Page 1

Technical Information

Omnigrad S TMT162C

Thermocouple assembly

®

with HART

or PROFIBUS

-, FOUNDATION Fieldbus™-

®

PA field transmitter

Application

• Chemical/pharmaceutical industry

• Petrochemical industry

• Energy industry

• Paper industry

• General industrial applications

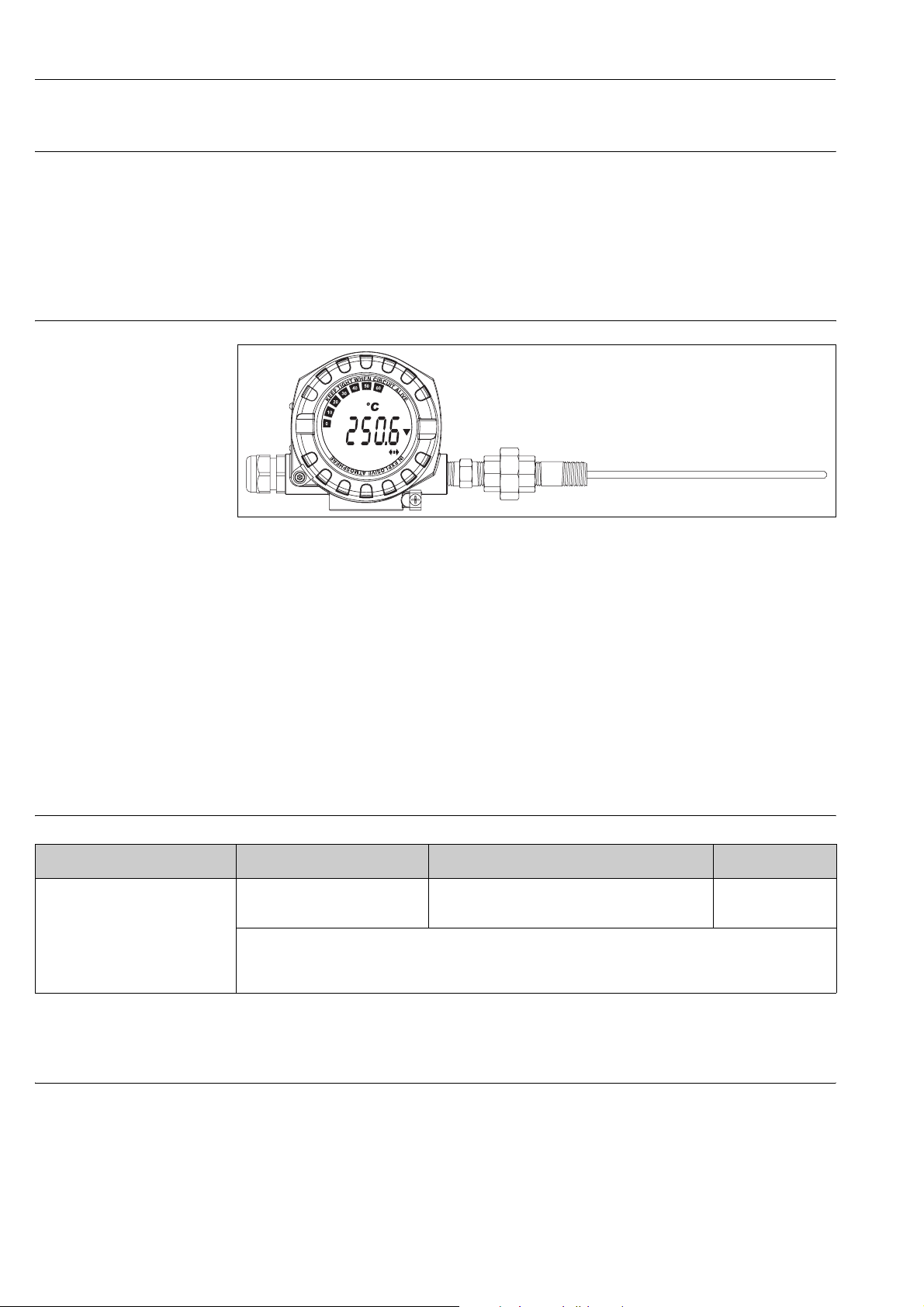

The TMT162C thermocouple thermometer comprises a

measuring insert with a type J or K thermocouple and an

electronic field transmitter with HART

Fieldbus™ or PROFIBUS

Features and benefits

• Dual compartment housing

• Backlit display with large measured value, bargraph

and fault condition indication

• Galvanic isolation 2 kV (sensor input to the output)

• Wide range of threaded thermowell connections available as standard, additional connections available on

request

• Replaceable measuring insert comprising a mineralinsulated tube (SS 316L/1.4404)

• Thermocouple (type J or K) with accuracy class 1 or 2

(IEC 60584)

• Aluminum or stainless steel housing,

degree of protection IP67, NEMA 4x

• Approvals for hazardous areas:

Flameproof enclosure (Ex d)

Intrinsic safety (Ex ia)

Non-sparking (Ex nA)

• Optional: 2 thermocouples can be connected, e.g. for

redundant applications or differential measurement

• Optional factory calibration

®

PA protocol.

®

, FOUNDATION

TI267t/02/en

71093904

Page 2

TMT162C

Function and system design

Measuring principle In the thermocouple, two electrically conductive conductors made of different metals are connected at the ends

(thermocouple), thereby producing a thermoelectric circuit. The weld point forms the "measuring point" and

the other end with the free wires forms the "cold junction". When the "measuring point" of this thermoelectric

circuit is heated, a current flows through the circuit and a weak electrical voltage (known as the thermoelectric

voltage) is generated.

If the measuring point and the reference junction have the same temperature, a thermoelectric voltage is not

generated. The strength of the thermoelectric voltage (also know as the electromagnetic force), primarily

depends on the materials of the thermocouple and the size of the temperature differential. The sensors (thermocouple) meet the requirements of IEC 60584 and ANSI MC96.1.

Measuring system

TMT162C

TMT162R_G_dd_07_xx_04

The TMT162C thermocouple thermometer comprises a measuring insert with a thermocouple (TC) and the

iTEMP® TMT162 field transmitter which can be configured using the HART®, FOUNDATION Fieldbus™ or

PROFIBUS® PA protocol. A thermowell can be ordered separately.

The sensor element is integrated in the tip of the measuring insert and complies with IEC 60584 and ANSI

MC96.1. It withstands loads that typically occur in the most common industrial processes. The sensor element

consists of 2 metal alloy wires, type J (iron/copper nickel) or type K (nickel chromium/nickel). The measuring

range and tolerance errors differ depending on the thermocouple. The measuring insert is a replaceable unit

and is installed in a thermowell. A spring system presses it against the base of the thermowell to improve the

transmission of heat.

The transmitter housing is made of die-cast aluminum or stainless steel. It can be purchased with or without

an LC display. The minimum degree of protection, IP65, is achieved by sealing glands at the cable entry and

the thermometer connection. Depending on the customer's requirements, customers can choose from thermowells constructed from welded tubes and thermowells made of drilled barstock material. The thermowells

are available in various shapes and sizes and with a wide range of process connections (thread, flange or weldon connections, see page 12).

Measurement range

Input Designation Measuring range limits Min. span

Thermocouples (TC)

to IEC 60584 part 1

Type J (Fe-CuNi)

Type K (NiCr-Ni)

• Internal cold junction (Pt100)

• Accuracy of cold junction: ± 1 K

• Max. sensor resistance 10 kΩ (if sensor resistance is greater than 10 kΩ, error message as per NAMUR NE 89)

-210 to +1200 °C (-346 to 2192 °F)

-270 to +1372 °C (-454 to 2501 °F)

50 K

50 K

Performance characteristics

Operating conditions Ambient temperature limits

• Without display: -40 to +85 °C (-40 to 185 °F)

• With display: -40 to +80 °C (-40 to 176 °F)

For use in Ex area, see Ex certificate.

2 Endress+Hauser

Page 3

Note!

!

At temperatures < -20 °C (-4 °F), the display may react slowly. Readability of the display cannot be guaranteed

at temperatures < -30 °C (-22 °F).

Storage temperature • Without display: -40 to +100 °C (-40 to 212 °F)

• With display: -40 to +80 °C (-40 to 176 °F)

Process pressure/flow velocity

The load limits of the thermometer depend on the thermowell used and are listed in the technical information

specific to the individual thermowells (see page 12). Factors that affect the load limits include the process pressure, flow velocity, density of the medium, temperature, immersion depth, length of the thermowell in the

flowing medium etc. In critical situations, a load capacity calculation for the thermowell can be ordered from

Endress+Hauser.

Shock and vibration resistance

3 g (max. value)/ 10 to 500 Hz as per IEC 60 068-2-6

Accuracy Thermocouple corresponding to IEC 60584

Type Standard tolerance (IEC 60584) Reduced tolerance (IEC 60584)

Class Deviation Class Deviation

J (Fe-CuNi) 2 ±2.5 °C (-40...333 °C)

±0.0075 |t|

K (NiCr-Ni) 2 ±2.5°C (-40...333°C)

±0.0075 |t| (333...1200 °C)

1. |t| = absolute value °C

1

(333...750 °C)

TMT162C

1 ±1.5 °C (-40...375 °C)

±0.004 |t| (375...750 °C)

1 ±1.5 °C (-40...375 °C)

±0.004 |t| (375...1000 °C)

Note!

!

For measurement errors in °F, calculate using equations above in °C, then multiply the outcome by 1.8.

Response time Tests in water at 0.4 m/s (1.3 ft/s), according to IEC 60584; 10 K temperature step changes; response time

for the assembly without thermowell and transmitter:

•t50: 2.5 s

•t90: 7 s

Insulation resistance Insulation resistance ≥100 MΩ at ambient temperature.

Insulation resistance between each terminal and the sheath is tested with a voltage of 500 V DC.

Transmitter specifications

TMT162 FF/PA TMT162 HART

Digital D/A

Accuracy 0.25 °C (0.45 °F)

Galvanic isolation

(input/output)

1. % relates to the set span. Total accuracy = digital + D/A, for 4 to 20 mA output

typ. 0.25 °C (0.45 °F) 0.02%

U = 2 kV AC

Accuracy

®

1

Self heating Negligibly small

Endress+Hauser 3

Page 4

TMT162C

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

Material

Housing Nameplate Neck, insert

Die-cast aluminum housing AlSi10Mg

with powder coating on polyester basis

Stainless steel 1.4435 (AISI 316L) 1.4301 (AISI 304)

Installation conditions

Orientation No restrictions

Aluminum AlMgl, anodized in black Stainless steel 1.4404 (AISI 316L)

Electromagnetic compatibility (EMC)

Installation instructions

CE Electromagnetic Compatibility Compliance

EMC meets all relevant requirements listed under EN 61326 Series and NAMUR NE21. Details as per declaration of conformity.

This recommendation is a uniform and practical way of determining whether the devices used in laboratories

and process control are immune to interference with an objective to increase its functional safety.

ESD (Electrostatic discharge) IEC 61000-4-2 6 kV cont., 8 kV air

Electromagnetic fields IEC 61000-4-3 0.08 to 2 GHz

(0.08 to 4 GHz for FF)

0.08 to 2 GHz for HART

2 to 2.7 GHz

Burst (fast transient) IEC 61000-4-4 1 kV (2 kV for HART)

surge IEC 61000-4-5 1 kV asym. (0.5 kV sym. for HART)

Conducted RF IEC 61000-4-6 0.01 to 80 MHz 10 V

10 V/m

10 V/m

30 V/m

1V/m

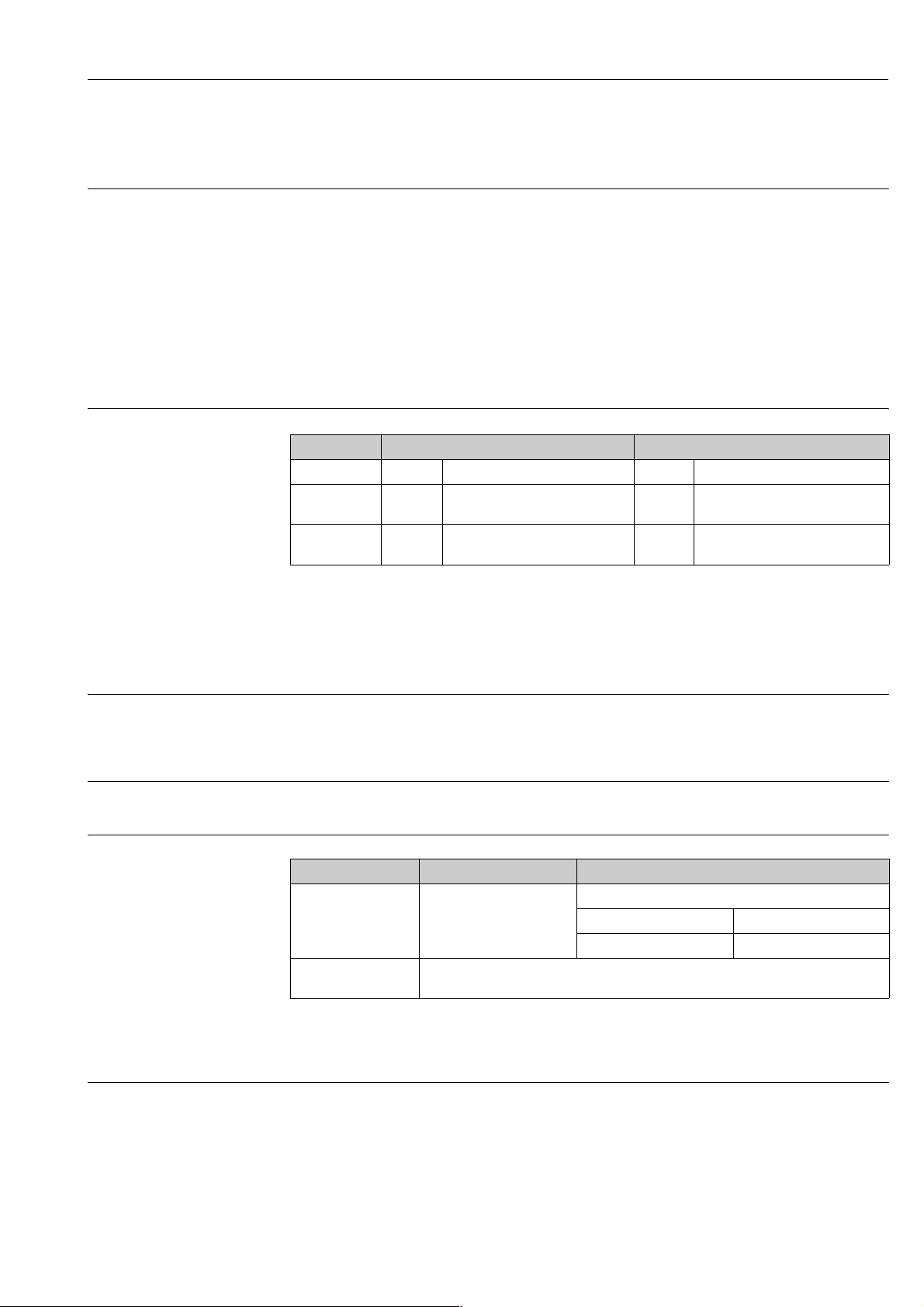

Installation examples

T09-TMT162RC-11-xx-xx-xx-003

A: In pipes with a small cross section the sensor tip should reach or extend slightly past the center line of the pipe (= L).

B, D: Tilted installation

C: Flanged installation

4 Endress+Hauser

Page 5

!

TMT162C

The immersion length of the thermometer influences the accuracy. If the immersion length is too small then

errors in the measurement are caused by heat conduction via the process connection and the pipe wall. If

installing into a pipe then the immersion length must be half of the pipe diameter, ideally.

• Installation possibilities: Pipes, tanks or other plant components

• Minimum immersion length = 80 to 100 mm (3.15 to 3.94 in)

The immersion length must be at least 8 times the protection tube diameter. Example: Protection tube diameter 12 mm (0.47 in) x 8 = 96 mm (3.8 in). Recommended standard immersion length according to DIN

43772: 120 mm (4.72 in)

• ATEX certification: Always take note of the installation regulations!

Note!

When operating in small nominal bore pipes it must be guaranteed that the protection tube tip is long enough

to extend past the pipe center line (see Pos. A and B). A further solution could be an angled (tilted) installation

(see Pos. C and D). When determining the immersion length all thermometer parameters and the process to

be measured must be taken into account (e.g. flow velocity, process pressure).

In the case of pipes in which the direction of flow changes, extreme caution should be exercised when selecting

the measuring point since these flows can cause the measured value to fluctuate. With regard to corrosion, the

choice of material for the thermowell is particularly important.

If the thermometer is to be disassembled into its individual component parts, the specified tightening torques

have to be observed when subsequently reassembling the thermometer in order to comply with the IP protection class of the coupling between the field transmitter and thermowell.

System components

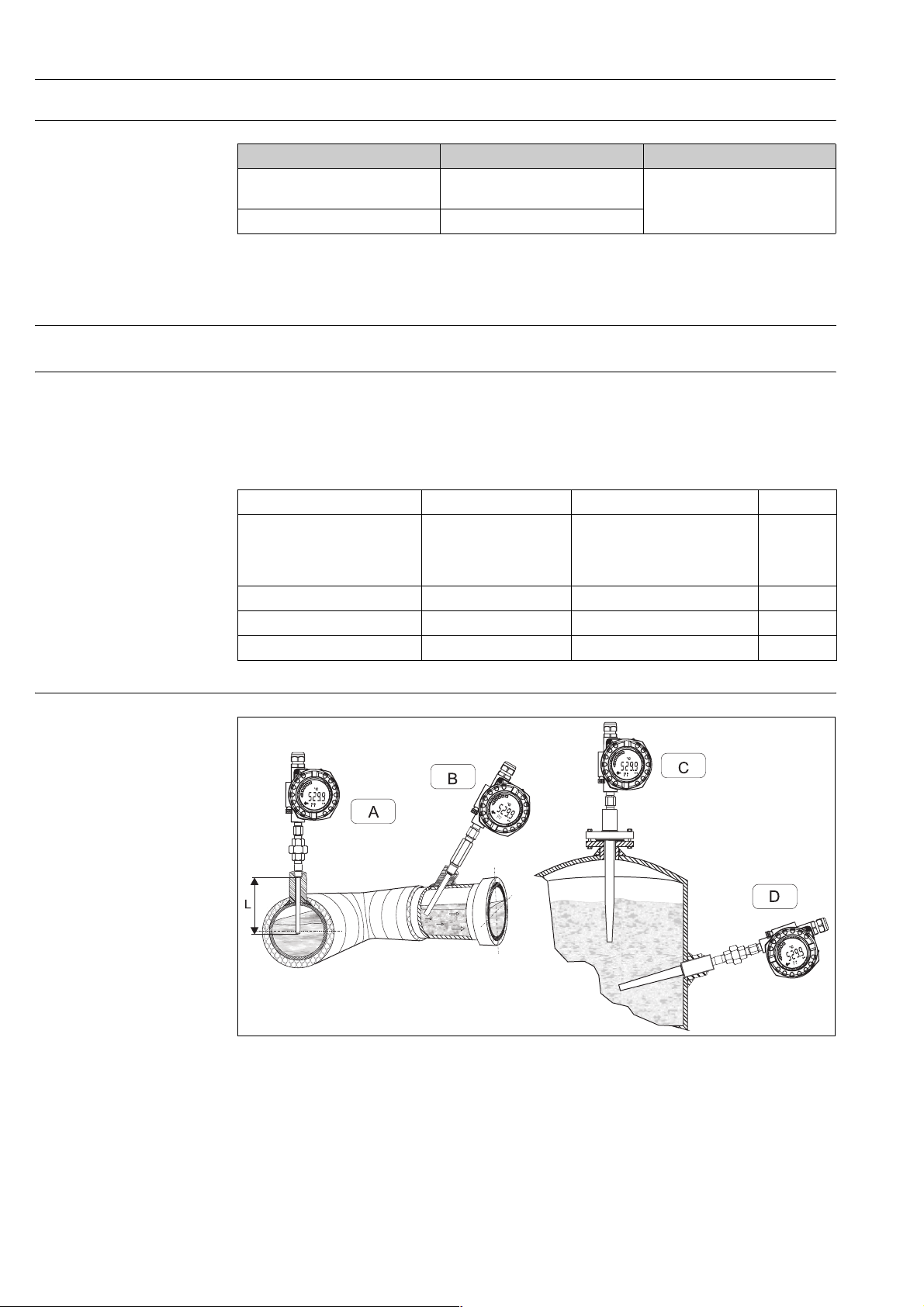

Field transmitter The field transmitter offers high reliability particularly in harsh industrial environments due to the dual com-

partment housing and fully potted electronics.

Temperature field transmitter iTEMP® TMT162

* Dimensions without display = 112 mm (4.41“)

T09-TMT162ZZ-06-00-xx-xx-001

• Material: die-cast aluminum housing AlSi10Mg with powder coating on polyester base or stainless steel 1.4435 (AISI 316L)

• Separate electronics compartment and connection compartment

• Display pluggable in 90° stages

• Cable entry: 2x ½" NPT, M20x1.5

• Thermowell connection (min. IP 65): M24x1.5, ½" NPT, ¾" NPT, G½"

• Degree of protection IP 67 (NEMA 4X)

• Blue backlit display with large measured value, bargraph and fault condition

indication

• Gold-plated terminals prevent corrosion and additional measured errors

For detailed information, see Technical Information iTEMP

(see page 12).

®

TMT162

Endress+Hauser 5

Page 6

TMT162C

Neck tube A neck tube is integrated between the thermowell and the field transmitter to prevent the field transmitter from

overheating as a result of the process temperature. This neck tube is made up of one or more different pipe

fittings (N, L = nipples and C, U = coupling, unions). The material of the neck tube is SS 316L/1.4404 as standard.

The neck tube versions and standard lengths (N) can be selected as follows:

.

Neck tube versions

Type Neck tube type Neck tube length N Thermowell con-

nection thread

– 156 mm (6.14 in)

(type LUN, field transmitter can

be aligned)

nckLUN_g_gd_15_xx_01

– 148 mm (5.83 in)

G ½”

(type LCN, field transmitter cannot be aligned)

nckLCN_g_gd_15_xx_01

– 52 mm (2 in)

*only ½” NPT

(type L, field transmitter cannot

External thread

nckLxx_g_gd_15_01

be aligned)

– 148 mm (5.83 in)

(type LCN, field transmitter can-

nckLUN_g_gd_15_xx_01

not be aligned)

– 156 mm (6.14 in)

½“ NPT,

¾” NPT

(type LUN, field transmitter can

nckLCN_g_gd_15_xx_01

be aligned)

– 104 mm (4.1 in)

(type LU, field transmitter can

be aligned)

nckLUx_g_gd_15_xx_01

½” NPT

– 96 mm (3.8 in)

(type LC, field transmitter can-

nckLCx_g_gd_15_xx_01

not be aligned)

Thread length C Digit

15 mm

(0.6 in)

ConGAS_G_dd_09_xx_01

8 mm

(0.3 in)

8.5 mm

(0.33 in)

ConNPT_G_dd_09_xx_01

8 mm

(0.3 in)

ConNPT_G_dd_09_xx_02

D

N

P

U

Internal thread

nckLCx_g_gd_15_xx_01

– 96 mm (3.8 in)

(type LC, field transmitter cannot be aligned)

M24x1.5

16 mm

(0.63 in)

5

ConM24_g_dd_09_xx_01

In addition to the standard versions listed, neck tubes with specific lengths can be ordered as part of the product

structure for the measuring insert.

6 Endress+Hauser

Page 7

TMT162C

As illustrated in the following figure, the neck tube length may influence the temperature in the field transmitter. It is necessary that this temperature is kept within the limit values defined in the chapter "Operating conditions".

Heating of the field transmitter consequent to the process temperature.

Temperature in the field transmitter = ambient temperature + ΔT

a0010513-en

Thermowell The assembly is designed for installation in an existing thermowell, or a thermowell that has to be ordered sep-

arately. For this purpose, the neck tube connection to the thermowell is available in various sizes.

To make selection easier, please use the table with the insertion lengths of the measuring insert (ML) which is

described in the next section.

Measuring insert

Omnigrad S TMT162C, dimensions in mm (inch)

T09-TMT162RC-04-xx-xx-xx-000

The insertion length (ML) of the measuring insert can be selected anywhere in the range between 50 and 990

mm (1.97 and 39 in). Insertion lengths over 990 mm (39 in) are available on request.

The insertion length (ML) must be selected depending on the total length of the thermowell (A) and the type

of thermowell used (applies to standard thermowell base sizes). This also applies when ordering the measuring

insert as a spare part. Please refer to the table below for exact details.

Thermowell

type

TW10* ML = A - 8 mm (0.31 in) TA535 ML = A - 8 mm (0.31 in) TA560 ML = A - 11 mm (0.43 in)

TW11* ML = A - 8 mm (0.31 in) TA540 ML = A - 10 mm (0.4 in) TA566 ML = A - 11 mm (0.43 in)

ML in mm (inch) Thermowell

type

ML in mm (inch) Thermow-

ell type

ML in mm (inch)

Endress+Hauser 7

Page 8

TMT162C

Thermowell

type

TW12* ML = A - 8 mm (0.31 in) TA541* ML = A - 10 mm (0.4 in) TA570 ML = A - 11 mm (0.43 in)

TW13* ML = A - 8 mm (0.31 in) TA550 ML = A - 11 mm (0.4 in) TA571 ML = A - 11 mm (0.43 in)

TW10** ML = A - 15 mm (0.6 in) TA555 ML = A - 10 mm (0.4 in) TA572 ML = A - 11 mm (0.43 in)

TW11** ML = A - 15 mm (0.6 in) TA556 ML = A - 10 mm (0.4 in) TA575 ML = A - 11 mm (0.43 in)

TW12** ML = A - 15 mm (0.6 in) TA557 ML = A - 10 mm (0.4 in) TA576 ML = A - 10 mm (0.4 in)

TW13** ML = A - 15 mm (0.6 in) TA562 ML = A - 11 mm (0.43 in)

TW15** ML = A - 12 mm (0.47 in) TA565 ML = A - 11 mm (0.43 in)

ML in mm (inch) Thermowell

type

ML in mm (inch) Thermow-

If the thermowell selected also contains a neck tube (e.g. TW15), the total length A of the thermowell is the

sum of the length of the thermowell L plus the length of the neck tube E (A = L + E).

Caution!

"

* TMT162C with NPT threaded connection to the thermowell

** TMT162C with metric (M24x1.5) connection to the thermowell

Weight From 1.5 to 5 kg (3.3 to 12.1 lbs) for standard options (aluminum housing).

Electronics

ell type

ML in mm (inch)

Wiring diagram

The iTEMP® temperature field transmitter TMT162 is a two-wire transmitter with analog output or fieldbus

protocol, two (optional) measuring inputs for thermocouples type J or type K. The LC display shows the current

measured value digitally and as a bar graph with an indicator for alarms.

Corrosion detection

Corrosion of the sensor connections can lead to corruption of the measured value. The field transmitter offers

the option of detecting corrosion on thermocouples and resistance thermometers with a 4-wire connection

before measured value corruption occurs.

If the conductor resistance exceeds plausible limits, the transmitter shows a status message on the display and

forwards the corresponding message to the higher-order system via HART, FOUNDATION Fieldbus™ or

PROFIBUS

®

PA protocol.

Optional 2-channel functions

These functions increase the reliability and availability of the process values:

• Sensor backup switches to redundant sensor if primary sensor fails

• Temperature dependent switching between sensors, which have advantages in different ranges

• Drift alert or alarm if sensor 1 and 2 deviate from one another

Electrical connection

TMT162Cx-04-xx-xx-en-000

8 Endress+Hauser

Page 9

TMT162C

Supply voltage

HART

®

Ub = 11 to 40 V (8 to 40 V without display), reverse polarity protection

Note!

!

(according to IEC 61010-1, CSA 1010.1-92)

The TMT162 must be powered by a 11 to 40 VDC power supply with a limited power according to NEC Class 02 (low

voltage, low current) limited to 8 A and 150 VA in case of a short circuit.

FOUNDATION Fieldbus™

U

= 9 to 32 V, reverse polarity protection,

b

max. voltage U

According to IEC 60079-27, FISCO/FNICO

= 35 V

b

PROFIBUS® PA

U

= 9 to 32 V, reverse polarity protection,

b

max. voltage U

According to IEC 60079-27, FISCO/FNICO

= 35 V

b

Certificates and approvals

CE-Mark The device meets the legal requirements of the EC directives. Endress+Hauser confirms that the device has

been successfully tested by applying the CE mark.

Hazardous area approvals

ATEX II1G EEx ia IIC T6/T5/T4 HART

Power supply (+ and - terminals) Ui ≤ 30 V DC

®

I

≤ 300 mA

i

P

≤ 1000 mW

i

C

≤ 5 nF

i

L

≈ 0

i

FOUNDATION Fieldbus™/PROFIBUS® PA

≤ 17.5 V DC or:

U

i

I

≤ 500 mA

i

P

≤ 5.5 W

i

C

≤ 5 nF

i

L

= 10 μH

i

≤ 24 V DC

U

i

I

≤ 250 mA

i

P

≤ 1.2 W

i

Suitable for connecting to a fieldbus system in accordance with

the FISCO/FNICO model (valid for FOUNDATION Fieldbus™

protocol)

ATEX II3G EEx nA II T6/T5/T4

HART

®

FOUNDATION Fieldbus™

PROFIBUS® PA

Power supply (+ and - terminals) U ≤ 40 V DC U ≤ 32 V DC

Output I = 4 to 20 mA Curr. consumption I ≤ 12 mA Curr. consumption I ≤ 11 mA

ATEX II2D EEx tD A21 IP67 T110°C

ATEX II2G EEx d IIC T6/T5/T4

Power supply (+ and - terminals) U ≤ 40 V DC

Temperature range for Ex d

(electronics)

T6

T5

T4

®

HART

P ≤ 3 W

Ta = -40 °C to +55 °C

Ta = -40 °C to +70 °C

Ta = -40 °C to +80 °C

FOUNDATION Fieldbus™

PROFIBUS

®

PA

U ≤ 35 V DC

P ≤ 3 W

Temperature range for dust (electronics) Ta = -40 °C to +80 °C

For further details on the available Ex versions (ATEX, CSA, FM, etc.), please contact your nearest

Endress+Hauser sales organization. All relevant data for hazardous areas can be found in separate Ex

documentation. If required, please request copies.

PED approval The thermometer complies with paragraph 3.3 of the Pressure Equipment Directive (97/23/CE) and is not

marked separately.

Endress+Hauser 9

Page 10

TMT162C

Test report and calibration With regards to the tests and calibration, the "Inspection Report" consists of a compliance declaration for the

essential points of the standard IEC 60584.

The "Factory calibration" is carried out in an EA (European Accreditation) authorized laboratory of

Endress+Hauser according to an internal procedure. A calibration may be requested separately according to an

EA accredited procedure (SIT calibration). Calibration is carried out on the thermometer insert.

Other standards and guidelines

• IEC 60529: Degree of protection by housing (IP-Code)

• IEC 61010-1: Safety requirements for electrical measurement, control and laboratory instrumentation.

• EN 61326-series: Electrical equipment for measurement, control and laboratory use - EMC requirements.

• NAMUR: User association of automation technology in process industries (www.namur.de)

• NEMA: Standardization association for the electrical industry in North America.

Ordering information

Product structure

TMT162C Housing material; Approval

A Alu; housing, general purpose

B Alu; ATEX II1G EEx ia IIC T4/T5/T6

E Alu; ATEX II 2GD EEx d IIC T6

H Alu; ATEX EEx d, EEx ia

L Alu; ATEX II 3G EEx nA IIC T4/T5/T6

M Alu; ATEX II 1/2GD EEx d IIC T6

P 316L; ATEX II 1G EEx ia IIC T4/T5/T6

Q 316L; ATEX II 2GD EEx d IIC T6

R 316L; ATEX II 1/2GD EEx d IIC T6

T Alu; ATEX II 1/2GD EEx ia IIC T4/T5/T6

1 Alu; NEPSI Ex ia IIC T4-T6

3 Alu; NEPSI Ex d IIC T4-T6

Cable connection; Display

A M20x1.5; w/o display, plug 7/8" FF

B M20x1.5; + display, plug 7/8" FF

C ½" NPT; w/o display, plug 7/8" FF

D ½" NPT; + display, plug 7/8" FF

E G½“; w/o display

F G½“; + display

1 M20x1.5; w/o display

2 M20x1.5; + display

3 ½” NPT; w/o display

4 ½” NPT; + display

5 M20x1.5; w/o display, plug M12 PA

6 M20x1.5; + display, plug M12 PA

7 ½" NPT; w/o display, plug M12 PA

8 ½" NPT; + display, plug M12 PA

Configuration; Communication

B TC; HART

E TC; PROFIBUS PA

F TC; FOUNDATION Fieldbus

Y Special version, to be specified

Neck length N; Type

1 52 mm; nipple type L

2 104 mm; nipple + union type LU

3 96 mm; nipple + union type LC

4 156 mm; nipple + union + nipple type LUN

5 148 mm; nipple + union + nipple type LCN

9 ... mm, as specified

Thermowell type

0 not needed

1 Bar stock, to order separately

2 Pipe, to order separately

Thermowell connection

D Thread G½"

N Thread ½" NPT-M

P Thread ¾" NPT-M

R Thread R ½", JIS B 0203

S Thread R ¾", JIS B 0203

10 Endress+Hauser

Page 11

TMT162C

U Thread M24x1.5-F

5 Thread ½" NPT-F

9 Special version, to be specified

TC type; Material

A 1x K IEC584, 6 mm; INCONEL600

B 2x K IEC584, 6 mm; INCONEL600

C 1x J IEC584, 6 mm; 316

D 2x J IEC584, 6 mm; 316

G 1x K ANSI, 6 mm; INCONEL600

H 2x K ANSI, 6 mm; INCONEL600

J 1x J ANSI, 6 mm; 316

K 2x J ANSI, 6 mm; 316

9 Special version, to be specified

TC Purity; Hot junction

1 Cl. 2; grounded

2 Cl. 1; grounded

4 High, cl. 1, hot junction grounded

5 Cl. 2; ungrounded

6 Cl. 1; ungrounded

8 High, cl. 1, hot junction insulated

9 Special version, to be specified

Insertion length ML

X ... mm

Y ... mm, as specified

TMT162C-

⇐ Order code, complete

This ordering information can give an overview about the available order options. The Endress+Hauser sales

organization can provide detailed ordering information and information on the order code.

Questionnaire

A0011423

Endress+Hauser 11

Page 12

TMT162C

Documentation

Technical information:

• Thermocouple thermometer Omnigrad TSC - General information (TI090T/02)

• Temperature field transmitter iTEMP

• Thermocouple insert TC type K, J, T - Omniset TEC300 (TI226T/02/en)

Fitting thermowells:

• TW10 (TI261T/02)

• TW11 (TI262T/02)

• TW12 (TI263T/02)

• TW13 (TI264T/02)

• TW15 (TI265T/02)

• TA540 (TI166T/02)

Operating instructions temperature field transmitter iTEMP® TMT162:

•HART®-protocol (BA132R/09/)

• FOUNDATION Fieldbus™-protocol (BA224R/09/)

• PROFIBUS® PA-protocol (BA275R/09/)

Hazardous area supplementary documentation:

• ATEX II 1G (XA005T/02/a3)

• ATEX II 1/2G or 2G, ATEX II 1/2D or 2D (XA006T/02/a3)

®

TMT162 (TI086R/09/en)

• TA550 (TI153T/02)

• TA555 (TI154T/02)

• TA557 (TI156T/02)

• TA560 (TI159T/02)

• TA565 (TI160T/02)

• TA576 (TI163T/02)

Instruments International

Endress+Hauser

Instruments International AG

Kaegenstrasse 2

4153 Reinach

Switzerland

Tel. +41 61 715 81 00

Fax +41 61 715 25 00

www.endress.com

info@ii.endress.com

TI267T/02/en/04.09

71093904

FM+SGML 6.0

Loading...

Loading...