Endress+Hauser Soliphant T FTM20, Soliphant T FTM21 Technical Information

TI00389F/00/EN/13.16

71346118

Products Solutions Services

Technical Information

Soliphant T FTM20, FTM21

Vibronic

Robust point level switch for bulk solids,

also for dust incendive hazard areas

Application

Soliphant T is a robust point level switch for silos with fine-grained or coarse-grained,

non-fluidised bulk solids.

The various designs means the device has a wide range of applications. Certificates are

also available for use in dust incendive hazard areas.

FTM20 compact design 250 mm (10 in) as vibrating rod for installation in any direction

FTM21 vibrating rod with extension pipe 500 mm, 1000 mm, 1500 mm (20 in, 40 in, 60 in)

for installation in any direction

Typical applications: cereals, coffee beans, sugar, animal feed, rice, detergents, dye

powder, chalk, gypsum, cement, sand, plastic granules

Your benefits

• No calibration: easy commissioning (plug and play)

• Insensitive to build-up: maintenance-free operation

• No mechanically moving parts: no wear, long operating life

• Sensor material 316L: hardly any abrasion even with building materials

• F16 plastic housing with cover with sight glass: switch status visible from outside

• F18 aluminium housing also available

• Insensitive to external vibration and flow noises

• Also available with explosion protection ATEX II 1/3 D, FM or CSA approval

Table of contents

Soliphant T FTM20, FTM21

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Temperature resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring range (application) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Switch behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power-on behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fail-safe mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Switching delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ex specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FEM22 electronic insert (DC PNP) . . . . . . . . . . . . . . . 5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FEM24 electronic insert (AC/DC with relay output). . 6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lateral load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 9

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operating elements of electronic inserts FEM22 and FEM24 . . . 11

Sediment detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 12

CE mark, declaration of conformity . . . . . . . . . . . . . . . . . . . . . . 12

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Type of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Equipment Directive 2014/68/EU (PED) . . . . . . . . . . . 12

RCM-tick mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EAC conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RoHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 13

Soliphant T FTM20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Soliphant T FTM21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sliding sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Supplementary documentation . . . . . . . . . . . . . . . . . 15

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation height as per IEC61010-1 Ed.3 . . . . . . . . . . . . . . . . . . 7

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Thermal shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Limiting medium pressure range . . . . . . . . . . . . . . . . . . . . . . . . . 8

State of aggregation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grain size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bulk density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Endress+Hauser

Soliphant T FTM20, FTM21

AA

tt

+–

U–

~

U–

…

E

X

E

X

Function and system design

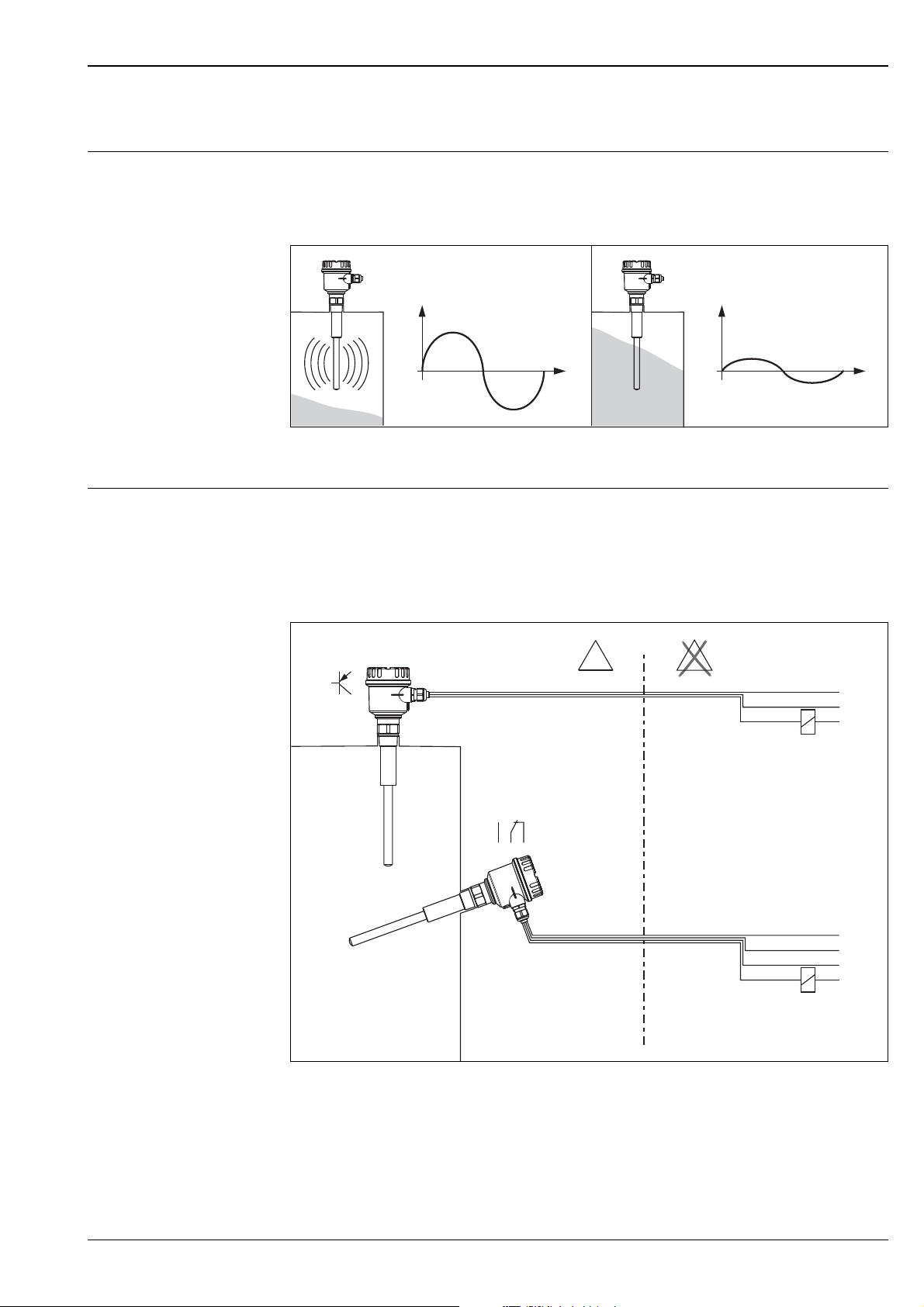

Measuring principle A piezoelectric drive excites the vibrating rod of Soliphant T FTM20, FTM21 to its resonance frequency.

If medium covers the vibrating rod, the rod's vibrating amplitude changes (the vibration is damped).

Soliphant's electronics compare the actual amplitude with a target value and indicates whether the vibrating

rod is vibrating freely or whether it is covered by medium.

L00-FTM2xxxx-15-06-xx-xx-001

A = amplitude

Measuring system Soliphant T is a compact electronic switch.

Thus, the entire measuring system only consists of:

• Soliphant T FTM20 or FTM21 with FEM22 or FEM24 electronic insert

• a supply point and

• the connected control systems, switching units, signalling systems (e.g. lamps, horns, PCS, PLC, etc.)

L00-FTM2xxxx-14-06-xx-xx-001

Endress+Hauser 3

Cable specifications

Use a shielded cable in the event of strong electromagnetic radiation.

Temperature resistance The connecting cables must withstand an ambient temperature of +20 K.

Cable entries M20x1.5 (cable gland); NPT ½; G ½

Input

Measured variable Level (according to the mounting location and the overall length)

Soliphant T FTM20, FTM21

Measuring range (application)

Input signal Probes covered => small amplitude

Measuring frequency 700...800 Hz

The measuring range depends on the mounting location of Soliphant T and the length of the pipe extension

selected. The pipe extension is available in the following lengths: 500 mm, 1000 mm, 1500 mm (20 in, 40 in,

60 in).

Probe not covered => large amplitude

Output

Galvanic isolation FEM22:

Between sensor and power supply

FEM24:

Between sensor, power supply and load

Switch behaviour Binary

Power-on behaviour When switching on the power supply the output is set to "signal on alarm".

After a maximum of 3 s it switches to the correct output signal.

Fail-safe mode Minimum/maximum quiescent current safety can be switched at electronic insert

MAX = maximum safety:

When the vibrating rod is covered, the output switches in the direction of the signal on alarm

Used for overfill protection for example

MIN = minimum safety:

When the vibrating rod becomes exposed, the output switches in the direction of the signal on alarm

Used for empty running protection for example

Switching delay 0.5 s when the sensor is covered

1 s when the sensor is exposed

Ex specifications FEM22, FEM24:

– Explosion protection for explosive dust-air mixtures:

Dust-Ex, DIP

4 Endress+Hauser

Soliphant T FTM20, FTM21

1 2 3

L+ L–

(+)

–

F

0.5 A

R

FEM22

U – 10 V…45 V(DC)

…

PE (Ground)

Relais,

PLC, ...

MAX

MIN

L+ +

1 3

L+ +

1 3

1 3

1 3

I

L

I

L

< 100 μA

< 100 μA

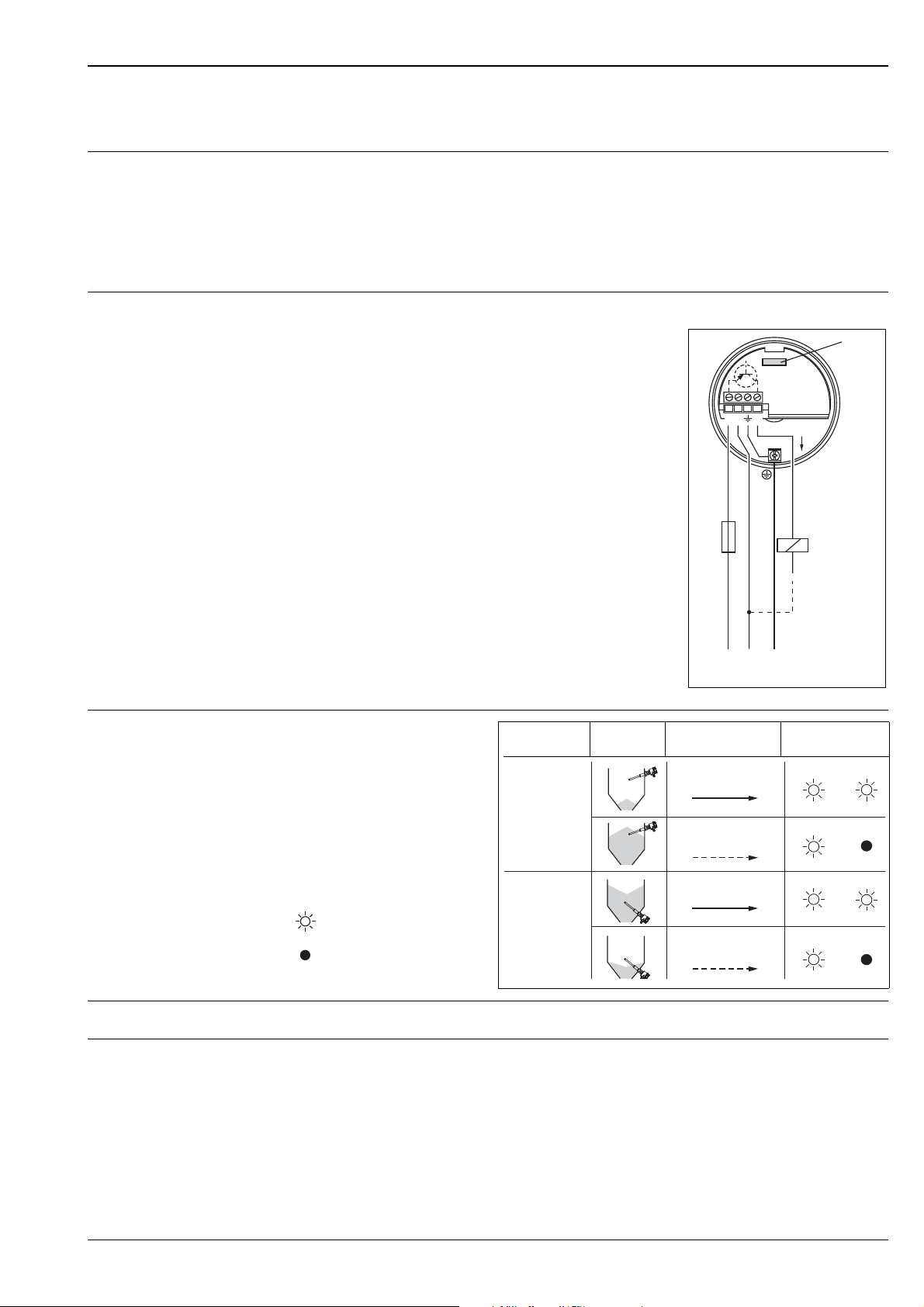

FEM22 electronic insert (DC PNP)

Power supply Voltage DC: 10…45 V

Ripple max. 5 V, 0…400 Hz

Current consumption max. 18 mA

Power consumption max. 0.81 W

Reverse polarity protection

Separation voltage: 2.2 kV

FEM22 overvoltage protection: overvoltage category II

Electrical connection Three-wire direct current connection

Preferred in conjunction with programmable logic controllers (PLC),

DI modules as per EN 61131-2.

Positive signal at electronics switch output (PNP);

Output blocked at point level.

L00-FTM2xxxx-04-05-xx-xx-002

Output signal

IL

= Load current

Fail-safe

mode

Level Output signal LEDs

green yellow

(switched through)

< 100 μA

= Residual current

(blocked)

= Lit

L00-FTL2xxxx-07-05-

xx-xx-000

= Not lit

L00-FTM2xxxx-04-05-xx-xx-003

Signal on alarm Output signal on power failure or in the event of device failure: < 100 μA

Connectable load • Load switched via transistor and separate PNP connection

• Load current: max. 45 V (cyclical overload and short-circuit protection),

continuous max. 350 mA

• Residual current: < 100 μA (for blocked transistor)

• Capacitive load: max. 0.5 μF for 45 V, max. 1.0 μF for 24 V

• Residual voltage: < 3 V (for transistor switched through)

Endress+Hauser 5

Loading...

Loading...