applications, please contact the E+H Customer Service Department.

In the case that the sensor components are disassembled, in the following reassembly procedure the definite

torques must be employed. This will assure the housings with the IP grade defined.

In the case of vibrations the thin film sensing element Pt100 (TF) may offer advantages; the wire wound Pt100

(WW), besides having a larger measurement and accuracy range, guarantees greater long term stability.

4 Endress+ Hauser

Page 5

Omnigrad S -TR61

System components

Housing The protection housing, our "TA21H", commonly referred to the “connection head”, is used to contain and

protect the terminal block or the transmitter and to join the electric connections to the mechanical component.

The TA21H used for the TR61 is compliant

with EN 50014/18 and EN 50281-1-1, EN

½ NPT, NPT

Ø90

64

Fig. 4: Housing TA21H

¾

G ½", M20x1.5

39

ø38

ø72

Extension neck The extension neck is the part between the process connection and the housing.

It is normally made of a tube with dimensional and physical characteristics (diameter and material) which are

the same of the tube under the connection.

30

°C

25

20

15

10

Head heating

5

0

100 125 150 175 20075

Neck extension length

Process temperature

225 250

570°C

400°C

220°C

mm

50281-1-2 standards (EEx-d certification for

explosion proof type of protection).

The matching of the head with the extension

below the head and the cover (threaded)

ensures a degree of protection from IP66 to

115

~

IP68. The head also has a chain to connect

the body to the cover, which facilitates the

use of the instrument during the maintenance

on systems.

The single or double threaded electrical cable

entry can be: M20x1.5, 1/2” NPT or 3/4”

NPT, G1/2".

The standard lengths of the neck are 80 or

145 mm, according to the selected option. In

accordance with the norm DIN 43772, in the

case of a thermowell with a diameter of 12

mm and a tapered tip (form 3G), the extension neck will be respectively 82 or 147 mm.

The connection situated in the upper part of

the neck allows for orientation of the sensor

head. As illustrated by the drawing in figure 5,

the length of the extension neck may influence the temperature in the head. It is necessary that this temperature is kept within the

limit values defined in the paragraph “Operating Conditions”.

Fig. 5: Heating of the head consequent to the process temperature

Endress+Hauser 5

Page 6

Omnigrad S -TR61

1

-

+

-

+

1

Electronic head transmitter The required type of output signal can be obtained by choosing the correct head mounted transmitter.

Endress+Hauser supplies “state-of-the-art” transmitters (the iTEMP® series) built in 2-wire technology and

with 4…20 mA output signal, HART® or PROFIBUS-PA®. All of the transmitters can be easily programmed

using a PC:

Head transmitter Communication software

PCP TMT181 ReadWin® 2000

® TMT182 ReadWin® 2000, FieldCare, Hand held module DXR275, DXR375

HART

PROFIBUS PA® TMT184 FieldCare

In the case of PROFIBUS-PA® transmitters, E+H recommends the use of PROFIBUS® dedicated connectors.

The Weidmüller type is provided as a standard option. For detailed information about transmitters, please refer

to the relevant documentation (refer to TI codes at the end of the document). If a head-mounted transmitter

is not employed, the sensor probe may be connected through the terminal block to a remote converter (i.e.

DIN rail transmitter). The customer may specify the configuration desired during the order phase. The headmounted transmitters available are:

Description Dwg

TMT180 and TMT181:PCP 4…20 mA. The TMT180

and the TMT181 are PC programmable transmitters.

The TMT180 is also available in a version with

enhanced accuracy (0.1°C vs. 0.2°C) in the temperature

range -50…250°C and in a version with a fixed measurement range (specified by the customer in the order

phase).

The TMT182 output consists of 4…20 mA and HART®

superimposed signals. TMT182: Smart HART®.

Ø33

2

Ø 6.5

6

5

Ø 4.5

Ø44

3

4

22.5

Ø44

Ø33

TMT184: PROFIBUS-PA®.

For the TMT184, with PROFIBUS-PA® output signal,

the communication address may be set via software or

via mechanical dip-switch.

Ø33

+

2

1

6

-

Ø 6.5

8

+

-

5

Ø 4.5

Ø44

3

4

26.8

Ø44

Ø33

Process connection Standard connections are available in the following types: Threaded or Flanged

Other versions may be supplied upon request, while other characteristic are available in the structure at the

and of this document. The table below illustrate the engaging lengths and typies of process connections.

Type ØD1 ØD2 ØS ØF C Thread/Flanged DWG

Flange 110 79.5 14,5 16 // 1” ANSI 150 RF

Flange 124 50,8 17,5 19 // 1” ANSI 300 RF

GAS NPT

FLANGE

NPT TA50

Flange 115 85 16 14 // DN25 PN40 B1

Flange 150 110 18 18 // DN40 PN40 B1

Flange 165 125 20 18 // DN50 PN40 B1

Thread // // // // 15 G1”

Thread // // // // 15 G1/2"

Thread // // // // 15 G3/4"

E

C

C

L

ØD2

ØD1

ØF

E

S

C

C

L

Thread // // // // 8 1/2" NPT

Thread // // // // 8 3/4" NPT

Probe In the TR61 the measuring probe is made up of a mineral insulated insert (MgO) positioned inside the ther-

mowell. The insert length is available in the standard dimensions DIN 43772 and in the most commonly used

ones, or it can be personalized by the client within a range of values (refer to “Sales Structure” at the end of

the document).

For replacement, the length of the insert (IL) must be chosen in compliance with the immersion length (L) of

the thermowell (see fig. 6). If spare parts are required, refer to the following table.

Although the wiring diagram of single Pt 100s is always supplied with 4 wires configuration, the connection of

a transmitter can be executed with 3 wires as well, by avoiding to connect whichever of the terminals (see fig.

6). The configuration Pt100 double with 2 wires and Pt100 single with 2, 3 and 4 wires are available for the

ATEX certified inserts.

6 Endress+ Hauser

Page 7

Omnigrad S -TR61

With regards to the thermowell, the surface roughness (Ra) of the wetted parts is 0.8 mm, while the various

kinds of tips (reduced or tapered) are described in fig. 6;

Thermowell type Tip of the sensor Insert type Insert (E) Neck Insert Length (mm)

TW 10

TW 13

TW 12

TW 11

(GAS)

TW 11

(NPT)

Straight

Reduced on Ø 9 and Ø 11

Tapered on Ø 9 Ø = 3 mm

Tapered on Ø 12

Straight

Reduced on Ø 9 and Ø 11

Tapered on Ø 9 Ø = 3 mm

Tapered on Ø 12

Straight

Reduced on Ø 9 and Ø 11

Tapered on Ø 9 Ø = 3 mm

Tapered on Ø 12

Straight

Reduced on Ø 9 and Ø 11

Tapered on Ø 9 Ø = 3 mm

Tapered on Ø 12

TPR100/TPR

300

TPR100/TPR

300

TPR100/TPR

300

TPR100/TPR

300

Ø = 6 mm

E = 80/82 mm

E = 145/147mm IL = L + E + 33

Ø = 6 mm

E = 80/82 mm

E = 145/147mm IL = L + 63

Ø = 6 mm

// IL = L + 70

Ø = 6 mm

// IL = L + 75

Fig. 6: Functional components, standard electrical diagrams (ceramic terminal block), Tip on the end of the probe

Endress+Hauser 7

Page 8

Omnigrad S -TR61

Certificates & approvals

Ex approval • ATEX Certificate CESI 05ATEX038 for explosion proof type of protection: ATEX II 2 GD EEx-d IIC T6..T5

T85°...T100°C. The TR61 is 4 marked.

• ATEX Certificate KEMA 01ATEX1169 X for intrinsecaly safe type of protection: 1GD or 1/2 GD EEx-ia IIC

T6...T1 T85...450°C. The TR61 is 4 marked.

With regards to the NAMUR NE 24 certificate and the Manufacturer’s Declaration according to the standard

EN 50018, EN 50020, EN 50281-1-1, EN 50281-1-2, E+H Customer Service will be able to provide further

detailed information.

PED approval The Pressure Equipment Directive (97/23/CE) is respected. As paragraph 2.1 of article 1 is not applicable to

these types of instruments. The 4 mark according to PED Directive is not requested.

Material certification The material certificate EN 10204 3.1 can be directly selected from the sale structure of the product and refers

to the parts of the sensor in contact with the process fluid.

Other types of certificates related to materials can be requested separately.

The “short form” certificate includes a simplified declaration with no enclosures of documents related to the

materials used in the construction of the single sensor and guarantees the traceability of the materials through

the identification number of the thermometer.

The data related to the origin of the materials can subsequently be requested by the client if necessary.

Test on thermowell The pressure tests are carried out at ambient temperature in order to verify the resistance of the thermowell to

the specifications indicated by the norm DIN 43772.

With regards to the thermowells that do not comply with this norm (with a reduced tip, a tapered tip on a 9

mm tube, special dimensions, ...), the pressure of the corresponding straight tube with similar dimensions is

verified. The sensors certified for use in Ex Zones, are always tested to pressure according to the same criterions.

Further details

Maintenance The Omnigrad S TR61 thermometers do not require any specific maintenance.

In the case of ATEX certified components (transmitter, insert or thermowell) please refer to the corresponding

specific relevant documentation (at the end of the document).

8 Endress+ Hauser

Page 9

Omnigrad S -TR61

Ordering information

Sales structure

TR61-

Omnigrad S TR61. RTD thermometer

Thermometer complete of DIN style pipe thermowell. Replaceable mineral insulated inset, spring loaded in terminal head,

IP66 connection with epoxy coating.

Two operating and measurement ranges: from -50 to 400°C (with TF); -200 to 600°C (with WW)

Approval:

Non-harzarus area

A

*ATEX II 1/2 GD EEx ia IIC

C

*ATEX II 2 GD EEx d IIC

E

*ATEX II 1/2 GD EEx d IIC

M

Head, material, IP grade

TA21H Alu. epoxy coating, , IP66

A

Special version, to be specified

Y

Cable entry

1 x 1/2 NPT

A

2 x 1/2 NPT

B

1 x 3/4 NPT

C

2 x 3/4 NPT

D

1 x M20 x1,5

E

2 x M20 x1,5

F

Special version, to be specified

Y

Pipe Diameter; Material: (price for 100 mm of L)

9 mm; 316L

A

11 mm; 316L

B

9 mm; 316Ti

D

11 mm; 316Ti

E

12 mm; 316Ti

F

9 mm; Alloy C276

G

11 mm; Alloy C276

H

Special version, to be specified

Y

Neck length E:

Not needed

0

80 mm

1

82 mm

2

145 mm

3

147 mm

4

... mm

X

Special version, to be specified

Y

Process connection:

Special version, to be specified

AA

TA50, G1/2", 316L

11

TA50, G1/2”, PTFE

12

TA50, G1”, 316L

13

TA50, G1”, PTFEL

14

Thread G1/2” A DIN 43772; 316Ti

BH

Thread G1” A DIN 43772; 316Ti

BJ

Thread G1/2” ; 316L

CA

Thread G3/4” ; 316L

CB

Thread G1” ; 316L

CC

Thread 1/2” NPT; 316L

CD

Thread 3/4” NPT; 316L

CE

Thread G1/2” A DIN 43772; HAST. C 276

HD

Thread 1/2” NPT; HAST. C 276

HH

Flange 1” ANSI 150 RF B16.5; 316L

AB

Flange 1” ANSI 300 RF B16.5; 316L

AD

Flange DN25 PN40 B1 EN1092-1; 316L

EA

Flange DN40 PN40 B1 EN1092-1; 316L

EB

Flange DN50 PN40 B1 EN1092-1; 316L

EC

Flange DN25 PN40 B1 EN1092-1; 316Ti

FA

Flange DN40 PN40 B1 EN1092-1; 316Ti

FB

Endress+Hauser 9

Page 10

Flange DN50 PN40 B1 EN1092-1; 316Ti

FC

Flange DN25 PN40 B1 EN1092-1; C276 > 316L

HA

Flange DN50 PN40 B1 EN1092-1; C276 > 316L

HC

Special version, to be specified

YY

Tip Shape

Reduced, L>=80 mm

M

Reduced, L>=60 mm

R

straight

S

Tapered, L>=100 mm

T

Tapered DIN 43772-3G, , L>=120 mm

W

Special version, to be specified

Y

Immersion length L

...mm

X

Special version, to be specified

Y

Head transmitter; Range:

Flying leads

F

Terminal block

C

TMT180-A21 fix; 0.2K, from..to..°C, span limit -200/650°C

2

TMT180-A22 fix; 0.1K, from..to..°C, span limit -50/250°C

3

TMT180-A11 prog.; 0.2K, from..to..°C, span limit -200/650°C

4

TMT180-A12 prog.; 0.1K, from..to..°C, span limit -50/250°C

5

TMT181-A, PCP, from...to...°C, 2-wire, isolated

P

TMT181-B, PCP ATEX, from...to...°C, 2-wire, isolated

Q

TMT182-A, HART, from...to...°C, 2-wire, isolated

R

TMT182-B, HART ATEX, from...to...°C, 2-wire, isolated

T

TMT184-A, Profibus PA, from...to...°C, 2-wire, isolated

S

TMT184-A, Profibus PA ATEX, from...to...°C, 2-wire, isolated

V

THT1 separate item

1

RTD Class; Wiring

1 x Pt100 TF, cl. A, range: -50/400°C; 4-wire

3

1 x Pt100 TF, cl. 1/3 DIN B, range: -50/400°C; 4-wire

7

2 x Pt100 WW, cl. A, range: -200/600°C; 3-wire

B

1 x Pt100 WW, cl. A, range: -200/600°C; 4-wire

C

2 x Pt100 WW, cl. A, range: -200/600°C; 2-wire

D

2 x Pt100 WW, cl. 1/3 DIN B, range: -200/600°C; 3-wire

F

1 x Pt100 WW, cl. 1/3 DIN B, range: -200/600°C; 4-wire

G

Special version, to be specified

Y

Additional options

TW10, Assembly

A

TW11, Assembly

B

TW12, Assembly

C

TW13, Assembly

D

Special version, to be specified

Y

Not needed

0

TR61- ⇐ Order code (complete)

Omnigrad S -TR61

10 Endress+ Hauser

Page 11

Omnigrad S -TR61

Sales structure

THT1 Model and version of the head transmitter

TMT180-A11 programmable from...to...°C, accuracy 0.2 K, span limit -200...650°C

A11

TMT180-A12 programmable from...to...°C, accuracy 0.1 K, span limit -50...250°C

A12

TMT180-A21AA fixed range, accuracy 0.2 K, span 0...50°C

A13

TMT180-A21AB fixed range, accuracy 0.2 K, span 0...100°C

A14

TMT180-A21AC fixed range, accuracy 0.2 K, span 0...150°C

A15

TMT180-A21AD fixed range, accuracy 0.2 K, span 0...250°C

A16

TMT180-A22AA fixed range, accuracy 0.1 K, span 0...50°C

A17

TMT180-A22AB fixed range, accuracy 0.1 K, span 0...100°C

A18

TMT180-A22AC fixed range, accuracy 0.1 K, span 0...150°C

A19

TMT180-A22AD fixed range, accuracy 0.1 K, span 0...250°C

A20

TMT180-A21 fixed range, accuracy 0.2 K, span limit -200...650°C, from...to...°C

A21

TMT180-A22 fixed range, accuracy 0.1 K, span limit -50...250°C, from...to...°C

A22

TMT181-A PCP, 2-wire, isolated, programmable from...to...°C

F11

TMT181-B PCP ATEX, 2-wire, isolated, programmable from...to...°C

F21

TMT181-C PCP FM IS, 2-wire, isolated, programmable from...to...°C

F22

TMT181-D PCP CSA, 2-wire, isolated, programmable from...to...°C

F23

TMT181-E PCP ATEX II3D, 2-wire, isolated, programmable from...to...°C

F24

TMT181-F PCP ATEX II3D, 2-wire, isolated, programmable from...to...°C

F25

TMT182-A HART®, 2-wire, isolated, programmable from...to...°C

L11

TMT182-B HART® ATEX, 2-wire, isolated, programmable from...to...°C

L21

TMT182-C HART® FM IS, 2-wire, isolated, programmable from...to...°C

L22

TMT182-D HART® CSA, 2-wire, isolated, programmable from...to...°C

L23

TMT182-E HART® ATEX II3D, 2-wire, isolated, programmable from...to...°C

L24

TMT182-F HART® ATEX II3D, 2-wire, isolated, programmable from...to...°C

L25

TMT184-A PROFIBUS-PA®, 2-wire, programmable from...to...°C

K11

TMT184-B PROFIBUS-PA® ATEX, 2-wire, programmable from...to...°C

K21

TMT184-C PROFIBUS-PA® FM IS, 2-wire, programmable from...to...°C

K22

TMT184-D PROFIBUS-PA® CSA, 2-wire, programmable from...to...°C

K23

TMT184-E PROFIBUS-PA® CSA, 2-wire, programmable from...to...°C

K24

TMT184-F PROFIBUS-PA® ATEX II3D, 2-wire, isolated, programmable from...to...°C

K25

Special transmitter

YYY

Application and services

Assembled into position

1

Special version

9

THT1- ⇐ Order code (complete)

Endress+Hauser 11

Page 12

Supplementary documentation

71098772

Brochure Field of activities - Temperature measurement FA006T/09/en

Temperature head transmitter iTEMP® Pt TMT180 TI088R/09/en

Temperature head transmitter iTEMP® PCP TMT181 TI070R/09/en

Temperature head transmitter iTEMP® HART® TMT182 TI078R/09/en

Temperature head transmitter iTEMP® PA TMT184 TI079R/09/en

RTD insert for temperature sensors - Omniset TPR100 TI268T/02/en

RTD insert for temperature sensors - Omniset TPR300 TI290T/02/en

Safety instructions for use in hazardous areas (TPR100) XA003T/02/z1

Industrial thermometers, RTD and thermocouples TI236T/02/en

Safety instructions for use in hazardous areas (TPR300 to be relais) XA015T/02/z1

TA fittings & sockets Omnigrad TA50, TA55, TA60, TA70, TA75 TI091T/02/en

International Head Quarter

Endress+Hauser

GmbH+Co. KG

Instruments International

Colmarer Str. 6

79576 Weil am Rhein

Germany

Tel. +49 76 21 9 75 02

Fax +49 76 21 9 75 34 5

www.endress.com

info@ii.endress.com

TI280T/02/en/07.05

FM+SGML6.0

Loading...

Loading...